Patents

Literature

83results about How to "Convenient crushing work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing wheat and producing whole wheat flour by using steam blasting technology

ActiveCN103750140AAchieve primary degradationImprove digestibilityFood preparationAgricultural scienceAgricultural engineering

The invention discloses a method for processing wheat and producing whole wheat flour by using a steam blasting technology. According to the method, the wheat is subjected to steam blasting treatment, and in the steam blasting process, the temperature is controlled to be 143-180 DEG C and the pressure is controlled to be 0.4-1.9MPa, the process is maintained for 5-20min, and then the blasting is performed instantly to obtain blasting-state wheat, and the whole wheat flour is further prepared. Through processing the wheat by using the steam blasting technology, the wheat can absorb the moisture in the steam, thereby reducing the mechanical strength of wheat bran, the wheat is likely to be peeled and crushed in mutual extrusion, rubbing and collision. In addition, due to the adoption of the pressurizing high-temperature treatment, the problems that the wheat bran is rough and unsmooth, has strange odor, is difficult to digest and the like, are solved.

Owner:廊坊承泰能食品有限责任公司

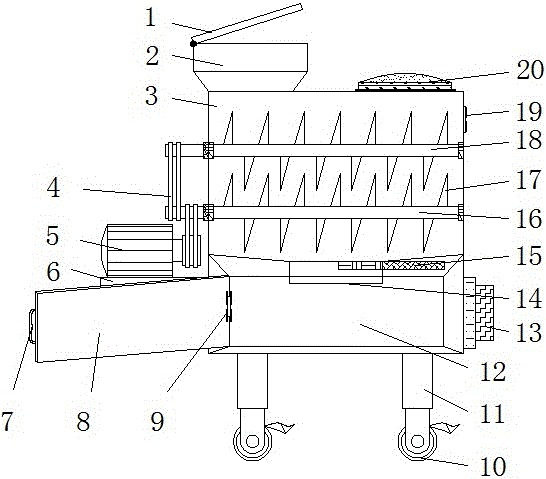

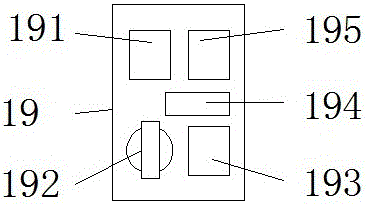

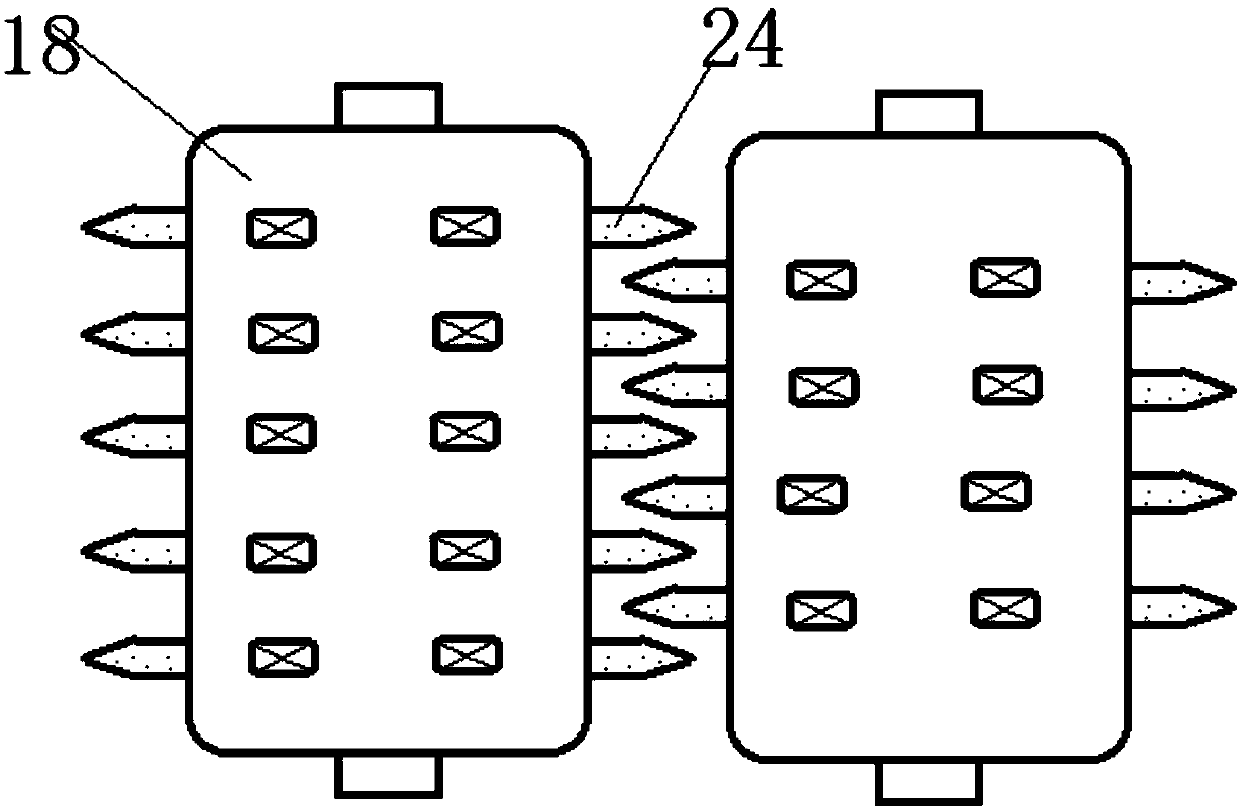

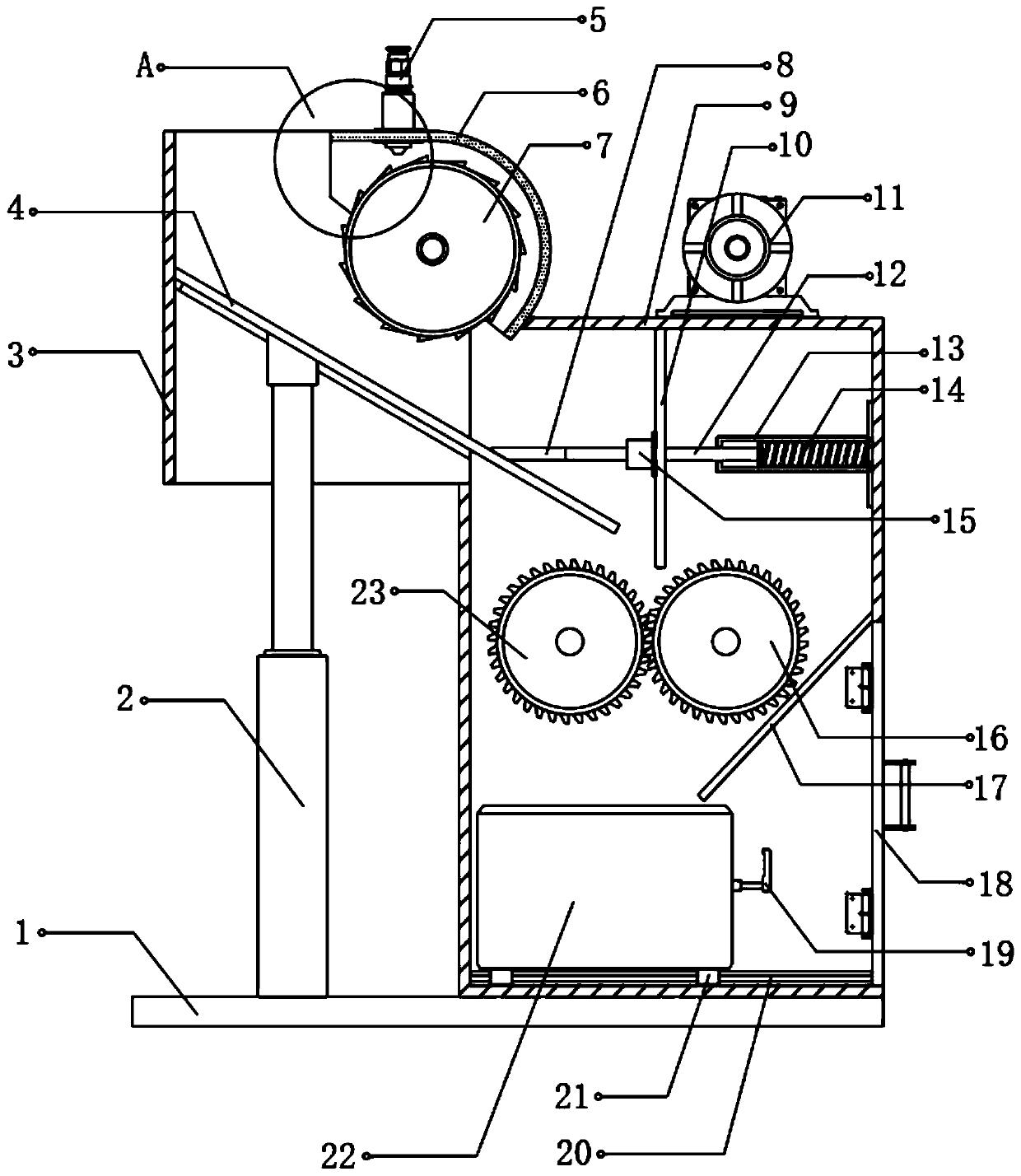

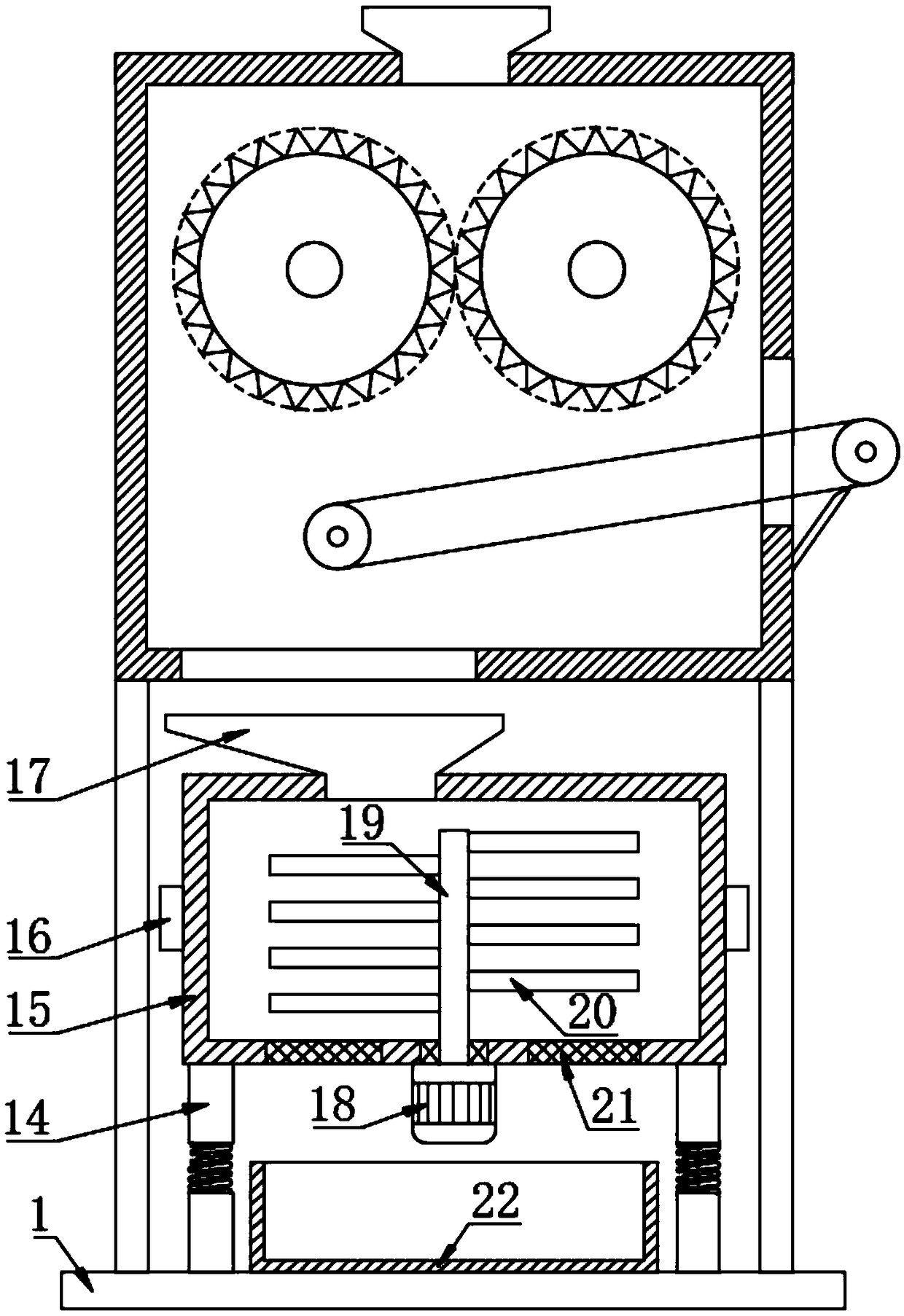

Medical waste crusher

InactiveCN106378243AImprove crushing effectEasy to transportGrain treatmentsRadiationArchitectural engineeringMedical waste

The invention discloses a medical waste crusher which comprises a shell and a waste collecting bin. The waste collecting bin is arranged at the bottom of an inner cavity of the shell. The waste collecting bin is connected with a movable door through a hinge. A handle is arranged on the outer surface of the movable door. Lifting hydraulic rods are arranged at the bottom of the outer surface of the shell. Wheels are arranged at the bottoms of the outer surfaces of the lifting hydraulic rods. A motor support is arranged at the lower end of the left side of the outer surface of the shell. A motor is arranged on the upper surface of the motor support. The motor is in transmission connection with a first crushing shaft through a belt. The first crushing shaft is in transmission connection with a second crushing shaft through a belt. Crushing teeth are arranged on the outer surface of the first crushing shaft, and crushing teeth are arranged on the outer surface of the second crushing shaft. According to the medical waste crusher, due to the fact that the two sets of crushing shafts are arranged, the crushing effect of medical waste is greatly improved, and due to the action of one set of motor, the manufacturing cost of equipment is reduced.

