Patents

Literature

30results about How to "Mix in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

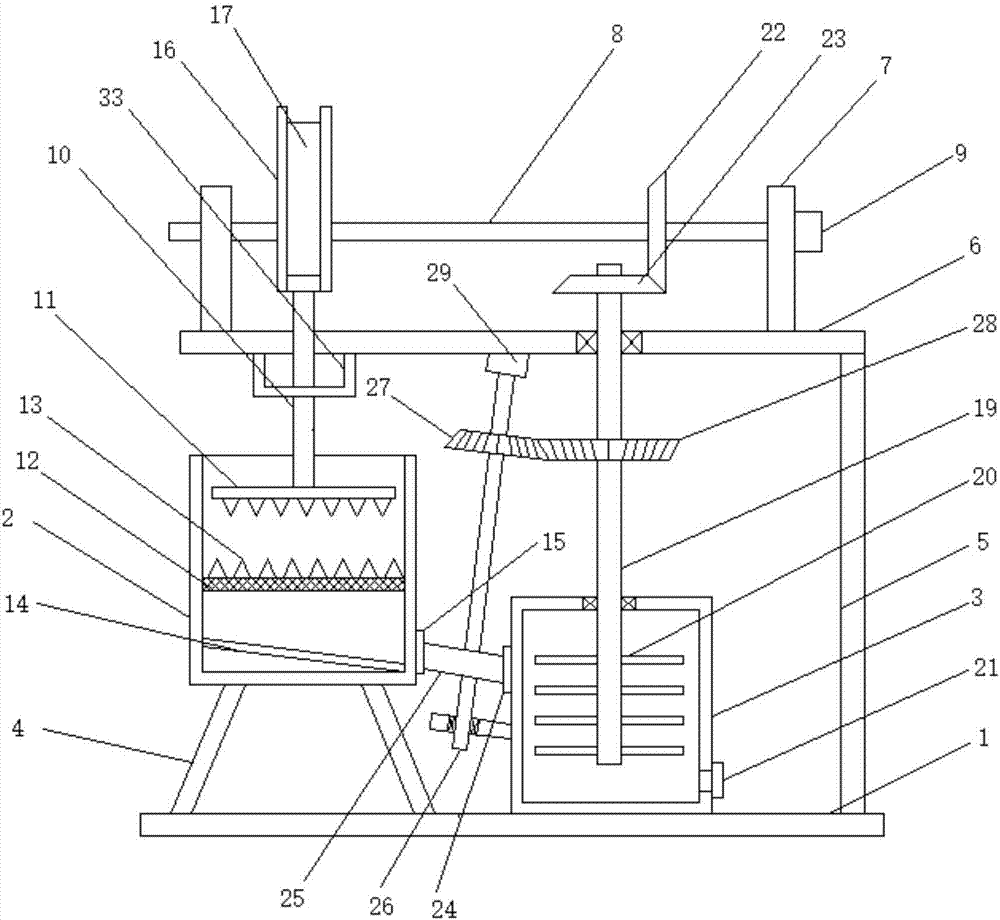

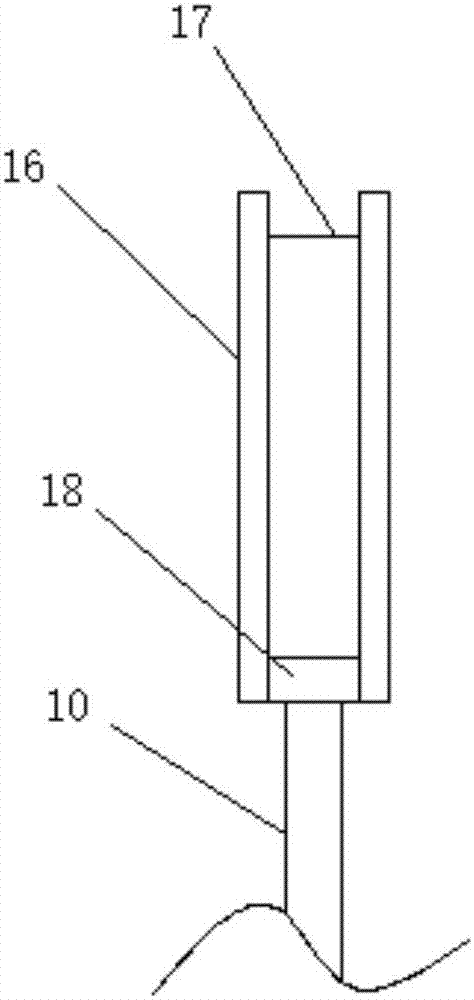

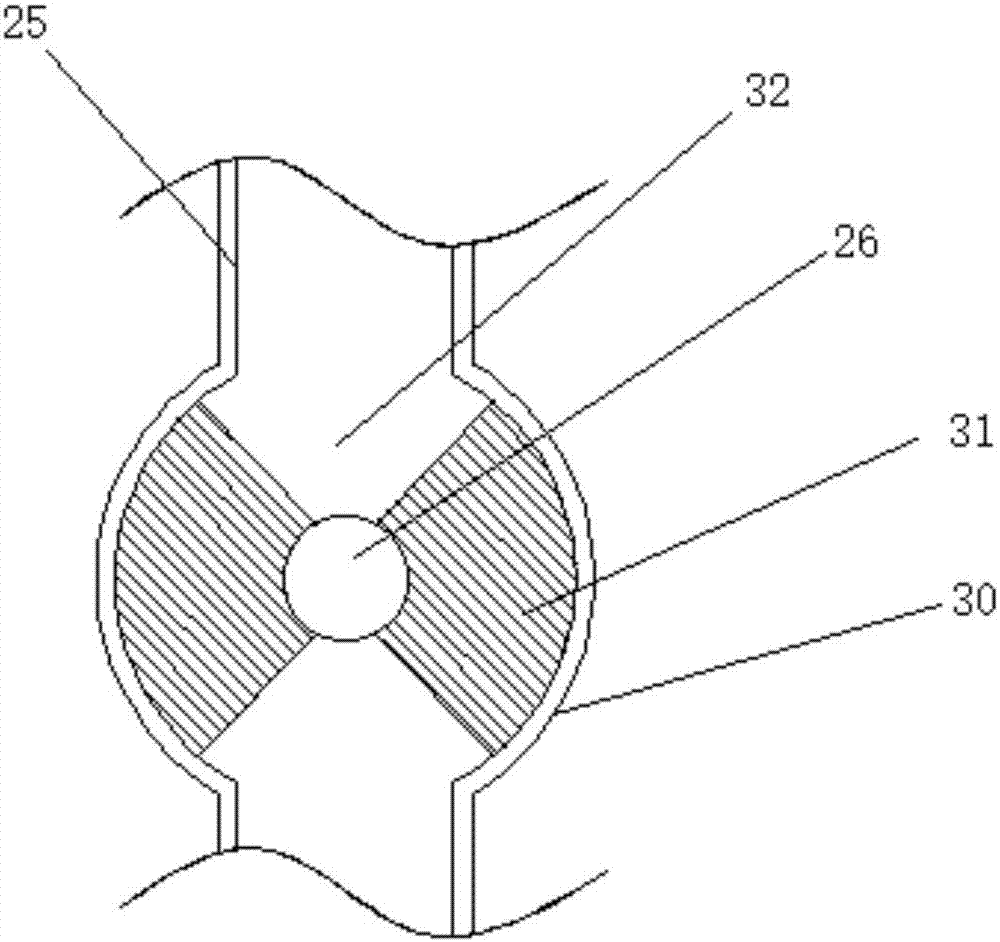

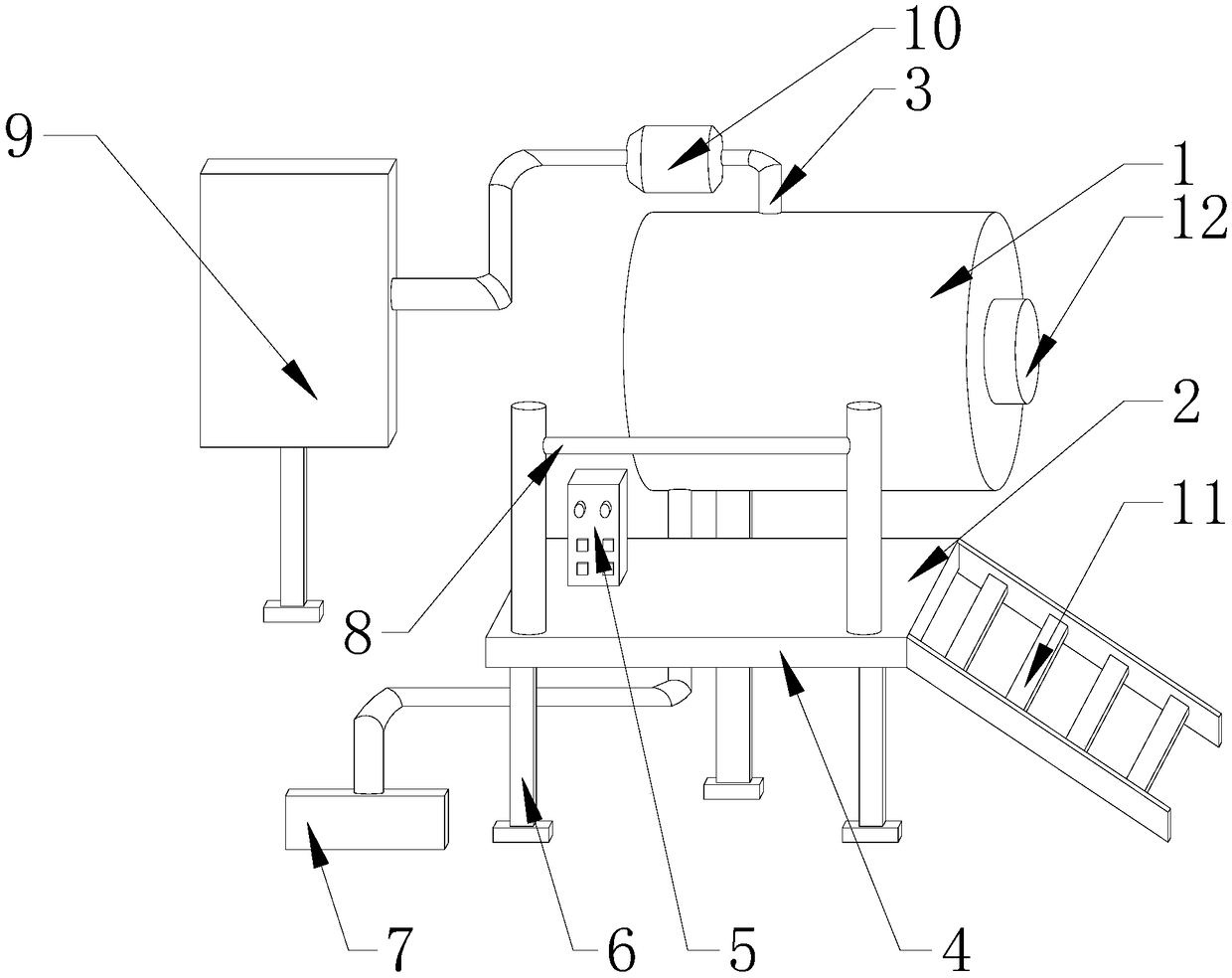

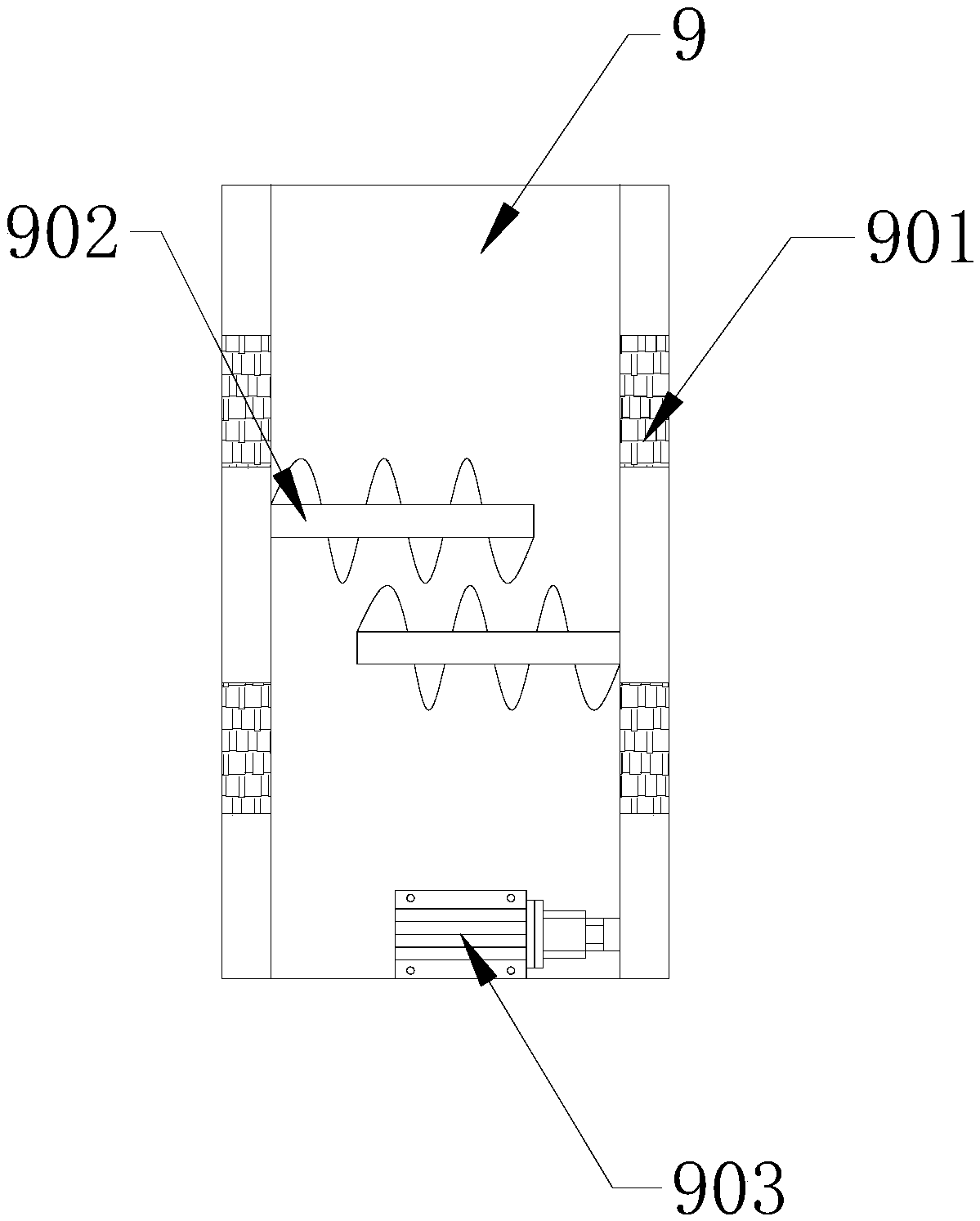

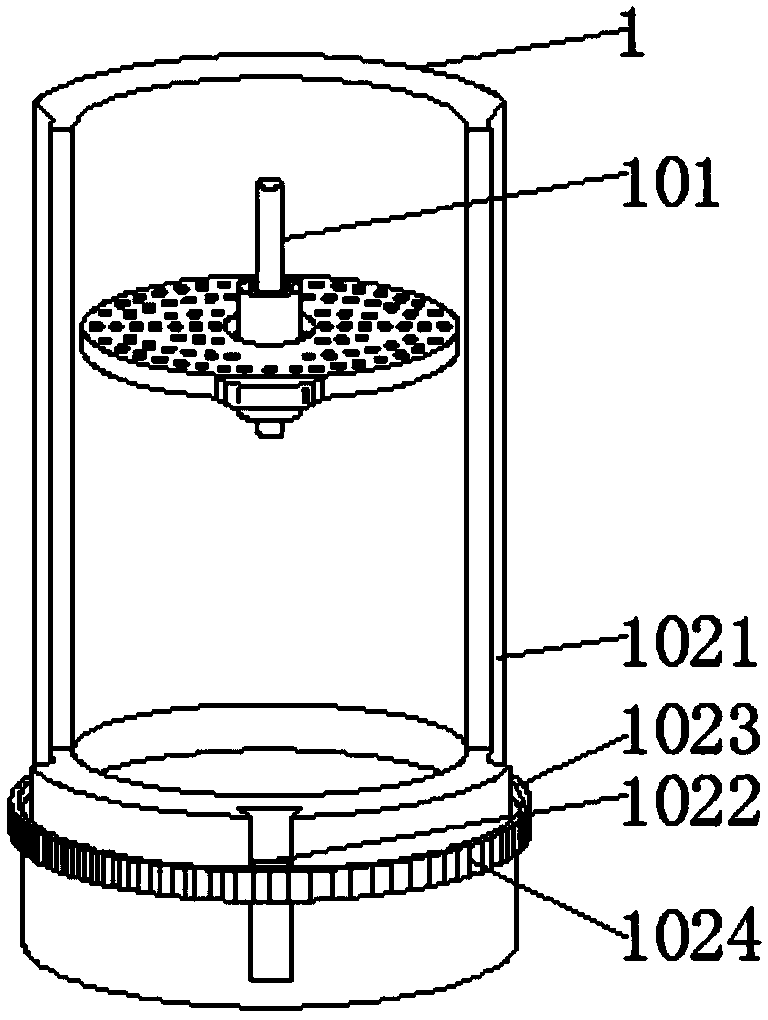

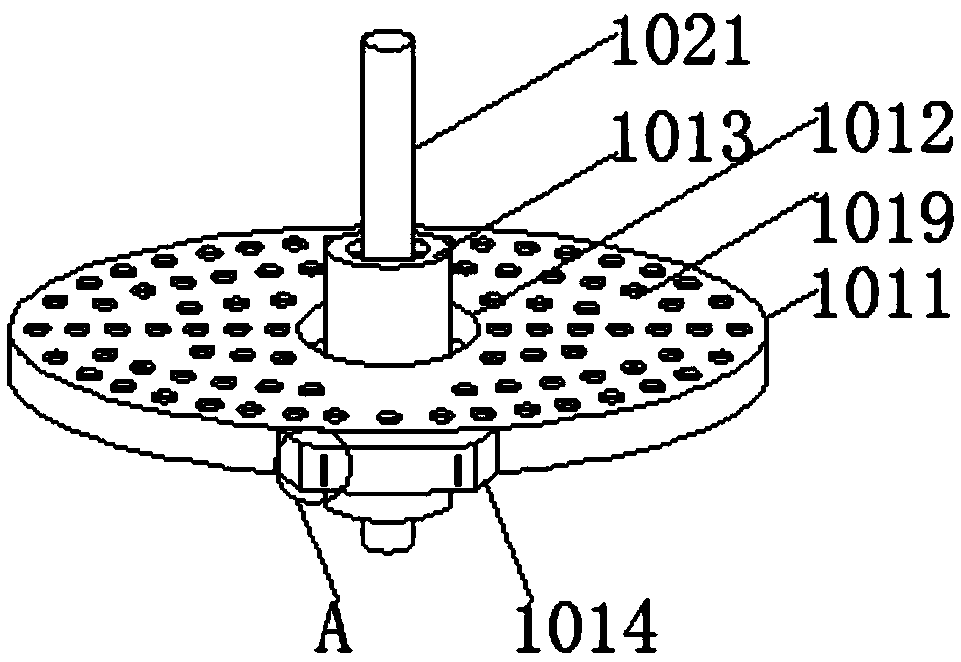

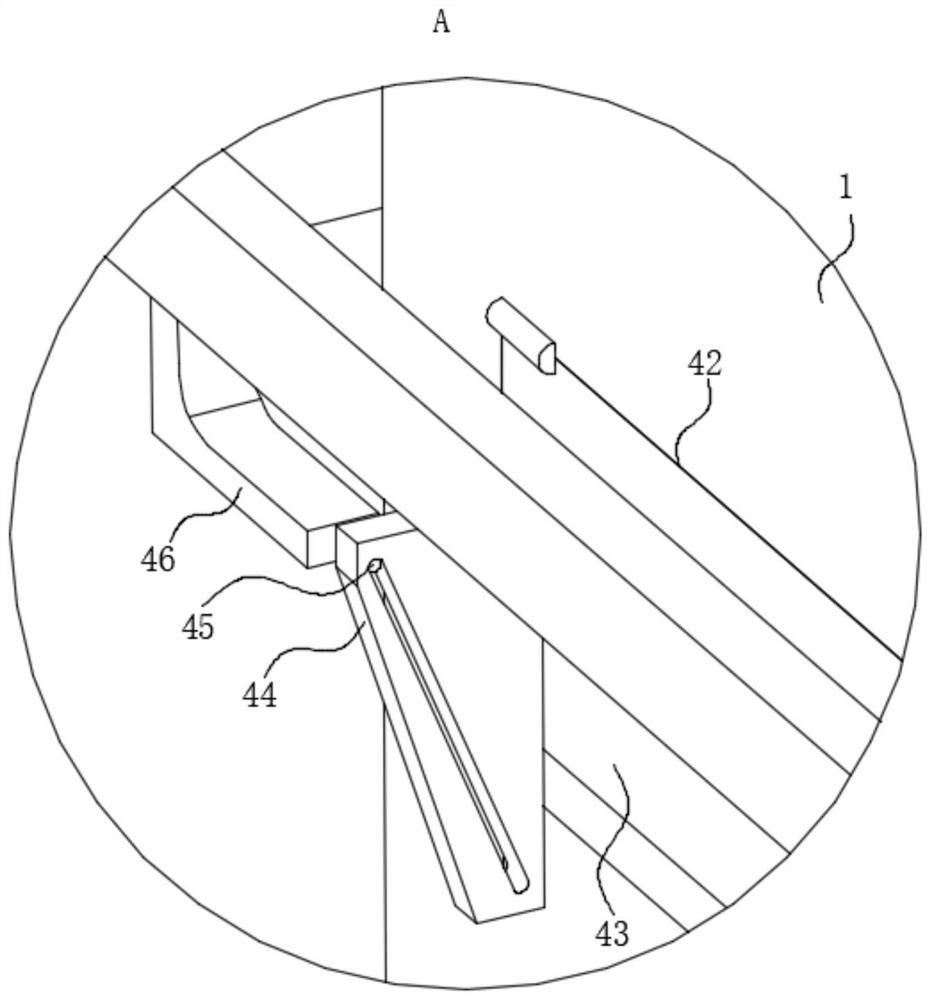

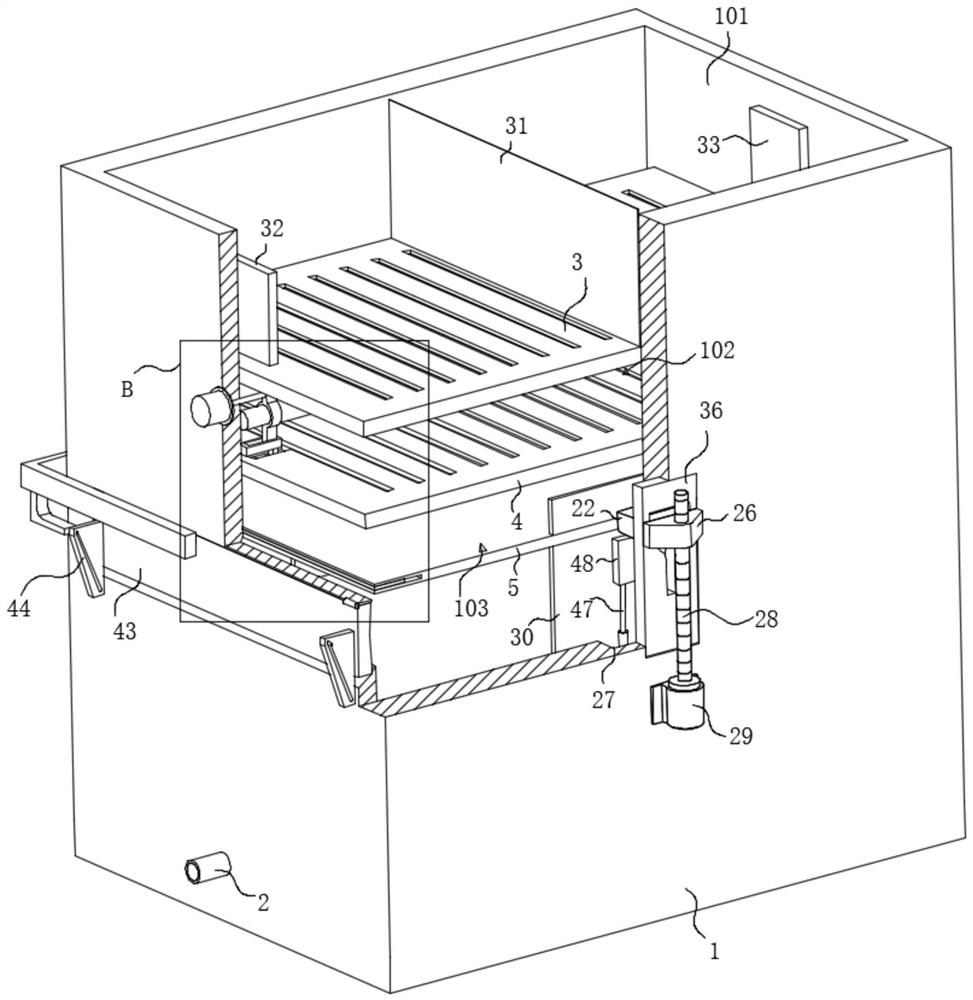

Integrated crushing, stirring and mixing device for construction coating particles

InactiveCN107442031AAvoid affecting useMix in timeTransportation and packagingMixer accessoriesDrive shaftArchitectural engineering

