Patents

Literature

192results about How to "Good catalytic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Imidazole grafting-type ionic liquid catalyst and preparation method and application

InactiveCN101844090AGood catalytic effectImprove conversion rateOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsGraftingPropylene oxide

The invention relates to an imidazole grafting-type ionic liquid catalyst, which is hydroxide of 1-propyl (triethoxysilyl)-3-methylimidazole grafted on a carrier. The representation formula of the imidazole grafting-type ionic liquid catalyst is [Smim]OH / X and a mass grafting amount of ionic liquid is between 5 and 25 percent, wherein Smim represents 1-propyl (triethoxysilyl)-3-methylimidazole; and X represents the meso-porous carrier. The imidazole grafting-type ionic liquid catalyst has the advantages of good catalytic effect, high conversion rate of propylene oxide, 100 percent of selectivity of propene carbonate, mild reaction condition and capability of being recycled better.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

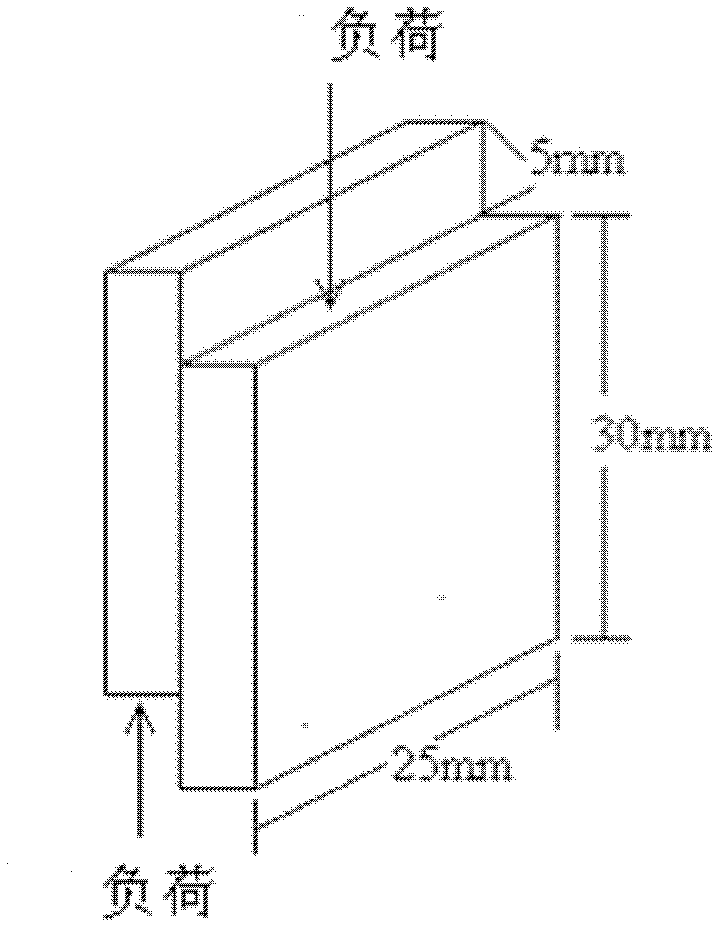

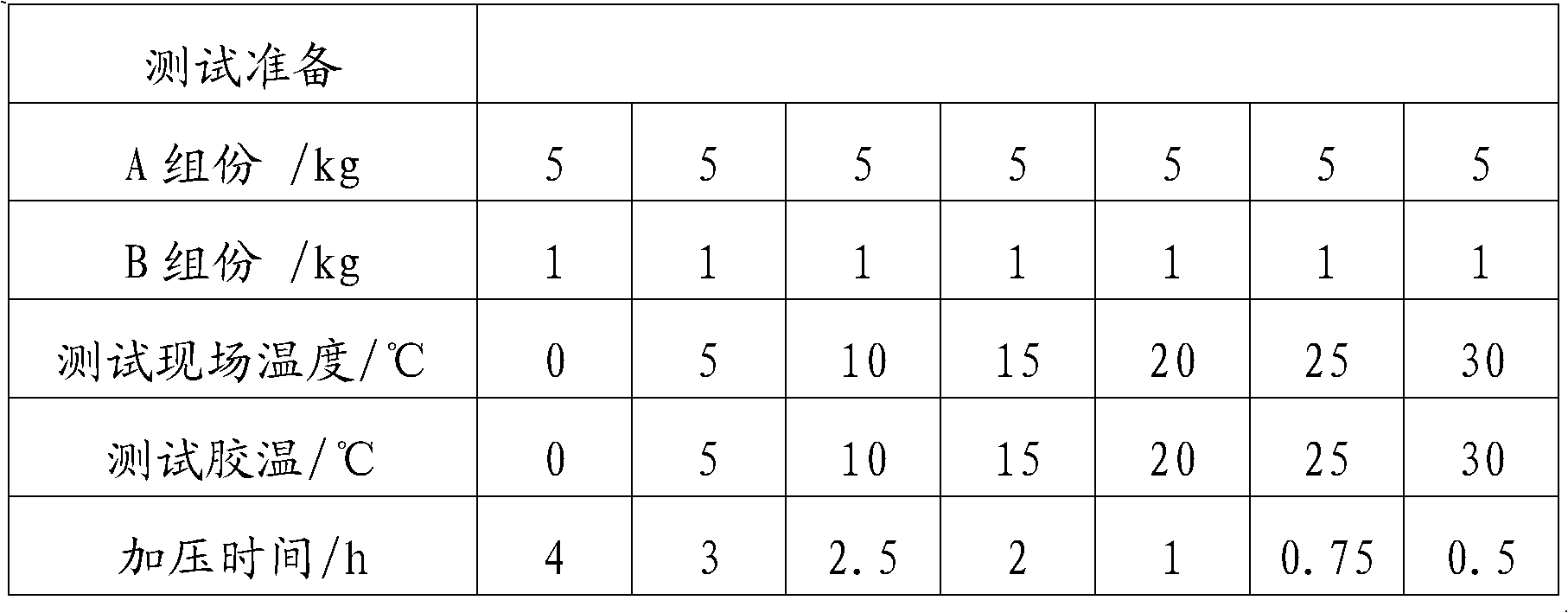

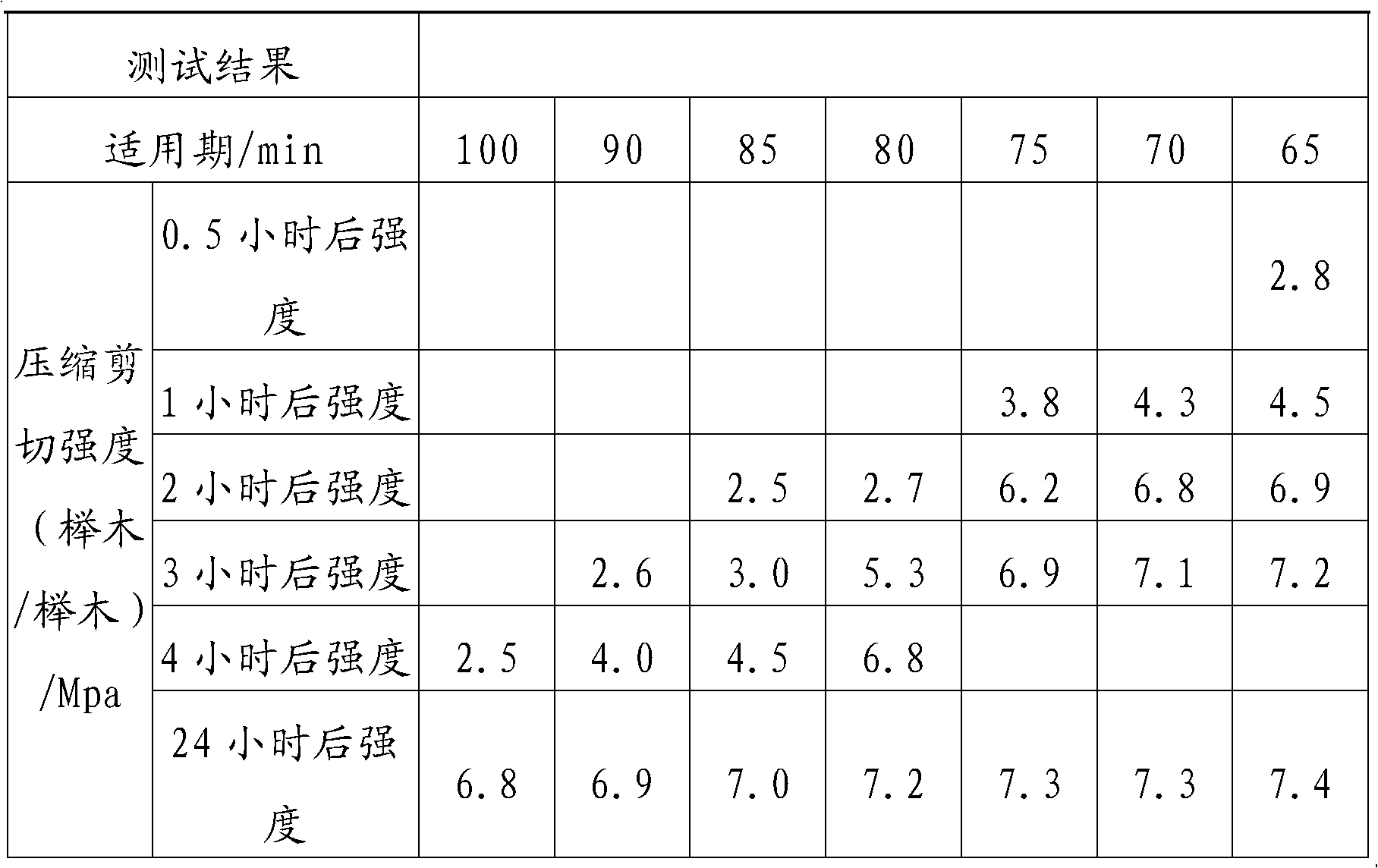

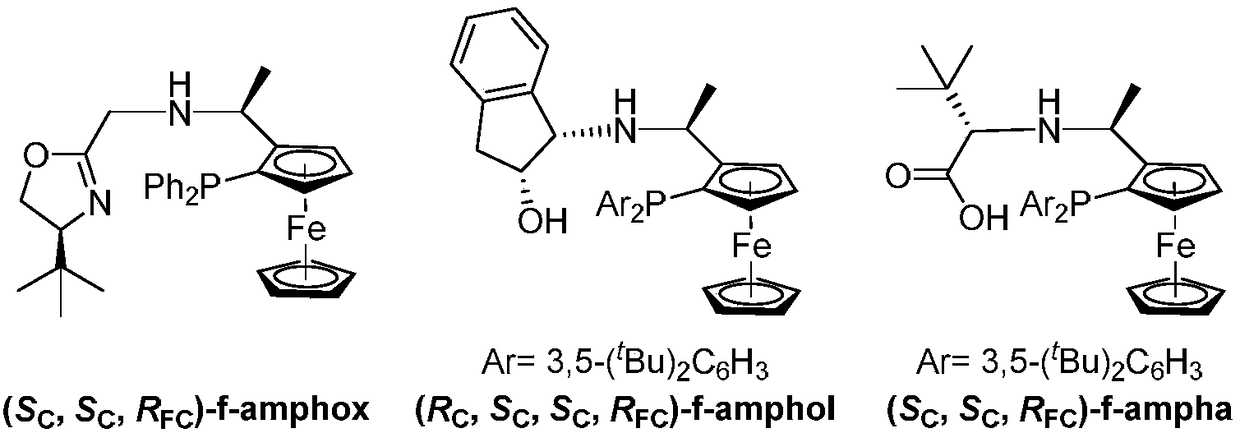

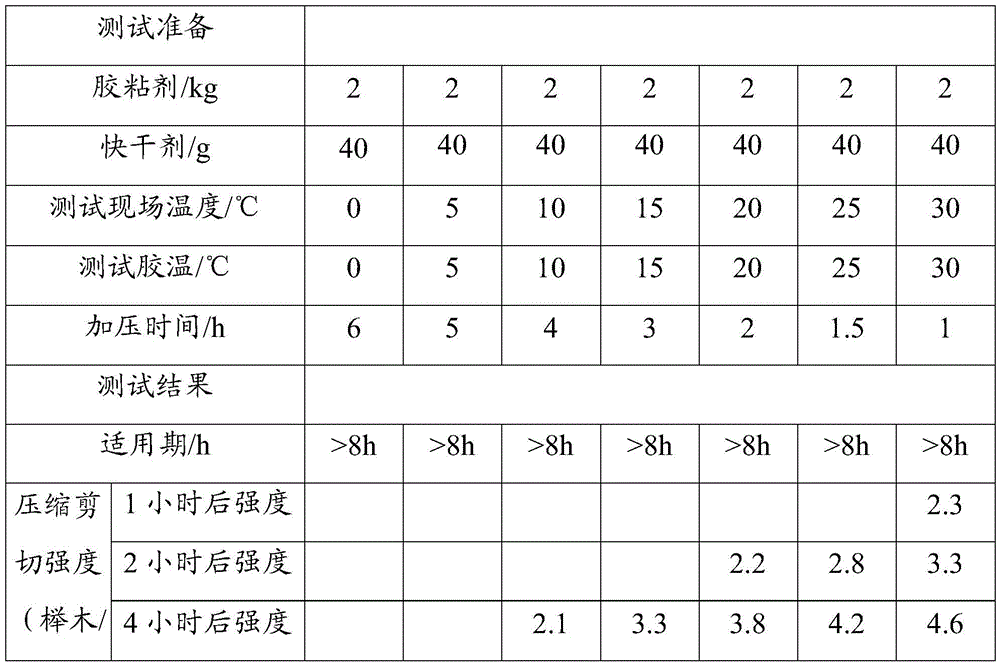

Bi-component polyurethane adhesive

ActiveCN102533200AQuick unblockSpeed up unblockingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesivePolyol

The invention discloses a bi-component polyurethane adhesive, which consists of a component A and a component B. The component A comprises the following raw materials in percentage by weight: 0-10% of monohydric alcohol, 30-90% of polyhydric alcohol, 8-60% of pigments and fillers, 1-10% of nano-filler, 0.01-1% of catalyst and 0.1-5% of silane coupling agent, wherein the sum of the raw materials is equal to 100%; the component B is isocyanate; and the weight ratio of the component A to the component B is 1-5:1. According to the bi-component polyurethane adhesive, the shelf life of the prepared bi-component polyurethane adhesive is obviously prolonged, and the curing speed is doubled.

