Flue gas adsorption catalytic reaction high-precision desulfurization method

A technology for adsorption catalysis and flue gas, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of technical operation cost, high investment, limited adsorption capacity of adsorbent, and difficulty in realizing continuous production, etc. Adsorption catalytic reaction function, complete reaction, and the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

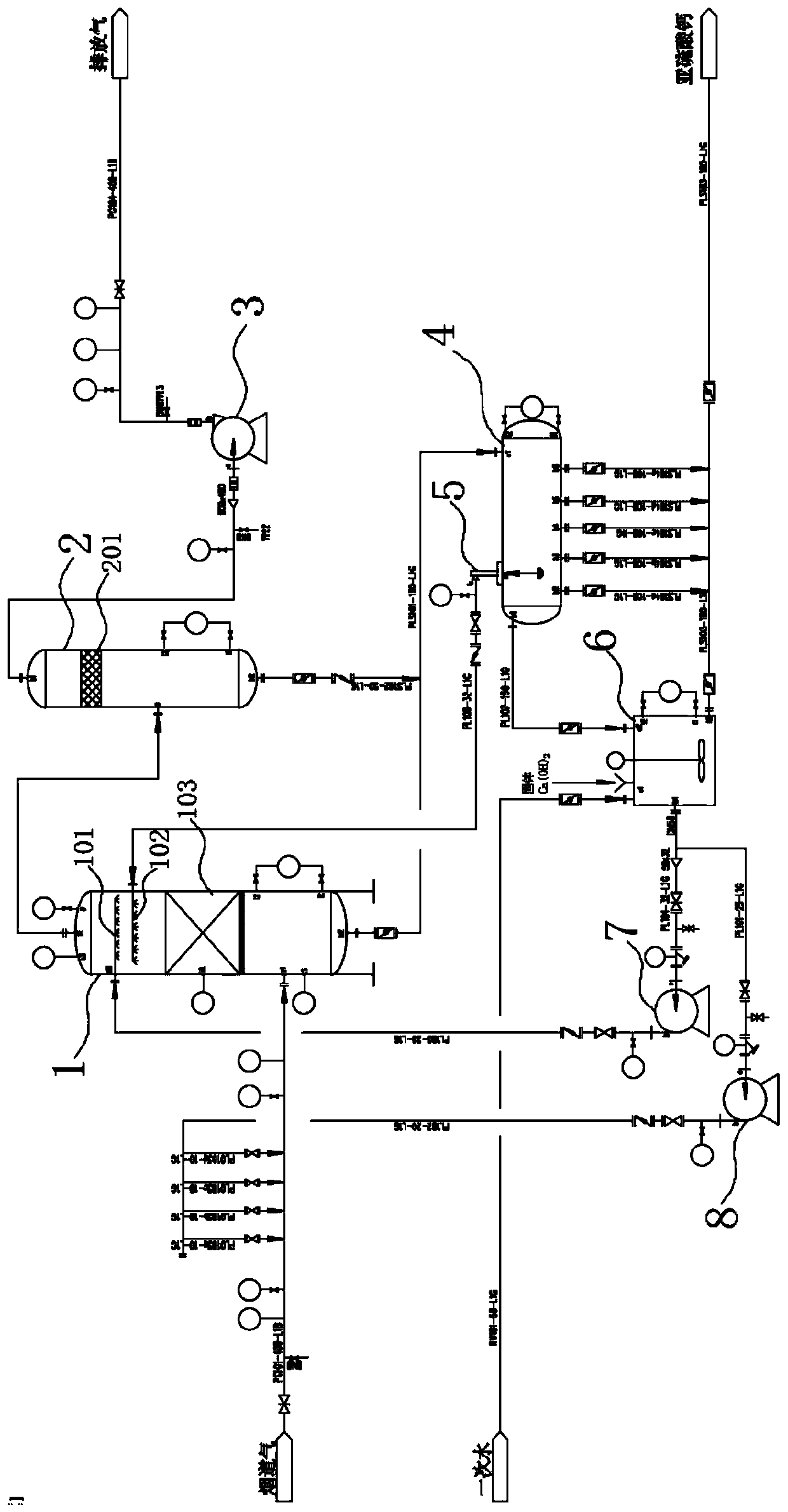

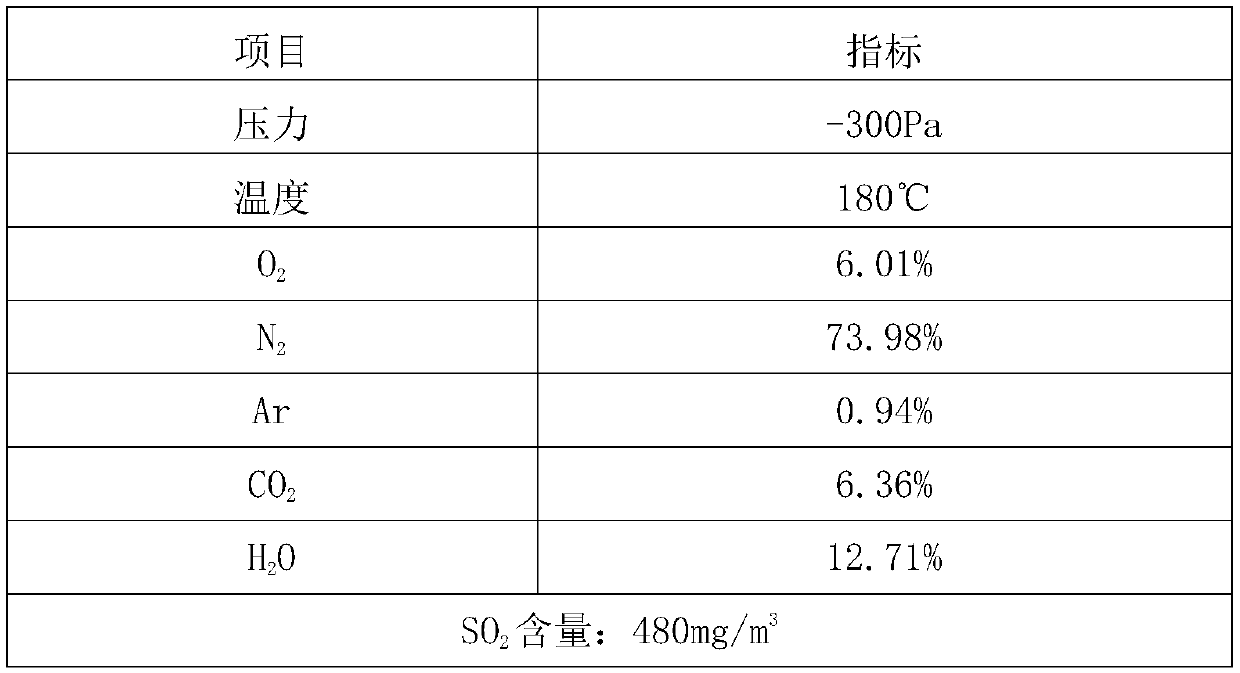

[0035] Follow the steps below to treat the above flue gas:

[0036] S1. The flue gas from the flue gas main pipe enters the flue gas pipe under the action of the induced draft fan 3, and the flue gas flow rate is 3500m 3 / h. At the same time, the prepared alkaline spray water is pumped through the circulating cooling pump 8 into the flue gas pipeline to spray and cool the high-temperature flue gas, so as to cool down the flue gas and complete the process of preliminary desulfurization and dust collection at the same time. It is measured that the flue gas temperature drops to 58°C before entering the desulfurization tower.

[0037] S2. After the flue gas is cooled, it enters the desulfurization tower, and the desulfurization tower is provided with an adsorption catalyst solid bed 103. The adsorption catalyst filled in the adsorption catalyst solid bed 103 is based on pseudo-boehmite, aluminum magnesium silicon Salt as an auxiliary material after roasting, then loaded CuO, LiO, ...

Embodiment 2

[0044] Follow the steps below to treat the above flue gas:

