Patents

Literature

58results about How to "Reduce health threats" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of cultivation method of hypoglycemic ganoderma

InactiveCN102265752AReduce health threatsImprove the quality of lifeHorticultureFertilizer mixturesHerb medicineQuality of life

The invention provides a cultivation method of lucid ganoderma for reducing blood sugar. In the method, a Chinese medicinal herbal composition for reducing the blood sugar in a certain rate is added into a culture base stock, so that nutrient components in the culture base stock are fully absorbed by the lucid ganoderma in the growth and development process; therefore, the cultivated lucid ganoderma has the effect of efficiently reducing the blood sugar, medicines for reducing the blood sugar can be completely replaced, various complications brought to a patient by the medicines for reducing the blood sugar are greatly reduced, and the quality of life of the patient is improved.

Owner:林范亮

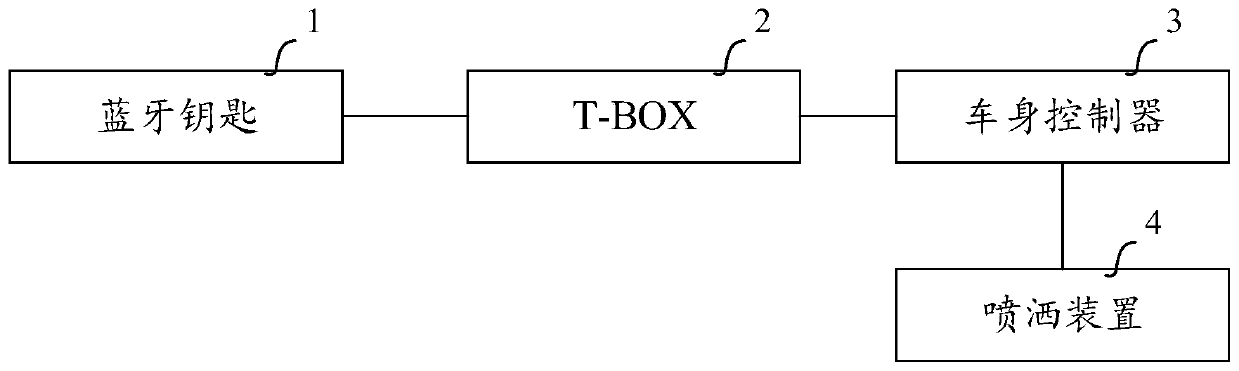

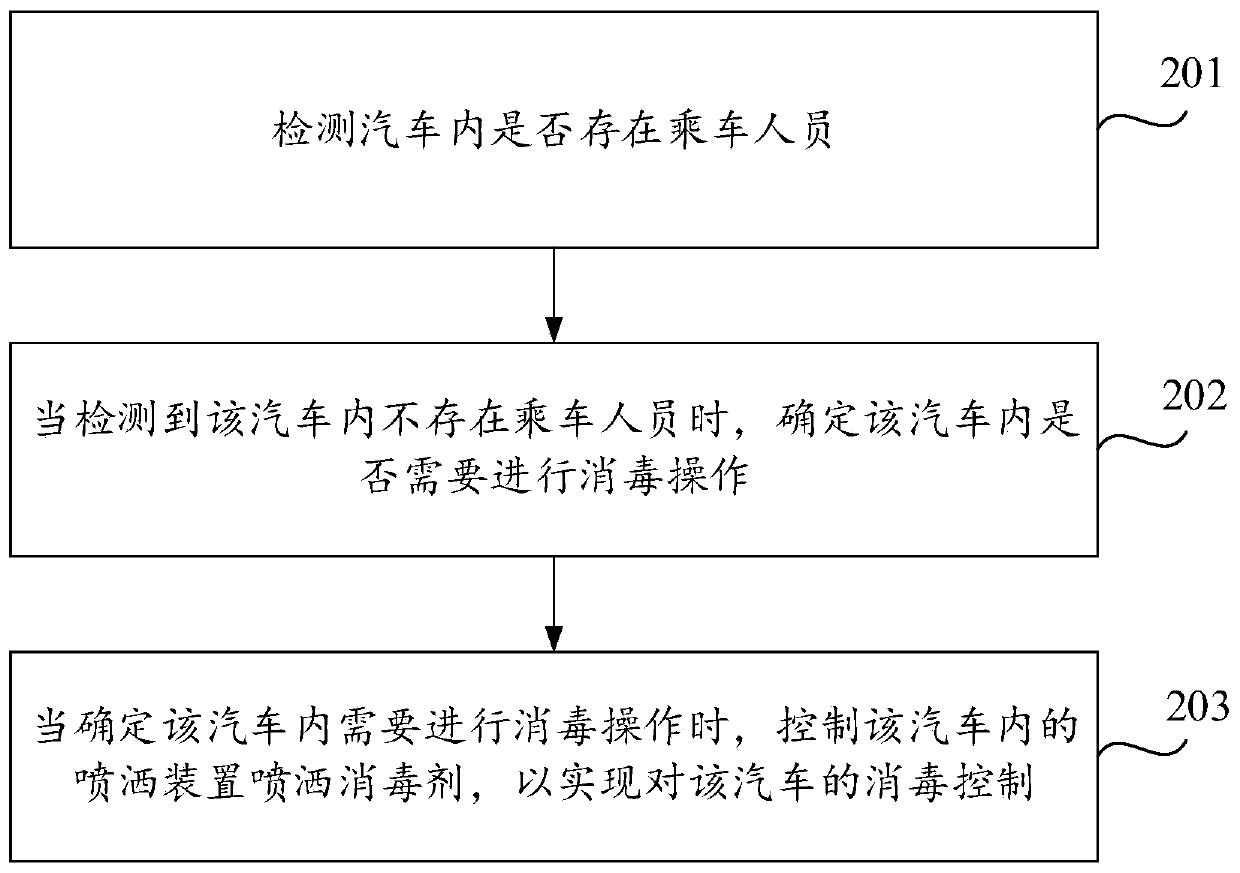

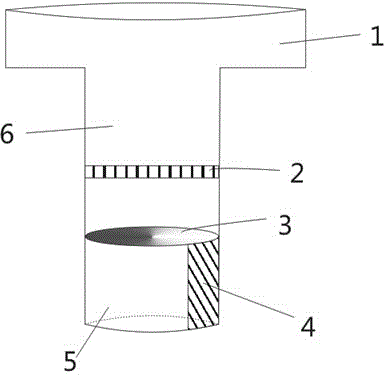

Automobile disinfection control method and device and storage medium

InactiveCN111562751AAchieving Disinfection ControlGuarantee the environmentAir-treating devicesLavatory sanitoryProcess engineeringMechanical engineering

The invention discloses an automobile disinfection control method and device and a storage medium, and belongs to the technical field of automobile engineering. The method comprises the steps of detecting whether there is a passenger or not in an automobile; when it is detected that no passenger exists in the automobile, determining whether disinfection operation needs to be conducted in the automobile or not; and when it is determined that disinfection operation needs to be conducted in the automobile, controlling a spraying device in the automobile to spray a disinfectant so as to achieve disinfection control over the automobile. According to the invention, when it is detected that the automobile needs to be disinfected, the spraying device in the automobile is controlled to spray the disinfectant to achieve disinfection control over the automobile, and thus bacteria appearing in the automobile and threats of the bacteria to the health of passengers are reduced.

Owner:CHERY AUTOMOBILE CO LTD

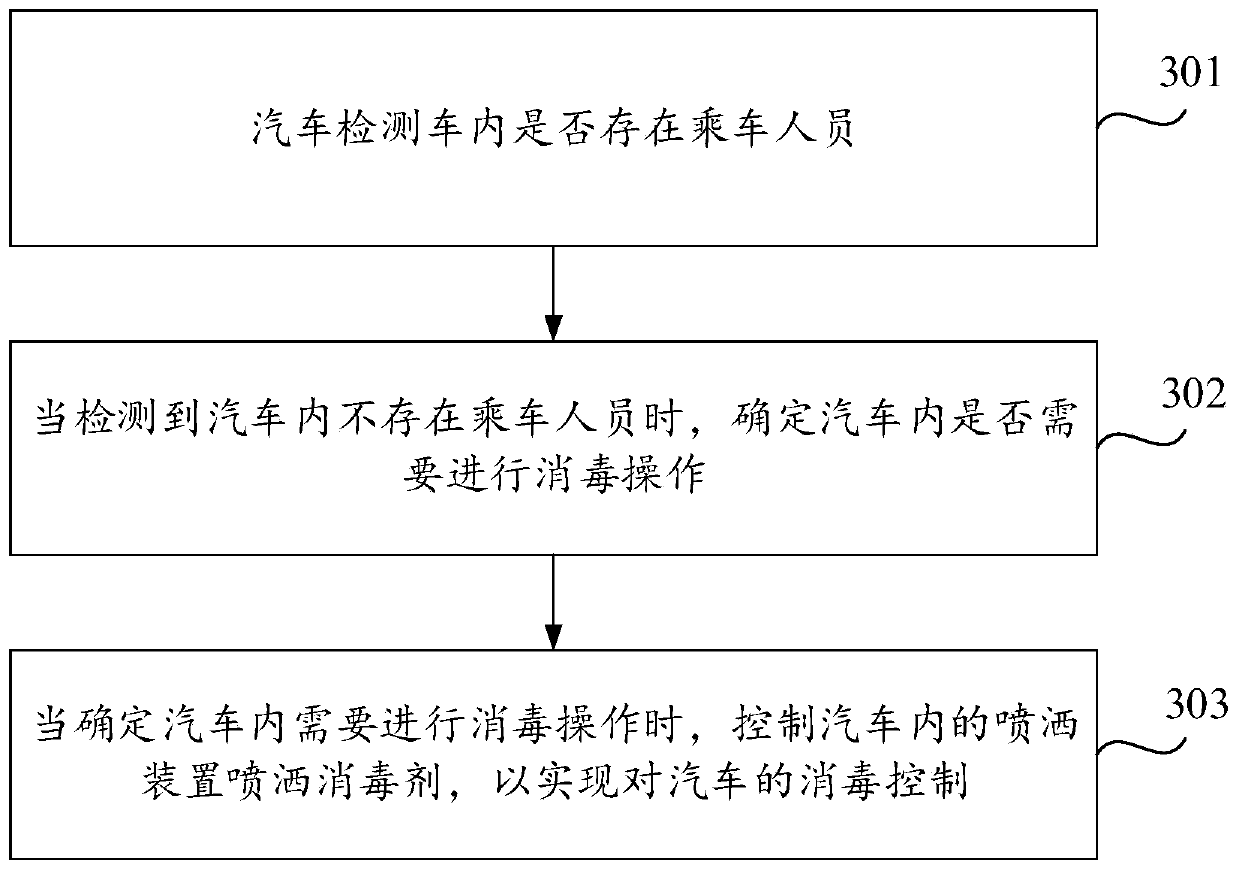

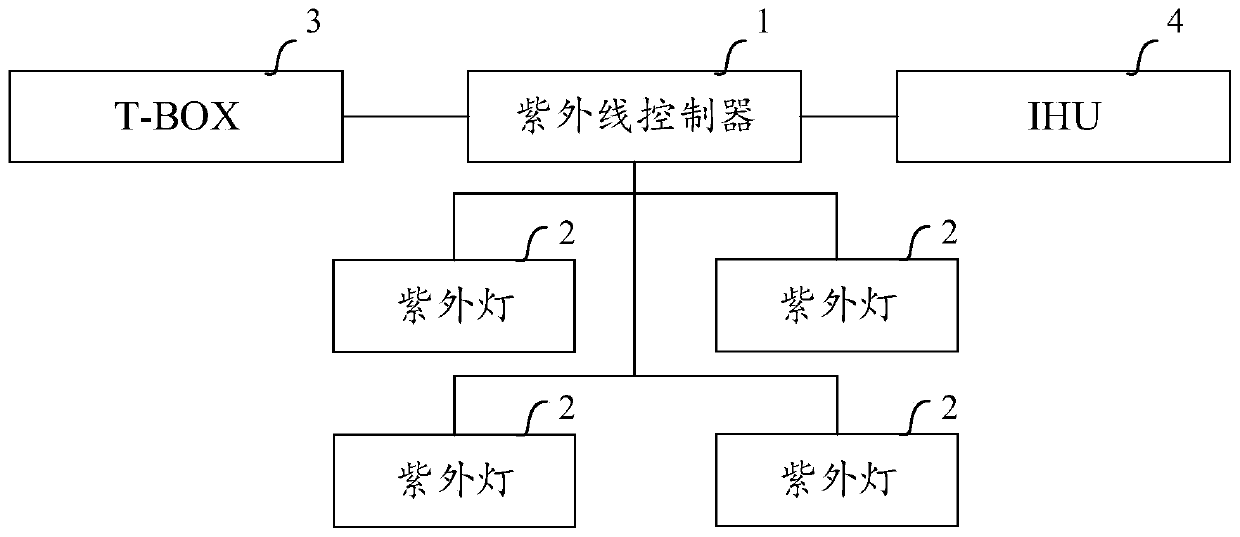

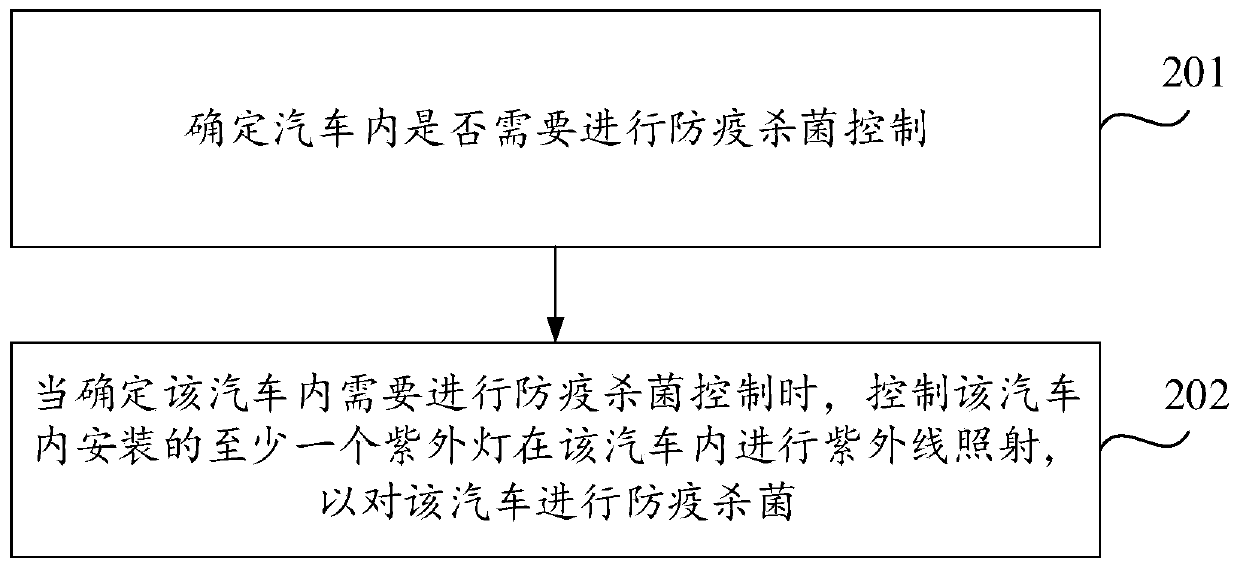

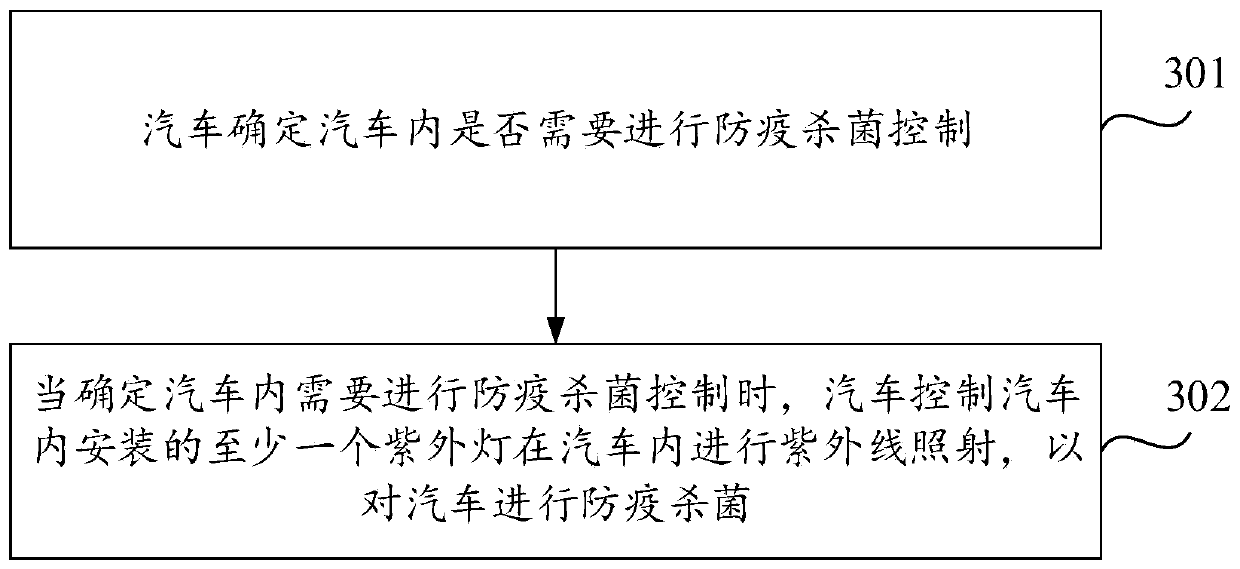

Automobile epidemic prevention and sterilization control method and device and storage medium

PendingCN111569099AGuarantee the environmentReduce health threatsAir-treating devicesLavatory sanitoryVehicle engineeringReliability engineering

The invention discloses an automobile epidemic prevention and sterilization control method and device and a storage medium, and belongs to the technical field of vehicle engineering. The method comprises the steps that whether epidemic prevention and sterilization control needs to be conducted in an automobile or not is determined; and when it is determined that epidemic prevention and sterilization control needs to be conducted in the automobile, at least one ultraviolet lamp installed in the automobile is controlled to conduct ultraviolet irradiation in the automobile so as to conduct epidemic prevention and sterilization on the automobile. When it is detected that the automobile needs to be subjected to epidemic prevention and sterilization control, at least one ultraviolet lamp in theautomobile is controlled to conduct ultraviolet irradiation in the automobile, so that epidemic prevention and sterilization control over the automobile is achieved, and therefore bacteria appearing in the automobile and threats of the bacteria to the health of passengers are reduced.