Owner:GUANGZHOU RETAN NEW MATERIALS & HI TECH CO LTD

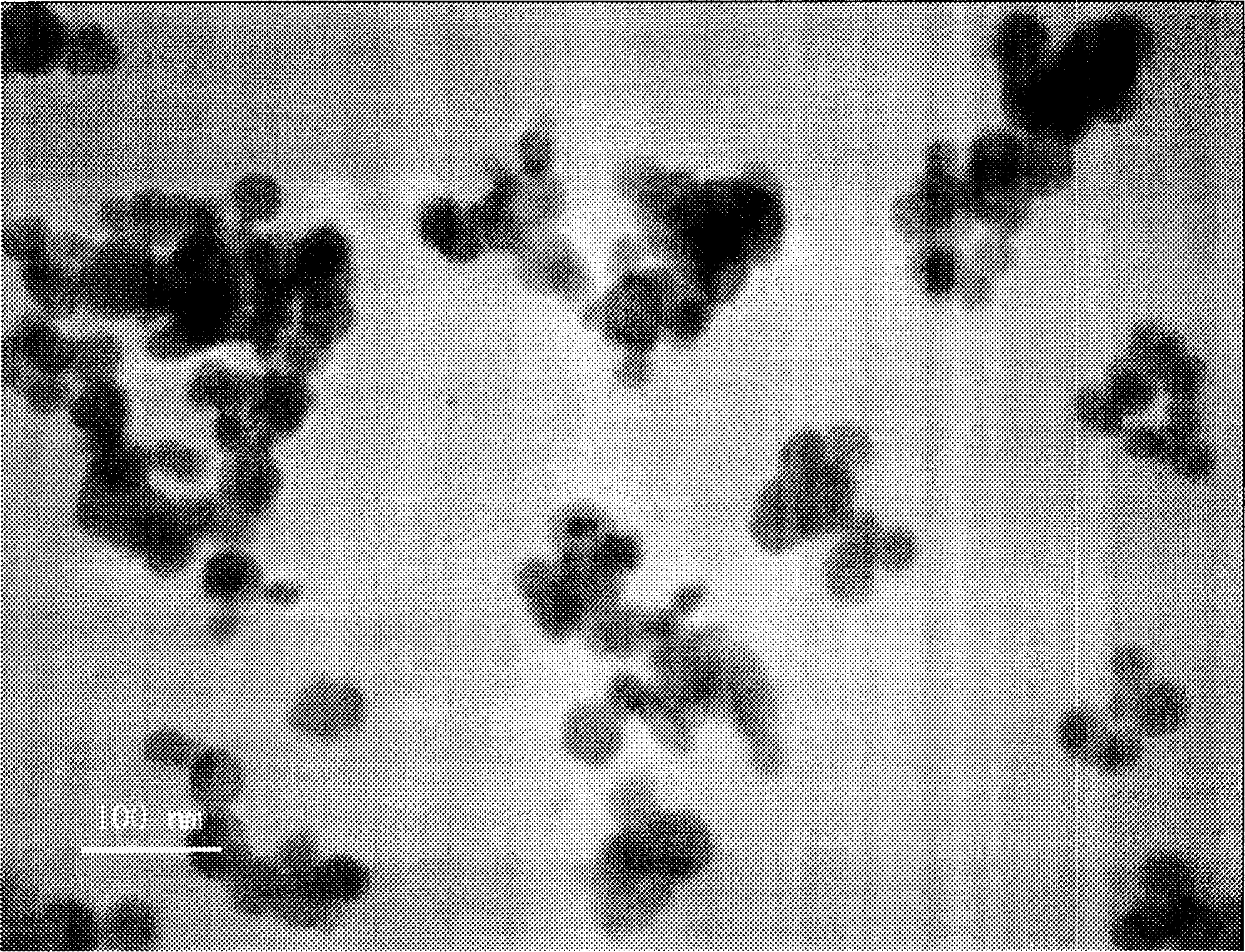

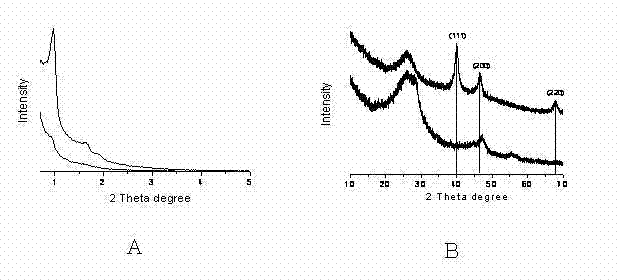

Gas-sensing material with noble metal doped composite metal oxide and its production

InactiveCN1746131ALarge specific surface areaHigh sensitivity and selectivityMaterial resistancePrecious metalNoble metal

A composite metal oxide gas-sensing material with noble metal doped and its production are disclosed. The procedure is carried out by doping noble metal into ZnO-SnO2 to obtain metal composite oxide material Mo-ZnO-SnO2, and regulating compound composition, concentration of metal salt solution, Zn / Sn mol ratio, precipitation value and aging time. The metal composite oxide consists of noble metal 0.5-6mol%, its grain size distribution is 20-80nm and specific surface is 30-120m2 / g.

