Patents

Literature

366results about How to "Guarantee the environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

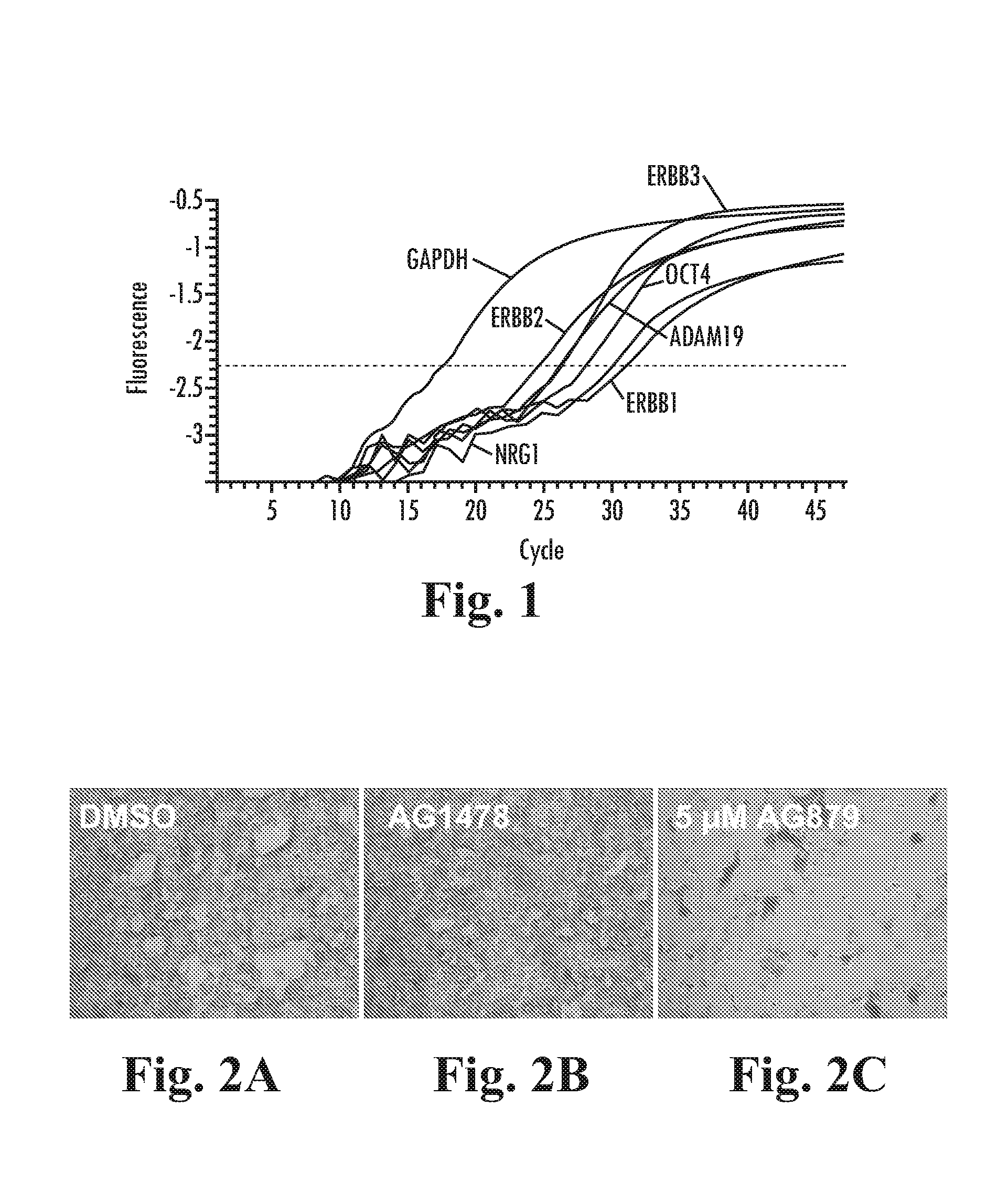

Scalable primate pluripotent stem cell aggregate suspension culture and differentiation thereof

ActiveUS20130115695A1Little and no turbulenceGuarantee the environmentBioreactor/fermenter combinationsBiological substance pretreatmentsSingle cell suspensionSuspension culture

The present invention relates to methods for production of undifferentiated or differentiated embryonic stem cell aggregate suspension cultures from undifferentiated or differentiated embryonic stem cell single cell suspensions and methods of differentiation thereof.

Owner:VIACYTE INC

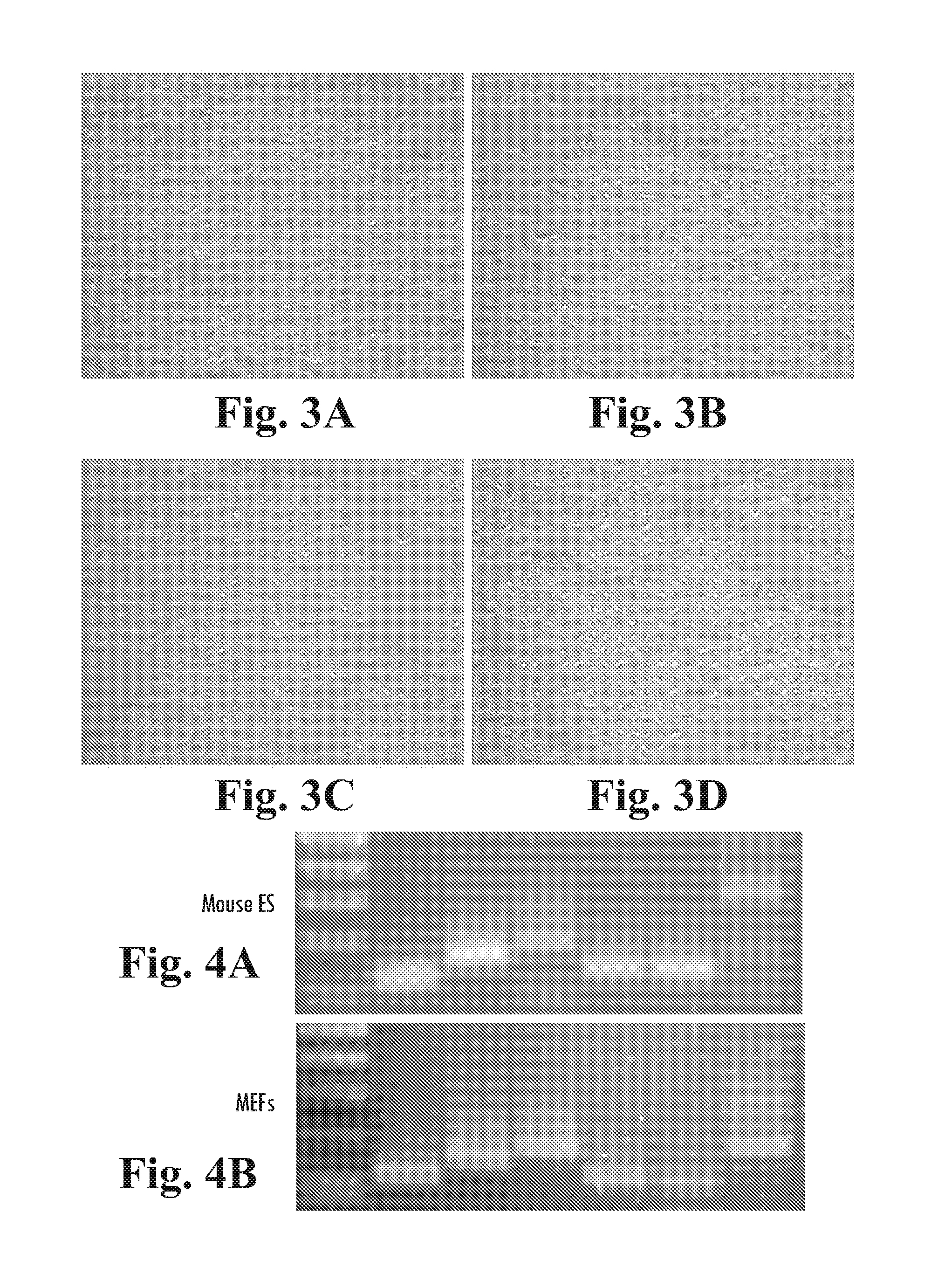

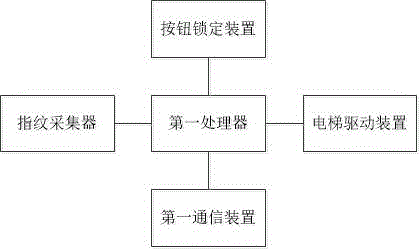

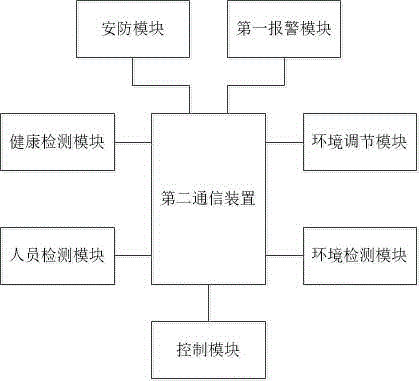

Smart community monitoring system

InactiveCN106358021AAvoid enteringImprove securityData processing applicationsCharacter and pattern recognitionVideo monitoringMonitoring system

The invention discloses a smart community monitoring system, including an access control system for opening a door when the first human body feature information of a person trying to open a corresponding door is verified to be successful, an elevator control unit for unlocking the button for a target floor in an elevator for a first preset time when the second human body feature information of a passenger is verified to be successful, a video monitoring unit for acquiring real-time video images in a community, a security detection unit for detecting whether someone fall down according to the video images and alarming when a person falls down over a second preset time, a person recognition unit for detecting a facial image in the video images and comparing the facial image with a prestored target person image and alarming when detecting a facial image consistent with the target person image, a rubbish detection unit for alarming when detecting the rubbish quantity at a rubbish spot exceeds standards, and a smart home unit for performing indoor safety protection and environmental conditioning. According to the invention, real-time smart monitoring and safeguard of the community are achieved.

Owner:CHENGDU HONGRUAN SCI & TECH IND CO LTD

Fresh-keeping method for lichee

InactiveCN1965660AHas antibacterial propertiesImprove ventilation and water permeabilityFruits/vegetable preservation by heatingFruits/vegetable preservation by coatingSulfurEngineering

The invention relates to an antiseptic method of leechee, wherein the invention uses antiseptic polypropylene non-woven cloth, to prepare different fresh-keeping bags, and packs dibutyl fumarate into common non-woven cloth to prepare the non-woven package, while the mass ratio between leechee and fresh agent is 10000:0.1-2; then putts leechee into the fresh-keeping bags, uses lines to tie the bag or uses thermal method to seal the bag, putts into ventilate package box, or putts packed leechee into bamboo frame to be put into fresh-keeping bag. The invention can store leechee at 0-5Deg. C for 30-35days. When the leechee is treated with sulfur, the leechee can be stored at 0-5Deg. C for 90-100day.

Owner:SOUTH CHINA UNIV OF TECH

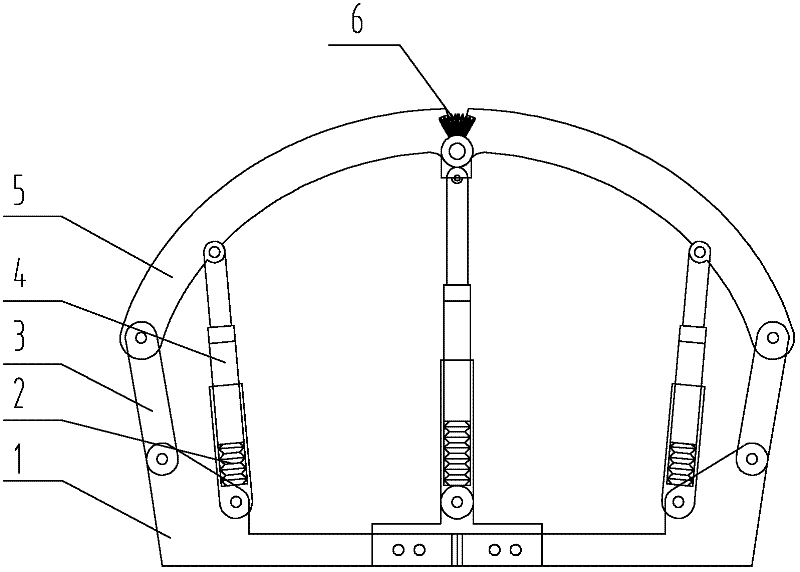

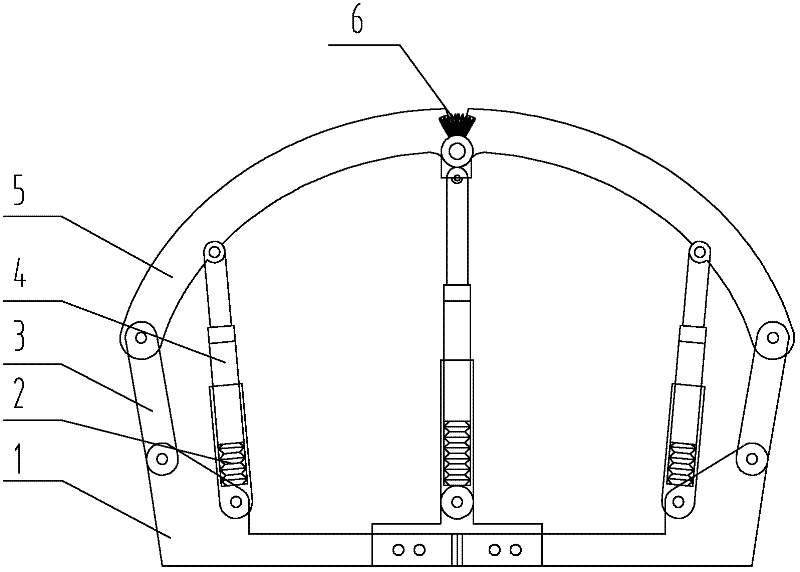

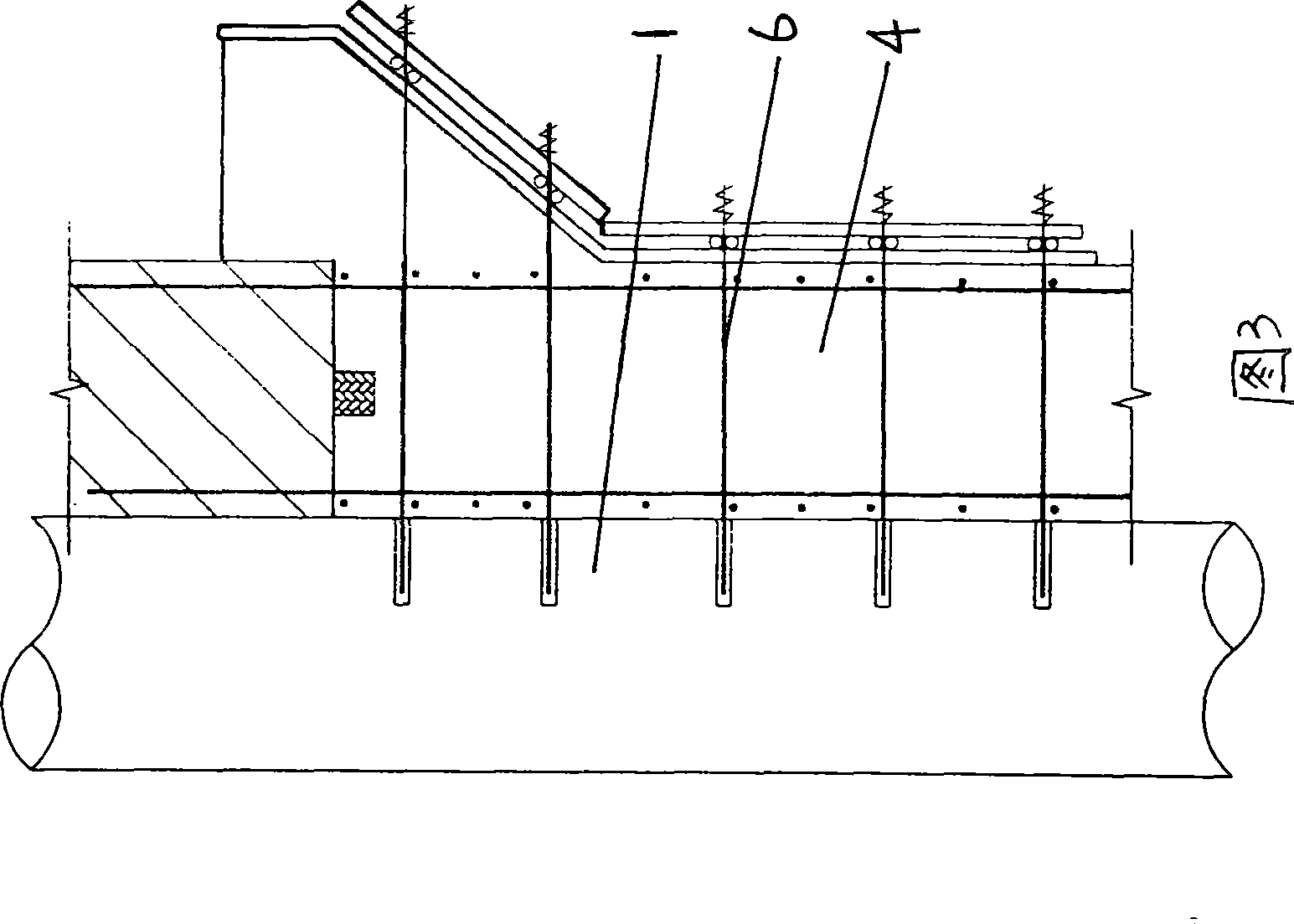

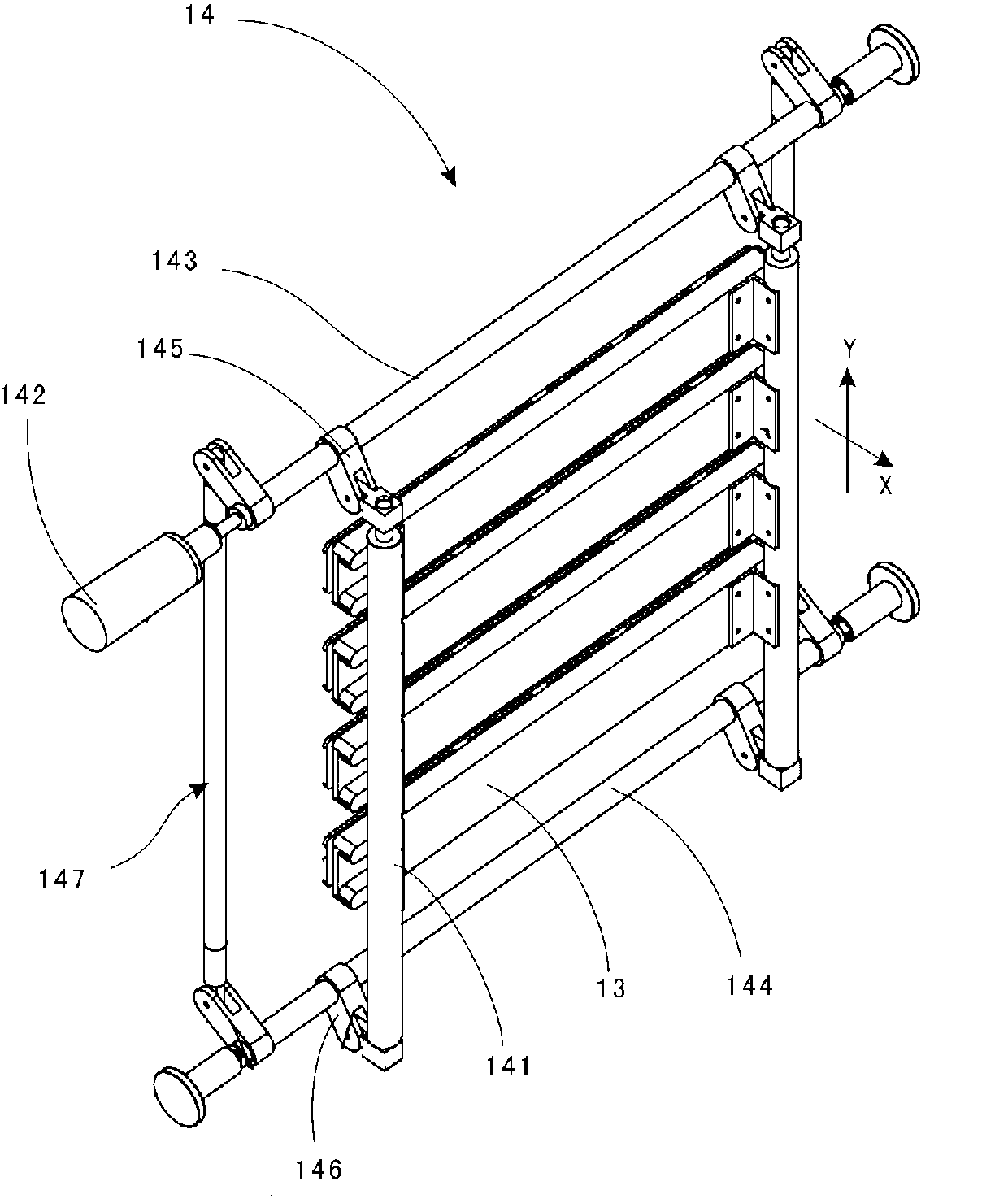

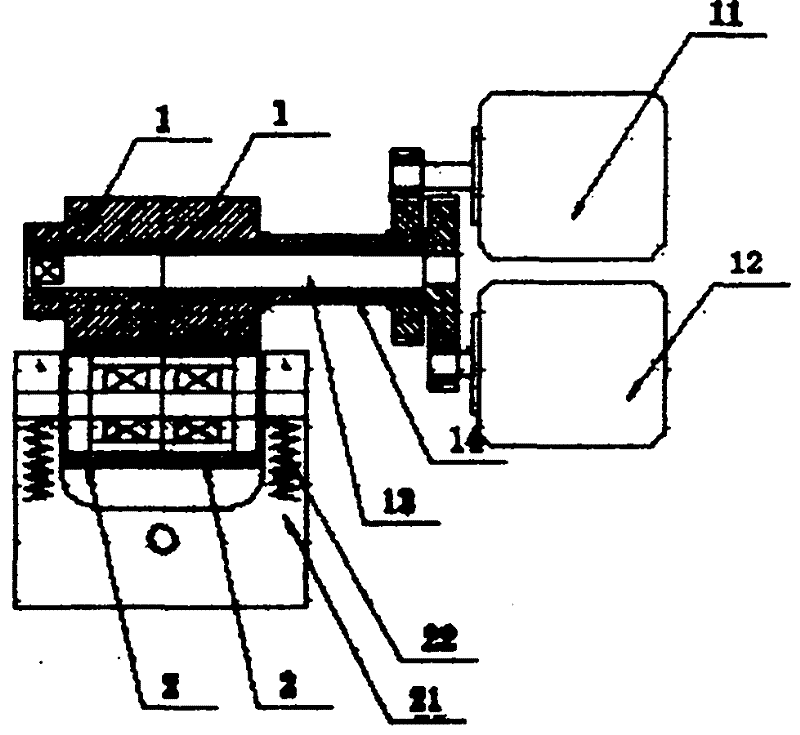

High-speed energy absorption anti-impact retreat hydraulic support for coal mine

InactiveCN102418538AOptimize the force structureIncrease profitProps/chocksEnergy absorptionEngineering

The invention provides a high-speed energy absorption anti-impact retreat hydraulic support for a coal mine. The hydraulic support comprises a bottom beam, energy absorption retreat members, connecting rods, hydraulic props and top beams, wherein two top beams are connected together in a hinged mode; an energy absorption material is filled at the hinged position of the two top beams; the bottom beam is connected with the top beams through the connecting rods; energy absorption materials are filled in the energy absorption retreat members; one end of each energy absorption retreat member is connected with the bottom beam or each top beam, and the other end of each energy absorption retreat member is matched with one end of each hydraulic prop; and the other end of each hydraulic prop is arranged in a needling of each top beam or the bottom beam. The hydraulic support has the characteristics of a rigid support and a flexible support simultaneously, the whole hydraulic support can be prevented from being damaged, the damage degree of surrounding rocks is effectively reduced, and the safety of underground operating personnel is ensured; in addition, production recovery time can be greatly shortened after rock burst occurs.

