Patents

Literature

688 results about "Treatment quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quality treatment programs offer a full range of services which have been shown to be effective in treatment and recovery from addiction.

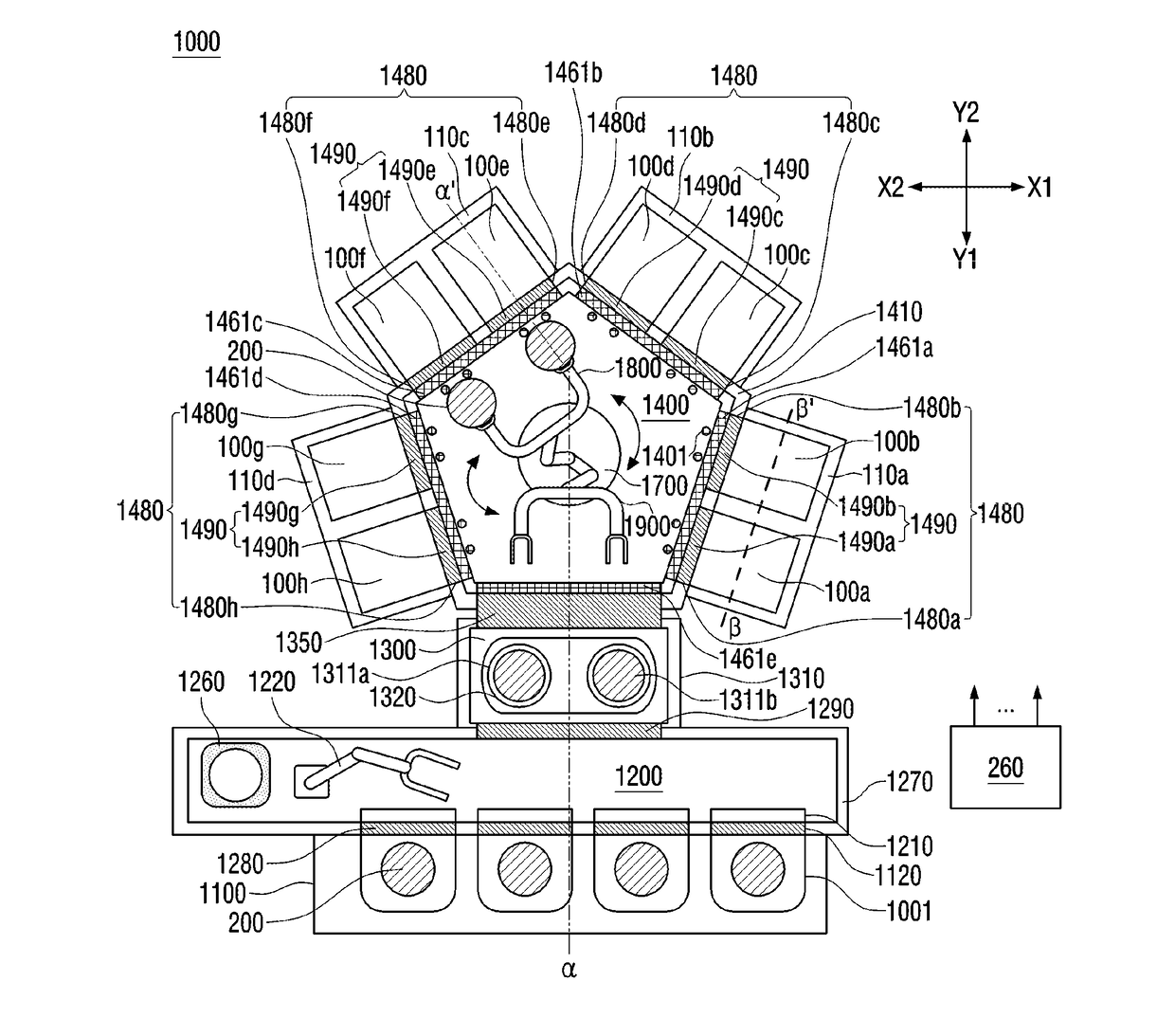

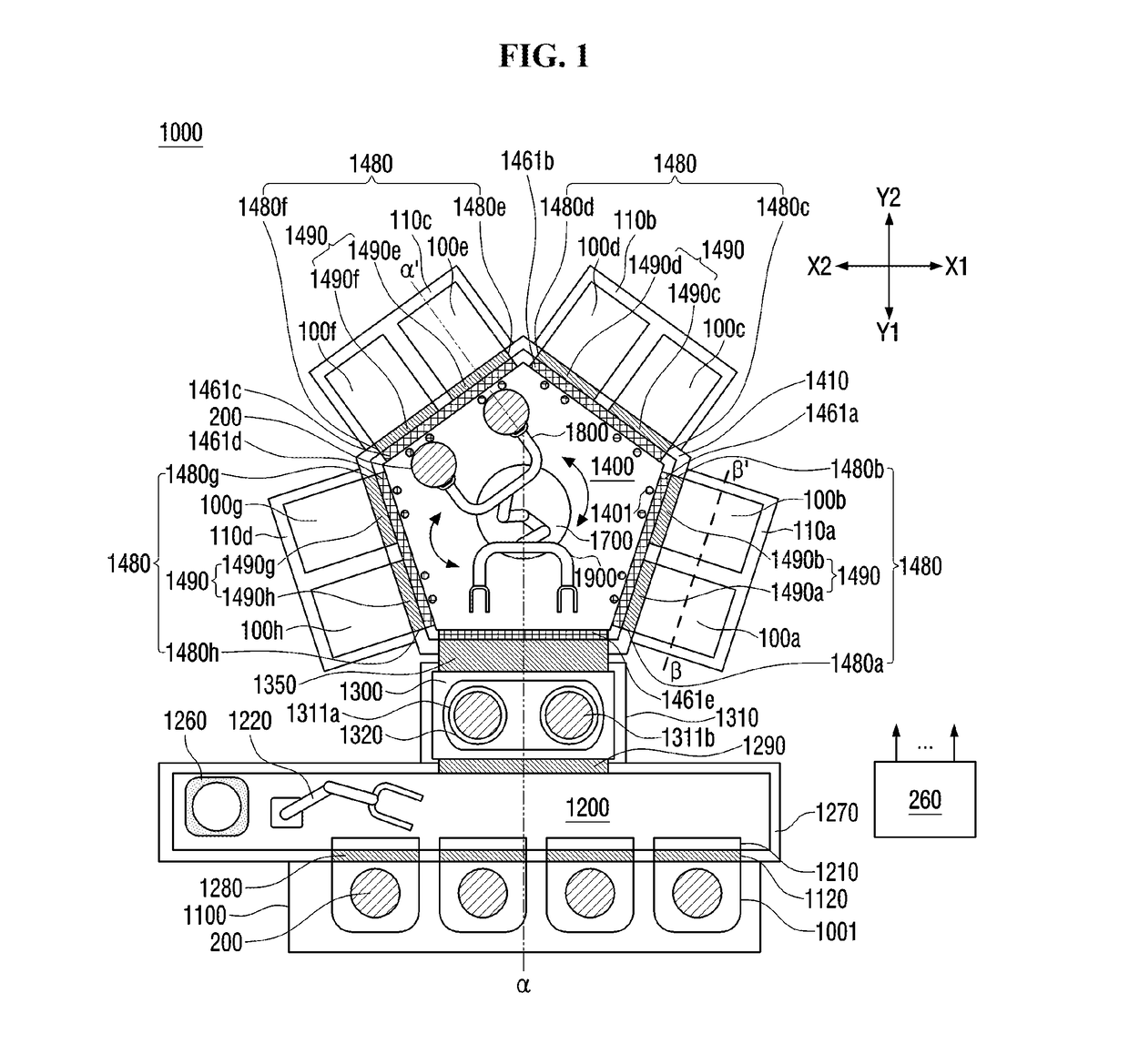

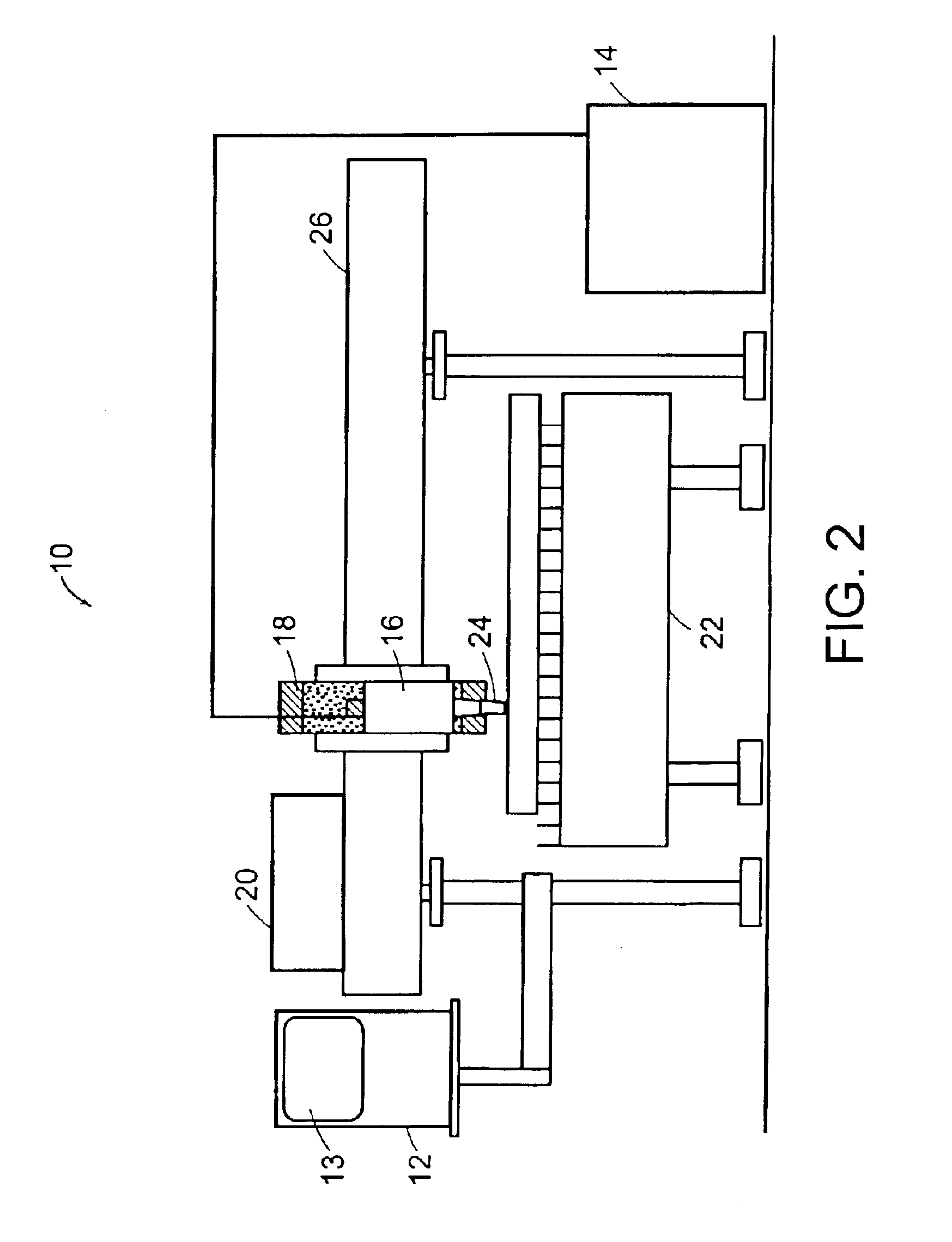

Substrate processing apparatus

ActiveUS20170253968A1Quality improvementSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringGas supply

Described herein is a technique that can improve a quality of substrate processing. A substrate processing apparatus may include: a plurality of processing chambers; a vacuum transfer chamber; a plurality of transfer chambers; a plurality of gate valves; a plurality of first gas supply units configured to supply an inert gas to a substrate; a transfer robot; and a control unit configured to control the plurality of first gas supply units and the transfer robot to: supply the inert gas to the substrate at a first flow rate when a distance between a gas supply port and the substrate passing through the plurality of gate valves is a first distance; and supply the inert gas to the substrate at a second flow rate greater than the first flow rate when the distance between the gas supply port and the substrate is a second distance greater than the first distance when the substrate passes through the plurality of gate valves.

Owner:KOKUSA ELECTRIC CO LTD

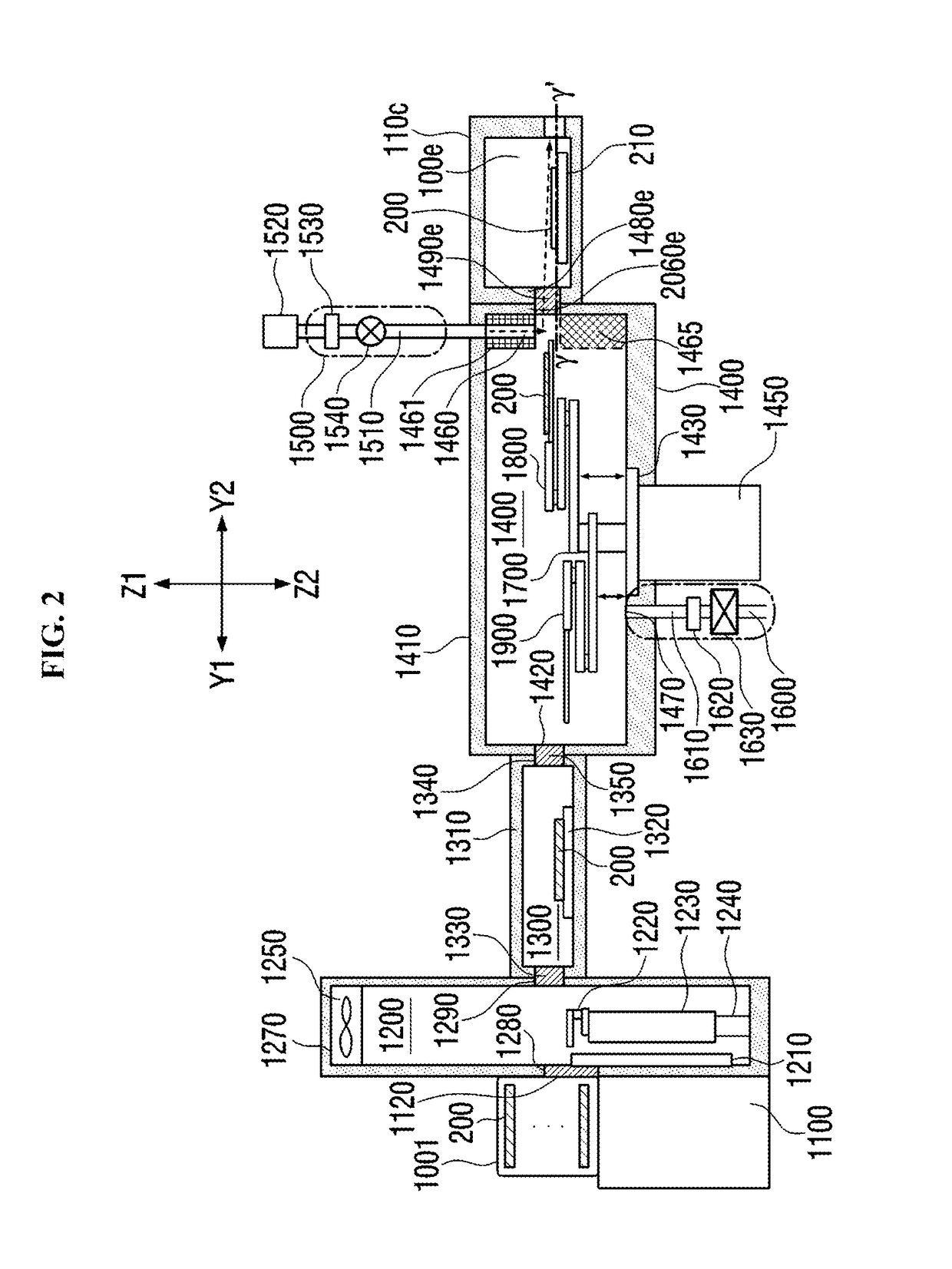

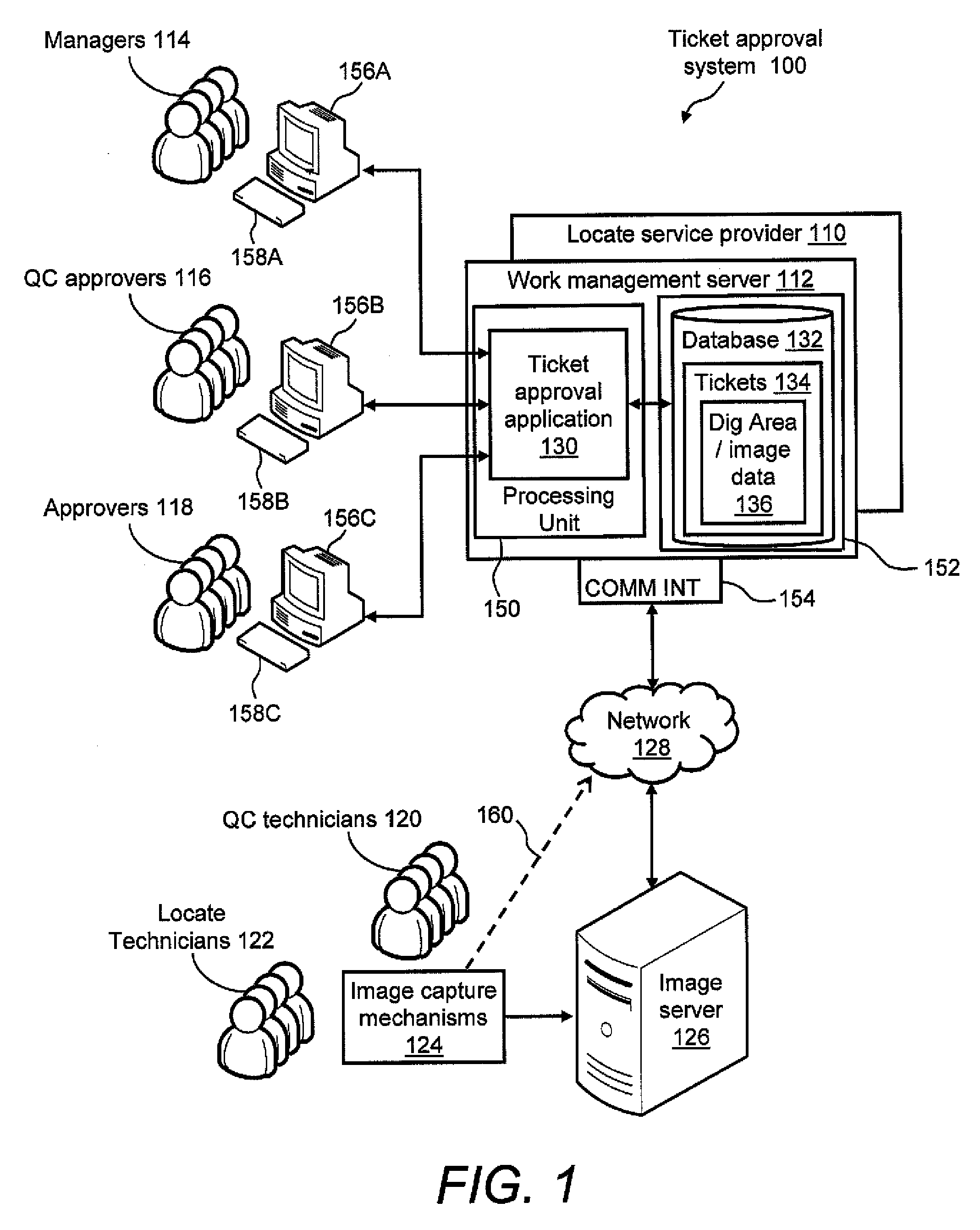

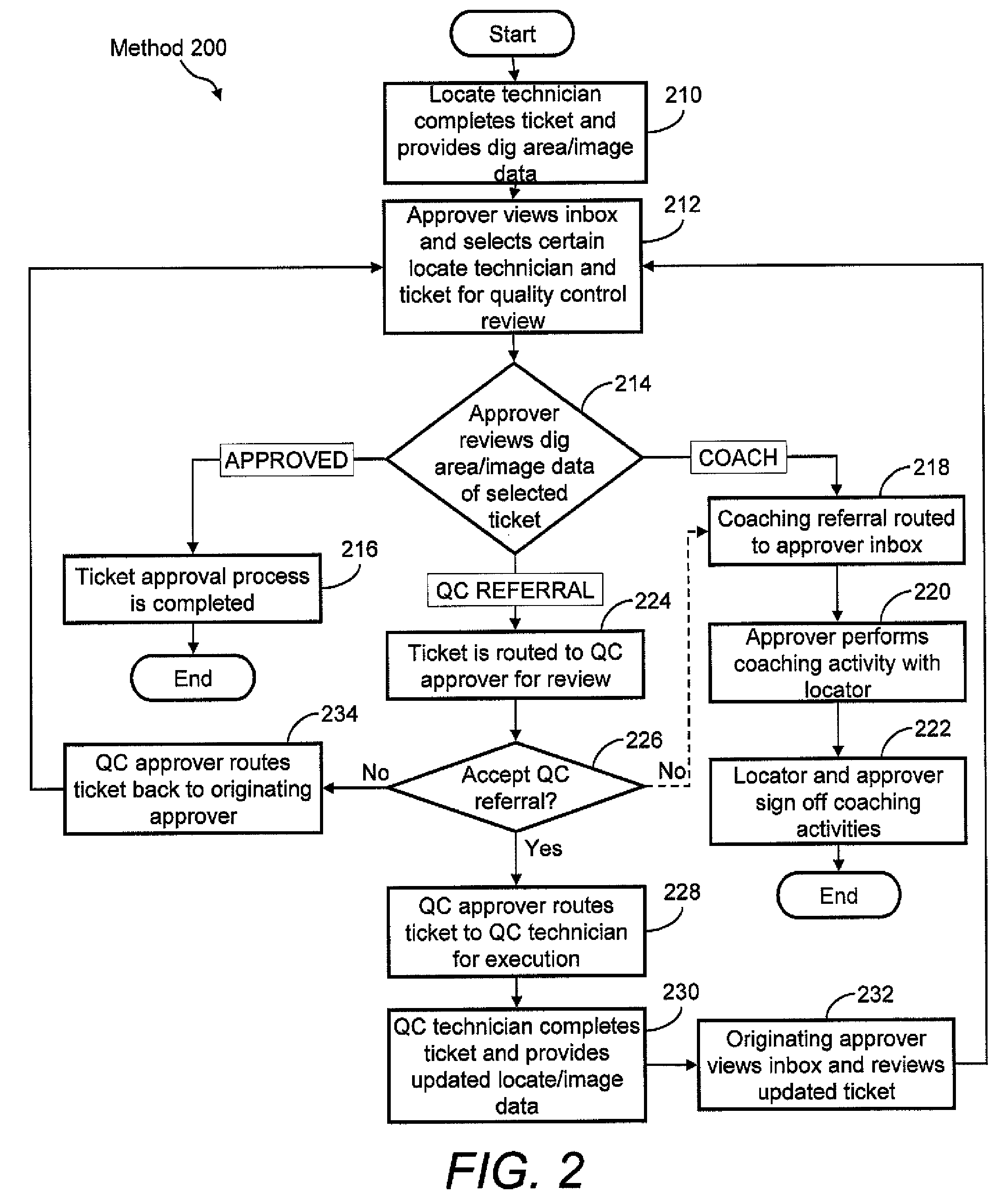

Ticket approval system for and method of performing quality control in field service applications

Methods and apparatus for facilitating a quality assessment of a locate and marking operation. Ticket information and a locate manifest are received regarding the operation as performed by a technician. One or more electronic indications of the quality assessment are processed based on the locate manifest, the ticket information, and at least one of: a time required to complete the locate and marking operation; a time at which the locate and marking operation was performed; a cost of the locate and marking operation; one or more conditions associated with a dig area in which the operation was performed; a number of facilities to be located as indicated in the ticket information; a discrepancy between the facilities to be located as indicated in the ticket information, but not indicated as marked in the locate manifest; and an efficiency with which the technician performed the locate and marking operation.

Owner:CERTUSVIEW TECH LLC

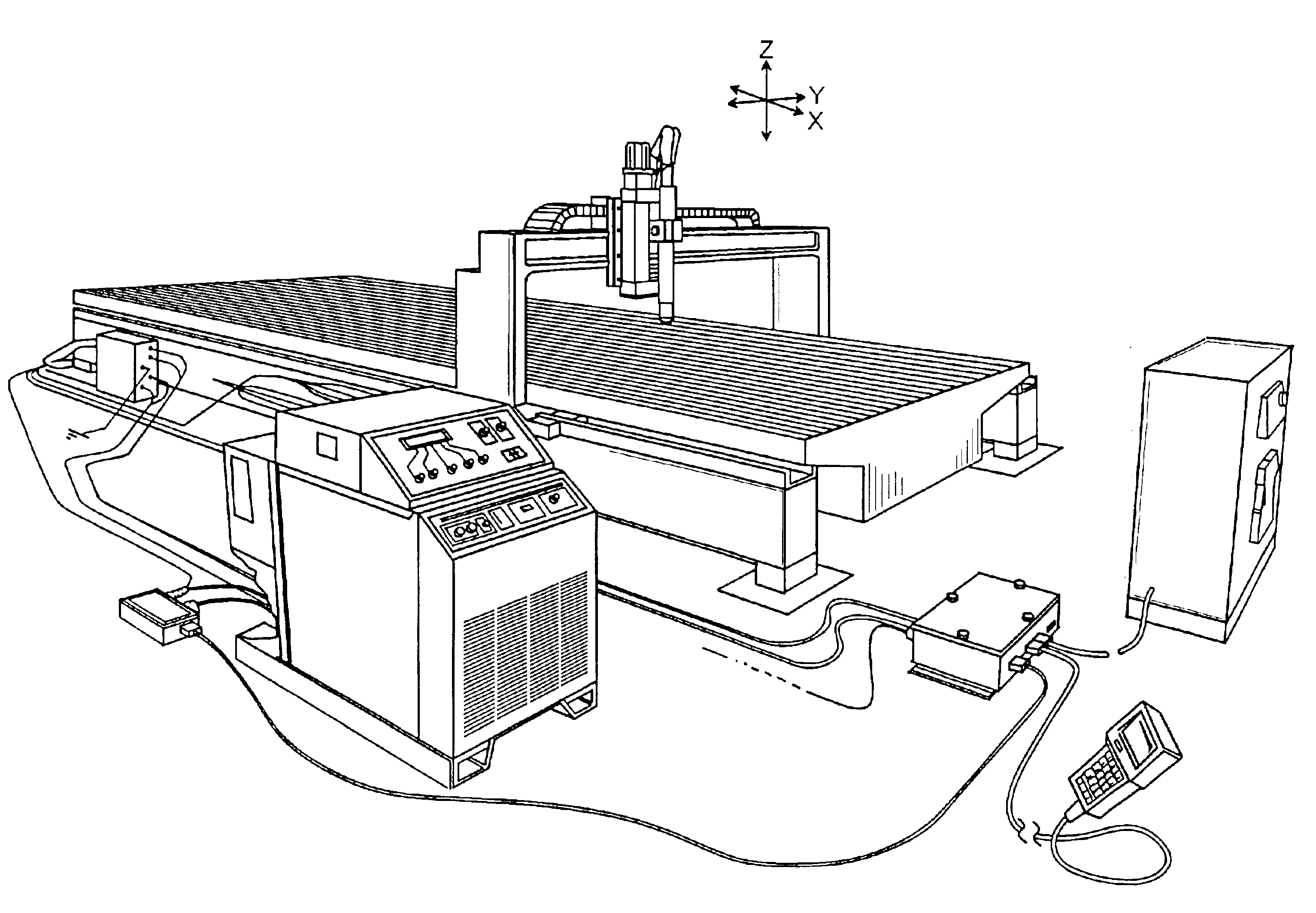

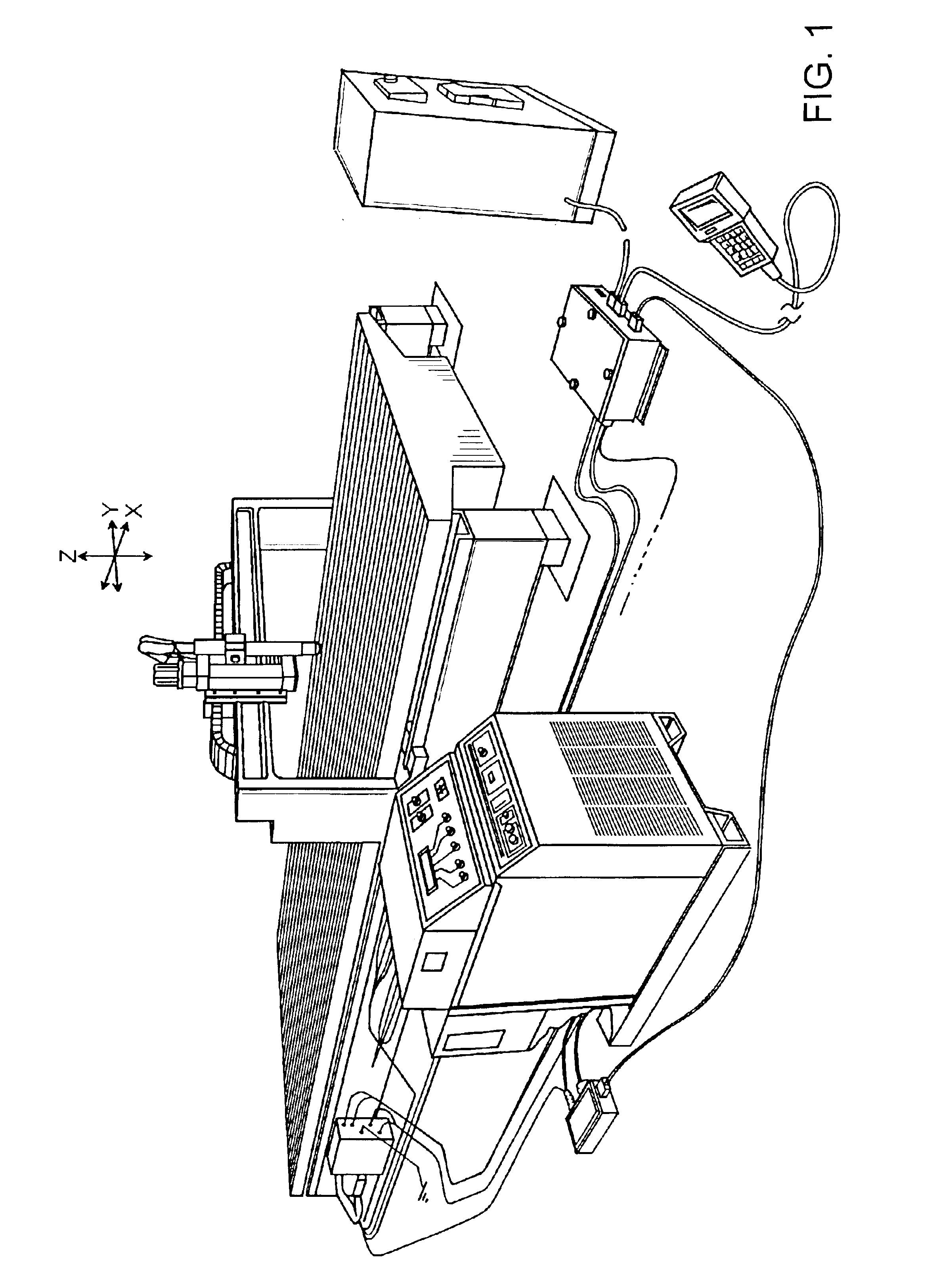

Centralized control architecture for a laser materials processing system

InactiveUS6947802B2Welding/cutting auxillary devicesArc welding apparatusHandling systemMaterials processing

Apparatus, systems, and methods for monitoring the processing of a workpiece that includes directing an incident laser beam onto the workpiece and using an optical detector for measuring a signal emitted from the workpiece as a result of the incident laser beam. The detector generates at least two signals based upon the optical signal. The method also involves use of a light source monitor in determining workpiece processing quality based upon the quotient of the two outputs as well as a magnitude of one of the two quotients.