[0045] S1. The flue gas from the flue gas main pipe enters the flue gas pipe under the action of the induced draft fan 3, and the flue gas flow rate is 8600m 3 / h. At the same time, the prepared alkaline spray water is pumped through the circulating cooling pump 8 into the flue gas pipeline to spray and cool the high-temperature flue gas, so as to cool down the flue gas and complete the process of preliminary desulfurization and dust collection at the same time. It is measured that the flue gas temperature drops to 62°C before entering the desulfurization tower.

[0046] S2. After the flue gas is cooled, it enters the desulfurization tower, and the desulfurization tower is provided with an adsorption catalyst solid bed 103. The adsorption catalyst filled in the adsorption catalyst solid bed 103 is based on pseudo-boehmite, aluminum magnesium silicon Salt as an auxiliary material after roasting, then loaded CuO, LiO...

Embodiment 3

[0053] Follow the steps below to treat the above flue gas:

[0054] S1. The flue gas from the flue gas main pipe enters the flue gas pipe under the action of the induced draft fan 3, and the flue gas flow rate is 11200m 3 / h. At the same time, the prepared alkaline spray water is pumped through the circulating cooling pump 8 into the flue gas pipeline to spray and cool the high-temperature flue gas, so as to cool down the flue gas and complete the process of preliminary desulfurization and dust collection at the same time. It is measured that the flue gas temperature drops to 57°C before entering the desulfurization tower.

[0055] S2. After the flue gas is cooled, it enters the desulfurization tower, and the desulfurization tower is provided with an adsorption catalyst solid bed 103. The adsorption catalyst filled in the adsorption catalyst solid bed 103 is based on pseudo-boehmite, aluminum magnesium silicon Salt as an auxiliary material after roasting, then loaded CuO, Li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com