Flock fiber feeding equipment

A technology of fiber feeding and equipment, which is applied in the field of yarn manufacturing devices, can solve the problems of insufficient softness, fluffiness, inability to card the thick yarn, cloth softness, skin affinity and warmth retention, etc., and achieve carding Fast, guaranteed environmental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

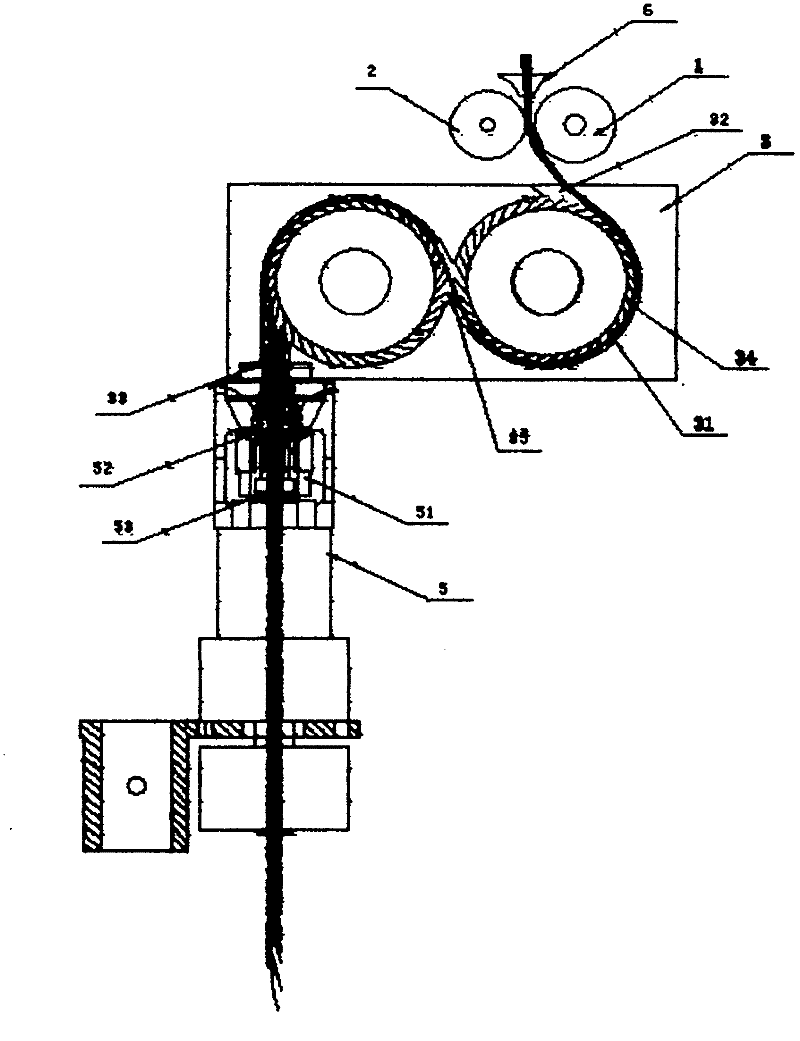

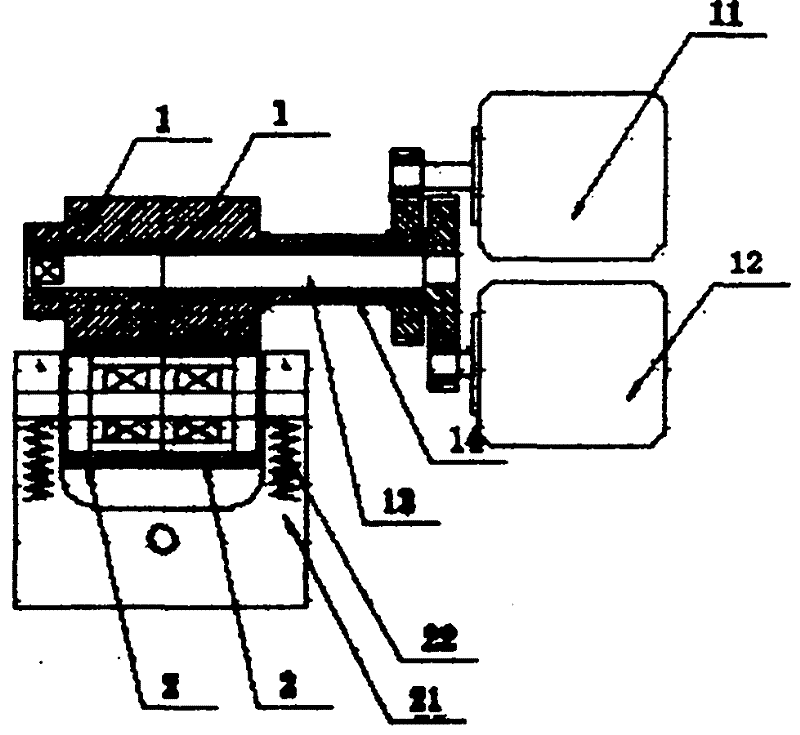

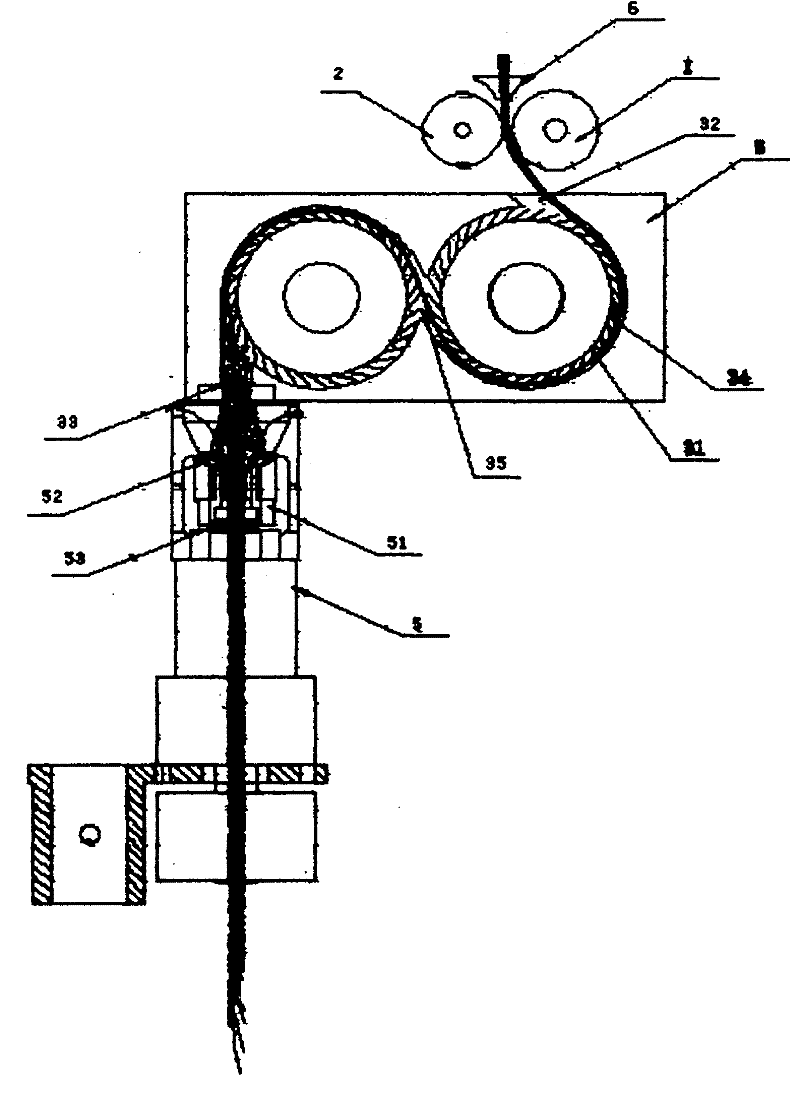

[0017] Embodiment: a kind of floc fiber feeding equipment, including frame, feeding roller 1, feeding pressure roller 2, carding box 3, scattered fiber collector 4 and hyperbolic knitting cylinder 5, based on the use direction , at least one pair of feeding roller 1 and feeding pressure roller 2 are elastically tight on the outer circumferential surface and rotate relative to each other and are positioned on the frame above the carding box 3. The inside of the carding box 3 is provided with at least two interconnected cylindrical Inner cavity 31, on the two inner cavities 31 that deviate from each other on the box body, be respectively provided with the inlet channel 32 that communicates with the outside and the outlet channel 33, can rotate and be provided with a carding roller 34 respectively in each cylindrical inner cavity 31, carding The outer wall of roller 34 is provided with combing teeth, and two adjacent combing sticks can rotate oppositely under the drive of the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com