Energy efficiency improvements for turbomachinery

A technology of energy efficiency and operating capability, applied in the field of Newtonian fluid flow aerodynamic/hydrodynamic processing devices, to achieve the effect of reducing resistance, improving existing technology, and reducing absolute resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

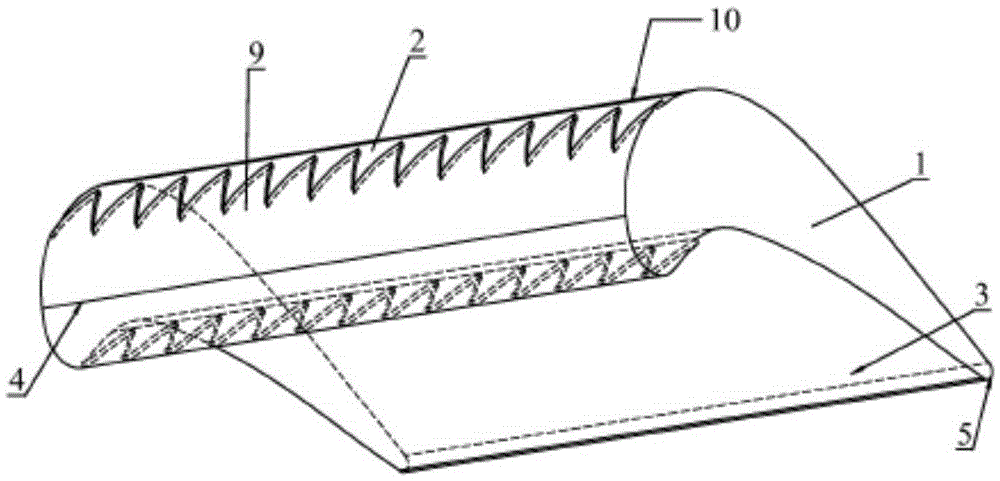

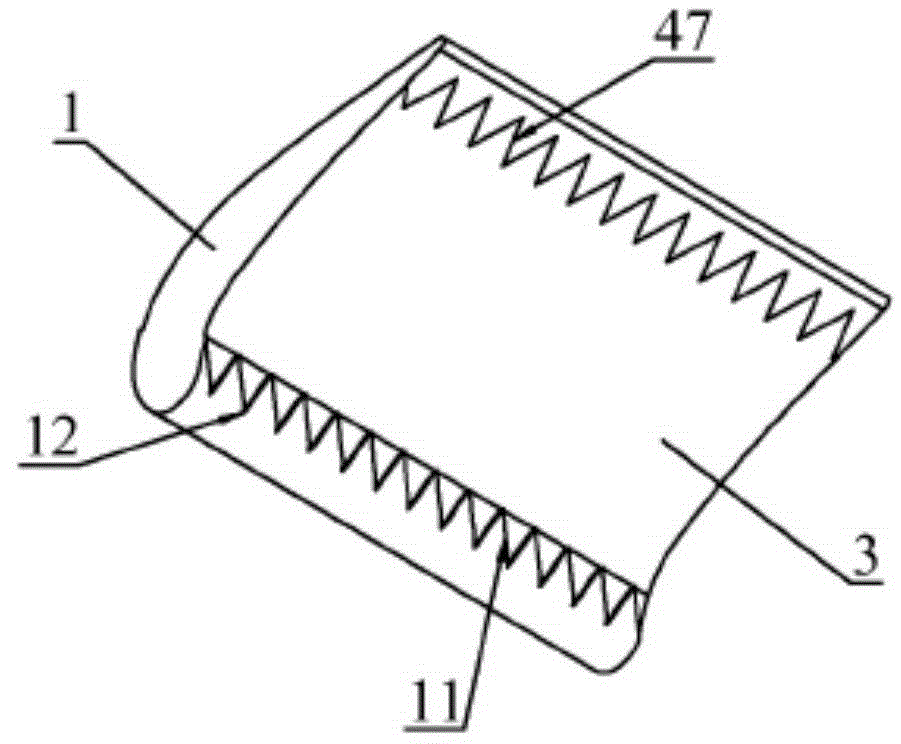

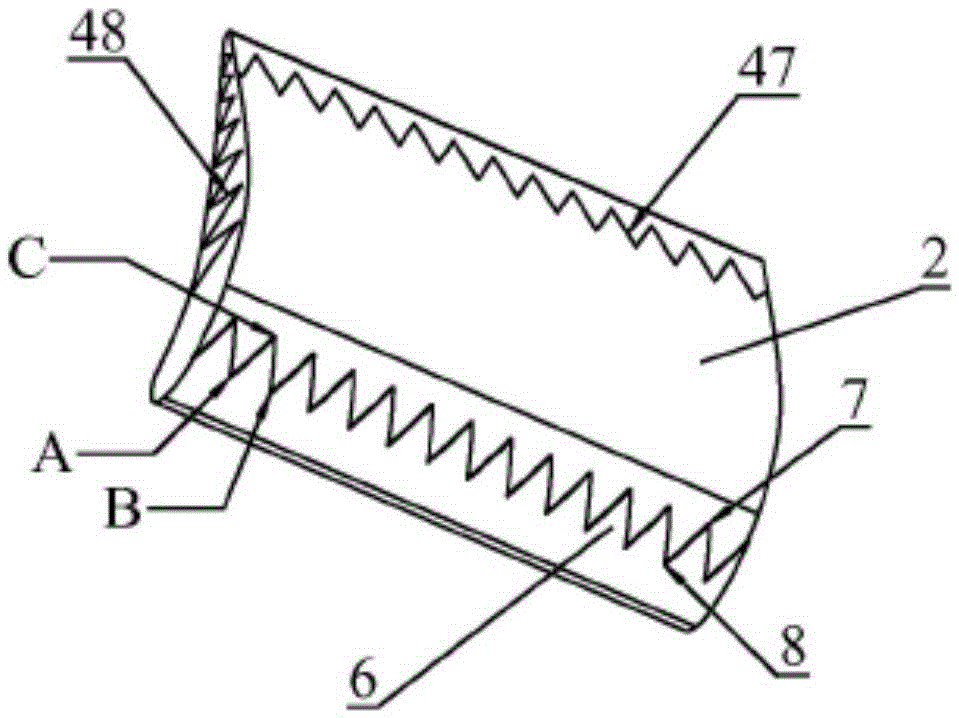

[0081] The best mode for carrying out the invention is an example of a turbofan jet engine, which can teach many typical aspects and methods of application, which can be achieved by applying properly configured integrated conformal vortex generators. The turbofan engine provides a considerable number of examples of useful integrated application of conformal vortex generators because it employs extensive hydrodynamic surface treatment of the flow of Newtonian fluids to produce beneficial work and effects. This example is only one form of a fluid flow machine that uses a gas as the working fluid, but most conformal vortex generator methods can be easily adapted to use liquid or mixed phase Newtonian physical fluids and obtain similar improvements, such as Many useful examples of drag and separation / cavitation reduction are achieved by scaling; velocity, pressure, Reynolds number, fluid phase (gas / liquid state transition) and flow viscosity.

[0082] Figure 1a Callout 1 describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com