Patents

Literature

40results about How to "Suitable for industrial scale applications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-pollution modification method of polypropylene hollow fiber membrane module

ActiveCN104548959ASimple processThe treatment effect is stable and reliableSemi-permeable membranesCross-linkTherapeutic effect

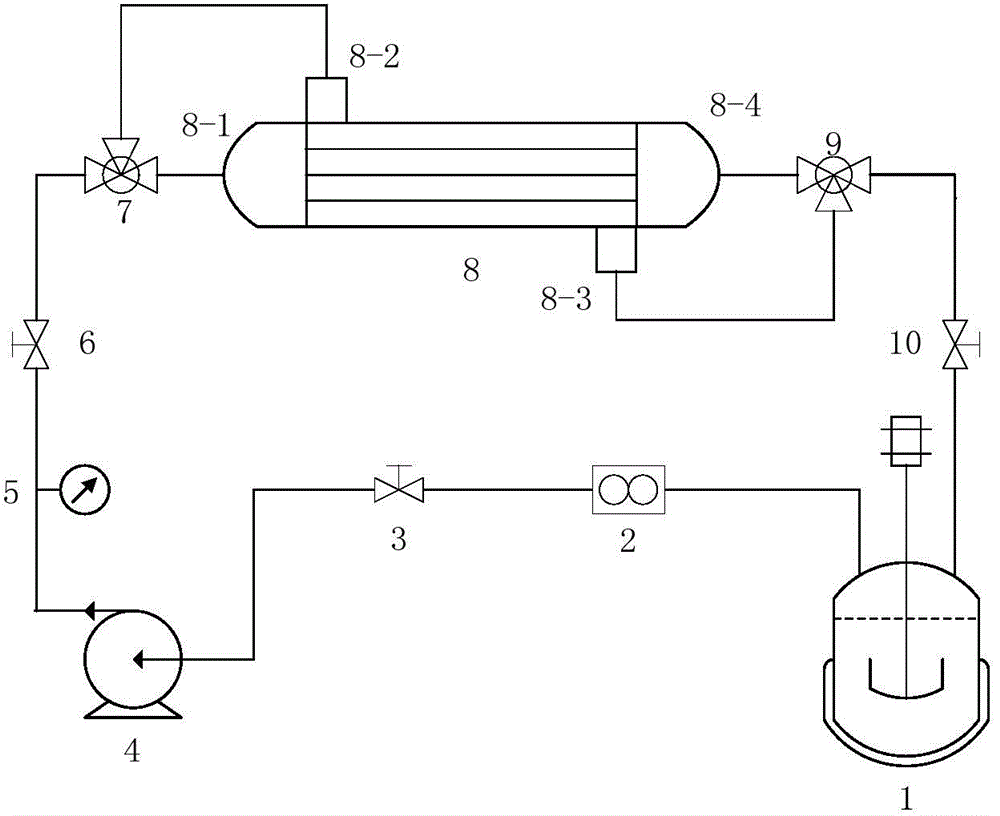

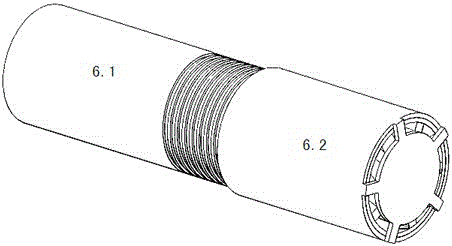

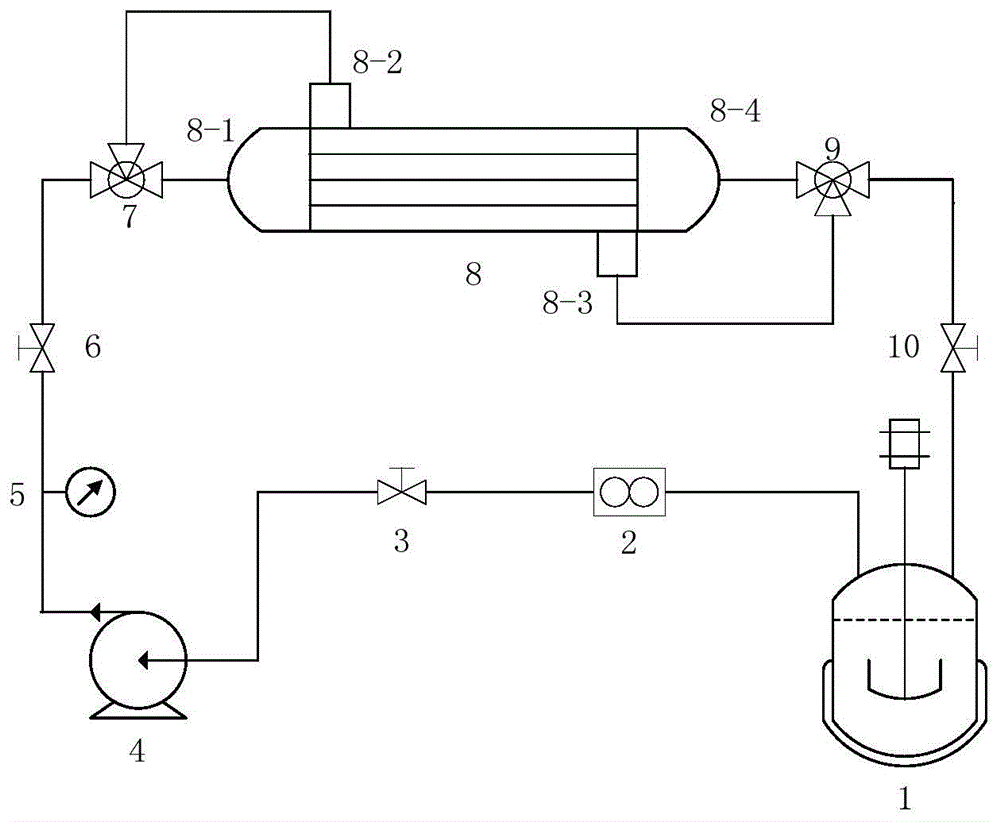

The invention relates to the field of a membrane technology and membrane surface modification and concretely relates to an anti-pollution modification method of a polypropylene hollow fiber membrane module. The method comprises the following steps of selecting a compound with strong hydrophily and multiple active groups as a modifier, adsorbing the modifier by the surface of the polypropylene hollow fiber membrane module in a dynamic cycle way, and under coordination complexation of the active groups in the modifier molecule and an inorganic bacteriostatic agent, fixing the modifier to the polypropylene hollow fiber membrane module so that the polypropylene hollow fiber membrane module with hydrophily and antibacterial properties is prepared. Through control of a flowing direction of a cross-linking agent solution, a modification compound solution and a metal ion soluble salt solution, the method realizes hydrophilic and antibacterial modification of an inner surface, an outer surface and membrane apertures of the polypropylene hollow fiber membrane module, greatly improves work efficiency and treatment effects, needs simple requirement and is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

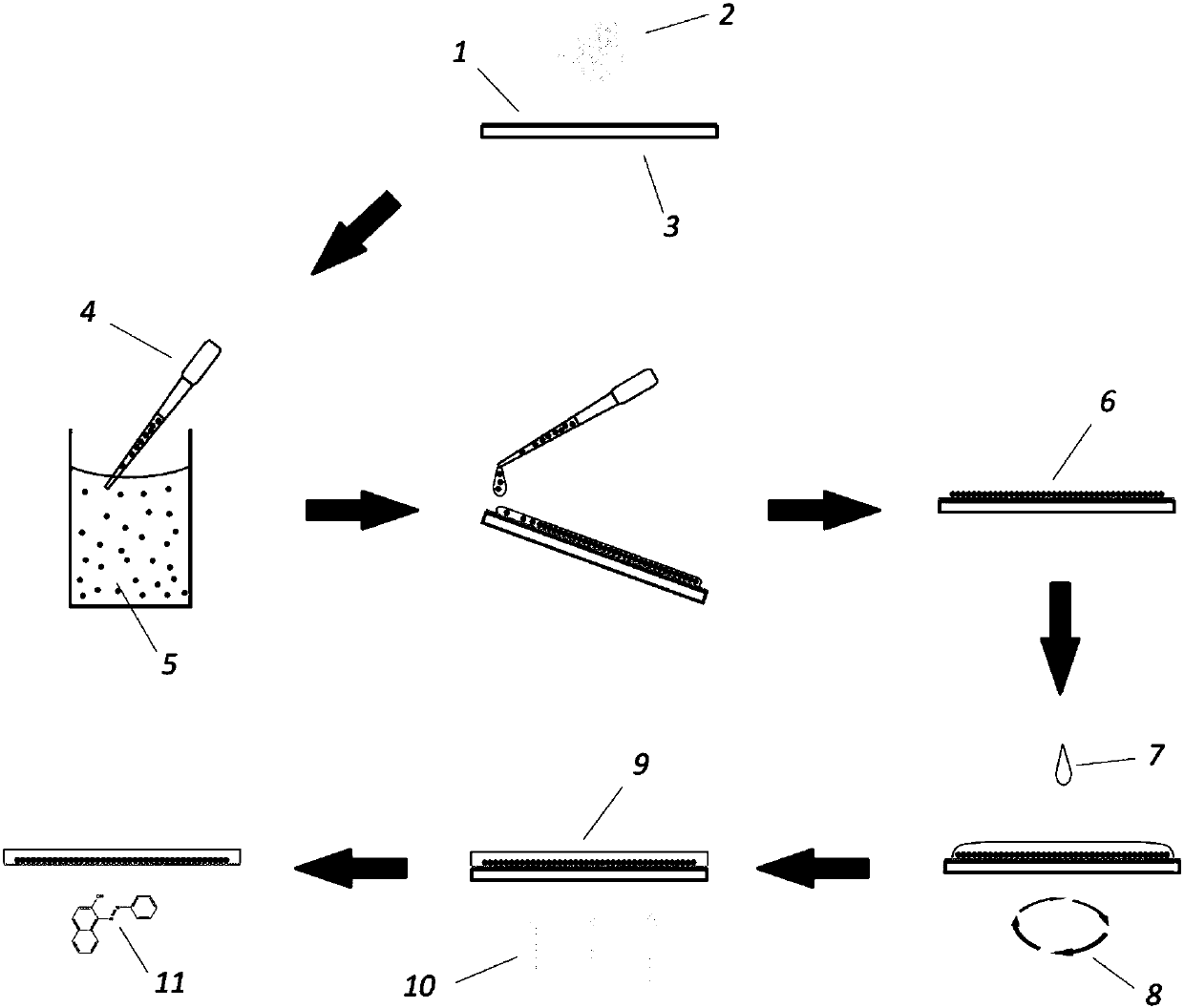

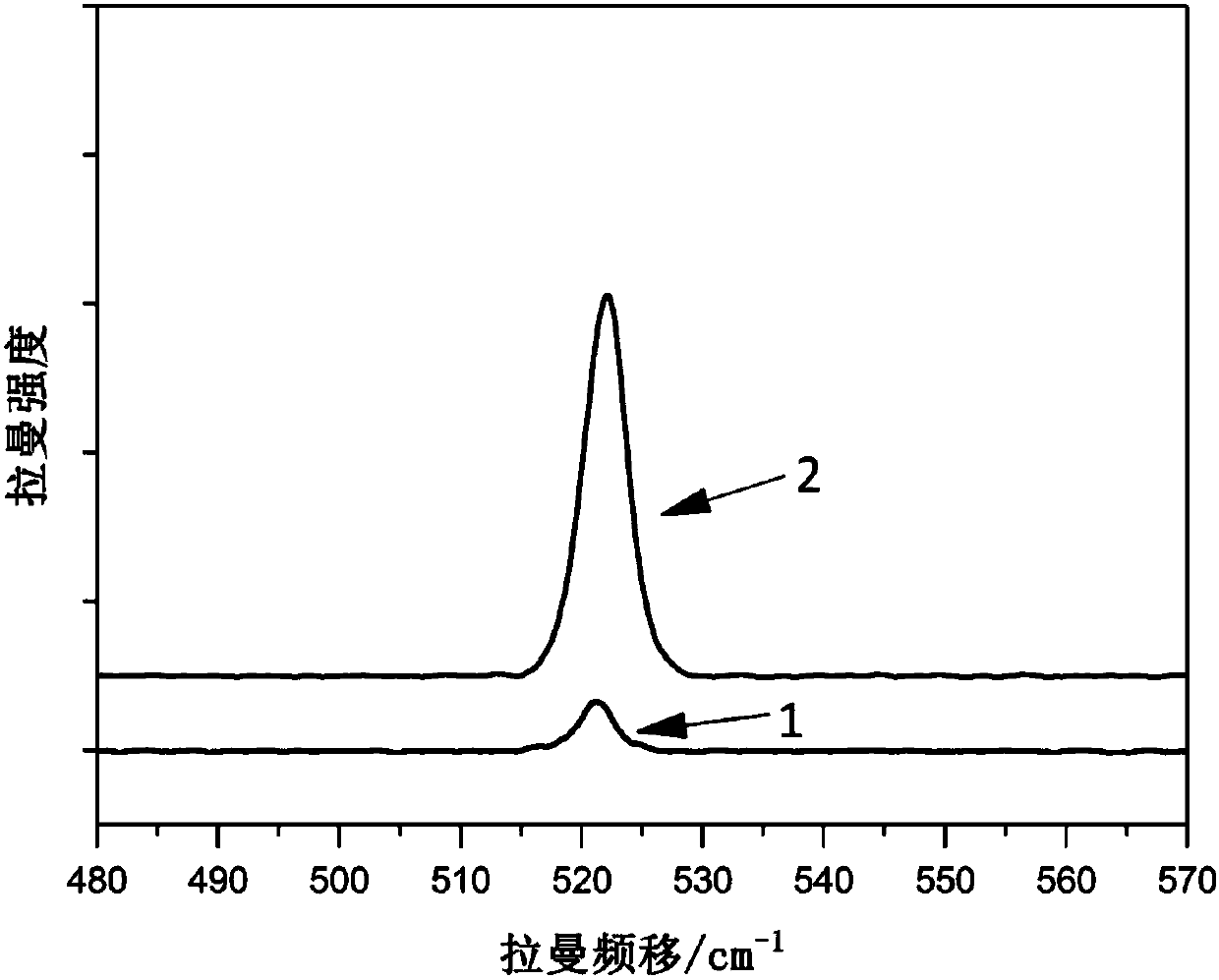

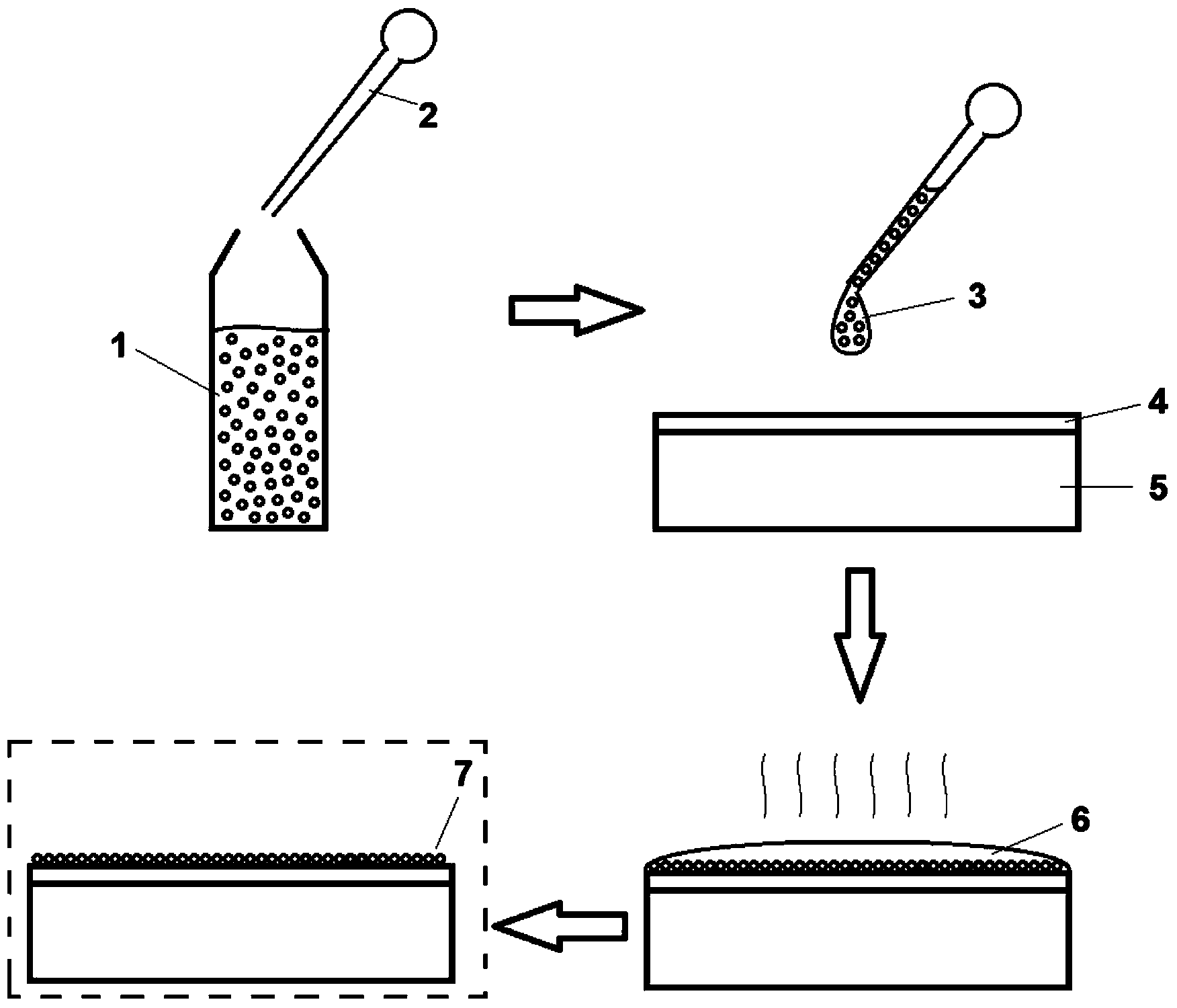

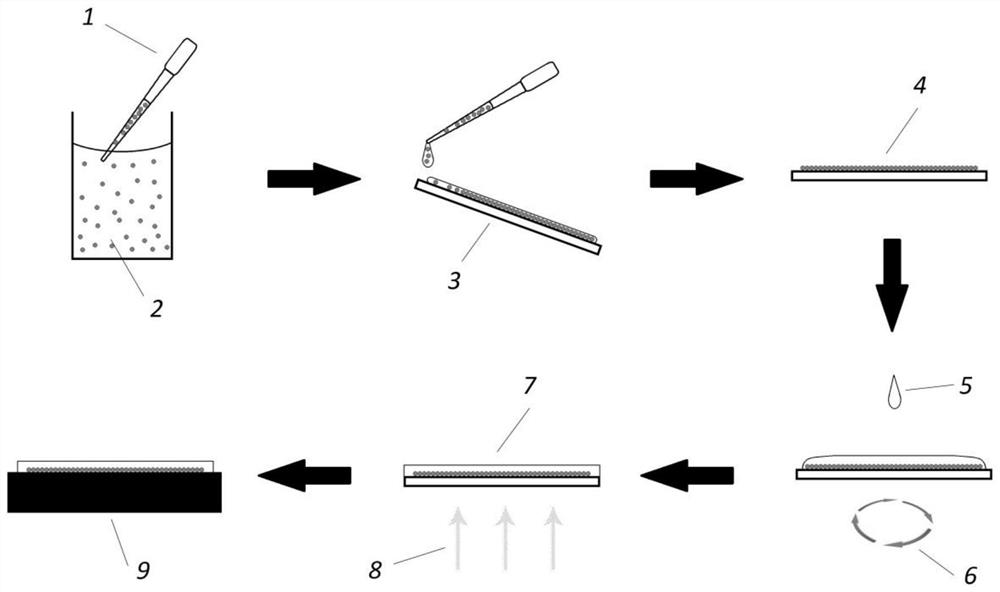

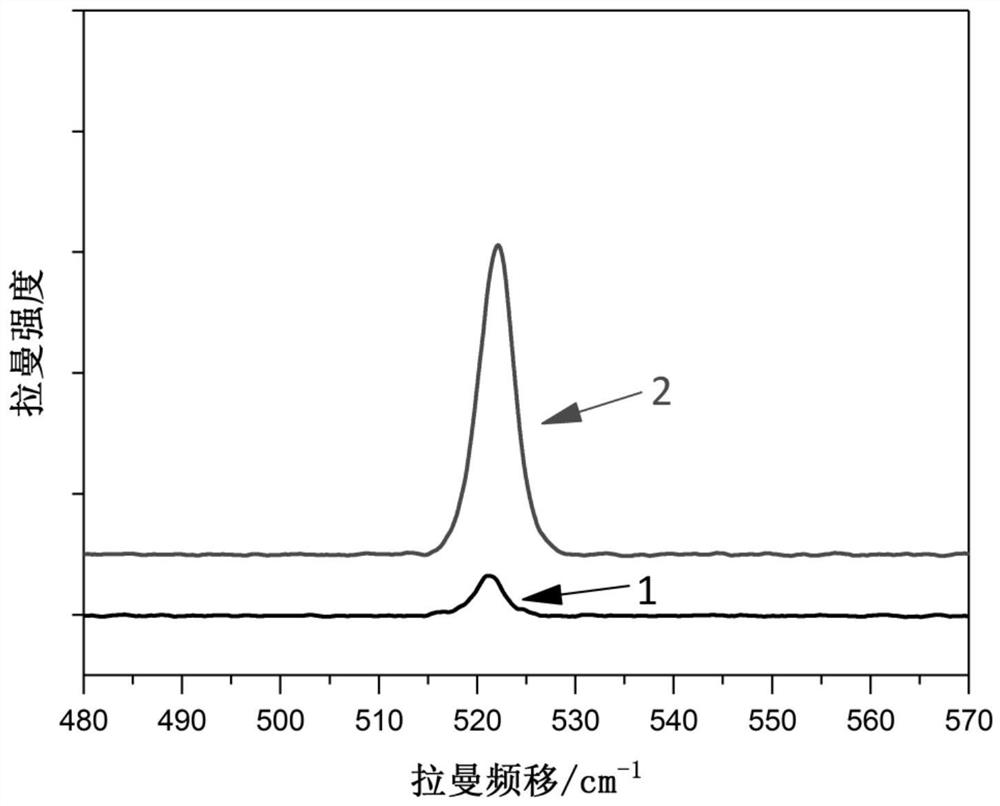

Preparation method for transparent dielectric microsphere flexible film used for strengthening raman scattering spectral intensity