Owner:林丽芳

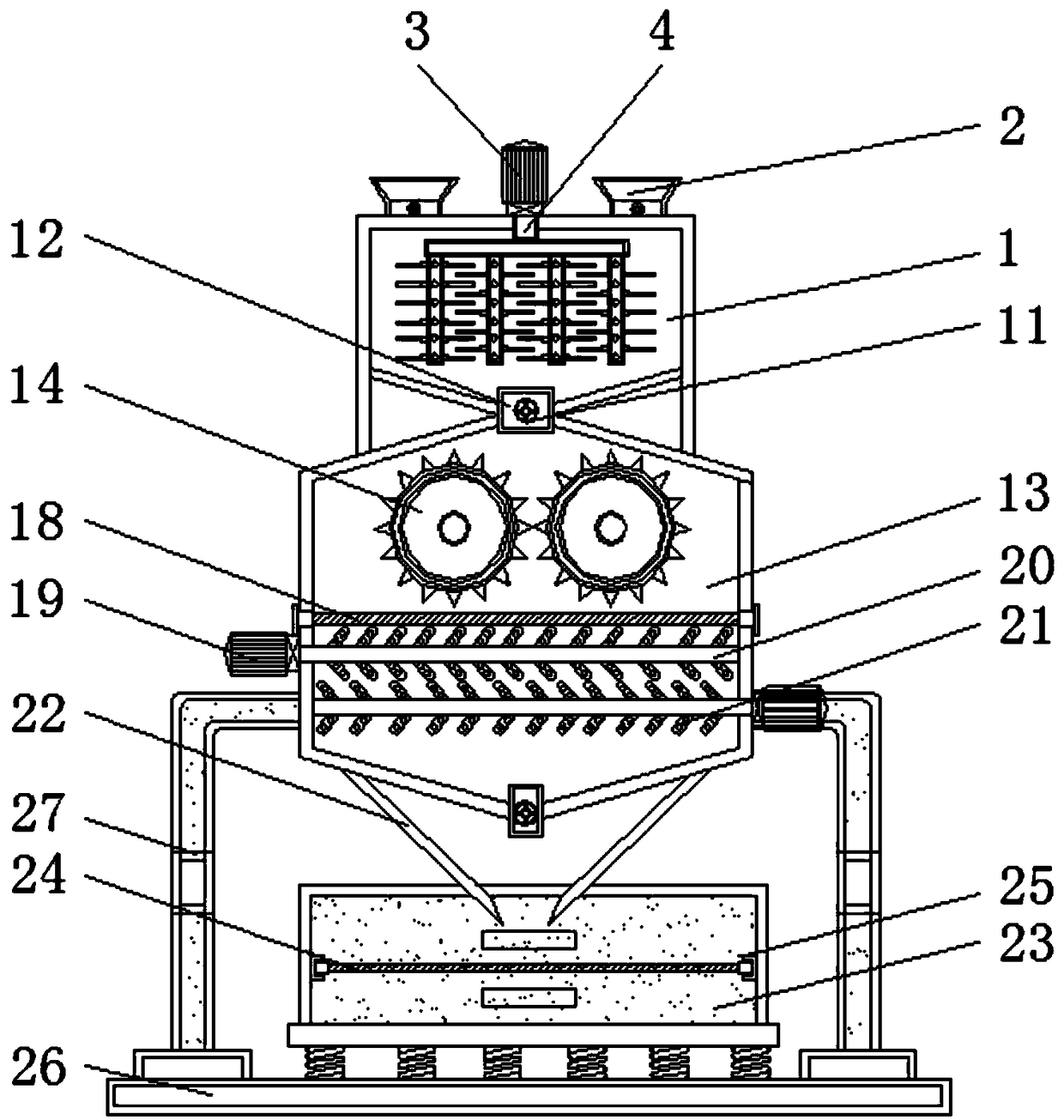

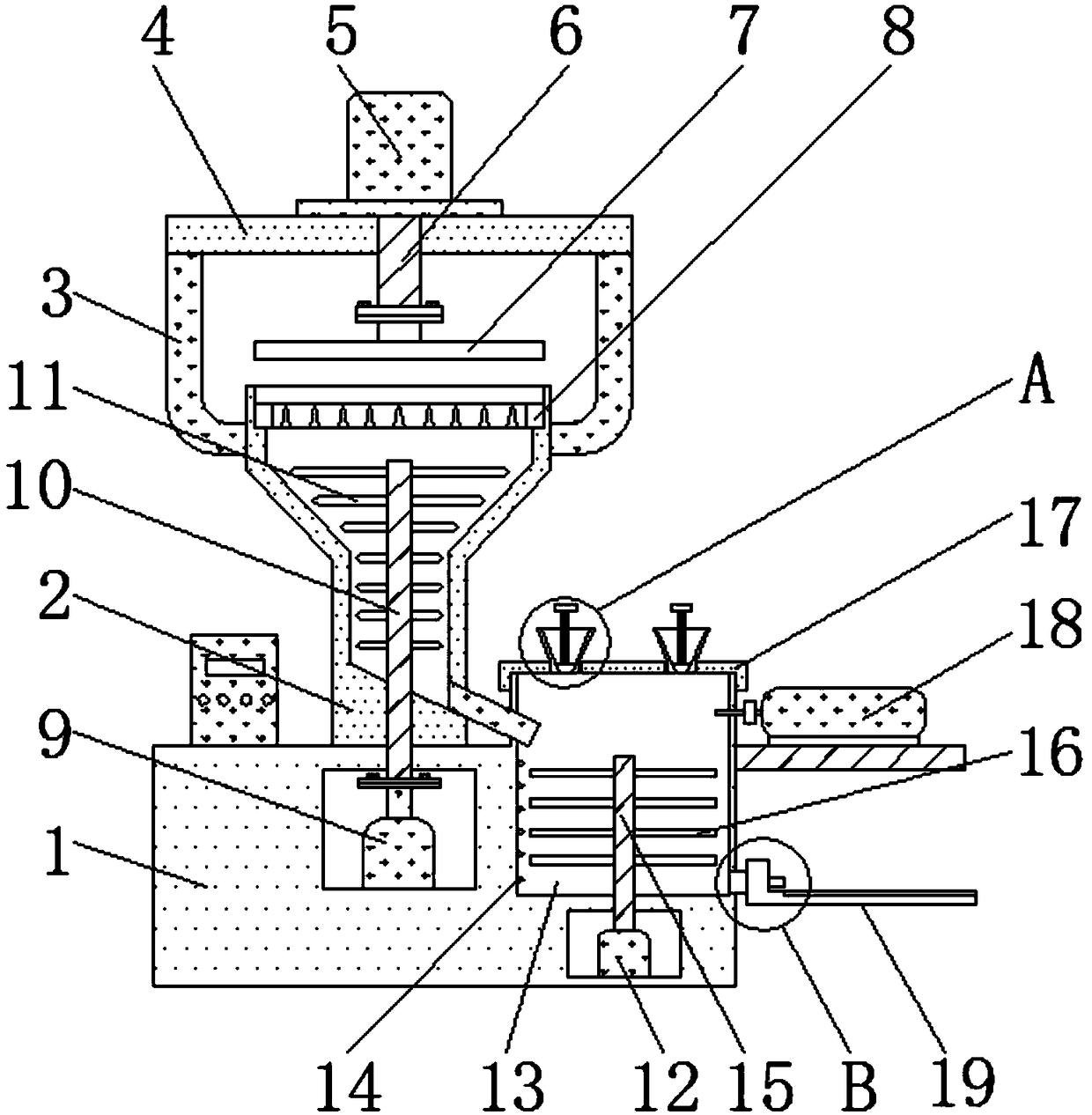

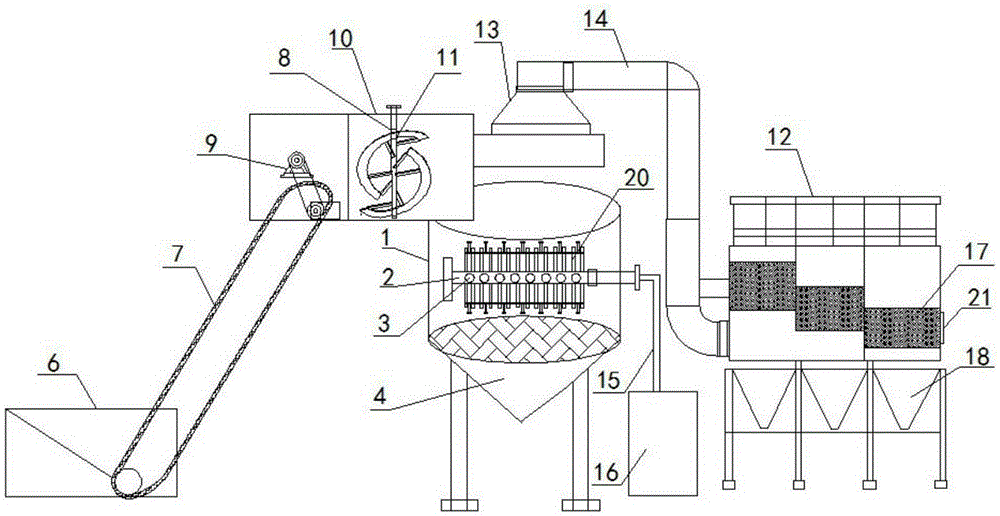

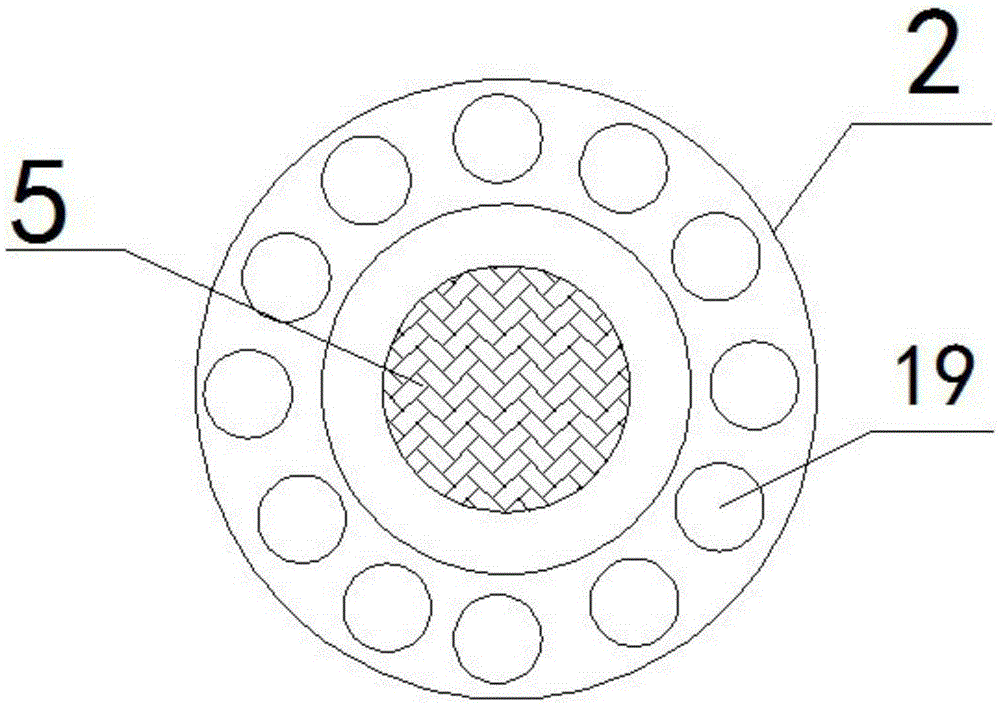

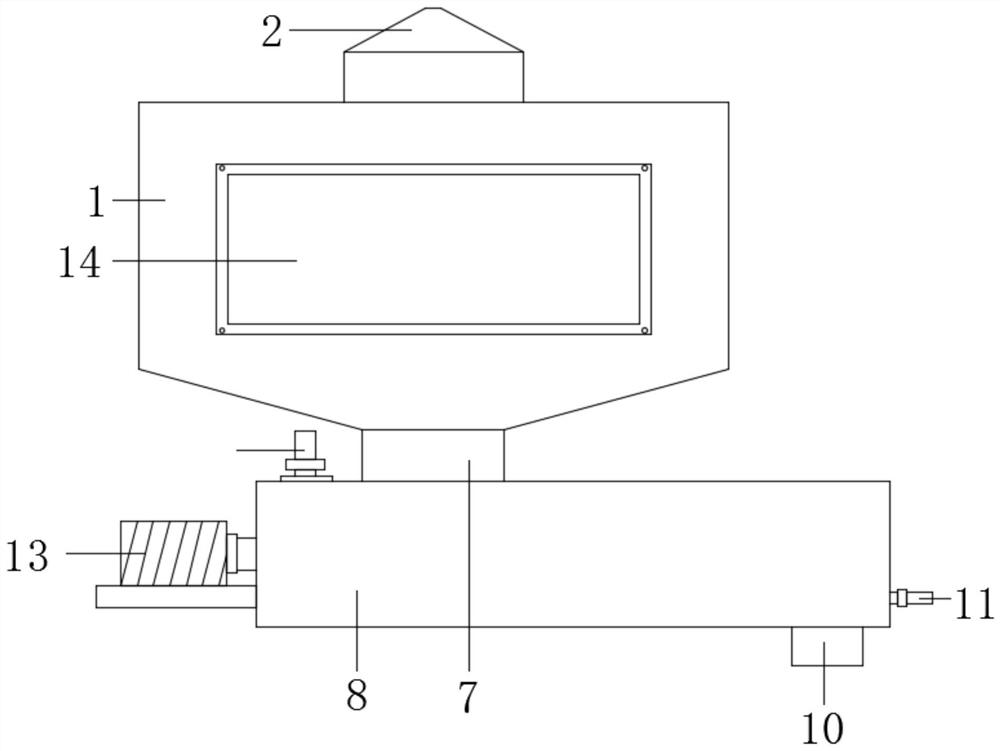

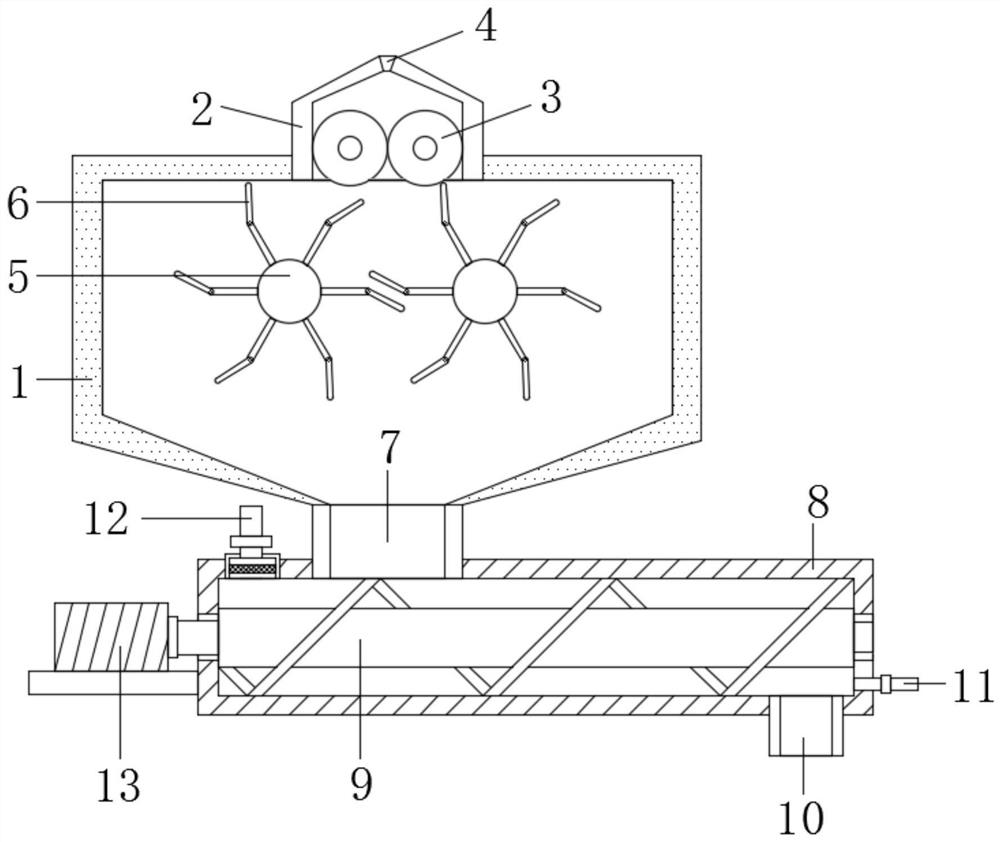

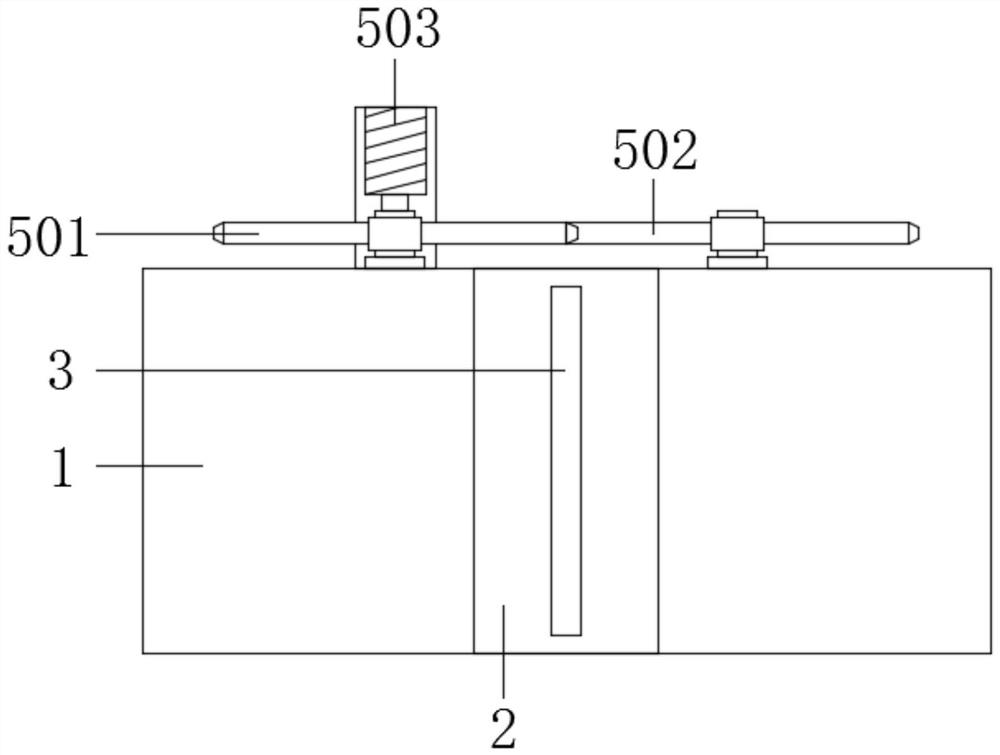

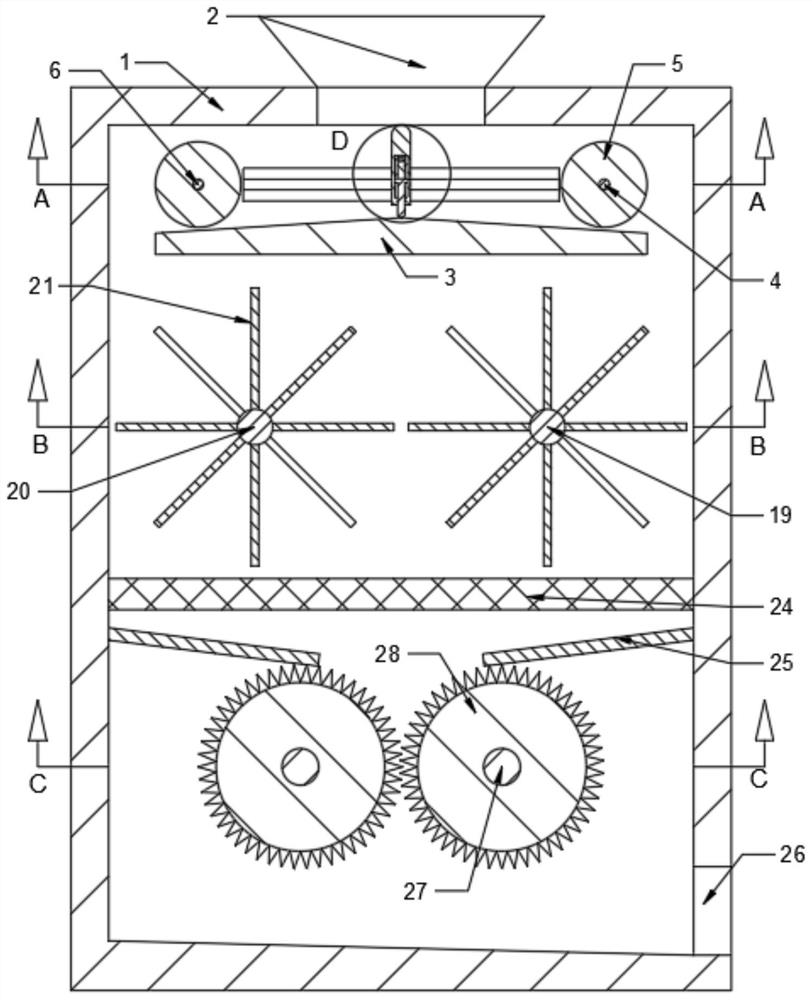

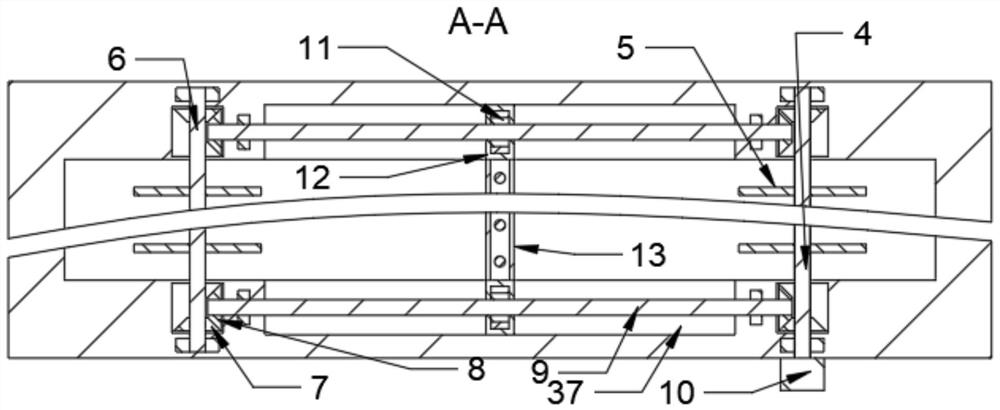

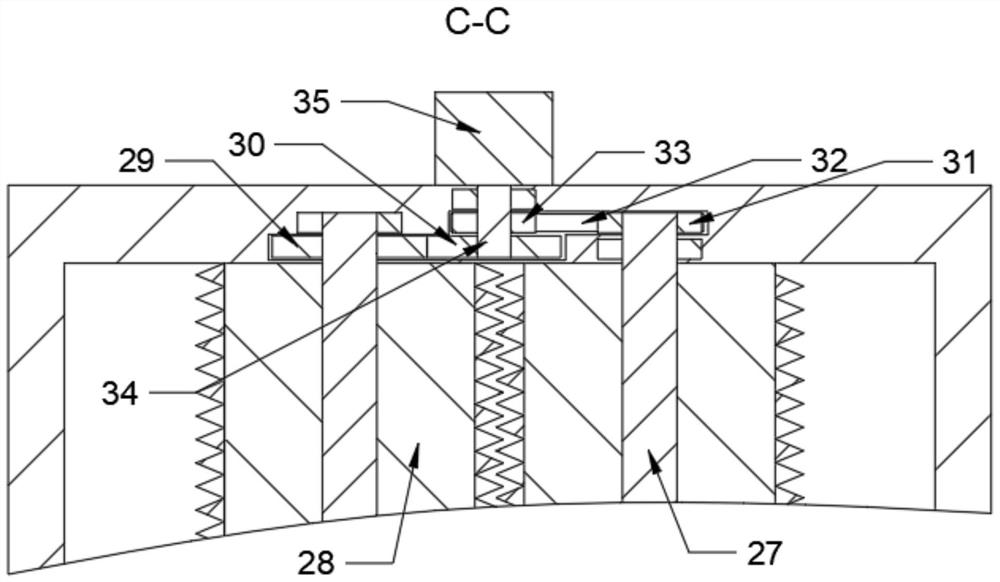

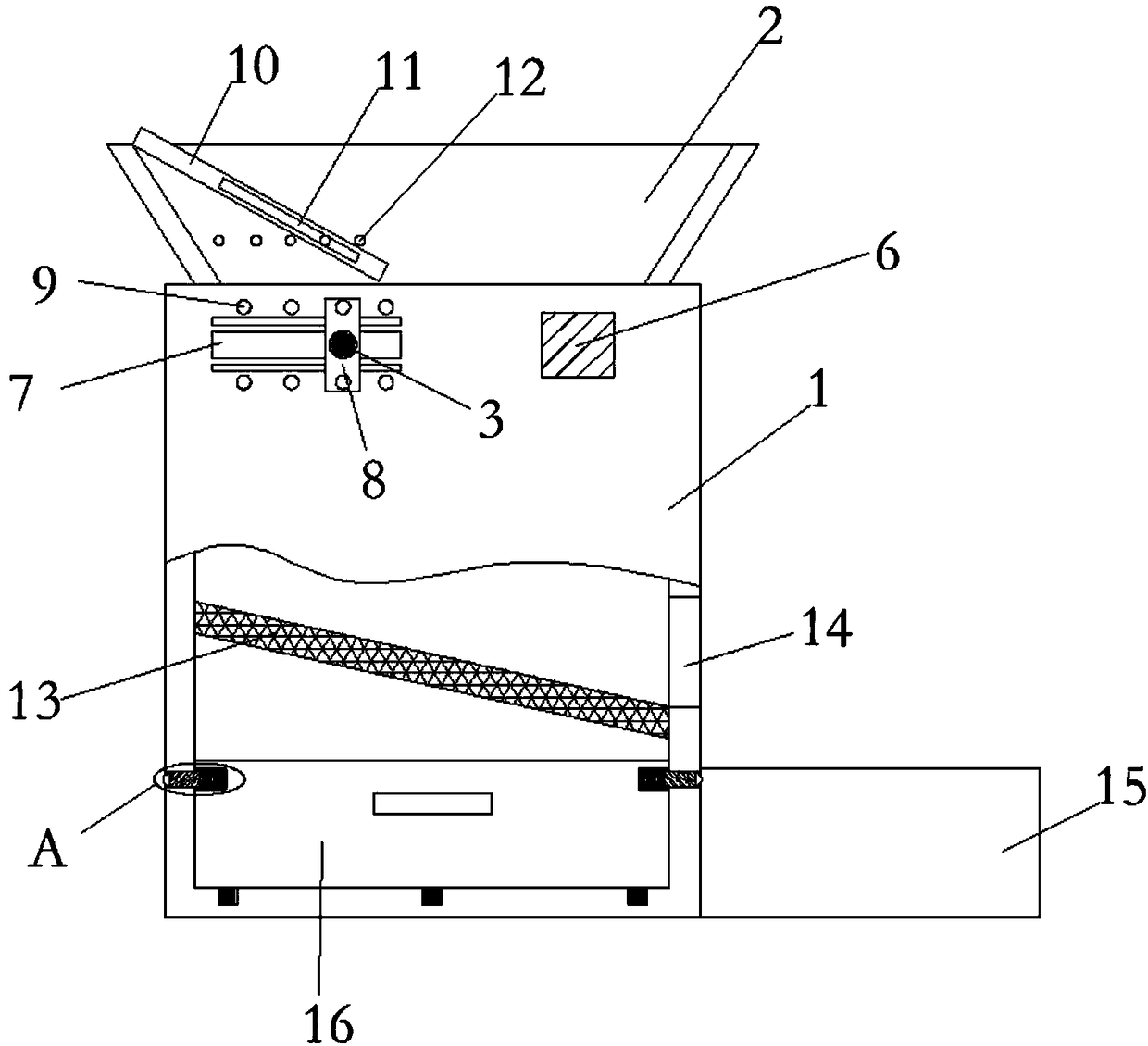

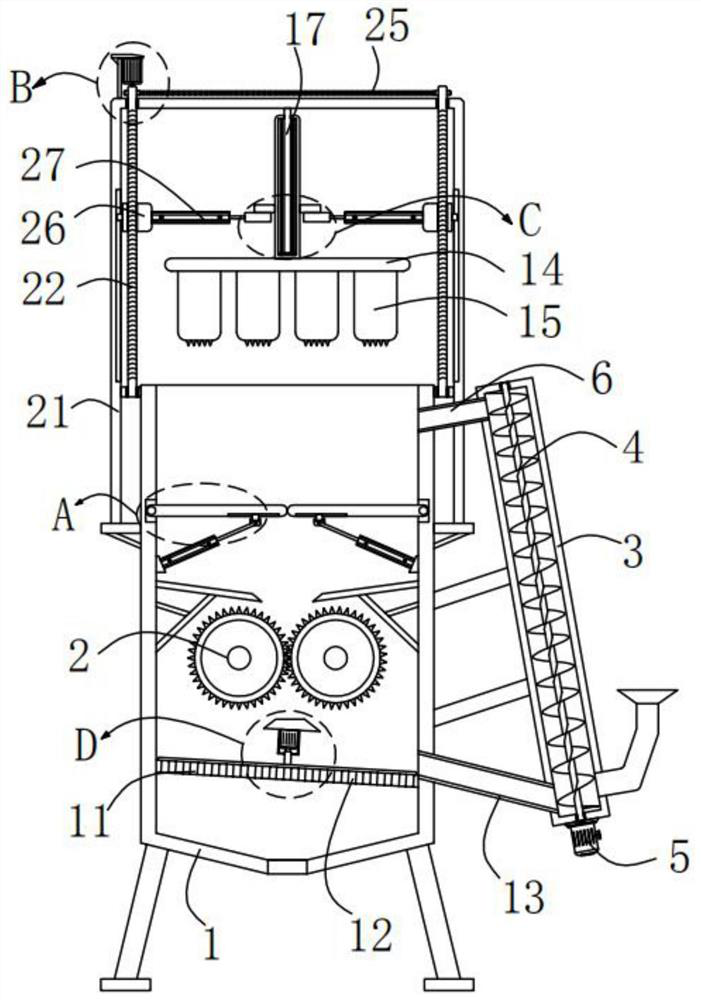

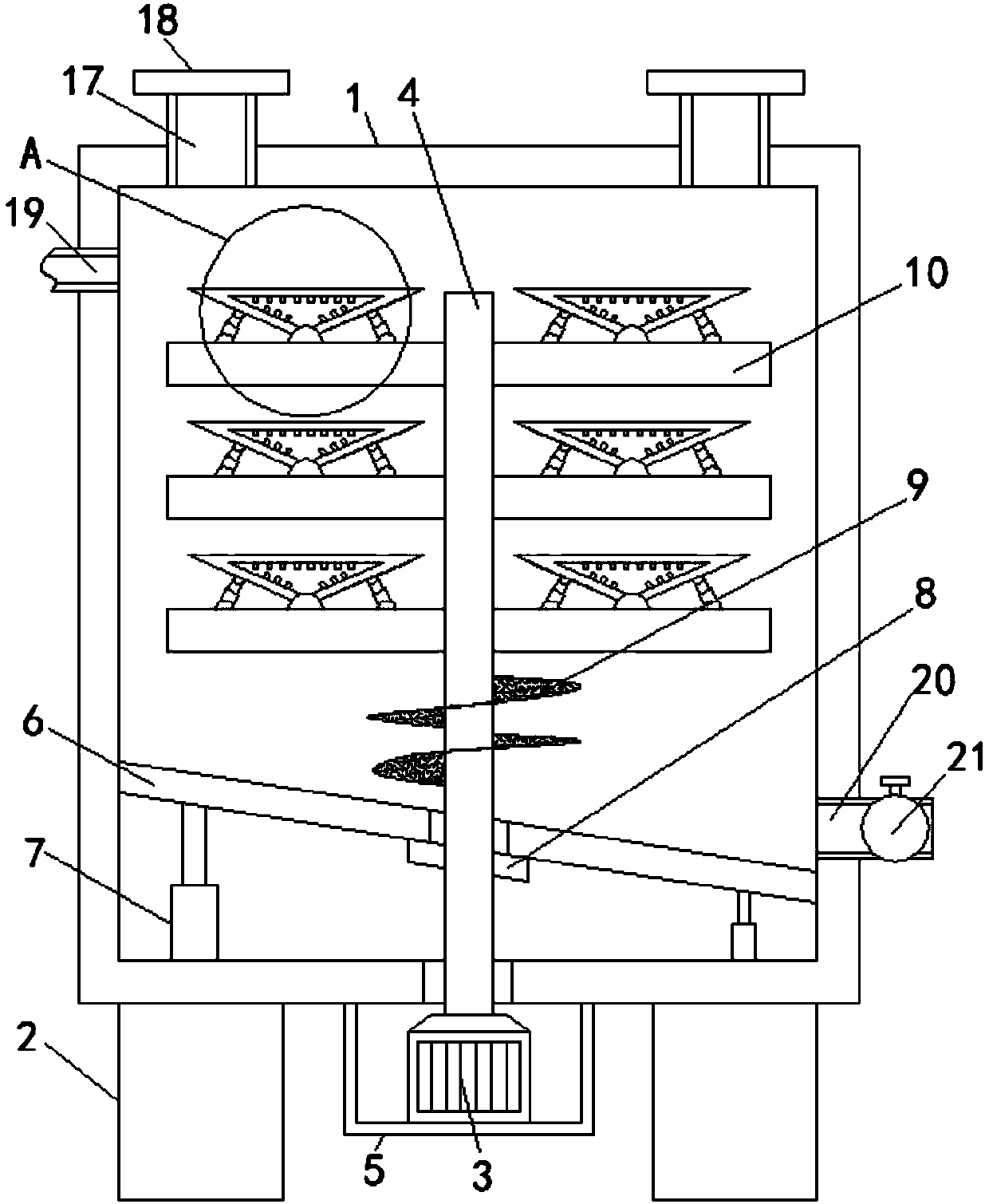

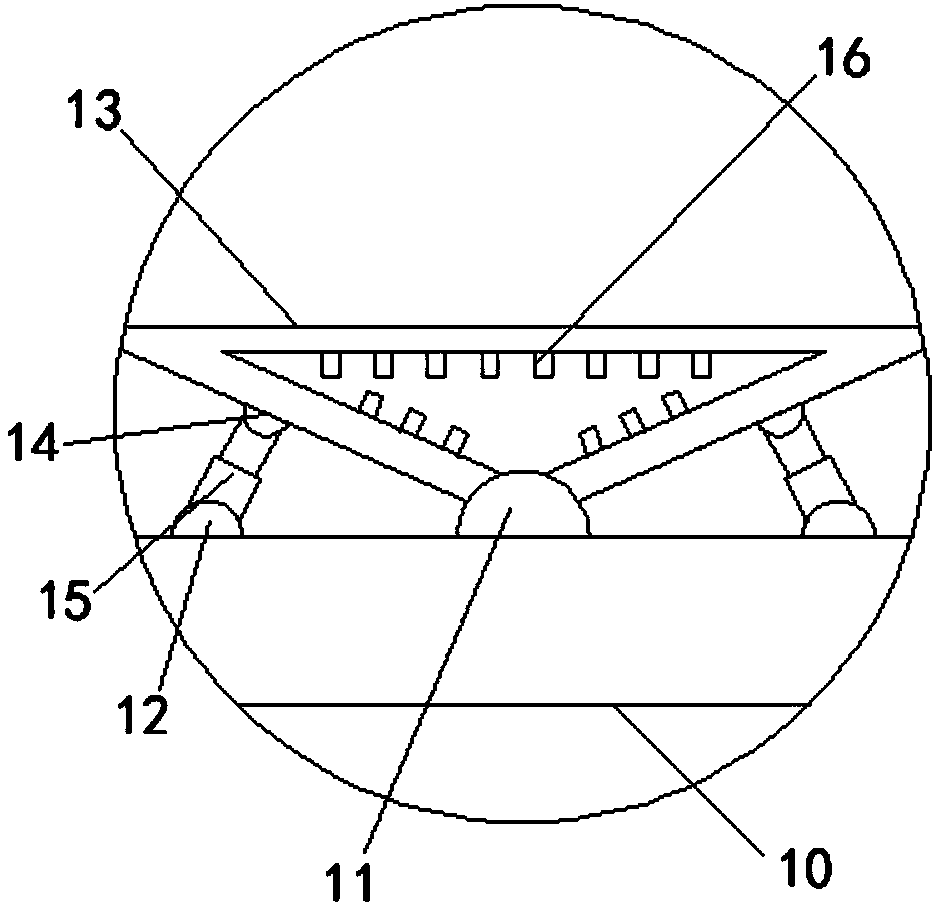

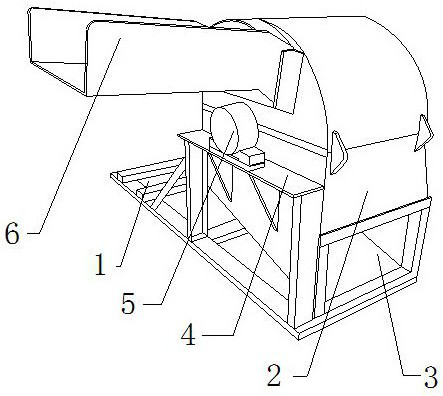

Crushing and screening integrated mine stone crusher

InactiveCN107138224AConvenient crushing workEasy to filter jobsSievingUsing liquid separation agentScreening effectCrushed stone

The invention discloses a crushing and screening integrated mine rock crusher, which comprises a screening box, a support plate is slidably connected between the top and bottom of the inner wall of the screening box, and a screen is fixedly connected between the two support plates. The bottom of the inner wall of the screening box and one side of the support plate are fixedly connected with a shaking motor, the outer surface of the output end of the shaking motor is covered with a turntable, and the side of the turntable away from the shaking motor is fixedly connected with a sliding rod. The bottom of the inner wall and one side of the shaking motor are rotatably connected to a swing plate through a connecting block. The invention relates to the technical field of mining crushing equipment. The crushing and screening integrated mine stone crusher greatly enhances the screening effect, and avoids the accumulation of crushed stones on the screen, which will cause the screen to be blocked, thus ensuring that the stone crusher can perform normal operation. Crushing and screening greatly facilitate people's ore crushing and screening work.

Owner:LIAONING TECHNICAL UNIVERSITY

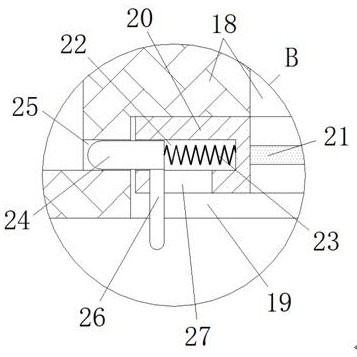

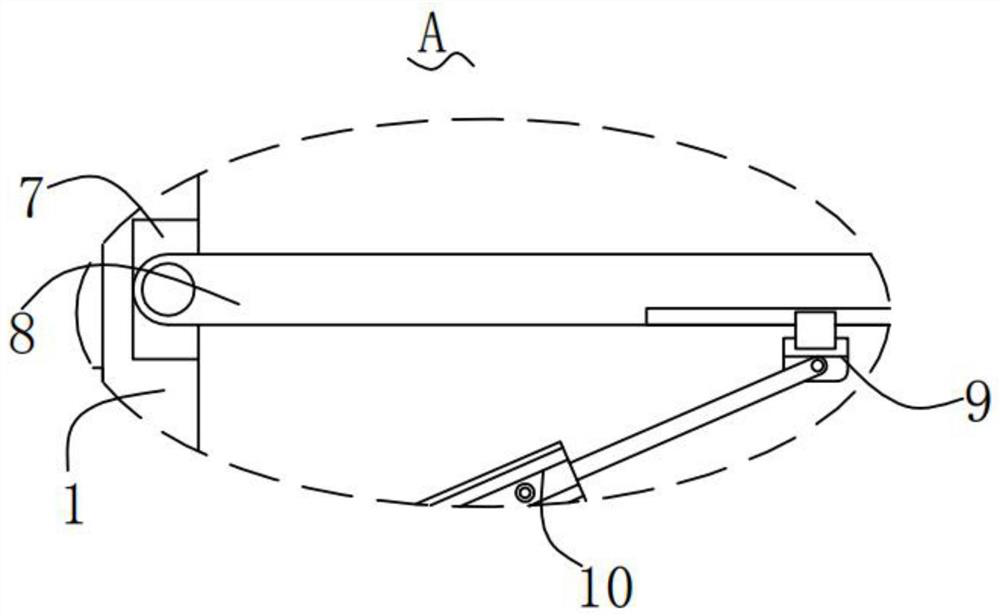

Ore crushing device with dust prevention structure for mine mining

InactiveCN109078737AImprove work efficiencyEasy to useNon-rotating vibration suppressionGrain treatmentsCrushed stoneDrive motor

The invention discloses an ore crushing device with a dust prevention structure for mine mining. The ore crushing device with the dust prevention structure for mine mining comprises a first crushing cavity, a second crushing cavity, a filter plate, a flowing guide dust prevention plate and a filter screen. A feeding port is formed in the upper end of the first crushing cavity, a second rotary shaft is connected to the output end of a second driving motor, the filter plate is mounted in the second crushing cavity, discharging ports are formed in the lower ends of the first crushing cavity and the second crushing cavity, and valves are mounted on the surfaces of the discharging ports. The head and tail ends of the filter screen are connected with the inner wall of a material collecting box through mounting blocks, and a damping device is mounted between supporting frames. According to the ore crushing device with the dust prevention structure for mine mining, a main position rod can be driven to rotate in the function of driving motors, a first time of striking and stirring for crushed stone is facilitated, so that the crushed stone generates cracks, each surface of the crushed stonecan be struck completely, so that convenience is brought for the subsequent crushing working, and the improvement of the working efficiency of ore crushing is facilitated.