Owner:BEIJING UNIV OF CHEM TECH

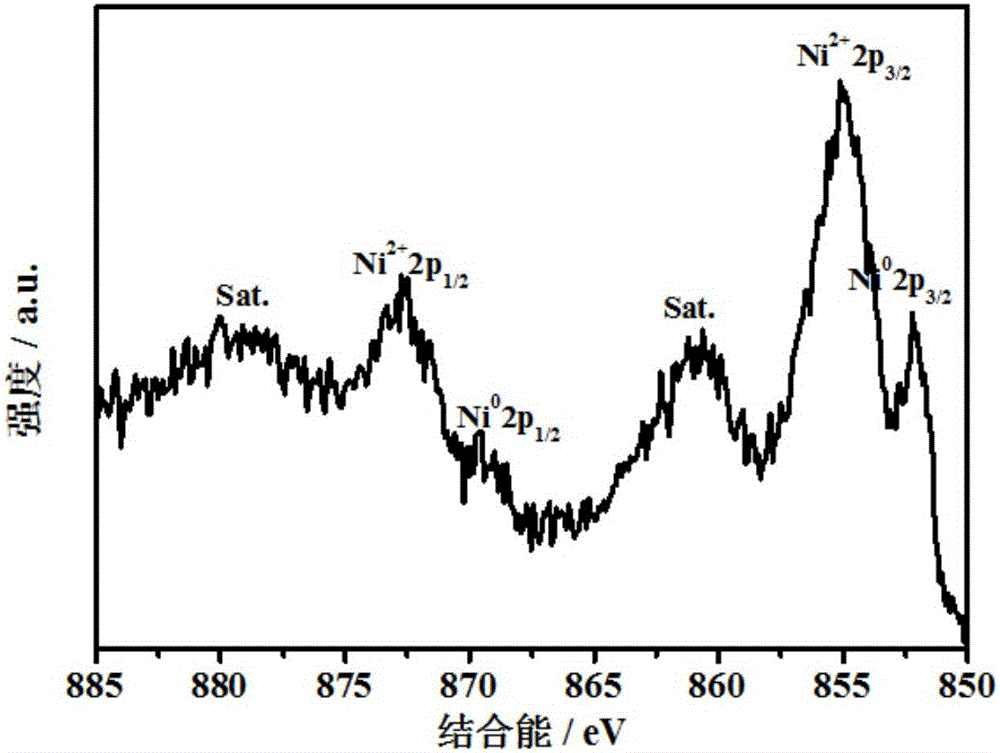

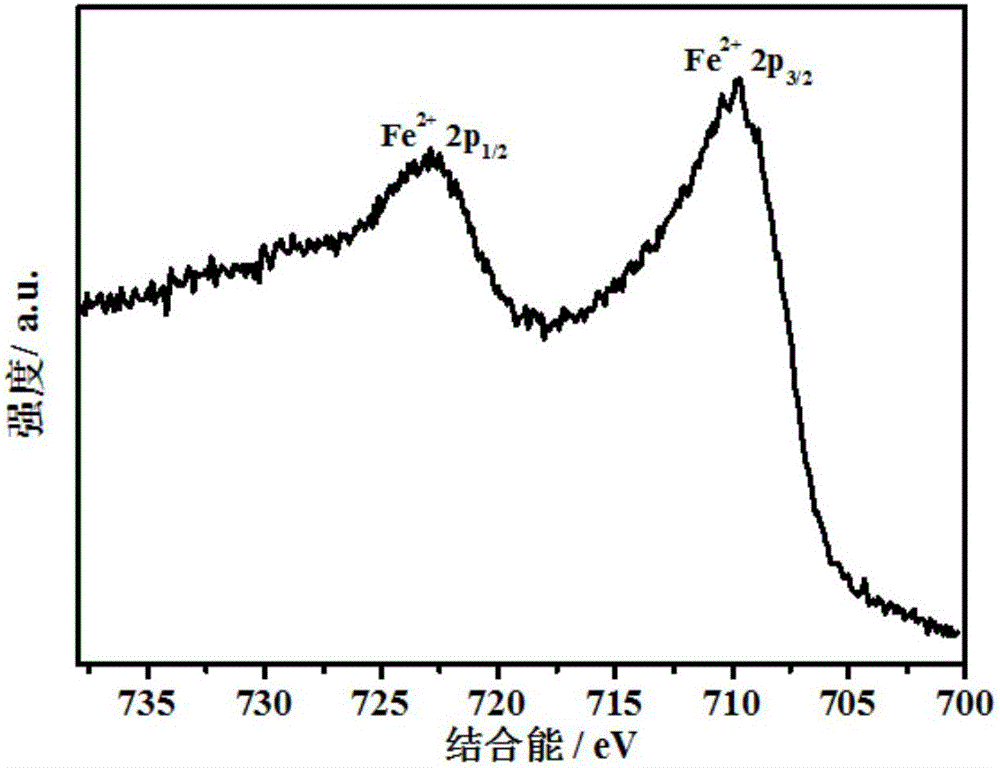

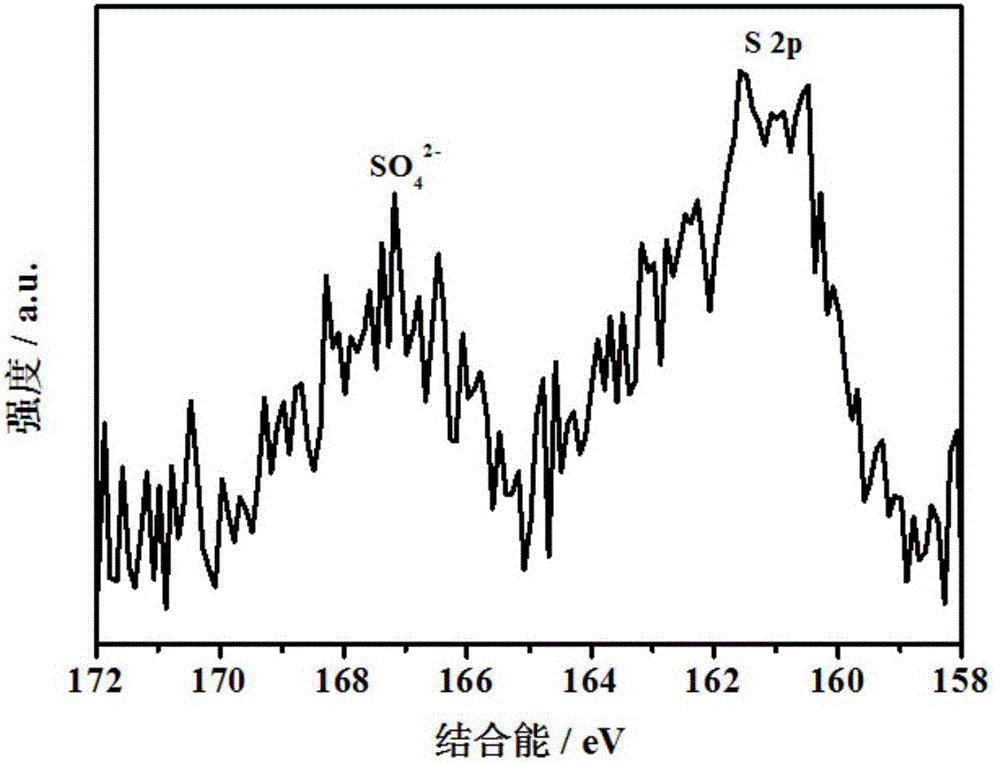

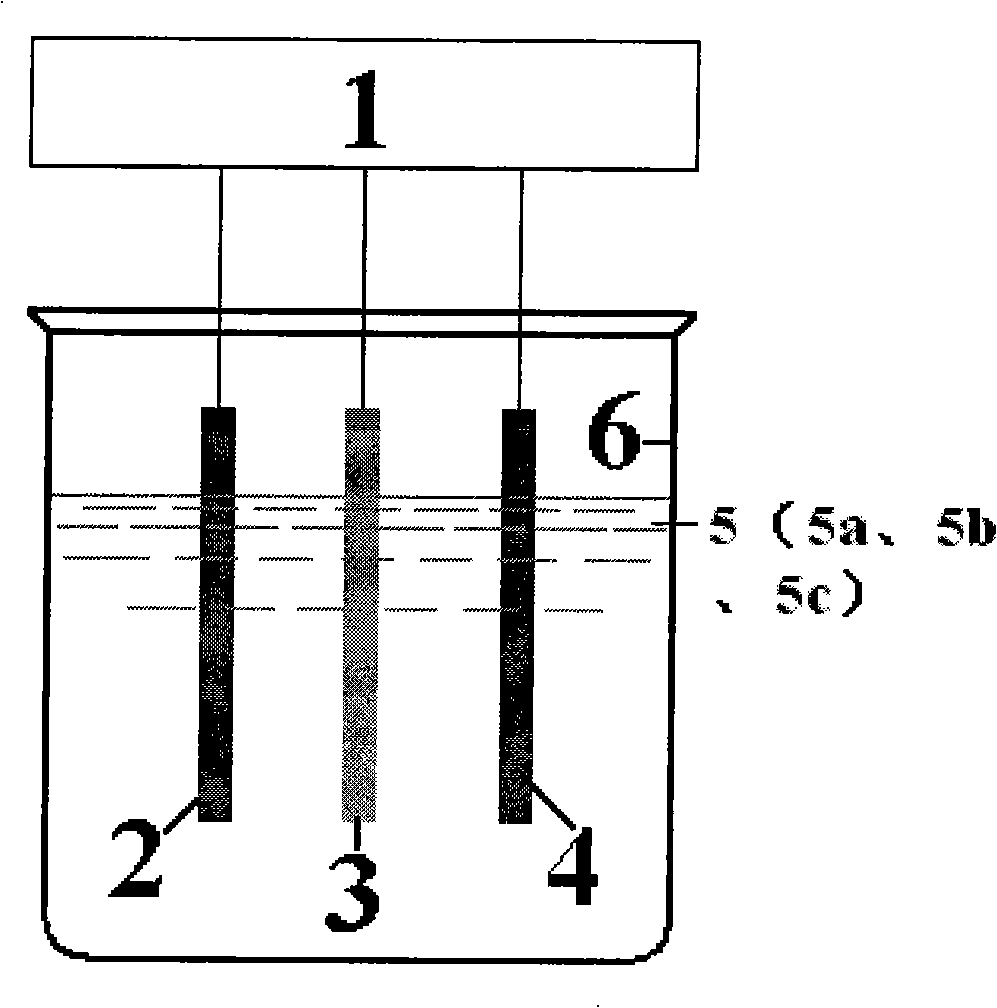

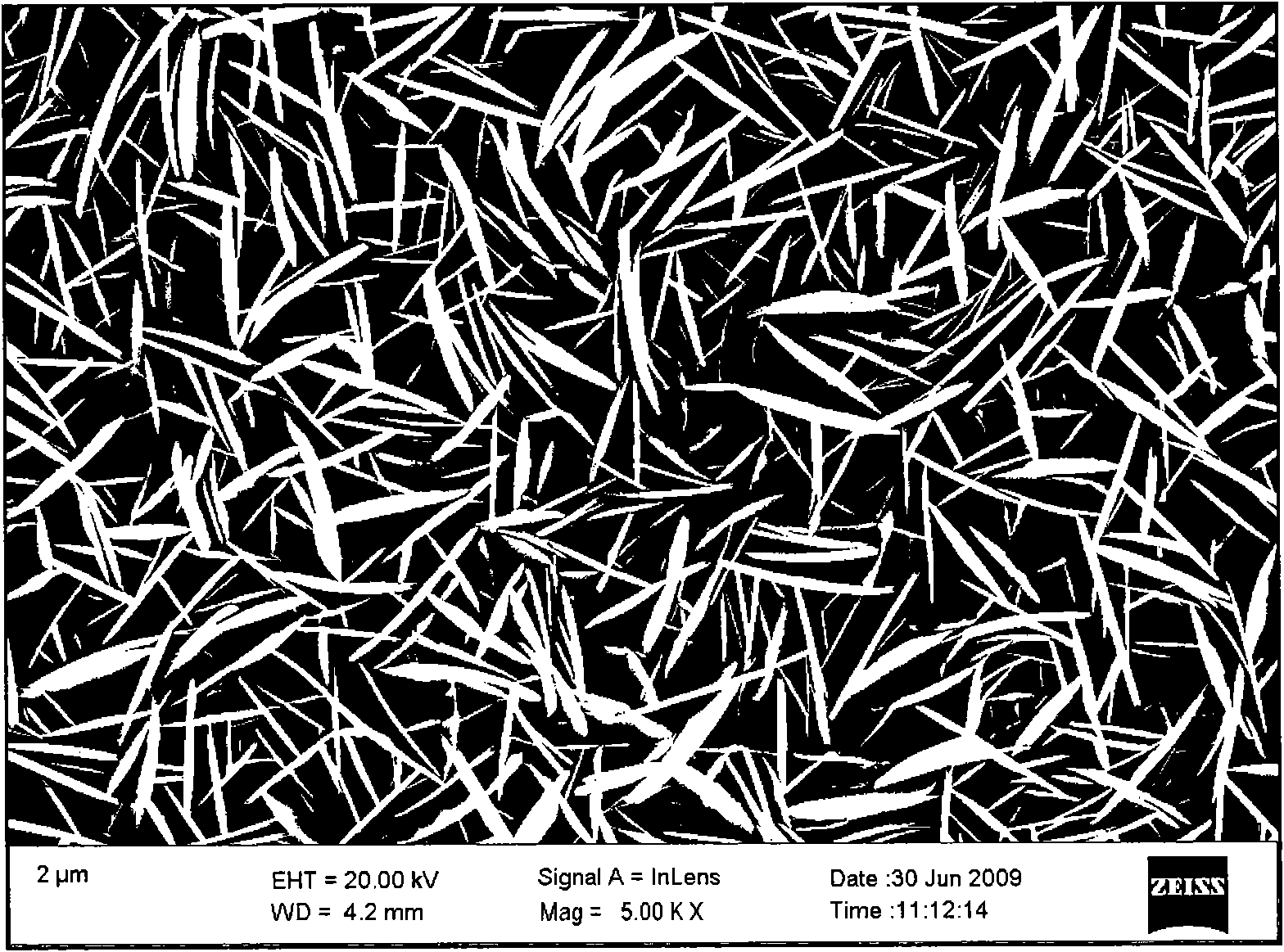

Preparation method of sulfur doped Ni-Fe hydroxide nano-film catalyst for decomposing water to produce oxygen

InactiveCN105970265AGood catalytic effectSimple methodPhysical/chemical process catalystsElectrolytic inorganic material coatingChemistryDecomposition

The invention discloses a preparation method of a sulfur doped Ni-Fe hydroxide nano-film catalyst for decomposing water to produce oxygen. According to the method, an aqueous solution which contains NiCl2, FeCl2, thiocarbamide and polyethylene glycol 1,000 is used as electrodeposition liquid, and a sulfur doped Ni-Fe hydroxide nano-film catalyst is directly electro-deposited on the surface of a metal strip or a foam metal substrate by an electrodeposition method. The preparation method is simple, the cost is low, the obtained catalyst is used for catalyzing decomposition of water to produce oxygen, a function of reducing overpotential of oxygen evolution of electrolysed water is good under larger current density, the catalytic activity is high, and the catalyst cannot drop from the surface of the substrate easily.

Owner:SHAANXI NORMAL UNIV

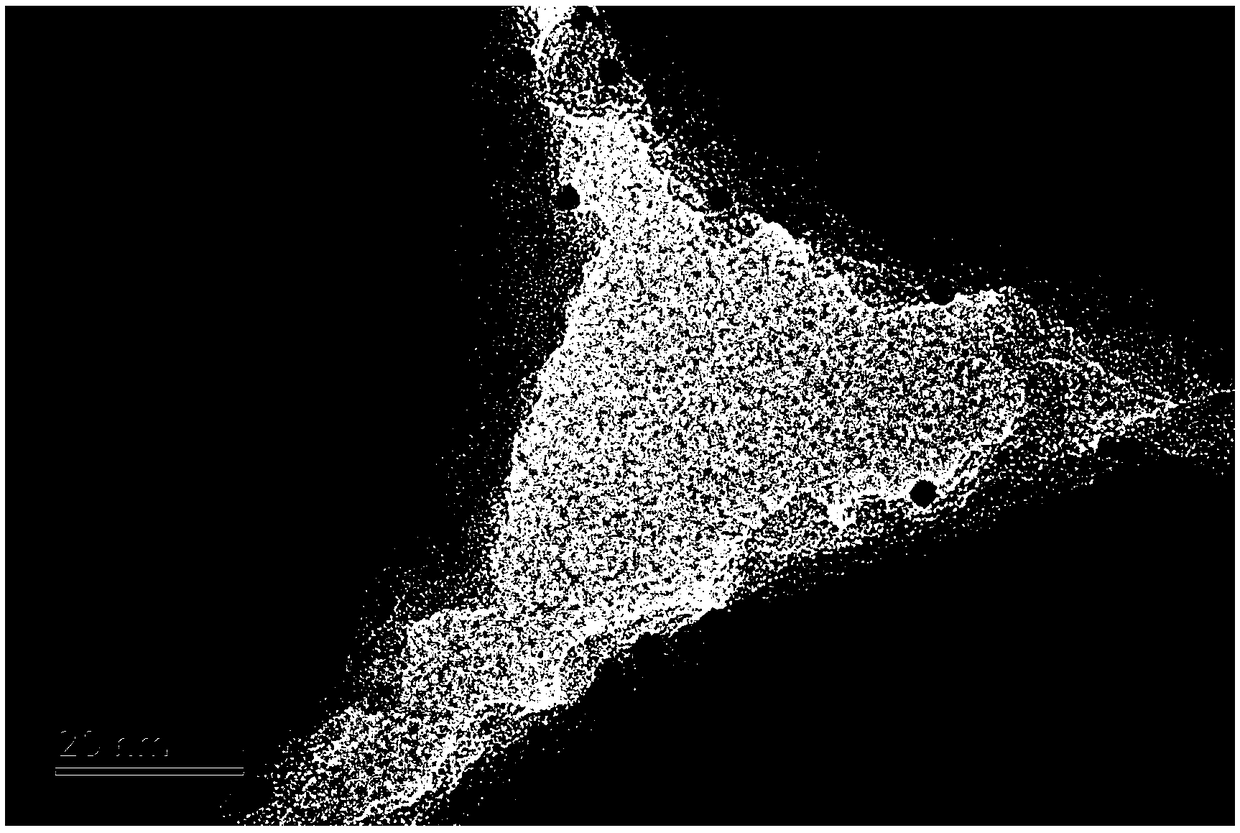

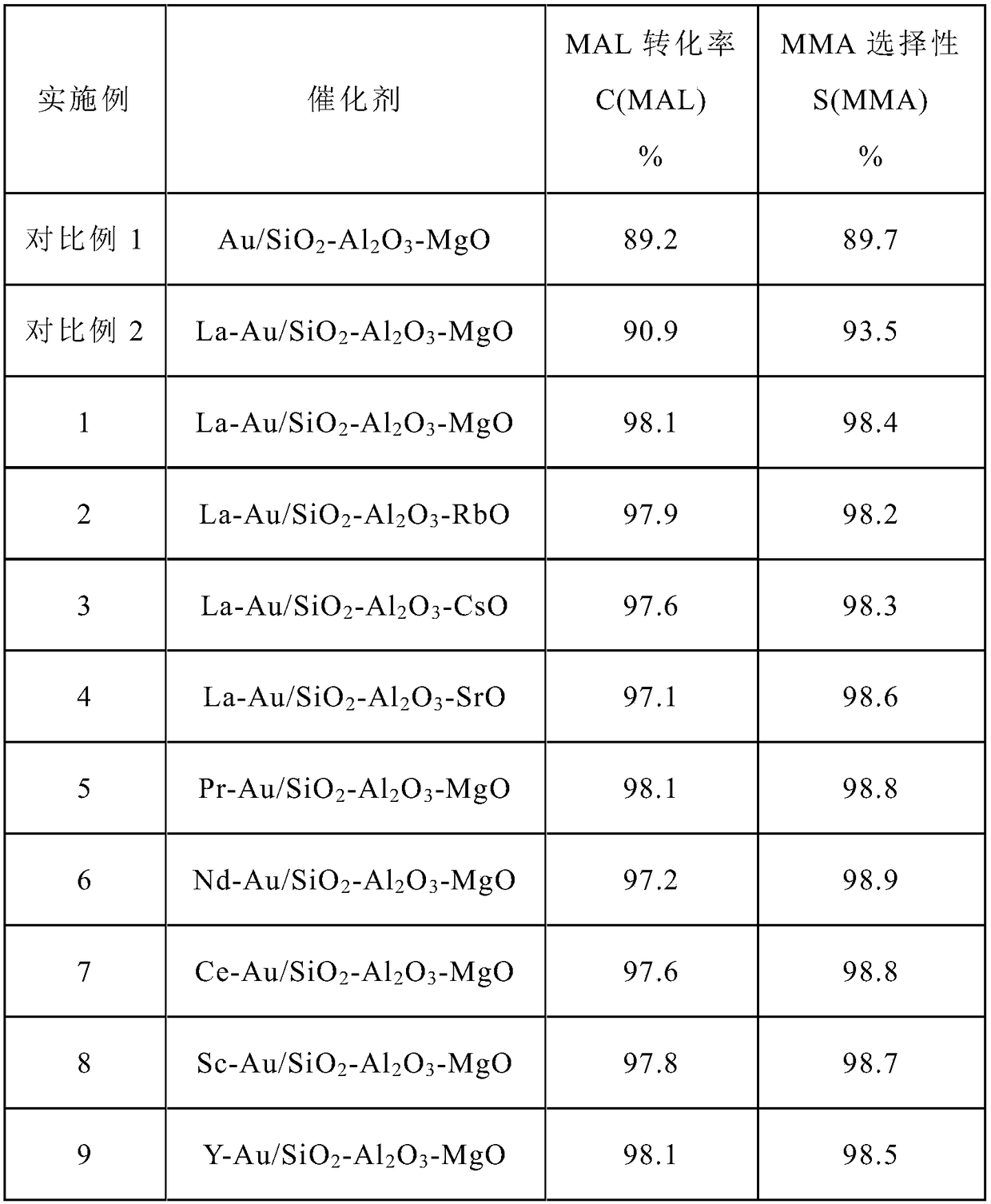

Catalyst to produce methyl methacrylate efficiently at low cost and preparation method of catalyst

ActiveCN109395732AImprove performanceLow priceOrganic compound preparationCarboxylic acid esters preparationMolecular sieveParticulates

The invention discloses a preparation method of a catalyst to produce methyl methacrylate efficiently at low cost. The catalyst is made by a polymeric protection process and is a supported catalyst with an active center supported on a support; the active center includes gold and a rare-earth metal; the support is one of SiO2, SiO2-Al2O3, CaCO3, carbon material, and molecular sieve material; the catalyst is 0.05-0.98% by weight in gold loading capacity and 1-2.5% by weight in rare-earth metal loading capacity. The preparation method is suitable for preparing a gold particulate catalyst having uniform particle size and high activity; the preparation process is simple; the preparation method is convenient to perform; active component loading capacity is low; the catalyst has excellent activity and good stability; the catalyst is prepared at low cost; methylacrolein conversion rate and MMA (methyl methacrylate) selectivity are high; the preparation method is suitable for industrial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

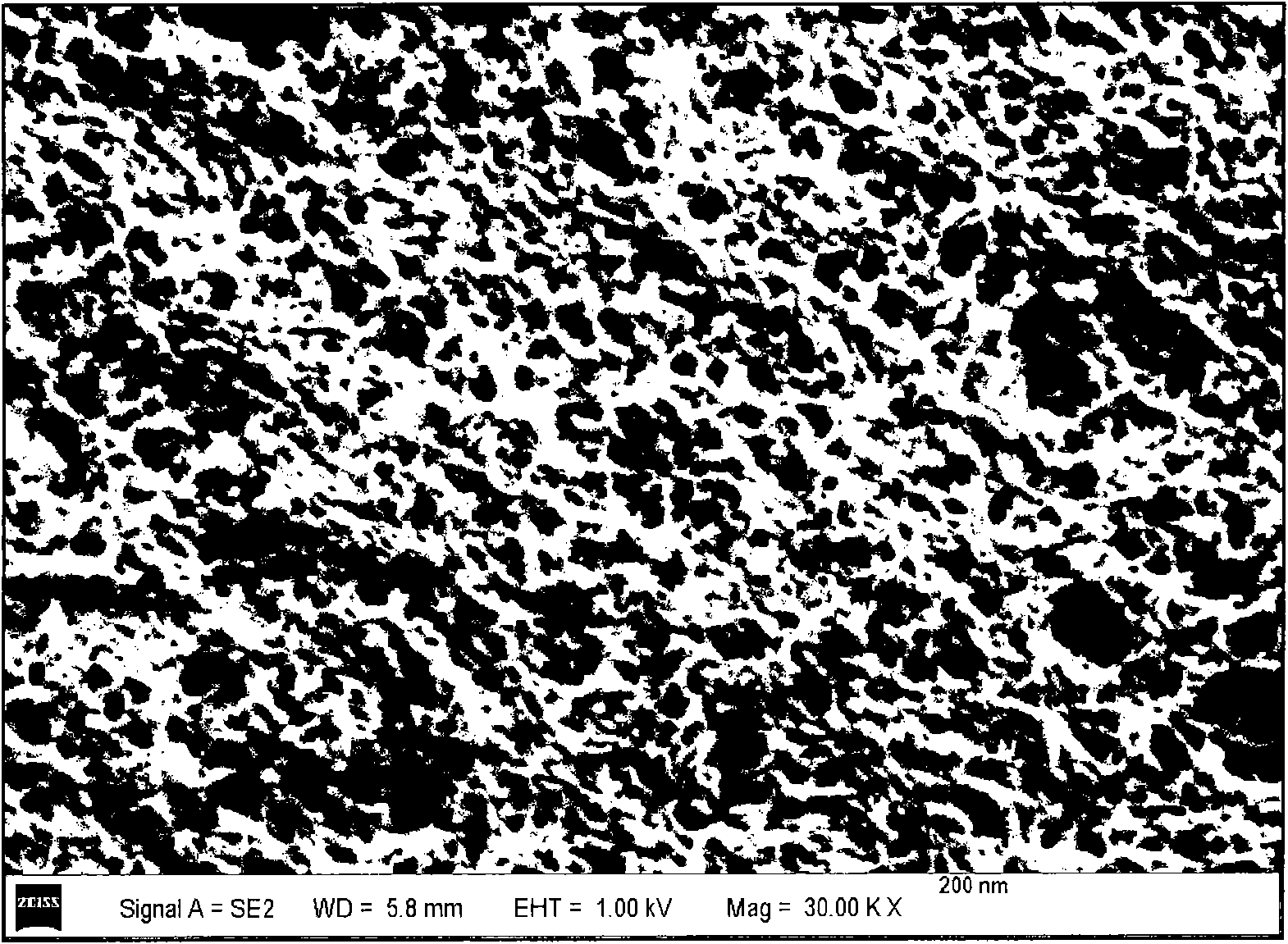

Method for preparing platinum nanometer perforated electrodes with electrodeposition

InactiveCN101303325AGood catalytic effectSimplify operation stepsMaterial analysis by electric/magnetic meansBiological testingElectrochemical detectionMaterials preparation

The invention discloses a method for preparing platinum nano-porous electrode by electrodeposition, which pertains to the technical field of material preparation and electrochemical detection. The method includes that: a layer of platinum alloy is deposited on a substrate of a working electrode by electrodeposition, and then the substrate is carried out inverse alloying by electrochemical etching, so as to form the platinum nano-porous electrode. The method of the invention has the advantages that: a high quality platinum nano-porous electrode can be obtained, with the surface area improved by over 500 times than that of a planar electrode and has good catalytic effect, which can completely satisfy the requirements of measuring glucose without enzyme; the preparation steps of the electrode is simple, with small quantity of reagent, low cost and easy operation; and the operation can be conducted under normal temperature, which has no danger of high temperature and is safe and environment protective.