ActiveCN107688015ALow priceSuitable for industrial scale applicationsRaman scatteringDielectricSemiconductor materials

The invention discloses a preparation method for a transparent dielectric microsphere flexible film used for strengthening raman scattering spectral intensity, and belongs to the field of spectrum detection. The preparation method comprises the following steps: preparing a transparent dielectric microsphere turbid liquid; dispensing the dielectric microsphere turbid liquid on an inclined glass sheet surface; after a solvent in the turbid liquid on the inclined glass sheet is evaporated, forming a microsphere single-layer densely paved array structure; preparing a polydimethylsiloxane (PDMS) solution; dispensing the uniformly mixed PDMS solution on the glass sheet deposited with the microsphere array, and thinning by equalizing glue; heating the glass sheet covered with the microsphere array and a PDMS liquid-state thin layer and cooling the glass sheet to the room temperature, embedding the microsphere array into a PDMS film and curing the PDMS film; and separating the microsphere filmfrom the glass sheet. The flexible film can be adhered to the surfaces of various samples, so that raman scattering strengthening on a semiconductor material, one-dimensional and two-dimensional nanomaterials and a three-dimensional structural surface material can be realized.

Owner:BEIJING UNIV OF TECH

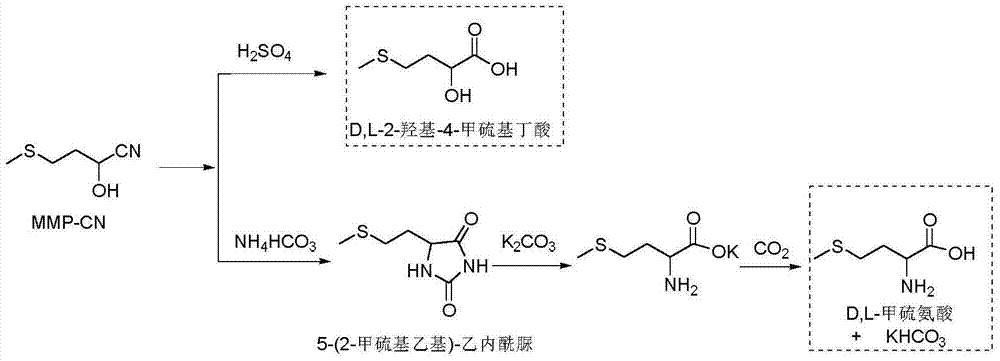

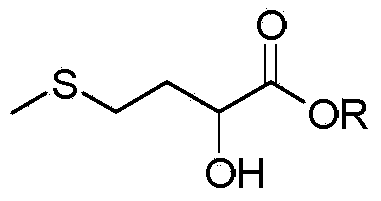

Method for preparing 5-(2-methylmercapto-ethyl)-hydantoin by utilizing crude hydrocyanic acid gas

ActiveCN103408498AShorten production timeIncrease productivitySulfide preparationChemical industryHydroxy group

The invention relates to a method for preparing 5-(2-methylmercapto-ethyl)-hydantoin by utilizing crude hydrocyanic acid gas and relates to the field of chemical industry. The method disclosed by the invention comprises the following steps of: completely reacting hydrocyanic acid mixed gas made by adopting an Ann method with methylmercapto propionaldehyde to obtain a 2-hydroxyl-4-methylmercapto-butyronitrile reaction system under the catalytic action of organic alkali; and sufficiently reacting the 2-hydroxyl-4-methylmercapto-butyronitrile reaction system with ammonium bicarbonate in a water medium to obtain 5-(2-methylmercapto-ethyl)-hydantoin. Due to adoption of raw materials which are not rectified or purified, the method disclosed by the invention is short in production time, high in production efficiency and low in production cost; the prepared 2-hydroxyl-4-methylmercapto-butyronitrile reaction system is steady in property and can be stored for a long time; and 5-(2-methylmercapto-ethyl)-hydantoin with high purity and high yield can be obtained through simple separation and purification operations under the synergistic effect of other substances in reaction liquid.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

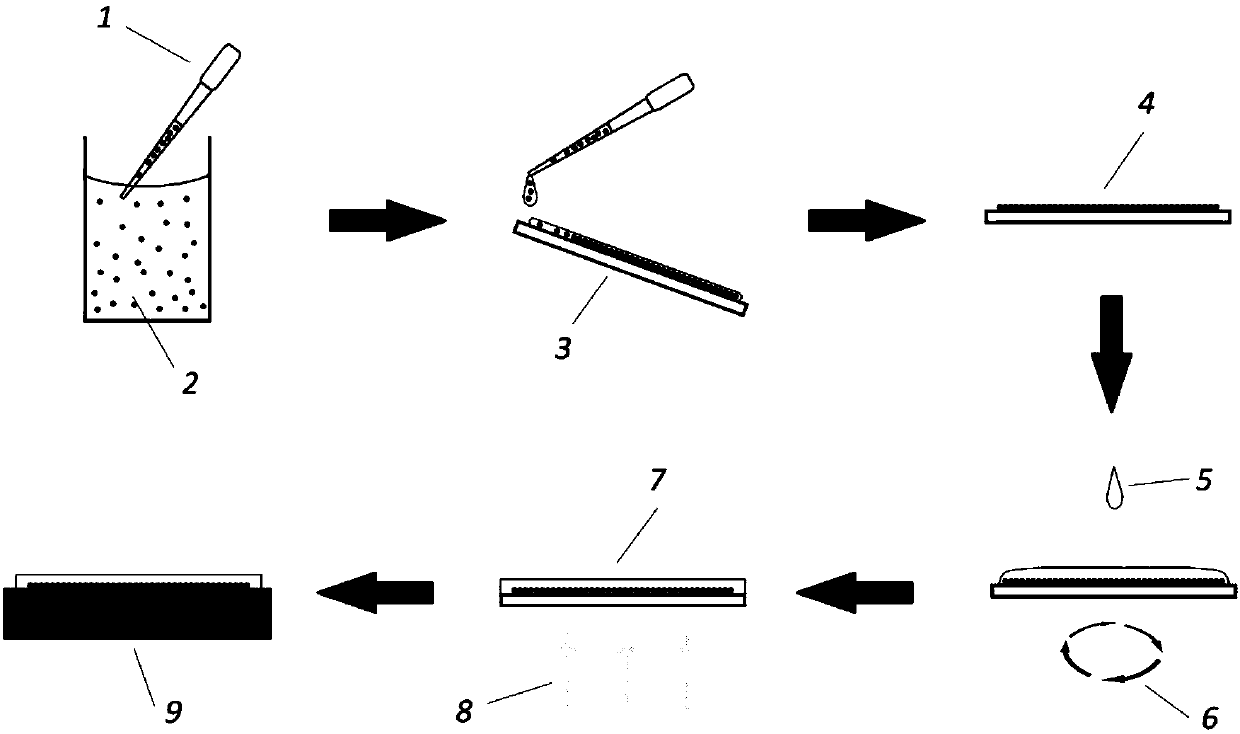

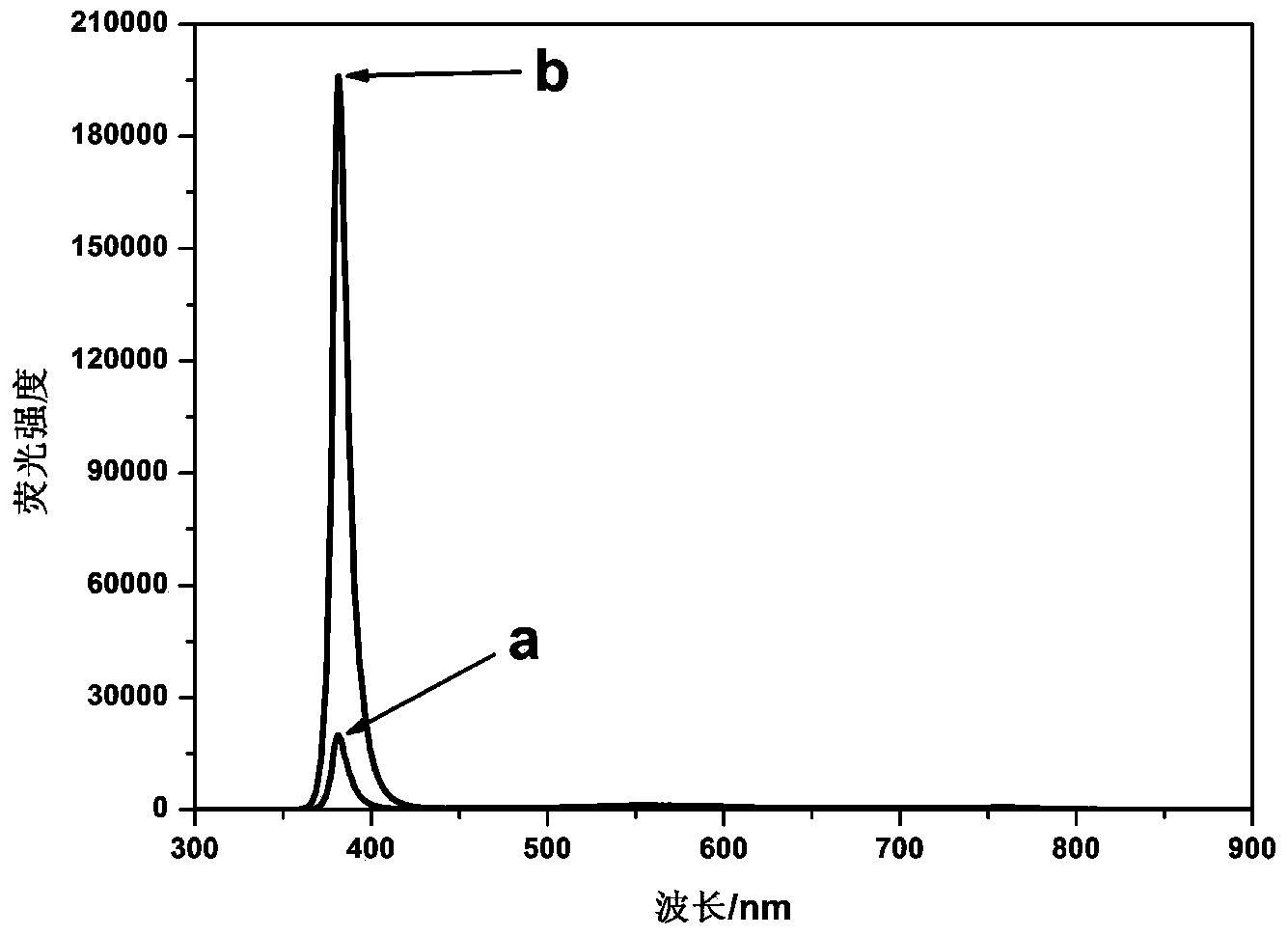

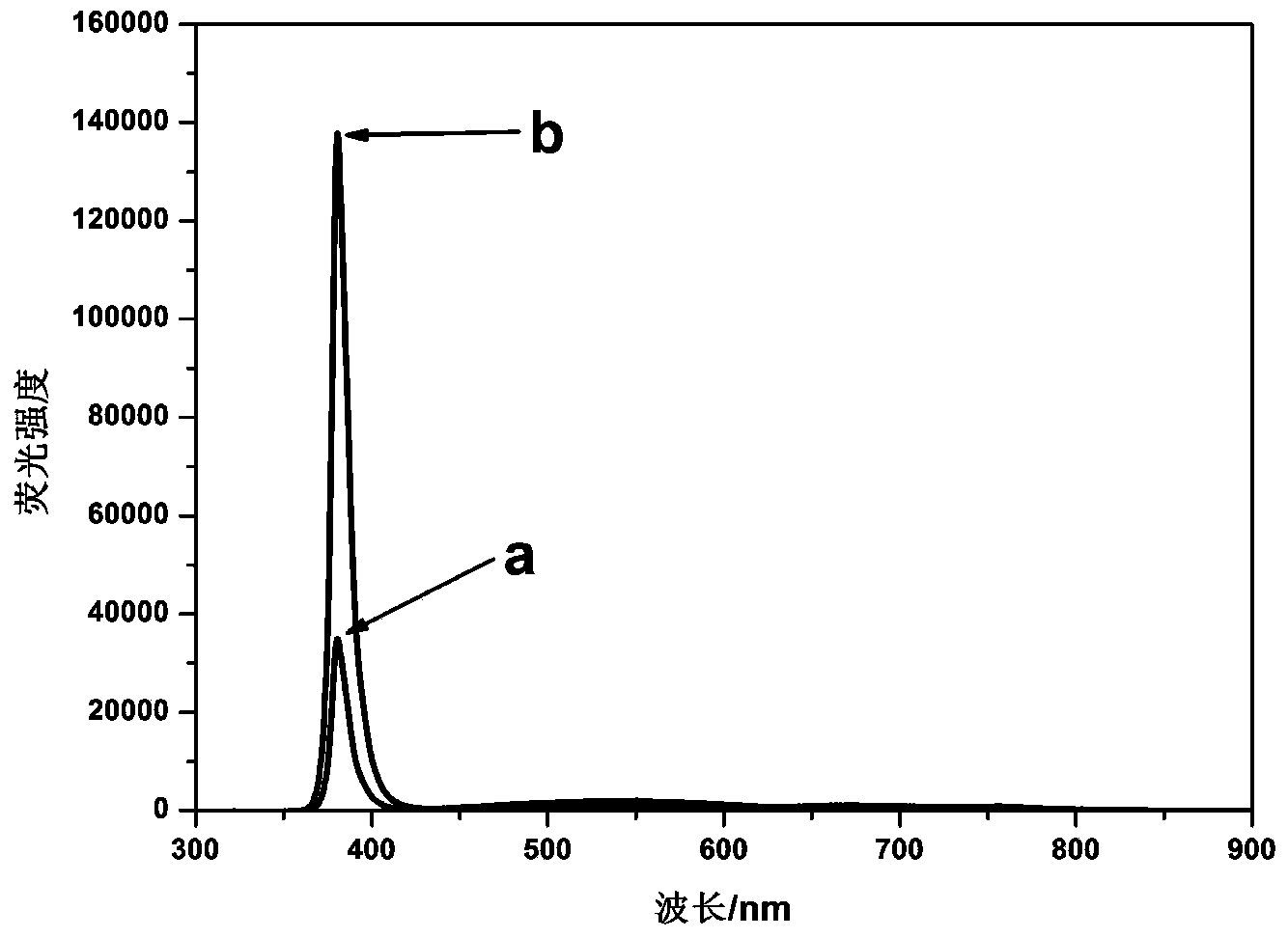

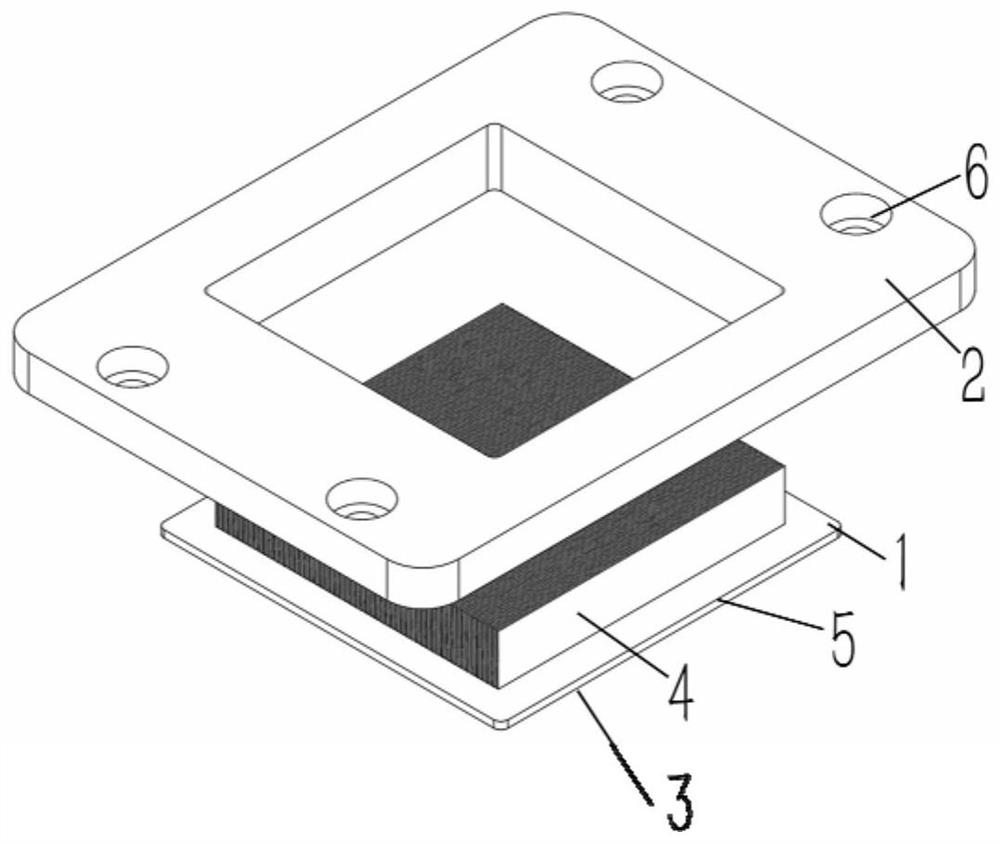

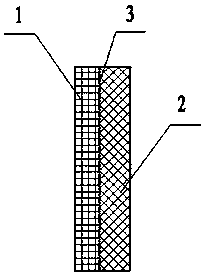

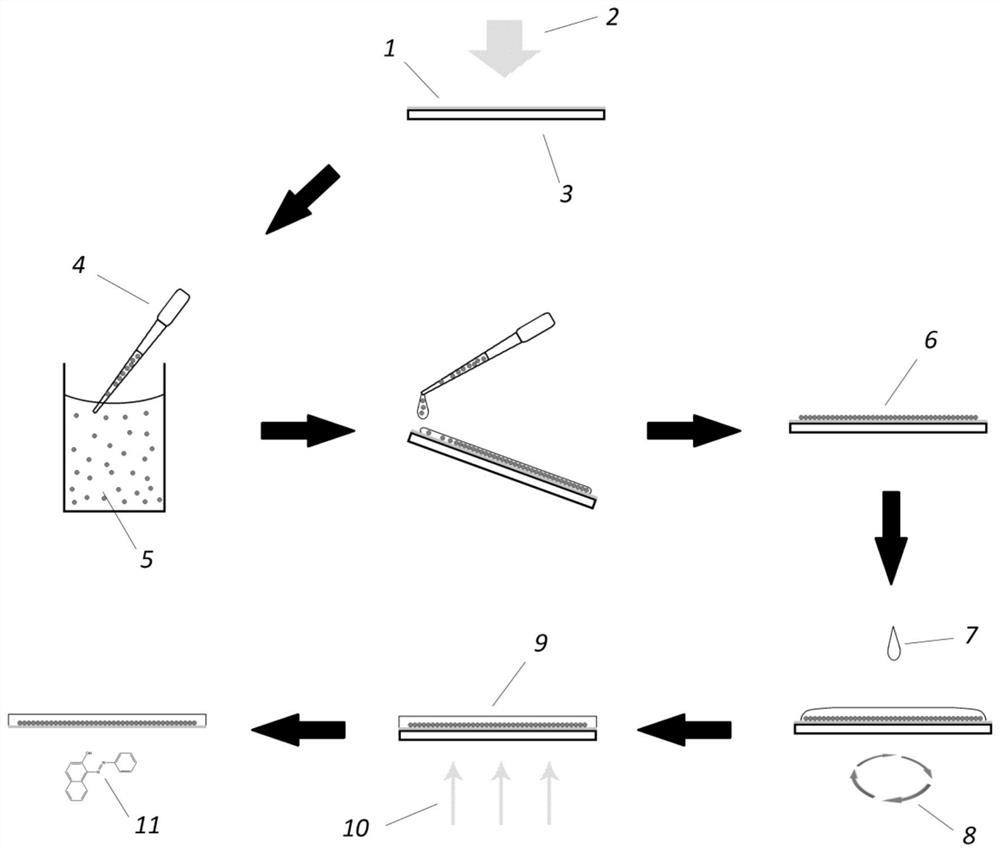

Sandwich structure for enhancing luminous intensity of photoluminescence of luminous film and preparation method of sandwich structure

