Agricultural pulverizer

A pulverizer, agricultural technology, applied in the agricultural field, can solve problems such as clogging, uneven soybean particle size, and single structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

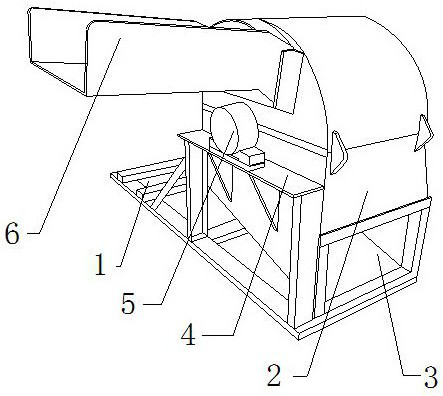

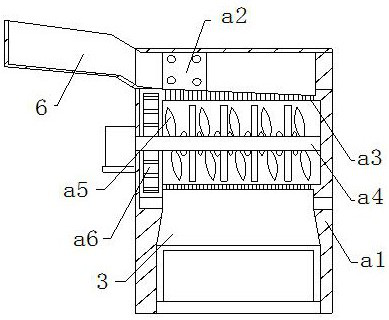

[0026] Such as Figure 1-Figure 6 Shown:

[0027] The invention provides an agricultural pulverizer, the structure of which comprises a bottom frame 1, a pulverizer 2, a discharge port 3, a fixed table 4, a motor 5, and a feed plate groove 6, and the discharge port 3 is nested and connected to At the bottom right of the pulverizer 2, the motor 5 is bolted to the top of the fixed table 4, the pulverizer 2 is welded to the top of the bottom frame 1, and the fixed table 4 is embedded and connected to the angle between the bottom frame 1 and the pulverizer 2 The feed plate groove 6 is bolt-connected to the front upper end of the pulverizer 2, and the motor 5 is embedded and connected to the front end of the pulverizer 2. The pulverizer 2 mainly includes a body a1, a beating device a2, a sieve plate a3, The rotating shaft a4, the crushing paddle a5, and the anti-slip device a6, the rotating shaft a4 is movably engaged on the right side of the motor 5, the crushing paddle a5 is emb...

Embodiment 2

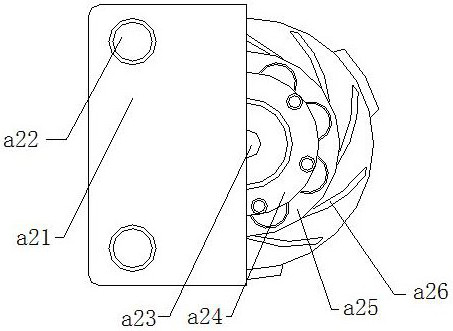

[0035] Such as Figure 7-Figure 8 Shown:

[0036] The present invention provides an agricultural pulverizer. The anti-skid device a6 mainly includes a joint plate c1, a blocking plate c2, and a rotating anti-slip wheel c3. The rotating anti-slip wheel is movably engaged inside the joint plate c1, and the blocking plate c2 Embedded and connected in front of the joint plate c1, the rotating anti-slip wheel c3 is connected to the rotating shaft a4, and the anti-slip device a6 is nested and connected outside the rotating shaft a4 to increase the rotation rate of the rotating shaft a4 so that it can better carry out grain grains crushing work.

[0037] Wherein, the rotating anti-skid wheel c3 mainly includes a fixed sleeve c31, a wheel cover c32, a roller c33, and a sleeve shaft c34. The wheel sleeve c32 is nested and connected outside the roller c33, and the sleeve shaft c34 is installed on the Inside the fixed sleeve c31, there are three rollers c33 in total, and they evenly su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com