Owner:辽宁工大太阳石科技园有限公司 +1

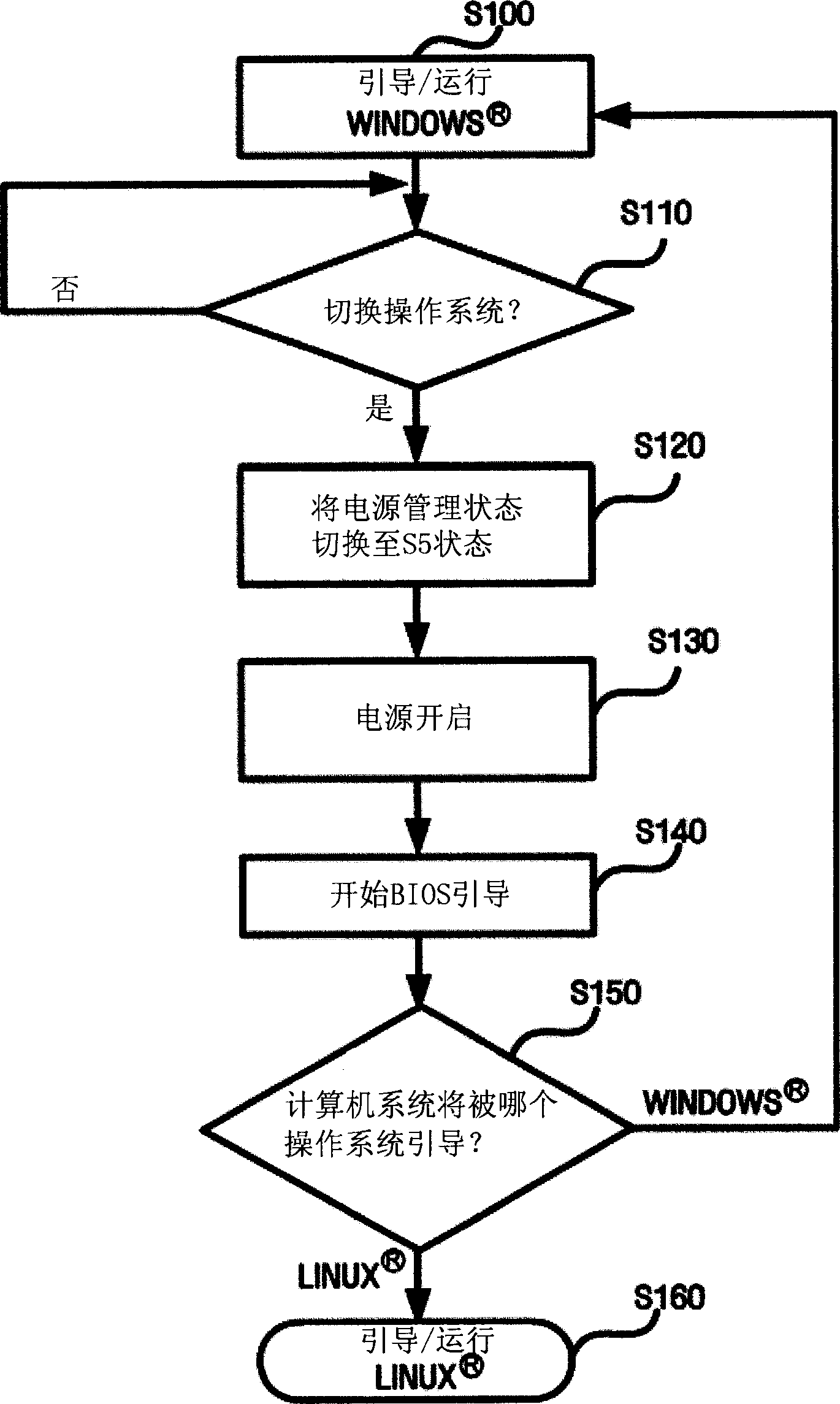

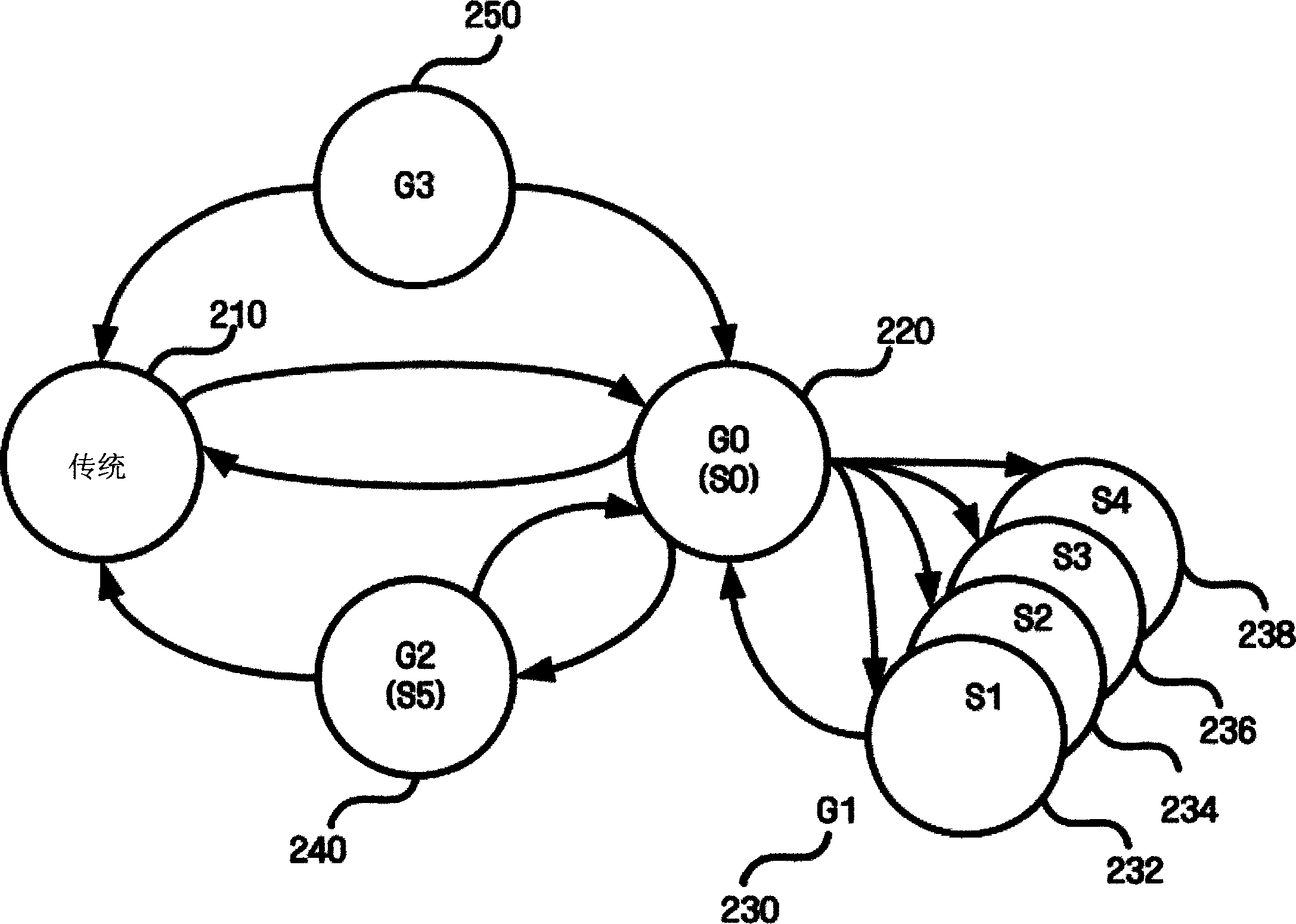

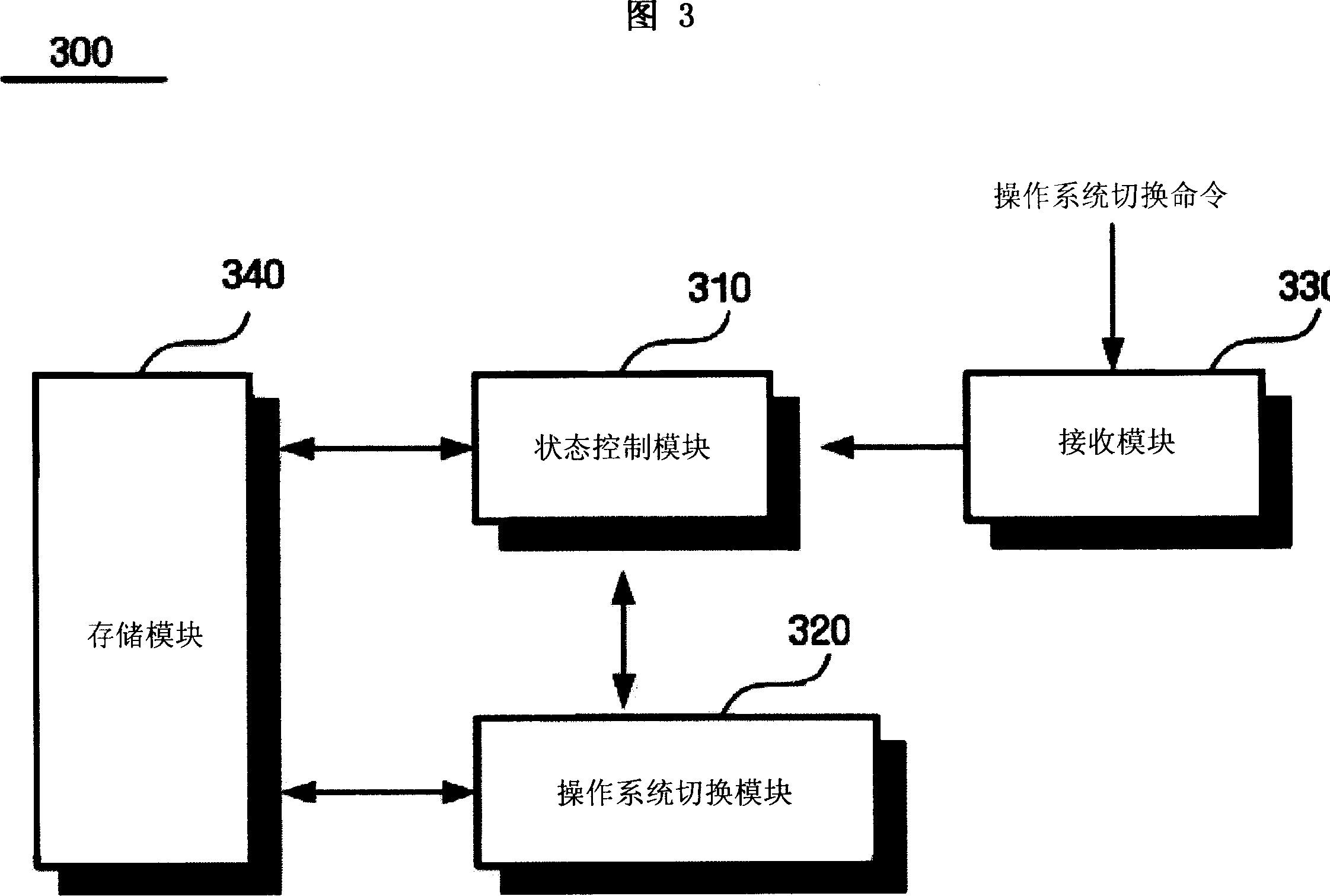

Computer system, method and medium for switching operation system

InactiveCN1700175AGuarantee the environmentLow power state holdProgram control using stored programsMultiprogramming arrangementsSleep stateOperational system

An operating system switching method in a computer system having at least two operating systems is provided. The operating system switching method may include receiving a command of switching a first operating system that is currently running to a second operating system, causing the computer system to make a transition to a low-power sleeping state in response to the command, and booting the computer system using the second operating system in the transitioned state.