Owner:CHERY AUTOMOBILE CO LTD

Alcohol-dissoluble polyurethane resin compound printing ink and preparation method thereof

The invention discloses an alcohol-dissoluble polyurethane resin compound printing ink and a preparation method thereof. The printing ink is prepared by processing the following components by weight percent: 25-35% of alcohol-dissoluble polyurethane resin liquor, 1-3% of polyvinyl butyral resin, 1% of extinction powder, 8-33% of pigment, 0-0.5% of an adhesion reinforcing agent, 15-40% of ethanol and 15-25% of ethyl acetate; and polyurethane resin in the alcohol-dissoluble polyurethane resin liquor accounts for 30-35% by weight percent. The printing ink has the advantages of environmental friendliness, safety, wide application scope, good thermal stability and the like.

Owner:HUIZHOU SURE SCI & TECH CO LTD +1

Potato chips and preparation method thereof

InactiveCN103610000AHigh medicinal valueCrispy tasteFood ingredient functionsFood preparationChipped potatoesSolanum tuberosum

The invention relates to potato chips and a preparation method thereof. The potato chips are prepared through the following steps: (1) washing potatoes, peeling off and cutting into potato slices of 2-3mm; (2) mixing Xinhui dried orange peel with water at the weight ratio of the Xinhui dried orange peel to water being 1:20, boiling a mixture for 20-30 minutes, and filtering so as to obtain a Xinhui dried orange peel extract; (3) soaking the potato slices into the Xinhui dried orange peel extract for 6 hours, fishing out, and drying in air for 3-4 days; (4) pouring the dried potato slices into an oil pot to be fried. The potato chips are crisp, has the fragrance of dried orange peel, and has the health-care effects of regulating qi-flowing for strengthening spleen, relieving cough and reducing sputum, and the like.

Owner:XUZHOU XUSHU SHUYE TECH

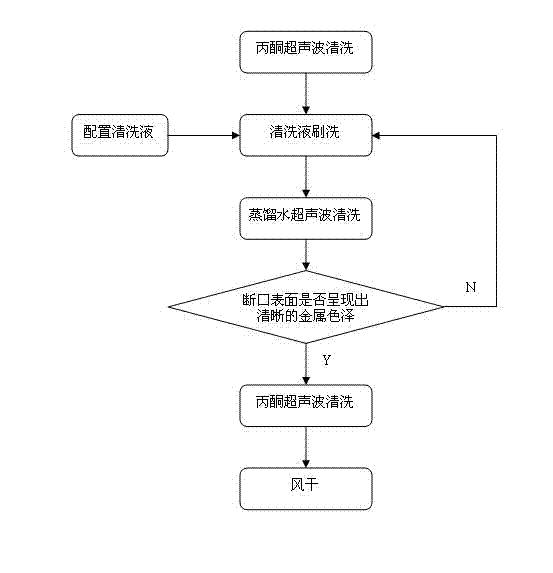

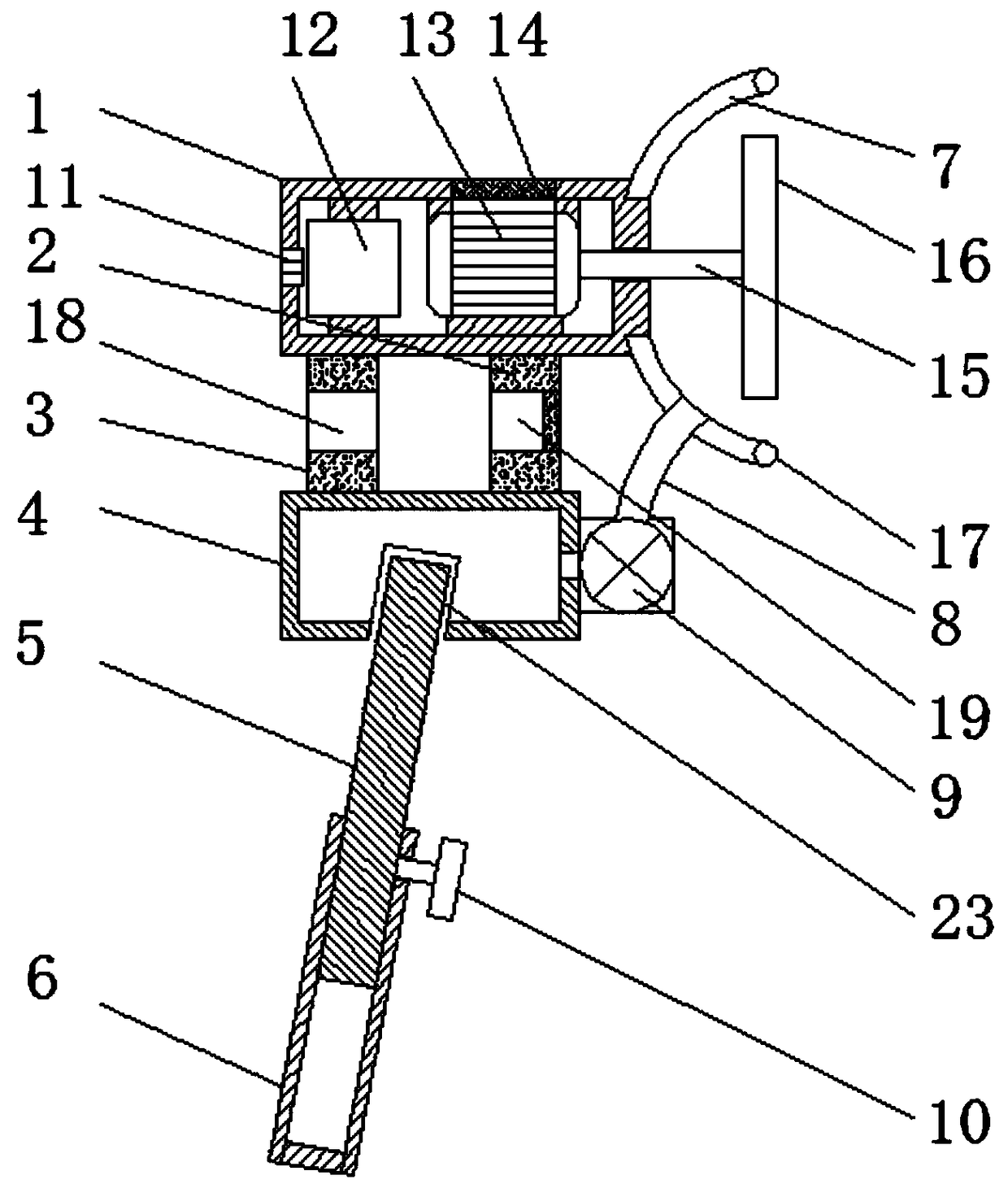

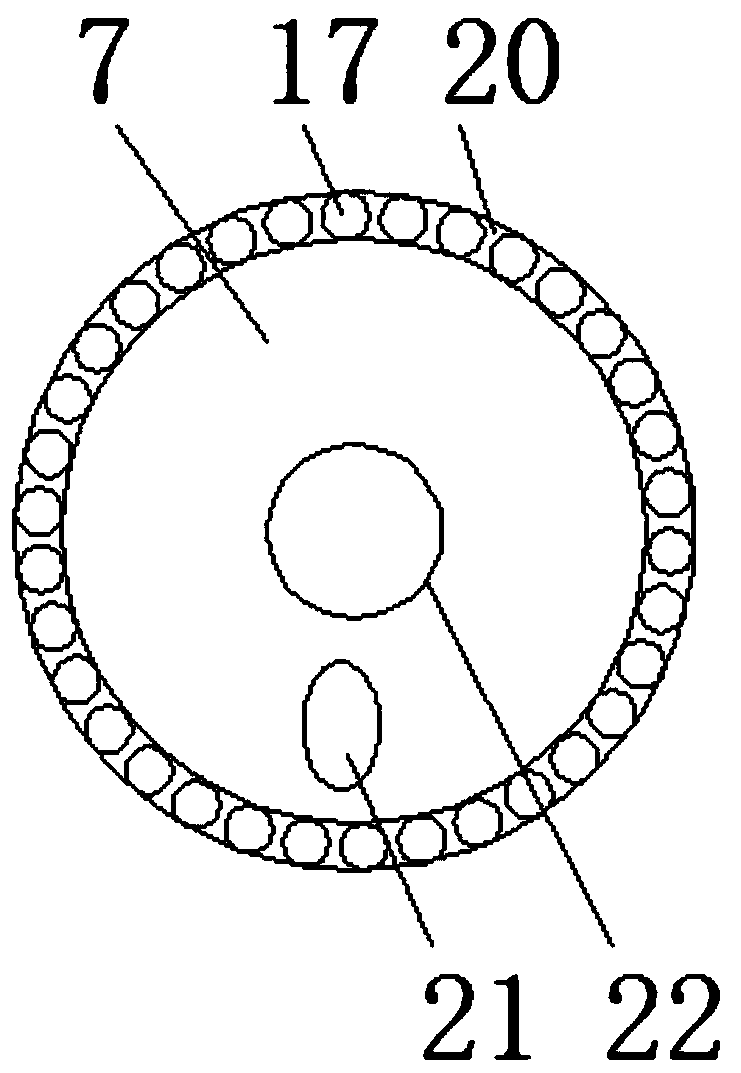

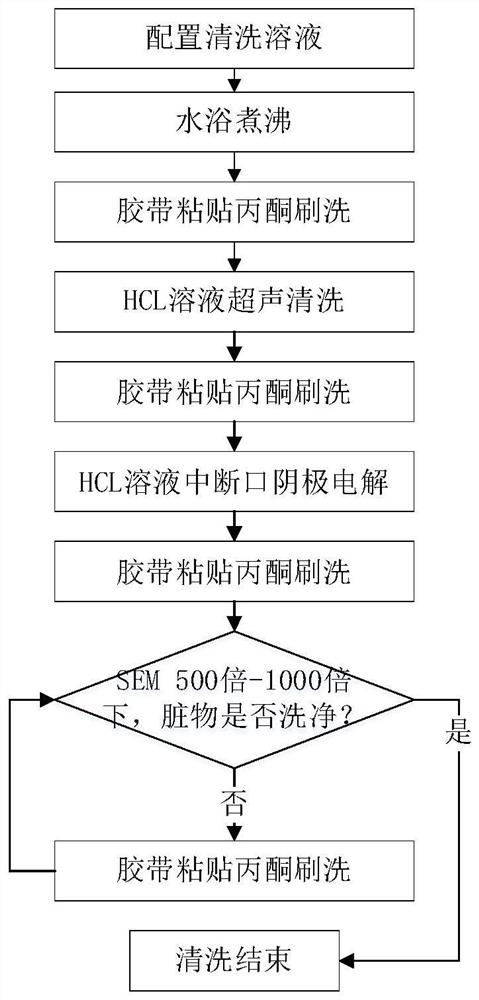

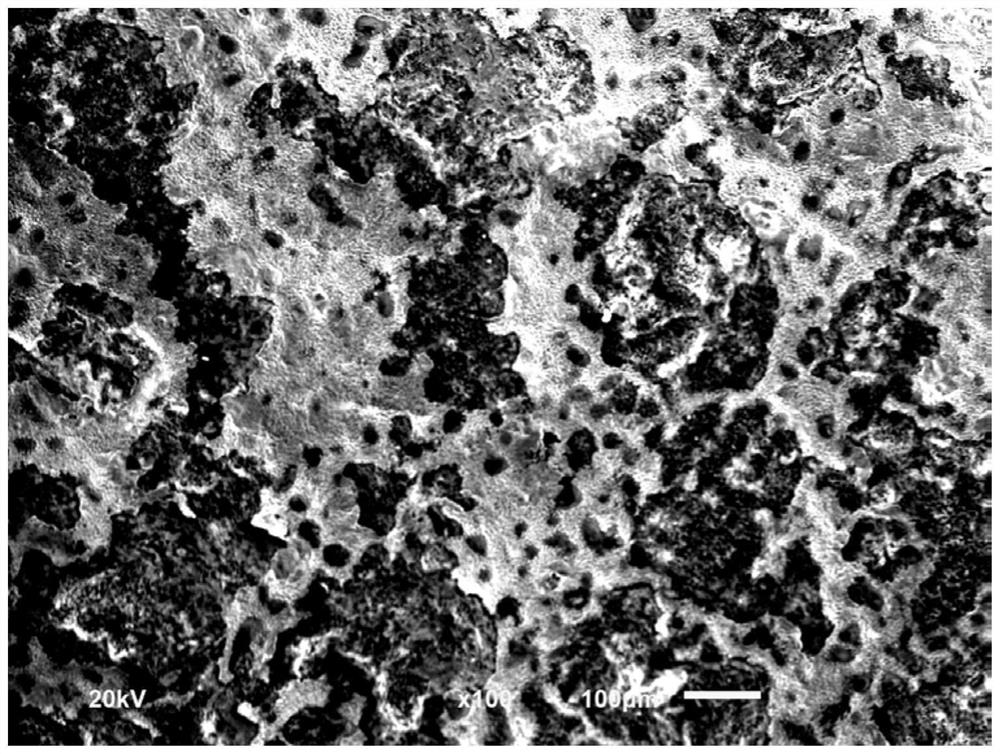

A method of cleaning fractures of steel failed components

InactiveCN104120433AEasy to configureSimple configurationCleaning using liquidsMegasonic cleaningCleaning methods

The invention discloses a method of cleaning fractures of steel failed components and belongs to the technical field of fracture analysis of steel failed components. Aiming at disadvantages of steel failed fracture cleaning methods at present, such as problems of inconvenient preparation of cleaning liquids, poor cleaning effects, and low cleaning efficiency, the method of cleaning the fractures of the steel failed components, which has characteristics of simple cleaning fluid preparation, simple and convenient operation, short consumed time, significant cleaning effects and easy monitoring, is provided. A hydrochloric acid solution is adopted as a cleaning liquid in the method, an ultrasonic wave cleaning technology is used in cooperation, and compact corrosives on the fracture surfaces are conveniently and efficiently removed under the premise of not damaging fracture morphological features. The method is easy to implement, low in energy consumption and suitable for cleaning of various metal failed component fracture surfaces.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD

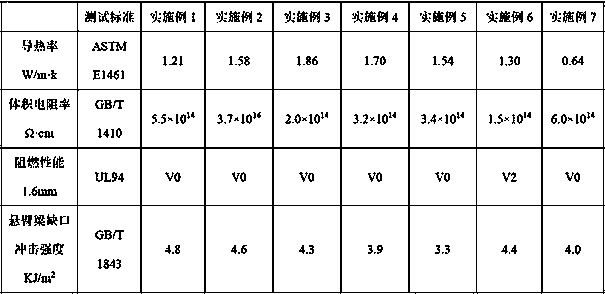

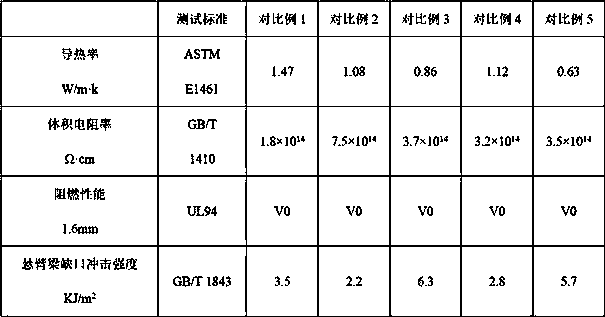

PPS (polyphenylene sulfide) composite material and preparation method thereof

ActiveCN104262965AReduce workplace contamination and human health threatsSolve the difficulty of blankingPolyamideMagnesium

The invention discloses a PPS (polyphenylene sulfide) composite material and a preparation method thereof. The PPS composite material is prepared by raw materials in percentage by weight as follows: 19%-49.5% of PPS, 50%-80% of heat conducting master batch taking PA (polyamide) 12 as a matrix and 0.5%-1.0% of a lubricating agent. According to the preparation method, the heat conducting master batch is firstly prepared by raw materials in percentage by weight as follows: 13%-19% of PA 12, 20%-65% of magnesium oxide with small particle size, 20%-65% of magnesium oxide with large particle size, 0.5%-1.0% of an antioxidant and 0.5%-1.0% of an lubricating agent; and the well prepared master batch, PPS and the lubricating agent are blended to prepare the PPS composite material. The PPS composite material prepared with the heat conducting master batch method is provided with high-filling heat conducting filler, has excellent processing property, impact strength and heat conduction property and is simple in process.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