Owner:EAST CHINA NORMAL UNIVERSITY

Titanium-silicon molecular sieve and resin composite catalyst and preparation method thereof

ActiveCN102049304AGood catalytic effectImprove reaction efficiencyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSolventMolecular sieve

The invention discloses a titanium-silicon molecular sieve and resin composite catalyst and a preparation method thereof. The catalyst mainly comprises a titanium-silicon molecular sieve and resin. The preparation method comprises the following steps of: fully mixing titanium-silicon molecular sieve powder, a polymeric monomer and a porogen, performing polymerization reaction in the presence of an initiator to obtain a blocky solid catalyst, crushing, adding into halogenated hydrocarbon for swelling, and performing solvent extraction to obtain a formed catalyst. The catalyst prepared by the method solves the problem that titanium-silicon catalyst powder and reaction liquid are difficult to separate, improves reaction efficiency, is applied to the catalytic reaction process of olefin epoxidation in a fixed bed process, and has good catalytic effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

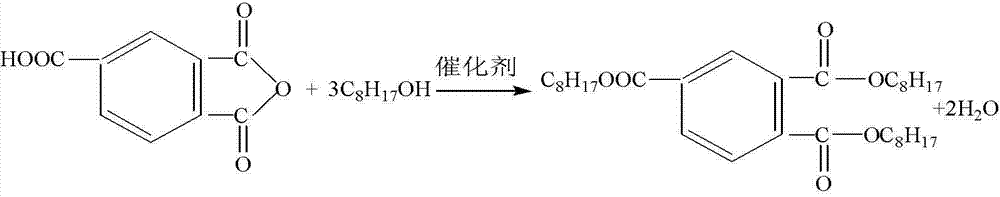

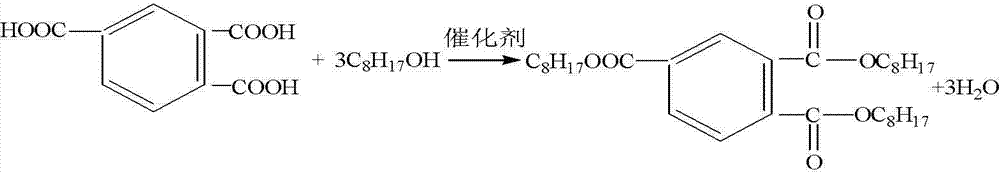

Catalytic synthesis method of tri-octyl tri-meta-benzoate

ActiveCN102924279AGood catalytic effectLight colorOrganic compound preparationCarboxylic acid esters preparationOxideTrioctyl trimellitate

The invention discloses a catalytic synthesis method of tri-octyl tri-meta-benzoate. A solid oxide is adopted as a catalyst and has a better catalysis effect; the catalytic synthesis method is an innovative novel catalytic synthesis process; the catalyst can be recycled; and the obtained tri-octyl tri-meta-benzoate is light in color and has high mass resistivity. Non-acid catalysis is adopted, and operations of neutralization and water washing are not needed in a production process, therefore, an aftertreatment procedure is simplified, and no wastewater is discharged in a production process; and the catalytic synthesis method is a cleaner production process, and accords with the requirement of relevant industrial policies for encouraging energy saving and emission reduction in the chemical engineering industry in China.

Owner:JIANGSU ZHENGDAN CHEM IND CO LTD

Catalytic preparation method of dicyclopentadiene dioxide by quaternary ammonium heteropoly phosphato tungstate

The invention discloses a catalytic preparation method of dicyclopentadiene dioxide by quaternary ammonium heteropoly phosphato tungstate, which is characterized by comprising the following steps: epoxidation reaction: adding the raw materials of dicyclopentadiene, solvent I and quaternary ammonium heteropoly phosphato tungstate in a reactor, heating the temperature to 30-80 DEG C, stirring and dropwise adding aqueous hydrogen peroxide solution, and reacting for 3-36h under the temperature of 30-80 DEG C after dropwise adding; post-treatment: cooling the reacted materials to room temperature, evaporating solvent I by reduced pressure distillation and separating and removing water to obtain the mixture of the product and the quaternary ammonium heteropoly phosphato tungstate catalyst, dissolving and filtering the mixture by ethyl acetate to obtain filter cake, namely the recovered quaternary ammonium heteropoly phosphato tungstate catalyst, recovering ethyl acetate by performing reduced pressure distillation on filtrate to obtain the crude product, performing recrystallization on the crude product by solvent II, and drying to obtain the product. The invention has the advantages of convenient operation, high safety, small pollution, simple post treatment, and high product yield and purity.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

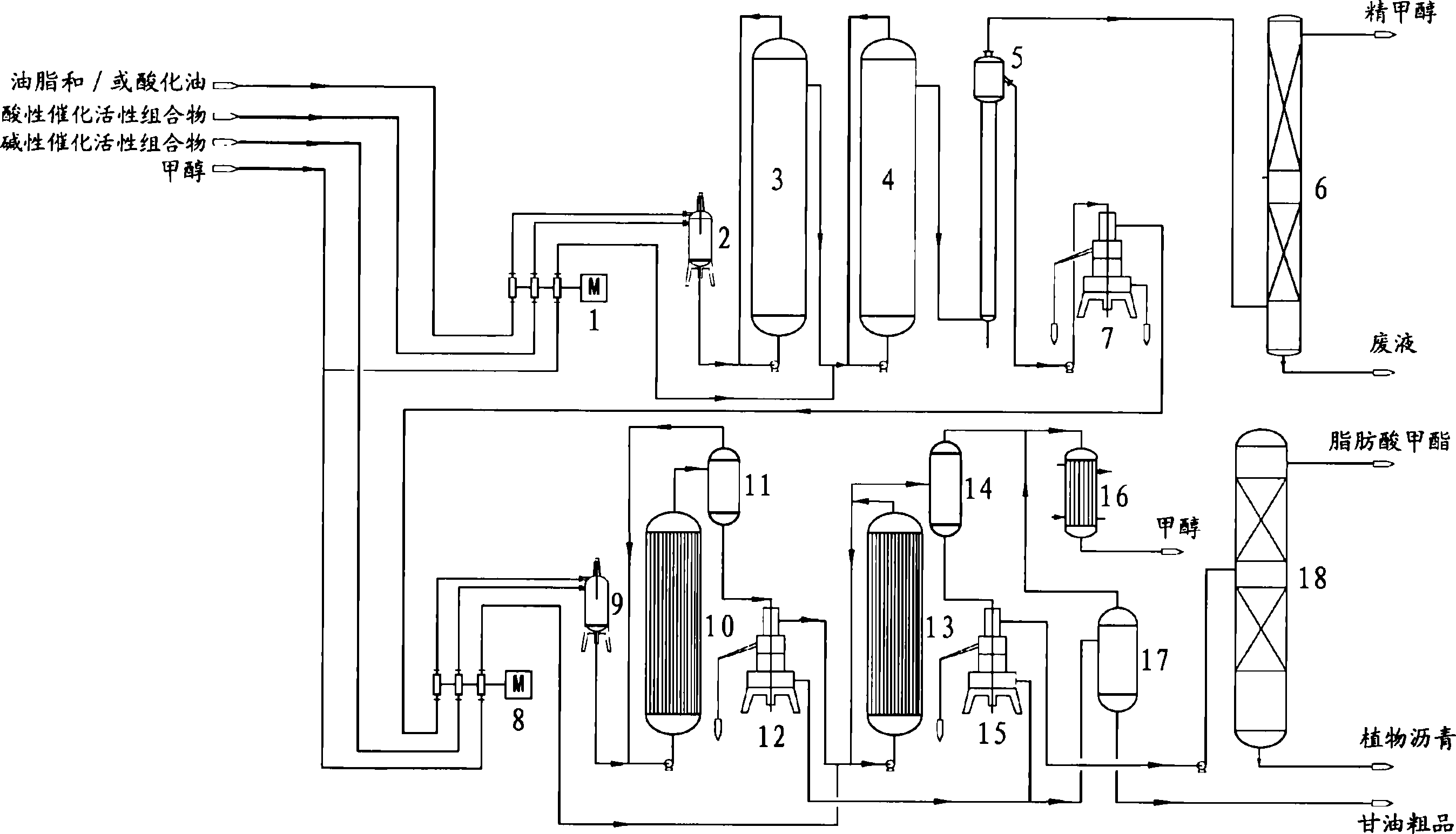

Catalyst system and biological diesel oil producing process with the catalyst system

InactiveCN1887417AGood catalytic effectGood compatibilityOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsOil and greaseBiodiesel

The present invention provides one kind of catalyst system for producing biological diesel oil, and the catalyst system includes active acid catalytic composition and active alkaline catalytic composition. The present invention also provides biological diesel oil producing process with the catalyst system. The biological diesel oil producing process includes the steps of: the esterification of grease and / or acidified oil in the presence of acid catalytic composition and the subsequent ester exchange reaction in the presence of alkaline catalytic composition. The process converts grease and / or acidified oil into biological diesel oil completely. The present invention has the advantages of high catalytic activity of the catalyst system, short reaction period, low reaction temperature, high yield, low production cost, less corrosion to the production apparatus, high product quality, low power consumption, less pollution, etc.

Owner:张冰青

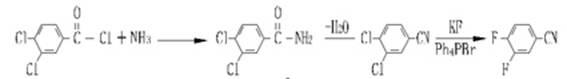

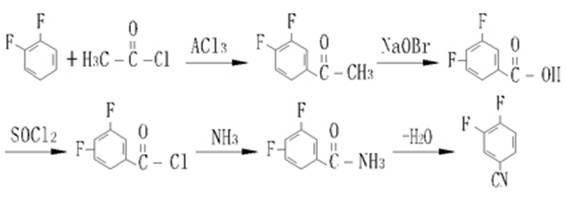

Industrial preparation process for 3,4-difluorobenzonitrile

InactiveCN102690214AGood catalytic effectWide operating temperatureCarboxylic acid nitrile preparationOrganic compound preparationMethylene radicalDimethylamines

The invention relates to an industrial preparation process for 3,4-difluorobenzonitrile. The method comprises the following steps of: reacting 3,4-dichlorobenzonitrile and anhydrous potassium fluoride under the protection of nitrogen by taking 1.3-dimethyl-2-imidazolone as a reaction solvent and N-bis(dimethylamino)methylene-1.3-dimethyl imidazoline-2-ammonium chloride salt as a catalyst at the temperature of between 200 and 230 DEG C for 20 hours, reacting with rectifying to obtain a 3,4-dichlorobenzonitrile crude product, rectifying the 3,4-dichlorobenzonitrile to obtain high-purity 3,4-dichlorobenzonitrile, and distilling the solvent and recycling. The method has the advantages of simplicity, mild reaction, short period, and high yield.

Owner:TAIXING YUANDONG CHEM

Method for preparing titanium silicon molecular sieve catalyst

ActiveCN102049305AGood catalytic effectImprove reaction efficiencyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveTitanium

The invention discloses a method for preparing a titanium silicon molecular sieve catalyst. The method comprises the following steps of: mixing titanium silicon molecular sieve powder, polymer monomer styrene, a polymer monomer multi-alkenyl compound and a pore-forming agent completely; in the presence of an initiator, performing a polymerization reaction; smashing the obtained blocky solid catalyst; adding the smashed catalyst into halohydrocarbon to swell; and performing extraction by using a solvent to obtain the formed titanium silicon molecular sieve catalyst. The titanium silicon molecular sieve catalyst prepared by the method solves the problem that the titanium silicon catalyst powder and reaction solution are difficult to separate and improves the reaction efficiency. The titanium silicon molecular sieve catalyst is applied to a catalytic reaction of alkene epoxidation of a fixed bed process and has excellent catalytic effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite anode electrocatalyst for direct methanol fuel cell

InactiveCN101306365AImprove anti-poisoning performanceReduces anodic polarizationCell electrodesMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalPt element

The invention relates to a direct methanol fuel cell used anode catalyst which contains the following constituents (by weight percent): 20%-40% of Pt, 17.1%-34.2% of M1-xNxO2-Delta and 25.8%-62.9% of C, wherein x is mol ratio between 0.02 and 0.08, M is Zr or Ce, and N is transition metal or alkaline-earth metal. The catalyst accelerator in the catalyst of the invention is the improved doped metal oxide with stronger bi-functional effects compared with the un-doped metal oxide, the methanol oxidative current is higher than the common carbon supported platinum or un-improved similar composite catalyst, the efficiency of the direct methanol fuel cell used anode catalyst is improved, and the preparation process is simpler, thereby being suitable for scale-up production.

Owner:SHANGHAI JIAO TONG UNIV

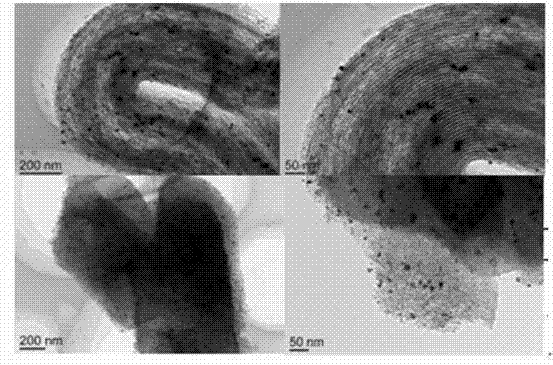

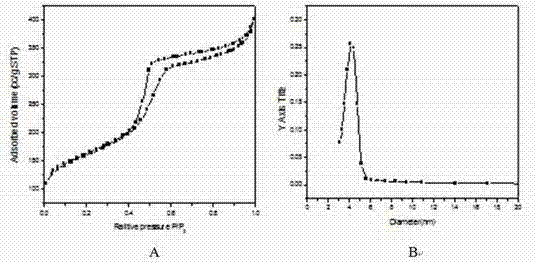

Preparation method of mesoporous carbon nitride loaded precious nano particle

InactiveCN102931418AGood catalytic effectSave raw materialsCell electrodesIon exchangeMolecular sieve

The invention discloses a preparation method of a mesoporous carbon nitride loaded precious nano particle, which comprises the steps of: with mesoporous silica as a hard template, preparing a mesoporous nitrogen-doped carbon material by using a nano pouring method; then carrying out alkylation reaction by using halohydrocarbon to ensure that the nitrogen-doped carbon surface is subjected to quaternization; enabling an anion group with precious metals to replace a halide ion by means of an ion exchange method, binding on the surface of the material; and finally reducing metal ions by using a reducing agent, and preparing the mesoporous carbon nitride loaded precious nano particle. According to the method, a precious metal particle precursor and a mesoporous material are tightly combined by means of an ion bond, and the precious metal particle is well dispersed on the ordered mesoporous material to form a precious metal / nitrogen carbon compound material. The mesoporous carbon nitride loaded precious nano particle has the activity of the precious nano particle and is high in specific area and large in hole volume of a mesoporous molecular sieve. The mesoporous carbon nitride loaded precious nano particle has excellent catalysis activity and catalysis stability for cathode oxygen reduction of a fuel cell, and has a potential commercial application prospect.