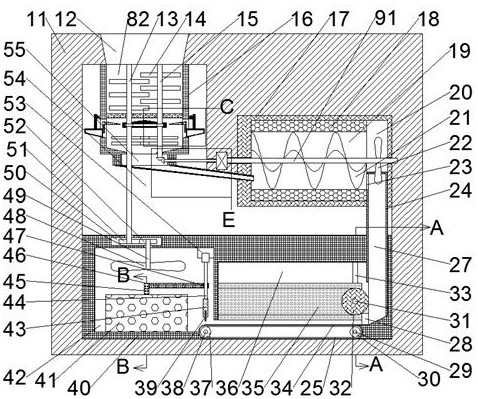

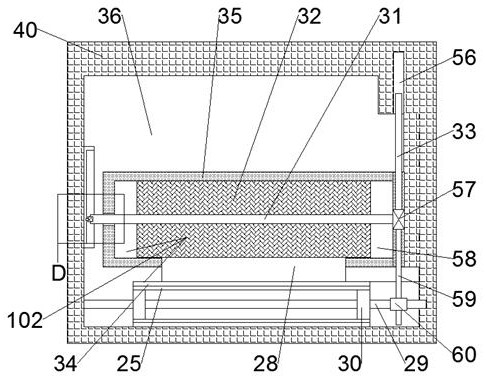

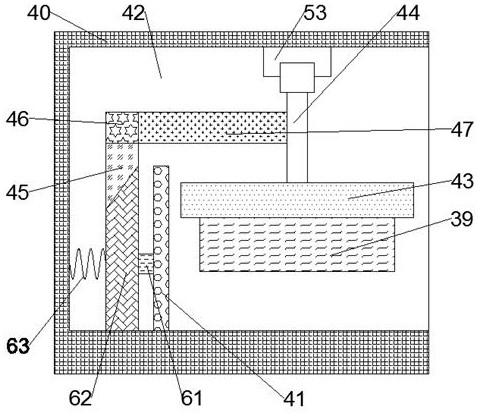

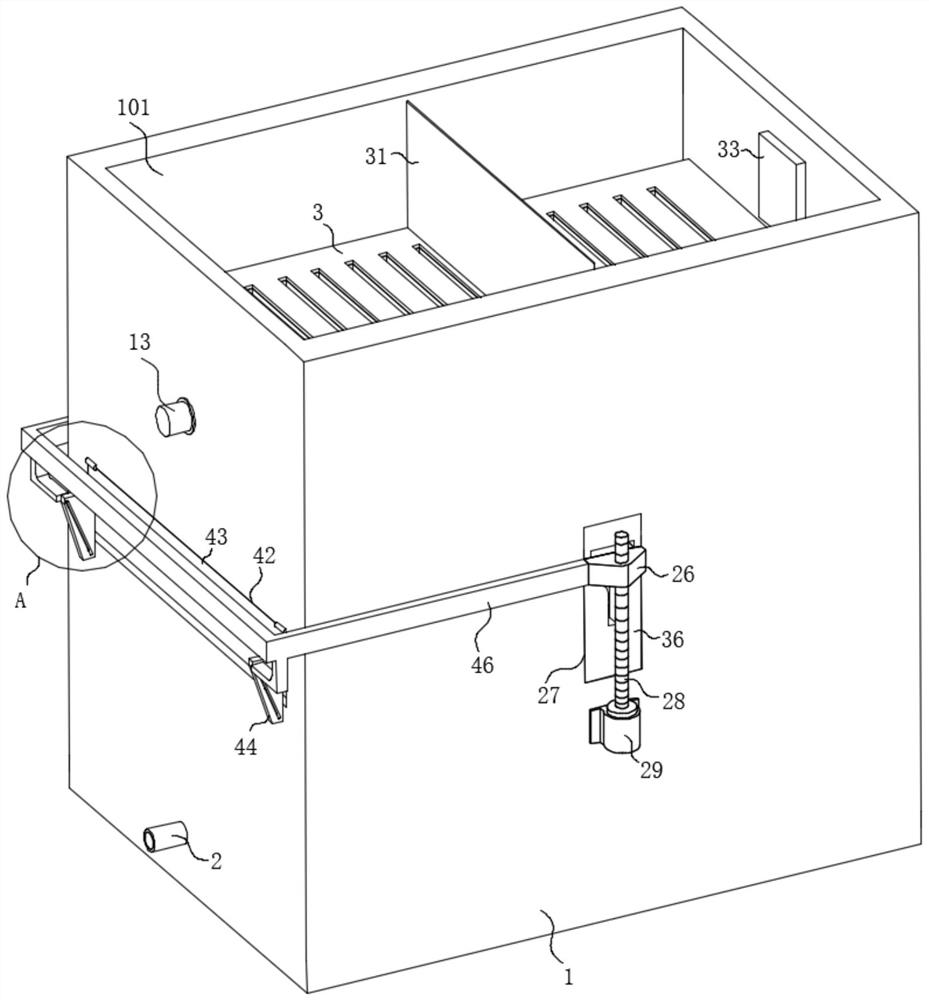

The invention discloses an integrated crushing, stirring and mixing device for construction coating particles, which comprises a bottom plate, a crushing groove and a mixing box, wherein a driving shaft is mounted on a support rack; one end of the driving shaft is connected with a driving motor arranged on the support rack; a vertical upward pressure rod is arranged at a port of the crushing groove; a crushing pressure plate is arranged at the lower end of the pressure rod; a sieve plate is arranged in the crushing groove; a material inlet is formed in a side wall, close to the crushing groove, of the top end of the mixing box, and connected with a material outlet by a material guide channel; a stirring shaft is arranged in the crushing groove; the upper end of the stirring shaft is connected with the driving shaft by a gear mechanism; a plurality of stirring and mixing rods arrayed in a circular ring manner are arranged at the lower end of the stirring shaft; and a discharge port is formed in a side wall of the bottom end of the mixing box. The device is simple in structure, higher in processing and production efficiency, better in linkage, stable in transmission, uniform and sufficient in mixing, easy and simple to operate and higher in practicability, and can simultaneously perform crushing and mixing.

Owner:林红英

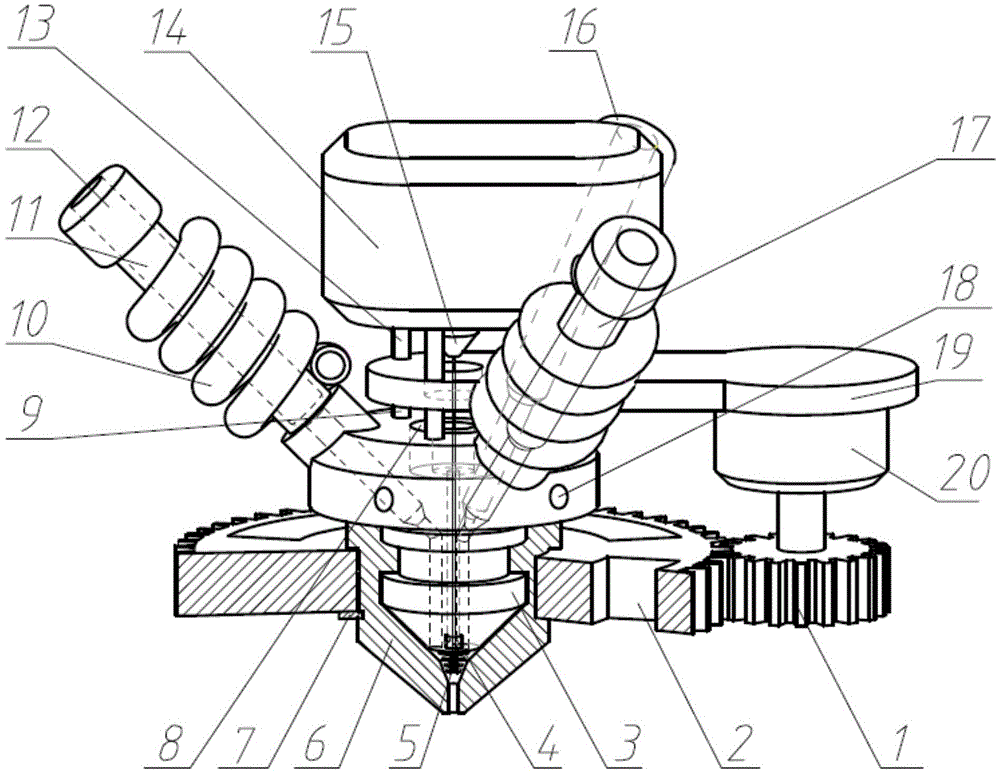

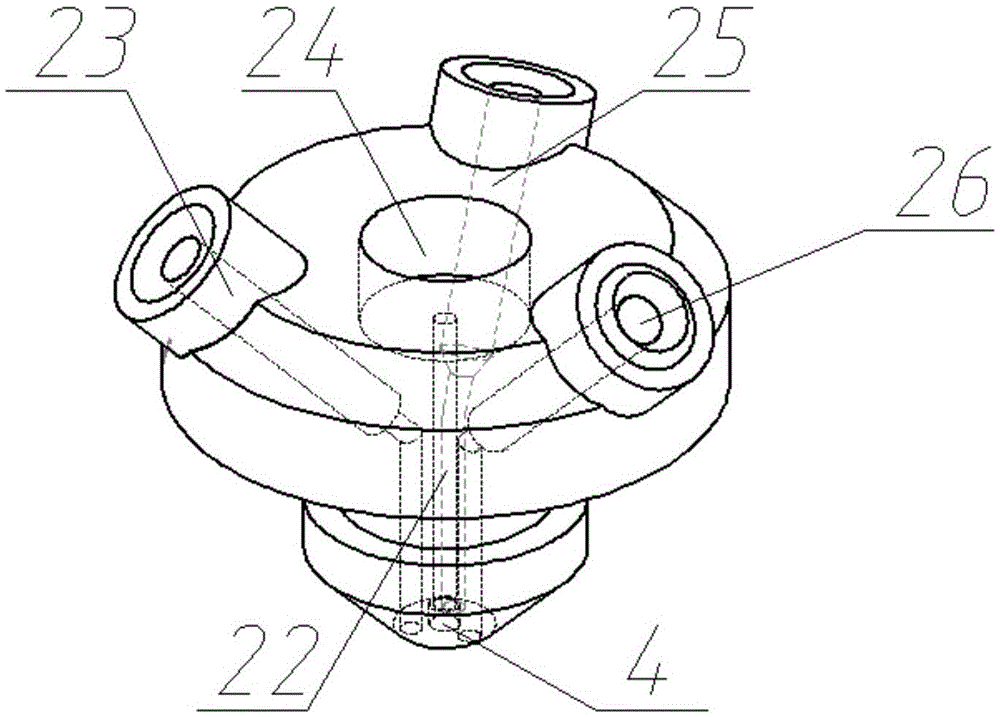

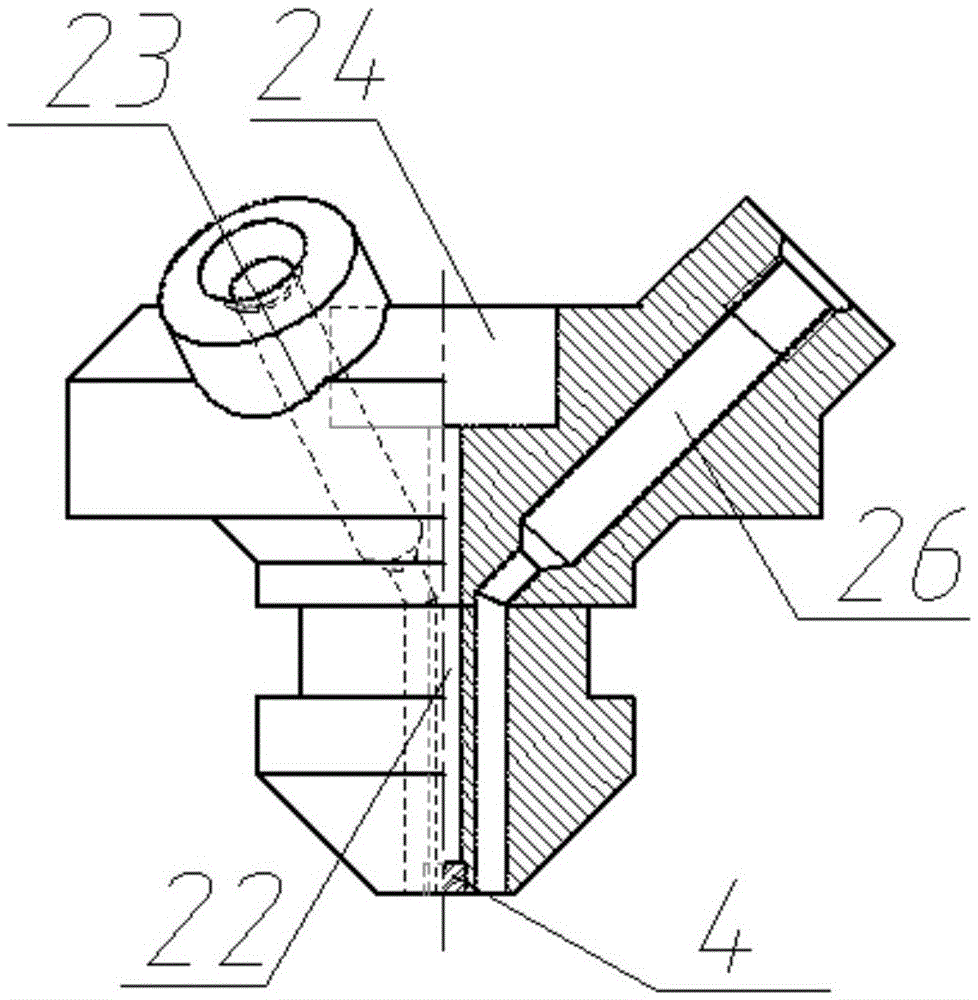

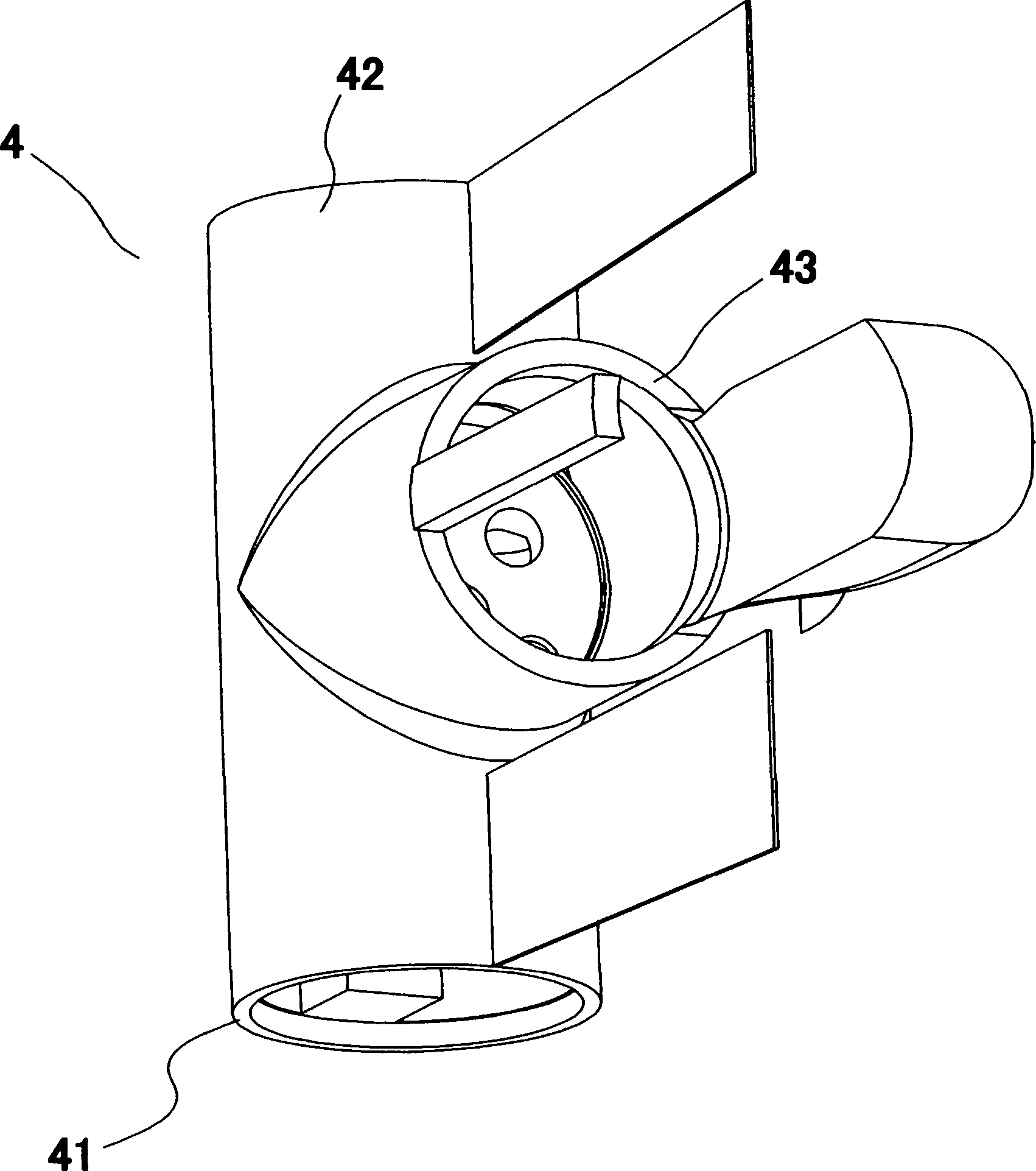

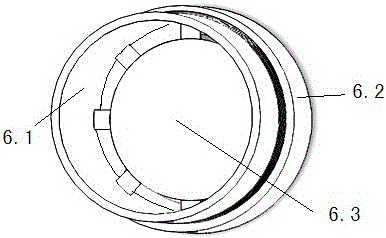

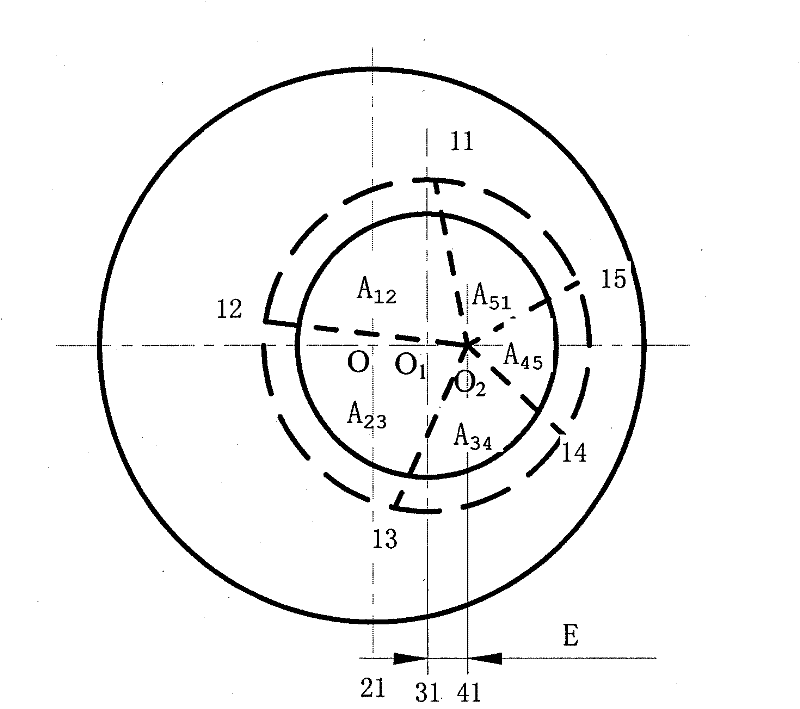

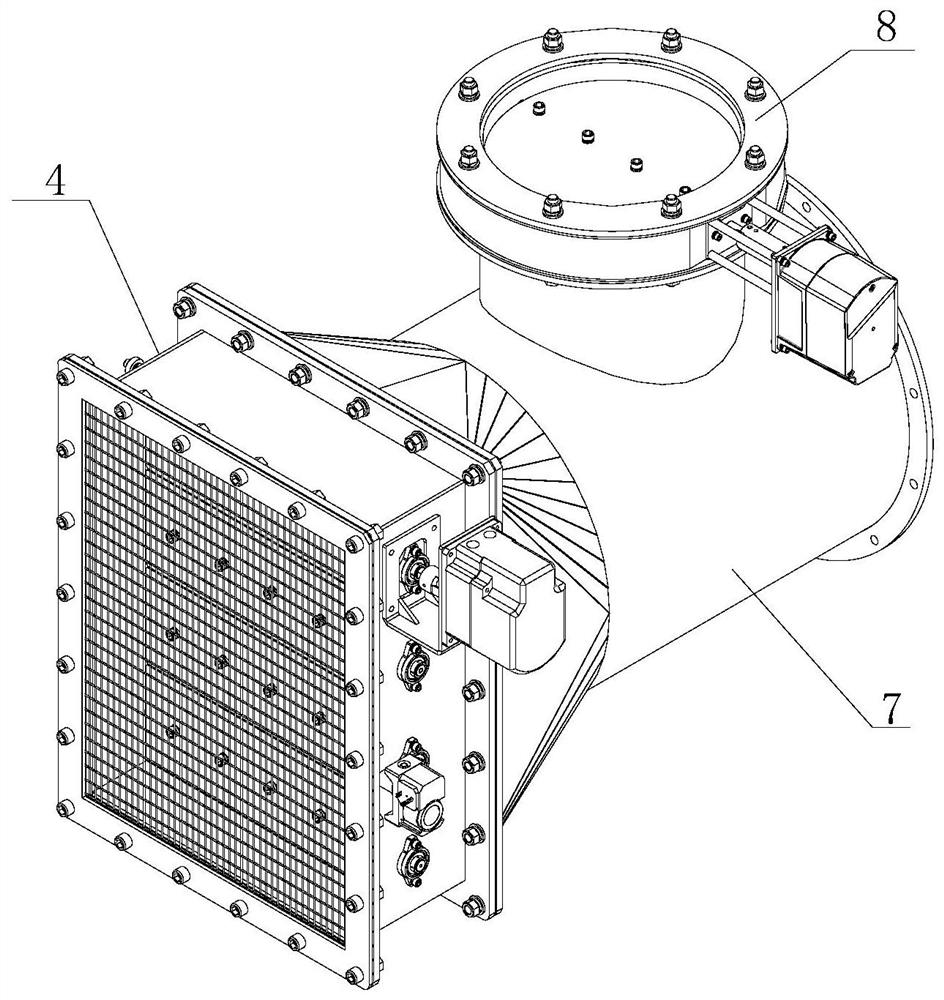

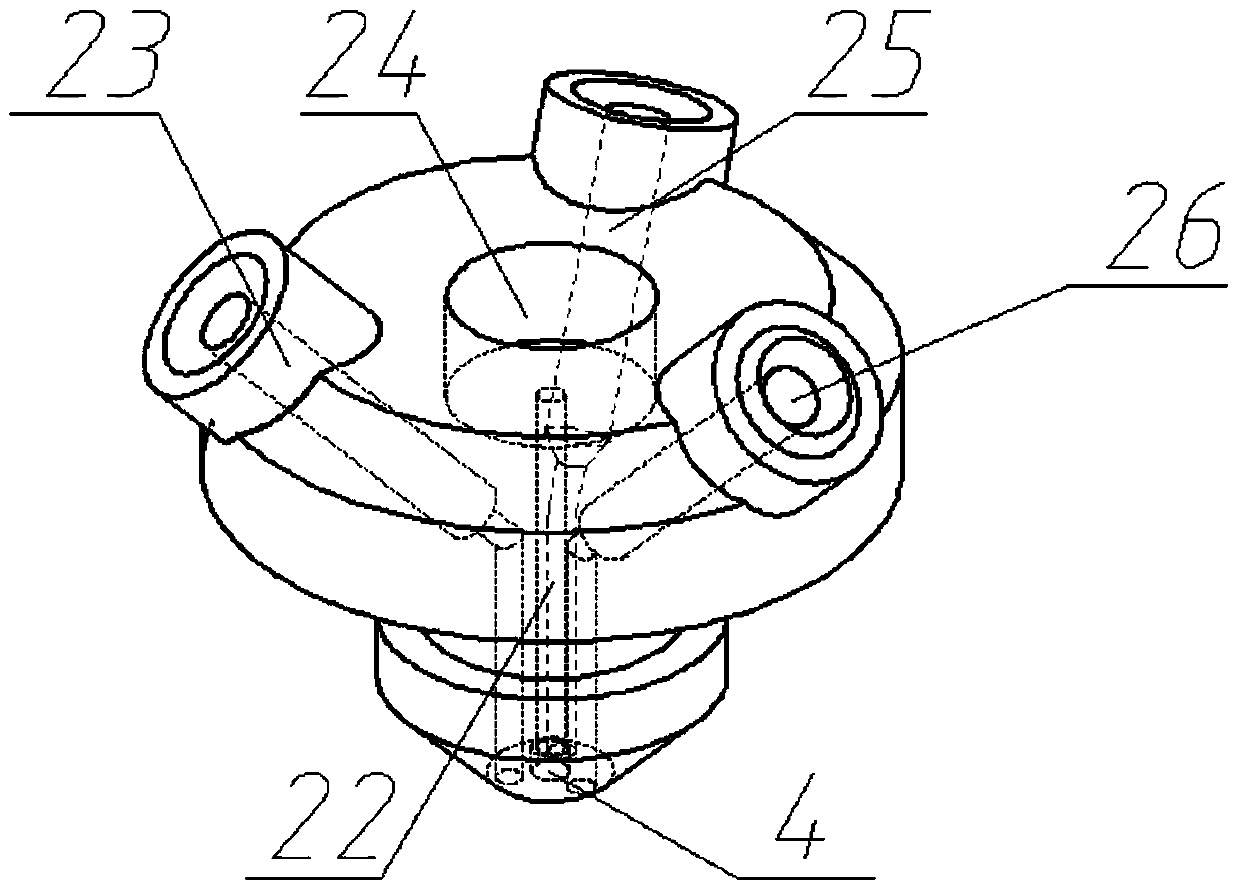

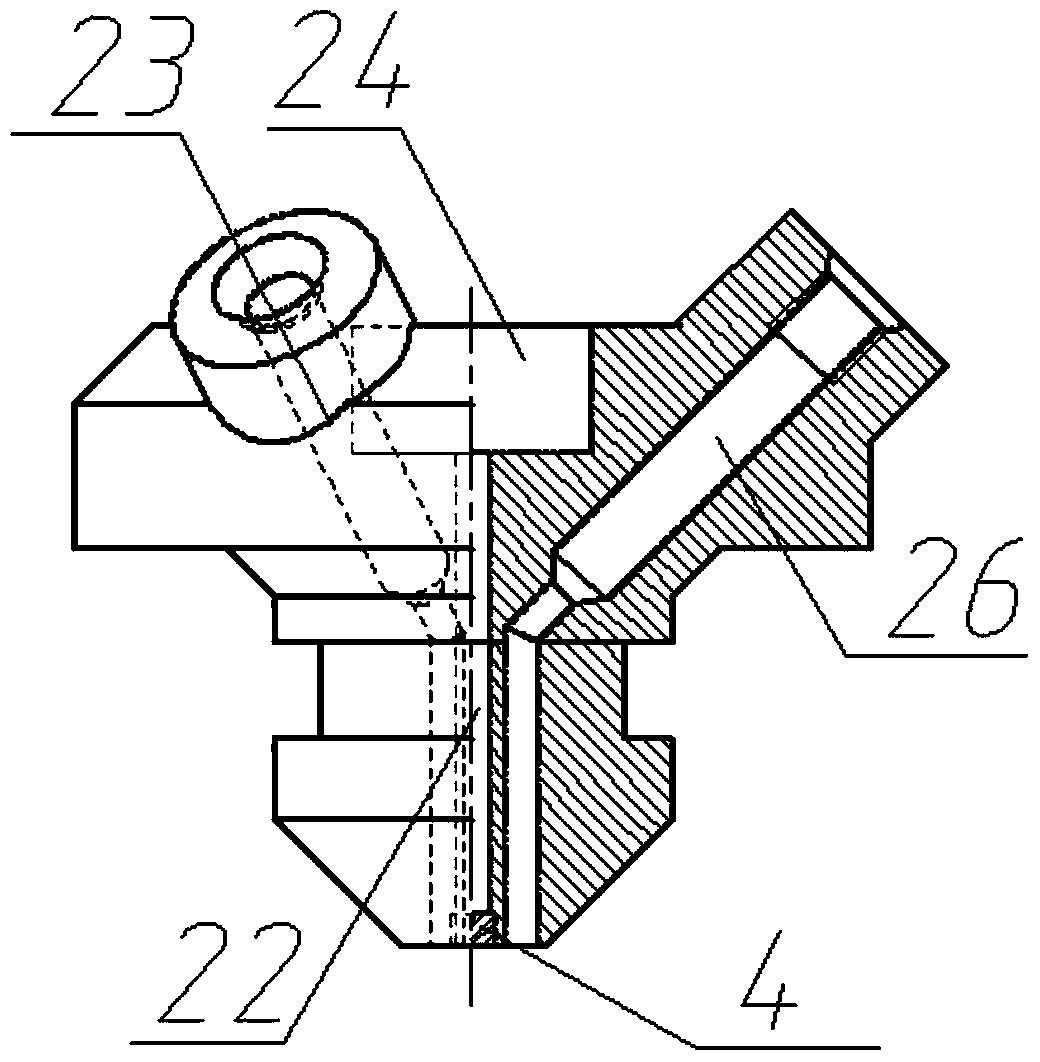

Extrusion nozzle for 3D color printer

ActiveCN105479744AMix in timeDoes not affect the accuracy of single-point color matchingAdditive manufacturing apparatus3d printGear wheel