Owner:HYPERTHERM INC

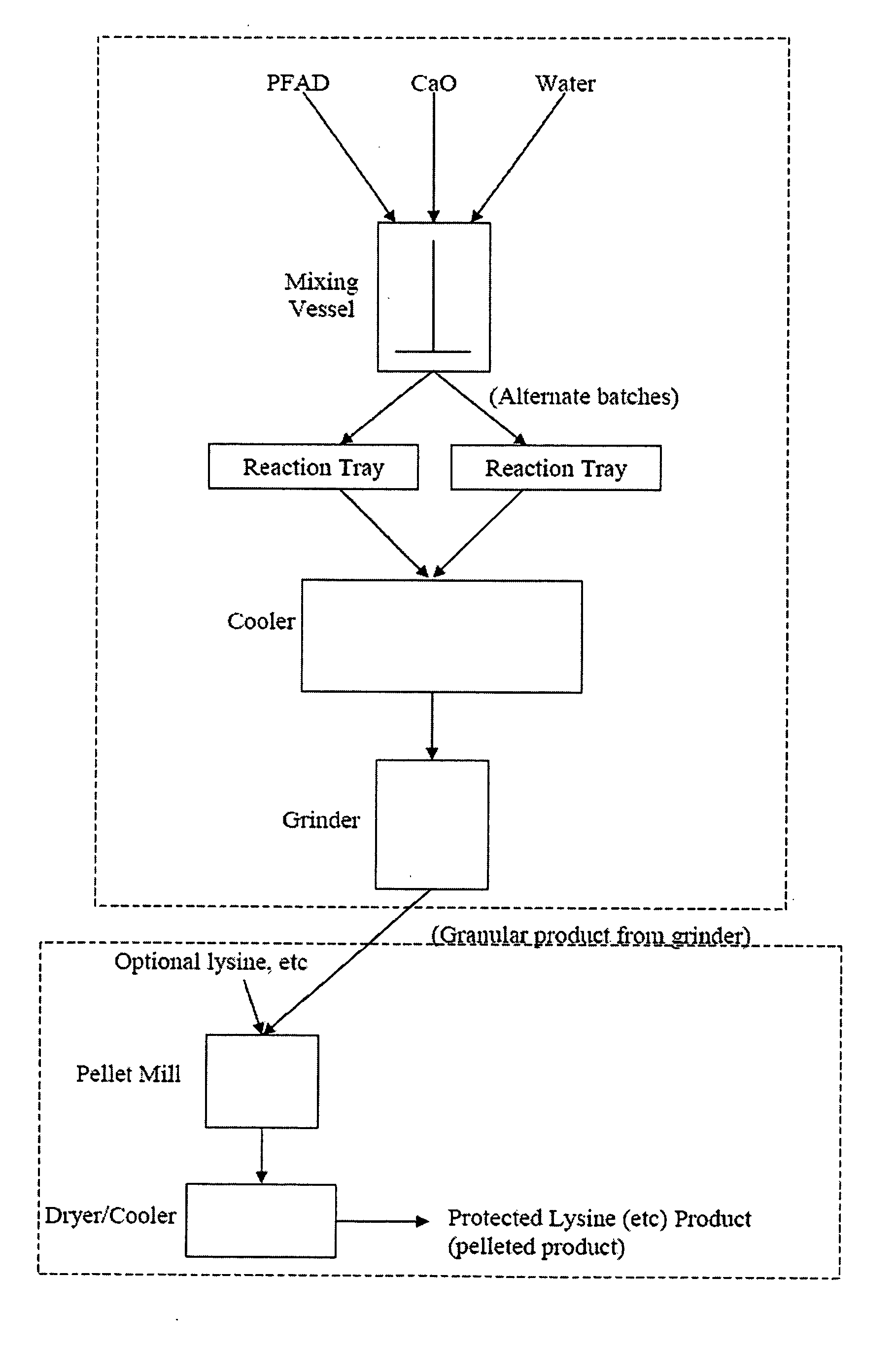

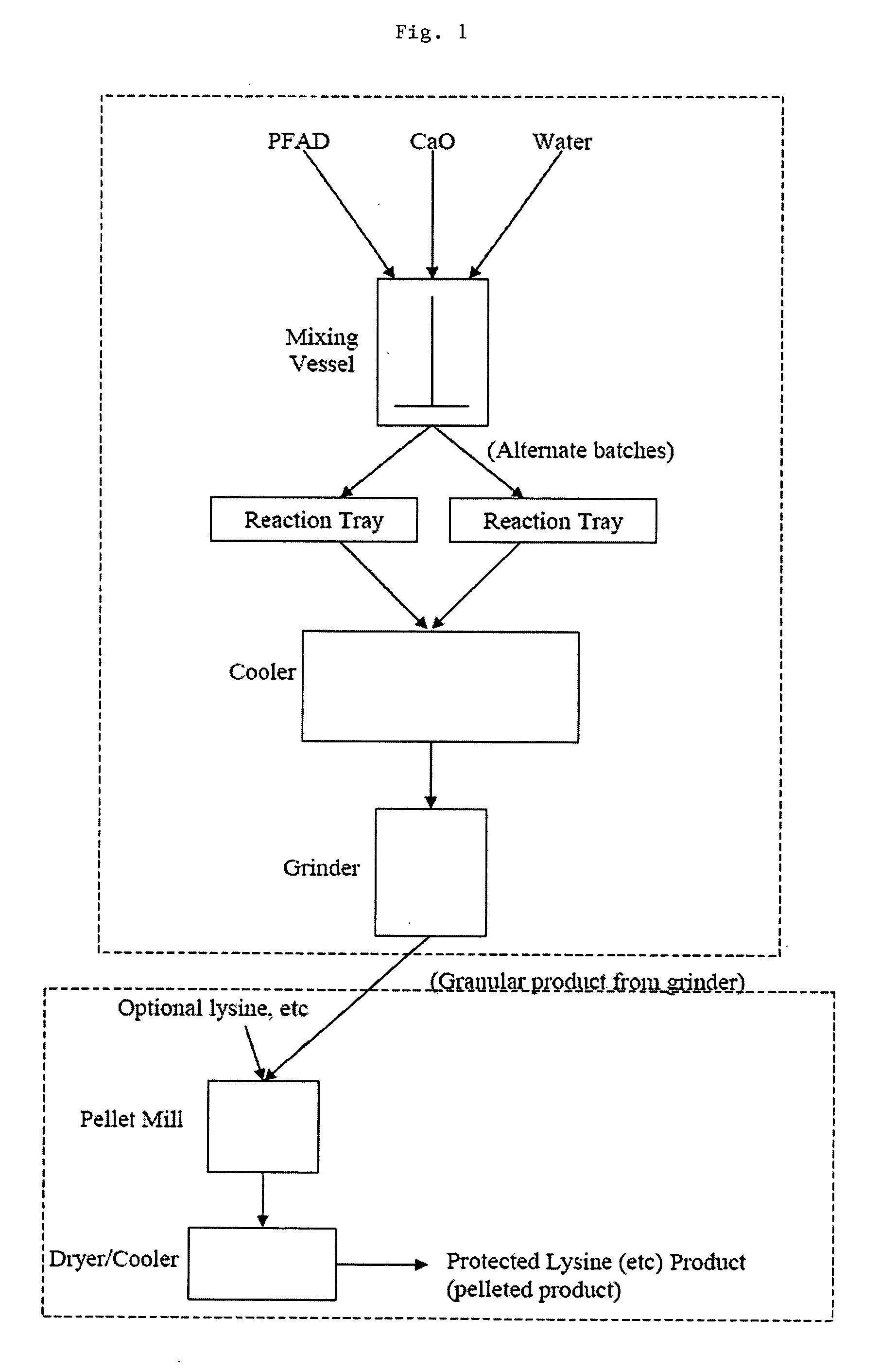

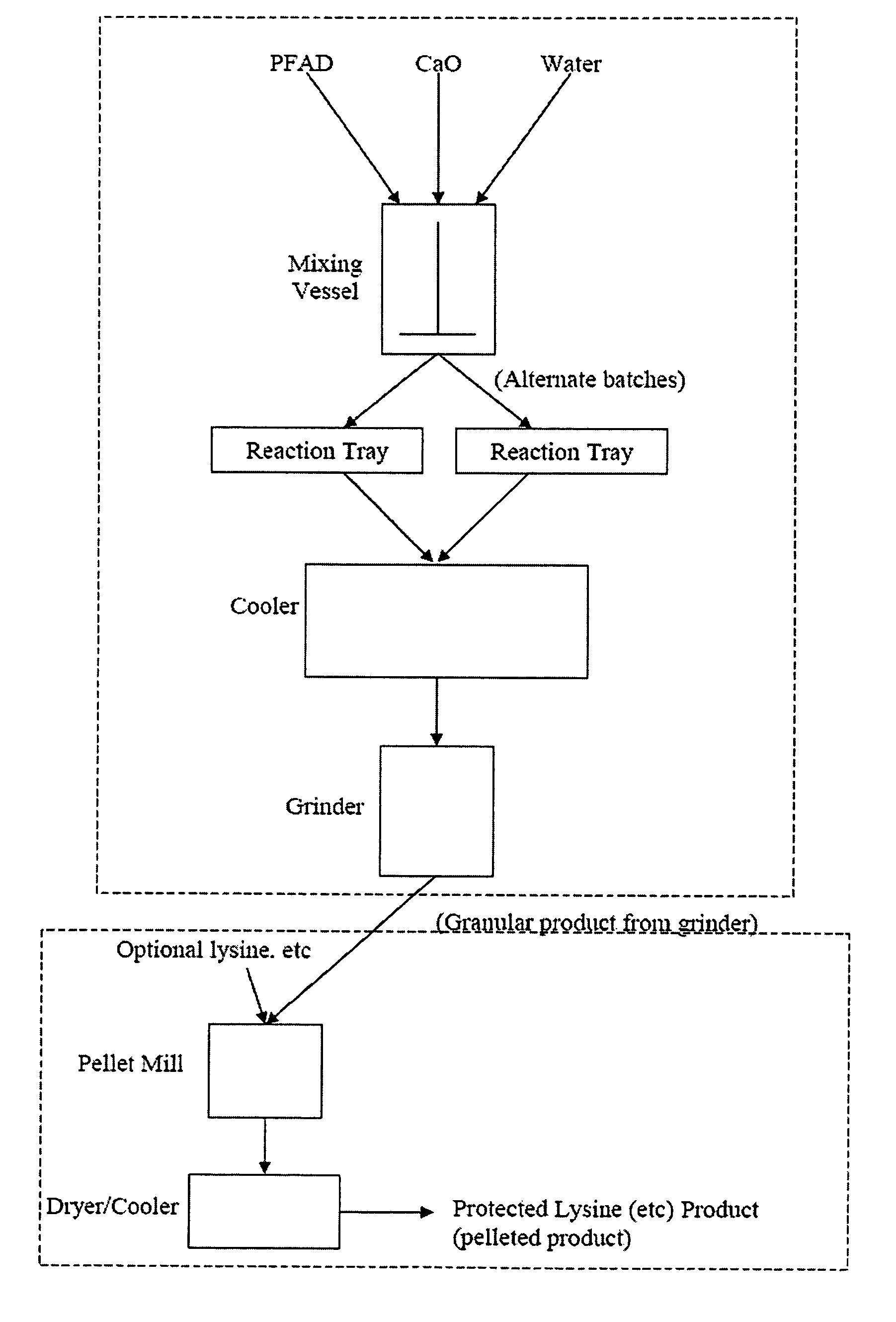

High-fat animal feed pellets and method for making same

A method is provided for producing animal feed pellets that are made entirely or predominantly of fat. Fats, oils, and waxes with complimentary physical properties also can be included, as can nutrients. Cohesive pellets of high flowability and durability are achieved. The superior handling quality of the pellets allows for their use in further formulation of animal feeds, where homogeneous distribution of nutrients throughout the final feed mix is desired.

Owner:ARCHER DANIELS MIDLAND CO

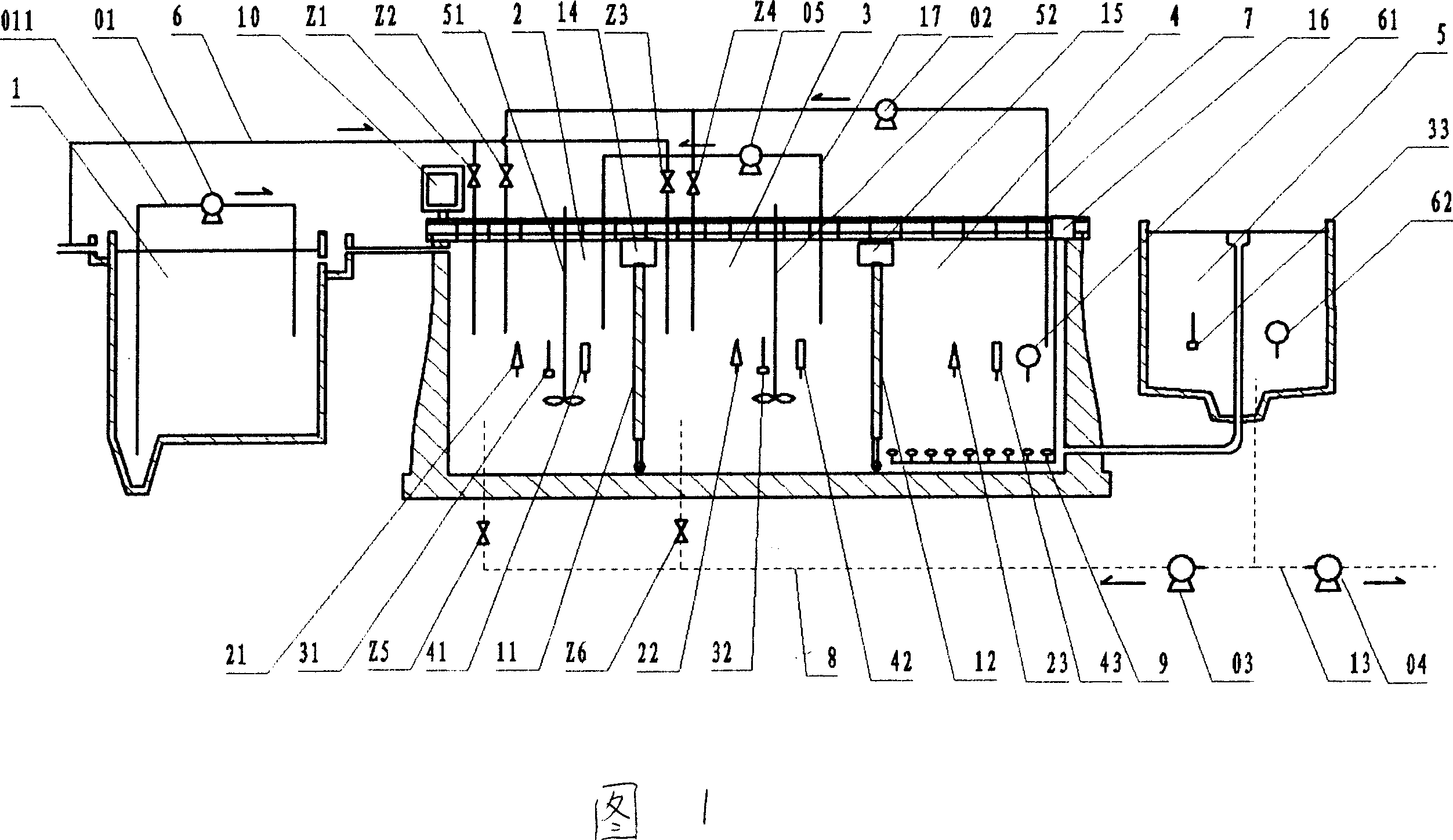

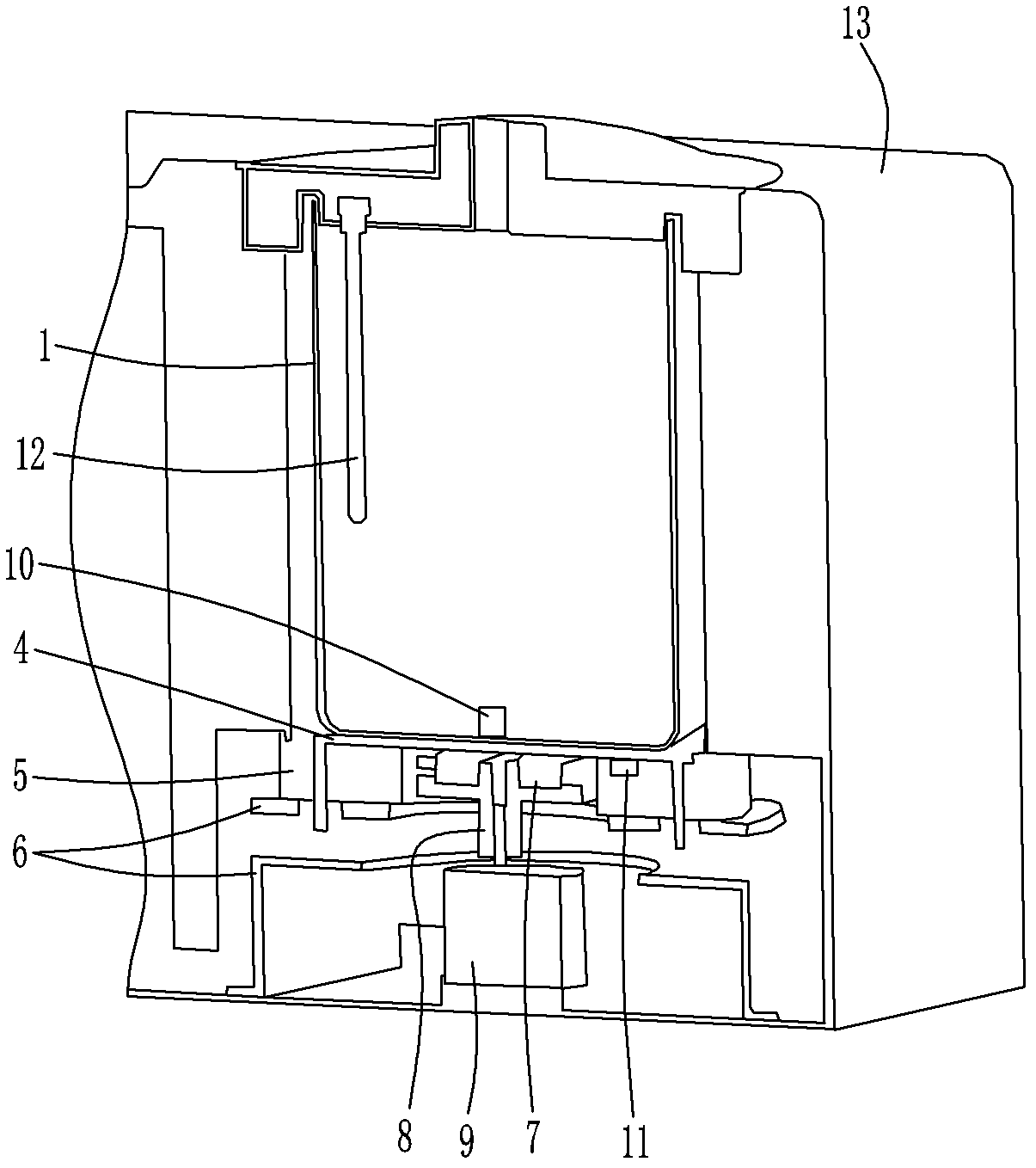

Five-factor wastewater treating apparatus

InactiveCN1990393AGood effectEasy to handleTreatment with aerobic and anaerobic processesRefluxSludge

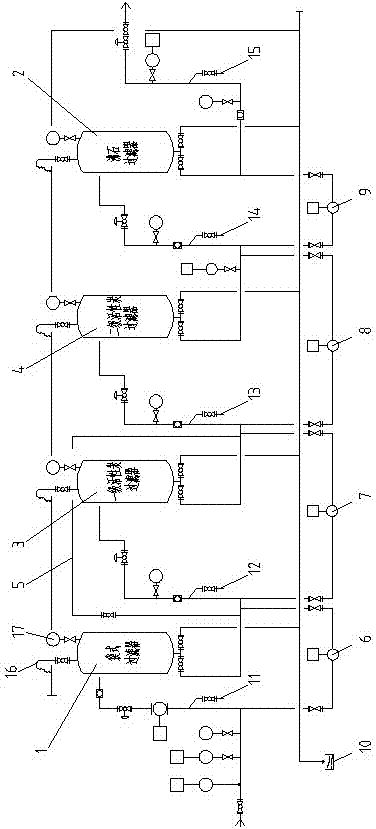

The invention relates to a wastewater treatment device with five factors being adjustable, which is the improved device for A / A / O wastewater treatment process. It mainly comprises primary sedimentation pool, anaerobic pool, anoxic pond, aerobic pool and secondary sedimentation tank. It is characterized in that: among anaerobic, anoxic and aerobic pool, there is a movable partition wall; a controllable valve and reflux pump with adjustable flow rate are fixed on return conduit inside wastewater from aerobic pool to anaerobic pond and anoxic pond as well as return conduit outside sludge from secondary sedimentation pool to anaerobic pool and anoxic pond; and phosphate nitrate and dissolved oxygen detection head and a are set in said three pools. The five factors of sludge age, dissolved oxygen concentration in aerobic pool, carbon amount, proportion of pool size among said three pools and rate between inside return and outside return can be adjusted timely, which can optimize effect of biological removal of nitrogen and phosphorus and improve wastewater treatment quality.

Owner:BEIJING DRAINAGE GRP CO LTD +1

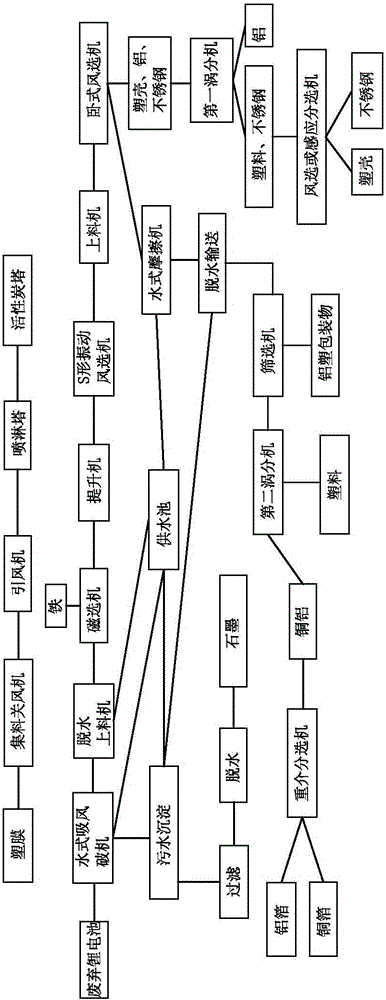

Method for smashing, detaching and recycling lithium battery

ActiveCN105811040AAvoid it happening againImprove processing efficiencyWaste accumulators reclaimingBattery recyclingCyclic processWater source

The invention relates to a method for smashing, detaching and recycling a lithium battery. Plastics, diaphragms, stainless steel, aluminium plastic films, aluminium, plastics, copper foils, aluminium foils, graphite and other materials are sorted from waste lithium batteries through a water type air-suction smashing machine, a magnetic separator, a horizontal type winnowing machine, a water-type friction machine, a first vortex separator, a second vortex separator and the like; the sorting purity can reach 94-99%; various kinds of harmful gases generated in the production process of the lithium batteries are processed by spray towers and activated carbon, and then the standardized gases are discharged; all the water required in the production process is recycled without an externally-discharged water source; and in addition, the water is precipitated, filtered and added with chemical drugs in the cycle process to carry out water treatment. According to the method, the waste batteries are not required to be pre-processed; instead, the waste batteries can be smashed, detached and recycled directly; therefore, the processing quality and processing efficiency of the waste batteries can be greatly improved; and in addition, pollutant emissions in the processing process can be effectively controlled.

Owner:哈尔滨巴特瑞资源再生科技有限公司

Method for identifying positive cells and negative cells of immunologic tissue

ActiveCN103020585AThe overall calculation is smallImprove adaptabilityCharacter and pattern recognitionProcess qualityPrior information

The invention discloses a method for identifying positive cells and negative cells of an immunologic tissue. The method provided by the invention can be used for determining a corresponding threshold value without using a certain threshold in a self-adaptive manner according to an own maximum between-cluster variance method of immunohistochemical image data to be processed, and can be adapted to deviations of an image on the color and the light intensity, so that the method is more stable when being compared with the conventional method; when nucleuses are judged to be positive or negative, dyeing processing information of the immunohistochemical image is used as prior information without manual marking, so that the intervene of subjective factors can be avoided, the full-automatic processing can be realized, and the stability of analysis efficiency and process quality can be improved.