ActiveCN103756671ALow priceSuitable for industrial scale applicationsThin material handlingLuminescent compositionsTriboluminescenceLuminous intensity

The invention relates to a sandwich structure for enhancing luminous intensity of photoluminescence of luminous film and a preparation method of the sandwich structure. The sandwich structure is a sandwich structure of substrate-luminous film-monolayer dense-paving sphere array formed by densely paving a micrometern transparent dielectric sphere monolayer on the luminous film; the used micrometer transparent dielectric spheres have relatively high transmissivity to wave lengths of exciting light and fluorescent light in the photoluminescence; the used fluorescence enhancing medium-micrometer transparent dielectric spheres are low in price and are suitable for industrial large-scale application. The used micrometer transparent dielectric spheres are not oxidized under air environment and can be used for steadily enhancing the luminous intensity of the fluorescence of the luminous film for a long time; the used micrometer transparent dielectric spheres have no requirements on the luminous film; the substrate can be nonmetal or metal, and due to substrate, the application range of the luminescence enhancement technology of the photoluminescence of the luminous film is effectively extended.

Owner:BEIJING UNIV OF TECH

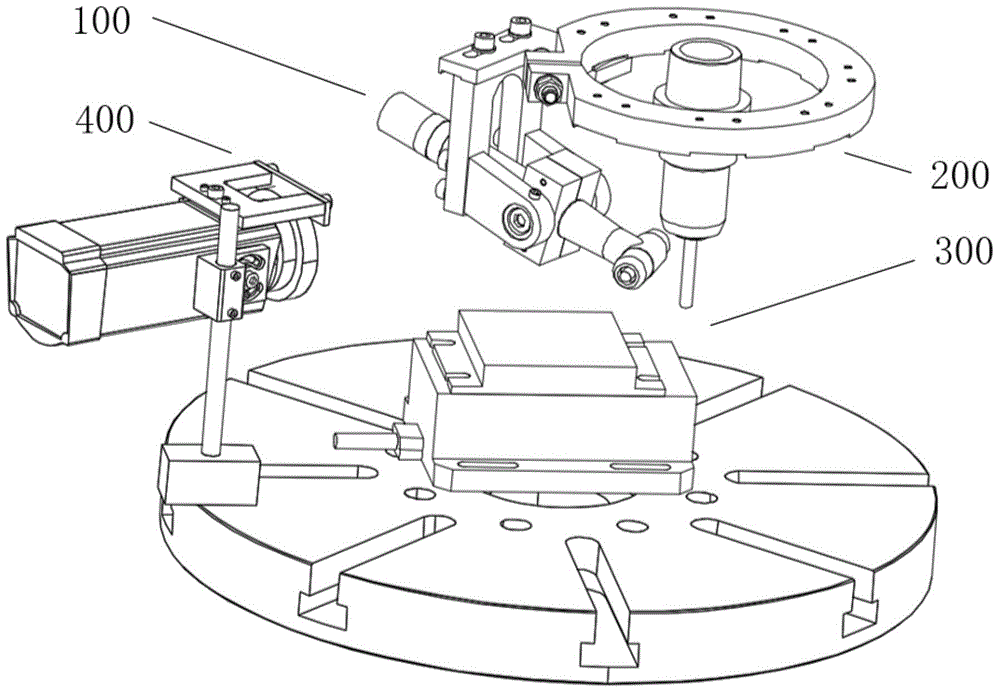

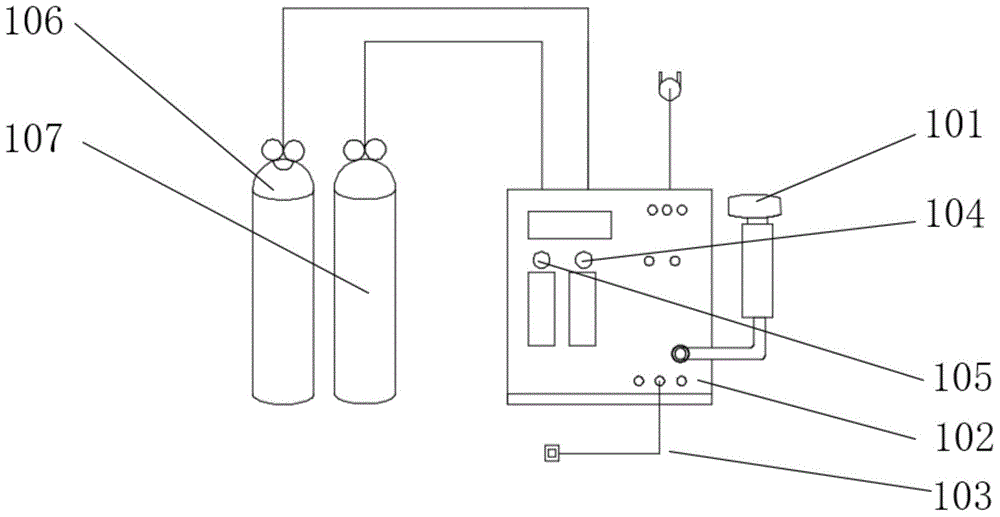

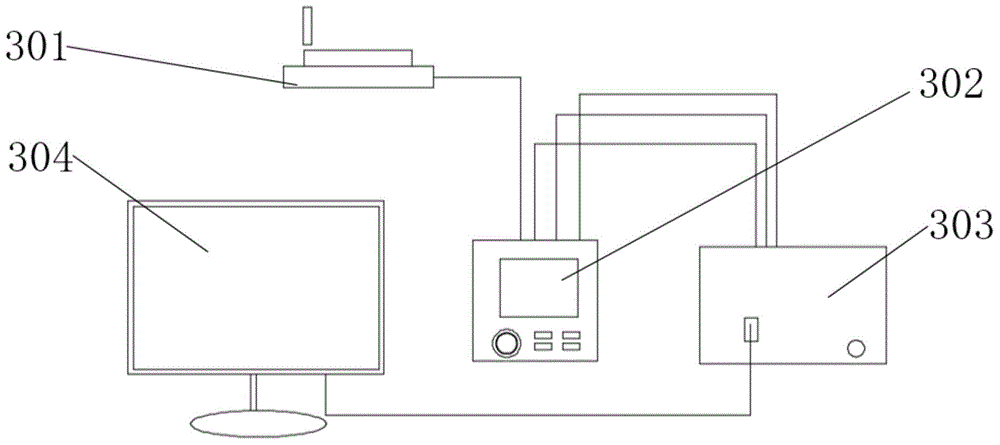

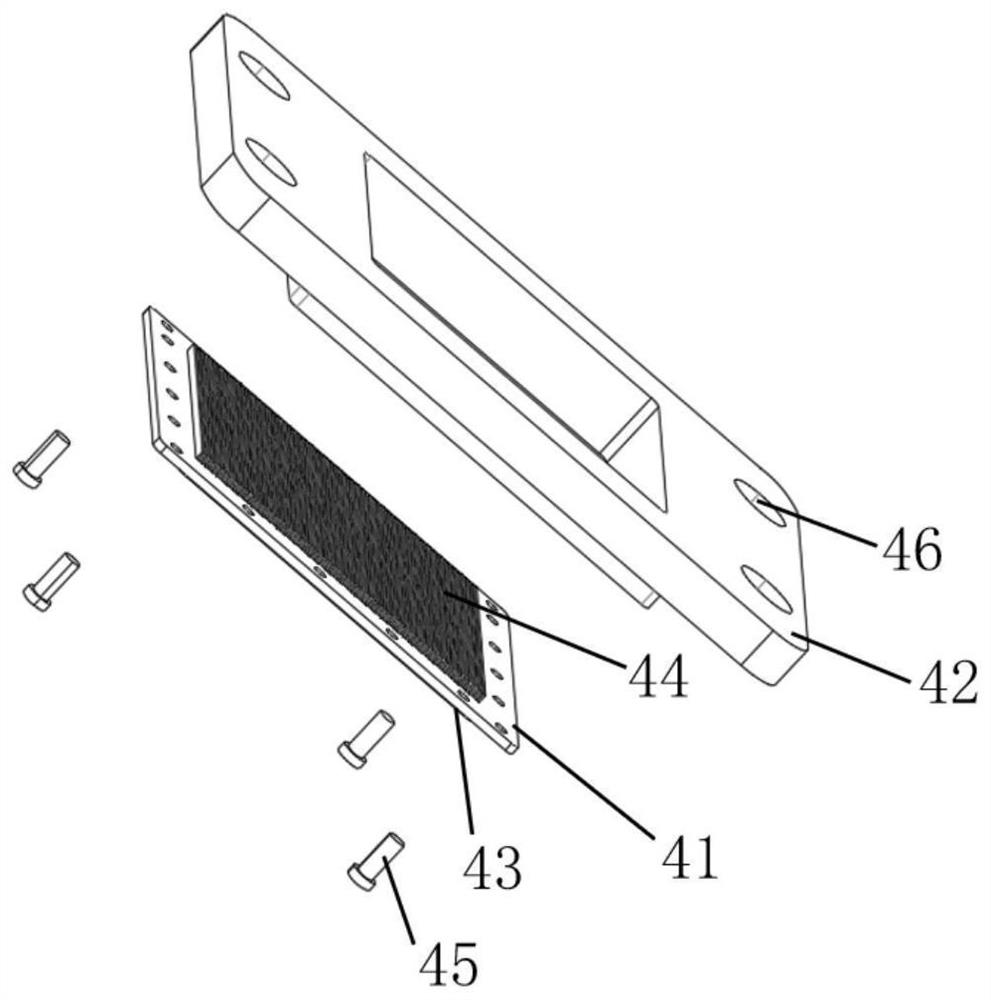

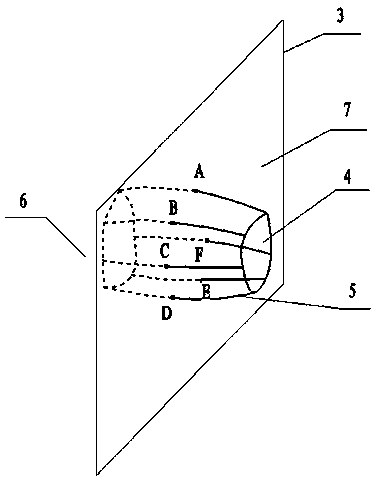

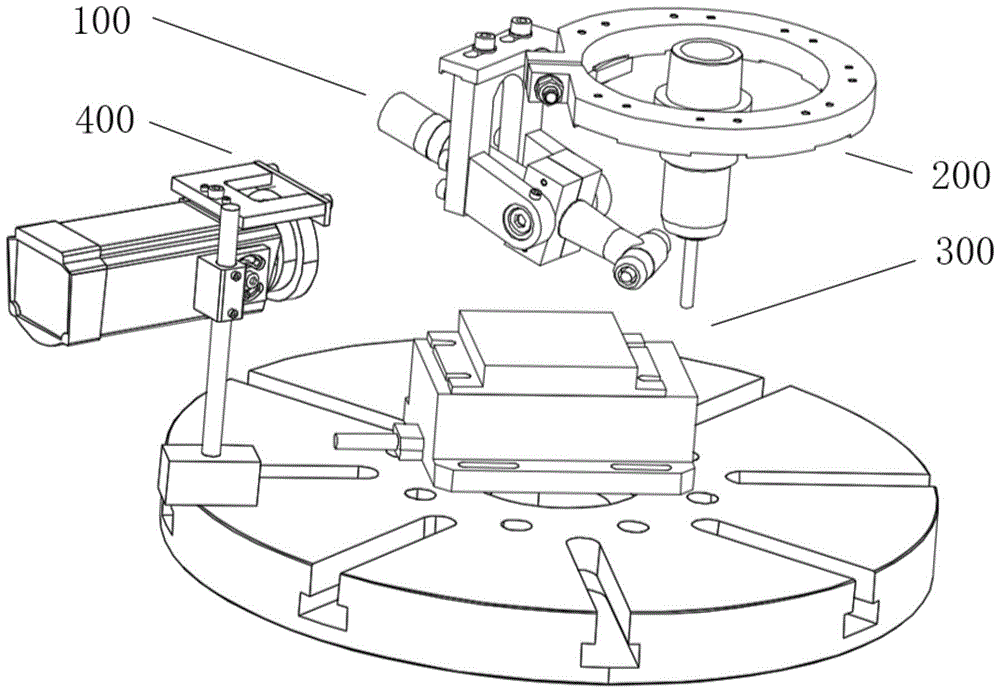

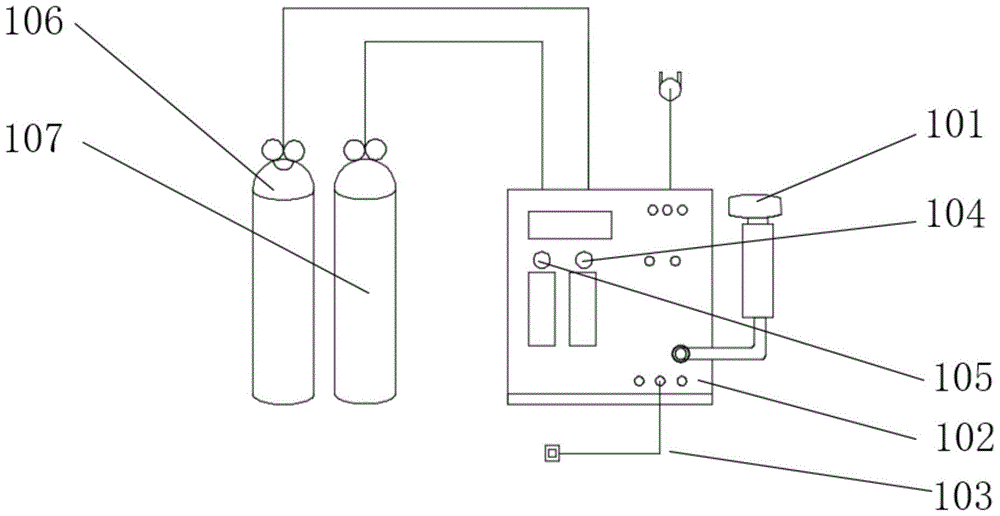

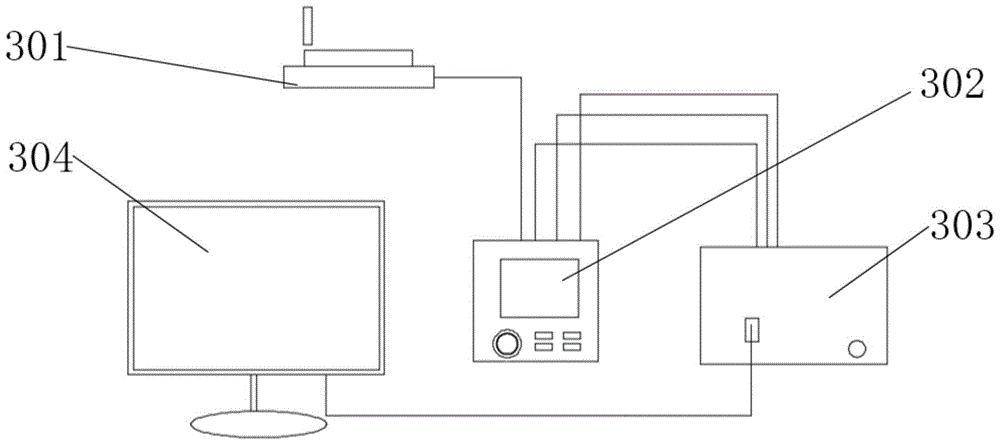

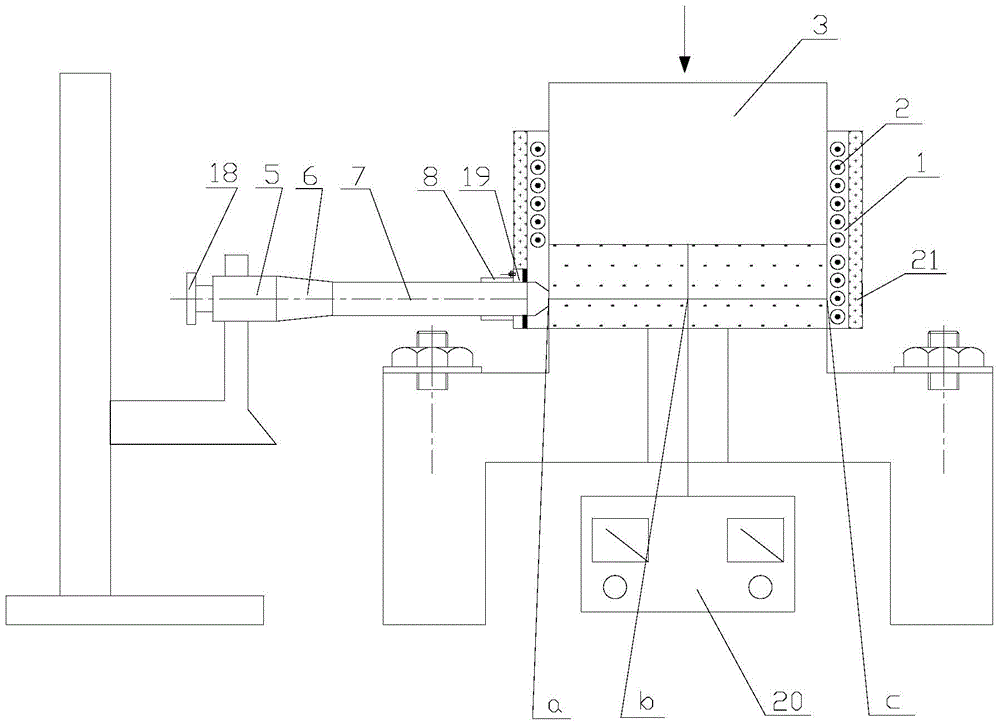

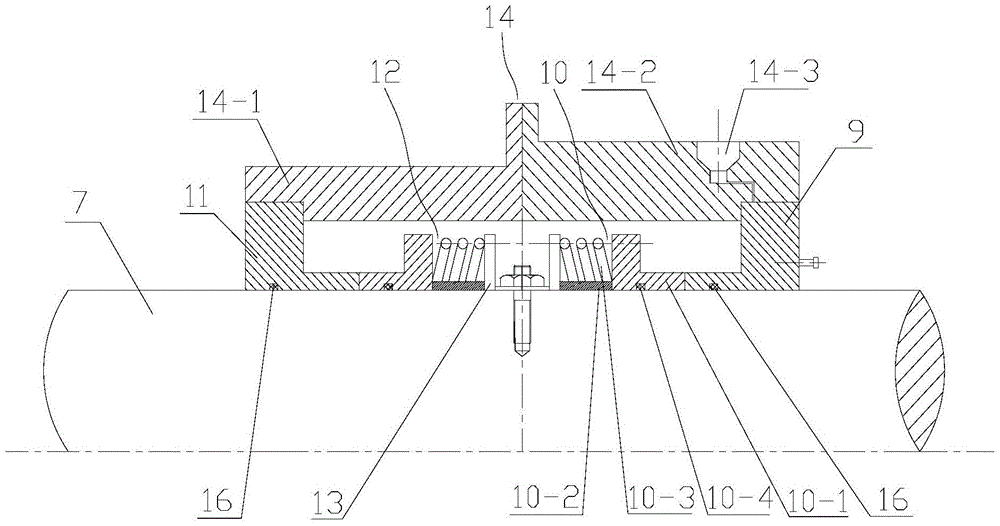

Auxiliary device for high-temperature alloy machining

The invention discloses an auxiliary device for high-temperature alloy machining and belongs to the technical field of metal cutting machining. The auxiliary device for high-temperature alloy machining is used for achieving cutting machining conducted on a high-hardness high-temperature alloy workpiece and comprises a plasma heating unit, a clamping unit, a cutting force measurement unit and a temperature measuring unit, wherein the plasma heating unit comprises a plasma transmitting spray head, is used for heating and softening the position to be cut of the high-temperature alloy workpiece and can perform cutting machining. The clamping unit comprises multiple clamping plates, wherein the clamping plates are oppositely installed so as to clamping the plasma transmitting spray head. A force measurement instrument in the temperature measuring unit is used for being in contact with the high-temperature alloy workpiece so as to measure cutting force borne by the high-temperature alloy workpiece in cutting. An infrared camera of the temperature measuring unit is used for measuring the temperature of the position to be cut of the high-temperature alloy workpiece heated by the plasma transmitting spray head. The auxiliary device for high-temperature alloy machining is low in price and energy consumption and capable of achieving accurate controllability of cutting machining process.

