Method for preparing 5-(2-methylmercapto-ethyl)-hydantoin by utilizing crude hydrocyanic acid gas

A technology of methylthioethyl and hydantoin, applied in the chemical industry, can solve the problems of limited industrial application, no purification treatment operation, high production cost, etc., to save production time, stable properties, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

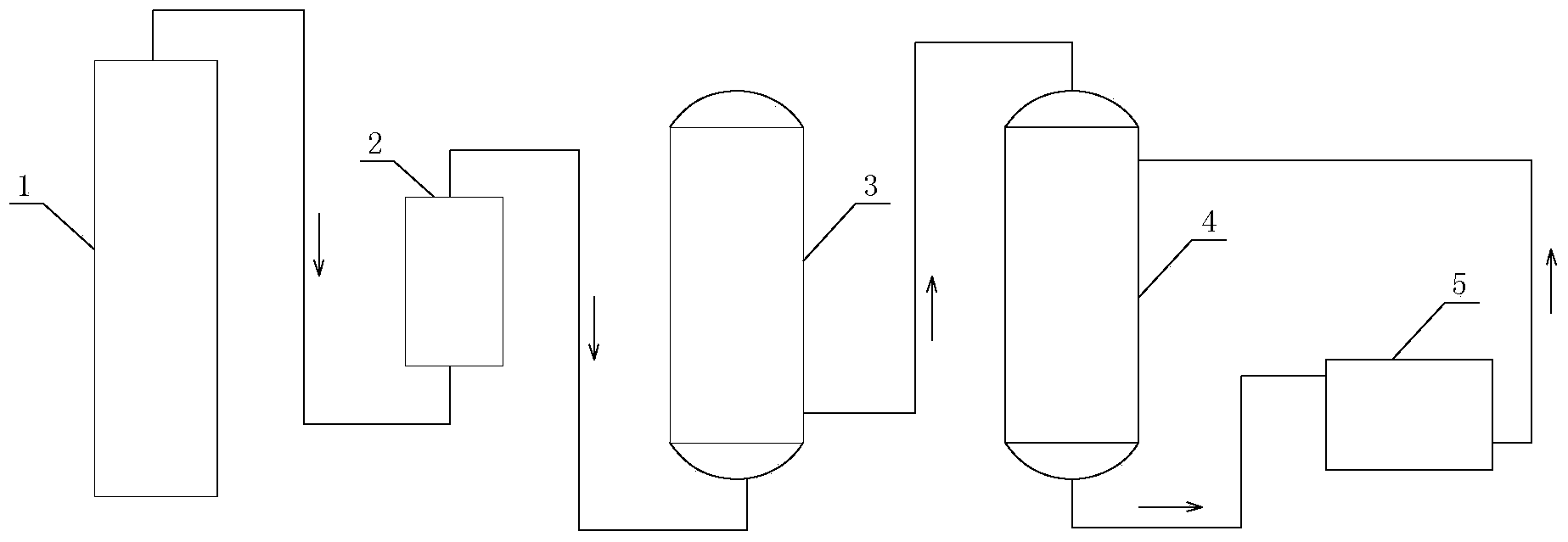

Image

Examples

Embodiment 1

[0042] The hydrocyanic acid mixed gas I from the hydrocyanic acid synthesis tower was detected. The composition of the hydrocyanic acid mixed gas I was: 8.87% hydrocyanic acid gas, 3.88% water vapor, 1.64% ammonia gas, 1.13% hydrogen gas, nitrogen gas 76.01%, oxygen 1.48%, carbon monoxide 5.67%, carbon dioxide 1.13%, methane 0.39%.

[0043] Hydrocyanic acid mixed gas I passes through a 75% sulfuric acid tower to absorb ammonia and water vapor in the mixed gas to obtain hydrocyanic acid mixed gas II. After testing, its composition is: hydrocyanic acid gas 9.35%, hydrogen gas 1.57%, Nitrogen 79.44%, Oxygen 1.71%, Carbon Monoxide 5.79%, Carbon Dioxide 1.50%, Methane 0.64%.

Embodiment 2

[0045] Pass hydrogen cyanide mixed gas II into 223.3g of 94.5% methional, which contains 3.3g of pyridine. React under normal pressure, control the reaction temperature to 45°C, the ventilation rate to 300L / min, absorb the tail gas with sodium hydroxide, and monitor the residual amount of methionaldehyde by HPLC. When the residual amount of methionaldehyde is less than 0.5%, it is the end of the reaction, and the feeding can be stopped. A total of 270.64 g of light yellow liquid was obtained, the content of 2-hydroxy-4-methylthiobutyronitrile was 98%, and the residual hydrocyanic acid was 0.5%. The obtained 2-hydroxy-4-methylthiobutyronitrile together with its reaction solution (ie, 2-hydroxy-4-methylthiobutyronitrile reaction system) was stored at 3°C for 120 days without any decomposition.

Embodiment 3

[0047] Pass hydrogen cyanide mixed gas II into 222.2g of 94.5% methional, which contains 2.2g of pyridine. React under normal pressure, control the reaction temperature to 40°C, the ventilation rate to 280L / min, absorb the tail gas with sodium hydroxide, and monitor the residual amount of methionaldehyde by HPLC. When the residual amount of methionaldehyde is less than 0.5%, it is the end of the reaction, and the feeding can be stopped. A total of 269.54 g of light yellow liquid was obtained, the content of 2-hydroxy-4-methylthiobutyronitrile was 98%, and the residual hydrocyanic acid was 0.07%. The obtained 2-hydroxy-4-methylthiobutyronitrile together with its reaction solution were stored at 3°C for 120 days without any decomposition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com