Composite material for membrane distillation

A composite material and membrane distillation technology, applied in the field of membrane distillation, can solve the problems of small membrane flux, unsuitable for industrial application, etc., and achieve the effect of small passing resistance, increasing unit processing capacity, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

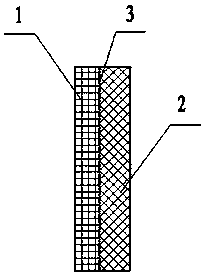

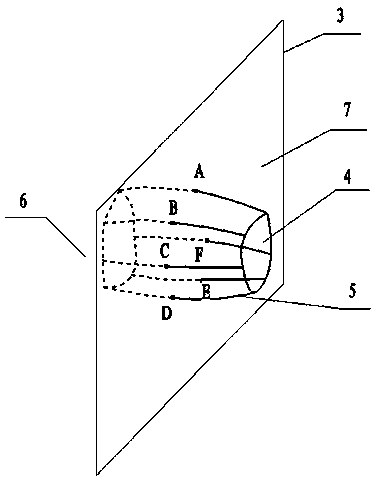

[0026]A composite material for membrane distillation, which is composed of a hydrophobic porous material layer and a hydrophilic porous material layer. The hydrophobic porous material layer is a commercially available polyvinylidene fluoride microporous membrane. After testing, its porosity is 82%. It is 2µm-4µm, the pores are three-dimensionally connected, and the film thickness is 50µm. After testing with the PT-705D contact angle measuring instrument of Puset Testing Equipment Co., Ltd. according to the operation manual, the water contact angle on the surface of the hydrophobic porous material layer is 113° The hydrophilic porous material layer is a polyimide microporous membrane with a porosity of 84%, a pore size of 5µm-9µm, and three-dimensional interconnected pores. The membrane is prepared by adding thermoplastic Polyimide powder, the ratio of tetrahydrofuran and benzene in the mixed solvent is 1:10 by weight, the solution concentration is 20g / L, fully stirred under nit...

Embodiment 2

[0030] A composite material for membrane distillation, consisting of a hydrophobic porous material layer and a hydrophilic porous material layer, wherein the hydrophobic porous material layer is a polypropylene microporous membrane with a porosity of 85%, a pore size of 4µm-8µm, and three-dimensional pores Three-dimensionally connected, the water contact angle is 146°; the hydrophilic porous material layer is a polypropylene microporous membrane, and the surface of the cavity wall is impregnated with polyacrylic acid / nano-silicon dioxide, and the water contact angle on the surface of the hydrophilic porous material layer is 28° , the porosity is 82%, the pores are uniform, the pore diameter is 3µm-6µm, and the pores are three-dimensionally connected; 50% of the thickness is impregnated with polyacrylic acid / nano silica hydrophilic coating, that is, the hydrophobic porous material layer and the hydrophilic porous material layer are an integrated composite material, and the three...

Embodiment 3

[0032] A composite material for membrane distillation, which is composed of a hydrophobic porous material layer and a hydrophilic porous material layer. The hydrophobic porous material layer is a polyvinylidene fluoride microporous membrane with a porosity of 86% and a pore size of 1µm-2µm. The pores are Three-dimensionally connected, the water contact angle is 151°, and the film thickness is 50 µm; the hydrophilic porous material layer is a polyimide microporous film, prepared according to the method in Example 1, with a porosity of 84%, a pore size of 5 µm-9 µm, and a pore size of 5 µm to 9 µm. It is three-dimensionally connected, after plasma treatment, the water contact angle is 4.5°, and the film thickness is 100µm; HR-5198 glue is used as the adhesive to bond the hydrophobic porous material layer polyvinylidene fluoride microporous membrane and the hydrophilic porous material layer polyamide The imide microporous membrane is made into a composite material for membrane dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com