Owner:SAMSUNG ELECTRONICS CO LTD

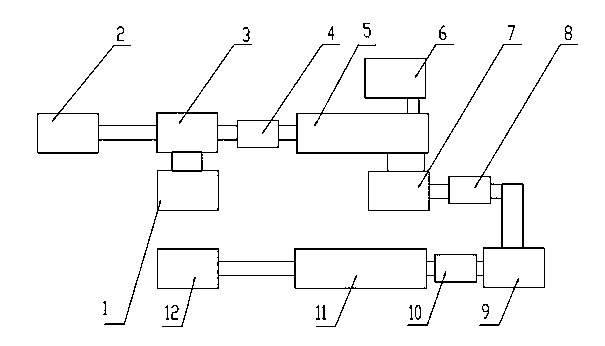

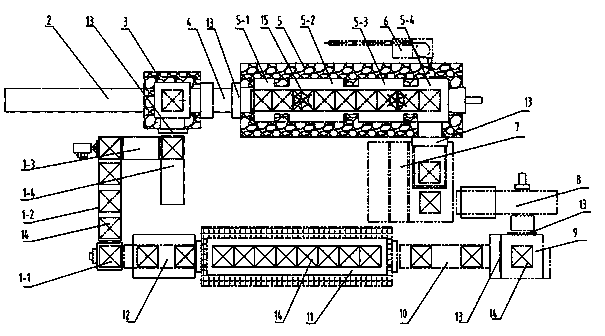

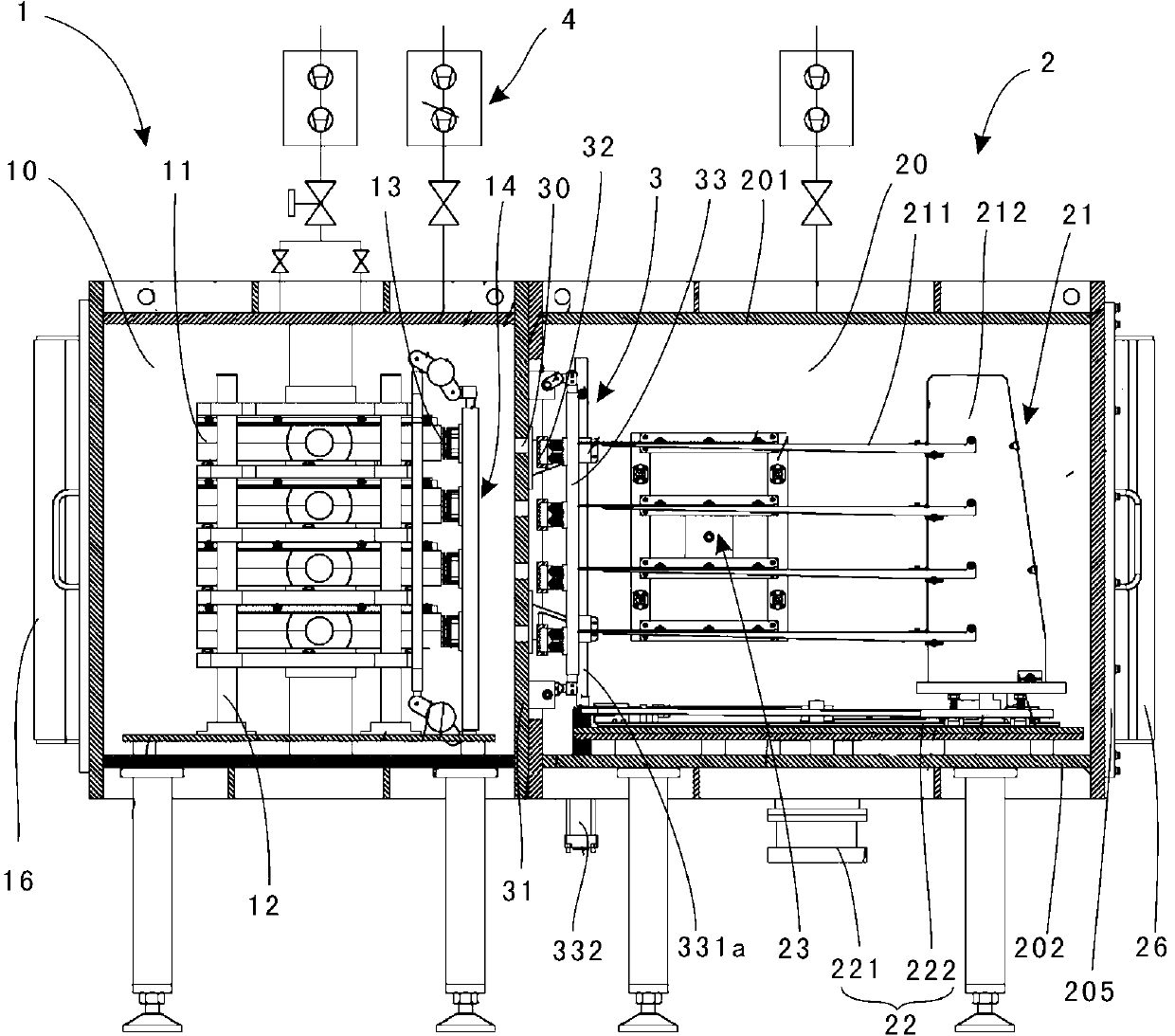

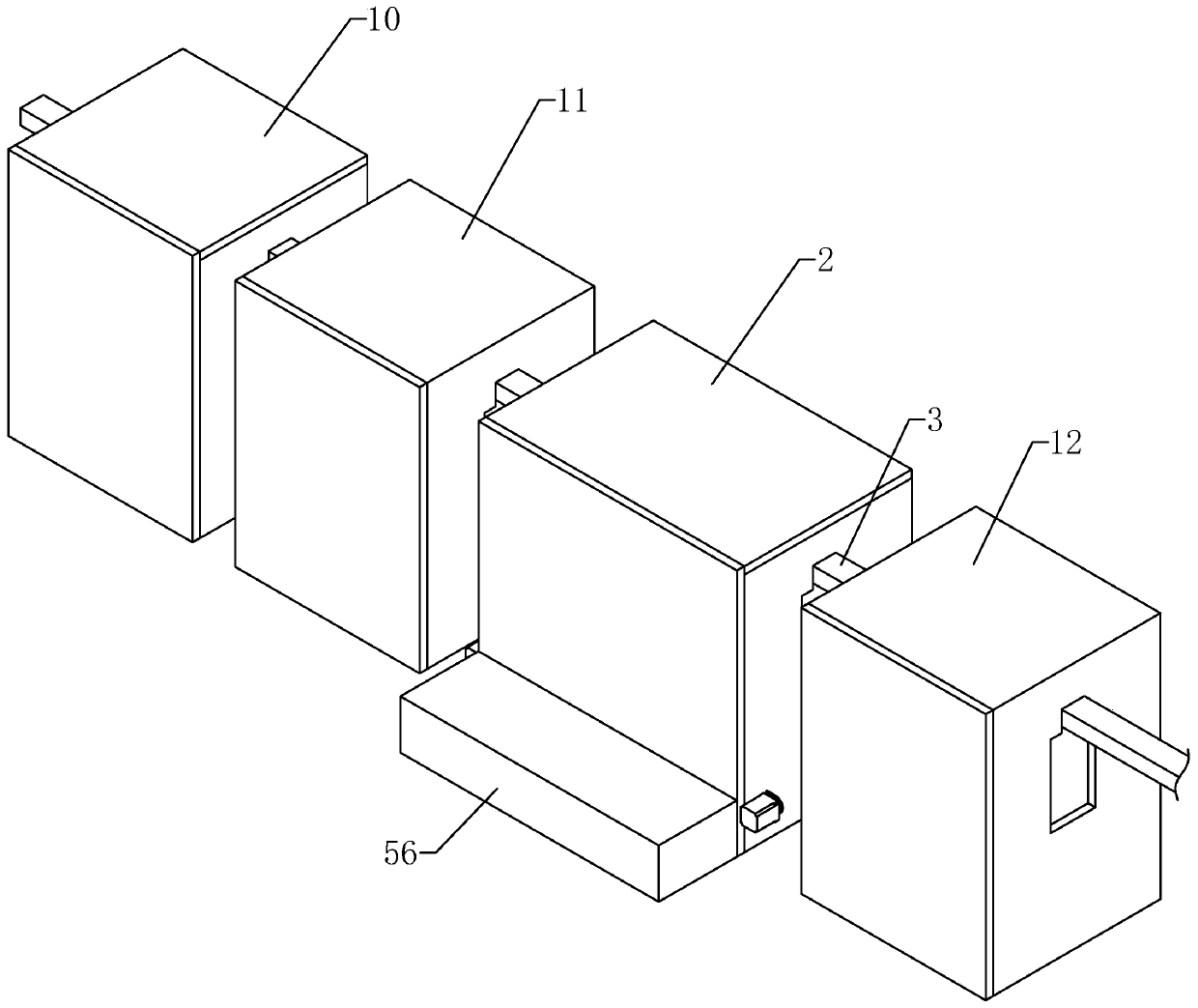

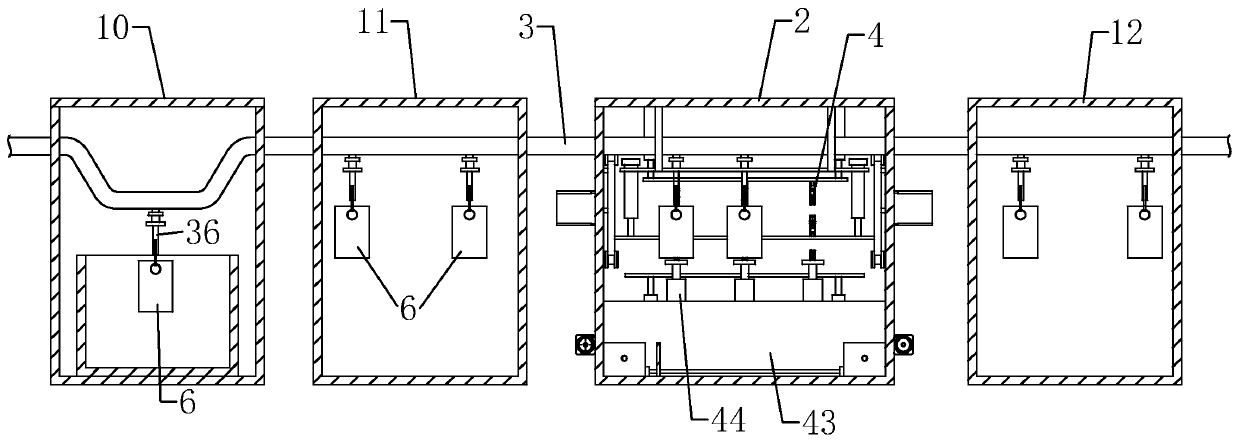

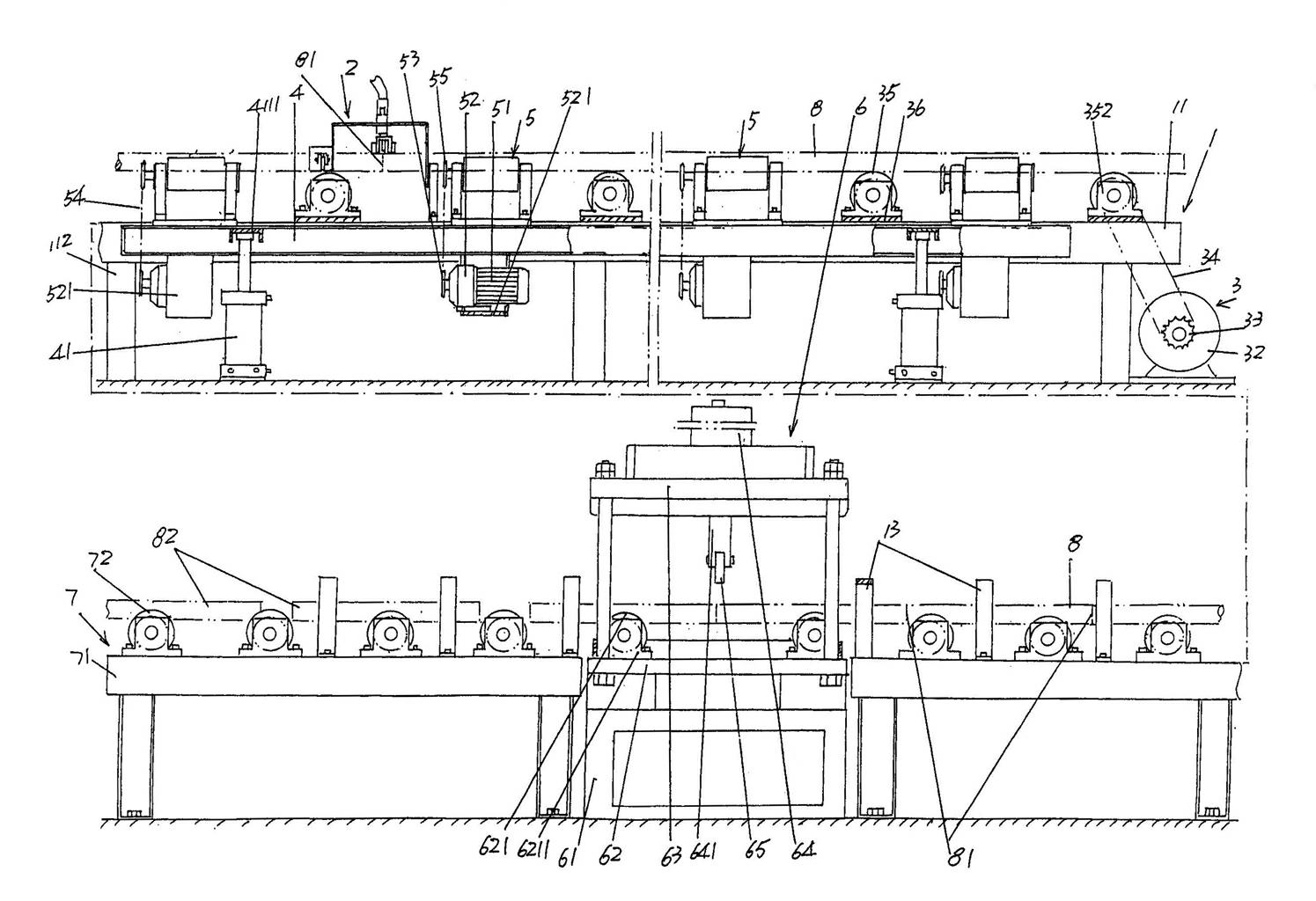

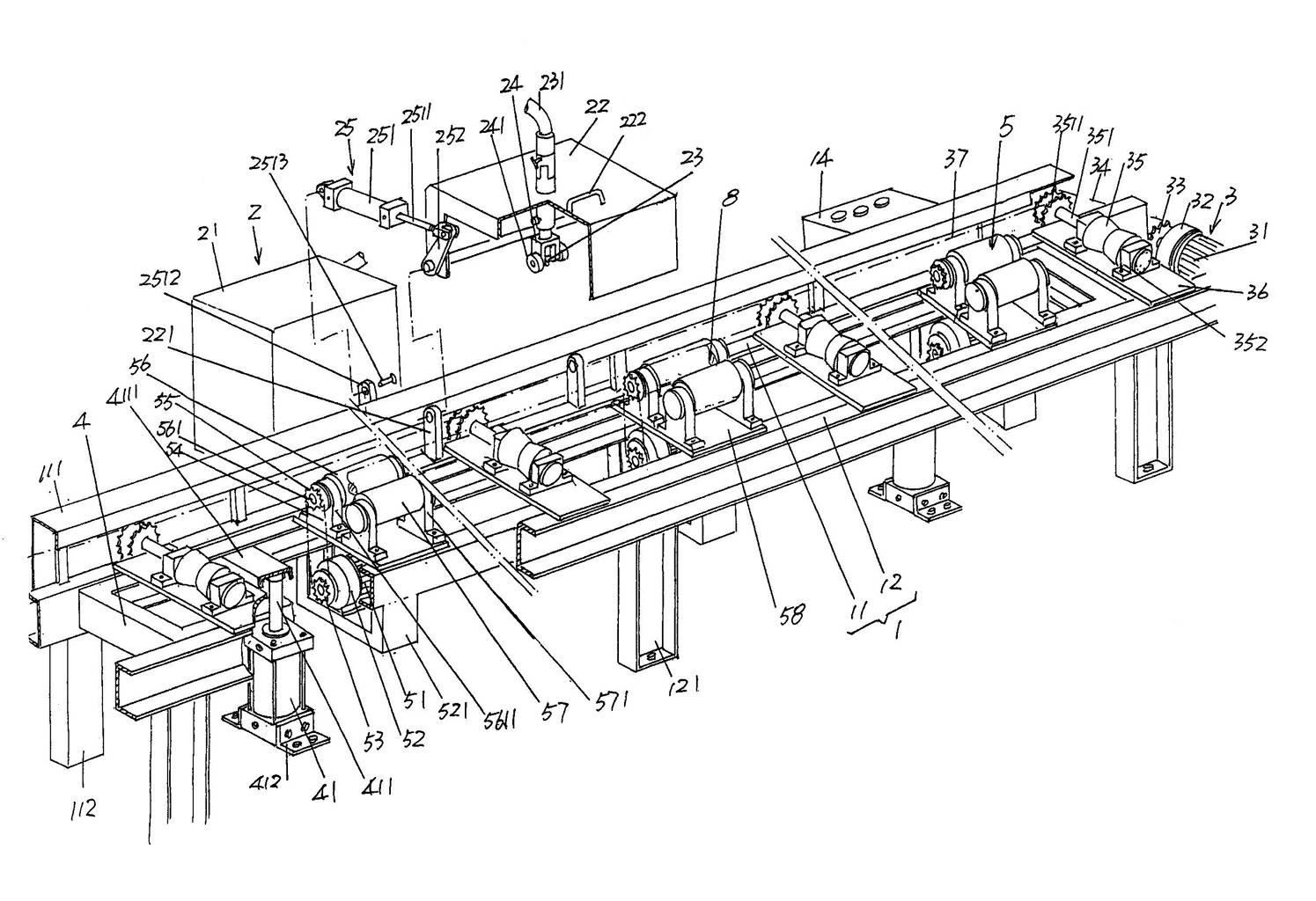

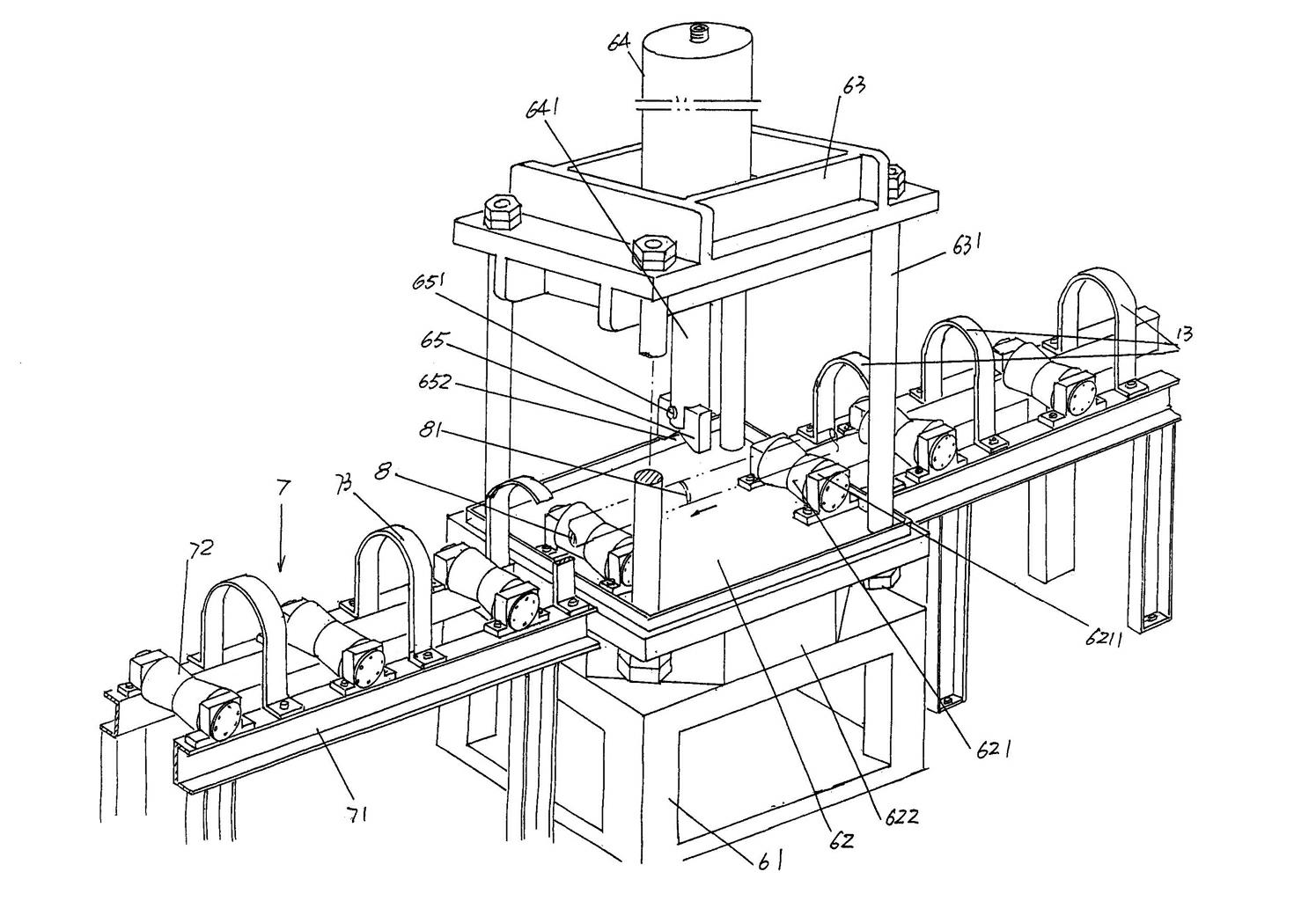

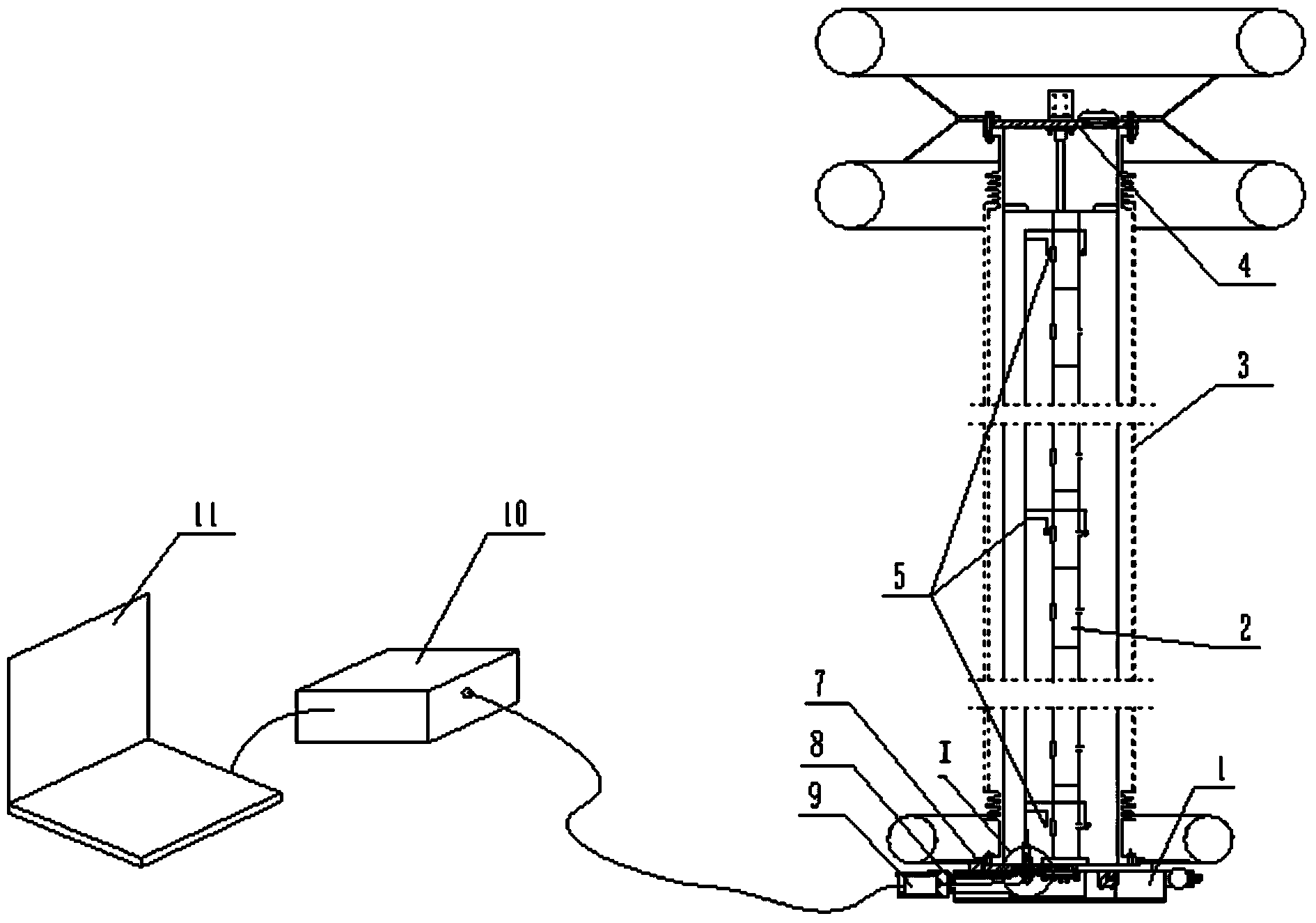

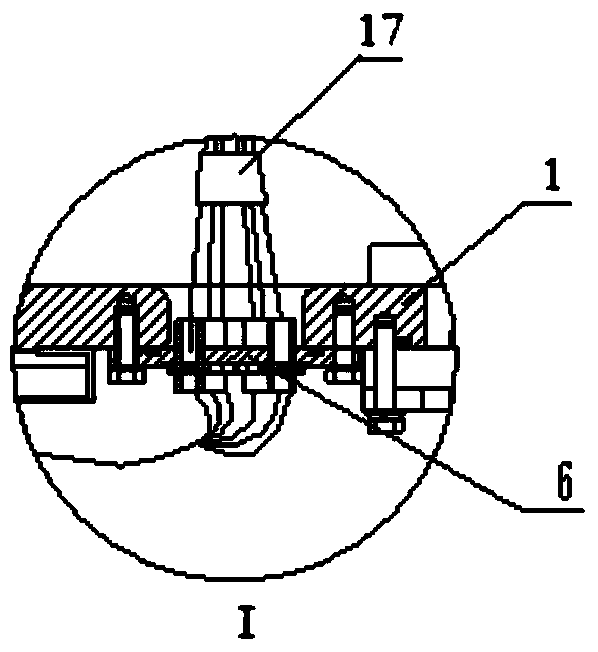

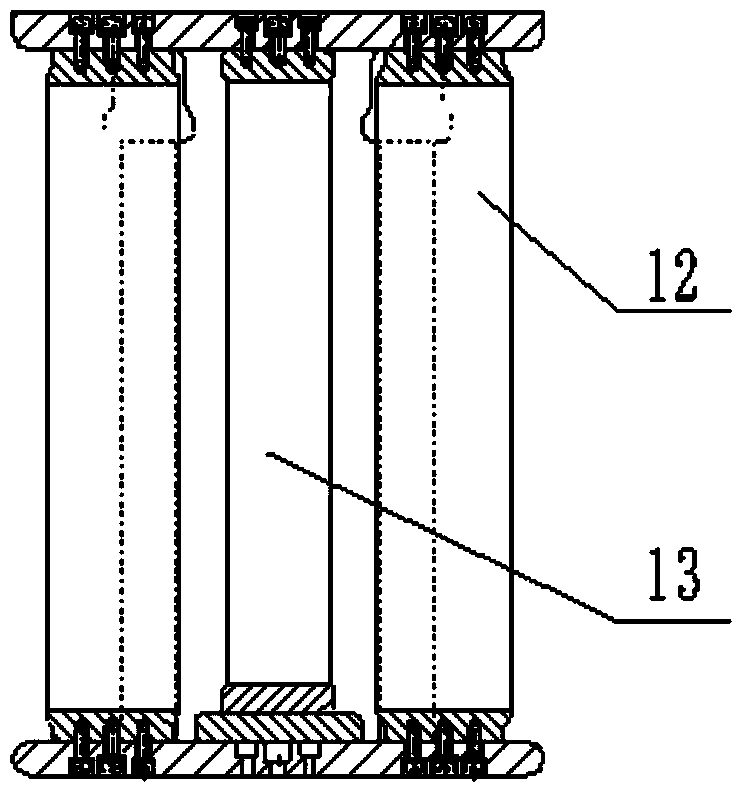

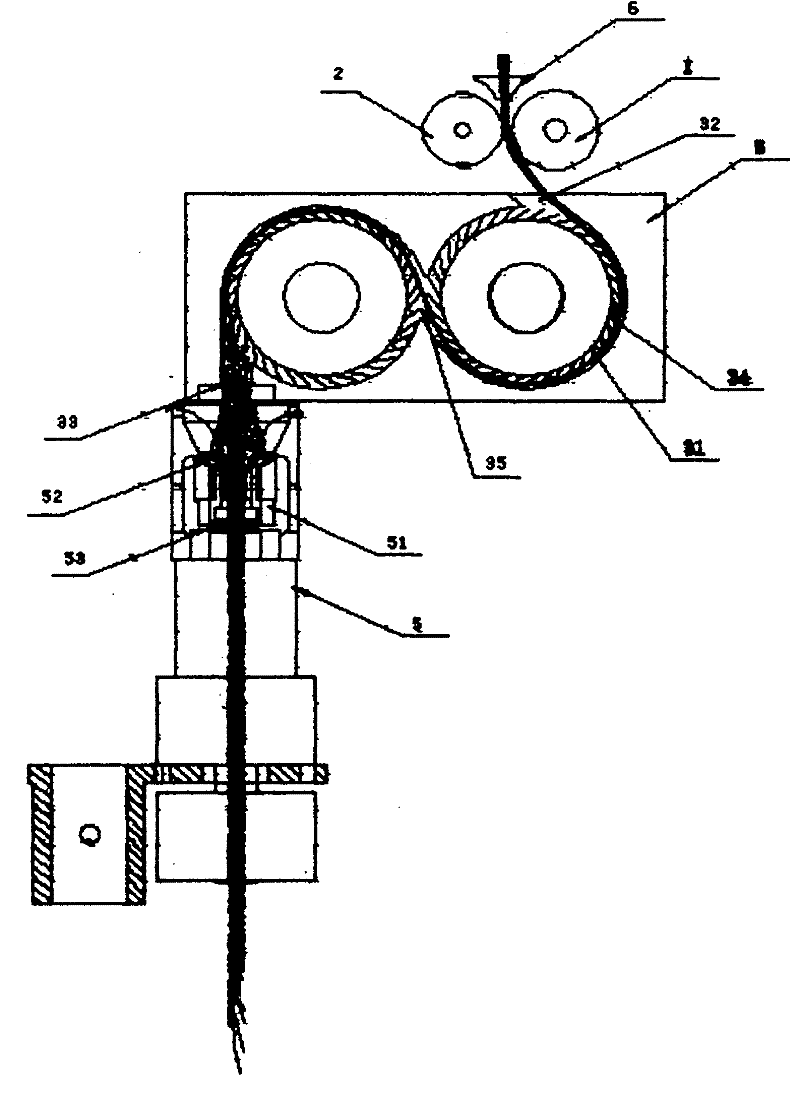

Automatic production line for saw blade heat treatment

InactiveCN103146902AGuarantee the environmentGuaranteed atmosphereFurnace typesHeat treatment furnacesProduction lineEngineering

The invention discloses an automatic production line for saw blade heat treatment, and belongs to the technical field of work piece heat treatment. The automatic production line for the saw blade heat treatment is characterized by comprising a feed mechanism, a feeding tray stepping advancing mechanism, a heat preserving furnace, a carbon-nitrogen furnace, a quenching mechanism, a cleaning machine, a tempering furnace and feeding tray conveying mechanisms, wherein the feed mechanism, the feeding tray stepping advancing mechanism, the heat preserving furnace, the carbon-nitrogen furnace, the quenching mechanism, the cleaning machine, the tempering furnace are sequentially arranged according to a manufacturing process order, and the feeding tray conveying mechanisms are arranged between each two adjacent devices. The feeding tray conveying mechanisms comprise a transition cylinder, a carbon-nitrogen furnace discharging advancing device, a quenching discharging advancing device, a tempering furnace feeding advancing device and a tempering furnace discharging advancing device, wherein the transition cylinder is arranged between the heat preserving furnace and the carbon-nitrogen furnace, the carbon-nitrogen furnace discharging advancing device is arranged on one side of the carbon-nitrogen furnace, the quenching discharging advancing device is arranged between the quenching mechanism and the cleaning machine, the tempering furnace feeding advancing device is arranged between the cleaning machine and the tempering furnace, and the tempering furnace discharging advancing device is arranged at an outlet of the tempering furnace. The automatic production line for the saw blade heat treatment has the advantages of improving production efficiency and energy use rates of the devices, ensuring heat treatment quality of saw blades due to continuous production, achieving automation operation of the whole production line and being small in number of employed workers and good in labor environment.

Owner:烟台金都锯业有限公司

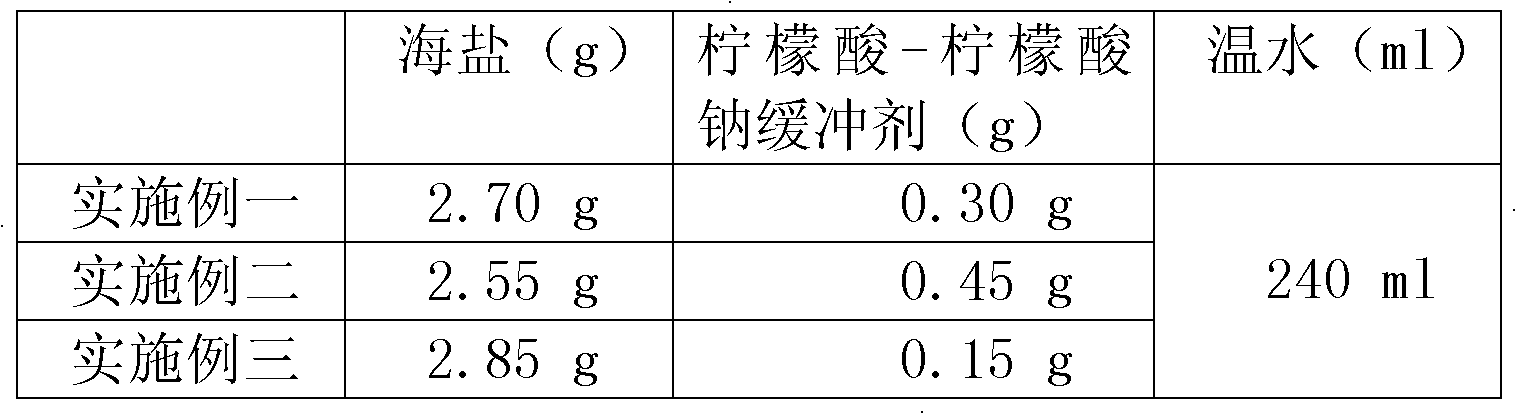

Nasal cavity cleaning agent

InactiveCN102204926AWith sterilizationBacteriostaticPharmaceutical delivery mechanismPharmaceutical non-active ingredientsNasal cavitySide effect

The invention relates to a nasal cavity cleaning agent applied to health care of the nasal cavity of a human body. The nasal cavity cleaning agent comprises the following components in percentage by weight: 0.9 to 1.2 percent of sea salt, 0.05 to 0.2 percent of buffering agent and the balance of water, wherein the buffering agent is prepared from citric acid and sodium citrate in the weight proportion of 1 to 100. The nasal cavity cleaning agent has the advantages that: the environment in the nasal cavity is maintained because of sodium chloride with the physical concentration and pH value; 2, secretions in the nasal cavity can be diluted and discharged, nose scabs are eliminated, and breath becomes smooth; 3, the nasal cavity is moisturized and bleeding caused by dryness of the nasal cavity is avoided; 4, pathogenic bacteria and harmful substances in the nasal cavity are cleaned and the automatic secreting and cleaning function of the nasal cavity is recovered; 5, nasal mucosa is protected and the ciliated epithelium of the nasal mucosa is promoted to swing; and 6, the nasal cavity cleaning agent does not have any adverse reaction and any side effect on human bodies because no chemical drug is contained in the nasal cavity cleaning agent.

