A nano-calcium carbonate catalyst coated with ag titanium dioxide nanoparticles and its preparation method and application

A nano-calcium carbonate and nano-particle technology, applied in physical/chemical process catalysts, chemical instruments and methods, applications, etc., can solve the problems of high carbonyl compound release, increase smoke irritation, and affect cigarette quality, etc. The process is simple and economical, the catalytic effect is remarkable, and the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

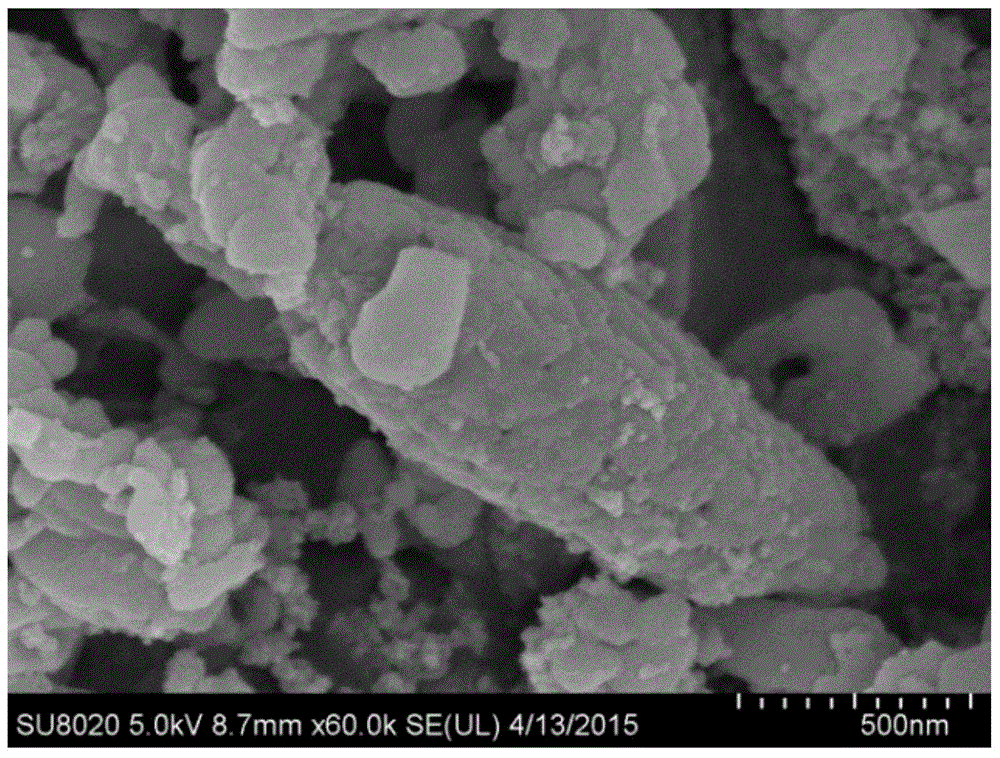

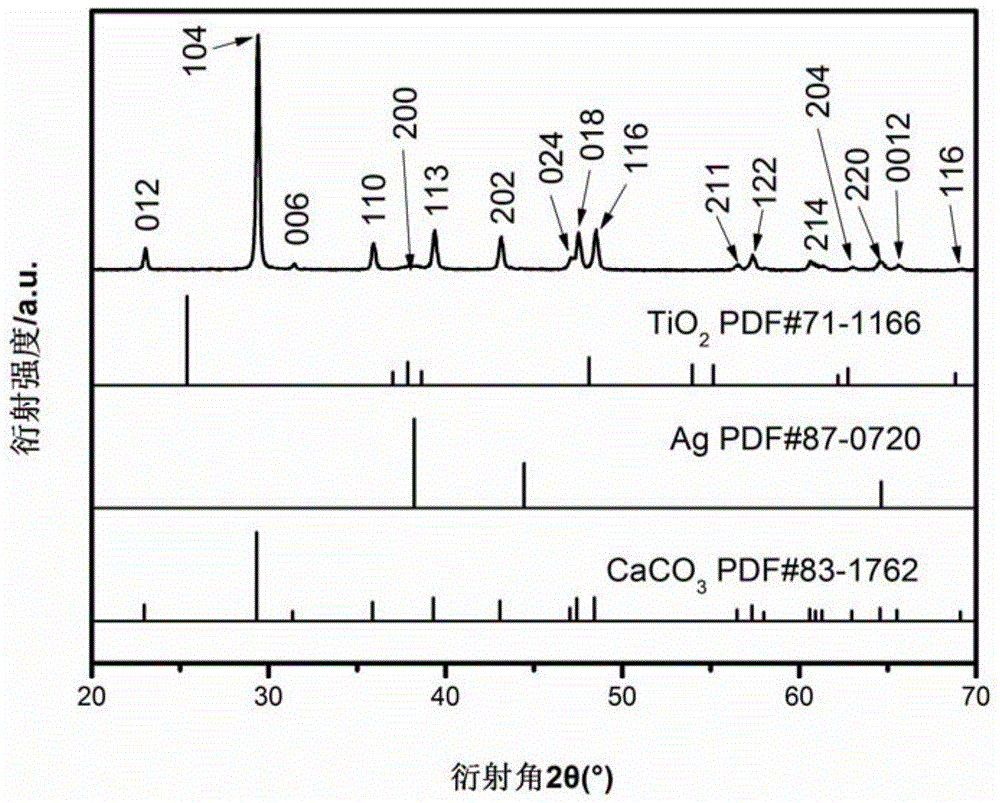

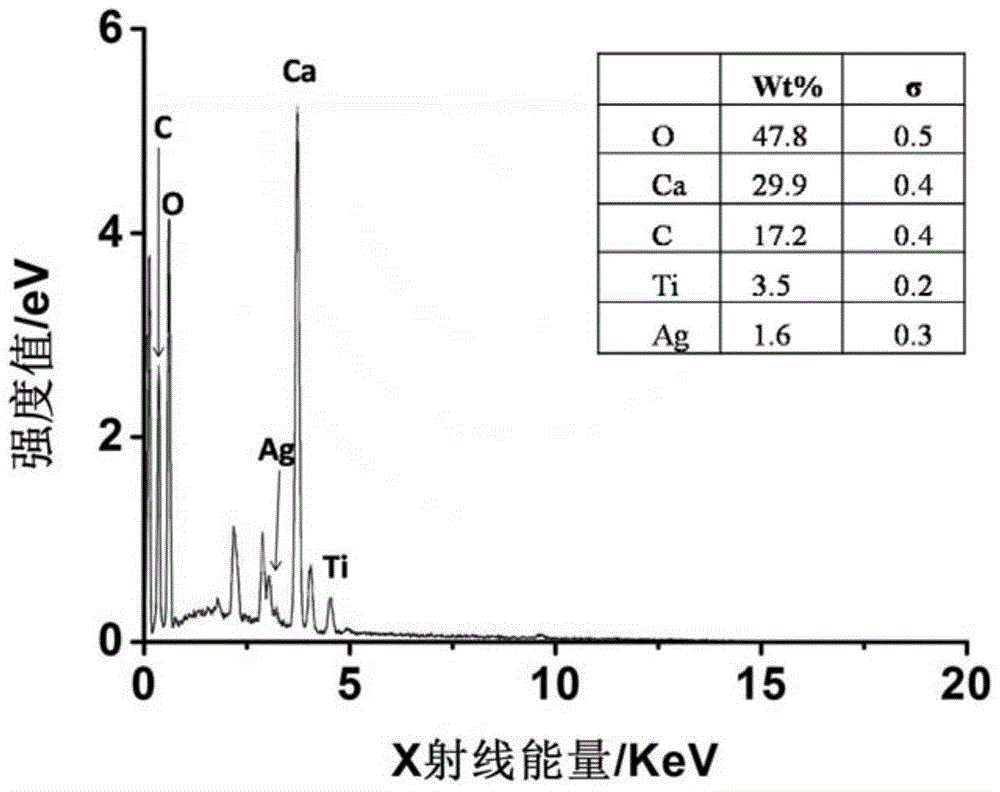

[0033] The present embodiment prepares the nano-calcium carbonate catalyst that loads Ag titania nanoparticle coating as follows:

[0034] 1. Properly pulverize 10g of calcium oxide and add it to 30mL of water at 80°C, stir and react at a constant temperature for 1 hour, and then leave it to age for 12 hours to obtain milk of lime.

[0035] 2. NaCO 3 Block and dilute hydrochloric acid are added to the Kipp generator in proportion to control the reaction rate and obtain stable CO 2 airflow.