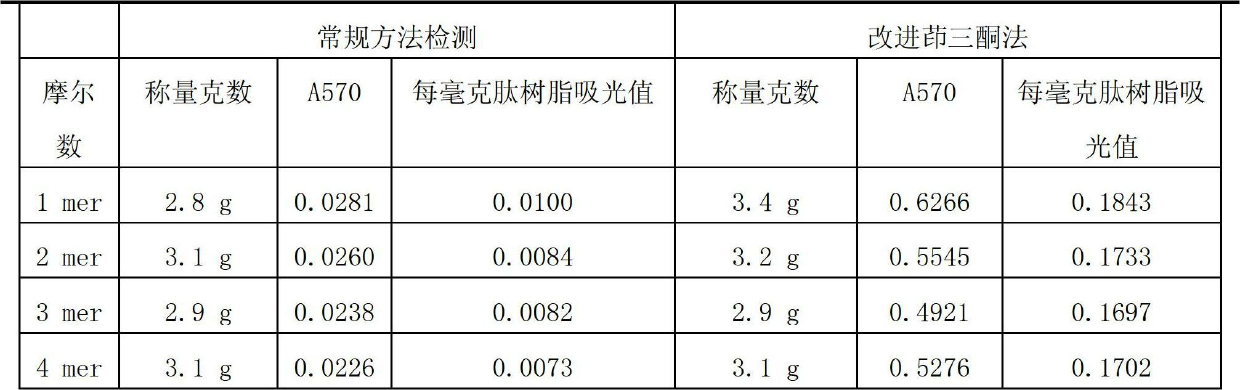

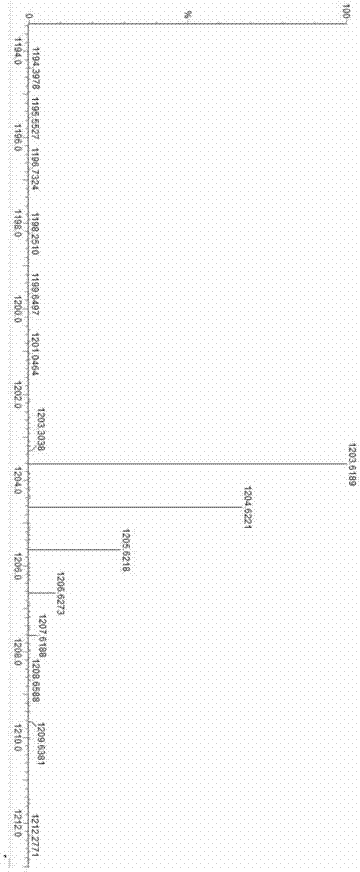

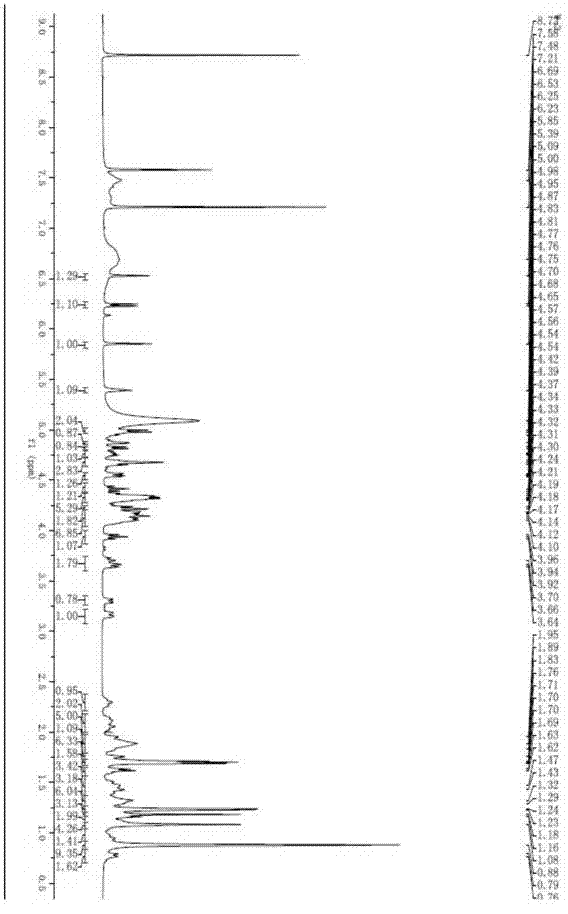

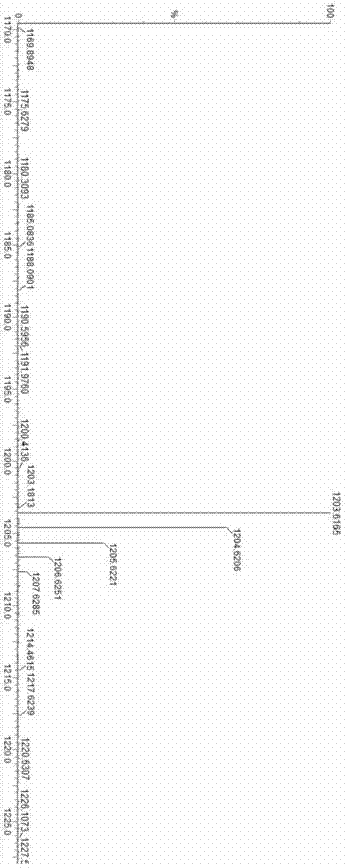

Improved detecting method for solid phase polypeptide synthesis by use of triketohydrindene hydrate

ActiveCN102680463AReduce health threatsChange sampling timeMaterial analysis by observing effect on chemical indicatorVitamin CAbsorbance

The invention provides an improved detecting method for solid phase polypeptide synthesis by use of triketohydrindene hydrate, and the method comprises the following steps of: 1) dissolving 500mg of triketohydrindene hydrate with 12.5ml of boiled distilled water to obtain a yellow solution; adding a vitamin C solution under agitation and continuously agitating after sediment for 15 minutes, moving to a refrigerator to be cooled to 4 DEG C, washing with purified water for 2-3 times, processing with a vacuum drier to obtain reduced triketohydrindene hydrate; 2) weighing 2g of Rink_Amide_MBHA resin, calculating mole number, selecting amino acid with a Fmoc protective radial, reacting for 2 hours under effect of a nitrogen methyl pyrrolidone solution with 8% of carbodiimide to obtain peptide resin, then processing with 25% of a piperidine solution for 30min to obtain peptide resin without the protective radial; and 3) taking 2-5mg of peptide resin without the protective radial, adding 300 microlitres of Buffer A and 75 microlitres of Buffer B, mixing uniformly, adding by water at 100 DEG C for 15min and placing in water at 15-20 DEG C to be cooled to room temperature; and adding 1.2ml of 60% ethanol solution, mixing uniformly, and measuring absorbance and reading the absorbance.