Owner:EAST CHINA NORMAL UNIVERSITY

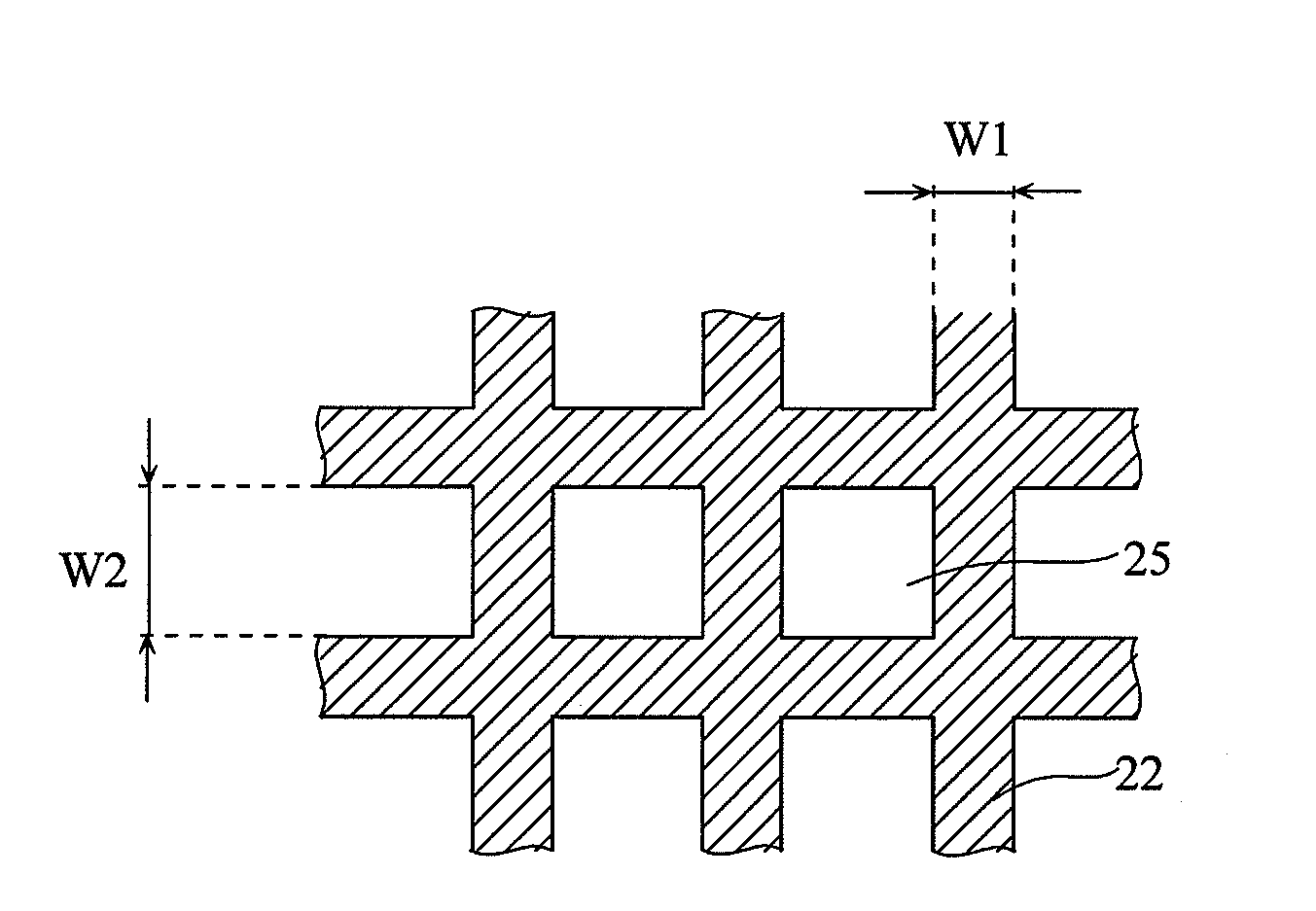

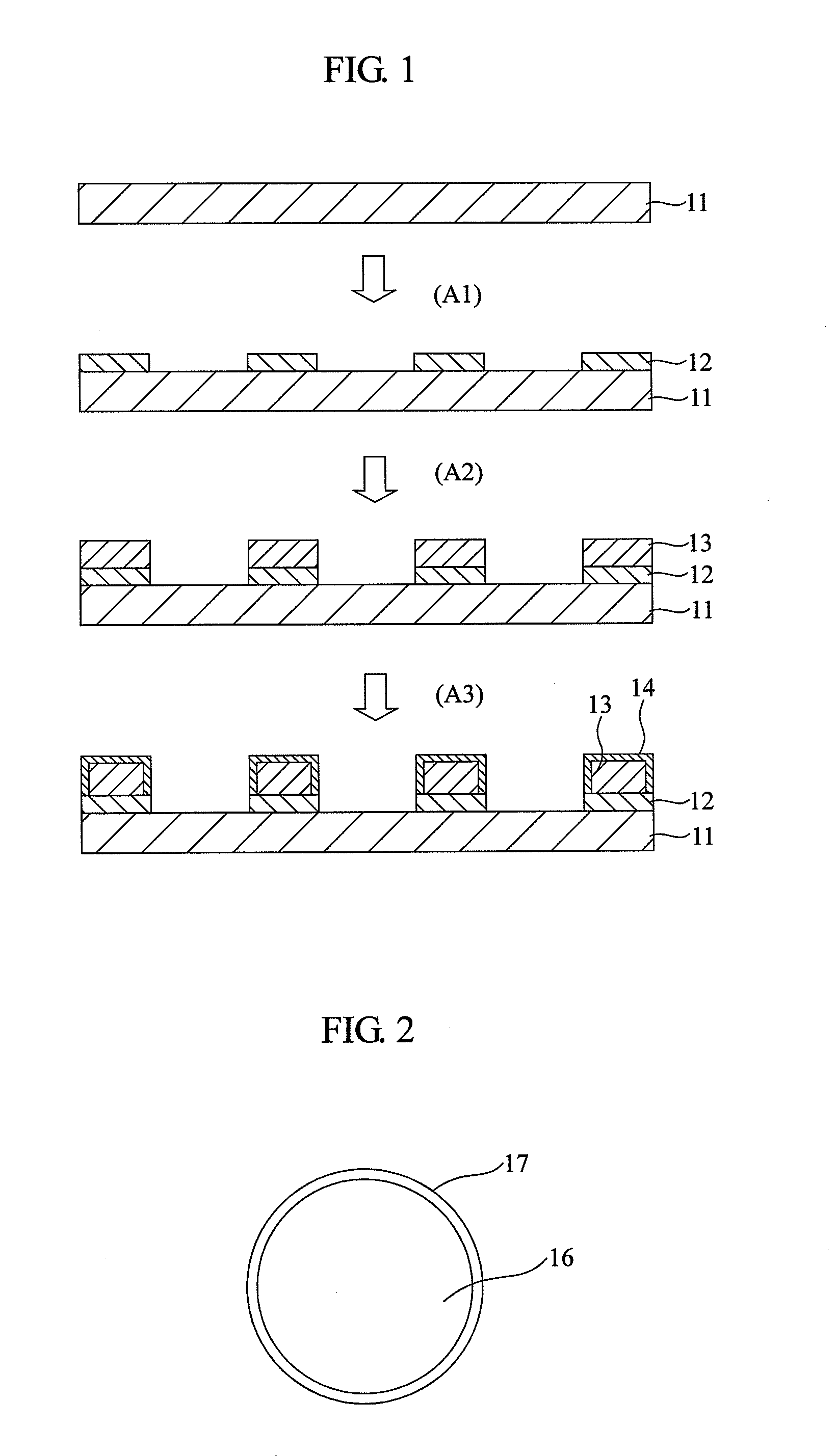

Process for the preparation of light transmissive electromagnetic wave shielding material, light transmissive electromagnetic wave shielding material and fine particle having extremely-thin noble metal film

InactiveUS20100126767A1Accurate fine patternUniform thicknessScreening rooms/chambersSynthetic resin layered productsElectroless platingOptics

The present invention provides a process for efficiently preparing a light transmissive electromagnetic wave shielding material enhanced in light transmissive property, electromagnetic wave shielding property, appearance and legibility, and having high-accuracy mesh-pattern. The process for the preparation of a light transmissive electromagnetic wave shielding material comprising; printing in the form of mesh a pretreatment agent for electroless plating on a transparent substrate to form a mesh-shaped pretreatment layer, the pretreatment agent comprising a fine particle having an extremely-thin film of noble metal on its surface, and subjecting the mesh-shaped pretreatment layer to electroless plating to form a mesh-shaped metal conductive layer on the pretreatment layer.

Owner:BRIDGESTONE CORP

ZSM-5 zeolite molecular sieve and preparation method thereof

ActiveCN104211086AGood catalytic effectPlay a catalytic effectPentasil aluminosilicate zeoliteMolecular sieveKaolin clay

The invention relates to a composite material containing ZSM-5 zeolite and a preparation method thereof. By taking kaolin, diatomite and modified kaolin as main raw materials, the preparation method comprises the following steps: A) roasting the kaolin at the temperature of 500-1000 DEG C for 0.5-10h to obtain a roasted material, adding water into the roasted material, uniformly stirring to prepare slurry, adding an alkali or acid, then reacting at the temperature of 60-90 DEG C for 30-120min and filtering to obtain the modified kaolin; B) adding water and one or more of a dispersant and a pore expanding agent into the material obtained in the step A), the kaolin and the diatomite, uniformly stirring to prepare slurry, forming by spray drying, and roasting the formed material at the temperature of 700-1000 DEG C for 0.5-6h to obtain the roasted material; C) adding sodium silicate, lye and zeolite into the material obtained in the step B), then putting into a crystallization reaction kettle, adjusting the final pH value of the slurry to 9.5-11.5 with an acid, performing hydrothermal crystallization at the temperature of 120-180 DEG C for 30-120h, filtering to remove mother liquor, washing the filtered material with deionized water, filtering and drying the filtered material to prepare a target product. The method has low preparation cost, the content of the ZSM-5 zeolite in the material is high, and the material has good wear resistance and has rich microporous and macroporous structures.

