Preparation method of graphene dispersion liquid, and preparation method of graphene film

A technology of graphene dispersion liquid and graphene film, which is applied in the field of materials, can solve problems such as limited application, influence of electronic properties, and damage to the integrity of graphene electronic structure, and achieve low cost, high controllability, and good flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

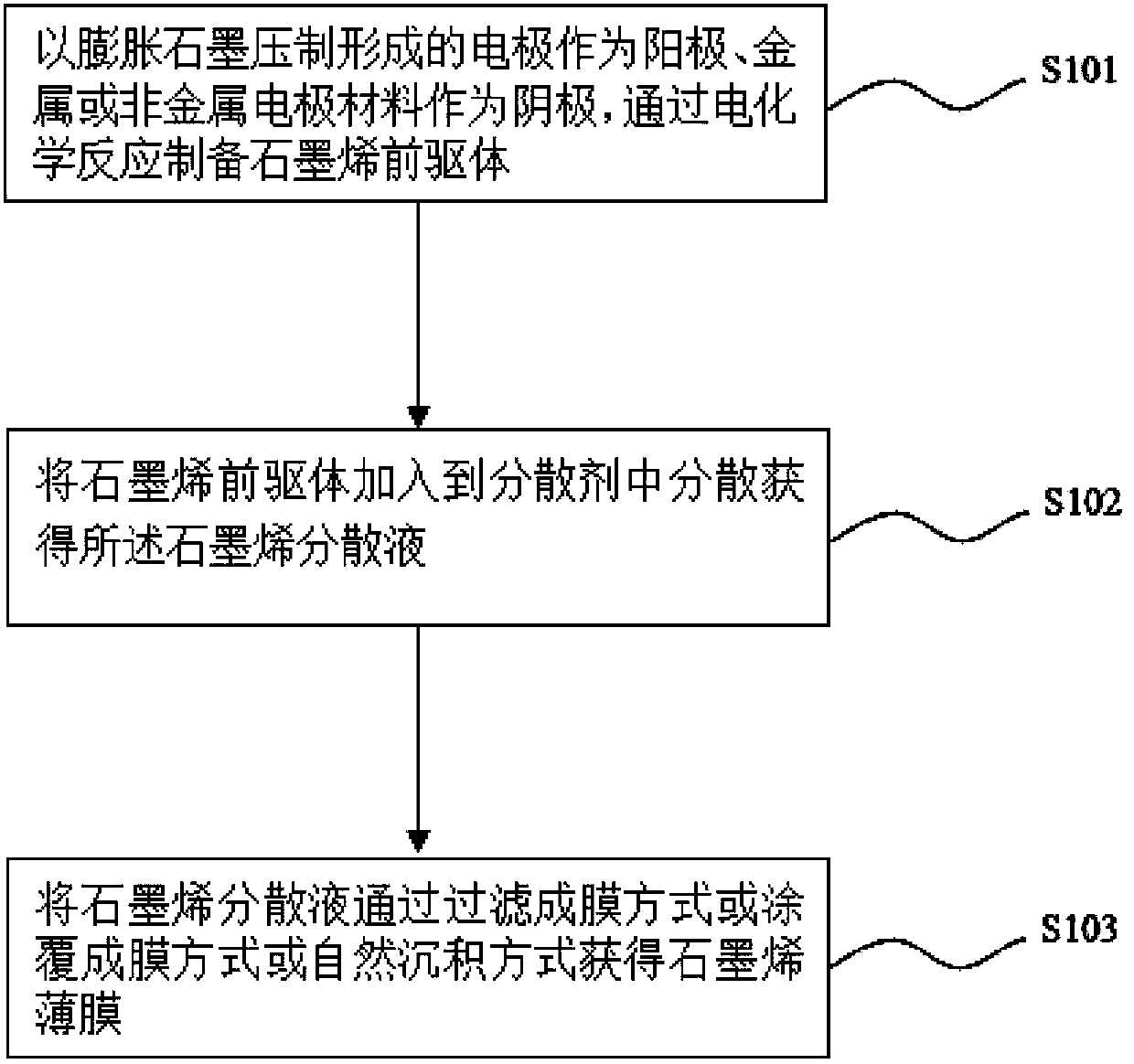

[0029] As mentioned above, the present invention provides a kind of preparation method of graphene dispersion liquid in order to solve the problem existing in the prior art, refer to figure 1 , the method includes the steps: S101, preparing graphene precursor: using expanded graphite to press the electrode formed as the anode, metal or non-metal electrode material as the cathode; the anode and the cathode are placed in the electrolyte solution, and the anode Apply a voltage of 1-20V and / or a density of 1-200mA / cm between the cathode and the cathode 2 Electrochemical reaction is carried out for 1 to 120 minutes with an electric current, and the anode product in the reaction is the graphene precursor; S102, dispersed graphene precursor: after the graphene precursor is washed, it is added to a dispersant to disperse to obtain the graphene precursor Graphene dispersion. Another aspect of the present invention provides a kind of preparation method of graphene film, such as figure...

Embodiment 1

[0033] Step A: Press 400 mg of expanded graphite into a sheet with a diameter of 1 to 2 cm under a pressure of 20 MPa, and use Ag glue to connect the expanded graphite sheet with a copper wire to form an electrode as an anode; use a platinum sheet as a cathode. The anode and cathode were placed in a sulfuric acid aqueous solution with a concentration of 10mol / L and 10ml, and the constant voltage was adjusted to 2V to perform anodic oxidation on the expanded graphite, and the electrolytic reaction time was 30min. The interlayer of graphene is widened during the oxidation reaction of the anode to generate oxygen. At the same time, the sulfate ions adsorbed around the anode are intercalated into the interlayer of graphene. Large; finally, the product obtained from the anode after the electrolysis reaction is a graphene precursor.

[0034] Step B: washing the graphene precursor with distilled water to remove impurities adsorbed on the surface, and then freeze-drying. Take 80 mg o...

Embodiment 2

[0041] Step A: Press 500 mg of expanded graphite into a sheet with a diameter of 2 to 3 cm under a pressure of 30 MPa, and use Ag glue to connect the expanded graphite sheet with a copper wire to form an electrode as an anode; use a platinum sheet as a cathode. The anode and cathode are placed in a sulfuric acid aqueous solution with a concentration of 10mol / L and 10ml, and the applied current is adjusted to be 20mA / cm 2 Under conditions, the expanded graphite is subjected to anodic oxidation, the electrolysis reaction time is 60 minutes, and the product obtained from the anode is a graphene precursor.

[0042] Step B1: washing the graphene precursor with distilled water to remove impurities adsorbed on the surface, and then freeze-drying. Take 50 mg of the washed graphene precursor and add it to 30 mL of ethanol / water (volume ratio 1:1) mixed solution, ultrasonically strip it for 30 min, and centrifuge at a speed of 3000 rpm to obtain a concentration of 1 mg / mL Graphene disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com