The invention aims at providing an extrusion nozzle for a 3D color printer. The extrusion nozzle comprises a nozzle assembly. The nozzle assembly comprises a nozzle, a rotary sleeve, a bull gear, a pinion and a stepping motor. The rotary sleeve is installed outside the nozzle and located through an annular protrusion on the rotary sleeve. A conic mixing cavity is formed between the portion below the nozzle and the rotary sleeve. The nozzle is arranged below the conic mixing cavity. The bull gear is installed at the outer portion of the rotary sleeve through an elastic check ring. The pinion is engaged with the bull gear. The stepping motor fixed to a motor support is connected with the pinion. The motor support is fixed to the nozzle. An annular groove, a runner I, a runner II and a runner III are formed in the nozzle. The runner I, the runner II and the runner III are all communicated with the conic mixing cavity. A resistance wire heater is installed in the annular groove. A feeding assembly I, a feeding assembly II and a feeding assembly III are installed outside the runner I, the runner II and the runner III respectively. By the adoption of the extrusion nozzle, the problems that single-nozzle color printing of an existing 3D printer is difficult to achieve and chromatic aberration exists in the 3D color printing process are solved.

Owner:HARBIN ENG UNIV

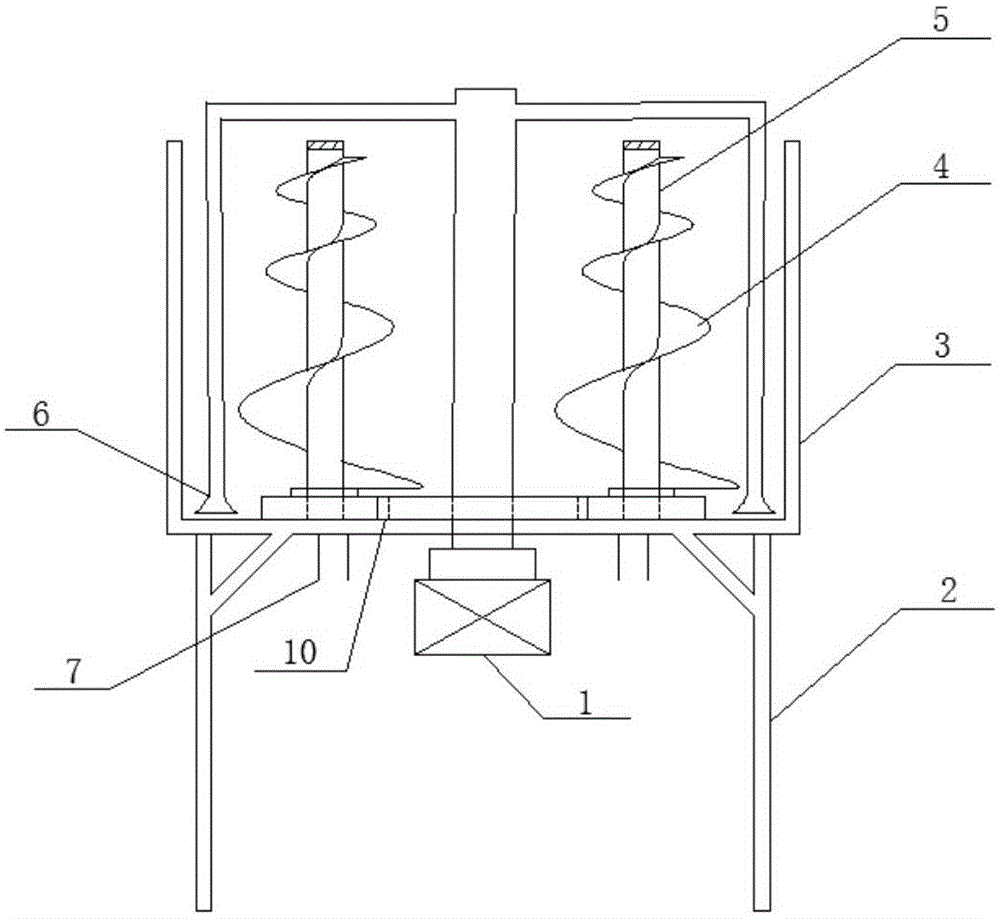

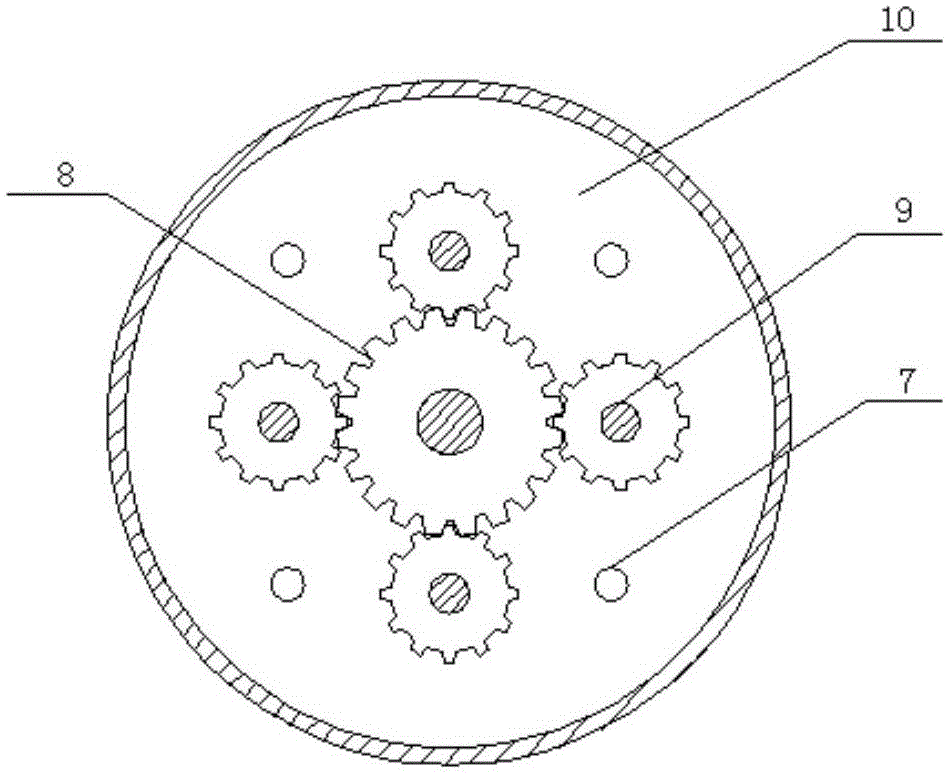

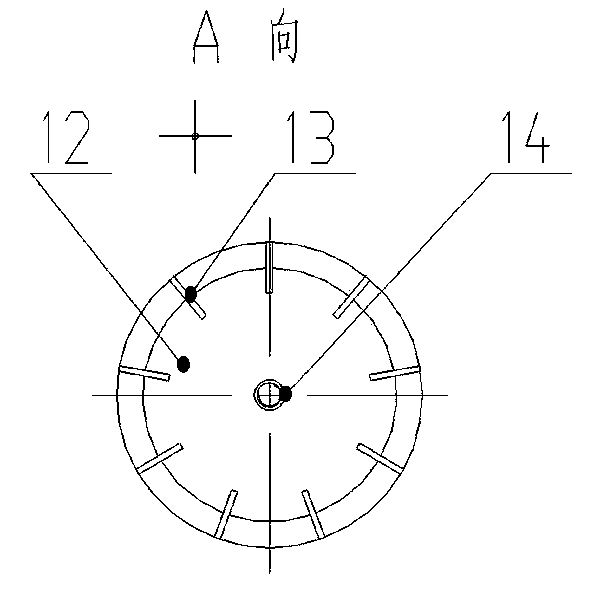

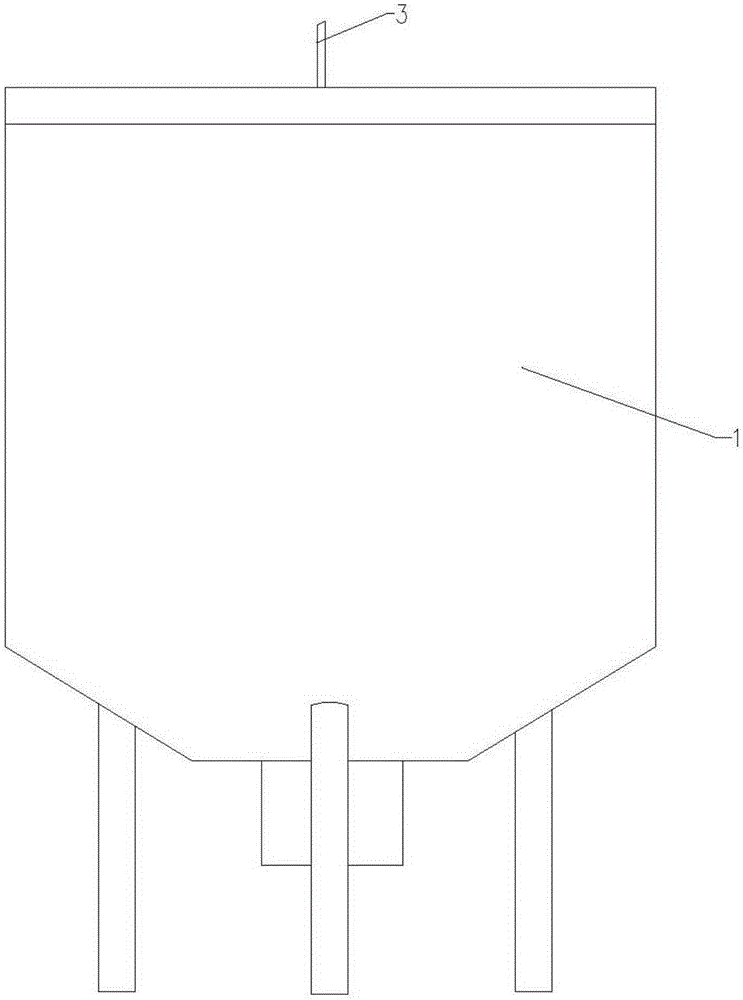

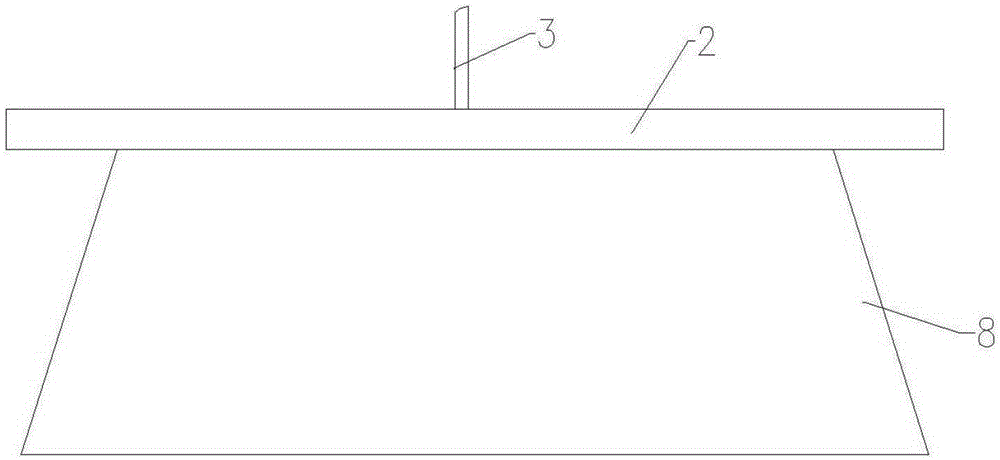

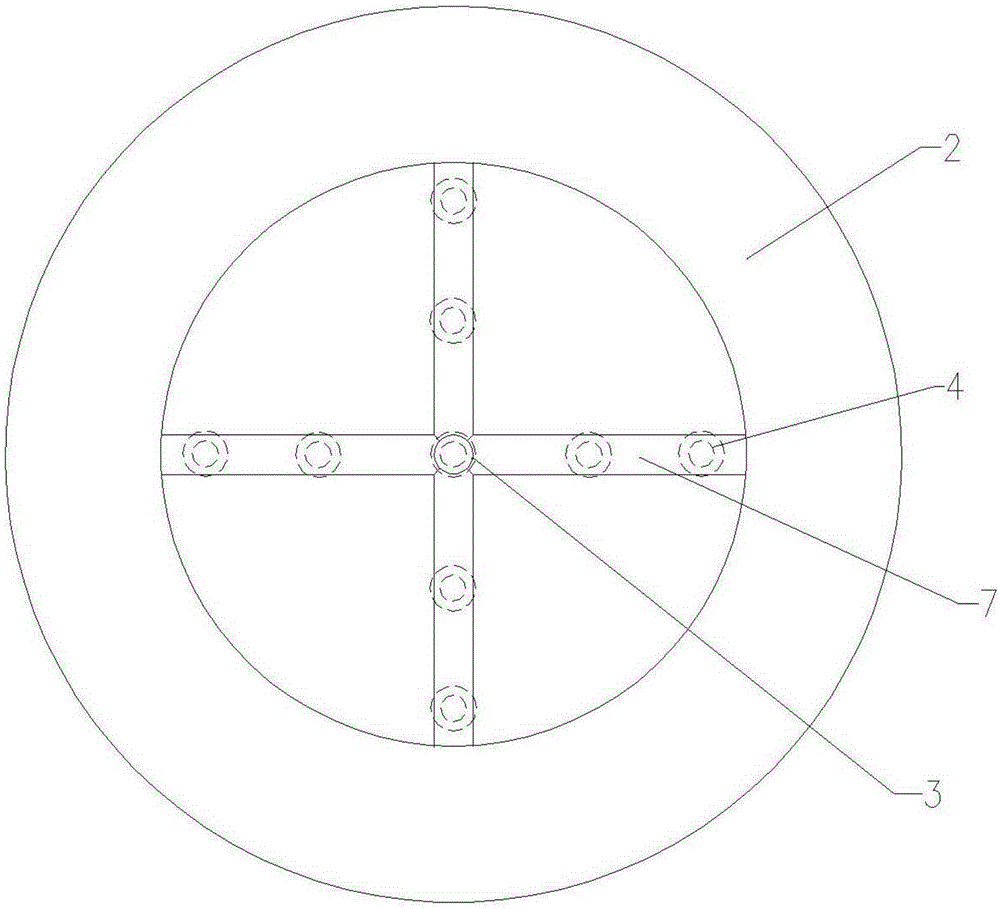

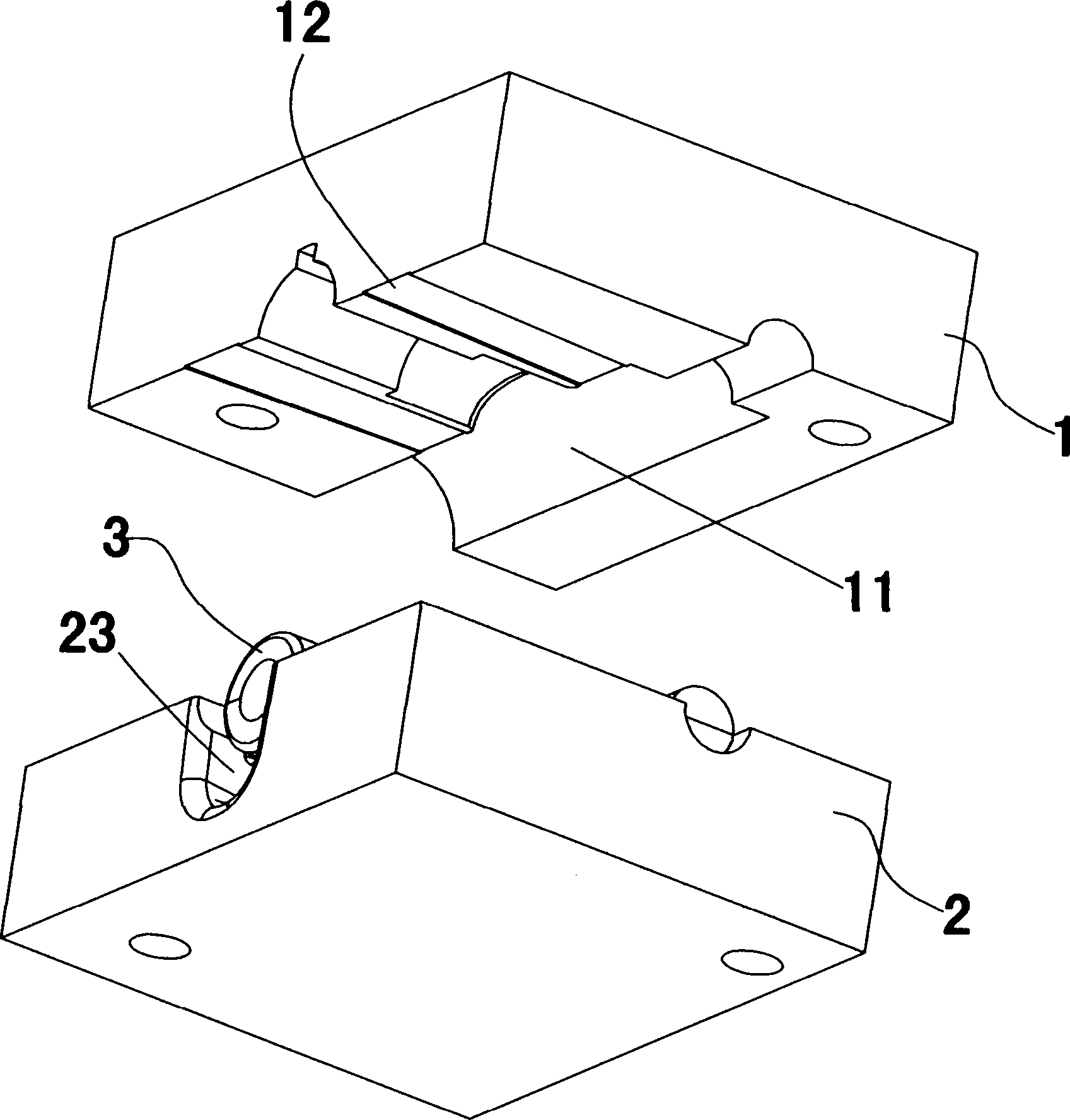

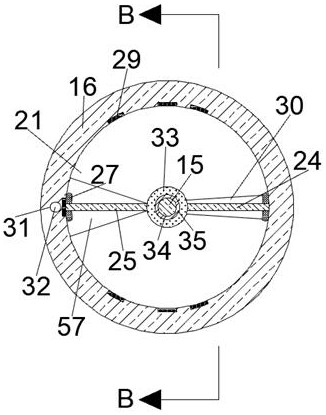

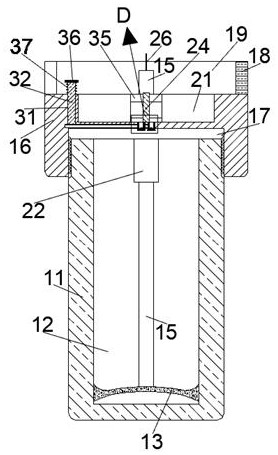

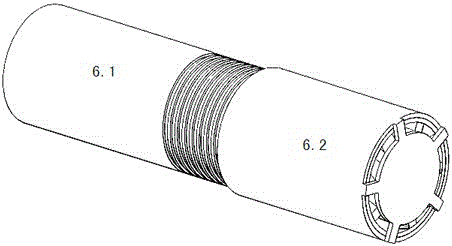

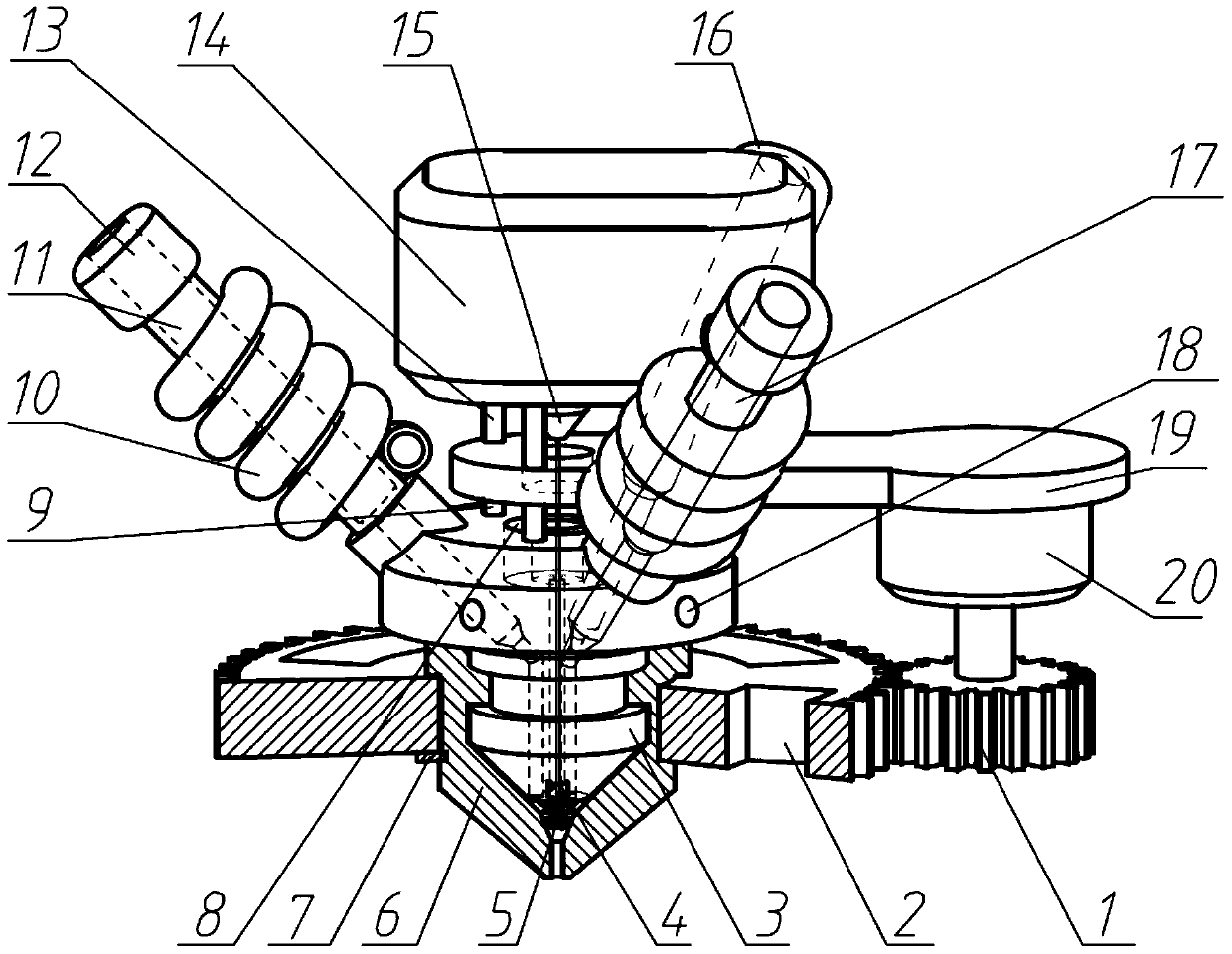

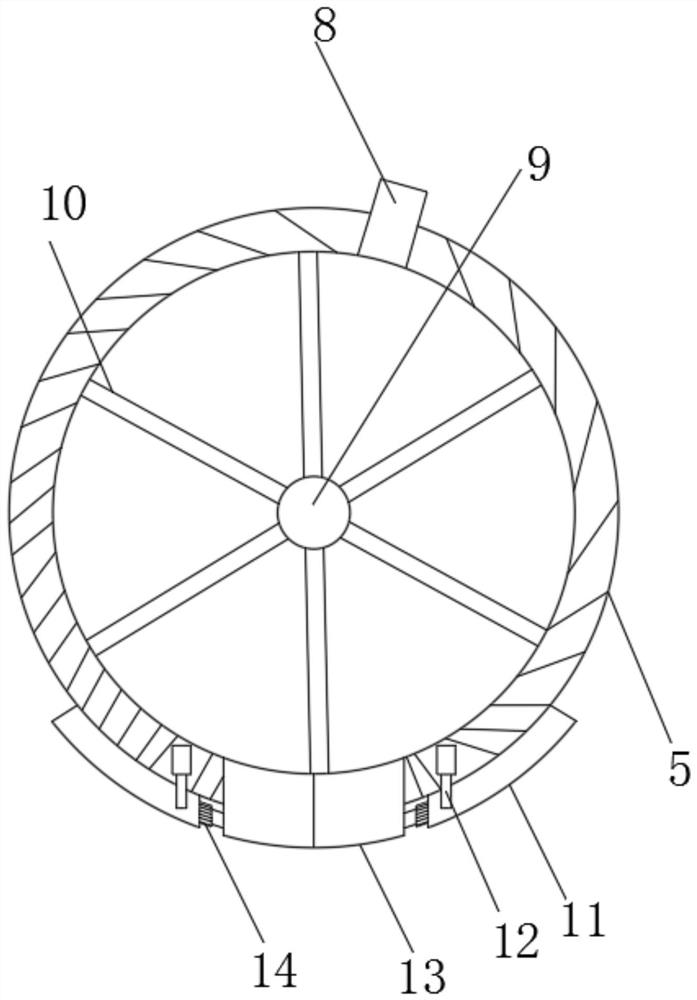

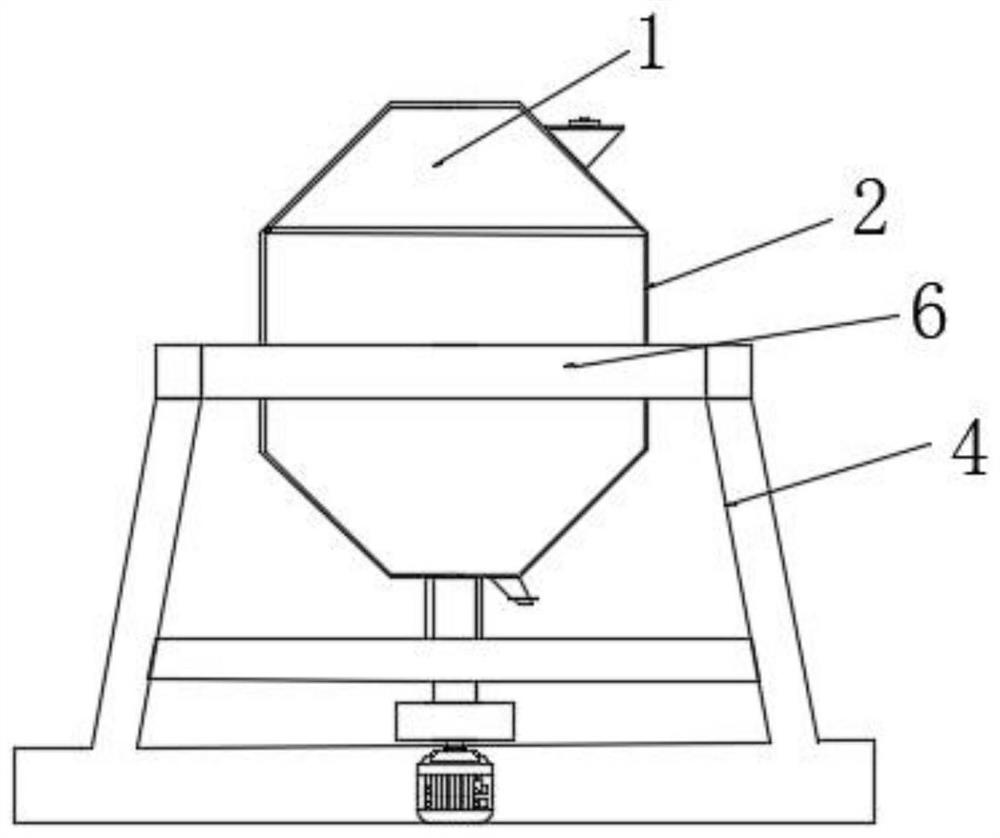

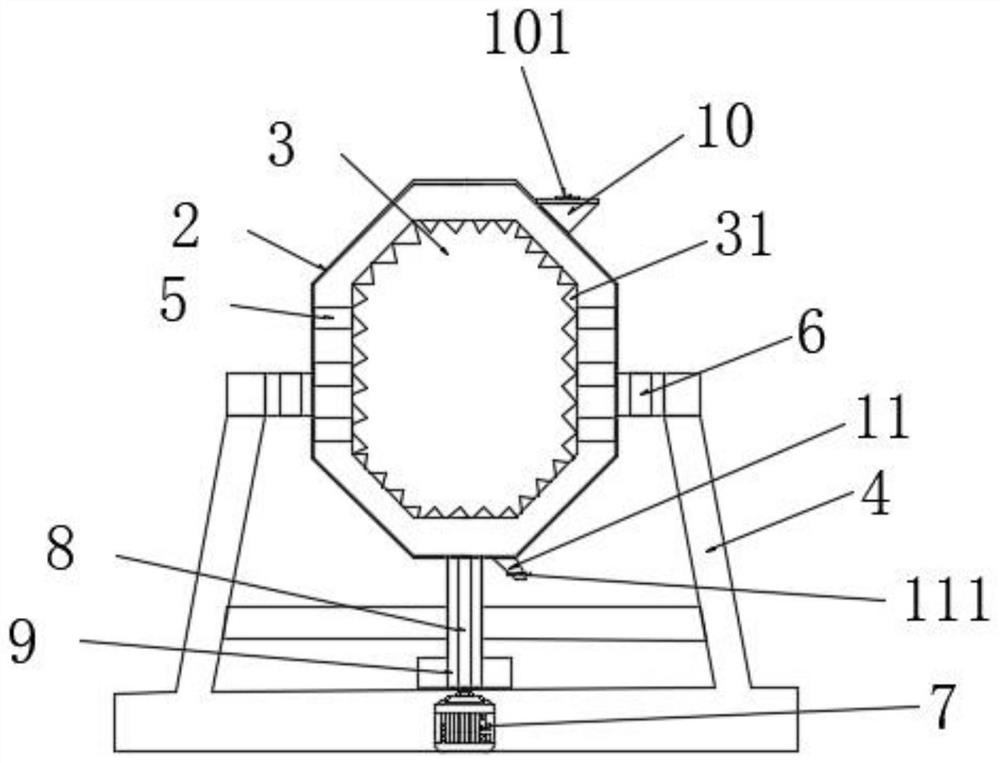

Screw type concrete stirrer

InactiveCN104999562AIncrease flow speedImprove stirring efficiencyCement mixing apparatusSurface typeMotor drive

The invention discloses a screw type concrete stirrer. The screw type concrete mixer comprises a rack, a stirring bucket arranged on the rack, a bottom disc fixed to the bottom of the stirring bucket, two or more stirring mechanisms arranged on the bottom disc and a motor driving the stirring mechanisms to rotate through a transmission device. Each stirring mechanism comprises a stirring arm and a screw blade detachably connected to the stirring arm, the rotation directions of the screw blades on the adjacent stirring mechanisms are opposite, and a discharging opening is formed in the bottom of the stirring bucket. The rotation directions of the adjacent stirring mechanisms are opposite, the flowing speed of materials in the stirring bucket is improved, and therefore stirring efficiency is improved. In a further embodiment, the screw surface type screw blades are adopted, mixing can be accelerated, and stirring efficiency is higher. Meanwhile, the screw blades can be replaced in time, and maintenance time is saved.

Owner:HOHAI UNIV

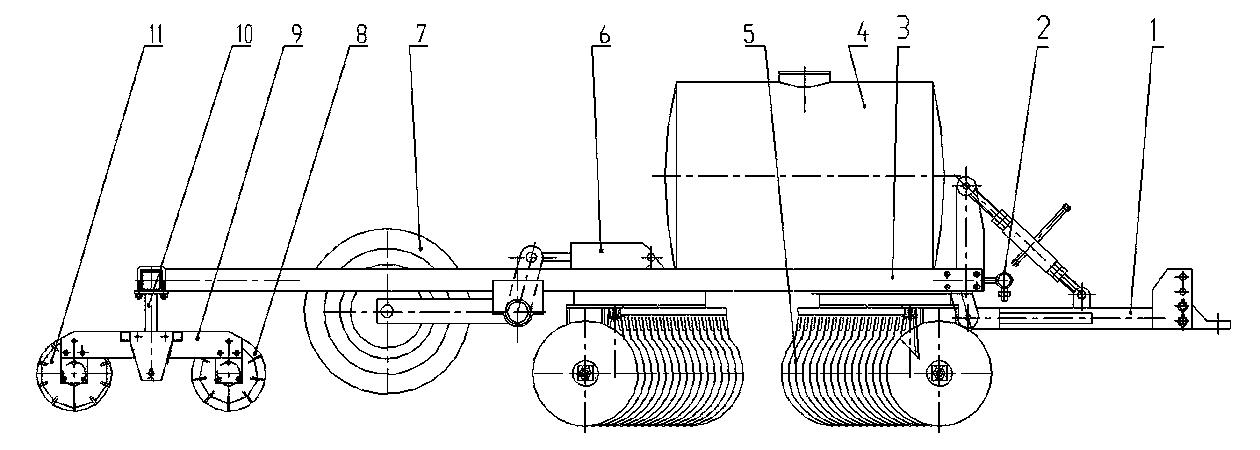

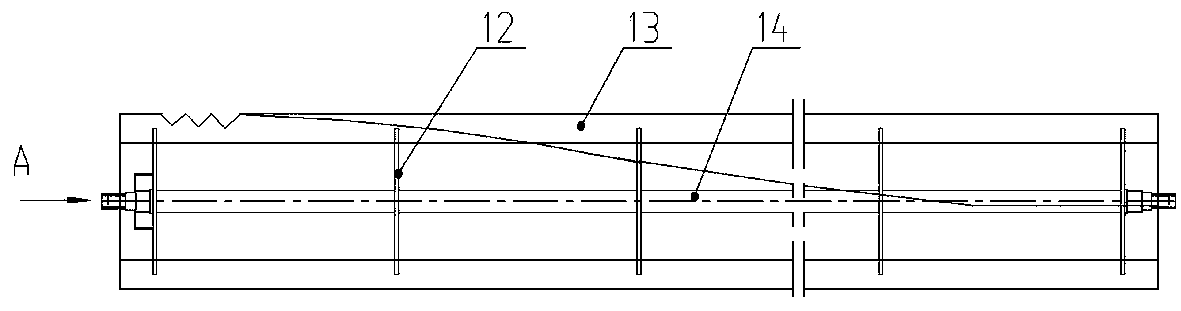

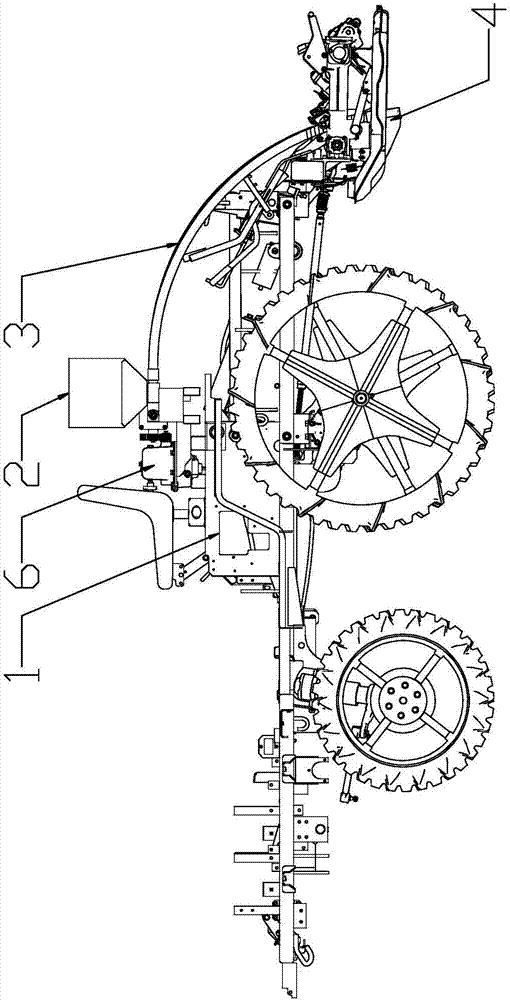

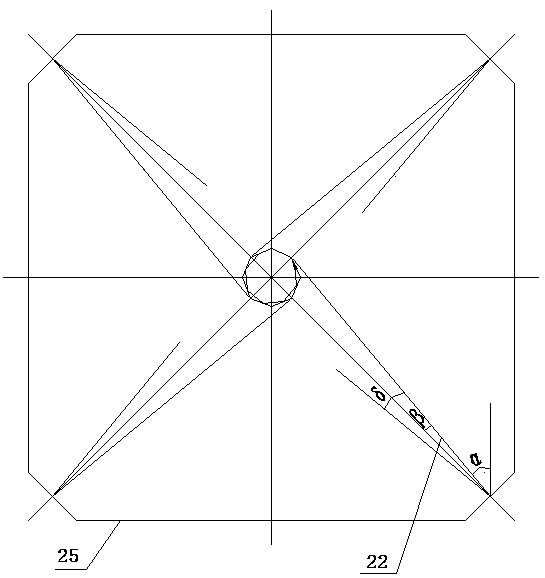

Soil preparation and pesticide spraying combined machine

InactiveCN103891439AAvoid volatile lossReduce harmful compactionSpadesPloughsProduction rateEngineering