Owner:张艳

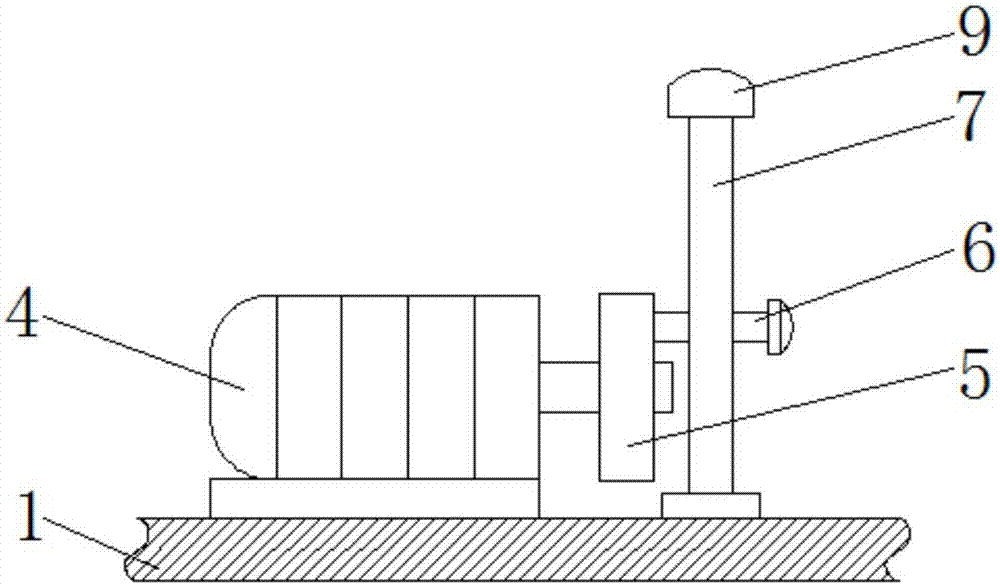

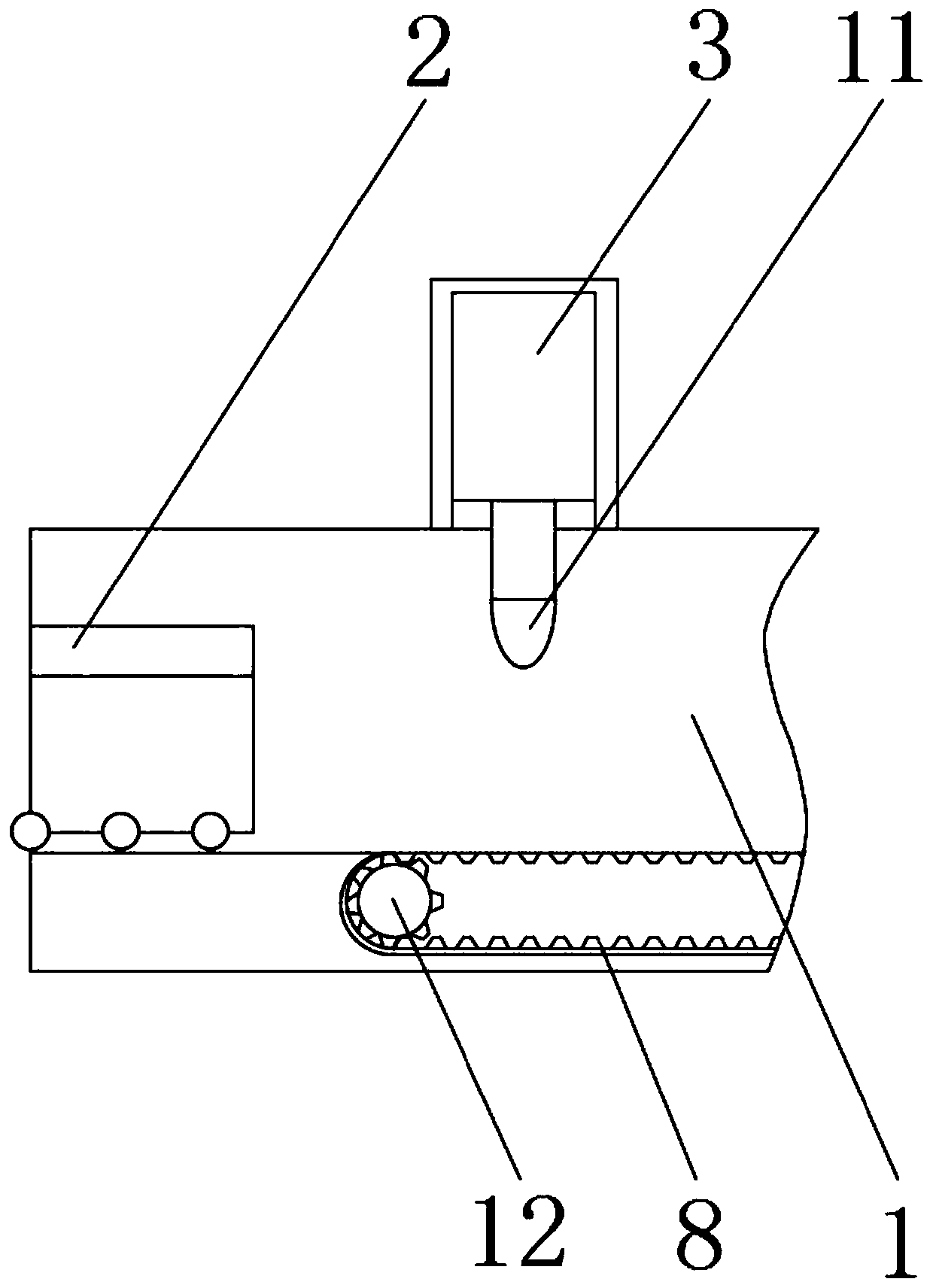

Automatic pork sausage filling machine

InactiveCN108308248AAvoid stickingRealize masteringSausage filling/stuffing machinesMeat mixing apparatusHydraulic cylinderPork meat

The invention discloses an automatic pork sausage filling machine. The automatic pork sausage filling machine comprises a first casing and a first driving machine; a second casing is arranged at an upper left end of the first casing; supporting rods are connected to both sides of the second casing; a roof plate is arranged above the supporting rods; a hydraulic cylinder is installed above the roofplate at the middle; switching gates are installed both at front sides of the first driving machine and a second driving machine; a movable rod is arranged inside a feeding hopper; a sealing plug isconnected to a lower end of the movable rod; a second material outlet is arranged on the right side of a placing plate; a groove is arranged at a lower right part of the second material outlet, and isformed in advance at an upper right part of the placing plate; and a cutting knife is connected to the interior of a mounting plate. The automatic pork sausage filling machine is capable of cutting pork into pieces in advance so as to effectively avoid blockage inside the machine; moreover, the automatic pork sausage filling machine integrates pork crushing, seasoning stirring and sausage filling, and is capable of adding seasonings at quantitative amounts so as to realizing rapid filling of sausages.

Owner:钱松元

Efficient and safe gravel crushing device

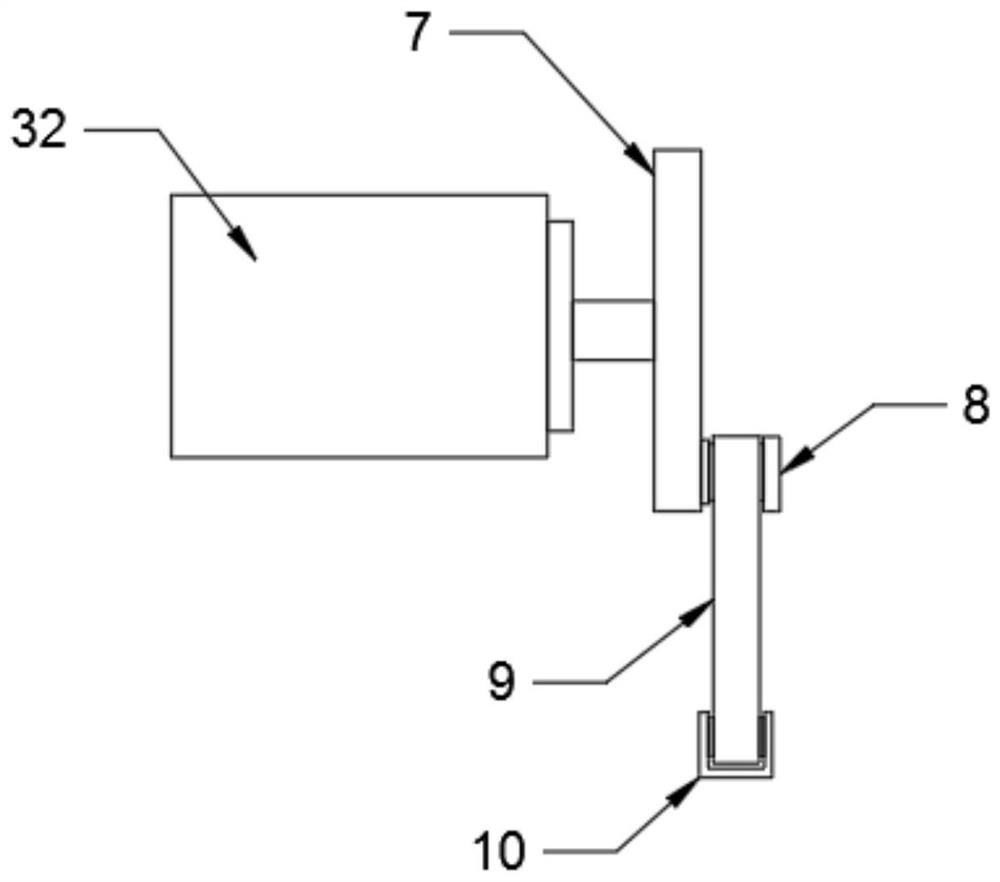

InactiveCN107626427AAvoid cloggingAvoid clogging some telescoping rod adjustmentsDirt cleaningGrain treatmentsEngineeringDust particles

The invention discloses an efficient and safe gravel crushing device comprising a guide wheel, a box, telescopic rods, pressure bearing plates, baffles, a flow meter, a water inlet pipe, a sprayer, acamera, a feeding pipe, a crushing device, a discharging pipe, an inclined guide plate and a motor. A guide wheel is arranged at the bottom face of the box. The feeding pipe is arranged at the top endof the box. The camera is arranged on the inner wall of the top end of the box. The crushing device is arranged in the damping plate. The motor is arranged below the crushing device. Pressure bearingplates are arranged on the two sides of the crushing device. The pressure bearing plates are connected with the side walls of the box through the telescopic rods. The baffles are arranged on the upper sides of the pressure bearing plates. The inclined guide plate is arranged on the lower side of the crushing device. The lowest end of the inclined guide plate is provided with the discharging pipe.The water inlet pipe communicates with the upper end of the box. The sprayer is arranged at the outlet end of the water inlet pipe. The flow meter is installed on the water inlet pipe. The efficientand safe gravel crushing device can conveniently crush gravel of different sizes, lowers the high temperature in time and prevents aging, the service life of the efficient and safe gravel crushing device is prolonged, the concentration of dust particles is reduced, and the efficient and safe gravel crushing device is simple in structure, convenient to use and beneficial for popularization.

Owner:刘晓菊

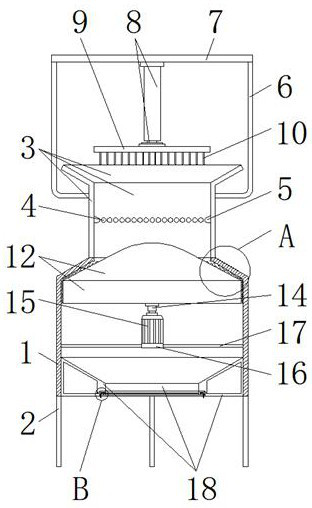

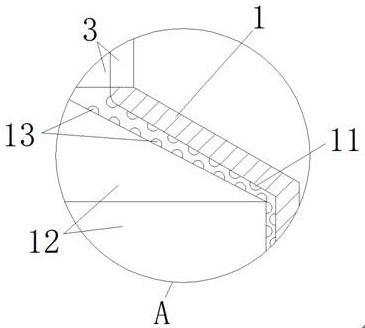

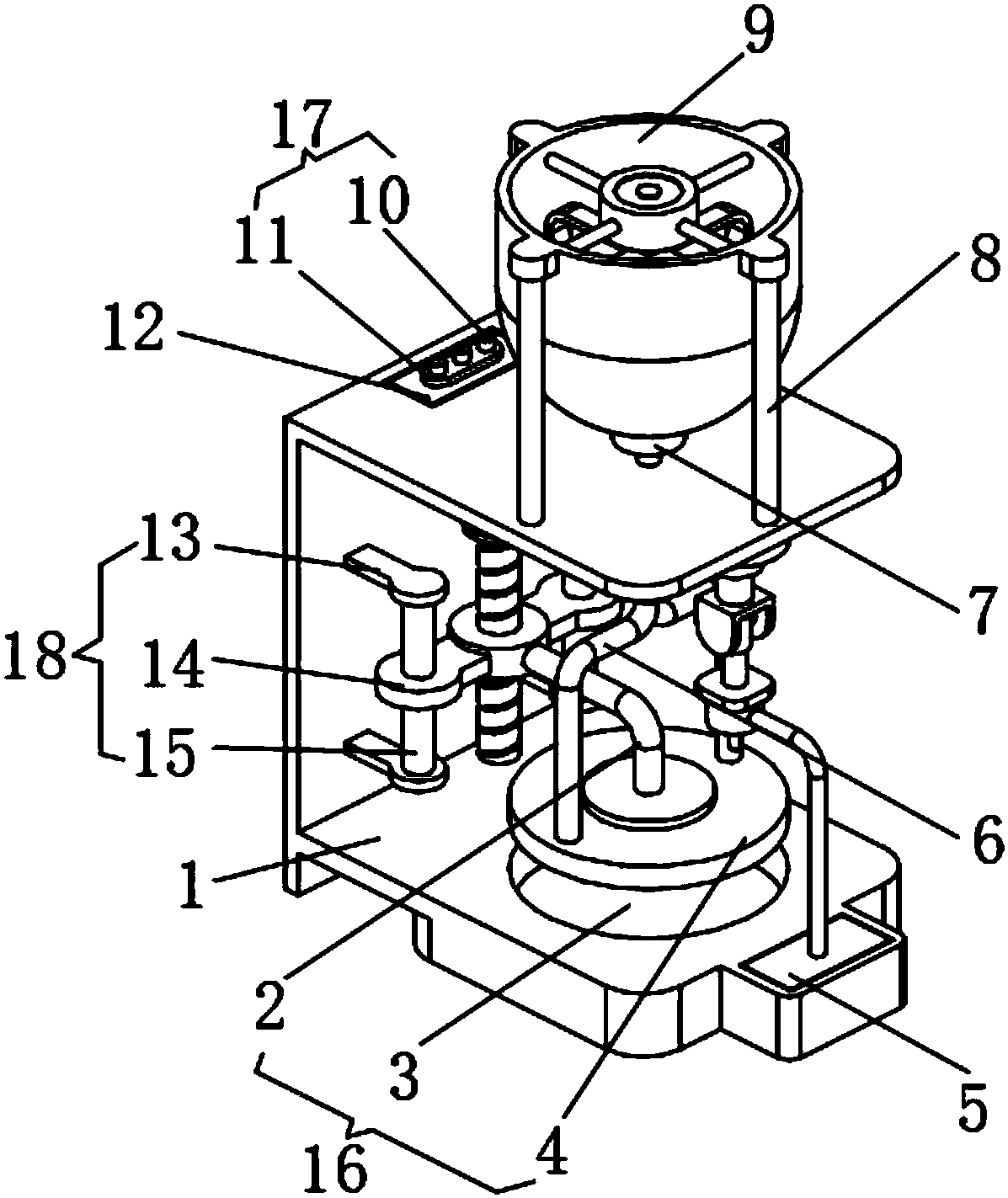

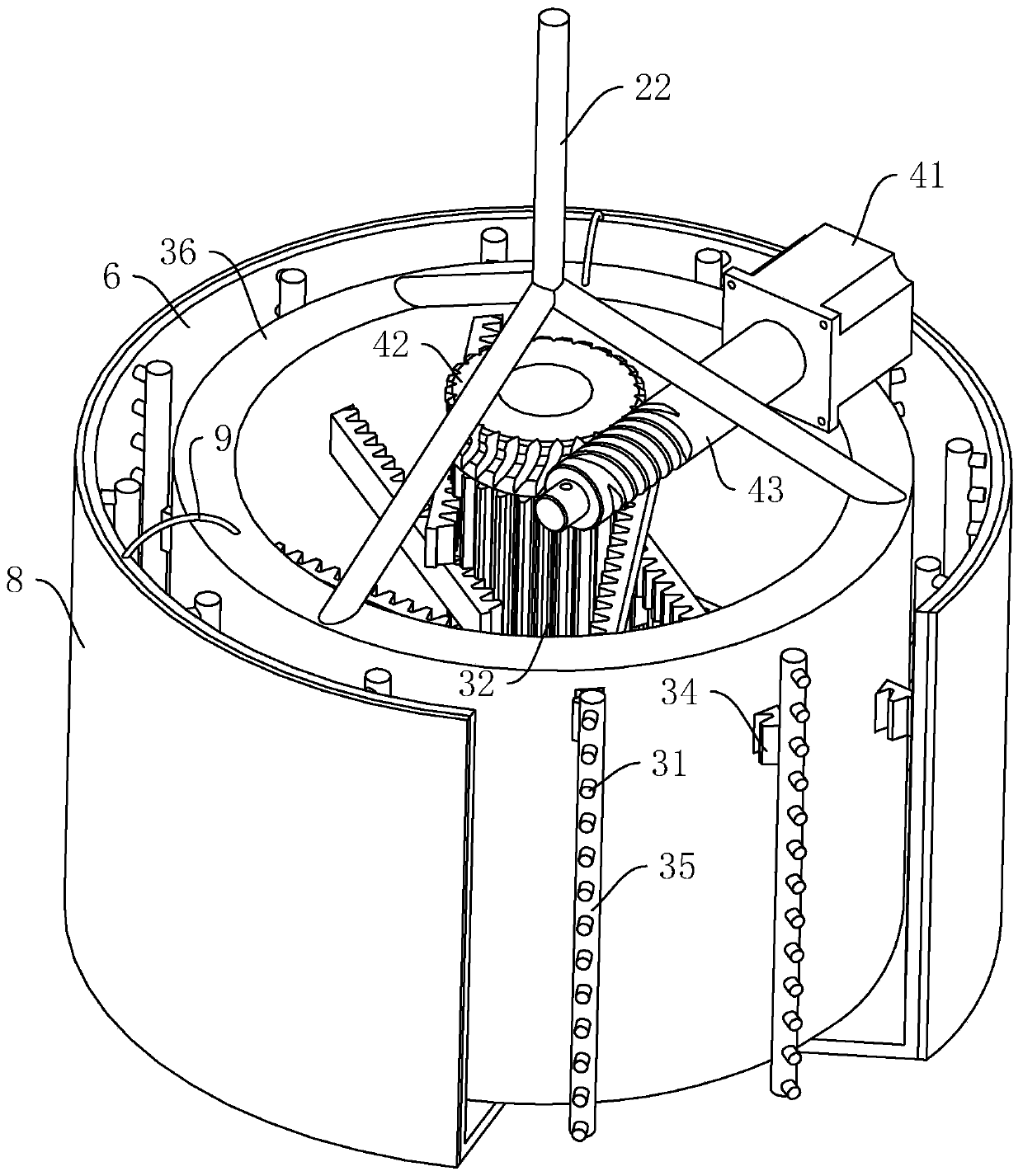

Agricultural saline-alkali land treatment device

InactiveCN111686848AAvoid falling intoConvenient crushing workSoil lifting machinesGrain treatmentsAlkali soilAgricultural engineering

The invention discloses an agricultural saline-alkali land treatment device which comprises a storage bucket, supporting columns, fixed rods, a rotary shaft, a servo motor and a filtering plate. The supporting columns are welded and fixed to the bottom face of the storage bucket, and a feeding bucket is welded and fixed to the top face of the storage bucket. A first fixed shaft and a second fixedshaft are welded and fixed to the inner wall of the feeding bucket. The fixed rods are welded and fixed to the outer surface of the feeding bucket, and a first grinding block is fixedly mounted on theinner wall of the top end of the storage bucket. A grinding disc is mounted in the top end of the storage bucket. According to the agricultural saline-alkali land treatment device, smashed gypsum canslide onto a filtering plate to be filtered through a fixed frame, and the gypsum can be filtered and screened conveniently; and after overall machining work is completed, debris can be stacked on the filtering plate, a sleeve ring and the filtering plate can be demounted through stirring of a stirring rod, the filtering plate can be cleaned or replaced conveniently, and the convenience of overall operation is improved.

Owner:王䶮飞

Solid waste crushing device

InactiveCN105327738AReasonable designImprove work efficiencyGrain treatmentsMechanical equipmentHigh pressure

The invention belongs to the technical field of mechanical equipment and discloses a solid waste crushing device which comprises a crusher body, crushing blades, a discharge opening and a rotating shaft. The crushing blades are arranged on the rotating shaft. The crushing blades and the rotating shaft are mounted in the crusher body. The solid waste crushing device is provided with a cutting chamber. Cutting blades are mounted in the cutting chamber and arranged on a cutting rotating shaft. The cutting chamber is connected with a feed opening through a conveying device. High-pressure nozzles are arranged on the rotating shaft and communicated with a waste reservoir through a connecting pipeline. The connecting pipeline is arranged in the rotating shaft which is a hollow pipe. Rolling balls are arranged between the rotating shaft and the connecting pipeline. The solid waste crushing device is reasonable in design, high in automation degree and high in market popularization value.

Owner:重庆睿容环保科技有限公司

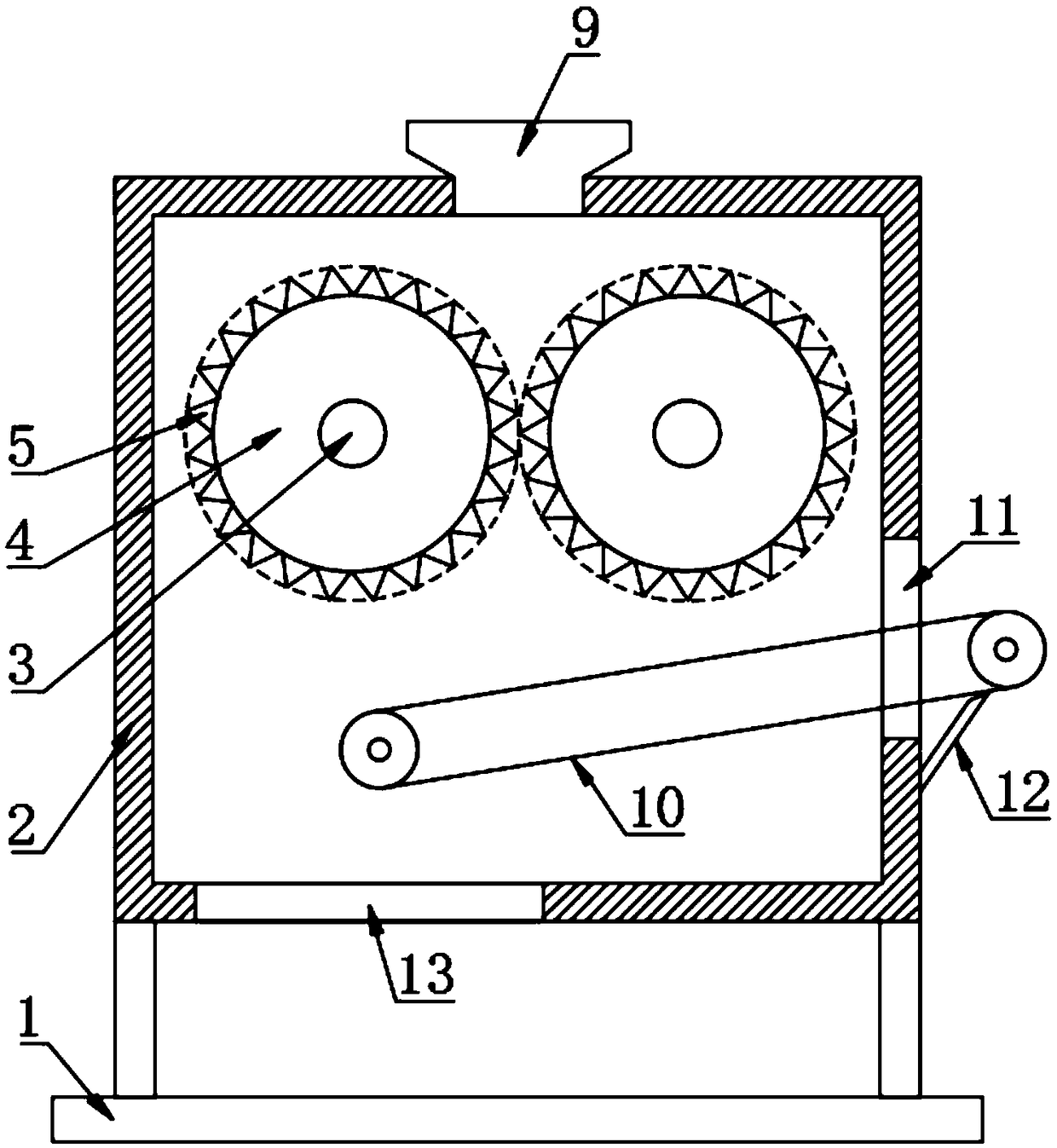

Waste recovery device for automotive interior trim production

ActiveCN111195999AReduce volumeImprove crushing effectPlastic recyclingGrain treatmentsScrapWaste recovery

The invention discloses a waste recovery device for automotive interior trim production. The waste recovery device comprises a base. One side of the top of the base is fixedly connected with a box, and the top of one side of the box is in bolted connection with a feeding barrel. The inner wall of the middle of the feeding barrel is fixedly connected with a discharging plate, and the bottom of thedischarging plate extends into the box. In the use process, the distance between waste and a crushing roller is gradually reduced in the process that the waste slides down from the discharging plate,the waste can be extruded sufficiently, the waste sizes can be reduced effectively, and subsequent further crushing work is facilitated; by means of crushing teeth on the surface of the crushing roller, the pressure intensity applied to the waste can be increased, and the crushing effect can be optimized; and an air pipe joint is connected to an air supply system, airflow is blown to the crushingroller through a spray head, scraps adhering to the surface of the crushing roller are cleared away, the waste with the sizes reduced falls between a driving roller and a driven roller, and the wasteis subjected to crushing treatment of the next step through engaged blades.