Owner:天康生物制药有限公司

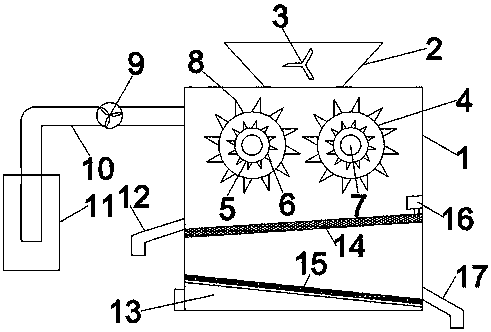

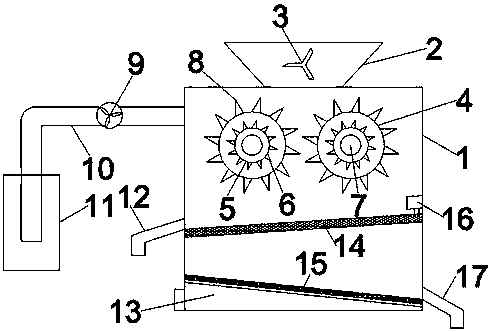

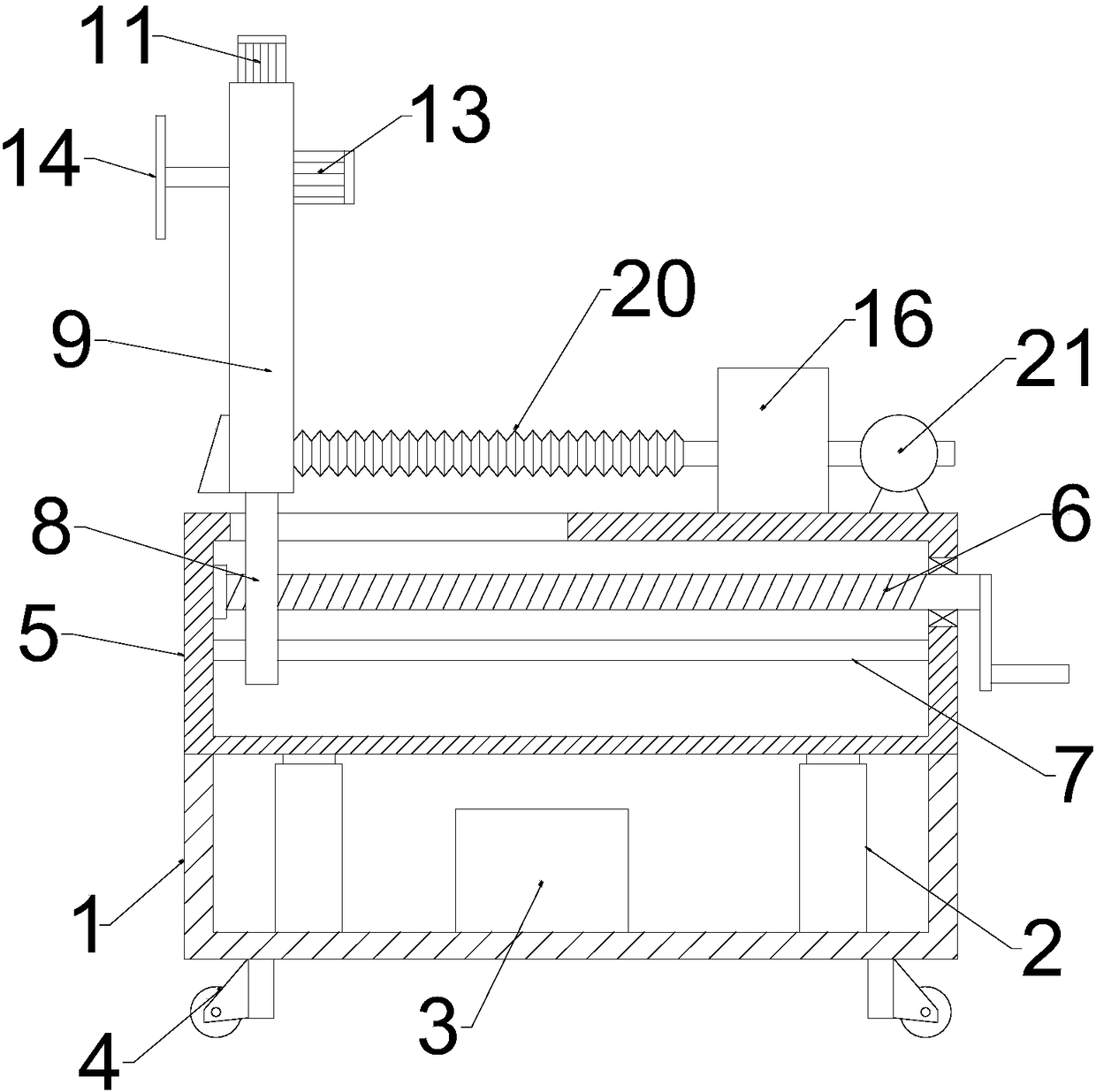

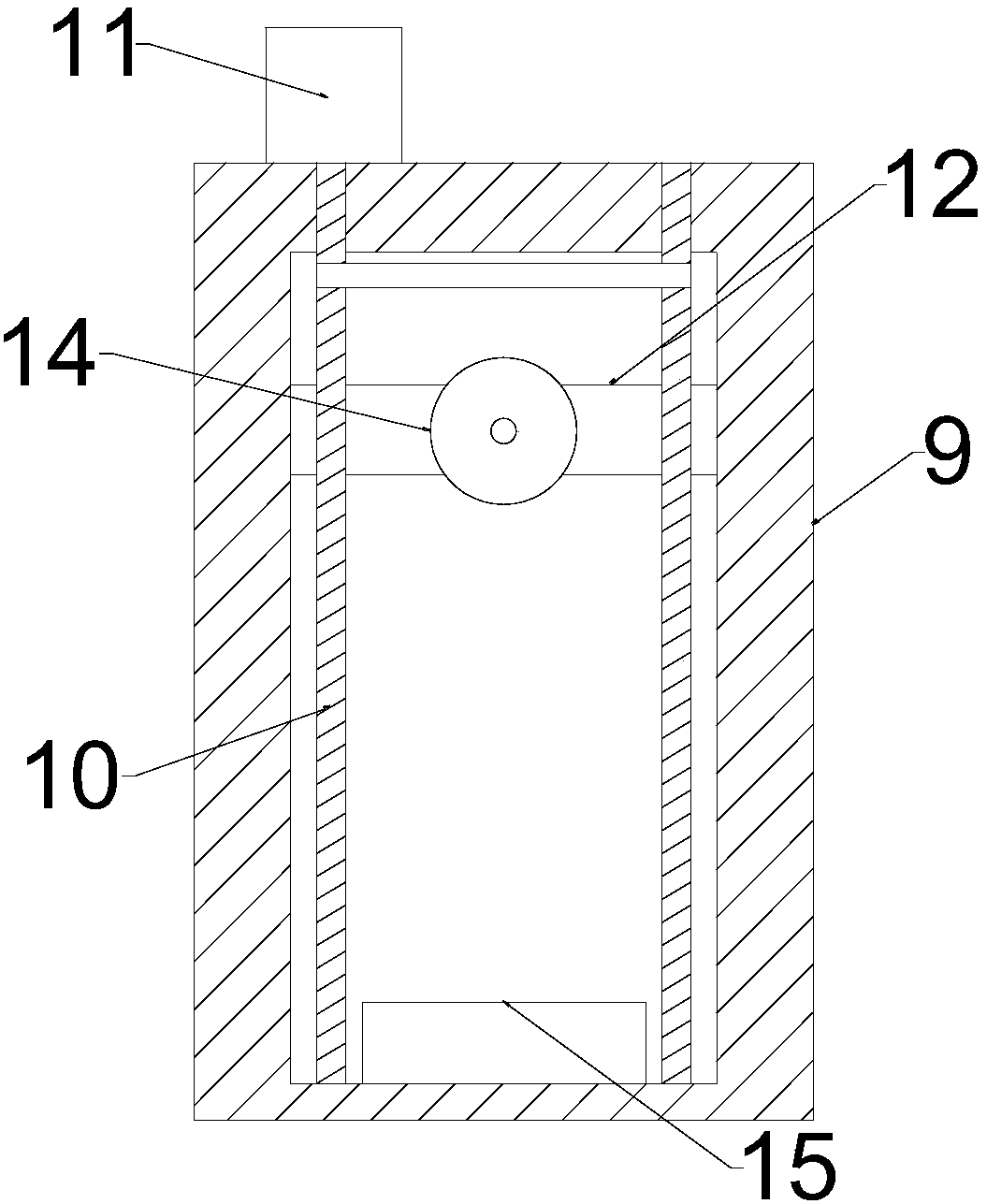

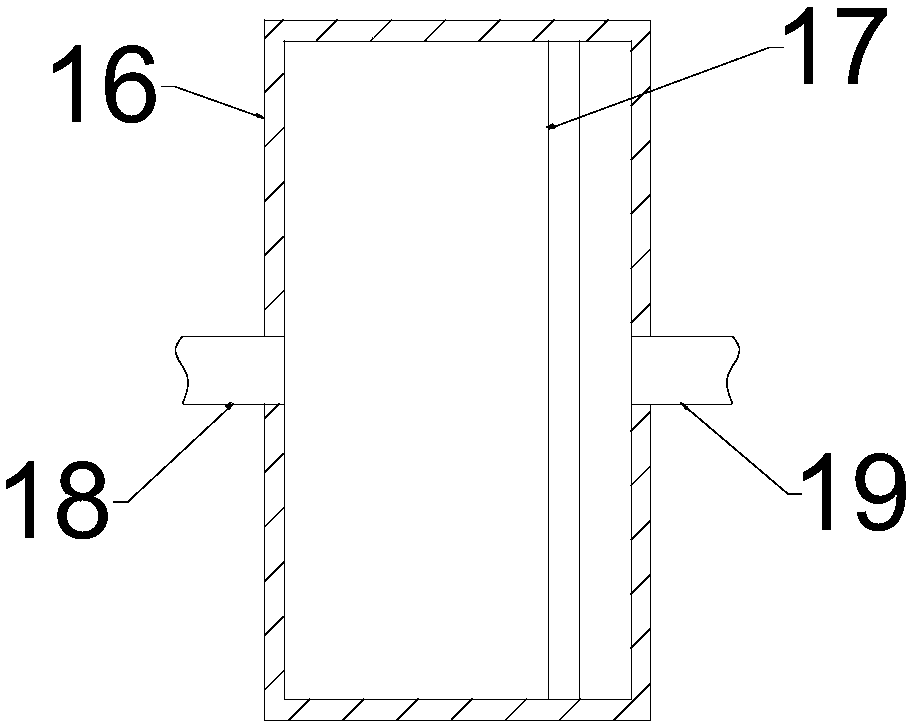

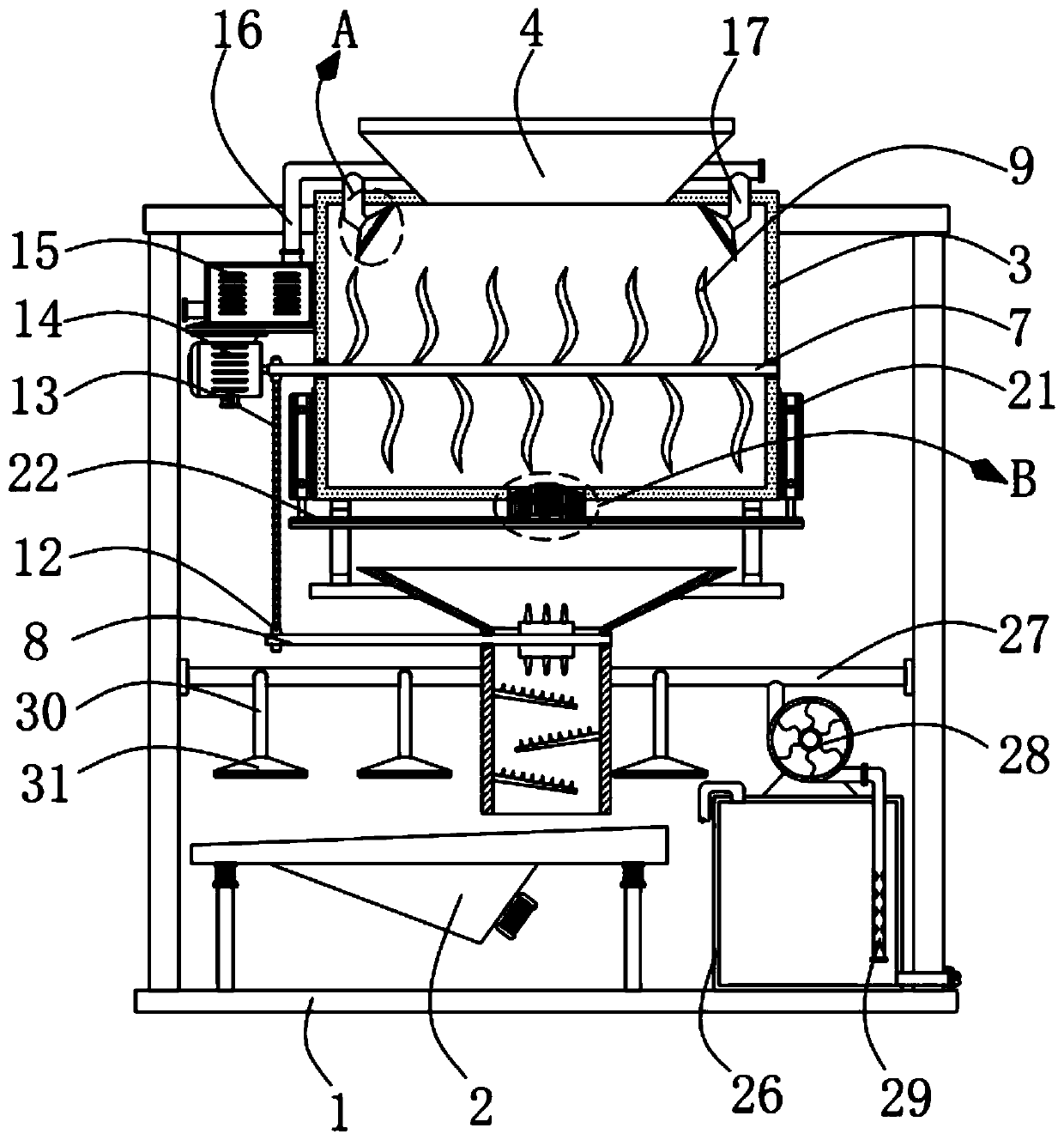

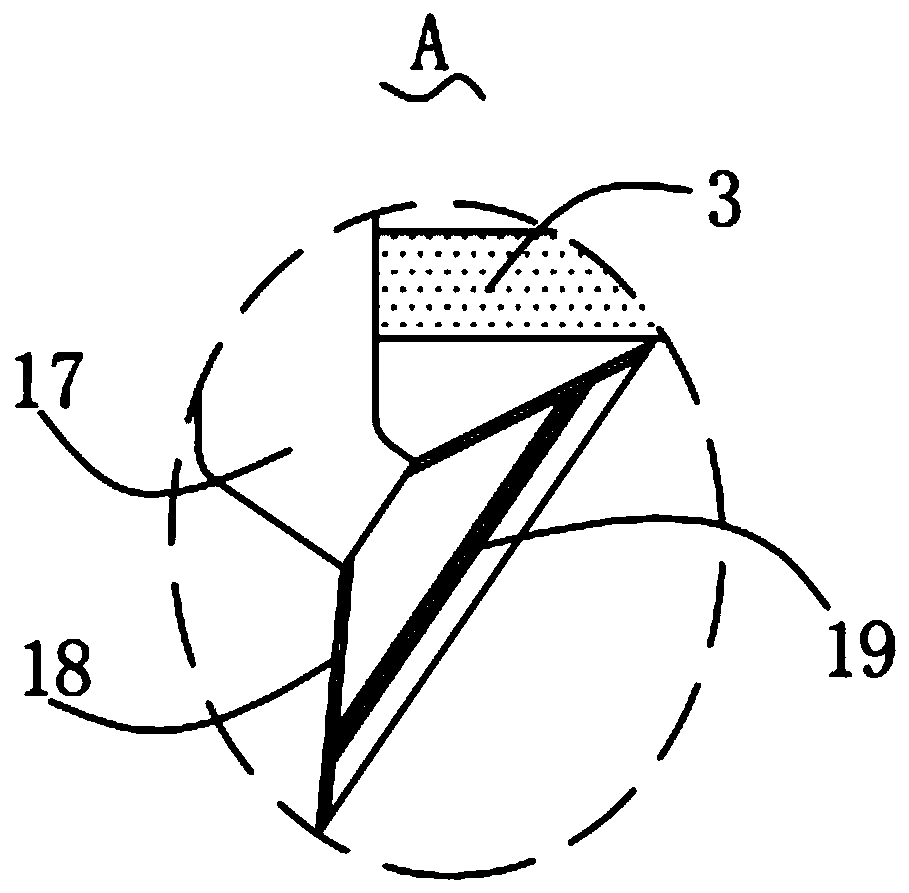

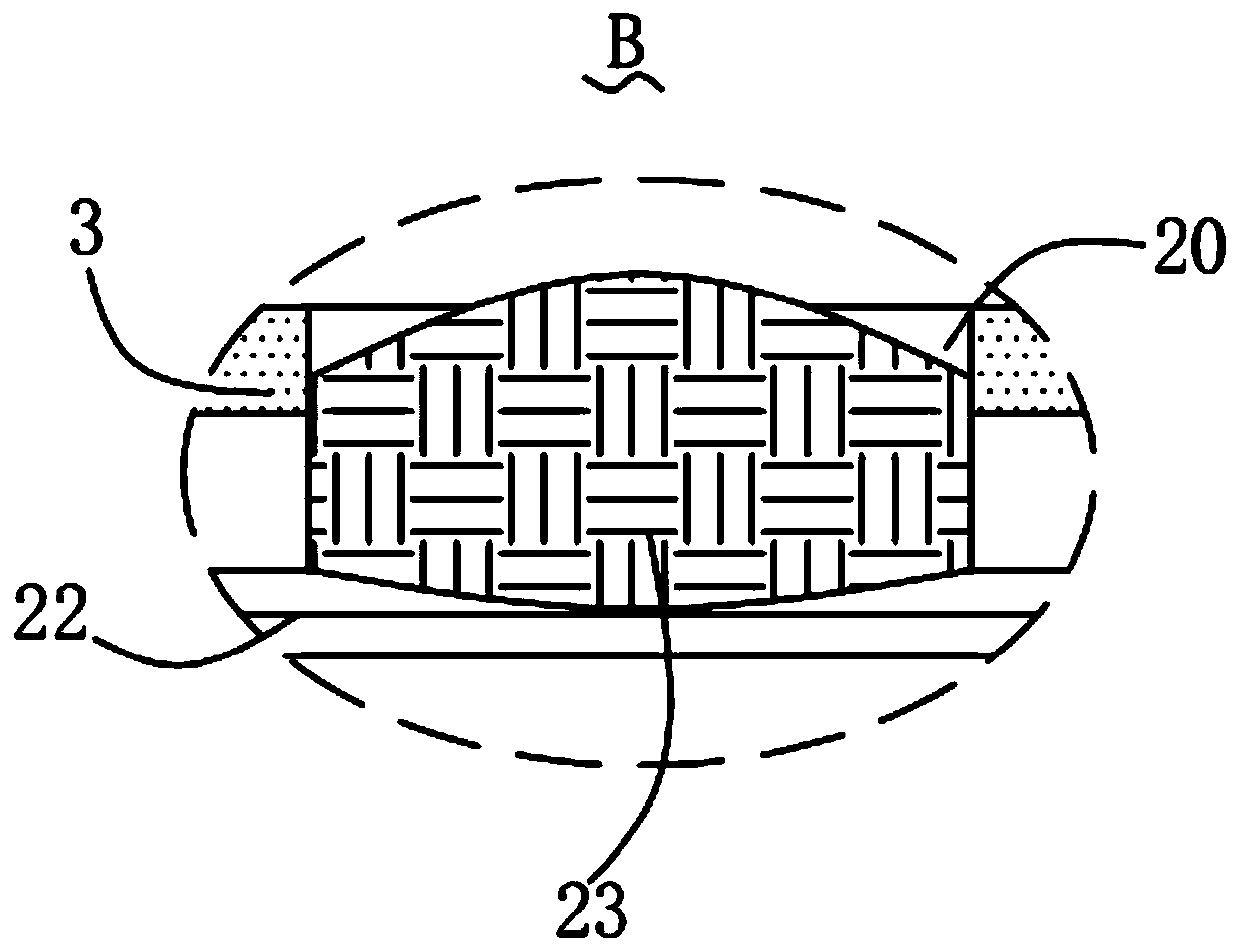

Feed crushing device

InactiveCN109967163AScreening is reasonableEffective classificationFeeding-stuffUsing liquid separation agentEngineeringWater tanks

The invention discloses a feed crushing device. The feed crushing device comprises a shell, a feeding inlet, a first discharging pipe, a second discharging pipe, a stirring body, a crushing roller shaft, first crushing teeth, second crushing teeth and a vibrator, wherein the bottom end of the feeding inlet and the top end of the shell are in welded connection, the two ends of the stirring body andthe inner wall of the feeding inlet are in welded connection, the stirring body rotates through a rotating shaft, the two ends of the crushing roller shaft are in welded connection with the inner side of the shell, the inner side of a first crushing roller is in welded connection with the outer side of the crushing roller shaft, the inner side of a second crushing roller is also in welded connection with the outer side of the crushing roller shaft, one ends of the first crushing teeth are in welded connection with the side face of the first crushing roller, one ends of the second crushing teeth are in welded connection with the side face of the second crushing roller, one end of a dust suction pipe and the shell are in communicating connection, the other end of the dust suction pipe stretches into a water tank, one side of the vibrator and the shell are in welded connection, and one end of the vibrator is in matched connection with a first screen net. The feed crushing device conductsgraded screening on feed, and using is convenient and flexible.

Owner:杨建

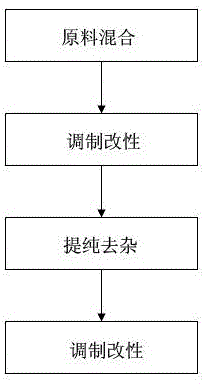

Special heat-salinity-resistant drag reducer for shale gas fracturing and manufacturing technology thereof

InactiveCN105131179AReduce manufacturing costReduce use costDrilling compositionManufacturing technologyDissolution

The invention provides a special heat-salinity-resistant drag reducer for shale gas fracturing. The special heat-salinit-resistant drag reducer is prepared from the following raw materials by mass percent: 20-40 percent of nonionic monomers, 10-30 percent of salinity-resistant monomers, 1-10 percent of an emulsifier, 0.1-0.8 percent of an initiator, 0.1-1.5 percent of sodium bisulfite, 5-20 percent of an organic solvent, 1-3 percent of a phase inversion agent and the balance of deionized water. A manufacturing technology of the special slickwater resistance reducing agent comprises the steps of raw material mixing, modulation and modification, purification for impurity removal and modulation and modification. The manufacturing technology is simple, high in production efficiency and low in production cost, and can effectively reduce the production and application costs of the drag reducer, and meanwhile, the prepared drag reducer is quick in dissolution, low in energy consumption, good in shearing resistance, nontoxic, pollution-free and dust-free, nondestructive to health, good in fluidity, easy to operate, and high in heat-and-salinity resistance. Therefore, on one hand, the application requirements for shale gas exploitation are effectively met, and the exploitation cost is lowered, and on the other hand, damages caused by shale gas resource exploitation to the natural environment and threats caused by shale gas resource exploitation to the health of operators can be effectively reduced.

Owner:焦作市宏达力生物化工有限公司

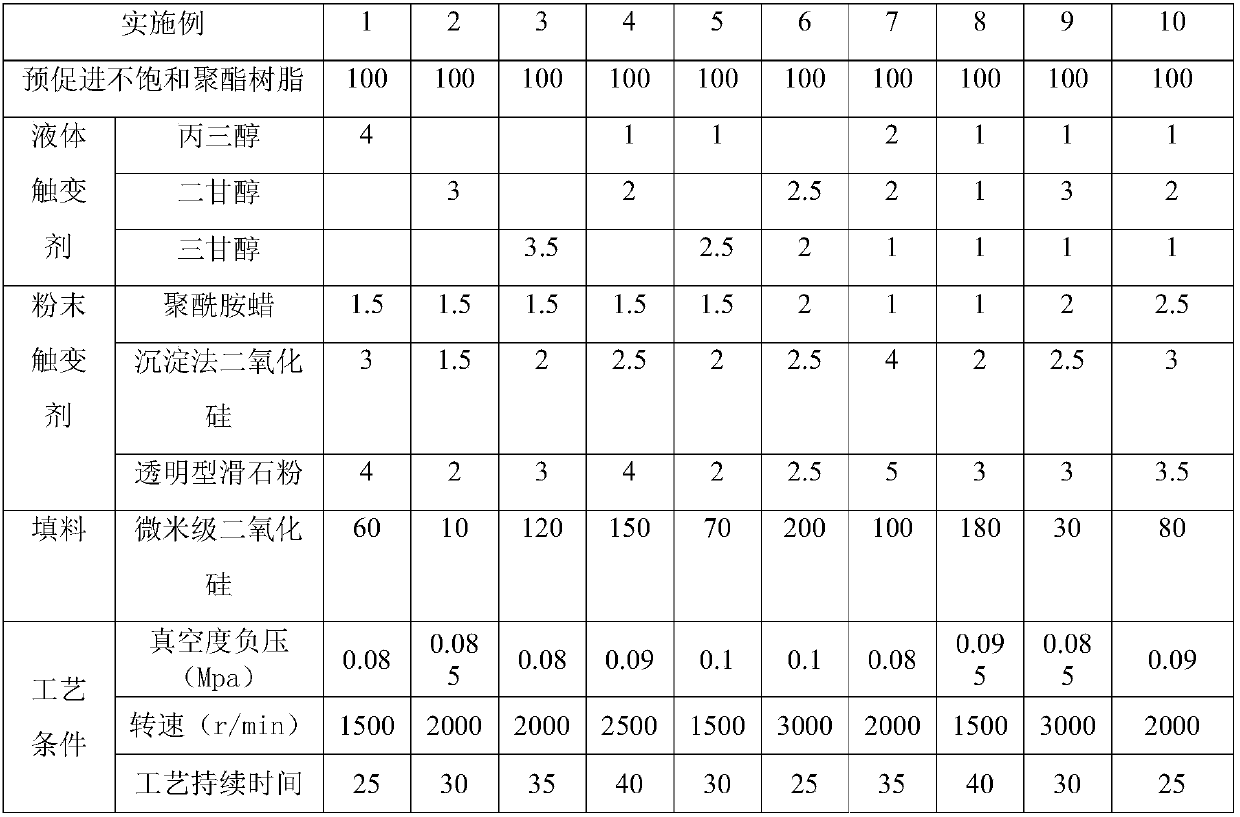

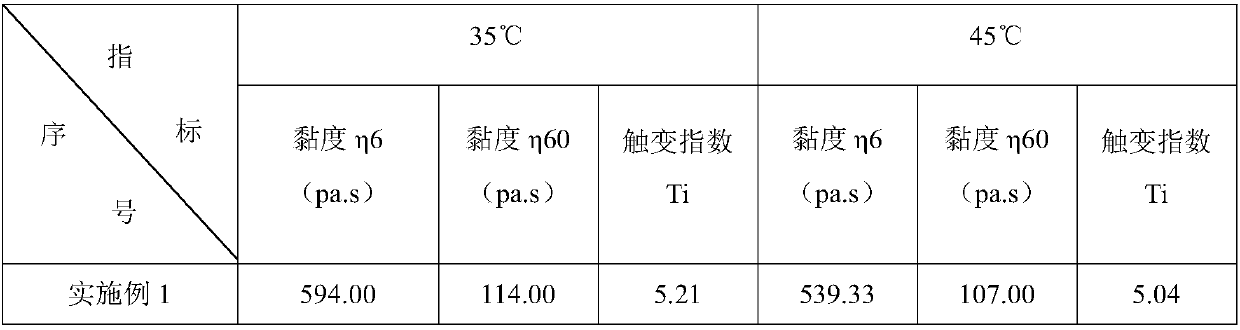

High thixotropic transparent marble adhesive and preparation method thereof

ActiveCN107674626ASolve technical problems that are thin or even runnyImprove mechanical propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesWaxAdhesive

The invention discloses a high thixotropic transparent marble adhesive which includes, by weight parts, 100 parts of pre-accelerated unsaturated polyester resin, 3-5 parts of liquid thixotropic agent,5-10 parts of powder thixotropic agent and 10-200 parts of filler. The liquid thixotropic agent includes one or more selected from a group consisting of glycerol, diethylene glycol and triethylene glycol. The powder thixotropic agent includes polyamide wax, precipitated silica and transparent talc. The high thixotropic transparent marble adhesive is prepared by a preparation method of performinghigh-speed stirring at a negative pressure state with a negative pressure of 0.08-0.1 MPa and a rotating speed of no smaller than 1500 r / min and performing ultrasonic dispersion. The preparation method is simple, the prepared marble adhesive is good in thixotropic property, and the problem of being too thin or flowing does not occur even if at medium and high temperatures (35-65 DEG C).

Owner:江苏大力士云石护理材料有限公司

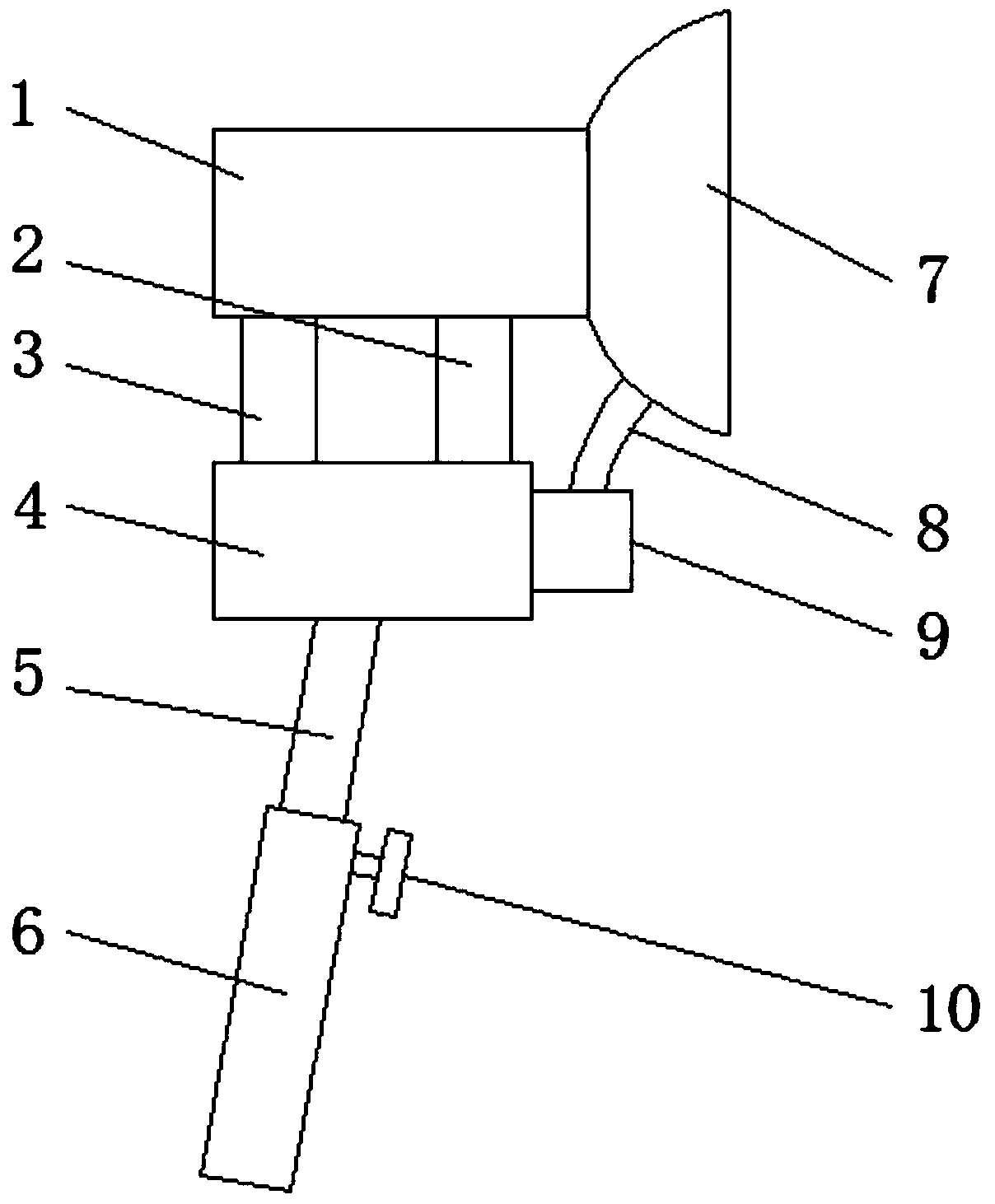

Cleaning and grinding device for building wall surface

InactiveCN108274320AReduce health threatsGuaranteed cleanlinessGrinding carriagesGrinding bedsArchitectural engineeringGrinding wheel

The invention discloses a cleaning and grinding device for a building wall surface. The device comprises a supporting bottom shell, a placement shell and a dust removing cavity, wherein supporting hydraulic telescopic rods and a storage battery are arranged in the supporting bottom shell, and the upper ends of the supporting hydraulic telescopic rods are provided with the placement shell; a firstthreaded rod, a sliding rod, the dust removing cavity and an air pump are arranged on the placement shell, wherein a sliding supporting plate is arranged on the periphery of the first threaded rod andthe periphery of the sliding rod, and a support is arranged at the upper end of the sliding supporting plate; second threaded rods, a first motor, a lifting placement plate, a second motor, a grinding wheel and a dust hood are arranged on the support; and a dust removing sponge plate, an air inlet pipeline, an air outlet pipeline and a connecting hose are arranged in the dust removing cavity. Thecleaning and grinding device for the building wall surface can flexibly move and controls the grinding wheel to act various heights; and meanwhile, the dust hood is additionally arranged to be cooperated with the dust removing cavity for collecting and recycling the dust, so that the cleaning performance can be improved, and the influence of raised dust on operators is avoided.

