Method for using hydrocyanic acid mixed gas to prepare 2-hydroxy-4-methylthio-butyronitrile and continuous production method for 2-hydroxy-4-methylthio-butyronitrile

A technology of methylthiobutyronitrile and hydrocyanic acid, applied in the field of chemical industry, can solve the problems of high energy consumption of 3-methylthiopropanal, loss of 3-methylthiopropanal, cost increase, etc., and achieve hydrogen cyanide The effect of high acid utilization rate, lower production cost and higher production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

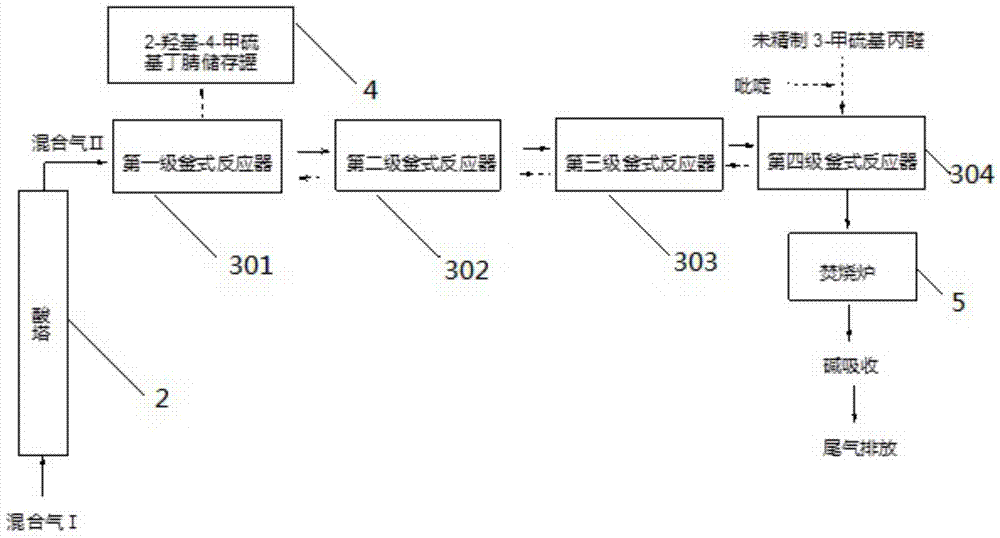

[0052] The hydrocyanic acid mixed gas I from the hydrocyanic acid synthesis tower was detected, and the composition of the hydrocyanic acid mixed gas I was: 8.87% hydrocyanic acid gas, 3.88% water vapor, 1.64% ammonia gas, 1.13% hydrogen gas, nitrogen gas 76.01%, oxygen 1.48%, carbon monoxide 5.67%, carbon dioxide 1.13%, methane 0.39%.

[0053] Hydrocyanic acid mixed gas I passes through a 75% sulfuric acid tower to absorb ammonia and water vapor in the mixed gas, and the composition of the obtained hydrocyanic acid mixed gas II is: 9.35% hydrogen cyanide gas, 1.57% hydrogen gas, and 79.44% nitrogen gas %, oxygen 1.71%, carbon monoxide 5.79%, carbon dioxide 1.50%, methane 0.64%.

Embodiment 2

[0055] Pass hydrogen cyanide mixed gas II into 223.3g of 94.5% methional, which contains 3.3g of pyridine. React under normal pressure, control the reaction temperature to 45°C, the ventilation rate to 300L / min, absorb the tail gas with sodium hydroxide, and monitor the residual amount of methionaldehyde by HPLC. When the residual amount of methionaldehyde is less than 0.5%, it is the end of the reaction, and the feeding can be stopped. A total of 270.64 g of light yellow liquid was obtained, the content of 2-hydroxy-4-methylthiobutyronitrile was 98%, and the residual hydrocyanic acid was 0.5%.

Embodiment 3

[0057] Pass hydrogen cyanide mixed gas II into 223.3g of 94.5% methional, which contains 2.2g of pyridine and 10g of water. Under 0.15MPa, the reaction temperature is controlled to be 42°C, the ventilation rate is 280L / min, the tail gas is absorbed with sodium hydroxide, and the residual amount of methional is monitored by HPLC. When the residual amount of methionaldehyde is less than 0.5%, it is the end of the reaction, and the feeding can be stopped. A total of 279.54 g of light yellow liquid was obtained, the content of 2-hydroxy-4-methylthiobutyronitrile was 98%, and the residual hydrocyanic acid was 0.07%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com