Municipal construction waste circulating crushing device and using method thereof

A construction waste and recycling crushing technology, which is applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of reducing crushing effect and crushing efficiency, threats to human health, and difficulty in meshing and touching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

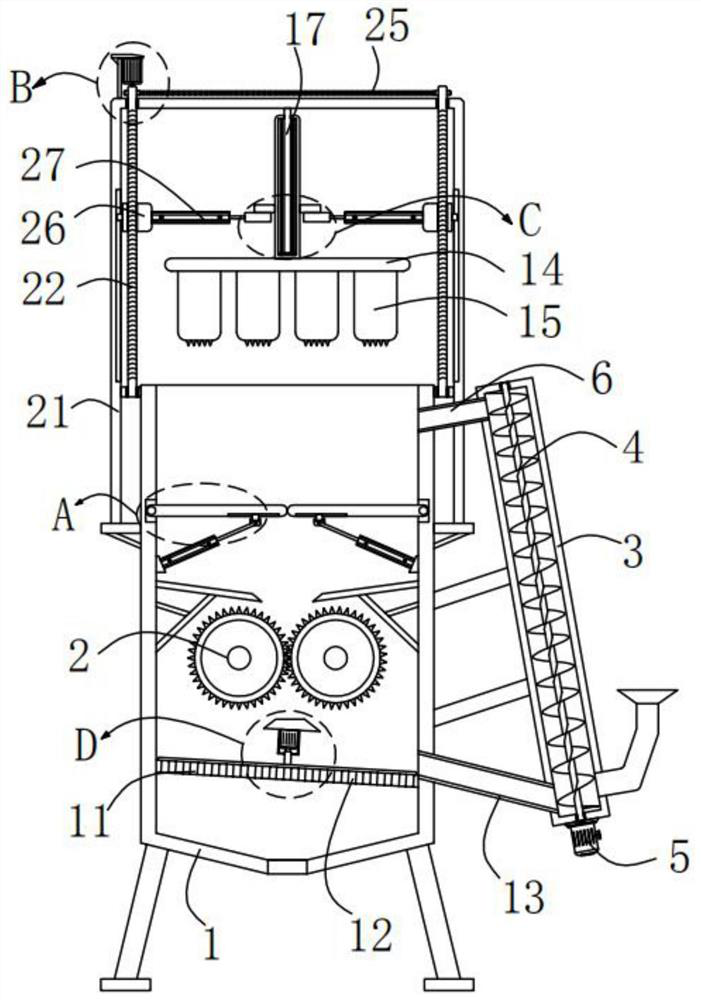

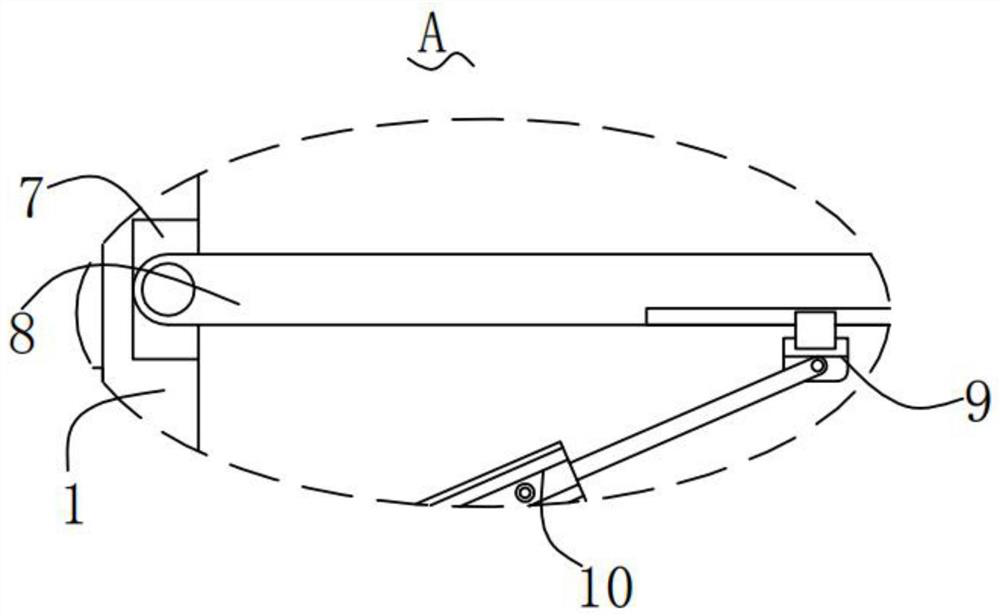

[0034] Please refer to Figure 1-Figure 5 , in the first embodiment of the present invention, the municipal construction waste circulation crushing device comprises: the processing box 1 that the top is an opening; The crushing mechanism 2, the crushing mechanism 2 is arranged in the described processing box 1; The feeding box 3, the The feeding box 3 is fixedly installed on one side outer wall of the processing box 1; the auger 4, the auger 4 is rotatably installed on the top and bottom inner wall of the feeding box 3; the motor one 5, the motor one 5 is fixedly installed on the bottom of the feeding box 3, and the output shaft of the motor one 5 is fixedly connected with the bottom end of the