Patents

Literature

188results about How to "Avoid stuck problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

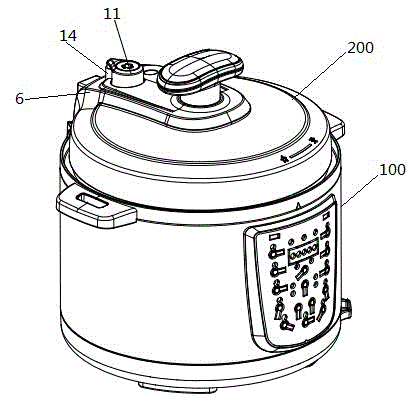

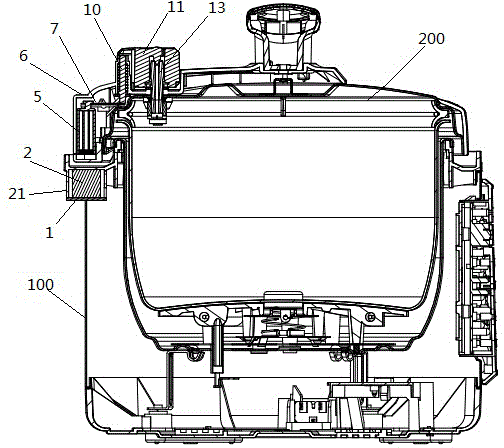

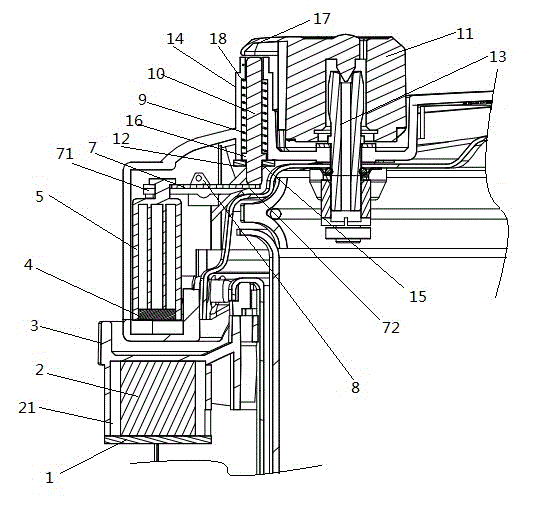

Electric pressure cooker capable of automatically exhausting

InactiveCN105768859ASimplify the automatic exhaust structureShorter drivelinesPressure-cookersMagnetic effectEngineering

The invention provides an electric pressure cooker capable of automatically exhausting. The electric pressure cooker comprises a cooker body, a cooker cover and a control circuit, wherein an exhaust pipe and a gravity hammer which is in sealed contact with the exhaust pipe are arranged on the cooker cover; a first connecting rod is additionally arranged on the cooker cover; a ferromagnetic material is arranged at the first end of the first connecting rod; the position, corresponding to the ferromagnetic material, of the cooker body, is provided with an electromagnet which can take a magnetic effect on the ferromagnetic material; the electromagnetic is electrically connected to the control circuit; the second end of the first connecting rod is in transmitted connection to the gravity hammer; and the gravity hammer is displaced directly or indirectly when the second end of the first connecting rod displaces upwards, and the gravity hammer is separated away from the port of the exhaust pipe. By virtue of the electromagnet and a lever linkage device which are mutually matched, the electric pressure cooker can simplify an automatically exhausting structure, shorten a power transmission route, reduce a probability of a jamming phenomenon in a power transmission process and improve product quality.