Owner:临朐县大地汽车零部件有限公司

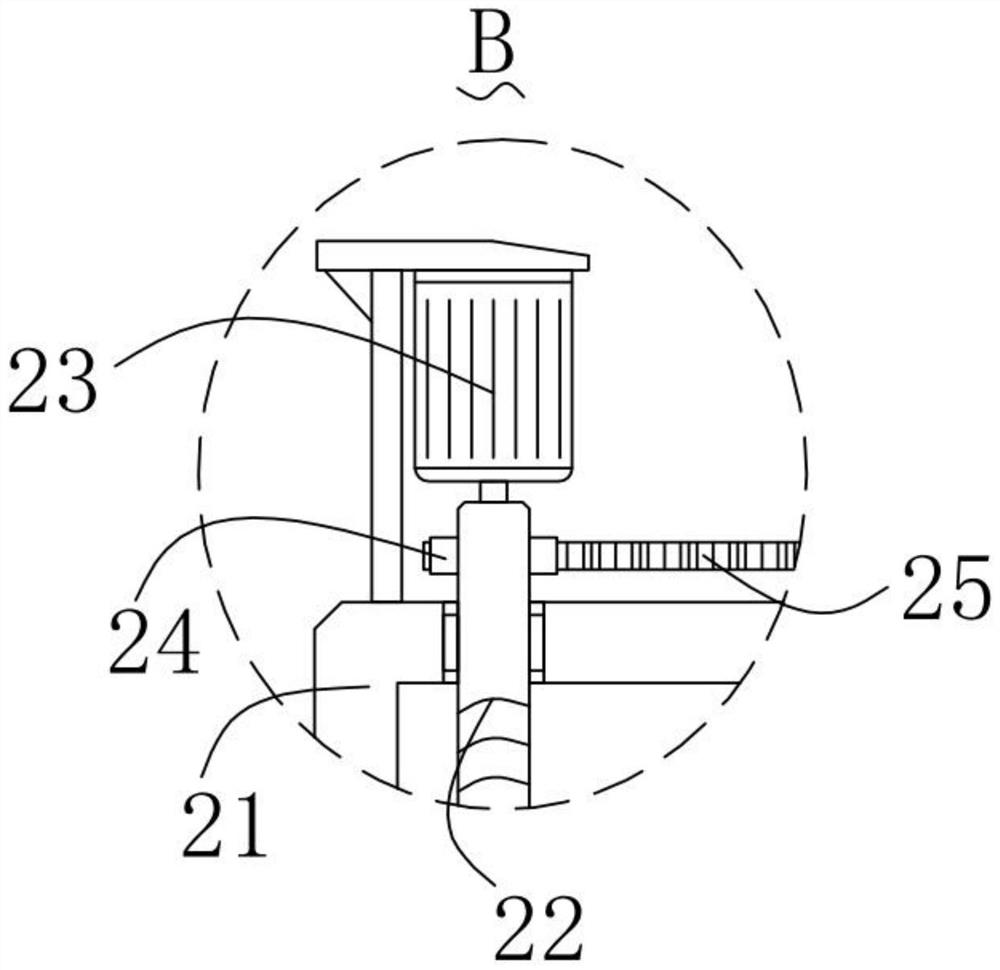

Intelligent environmental protection construction crusher

InactiveCN111389497AEnsure personal safetyAvoid splashing stonesCombination devicesGrain treatmentsElectric machinerySmart control

The invention provides an intelligent environmental protection construction crusher. The intelligent environmental protection construction crusher includes a crusher frame, an intelligent control switch, supporting legs, a crushing powder diversion pipe, a crushing motor, a driving belt wheel, a double groove plane belt wheel, a driving wheel shaft, a driving broken sawtooth gear, a single grooveplane belt wheel, a driven wheel shaft, a driven crushing sawtooth gear, a V-shaped transmission belt, a V belt and a stone anti-splash inlet adjusting baffle structure. According to the intelligent environmental protection construction crusher, through the arrangement of a stone anti-splash baffle, an inlet adjustable plate, a fixed seat, a stone to be crushed guide pipe, a connecting seat and aninlet size adjusting rod, avoiding the problem of stone splashing when crushing is facilitated, the personal safety of operators is ensured, by stretching and adjusting the inlet size adjusting rod,the inlet adjustable plate can act inside the fixed seat, and the inlet size can be changed; and the stone anti-splash baffle plays a side protection role to avoid stone splashing, and the stone diversion can be carried out through the stone to be crushed guide pipe so as to facilitate the work of crushing stones

Owner:丁金旺

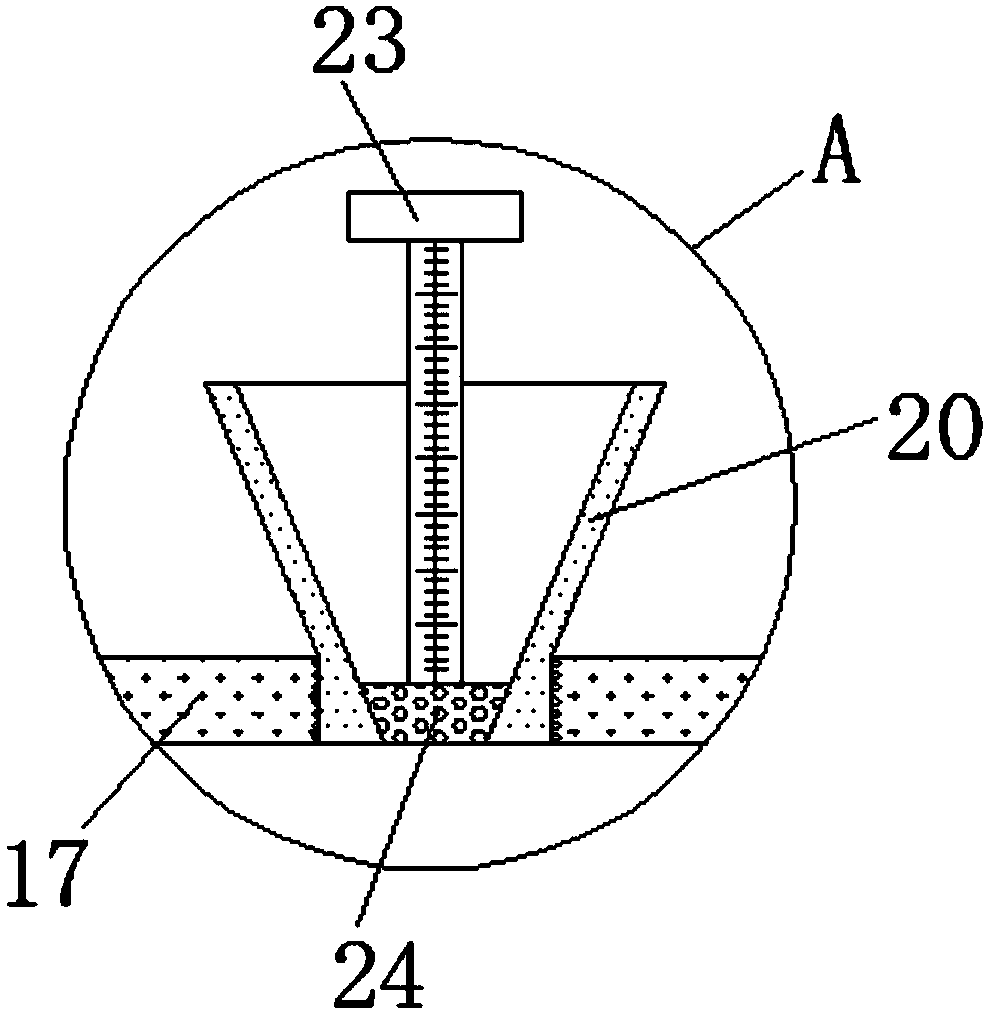

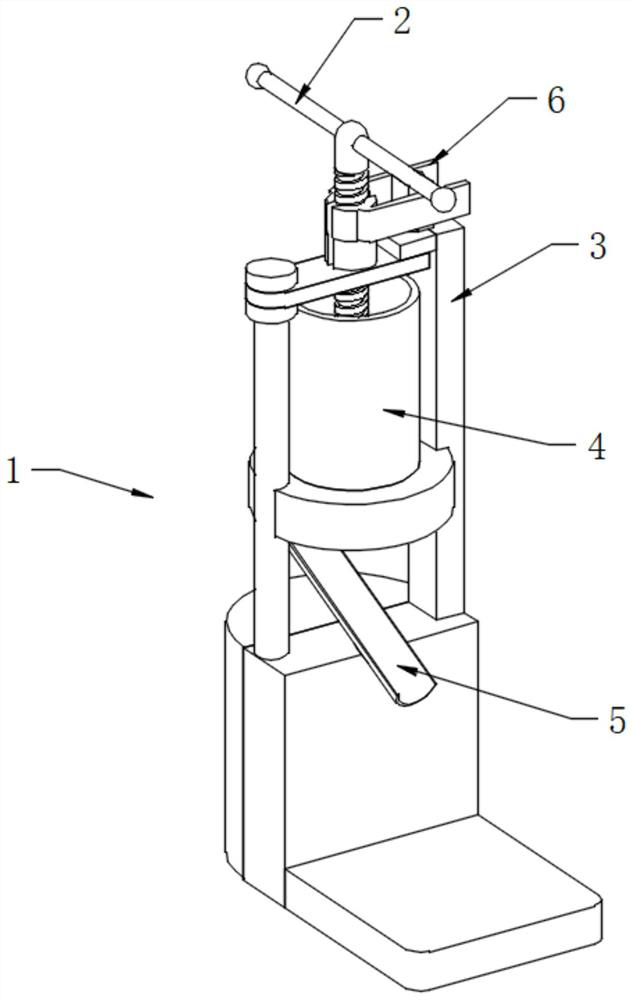

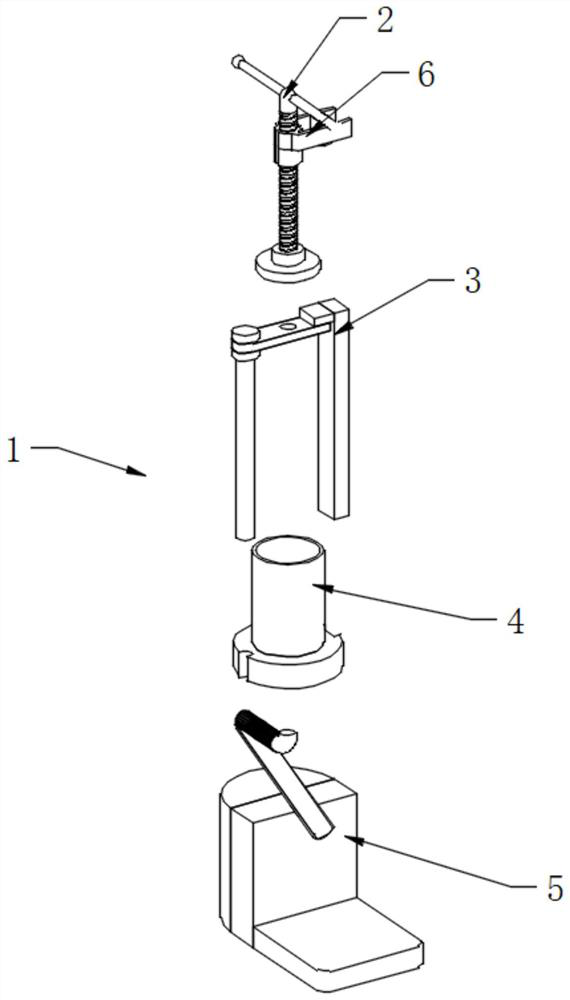

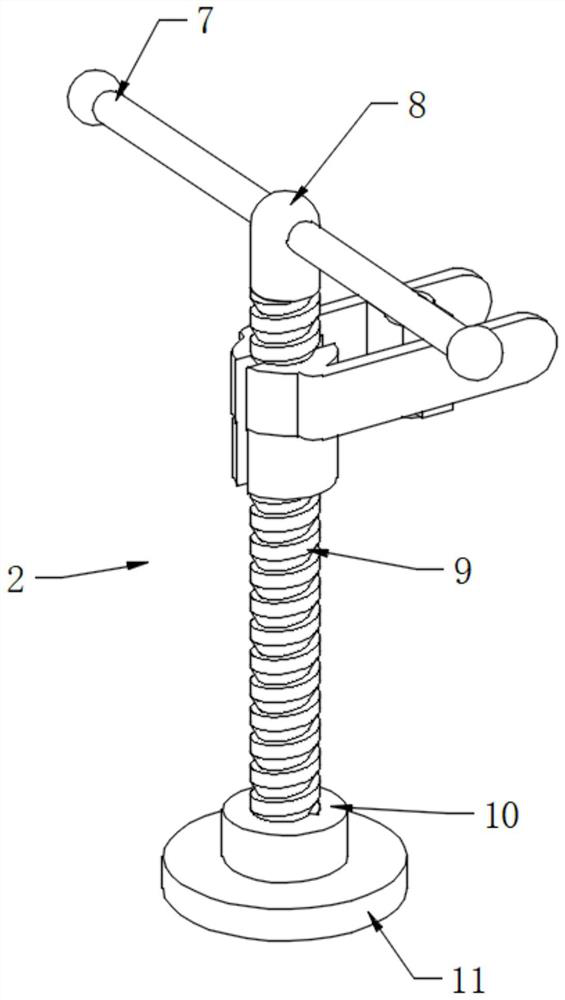

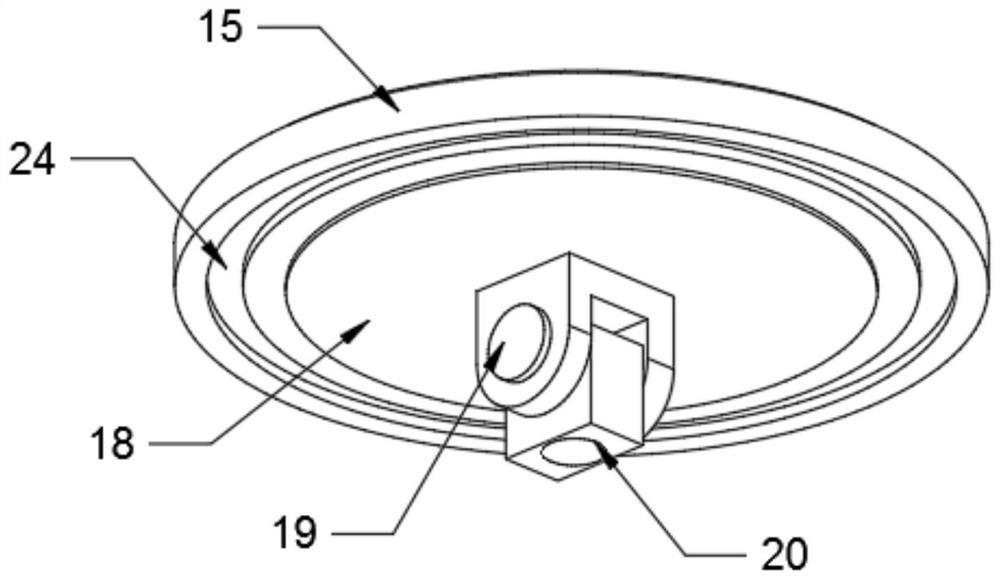

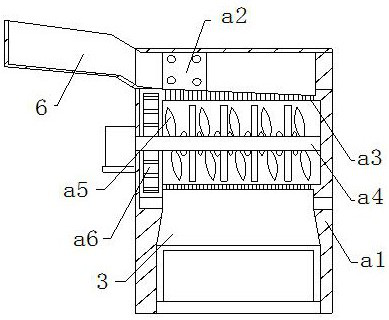

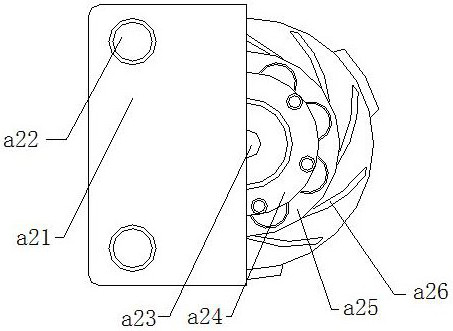

Fruit crushing device for beverage processing

InactiveCN112060661AConvenient crushing workConvenient processing workJuice extractionPress ramBiotechnologySliding contact

The invention discloses a fruit crushing device for beverage processing. The fruit crushing device for beverage processing comprises a fruit crushing structure. The fruit crushing structure comprisesan operation main body, an operation frame, a crushing main body, a solid-liquid separation main body and a control main body, the middle of the operation main body is installed at the inner end of the control main body in a threaded manner, and the lower portion of the operation main body makes sliding contact with the crushing main body. The lower portion of the operation main body is located onthe inner side of the crushing main body, the operation main body is inserted into the inner end of the upper portion of the operation frame in a sliding manner, the lower end of the operation frameis fixedly installed at the upper end of the solid-liquid separation main body, and the outer end of the crushing main body is fixedly installed at the inner end of the upper portion of the operationframe. The upper end of the solid-liquid separation main body and the crushing main body are fixedly installed together, and the internal space of the crushing main body communicates with the upper space of the solid-liquid separation main body. According to the fruit crushing device for beverage processing, juicing work can be directly carried out after crushing, slag can be automatically discharged, and the use requirement can be better met.

Owner:绍兴市上虞裕润农业科技有限公司

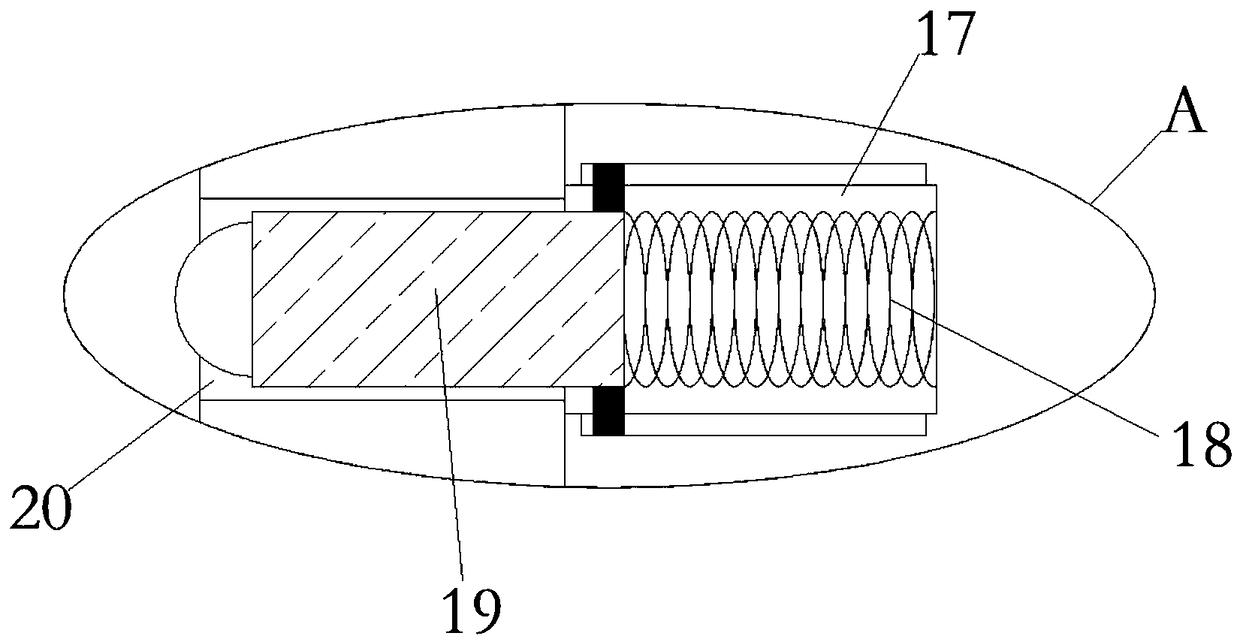

Environment-friendly wet paper shredder

PendingCN111701688AImprove wear resistanceIncrease elasticityTransportation and packagingMixersProcess engineeringMechanical engineering

The invention discloses an environment-friendly wet paper shredder. The environment-friendly wet paper shredder comprises a paper shredding device main body; a feeding cavity is formed in the center of the top of the paper shredding device main body; guide rollers are symmetrically arranged on the left side and the right side of the inner cavity of the feeding cavity; a feeding hole is formed in the center of the top of the feeding cavity; crushing rollers are symmetrically arranged on the left side and the right side of the inner cavity of the paper shredding device main body; crushing teethare fixedly mounted on the outer walls of the crushing rollers; a material falling hole is formed in the bottom of the paper shredding device main body; a soaking mixing tank is arranged at the bottomof the material falling hole; a spiral stirring roller is horizontally arranged in the inner cavity of the soaking mixing tank; a discharging hole is formed in the right side of the bottom of the soaking mixing tank; a water drainage pipe is arranged on the left side of the top of the soaking mixing tank; a water inlet pipe is arranged at the bottom of the right side wall of the soaking mixing tank; and a driving motor is arranged on the left side of the soaking mixing tank. According to the environment-friendly wet paper shredder, the problems that the existing waste paper recycling effect is not very ideal, first, the crushing effect is poor when waste paper is shredded, and second, both the soaking effect and efficiency are not very high when the paper is soaked are solved.

Owner:新沂市北沟镇福利厂

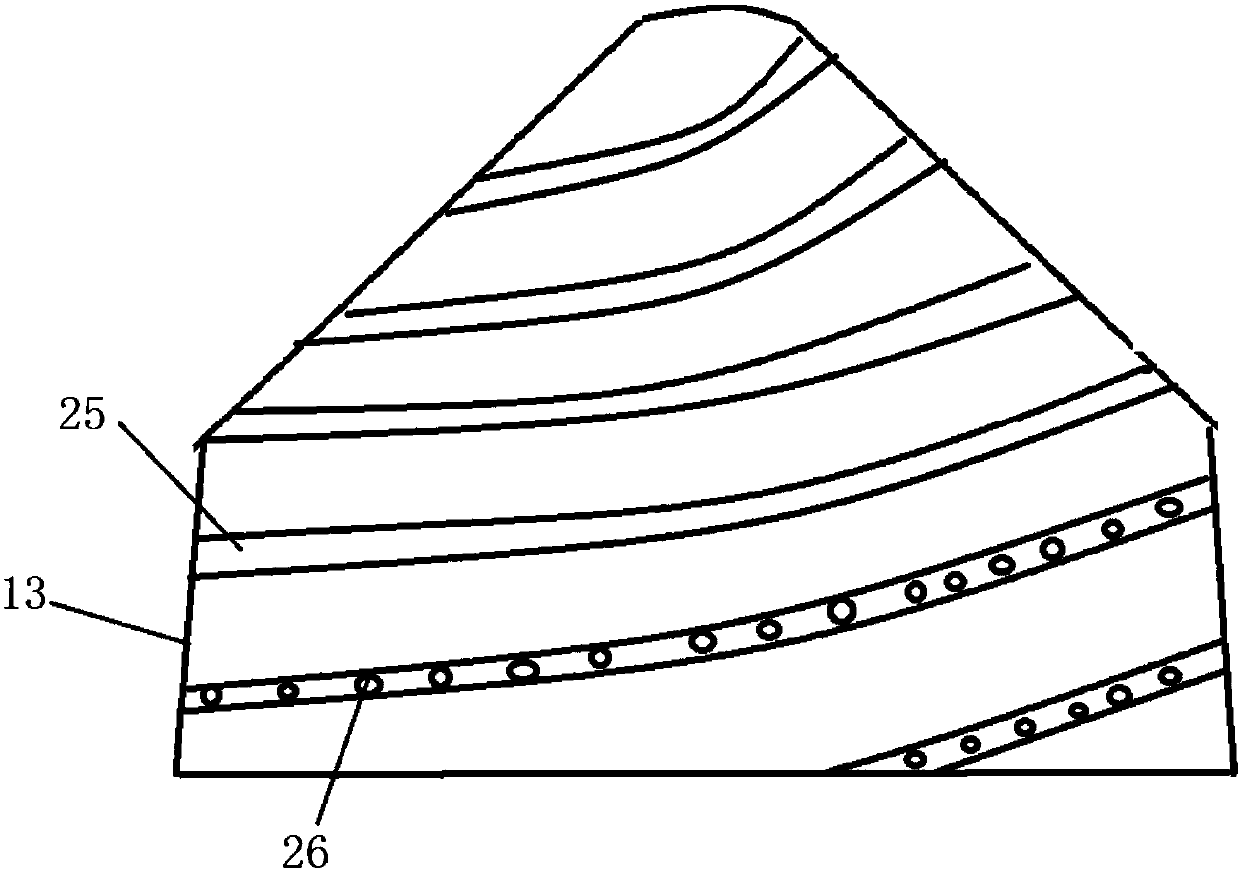

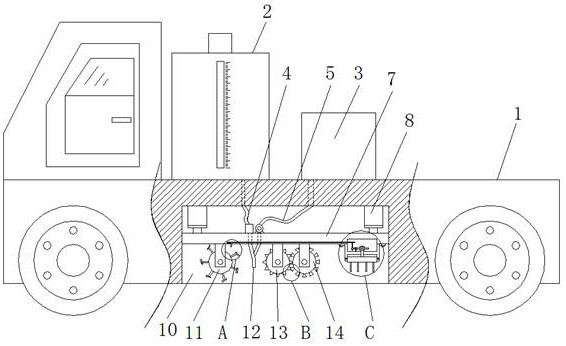

Saline-alkali soil repairing and improving device capable of carrying out multi-level mixed digging

InactiveCN112913368AImprove flatnessSolve the blockageSpadesSoil lifting machinesAlkali soilSoil science

The invention discloses a saline-alkali soil repairing and improving device capable of carrying out multi-level mixed digging. The saline-alkali soil repairing and improving device capable of carrying out the multi-level mixed digging comprises an improving and repairing vehicle, an improvement agent storage tank, an air pump tank, a material guiding pipe, an air pipe, a telescopic hydraulic cylinder, an installation frame, a telescopic cabin and a spring, wherein the improvement agent storage tank is arranged on the top of the improving and repairing vehicle; the improving and repairing vehicle on one side where the improvement agent storage tank is positioned is provided with the air pump tank; the front side of a supporting plate is connected with a ditching roller through the installation frame; the right side of the ditching roller is provided with a discharging pipe; one side of the right side of the discharging pipe is provided with a first smashing roller and a second smashing roller; and meanwhile, the right side of the second smashing roller is provided with an installation cover. By use of the saline-alkali soil repairing and improving device capable of carrying out the multi-level mixed digging, the structure of an existing saline-alkali soil repairing device is improved, when soil is dug, especially by aiming at land of which the soil is wet, the problems that splashing soil blocks are attached to a material outlet to cause blockage can be solved, and the integral surface of the soil can be leveled.