Owner:JIANGSU FOLEE MEDICAL EQUIP

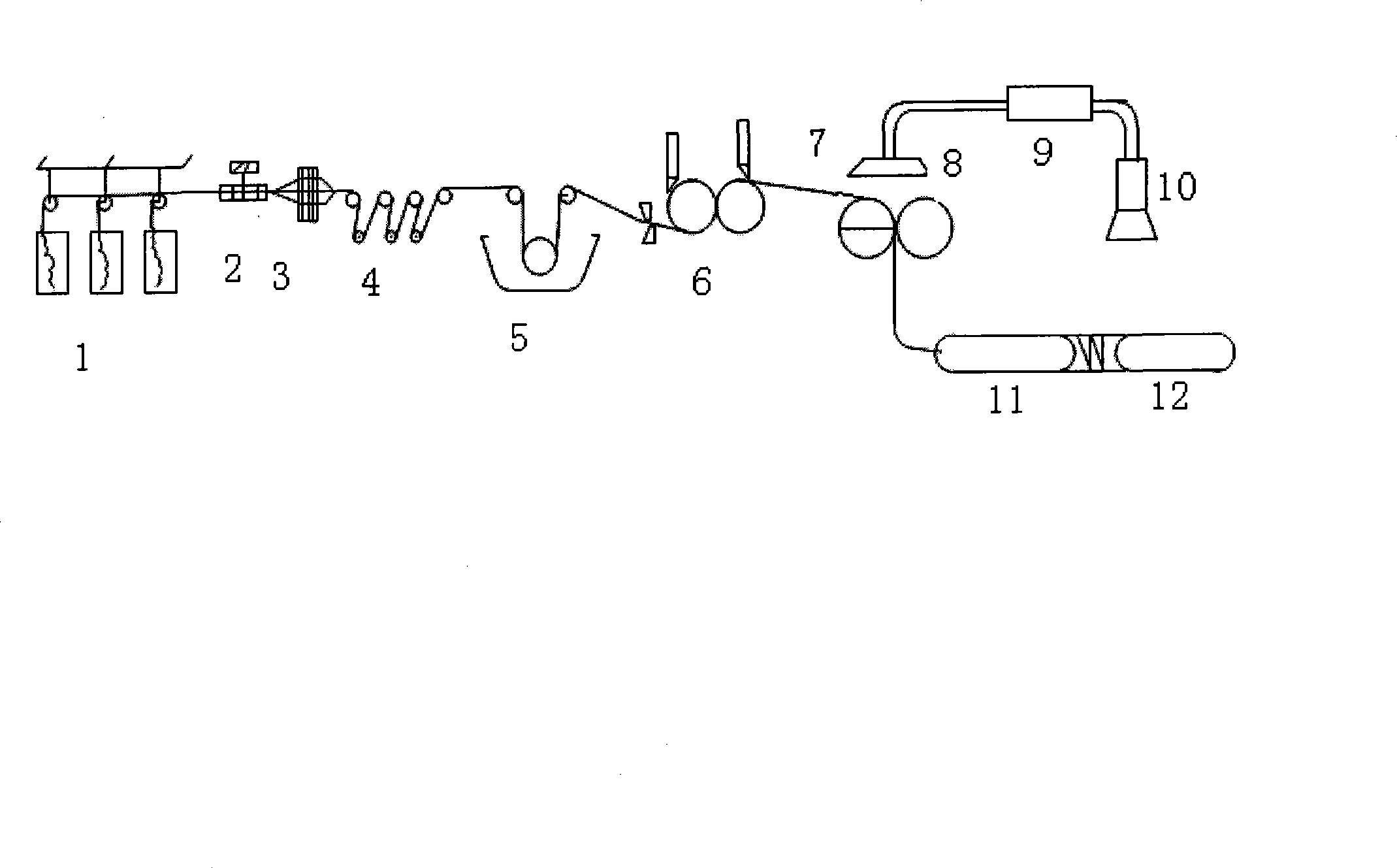

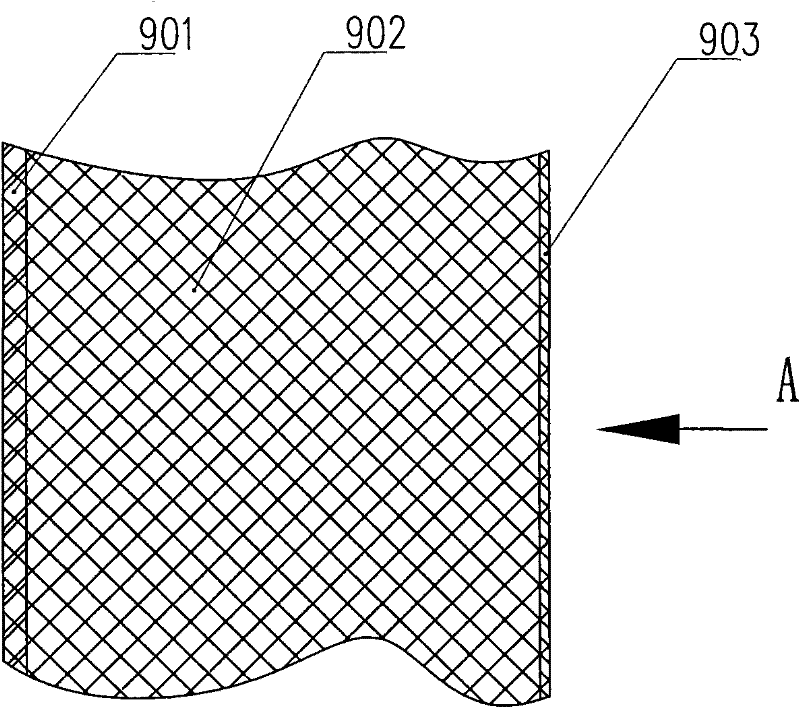

Method for preparing novel welfless cloth and composite UD profile

InactiveCN101177846AHigh bond strengthGuaranteed overall uniformitySheets/panelsPersonal protection gearSizingEngineering

The invention relates to a preparation method of a novel weftless cloth and composite UD material, including the steps: (1) a feeding tension box of a tow frame is provided with a constant static generator; (2) the tow is parallel laid and is put into a steeping vat, then the weftless cloth is topped with gum at the face and the back on a roller and by an atomizing and spraying device; (3) gum at both the face and the back of the weftless cloth is scraped in parallel; (4) the formed weftless cloth is hauled by a chain and parallel conveying way, parallel cut or conversely folded to form an UD composite board of multi-layer structure. The method of the invention is a continuous production method of stable quality and requires low cost, and the prepared UD material is characterized by even quality, fiber being evenly stressed, even sizing rate, etc.

Owner:DONGHUA UNIV +1

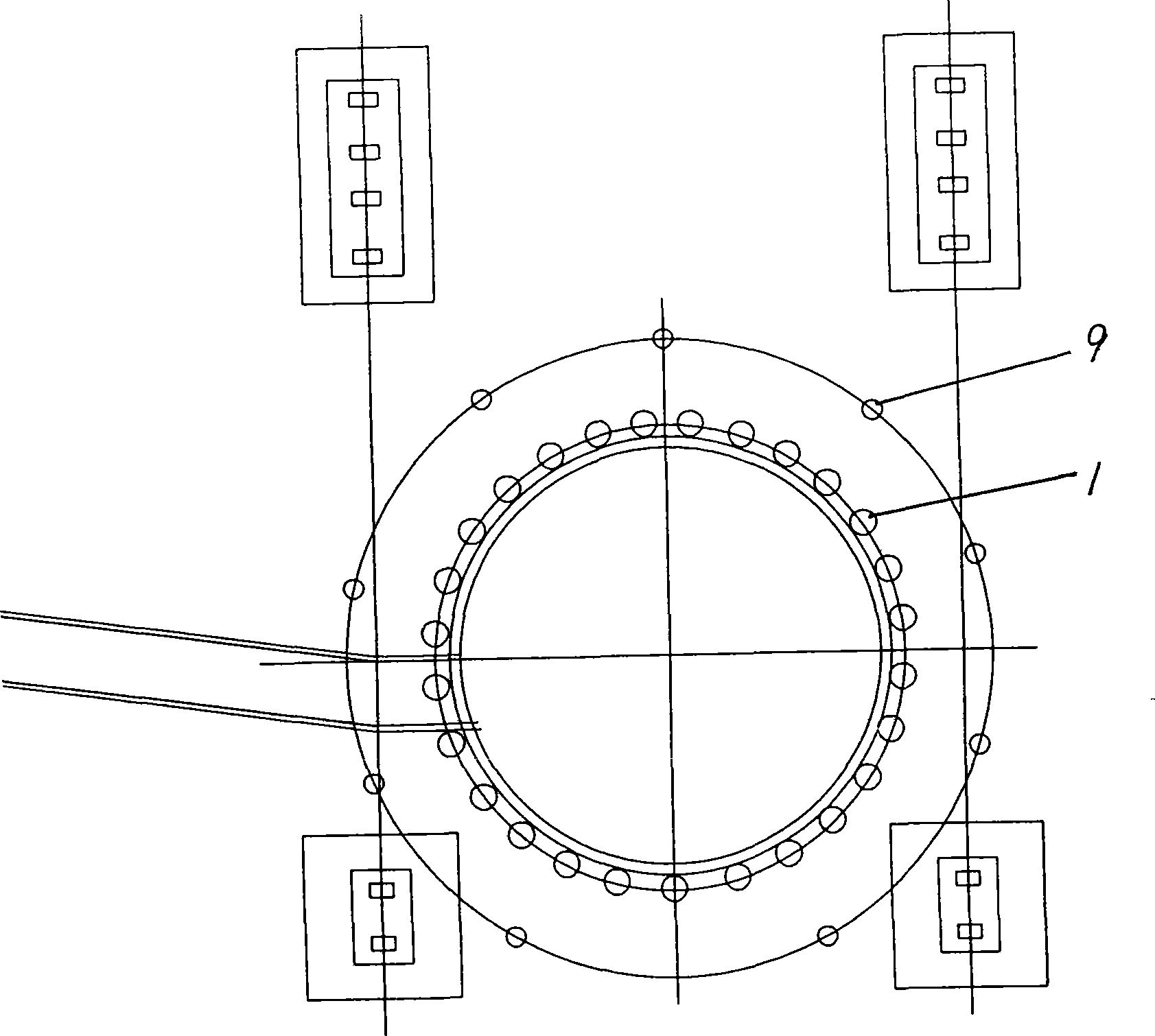

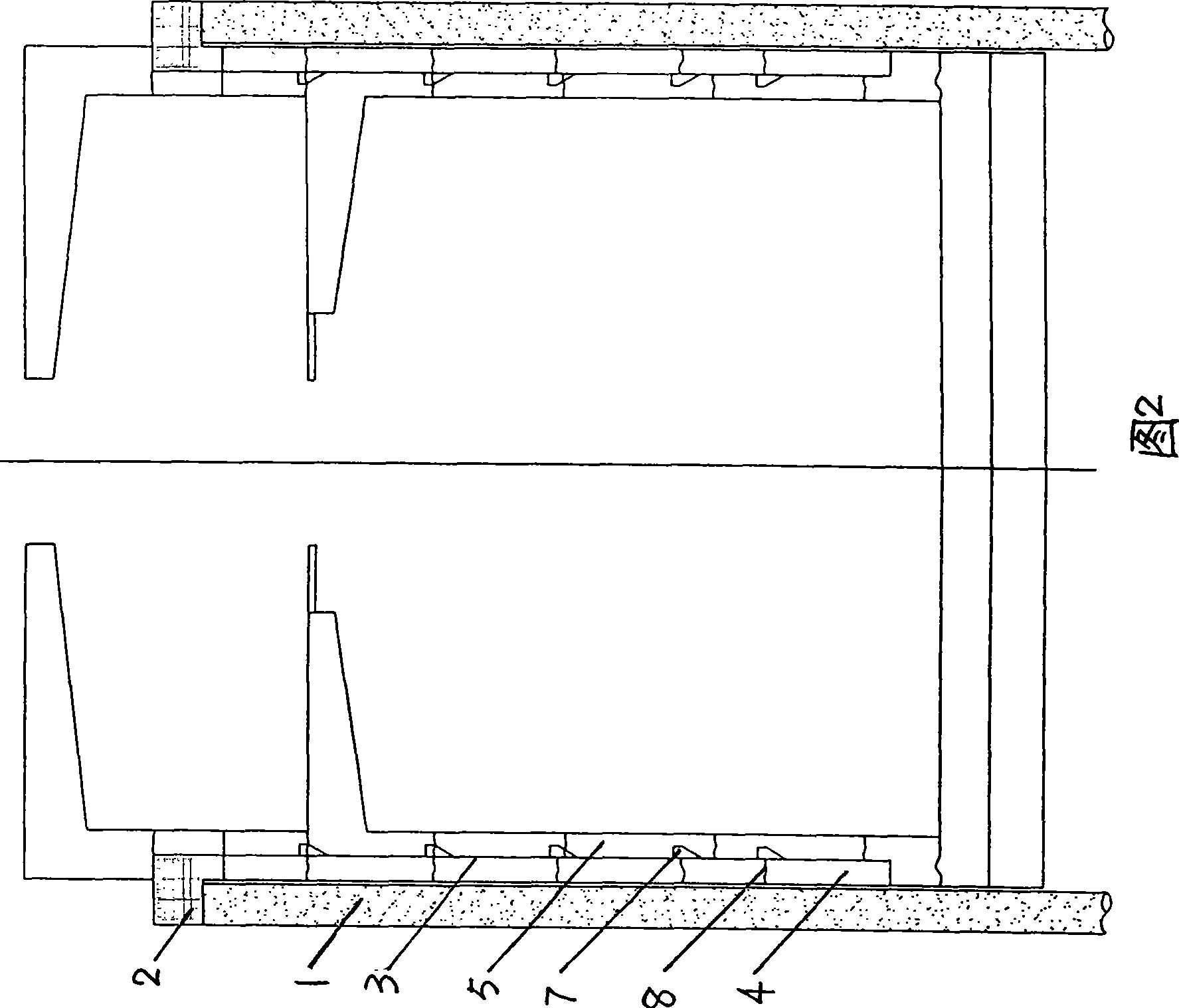

Circular deep foundation ditch concrete pile arranging support and major structure inversing construction method

InactiveCN101457526AEasy constructionFast progressExcavationsBulkheads/pilesIndustrial constructionSoil horizon

The invention belongs to the construction method of a deep foundation pit of industrial construction, particularly relates to a reverse operating construction method of a round deep foundation pit concrete piling support and a main structure and solves the problem that the existing construction method of the deep foundation pit is not suitable for complex geological condition and the construction cost is too high. The construction method comprises the following steps: the center of the foundation pit is adopted as the center and the outer sides of the position of the main structure are respectively distributed with pilings; the top parts of the pilings are poured with crown bore beams which connects the top parts of the pilings into one body; the first section of the foundation pit is excavated, reverse operation is carried out to the outer layer of the first section of the main structure; the outer layer of the first section of the main structure and the pilings are integrated by the crown bore beams so as to form a primary support of the foundation pit; the foundation pit is excavated by sections, reverse operating construction of the outer layer of the main structure is carried out by sections, which form a foundation pit support together; and normal operating construction is carried out to the inner layer of the main structure. The invention is applicable to poor geological condition and is particularly applicable to structural diversity of the soil layer in the depth range of excavation of earthwork, thus ensuring the stability of the soil body of the main structure in the construction period, greatly reducing the cost of construction measures and improving the construction speed.

Owner:MCC TIANGONG GROUP

Detergent putting structure and washing machine

InactiveCN108729141ASolve the problem of residual waterAvoid damageOther washing machinesTextiles and paperInlet valveEngineering

The invention belongs to the technical field of washing machines and particularly relates to a detergent putting structure and a washing machine. The detergent putting structure comprises a water inlet valve, a water inlet pipeline and a putting device, wherein one end of the water inlet pipeline is connected to the water outlet of the water inlet valve, and the other end of the water inlet pipeline extends into the putting device and is provided with a water outlet part; a ventilation structure is disposed on the portion, between the water inlet valve and the water outlet part, of the interior of the putting device and uses hydraulic pressure difference formed when the water inlet valve is closed for draining water remaining in the water inlet pipeline and the water outlet part. The detergent putting structure can effectively overcome the defect that water easily remains in pipes and water outlet parts in putting devices; the structure is simple, the occurrence probability of faults of the washing machine is decreased, costs for production, research and development of the washing machine are reduced at the same time, and a promising market prospect is achieved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

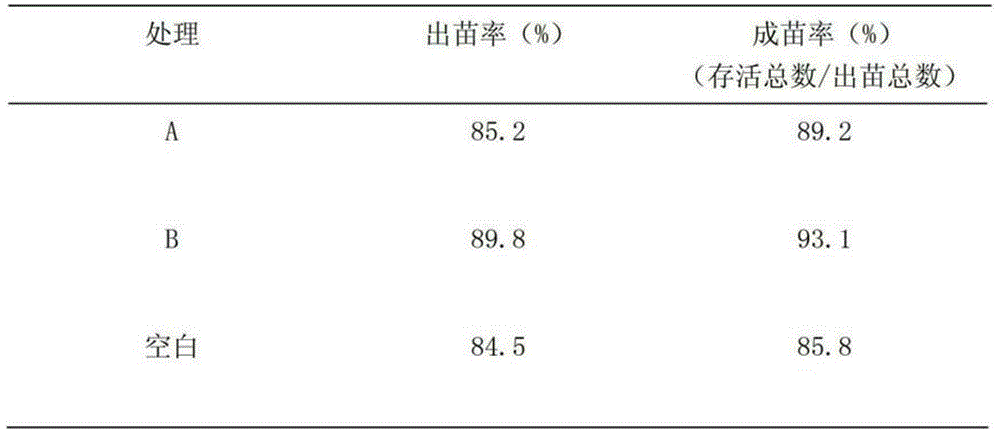

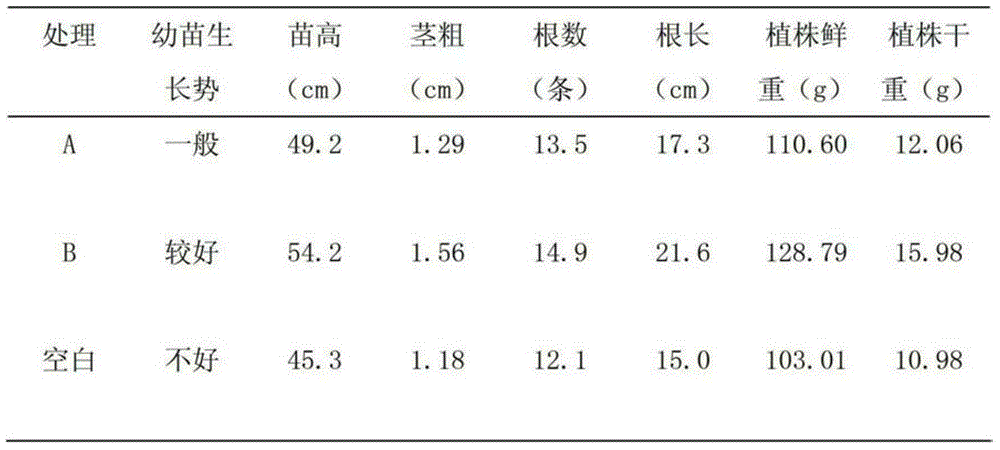

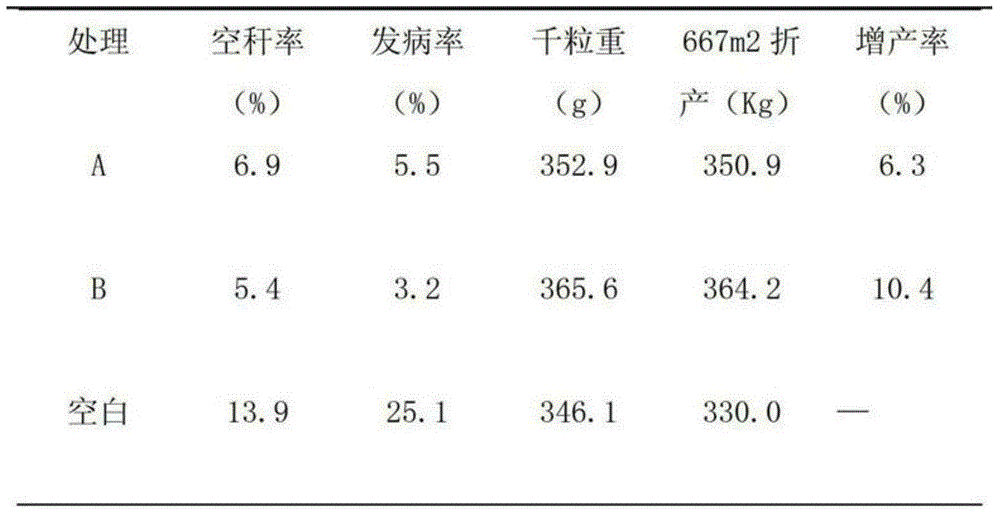

Efficient seed coating agent, preparation method and applications thereof, and method using same to process seeds

InactiveCN105052933AStrong targetingImprove versatilityBiocideFungicidesEnvironmental resistanceFruit tree

The invention belongs to the technical field of seed processing, and especially relates to an efficient seed coating agent, a preparation method and applications thereof, and a method using the same to process seeds. The efficient seed coating agent comprises the following components: amino-oligosaccharin, a dispersant, an adhesive, a surfactant, vigilance dye, and water. The preparation method comprises the following steps: weighing all raw materials other than amino-oligosaccharin according to a certain ratio, evenly mixing the weighed raw materials, then adding amino-oligosaccharin, and grinding the mixture until the particles of each component is less than 5 mm. The efficient seed coating agent is mixed with seeds according to a mass ratio of 1:50 to coat the seeds. The efficient seed coating agent can be used to prevent and treat diseases of fruit trees, vegetables, underground roots, tobaccos, traditional Chinese herbals, grain crops, cotton, and the like. The seed coating agent has the advantages of strong pertinence, good universality, sustain-released property, and fertilizer-retaining performance, and is capable of preventing the diseases and pests. Moreover, the raw materials are easily-available and cheap, so the production cost is low. Besides the raw materials are environment-friendly and harmless, and meet the nuisance-free requirements.

Owner:山东亿嘉农化有限公司

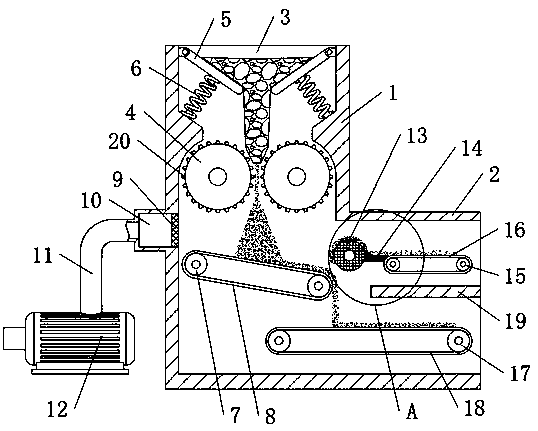

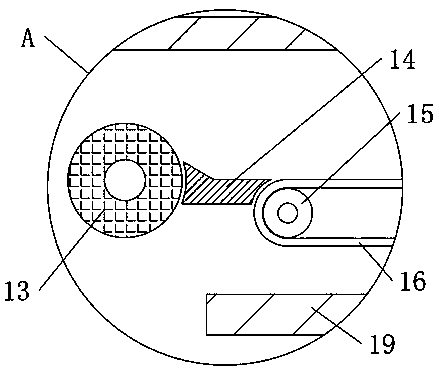

Classified processing device for construction wastes

InactiveCN110801895AAvoid direct impactReduced service lifeCleaning using toolsMagnetic separationArchitectural engineeringStructural engineering

The invention discloses a classified processing device for construction wastes and relates to the field of garbage classified processing. The classified processing device for construction wastes comprises a crushing box and a screening box. The crushing box is provided with a pair of crushing rollers, buffer plates are arranged on two side walls of a feed inlet of the crushing box, a first guidingbelt is arranged right below the two crushing rollers, an electric absorbing magnetic roller is arranged on the upper side, close to the lower end, of the first guiding belt, and a third guiding beltwhich is horizontally arranged is arranged below the lower end of the first guiding belt. When the classified processing device for construction wastes works, the electric absorbing magnetic roller is electrified and magnetized to absorb crushed metals in crushed garbage conveyed on the first guiding belt, and when the electric absorbing magnetic roller rotates, the metals bonded to the outer wall of the electric absorbing magnetic roller fall onto a hanging plate as being scratched by the hanging plate. Then the crushed metals scratched by the hanging plate are conveyed by the second guidingbelt and are exported and collected, so that the separating efficiency is high.

