Reciprocating rotary type membrane bioreactor

A membrane bioreactor, reciprocating rotation technology, applied in the field of environmental engineering of water resource reuse, can solve the problems of large aeration volume of membrane bioreactor, complicated membrane cleaning process, cumbersome operation, etc., and achieve the suppression of concentration polarization Phenomenon, remarkable cleaning effect, high concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

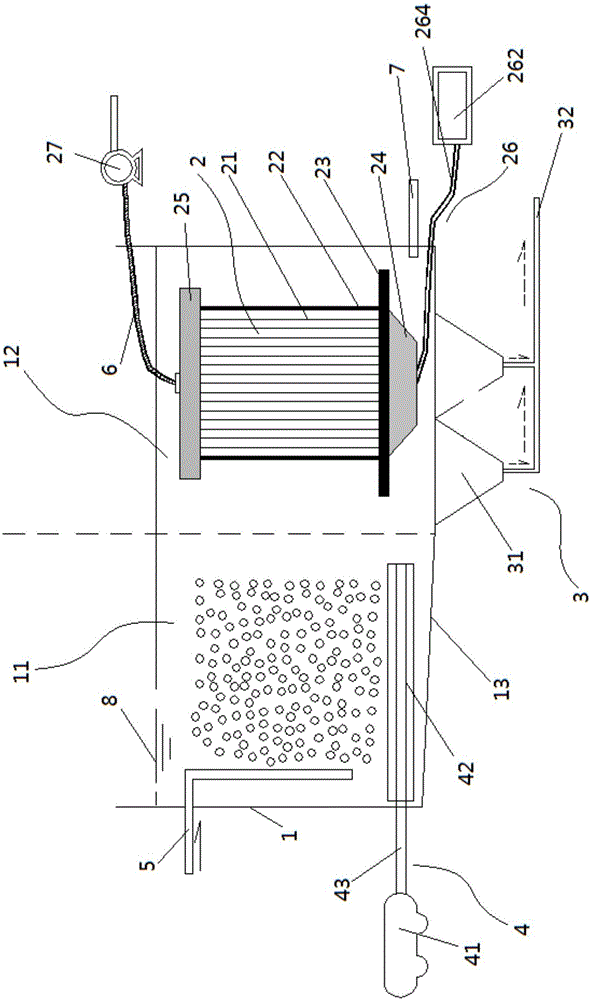

Embodiment 1

[0133] The domestic sewage discharged from a residential area in Miyun County, Beijing is used as raw water, the treated water volume is 10t / h, the sewage flow rate is 1.2-1.5m / s, and the aeration volume is 100m 3 / h, the gas-water ratio is 10:1, and the dissolved oxygen (DO) concentration is 2.8mg / L. The reciprocating rotary membrane bioreactor of the present invention is used to treat domestic sewage, and the membrane silk adopts organic hollow fiber ultrafiltration membrane, and the initial membrane flux is 40L / m 2 .h. The speed of reciprocating rotation is 20rpm, and the period of reciprocating rotation is: rotate counterclockwise for 2 seconds and then rotate clockwise for 2 seconds; the angle of reciprocating rotation is: rotate 90°counterclockwise, rotate 90°clockwise, that is, rotate 90°counterclockwise (1 second); rotate clockwise to return to the initial position (1 second); rotate clockwise 90 degrees (1 second); rotate counterclockwise to return to the initial pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com