Owner:查桂霞

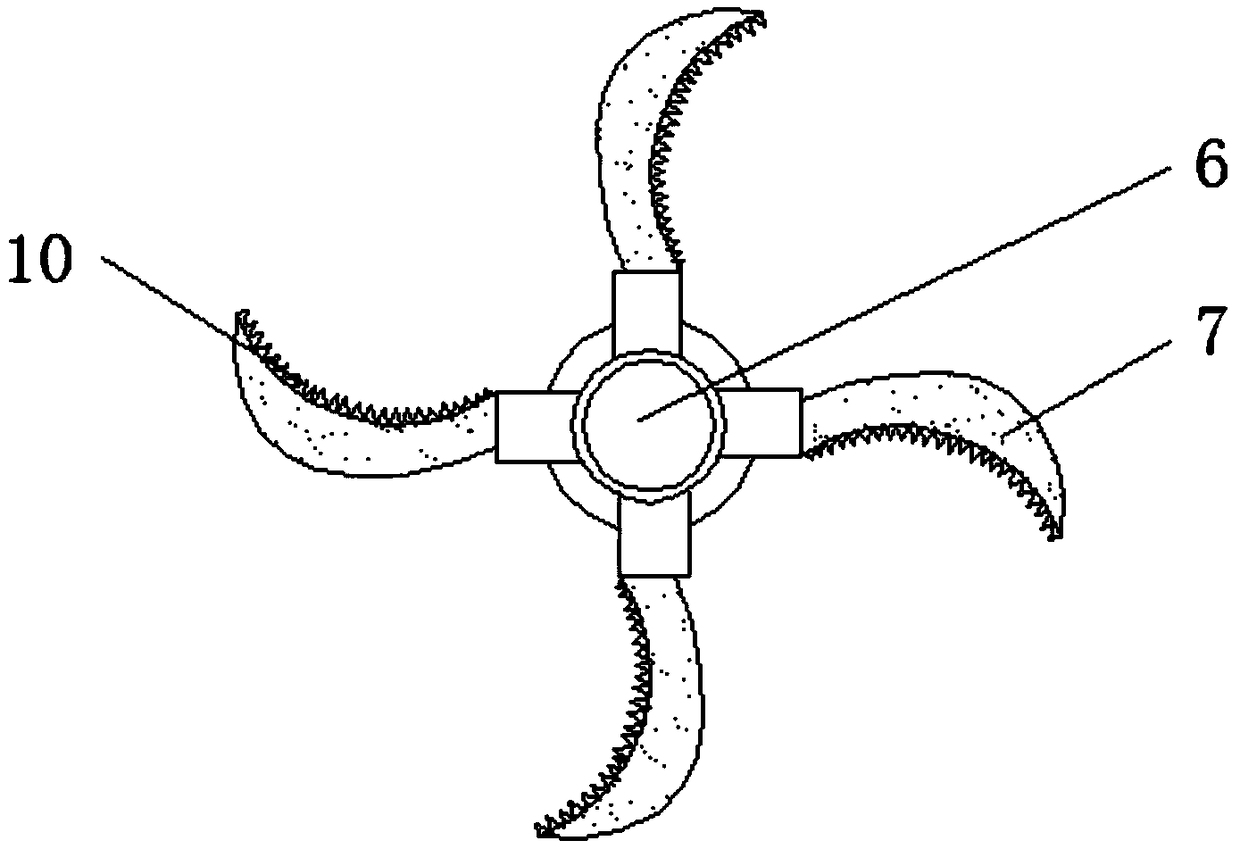

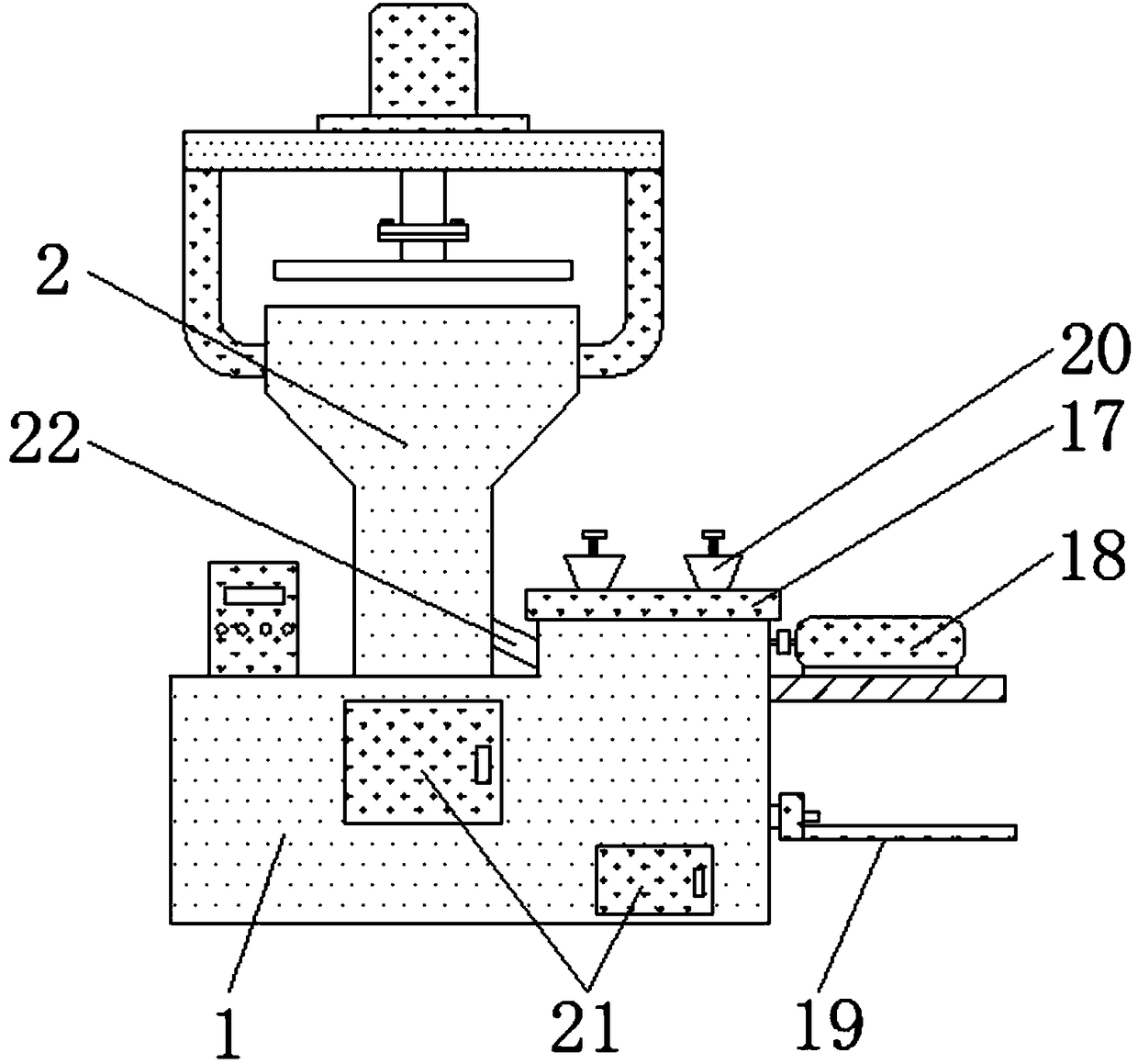

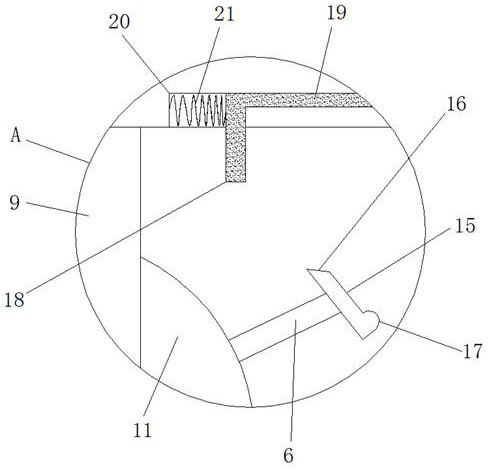

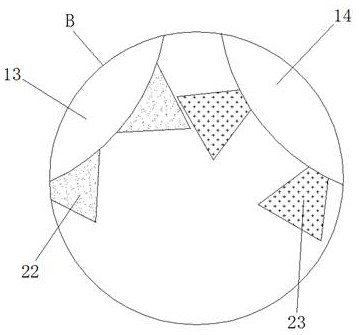

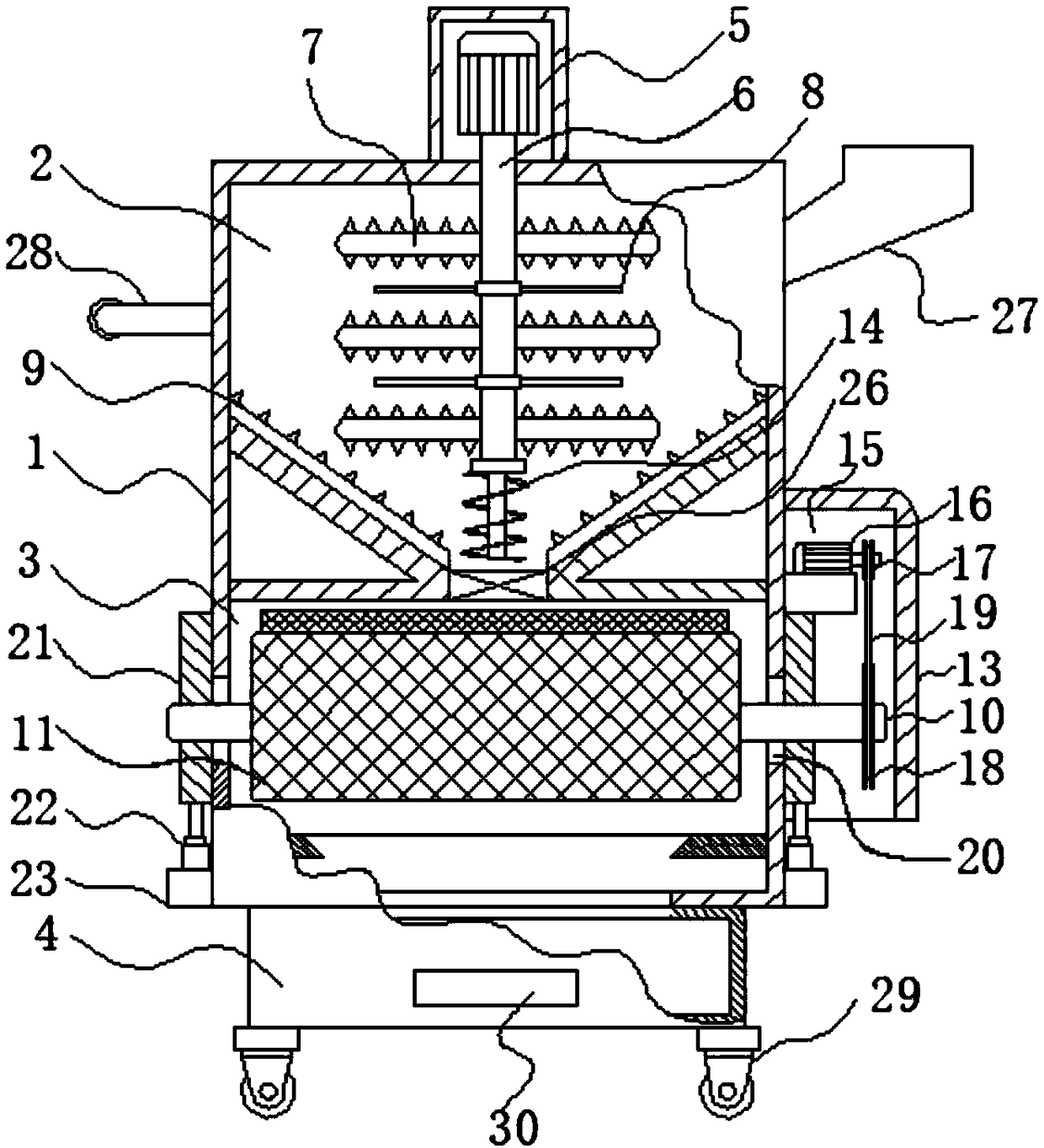

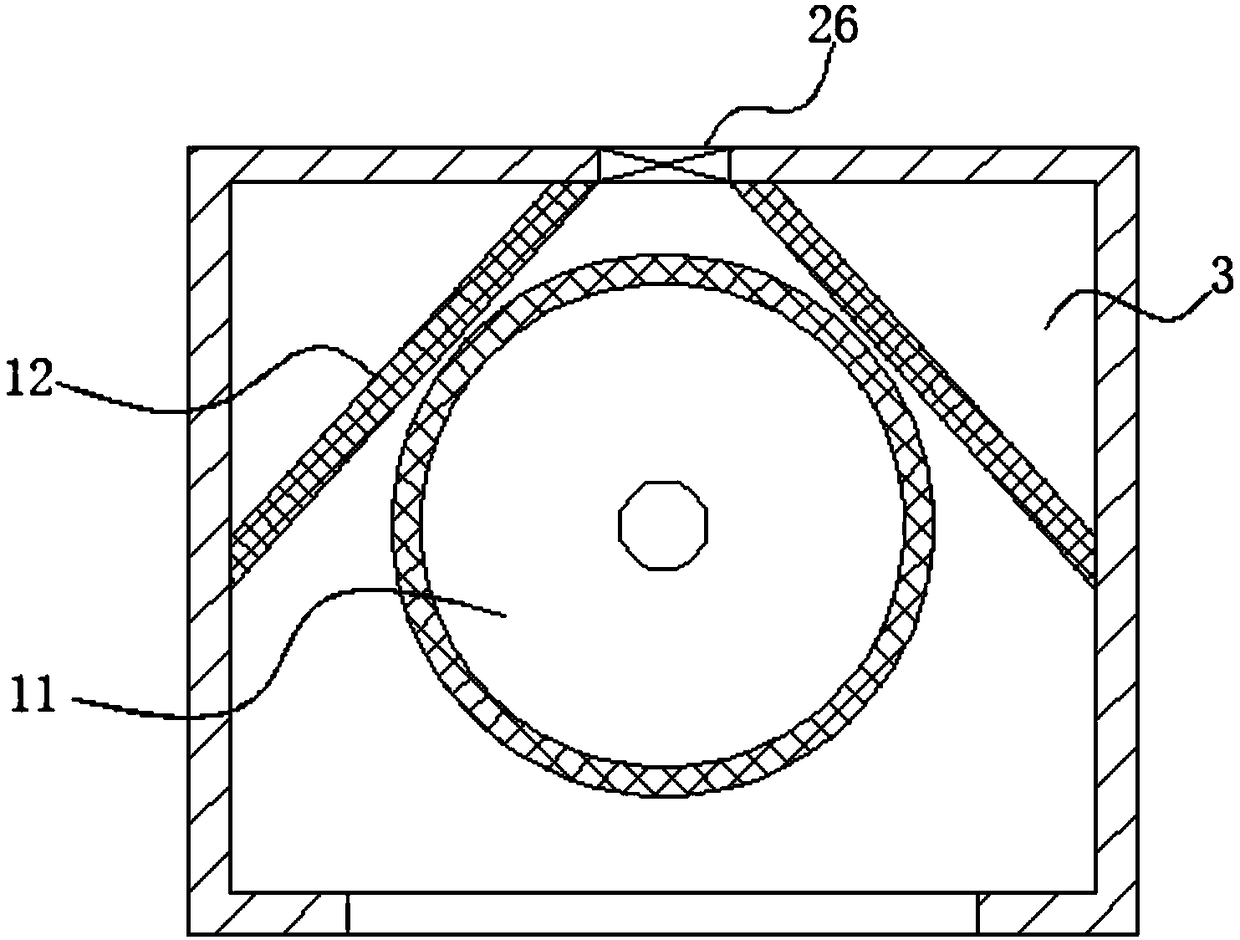

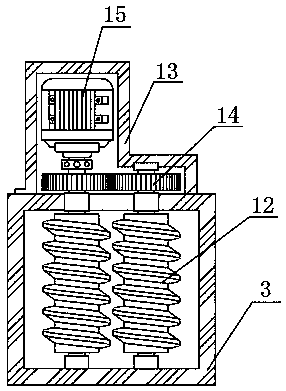

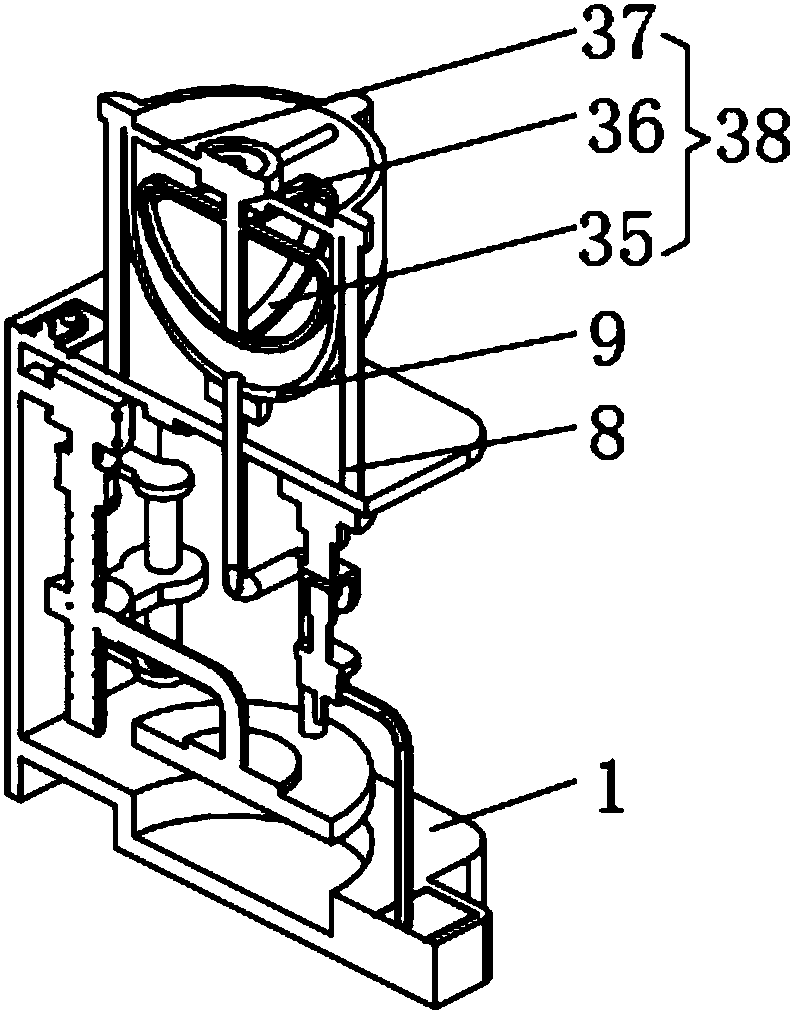

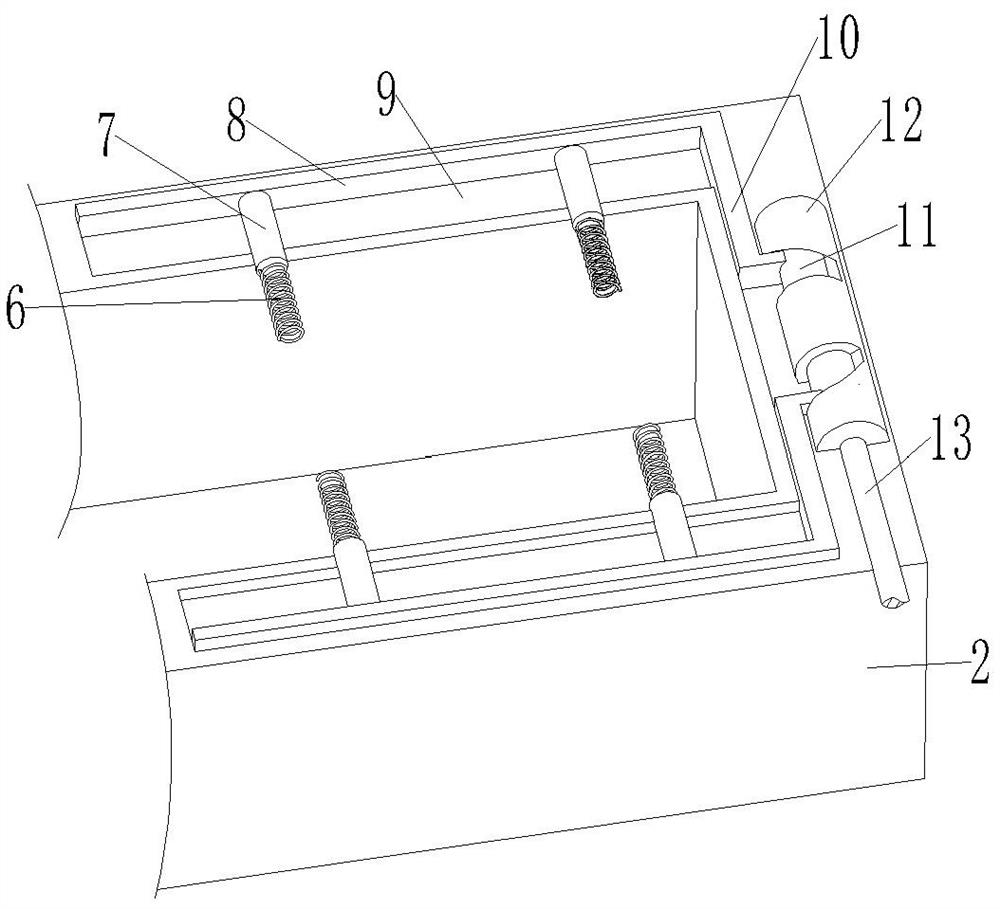

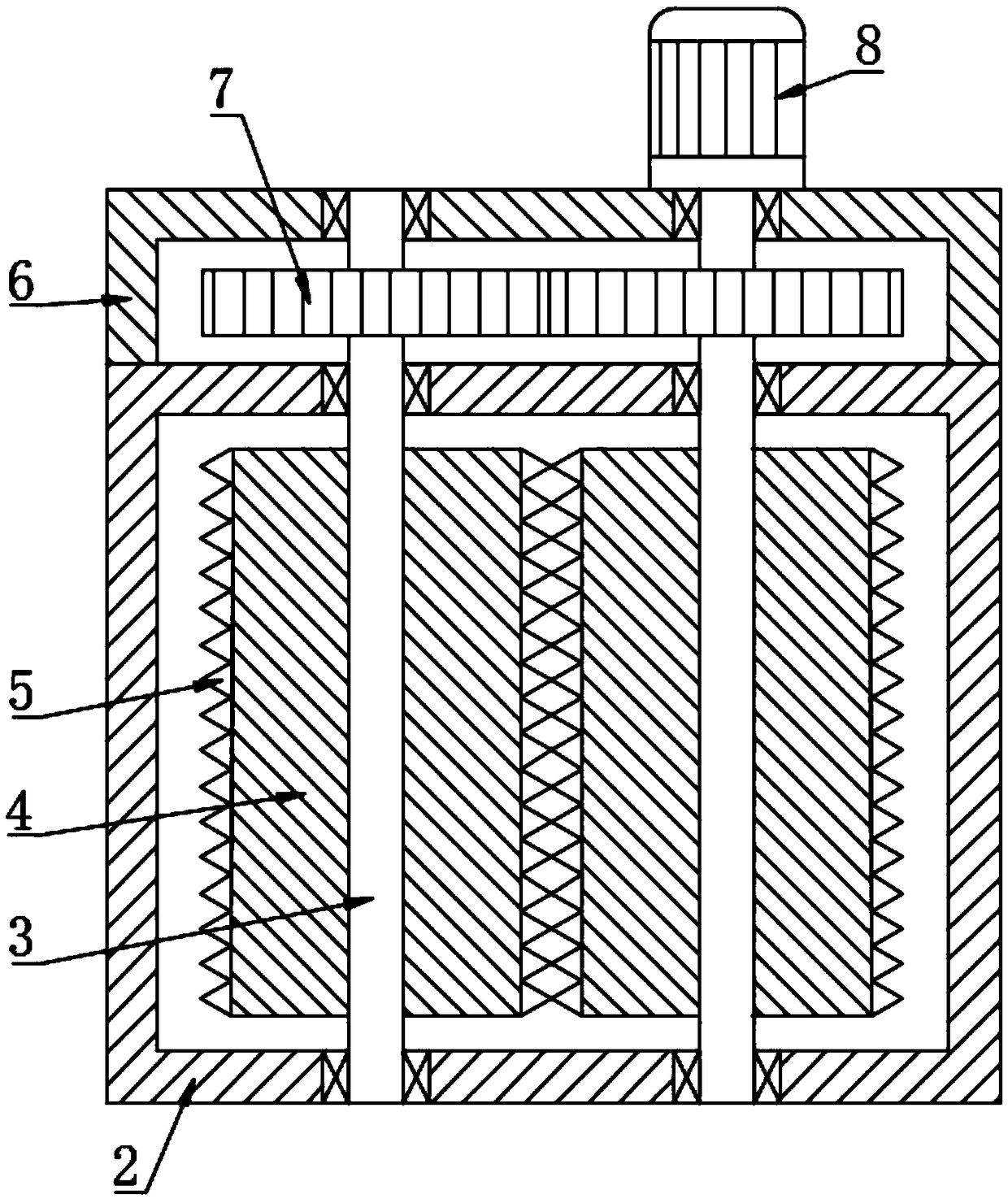

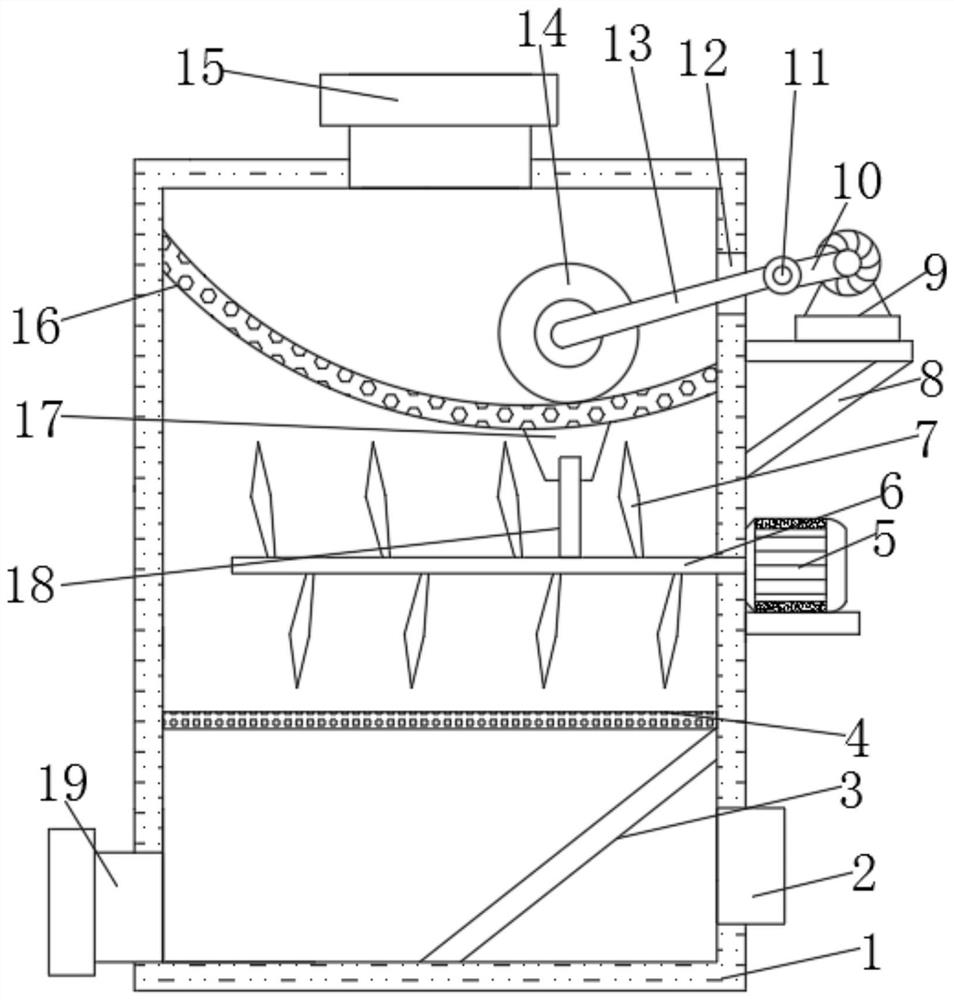

Material crushing and grinding device

The invention discloses a material crushing and grinding device which comprises a machine shell. A crushing chamber and a grinding chamber are arranged in the machine shell. A first motor is mounted above the crushing chamber. The output end of the first motor is connected with a stirring rod. The outer side of the stirring rod is fixedly connected with stirring blades. Cutting mechanisms are arranged between the stirring blades and mounted on the outer side of the stirring rod. A spiral rod is fixedly connected to the bottom end of the stirring rod. Nail plates are connected to the two sidesof the inner wall of the crushing chamber. Open grooves are formed in the two sides of the grinding chamber. Under drive of a drive device, a grinding roller and grinding plates in the grinding chamber grind crushed materials; and through the arrangement of air cylinders, supporting plates can ascend and descend, meanwhile, the grinding roller is driven to ascend and descend, the distance betweenthe grinding roller and the grinding plates is adjusted, and therefore the size of particles in the grinding process of the materials is adjusted, and particles of different required diameters can beground out during grinding production.

Owner:浙江斯菲诺电气有限公司

Chili product production equipment

PendingCN108745529AConvenient grinding workEasy to makePreparing sample for investigationCocoaPulp and paper industryGrinding wheel

The invention provides chili product production equipment. The chili product production equipment comprises a base, a U-shaped fixed seat, insertion seats, cylinders, a grinding adjustment grinding wheel structure, an anti-scattering crushing barrel structure, windproof collection sampling box structures, a pouring barrel, a leaking plate, a discharge plate, an inclined plate, a fixed grinding wheel, a crushing switch, a grinding wheel switch and an adjusting switch. The base is in bolted connection with the lower portion of the inner wall of the U-shaped fixed seat. Through cooperation of a grinding seat, a grinding motor, a connecting shaft, a rotary grinding wheel and a fixed grinding wheel, the chili product production equipment conveniently conducts grinding on chilies to grind the chilies into powder conveniently; through arrangement of a crushing and stirring barrel, a crushing motor, a stirring rod, a connecting sleeve, crushing blades and the leaking plate, the chilies can befiltered conveniently to facilitate subsequent grinding operation after being crushed and cut; through arrangement of a collection box, a windproof cover and a sliding tube, worker staff can be prevented from being choked by the chili powder in the process of collecting and taking the chili powder.

Owner:贵州关岭花江高扬牛肉干有限责任公司

Ore crushing equipment for metal smelting

ActiveCN112473935AImprove crushing efficiencyImprove crushabilityGrain treatmentsElectric machineryStructural engineering

The invention discloses ore crushing equipment for metal smelting. The ore crushing equipment comprises an equipment body, a smashing device is arranged in the middle of the equipment body, a guide plate is fixedly installed in the upper portion of the equipment body, a second rotating shaft and a first rotating shaft are symmetrically arranged on the two sides of the upper portion of the guide plate, multiple sets of cutting discs are evenly distributed and fixedly installed on the first rotating shaft and the second rotating shaft, first bevel gears are fixedly installed at the two ends of the first rotating shaft and the two ends of the second rotating shaft correspondingly, the first bevel gears are in transmission engagement with moving devices, a T-shaped plate movably abuts againstthe middle of the upper portion of the guide plate and is arranged in the bottom end of a push plate in a sliding mode, multiple sets of telescopic devices are evenly distributed and fixedly installedabove the T-shaped plate, the two sides of the push plate are fixedly installed on the moving devices, and one end of the first rotating shaft is in transmission connection with a first motor. The ore crushing equipment is provided with the cutting discs and the push plate, so that ores are cut into small ores before being smashed, the next smashing work is facilitated, the smashing efficiency ishigh, smashing is easier, and the smashing effect is better.

Owner:安徽省金鼎矿业股份有限公司

Mine crusher

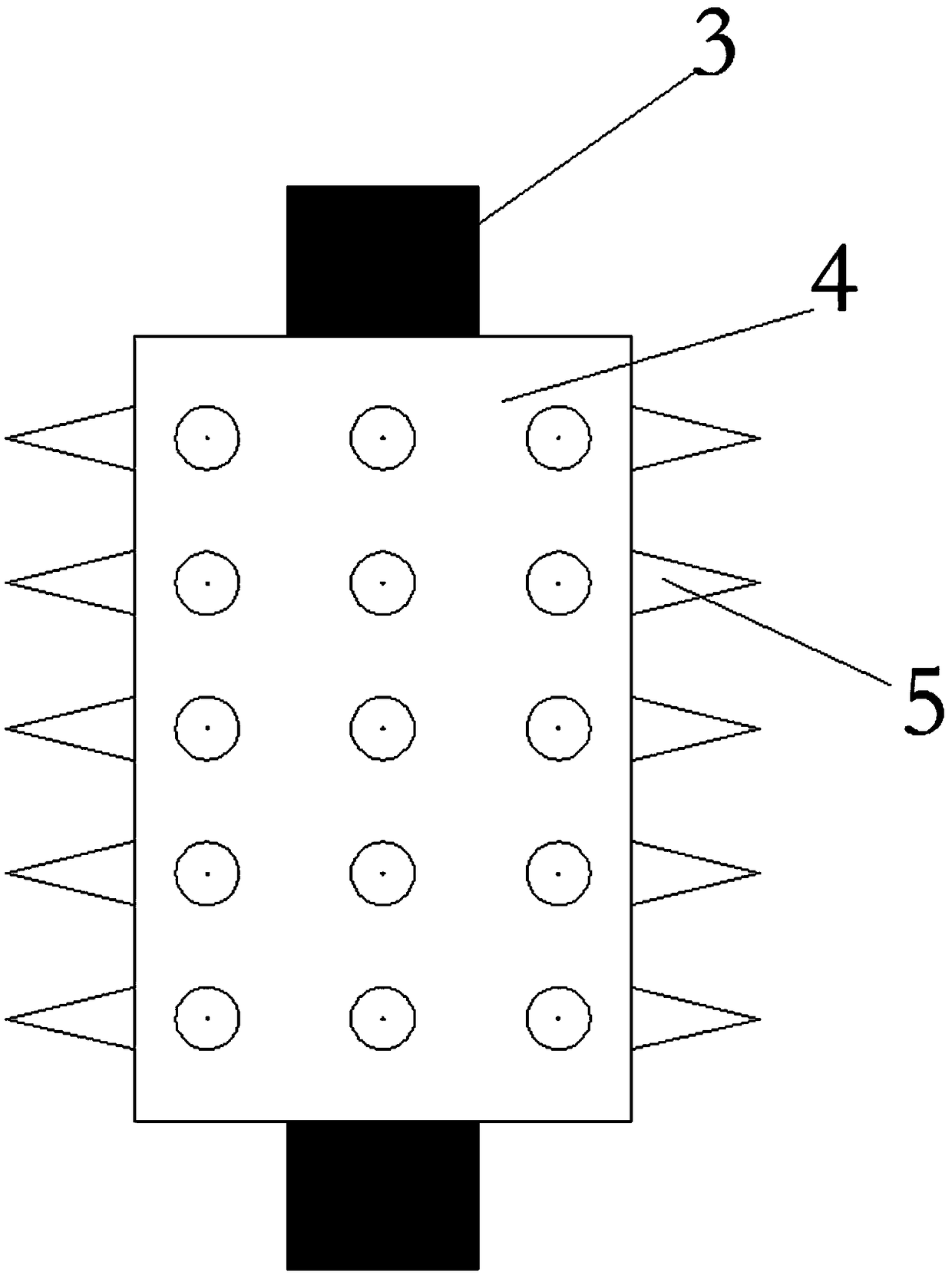

PendingCN108970702ADedicated to precisionAvoid the problem of falling into the broken boxGrain treatmentsBall bearingCrushed stone

The invention discloses a mine crusher. The mine crusher comprises a crushing box, wherein the upper end of the crushing box is fixedly communicated with a feeding hopper; the inner wall, close to theupper end, of the crushing box is symmetrically provided with two rotating shafts; the shaft walls of the rotating shafts are fixedly sleeved with crushing tubes; the surfaces of the crushing tubes are uniformly and fixedly connected with a plurality of crushing protruded pricks; one of the rotating shafts is rotatably connected with the inner wall of the crushing box through a ball bearing and one end of one of the rotating shafts extends out of the crushing box through a through hole; the outer wall of the crushing box is fixedly provided with a motor; an output shaft of the motor is fixedly connected with one end, extending out of the crushing box, of the upper rotating shaft; the two ends of the other rotating shaft extend out of the crushing box through a strip-shaped opening which is formed in the surface of the crushing box in the horizontal direction and are rotatably connected with a positioning plate through the ball bearing; the inner wall of the upper end of the feeding hopper is connected with a material blocking plate through hinges. According to the mine crusher disclosed by the invention, a crushing space can be changed according to actual demands so as to obtain crushed stone materials with different sizes, and thus, the stone materials can be separated from limes better.