The invention belongs to agricultural equipment, and relates to a soil preparation and pesticide spraying combined machine which comprises a traction frame, a pesticide spraying device, a rack, a pesticide box, a disc harrow set, a lifting oil cylinder, a conveying wheel, a soil crushing roll, a soil crushing and pressing roll frame, a supporting arm and a pressing roll. The pesticide box is arranged on the rack. The pesticide spraying device is arranged on the front portion of the rack, and the disc harrow set, the soil crushing roll and the pressing roll are arranged on the lower portion of the rack. The soil crushing roll and the pressing roll are arranged on the soil crushing and pressing roll frame through bearings, one end of the supporting arm is fixedly connected with the rack, and the other end of the supporting arm is hinged to the soil crushing and pressing roll frame. When the machine works, the pesticide spraying device firstly sprays pesticide on the earth surface, then the disc harrow set carries out soil aeration and soil loosening work, meanwhile, the pesticide and soil are mixed, then the soil is crushed through the soil crushing roll and is further mixed with the pesticide, and finally the soil is pressed by the pressing roll. The soil preparation and pesticide spraying combined machine is adopted for work, the pesticide and the soil can be mixed timely, volatilization losses of the pesticide are avoided, and meanwhile the production rate of the machine is improved.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

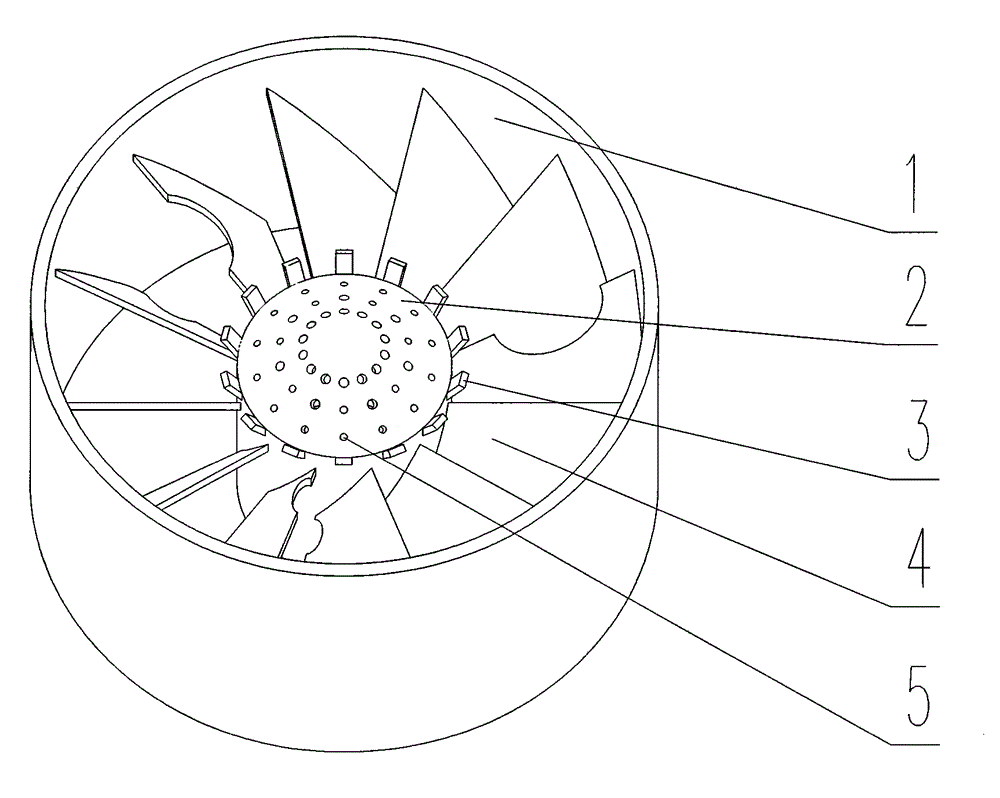

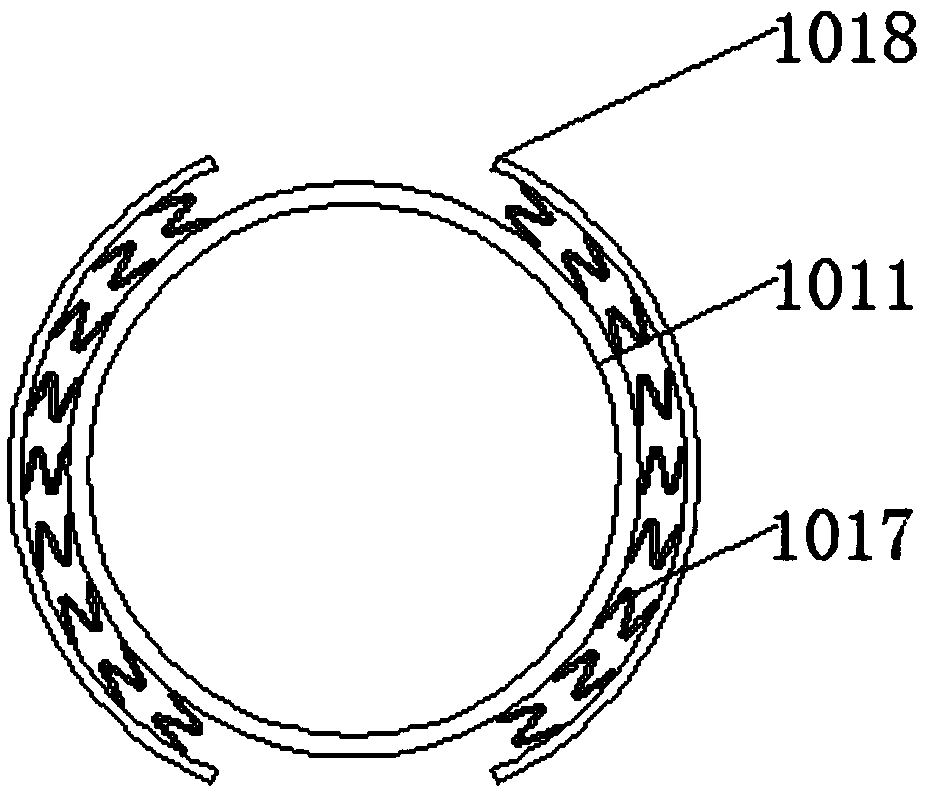

Zigzag gas burner

InactiveCN104421939AAdaptableIgnition and stable combustionBurner safety arrangementsGaseous fuel burnerGas burnerFuel gas

The invention discloses a zigzag gas burner. A tapered gas nozzle is formed in the center of the inside of a jet. Air distribution blades are circumferentially formed between the jet and the tapered gas nozzle. Zigzag flame stabilizing bodies are arranged on the circumference of the taped gas nozzle. Gas spraying holes are formed in the tapered gas nozzle. Gas enters from the tapered gas nozzle and is sprayed out through the gas spraying holes. Gas distributed air enters a circular channel between the jet and the tapered gas nozzle and generates rotational-flow distributed air by the aid of the air distribution blades with angles. At the front end of the jet, the gas and the rotational-flow distributed air are intensely mixed and then meet an igniting device to fire. The zigzag gas burner is effective in preventing the flame from lifting, returning and extinguishing.

Owner:SHAANXI SHENGHUIYUAN INFORMATION SCI & TECH

Mixer

InactiveCN105195036AAvoid wasting jetsRadiation area is largeFlow mixersMixing methodsSilicon carbideNozzle

Provided is a mixer. The mixer comprises a mixing drum, a head cover is arranged on the mixing drum, a main pipe is installed on the head cover, a pressure type nozzle extending into the mixing drum is installed on the main pipe, a mist vent of the pressure type nozzle faces downwards, multiple mounting grooves which extend in the radial direction along the head cover and are evenly distributed in the circumferential direction are formed in the head cover, branched pipes which are communicated with the main pipe are installed in the mounting grooves, multiple pressure type nozzles extending into the mixing drum are installed on the branched pipes, mist vents of the multiple pressure type nozzles face downwards, the depths, extending into the mixing drum, of pressure type nozzles installed on the branched pipes are different from the depth, extending into the mixing drum, of the pressure type nozzle on the main pipe, head cover plates which cover the mounting grooves are arranged on the mounting grooves and hinged to the head cover, a big-end-down cone-shaped mist collecting cover is installed on the inner wall close to the edge of the head cover, and the diameter of the major diameter end is smaller than or equal to that of the head cover. According to the mixer, the radiating area can be larger when atomized absolute ethyl alcohol is sprayed out, the atomized absolute ethyl alcohol can make contact with carborundum in time to be mixed fully and evenly.