Owner:HUST WUXI RES INST

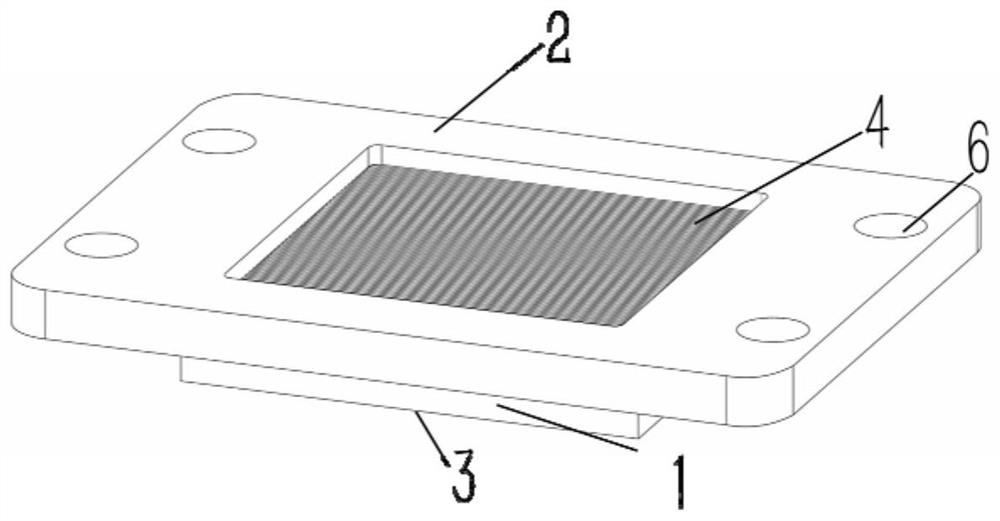

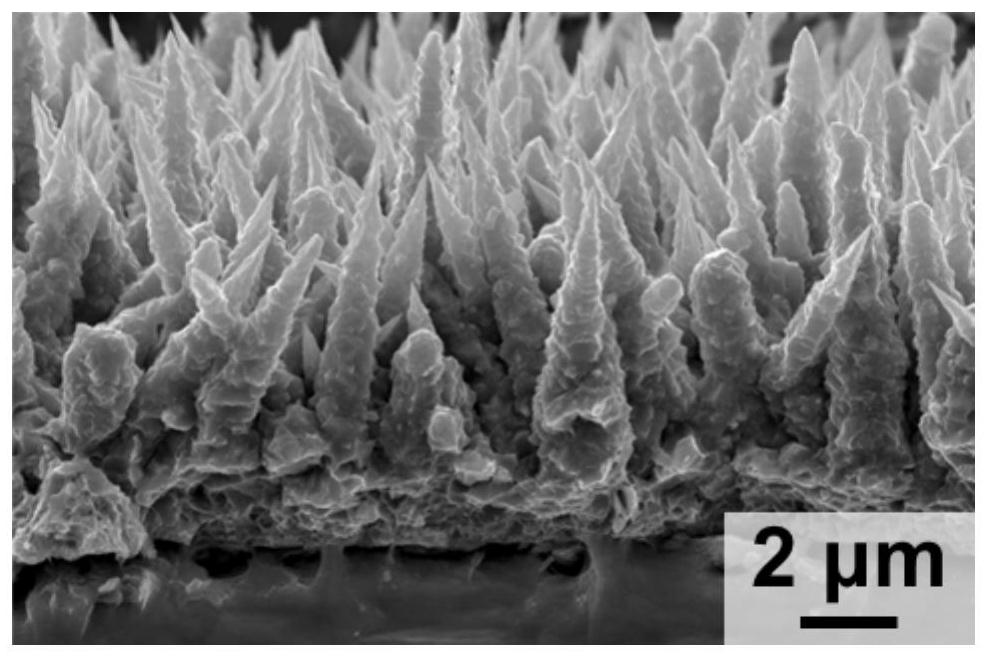

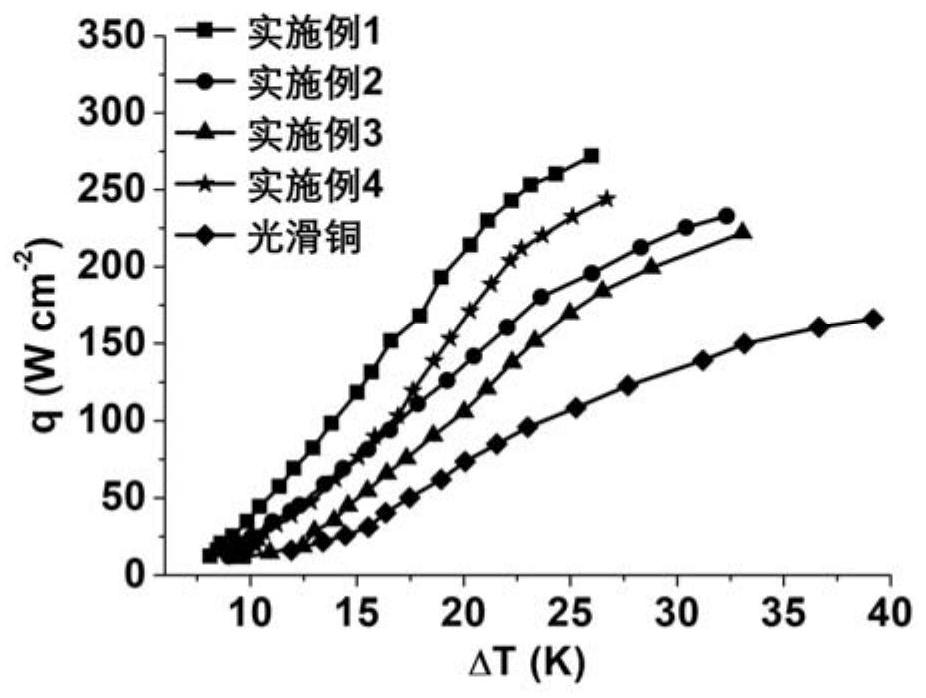

Immersion cooling heat dissipation structure, radiator, heat dissipation system and manufacturing method of immersion cooling heat dissipation structure

PendingCN112071817AAvoid the defect of high contact thermal resistanceIncrease the heat exchange areaSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyThermodynamics

The invention discloses an immersion cooling heat dissipation structure, a radiator, a heat dissipation system and a manufacturing method of the immersion cooling heat dissipation structure. The immersion cooling heat dissipation structure comprises a boiling heat exchange unit, and the boiling heat exchange unit comprises a first surface and a second surface which are arranged back to back; a microstructure composed of a plurality of opposite convex parts and / or a plurality of opposite concave parts is distributed on the first surface, and the first surface is at least used for making contactwith an electrically insulating immersion cooling medium; the second surface is a smooth face and used for being attached to a heating element, or the second surface and the heating element are integrally arranged. The immersion cooling heat dissipation structure provided by the invention has the advantages of higher heat exchange area, more nucleation sites, stronger capillary fluid infusion capability, excellent boiling heat exchange performance, high heat transfer coefficient and critical heat flux density, low superheat degree of a nucleation boiling starting point and great advantages ina small-space high-heat-flux heat dissipation application scene; meanwhile, the manufacturing process is relatively flexible and controllable, the cost is low, industrial large-scale application canbe achieved, and the market competitiveness is high.

Owner:SUGON DATAENERGYBEIJING CO LTD

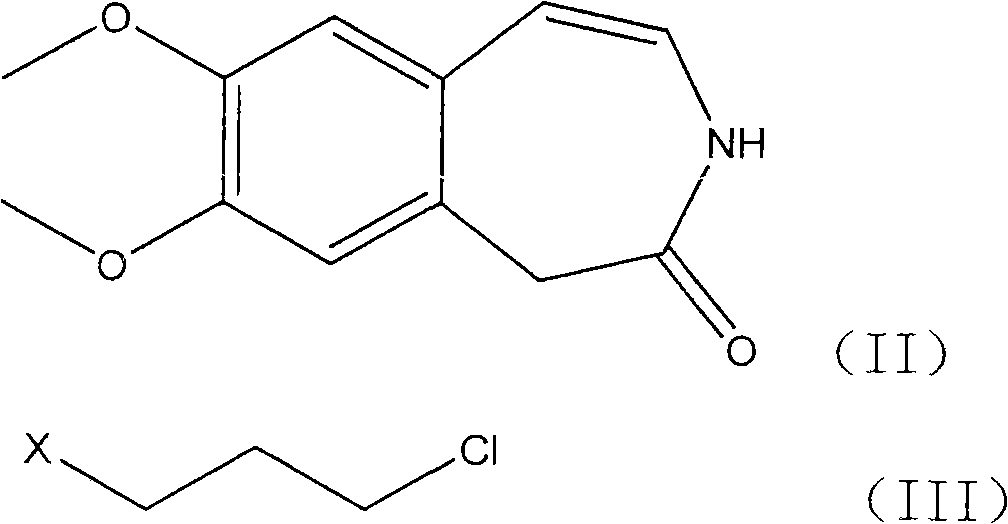

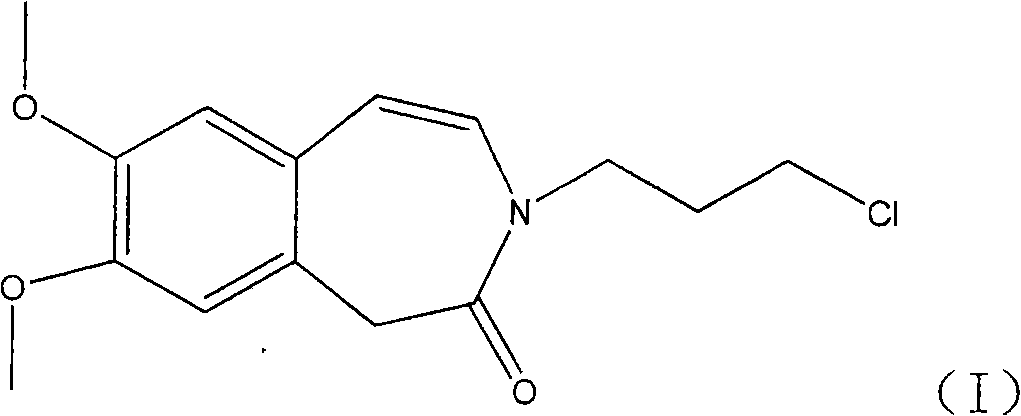

Preparation of 3-(3-chlorine propyl)-7, 8-di methoxy-1, 3-dihydrogen-2H-3-benzo aza -ketone

InactiveCN101343249AEasy to handleSuitable for industrial scale applicationsOrganic chemistryCardiovascular disorderAlkyl transferKetone

The invention relates to the technique field of a preparation method of an intermediate compound of Ivabradine. The preparation method of 3-(3-chloropropyl)-7, 8-dimethoxy-1, 3-dihydro-2H-3-benazepine-2-ketone comprises: making 7, 8-dimethoxy-1, 3-dihydro-2H-3-benazepine-2-ketone and 1, 3-chlorobromide have the alkylation reaction. The preparation method unexpectedly selects an alkaline reagent used commonly, and has advantages of mild reaction conditions, safety and reliability, and rather high yield, and the method fully overcomes the defects of strong water absorption, easy deterioration, or easy explosion under rather low temperature of the alkylation reagent used in the prior art, and is extremely applied to the industrialized big-production.