Owner:上海启肽智能科技有限公司

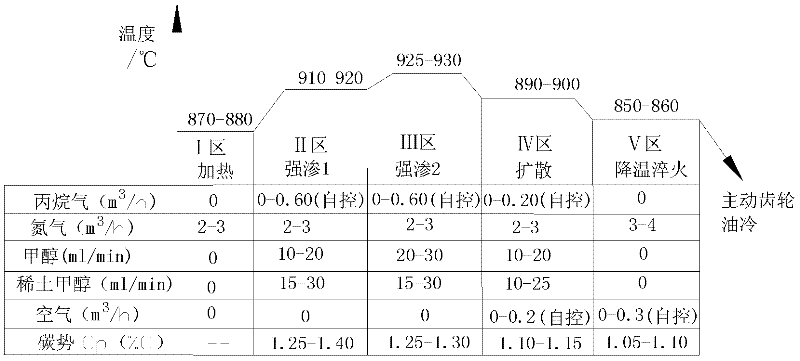

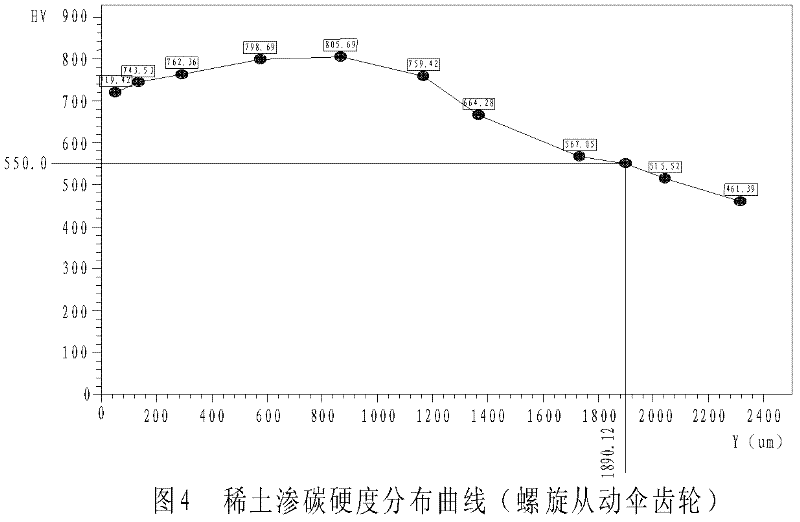

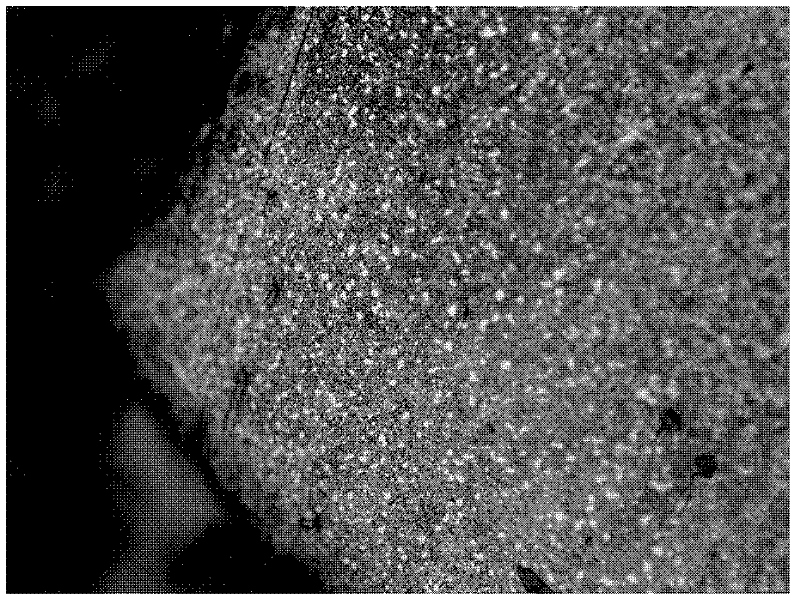

Heat treatment method of spiral bevel gear of cargo truck on double-row rare earth carburization equipment

ActiveCN102373400AEmission reductionIncrease carburizing speedSolid state diffusion coatingCarbon potentialRare earth

The invention provides a heat treatment method of a spiral bevel gear of a cargo truck on double-row rare earth carburization equipment, and relates to a carburization heat treatment technological process of the spiral bevel gear of the cargo truck. The invention solves the problems that energy consumption of carburization heat treatment is high, production cost of a product is high and carburization quenching and gear thermal distortion still exist in a carburization process. The method provided by the invention comprises the following steps of: taking a preheating zone as a strong leakage region 1 and taking a carburizing region as a strong leakage region 2, namely taking a region II and a region III as a carburizing speed main control region and taking a region IV and a region V as a metallographic structure main control region, carrying out temperature control in the regions I, II, III, IV and V, carrying out carbon potential control in the regions II, III, IV and V, and inputtingcarburizing medium propane gas, rare earth methanol penetrating agent, nitrogen, methanol and air into a furnace, thus the heat treatment method is realized. The metallographic structure and surface hardness of the spiral bevel gear subjected to the heat treatment method provided by the invention are all optimized, and heat treatment quality of the spiral bevel gear is improved; meanwhile, capacity is improved by 23%, heat treatment production cost is reduced by 18.9%, and pollution of exhaust emission to the environment is reduced.

Owner:哈尔滨汇隆汽车箱桥有限公司 +3

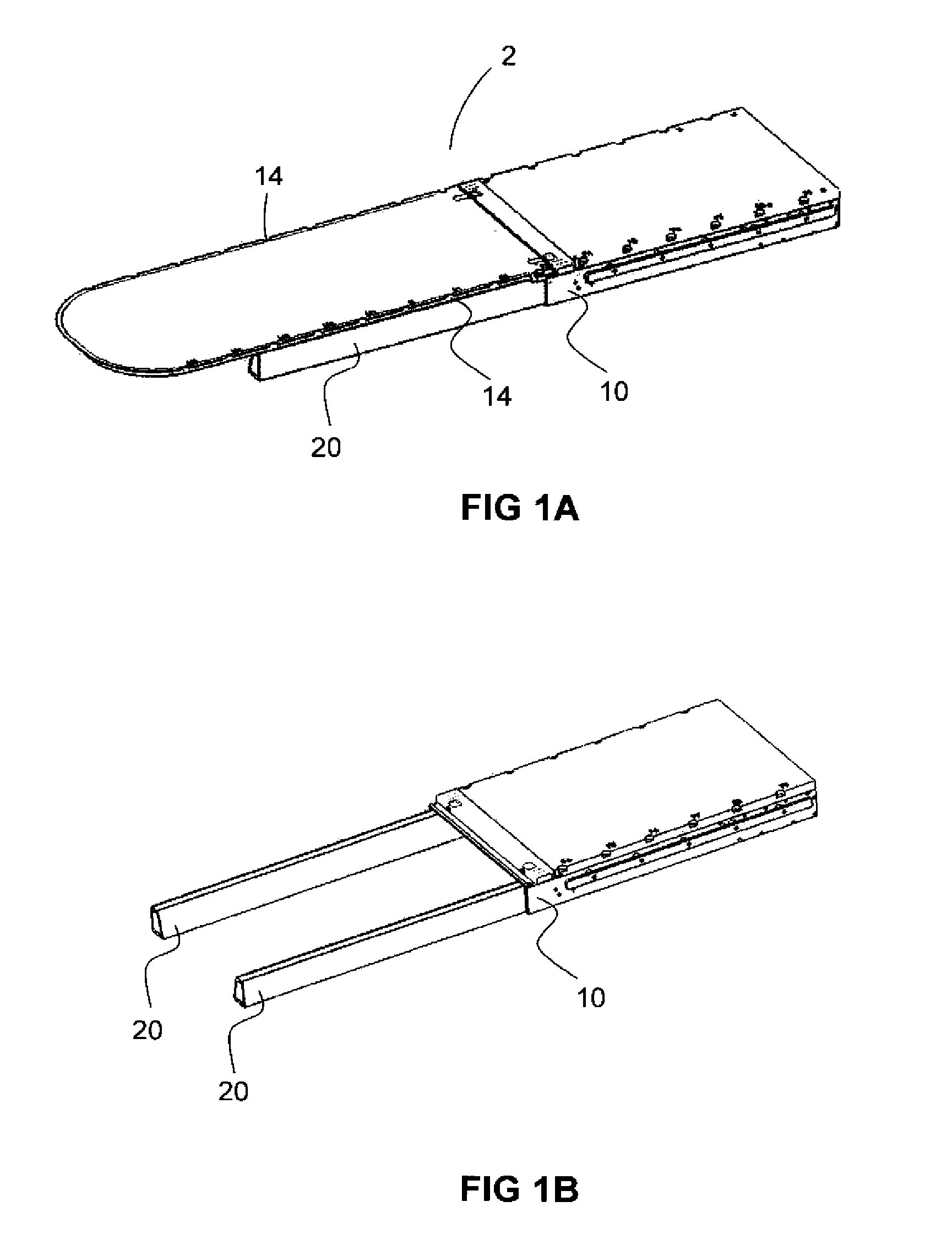

Radiation therapy patient couch top compatible with diagnostic imaging

ActiveUS20070074347A1Reduce image qualityDimensionally accurateCabinetsRadiation diagnosticsImaging qualityHigh energy

A radiation therapy patient couch top which provides optimal fields of treatment in a high-energy radiation therapy environment. In addition, the patient couch top provides superior imaging qualities when used in a diagnostic imaging x-ray environment. All metal is eliminated from the treatment / imaging area. This ensures that no metal will be in the way of the radiation treatment beam and that no artifacting will occur when used with diagnostic imaging techniques such as Computed Tomography. By employing moveable fiber reinforced support beams, the main patient support structure can be positioned so that a minimum of electron generation will occur through Compton scattering. By allowing for a removable insert, the top patient surface can be optimized for treatment, diagnostic imaging or the addition of other useful features. The novel design of these inserts allows the tip end of the beams to be free from any cross members, further improving the imaging and treatment qualities of the resulting patient couch top. Further, a CT simulator insert is provided which provides the same dosimetric properties for the patient couchtop and devices during patient treatment planning.

Owner:QFIX SYSTEM LLC

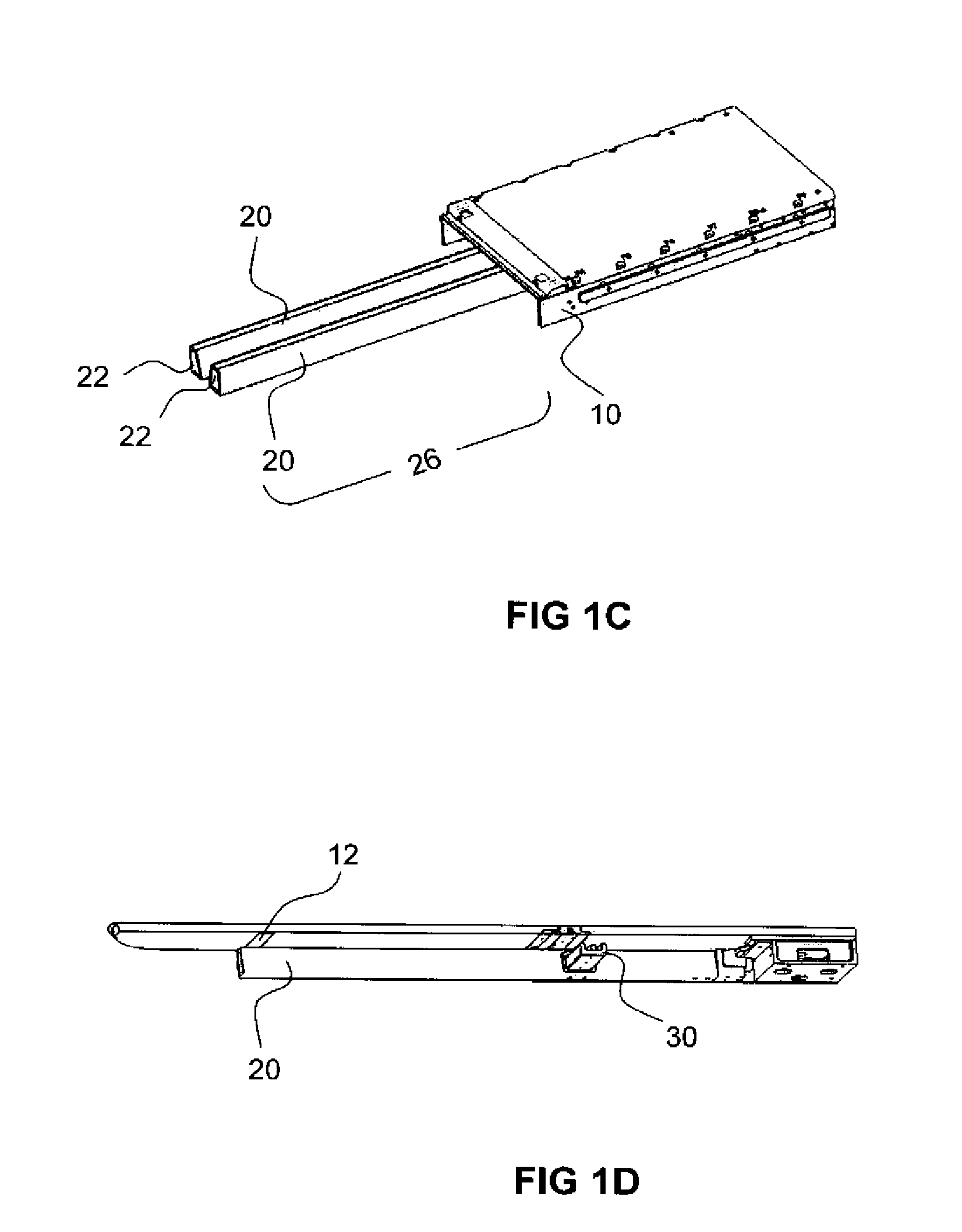

Vision field definition enhancement system and method for gastrointestinal endoscope diagnosis and treatment

ActiveCN102631179AFlow is easy to controlEasy flow controlGastroscopesEnemata/irrigatorsPeristaltic pumpMedicine

The invention discloses a vision field definition enhancement system for gastrointestinal endoscope diagnosis and treatment (ESCGV). A liquid delivery pipe (2) is led out from a washing bottle (1), and passes by a first peristaltic pump (3); and the washing bottle (1) is also provided with a stirring and heating sub-system for stirring and heating the washing liquor therein. The invention also discloses a vision field definition enhancement method for gastrointestinal endoscope diagnosis and treatment. The method comprises the following steps: 1) adding the washing liquor into the washing bottle; 2) magnetically stirring the washing liquor in the washing bottle, and simultaneously heating the washing liquor; 3) setting the temperature of the washing liquor at 25-37 DEG C; and 4) sending the washing liquor into an observation window of a gastrointestinal endoscope. The system and method can obviously enhance the vision field definition under the gastrointestinal endoscope, make the operation convenient and simple, greatly reduce the missed diagnosis and erroneous diagnosis, and obviously increase the treatment quality of the gastrointestinal endoscope.

Owner:CHONGQING SKYFORBIO

Pretreatment technique for steel member hot spraying

InactiveCN101158013ALess investmentImprove processing efficiencyMolten spray coatingSuperimposed coating processThermal sprayingSurface cleaning

The invention discloses a pretreatment technique for the heat spraying for a steel part, belonging to the technique field of surface treatment. The process is as follows: surface cleaning-degreasing-derustin-sealing-surface coarsening-heat spraying. The invention has the advantages that the technique has simple requirements to the treatment of the parts, the distribution of the technique, and is easy to operate, good pretreatment quality, which warrants the quality of the heat spraying; besides, the technique requires little investment to the infrastructure, and has high treatment efficiency, low construction cost, and good economic benefit.

Owner:XUZHOU ZENITH COATING

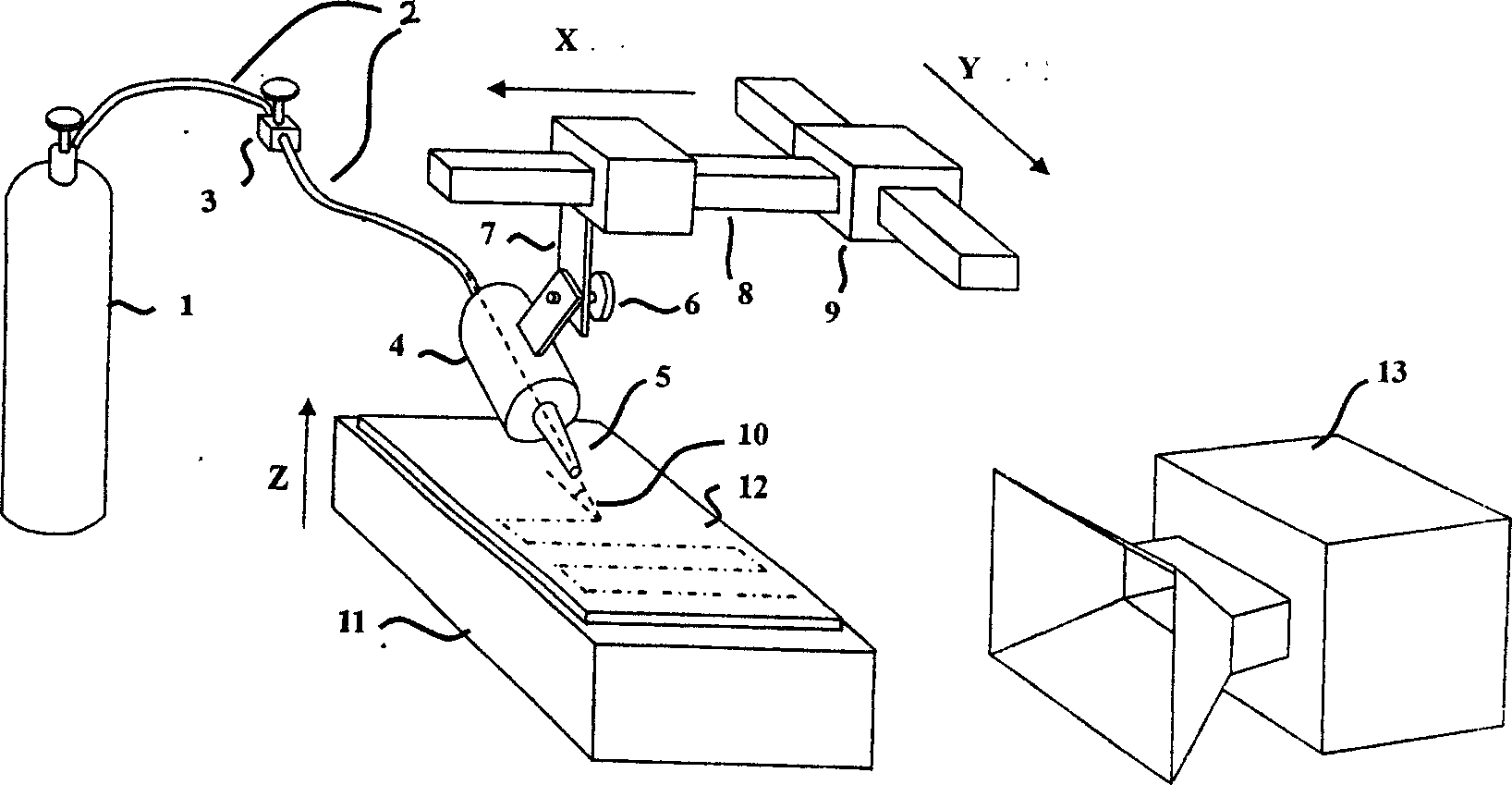

Method and apparatus for processing transparent conductive glass surface by dry ice particle spraying technique

The method of ice particle injection treating transparent electric conductive glass surface uses carbon dioxide ice with radius ranging from several millimeter and 100 millimeter in certain speed, injection angle and distance to spray the transparent glass surface to complete the polishing and cleaning of the transparent electric conductive thin film. It comprises high pressure carbon dioxide gas bottle, air transmission air pipe, gas flow control valve, nozzle connector, nozzle and its angel adjuster, through linkage to connect with the working platform and the gas recovery device. It can improve the surface treatment quality free from water or small quantity of water. It can save water source, reduce the discharge of exhaust water and goods, recover the generated carbon dioxide to reduce contamination to the environment.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

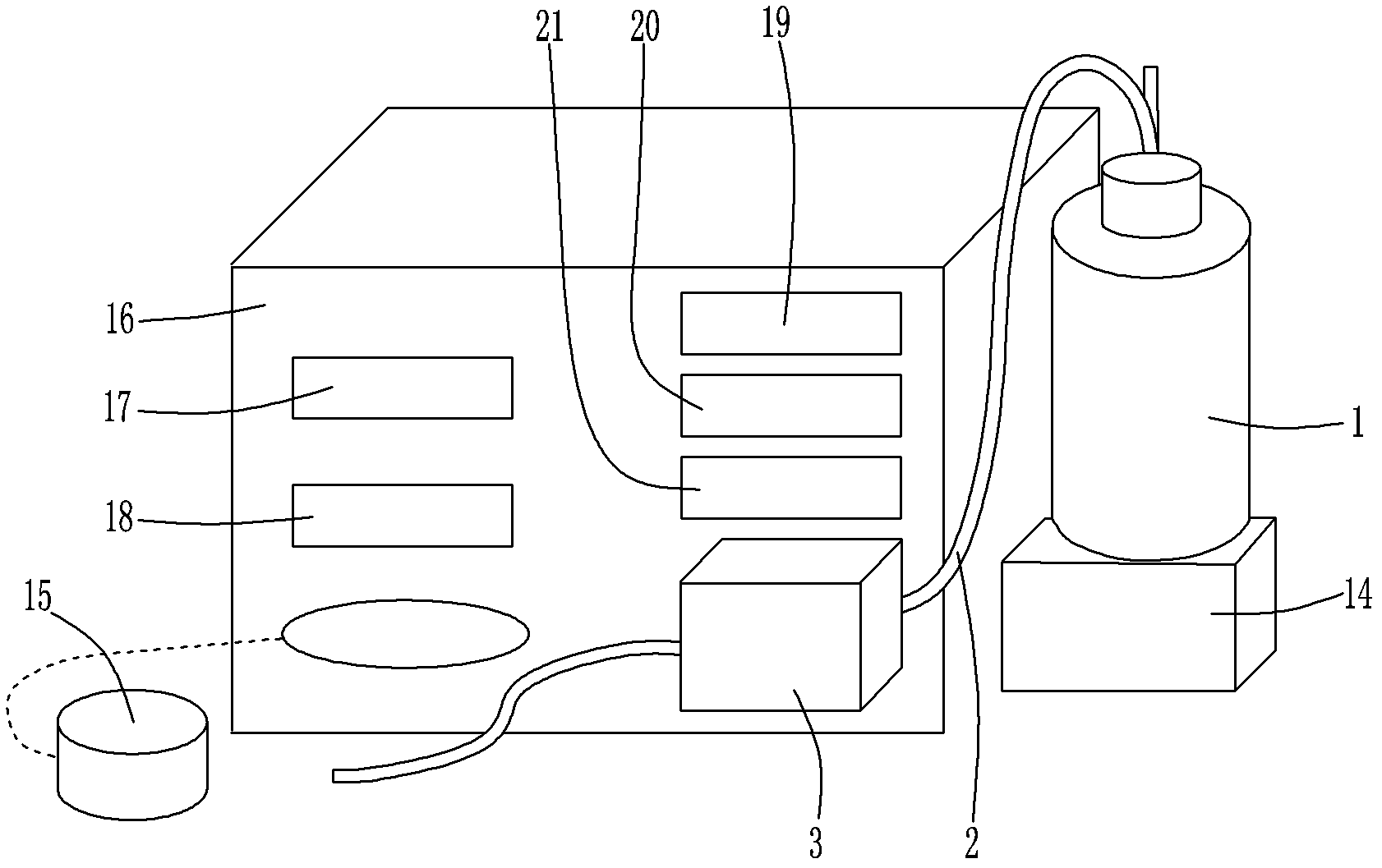

Vapor-phase process apparatus, vapor-phase process method, and substrate

InactiveUS20090148704A1Reduce amountReduce amount of depositPolycrystalline material growthElectric discharge tubesProcess engineeringProduct gas

A vapor-phase process apparatus and a vapor-phase process method capable of satisfactorily maintaining quality of processes even when different types of processes are performed are obtained. A vapor-phase process apparatus includes a process chamber, gas supply ports serving as a plurality of gas introduction portions, and a gas supply portion (a gas supply member, a pipe, a flow rate control device, a pipe, and a buffer chamber). The process chamber allows flow of a reaction gas therein. The plurality of gas supply ports are formed in a wall surface (upper wall) of the process chamber along a direction of flow of the reaction gas. The gas supply portion can supply a gas into the process chamber at a different flow rate from each of one gas supply port and another gas supply port different from that one gas supply port among the plurality of gas supply ports.