Owner:王思尹

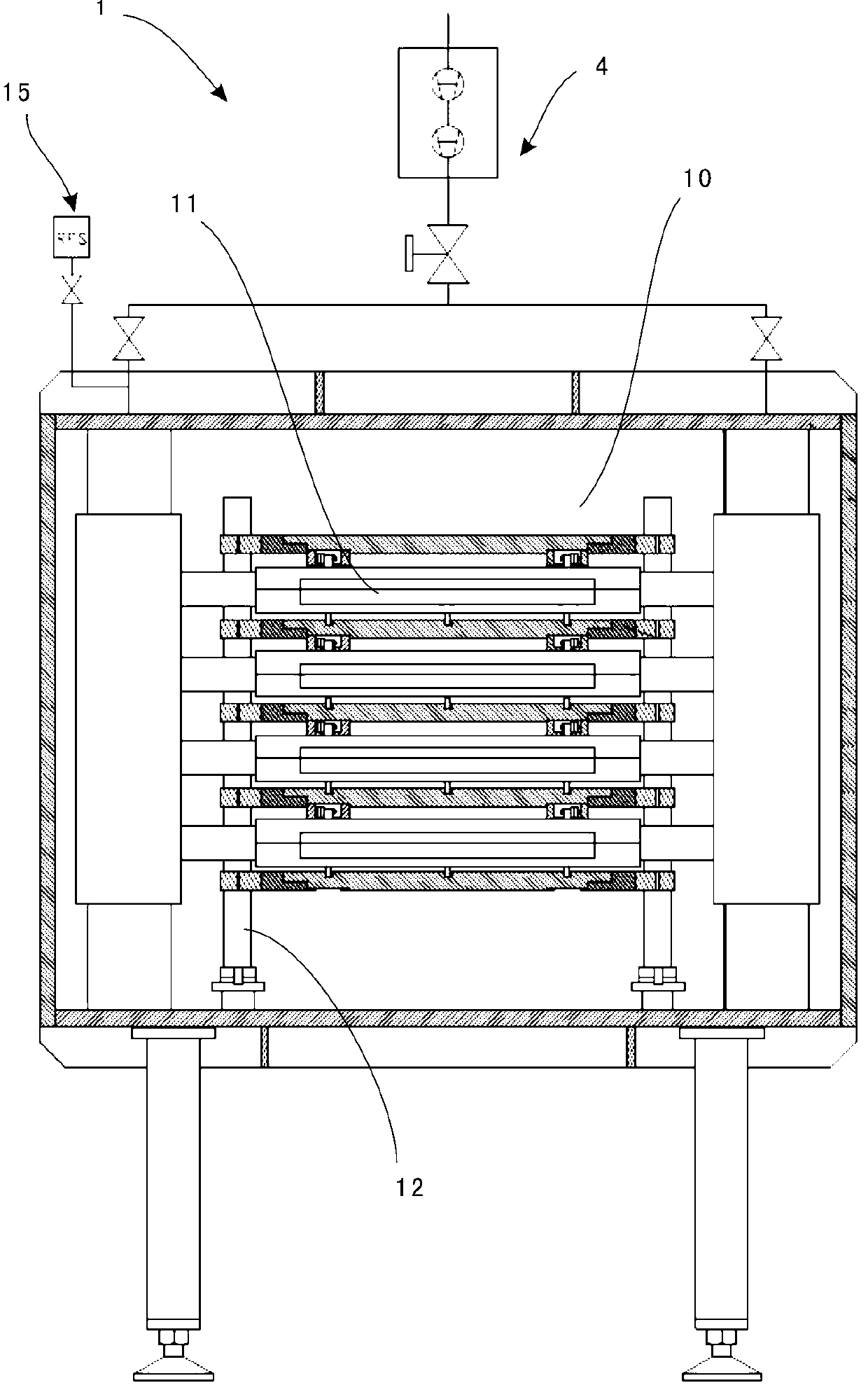

PECVD (plasma enhanced chemical vapour deposition) film-coating system

ActiveCN103276369AGuaranteed connectivityGuarantee the environmentChemical vapor deposition coatingProcess systemsReciprocating motion

The invention discloses a PECVD (plasma enhanced chemical vapour deposition) film-coating system. The PECVD film-coating system comprises a process system, a loading-unloading system and a valve mechanism, wherein the process system comprises a process cavity and a process reaction chamber; the process reaction chamber is arranged in the process cavity; the loading-unloading system comprises a loading-unloading cavity and a transmission manipulator; the transmission manipulator is slidably arranged between the loading-unloading cavity and the process cavity; the valve mechanism is arranged between the process cavity and the loading-unloading cavity and used for communication or isolation between the process cavity and the loading-unloading cavity, and via the valve mechanism, the transmission manipulator can perform a reciprocating motion in the cavities, and mutual communication between the cavities and the mutual independence of vacuum environments are ensured simultaneously; the loading-unloading cavity also has the functions of a loading cavity and a transit transmission cavity, and can meet the functions of loading and unloading for a substrate, and mutual transmission between the cavities; and due to only two cavities, the structure is simpler, so that equipment cost is low, installation and maintenance are simple and convenient, transmission structure is simple and convenient, and requirements on mechanical accuracy are low.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

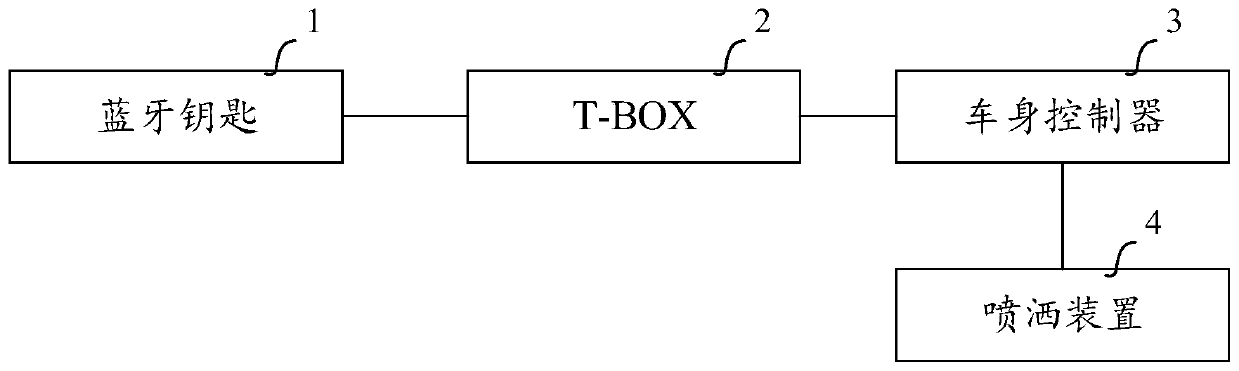

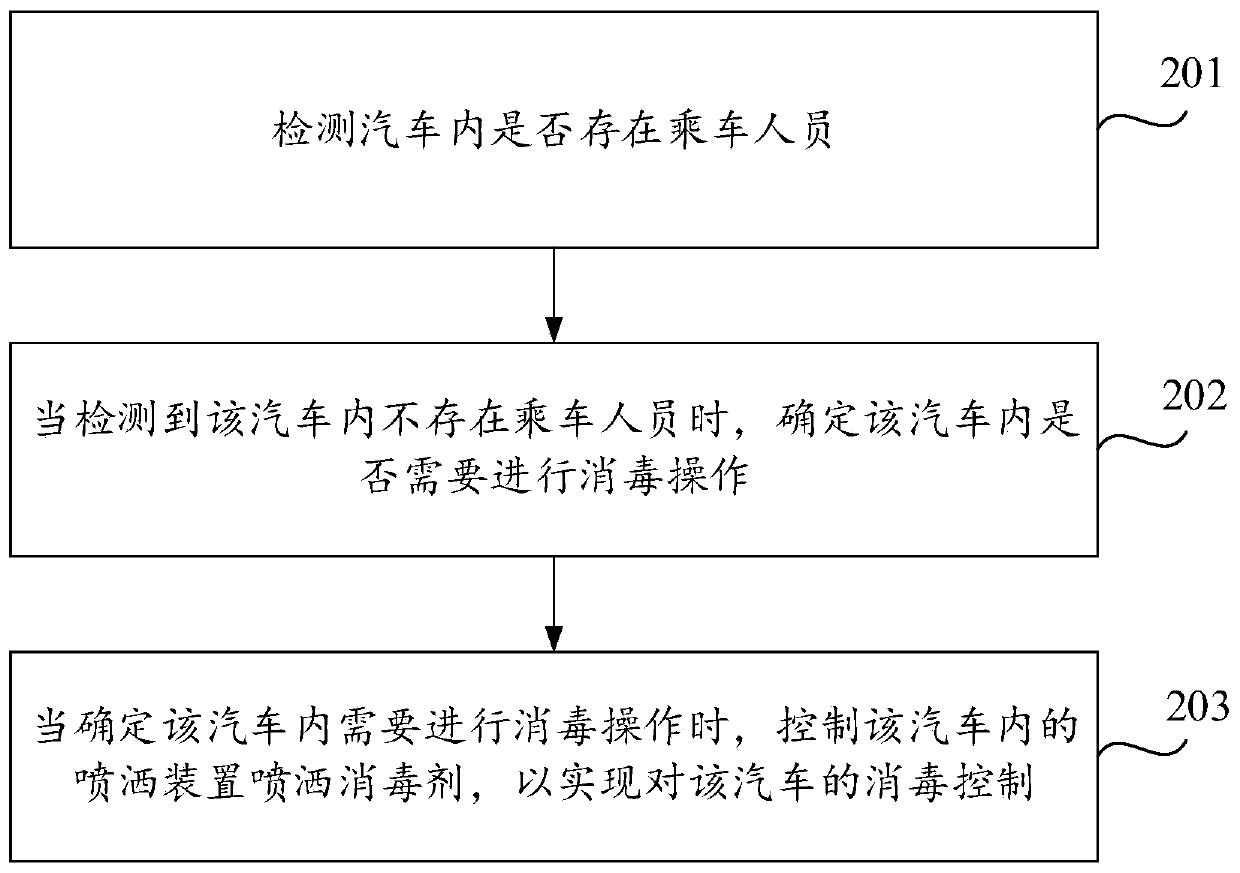

Automobile disinfection control method and device and storage medium

InactiveCN111562751AAchieving Disinfection ControlGuarantee the environmentAir-treating devicesLavatory sanitoryProcess engineeringMechanical engineering

The invention discloses an automobile disinfection control method and device and a storage medium, and belongs to the technical field of automobile engineering. The method comprises the steps of detecting whether there is a passenger or not in an automobile; when it is detected that no passenger exists in the automobile, determining whether disinfection operation needs to be conducted in the automobile or not; and when it is determined that disinfection operation needs to be conducted in the automobile, controlling a spraying device in the automobile to spray a disinfectant so as to achieve disinfection control over the automobile. According to the invention, when it is detected that the automobile needs to be disinfected, the spraying device in the automobile is controlled to spray the disinfectant to achieve disinfection control over the automobile, and thus bacteria appearing in the automobile and threats of the bacteria to the health of passengers are reduced.

Owner:CHERY AUTOMOBILE CO LTD

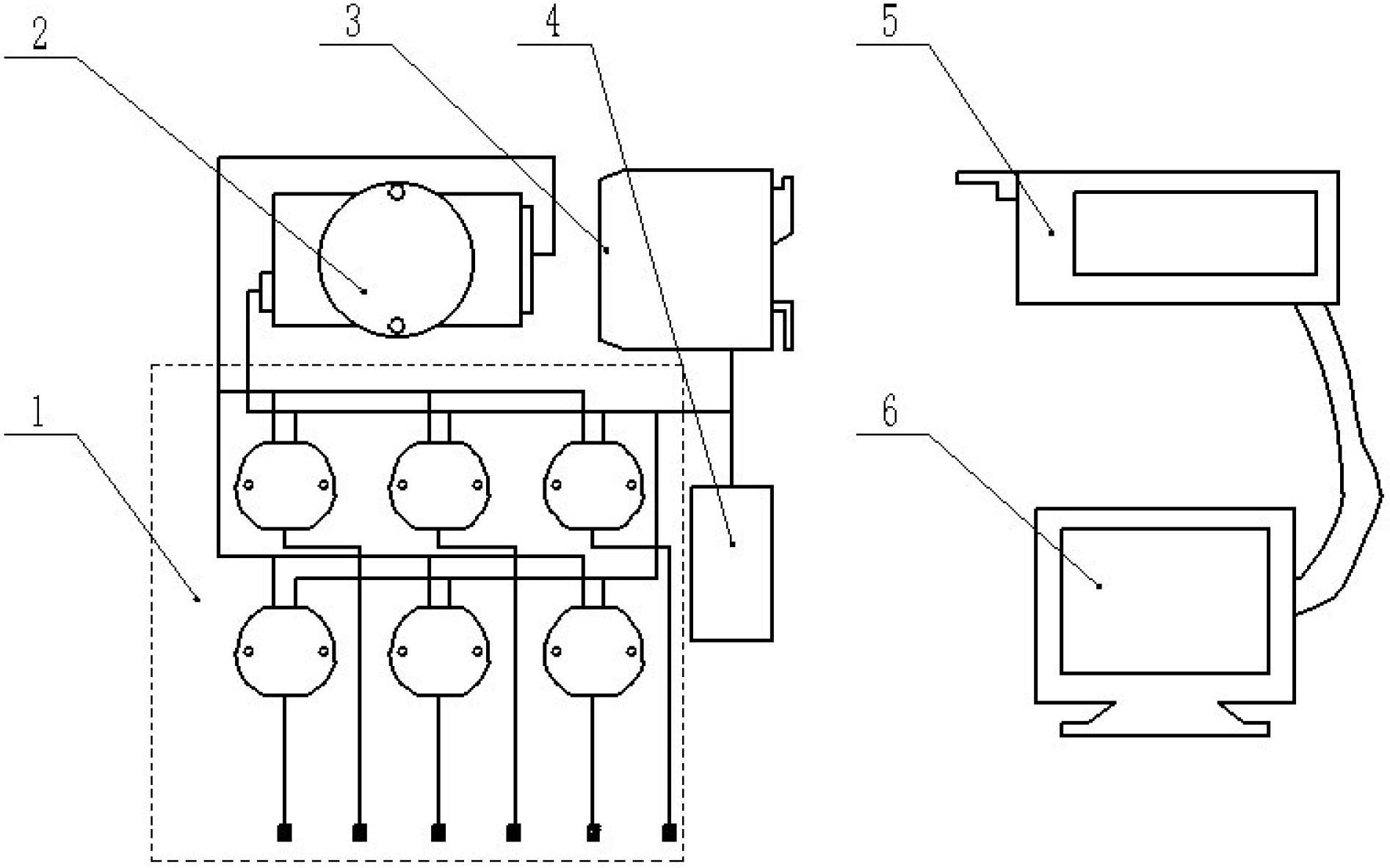

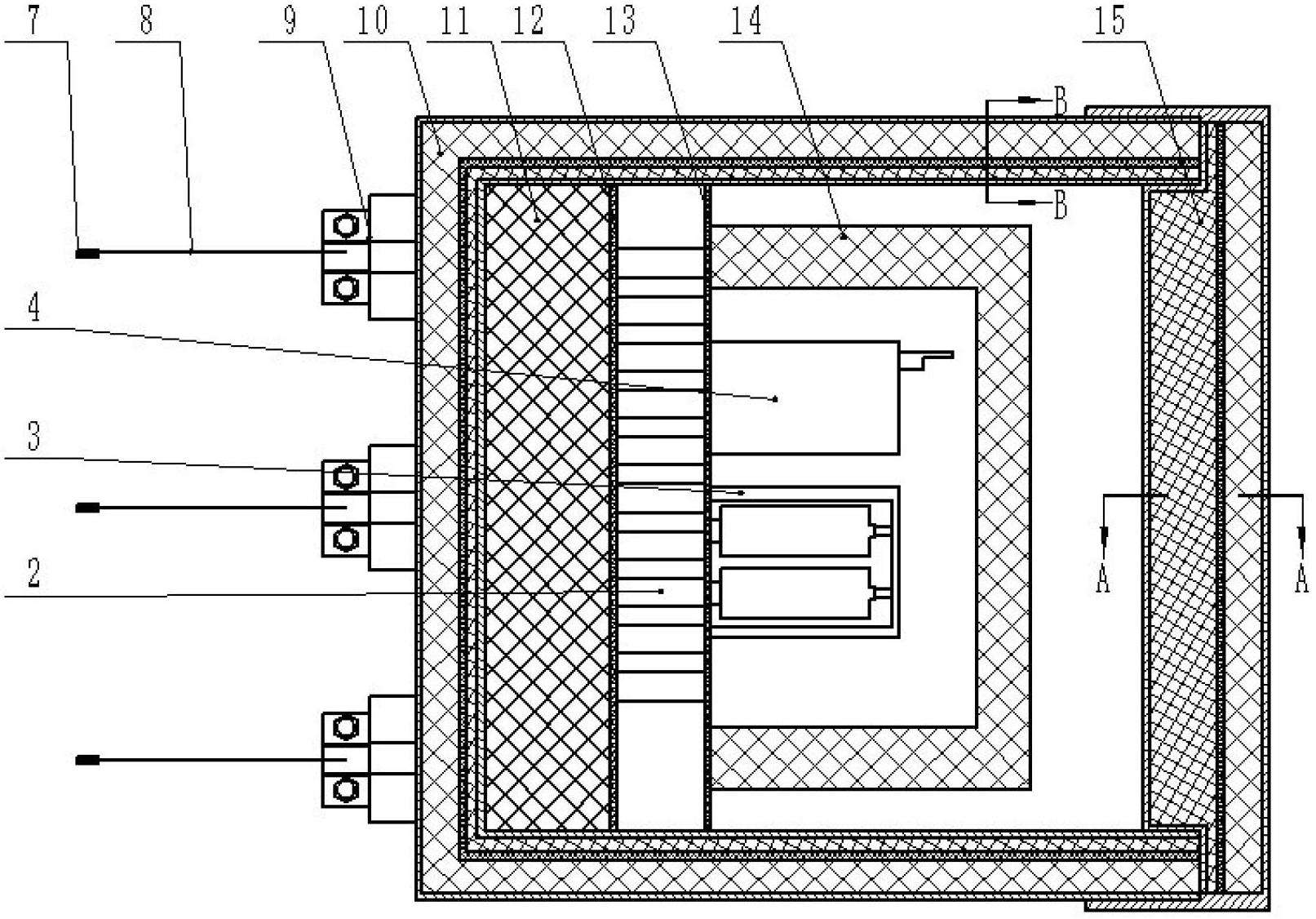

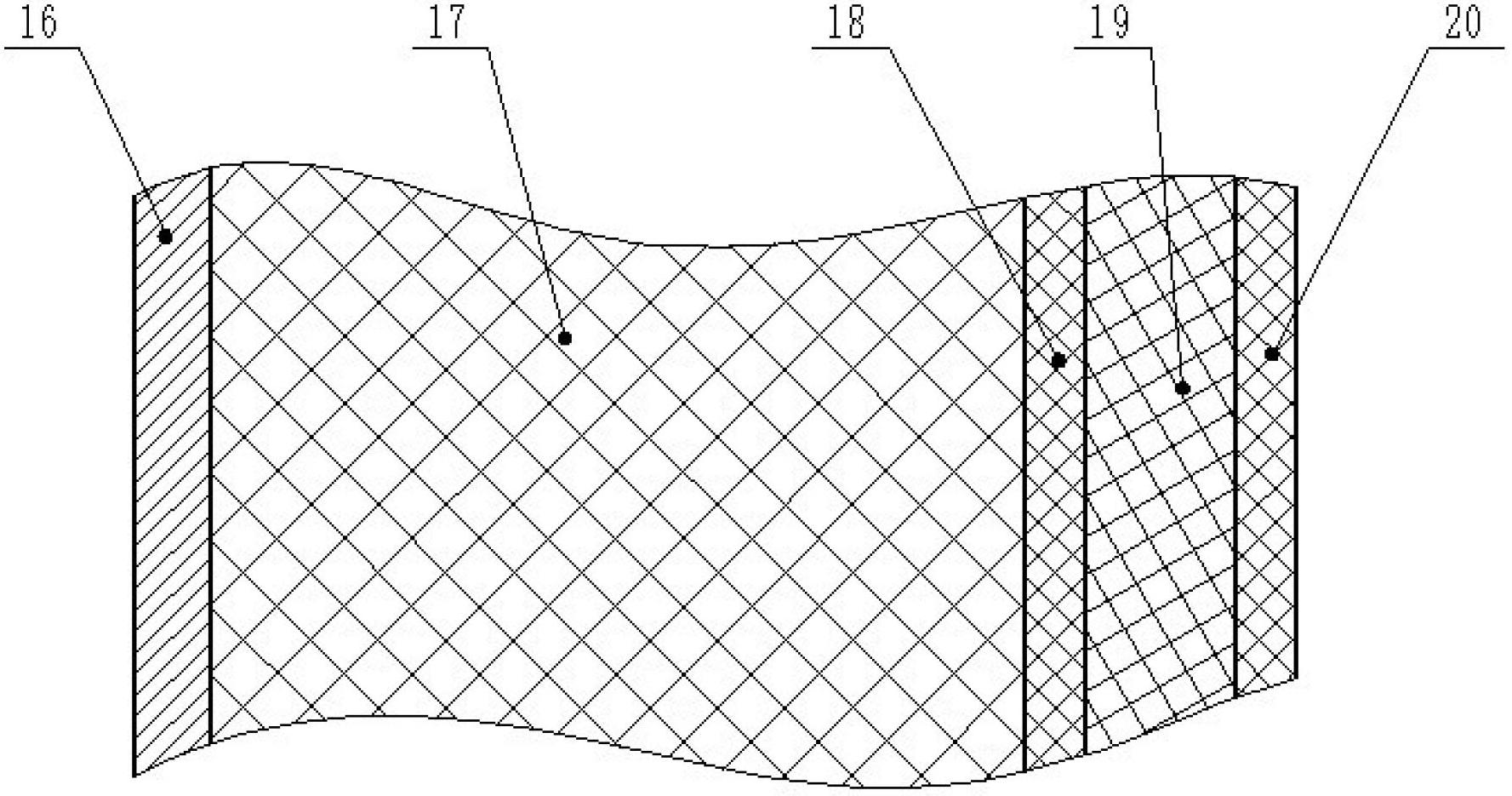

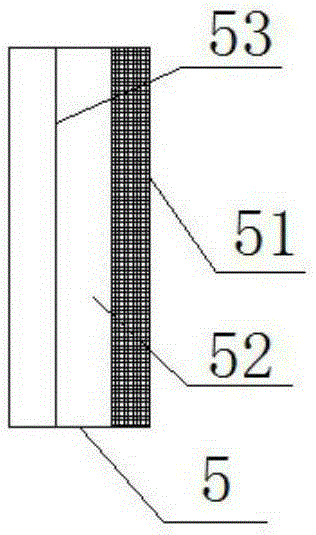

Wireless temperature measuring device for rotational molding equipment

ActiveCN102632577AGuaranteed temperature measurement environment and accuracyImprove rotational molding efficiencyCoatingsInstrumentationElectric signal

The invention relates to a wireless temperature measuring device for rotational molding equipment. The wireless measuring device mainly comprises an insulation box for a thermometer, an end cap for the thermometer, an information acquisition module, an FSK (frequency shift keying) radiofrequency transmitter, a power supply, a FSK radiofrequency receiver, an information processing module and a data processing system, wherein the information acquisition module acquires the temperature inside an oven of a rotational molding machine, the temperature of inside and outside walls of a mold and the temperature of materials, and converts the temperature into electric signals, the FSK radiofrequency transmitter transmits the converted signals to a receiving device, the FSK radiofrequency receivers receives the signals transmitted by the FSK radiofrequency transmitter, the data processing system processes and analyzes the temperature change signals received and acquired by the FSK radiofrequency receiver, and sends feedback the control system of the rotational molding equipment. A five-layer structure between the insulation box for the thermometer and the end cap for the thermometer can efficiently ensure the temperature measuring environment and precision of the equipment. The temperature measuring device can monitor the temperature change in real time, remarkably improve the efficiency of the rational molding, reduce the energy consumption, and improves the quality and the precision of the product.

Owner:BEIJING UNIV OF CHEM TECH

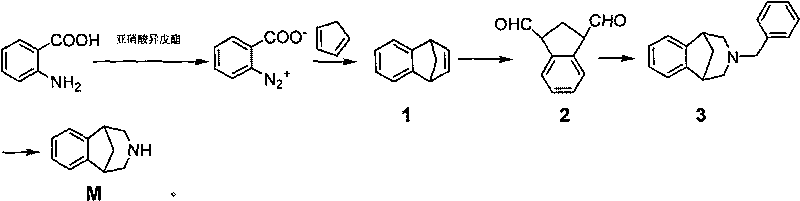

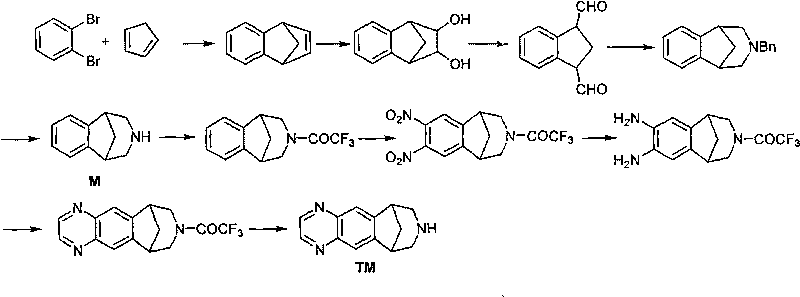

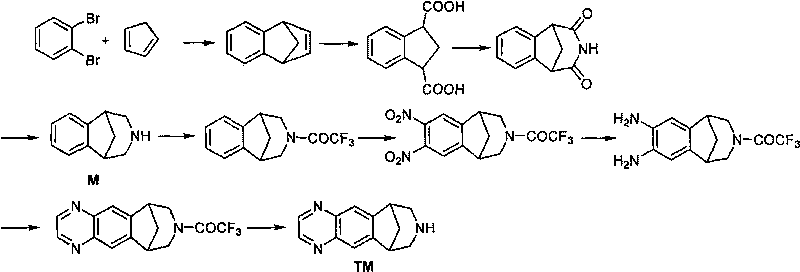

Method for synthesizing Varenicline intermediate 2, 3, 4, 5-tetralin-1, 5-methylene-hydrogen-benzoazepine

The invention relates to a method for synthesizing Varenicline intermediate 2, 3, 4, 5-tetralin-1, 5-methylene-hydrogen-benzoazepine. The method includes the following steps: under the action of catalyst, mixing amyl nitrite with o-aminobenzoic acid solution to generate diazonium salt, then mixing the diazonium salt with cyclopentadiene, and heating to react to generate compound 1; feeding ozone into the solution of compound 1, after complete conversion, adding reducing agent to generate compound 2, then dripping the compound 2 to the mixed solution of triacetoxy sodium borohydride and benzylamine to generate compound 3 by loop closing; and hydrogenating the compound 3 under the action of palladium and carbon for debenzylation and reduction to obtain M intermediate 2, 3, 4, 5-tetralin-1, 5-methylene-hydrogen-benzoazepine. The method has the advantages of greatly simplifying the method for preparing Varenicline intermediate, being simple in production process and safe in operation, well ensuring no harm to the environment and control on production cost, increasing yield and being capable of becoming a process in great industrial production.