Owner:SHANGHAI INST OF PHARMA IND

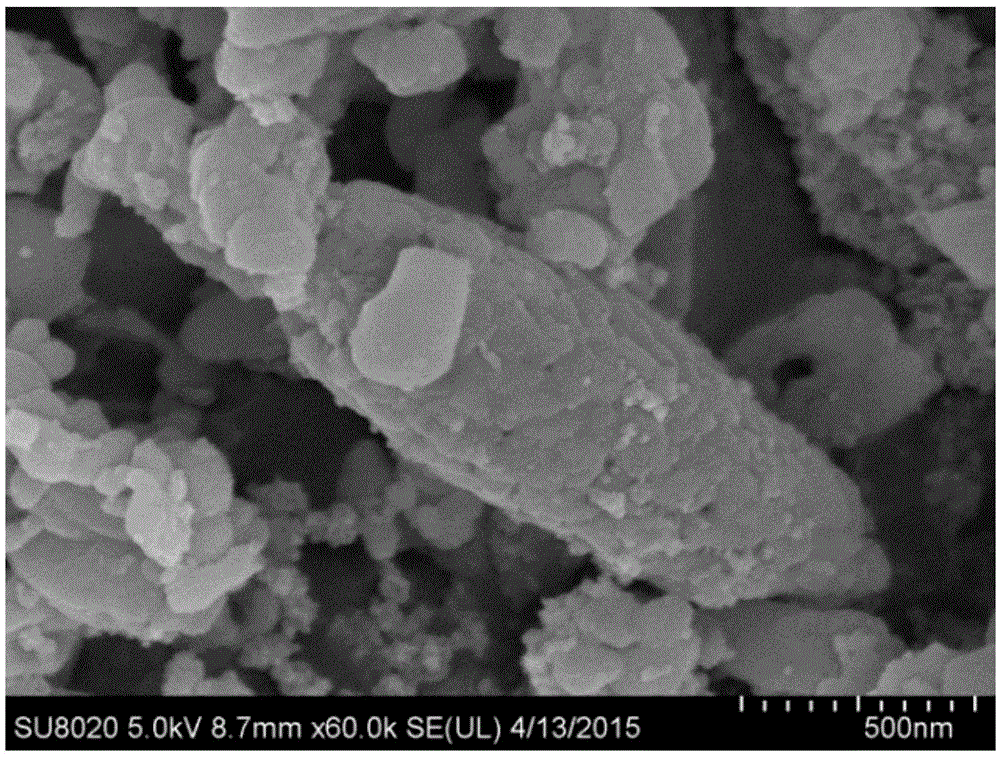

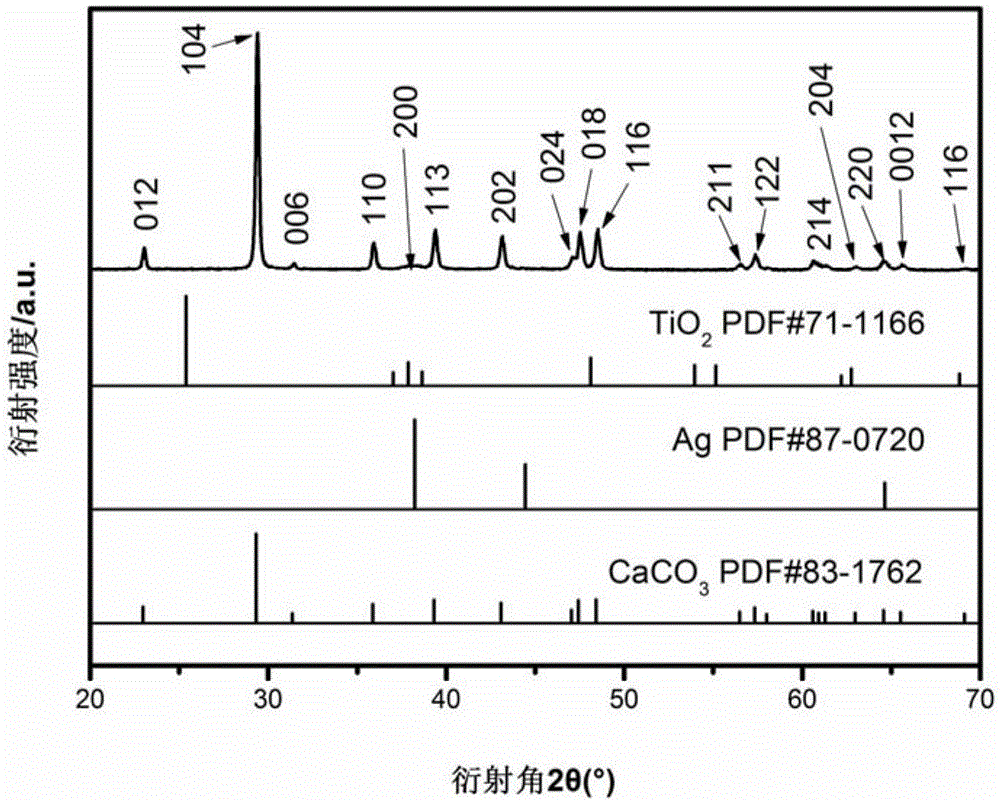

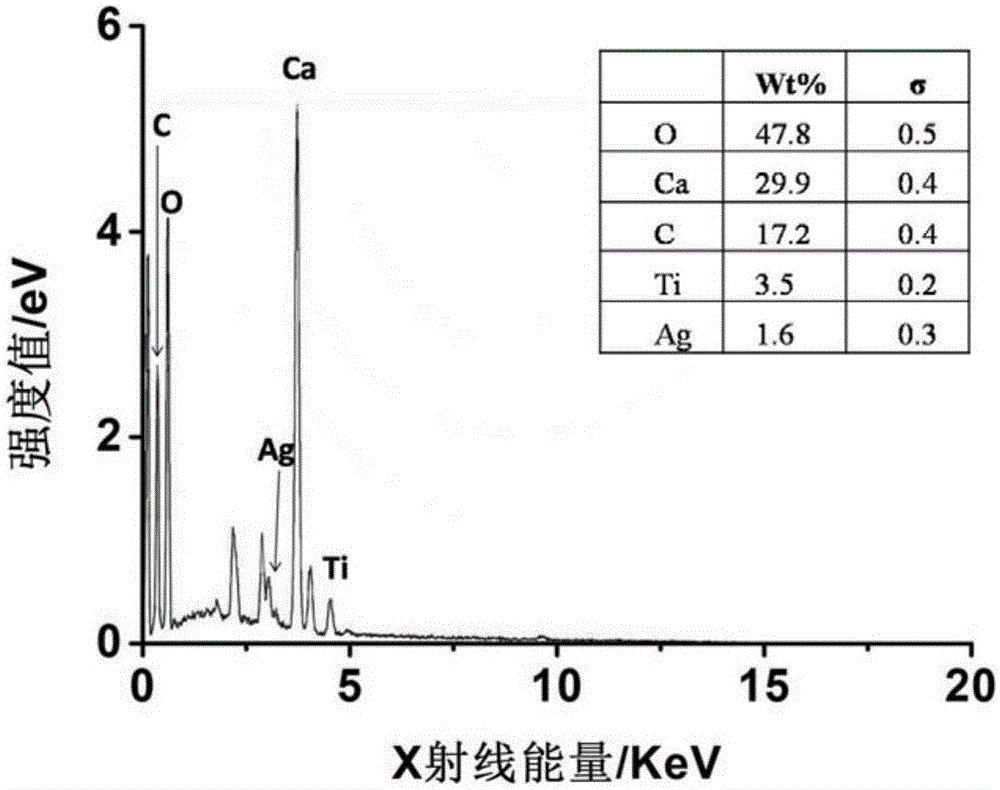

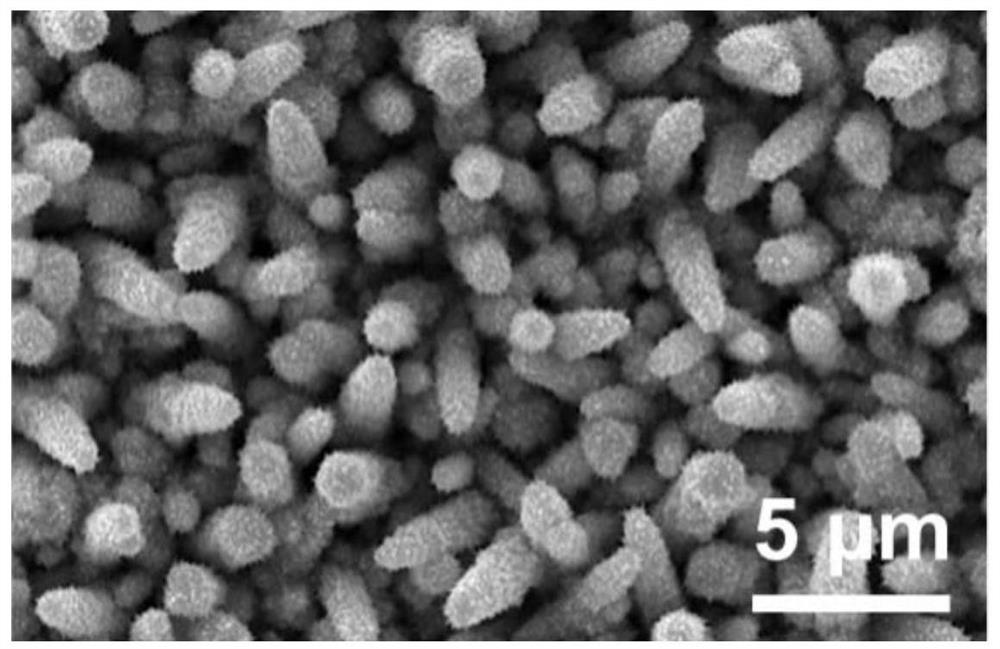

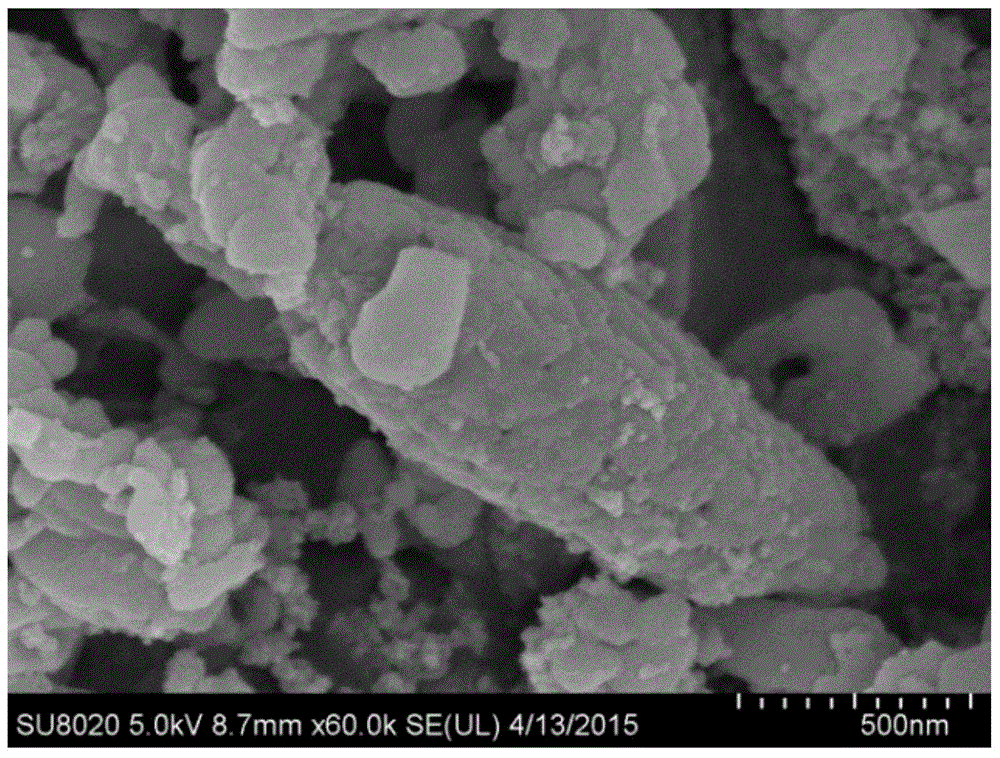

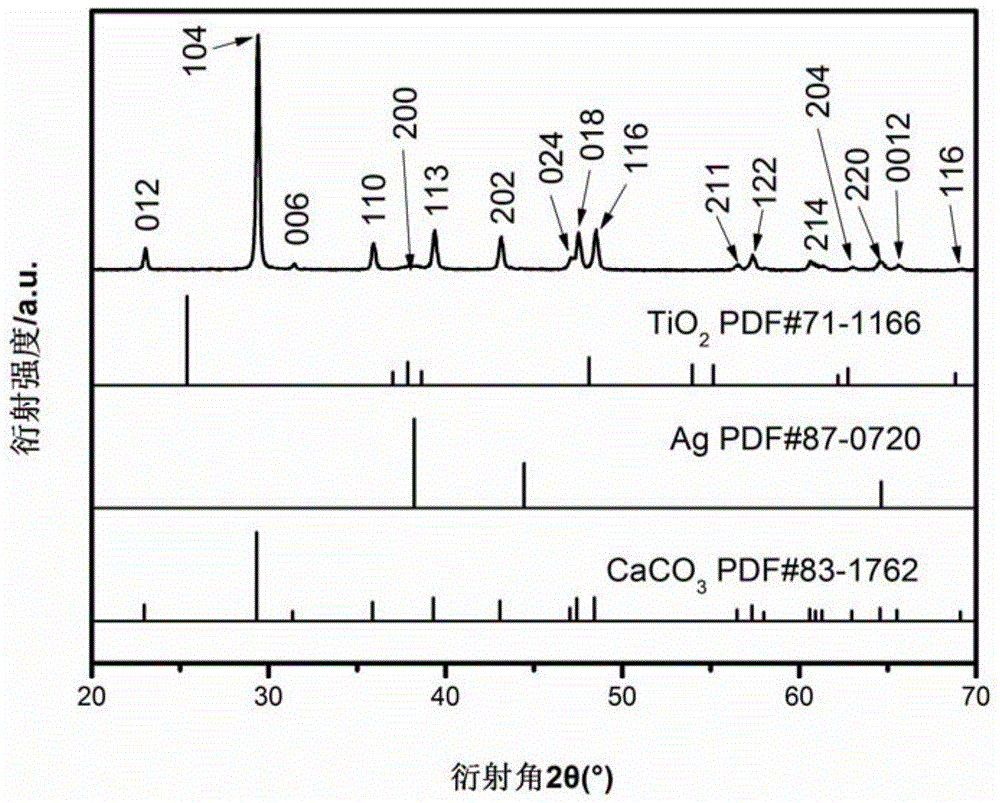

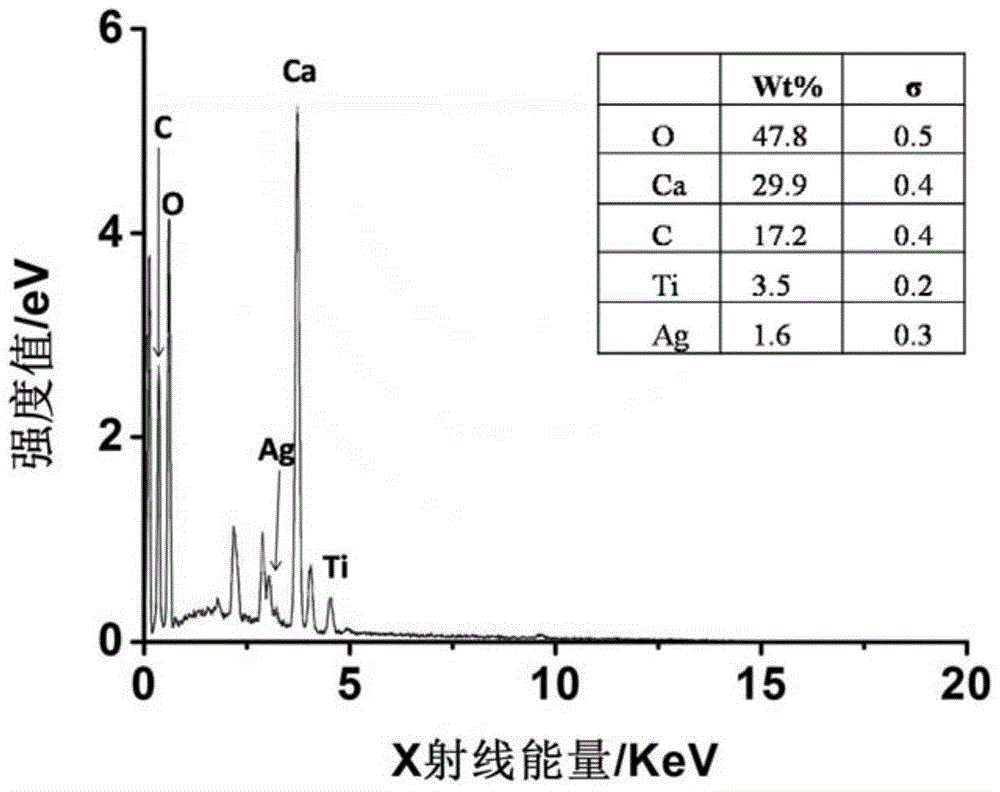

Nano calcium carbonate catalyst wrapped by Ag-loaded titanium dioxide nanoparticles, as well as preparation method and application of nano calcium carbonate catalyst

ActiveCN105107537AImprove catalytic performanceReduce contentPhysical/chemical process catalystsTobacco treatmentSmokeCatalysis

The invention discloses a nano calcium carbonate catalyst wrapped by Ag-loaded titanium dioxide nanoparticles as well as a preparation method and application of the nano calcium carbonate catalyst. The surfaces of spindle-shaped nano calcium carbonate particles are wrapped by Ag-loaded titanium dioxide nanoparticles. The catalyst can be added into paper-making process reconstituted tobaccos so as to be added into cigarettes containing the reconstituted tobaccos, so that the smoke reaction is catalyzed in cigarette igniting and smoking processes and the carbonyl compound content of the smoke can be reduced. According to the invention, the preparation process is simple, convenient and economical, and the prepared catalyst has a remarkable particle catalysis effect, is low in cost and is suitable for industrial application.

Owner:CHINA TOBACCO ANHUI IND CO LTD +1

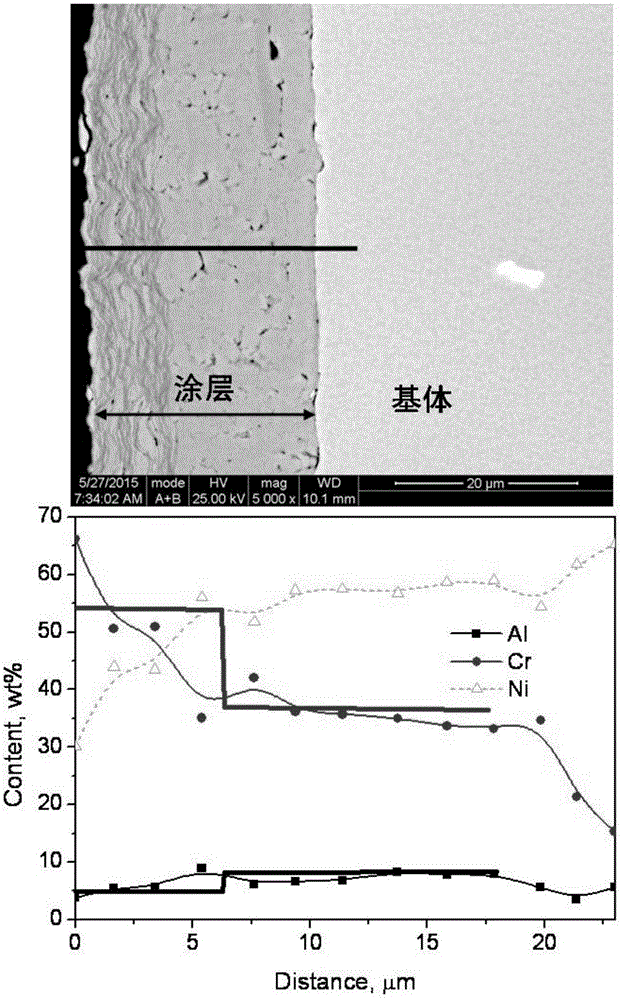

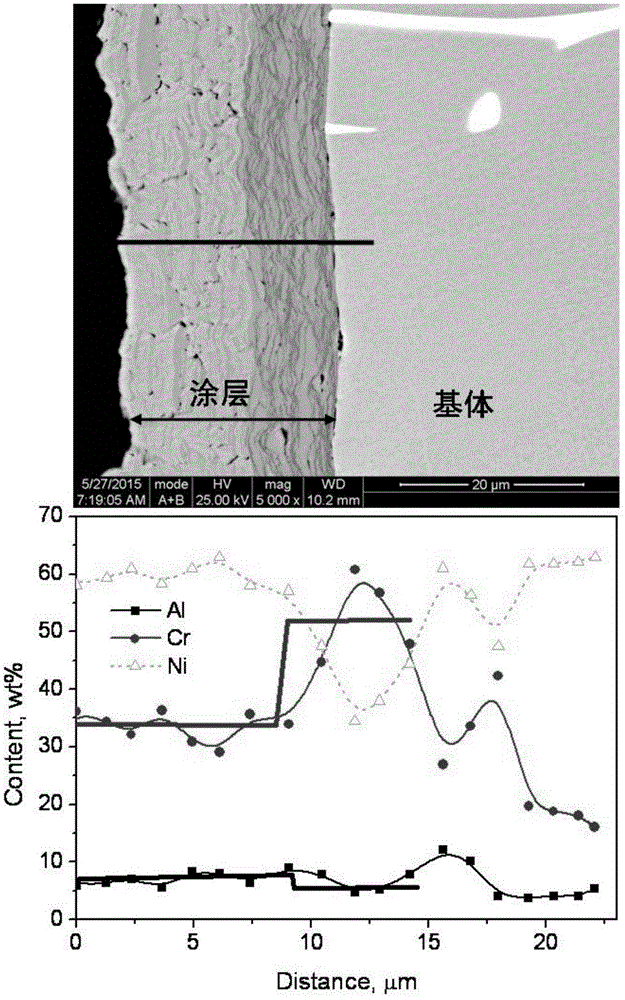

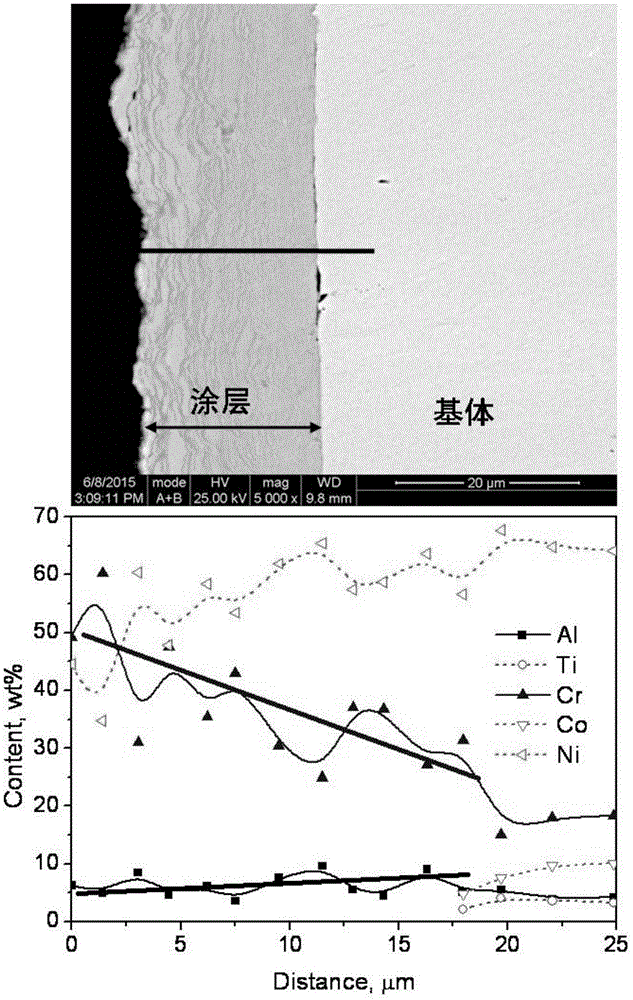

Gradient MCrAlX coating single-target electric arc ion plating one-step preparation method

InactiveCN106319454ADense tissueImprove processing stabilityVacuum evaporation coatingSputtering coatingRare-earth elementSputtering

The invention relates to a gradient MCrAlX coating single-target electric arc ion plating one-step preparation method, and belongs to the technical field of coatings, wherein the method can be used for preparing the adhesion layer and the like of anti-high temperature oxidation and hot corrosion coatings, and thermal barrier coatings, MCrAlX:M comprises, but is not limited to, Fe, Co, Ni, Ti, Pt, Zr, W, Nb, B or a combination thereof, X is a rare earth element and comprises, but is not limited to, Y, La, Hf, Ce, Gd, Dy or a combination thereof, and by using the two sputtering phenomenon and by real-timely adjusting the bias voltage during a film plating process, the gradient MCrAlX coating can be obtained from the single MCrAlX target in one step without other processes, wherein the aluminum and the chrome component present the gradient change from the coating surface to the internal. According to the present invention, the high ionization rate of the electric arc ion plating and the coating anti-sputtering under the high bias voltage are utilized, such that the gradient MCrAlX coating can be obtained from the single target, the prepared coating has the compact structure, the process stability and the preparation efficiency are high and are much better than other multiple process combined gradient coating preparation methods, the cost is low, and the method is suitable for industrial application.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