Owner:马良彬

Method of preparing flaccid anemone saponins W1 and W3 from rhizome of flaccid anemone

The invention discloses a method of preparing flaccid anemone saponins W1 and W3 from rhizome of flaccid anemone. The method is high in end-product yield, and no toxicity or flammable solvent is used in the preparation process. The method includes: 1, adding rhizome of flaccid anemone to a heating vessel; 2, adding water into the heating vessel, decocting and filtering, and keeping residue; 3, repeating the step 2 for once to two times, and combining filtered decoctions; 4, applying the decoction combination to D-101 macroporous resin columns, performing gradient elution with 10% ethanol solution, 50% ethanol solution and 95% ethanol solution respectively, collecting eluent after 50% ethanol elution, and concentrating and drying under reduced pressure; 5, dissolving obtained flaccid anemone total saponins in water, adding a sample of solution to reverse phase ODS columns, eluting with 30% ethanol solution, 65% ethanol solution and 100% ethanol solution respectively, and drying under reduced pressure; 6, separating by means of preparative efficient liquid chromatography to obtain purified flaccid anemone saponins W1 and W3.

Owner:广州康和药业有限公司

High-efficiency building sand screening equipment

InactiveCN111570266AUnobstructed whereaboutsReduce health threatsSievingSand dryingArchitectural engineeringStructural engineering

The invention provides high-efficiency building sand screening equipment. The high-efficiency building sand screening equipment comprises a base, a vibrating screen, a pretreatment box, a sand discharging hopper, a material guiding hopper, a rectangular leakage pipe, and a first rotating rod, wherein the vibrating screen is arranged at the top of the base; the pretreatment box is arranged above the vibrating screen; the sand discharging hopper is fixedly arranged at the top of the pretreatment box; the material guiding hopper is arranged below the pretreatment box; the rectangular leakage pipeis fixedly arranged at the bottom of the material guiding hopper, and the rectangular leakage pipe is matched with the vibrating screen; and the first rotating rod is rotationally arranged on the inner walls of the two sides of the pretreatment box, and one end of the first rotating rod extends out of the pretreatment box. The high-efficiency building sand screening equipment has the advantages that sand can be evenly scattered and dewatered, the sand screening efficiency and quality are improved, and the sand screening environment is improved.

Owner:甘肃一安建设科技集团有限公司

Bifenthrin purification and granulation method

InactiveCN107032997AReduce pollutionReduce health threatsOrganic compound preparationCarboxylic acid esters preparationSlow coolingMoisture

The invention relates to the field of chemical engineering and discloses a bifenthrin purification and granulation method. The bifenthrin purification and granulation method comprises the following steps that S1, bifenthrin crude oil, an organic solvent, water and an emulsifying agent are added into a stirring kettle, and stirring and heating are performed to 60-70 DEG C till the bifenthrin crude oil in the mixture is completely dissolved in a reflux state; S2, slow cooling is performed to reach 15-25 DEG C at the cooling speed of 8-12 DEG C / hour till a bifenthrin crystal precipitates on the wall of the kettle, and then heat preservation is performed for 0.5-1.5 hours; S3, slow cooling is performed to reach 4-6 DEG C at the cooling speed of 1-3 DEG C / hour, and heat preservation is performed for 1.5-2.5 hours; S4, granular bifenthrin is obtained after discharging centrifugation, filtering and drying. The granular bifenthrin can be obtained, the specific gravity is up to 0.65-0.75, the same size of packaging buckets can contain heavier bifenthrin, and thus the transportation cost is greatly reduced; the moisture content is smaller, the centrifugation time is short, the dust amount is small, and thus environmental pollution is reduced.

Owner:JIANGSU HUANGMA AGROCHEM

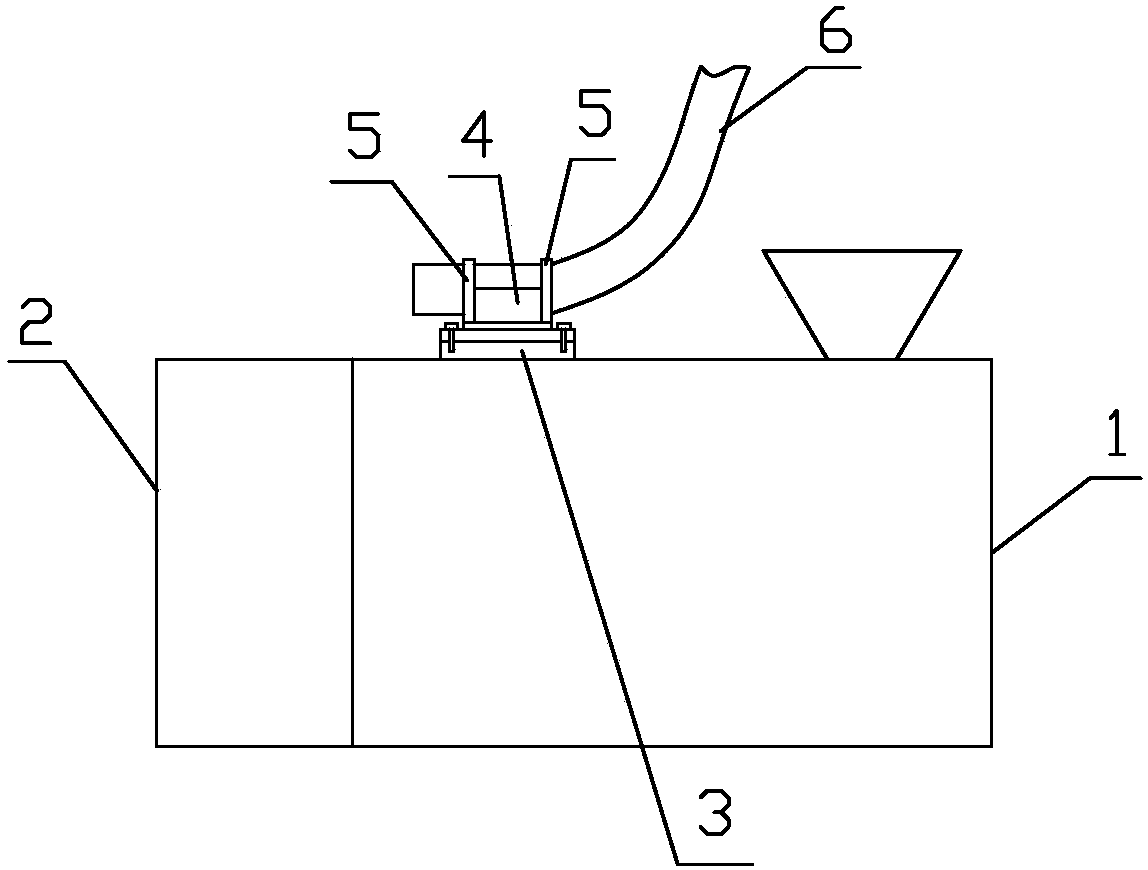

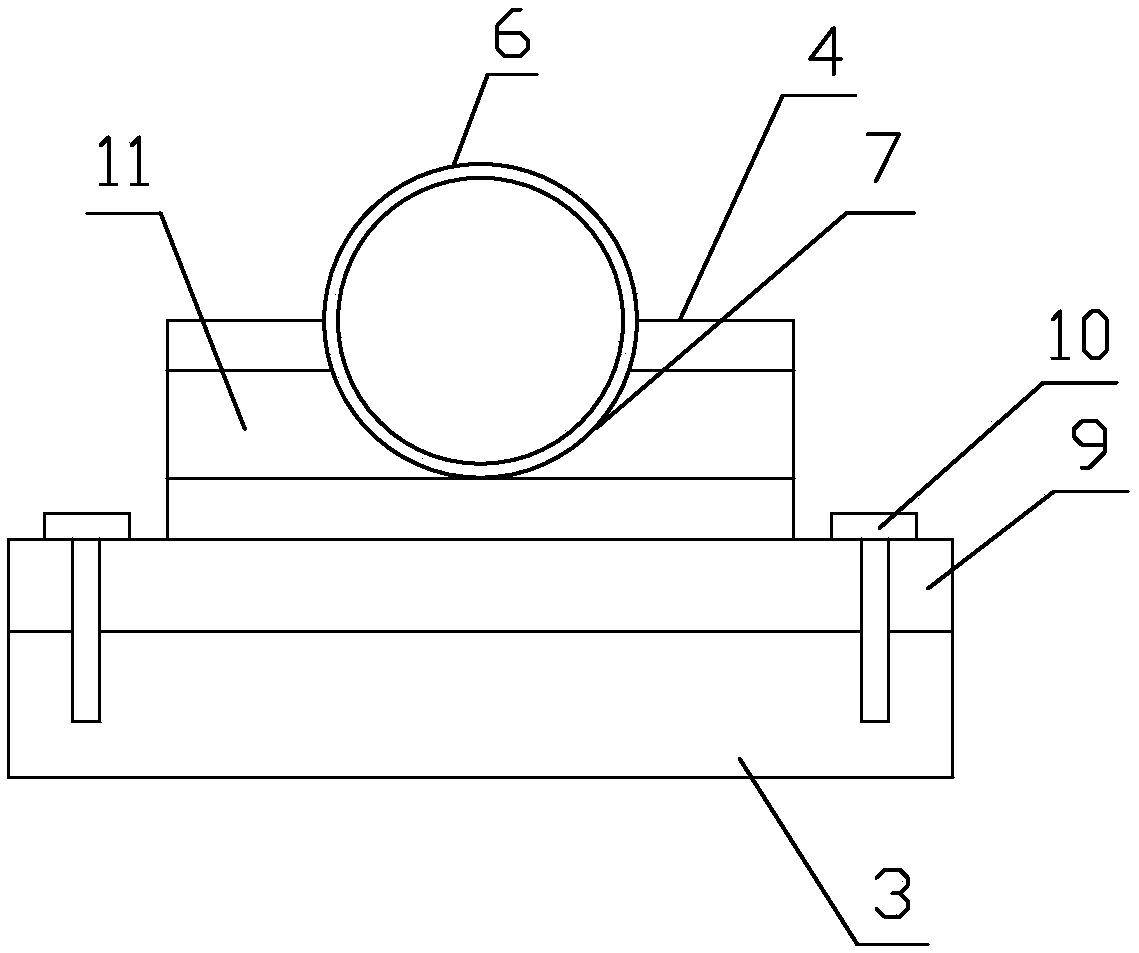

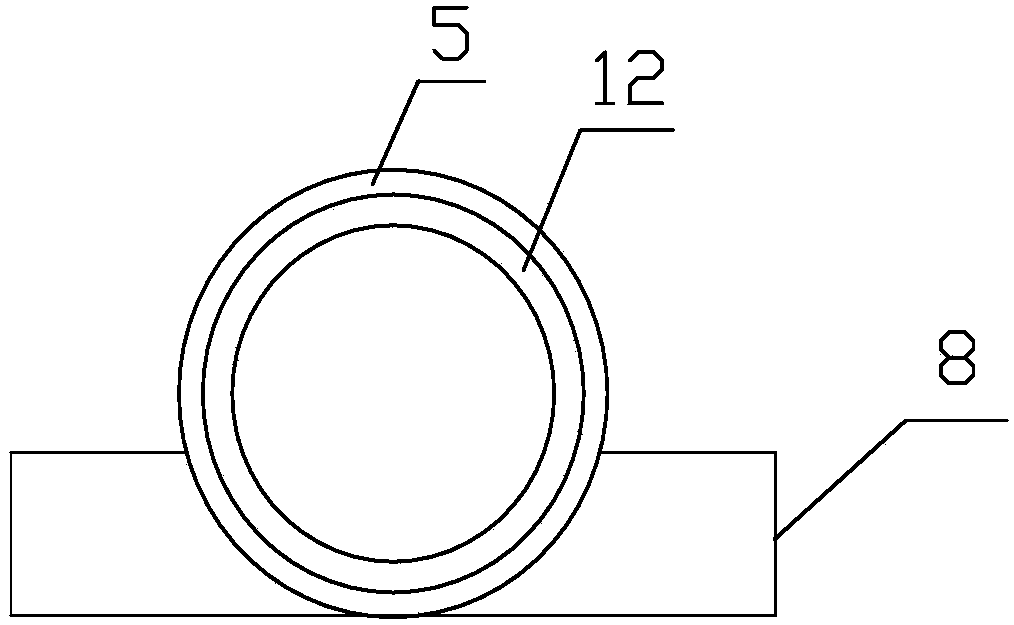

High-efficiency intelligent exhaust gas treatment system

PendingCN108159785ADoes not hinder replacementReduce health threatsDispersed particle separationVapor condensationAir pumpProduct gas

The invention discloses a high-efficiency intelligent exhaust gas treatment system. The shell of an injection molding machine body is provided with a mounting base, the bottom surface of a mounting block is arranged on the mounting base, and the top surface of the mounting block is provided with a semicircular groove for accommodating gas suction and collection tubes; two snap rings transitionallycooperatively sleeve the input end tube segments of the gas suction and collection tubes, the mounting block is positioned between the two snap rings, the sidewalls of the snap rings are provided with a limiting plate, and the limiting plate is detachably connected and fixed to the sidewall of the mounting block; and the output ends of the gas suction and collection tubes are communicated with the input end of a cyclone separator through a connecting pipeline, the connecting pipeline is provided with a first suction pump, the gas output end of the cyclone separator is communicated with the input end of a condenser through a pipeline, and a gas discharging tube is arranged at the output end of the condenser. The high-efficiency intelligent exhaust gas treatment system has the advantages ofeffective connection of exhaust gas discharged from the die port of an injection molding machine, simple structure, and convenience in dismounting and operation.