Owner:上海立科化学科技有限公司

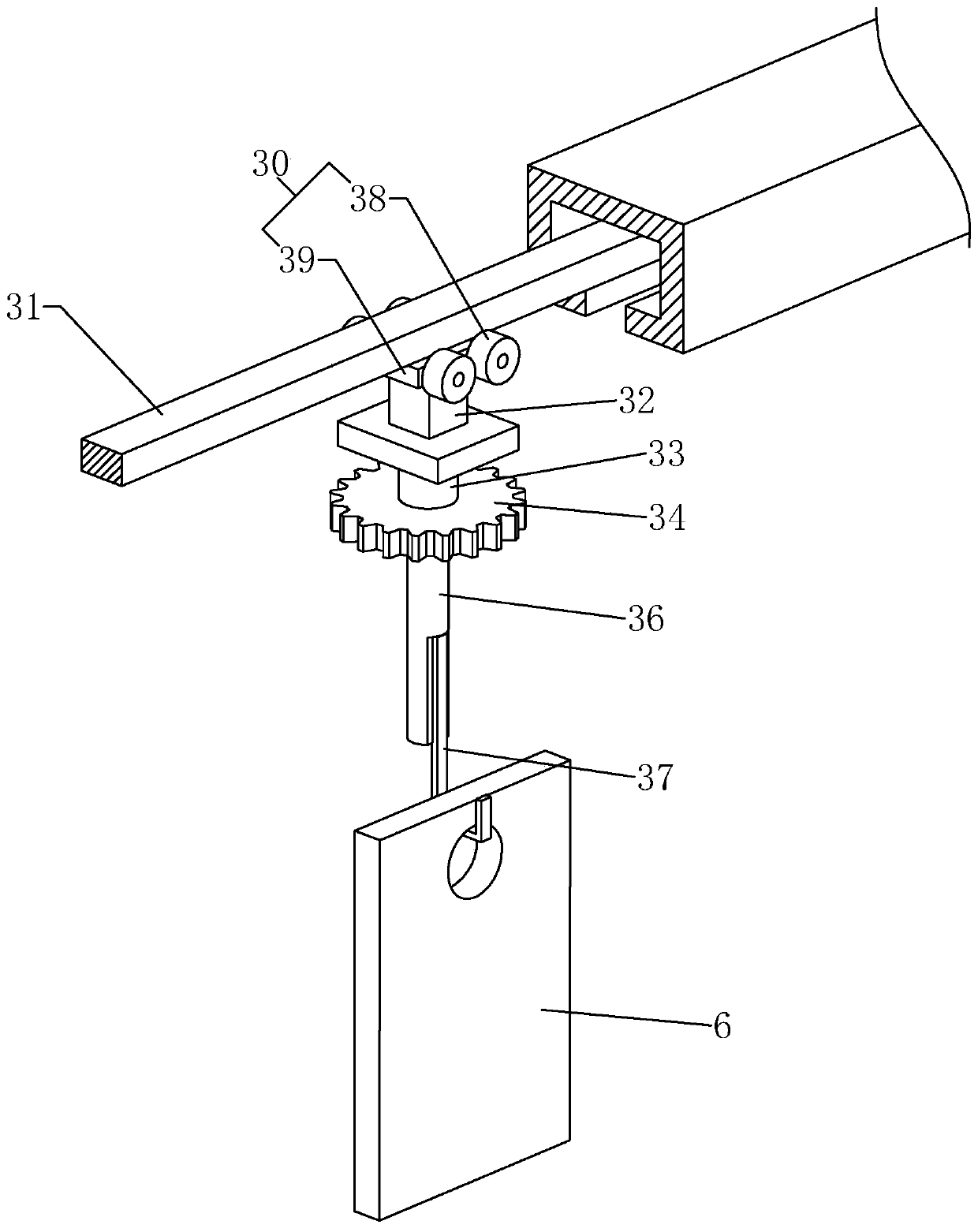

Powder spraying process and powder spraying equipment

The invention discloses a powder spraying process and powder spraying equipment. The powder spraying equipment comprises a cleaning pool, a drying room, a powder spraying chamber, a curing chamber anda conveying chain assembly enabling the cleaning pool, the drying room, the powder spraying chamber and the curing chamber to communicate, wherein the cleaning pool, the drying room, the powder spraying chamber and the curing chamber are arranged sequentially; and the conveying chain assembly comprises a guide rail and a chain located in the guide rail, a connecting rod extending out of the guiderail is arranged on the chain, a rotating sleeve is rotationally connected to the connecting rod, a gear is arranged on the rotating sleeve, a hanging rod is fixedly arranged on the rotating sleeve,a hook used for being in hanging connection with a workpiece is arranged on the hanging rod, the powder spraying chamber is internally provided with a rack which can mesh with the gear, and a plurality of powder spraying guns are arranged in the positions, on the two sides of the a workpiece, of the powder spraying chamber. The powder spraying process and the powder spraying equipment has the effect that the steps of cleaning, drying, powder spraying and the like are connected in series through the conveying chain assembly to realize continuous automatic production and improve the production efficiency.

Owner:顺景园精密铸造(深圳)有限公司

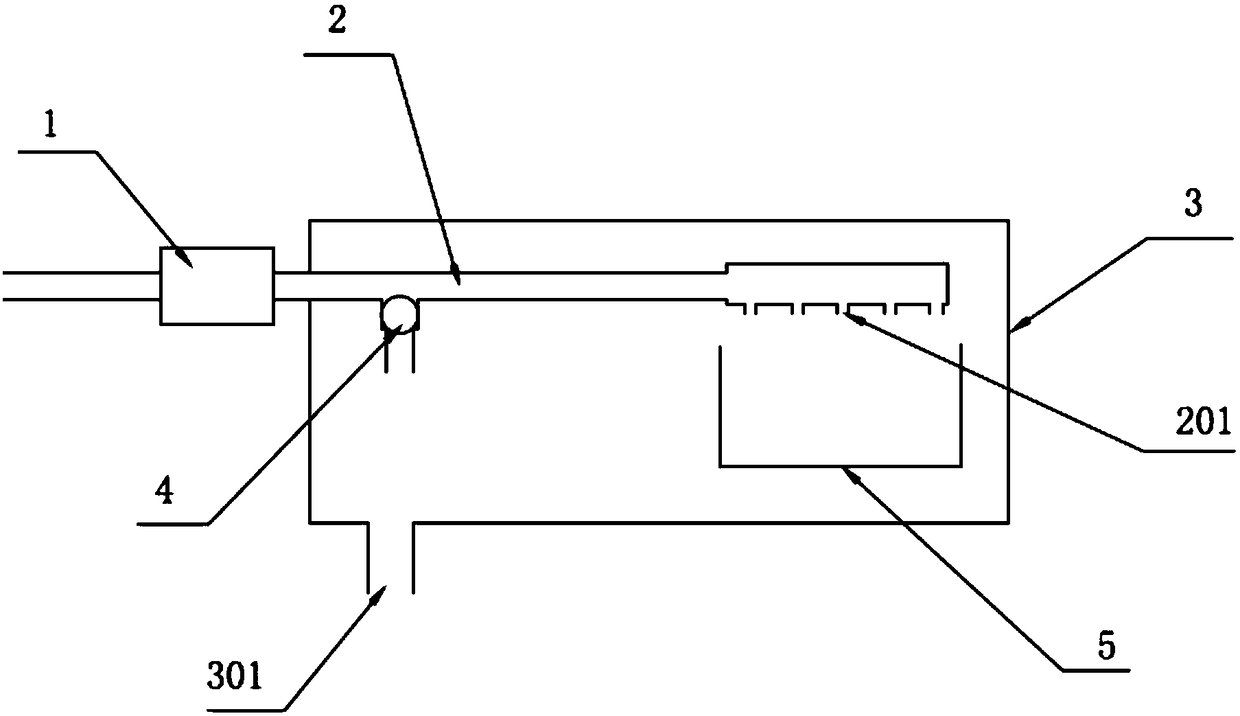

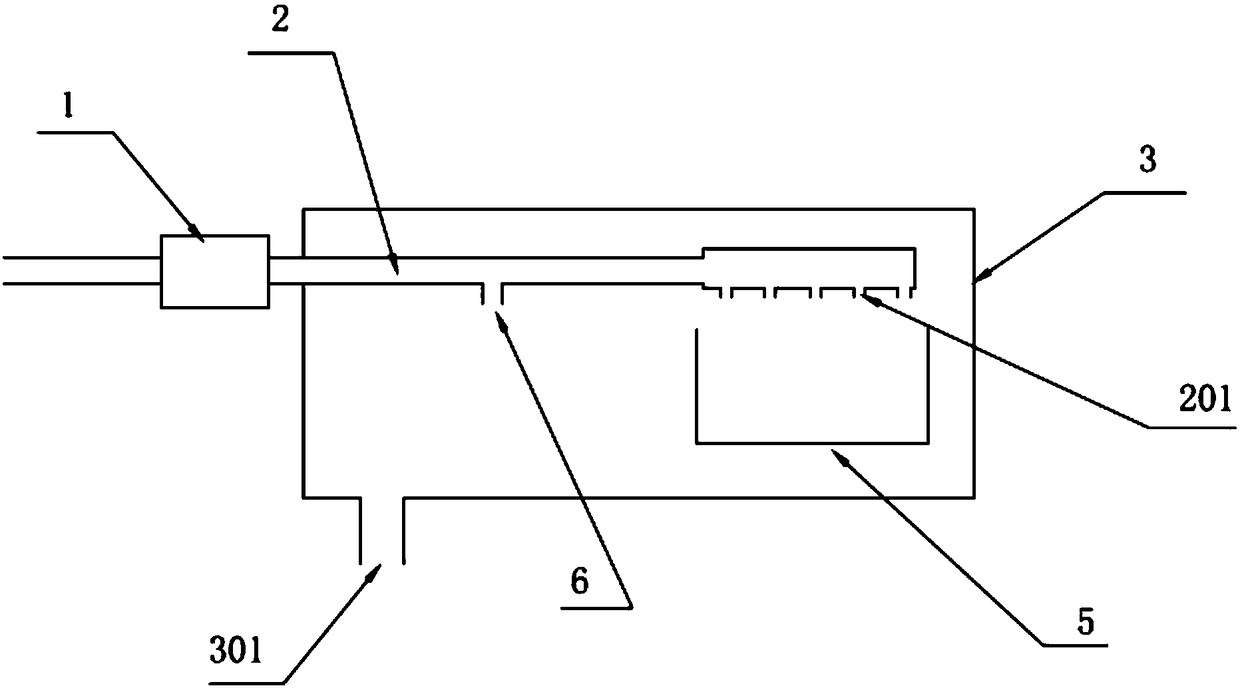

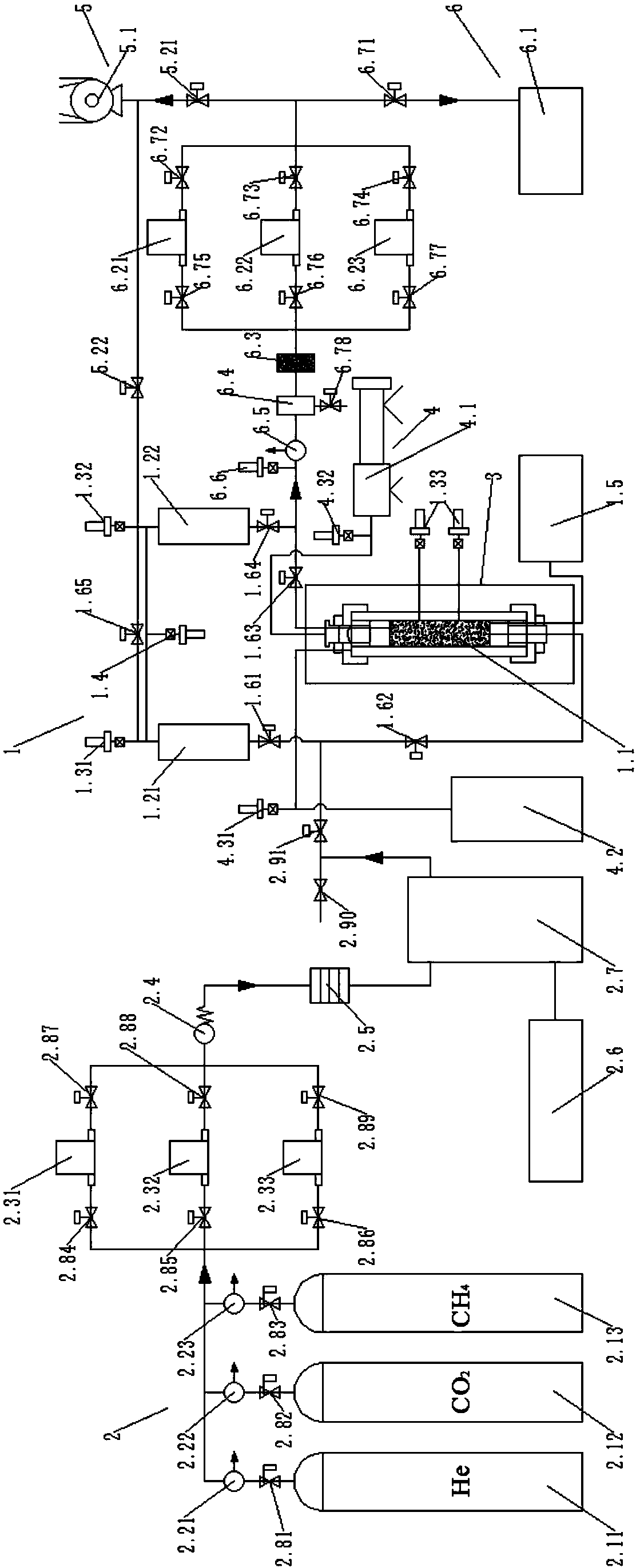

Three-axis permeability testing method

ActiveCN108414418AEasy connectionGuarantee system securityPermeability/surface area analysisPetrologyTest efficiency

The invention discloses a three-axis permeability testing method, and belongs to the field of coal bed gas exploitation. A rock sample is placed in a model system (1), then pressure pulse is applied on the rock sample; a gas control system (2) supplies test gas to the model system (1); a temperature control system (3) controls the temperature of the model system (1); a three-axis loading system (4) applies confining pressure and axial pressure on the rock core clamper of the model system (1); a vacuumizing system (5) vacuumizes the test device; a gas sample collecting system (6) detects the gas components after the test; and an electrical controlling and monitoring system monitors the test process. The method comprises following steps: filling a sample into a tank, checking the airtightness, carrying out a permeability test, and cleaning the test system. The provided method can simulate a high temperature and high pressure environment of a deep stratum in a lab; pressure pulse is applied on the inlet end of a rock sample, the attenuation data of pressure pulse can be obtained, and then the rock sample permeability is calculated based on the attenuation data. The test efficiency ishigh, the external interference is little, and the test result is more accurate.

Owner:CHINA UNIV OF MINING & TECH

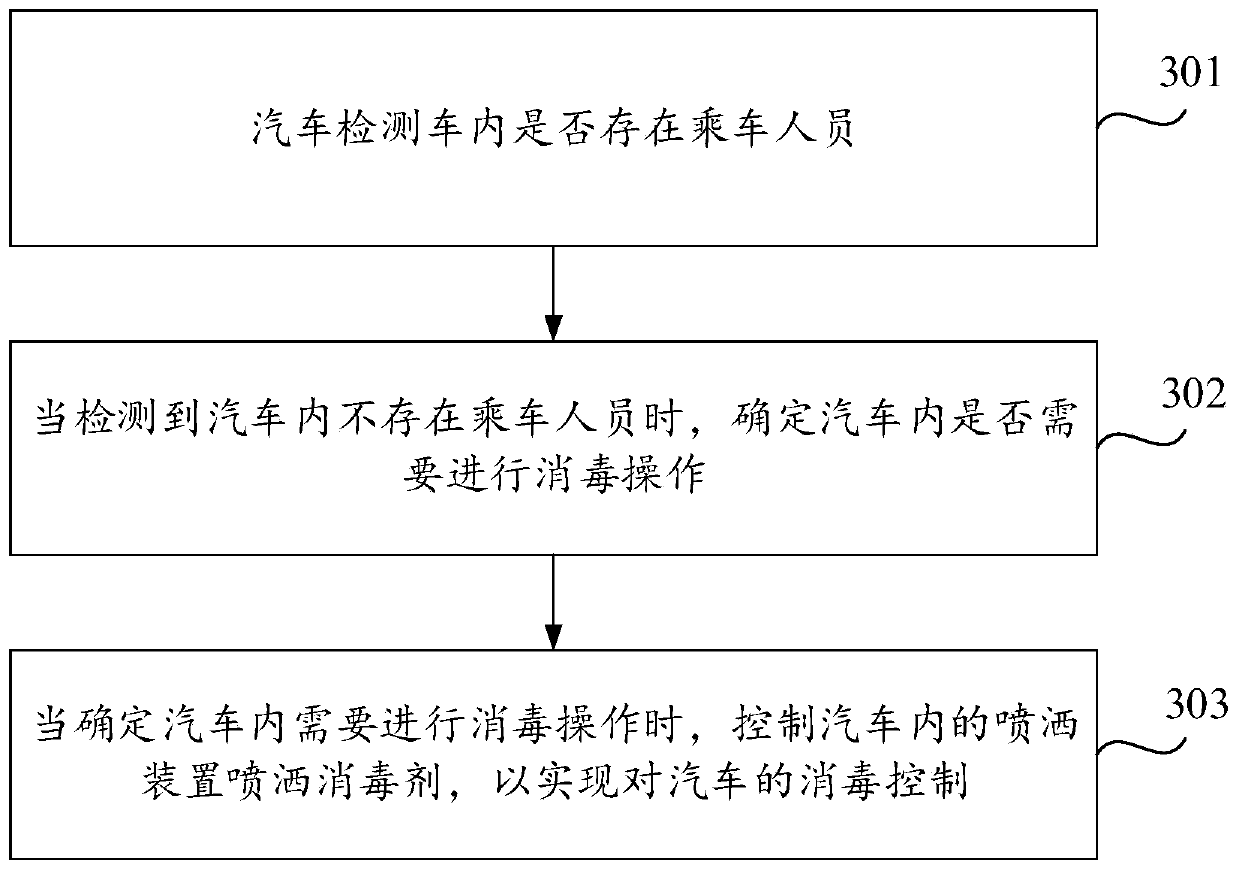

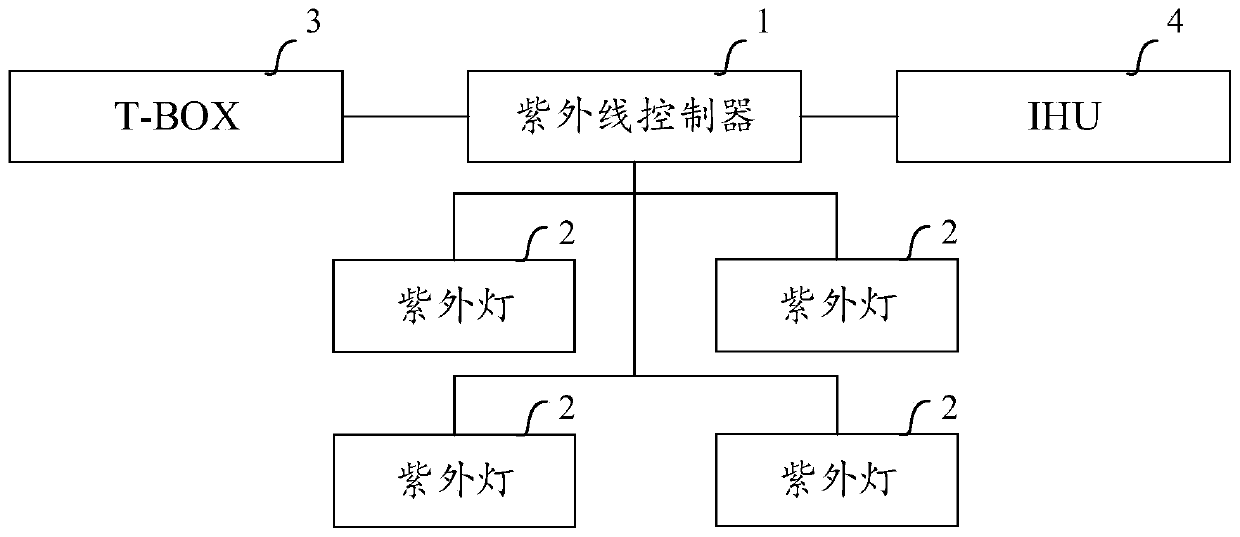

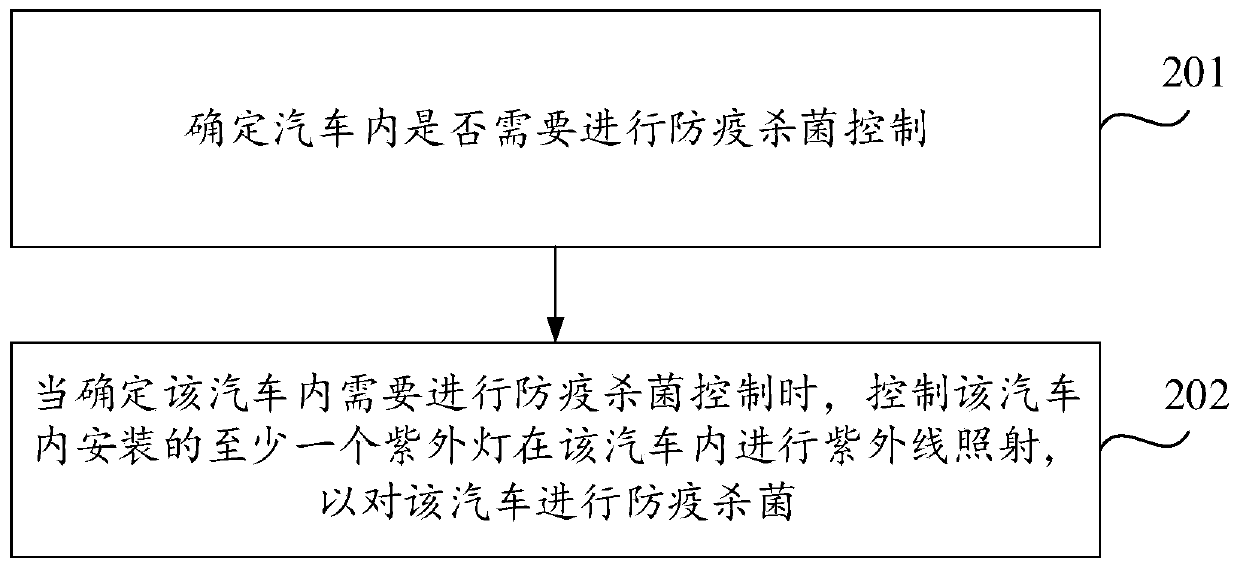

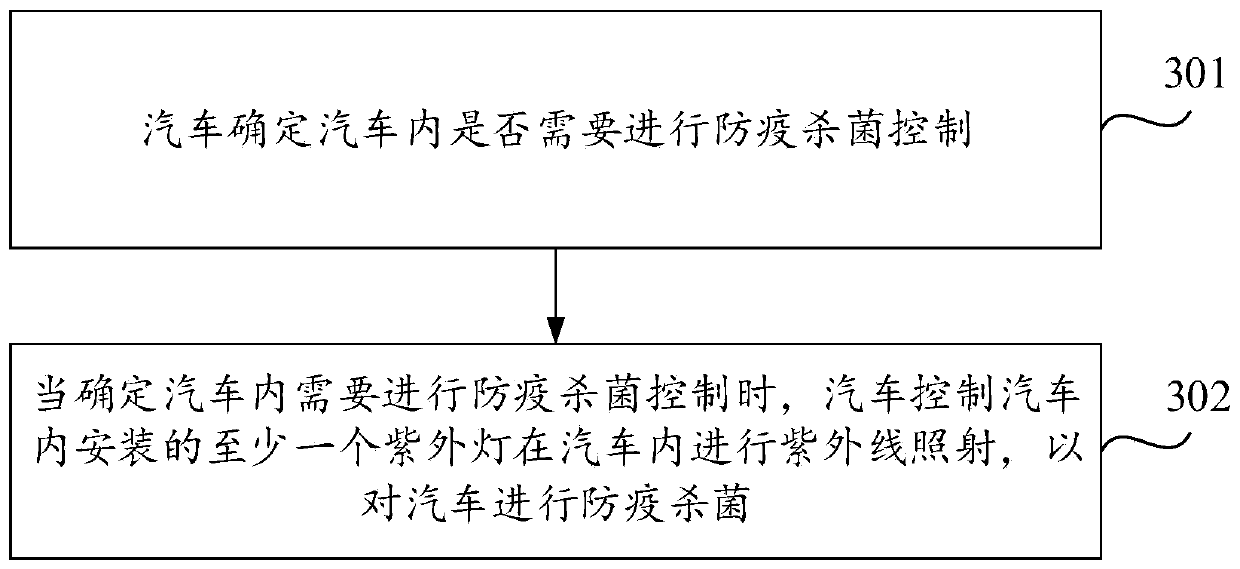

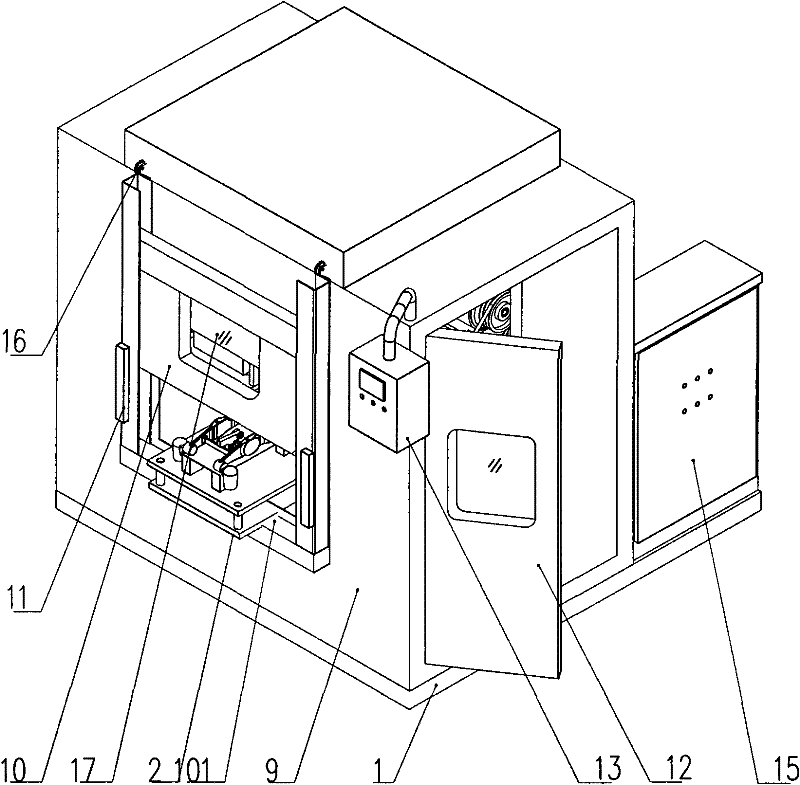

Automobile epidemic prevention and sterilization control method and device and storage medium

PendingCN111569099AGuarantee the environmentReduce health threatsAir-treating devicesLavatory sanitoryVehicle engineeringReliability engineering

The invention discloses an automobile epidemic prevention and sterilization control method and device and a storage medium, and belongs to the technical field of vehicle engineering. The method comprises the steps that whether epidemic prevention and sterilization control needs to be conducted in an automobile or not is determined; and when it is determined that epidemic prevention and sterilization control needs to be conducted in the automobile, at least one ultraviolet lamp installed in the automobile is controlled to conduct ultraviolet irradiation in the automobile so as to conduct epidemic prevention and sterilization on the automobile. When it is detected that the automobile needs to be subjected to epidemic prevention and sterilization control, at least one ultraviolet lamp in theautomobile is controlled to conduct ultraviolet irradiation in the automobile, so that epidemic prevention and sterilization control over the automobile is achieved, and therefore bacteria appearing in the automobile and threats of the bacteria to the health of passengers are reduced.