Owner:宁波天工机械密封有限公司

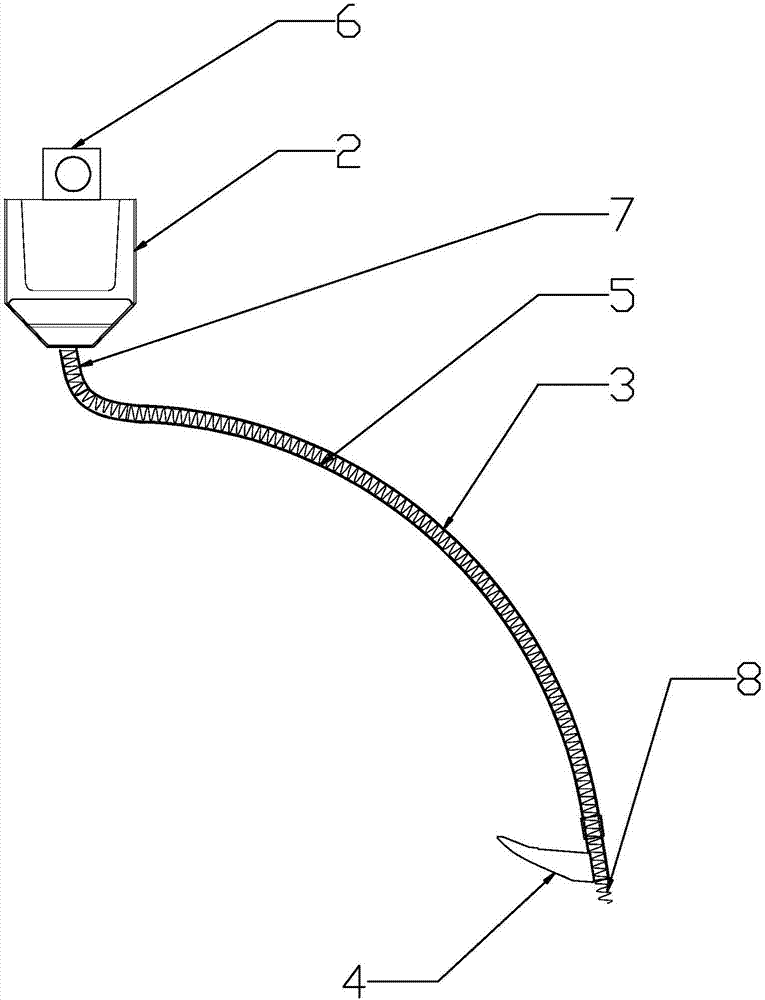

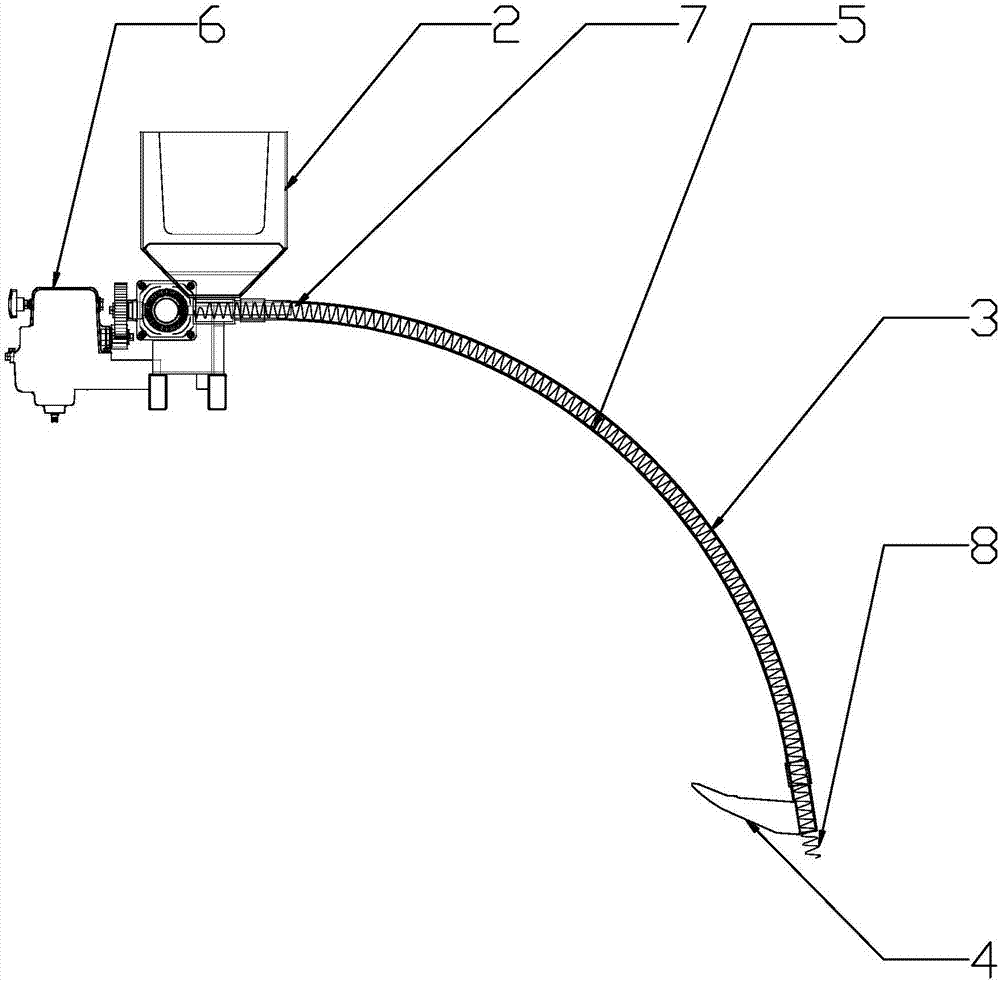

Precise fertilizing mechanism of rice transplanter

PendingCN107079647AProtection variantExtended service lifeFertiliser distributersTransplantingEngineering

The invention provides a precise fertilizing mechanism of a rice transplanter. The precise fertilizing mechanism of the rice transplanter comprises a frame, a fertilizer storage box, a fertilizing pipe, an opener and a fertilizer feeding mechanism. The fertilizer storage box is arranged on the frame, the feeding end of the fertilizing pipe is connected to a fertilizer outlet of the fertilizer storage box while the discharge end is connected to the back end of the opener; a flexible auger is arranged in the fertilizing pipe, and the upper end of the flexible auger is connected to a power device. The fertilizing precision of the flexible auger is far higher than that of a fertilizing mechanism of an air blower, and the flexible auger is flexible and sensitive. The whole fertilizing pipe can fertilize dynamically and the flexible auger can deform, so that the mechanism is more conveniently placed and mounted.

Owner:河北锦禾农业机械有限公司

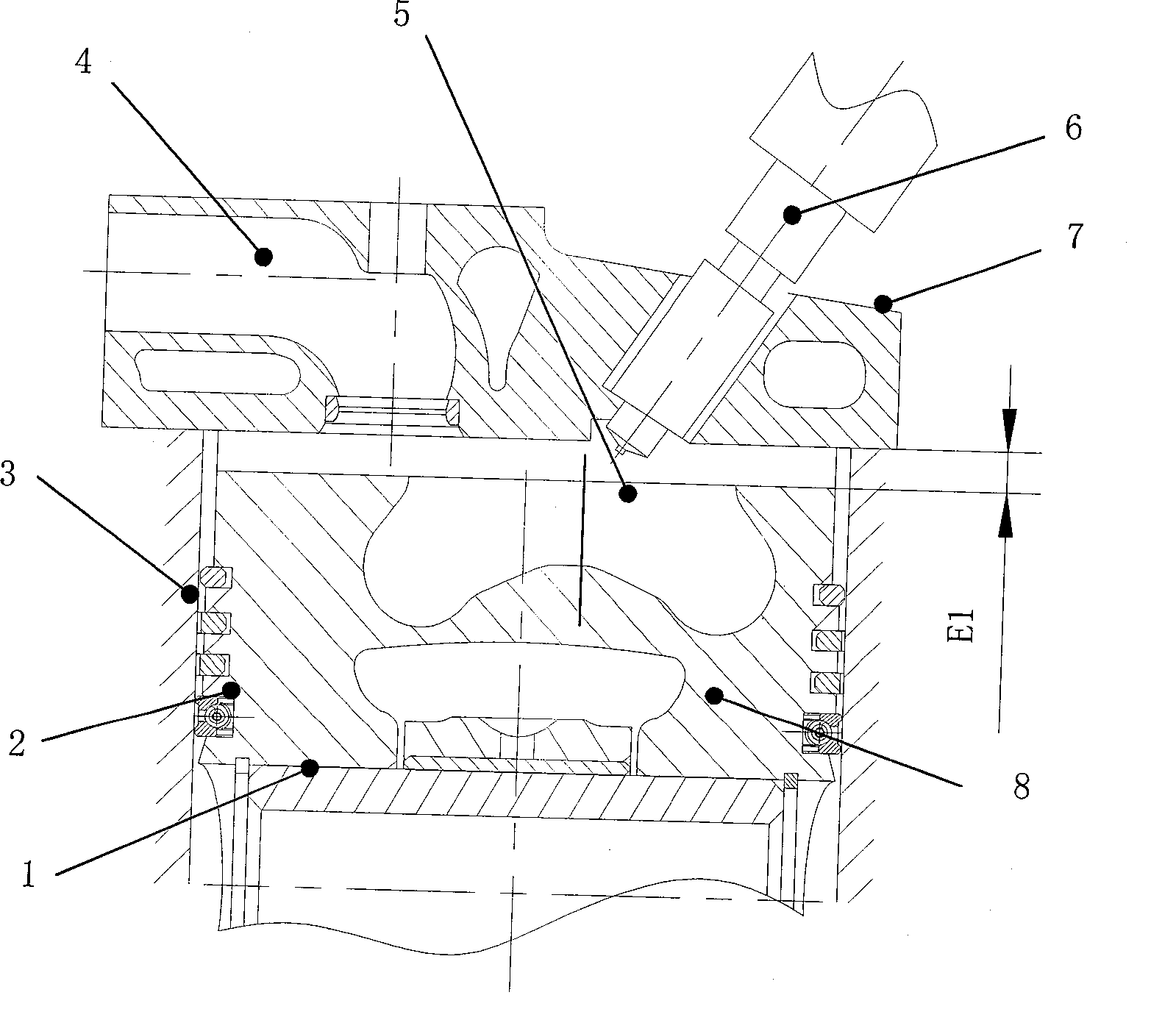

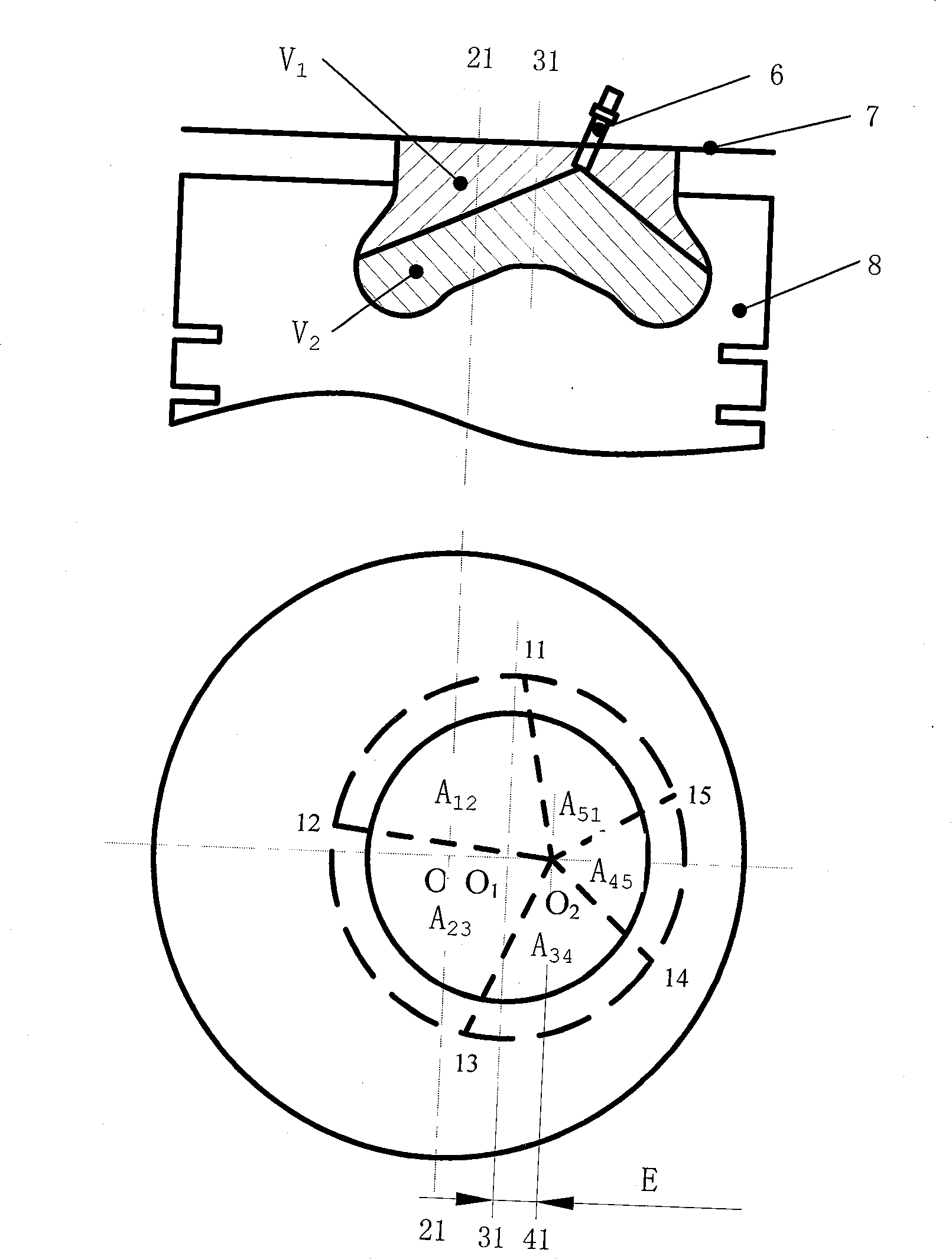

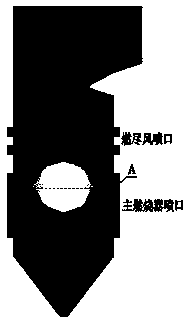

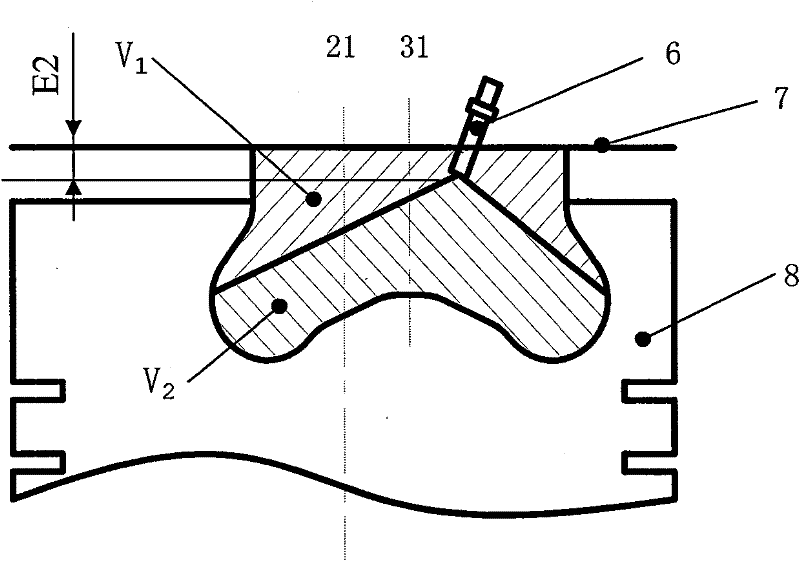

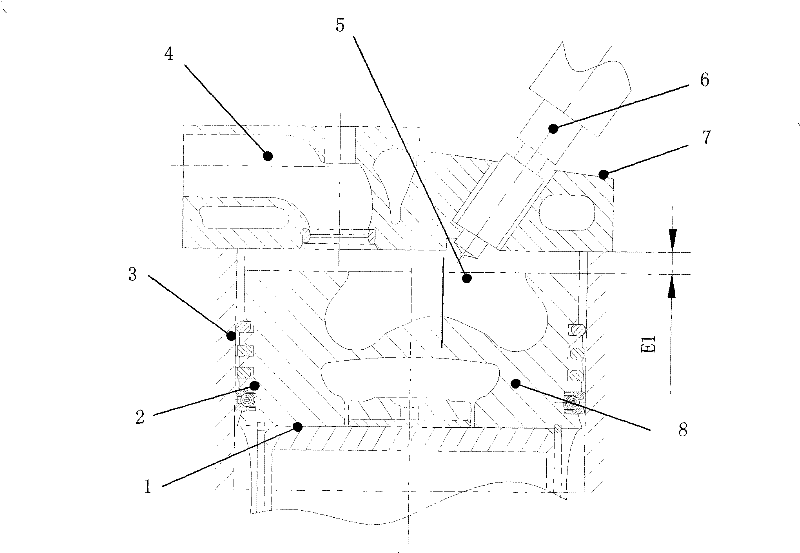

Fuel oil uniform mixing and burning system of double air ports diesel engine

InactiveCN101451463AImprove performanceReduce angleInternal combustion piston enginesFuel injection apparatusCombustion systemCombustion chamber

The present invention relates to a fuel equipartition mixture and combustion device design proposal of two valve diesel. A fuel injector set on the cylinder cap and an inlet channel; a burning compartment is below the fuel injector and inlet channel; the inlet channel is eddy flow type inlet channel; a drop pit shape shrunk burning compartment in the shape of letter W is set above the valve; head section of the fuel injector stretches out of the bottom of the cylinder cap and against the burning compartment. Parameter design of cylinder cap, fuel injector and burning compartment make fuel and air adequate distribution in certain rules on axial and circumferential direction within effective combustion space, and realize oil gas mixing design of equal excess air factor within effective combustion space. Under effect of high jet pressure and air-intake transverse currents of fuel injection system, oil gas inside the cylinder mixes uniformly, velocity of combustion quicker, duration short, oil spout can be postponed, and high-efficiency quick burning of low discharge can be realized. Engine synthetic performance can be optimized through the invention, and engine power can be improved while nocuousness discharged object can be reduced.

Owner:JIANGSU UNIV

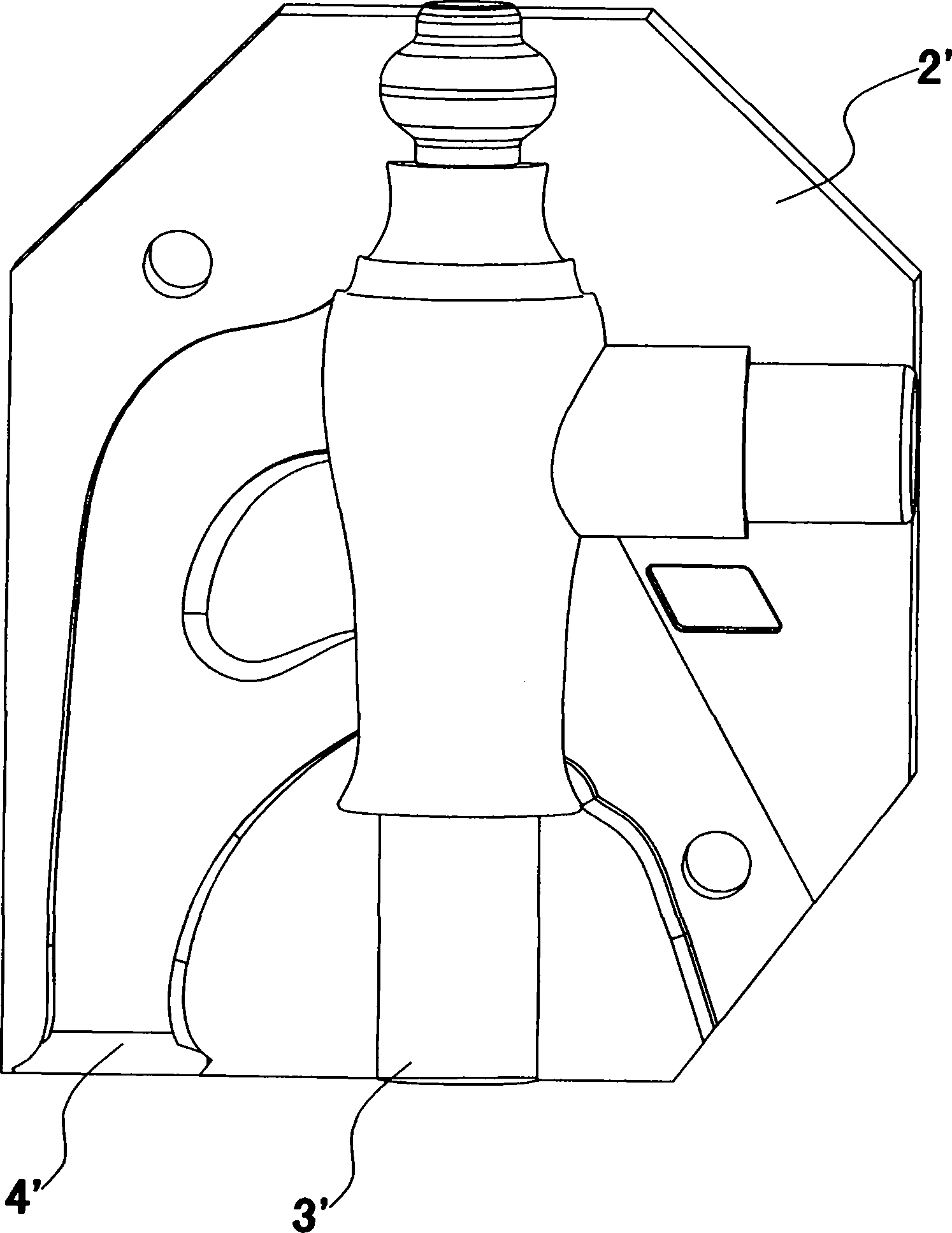

Casting technology for lead-free brass tap

ActiveCN104259393AGuaranteed thermal balanceSimple structureFoundry mouldsFoundry coresHeat balanceMaterials science

The invention provides a casting technology for a lead-free brass tap, which the advantages that the flowing distance of products in the pouring process is short, simultaneous solidification is realized, and hot cracks are reduced; the die has excellent heat balance effect, is favorable to the heat balance of the products and reduces stress micro-cracks during cooling. The casting technology comprises the step of casting-molding lead-free brass fluid through a gravity casting device, wherein the gravity casting device comprises an upper half die, a lower half die and a sand core, die cavities fitted with the shape of a tap body are respectively correspondingly arranged between the upper half die and the lower half die, the sand core is arranged in the die cavities between the upper half die and the lower half die, the shape of the sand core is matched with the shape of a water-in part, a water-out part and an inner cavity of a valve core mounting part of the tap body, pouring cavities are formed between the sand core and the die cavities, a gate for allowing lead-free melt copper to be poured is further formed in the upper half die or the lower half die, the gate is connected with the pouring cavities, the gate is provided with an inner gate and an outer gate, and the inner gate is correspondingly arranged at the pouring cavity part for molding the valve core mounting part of the tap body.

Owner:GUANGDONG WEIXIANG SANITARY WARE

Fixed-proportion coating mixing bottle capable of reducing residues

InactiveCN112774567AAccurate and convenient color matchingAvoid wastingTransportation and packagingMixer accessoriesChemistryCoating

The invention relates to the related field of coatings, and discloses a fixed-proportion coating mixing bottle capable of reducing residues. The fixed-proportion coating mixing bottle comprises a bottle body, wherein a residue scraping plate is slidably arranged in the bottle body, the residue scraping plate can scrape off the coating on the inner wall of a mixing cavity, a lifting rod is fixedly arranged on the upper end surface of the residue scraping plate, a cover body sleeves the upper end of the bottle body, a coating containing groove is formed in the bottom of the cover body, the inner circular wall of the coating containing groove is in threaded connection with the outer circular surface of the bottle body, a mixing cavity is upwards formed in the bottle body, and a matching fixing column is fixedly arranged at the circle center of the bottom wall. According to the fixed-proportion coating mixing bottle capable of reducing the residues, a user can conveniently proportion coatings according to a certain ratio, and the coatings on the inner wall of the mixing bottle can be scraped off, so the residues of the mixed coatings are reduced, the utilization rate of the coatings is increased, and the service life of the mixing bottle is prolonged.

Owner:深圳市华温锦商贸有限公司

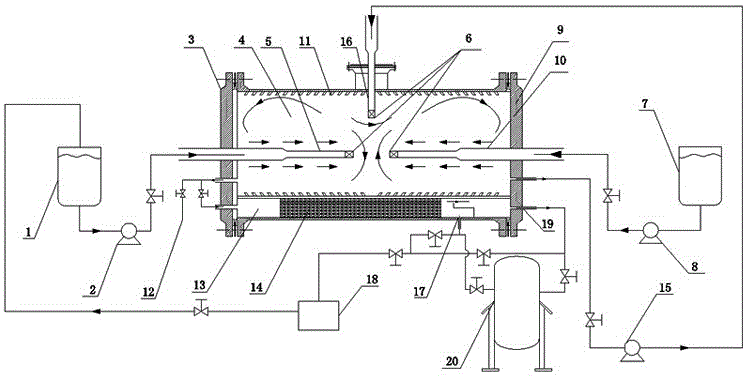

Impinging stream reaction and separation integration device and impinging stream reaction and separation integration method for liquid-liquid reaction system

InactiveCN106423002AEnhanced mixing processWell mixedLiquid-liquid reaction processesPropellerHorizontal axis

The invention relates to an impinging stream reaction and separation integration device and an impinging stream reaction and separation integration method for a liquid-liquid reaction system. The impinging stream reaction and separation integration device comprises a device barrel body, three storage tanks and three booster pumps, wherein the device barrel body is divided into a reaction cavity and a separation cavity; the reaction cavity is internally provided with three main guide cylinders, two of the main guide cylinders are opposite to each other along a horizontal axis, and the circulating main flow guide cylinder is arranged at the upper side of the middle of the device barrel body, so that circulating repeated impinging of two-phase liquids is realized; end openings of the three guide cylinders are provided with guide vanes; the separation cavity is internally provided with a corrugated plate; the middle lower part of the device barrel body is provided with a sampling opening; the separation cavity is internally provided with two discharging holes. The impinging stream reaction and separation integration device has the beneficial effects that movable components such as a propeller are not arranged in the device barrel body, and the guide vanes are adopted to replace a propeller-type structure, so that the problems such as vibration caused by the propeller-type structure are reduced; the circulating guide cylinder is arranged in the reaction cavity, so that circulating repeated impinging of the two-phase liquids is realized, the mixing process of two liquids is strengthened, and the process flow is reduced.

Owner:李泽深

Dyeing machine with eco-friendly effect

PendingCN108914436AImprove work efficiencyEmbody efficiencyTextile treatment machine arrangementsTextile treatment by spraying/projectingEnvironmental resistanceWater resources

The invention discloses a dyeing machine with eco-friendly effect. The machine comprises a body of the dyeing machine, a support board, an operation platform and a power box. The operation platform isfixedly connected right ahead of the body of the dyeing machine. The support board is fixedly connected with the top end of the operation platform. The other side of the operation platform is fixedlyconnected with a pedal. One end of the body of the dyeing machine is fixedly connected with a dye box. One side at the top of the support board is fixedly connected with the power box. A cloth guideroll is connected at the top end right ahead of the support board in an embedding manner. One side at the bottom end of the body of the dyeing machine is fixedly connected with a filtering box. The filtering box ensures that discharged waste water does not cause pollution to the environment, thereby protecting the nature. Meanwhile, waste of water resources is saved. The body of the dyeing machineis eco-friendly. The dye box can ensure that dyes can be more quickly put into use. Therefore, the body of the dyeing machine is efficient. A nozzle can uniformly spray dyes to cloth material when cloth is dyed so that uniformity of the body of the dyeing machine is ensured.