Owner:安徽蓝清源环境科技有限公司

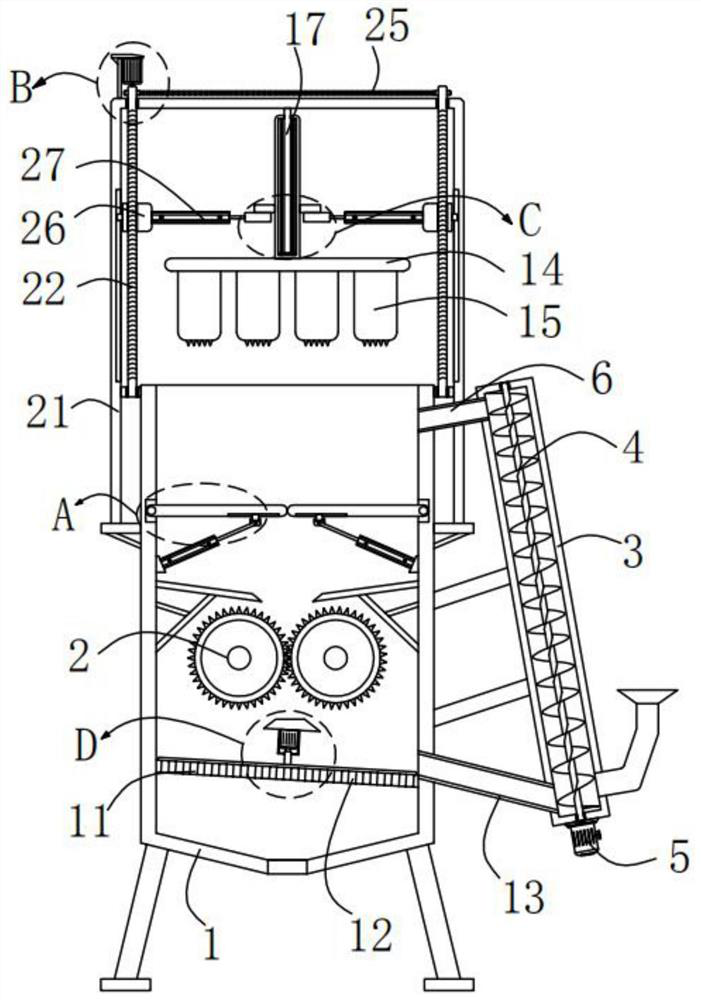

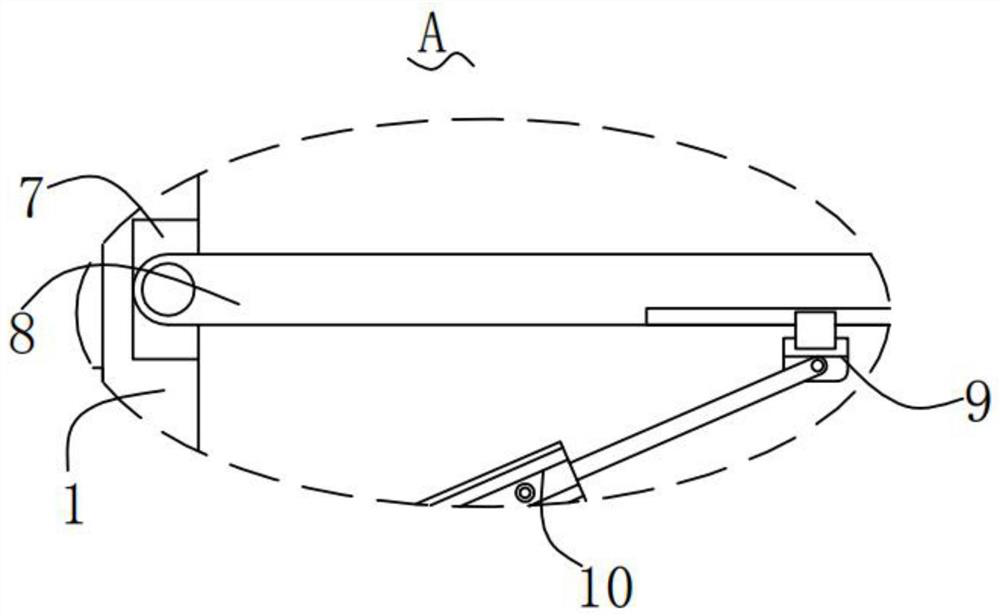

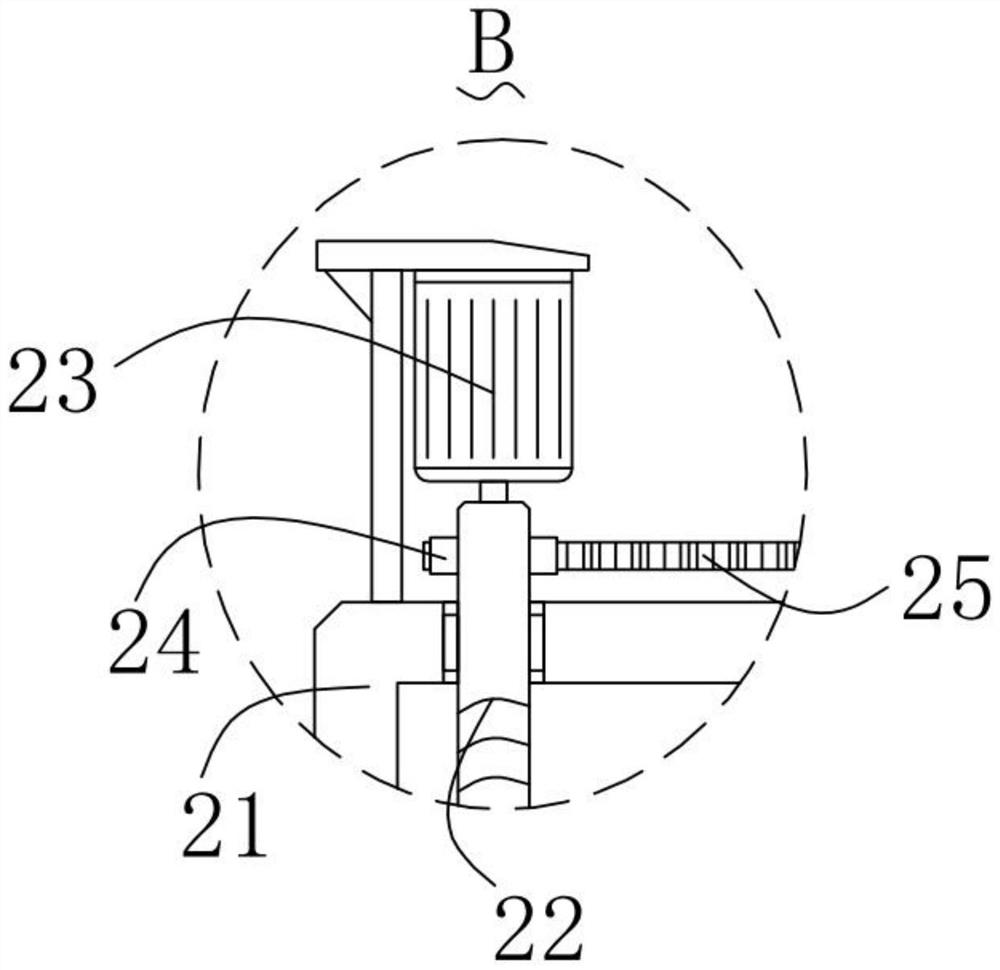

Municipal construction waste circulating crushing device and using method thereof

InactiveCN112169977AImprove crushing effectImprove efficiencyCombination devicesGrain treatmentsElectric machineArchitectural engineering

The invention provides a municipal construction waste cyclic crushing device and a using method thereof. A municipal construction waste cyclic crushing device comprises a treatment box with an openingin the top, a crushing mechanism arranged in the treatment box, a feeding box fixedly mounted on the outer wall of one side of the treatment box, a packing auger rotationally mounted on the inner walls of the top and the bottom of the feeding box, a first motor fixedly installed at the bottom of the feeding box, and a feeding pipe fixedly installed on the feeding box, wherein an output shaft of the first motor is fixedly connected with the bottom end of the packing auger, and one end of the feeding pipe is fixedly connected with one side of the treatment box. The municipal construction wastecyclic crushing device and the using method thereof have the advantages that construction waste can be pretreated, the subsequent crushing effect and crushing efficiency are improved, dust flying is reduced, and the working environment quality is improved.

Owner:LIANHAI GUANGAN CONSTR ENG

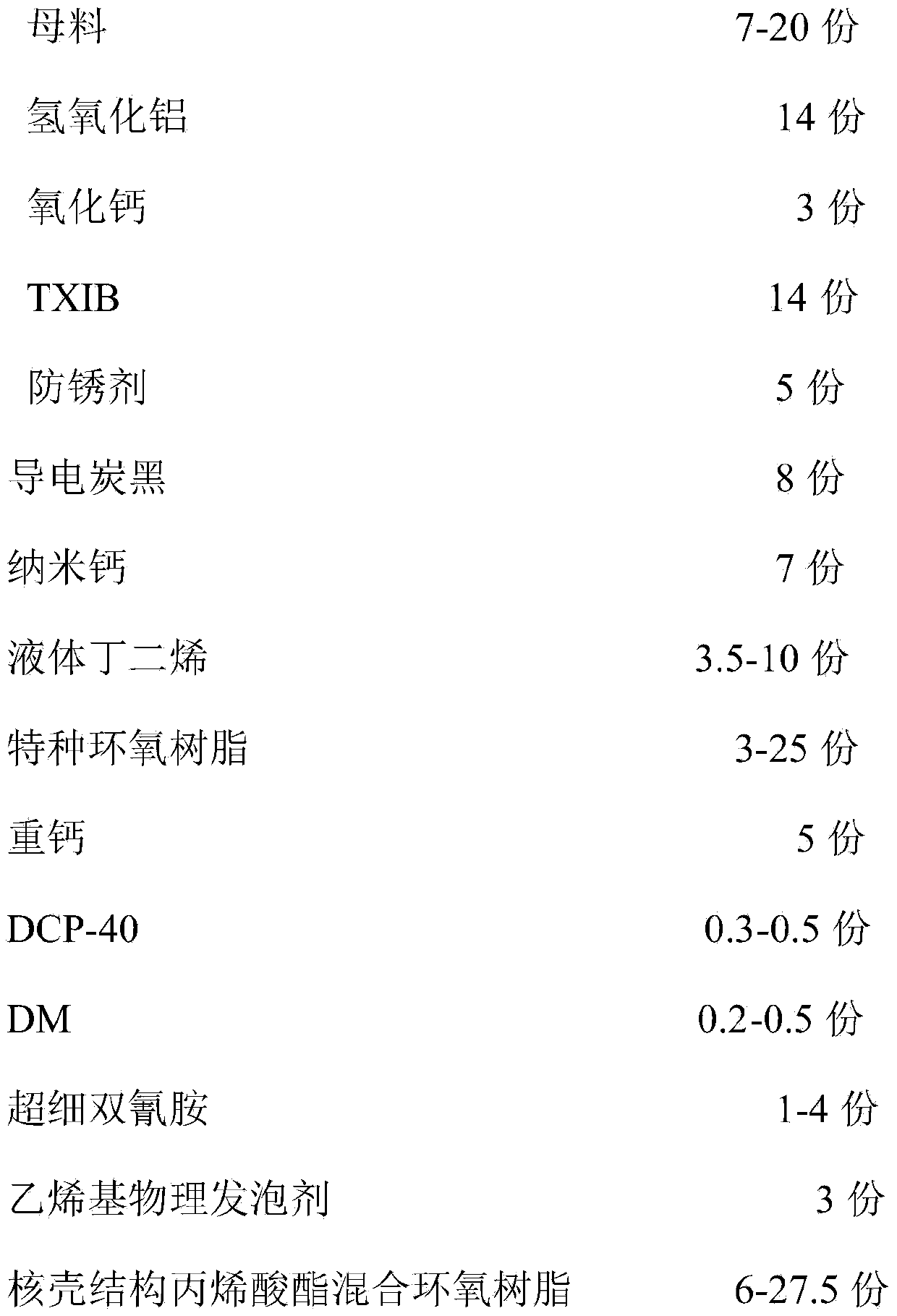

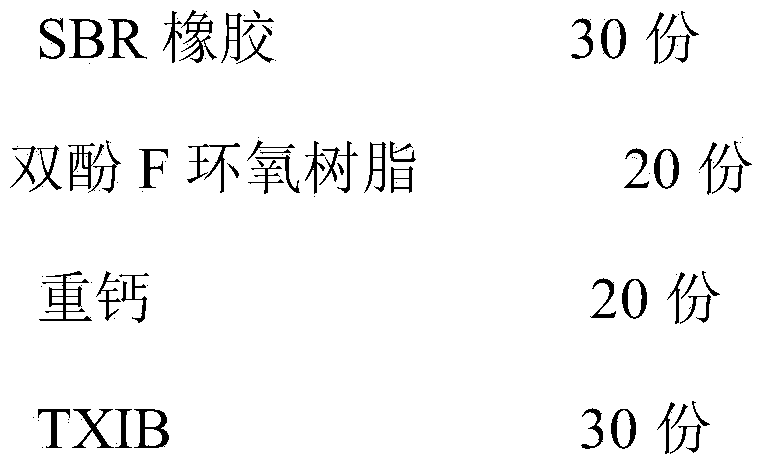

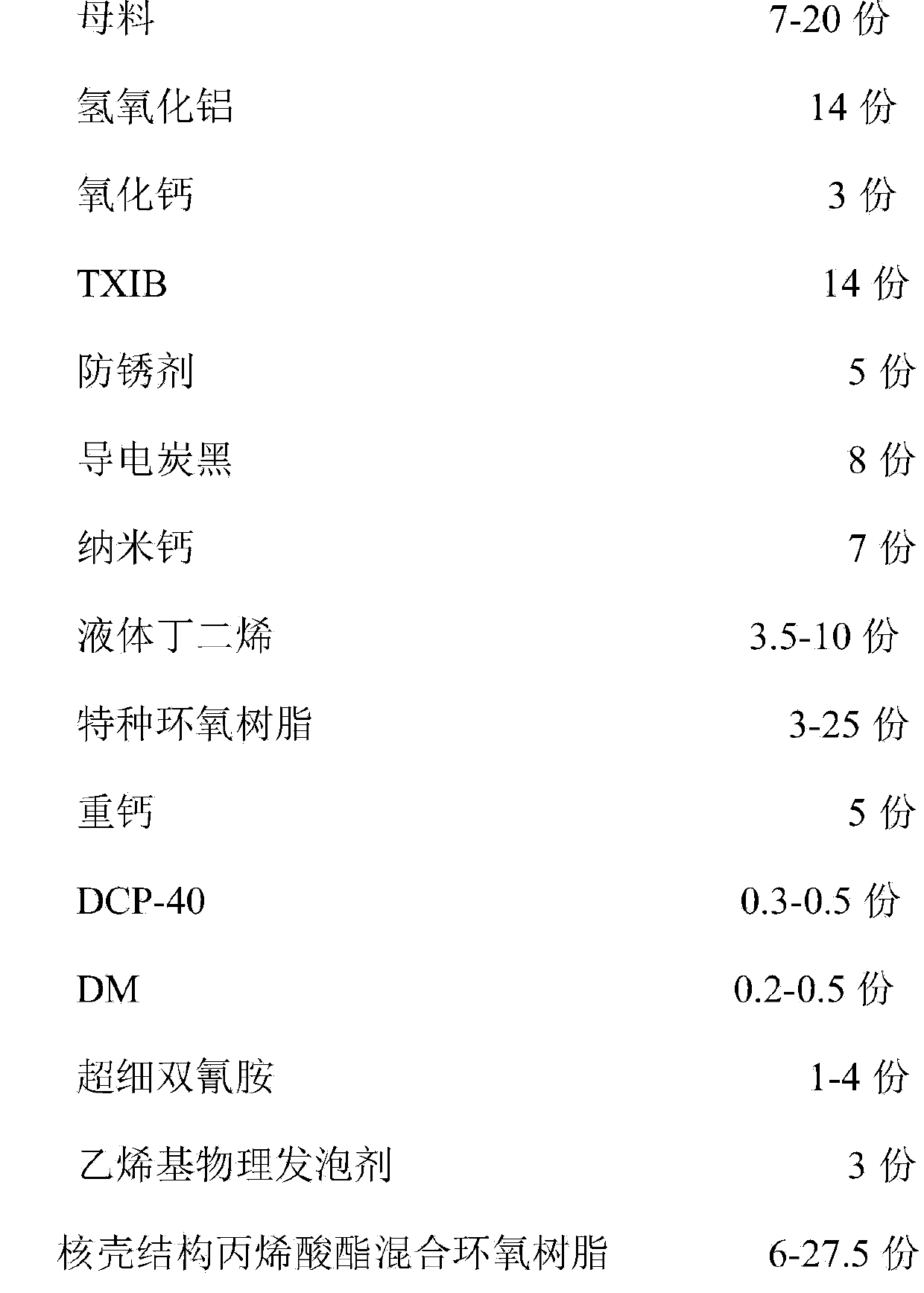

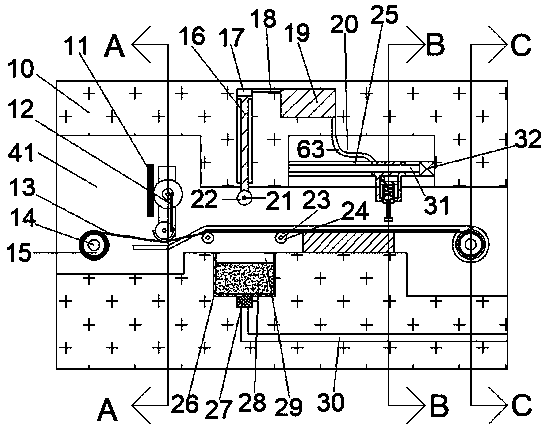

Expanding rust-preventing spot welding structural sealant for car, and preparation method thereof

The invention provides an expanding rust-preventing spot welding structural sealant for a car, and a preparation method thereof. The preparation method comprises the following steps: preparing 7-20 parts of master batch, 8 parts of aluminium hydroxide, 3 parts of calcium oxide and 3 parts of TXIB, kneading the prepared raw materials for 30 minutes on a kneader; adding in 6 parts of aluminium hydroxide, 5 parts of a rust inhibitor, 8 parts of conductive carbon black and 5 parts of TXIB for kneading for 15 minutes in the kneader to enable materials to be conglomerated; adding in 7 parts of nano-calcium, 3.5-10 parts of liquid butadiene, 3-25 parts of bisphenol F epoxy resin and 3 parts of TXIB for kneading for 25 minutes in the kneader; adding in 5 parts of coarse whiting, 0.3-0.5 part of DCP-40, 0.2-0.5 part of DM, 1-4 parts of superfine dicyandiamide and 3 parts of an ethenyl physical foaming agent for kneading for 20 minutes in the kneader; adding in 6-27.5 parts of acrylate mixed epoxy resin in the core-shell structure for kneading for 10 minutes in the kneader; adding in 1.5 parts of TXIB; reserving 1.5 parts of TXIB for adjusting viscosity. The structural sealant after curing is high in strength, good in tenacity and excellent in rust prevention.

Owner:保光(天津)汽车零部件有限公司

Device for dyeing and ironing-into-bolt of textile fabrics

ActiveCN111549478AEven by forceGuaranteed cleaning qualityMechanical cleaningPressure cleaningHydraulic cylinderStructural engineering

The invention discloses a device for dyeing and ironing-into-bolt of textile fabrics. The device for dyeing and ironing-into-bolt of the textile fabrics comprises a device box body, a hydraulic cylinder is fixedly installed in the device box body, and two groups of front-and-back symmetrical dyeing hydraulic chambers are formed in the device box body. A dyeing oil pipeline is arranged between thedyeing hydraulic chambers and the hydraulic cylinder, and an ironing cavity and a working cavity are formed in the device box body. The device is provided with a cleaning device to automatically cleanthe textile fabrics, and the up-and-down position of the cleaning device can be automatically adjusted according to the pressure on the fabrics during cleaning, so that the fabrics are uniformly stressed during cleaning, and the cleaning quality is ensured while the fabrics are not damaged due to excessive pressure. The device is further provided with an ironing device which can be used for ironing and drying the dyed fabrics, the fabrics are leveled and conveniently made into bolts. The device is internally provided with a traction device to facilitate the replacement and transportation of afabric roller, efficiency is improved, and the threat to the health of employees is reduced.