Owner:SUMITOMO ELECTRIC IND LTD

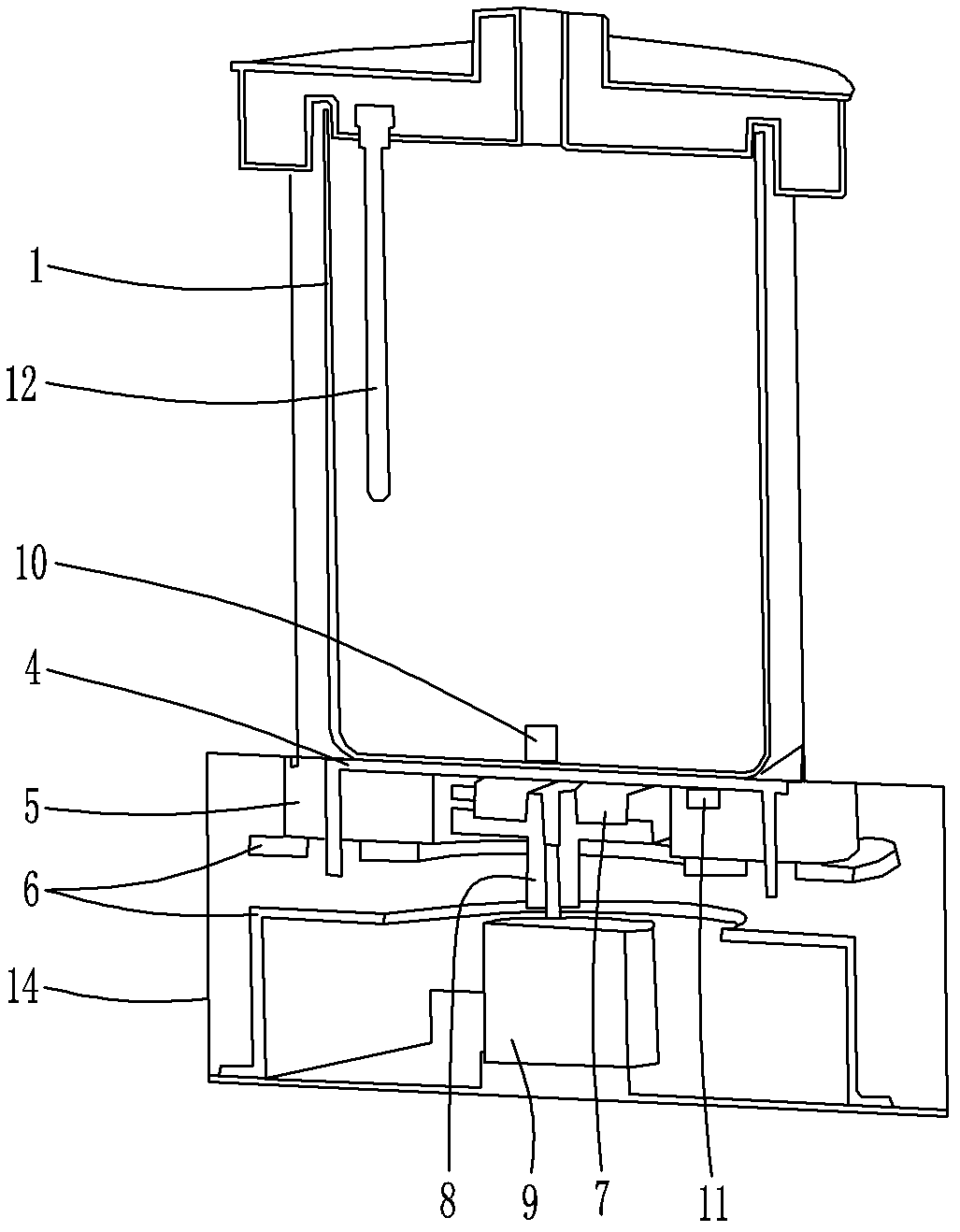

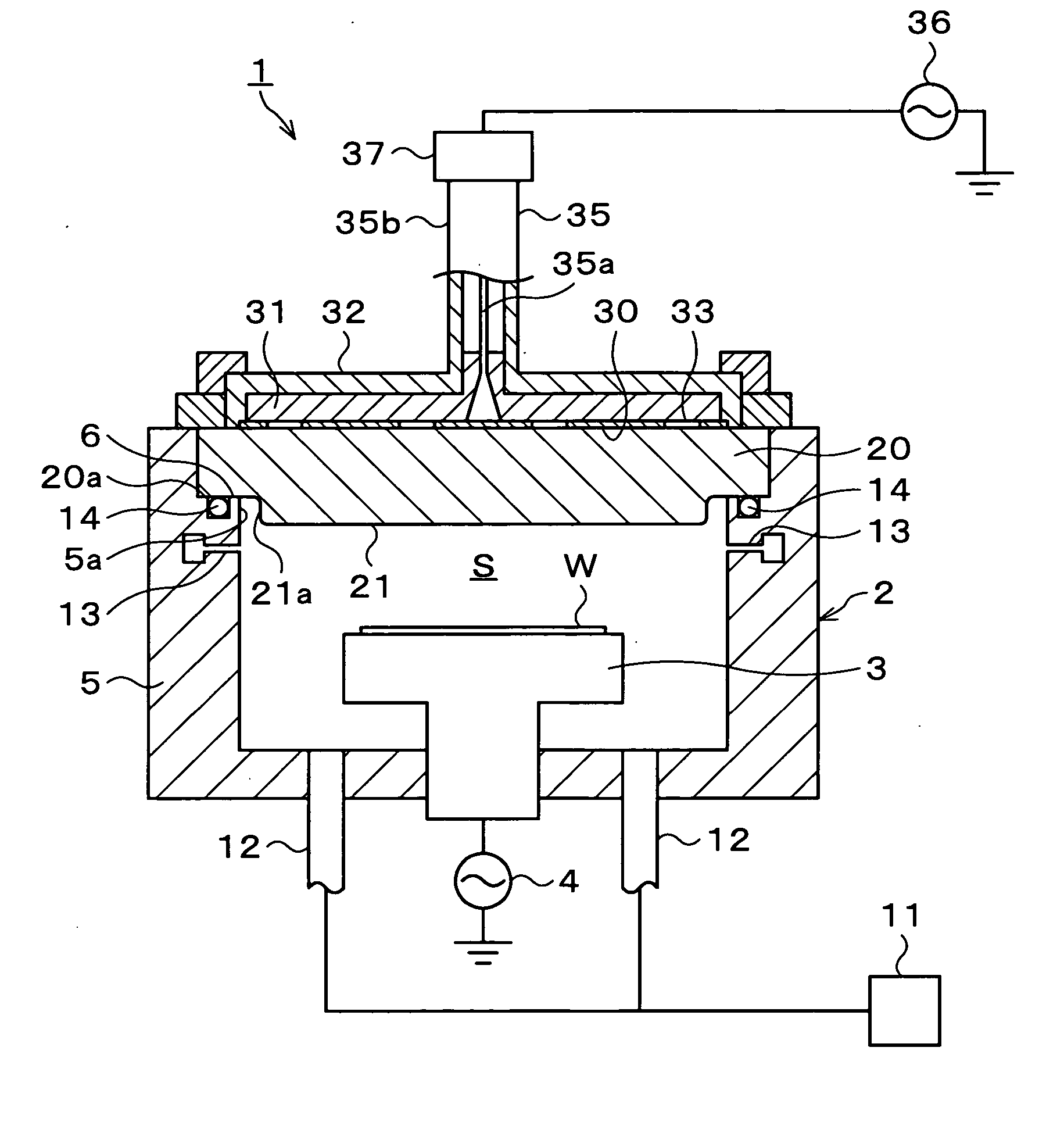

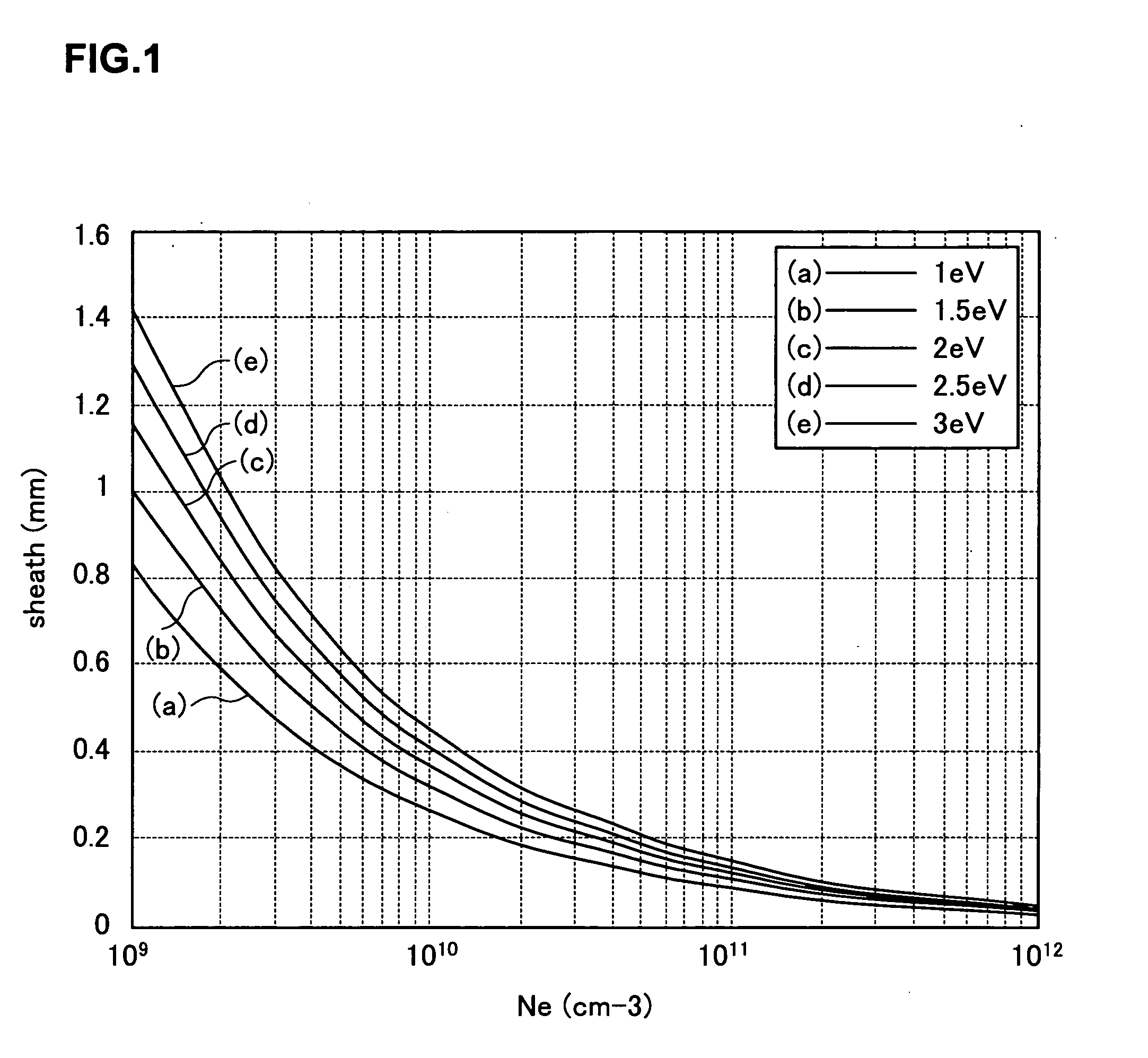

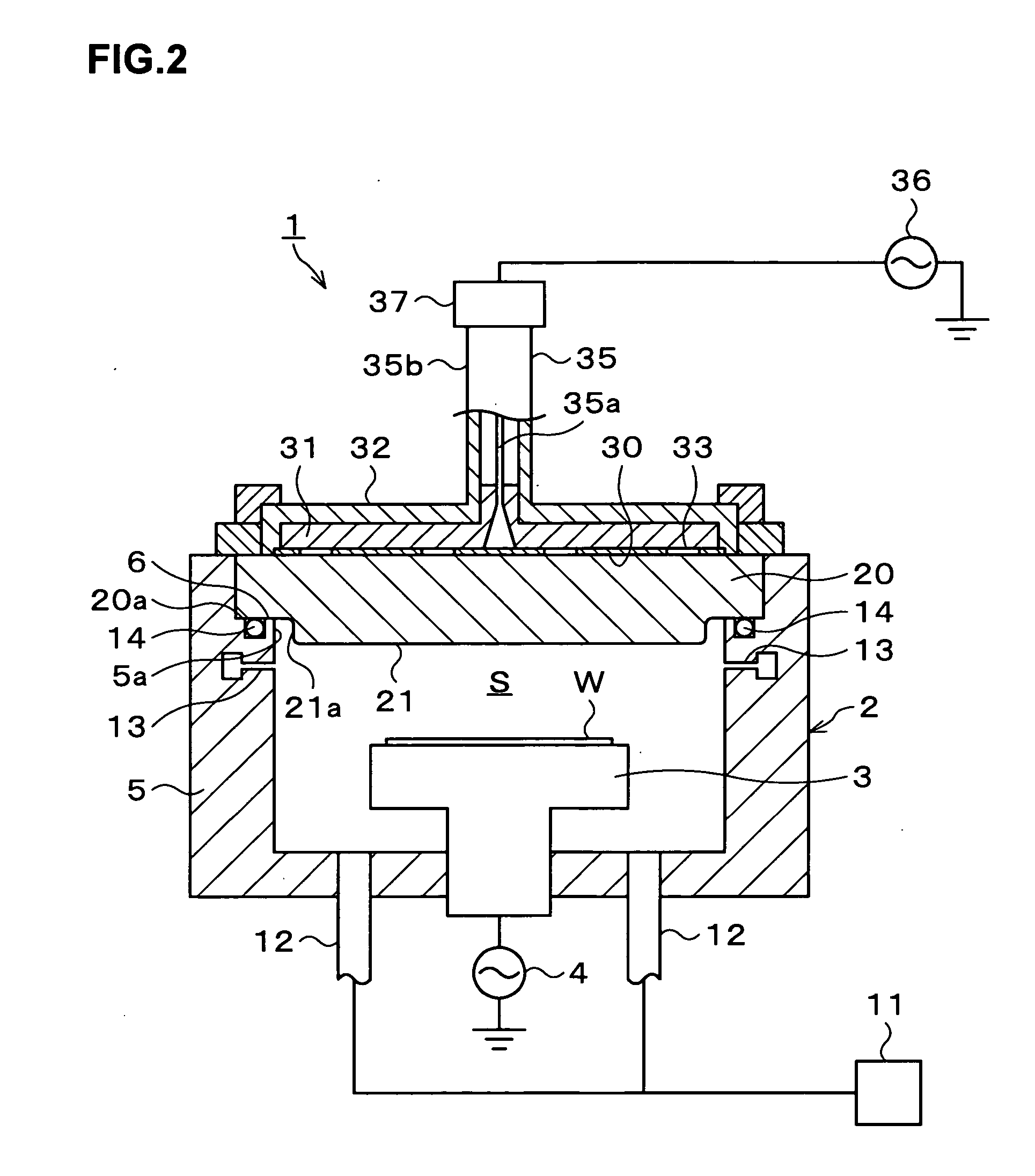

Plasma Processing Apparatus and Plasma Processing Method

ActiveUS20070264441A1Avoid processing qualityElectric discharge tubesSemiconductor/solid-state device manufacturingHigh densityEngineering

To improve processing quality by inhibiting the generation of a strong electric field and high-density plasma, near a contact point between a support part supporting a transmissive window and the transmissive window in a plasma processing apparatus utilizing a microwave. In a plasma processing apparatus that processes a wafer W in a process vessel 2 by plasma generated by the supply of a microwave, a transmissive window 20 has, in a center area of its lower surface, a hanging portion 21 made of the same material as a material of the transmissive window 20. Between an outer peripheral surface 21a of the hanging portion 21 and a sidewall inner surface 5a continuing from a support part 6, a gap d is formed, the gap d having a gap length of 0.5 to 10 mm, more preferably 0.5 to 5 mm. The generation of a strong electric field and plasma at the contact point C is inhibited and an amount of sputtered particles, radicals, or the like reaching the wafer W is also reduced.

Owner:TOKYO ELECTRON LTD

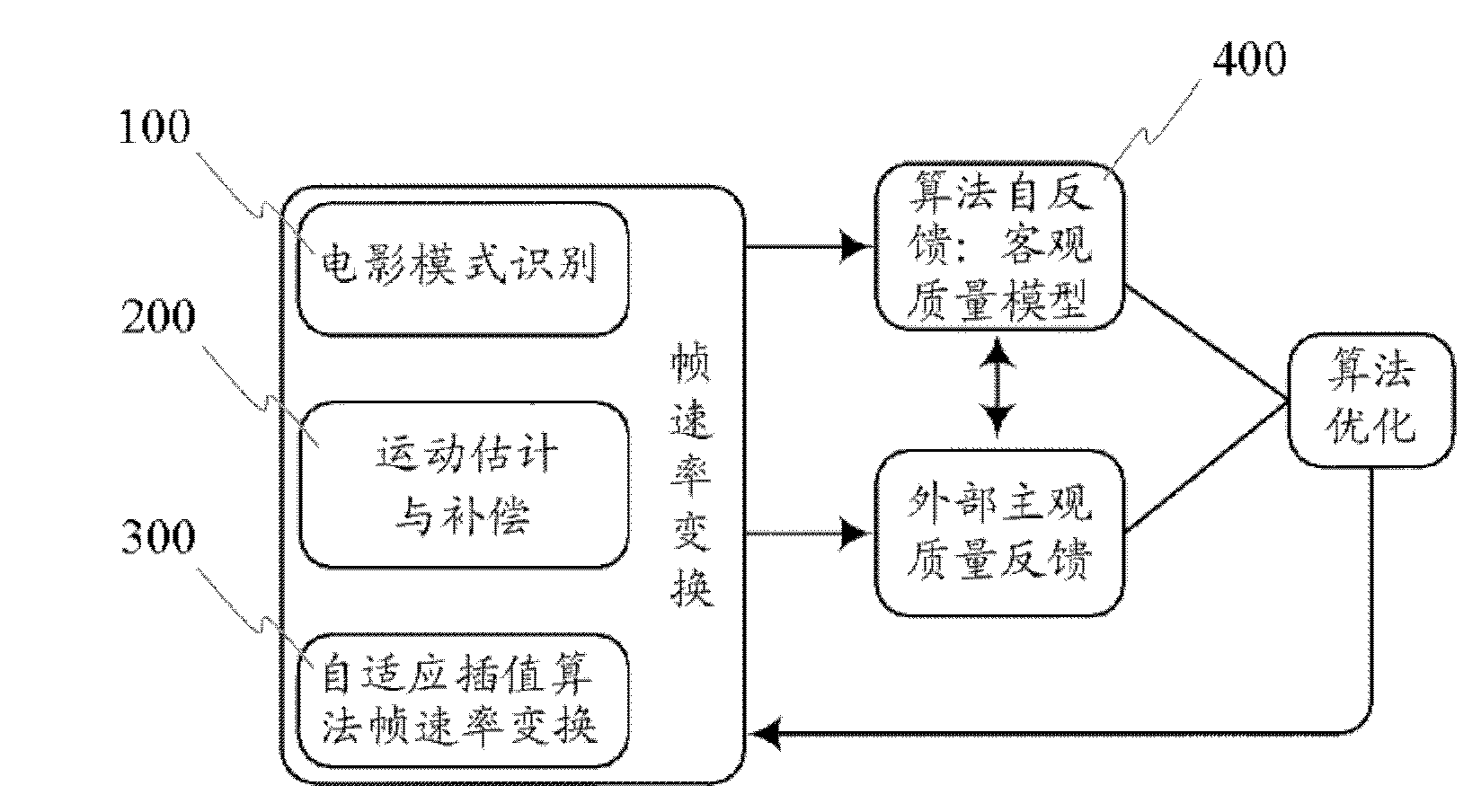

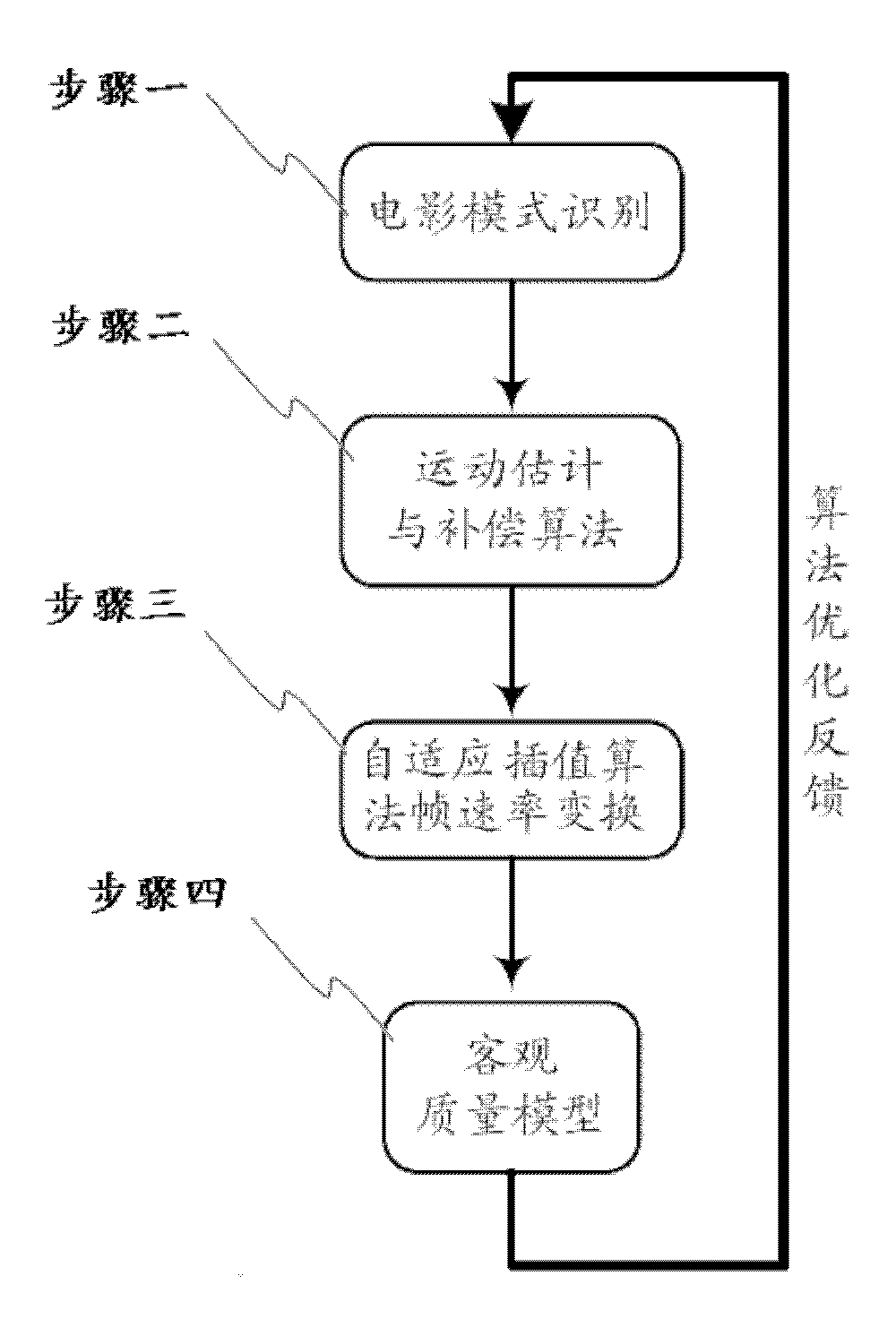

Speed conversion processing module and method of high definition digital video frame

InactiveCN102131058AGood handling qualityEliminates grooming imperfectionsTelevision system detailsColor television detailsDigital videoObjective quality

The invention provides a speed conversion processing module of a high definition digital video frame. The module provided by the invention comprises a film mode recognition pretreatment module, a movement estimation and compensation module, an adoptive interpolation algorithm frame speed conversion module and an objective quality evaluation module. The invention also provides a speed conversion method of the video frame. The method comprises the following steps: recognizing the type of a video source and determining the video format of the video source, interweaving or reversely intersecting a video stream, completing restoration from a video field to the frame and eliminating the dressing defect of an image; estimating a movement vector between the frames by using a movement estimation and compensation algorithm, recognizing whether a moving object is shielded or not and determining the position of the moving object; according to the movement estimation information, adaptively carrying out weighted average interpolation between the unshielded frames of the moving object, or adaptively carrying out protective interpolation on different areas based on the shielded image situation of the moving object; and establishing an objective evaluation model of video processing quality, and correcting adjustable parameters of frame speed conversion by using quality grade provided by the objective evaluation model, thereby optimizing the processing quality of the video.