auger 4; the feeding pipe 6 is fixedly installed on the feeding box 3, one end of the feed pipe 6 is fixedly connected to one side of the treatment box 1; two embedding grooves 7 are provided on the inner walls of both sides of the treatment box 1; Two load-bearing plates 8, the two lo...

no. 2 example

[0046] Based on the municipal construction waste cyclic crushing device provided in the first embodiment of the present application, the second embodiment of the present application proposes another municipal construction waste cyclic crushing device. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0047] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

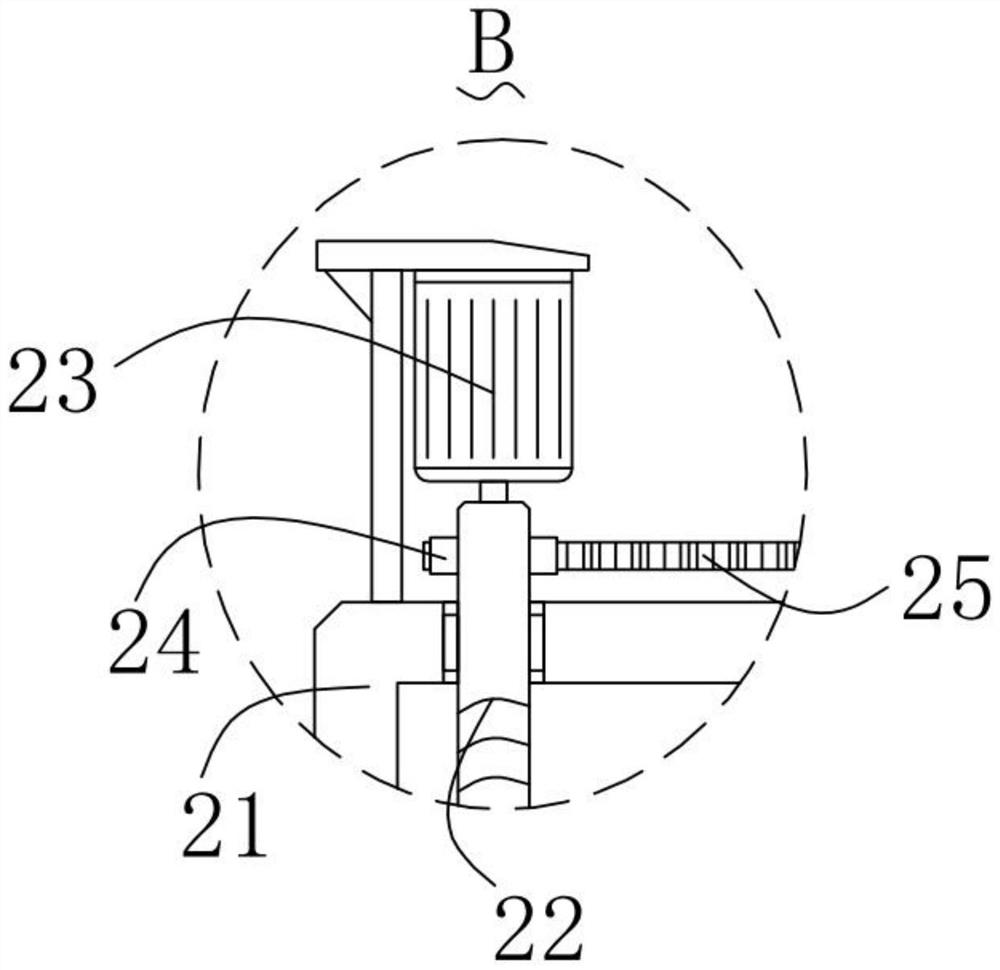

[0048] Please refer to Figure 6-Figure 8 , the municipal construction waste recycling crushing device also includes a dust removal box 32, the dust removal box 32 is arranged on one side of the treatment box 1, and one end of a dust suction pipe 33 is fixedly installed on the top of the dust removal box 32, and the suction The other end of the dust pipe one 33 extends to the top of the treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com