Owner:CHERY AUTOMOBILE CO LTD

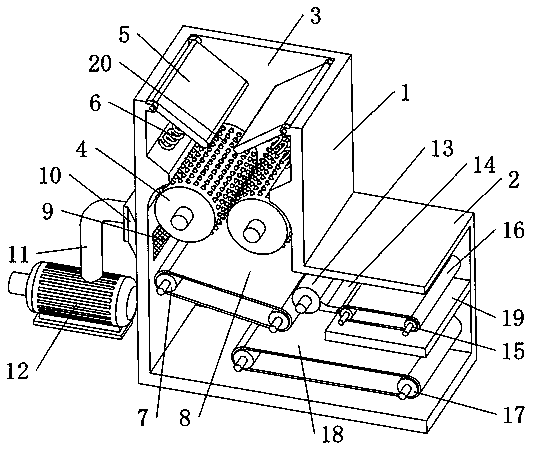

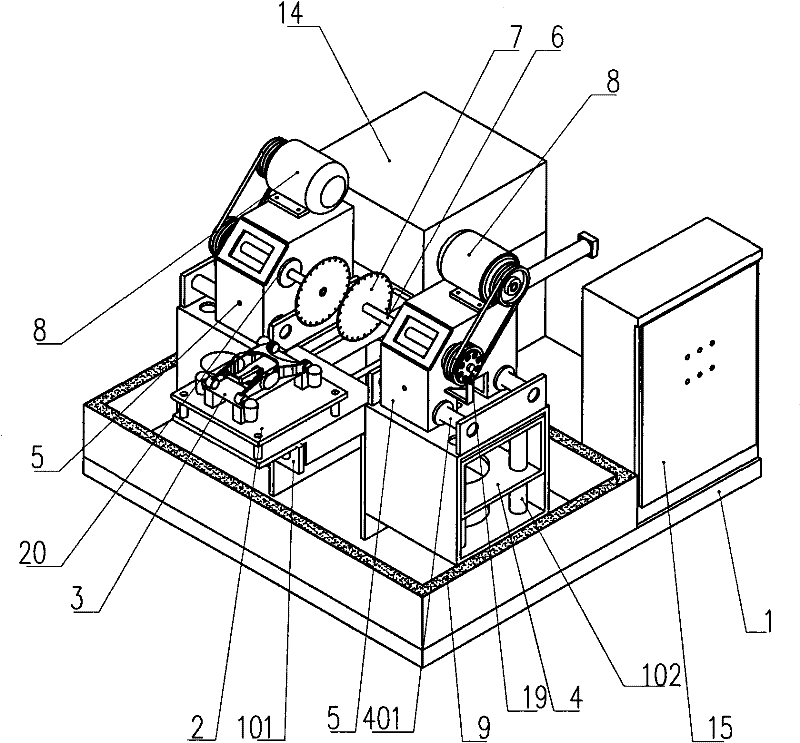

Sealed automatic cutting machine for cutting black metal

InactiveCN102218568AGuarantee the environmentReduce noiseMetal sawing devicesMetal sawing accessoriesHydraulic ramAlloy composite

The invention discloses a sealed automatic cutting machine for cutting black metal, and the machine provided by the invention comprises a base, an X-direction work sliding table, an X-direction hydraulic ram, a hydraulic dedicated fixture, a Y-direction work sliding table, a Y-direction hydraulic ram, a Z-direction work sliding table, a Z-direction hydraulic ram, a main shaft, a high-alloy composite cutter, a motor, a soundproof room, a visual protection door, a safe light curtain sensor, an inspection door, a display screen, a button box, a hydraulic station and an electric control cabinet. The sealed automatic cutting machine has the advantages that the cutting machine can be used for automatically cutting the casting head of a casting in black metal under a totally closed condition. In the equipment, a targeted and flexible machining scheme can be realized according to the shape particularity of the casting and the irregularity of machining stations. The sealed automatic cutting machine has the advantages of high production efficiency, good machining adaptability and reasonable structure and is convenient to use and maintain, can be used for lightening the labor intensity of workers, totally meets the requirement of mass assembly line production, and ensures the safety of operation personnel.

Owner:JINGMEN DELIDA MACHINERY

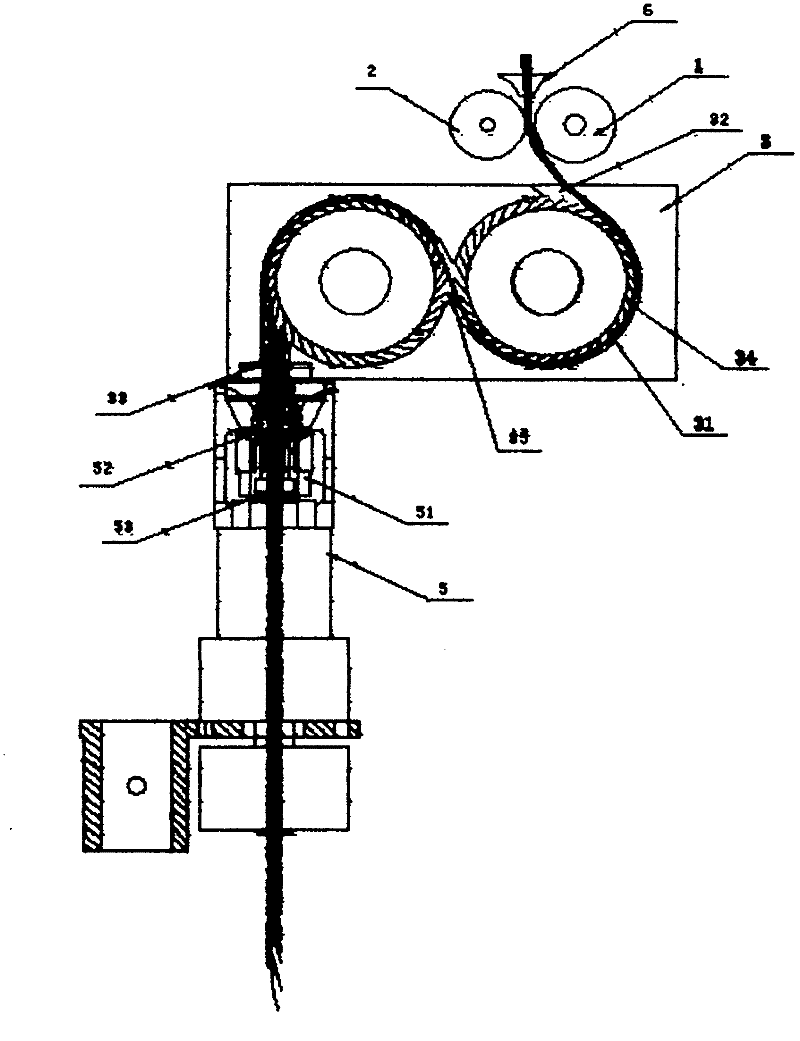

Steel round bar heading-off mechanism for plasma cutting machine

InactiveCN102626864AImprove upsetting efficiencyAvoid lossOther manufacturing equipments/toolsPlasma welding apparatusEngineeringRound bar

The invention relates to a steel round bar heading-off mechanism for a plasma cutting machine and belongs to the technical field of metal cutting machinery. The plasma cutting machine comprises a rack formed by frist and second beam bodies, a plasma cutting mechanism, a steel round rod driving and transporting mechanism, a lifting frame and a group of steel round bar turnover mechanisms; the steel round bar heading-off mechanism is arranged at the end part of the other end of the rack; the steel round bar heading-off mechanism comprises a base, a bracket, an oil cylinder seat, an oil cylinder and a heading block; the base is arranged on the floor; the bracket is fixed on the base; carrier rollers are respectively arranged on the surface of the side of the bracket, which is toward the oil cylinder seat, and at both sides of the surface; the oil cylinder seat is fixed at the tops of one group of uprights; the bottoms of the one group of uprights are fixed together with the edge positon of the bracket; the oil cylinder is fixed at the center position of the oil cylinder seat; the heading block is connected to the tail end of an oil cylinder column; and an inverted V-shaped cavity is formed at the side of the heading block, which is toward the bracket. The steel round bar heading-off mechanism has the advantages of avoiding the material loss in the cutting process of a steel round bar, improving the heading-off efficiency, reducing the noise and saving electrode materials.

Owner:常熟市旋力轴承钢管有限公司

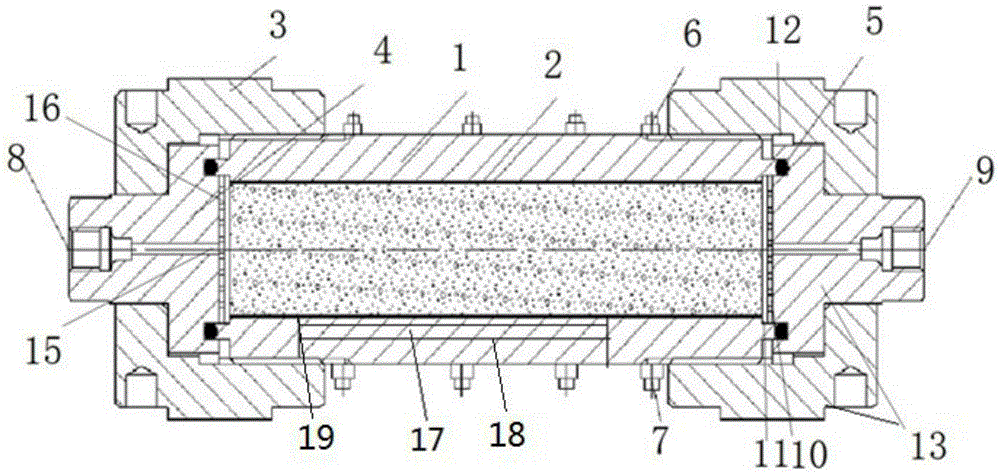

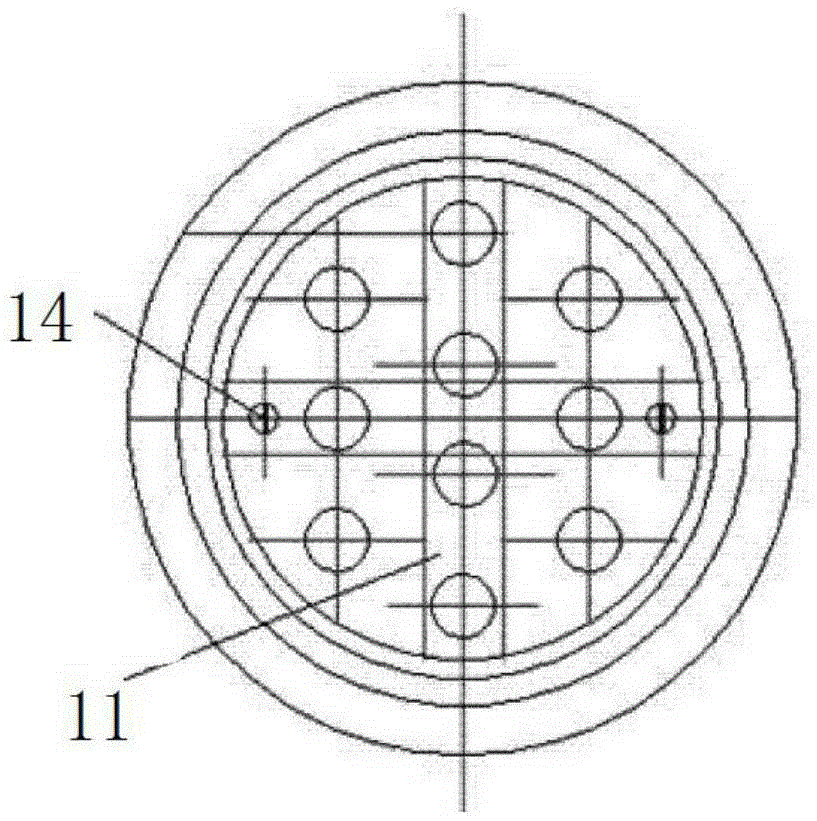

Sand filling model pipe

InactiveCN105239978APrevent flow phenomenonGuaranteed sealing performanceFluid removalEngineeringDouble ring

The invention provides a sand filling model pipe. The sand filling model pipe comprises a main body, plugs, pressing caps, an inlet and an outlet, wherein the main body is a hollow pipe, and is provided with a sampling port and a pressure measuring port; the plugs are positioned at the two ends of the main body, and are connected with the main body through screws; the pressing caps are fixedly connected with the plugs; the inlet and the outlet are positioned at the two ends of the sand filling model pipe; the inner wall of the main body is uniform and consistent in roughness, and is an electrospark roughened inner wall; the roughness of the inner wall of the main body is greater than Ra12.5; the plugs are double-ring sealing plugs; and a temperature sensing heating device is arranged in a shell of the main body, and is fixedly connected with the main body. The sand filling model pipe can effectively prevent the streaming phenomenon between sand particles and the inner wall in the experimental process, so that the precision of experimental results is guaranteed, and the tightness is good; and the sand filling model pipe is provided with the temperature sensing heating device, so that the cleaning is facilitated, and the accuracy of experimental conditions can be guaranteed.

Owner:南通市飞宇石油科技开发有限公司

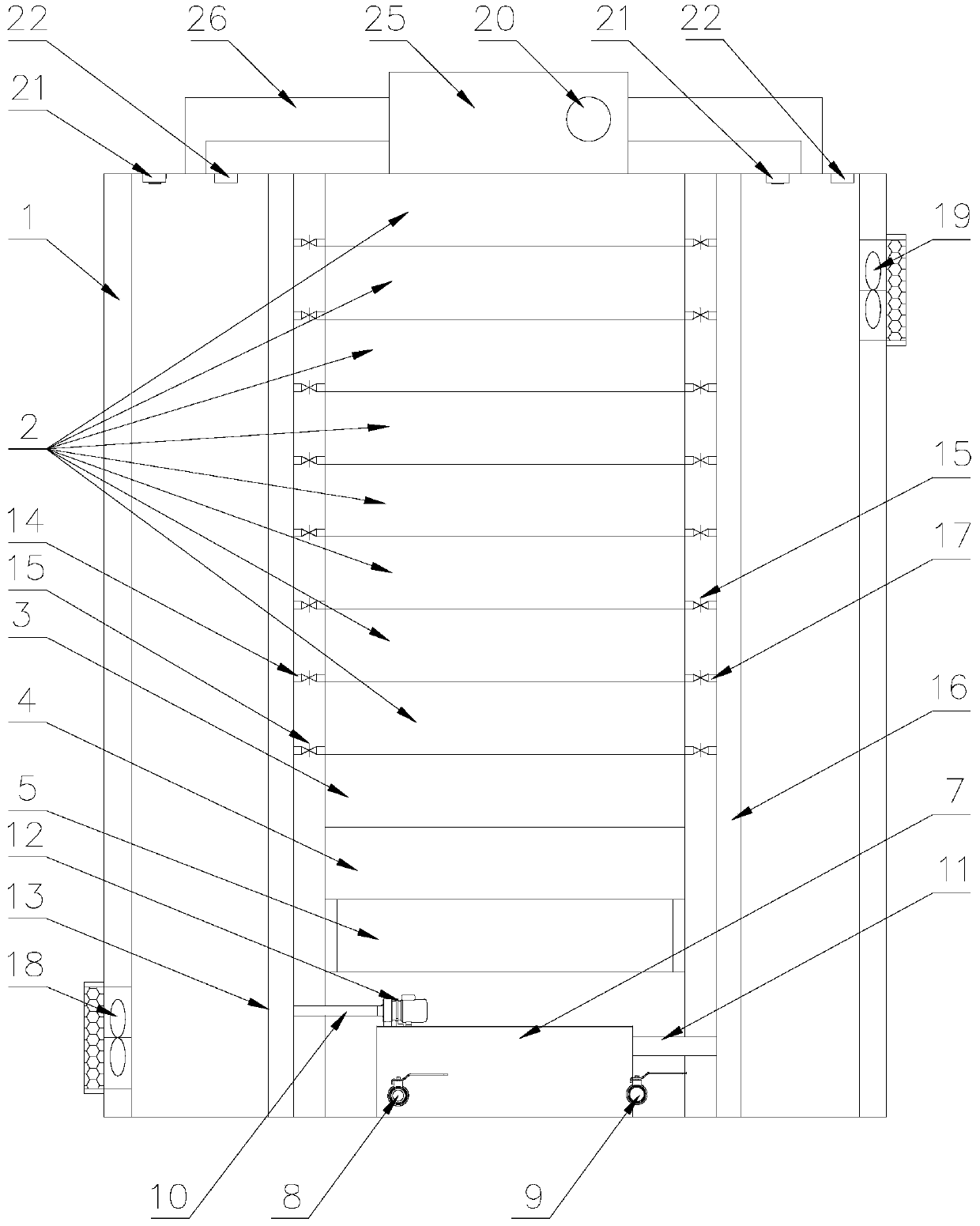

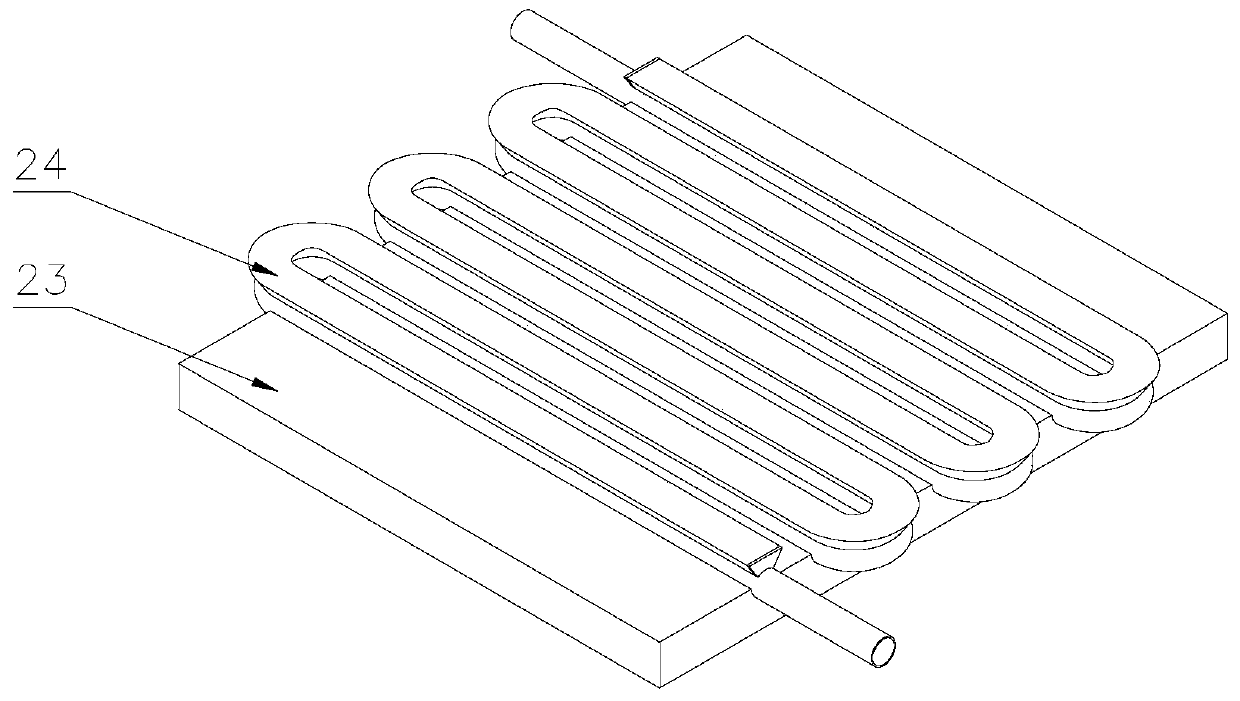

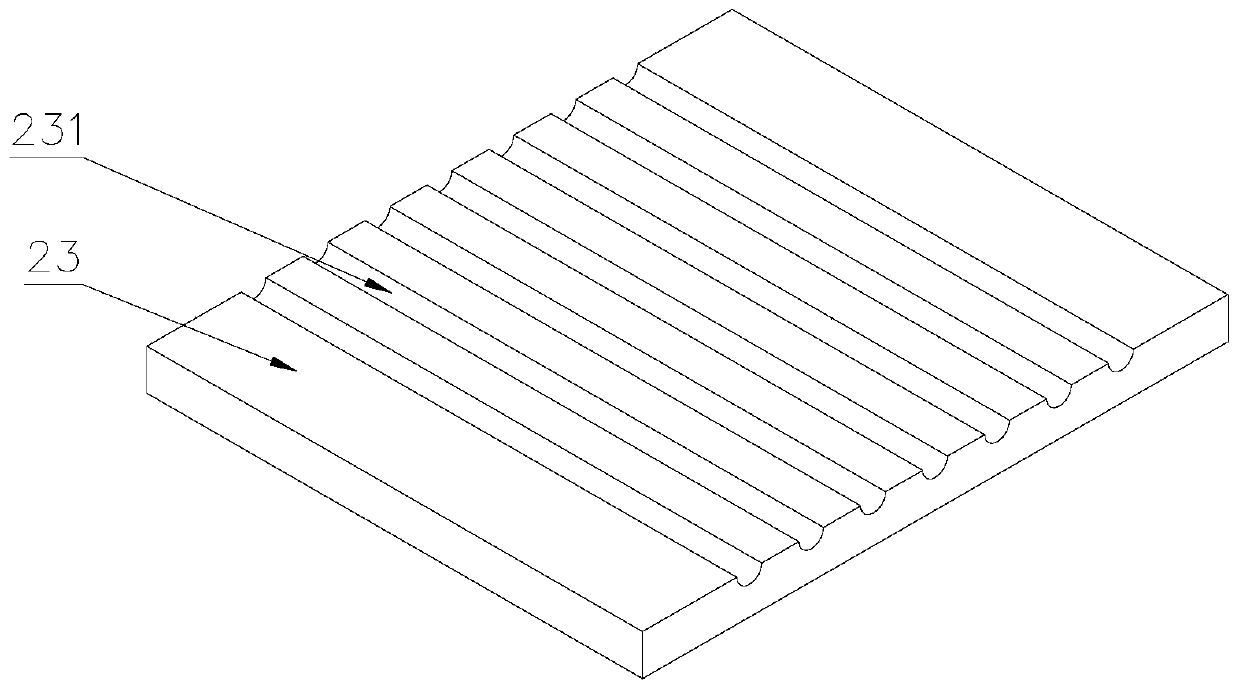

Liquid-cooled single cabinet data center

PendingCN110278690AImprove stabilityGuaranteed uptimeCooling/ventilation/heating modificationsData centerWarm water

The invention discloses a liquid-cooled single cabinet data center. A heat exchanger is installed at that bottom end inside the cabinet. A separating plate is arranged inside shell. A coolant is arranged on the upper side of the separating plate and circulating water is arranged on the lower side of the separating plate. The lower side of the separating plate is provided with a cold water inlet pipe. The other side of the lower part of the separating plate is provided with a warm water outlet pipe. One side of the water outlet pipe of a circulating water pump is connected with a cold water outlet pipe. One side of the cold water outlet pipe is connected with a water distribution pipe which is provided with multiple water inlet branch pipes. Multiple cold plates are arranged inside the cabinet. A cooling coil pipe is arranged in an installing groove. One end of the cooling coil pipe is connected with the water inlet branch pipes. A water collecting pipe is arranged on the server side. One end of the water collecting pipe is connected with the warm water inlet pipe. Multiple return water branch pipes are arranged on the water collecting pipe. The other end of the cooling coil pipe is connected with the return water branch pipes. The heat exchanger is arranged at the bottom of the cabinet, and the coolant flows into the cooling coil pipe of the upper part of the cold plate through the water distribution pipe and the water inlet branch pipes in turn to cool and dissipate heat for the server so as to improve the stability of the server operation.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

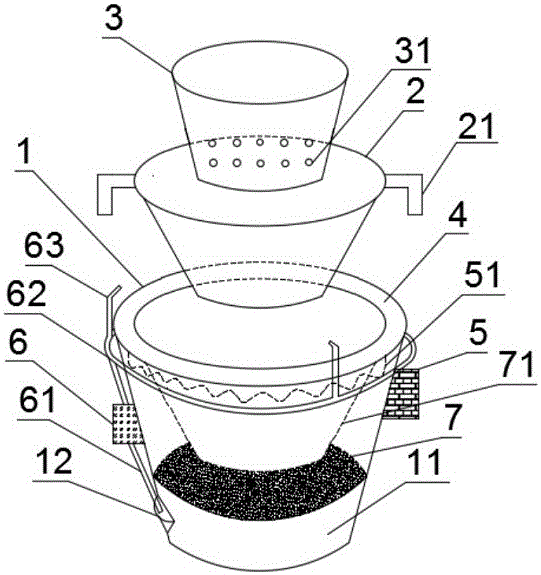

Medicinal herb planting pot

InactiveCN106561321AReasonable careTemperature controlSelf-acting watering devicesReceptacle cultivationMedicinal herbsEngineering

The invention discloses a medicinal herb planting pot which comprises a control pot. A garbage pot is movably placed above the control pot. A planting pot is movably placed above the garbage pot. The side surface of the planting pot is provided with a plurality of ventilating holes. The left side and the right side of top of the garbage pot are provided with handles which are mounted fixedly. The bottom of the control pot is provided with a water tank. Furthermore the side surface of the water tank is provided with a water inlet / outlet. A separator plate is fixedly mounted above the water tank. Annular glass is fixedly mounted at inside of top of the control pot. An annular baffle plate is fixedly mounted at inside of the annular glass. The annular baffle plate is fixedly connected with the separator plate. According to the medicinal herb planting pot, reasonable arrangement can be performed on medicinal herb in a combined manner so that the medicinal herb can be randomly moved to an outdoor position or a sunny position. Furthermore temperature and humidity required by the medicinal herbs can be well controlled through heating wires and stream outlets which are distributed around the medicinal herb. Furthermore through monitoring of a temperature-and-humidity controller, the environment required for the medicinal herb can be always kept.