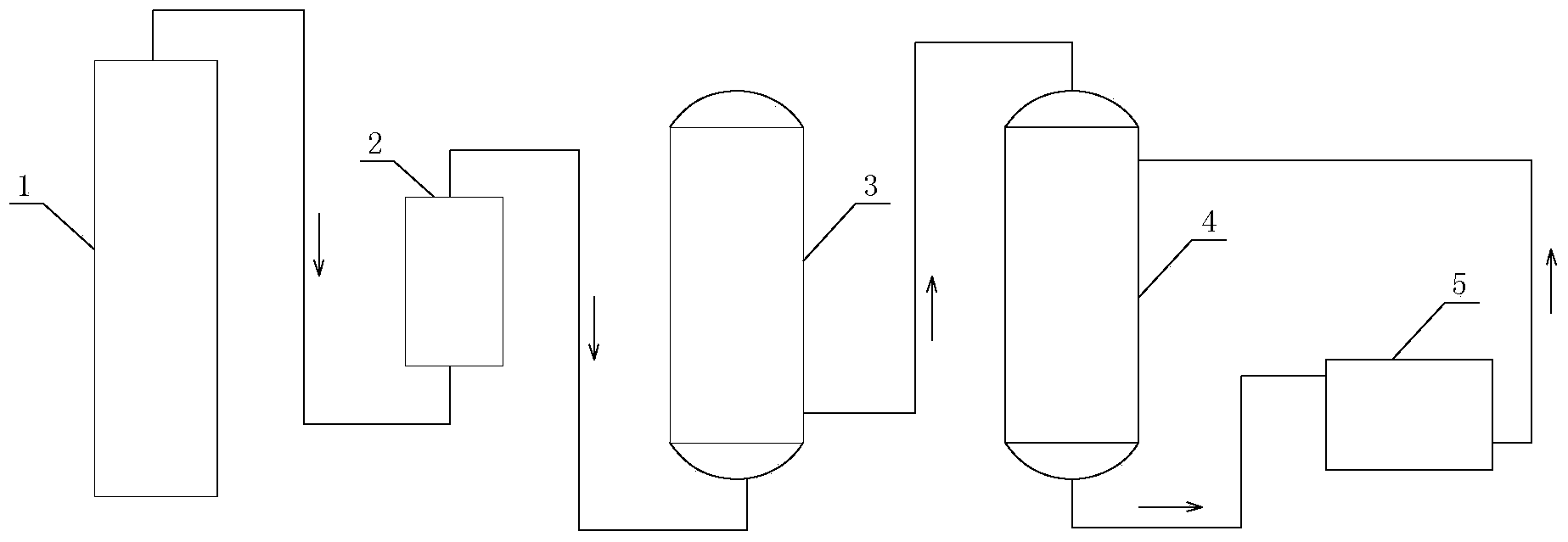

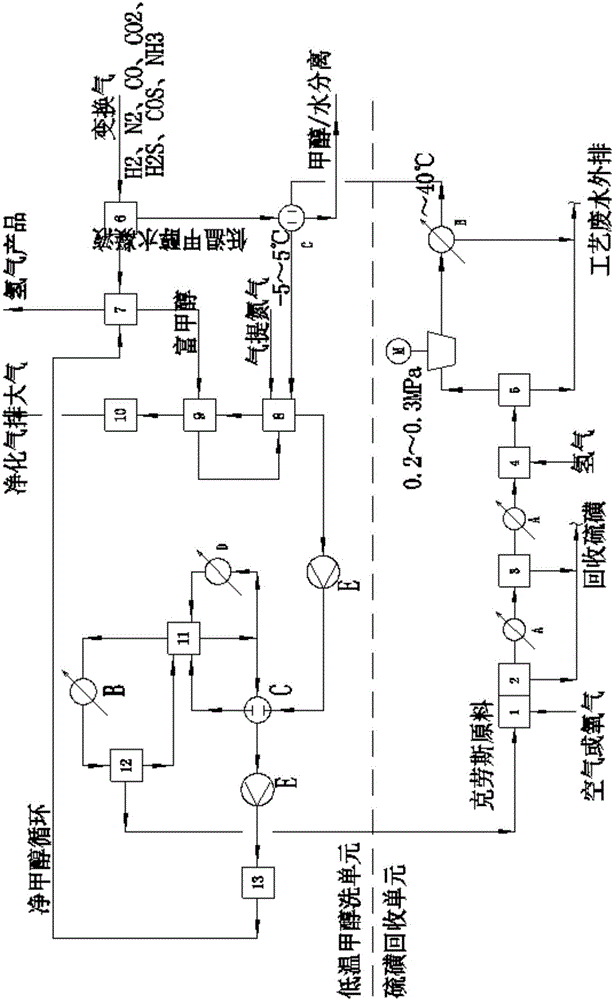

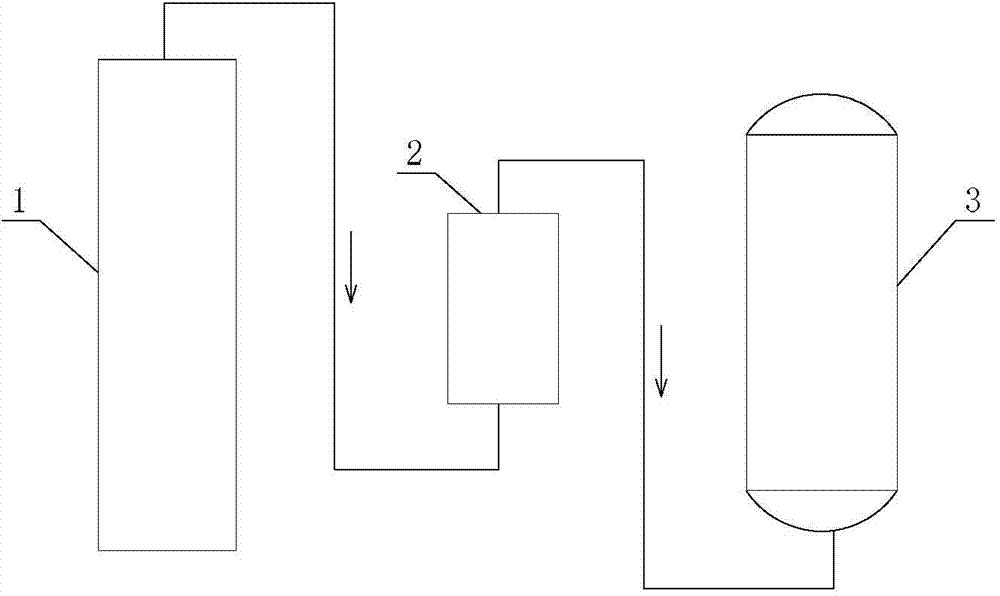

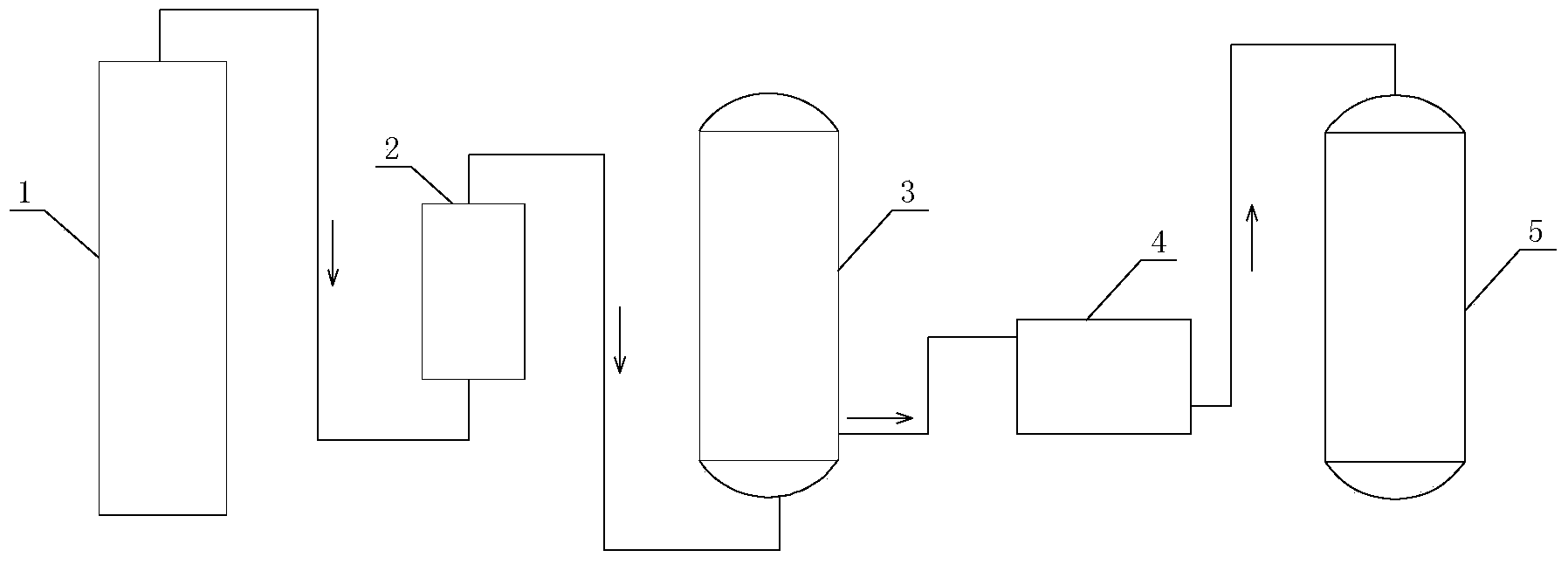

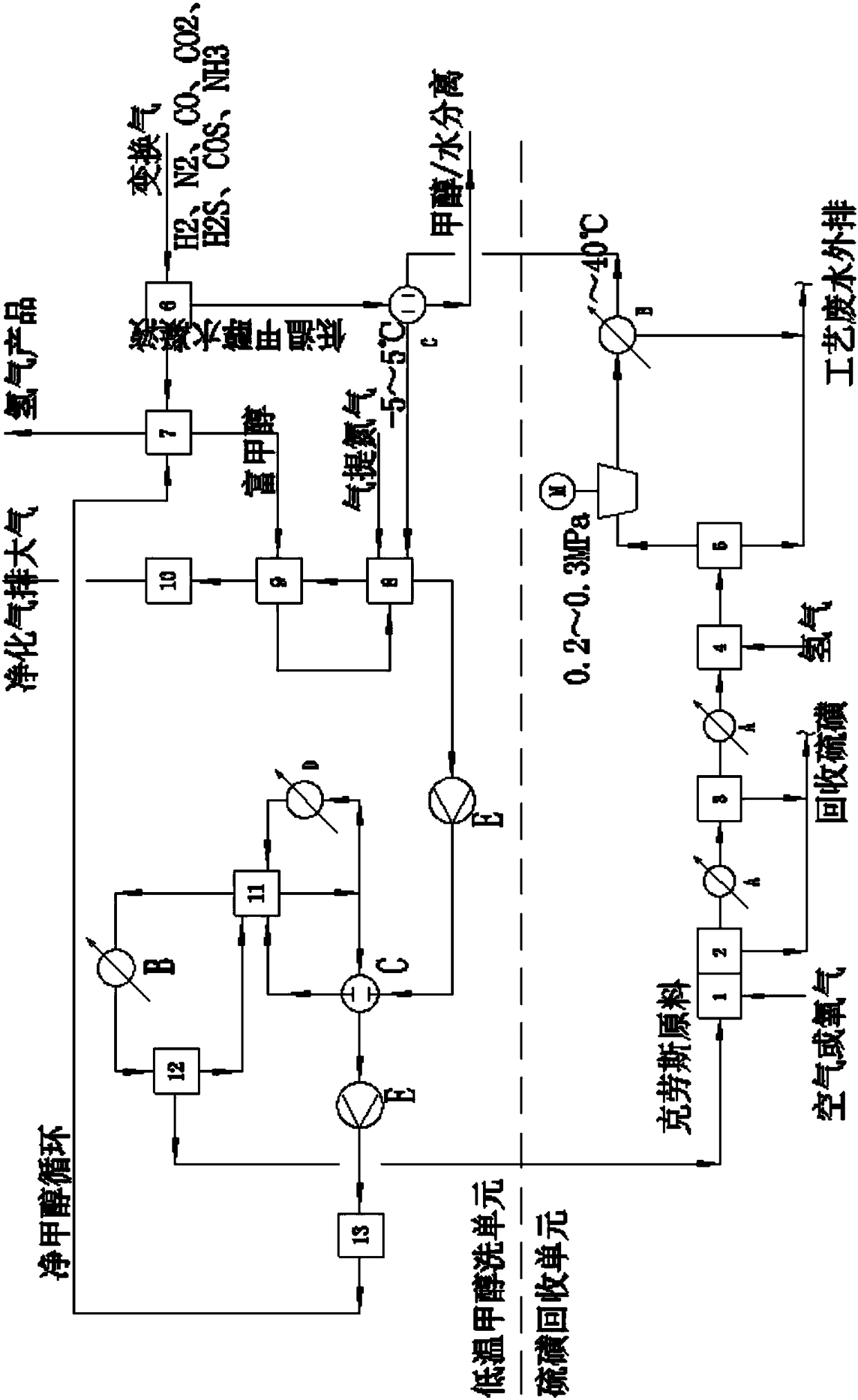

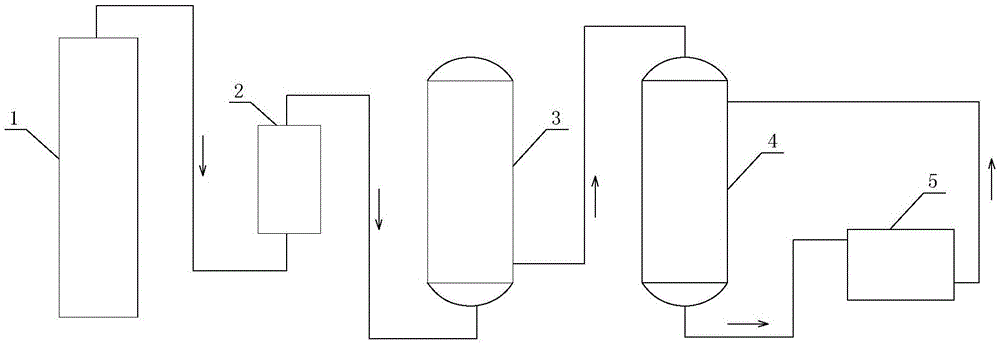

Device for increasing recovery rate of sulfur and recovery method of sulfur

InactiveCN106115632ASimple processReduce investment and operating costsSulfur preparation/purificationIndustrial scaleExhaust gas

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

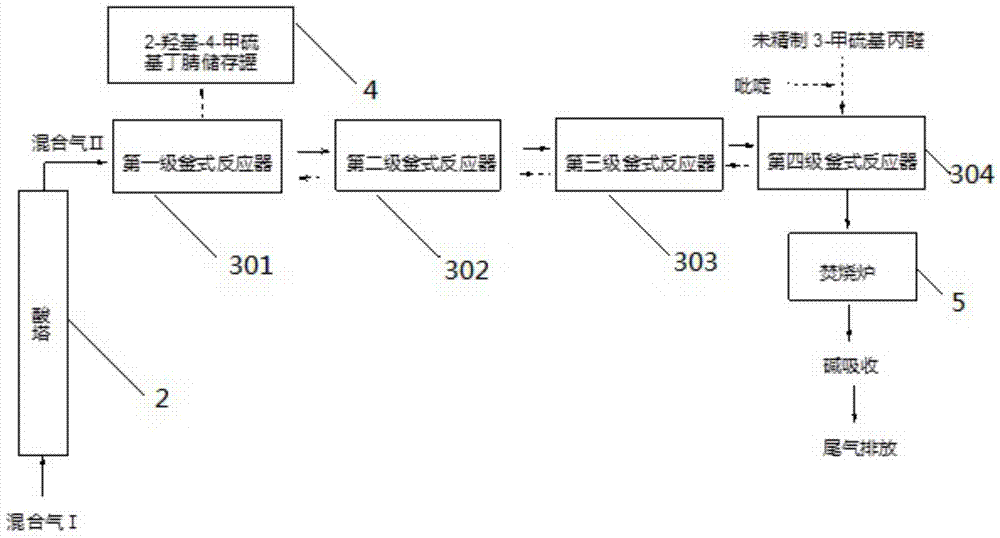

Method for using hydrocyanic acid mixed gas to prepare 2-hydroxy-4-methylthio-butyronitrile and continuous production method for 2-hydroxy-4-methylthio-butyronitrile

InactiveCN103664720AImprove controllabilitySuitable for industrial scale applicationsSulfide preparationOxygenReaction system

The invention belongs to the field of chemical engineering, and relates to a method for using hydrocyanic acid mixed gas to prepare 2-hydroxy-4-methylthio-butyronitrile and a continuous production method for the 2-hydroxy-4-methylthio-butyronitrile. The method comprises the following steps: preparing hydrocyanic acid mixed gas I by using methane, ammonia gas and oxygen as raw materials and adopting the synthetic principle of an Andrussow method; deaminizing the hydrocyanic acid mixed gas I to obtain hydrocyanic acid mixed gas II; enabling the hydrocyanic acid mixed gas II to fully react with methylthiopropanal under the catalysis of alkali, so as to obtain the 2-hydroxy-4-methylthio-butyronitrile. According to the invention, the method adopts raw materials not purified, the raw materials are low in cost and easy to obtain, and the prepared 2-hydroxy-4-methylthio-butyronitrile is high in yield and high in purity; the obtained 2-hydroxy-4-methylthio-butyronitrile reaction system not subjected to purification and separation is stable in property, and can be stored for a long time and used for the production of down-stream products conveniently. The continuous production method for the 2-hydroxy-4-methylthio-butyronitrile particularly adopts a multi-level series tank reactor, so that the continuous production method can realize industrial large-scale continuous production, is low in production cost, efficient, environment-friendly and suitable for industrial popularization and application.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

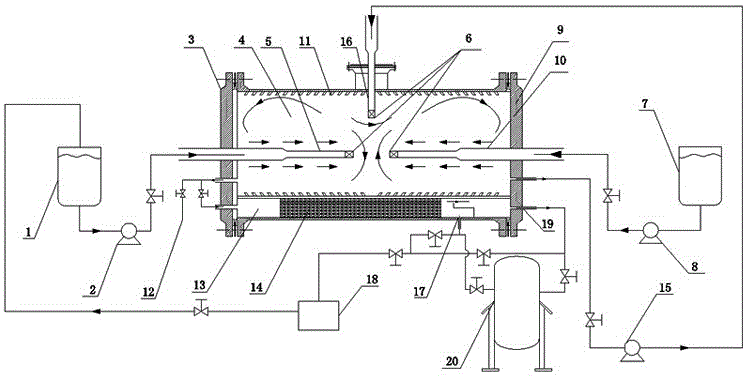

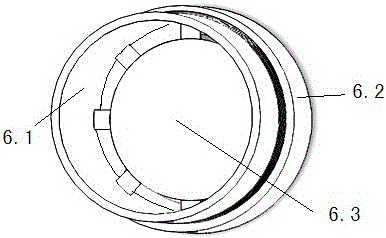

Impinging stream reaction and separation integration device and impinging stream reaction and separation integration method for liquid-liquid reaction system

InactiveCN106423002AEnhanced mixing processWell mixedLiquid-liquid reaction processesPropellerHorizontal axis

The invention relates to an impinging stream reaction and separation integration device and an impinging stream reaction and separation integration method for a liquid-liquid reaction system. The impinging stream reaction and separation integration device comprises a device barrel body, three storage tanks and three booster pumps, wherein the device barrel body is divided into a reaction cavity and a separation cavity; the reaction cavity is internally provided with three main guide cylinders, two of the main guide cylinders are opposite to each other along a horizontal axis, and the circulating main flow guide cylinder is arranged at the upper side of the middle of the device barrel body, so that circulating repeated impinging of two-phase liquids is realized; end openings of the three guide cylinders are provided with guide vanes; the separation cavity is internally provided with a corrugated plate; the middle lower part of the device barrel body is provided with a sampling opening; the separation cavity is internally provided with two discharging holes. The impinging stream reaction and separation integration device has the beneficial effects that movable components such as a propeller are not arranged in the device barrel body, and the guide vanes are adopted to replace a propeller-type structure, so that the problems such as vibration caused by the propeller-type structure are reduced; the circulating guide cylinder is arranged in the reaction cavity, so that circulating repeated impinging of the two-phase liquids is realized, the mixing process of two liquids is strengthened, and the process flow is reduced.