Owner:BEIJING WISDOM ELVES TECH

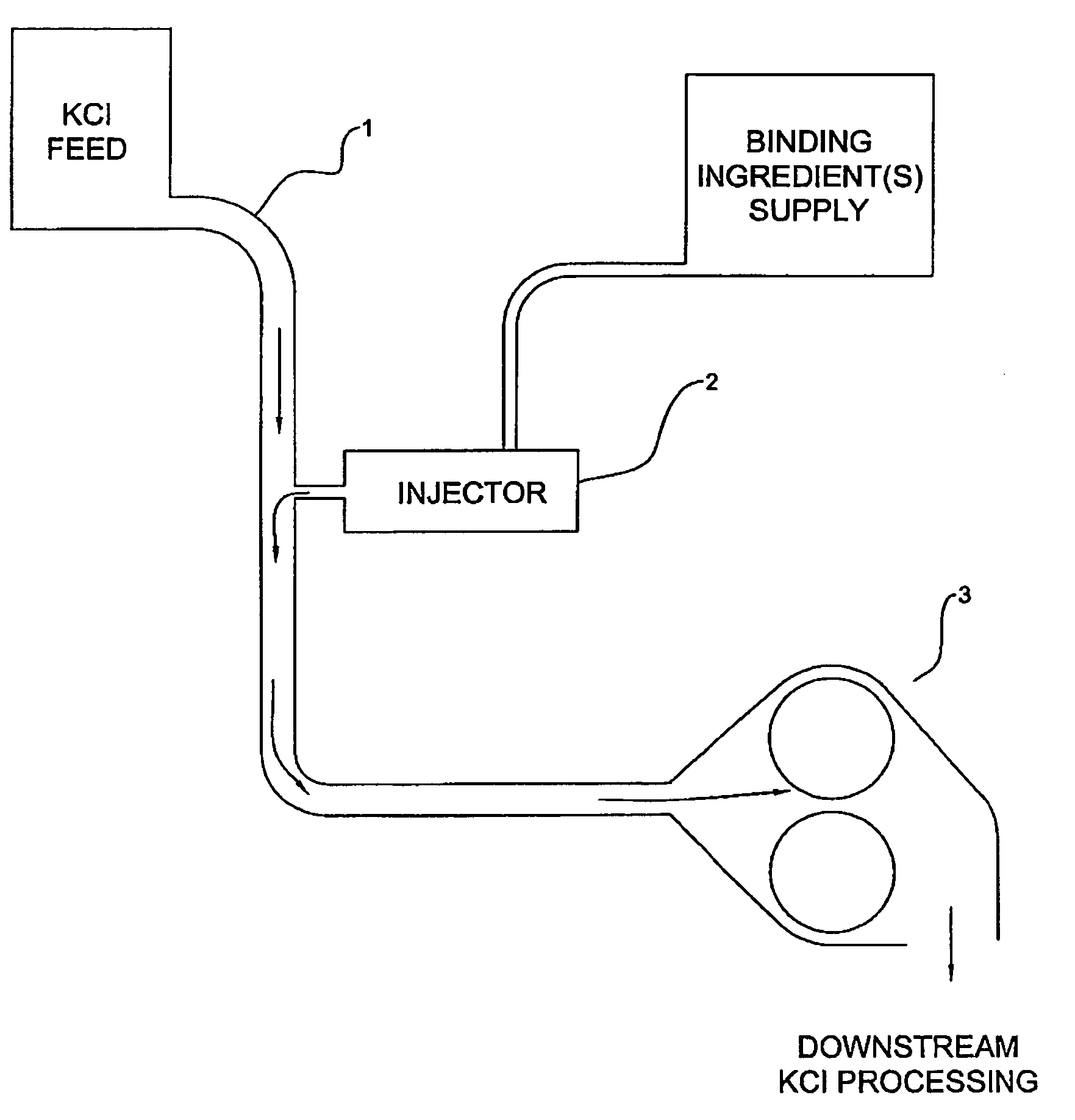

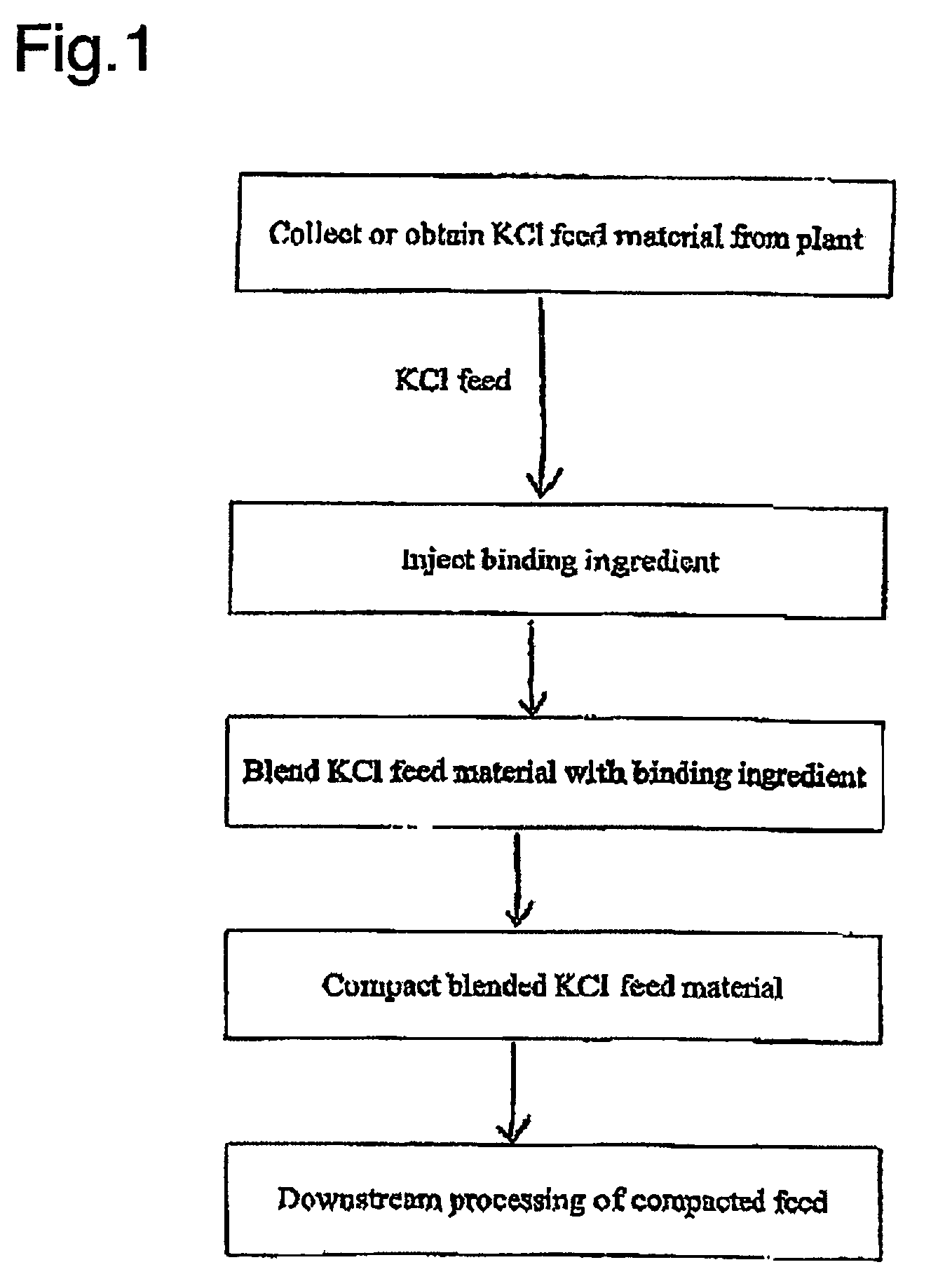

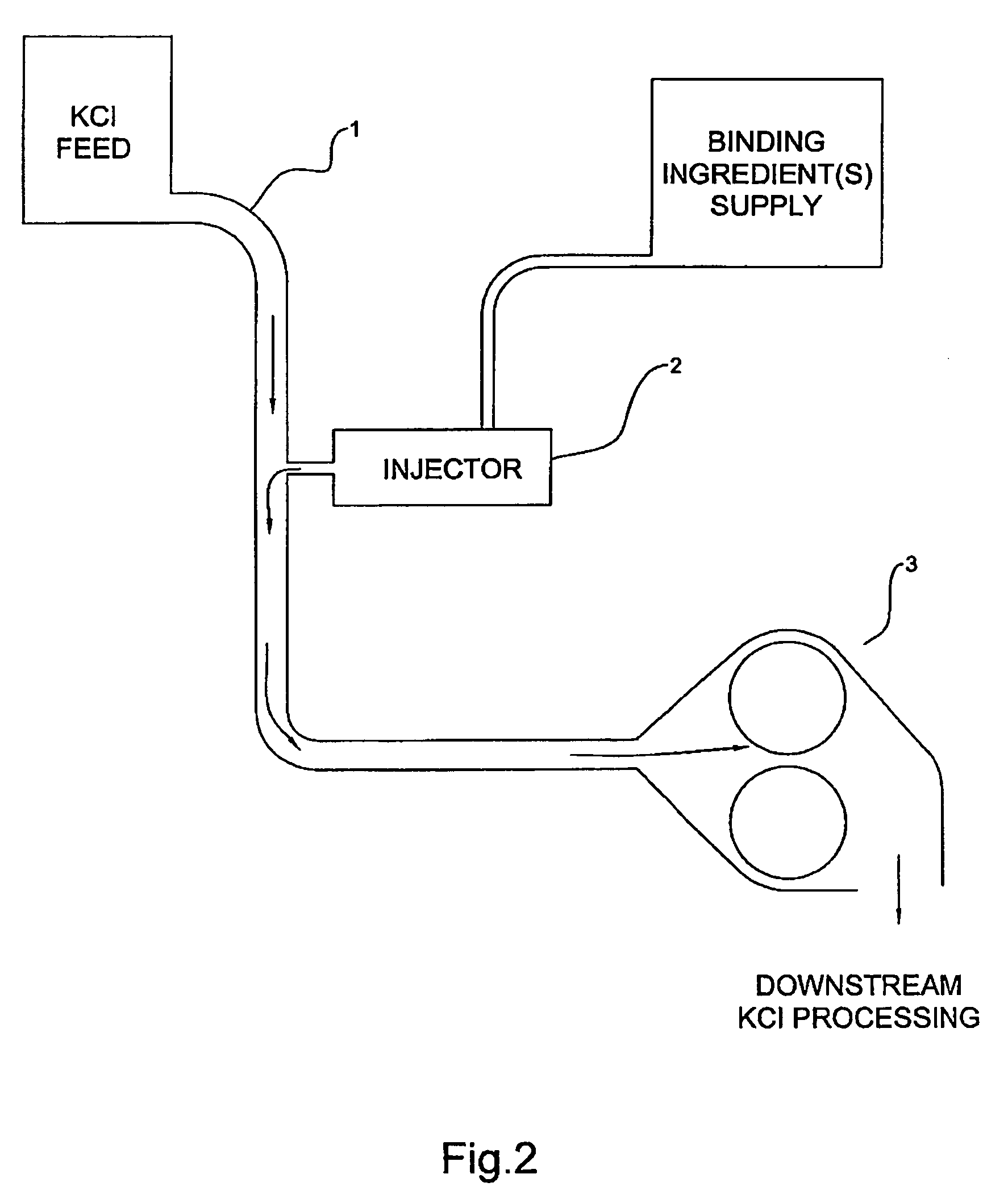

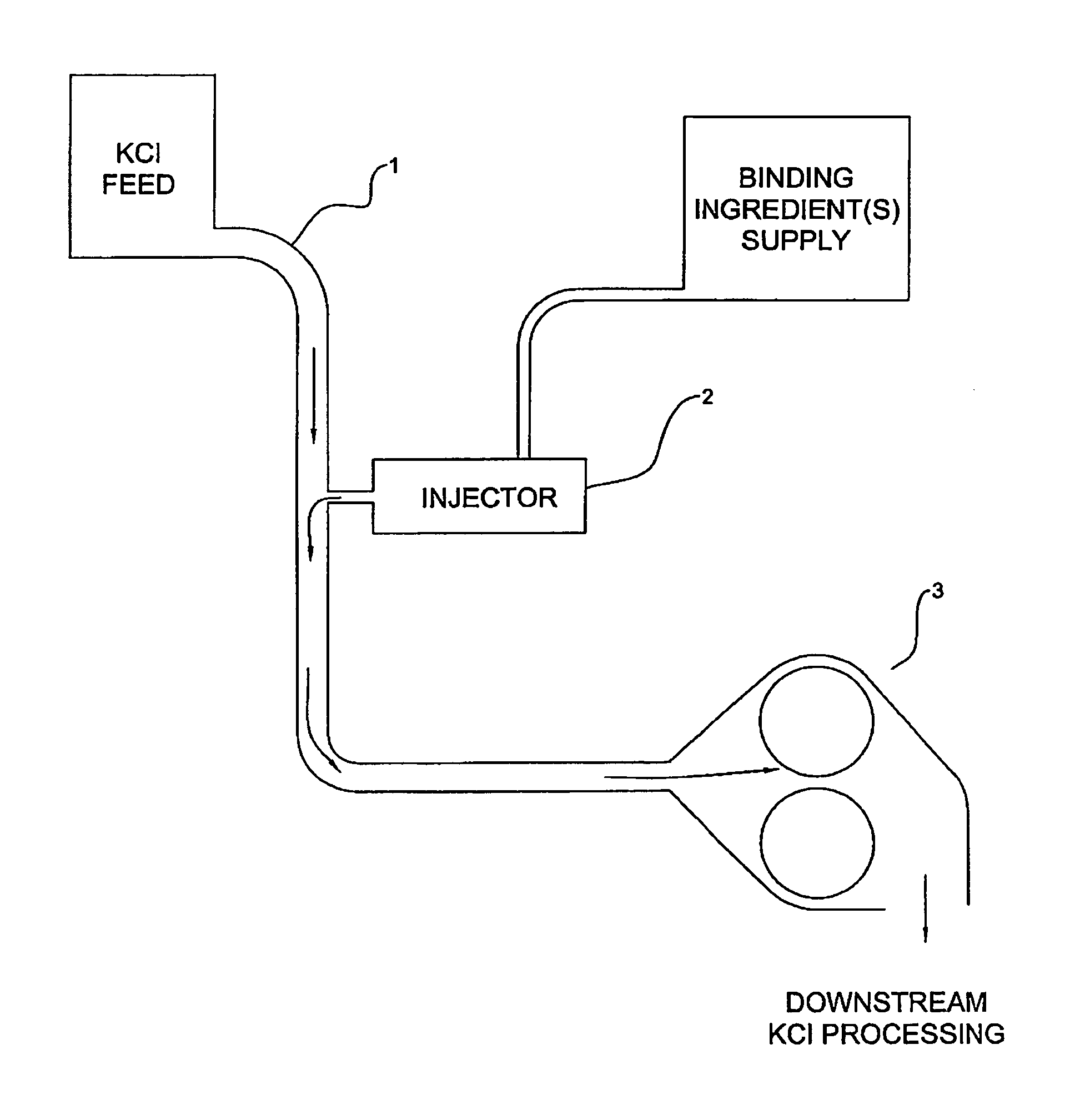

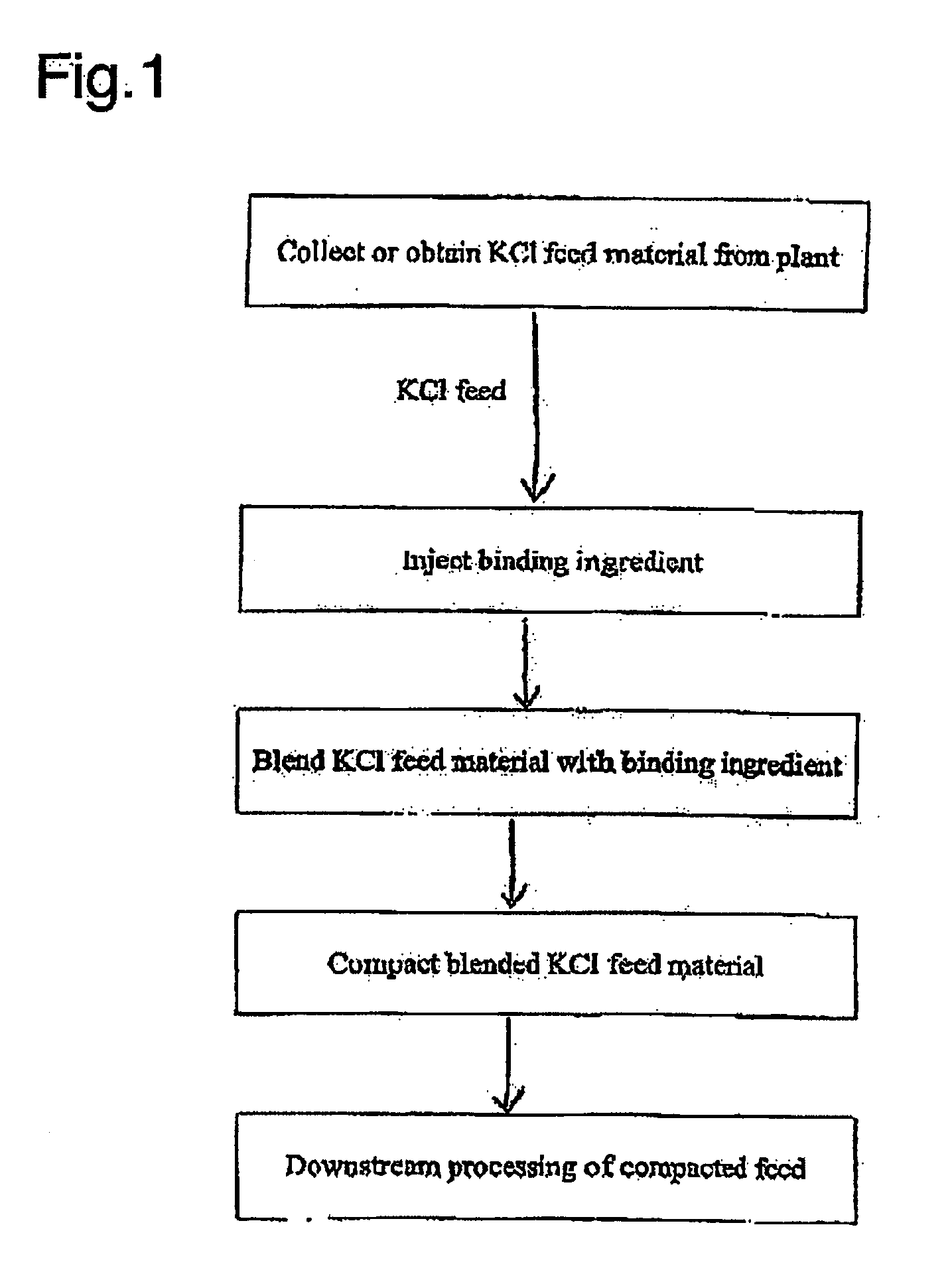

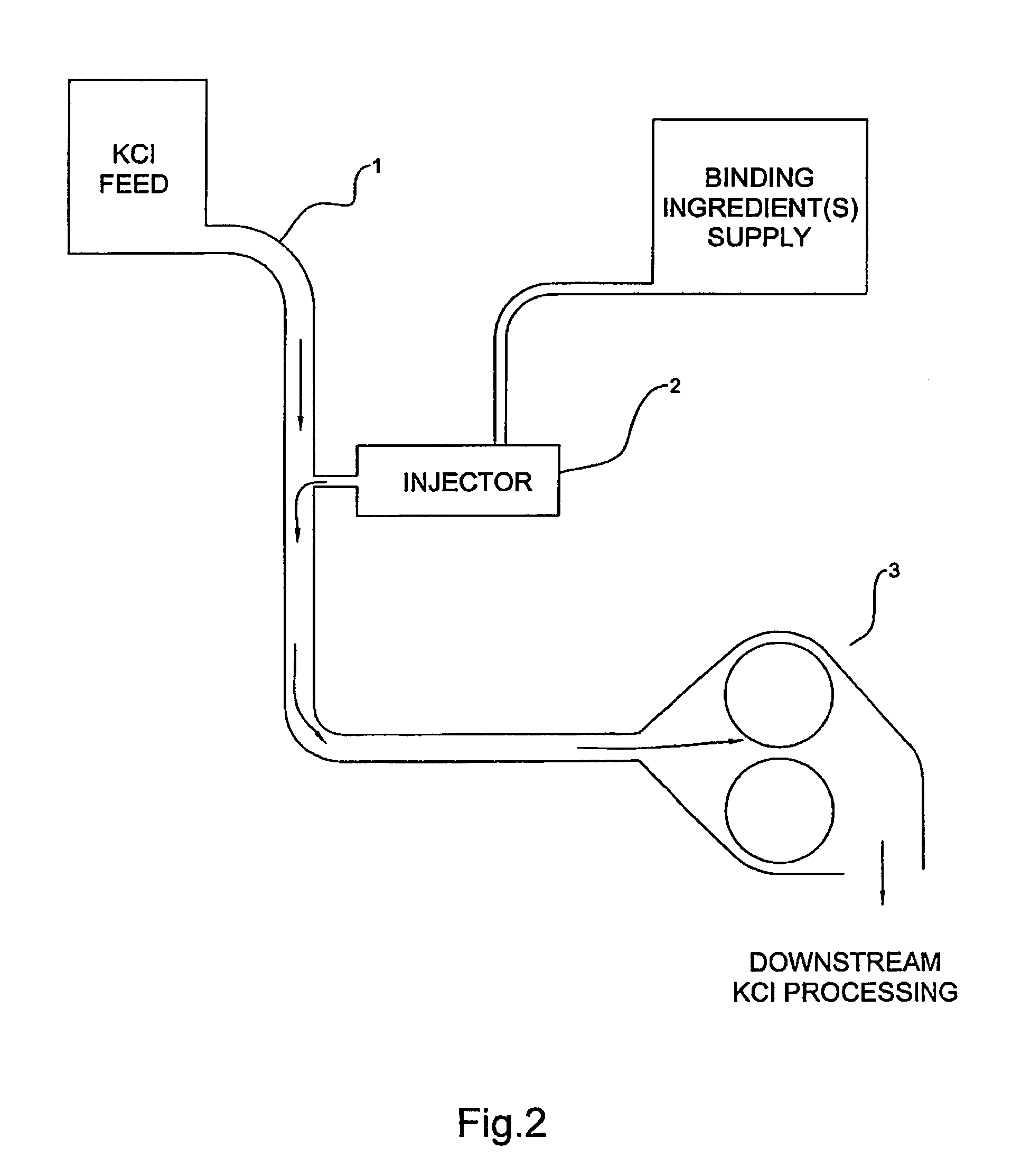

Compacted granular potassium chloride, and method and apparatus for production of same

ActiveUS7727501B2Improve handling qualityLess handlingAmmonium nitratesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPotassiumChloride

Apparatus and method are disclosed for the production of compacted granular potassium chloride with improved handling qualities. A binding ingredient such as sodium hexametaphosphate is blended with the potassium chloride feed material in advance of compaction. The product of this apparatus and method has improved handling, storage, strength and other qualities over compacted granular potassium produced using prior art methods.

Owner:THE MOSAIC COMPANY

Compacted granular potassium chloride, and method and apparatus for production of same

ActiveUS20050036929A1Improve handling qualityLess handlingAmmonium nitratesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPotassiumChloride

Apparatus and method are disclosed for the production of compacted granular potassium chloride with improved handling qualities. A binding ingredient such as sodium hexametaphosphate is blended with the potassium chloride feed material in advance of compaction. The product of this apparatus and method has improved handling, storage, strength and other qualities over compacted granular potassium produced using prior art methods.

Owner:THE MOSAIC COMPANY

High-fat animal feed pellets and method for making same

Owner:ARCHER DANIELS MIDLAND CO

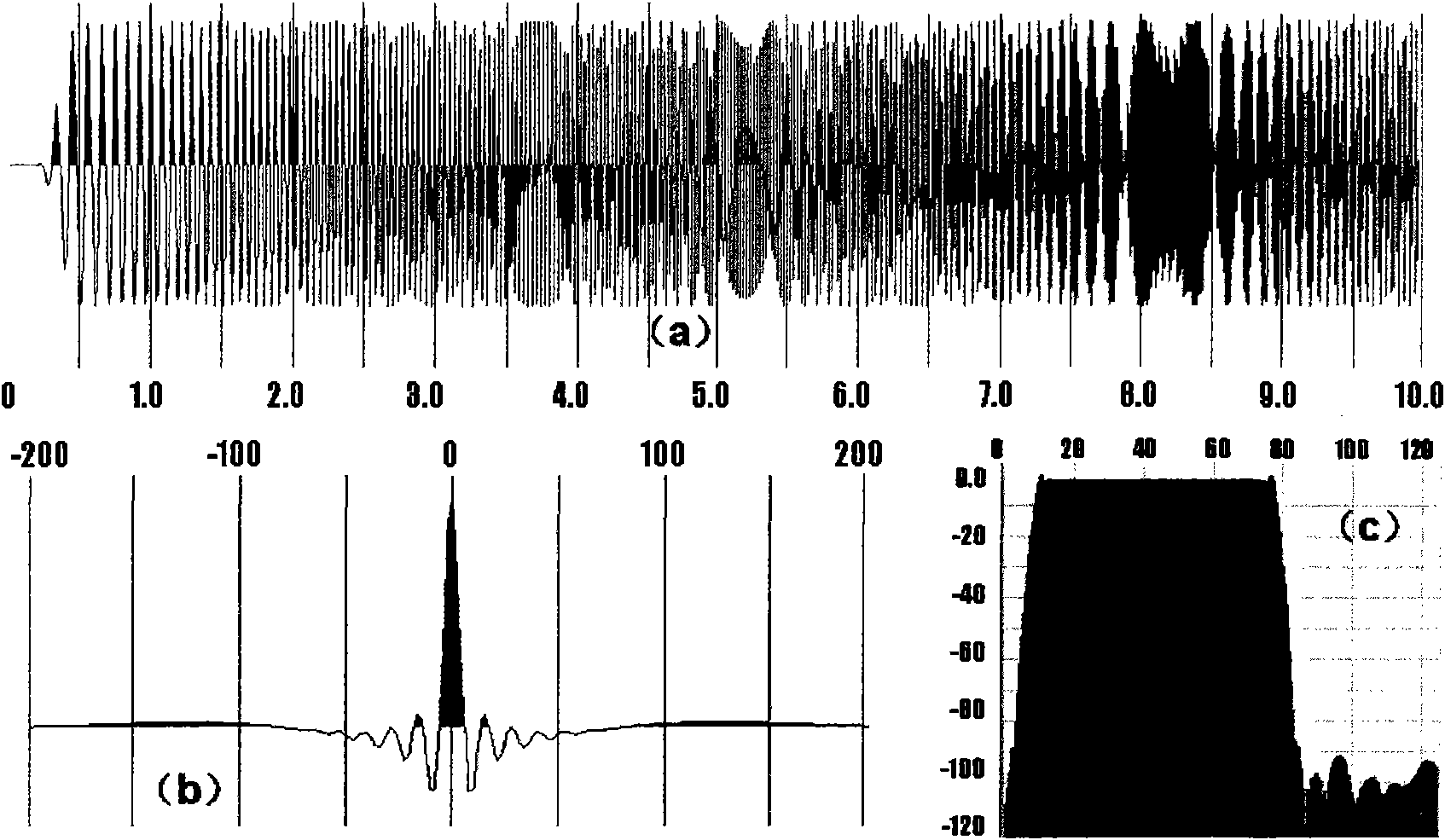

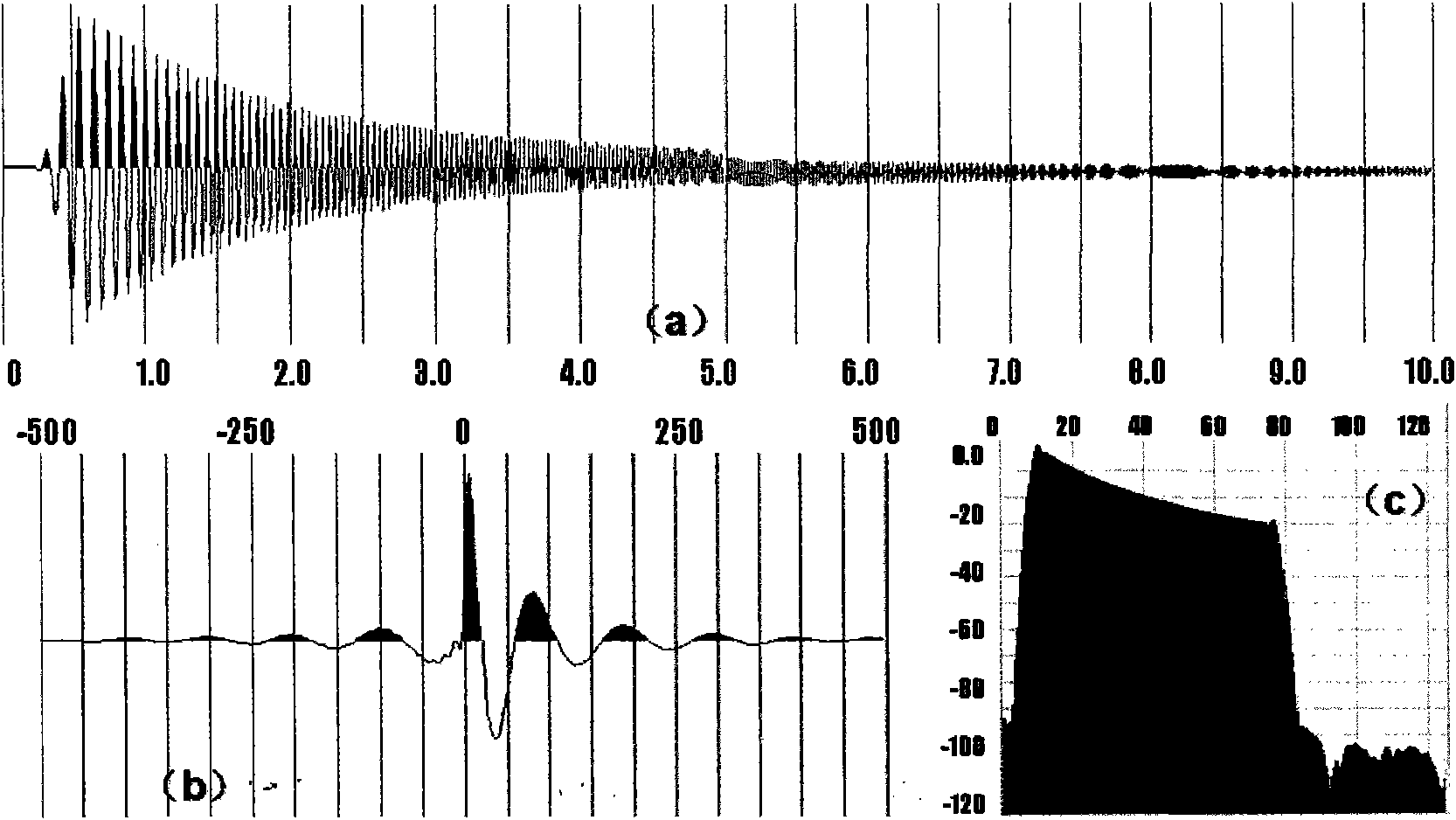

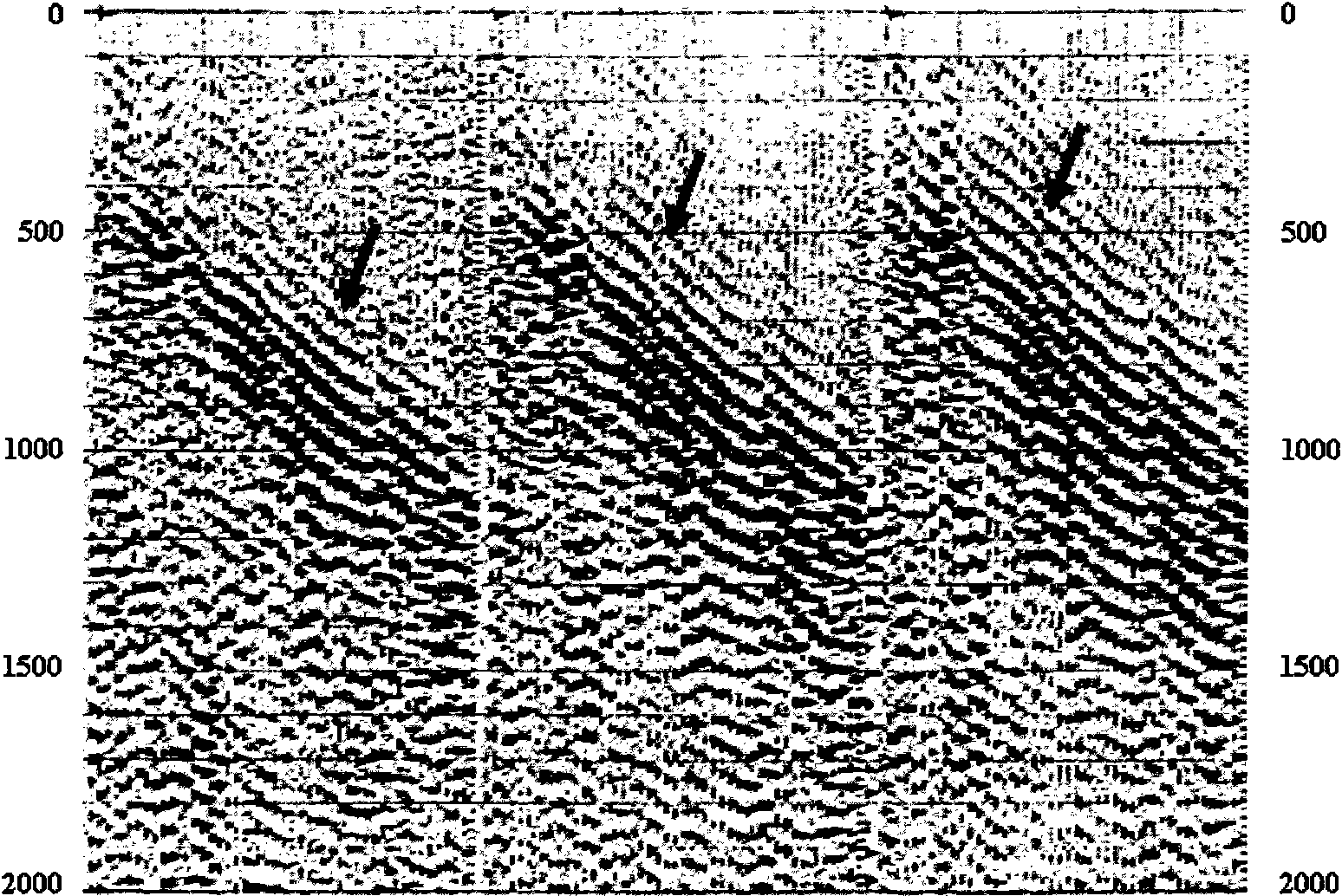

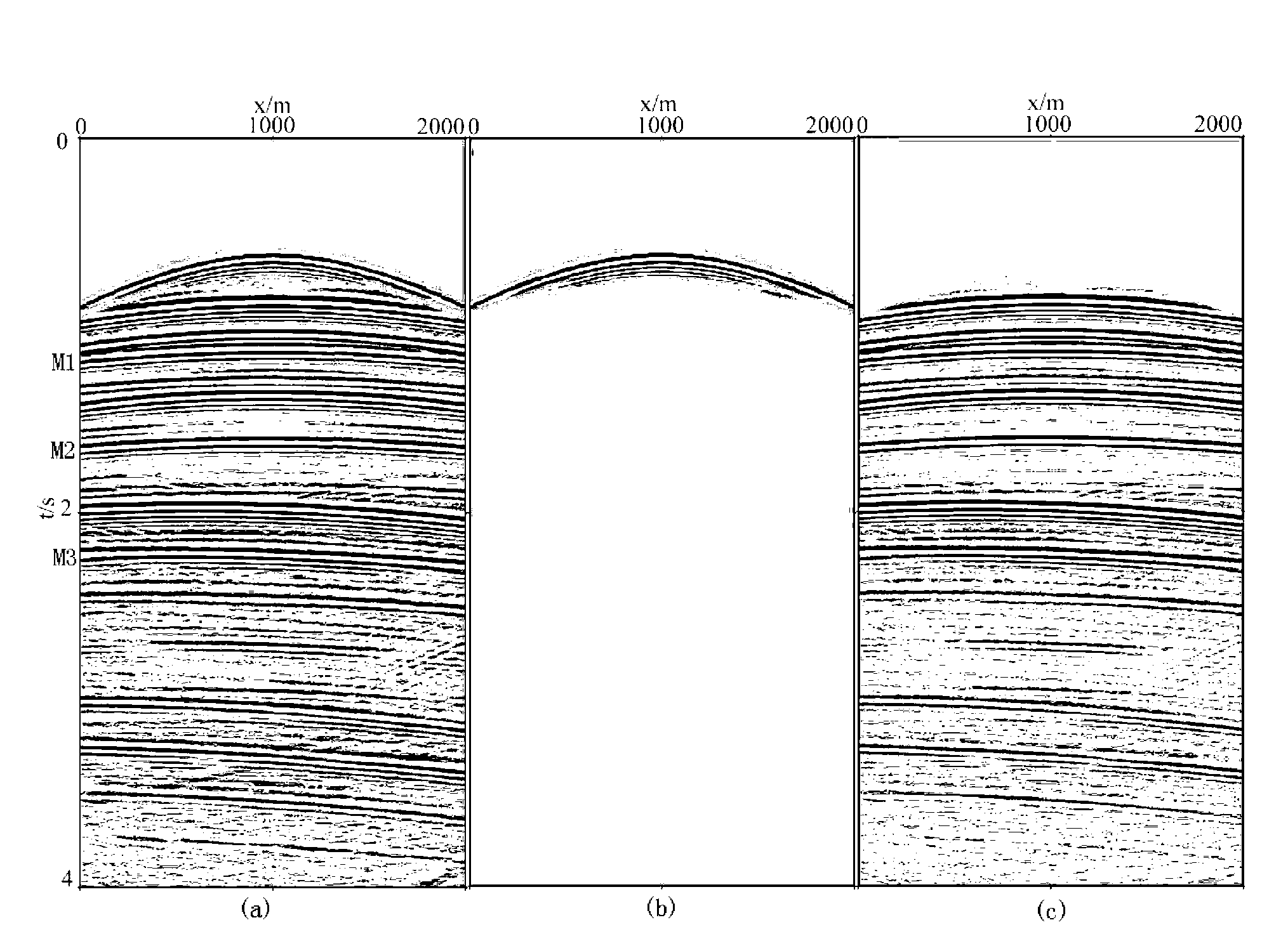

Self-adapting ground surface consistency deconvolution method of controllable earthquake source

InactiveCN101556338AEasy to closeSolving the picking problem of refracted wave staticsSeismic signal processingSeismology for water-loggingEarth surfacePetroleum

The invention relates to a processing technology of petroleum geophysical exploration data, which is a rapid and effective self-adapting ground surface consistency deconvolution method of a controllable earthquake source. The concrete steps are as follows: using a conventional controllable earthquake source to vitalize and record seismic wave data; adopting the earthquake record of the controllable earthquake source and performing absorption analysis at a selected time window to obtain an amplitude spectrum of a shot point or a demodulation point at a Q absorption model channel in a t1-t2 time window; performing Fourier transform to a scanning signal of a cannon to obtain the amplitude spectrum of scanning related wavelets; working out the exploration factor h(t); and obtaining an imaging section which has an obvious improvement in waveforms of a shallow layer, a middle layer and a deep layer and is vitalized by the controllable earthquake source and an explosive source. The invention can improve the resolving capability and realize phase switching, has the self-adapting capacity of ground surface consistency counting and can obviously improve a controllable earthquake source first-motion wave having larger near ground surface absorption influence to ensure that the processing quality of earthquake data is obviously improved.