[0036] 3. Add milk of lime into the carbonation reactor, control the required reaction temperature to 40°C, feed carbon dioxide gas from the bottom of the reactor, stir at a certain speed, start the pH meter to track the entire reaction process, and wait until the reaction reaches the end (pH=7.0), pour out the clinker, wash with deionized water, and dry at 80° C. for 24 hours to obtain spindle-shaped nano-calcium carbonate particles.

[0037] 4. Mix 40 mL of absolute ethanol with 200 m...

Embodiment 2

[0047] The present embodiment prepares the nano-calcium carbonate catalyst that loads Ag titania nanoparticle coating as follows:

[0048] 1. Properly pulverize 10g of calcium oxide and add it to 40mL of water at 80°C, stir and react at a constant temperature for 1 hour, and then leave it to age for 24 hours to obtain milk of lime.

[0049] 2. NaCO 3 Block and dilute hydrochloric acid are added to the Kipp generator in proportion to control the reaction rate and obtain stable CO 2 airflow.

[0050] 3. Add milk of lime into the carbonation reactor, control the required reaction temperature to 35°C, inject carbon dioxide gas from the bottom of the reactor, stir at a certain speed, start the pH meter to track the entire reaction process, and wait until the reaction reaches the end (pH=7.0), pour out the clinker, wash with deionized water, and dry at 80° C. for 24 hours to obtain spindle-shaped nano-calcium carbonate particles.

[0051] 4. Mix 30 mL of absolute ethanol and 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com