Owner:ZHONGSHAN YALESI ELECTRIC CO LTD

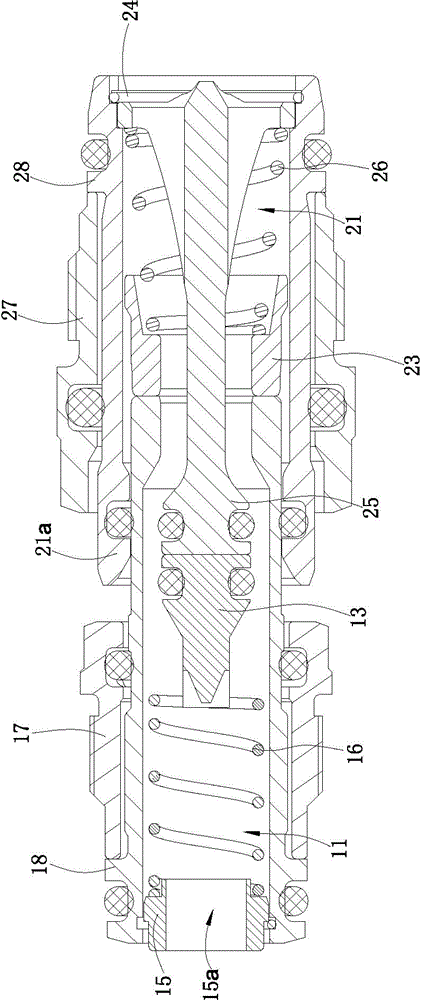

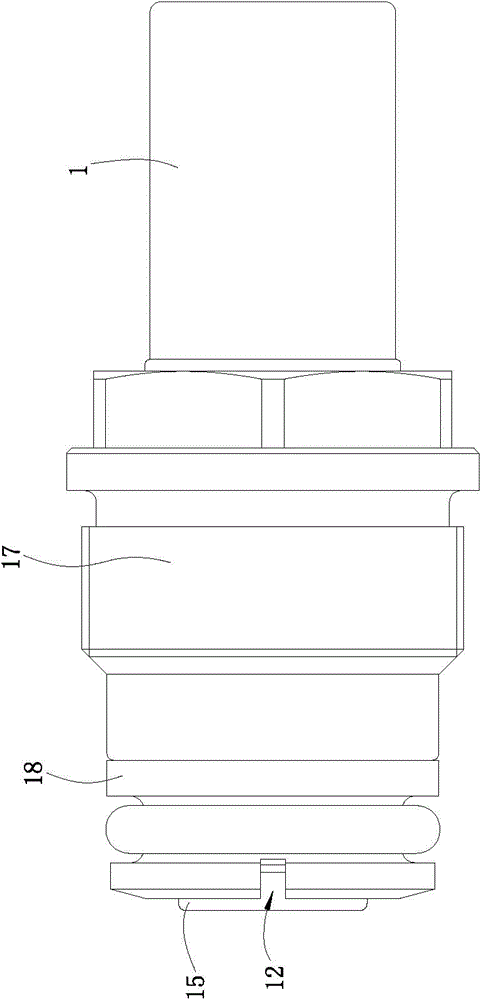

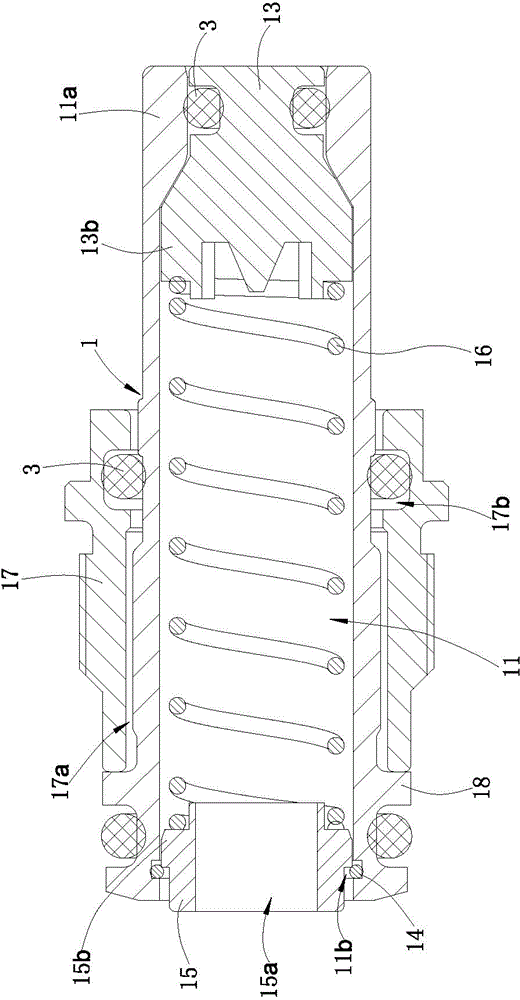

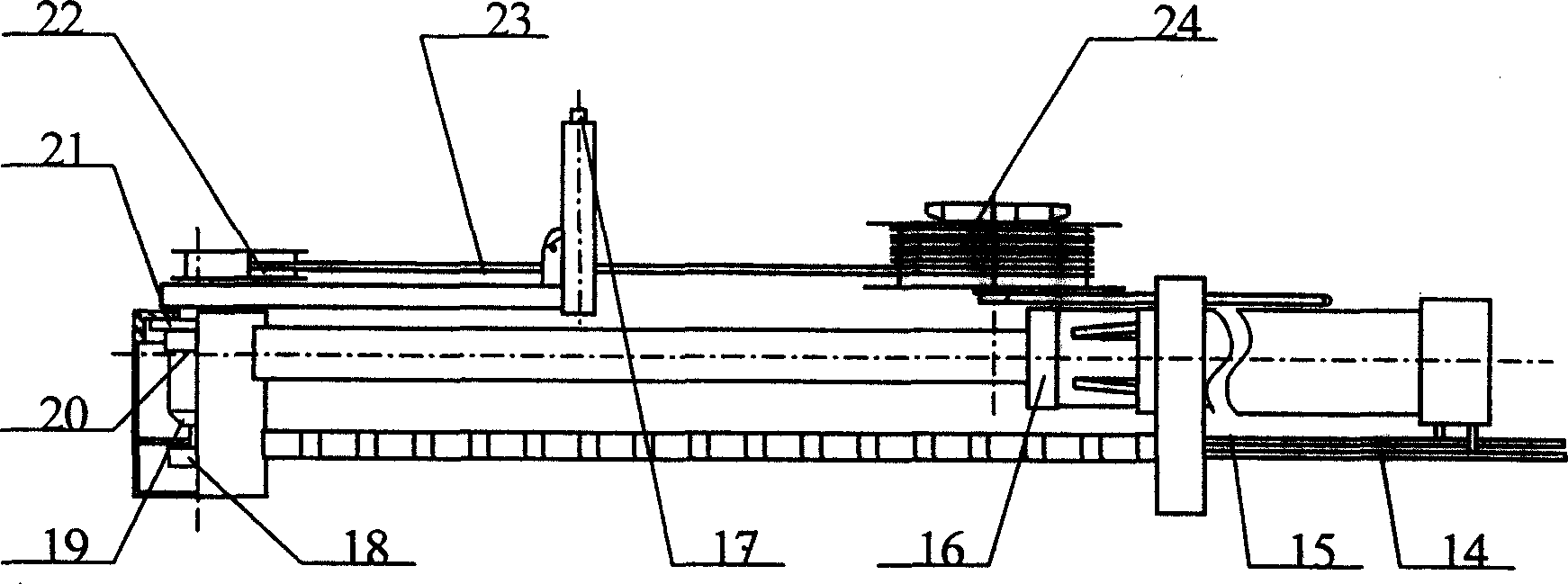

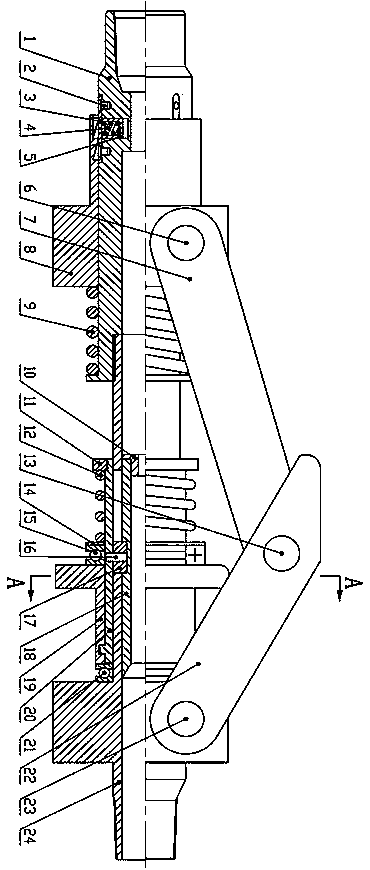

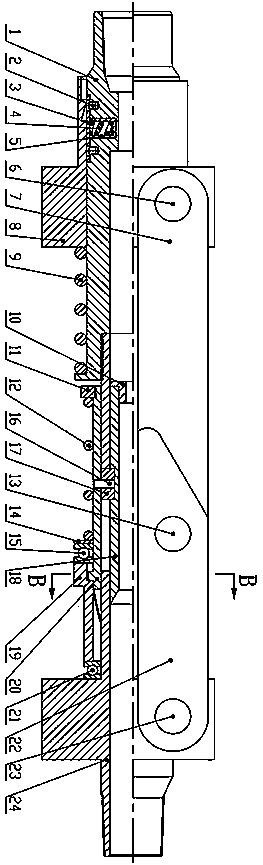

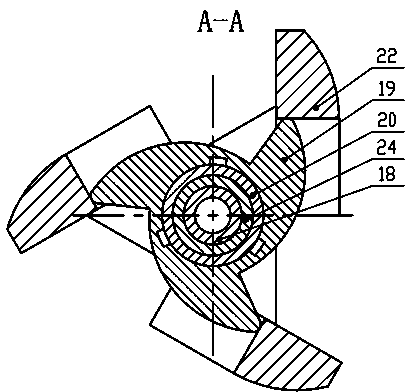

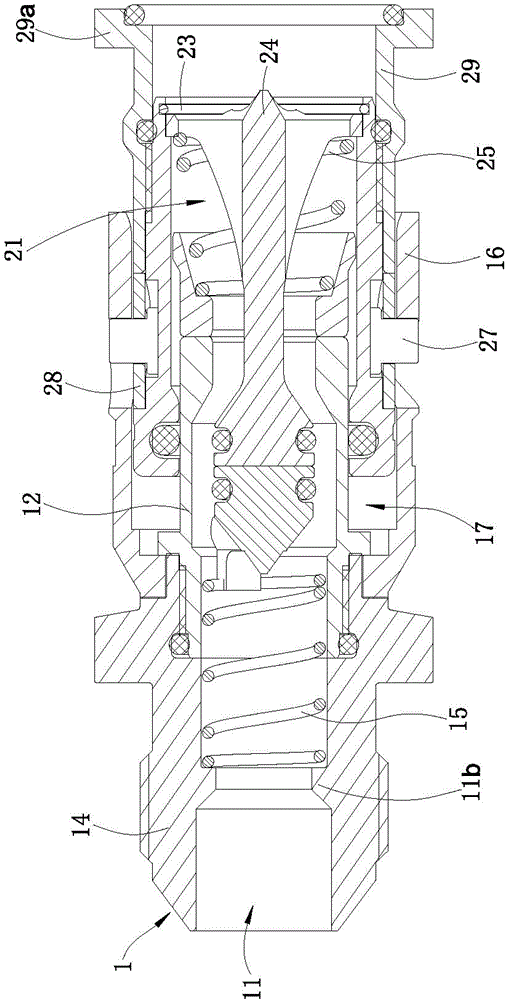

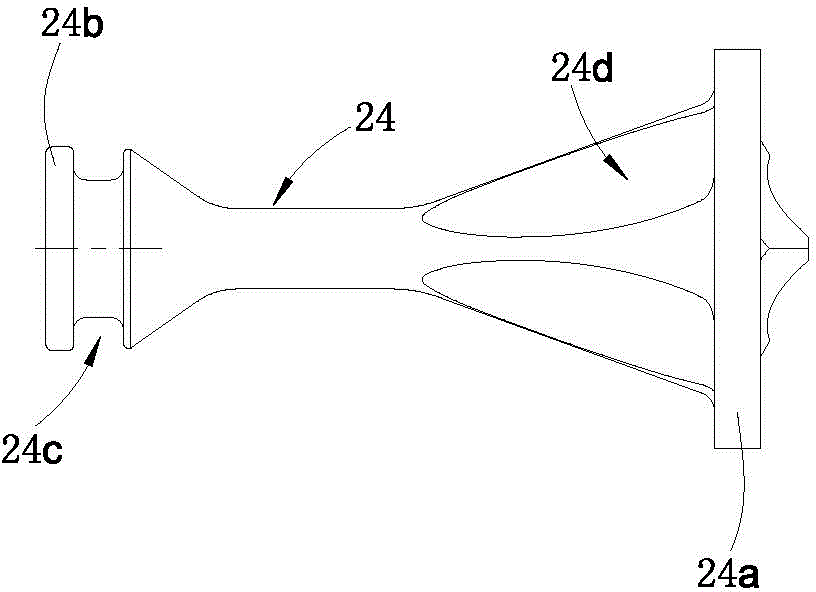

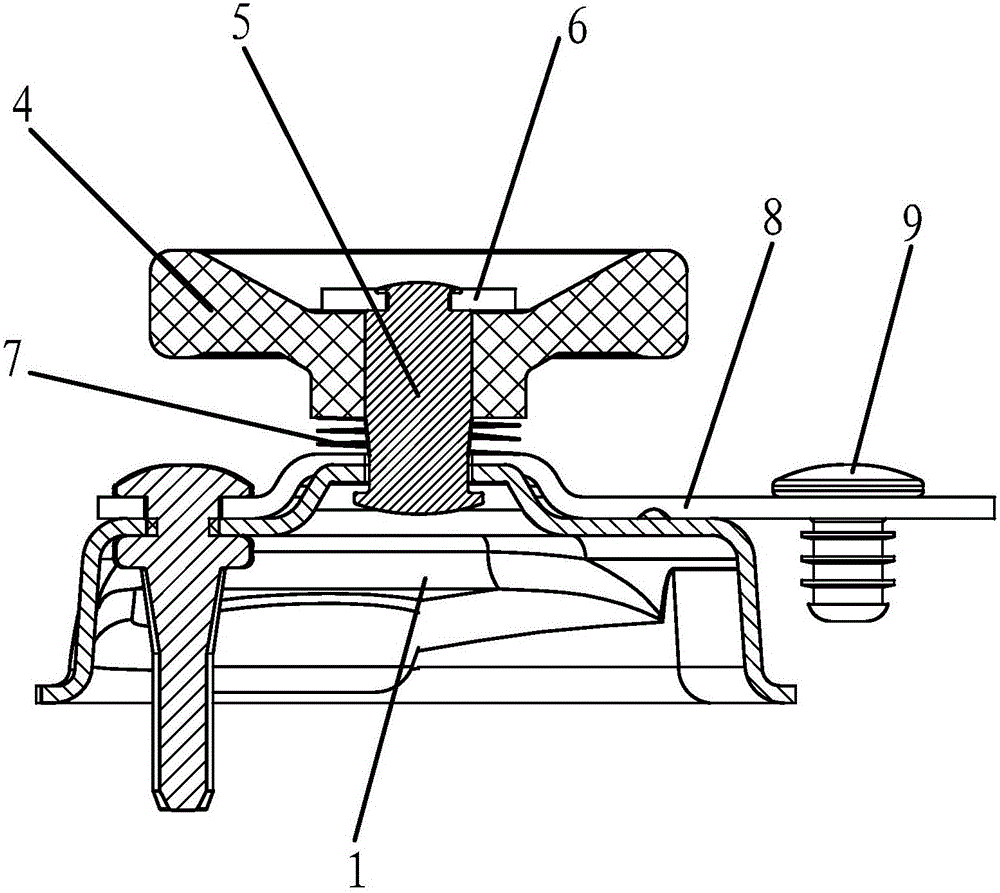

Floating blind-mating flow connector

ActiveCN103557392AImprove sealingExtended service lifeJoints with fluid cut-off meansEngineeringMechanical engineering

The invention discloses a floating blind-mating flow connector which comprises a socket and a plug matched with the socket, wherein a first flow guide hole is formed in the plug; a first snap ring, a valve bush, a first spring and a first valve core are arranged in the first flow guide hole; the valve bush is provided with a first bumping shoulder matched with the first snap ring; a first spring is arranged between the valve bush and the first valve core; a third flow guide hole is formed in the socket; a second snap ring groove is formed in the lateral wall at the front end of the third flow guide hole; a second snap ring, a flow guide post, a second ring and a second valve core are arranged in the third flow guide hole; the second snap ring is placed in the second snap ring groove; a third bumping shoulder matched with the second snap ring is arranged a the front part of the flow guide post; a fifth flow guide hole is formed in the third bumping shoulder; the second spring is arranged between the third bumping shoulder and the second valve core. According to the invention, both the socket and the plug can be used singly; the sealing effect is excellent and jamming is avoided when the socket and the plug are used together, so that, the fluid in the socket and the plug is enabled to run off quickly and the service life of the socket and the socket is prolonged.