Owner:BGP OF CHINA NAT GASOLINEEUM CORP

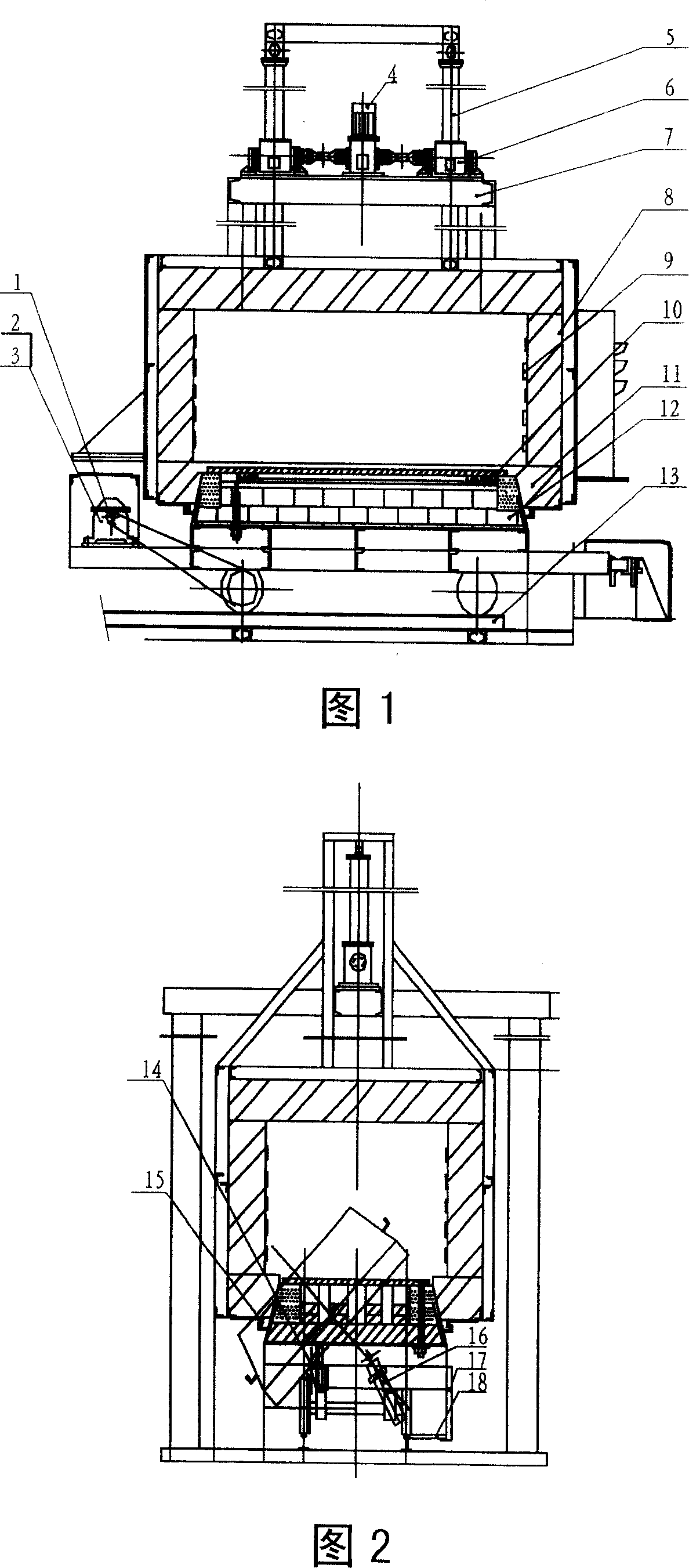

Car-type heat treatment furnace

InactiveCN1978675AImprove insulation effectExcellent heat treatment performanceFurnace typesHeat treatment furnacesTreatment qualityHeat treating

The invention discloses a bogie type heat treatment furnace. It includes furnace mantle, travel mechanism, and furnace bottom. Its features are that the furnace mantle and the bottom are formed sealed heating chamber; it also includes furnace mantle elevating mechanism. The invention can save power utilization, ensure casting heat treatment quality, reduce labor intensity, and increase production efficiency.

Owner:CIMC VEHICLES (GROUP) CO LTD +1

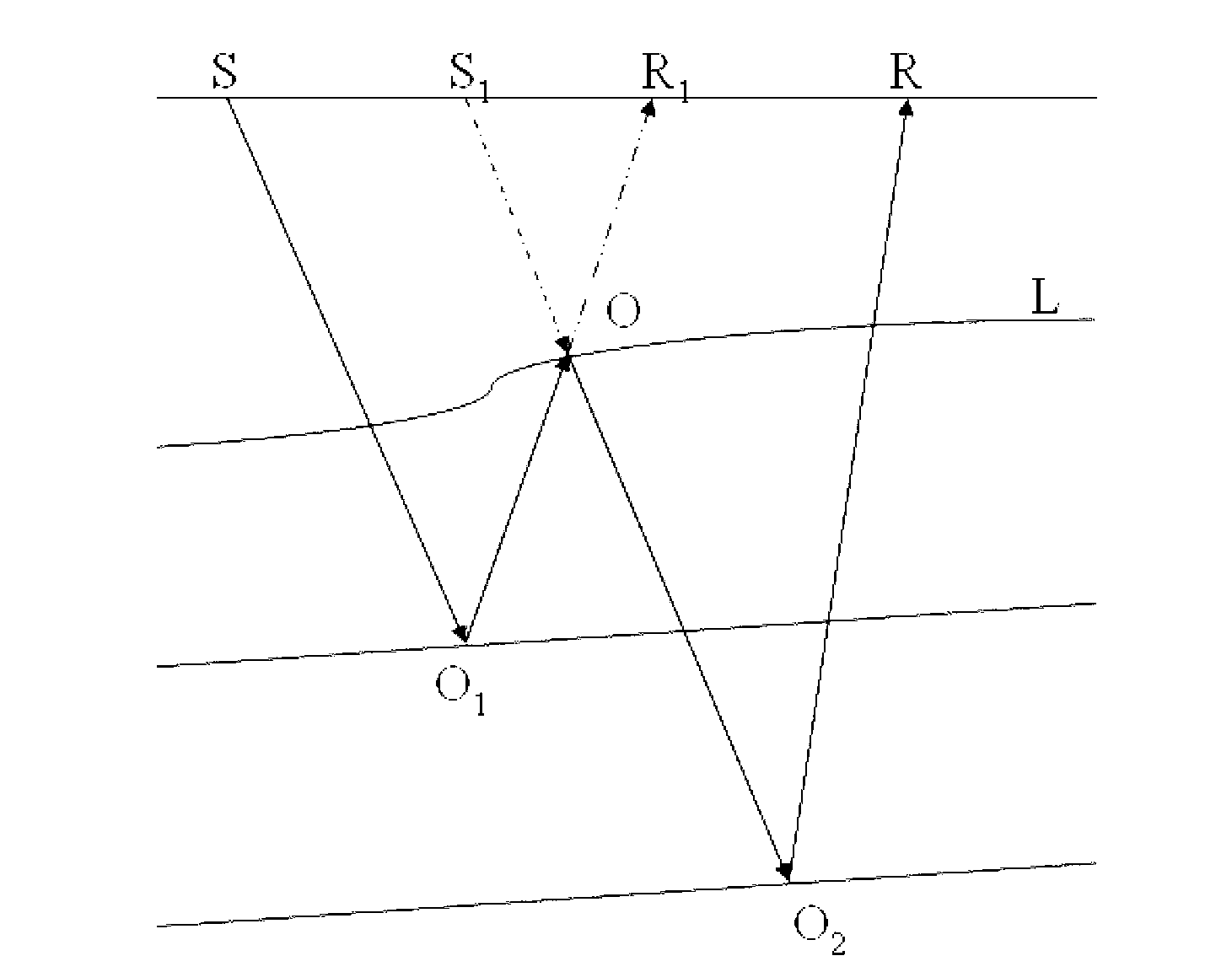

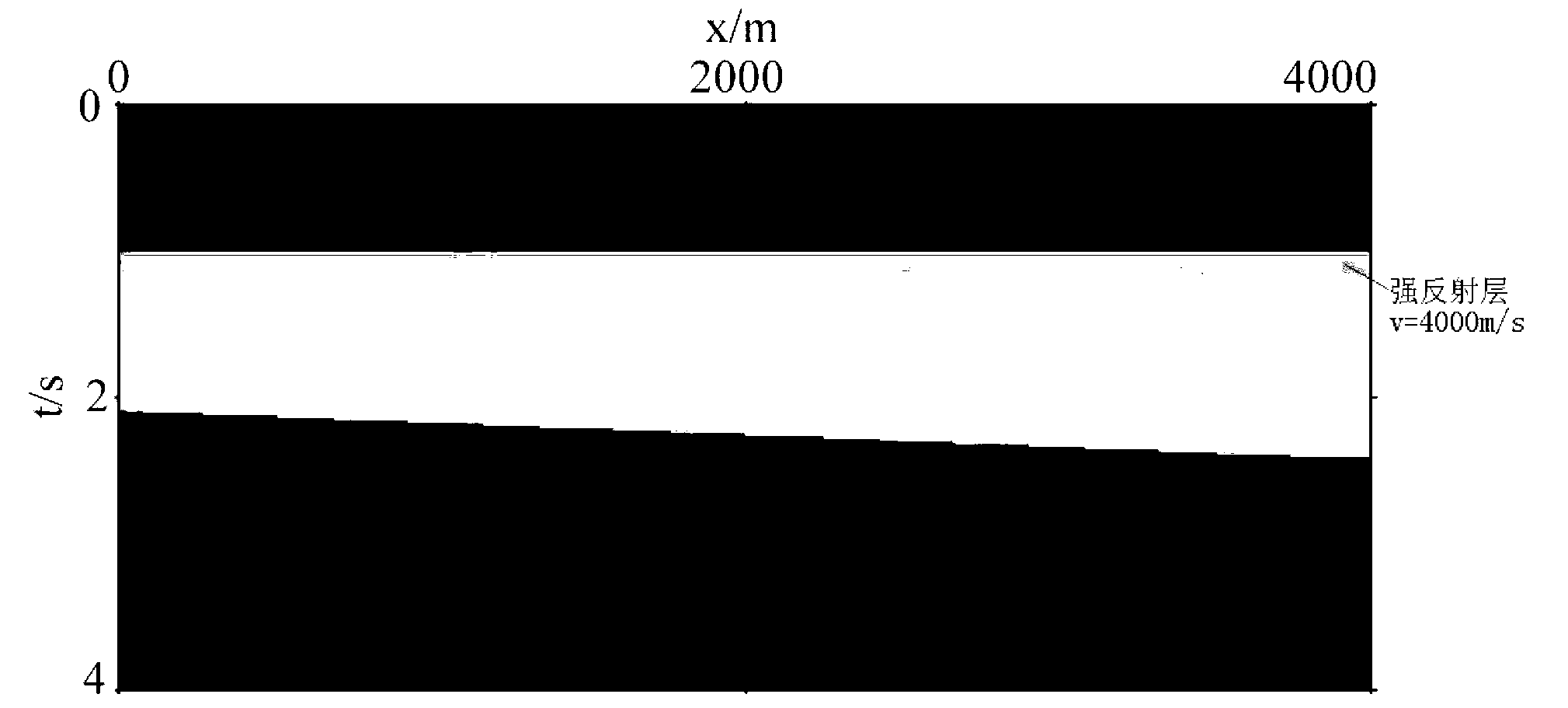

Method and device for attenuating interbed multiples during process of processing marine seismic data

The invention provides a method and a device for attenuating interbed multiples during the process of processing marine seismic data. The method comprises the following steps of preprocessing original seismic records to obtain preprocessed seismic records PPR (x, z0; t); overlapping the dynamically-corrected seismic records and obtaining the location of a strong reflecting interface L in which the interbed multiples are generated on the overlapped section; picking up primary reflection waves generated by the interface L from the dynamically-corrected seismic records, and correcting the primary reflection waves inversely and dynamically to obtain a second wave field item P2 (x, z0; t); deleting a reflected wave field above the interface L from the dynamically-corrected seismic records according to the location of the interface L, and carrying out inverse dynamic correction to obtain a first wave field item P1 (x, z0; t); setting a third wave field item P3 (x, z0; t) to be equal to the first wave field item; carrying out calculation according to the first wave field item P1 (x, z0; w), the second wave field item P2 (x, z0; w) and the third wave field item P3 (x, z0; w) to obtain the interbed multiples PLM (x, z0; w) relevant with the interface L; and attenuating the interbed multiples PLM (x, z0; t) of a time domain from the preprocessed seismic records PPR (x, z0; t) to obtain the records PME (x, z0; t) of the attenuated interbed multiples. By the adoption of the method and the device for attenuating the interbed multiples during the process of the processing marine seismic data, as the interbed multiples are predicted and attenuated only through data driving, independent of the precision of a velocity field, the processing quality of the marine seismic data is improved.