Owner:江苏欧斯曼纺织科技有限公司

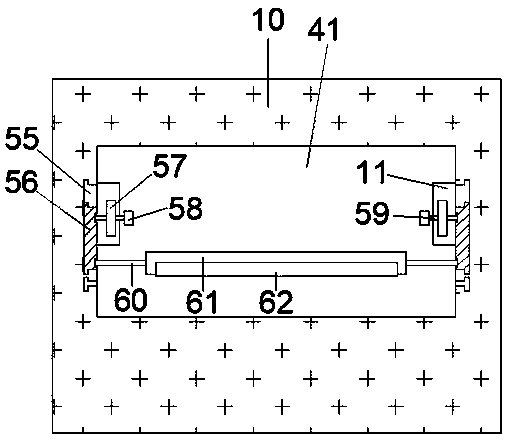

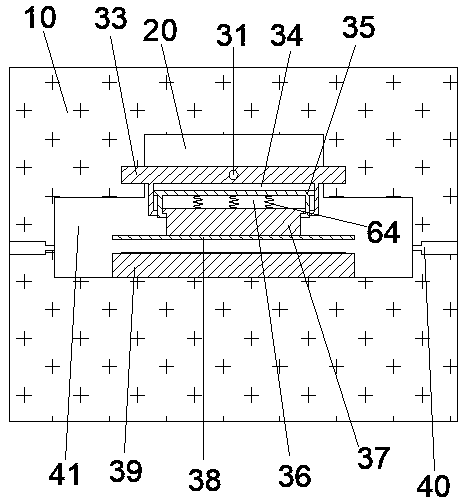

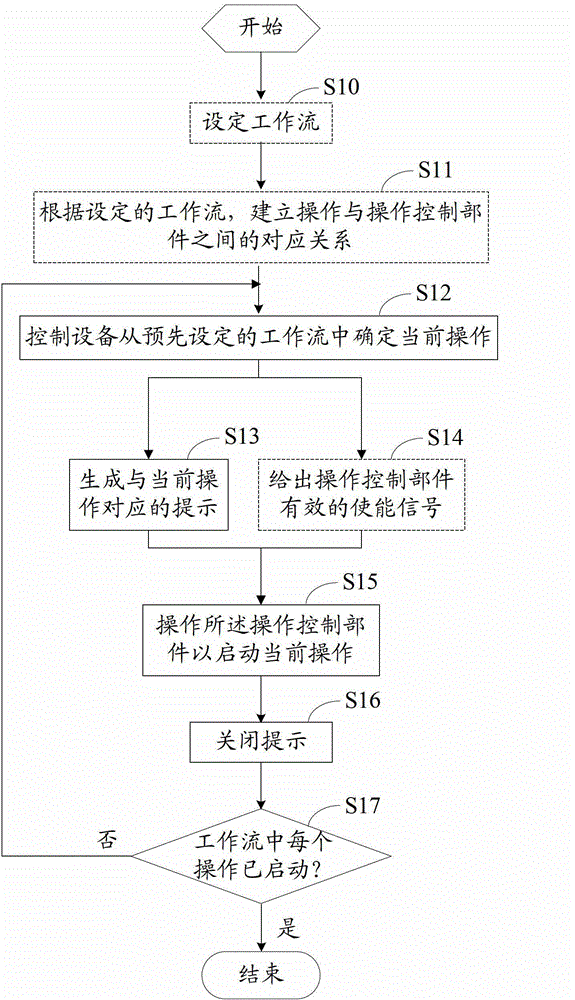

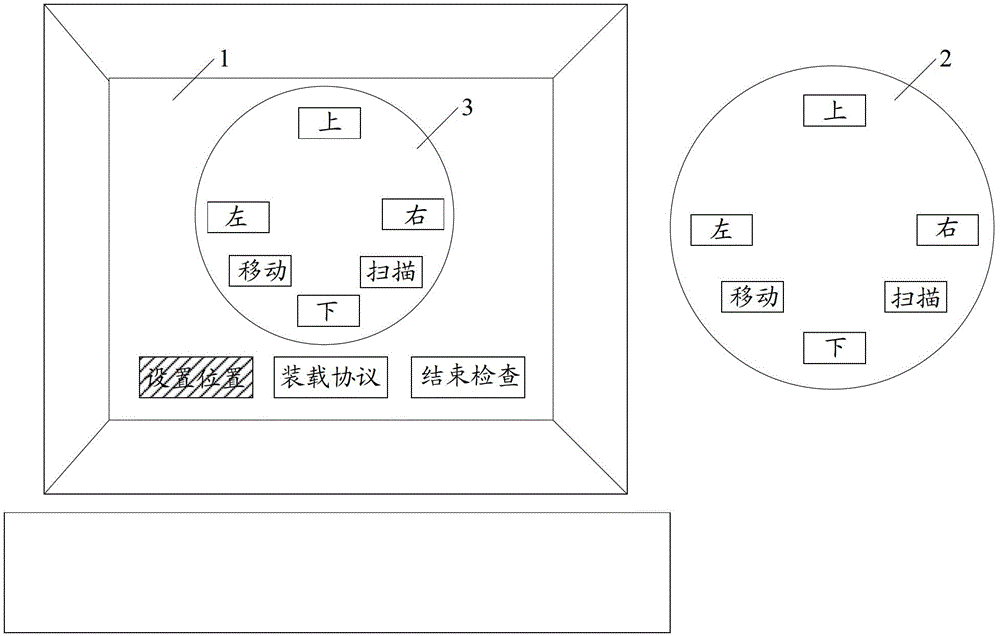

Medical imaging system and control method and device of workflows in medical imaging

ActiveCN103767721BReduce misuseImprove processing efficiencyUltrasonic/sonic/infrasonic diagnosticsComputerised tomographsMedical imagingComputer science

Disclosed are a medical imaging system and a control method and device of workflows in medical imaging. The control method of the workflows in the medical imaging comprises determining the current operation from the preset workflows through the control device, wherein the workflows comprise at least two operations and the relations between the operations; generating a prompt which is corresponding to the current operation based on the pre-established corresponding relations between the operations and an operation control part, wherein the prompt comprises the information of the operation control part; closing the prompt under the condition that the operation control part is operated to start the current operation. The control device of the workflows in the medical imaging comprises an operation determining unit, a prompt generating unit and a prompt closing unit. The medical imaging system comprises the control device of the workflows in the medical imaging. According to the medical imaging system and the control method and device of the workflows in the medical imaging, the control on the workflows in the medical imaging can be efficiently and accurately achieved.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

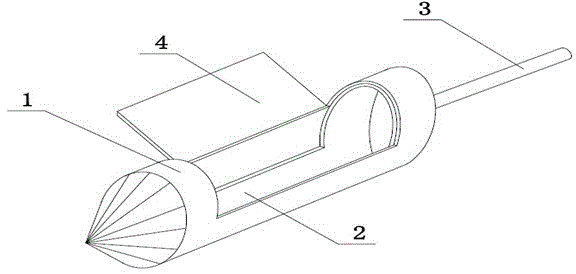

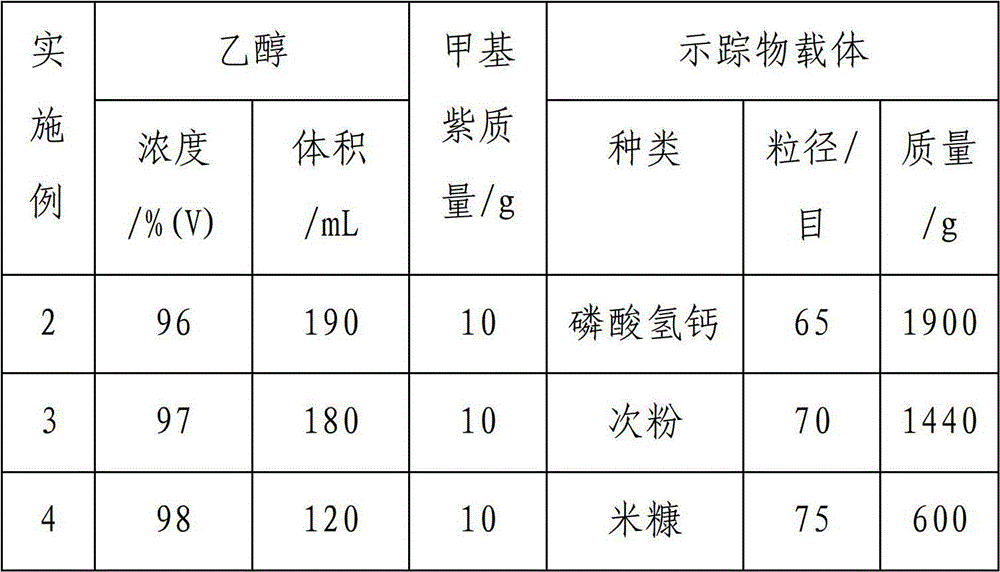

Method for measuring homogeneous degree of fodder

ActiveCN102928368BReduce health threatsReduce investmentColor/spectral properties measurementsMethyl violetFodder

The invention discloses a method for measuring the homogeneous degree of a fodder. The method comprises the following steps of: dissolving methyl violet by using ethanol with the volume percent concentration being more than 95% to prepare a methyl violet solution; mixing the prepared methyl violet solution with a tracer carrier for uniformly stirring and drying to obtain a methyl violet tracer; then adding the methyl violet tracer to the fodder for preparing a fodder sample; and measuring the homogeneous degree of the fodder sample. By utilizing the method, methyl violet solid does not need to be smashed, the method is environment-friendly, and health threat to operating workers is greatly reduced. Meanwhile, the methyl violet solid does not need to be smashed so that the method for preparing the methyl violet tracer is simple, convenient and easy to operate, investment in pulverizer equipment is also eliminated, and the production cost is reduced. Further more, a sampling device is adopted for sampling when the method is used for detecting the homogeneous degree of the samples, and the samples in different positions of a mixing machine can be sampled so that the condition of the homogeneous degree of the fodder can be truthfully reflected.