Owner:YUEYANG YITIAN CHEM

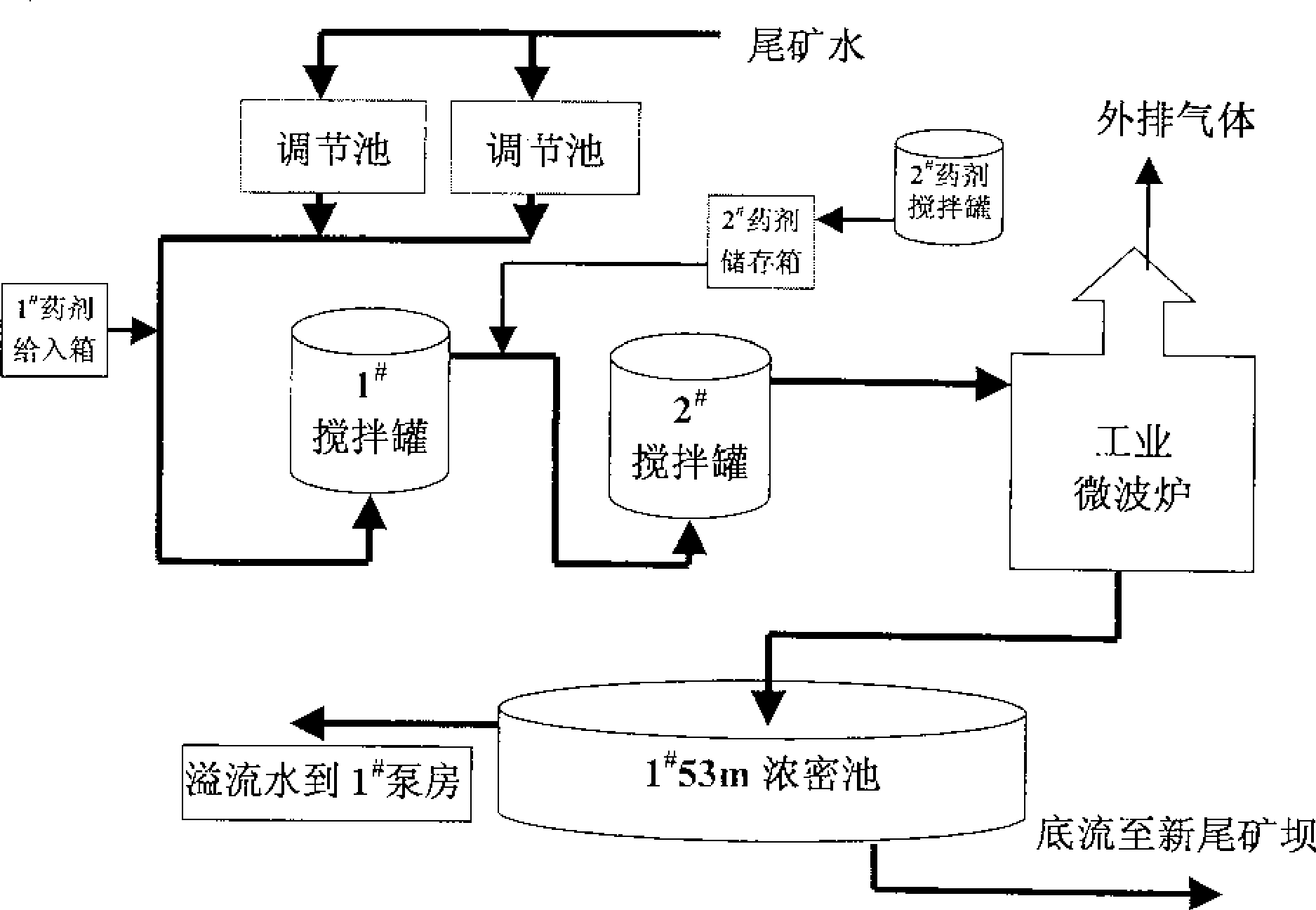

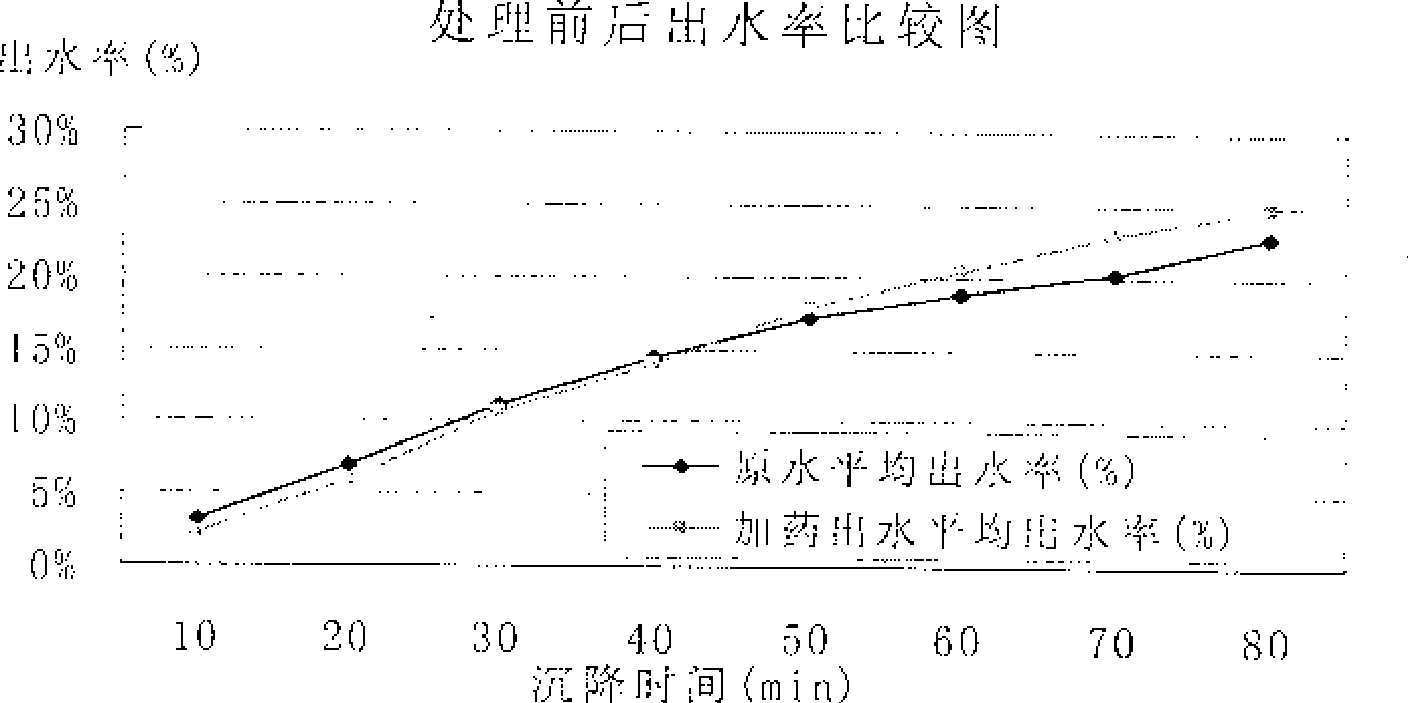

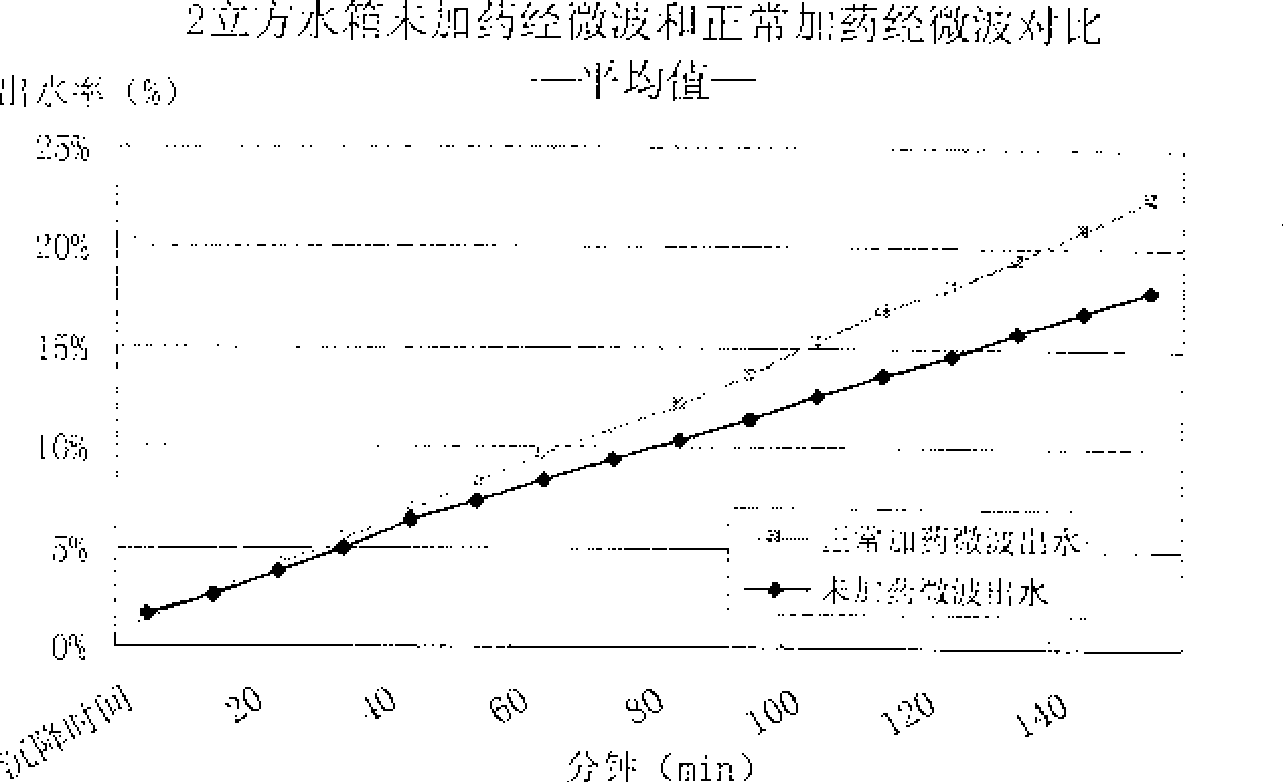

Method for treating tailing water from mineral processing plant by microwave

ActiveCN101391847AReduce moisture contentIncrease concentrationWater/sewage treatment by irradiationMultistage water/sewage treatmentTailings damMicrowave oven

The invention provides a method for treating iron ore site-selection tailing water by utilizing microwave, which comprises the following technical steps: tailing mash is sent to an adjusting tank for adjusting the concentration to 9-11 percent, then sent to a stirring tank with the flow of 160-292m<3> / h, and simultaneously quicklime is dosed into the tailing mash according to the dosing amount of 0.25-0.35kg / m<3>, the tailing mash is stirred at room temperature until the pH value is 10-14, a treatment agent is dosed into the tailing mash according to the dosing amount of 0.117-0.135L / m<3>, the tailing mash is stirred at room temperature until the pH value is 6-9, the tailing mash is sent to an industry microwave oven with the flow of 160-292m<3> / h, under the conditions of the power of 40-50kw and the frequency of 915 MHz, the tailing mash is treated for 1-2 seconds by the microwave and then sent to a turbidness tank for depositing for 240-300 minutes, overflow water is recycled, substrate sludge is sent to a tailing dam for placing. The method realizes the recycling of the tailing water, not only solves the problem of short water resources, but also avoids the potential safety hazard resulted from wet beaches and reduces the manufacture cost.

Owner:KUNMING IRON & STEEL GRP CO LTD

Accelerator of platinum catalyst for hydrosilylation, preparation method and application thereof

InactiveCN101850269AReduce use costGood catalytic effectGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsComposite materialAddition reaction

The invention belongs to the field of synthesizing an alkoxy silane monomer, relating to an accelerator of a platinum catalyst for hydrosilylation, which is carboxyl-containing or ethylenic bond-carboxyl-containing modified polyethylene glycol obtained by reaction of polyethylene glycol or methoxy polyethylene glycol with anhydride. The invention also provides a preparation method for the accelerator and an application thereof. The preparation method for the accelerator comprises the following step of modifying the polyethylene glycol or methoxy polyethylene glycol molecular monomer by using anhydride at the temperature of between 20 and 150 DEG C. The accelerator serving as an auxiliary agent is used for establishing a catalyst system for addition reaction of unsaturated olefin and hydrogenalkoxysilane by platinum catalysis, and solves the technical problems that the conventional catalyst has poor catalytic activity and low selectivity.

Owner:HANGZHOU NORMAL UNIVERSITY

Hydrotalcite-like structuring catalyst and method for catalytic synthesis of pseudo-ionone

InactiveCN101816950ALow molar ratioProcess environmental protectionOrganic compound preparationCatalyst activation/preparationCatalytic effectAluminum substrate

The invention discloses a hydrotalcite-like thin membrane which is grown on an aluminum substrate with surface anode oxidation and used as a structuring catalyst in the field of membrane catalysis, so as to catalyze the optimal feed ratio of citral to acetone during the aldol condensation reaction of the citral and the acetone. The in-situ synthesis technology is adopted for preparing the hydrotalcite-like thin membrane on an aluminum sheet after the surface anode oxidation, the high-temperature calcination and the re-hydration are further carried out, and the hydrotalcite-like structuring catalyst which takes aluminum as the substrate is finally obtained. The prepared structuring catalyst can be effectively used for the aldol condensation reaction of the citral and the acetone, solve a series of problems caused by a liquid base catalyst and a solid base catalyst and lead the process to meet the requirements on environmental protection and sustainable development; more importantly, the use of the structuring catalyst can effectively reduce the molar ratio of acetone / citral to 1, thereby obtaining great catalytic effect.

Owner:BEIJING UNIV OF CHEM TECH

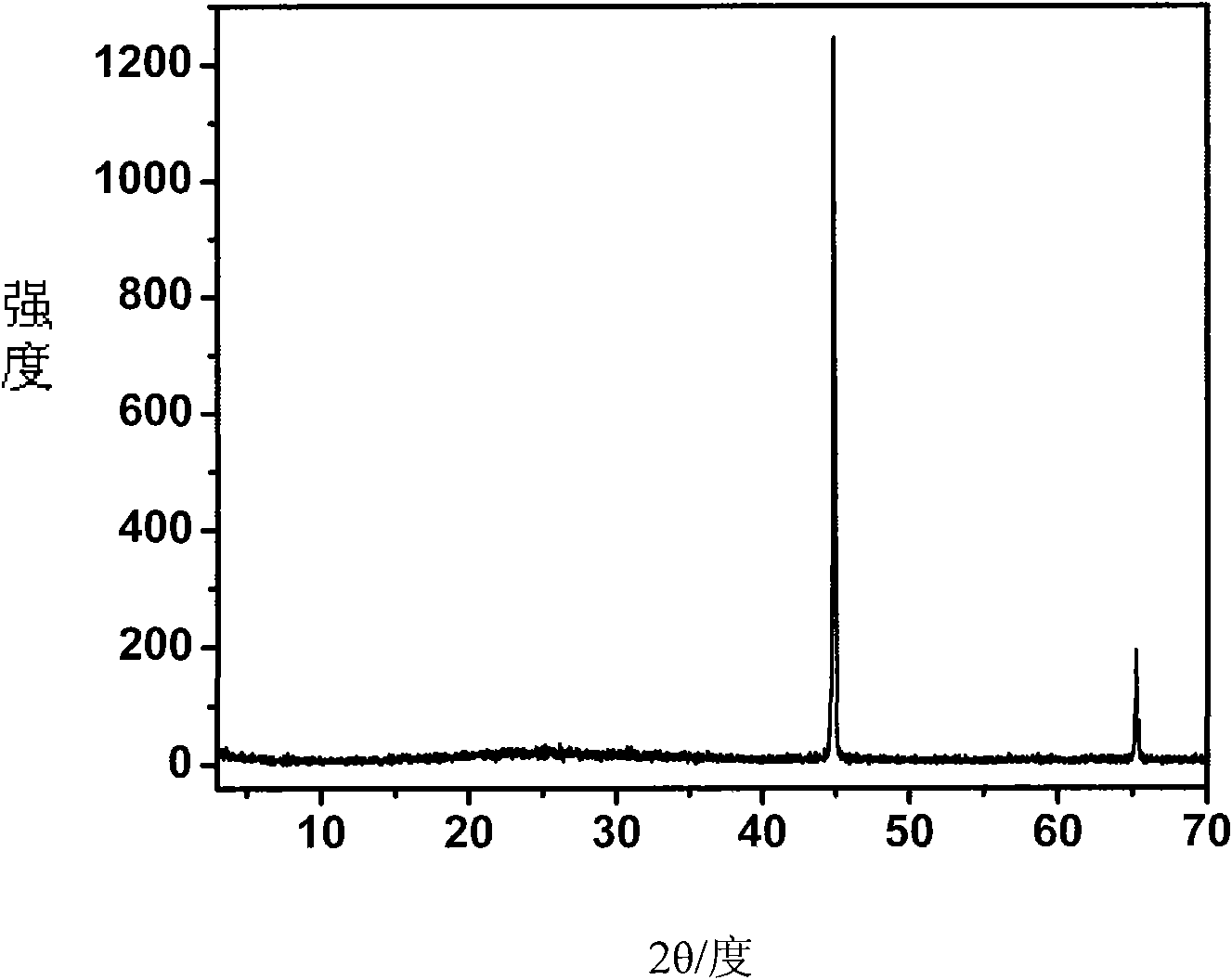

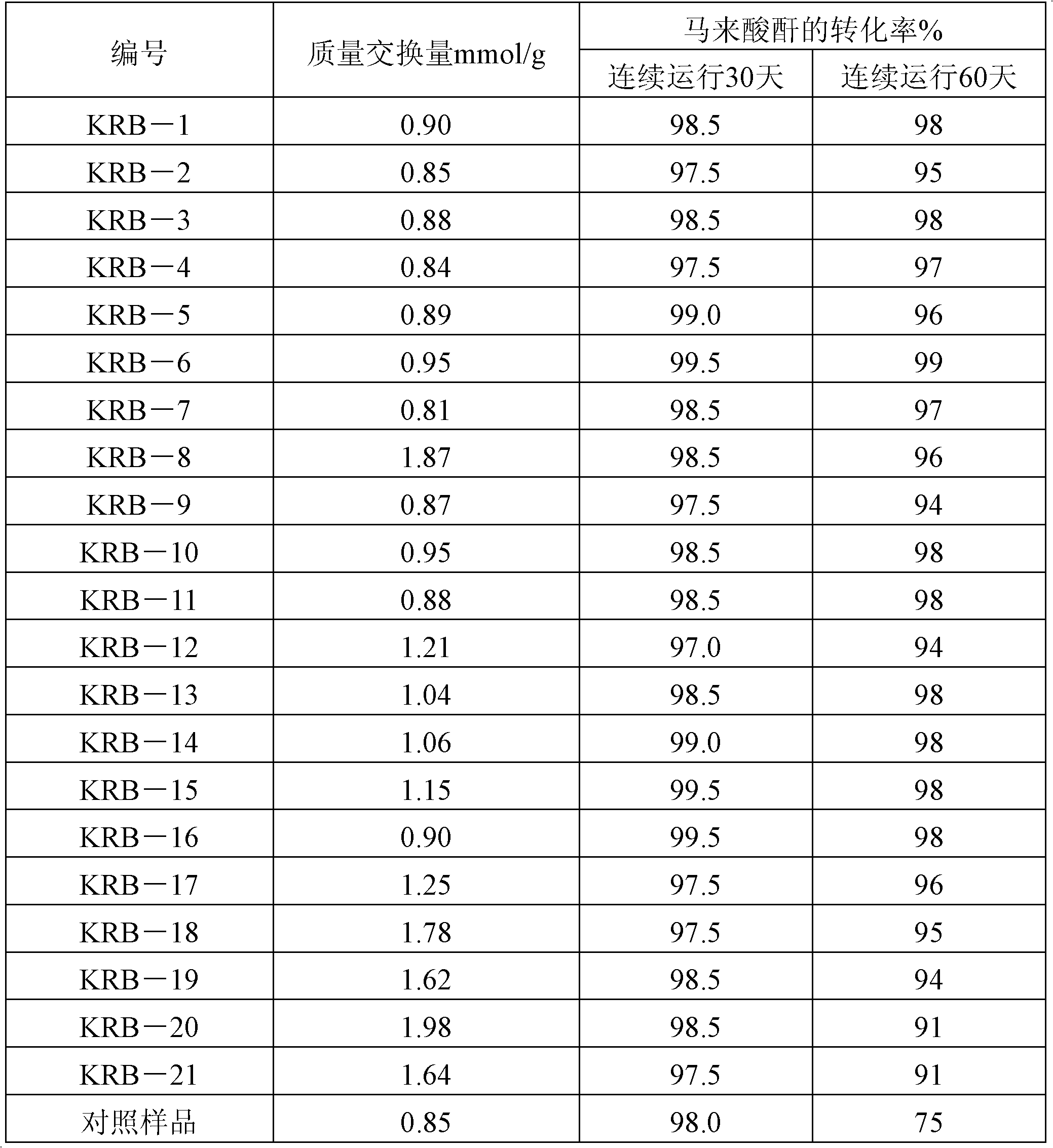

High-temperature-resistant maleic anhydride (MAH) resin catalyst and preparation method thereof

ActiveCN102319585AImprove temperature resistanceGood catalytic effectOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMaleic anhydrideTemperature resistance