Owner:PETROCHINA CO LTD

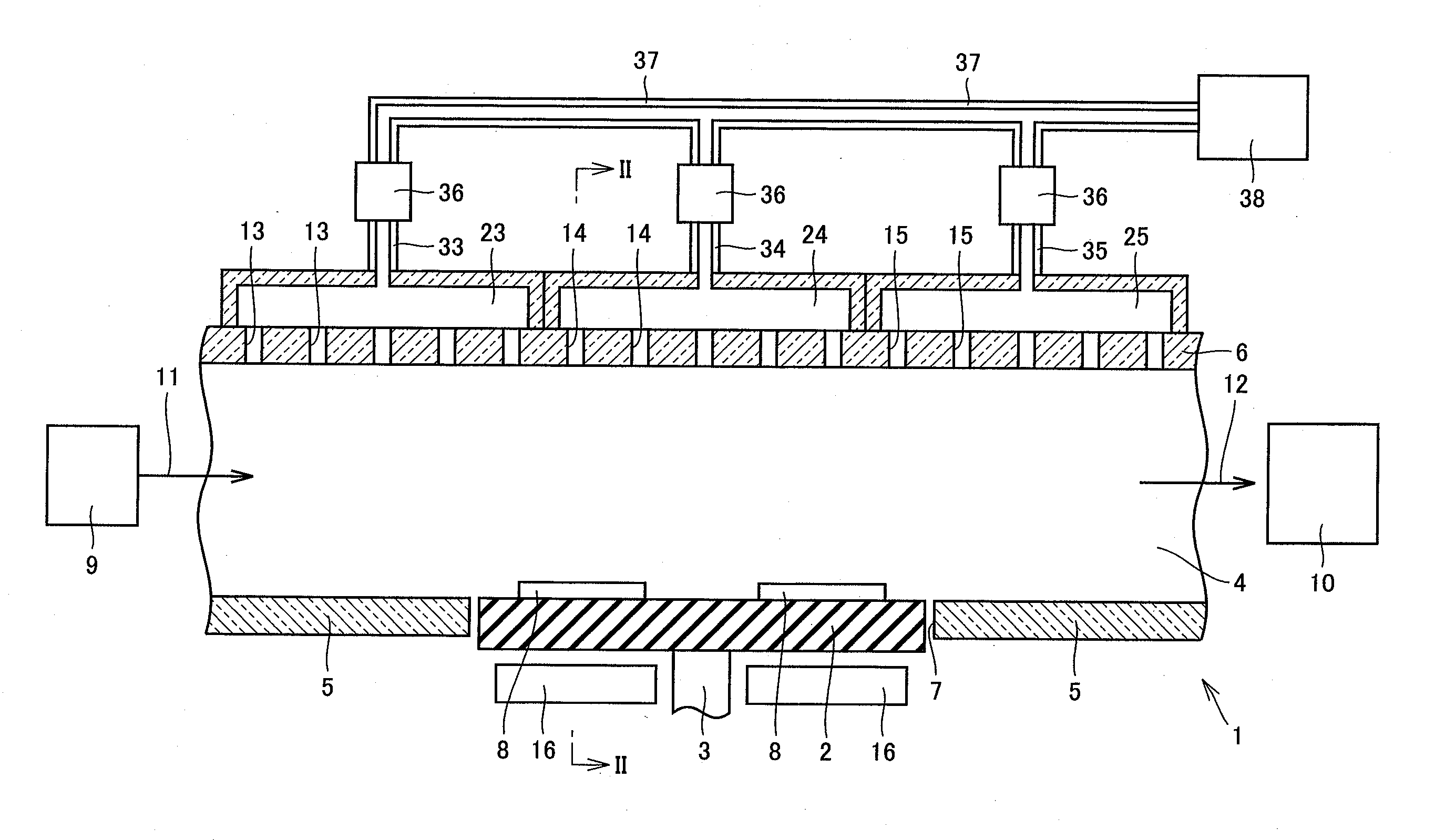

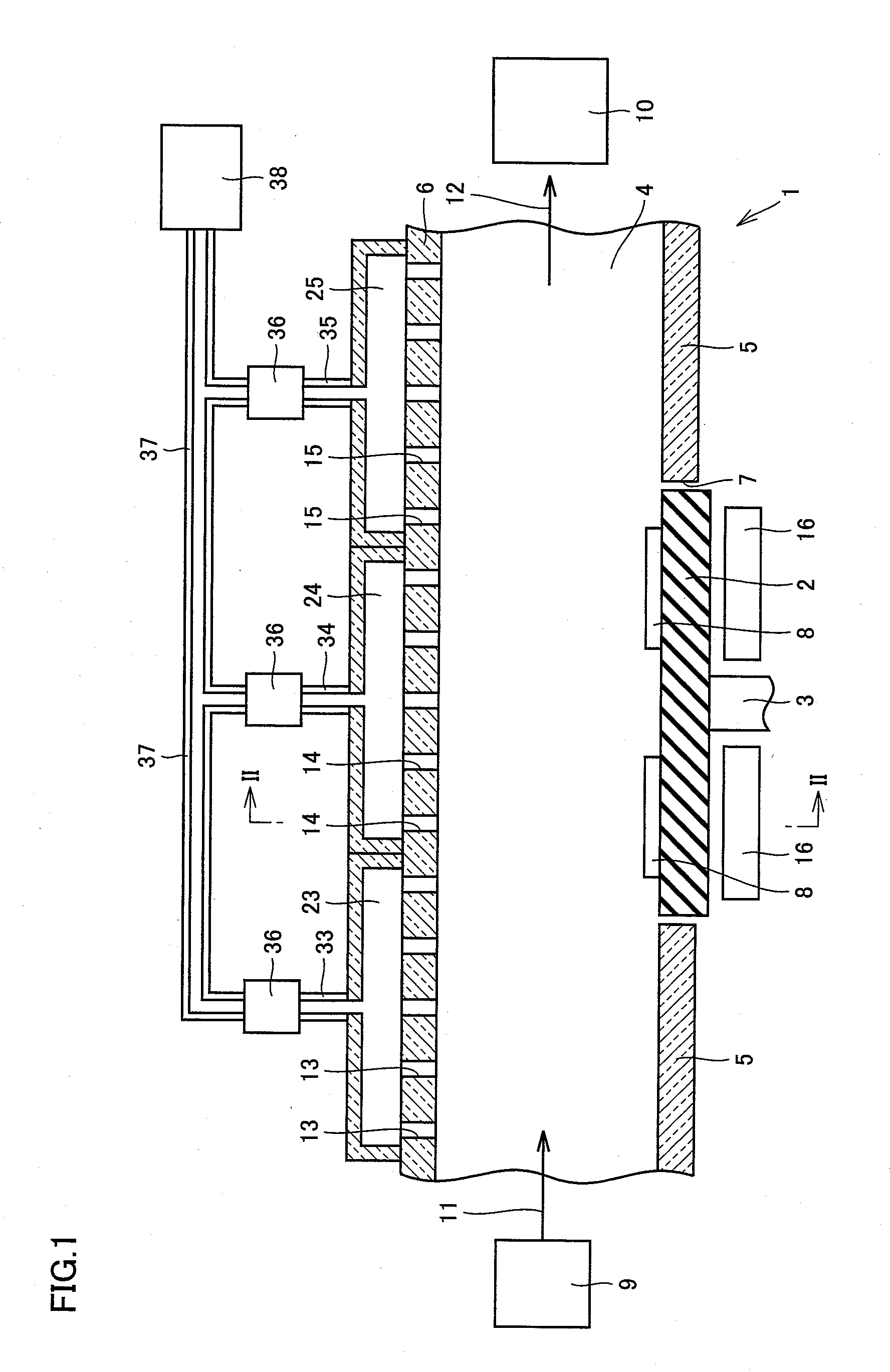

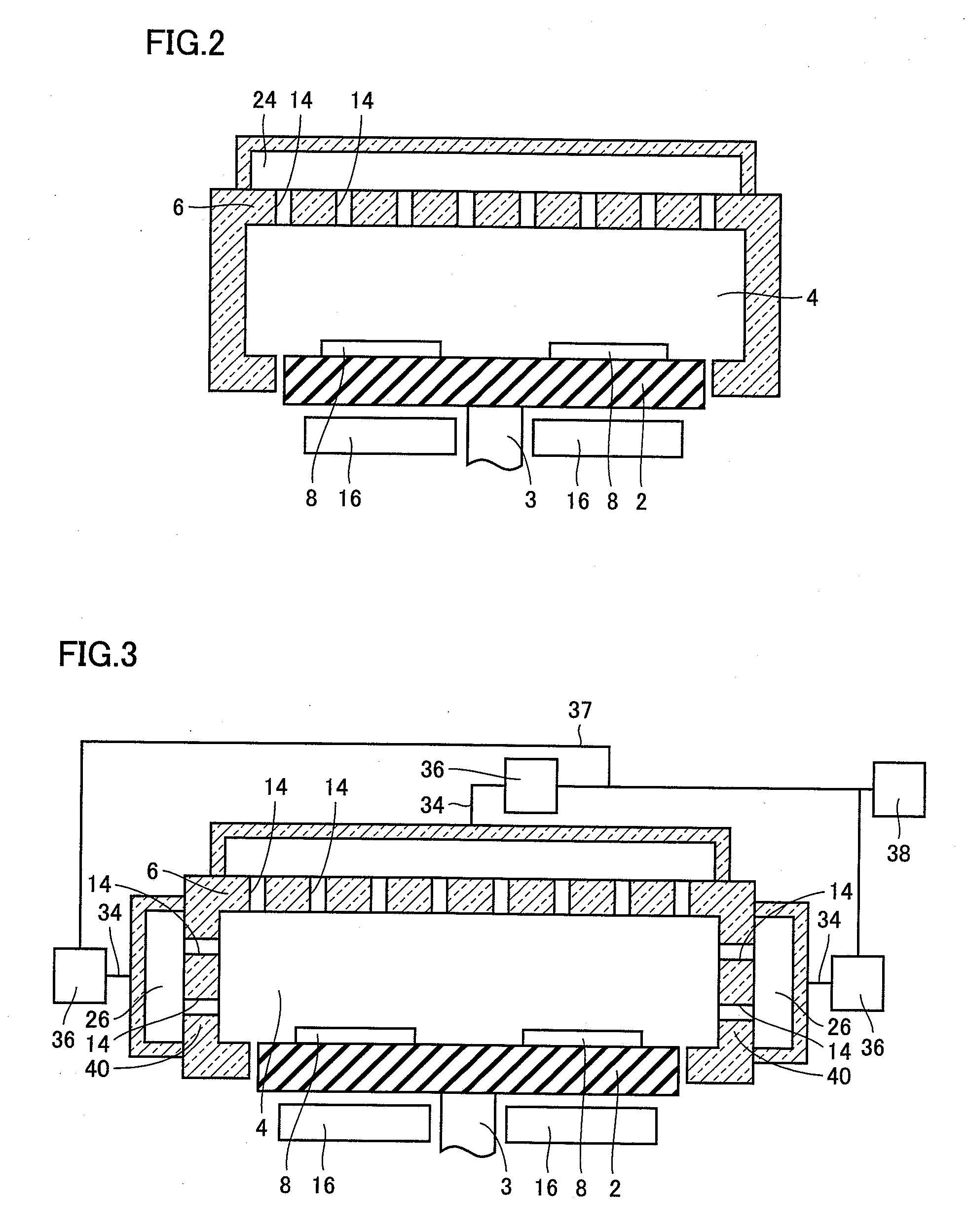

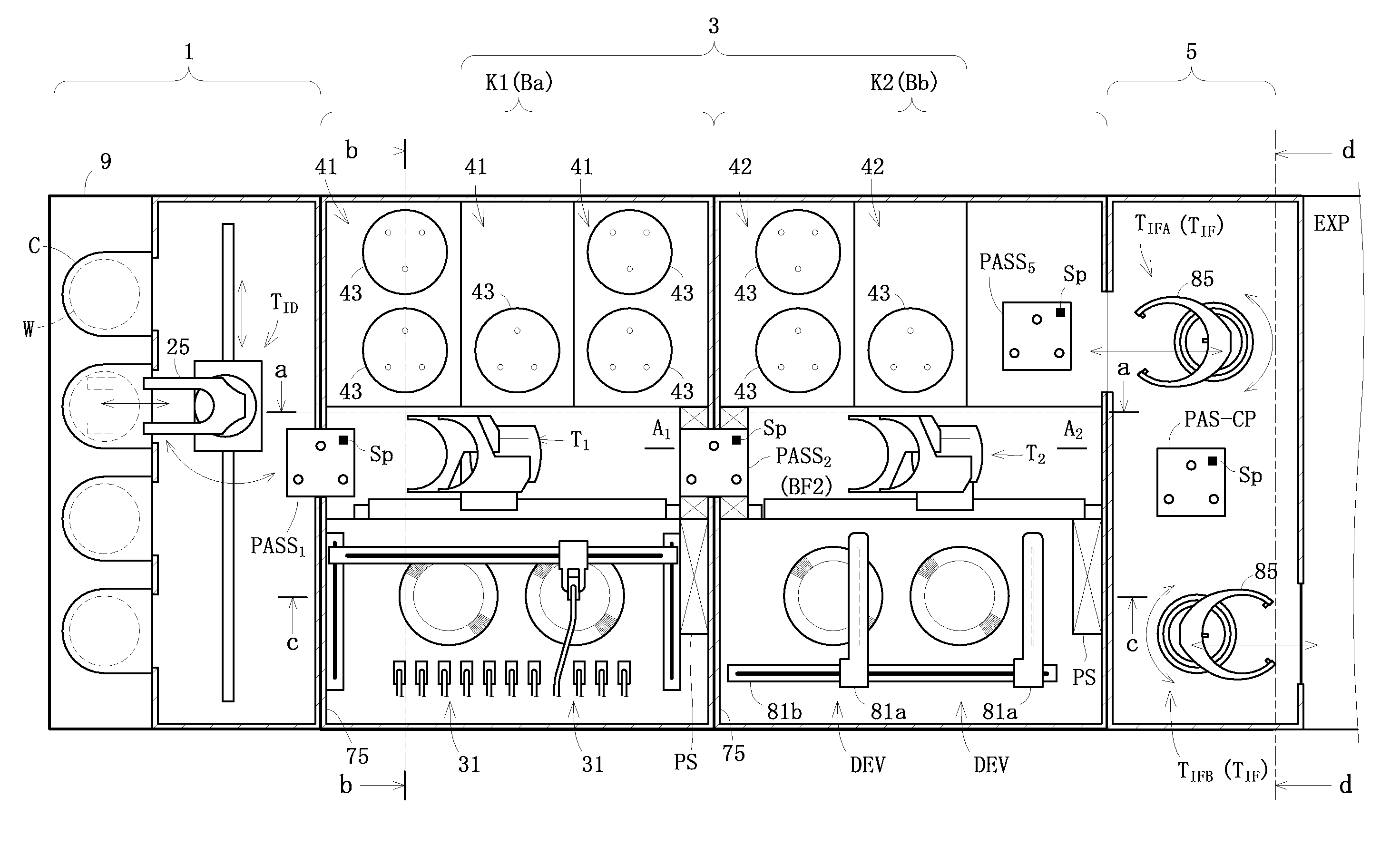

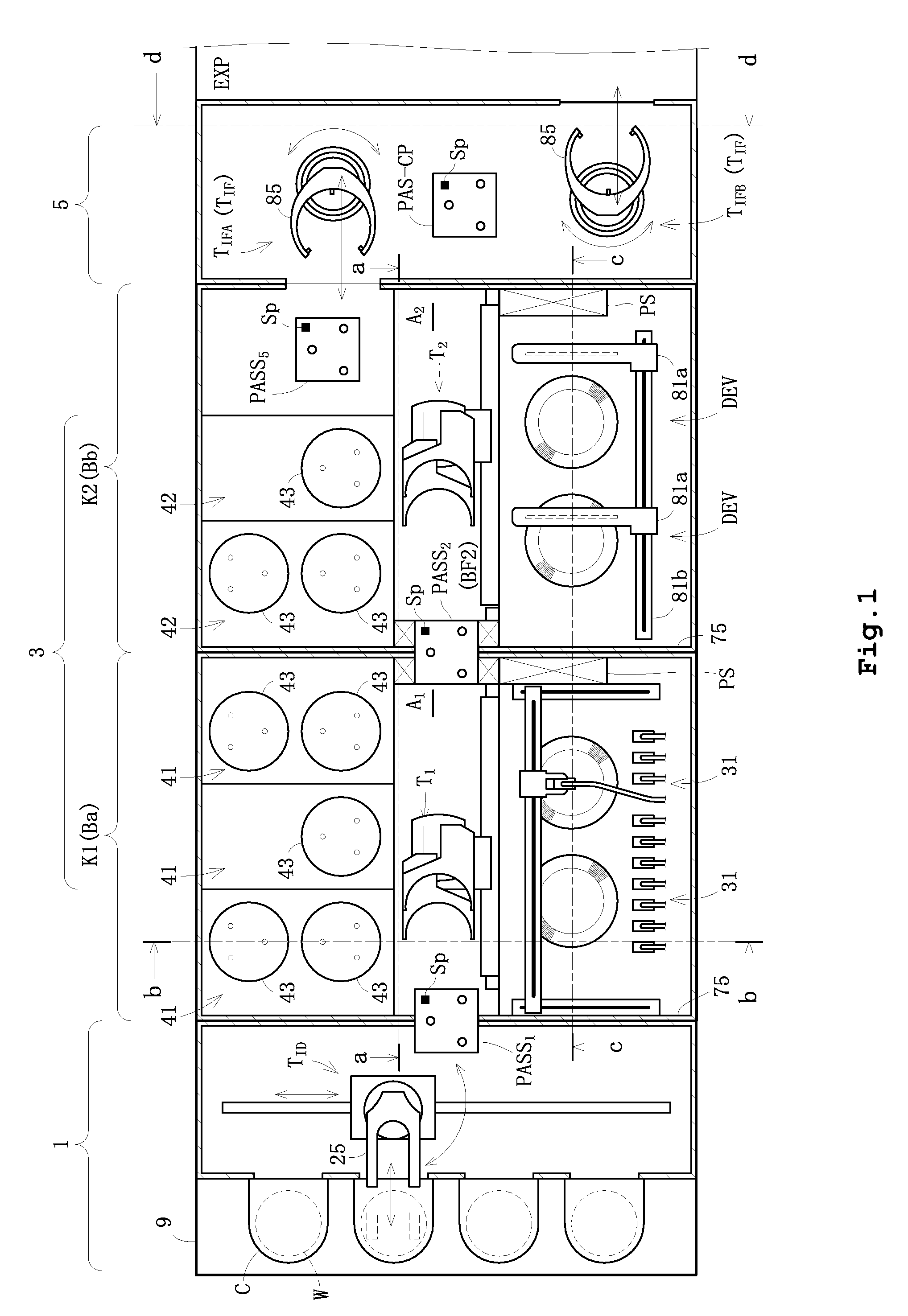

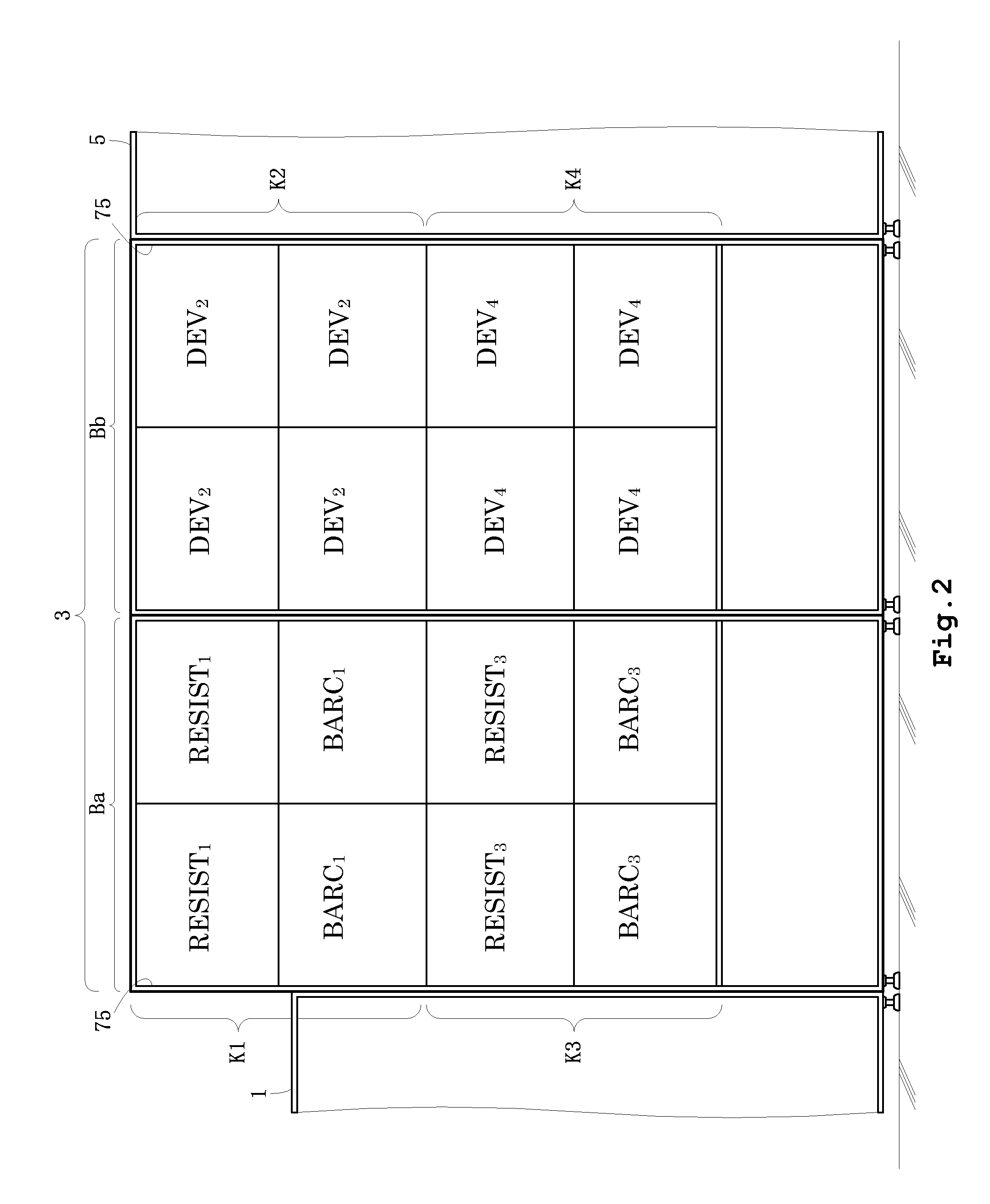

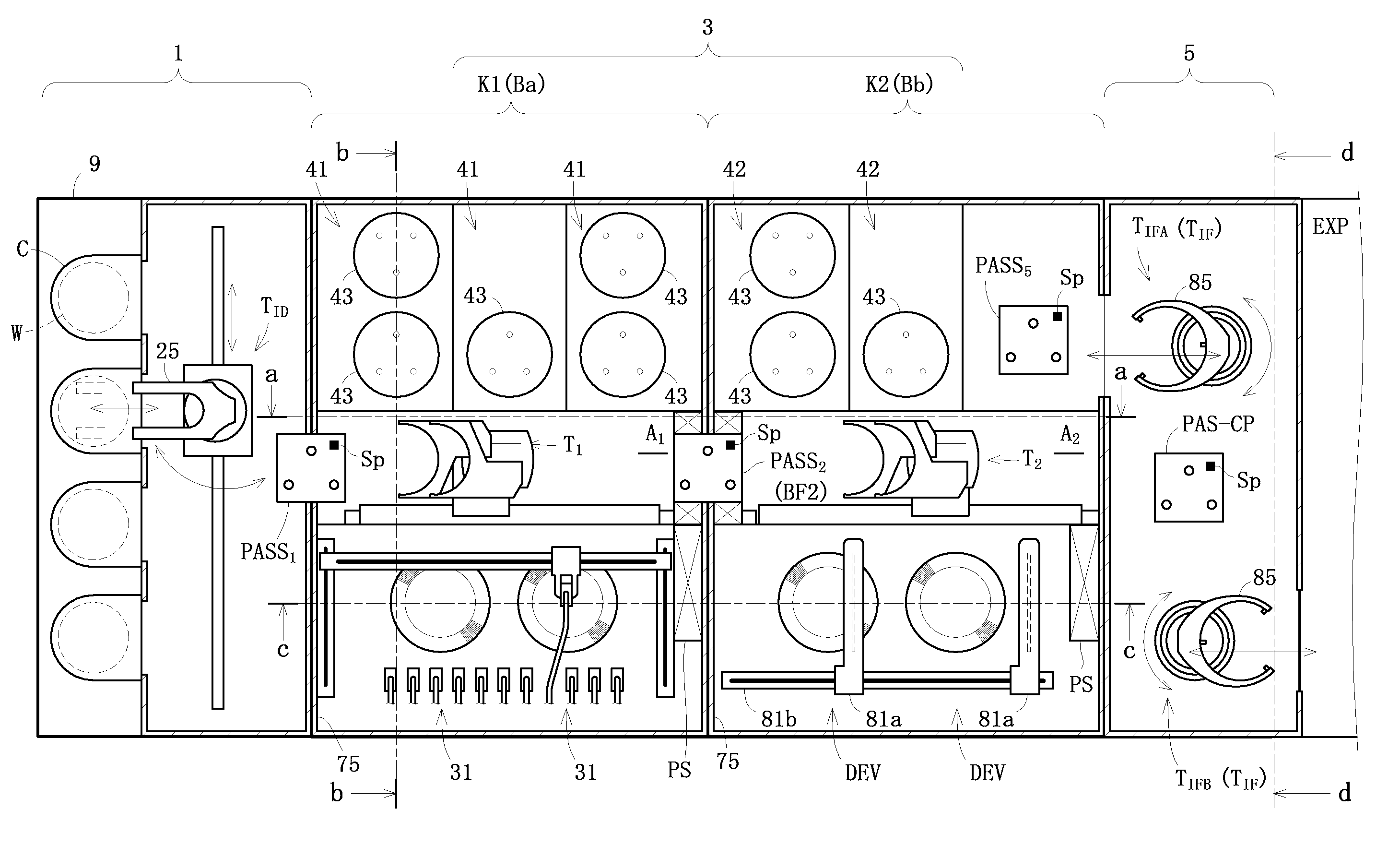

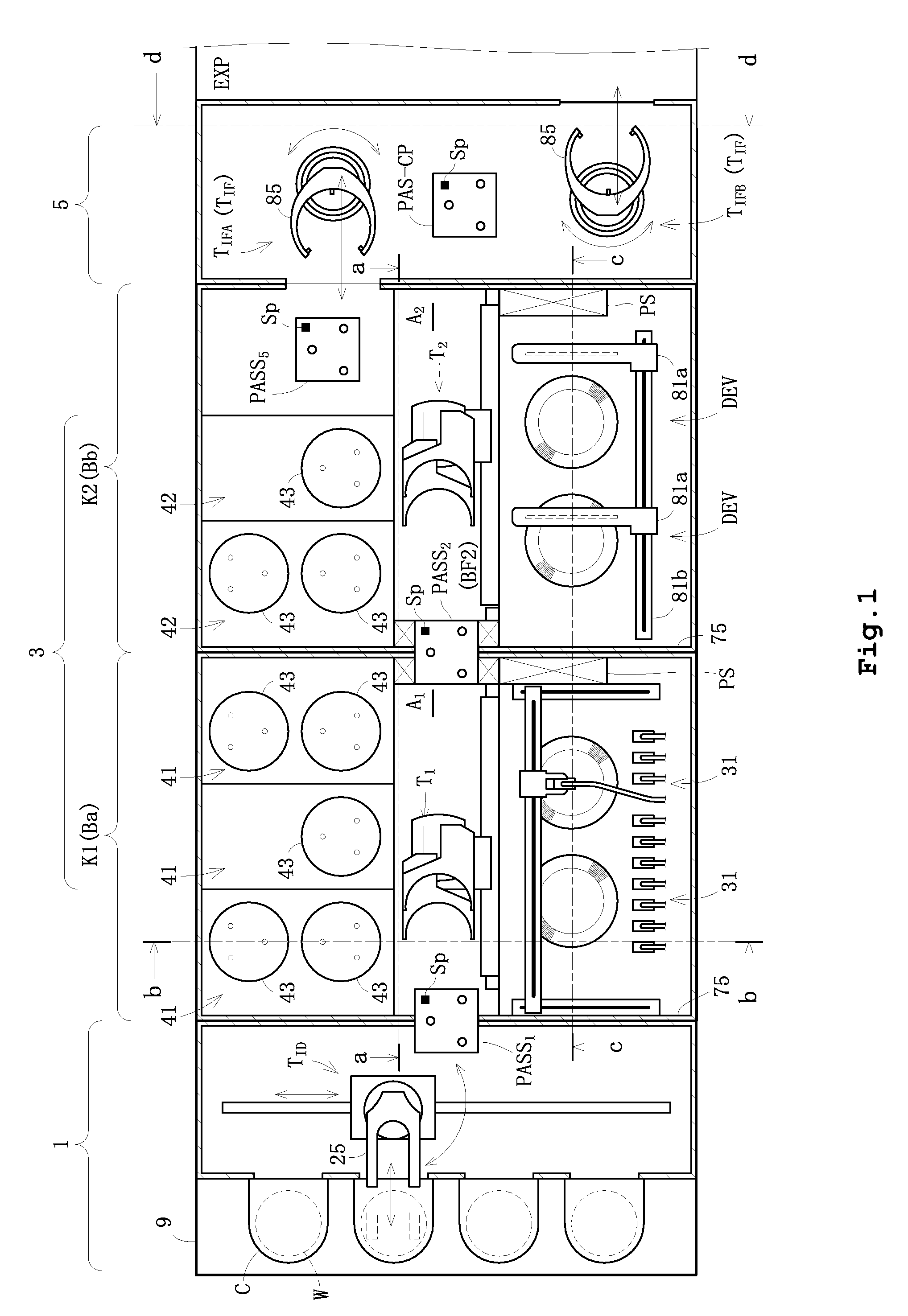

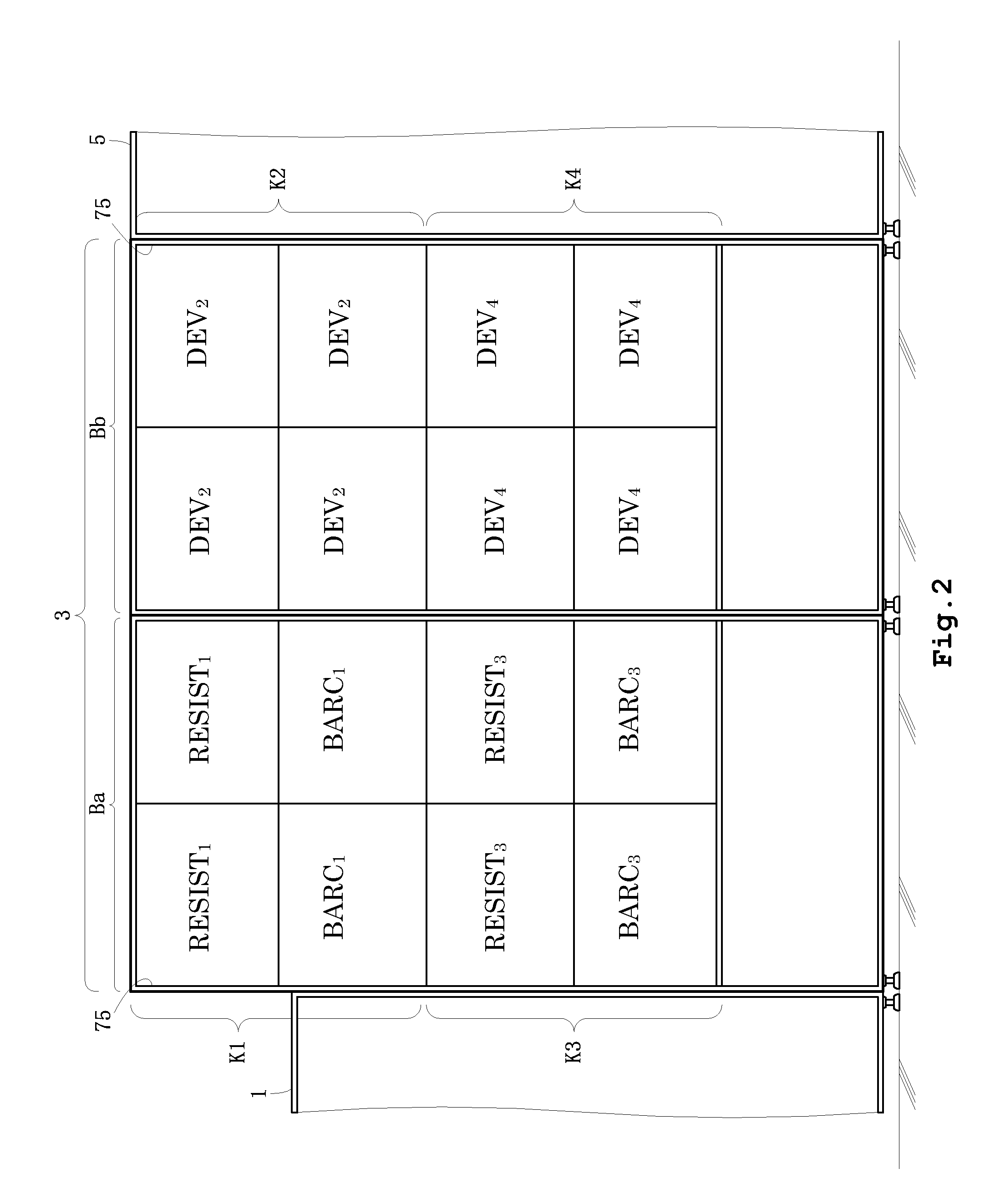

Substrate treating apparatus with inter-unit buffers

ActiveUS8545118B2Quality improvementLiquid surface applicatorsConveyorsEngineeringMechanical engineering

The invention provides coating units, heat-treating units, and a first main transport mechanism for transporting substrates to each of these treating units. The substrates are transferred from the first main transport mechanism to a second main transport mechanism through a receiver. When a substrate cannot be placed on the receiver, this substrate is placed on a buffer. Thus, the first main transport mechanism can continue transporting other substrates. The other substrates in the treating units are transported between the treating units without delay, to receive a series of treatments including coating treatment and heat treatment as scheduled. This prevents lowering of the quality of treatment for forming film on the substrates.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

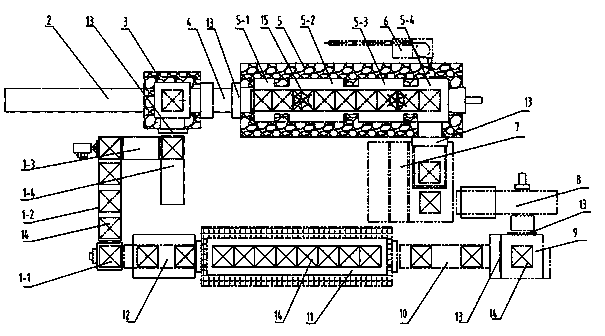

Automatic production line for saw blade heat treatment

InactiveCN103146902AGuarantee the environmentGuaranteed atmosphereFurnace typesHeat treatment furnacesProduction lineEngineering

The invention discloses an automatic production line for saw blade heat treatment, and belongs to the technical field of work piece heat treatment. The automatic production line for the saw blade heat treatment is characterized by comprising a feed mechanism, a feeding tray stepping advancing mechanism, a heat preserving furnace, a carbon-nitrogen furnace, a quenching mechanism, a cleaning machine, a tempering furnace and feeding tray conveying mechanisms, wherein the feed mechanism, the feeding tray stepping advancing mechanism, the heat preserving furnace, the carbon-nitrogen furnace, the quenching mechanism, the cleaning machine, the tempering furnace are sequentially arranged according to a manufacturing process order, and the feeding tray conveying mechanisms are arranged between each two adjacent devices. The feeding tray conveying mechanisms comprise a transition cylinder, a carbon-nitrogen furnace discharging advancing device, a quenching discharging advancing device, a tempering furnace feeding advancing device and a tempering furnace discharging advancing device, wherein the transition cylinder is arranged between the heat preserving furnace and the carbon-nitrogen furnace, the carbon-nitrogen furnace discharging advancing device is arranged on one side of the carbon-nitrogen furnace, the quenching discharging advancing device is arranged between the quenching mechanism and the cleaning machine, the tempering furnace feeding advancing device is arranged between the cleaning machine and the tempering furnace, and the tempering furnace discharging advancing device is arranged at an outlet of the tempering furnace. The automatic production line for the saw blade heat treatment has the advantages of improving production efficiency and energy use rates of the devices, ensuring heat treatment quality of saw blades due to continuous production, achieving automation operation of the whole production line and being small in number of employed workers and good in labor environment.

Owner:烟台金都锯业有限公司

Substrate treating apparatus with inter-unit buffers

ActiveUS20090142162A1Limit quality of treatmentQuality improvementLiquid surface applicatorsConveyorsEngineeringMechanical engineering

The invention provides coating units, heat-treating units, and a first main transport mechanism for transporting substrates to each of these treating units. The substrates are transferred from the first main transport mechanism to a second main transport mechanism through a receiver. When a substrate cannot be placed on the receiver, this substrate is placed on a buffer. Thus, the first main transport mechanism can continue transporting other substrates. The other substrates in the treating units are transported between the treating units without delay, to receive a series of treatments including coating treatment and heat treatment as scheduled. This prevents lowering of the quality of treatment for forming film on the substrates.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

Environmentally-friendly steel oil and rust removing solution at normal temperature

The invention relates to a preparation method of an environment-friendly steel oil and rust removing solution at normal temperature. The solution mainly comprises the following elements in percentage by weight: 82-94.5% of mixed inorganic aid solution, 4-8% of hydrofluoric acid, 0.3-3% of oxalic acid, 0.2-2% of mixed surfactant, 0.5-3% of lauryl sodium sulfate, and 0.5-2% of a compounded corrosion inhibitor. The oil and rust removing solution provided by the invention has the advantages that the preparation method is simple and the cost is low; the rust removal speed of the oil and rust removing solution is fast, the energy resource is saved, and the working efficiency is increased; the oil and rust removing solution is suitable for continuous use and does not need to discharge wastewater; the acid mist is effectively inhibited, the surface treatment quality is improved, and the rust removal effect is rather good. Therefore, the oil and rust removing solution can be widely applied to the field of steel washing.

Owner:常州市卯旺化工有限公司

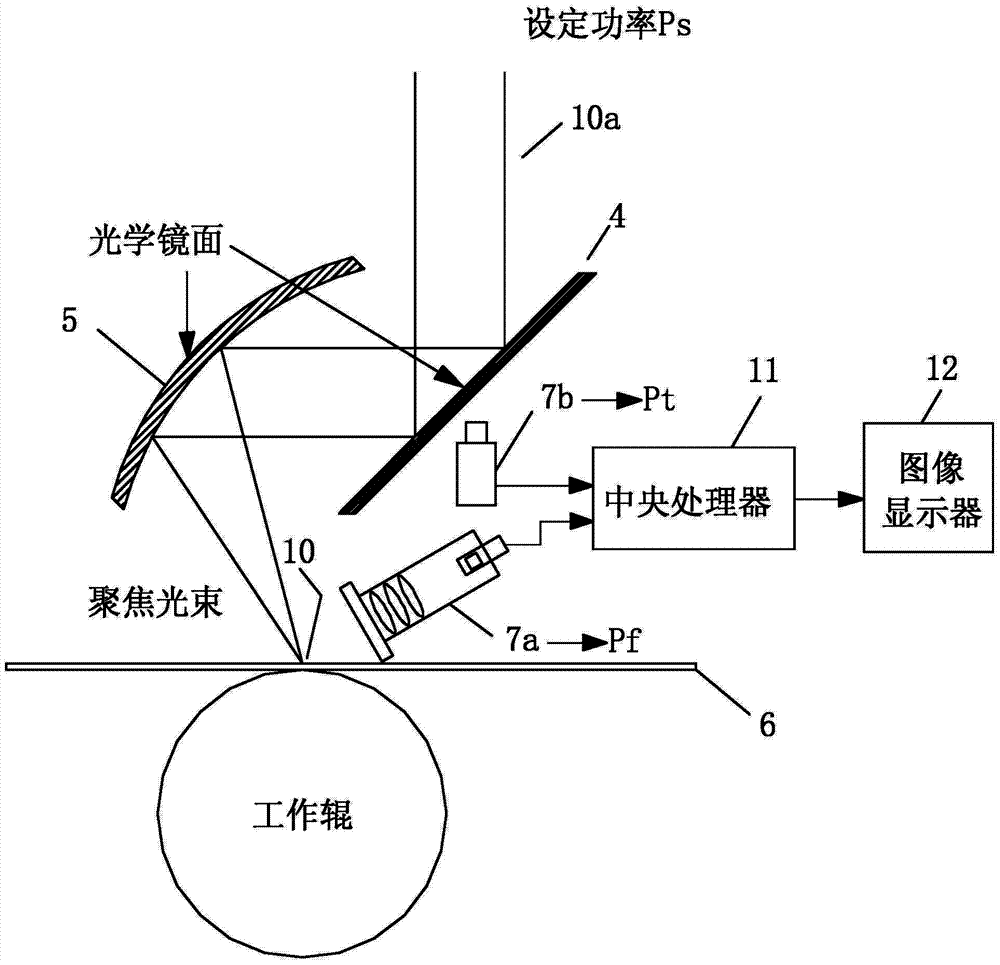

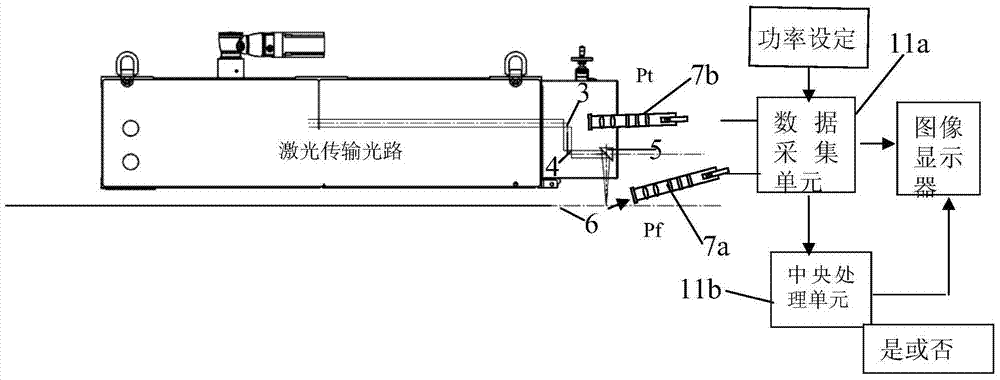

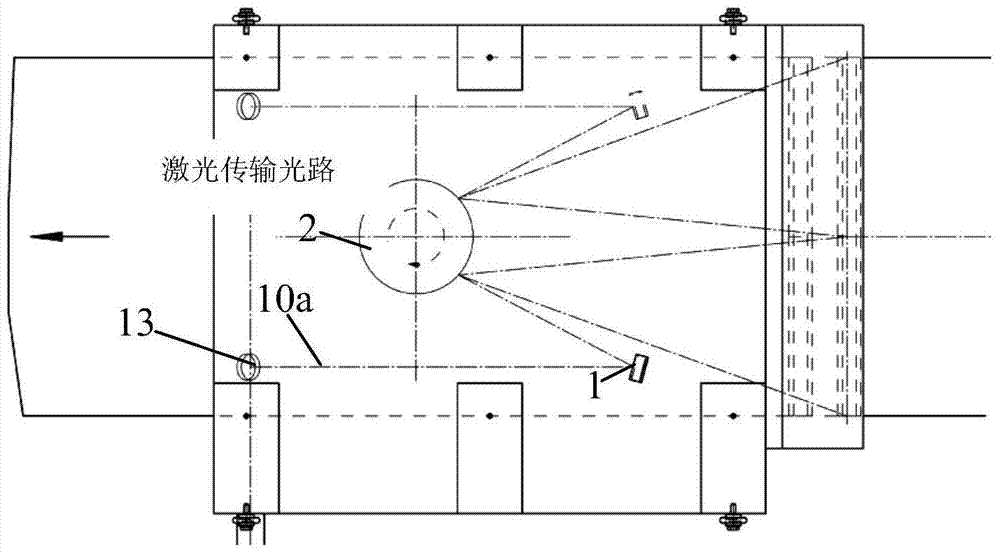

Laser surface treatment quality control method and on-line monitoring system thereof

ActiveCN104772568AInhibit productionGuaranteed reliabilityLaser beam welding apparatusTime informationDisplay device

The invention provides a laser surface treatment quality control method and an on-line monitoring system thereof. The laser surface treatment quality control method comprises the steps that incident laser is emitted through a laser, passes through an inner transmission light path, and at last is focused on a workpiece through a focus lens; the light reflected on the surface of the workpiece in practical processing is detected through a first photoelectric sensor; the light is converted to be a reflective power value through photovoltaic conversion; the residual penetration light of the reflective lens surface of a reflective lens in the transmission light path is detected through a second photoelectric sensor to obtain the practical power; parameters, set power, the reflective power value and the practical power are sent to a central processing unit to be subjected to comparison calculation through a data collection unit, and a mass control factor is determined through logic judgment; the mass control real-time information is displayed through an image display device. The invention guarantees the high consistence of laser power density of the laser in the material surface treatment process and the accuracy of the height position of a laser focal point on a material surface.