Owner:中国电子科技集团公司第四十研究所

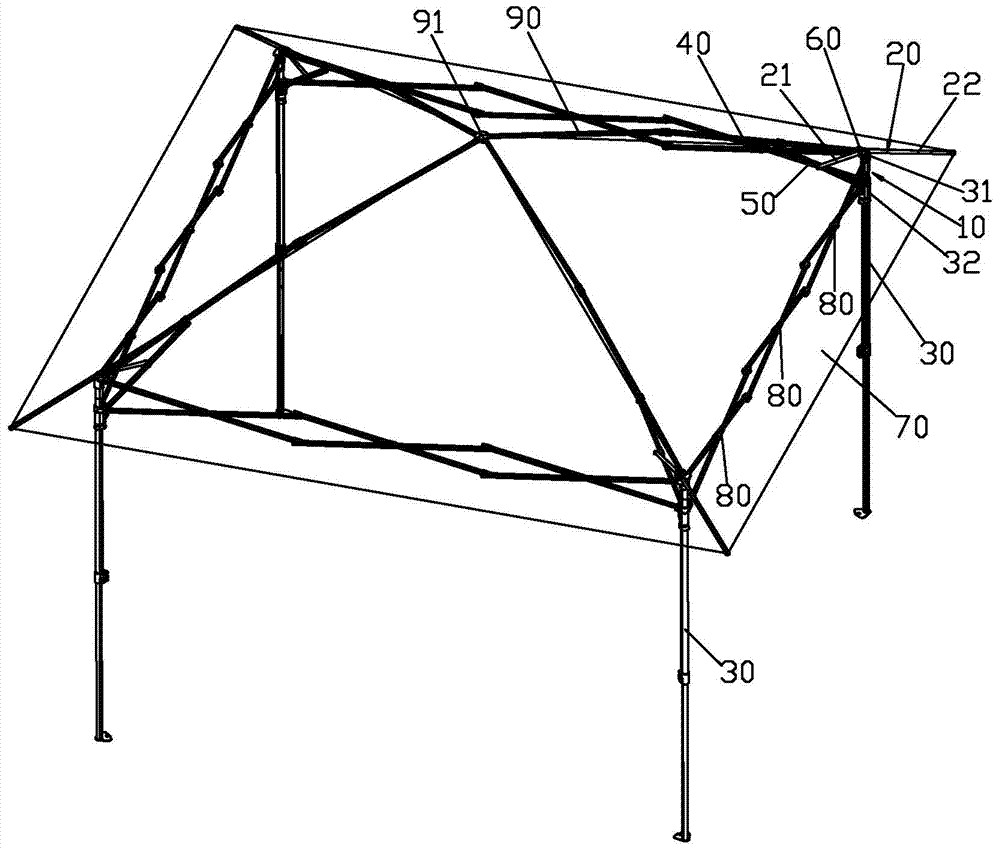