Owner:天津市乐矿机械设备制造有限公司

Plastic recovery method

InactiveCN107813439AConvenient crushing workIncrease surface areaPlastic recyclingMechanical material recoveryRecovery methodSolvent

The invention discloses a plastic recovery method. The plastic recovery method is characterized by mainly comprising the steps of: (1) precipitation: water is used for flushing in a pool; and such impurities as soil are removed after standing; (2) washing: oil removing solvent is used for cleaning plastic; (3) crushing: the plastic is crushed after oil stains are removed; (4) dissolving; and (5) recovery: plastic particles in the step (4) are recovered. The plastic recovery method has the following advantages: through multistage treatment, such impurities as soil can be removed through precipitation; the oil removing solvent is used for washing to remove such organic matters as the oil stains; the drying is performed after cleaning to conveniently perform the crushing work; after the plastic is crushed, the total surface area can be greatly increased; and finally, the plastic particles are dissolved through the dissolving agent for such operations as re-separation to obtain finer particles capable of reusing.

Owner:ZHANGJIAGANG DANENG PLASTIC PROD

Environment-friendly processing equipment and method for cosmetic production waste

InactiveCN110252780AGuaranteed uptimeImprove reuseSolid waste disposalCleaning using liquidsEngineeringSewage treatment

The invention discloses environment-friendly processing equipment and method for cosmetic production waste, and relates to the technical field of cosmetic processing equipment. The environment-friendly processing equipment comprises a supporting frame, a storage barrel, a crushing box and a separating box; the storage barrel is arranged on the right side of the supporting frame, the top end of the supporting frame is fixedly connected with the bottom of the separating box, and the middle of the top of the separating box is fixedly connected with a conveying box; and the left side of the bottom of the conveying box communicates with the top of the separating box, the right side of the top of the conveying box is fixedly connected with the bottom of the crushing box, and the right side of the top of the conveying box communicates with the bottom of the crushing box. According to the environment-friendly processing equipment and method for cosmetic production waste, a sewage processing system and a glass crushing device are integrally arranged, water resource consumption can be reduced, and in addition, enterprise expenses can be decreased; and meanwhile, the three-dimensional arrangement mode is adopted, more spaces are saved, resource utilization is more reasonable, large condensation blocks in sewage can be scattered, and sewage processing is facilitated.

Owner:常晶晶

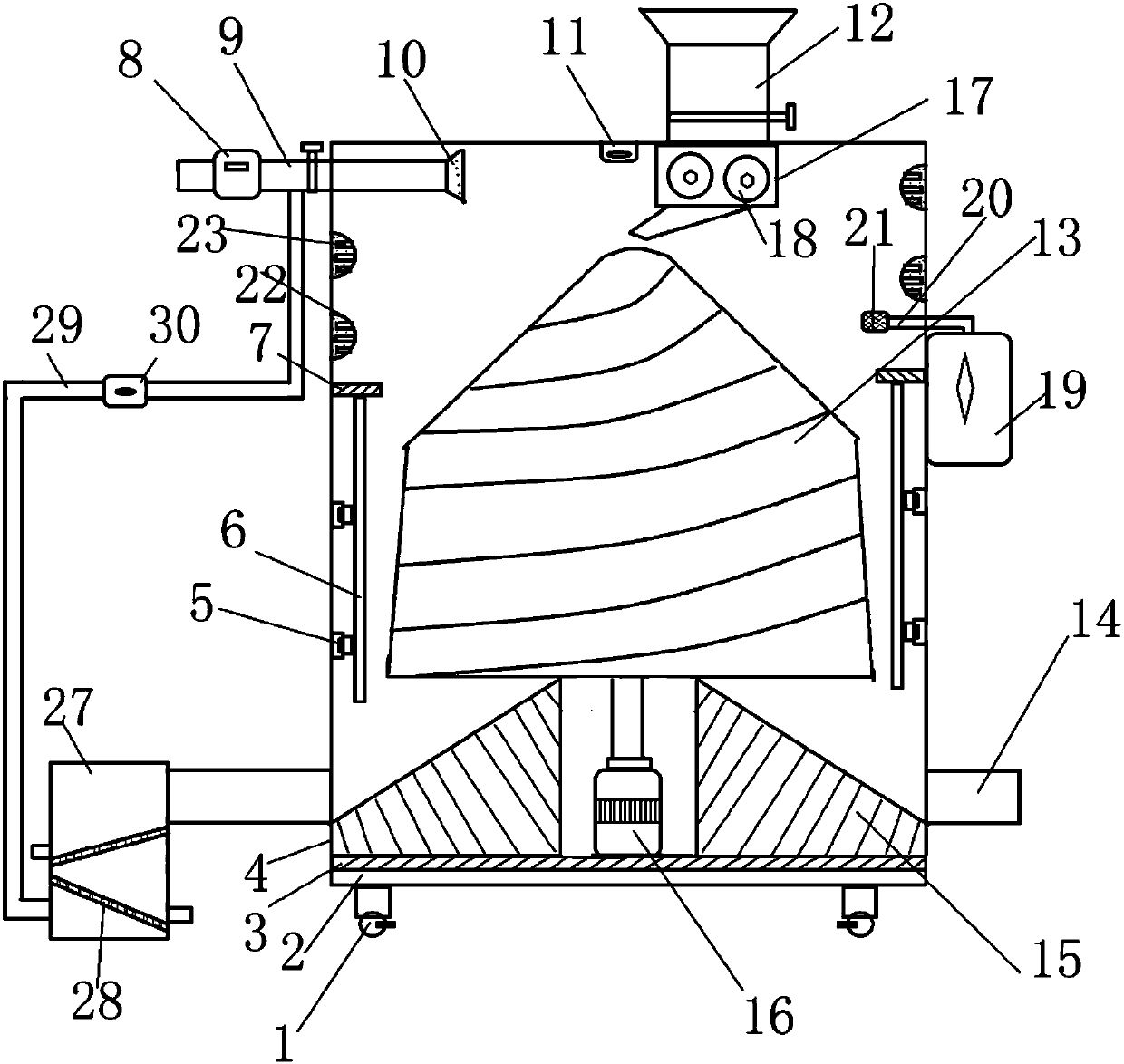

Municipal construction waste circulating crushing device and using method thereof

InactiveCN112169977AImprove crushing effectImprove efficiencyCombination devicesGrain treatmentsElectric machineArchitectural engineering

The invention provides a municipal construction waste cyclic crushing device and a using method thereof. A municipal construction waste cyclic crushing device comprises a treatment box with an openingin the top, a crushing mechanism arranged in the treatment box, a feeding box fixedly mounted on the outer wall of one side of the treatment box, a packing auger rotationally mounted on the inner walls of the top and the bottom of the feeding box, a first motor fixedly installed at the bottom of the feeding box, and a feeding pipe fixedly installed on the feeding box, wherein an output shaft of the first motor is fixedly connected with the bottom end of the packing auger, and one end of the feeding pipe is fixedly connected with one side of the treatment box. The municipal construction wastecyclic crushing device and the using method thereof have the advantages that construction waste can be pretreated, the subsequent crushing effect and crushing efficiency are improved, dust flying is reduced, and the working environment quality is improved.