Owner:李泽深

Composite material for membrane distillation

InactiveCN109550401AIncrease membrane fluxSuitable for industrial scale applicationsMembranesDistillationMembrane distillationMembrane flux

The invention relates to the technical field of membrane distillation, and provides a composite material for membrane distillation, the composite material is composed of a hydrophobic porous materiallayer and a hydrophilic porous material layer, and pores of the hydrophobic porous material layer and the hydrophilic porous material layer are in three-dimensional three-dimensional communication; and the pores of the hydrophobic porous material layer and the hydrophilic porous material layer at the interface are in three-dimensional three-dimensional communication, and the specific surface areaof the material is greatly increased, so that diffusion of water molecules and condensation of water are facilitated, more water molecules are enabled to pass through a composite membrane, a large membrane flux is realized, the membrane is not easy to block in use, and the composite material has a relatively long service life and is suitable for industrial application.

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of D,L-2-hydroxy-4-methylthiobutyrate

ActiveCN103524388AShorten production timeIncrease productivitySulfide preparationChemical industryAlcohol

The invention aims at the chemical industry field, and relates to a preparation method of D,L-2-hydroxy-4-methylthiobutyrate. The method comprises the following steps: fully reacting a hydrocyanic acid gas mixture prepared through an Andrussow method with methylthiopropionaldehyde under the catalysis of an alkali to obtain a 2-hydroxy-4-methylthiobutyronityile reaction system; and mixing the 2-hydroxy-4-methylthiobutyronityile reaction system with alcohol, and carrying out hydrolysis and esterification reactions under the catalysis of an inorganic acid to prepare the D,L-2-hydroxy-4-methylthiobutyrate. Initial raw materials which are not rectified or purified, and are cheap and easily available, an intermediate obtained through a reaction has stable properties, few reaction steps are realized, and a finally obtained product is simply separated and purified to obtain high-purity and high-yield D,L-2-hydroxy-4-methylthiobutyrate.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

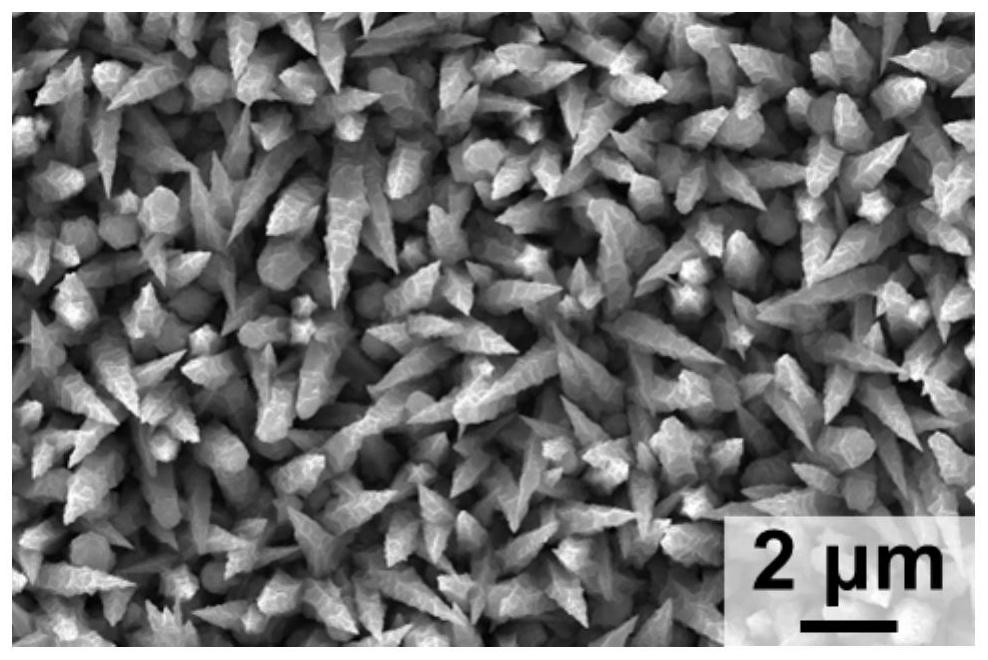

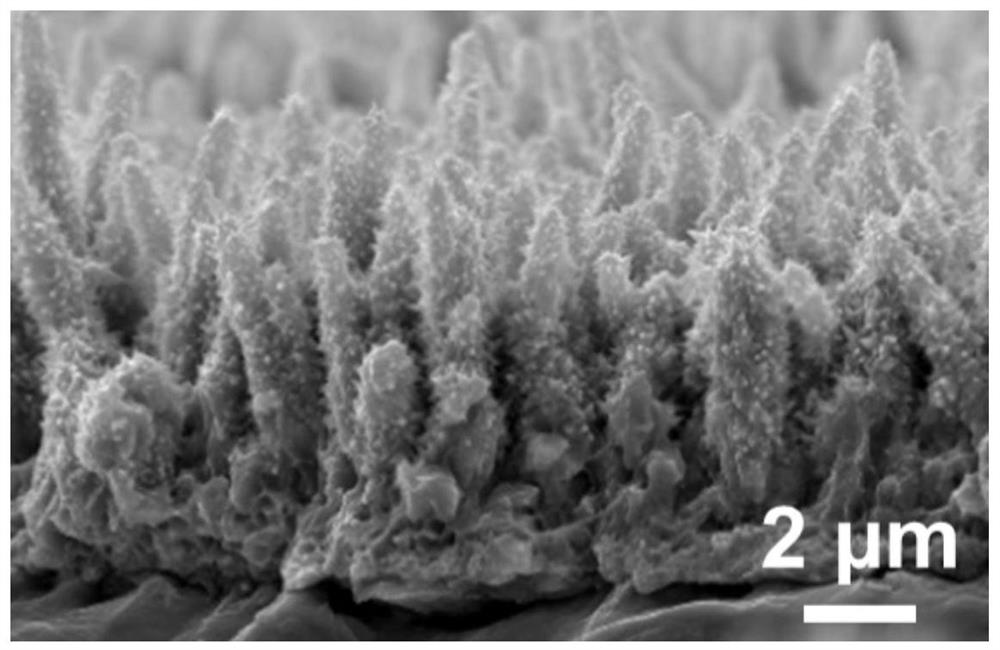

Efficient boiling heat transfer copper material and preparation method thereof

InactiveCN112176369AIncrease the heat exchange areaEasy to transportNanotechnologyElectrolytic agentEvaporation heat transfer

The invention discloses an efficient boiling heat transfer copper material and a preparation method thereof. The surface of the efficient boiling heat transfer copper material is coated with a porouscopper film; the porous copper film comprises a plurality of copper nanocones; and irregular open micro-cavities distributed among the plurality of copper nanocones communicate with one another to form a porous micro-cavity structure. The preparation method comprises the following steps of: assembling a base material serving as a working electrode, a counter electrode and a weakly alkaline coppersalt electrolyte to form an electrochemical working system, applying a reduction current between the working electrode and the counter electrode, and forming a porous copper film on the surface of thebase material through an electrodeposition reaction. The efficient boiling heat transfer copper material disclosed by the invention has the advantages of higher heat exchange area, far more nucleation sites, more excellent boiling heat transfer performance, a higher boiling heat transfer coefficient, higher critical heat flux density, lower superheat degree of nucleate boiling onset, a simple andconvenient preparation process, easiness in reaction regulation and control and low cost; and the efficient boiling heat transfer copper material is suitable for industrial scale application.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

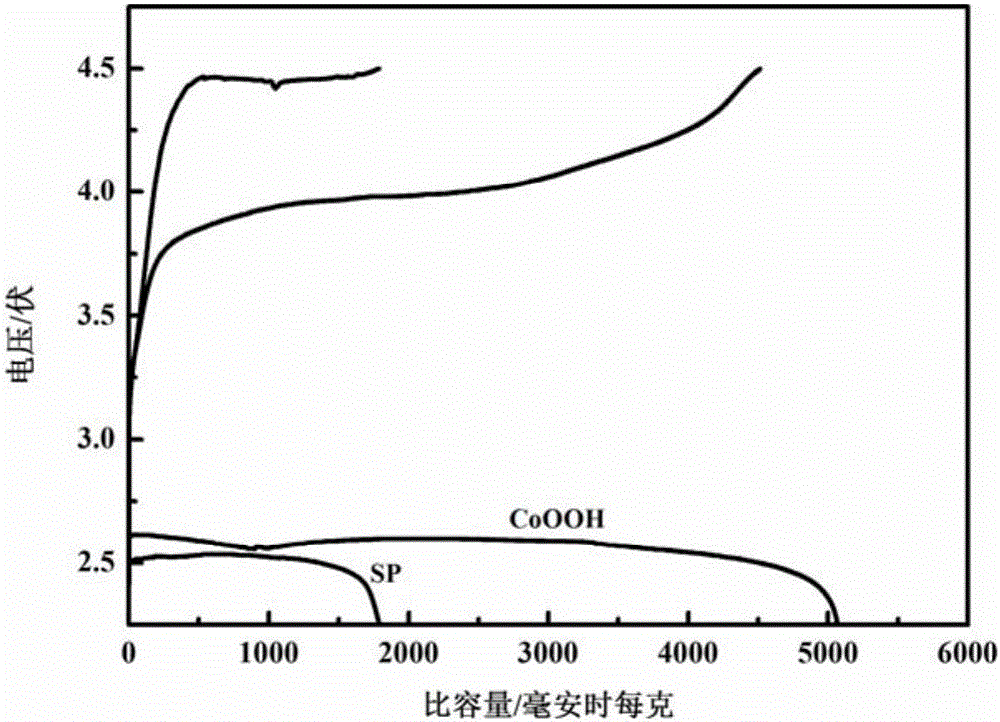

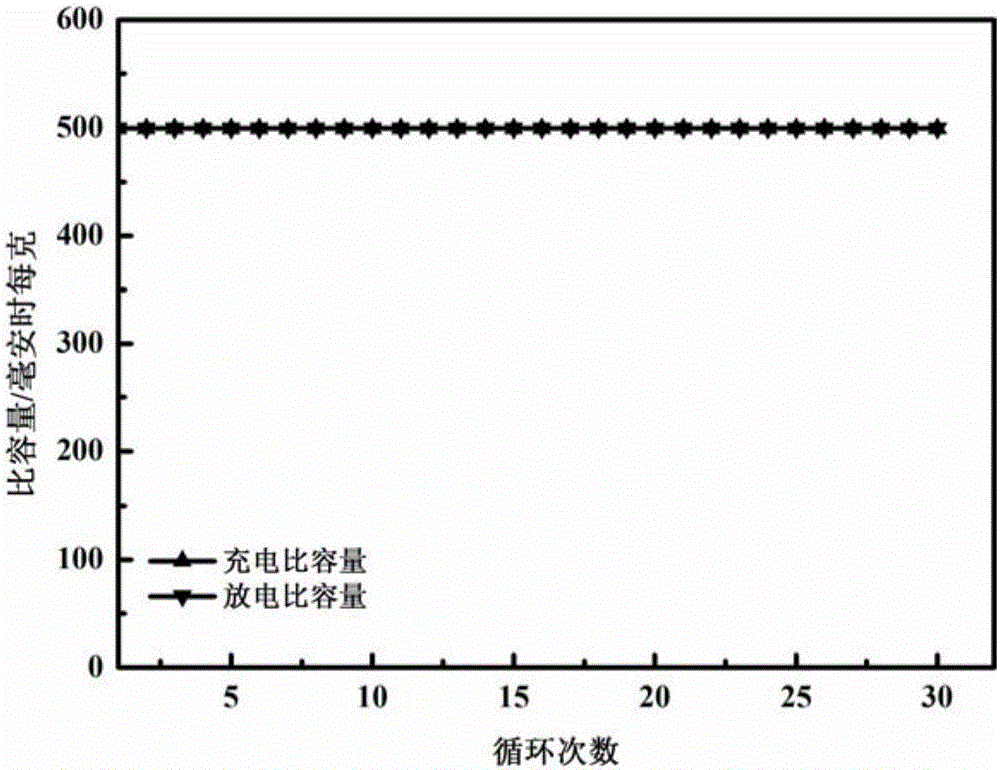

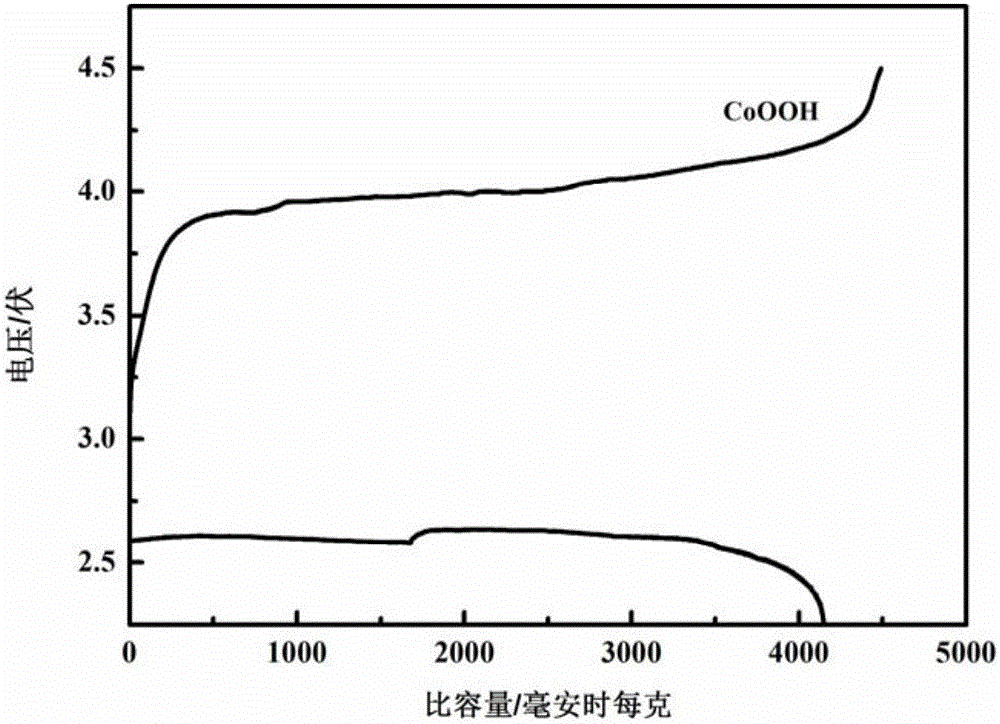

Lithium-air battery positive electrode employing hydroxyl cobalt oxide as catalyst and preparation method of positive electrode

InactiveCN105870466AFacilitate the transfer of electronsGood catalytic effectCell electrodesSolventCobalt oxide

The invention provides a lithium-air battery positive electrode employing hydroxyl cobalt oxide as a catalyst. The positive electrode comprises a positive electrode base material and a positive electrode material coating coated on the positive electrode base material; the positive electrode material coating is prepared from the following components in percentage by mass: 5%-40% of hydroxyl cobalt oxide as a catalyst component, 50%-90% of a carbon material and the balance of an adhesive. The invention further provides a method for preparing the positive electrode of the lithium-air battery. The method comprises the following steps: mixing and grinding a formula amount of hydroxyl cobalt oxide and carbon material, and dissolving the adhesive into a solvent to obtain an adhesive solution; mixing the fully mixed and ground mixture and the adhesive solution to from uniformly dispersed slurry; and coating the positive electrode base material with the uniformly dispersed slurry, and carrying out drying and pressing to obtain a positive plate of the lithium-air battery. The discharge capacity of the lithium-air battery can be improved; battery polarization is reduced; and the cycle times of the battery are improved.

Owner:SICHUAN UNIV

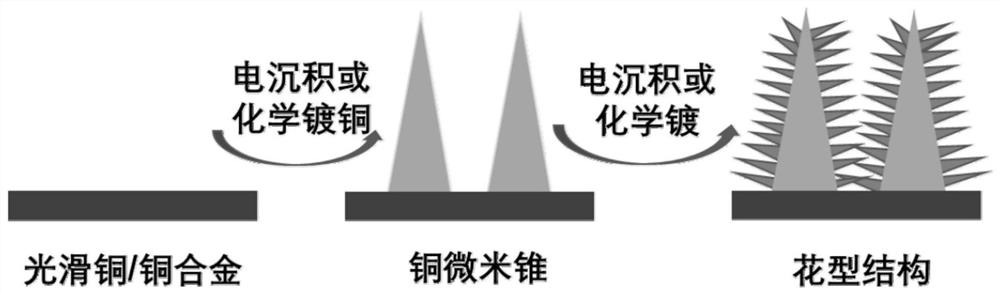

Flower type boiling heat transfer structure and preparation method thereof

InactiveCN112210802AIncrease the heat exchange areaExcellent boiling heat transfer performanceMaterial nanotechnologyElectrolytic agentNanofrustulum

The invention discloses a flower type boiling heat transfer structure and a preparation method thereof. The surface of the structure is covered with a micro-nano porous membrane, the micro-nano porousmembrane takes copper micron cones as a main body, and the surfaces of the copper micron cones are coated with nano cones to form graded composite cone structures; and unique micro-nano porous structures are formed among the composite cone structures. Compared with a single copper micron cone structure, the flower type boiling heat transfer structure of the invention has a larger heat exchange area, far more nucleation sites, more excellent boiling heat transfer performance, a higher boiling heat transfer coefficient and higher critical heat flux density, and the degree of superheat corresponding to a nucleate boiling starting point is lower. The electrolyte required for preparing the flower type boiling heat transfer structure is simple in formula, economical and easy to obtain, wide inthe selectable range of an electroplating mode, and suitable for industrial large-scale application.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

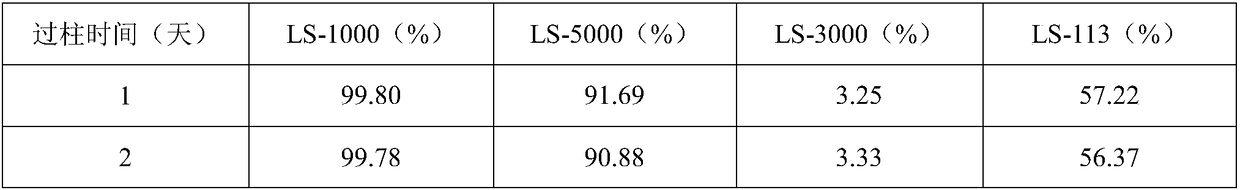

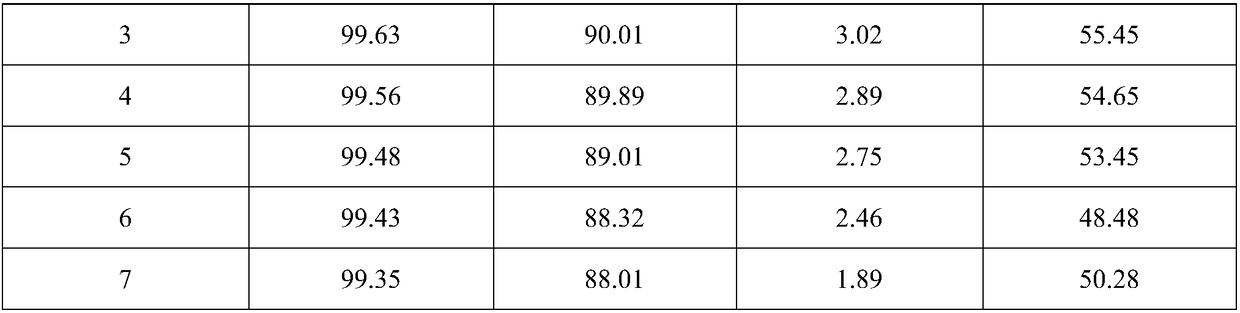

Method for separating heavy metals in trichlorosilane

InactiveCN108408729AImprove removal efficiencySuitable for industrial scale applicationsHalogenated silanesSafety controlQuality control

The invention provides a method for separating heavy metals in trichlorosilane. The method comprises the following steps of (1) pressurizing and cooling the to-be-treated trichlorosilane, wherein thepressure of trichlorosilane is 1.2MPa, and the temperature is lower than 50 DEG C; (2) enabling the pressurized and cooled trichlorosilane to pass through a resin adsorption tower at the pressure of 1.2MPa and the temperature being lower than 50 DEG C, and filling amino carboxylate chelating resin into the resin adsorption tower, so as to obtain trichlorosilane with separated heavy metal. The method has the advantages that the removal rate of heavy metal is high and is better than the removal rate of the existing distilling method; the safety and reliability are realized, the quality control and safety control have been verified on two industrial projects, and the method is suitable for industrialized scale application.