The invention provides a high-temperature-resistant maleic anhydride (MAH) resin catalyst. The resin catalyst is a high-temperature-resistant strong acid cation catalyzed resin obtained by chlorinating fluorine-containing white balls obtained by copolymerizing an acrylic acid fluorine-containing monomer which has the crosslinking degree 15-30 percent and serves as a third monomer, and performing shallow sulfonation. The high-temperature-resistant MAH resin catalyst has a good catalytic effect in an MAH esterification reaction, high high-temperature resistance and long service life, and can be used at high temperature 100-140 DEG C. The invention further provides a preparation method of the catalyst.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

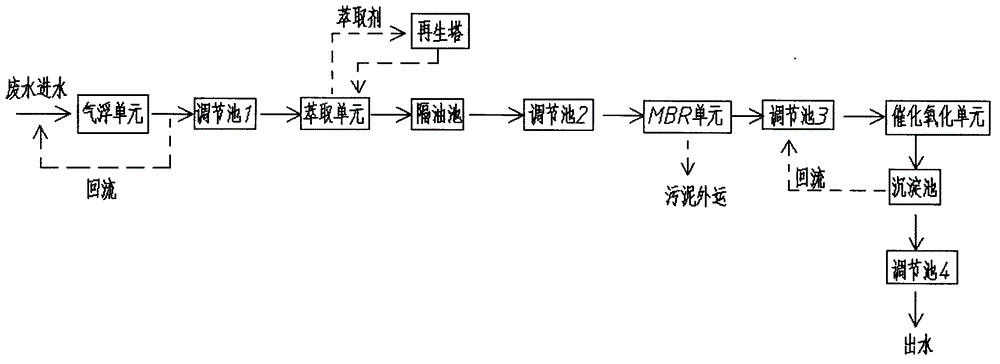

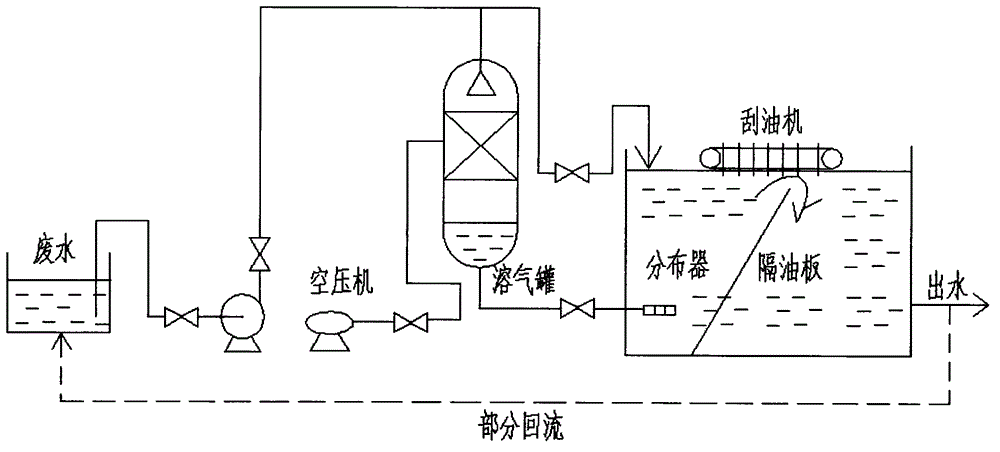

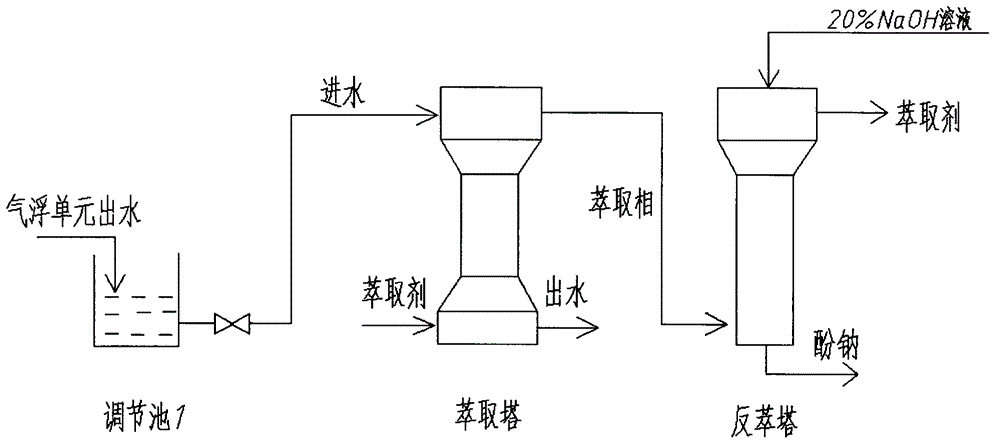

Technique for treating phenol/anisole-containing production wastewater

InactiveCN102976561ALow costGood catalytic effectMultistage water/sewage treatmentNature of treatment waterSolventChemistry

The invention discloses a technique for treating phenol / anisole-containing production wastewater, particularly a method for treating phenol / anisole-containing production wastewater by a floatation-high efficiency extraction-membrane bioreactor (MBR)-catalytic oxidation technique. The technique comprises steps as follows: raw water firstly enters a floatation unit to remove suspended substances, and then enters an extraction unit, wherein an extractant composed of N-octanoylpyrrolidine, tributyl phosphate, dimethyl carbonate and solvent kerosene in a ratio of 0.8:1.2:2.9:7 is utilized to carry out dephenolization treatment; the treated wastewater enters an MBR unit to carry out biochemical degradation of methanol; and the wastewater finally enters a sodium hypochlorite-alpha-Fe2O3 catalytic oxidation unit to remove anisole by deep oxidation. The invention provides a new technique for efficiently treating phenol / anisole-containing production wastewater; and by using the technique, the removal rates of wastewater COD (chemical oxygen demand), volatile phenols, methanol and anisole are respectively up to 99.7%, 99.99%, 99.12% and 99.97%.

Owner:TIANJIN POLYTECHNIC UNIV

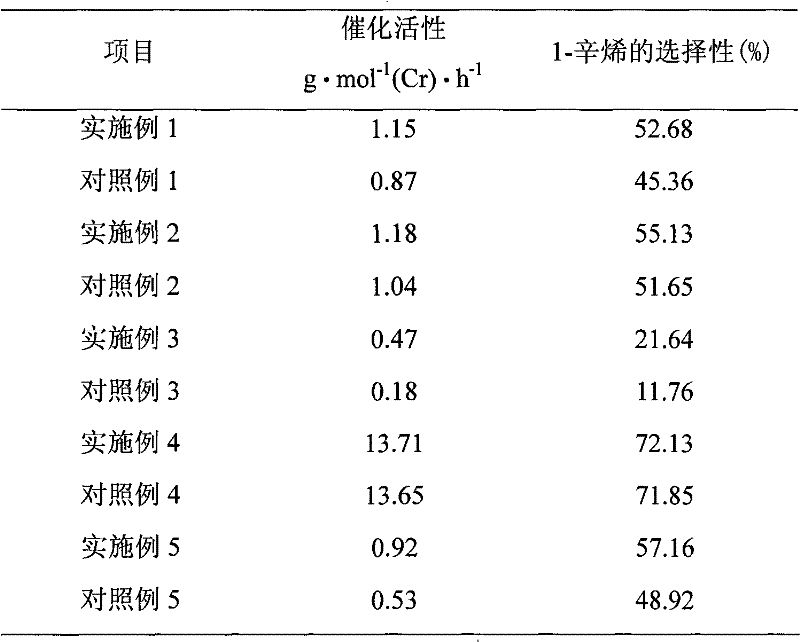

Method for preparing modification aluminoxane

InactiveCN102190678AHigh reaction yieldIncrease productivityOrganic-compounds/hydrides/coordination-complexes catalystsGroup 3/13 element organic compoundsAluminoxaneAluminium alkyl

The invention discloses a preparation method for modification aluminoxane, comprising the following steps: a) preparing an inertia solvent solution of aluminium alkyl under the protection of an inert gas; b) mixing water, a modifier and an inertia solvent to prepare a hydrolysis agent under the protection of an inert gas; c) mixing the inertia solvent solution of aluminium alkyl and the hydrolysis agent in a T-type pipe reactor at a temperature of between -10 DEG C and -50 DEG C, flowing the mixture into a kettle reactor, heating the mixture to a temperature of between 10 to 100 DEG C and reacting for 1 to 10 hours; d) obtaining a reaction solution by filtering, reducing pressure to remove the solvent to obtain alkylauminoxane. According to the method of the invention, the interacting effect of the modifier and water is utilized to control the local concentration of water and the composition and concentration of the modifier are used to influence the composition of the generated aluminoxane so as to improve the storage stability and usage effect of the alkylauminoxane.

Owner:NORTHEAST GASOLINEEUM UNIV

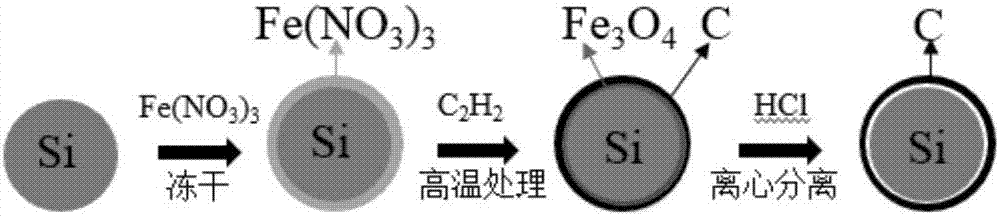

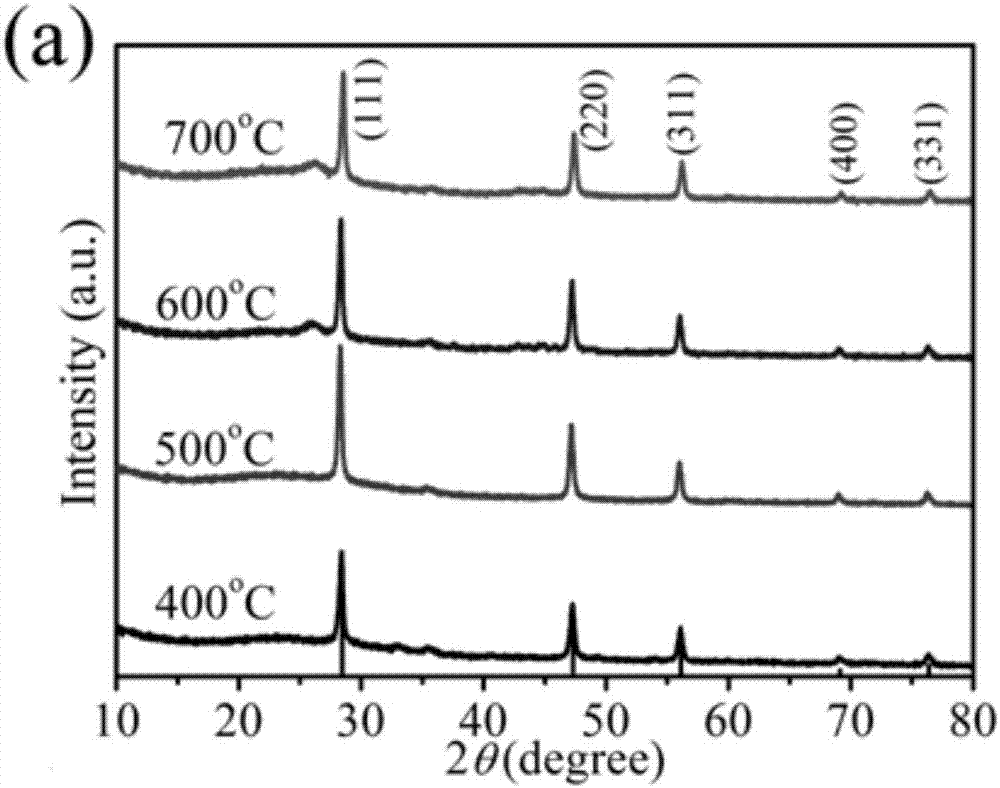

Core-shell structure Si/C material, preparation method and application

ActiveCN107248570APromote decompositionSolve the problem that it is difficult to deposit directly on the Si surfaceCell electrodesSecondary cellsCarbon coatingHigh concentration

The invention belongs to the field of lithium ion batteries and particularly relates to a preparation method of a core-shell structure Si / C material. The method comprises the following steps of (1) preparing Fe(NO3)3 solution; (2) uniformly stirring Si powder in the solution to form turbid liquid; (3) dropping liquid nitrogen into the turbid liquid to form icy Si / Fe(NO3)3; (4) carrying out vacuum freeze drying to obtain an Si / Fe(NO3)3 sample; (5) carrying out high-temperature carbon coating on the Si / Fe(NO3)3 sample to obtain Si / C powder including Fe3O4; and (6) carrying out acid pickling and drying to obtain the core-shell structure Si / C material. The invention also discloses the core-shell structure Si / C material and application thereof. The core-shell structure Si / C material prepared by the method of the invention has excellent electrochemical performance, no high-concentration acetylene and professional CVD device and higher operability and safety.

Owner:HUAZHONG UNIV OF SCI & TECH

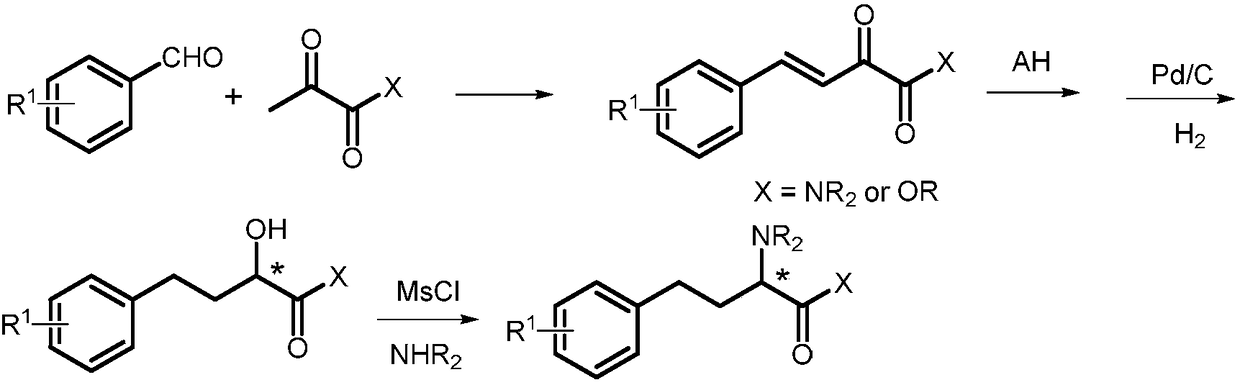

Asymmetric hydrogenation method of alpha-ketone amide compound

ActiveCN108546238AGood catalytic effectHigh catalytic efficiencyOrganic compound preparationOrganic chemistry methodsSolventIridium

The invention belongs to the field of asymmetric catalysis, and discloses an asymmetric hydrogenation method of an alpha-ketone amide compound. The asymmetric hydrogenation method comprises the following steps that under the existence of a catalyst, alkali and a solvent, an alpha-ketone-beta-alkene amide compound is subjected to reduction in the hydrogen atmosphere, and an alpha-hydroxyl-beta alkene amide compound is obtained; and the catalyst is obtained through complexing of metal iridium salt and a chiral ligand, and the chiral ligand is selected from the following compounds: (the formulasare shown in the description). The asymmetric hydrogenation method is easy to operate, high in conversion rate and selectivity and low in cost, has the advantages of being high in atom economy and environmentally friendly, and has a very good industrialized application prospect.

