Preparation method of sulfur doped Ni-Fe hydroxide nano-film catalyst for decomposing water to produce oxygen

A technology of hydroxide and nano-film, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effect of low cost, good catalytic effect and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Mix the following raw materials evenly to prepare electrodeposition solution:

[0030]

[0031]

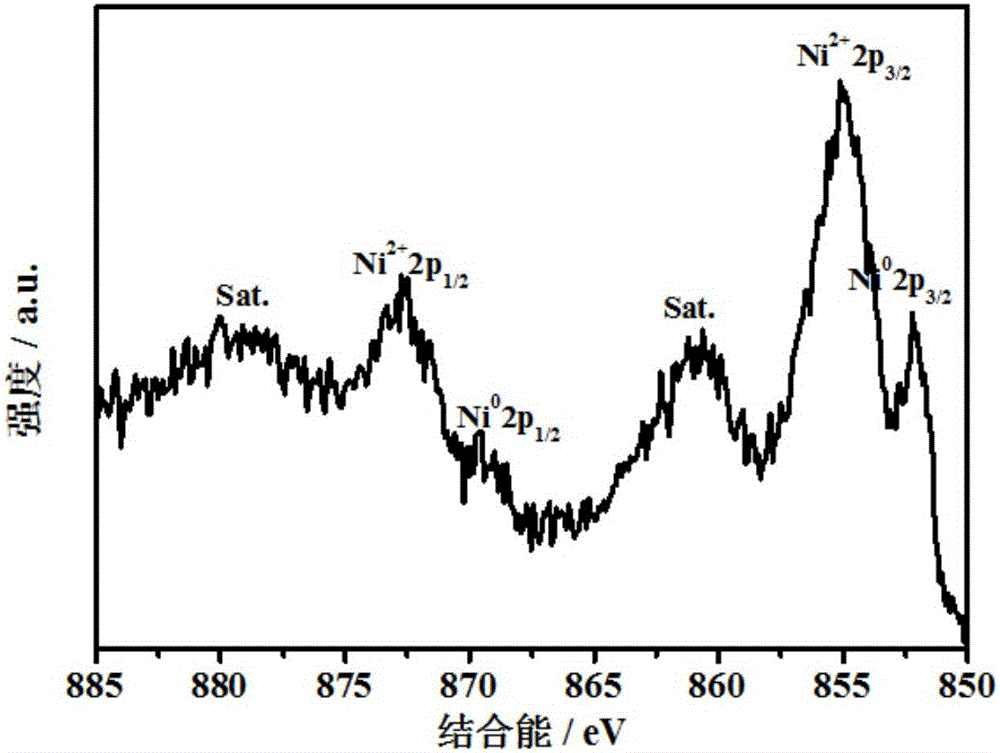

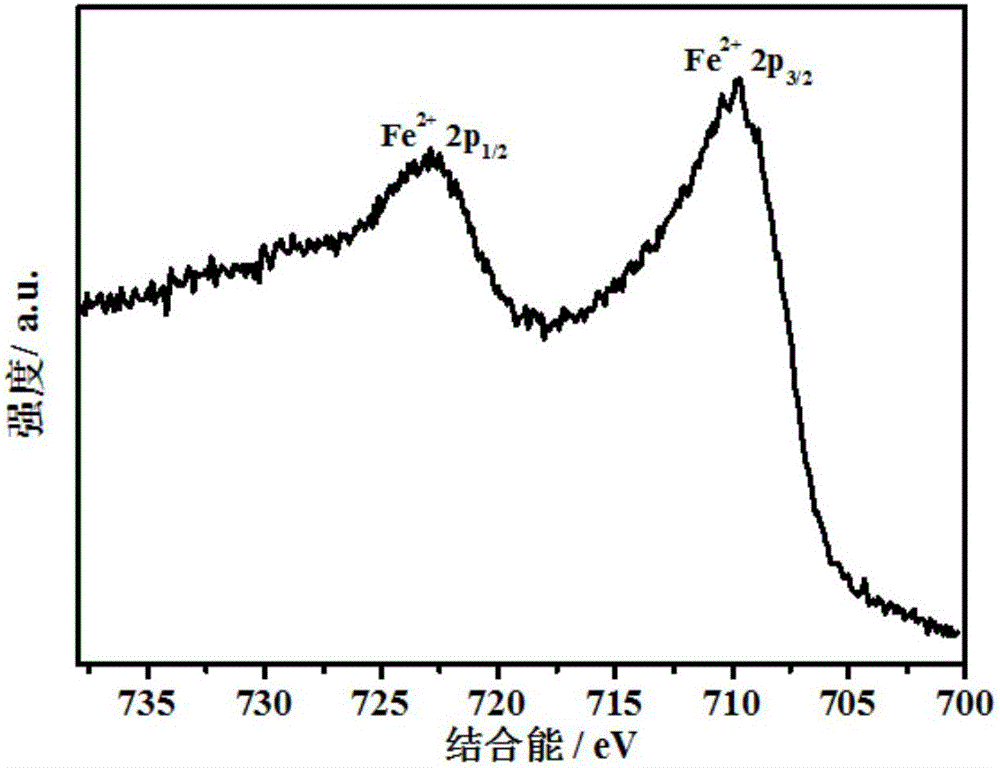

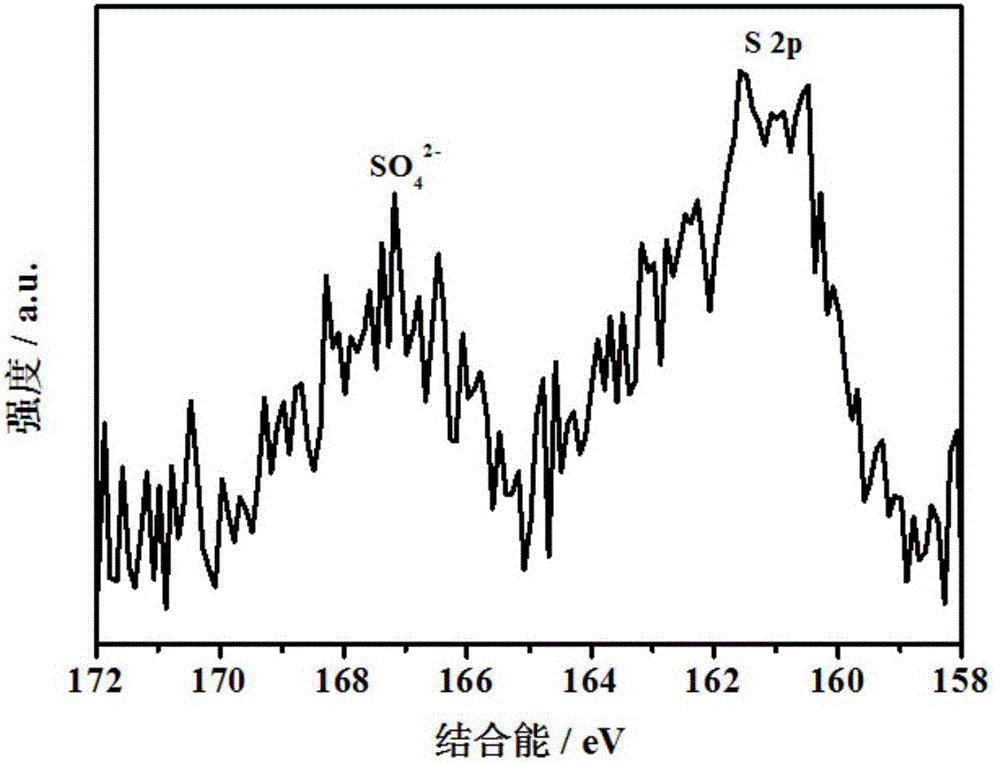

[0032] 2. Take the nickel foam substrate as the working electrode, the carbon rod as the counter electrode, and the Ag / AgCl electrode (3mol / L KCl) as the reference electrode, put it into the electrodeposition solution prepared in step 1, and conduct electrodeposition by cyclic voltammetry. The scanning range is -1.2~0.2V, the scanning rate is 5mV / s, and the cycle is 25 times, and the sulfur-doped Ni-Fe hydroxide nano-film catalyst is directly deposited on the surface of the nickel foam substrate. Depend on Figure 1~4 It can be seen that the nanofilm deposited on the surface of nickel foam contains Ni, Fe, S and O elements, and the XPS spectrum is calibrated by the C 1s (284.8eV) standard, in which Ni and Fe mainly exist in divalent forms, while S is mainly sulfur Urea decomposes to form sulfate and sulfur, which proves that the prepared nano-film is Ni-Fe hydroxi...

Embodiment 2

[0034] 1. Mix the following raw materials evenly to prepare electrodeposition solution:

[0035]

[0036] 2. Take the nickel foam substrate as the working electrode, the carbon rod as the counter electrode, and the Ag / AgCl electrode (3mol / L KCl) as the reference electrode, put it into the electrodeposition solution prepared in step 1, and conduct electrodeposition by cyclic voltammetry. The scanning range is -1.4~0V, the scanning rate is 10mV / s, and the cycle is 40 times, and the sulfur-doped Ni-Fe hydroxide nano-film catalyst is directly deposited on the surface of the nickel foam substrate.

Embodiment 3

[0038] 1. Mix the following raw materials evenly to prepare electrodeposition solution:

[0039]

[0040]

[0041] 2. Take the nickel foam substrate as the working electrode, the carbon rod as the counter electrode, and the Ag / AgCl electrode (3mol / L KCl) as the reference electrode, put it into the electrodeposition solution prepared in step 1, and conduct electrodeposition by cyclic voltammetry. The scanning range is -1 to 0.3V, the scanning rate is 15mV / s, and the cycle is 50 times, and the sulfur-doped Ni-Fe hydroxide nano-film catalyst is directly deposited on the surface of the nickel foam substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com