Air-lift membrane filtration complete equipment

A complete set of devices and membrane filtration technology, applied in the direction of total evaporation, can solve the problems of liquid entrainment and solvent recovery without considering high-pressure tail gas energy reuse, and achieve the effects of reducing membrane pollution, saving energy costs, and improving concentration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

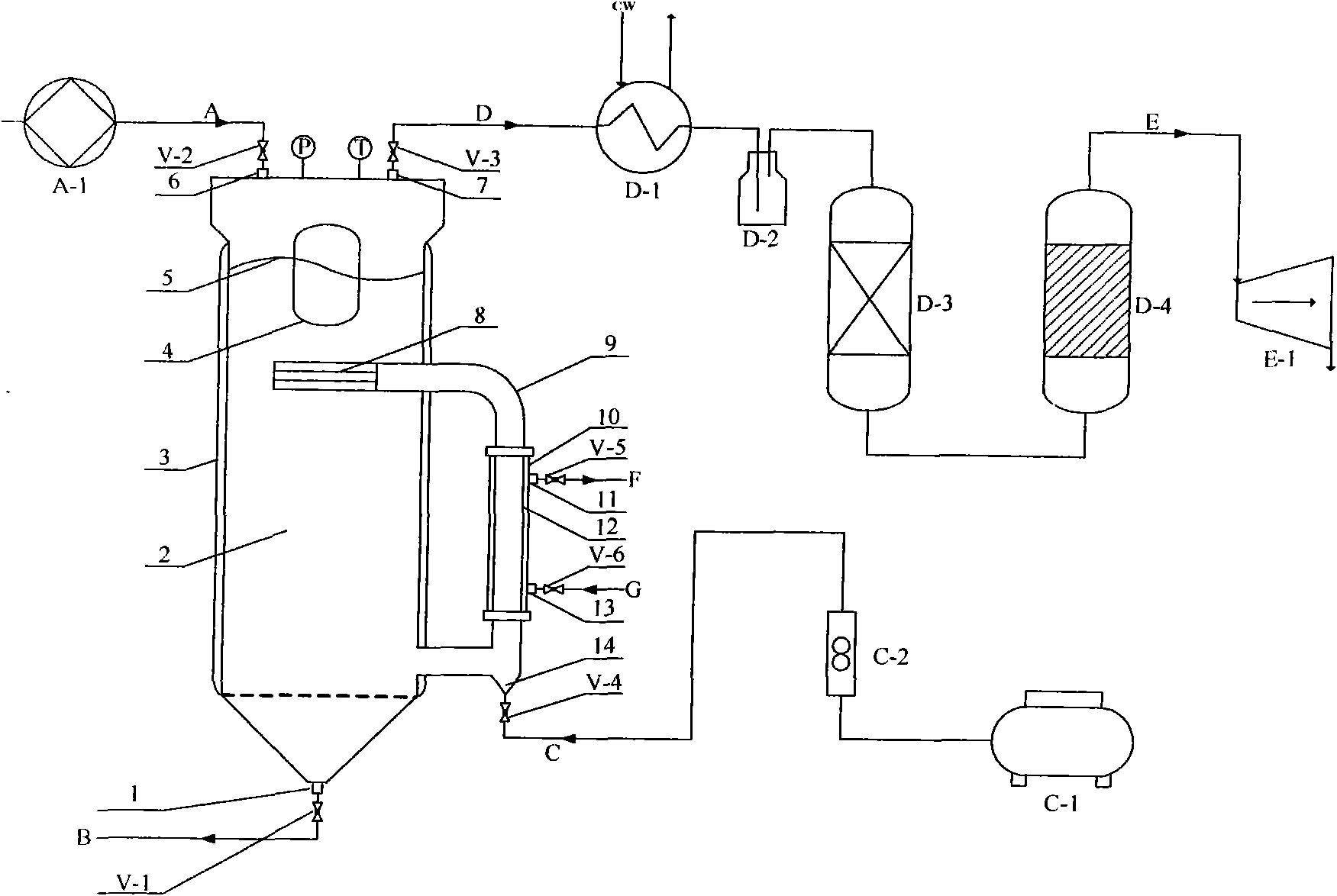

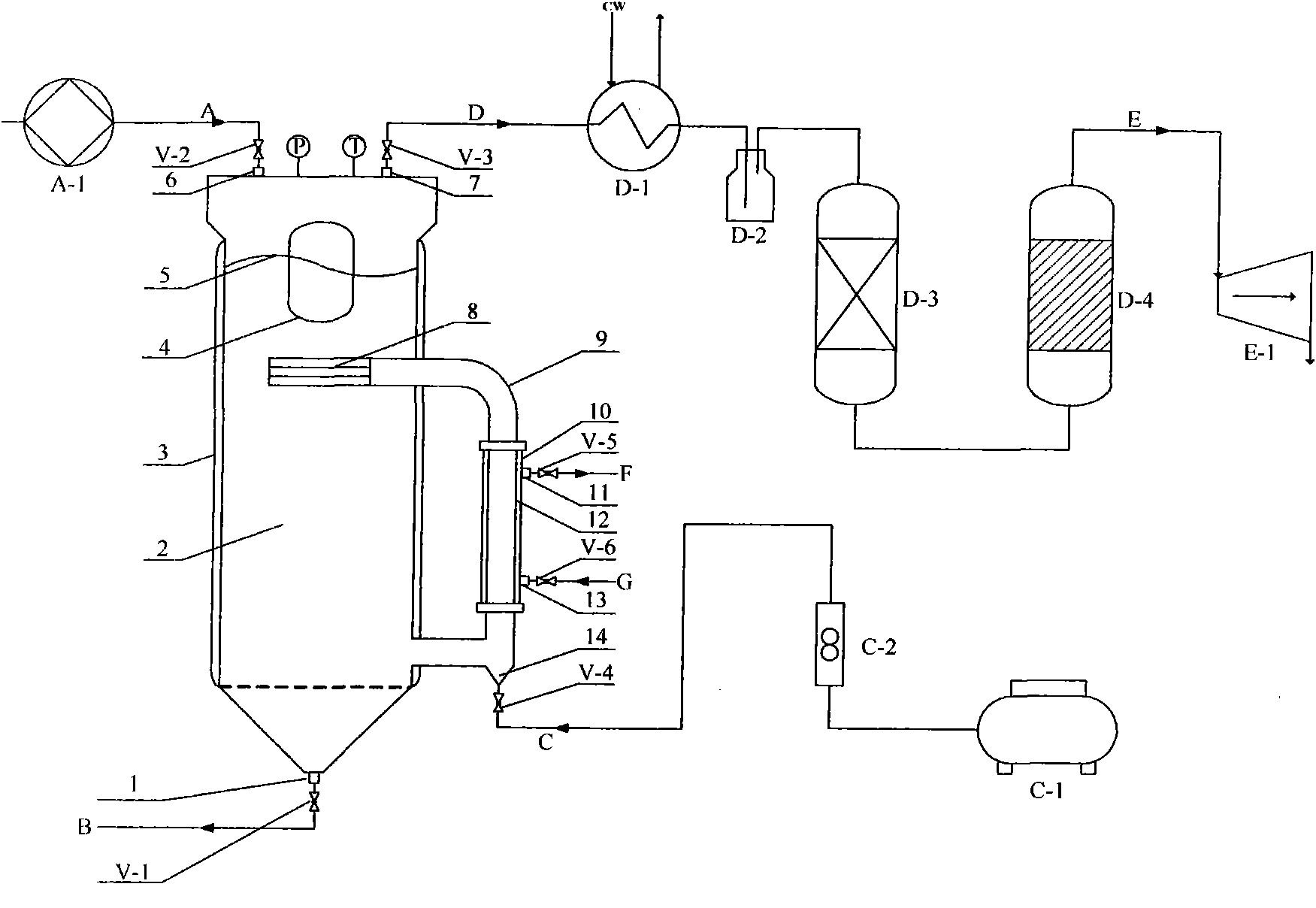

[0028] The air-lift membrane filtration complete set provided by the present invention consists of membrane filtration system (kettle body 2, circulation pipe 9, membrane module 10), feed system (feed pump A-1), gas supply system (compressed gas source C -1, gas flow meter C-2), tail gas solvent recovery system (tail gas condenser D-1, gas-liquid separation tank D-2, adsorption column D-3, dryer D-4) and energy recovery system (energy recovery device E-1) composition, such as figure 1 shown. The kettle body 2 is divided into two parts, the upper cylinder body is a circulation area, and the lower vertebral body is a settlement area; the circulation pipe 9 is installed at the side arm of the kettle body 2 and communicates with the kettle body; the upper end of the kettle body 2 is provided with a feed port 6, The exhaust port 7 has a discharge port 1 a...

Embodiment 2

[0032] In this example, the height-to-diameter ratio of the reactor body circulation area of the air-lift membrane filtration complete set is 5, the angle between the sedimentation slope of the reactor body settling area and the horizontal plane is 60°, the height of the circulation pipe is 2 / 5 of the height of the reactor