Owner:NEW HOPE LIUHE +1

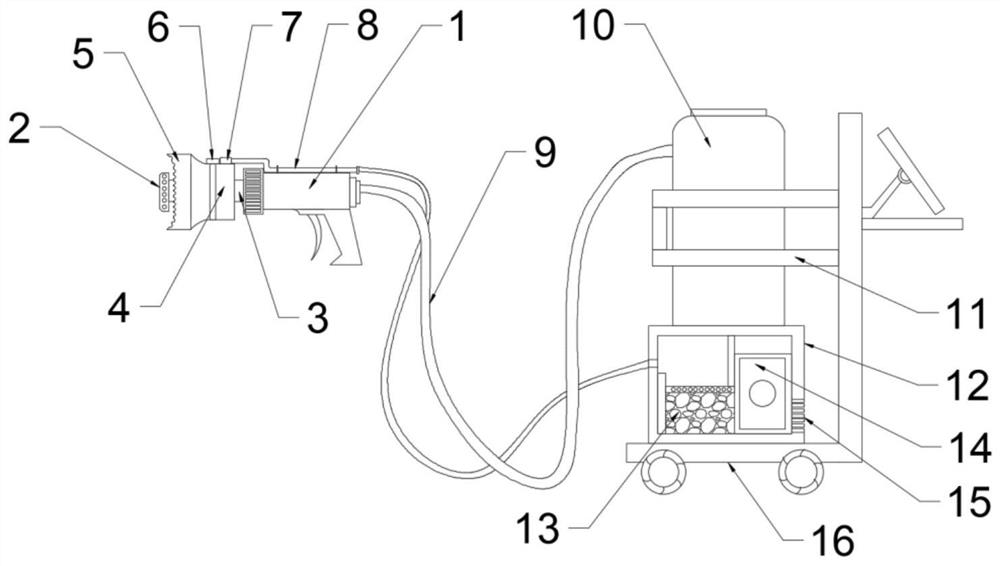

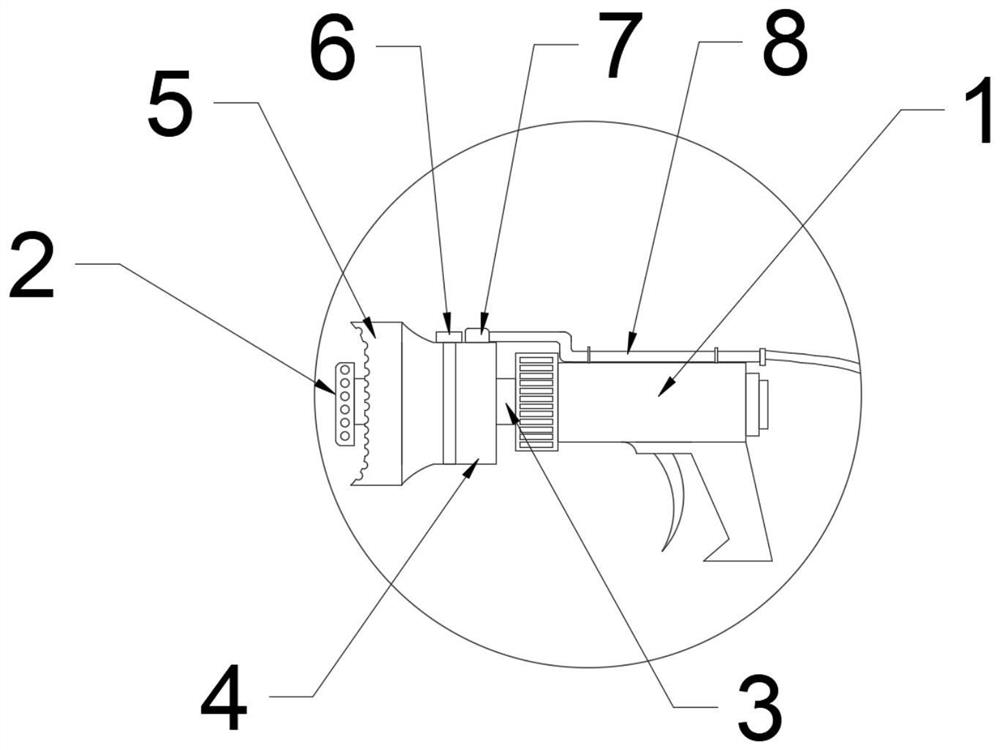

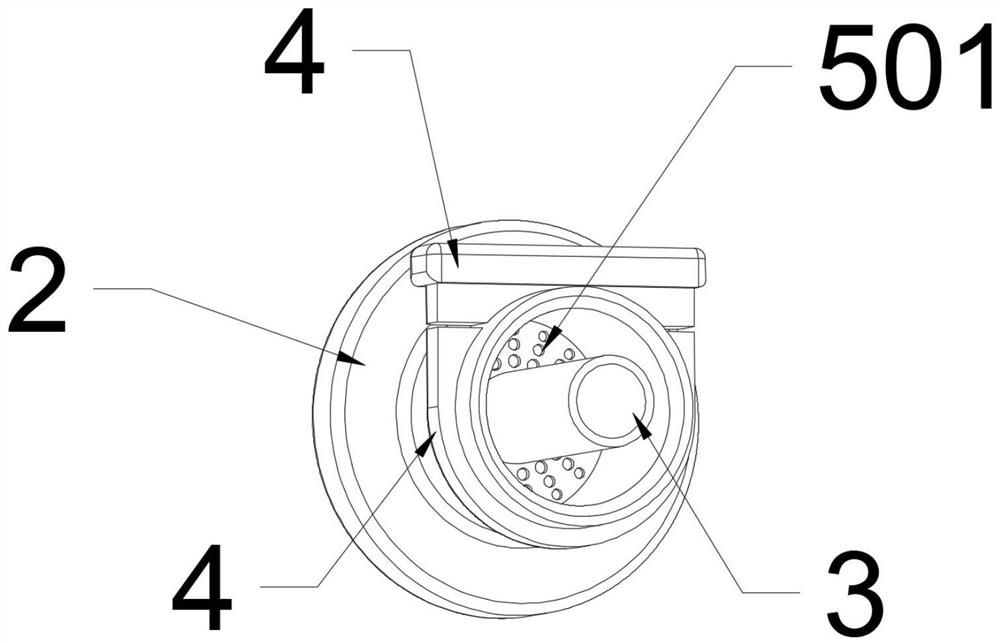

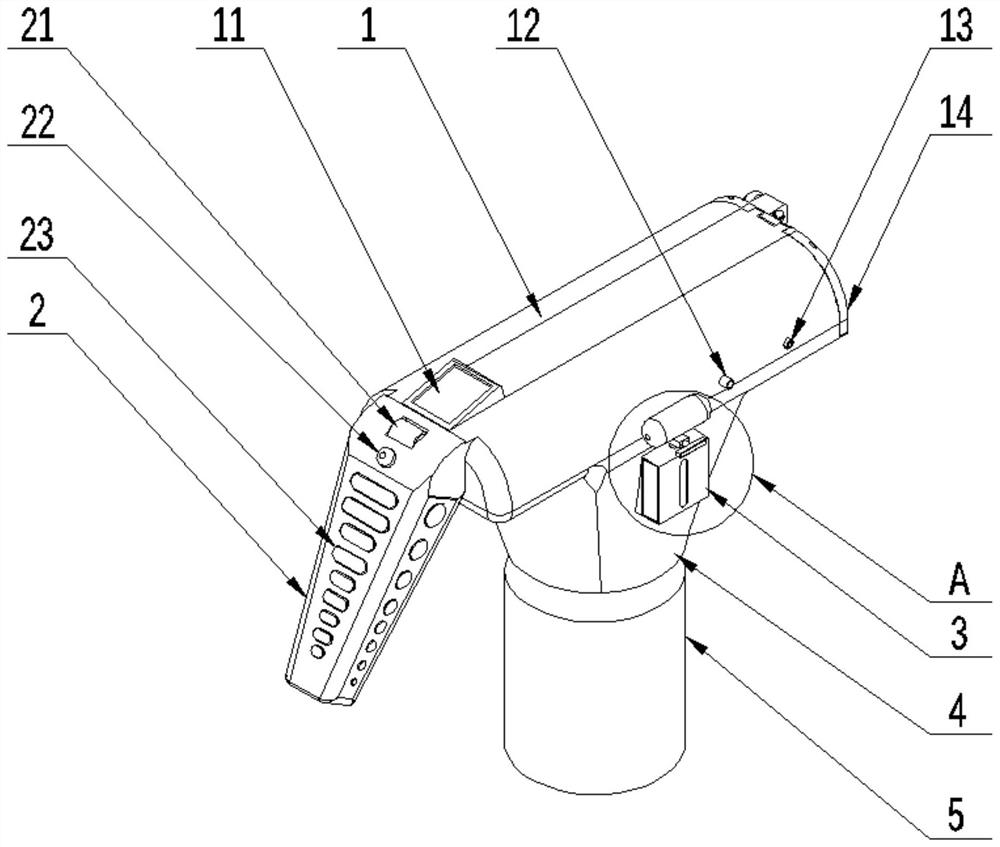

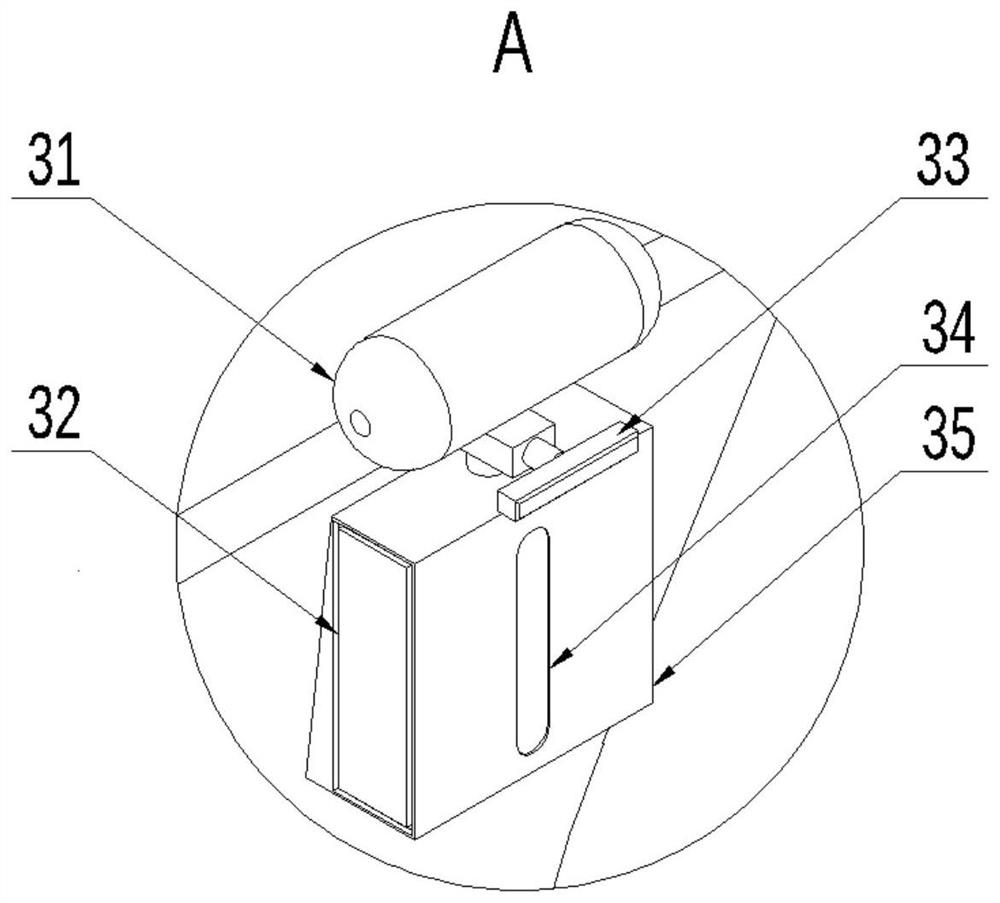

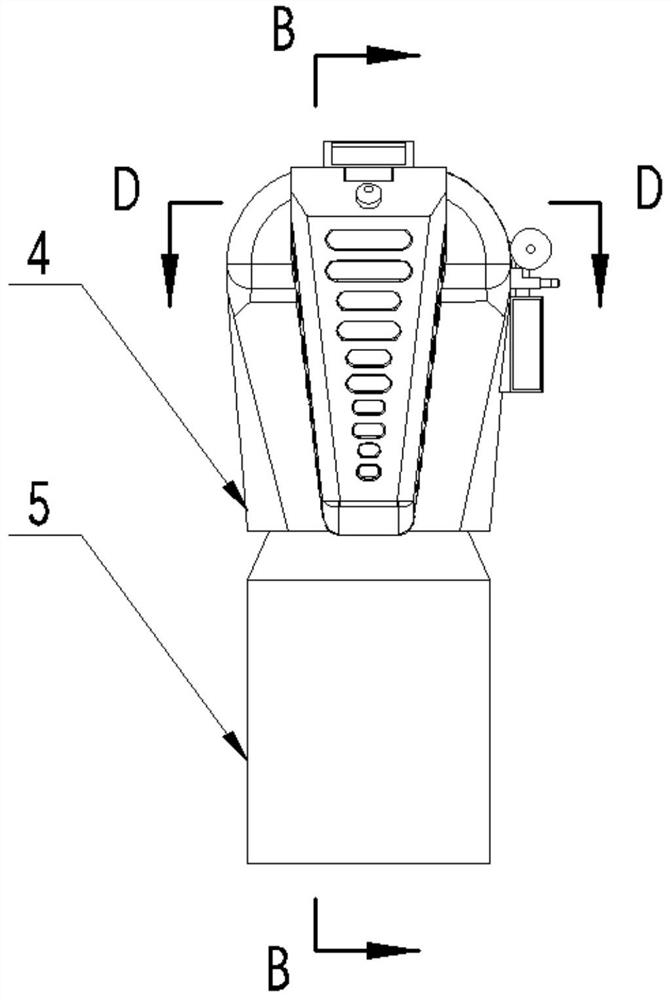

Industrial coating spraying device with purification function

InactiveCN112337666AReduce health threatsReduces the possibility of clinging to surrounding objectsSpray nozzlesActivated carbonSpray nozzle

The invention discloses an industrial coating spraying device with a purification function, and belongs to the technical field of industrial coatings. The industrial coating spraying device with the purification function comprises a coating spray gun, a coating spray nozzle, a spray pipe, an annular material suction plate, a filter disc insertion block, an air suction pipe and a purification box,the spray pipe is arranged in the interior of the coating spray gun used for spraying coatings, the left side of the spray pipe is connected with the coating spray nozzle, the annular material suctionplate is fixedly installed around the coating spray nozzle, the filter disc insertion block is arranged on the right side of the annular material suction plate and movably installed on the coating spray gun, the air suction pipe is arranged on the right side of the filter disc insertion block and comprises an activated carbon box and an air suction pump, and the activated carbon box is arranged on the left side of the air suction pump. According to the industrial coating spraying device with the purification function, the annular material suction plate and the material suction cavity are installed at the front end of the coating spray gun, and therefore redundant coating particles generated during spraying of the coating spray nozzle can be sucked to the interior of the material suction cavity to be purified, the threat of the scattered coating particles to the health of a user in the spraying process can be effectively reduced, and meanwhile, the possibility that the coating particles are attached to surrounding objects is reduced.

Owner:BECKER IND COATINGS (GUANGZHOU) LTD

Building wall surface grinding machine

InactiveCN108972194AImprove sealingEasy to movePortable grinding machinesPlane surface grinding machinesWorking environmentDrive motor

The invention discloses a building wall surface grinding machine which comprises a case. A transparent dust cover is arranged on the right side of the case, and a driving motor is arranged on the right side in the case. A rotary shaft is arranged at the output end of the driving motor, and a grinding disc is welded to the right end of the rotary shaft. A handle is welded to the left side of the surface of the bottom of the case, and a connecting rod is welded to the right side of the surface of the bottom of the case. The bottoms of the connecting rod and the handle are fixedly connected witha dust collecting box in a welded mode, and a draught fan is arranged on the surface of the right side of the dust collecting box. A first supporting rod is arranged below the dust collecting box, anda second supporting rod is arranged below the first supporting rod. The transparent dust cover is arranged, thus dust flying caused in the process that the wall surface is ground by the grinding machine can be prevented, dust is collected in the transparent dust cover and then conveniently treated in a unified mode, thus the working environment is not polluted, and health threatening to operatorsis lowered.

Owner:江苏泰华消防电气设备有限公司

Hericium erinaceus chips and preparation method thereof

InactiveCN107114735ACrispy tasteReduce health threatsFood ingredient as flavour affecting agentNatural extract food ingredientsBearded toothTiming/quantity

The invention discloses hericium erinaceus chips and a preparation method thereof. The hericium erinaceus chips are prepared from the raw materials in parts by weight: 80 to 100 parts of potato slices, 20 to 40 parts of hericium erinaceus, 10 to 15 parts of pericarpium citri reticulatae, 3 to 6 parts of radix ginseng, 4 to 8 parts of fructus nitrariae tangutori and 3 to 6 parts of pungent litse fruit. The preparation method comprises the steps: 1) weighing the hericium erinaceus, the pericarpium citri reticulatae, the radix ginseng, the frutus nitrariae tangutori and the pungent litse fruit according to matching, evenly stirring, mixing with 30 to 50 times quantity of water, stirring, evenly mixing, heating to 60 to 70 DEG C and keeping for 20 to 30 minutes; keeping 70 to 80 DEG C for 10 to 30 minutes; keeping 90 to 120 DEG C for 15 to 25 minutes; then naturally cooling to room temperature and filtering to take filtrate; 2) weighing 80 to 100 parts of potato slices, ultrasonically soaking the potato slices in the filtrate obtained in the step 1) for 1 to 2 hours and then fishing out to be air dried, wherein the air drying time is 3 to 4 days; and 3) pouring the air dried potato slices into an oil fryer to be fried. The potato chip has a low oil content and further has an effect of promoting digestion and appetite.

Owner:ANHUI HUACHUANG MODERN AGRI TECH

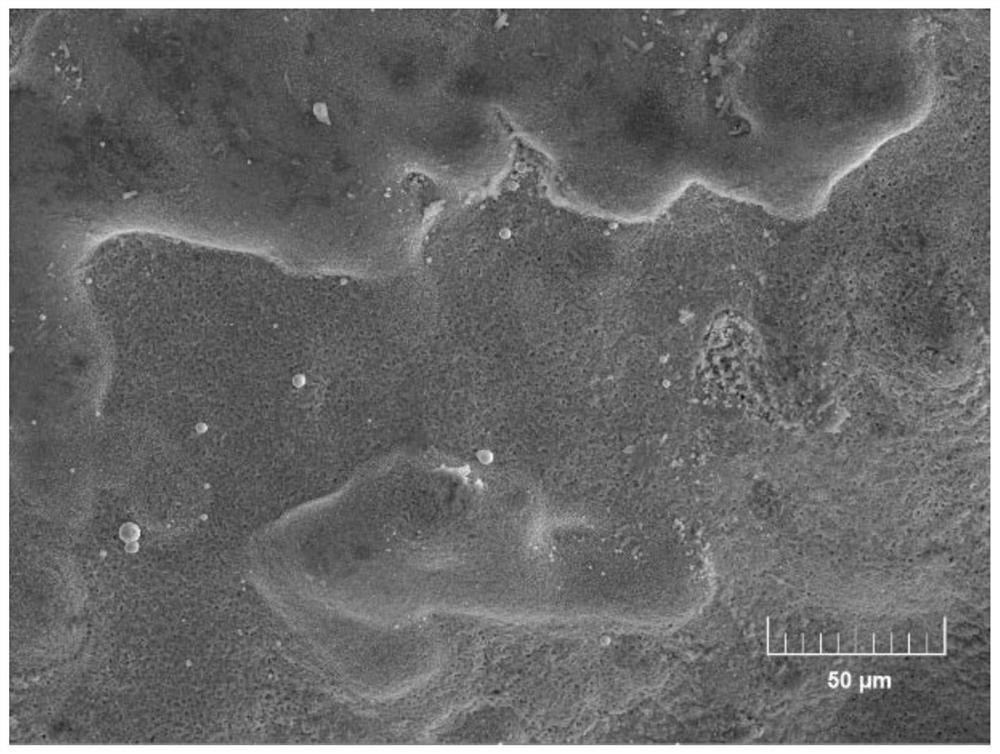

A kind of fracture cleaning method of nickel base superalloy

The invention discloses a nickel-based high-temperature alloy fracture cleaning method. The method comprises the following steps: 1) preparing a cleaning solution; 2) completely immersing the alloy fracture in a cleaning solution, and boiling in a water bath to obtain a primarily cleaned fracture; 3) repeatedly adhering the fracture by using an adhesive tape until the adhesive tape does not adheredirt; 4) brushing the fracture with a brush soaked with an acetone solution; 5) completely immersing the fracture into an HCl solution, and carrying out ultrasonic cleaning; 6) repeating the step 3)and the step 4); 7) taking the fracture as a cathode, taking a platinum electrode as an anode, and carrying out electrolytic cleaning in an HCl solution; and (8) repeating the step (3) and the step (4) until the scanning electron microscope is enlarged by 500-1000 times, cleaning up dirt on the fracture, and distinguishing fracture characteristics. According to the method, oxides on the fracture of the nickel-based superalloy can be effectively cleaned, secondary damage to the fracture is avoided, and sample preparation is made for finding out a real reason causing alloy service failure.

Owner:BEIHANG UNIV

Public place water quality sampler

PendingCN113405855AReduce difficultyReduce health threatsWithdrawing sample devicesMaterial electrochemical variablesPublic placeWater quality

According to the public place water quality sampler, a bottle sleeve and a sealing film are arranged outside an adopted sampling bottle, the joint of the bottle sleeve and an annular groove of a communication module is separated during multiple times of sampling, it is guaranteed that a sampling bottle opening is located in the communication module during sampling, and the situation that a water sample is directly irradiated by sunlight is also avoided; a disposable sealing film is arranged at a bottle opening, and an air suction pipe and a stabilizer spray pipe are communicated with a sampling bottle in a puncturing manner, so that insufficient air tightness in the bottle during air pumping of an air suction pump is prevented, and the sampling bottle is prevented from being polluted by bacteria in an external environment during sampling, and a telescopic sampling rod and a servo motor positioned at the end part of the telescopic sampling rod are also adopted; the telescopic sampling rod and the servo motor are controlled to zoom through a roller switch, and the extension lengths of the the telescopic sampling rod and the servo motor and the lowering depth of the lifting line can be observed through a display screen, so that the accuracy of multi-point sampling is ensured, and the influence of an operation error of a worker on a sampling result is reduced; the problems that workers are difficult to strictly sample according to specifications in different environments and the health is easily harmed are solved.

Owner:武汉市疾病预防控制中心

Waterborne epoxy resin porcelain coating and preparation method thereof

InactiveCN110172289ANo emissionsReduce health threatsAnti-corrosive paintsEpoxy resin coatingsEpoxyOrganic polymer

The invention provides a waterborne epoxy resin porcelain coating and a preparation method thereof, and belongs to the technical field of coatings. Epoxy-terminated organosilicon is grafted onto epoxyresin curing agent molecules; after curing, epoxy resin molecules, curing agent molecules and epoxy-terminated organosilicon molecules form a whole, silicon atoms on an organic high-molecular polymercan form hydrogen bonds with inorganic materials such as silicon atoms and aluminum atoms in fillers and auxiliaries. Compared with intermolecular forces formed by traditional physical mixing, the hydrogen bonds are combined more firmly, the overall performance of a coating film is improved, a dense organic polymer / inorganic oxide composite protective layer is formed, and an inorganic oxide protective structure of porcelain enamel is formed to the maximum extent. The hardness of a paint film can be effectively improved, and the abrasive resistance, the weather resistance, corrosion resistanceand the like of the paint film are improved.

Owner:TAIYUAN LUBANG TECH CO LTD

Method of preparing flaccid anemone saponins W1 and W3 from rhizome of flaccid anemone

The invention discloses a method for simultaneously preparing diwusaponin W1 and W3 from diwu medicinal material with high yield of final product and no toxicity, flammable and explosive solvents involved in the preparation process, comprising: 1) adding diwu medicinal material to 2) Add water to the heating vessel, decoct and filter to keep the residue; 3) Repeat step 2) for 1 to 2 times, and combine the filtered decoction; 4) Combine the combined decoction Put on D-101 macroporous resin column, carry out gradient elution with water, 10%, 50% and 95% ethanol solution successively, collect the eluate after 50% ethanol elution treatment, concentrate and dry under reduced pressure; 5) put The obtained total saponin extract of Diguanin was dissolved in water, and then the solution was loaded on a reversed-phase ODS column, and eluted with 30%, 65% and 100% ethanol solutions in sequence, and detected by TLC, and the samples rich in Diguanin were collected Ethanol eluents with corresponding concentrations of W1 and W3 were dried under reduced pressure; 6) Preparative high-performance liquid chromatography was used to separate and obtain pure diguanin W1 and W3.

Owner:广州康和药业有限公司

Portable cigarette smoke collecting filter

The present invention discloses a portable cigarette smoke collecting filter, which comprises a smoke collecting device and a smoke filtering device, wherein the smoke collecting device comprises an opened smoke absorbing and holding chamber, the smoke filtering device comprises a filtering channel, a filtering sheet and an exhaust fan, the filtering sheet and the exhaust fan are arranged inside the filtering channel, the filtering channel is communicated with the opened smoke absorbing and holding chamber, the filtering sheet is arranged on the inner side of the filtering channel inlet, and the exhaust fan is arranged on the inner side of the filtering channel outlet. Compared with the portable cigarette smoke collecting filter in the prior art, the portable cigarette smoke collecting filter of the present invention has the following characteristics that: the cigarette smoke discharged by the individual can be effectively collected and can be treated by the smoke filtering device so as to remove tar, particulates and other pollutants, such that the pollution of the cigarette smoke on the surrounding environment can be reduced, and the health threat of the cigarette on the surrounding population can be reduced.

Owner:南通百博丝纳米科技有限公司

Paint production dispersion machine

InactiveCN107983226AReduce volatilityReduce health threatsRotary stirring mixersTransportation and packagingPulp and paper industryRaw material

The embodiment of the invention discloses a paint production dispersion machine which comprises a blade rod, a dispersion disc, an opening tank cover, a dispersion tank, a multi-hole connecting part,an exhaust tube, a fan and a gas collection device, wherein the dispersion tank is sleeved by the opening tank cover; a dispersion disc through hole is formed in the middle of the opening tank cover;the multi-hole connecting part comprises a cylinder with a first through hole and a second through hole respectively formed in two ends; a third through hole which protrudes outwards is formed in a side wall of the cylinder; the blade rod penetrates through the first through hole and the second through hole; the first through hole is connected with the blade rod in a sealed manner; the second through hole is detachably connected with the dispersion disc through hole in the sealed manner; the third through hole is connected with the exhaust tube in the sealed manner; the exhaust tube is connected with the air inlet of the fan; the air outlet of the fan is connected with the gas collection device; a gas adsorbent is arranged inside the gas collection device. By adopting the paint productiondispersion machine disclosed by the embodiment of the invention, the problem that in the prior art, a great amount of a paint raw material is volatilized into the air when dispersion tanks are replaced is solved.

Owner:湖南太子化工涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com