Owner:BAOSHAN IRON & STEEL CO LTD

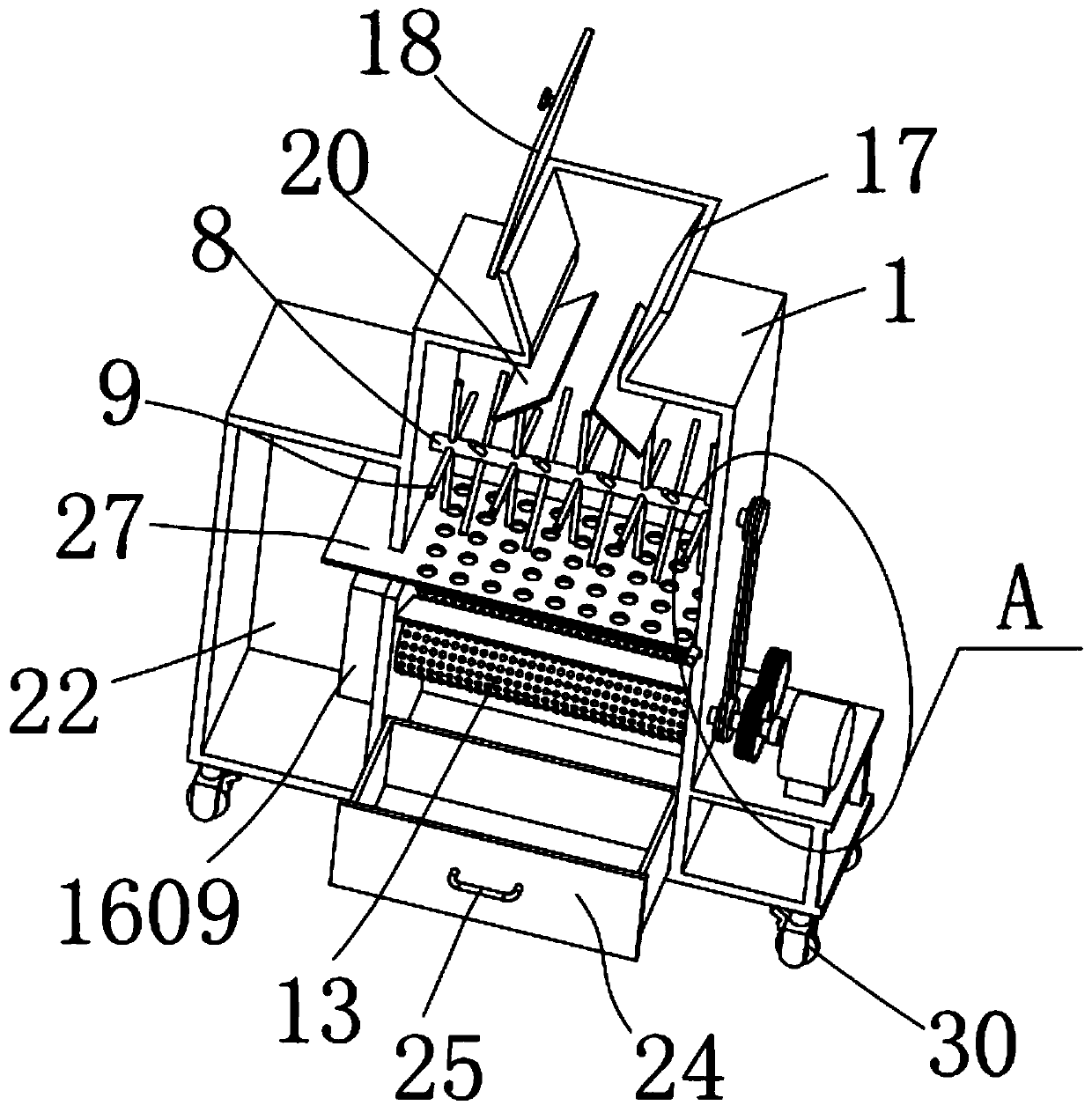

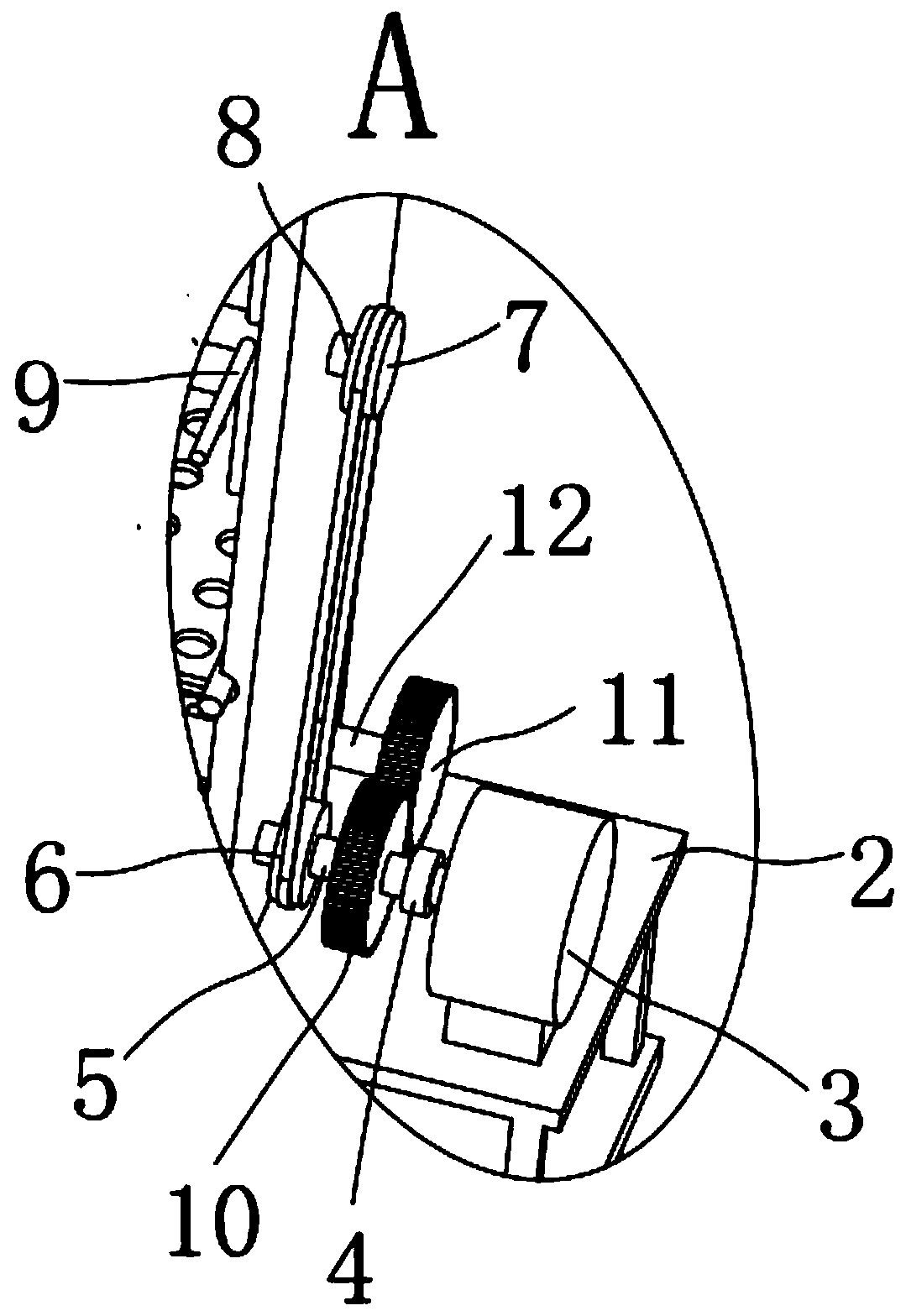

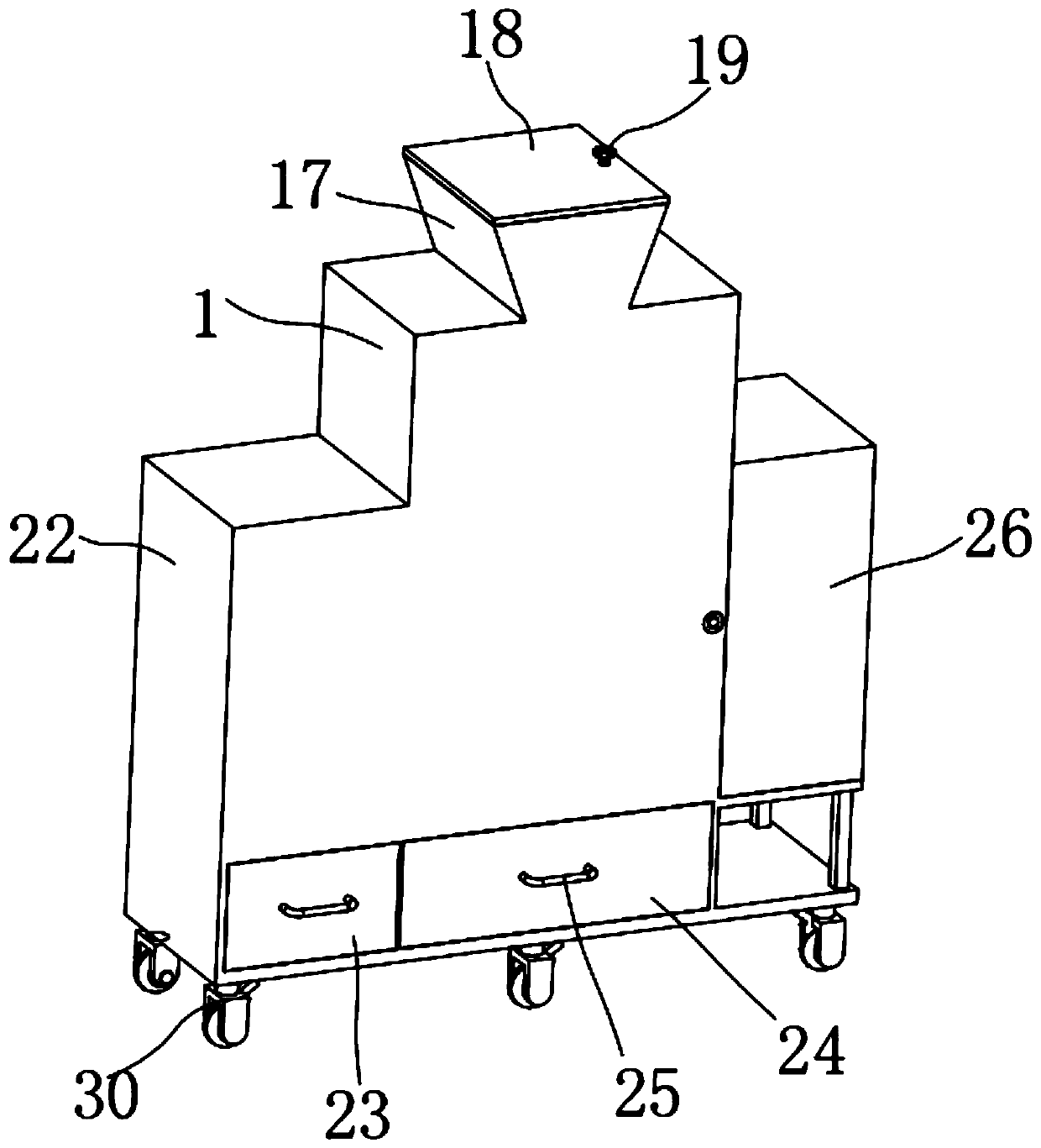

Construction solid waste multistage treatment device

The invention discloses a construction solid waste multistage treatment device. The construction solid waste multistage treatment device comprises a treatment box, wherein a servo motor is arranged onone side of the treatment box, an output shaft of the servo motor is fixedly provided with a first rotating shaft, the first rotating shaft is fixedly provided with a first belt wheel, the first beltwheel is in transmission connection with a second belt wheel, the second belt wheel is fixedly provided with a second rotating shaft, a smashing rod is fixed on the second rotating shaft, the smashing rod is located in the treatment box, a first gear is fixed to the first rotating shaft, the first gear is in transmission connection with a second gear, the second gear is fixed on a third rotatingshaft, a first grinding roller and a second grinding roller are fixed on the first rotating shaft and the third rotating shaft respectively, the first grinding roller and the second grinding roller are located in the treatment box, a screen is arranged below the smashing rod, and a vibrating mechanism is arranged on one side of the screen. According to the structure, waste crushing, screening andgrinding multistage treatment are realized, the working efficiency is high, and the treatment quality is good.

Owner:上海达人建设科技集团有限公司

System for treating overproof radioactive laundry waste water

InactiveCN102930912ALow running costImprove processing qualityRadioactive decontaminationActivated carbon filtrationIon exchange

The invention discloses a system for treating overproof radioactive laundry waste water, which comprises a bag filter, an active carbon filter and a zeolite filter; the outlet of the bag filter is connected with the inlet of the active carbon filter; and the outlet of the active carbon filter is connected with the inlet of the zeolite filter. According to the system for treating the overproof radioactive laundry waste water, the bag filter can effectively remove suspended solids and large particle impurities in laundry waste water; the active carbon filter can remove surface active agent and micromolecule organics in the waste water to further retain the suspended solids in the water and can eliminate toxic action of organic macromolecule such as the suspended solids generated during washing clothes, synthetic detergent in the waste water and the like; the zeolite filter has good ion exchange characteristic and can effectively remove radionuclide ions (cesium and strontium) in lower radioactive waste water. The system for treating the overpoorf radioactive laundry waste water is simple in structure, low in energy consumption and operating cost and high in treating quality for the overproof radioactive laundry waste water.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

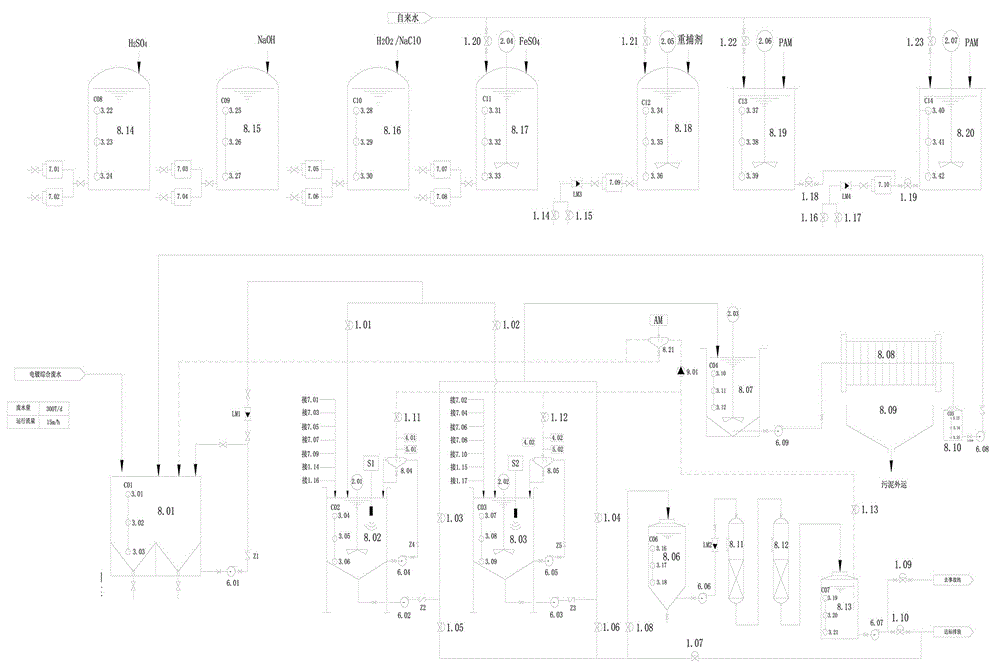

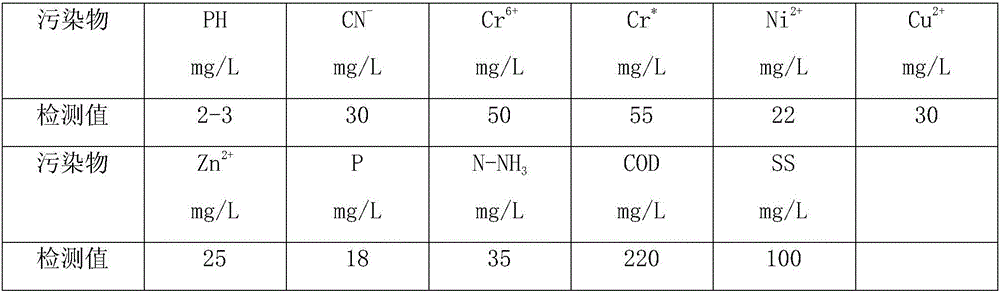

Intelligent treatment device for electroplating synthetical wastewater and control method thereof

ActiveCN106277427AEnter in time automaticallyShorten water intake timeWater treatment parameter controlWater contaminantsTreatment effectPh regulation

The invention relates to an intelligent control technology for electroplating synthetical wastewater, wherein through the steps of pH regulation of wastewater, oxidation, reduction, Cr<6+> filtering, heavy metal capture, settling of suspended solids, ion exchange and sludge treatment, the intelligent synthetical treatment of electroplating wastewater is realized, and the technology has the characteristics of high automation degree and good treatment effect. In the invention, the treatment process is finished by a sequencing bath method in a reactor, two or more reactors alternate to realize timely accurate dosing in the wastewater treatment process as well as real-time detection and control before discharge, the stability, reliability and economy of the wastewater treatment quality are guaranteed, and the wastewater treatment stably meets the requirements of the Discharge Standard for Electroplating Pollutants (GB21900-2008); furthermore, the intelligent unmanned operation can accurately control the wastewater treatment time, the drug adding amount and the wastewater treatment quality, so that the volume of the wastewater treatment equipment is reduced, and the treatment cost is lowered.

Owner:NANJING LINEHOME ENVIRONMENTAL TECH CO LTD

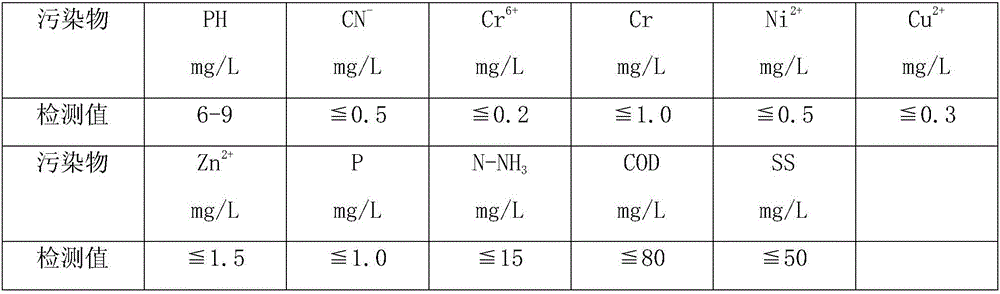

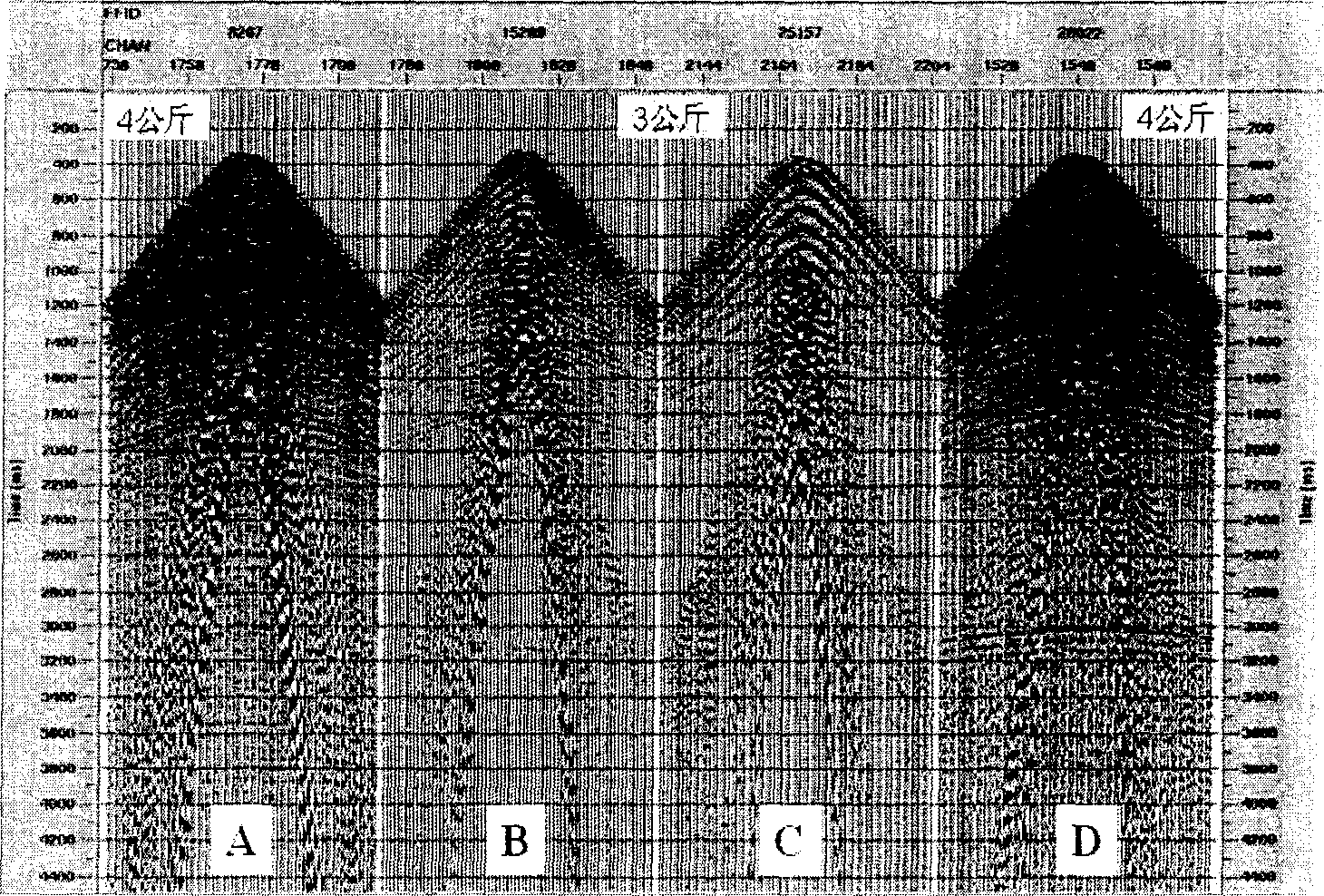

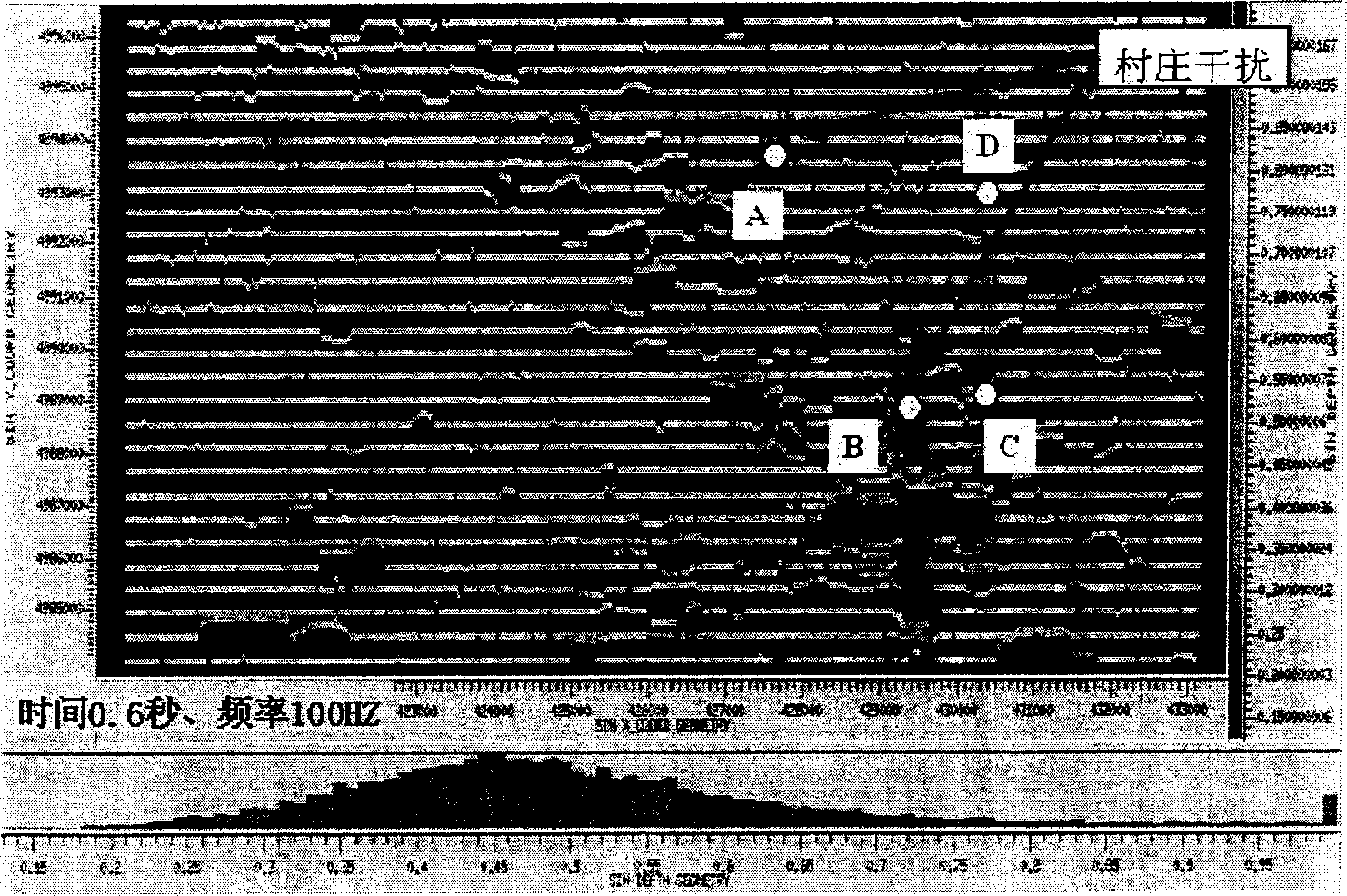

Three-dimensional seismic data processing quality monitoring technology

ActiveCN1837859AReduce the amount of calculation dataCalculation speedSeismic signal processingSmall dataComputer science

This invention relates to three-dimensional seismic data processing quality monitoring technology. Selecting time-window and analysis frequency for FFT to obtain frequency-domain conversion result for every channel; taking mean-filter to obtain the statistic excited energy or noise disturbance; plotting all results on plane graph to monitor the 3D excited energy or noise disturbance; taking normalization and autocorrelation to all earthquake channel; summating all autocorrelation statistic result to obtain opposite statistic autocorrelation result; finding out and plotting the zero-crossing of autocorrelation on plane position for monitoring excited wavelet. This invention computes fast with small data quantity and reliable result.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com