Owner:孝感市智强医疗器械有限公司

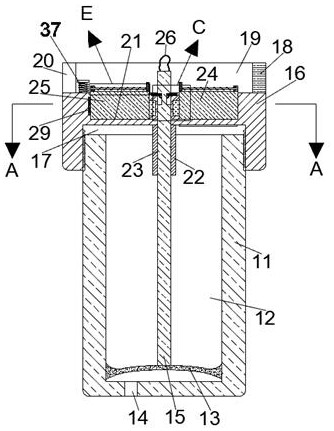

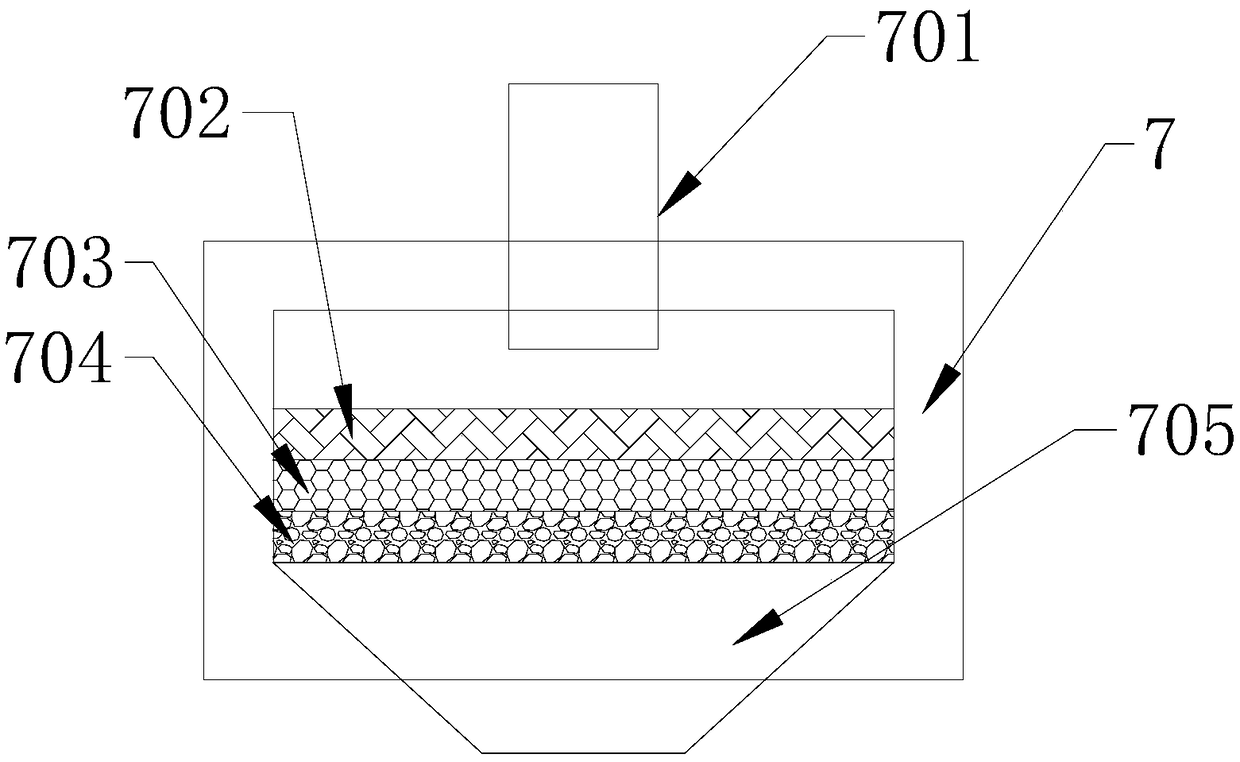

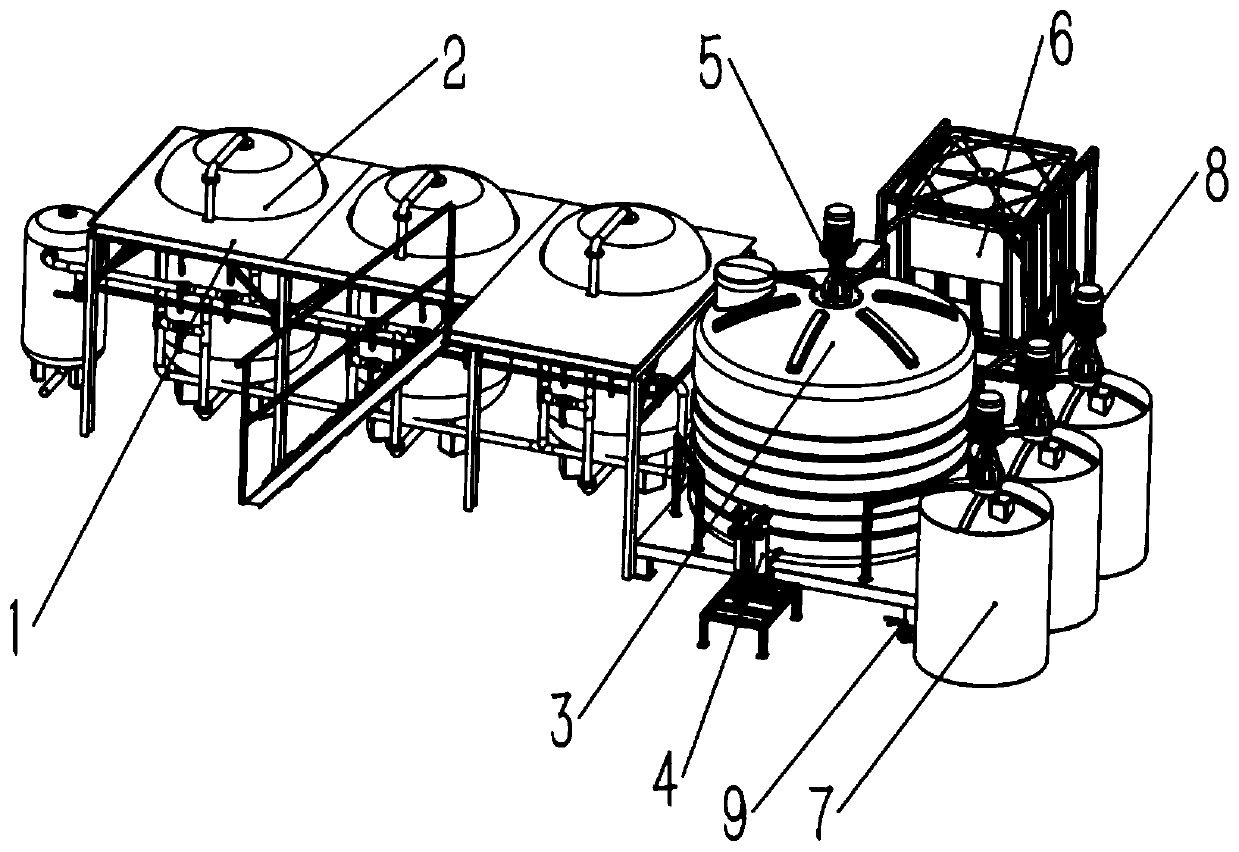

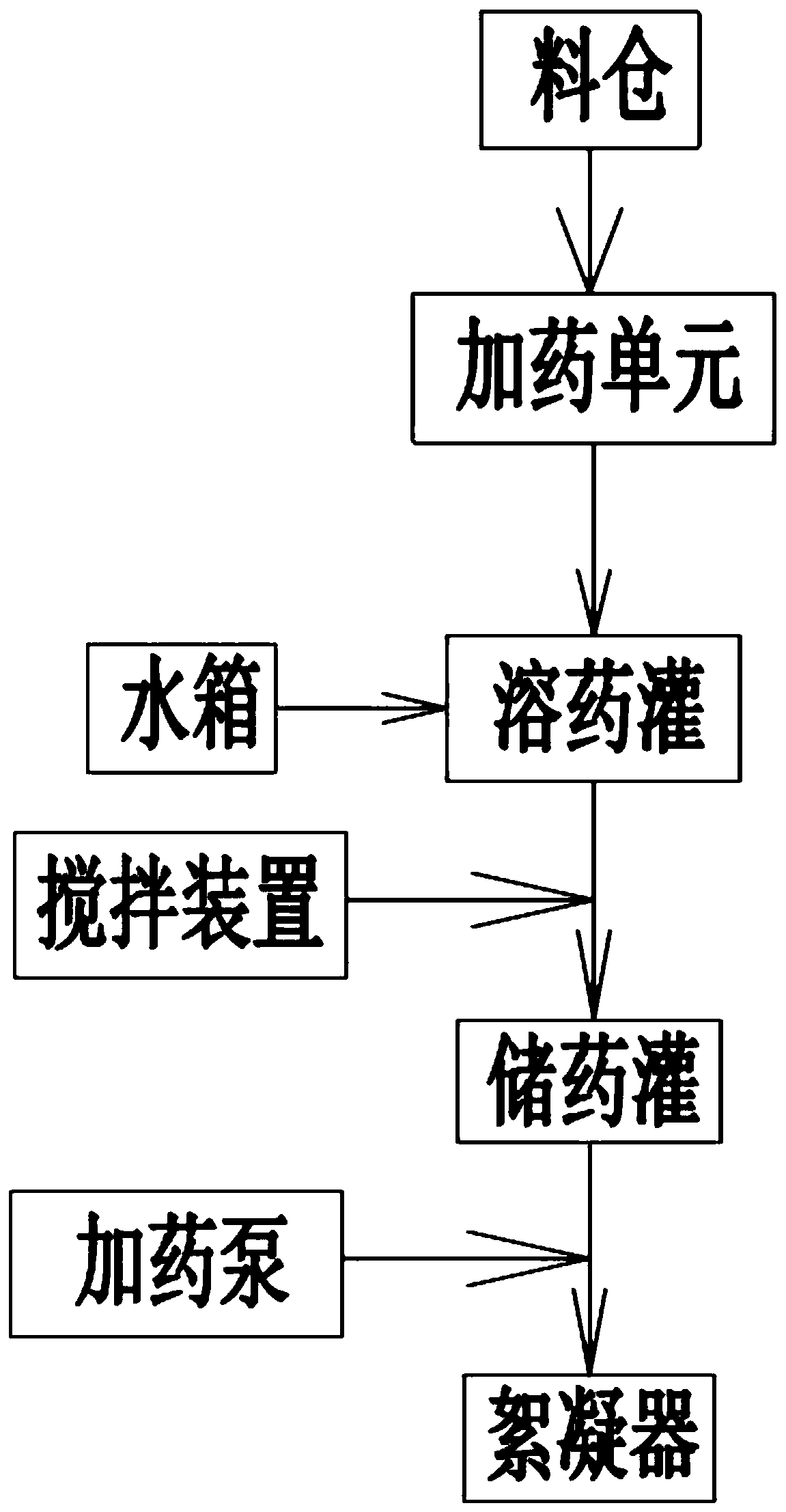

Full-automatic dosing device for sewage treatment and method thereof

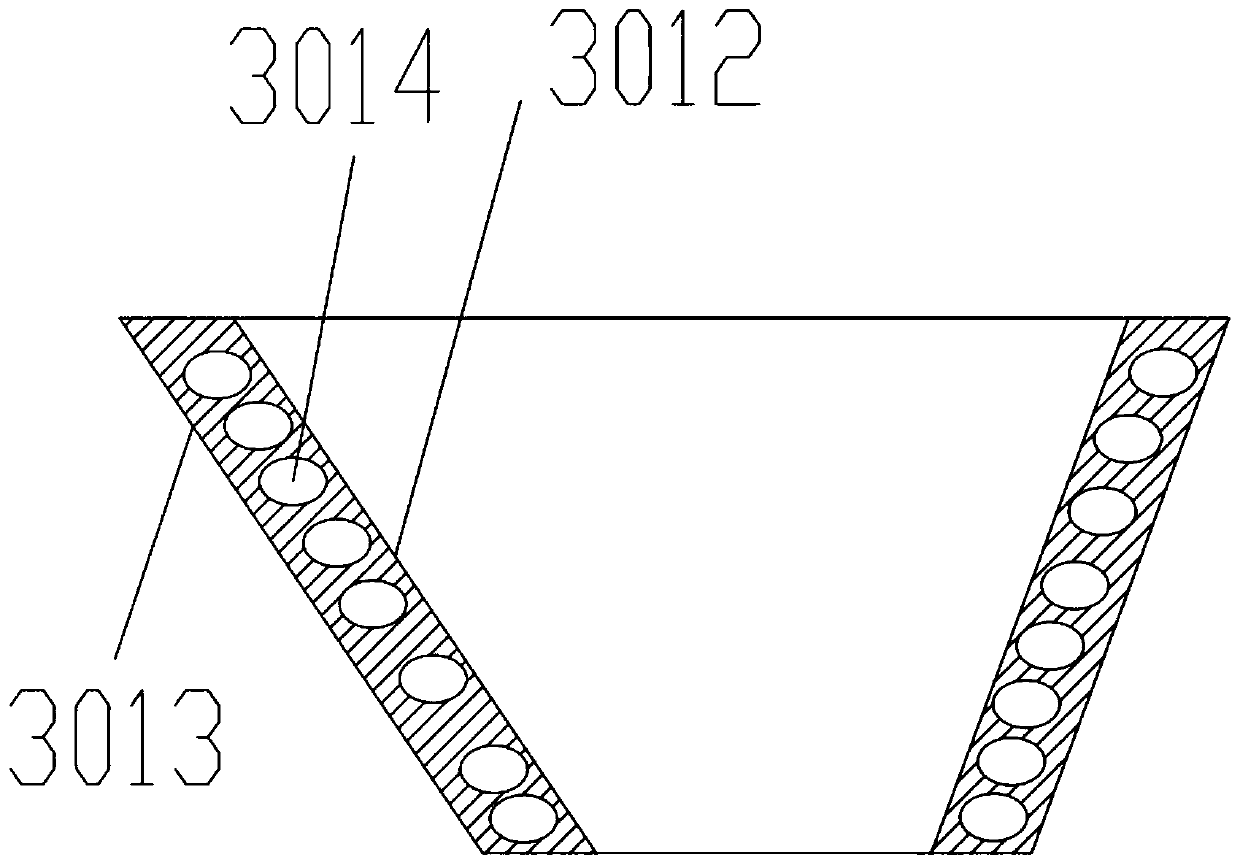

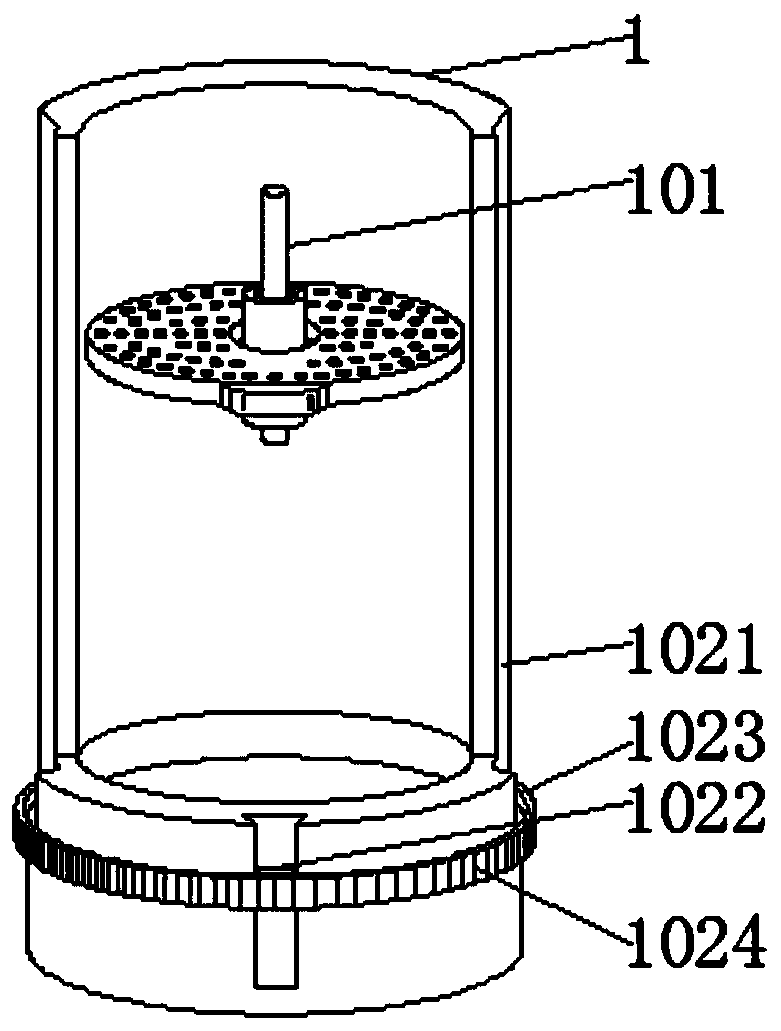

InactiveCN111470602AGuaranteed drynessReduce wasteRotary stirring mixersTransportation and packagingSewage treatmentResistance wire

The invention discloses a full-automatic dosing device for sewage treatment and a method thereof, and belongs to the technical field of water treatment. A resistance wire is added into the inner cavity of a dosing hopper; the dryness of powder is ensured; meanwhile, a stirring device is arranged at the top of a medicament dissolving tank; the phenomena that medicaments are not easy to dissolve anddust is generated are avoided; the screw pitch of a screw passing through a screw rod is gradually reduced from left to right; the powder entering screws is pressed more and more tightly; the pressure loss of the system is reduced; the leakage of compressed air in a pipeline of a conveying device is prevented; meanwhile, a water supply valve is opened before feeding; when a gas-material mixture reaches the outlet of a pneumatic conveying pipeline and is sprayed by a water column, separation of materials and gas is achieved, powder is taken away by water to enter the medicament dissolving tank, water is supplied in a spraying mode to guarantee that the powder can be evenly mixed with water in time after leaving the conveying device, dust is avoided, and dissolution is facilitated. Waste ofpowder is reduced, and finished products are saved.

Owner:南京帝艾环境科技工程有限公司

A multi-angle continuous uninterrupted spray liquid bottle

ActiveCN109332039BImprove continuityIncrease variabilitySingle-unit apparatusMedical atomisersContinuous/uninterruptedEngineering

The invention discloses a multi-angle continuous and uninterrupted spray liquid bottle, comprising a spray tank, the inner cavity of the spray tank is provided with a water pipe clamping mechanism, and the outer ring of the spray tank is provided with a nozzle adjustment mechanism, It involves the technical field of daily necessities. The liquid bottle for multi-angle continuous uninterrupted spray adopts a design method in which the position of the suction port of the infusion tube can be adjusted arbitrarily, so that no matter what position the spray bottle is in It can both absorb water and spray, which increases the continuity of the spray work and the variability of the spray state, making it more convenient to spray at the corner from the left. Drive the port of the internal water suction pipe to move up and down, so that the water suction pipe can move in different positions, and always be in contact with the aqueous solution, ensuring that the water absorption and spraying action can be carried out uninterrupted.

Owner:嘉兴市迅程信息技术有限公司

Tea leaf drying method with intermittent moisture removal

InactiveCN106376658AReduce churnPromote precipitationPre-extraction tea treatmentChemistryPrecipitation

The invention relates to the technical field of processing of tea leaves, in particular to a tea leaf drying method with intermittent moisture removal. The method comprises the following steps of S1, a water removal stage; S2, a water-fragrance mixing state; S3, a fragrance extracting stage. The tea leaf drying method with intermittent moisture removal provided by the invention is divided into several stages for removing humidity and extracting fragrance through utilizing the difference of precipitation time of water and fragrance substances in the tea leaves, and meanwhile, adopts an intermittent moisture removal way, so that the loss of the fragrance substances is reduced.

Owner:贵州省湄潭县黔茗茶业有限责任公司

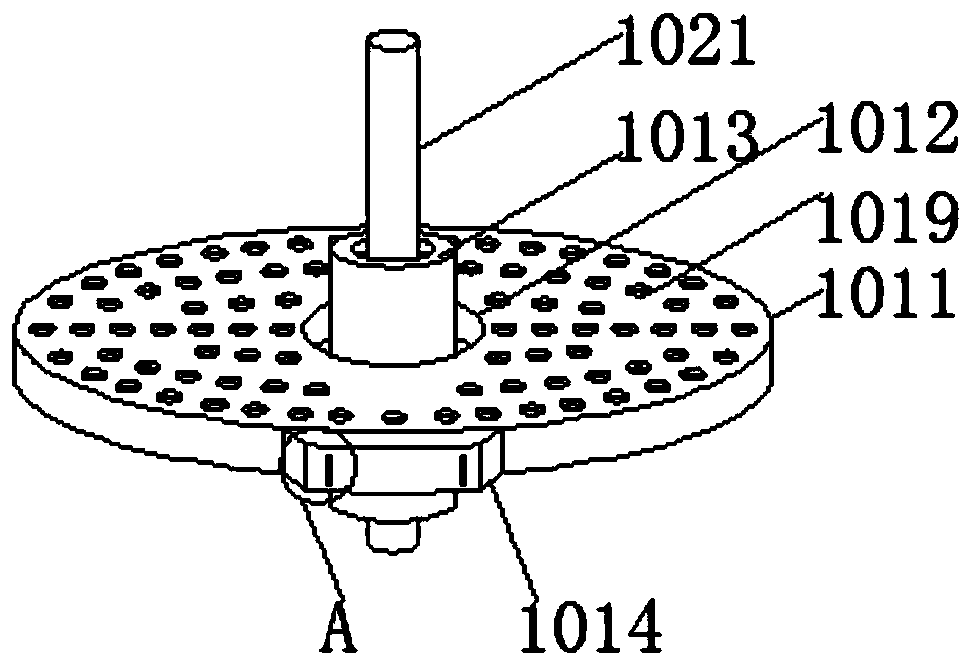

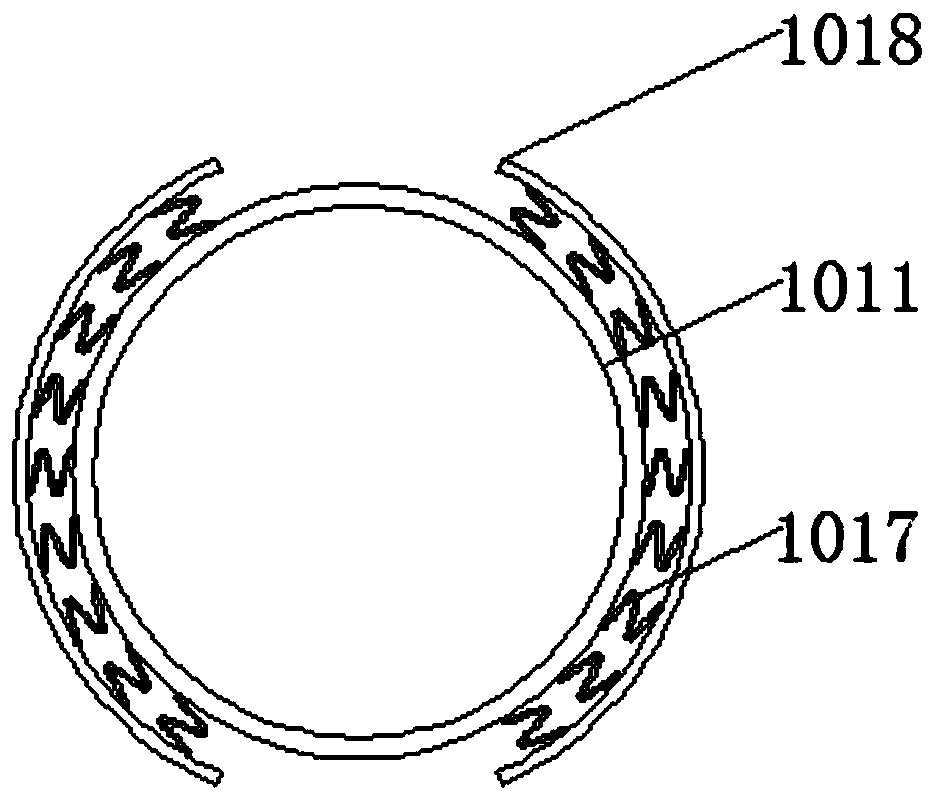

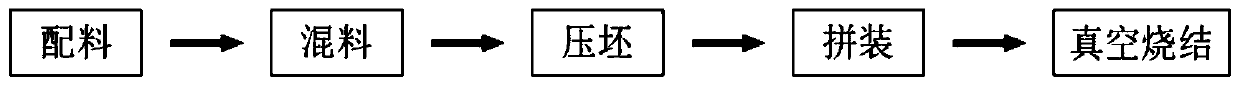

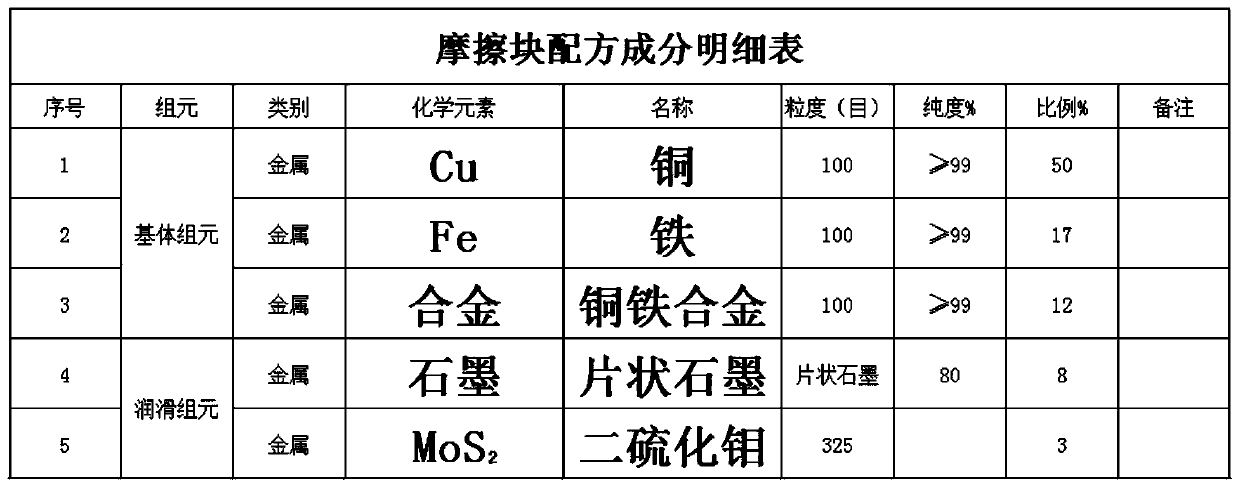

Novel processing method for powder metallurgy brake pad friction block

InactiveCN111590066AShorten the production cycleReduce manufacturing costTransportation and packagingMetal-working apparatusPowder metallurgyVacuum pressure

The invention discloses a novel processing method for a powder metallurgy brake pad friction block. The novel processing method comprises the following steps: proportioning, mixing, compacting, splicing and vacuum sintering. Through repeated test, performance of the friction block is improved by 50% or more and production efficiency is improved by 6.8 times or more on the original basis; vacuum pressure sintering is adopted, compacting can be performed in a compacting machine like a common powder metallurgy part, so that the production period is remarkably shortened, and production cost is reduced; a friction layer of a friction plate obtained by a vacuum pressure sintering process has lower porosity, so that a friction coefficient is higher; the most outstanding point is that relatively high shear strength can be kept as the friction plate is subjected to vacuum high-temperature sintering along with the friction block; and meanwhile, dimension precision also can be guaranteed by precision of a graphene mould in a vacuum pressure sintering furnace. The novel processing method reduces processes in production, reduces bad links in a production process, reduces number of used workers,and further reduces production cost.