Owner:LIANHAI GUANGAN CONSTR ENG

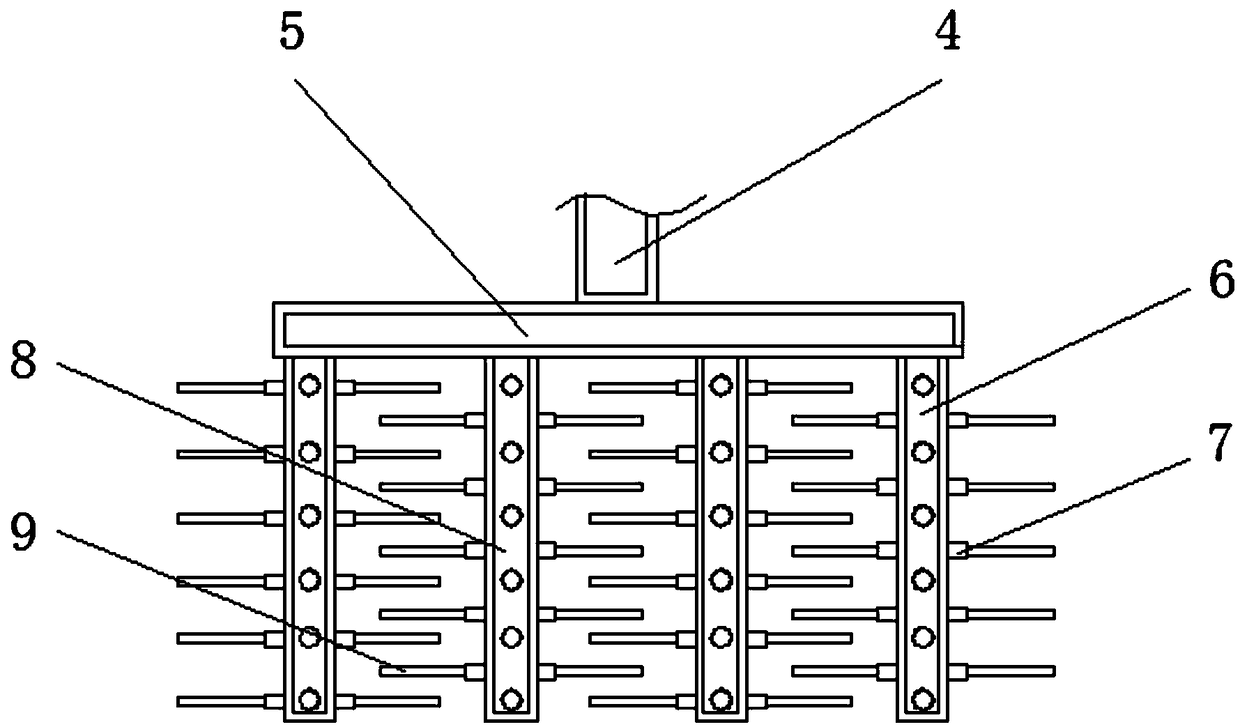

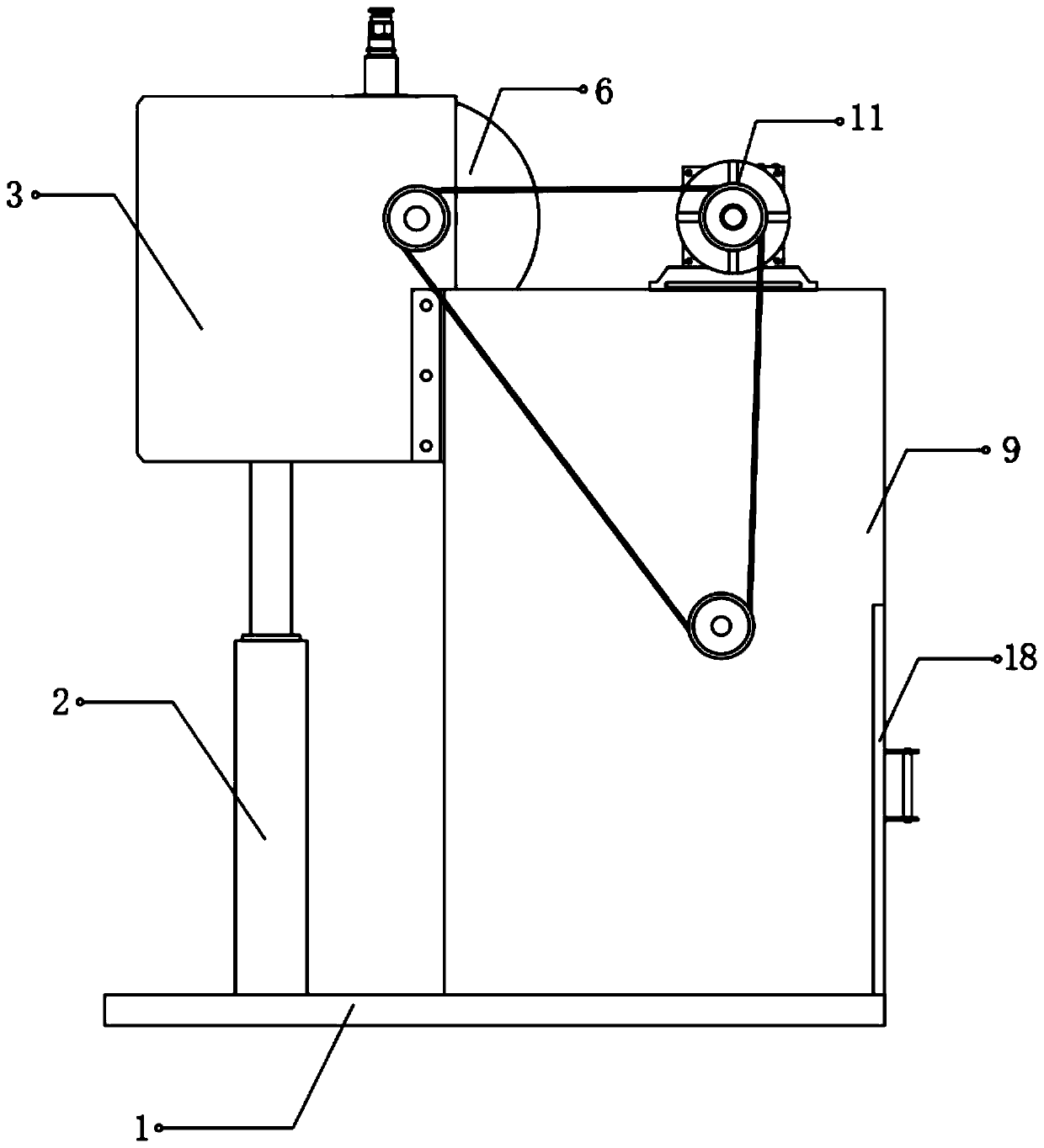

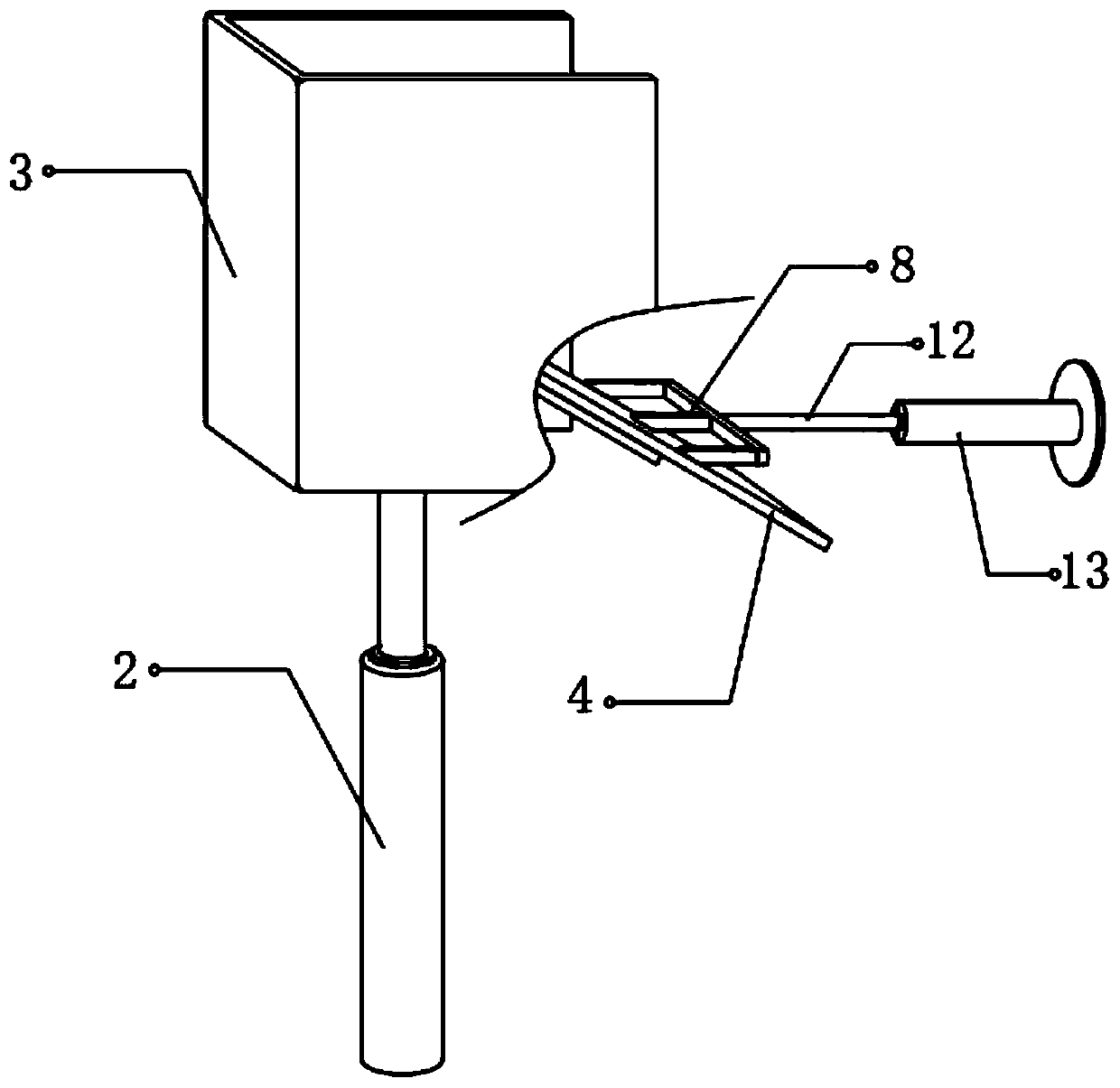

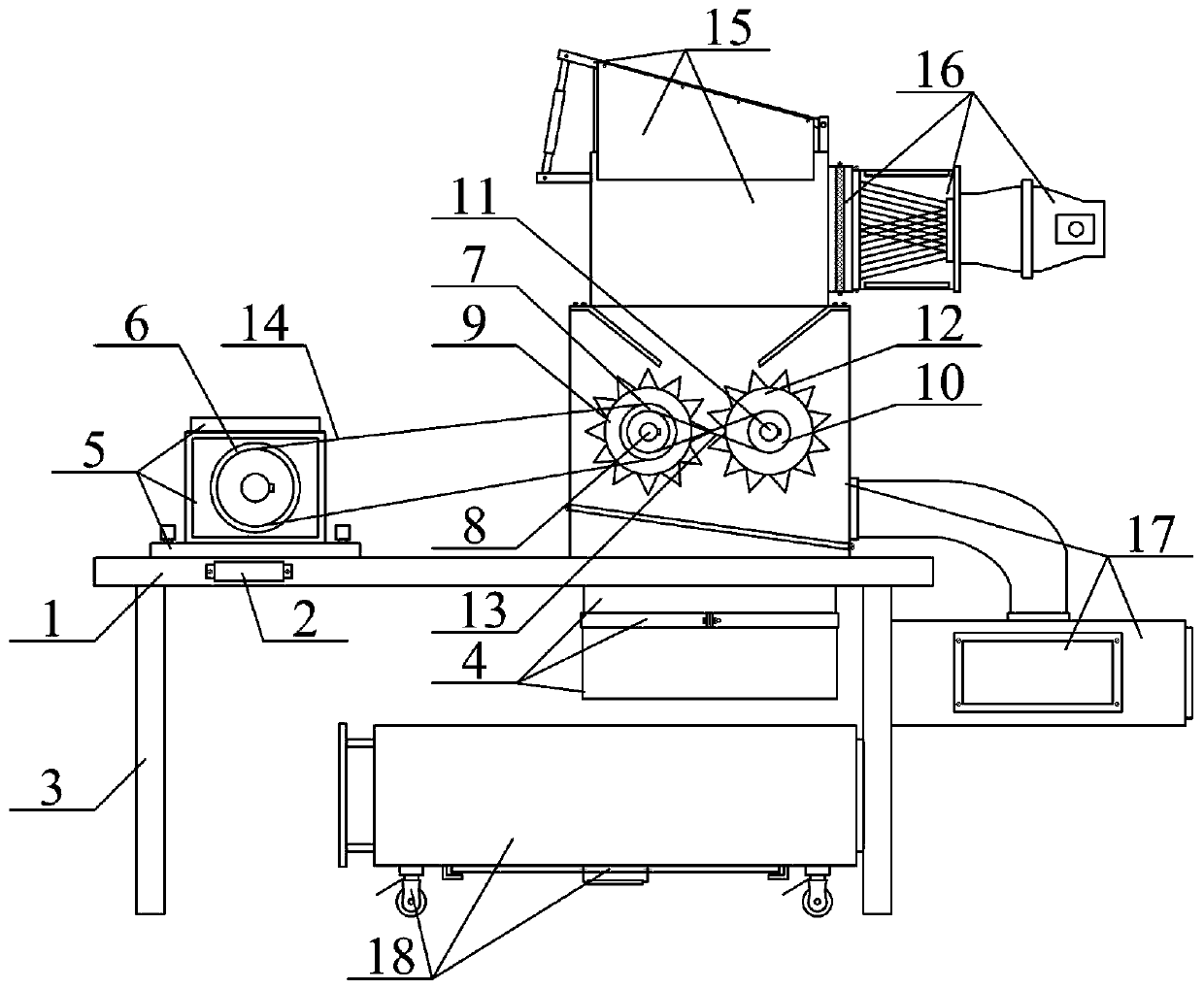

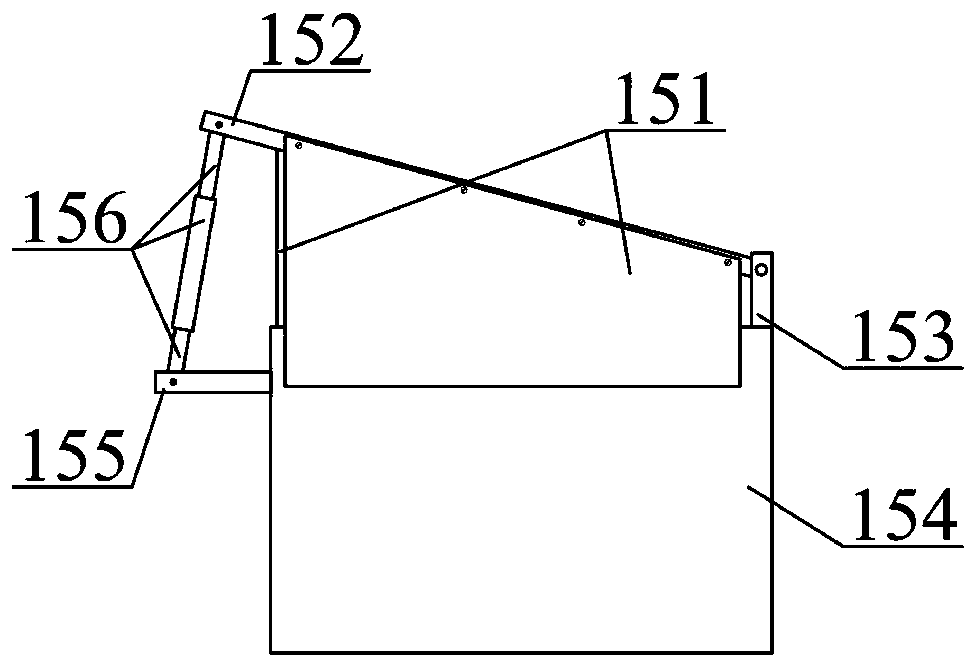

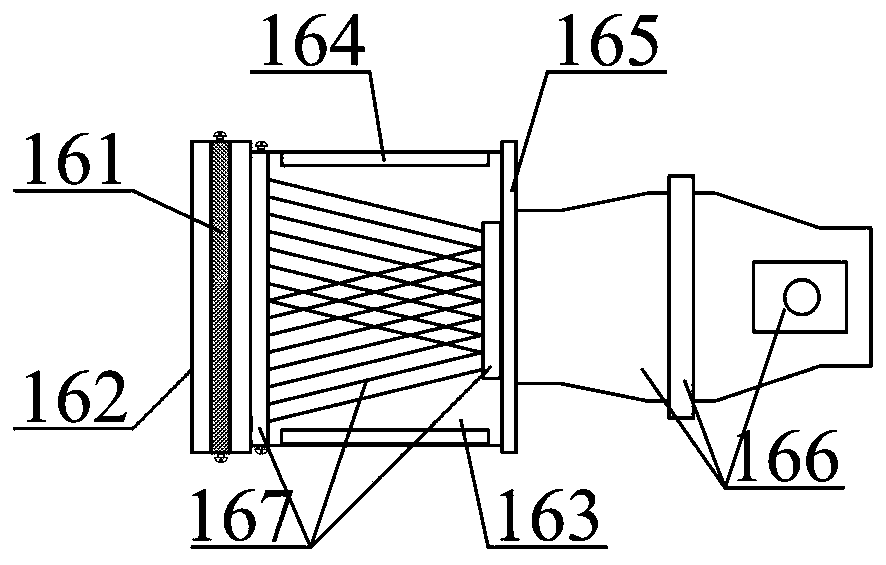

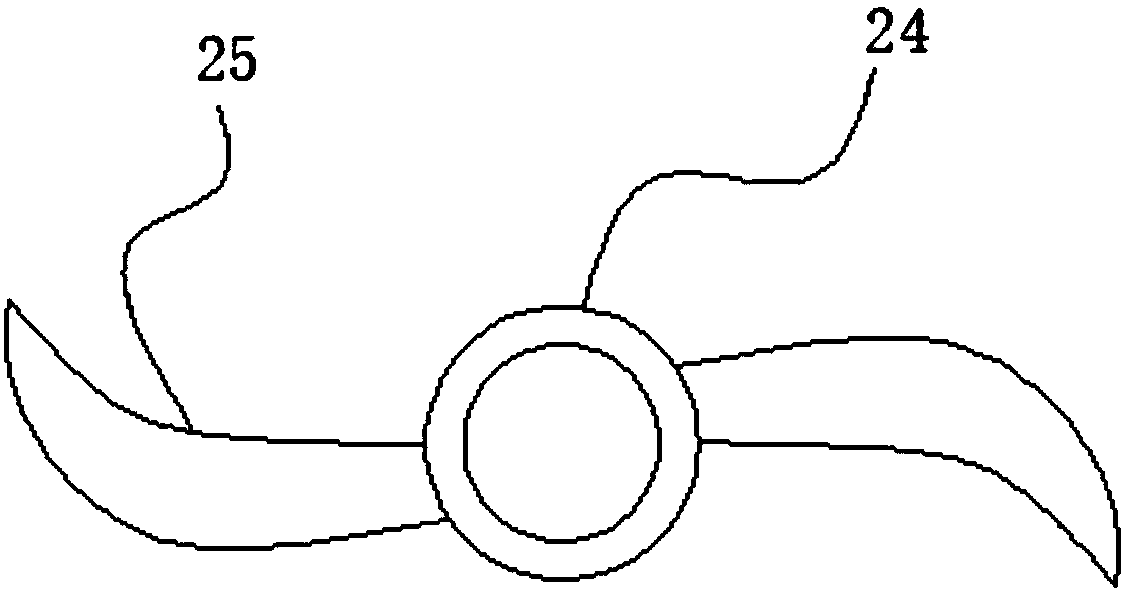

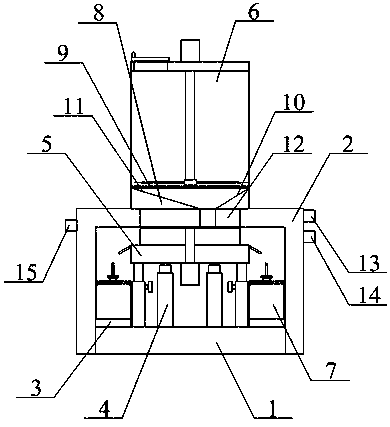

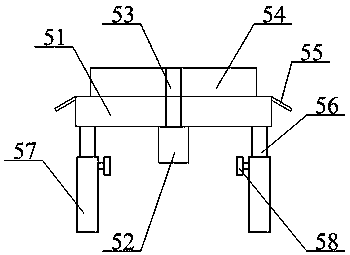

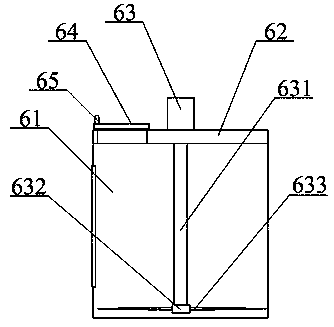

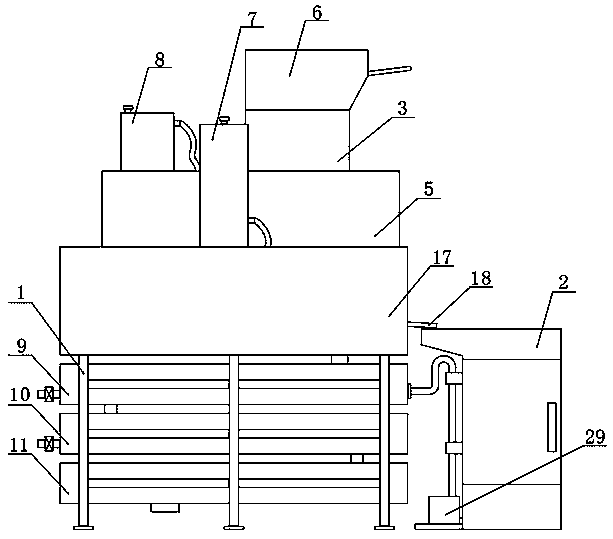

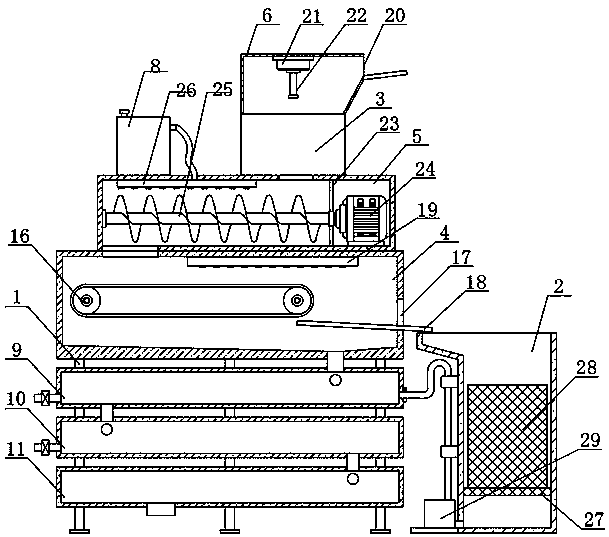

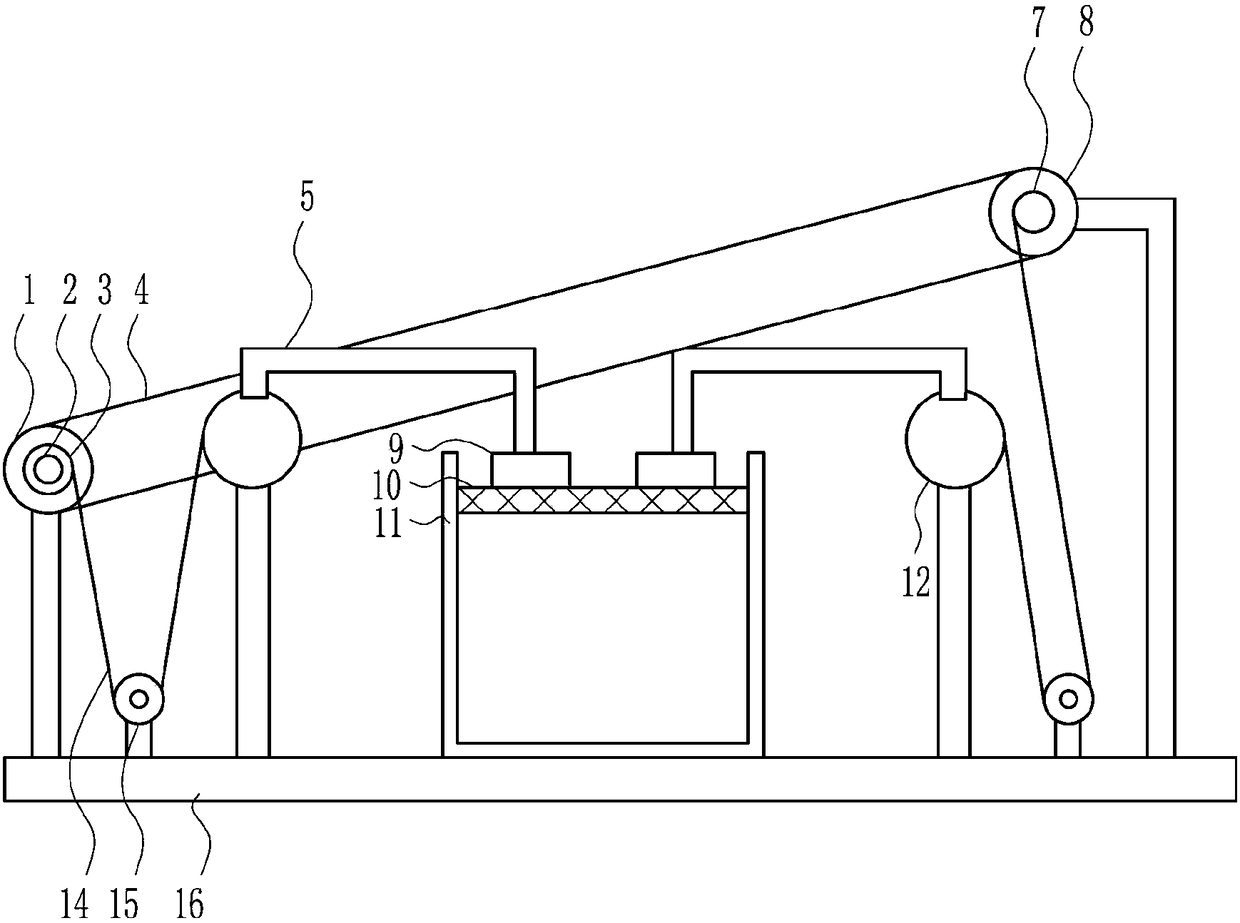

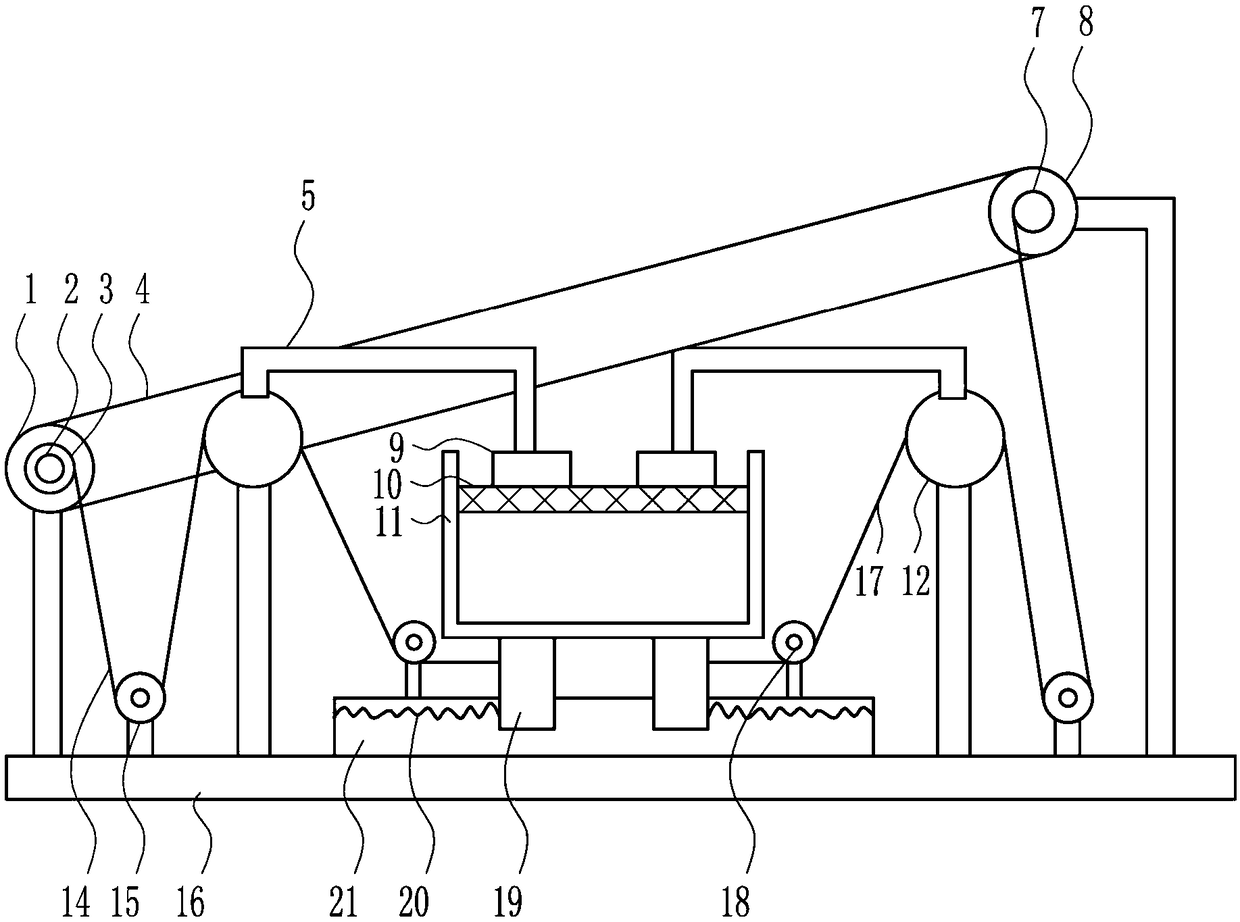

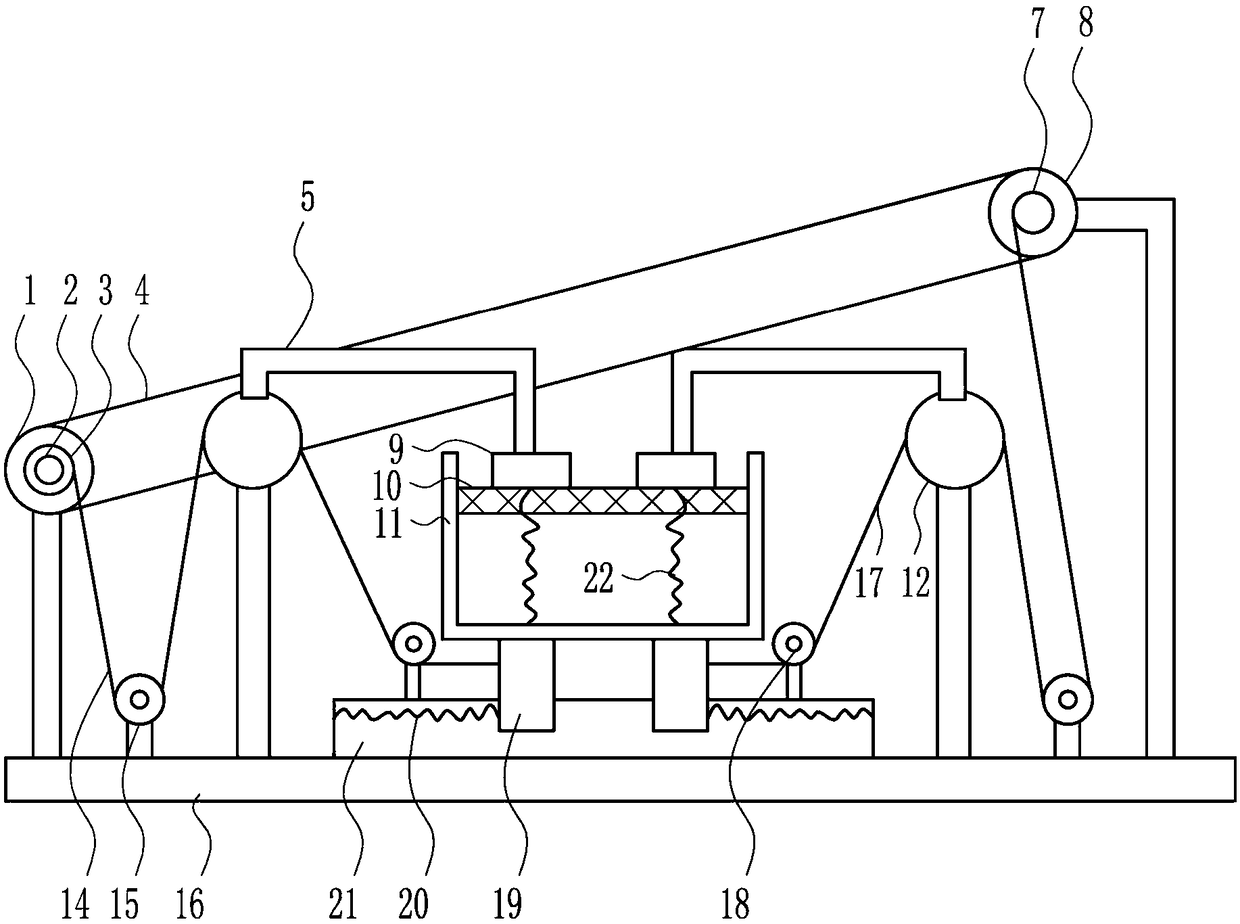

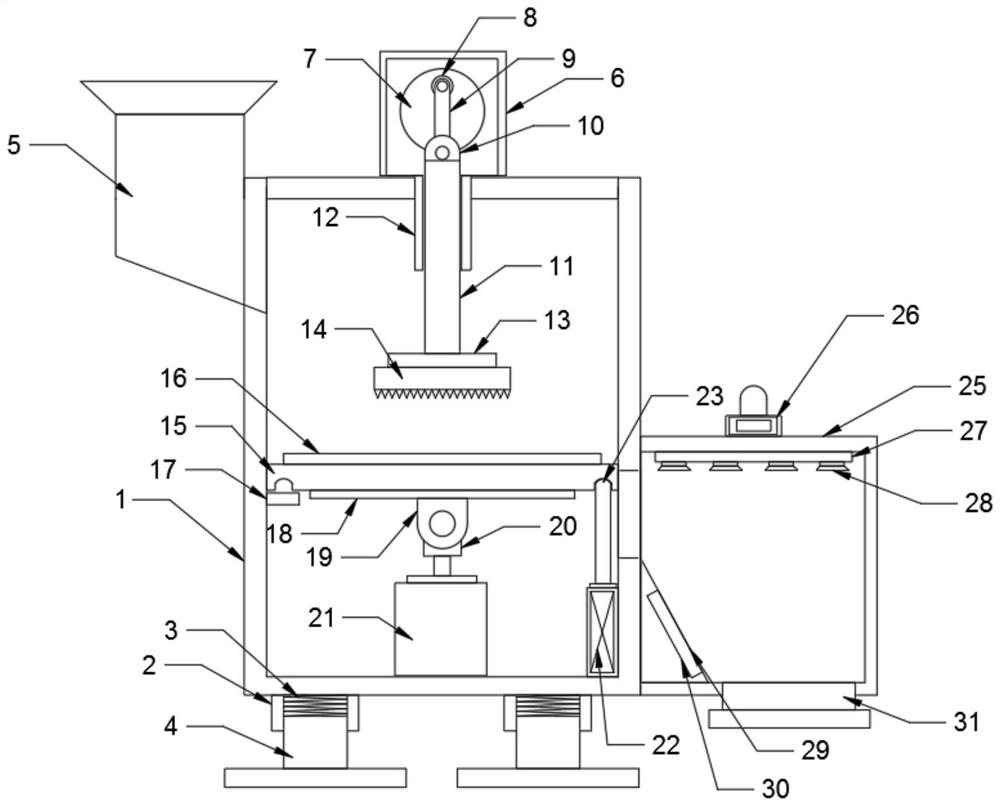

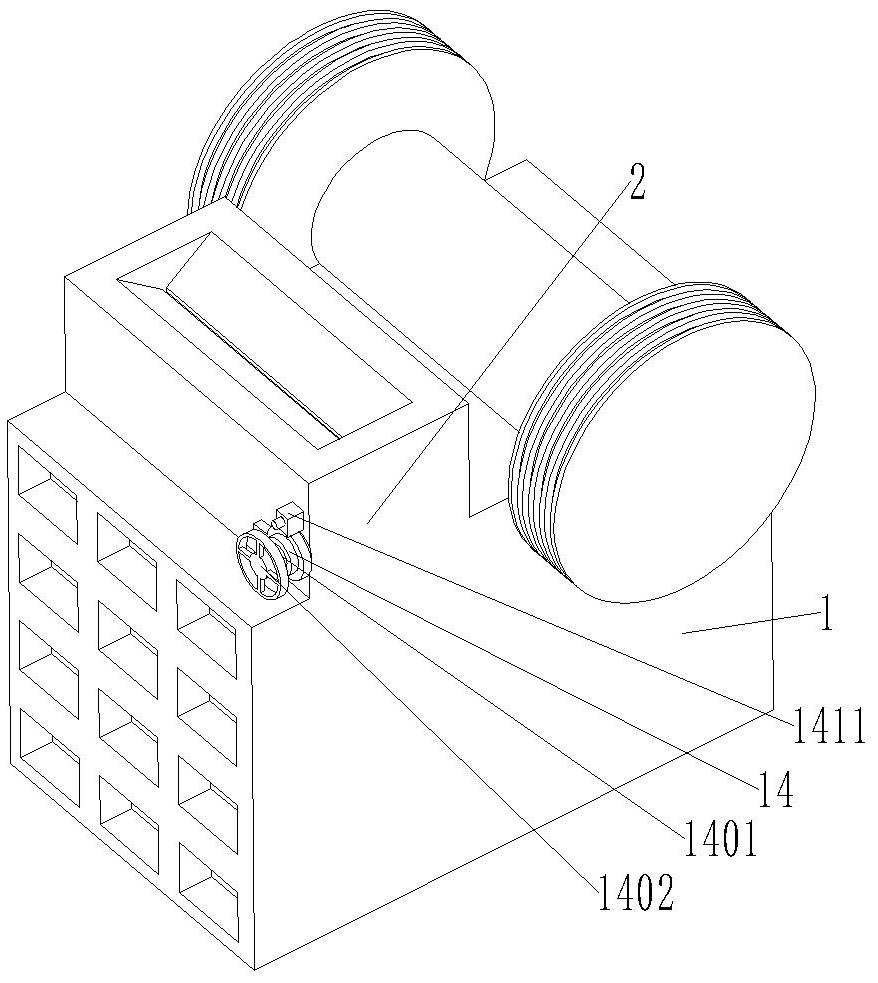

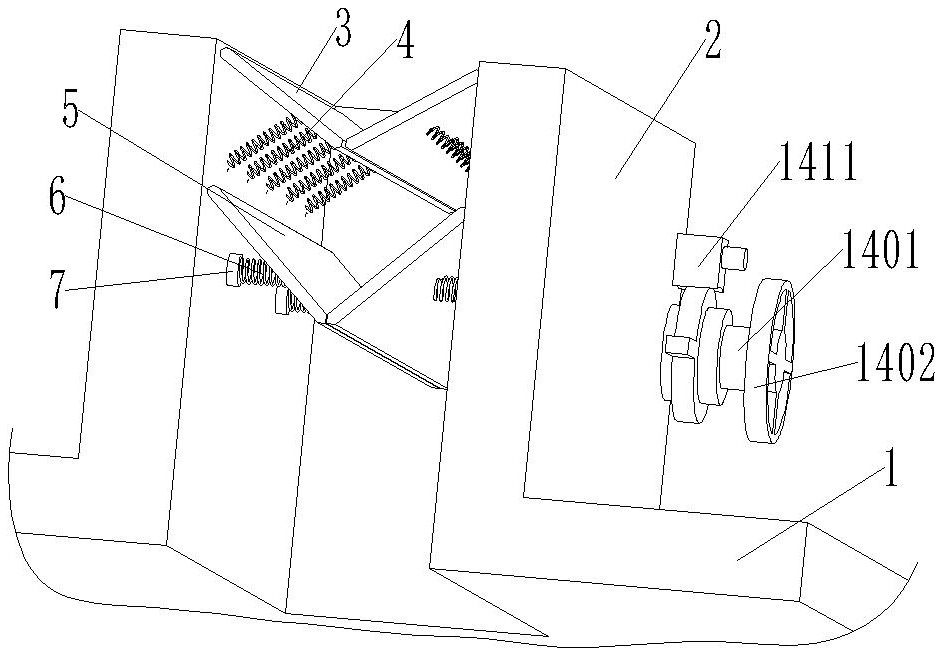

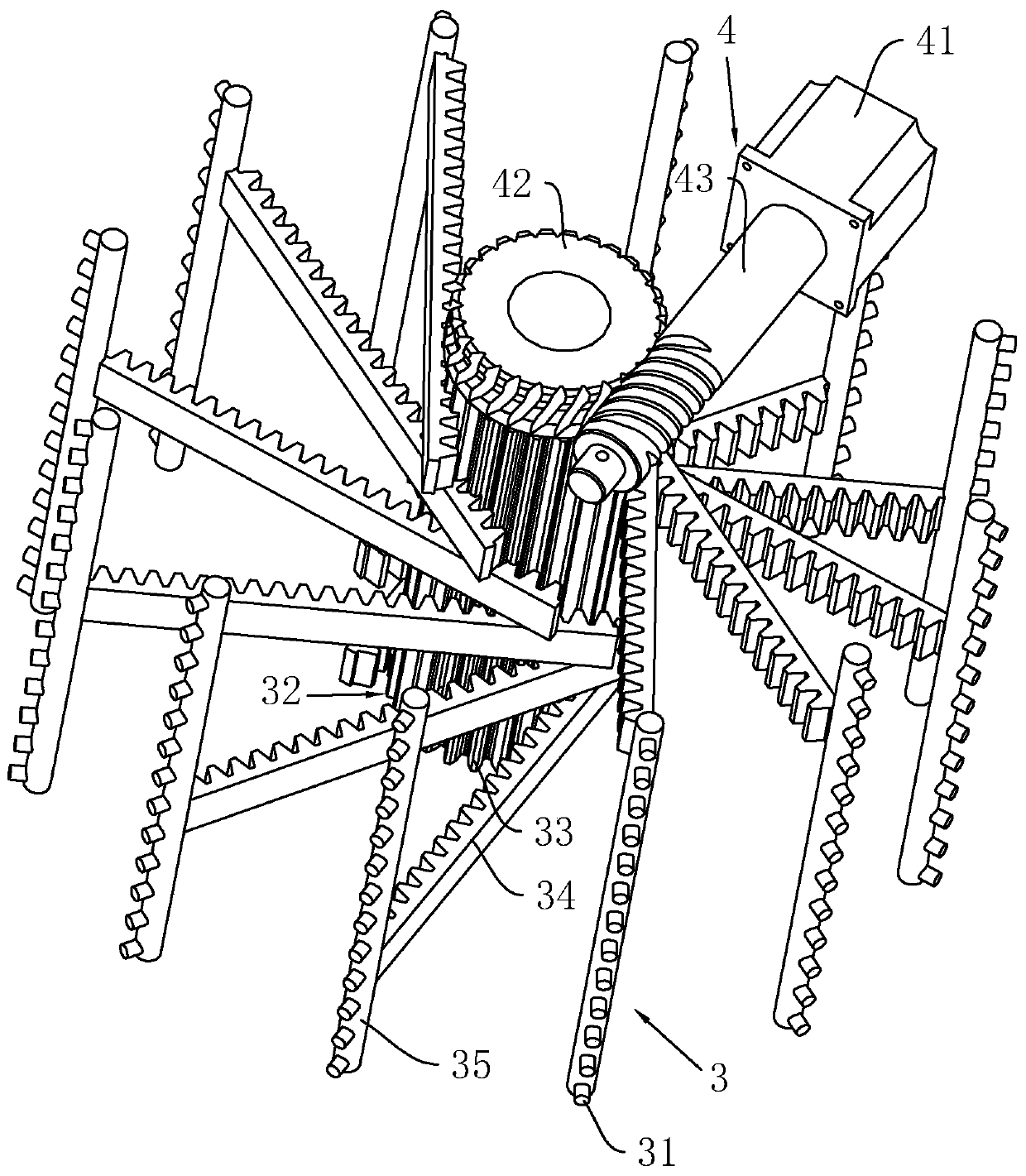

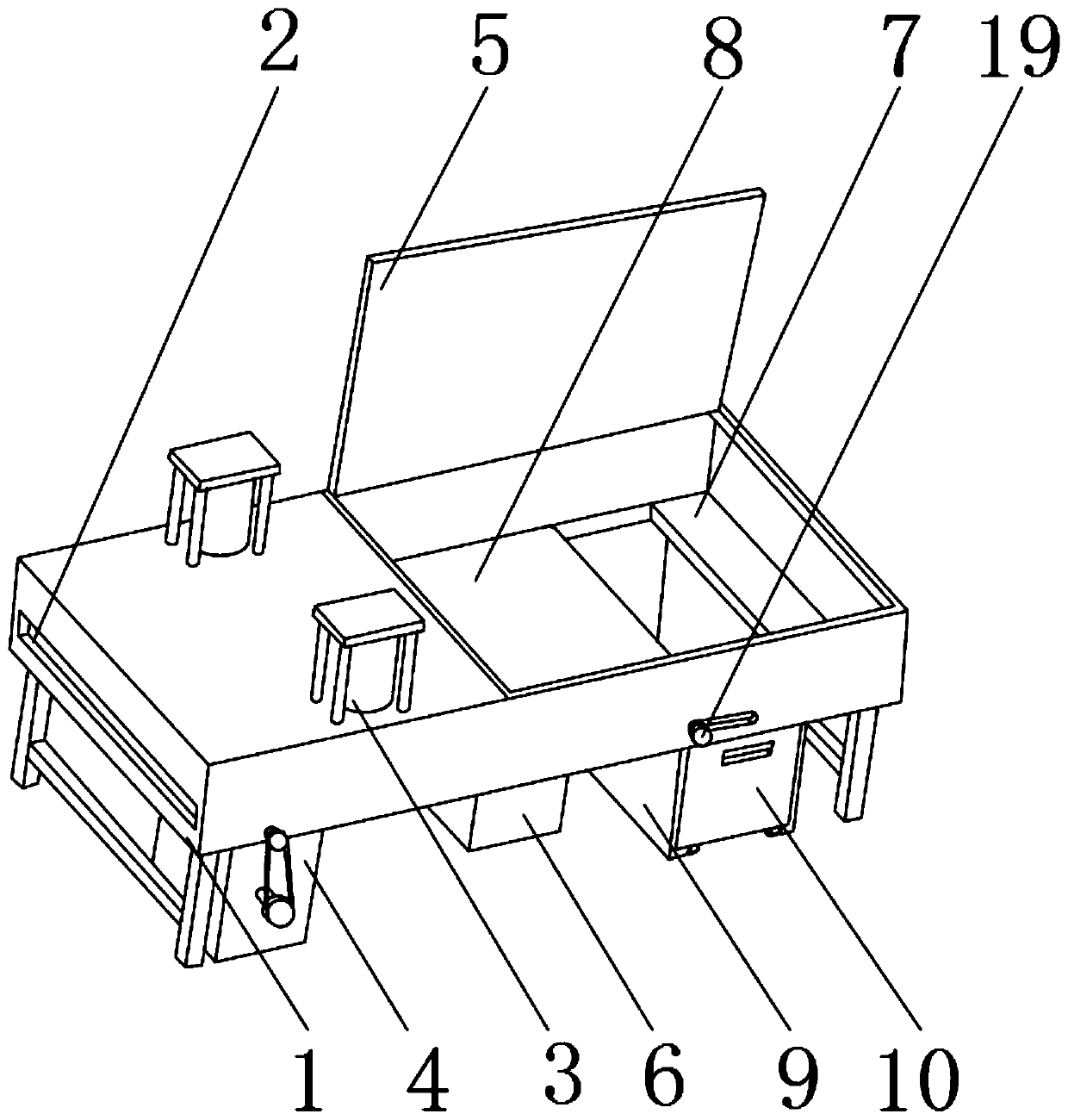

A fast crushing device for animal feed

ActiveCN106140363BConvenient crushing workFast crushingFeeding-stuffGrain treatmentsEngineeringFodder

The invention relates to a smashing device, in particular to a quick feed smashing device for animal husbandry. The technical problem to be solved by the invention is to provide the quick feed smashing device for the animal husbandry with fast smashing speed, thorough smashing and high practicability. In order to solve the technical problem, the invention provides the quick feed smashing device for the animal husbandry. The quick feed smashing device for the animal husbandry comprises a first belt wheel, a speed reducing motor, a first wire winding wheel, a flat belt, a support rod, a second wire winding wheel, a second belt wheel, a weight, an iron filter screen, a smashing box, turntables, a first steel wire rope, rollers and a base; the rollers are symmetrically arranged on the left and right two sides of the top of the base; the turntables are symmetrically arranged on the left and right two sides of the top of the base; and the turntables are positioned on the inner sides of the rollers. The quick feed smashing device for the animal husbandry achieves the effects of fast smashing speed, thorough smashing and high practicability; and when the feed smashing work for the animal husbandry cultivation needs to perform, the device can improve the working efficiency of the whole feed smashing work.