Owner:XIAN LANSHEN NEW MATERIAL TECHNOLOGY CO LTD +1

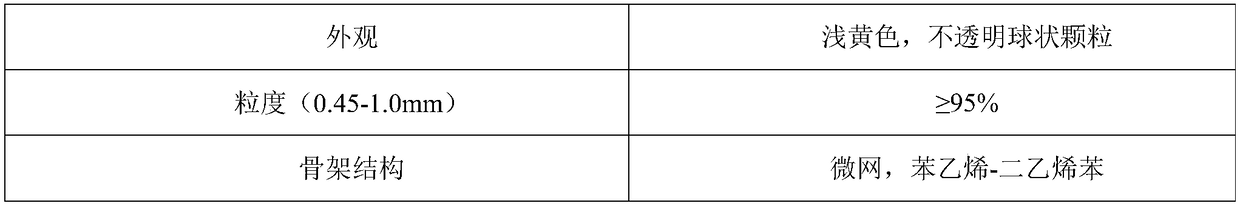

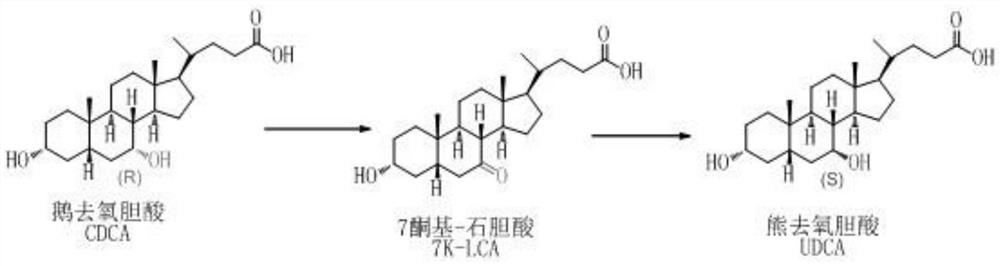

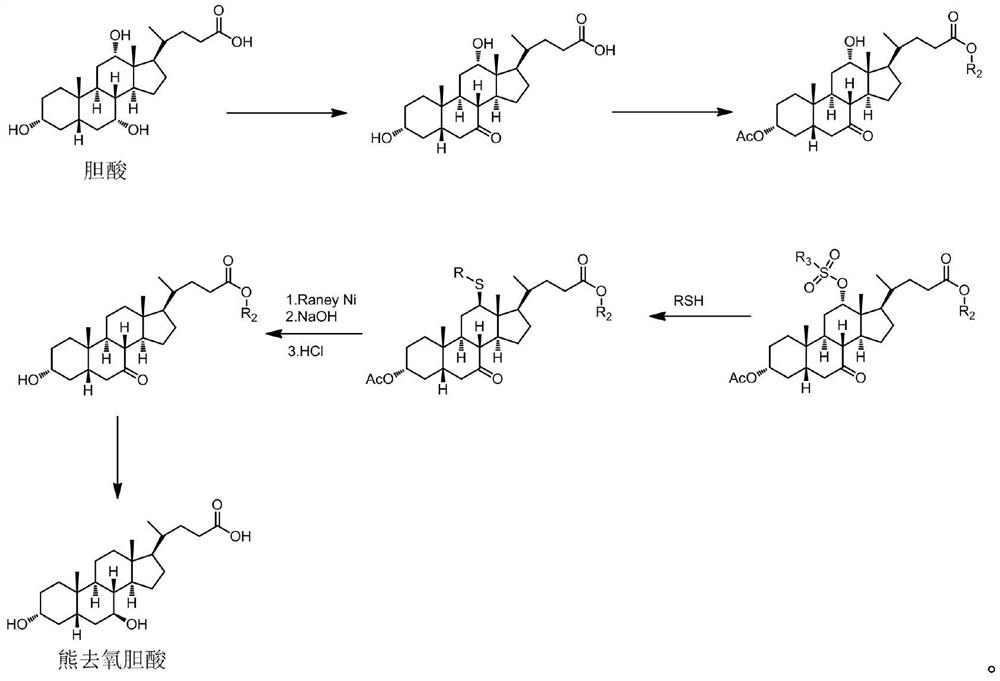

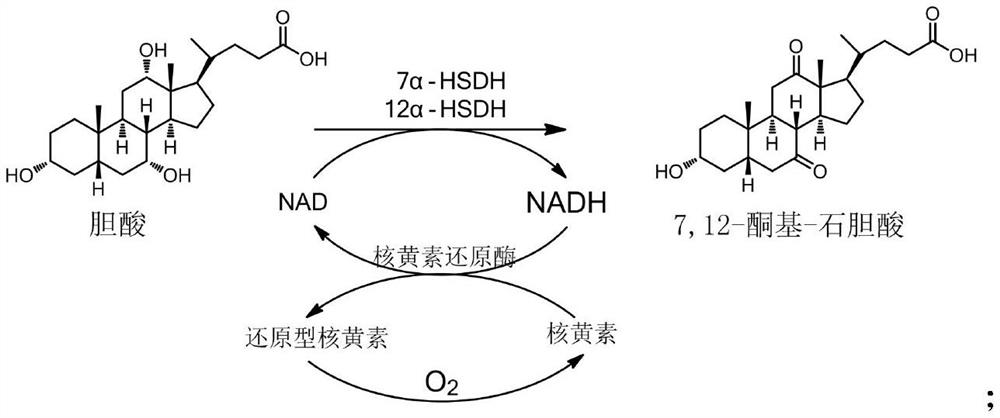

Preparation method of ursodesoxycholic acid

The invention discloses a preparation method of ursodesoxycholic acid. The preparation method is characterized by comprising the following preparation steps: (1) carrying out an oxidation reaction on cholic acid under the action of 7alpha-hydroxysteroid dehydrogenase, 12alpha-hydroxysteroid dehydrogenase, coenzyme, a coenzyme regeneration system and an aqueous solution to obtain 7,12keto-lithocholic acid; (2) carrying out a reduction reaction on the 7,12 keto-lithocholic acid under the action of 7beta-hydroxysteroid dehydrogenase, coenzyme and the coenzyme regeneration system to obtain 12keto-ursodesoxycholic acid; and (3) removing a 12-site carbonyl group of the 12 keto-ursodesoxycholic acid to obtain the ursodesoxycholic acid. The process for preparing ursodesoxycholic acid takes cholic acid as a starting raw material, is sufficient in raw material supply, low in cost, suitable for industrial large-scale application, short in production flow, mild and safe in technological process and few in side reaction.

Owner:四川百特芳华医药科技有限公司

Process for producing oxygen methyl isourea acetate

InactiveCN101245037AHigh purityHigh yieldUrea derivatives preparationOrganic compound preparationMentholSodium acetate

The invention discloses a preparation method of oxymethylisourea acetate, which comprises the following steps: 1) the methanol solution of the oxymethylisourea bisulfate is reacted with sodium acetate and sodium hydroxide at the temperature of 10 to 65 DEG C for 2 to 10 hours; the molar ratio of the oxymethylisourea bisulfate to the sodium hydroxide and the menthol is 1:1:6 to 10 and the molar ratio of the oxymethylisourea bisulfate to the sodium acetate and the sodium hydroxide is 1:0.8 to 1.5:0.8 to 1.50; 2) the precipitated sodium sulfate is removed from the reaction mixture at the temperature of the step 1); 3) the reaction solution is condensed by the distillation of the menthol and the condensation temperature is 40 to 80 DEG C; 4) the concentrated solution of the oxymethylisourea acetate is cooled, crystallized and centrifugally separated. The synthesized product of the invention is high in purity, high in yield and simple in technique; the method is especially suitable for the application of industrial scale.

Owner:JUHUA GRP +1

A nano-calcium carbonate catalyst coated with ag titanium dioxide nanoparticles and its preparation method and application

ActiveCN105107537BImprove catalytic performanceReduce contentPhysical/chemical process catalystsTobacco treatmentPtru catalystPhysical chemistry

The invention discloses a nano calcium carbonate catalyst wrapped by Ag-loaded titanium dioxide nanoparticles as well as a preparation method and application of the nano calcium carbonate catalyst. The surfaces of spindle-shaped nano calcium carbonate particles are wrapped by Ag-loaded titanium dioxide nanoparticles. The catalyst can be added into paper-making process reconstituted tobaccos so as to be added into cigarettes containing the reconstituted tobaccos, so that the smoke reaction is catalyzed in cigarette igniting and smoking processes and the carbonyl compound content of the smoke can be reduced. According to the invention, the preparation process is simple, convenient and economical, and the prepared catalyst has a remarkable particle catalysis effect, is low in cost and is suitable for industrial application.

Owner:CHINA TOBACCO ANHUI IND CO LTD +1

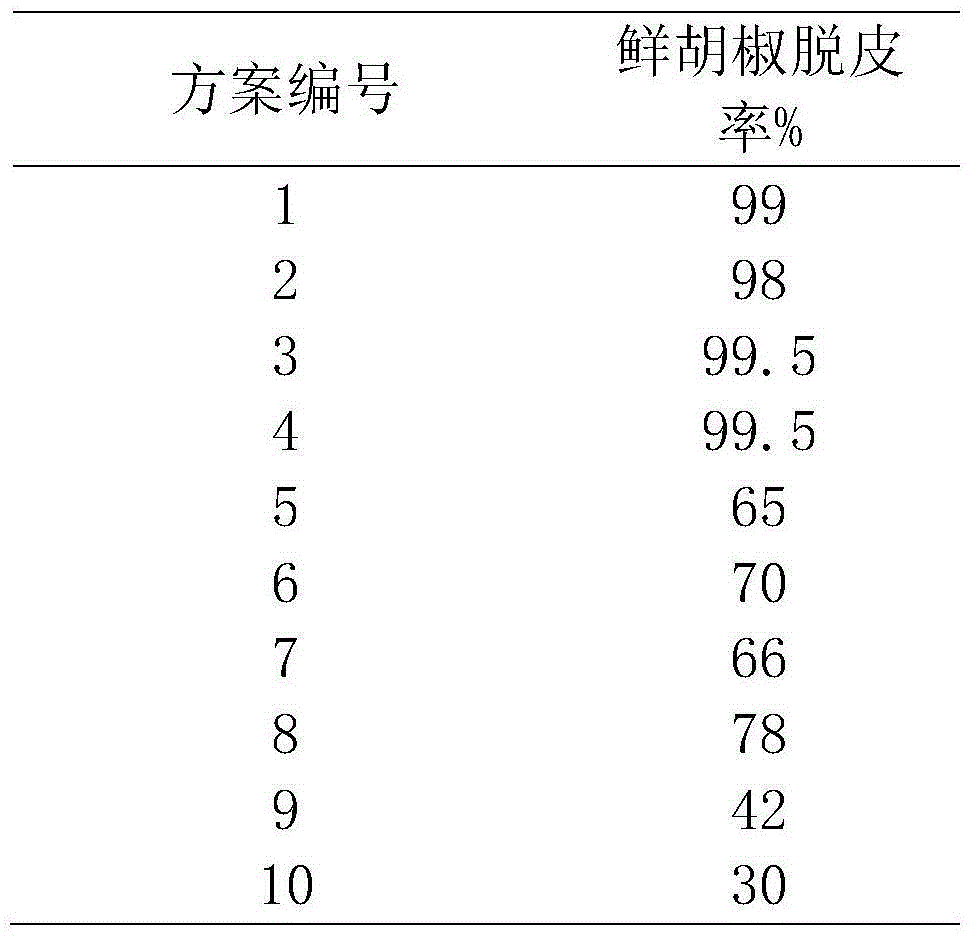

Method for peeling pepper by using ethylene

The invention discloses a method for peeling pepper by using ethylene, relating to the field of pepper processing. The pepper particles are complete in grain, high in peeling rate, bright in color, low in water consumption in the peeling process and free of pollution; odor generated by white pepper and the ambient environment through an impregnation method and a liquid fermentation method is avoided; the sensory quality and quality of a pepper product are improved; meanwhile, environment pollution is reduced; in addition, the method is short in time consumption, high in efficiency, easy to operate and high in peeling rate higher than 98%. The breakage rate of the obtained pepper is remarkably reduced, and the peeled pepper contains a great number of effective components, so that the method is suitable for large-scale industrial application.

Owner:康建国

A kind of preparation method of oxymethylisourea acetate

InactiveCN101245037BHigh purityHigh yieldUrea derivatives preparationOrganic compound preparationSodium acetateHydrogen Sulfate

The invention discloses a preparation method of oxymethylisourea acetate. The method comprises the following steps: 1) the methanol solution of oxymethylisourea hydrogen sulfate is reacted with sodium acetate and sodium hydroxide at a temperature of 10°C to 65°C, and the reaction time is 2 hours to 10 hours, and oxymethylisourea hydrogen sulfate The molar ratio of salt to sodium hydroxide and methanol is 1:1:6~10, and the molar ratio of oxymethylisourea bisulfate to sodium acetate and sodium hydroxide is 1:0.8~1.5:0.8~1.50; 2) The precipitated sodium sulfate is removed from the reaction mixture at the temperature of step 1); 3) the reaction solution is concentrated by distilling methanol at a temperature of 40°C to 80°C; 4) the oxymethylisourea acetate concentrate is cooled, Crystallization, centrifugation can be. The synthesized product of the invention has high purity, high yield and simple process, and the method is particularly suitable for industrial scale application.

Owner:JUHUA GRP +1

A method for anti-pollution modification of polypropylene hollow fiber membrane module

The invention relates to the field of a membrane technology and membrane surface modification and concretely relates to an anti-pollution modification method of a polypropylene hollow fiber membrane module. The method comprises the following steps of selecting a compound with strong hydrophily and multiple active groups as a modifier, adsorbing the modifier by the surface of the polypropylene hollow fiber membrane module in a dynamic cycle way, and under coordination complexation of the active groups in the modifier molecule and an inorganic bacteriostatic agent, fixing the modifier to the polypropylene hollow fiber membrane module so that the polypropylene hollow fiber membrane module with hydrophily and antibacterial properties is prepared. Through control of a flowing direction of a cross-linking agent solution, a modification compound solution and a metal ion soluble salt solution, the method realizes hydrophilic and antibacterial modification of an inner surface, an outer surface and membrane apertures of the polypropylene hollow fiber membrane module, greatly improves work efficiency and treatment effects, needs simple requirement and is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

An auxiliary device for high temperature alloy machining

The invention discloses an auxiliary device for high-temperature alloy machining and belongs to the technical field of metal cutting machining. The auxiliary device for high-temperature alloy machining is used for achieving cutting machining conducted on a high-hardness high-temperature alloy workpiece and comprises a plasma heating unit, a clamping unit, a cutting force measurement unit and a temperature measuring unit, wherein the plasma heating unit comprises a plasma transmitting spray head, is used for heating and softening the position to be cut of the high-temperature alloy workpiece and can perform cutting machining. The clamping unit comprises multiple clamping plates, wherein the clamping plates are oppositely installed so as to clamping the plasma transmitting spray head. A force measurement instrument in the temperature measuring unit is used for being in contact with the high-temperature alloy workpiece so as to measure cutting force borne by the high-temperature alloy workpiece in cutting. An infrared camera of the temperature measuring unit is used for measuring the temperature of the position to be cut of the high-temperature alloy workpiece heated by the plasma transmitting spray head. The auxiliary device for high-temperature alloy machining is low in price and energy consumption and capable of achieving accurate controllability of cutting machining process.

Owner:HUST WUXI RES INST

Chenodeoxycholic acid phenylethylamine salt, preparation method and refining method thereof, and chenodeoxycholic acid preparation method

PendingCN113912660AHigh refining yieldHigh purityAmino compound purification/separationAmino preparation from aminesChenodeoxycholic acidDeoxycholic acid

The invention discloses a chenodeoxycholic acid phenylethylamine salt, a preparation method and a refining method thereof, and a chenodeoxycholic acid preparation method, relates to the technical field of chenodeoxycholic acid extraction, and aims to solve the problem that a chenodeoxycholic acid product with the content of about 98% required by customers cannot be prepared in the prior art. Alpha-phenylethylamine is added into a chenodeoxycholic acid solution to form salt crystals, and chenodeoxycholic acid phenylethylamine salt is obtained through filtering, wherein the alpha-phenylethylamine is racemate or R-(+)-alpha-phenylethylamine. The method has the advantages that the salifying effect of chenodeoxycholic acid and R-(+)-a-phenylethylamine is the best, the selectivity is highest, the chenodeoxycholic acid impurities are mainly removed from the mother liquor obtained by pulping the chenodeoxycholic acid phenylethylamine salt, the lost chenodeoxycholic acid is minimum, the refining yield is highest, the purity is high, the content is high and is 98% or above, the batch is large, and the method is suitable for industrial large-scale application.

Owner:四川澄华生物科技有限公司

Device for improving sulfur recovery rate and its recovery method

InactiveCN106115632BSimple processLow investment costSulfur preparation/purificationRecovery methodSulfur

The invention relates to a device for increasing a recovery rate of sulfur and a recovery method of sulfur. The device comprises a sulfur production process tail gas recovery device, a shift gas recovery device and a circulating system. With the adoption of the recovery device and method, the sulfur recovery rate can be close to 100%, and further, the device and the method have the advantages of simple process and low investment and operating cost, and are suitable for large-scale industrial application.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

Method for preparing 5-(2-methylthioethyl)-hydantoin by using crude hydrocyanic acid gas

ActiveCN103408498BShorten production timeIncrease productivitySulfide preparationChemical industryHydrogen cyanide gas

The invention relates to a method for preparing 5-(2-methylmercapto-ethyl)-hydantoin by utilizing crude hydrocyanic acid gas and relates to the field of chemical industry. The method disclosed by the invention comprises the following steps of: completely reacting hydrocyanic acid mixed gas made by adopting an Ann method with methylmercapto propionaldehyde to obtain a 2-hydroxyl-4-methylmercapto-butyronitrile reaction system under the catalytic action of organic alkali; and sufficiently reacting the 2-hydroxyl-4-methylmercapto-butyronitrile reaction system with ammonium bicarbonate in a water medium to obtain 5-(2-methylmercapto-ethyl)-hydantoin. Due to adoption of raw materials which are not rectified or purified, the method disclosed by the invention is short in production time, high in production efficiency and low in production cost; the prepared 2-hydroxyl-4-methylmercapto-butyronitrile reaction system is steady in property and can be stored for a long time; and 5-(2-methylmercapto-ethyl)-hydantoin with high purity and high yield can be obtained through simple separation and purification operations under the synergistic effect of other substances in reaction liquid.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

Preparation method of transparent dielectric microsphere flexible film with enhanced Raman scattering light intensity

ActiveCN107688015BLow priceSuitable for industrial scale applicationsRaman scatteringDielectricSemiconductor materials

The invention discloses a preparation method for a transparent dielectric microsphere flexible film used for strengthening raman scattering spectral intensity, and belongs to the field of spectrum detection. The preparation method comprises the following steps: preparing a transparent dielectric microsphere turbid liquid; dispensing the dielectric microsphere turbid liquid on an inclined glass sheet surface; after a solvent in the turbid liquid on the inclined glass sheet is evaporated, forming a microsphere single-layer densely paved array structure; preparing a polydimethylsiloxane (PDMS) solution; dispensing the uniformly mixed PDMS solution on the glass sheet deposited with the microsphere array, and thinning by equalizing glue; heating the glass sheet covered with the microsphere array and a PDMS liquid-state thin layer and cooling the glass sheet to the room temperature, embedding the microsphere array into a PDMS film and curing the PDMS film; and separating the microsphere filmfrom the glass sheet. The flexible film can be adhered to the surfaces of various samples, so that raman scattering strengthening on a semiconductor material, one-dimensional and two-dimensional nanomaterials and a three-dimensional structural surface material can be realized.

Owner:BEIJING UNIV OF TECH

Squeeze casting equipment based on power ultrasonic and pressure coupling

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com