Owner:漯河久铖智能装备有限公司

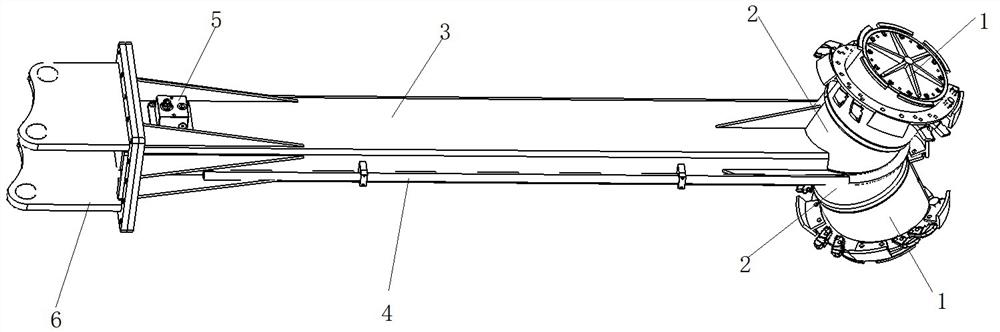

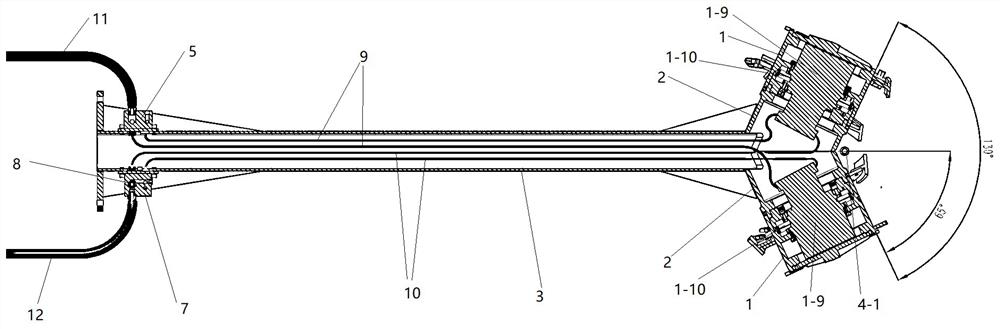

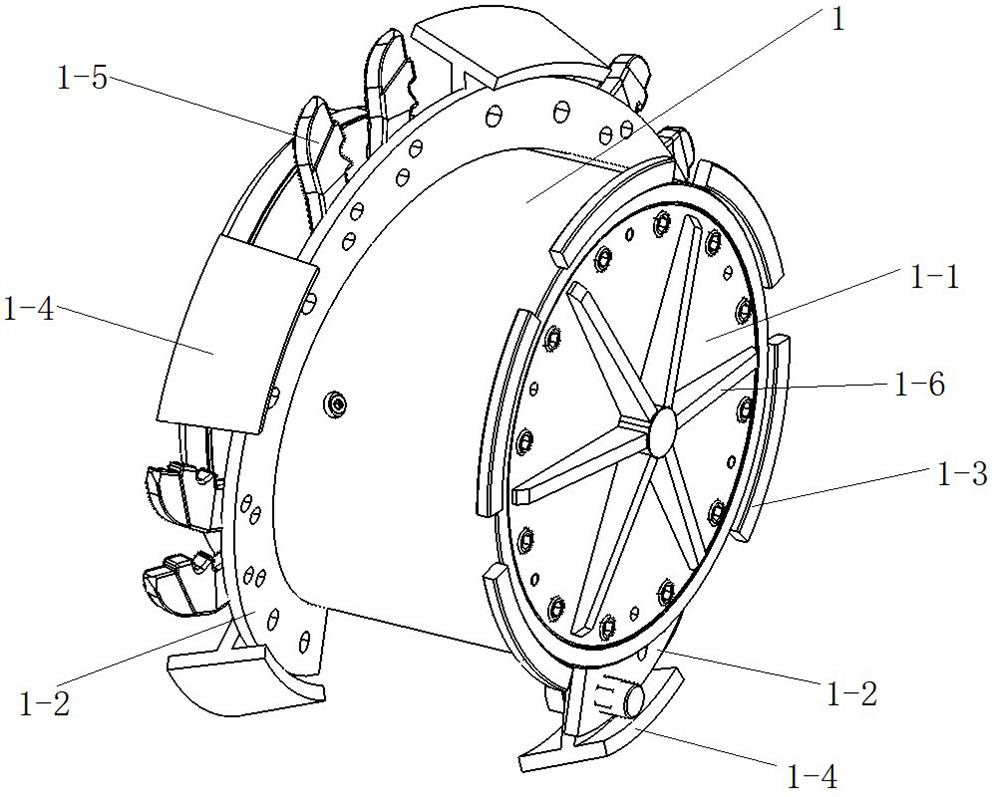

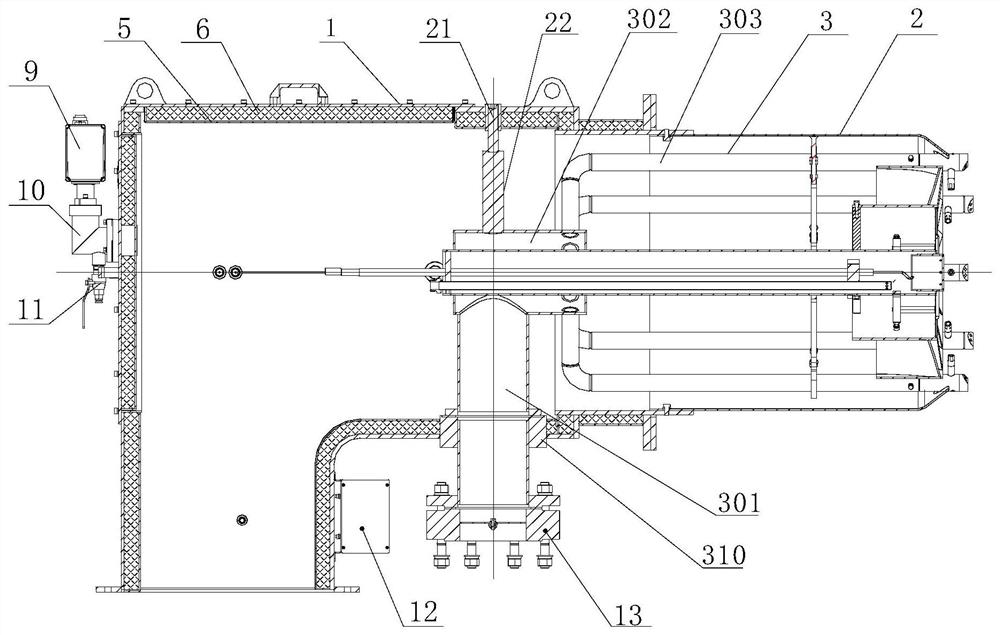

Sludge in-situ stirrer

PendingCN112144506AEnsure balanced operationPrevent idlingCement mixing apparatusSoil preservationHydraulic motorSludge

The invention provides a sludge in-situ stirrer. The sludge in-situ stirrer comprises an extension arm, wherein two stirring drums and a double-stirring-drum hydraulic driving oil way system for driving the stirring drums to rotate are arranged on the extension arm, the double-stirring-drum hydraulic drive oil way system involves a system oil inlet pipe, a system oil return pipe, an oil inlet valve block, an oil return valve block, two motor oil inlet pipes, two motor oil return pipes and two hydraulic motors installed inside the two stirring drums, the system oil inlet pipe is connected withthe two motor oil inlet pipes through the oil inlet valve block, the two motor oil return pipes are connected to the system oil return pipe through the oil return valve block, oil inlets and oil return ports of the two hydraulic motors are connected with the two motor oil inlet pipes and the two motor oil return pipes respectively, the two hydraulic motors are connected in parallel, and a flow balance valve is installed inside the oil inlet valve block or the oil return valve block. The sludge in-situ stirrer can automatically increase the working capacity of the hindered hydraulic motors, sothat the stirring drums break through resistance to continue to normally work, and the stirring drums are prevented from being hindered and stuck.

Owner:宁波恩特重工科技有限公司

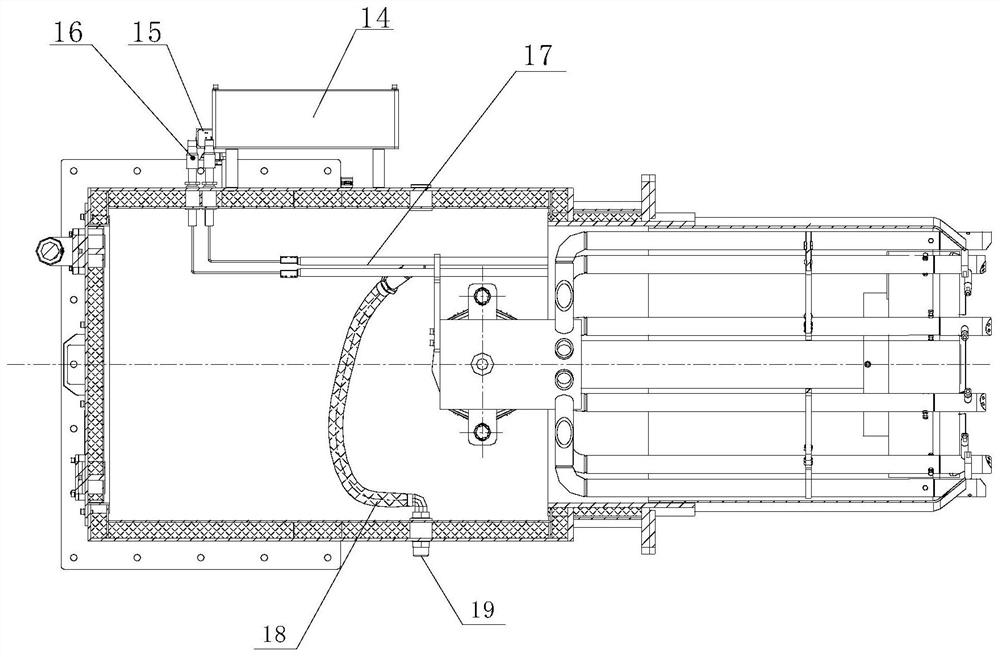

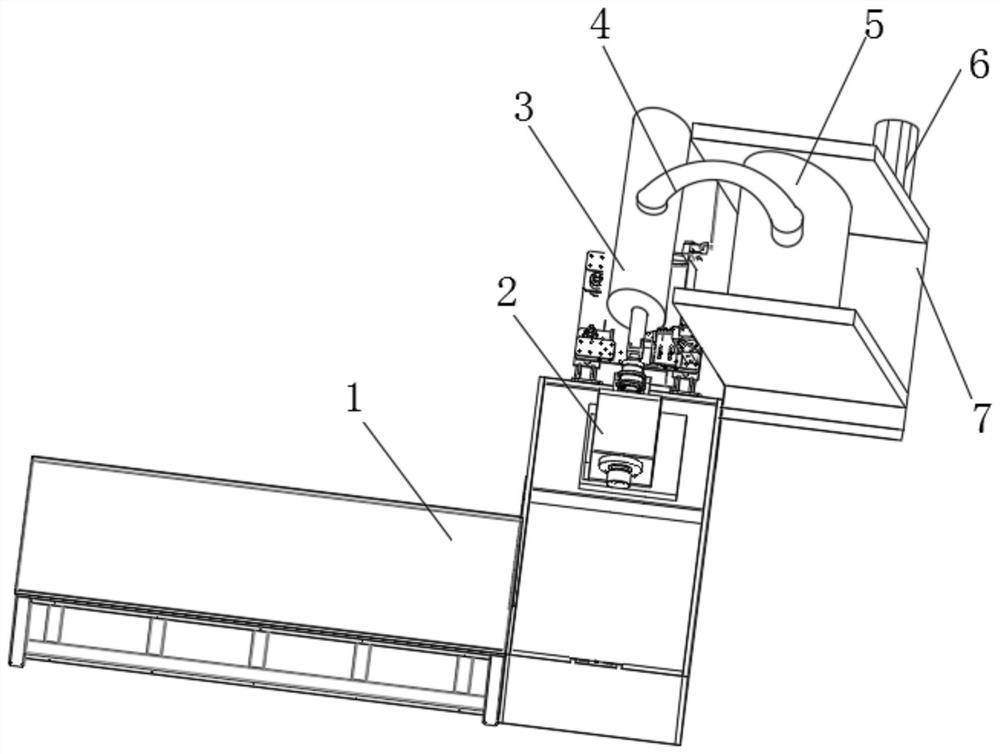

Multi-dimensional air staged low NOx combustion system and layout method

ActiveCN109028135BEmission reductionPrevent slaggingPulverulent fuel combustion burnersNon-combustible gases/liquids supplyLow loadSlag

Owner:HARBIN BOILER CO LTD

Fuel oil uniform mixing and burning system of double air ports diesel engine

InactiveCN101451463BWell mixedMix in timeInternal combustion piston enginesFuel injection apparatusCombustion chamberEngineering

The present invention relates to a fuel equipartition mixture and combustion device design proposal of two valve diesel. A fuel injector set on the cylinder cap and an inlet channel; a burning compartment is below the fuel injector and inlet channel; the inlet channel is eddy flow type inlet channel; a drop pit shape shrunk burning compartment in the shape of letter W is set above the valve; headsection of the fuel injector stretches out of the bottom of the cylinder cap and against the burning compartment. Parameter design of cylinder cap, fuel injector and burning compartment make fuel andair adequate distribution in certain rules on axial and circumferential direction within effective combustion space, and realize oil gas mixing design of equal excess air factor within effective combustion space. Under effect of high jet pressure and air-intake transverse currents of fuel injection system, oil gas inside the cylinder mixes uniformly, velocity of combustion quicker, duration short, oil spout can be postponed, and high-efficiency quick burning of low discharge can be realized. Engine synthetic performance can be optimized through the invention, and engine power can be improved while nocuousness discharged object can be reduced.

Owner:JIANGSU UNIV

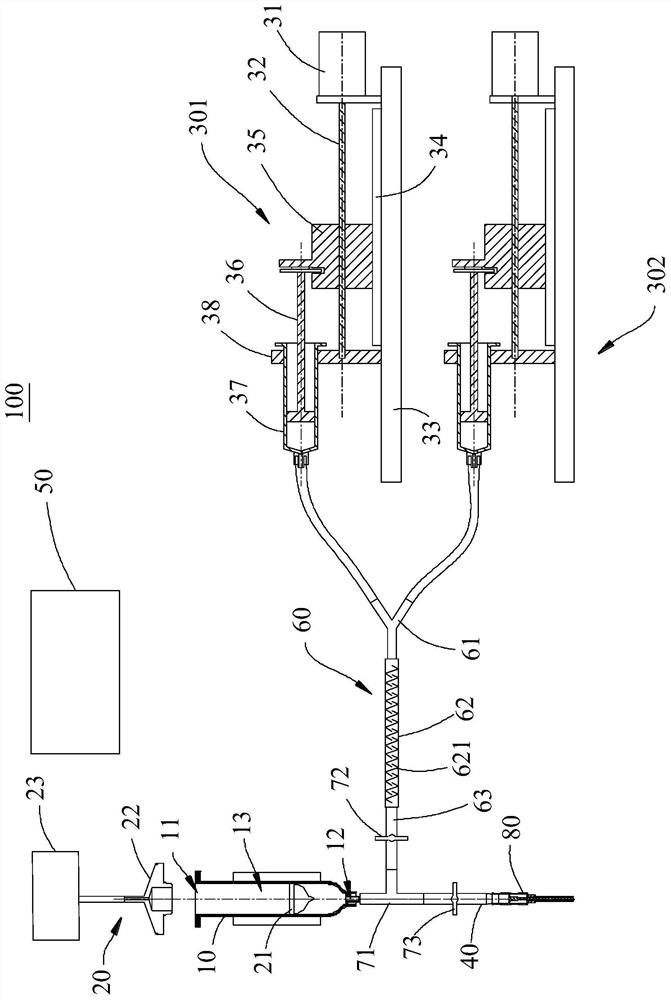

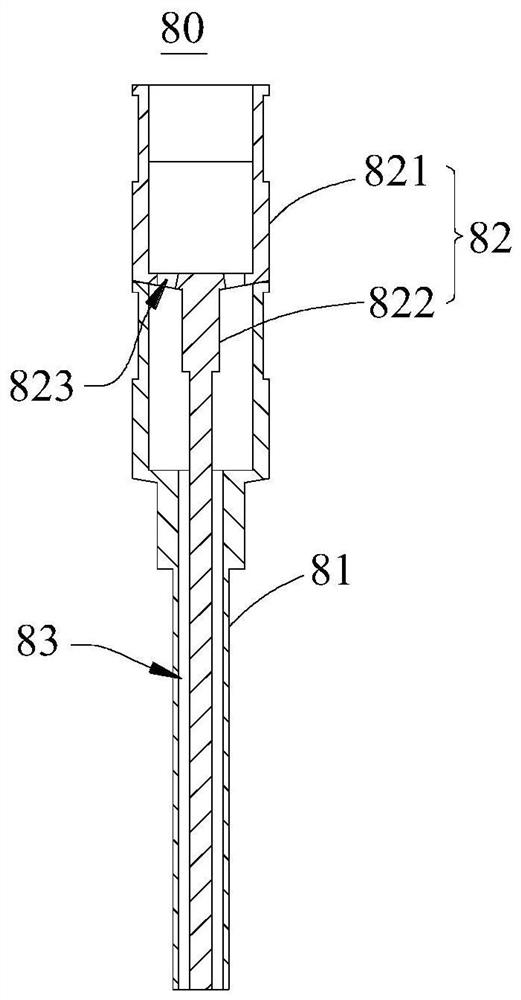

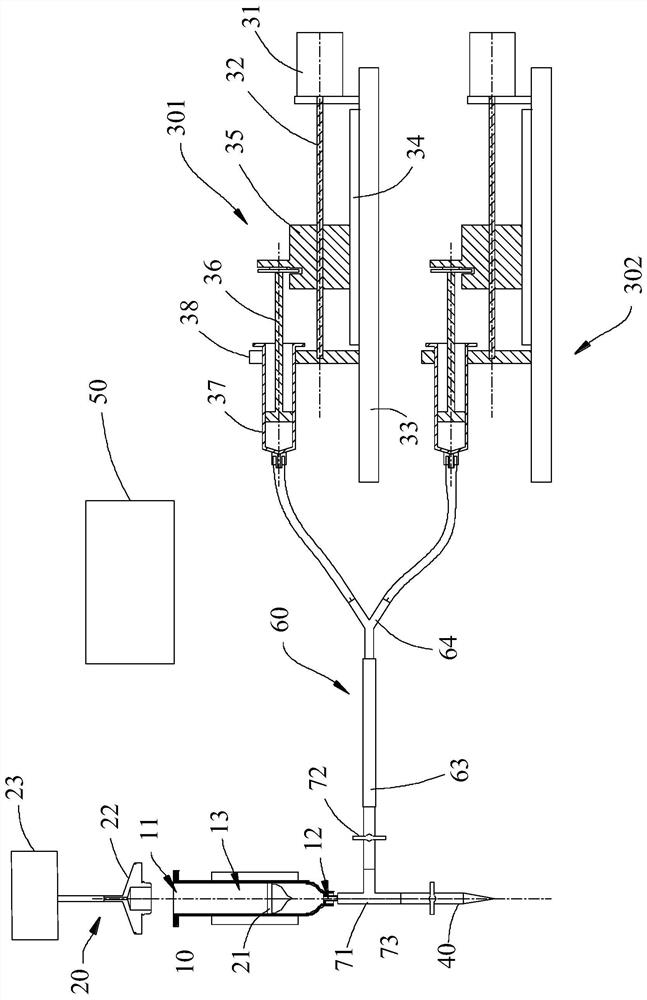

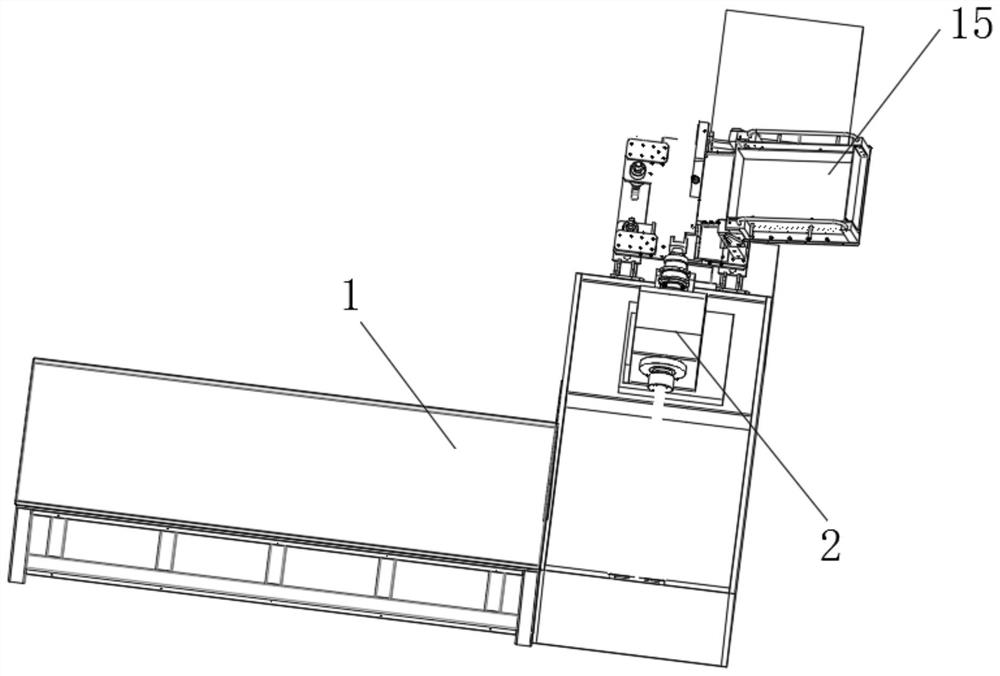

Composite extrusion type 3D printer

PendingCN113478825AGuaranteed mixPrecise control of mixing volume ratioAdditive manufacturing apparatus3D object support structuresComputer printingControl system

The invention relates to a composite extrusion type 3D printer, and belongs to the technical field of printers. The composite extrusion type 3D printer comprises a printing temporary storage ink box, a discharging driving system, a first material supplementing system, a second material supplementing system, a printing nozzle and a control system; the printing temporary storage ink box is used for containing a first material and a second material which are mixed or used for mixing the first material and the second material in the printing temporary storage ink box; the discharging driving system is an air pressure driving system and is used for extruding the mixed first material and second material in the printing temporary storage ink box out of the printing temporary storage ink box; the first material supplementing system is a motor driving system and is used for supplementing the first material into the printing temporary storage ink box; the second material supplementing system is a motor driving system and is used for supplementing the second material into the printing temporary storage ink box; the printing nozzle is connected to the discharging end of the printing temporary storage ink box; and the control system is used for controlling the discharging driving system, the first material supplementing system and the second material supplementing system. According to the composite extrusion type 3D printer, timely and accurate mixing of materials can be achieved, and timely and accurate printing of the materials can also be achieved.

Owner:REGENOVO BIOTECH

Split hot air type low-nitrogen gas burner

PendingCN111706860ARealize the outer loopReduce generationGaseous fuel burnerThermodynamicsCombustor

The invention relates to a split hot air type low-nitrogen gas burner. The split hot air type low-nitrogen gas burner comprises a burner shell, a flame cylinder, a central gas pipe assembly, a burningtorch assembly and an air door regulating mechanism assembly; a heat-preserving structure is arranged on the inner wall of the burner shell; the flame cylinder is mounted at the front end of the burner shell; the internal part of the flame cylinder and the internal part of the burner shell run through each other; the burning torch assembly and the central gas pipe assembly are fixedly connected together to form a whole body mounted in the burner shell, and the front end of the whole body extends towards the front end of the flame cylinder; and the air door regulating mechanism assembly is mounted at a fan air inlet on the burner shell through a three-way pipe. The split hot air type low-nitrogen gas burner has the following beneficial effects: the burner is arranged separately from a fanmechanism in an appearance structure, and external circulation of flue gas is realized by mounting the air door regulating mechanism to connect with an external fan, so that excessive air quantity isreduced and generation of NOX is reduced; and the structure is simpler, and the practicability is high under the condition that the national discharge standard is met.

Owner:上海迎韦热能设备有限公司

A color 3D printer extrusion nozzle

ActiveCN105479744BMix in timeDoes not affect the accuracy of single-point color matchingApplying layer meansColor printingEngineering

The purpose of the present invention is to provide a color 3D printer extrusion nozzle, including a nozzle assembly, the nozzle assembly includes a nozzle, a rotary sleeve, a large gear, a small gear, a stepping motor, and the rotary sleeve is installed on the outside of the nozzle and passed through the ring on the rotary sleeve. The protrusion is positioned, a conical mixing chamber is formed between the bottom of the nozzle and the rotary sleeve, the nozzle is set under the conical mixing chamber, the large gear is installed outside the rotary sleeve through the elastic retaining ring, the small gear meshes with the large gear, and is fixed on the motor bracket. The stepper motor is connected to the pinion, and the motor bracket is fixed on the nozzle. The nozzle is provided with an annular groove, flow channel I, flow channel II and flow channel III, and the flow channel I, flow channel II, and flow channel III are all connected to the conical mixing chamber. , The resistance wire heater is installed in the annular groove, and the feed assembly I, feed assembly II, and feed assembly III are respectively installed outside the flow channel I, flow channel II, and flow channel III. The invention can solve the problems that the current 3D printers are difficult to realize single nozzle color printing and the color difference exists in the color 3D printing.