Owner:SHENZHEN CATALYS SCI & TECH CO LTD +1

Single-component polyurethane adhesive and preparation method thereof

ActiveCN105542700AGood storage stabilityGood catalytic effectPolyureas/polyurethane adhesivesPolyurethane adhesiveSolvent

The invention relates to a single-component polyurethane adhesive and a preparation method thereof. The single-component polyurethane adhesive comprises an adhesive and a quick-drying agent. The adhesive is prepared from 0-3% of dibasic alcohol, 15-50% of polymer polylol, 30-70% of isocyanate, 0-0.3% of catalyst, 0-25% of solvent and 0-15% of plasticizer, totaling 100%. The quick-drying agent is prepared from 1-50% of catalyst, 0-80% of solvent, 0-80% of plasticizer, 0.1-15% of silane coupling agent, 0-10% of dibasic alcohol, 0-10% of polylol and 10-20% of polymer polylol, totaling 100%. The quick-drying agent accounts for 0-10% of the adhesive. The single-component polyurethane adhesive has the advantages of high storage stability and adjustable curing speed, and can adapt to different technological conditions and operating environment temperatures.

Owner:GUANGZHOU RETAN NEW MATERIALS & HI TECH CO LTD

Synthesis method of diglycidyl 4,5-epoxycyclohexane-1,2-dicarboxylate

InactiveCN102391211AHigh activityGood catalytic effectOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSolventChemistry

The invention discloses a synthesis method of diglycidyl 4,5-epoxycyclohexane-1,2-dicarboxylate. The method is characterized by comprising the steps of: epoxidation: adding a raw material tetrahydrophthalic acid diglycidyl ester, a solvent, a quaternary ammonium phosphotungstate catalyst and alkaline phosphate into a reactor; heating to 30-80 DEG C; stirring and adding the aqueous solution of hydrogen peroxide, and reacting for 3-12 hours at 30-80 DEG C; and postprocessing: cooling the material after the reaction, standing still for layering; removing the aqueous phase; filtering the organic phase solution to obtain a filter cake, namely that recycled quaternary ammonium phosphotungstate catalyst; distilling the organic phase filtrate and recycling the solvent; and drying the remaining product to obtain a liquid product. The method disclosed by the invention is easy to operate and has the advantages of high safety, low pollution, simple postprocessing and high yield.

Owner:四川东材绝缘技术有限公司

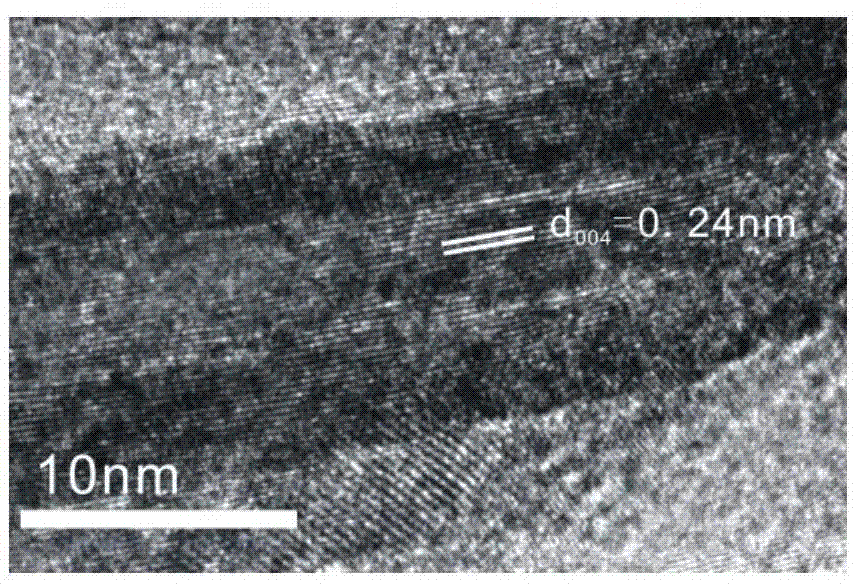

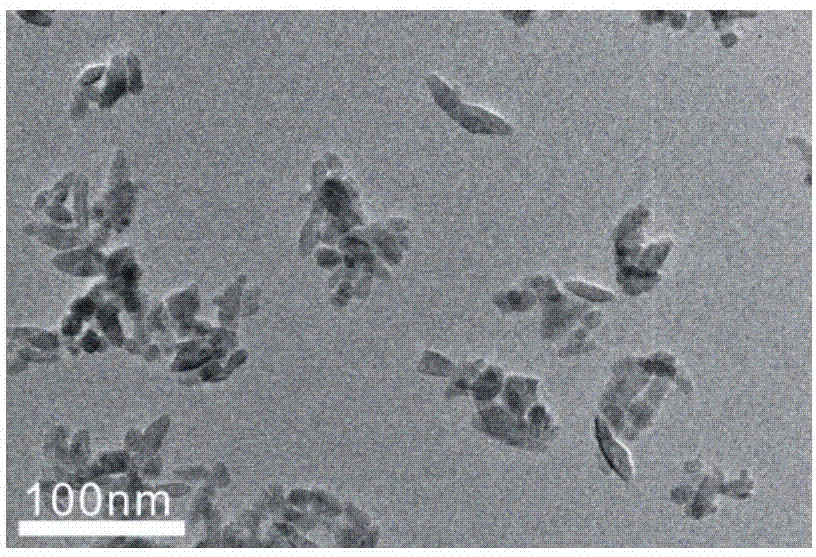

Au/TiO2 nanocrystalline catalysts and application thereof

ActiveCN104117352AGood catalytic effectOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsAir atmospherePropane

The invention relates to different morphological Au / TiO2 nanocrystalline catalysts, a catalytic application thereof in preparing epoxy propane from propylene through epoxidation, and a preparation method thereof. The preparation method comprises the following steps: first, carrying out controlled synthesis so as to obtain TiO2 nanocrystalline in two different morphologies of a main exposure (001) surface and a main exposure (100) surface, placing the TiO2 nanocrystalline in a three-mouth flask, adding a certain amount of deionized water, adding a gold precursor solution accounting for 1% of the total weight of Au-TiO2, adjusting the pH value of the solution to 7 to 10, stirring for 1 hour at a temperature of 60 DEG C; filtering and washing the obtained products until the filtrate does not carry out reactions with a AgNO3 solution (namely no precipitate is generated any more), drying for 12 hours at a temperature of 60 DEG C in vacuum, and finally burning for 2 hours at a temperature of 400 DEG C in an air atmosphere so as to obtain the catalysts. The serial catalysts have excellent activity and selectivity in catalyzing propylene epoxidation reactions to prepare epoxy propane. The preparation method is simple, no harmful byproduct is generated, and the obtained catalysts can increase the conversion rate of propylene.

Owner:UNIV OF SCI & TECH OF CHINA

Method for preparing active carbon with developed mesopores by using coal

InactiveCN108439399ASolve the problem of low mesoporosityHigh porosityCarbon compoundsActivated carbonNitrate

The invention discloses a method for preparing active carbon with developed mesopores by using coal. The method comprises: preparing coal by using weakly caking coal and gas coal as raw materials, andcrushing to obtain raw material coal; carrying out briquetting molding on the raw material coal, and granulating to obtain coal particles; carrying out oxidization treatment and carbonization treatment on the coal particles to obtain a carbonized material; and immersing the carbonized material by using a nitrate solution, drying the immersed carbonized material, and carrying out activation treatment to obtain active carbon. According to the present invention, the active carbon is prepared by using a certain amount of the weakly caking coal and the gas coal, such that the properties and the matching effect of the raw materials are well combined; compared to the traditional coal-based briquetting active carbon, the active carbon product of the present invention has the effectively-improvedmesoporosity under the action of the immersing with the nitrate; and with the method, the problem that the mesoporosity is low due to the complete application of coal as the raw material in the production of the traditional coal-based briquetting active carbon is solved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

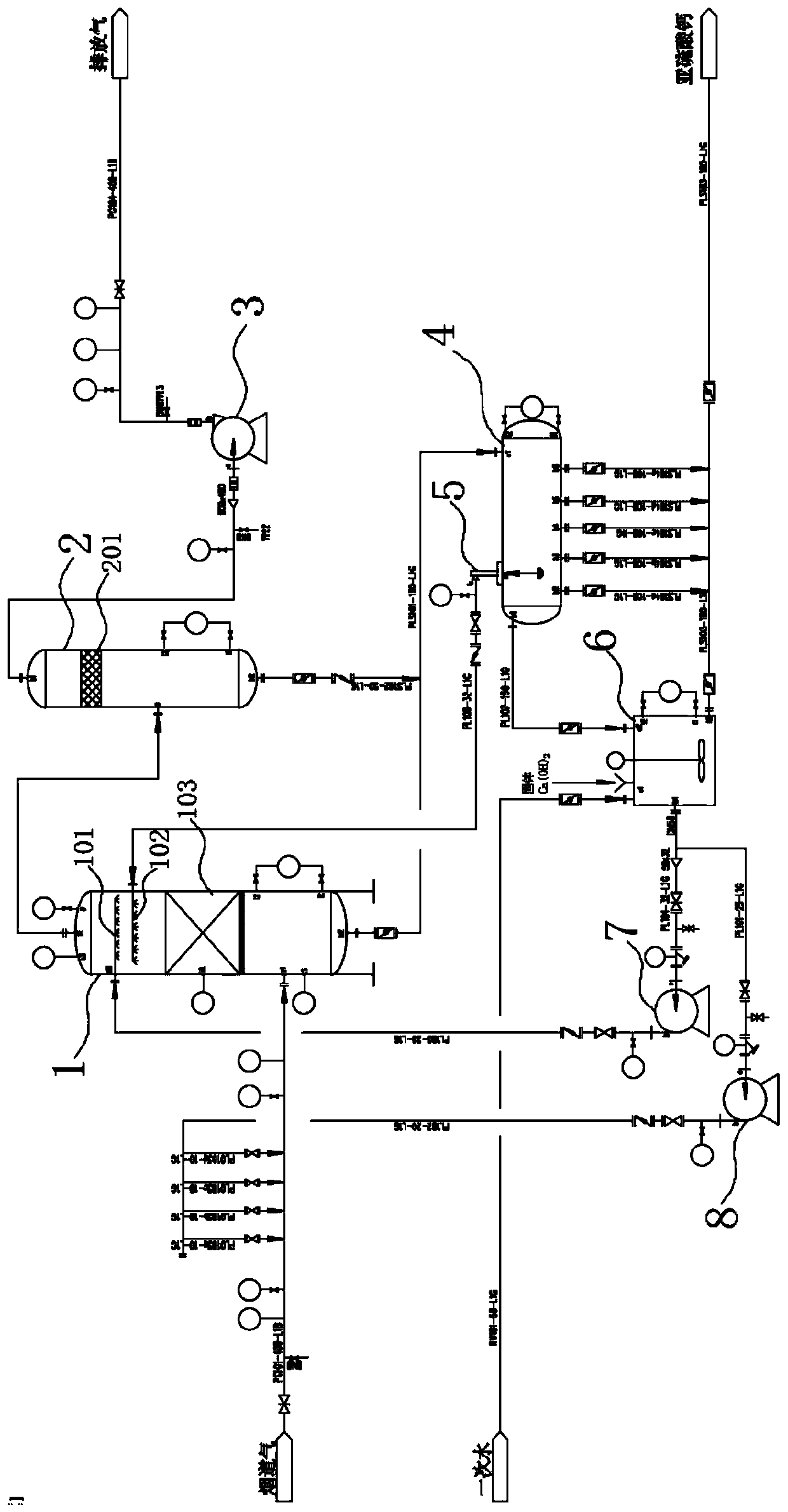

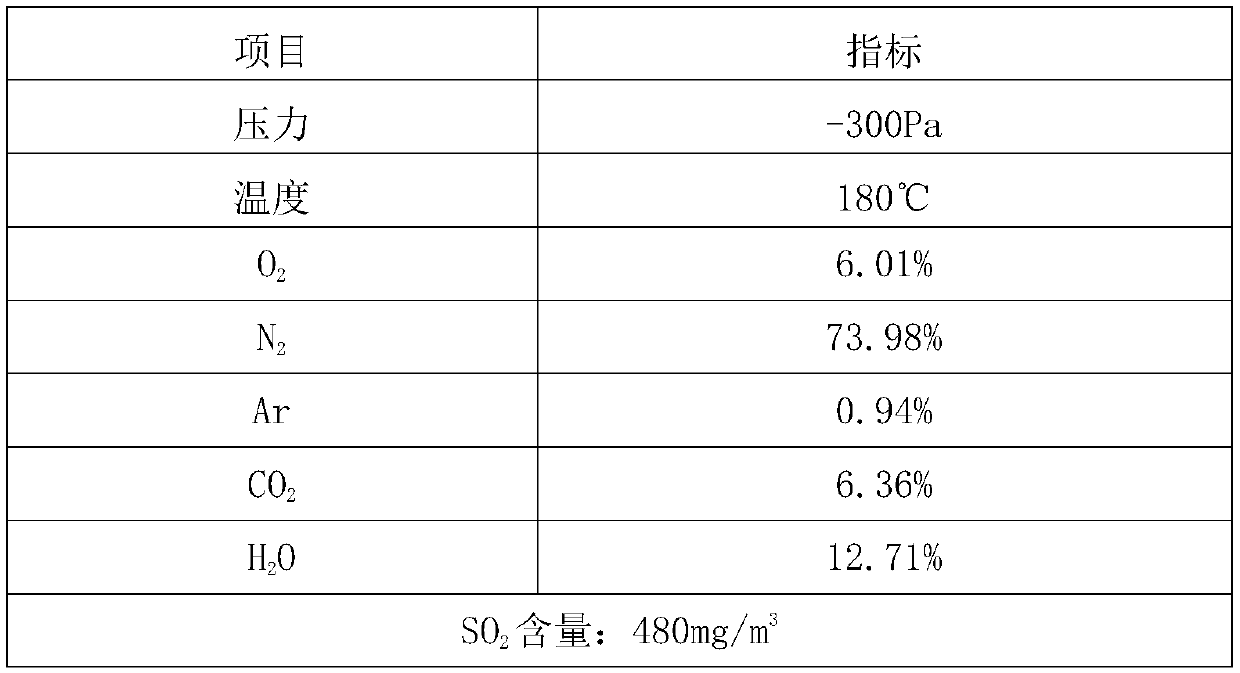

Flue gas adsorption catalytic reaction high-precision desulfurization method

InactiveCN110585919AOptimize mass transfer channelsBalanced Partial Pressure HighGas treatmentDispersed particle separationFlueExhaust gas

The invention discloses a flue gas adsorption catalytic reaction high-precision desulfurization method. The method comprises the following steps: A, pretreating flue gas and cooling; B, enabling the cooled flue gas to flow through an adsorption catalyst solid bed layer arranged in a desulfurization tower; then introducing alkali liquor into the desulfurization tower, and enabling the alkali liquorto flow through the adsorption catalyst solid bed layer, and carrying out a reaction with gas molecules adsorbed in the adsorption catalyst solid bed layer; C, carrying out solid-liquid separation onthe desulfurization solution to obtain a clear solution and a solid phase; D, allowing one part of the clear liquid to return to the desulfurization tower, swashing the adsorption catalyst solid bedlayer, and regenerating the adsorption catalyst solid bed layer; and supplementing an alkali into the other part of the clear liquid to adjust the pH, and then feeding the other part of the clear liquid into the desulfurization tower for recycling as alkali liquor; and E, carrying out gas-liquid separation to remove a liquid phase in the desulfurized flue gas, and thus obtaining exhaust gas. The method has the advantages that deep desulfurization of sulfur dioxide gas in the flue gas is realized, and the production process is simplified.

Owner:宋强

Uses of ionic liquid as catalyst in preparation of liquid crystal polyester, and liquid crystal polyester preparation method

Owner:KINGFA SCI & TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com