Owner:重庆大农科技集团有限公司

Reinforced concrete crusher

InactiveCN112246314AImprove adsorption capacityEasy to separateUsing liquid separation agentMagnetic separationReinforced concreteElectric machine

The invention discloses a reinforced concrete crusher comprising a crushing box, a discharging box and a crushing hammer, a motor frame is installed in the middle of the top end of the crushing box, asecond motor is installed on the inner side of the motor frame, a rotary disc is installed at the front end of a rotary shaft of the second motor, a rotating shaft is installed on the edge of the rotary disc, and a connecting rod is installed on the outer side of the rotating shaft; a first fixing frame is installed at the bottom end of the connecting rod, a long rod is installed at the bottom end of the first fixing frame, a limiting cylinder is arranged on the outer side of the long rod, and a connecting block and the crushing hammer are installed at the bottom end of the long rod. A supporting plate is arranged below the crushing hammer, a buffer pad is installed on the surface of the upper end of the supporting plate, a connecting plate is installed in the middle of the bottom end ofthe supporting plate, a second fixing frame is installed at the bottom end of the connecting plate, and a fixing block is installed on the inner side of the second fixing frame; a first motor is installed on the middle of the bottom end of the inner side of the crushing box, and the front end of a rotary shaft of the first motor is connected to the fixing block; the discharging box is arranged onthe right side of the crushing box. The reinforced concrete crusher is reasonable in structure, reinforced concrete can be crushed conveniently, and the crushing effect and the crushing efficiency areeffectively improved.

Owner:岑泽江

Waste material powder crushing device for 3D (Three-Dimensional) printer

PendingCN107639833AImprove working precisionConvenient crushing workAdditive manufacturing apparatusManufacturing recyclingInternet of ThingsEngineering

The invention discloses a waste material powder crushing device for a 3D (Three-Dimensional) printer. The waste material powder crushing device for the 3D printer comprises a machine frame; supportingrods are fixed to the top of the machine frame; the end parts of the supporting rods are connected with a crushing box; a crushing device is mounted in the crushing box; an open-source single chip microcomputer is mounted at the top of the crushing box; an Internet of things device is mounted at the top of the open-source single chip microcomputer; a power mechanism is mounted on the side surfacein the machine frame; a transmission mechanism is mounted on the power mechanism. According to the waste material powder crushing device for the 3D printer, a waste printing material is primarily crushed through the crushing device, so that convenience is provided for subsequent crushing work; power is provided for the crushing device through a screw transmission mechanism, and the maneuverability benefit of the waste material powder crushing device for the 3D printer is high; great pushing force can be achieved on the driving piece by applying not great torque to a driving piece; the crushing effect is greatly improved; a working position of a collecting device is positioned through a positioning device, so that the waste material powder crushing device for the 3D printer is high in intelligence degree and accurate in positioning.

Owner:徐咏杰

Ore jaw crusher with buffer feeding structure

ActiveCN112473784AGuaranteed to proceed normallyGood buffer feeding effectGrain treatmentsWorking environmentStructural engineering

The invention discloses an ore jaw crusher with a buffer feeding structure. According to the ore jaw crusher with the buffer feeding structure, through the arrangement of a feeding auxiliary box, a feeding buffer plate, an auxiliary plate and a regulation and control mechanism, in the ore feeding process, a very good buffer feeding effect is achieved on materials, on one hand, when the ore materials enter a crushing cavity of the crusher, violent collision and scraping of the materials on a movable jaw and a static jaw are avoided, thus damage to the movable jaw and the static jaw is reduced,and the working service lives of the movable jaw and the static jaw are ensured; and on the other hand, the situation that a large number of materials are accumulated in the crushing cavity can be avoided, it is guaranteed that the crushing work is normally conducted, dust generated in the material feeding process cannot be rushed out of a feeding port in the machine body, the comfort of the working environment is ensured, convenience is provided for work, and then the working efficiency is improved.

Owner:安福县德鑫矿业有限公司

Green grass crushing device used for animal husbandry

The invention relates to the technical field of animal husbandry, and discloses a green grass crushing device for animal husbandry, which includes a crushing box, four corners of the bottom of the crushing box are fixed with fixing feet, and the bottom of the crushing box is provided with a driving motor. The output shaft of the driving motor is fixedly connected to the transmission shaft, the outer side of the driving motor is provided with a protective cover, the bottom of the driving motor is fixedly connected to the inner bottom wall of the protective cover, and the top of the protective cover is fixedly connected to the crushing box . In this invention, the green grass can be put into the crushing box through the feed pipe, and the drive motor will be started to drive the transmission shaft to rotate, so that the spiral piece and the crushing piece can be rotated at the same time. Through the extension and shortening of the second hydraulic telescopic rod, it can The triangular slices move left and right to facilitate vertical cutting and crushing. The crushing teeth are convenient for cutting the green grass inside the triangular slices, which is more convenient and more thorough.

Owner:程建

Electronic product recycling device

InactiveCN109126973AHigh hardnessReduce lossNon-rotating vibration suppressionGrain treatmentsSoft magnetProduct processing

The invention relates to the technical field of electronic product processing, particularly to an electronic product recycling device. The electronic product recycling device comprises a base, and thetop of the base is fixedly provided with a crushing box through a support; in the forth-back direction inside the crushing box, two rotating shafts are arranged and rotatingly connected with the front and rear walls of the crushing box, the parts of left-right rotating shafts inside the crushing box are all fixedly provided with crushing rollers, and the side wall of every crushing roller is uniformly provided with a plurality of crushing teeth; the internal bottom of the crushing box is fixedly provided with a conveying belt mechanism, which is inclined towards the left top; the right end ofthe conveying belt mechanism penetrates through the right wall of the crushing box and out of the crushing box; the conveying belt of the conveying belt mechanism is made of soft magnets. According to the electronic product recycling device, magnetic materials contained inside crushed electronic products such as iron materials can be attracted to the conveying belt and move along with the conveying belt towards the right top and then out of the crushing box, so that the iron materials can be separated from the electronic products, further subsequent crushing operation can be facilitated, andworkpiece wearing and energy consumption as well as separating costs can be reduced.

Owner:苏州和必尔斯电子科技有限公司

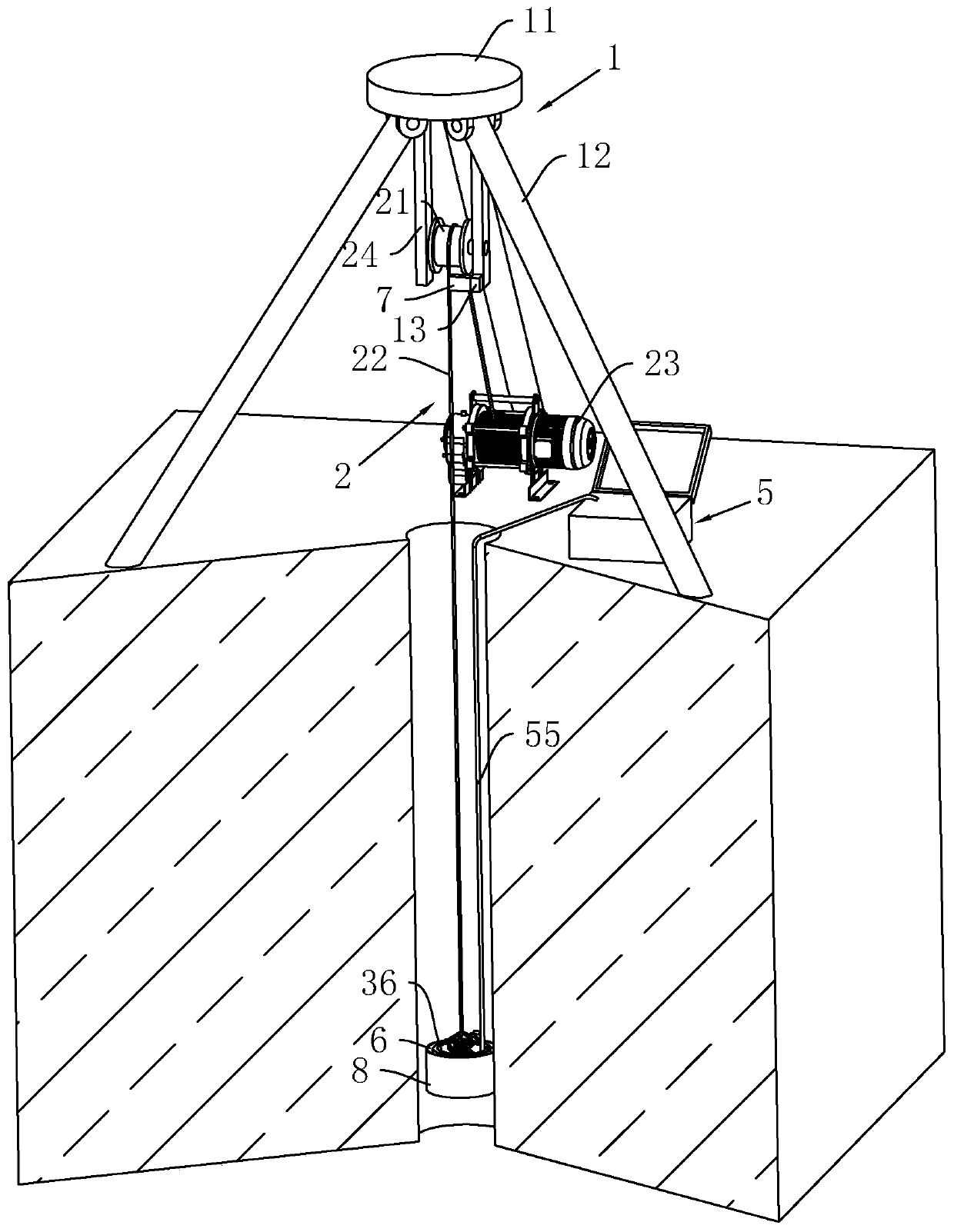

A method and equipment for boulder detection

ActiveCN110045421BReduce occupancyReduce the space occupied in the wellSeismology for water-loggingThree-dimensional spaceTransducer

The invention relates to a boulder detection method. The ultrasonic probe is placed at the position to be detected by drilling, and the driving device is started to drive several ultrasonic transducers in the direction perpendicular to the hole wall of the detection hole, so that the ultrasonic probe is in contact with the detection hole. The wall of the hole is tightly attached and coupled, and then ultrasonic detection is used to obtain the accurate spatial position of the wave-facing surface of the boulder. The data is transmitted to the control computer through a data line and the three-dimensional spatial position and size of the boulder are generated in proportion. The method of detecting boulders through ultrasonic waves can greatly reduce the workload of traditional exploration methods to reveal boulders, save a lot of costs, and can effectively avoid problems such as missing boulders and low accuracy caused by traditional exploration methods, and improve boulder exploration. Work efficiency improves the accuracy of solitary rock exploration and reduces engineering construction risks.

Owner:广东有色工程勘察设计院

Agricultural pulverizer

InactiveCN111804384AAvoid stuck problemsImprove crushing effectGrain treatmentsAgricultural engineeringElectric machinery

The invention discloses an agricultural pulverizer. The agricultural pulverizer structurally comprises a bottom frame, a pulverizer body, a discharging port, a fixing table, a motor and a feeding plate groove, wherein the motor is fixedly connected to the front end of the pulverizer body in an embedded mode, the pulverizer body comprises a machine body, a flapping device, a sieving plate, a rotating shaft, pulverizing blades and an anti-skid device, the flapping device is connected to the upper front portion of the sieving plate through bolts, and the anti-skid device is movably clamped to thefront end of a rotating shaft. According to the agricultural pulverizer, an inner wheel and an auxiliary wheel are driven to rotate through an axis, the flapping device rotates clockwise for flapping, a beating ball is nested in a combined arc plate, beating of the beating ball can rebound and buffer, the situation that equipment is jammed due to the fact that a large number of grain particles are thrown in is avoided, when the rotating shaft rotates, idler wheels are movably clamped between a fixed sleeve and a sleeve shaft, the three idler wheels uniformly surround the outer part of the sleeve shaft, and wheel sleeves of the idler wheels are engaged and matched between the fixed sleeve and the sleeve shaft, so that the anti-skid capability is achieved, and the condition that a rotatinganti-skid wheel rotates reversely is avoided.

Owner:广州赢帝工业设计有限公司

Toughened-glass crushing and recycling device

The invention discloses a toughened-glass crushing and recycling device. The toughened-glass crushing and recycling device comprises a recycling device shell, the front end of the interior of the recycling device shell is fixedly provided with a feeding frame through bolts, hydraulic rods are fixedly installed on the outer surface of the top end of the recycling device shell and near the two sidesof the front end through bolts, striking heads are welded to the outer surfaces of the bottoms of the hydraulic rods, and a motor box is welded to the position, close to the front end, of the outer surface of the bottom of the recycling device shell. According to the toughened-glass crushing and recycling device, the spatter range of crushed glass can be limited, the interior of the device can beconveniently observed and repaired, elongation and shortening of a conveyor belt can be changed, glass fragments can be controlled to enter different storage tanks so that the glass fragments of different materials can be conveniently classified and stored, pressure change can be detected through a pressure sensor, and a storage box can be pushed out and replaced through an electric telescopic rod, so that a better application prospect is brought.

Owner:安徽友谊钢化玻璃有限公司

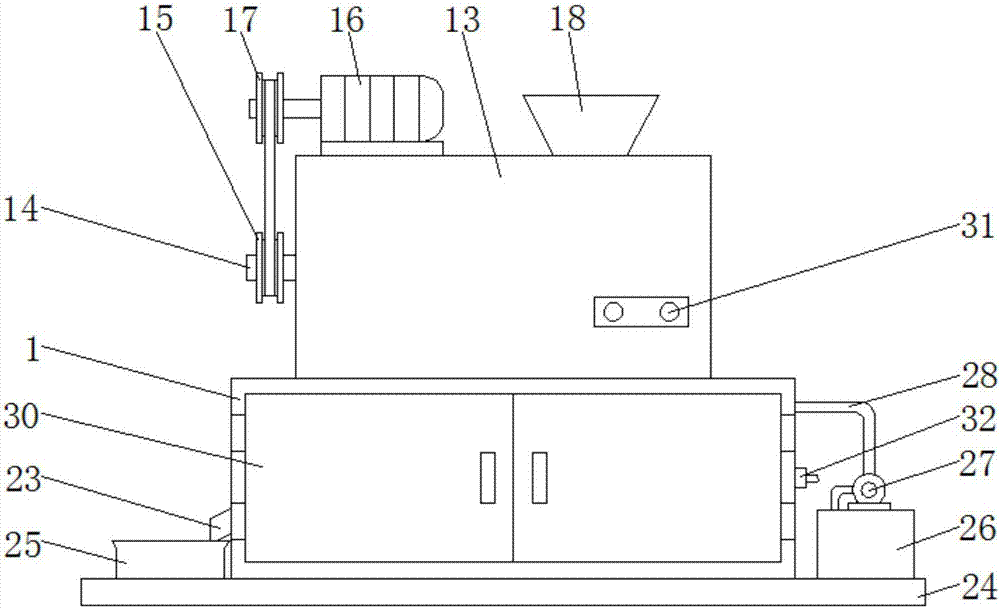

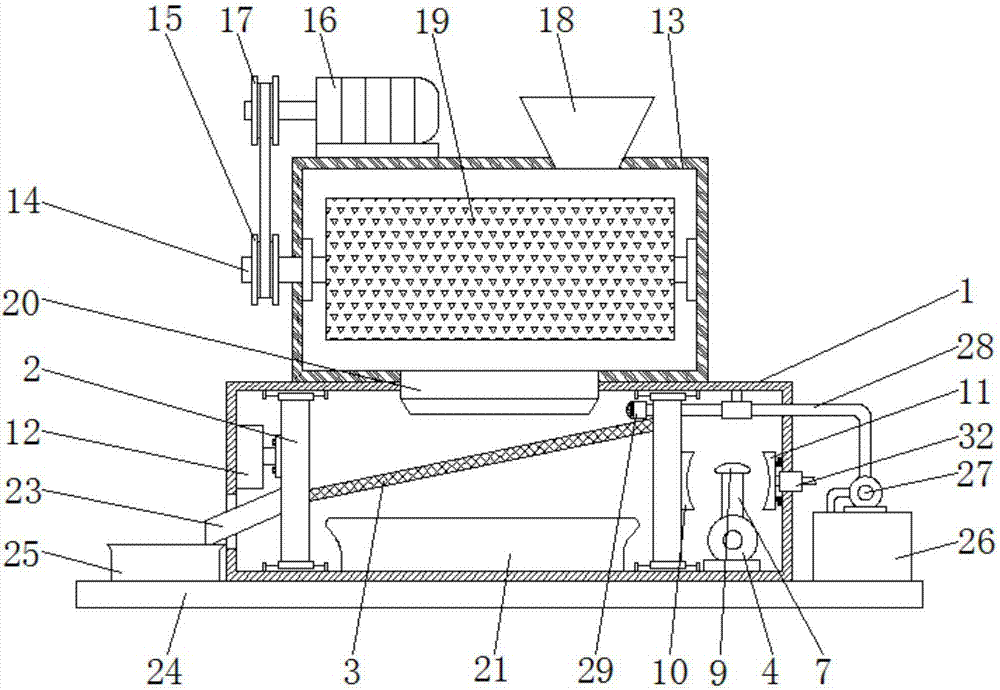

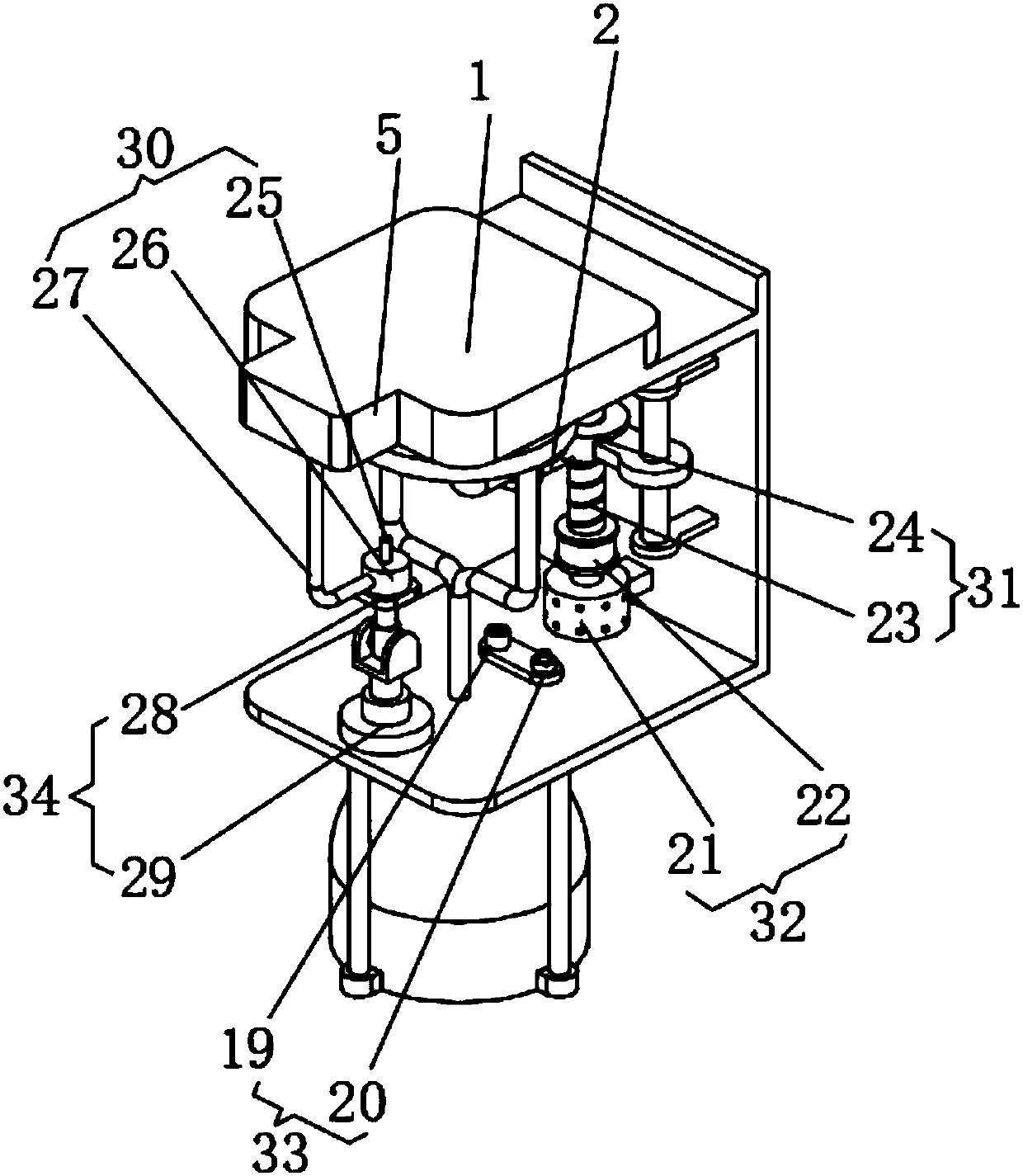

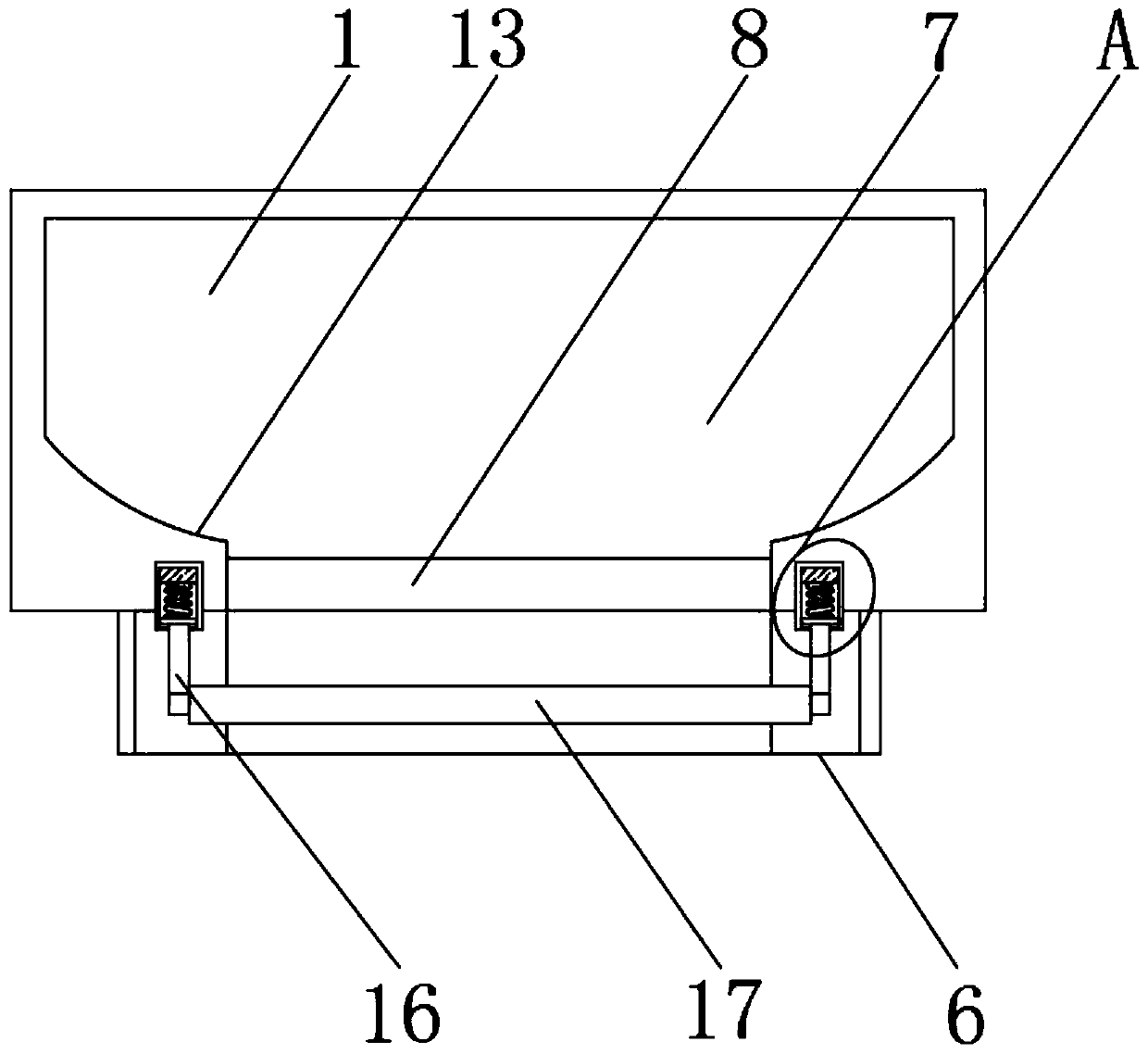

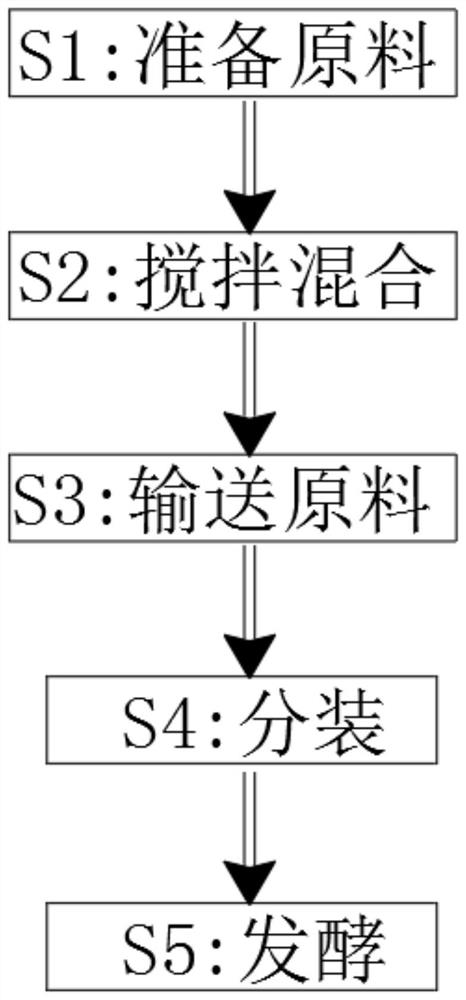

Fresh brewer's grain fermented feed additive and preparation method

PendingCN112401055AReduce manufacturing costImprove animal immunityFeeding-stuffFood processingChemistryNutrition

The invention relates to the technical field of feed additives, and discloses a fresh brewer's grain fermented feed additive. The feed additive comprises the following components: 60-70 parts of freshbrewer's grains, 10-20 parts of bran, 10-20 parts of corn flour and 0.4-0.7 part of a composite liquid strain. The invention further provides a preparation method of the fresh brewer's grain fermented feed additive. The preparation method comprises the following steps: S1, preparing raw materials, namely preparing the fresh brewer's grains, bran, corn flour and composite liquid strain according to corresponding parts; and S2, performing stirring and mixing. The invention further provides a preparation apparatus of the fresh brewer's grain fermented feed additive. The preparation apparatus comprises a box body, wherein a material inlet pipe is in welded connection with the top of the box body. According to the feed additive, the production cost is reduced, the animal immunity can be improved, the animal mortality is reduced, the medication is reduced, anti-nutritional factors can be degraded, and the digestibility of nutritional ingredients is improved, so that the animal production performance is improved.

Owner:广东亿博生物技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com