Impinging stream reaction and separation integration device and impinging stream reaction and separation integration method for liquid-liquid reaction system

A technology of impinging flow reaction and liquid-liquid reaction, which is applied in the field of reactors, can solve problems such as reactor dead zones, achieve the effect of reducing failure rate, reducing process flow, and realizing timely separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

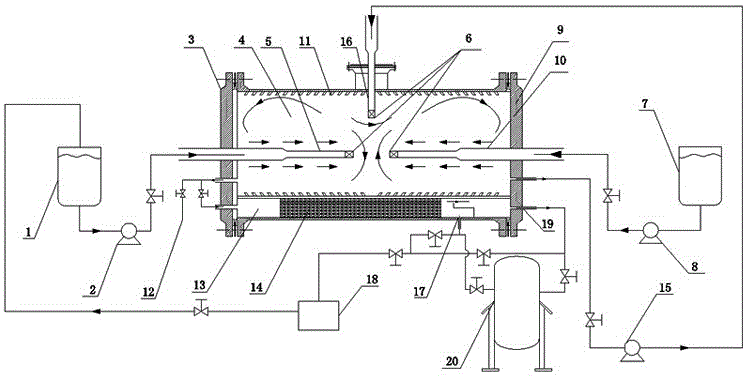

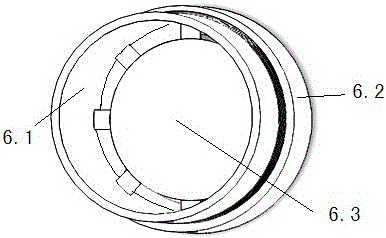

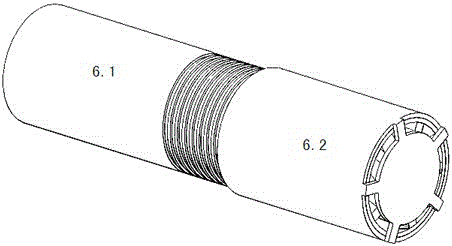

[0026] combined with Figure 1-6 , to further describe the present invention:

[0027] An impingement flow reaction separation integrated device for a liquid-liquid reaction system mentioned in the present invention includes a device cylinder with a horizontal structure, three storage tanks and three booster pumps, and the device cylinder is divided into The reaction chamber 4 and the separation chamber 13 are provided with three main guide tubes in the reaction chamber 4, and the three guide tubes are connected to the head and the flange in a welded manner; wherein the first main guide tube 5 and the second guide tube The main flow guide tube 10 is arranged facing the horizontal axis, and the circulation main flow guide tube 16 is arranged on the upper side of the middle part of the device cylinder to realize the circulation of the two-phase liquid for multiple collisions. The ports of the three flow guide tubes are all equipped with guide vanes 6 , and a corrugated plate 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com