body circulation area, and the inner diameter of the circulation pipe is 1 / 2 of the inner diameter of the systemic circulation area. Bovine serum albumin (molecular weight 67000Da) solution is used as the filtration concentration system, and 19-channel ZrO with a pore size of 50nm is selected. 2 Ceramic membranes are used as membrane elements. First adjust the pH of the bovine serum albumin solution to 4.7, add the bovine serum albumin solution with a concentration of 2g / L into the air-lift membrane filtration complete set, and then pass in compressed gas to adjust the transmembrane pressure to 0.3MPa and the gas velocity on the membrane surface 0.15m / s, ...

Embodiment 3

[0034] In this case, the height-to-diameter ratio of the reactor body circulation area of the air-lift membrane filtration complete set is 8, the angle between the sedimentation slope of the reactor body settling area and the horizontal plane is 60°, the height of the circulation pipe is 3 / 5 of the height of the reactor body circulation area, and the inner diameter of the circulation pipe is 1 / 3 of the inner diameter of the systemic circulation area. Chicken ovalbumin (molecular weight 43000Da) solution was used as the filtration and concentration system, and Al with a pore size of 10.0nm was selected. 2 o 3 A ceramic membrane single tube is used as the membrane element. First adjust the pH of the ovalbumin solution to 10.0, add the ovalbumin solution with a concentration of 300mg / L into the air-lift membrane filtration complete set, and then pass in compressed air to adjust the transmembrane pressure to 0.8MPa and the gas velocity on the membrane surface 0.3m / s, for posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com