Owner:GUIZHOU SHIBING WANFU AGRI TECH DEV CO LTD

Ultra-high voltage direct current voltage transformer

ActiveCN104111367AMonitor temperature in real timeReliable temperatureCurrent/voltage measurementThermometers using physical/chemical changesTransformerFluorescence

The invention relates to an ultra-high voltage direct current voltage transformer, including a base, a voltage divider, an insulator, a cover plate and fluorescent optical fiber temperature measuring equipment. The voltage divider is arranged in an airtight gas chamber surrounded by the base at the lower end, the insulator in the middle, and the cover plate at the upper end, and the airtight gas chamber is filled with SF gas; the fluorescent optical fiber temperature measuring equipment includes fluorescent optical fiber temperature sensors, an adapter optical fiber, a fluorescent optical fiber temperature measuring instrument, an optical fiber converter and a PC; and the fluorescent optical fiber temperature sensors are uniformly fixed on the voltage divider along a height direction of the voltage divider, and are connected with the adapter optical fiber through a through device fixed on the base in a sealed manner. The temperature of the voltage divider in the airtight gas chamber is monitored in real time through the fluorescent optical fiber temperature measuring equipment that is arranged, and temperature inside the direct current voltage transformer is detected; and in cooperation with the fluorescent optical fiber temperature sensors uniformly fixed on the voltage divider, temperature monitoring can be performed comprehensively and reliably, and the entire temperature monitoring adopts optical signal transmission, and is not affected by high voltage and strong electromagnetic interference.

Owner:CHINA XD ELECTRIC CO LTD

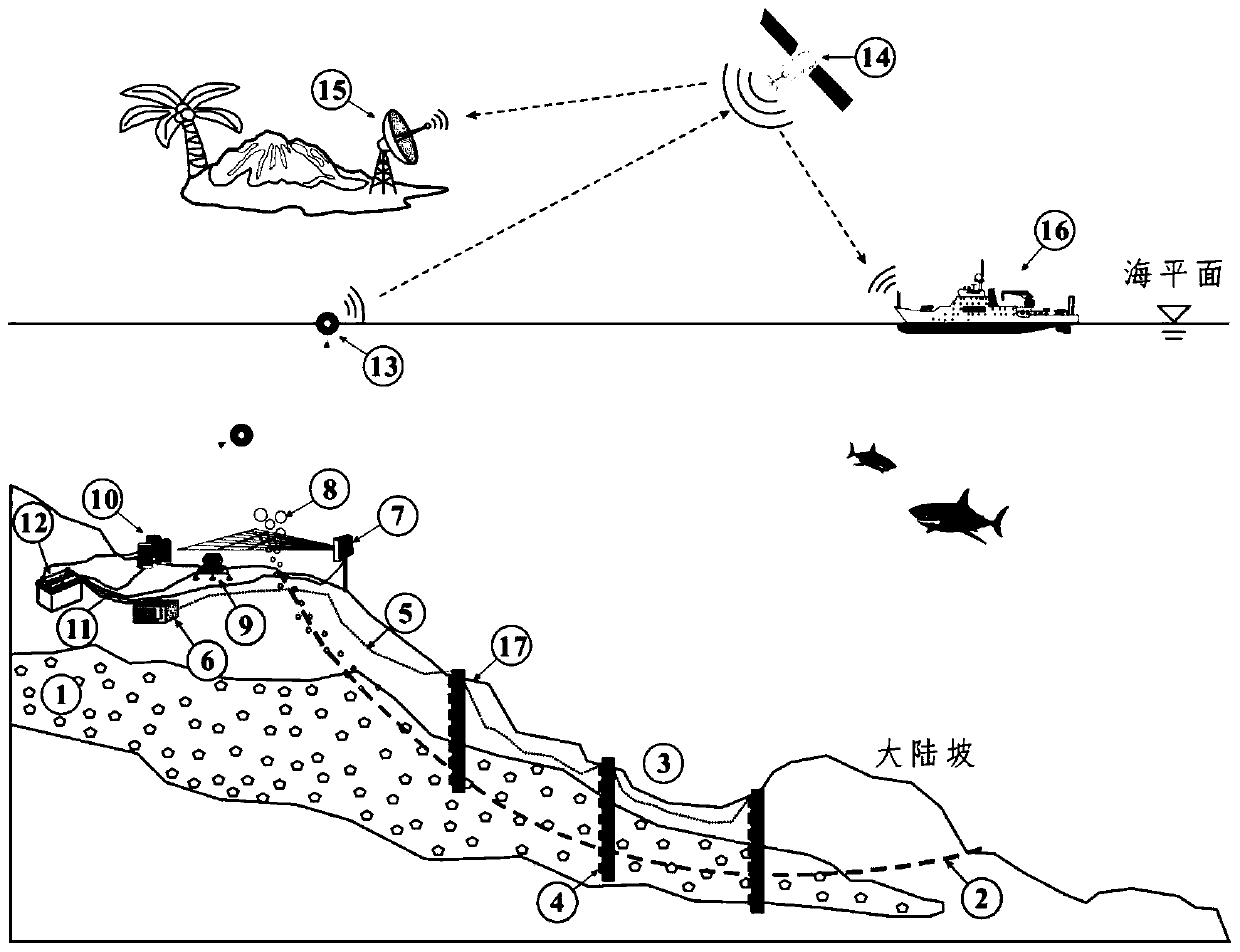

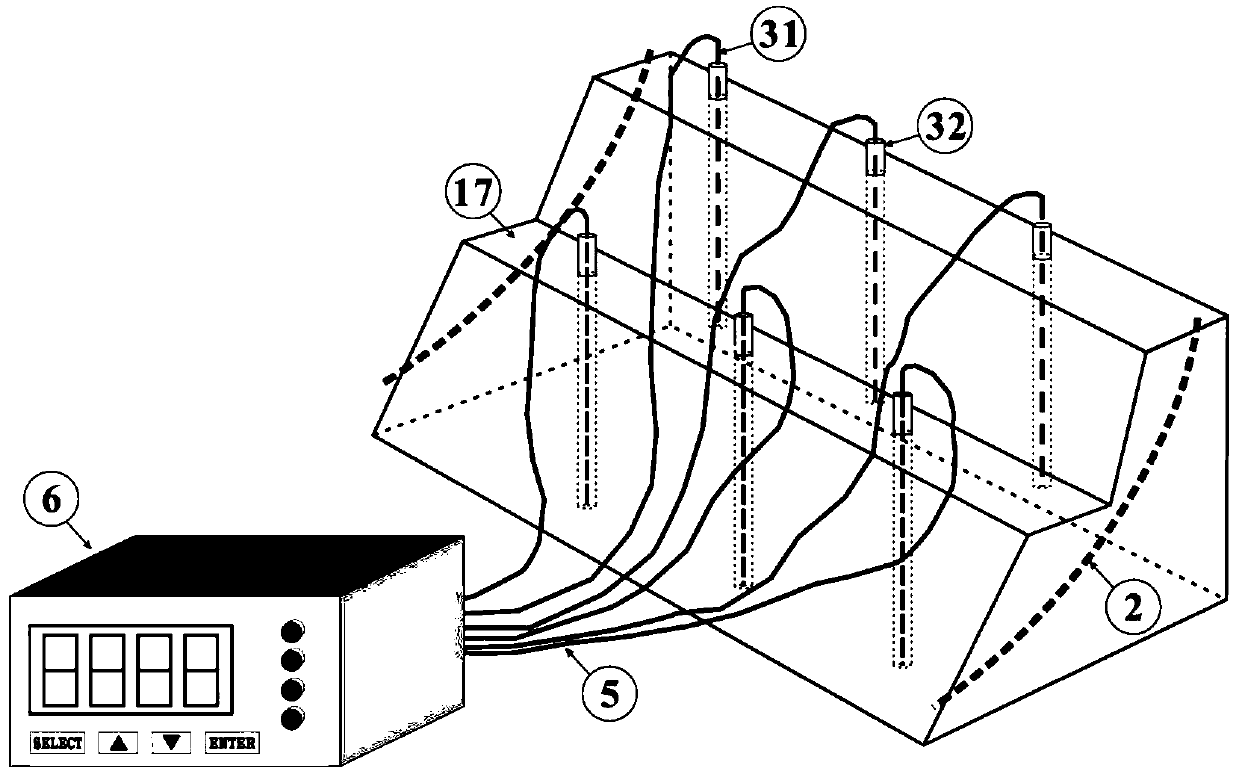

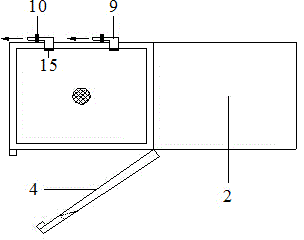

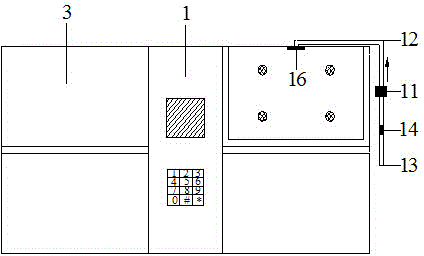

Continental margin hydrate environment geology dynamic monitoring system and method

ActiveCN111236896ALong-term monitoringContinuous monitoringSurveyFluid removalContinental marginDynamic monitoring

The invention discloses a continental margin hydrate environment geology dynamic monitoring system and method. The method comprises the steps of monitoring the dissolved methane flux, the dissolved oxygen content, the pH value, the Eh value and other parameters of a leakage source in a water body on the basis of a seabed multi-parameter sensor technology; monitoring the free methane flux leaked ina bubble plume mode by combining an ultrasonic flowmeter; based on a distributed optical fiber technology, monitoring the stress and strain of a potential unstable slope, so that comprehensive monitoring of landslide and environmental changes for the slope with natural gas hydrate existing on a continental margin is achieved; and through the establishment of a small-scale submarine observation network, unified power supply and data acquisition, monitoring the dynamic activity of a hydrate reservoir and the resulting environmental effects, so that the in-situ, long-term and continuous monitoring and early warning capabilities are formed, the mechanism and rules of geological hazards possibly induced by hydrates are mastered, technical support is provided for the hydrate exploitation process, the practical value is high and implementability is high.

Owner:QINGDAO INST OF MARINE GEOLOGY

Self-cleaning express cabinet and method

InactiveCN104867246AGuarantee the environmentWill not polluteLavatory sanitoryApparatus for meter-controlled dispensingVentilation ductEngineering

The invention provides a self-cleaning express cabinet and method. The self-cleaning express cabinet comprises an express cabinet body which is composed of a main cabinet and express boxes, each express box is provided with a box body and a box door, the express cabinet body is provided with a self-cleaning system, each self-cleaning device comprises a controller, a sterilization device and an odour removal device, each odour removal device comprises a gas detection device and ventilation ducts any box body of the express box is provided with the gas detection device and the ventilation ducts, each ventilation duct is provided with an air valve, each sterilization device comprises a sterilization vessel and a pipeline which is arranged in any box body of the express box, each pipeline is connected with the corresponding sterilization vessel which is provided with a main pipe, each main pipe is provided with a pressurizer, the controllers are connected with the sterilization devices and the odour removal devices, the controllers are connected with the main cabinet, a small exhaust fan is arranged inside each ventilation duct, and an atomizer is arranged in each pipeline.

Owner:SHENZHEN YIHAOGUI TECH CO LTD

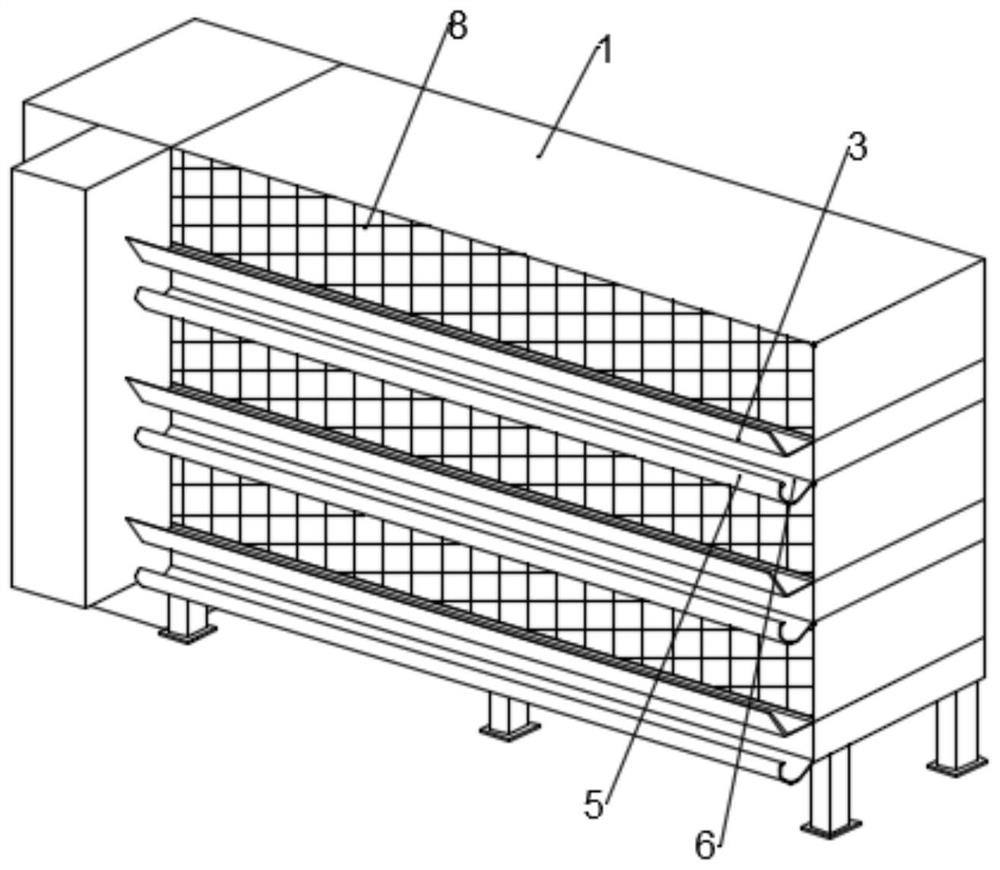

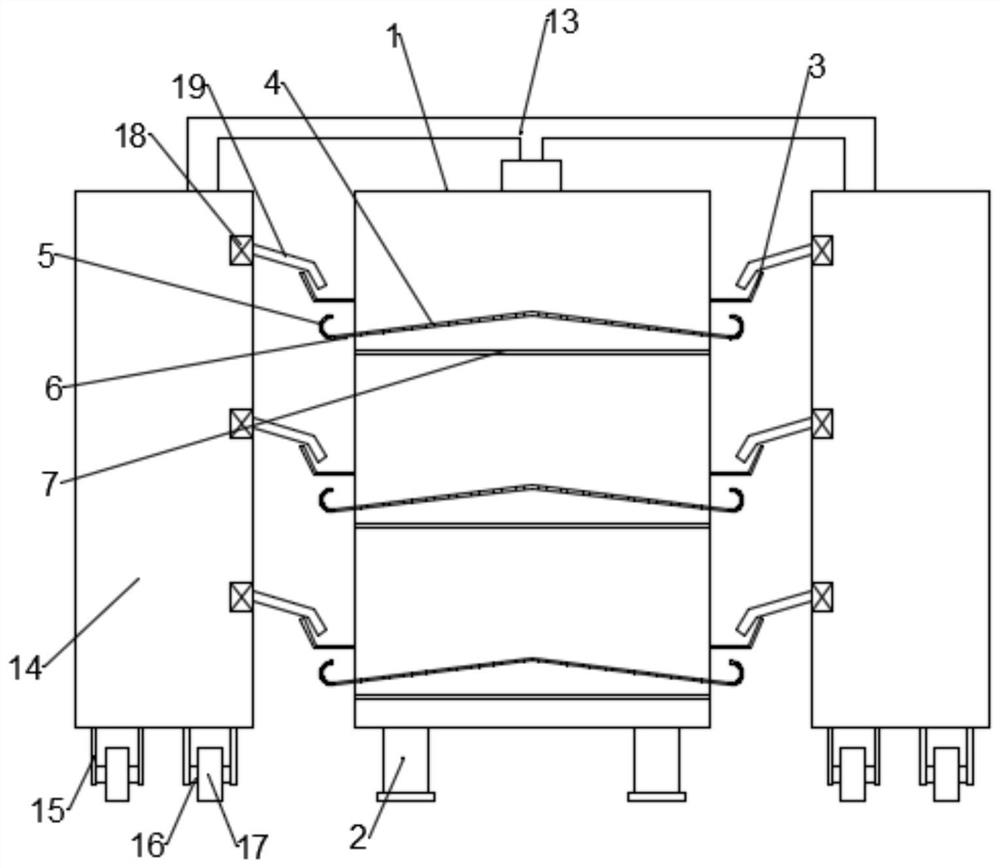

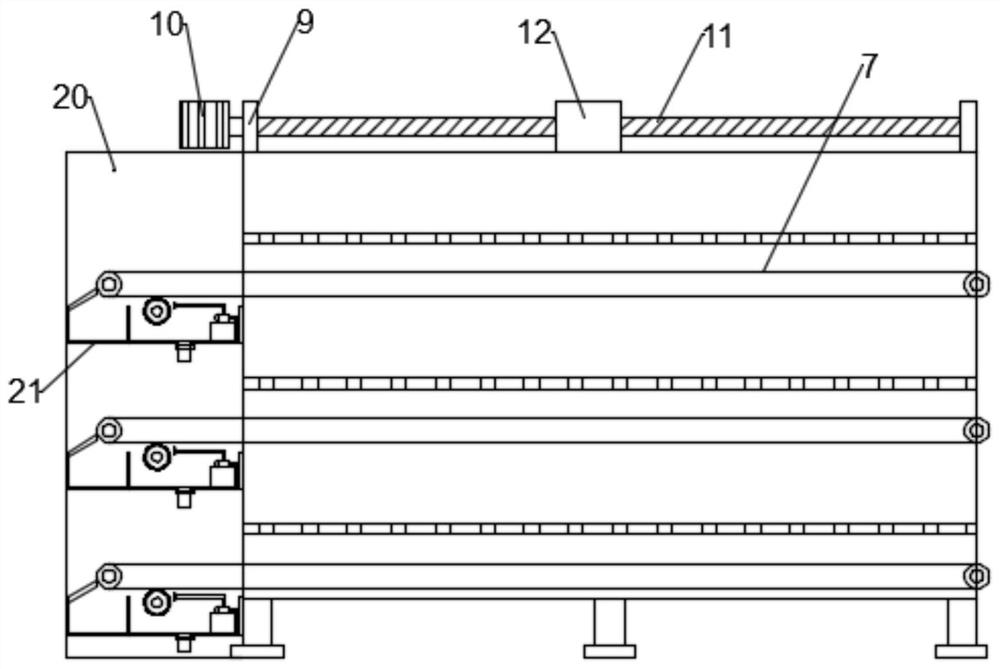

Excrement cleaning device for natural mating cage chicken house

The invention is applicable to the technical field of poultry breeding, and provides an excrement cleaning device for a natural mating cage chicken house. The excrement cleaning device comprises an outer frame body. Support legs are fixed at the bottom of the outer frame body. Three groups of same feeding mechanisms are arranged in the outer frame body. The feeding mechanisms comprise protective nets for connecting the outer frame body. Feeding troughs are fixed to the outer sides of the protective nets. Bottom nets are arranged in the protective nets. Bottom net arc-shaped protective plates are arranged on the outer sides of the bottom nets. Egg conveying belts are installed on the upper surfaces of the bottom net arc-shaped protective plates. Excrement cleaning belts are arranged below the bottom nets. The bottom net arc-shaped protective plates and the egg conveying belts penetrate through egg cleaning boxes at one end of the outer frame body. The excrement cleaning belts are connected with chicken excrement cleaning boxes at one end of the outer frame body. Automatic feeding mechanisms are arranged on the outer side of the outer frame body and connected with the feeding troughs. According to the excrement cleaning device for the natural mating cage chicken house, by arranging the chicken excrement cleaning boxes, chicken excrement on the excrement cleaning belts can be treated, the breeding environment is guaranteed, and bacteria are reduced.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY MEDICINE ANHUI ACAD OF AGRI SCI

Flock fiber feeding equipment

InactiveCN102286811AAvoid driftingGuarantee the environmentContinuous wound-up machinesOpen-end spinning machinesFiberEngineering

The invention discloses a floc fiber feeding device. At least one pair of feeding rollers and the outer peripheral surfaces of feeding pressing rollers are elastically pressed against and oppositely rotated on a frame. There are at least two connected cylindrical Inner cavity, the two inner cavities that deviate from each other are respectively provided with inlet and outlet passages that communicate with the outside, each inner cavity is equipped with a carding roller with combing teeth, adjacent carding rollers can rotate in opposite directions, and the scattered fibers gather The side wall of the funnel hole with a large top and a small bottom on the device is provided with a radial through hole, the upper end of the funnel through hole is connected with the outlet channel of the carding box, the lower end of the funnel through hole is connected with the upper end of the hyperbolic needle knitting cylinder, and the hyperbolic needle knitting There are longitudinal needle grooves on the longitudinal side wall of the fiber distributor in the cylinder, and the hook needles should be able to slide longitudinally and be positioned in the needle grooves, and there are through threading holes in the fiber distributor; the carding box of the present invention is fast and thorough in carding, The floc fiber is fully collected by the fiber collector to prevent it from floating in the air, ensuring the environment in the workshop.

Owner:KUSN MUFENG TEXTILE

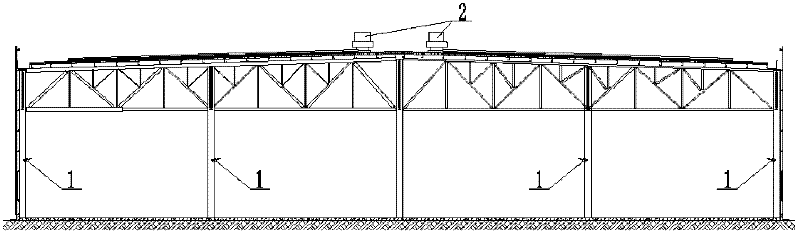

Ventilating air-conditioning system of large welding workshop

InactiveCN102444953AGuaranteed minimum number of air changesOrderly exclusionLighting and heating apparatusDirt cleaningWorking environmentEngineering

The invention relates to a ventilating air-conditioning system of a large welding workshop, which substantially comprises induced fans blowing in multi-angle mode and disposed in each span of the workshop, roof exhaust fans are correspondingly arranged on a roof, and a large ventilating airflow formed by the induced fans and the roof exhaust fan workshop is an induced type single-way flow. An air-conditioning tail end is installed at each working position and communicated with an air-conditioning machine case through an air supply pipe. A partial air exhaust cover is disposed above a welding frame of the workshop, communicated with a fan box through a pipeline and combined with supplied air at the air-conditioning tail end to form a small airflow In local blow-suck type ventilation mode. The ventilating air-conditioning system of a large welding shop substantially has the advantages of 1 ensuring the minimum number of times of ventilation of the workshop, 2 providing workers with a conformable working environment, 3 not only removing harmful substances but also lowering the temperature in working areas, 4 ensuring safe production, and creating a comfortable thermal environment in the working areas. In addition, the temperature in the working areas is adjustable and controllable, and the system is energy-saving, reliable and low in cost.

Owner:DONGFENG DESIGN INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com