Owner:HARBIN ENG UNIV

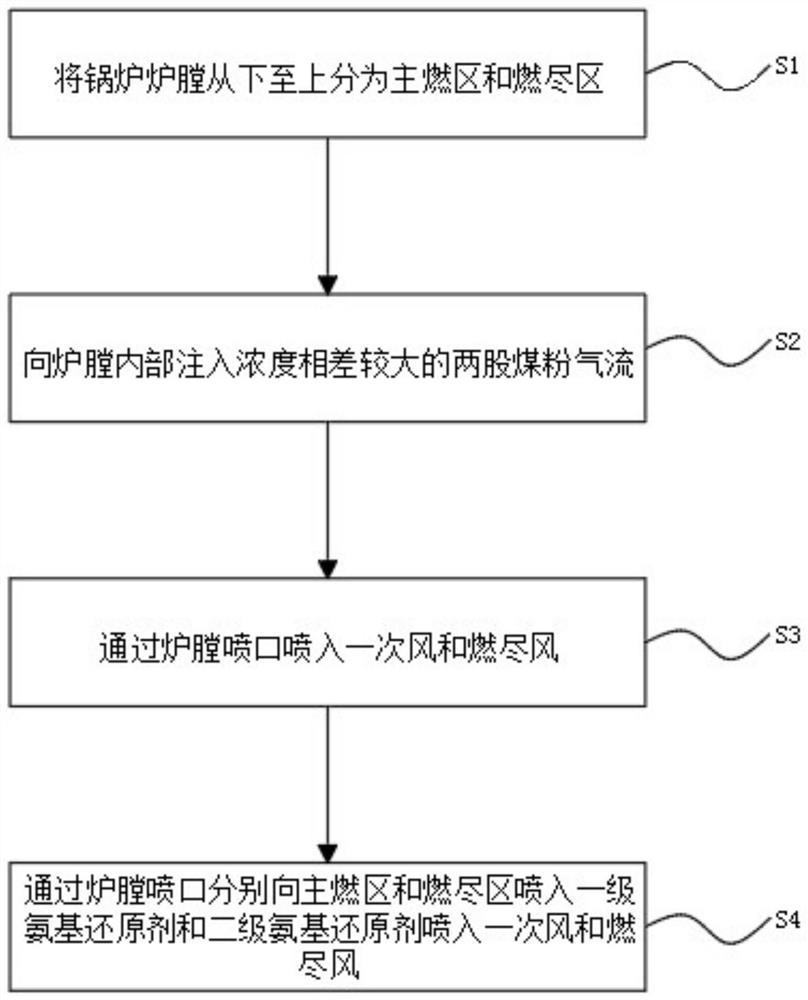

Combustion method for effectively reducing boiler furnace slagging and high-temperature corrosion

ActiveCN113654079AReduce generationPrevent fallingIndirect carbon-dioxide mitigationAir/fuel supply for combustionBoiler furnaceCombustor

The invention provides a combustion method for effectively reducing boiler furnace slagging and high-temperature corrosion. The combustion method comprises the steps that S1, a boiler furnace is divided into a main combustion area and a burn-out area from bottom to top; S2, two strands of pulverized coal airflow with a large concentration difference are injected into the furnace; S3, primary air and over fire air are sprayed in through a furnace nozzle; and S4, a first-stage amino reducing agent and a second-stage amino reducing agent are sprayed into the main combustion area and the burn-out area correspondingly. According to the combustion method for effectively reducing boiler furnace slagging and high-temperature corrosion, the problems that in the prior art, a good low NOx emission effect is achieved, after the overall air amount of the main combustion area is reduced, pulverized coal combustion is carried out in a reducing atmosphere, a melting point of coal ash is reduced, combustors are arranged in a centralized mode, the pulverized coal combustion temperature is high, the slagging condition of the water-cooled wall of the boiler furnace is deteriorated, and the high-temperature corrosion of the water-cooled wall is intensified are solved.

Owner:XIAN THERMAL POWER RES INST CO LTD

A kind of production method of biomass environment-friendly fuel

The invention discloses a production method of biomass environment-friendly fuel. The production method comprises the following steps: material selection-crushing-mixing-press molding; step 1: material selection, the environmentally-friendly fuel mainly consists of straw, wood and fruit shells 48%-50% of straw, 36%-55% of wood, 6%-9% of husk; step 2: crushing, the raw materials in step 1, straw, The wood and husks are dried and crushed into 1-2.5cm granules; step 3: mixing, mixing the straw, wood and husks in step 2 through a mixing device; step 4: pressing and forming, Utilize the molding device to extrude and cut the mixed material into blocks with edges of 2-5 cm. The binder in the material helps the combustion of the fuel, and the flame is better in the biofuel. Using the oil extracted from animal carcasses or the oil extracted from waste food residues as oil for processing can not only utilize waste, but also reduce energy consumption.

Owner:梁文静

Liquid containing bottle used for unceasingly conducting spraying at multiple angles

ActiveCN109332039AImprove continuityIncrease variabilitySingle-unit apparatusMedical atomisersEngineeringAqueous solution

The invention discloses a liquid containing bottle used for unceasingly conducting spraying at multiple angles. The liquid containing bottle comprises a spraying tank. A water pipe clamping mechanismis arranged in an inner cavity of the spraying tank. A pipe opening regulation mechanism is arranged on the outer circle of the spraying tank. The invention relates to the technical field of articlesfor daily use. According to the liquid containing bottle used for unceasingly conducting spraying at multiple angles, the design manner that the position of a water suction port of a liquid conveyingtube can be freely regulated is adopted, and therefore water suction and spraying actions can be conducted through a spraying bottle no matter what position state is the spraying bottle in, continuityof the spraying work and variability of the spraying state are increased, and therefore spraying conducted at the positions of corners can become more convenient. The main effect of a movable lanternring is to drive the port part of an internal water suction pipe to conduct vertical position movement through attraction force between magnetic blocks, and therefore the water suction pipe can moveat different positions and is in the state that the water suction pipe makes contact with an aqueous solution all the time, and it is ensured that the water suction and spraying actions can be unceasingly conducted.

Owner:嘉兴市迅程信息技术有限公司

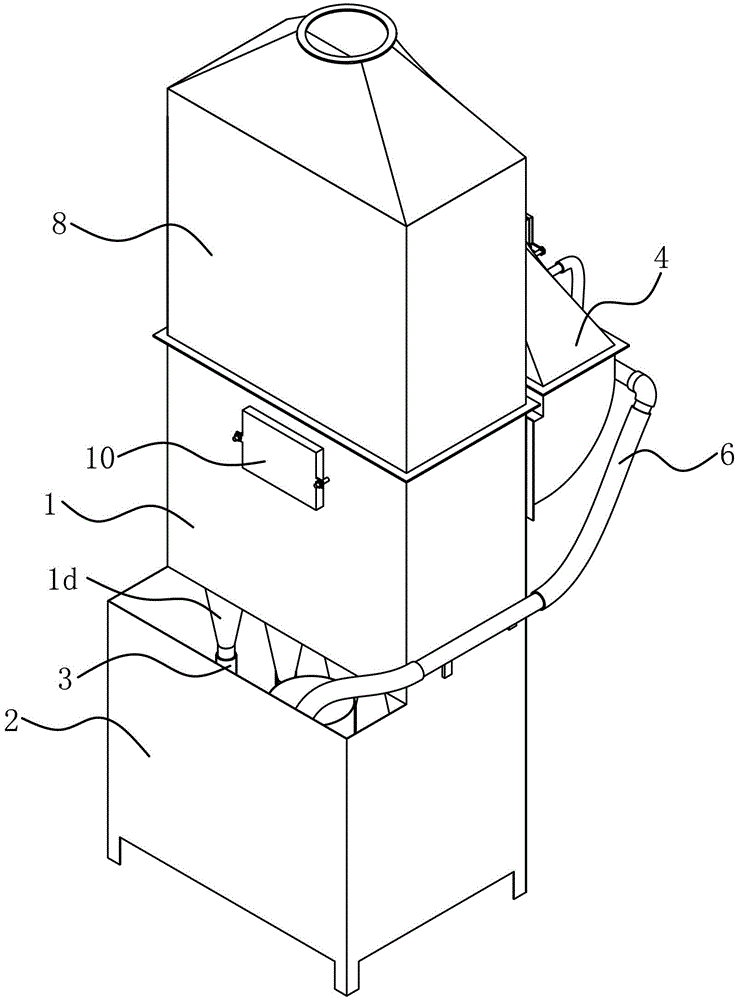

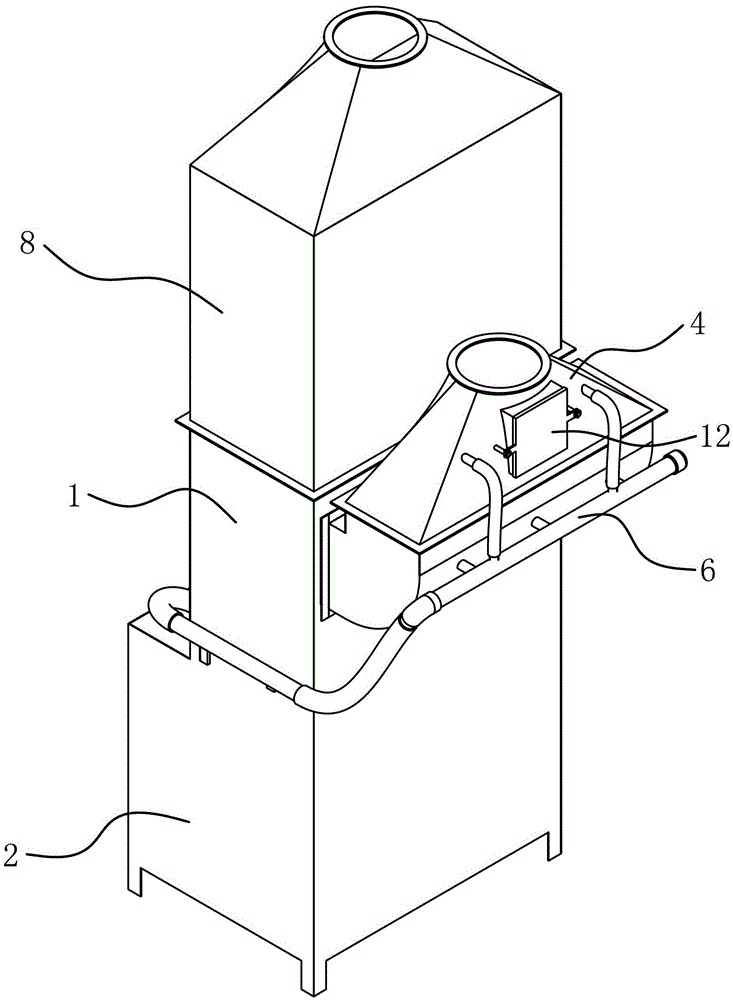

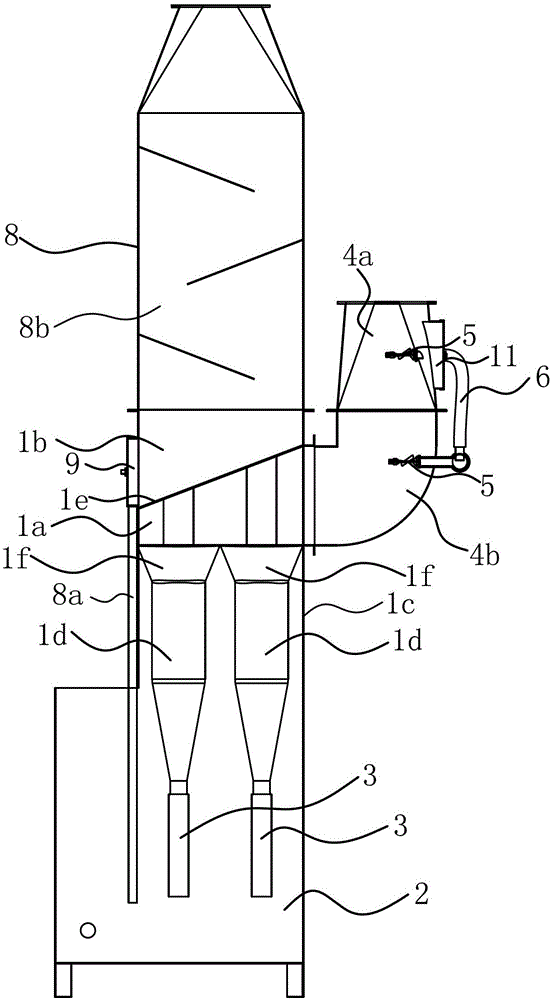

Wet multi-cyclone dust collector and dust removal system having the above dust collector

ActiveCN103157561BIncrease distanceReduce the temperatureReversed direction vortexCycloneEngineering

The invention provides a wet type multi-pipe cyclone dust removal device and a dust removal system with the dust removal device, belongs to the field of operations techniques, and solves the problem that the conventional wet type multi-cyclone dust removal device is low in dust removal efficiency. The wet type multi-pipe cyclone dust removal device comprises a multi-pipe cyclone dust removal component, and also comprises a water tank, wherein the multi-pipe cyclone dust removal component is positioned above the water tank; each cyclone dust exhaust port of the multi-pipe cyclone dust removal component is connected in series with a dust exhaust pipe; each dust exhaust pipe penetrates through the water tank; an air inlet of the multi-pipe cyclone dust removal component is connected in series with an air inlet pipe; and a spraying head capable of spraying water spray is fixedly arranged in the air inlet pipe. According to the wet type multi-pipe cyclone dust collector, the spraying is performed in the air inlet pipe, the distance between the spraying and each cyclone is increased, the water spray can be fully mixed with air, the purification effect is improved, and the temperature of high-temperature air is effectively reduced; and meanwhile, the influence of water mist flow on the stability of airflow entering the cyclones is avoided.

Owner:陈美青

Processing equipment capable of accurately controlling thickness of special glass

InactiveCN111807678AOrderly processingWon't cureCharging furnaceForehearthsEngineeringMachining process

The invention discloses processing equipment capable of accurately controlling the thickness of special glass. The processing equipment comprises a processing machine body, a processing cavity is formed in the processing machine body; a mixing main body is fixedly arranged on the upper wall of the processing cavity; a mixing cavity which is through up and down is formed in the mixing main body; the processing equipment is applied to processing and production needing to limit the thickness in glass processing; in the machining process, main materials can be completely pulverized through sufficient cooperation of the pulverizing cutters; meanwhile, the auxiliary materials can be ensured to be mixed with the main materials in time through the stressed pushing mechanism; it is ensured that thematerial before forming is not cured in the conveying process through the heat transfer fan; and meanwhile, free control over the thickness can be achieved through the rotary forming mechanism, it isguaranteed that glass with the thickness meeting the specified thickness is produced and machined, formed glass can be cut through the cutting blade, and then the glass can be machined in order.

Owner:GUANGZHOU LIANJIN GLASS TECH CO LTD

An integrated circuit lead frame etching solution recovery device

ActiveCN113969404BEasy to handleGuaranteed to be purePhotography auxillary processesElectrolysis componentsElectrolysisFiltration

Owner:天水华洋电子科技股份有限公司

Yellow peach tree grafting method

The invention discloses a yellow peach tree grafting method. The yellow peach tree grafting method comprises four steps of stock seed cultivation, stock sowing, scion selection and grafting; a Nankingcherry is selected as a stock so that the advantage of cold resistance is achieved; a kind of granular fertilizer is added during cultivation, and charcoal, beneficial bacteria and potassium fulvateare used as the granular fertilizer, so that nutrients for stock growth are more sufficient and more reasonable in supply, various physiological diseases, caused by lack of elements, of crops are avoided, and quick application to grafting can be achieved; the potassium fulvate can timely supplement lost nutrients in soil and activate the soil, and the fertilizer is prepared into mixed granules, sothat mixing of all components is facilitated, and convenience is brought to use; bud hiding type and bud growing type branches of yellow peach trees are selected as scions during scion grafting, so that healing is fast, the germination period is short, and the survival rate is high; and a growth solution is added, a natural plant growth promoting agent is added into the growth solution, and the growth after grafting is further promoted.

Owner:和县万源生态种养殖家庭农场

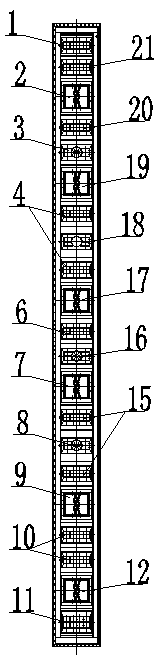

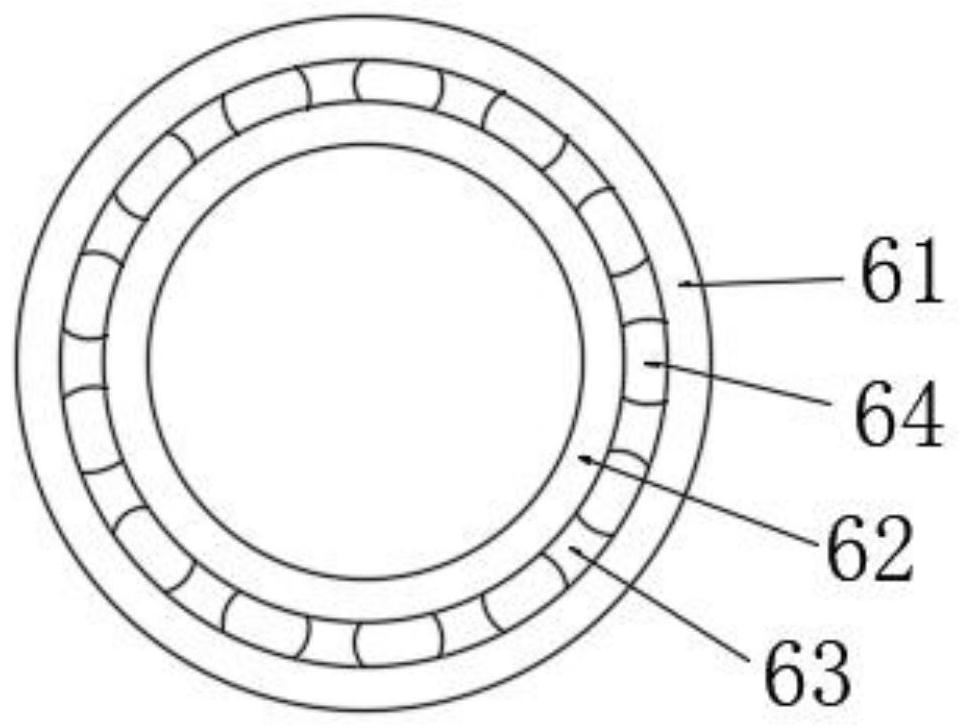

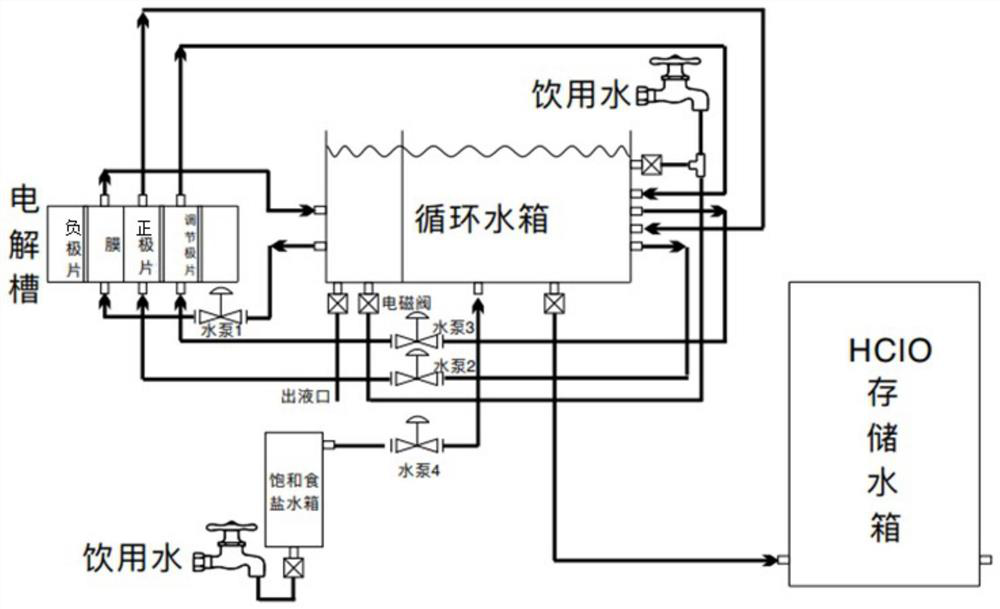

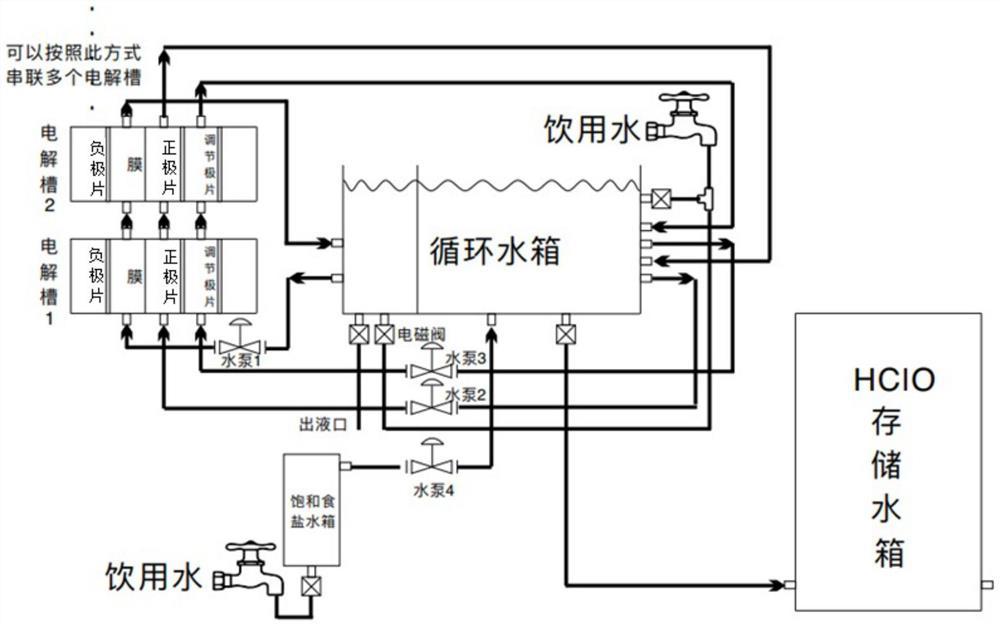

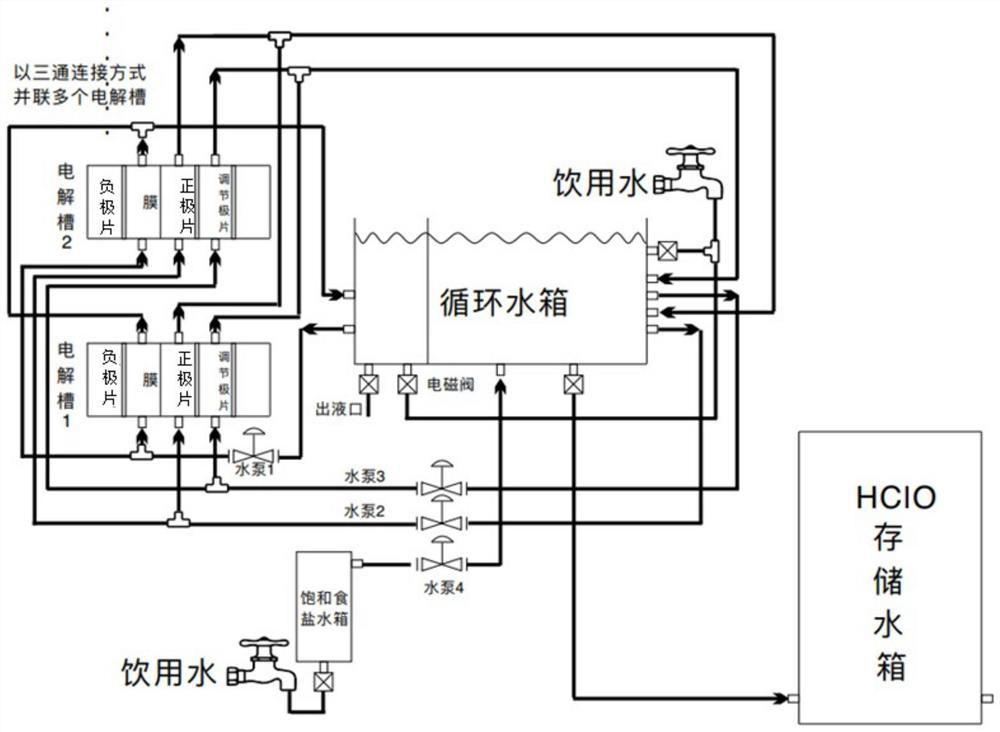

Generator and method for continuously generating slightly acidic hypochlorous acid

PendingCN113322482AImprove the efficiency of conversion to hypochlorous acidImprove efficiencyCellsWater storage tankPhysical chemistry

The invention discloses a generator and method for continuously generating slightly acidic hypochlorous acid. The generator comprises at least one group of three-cavity electrolytic cell and a circulating water tank, wherein electrolysis chambers 1 to 3 are respectively arranged between a negative plate and a diaphragm, between the diaphragm and a positive plate and between the positive plate and a regulating negative plate in the three-cavity electrolytic cell; the bottom of each electrolysis chamber is provided with an input port, and the upper part of each electrolysis chamber is provided with an output port; input and output ports of the electrolysis chambers 2 and 3 are connected with the right chamber of the circulating water tank through water pumps; the input port and the output port of the electrolysis chamber 1 are connected with the left chamber of the circulating water tank through water pumps; high-concentration salt water is input into the circulating water tank and a high-concentration salt water tank through water pumps, and liquid generated in the right chamber is input into an HClO storage water tank; and the current of the regulating pole pieces and the negative plate is adjustable. According to the above scheme, the generation efficiency of the hypochlorous acid can be improved, and the pH value and the available chlorine concentration of the generated hypochlorous acid can be adjusted according to actual requirements.

Owner:南京橙子电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com