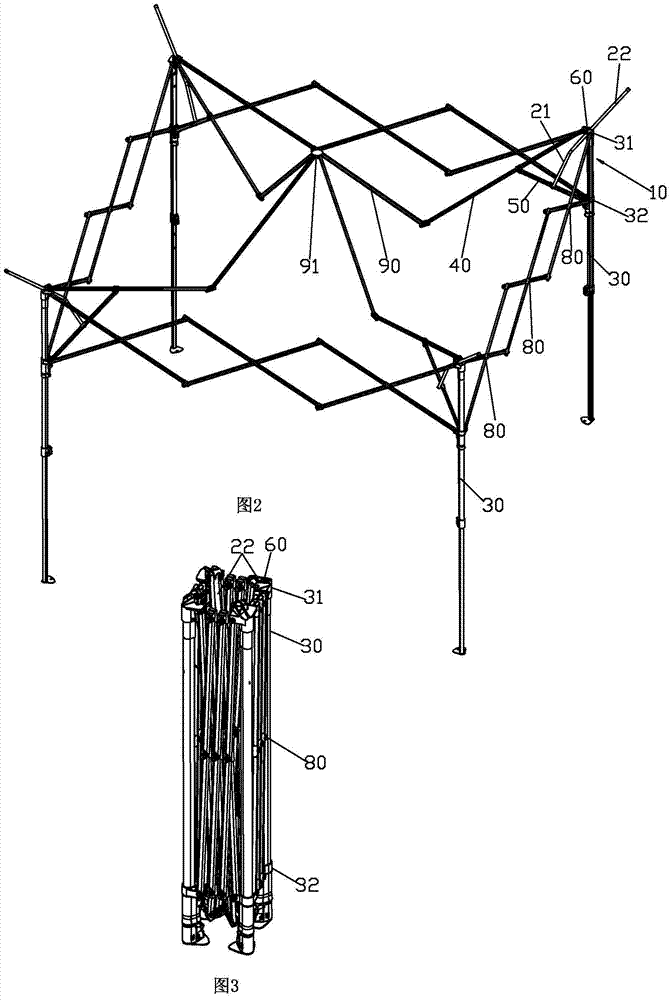

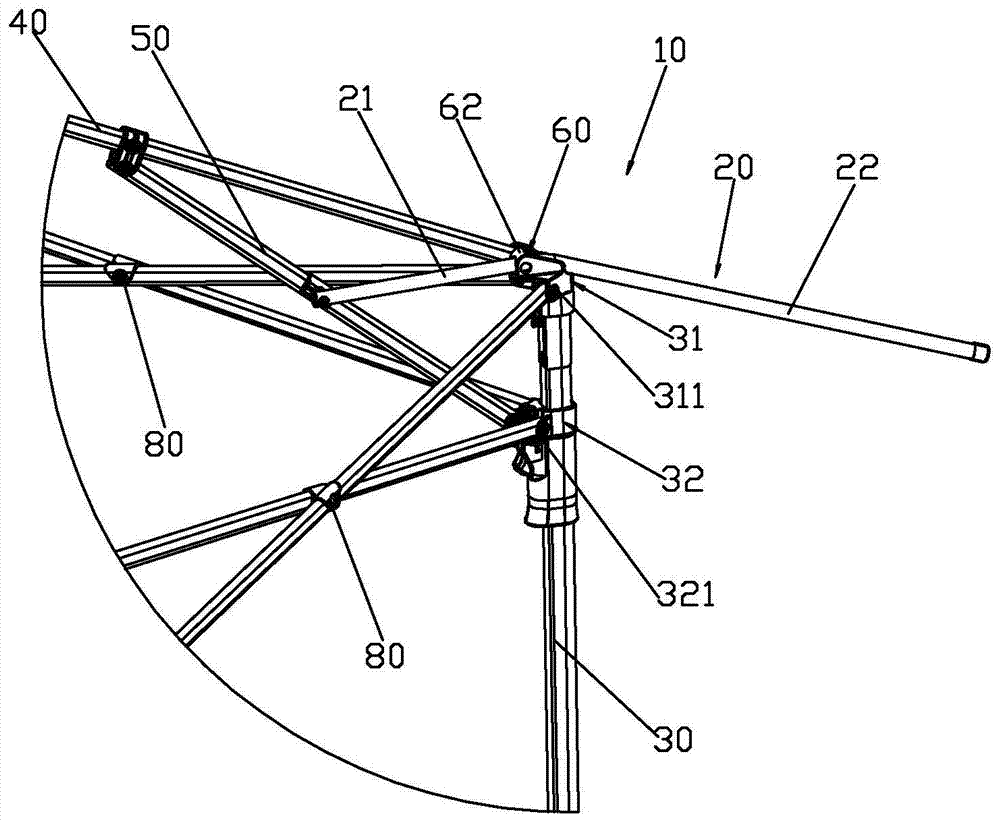

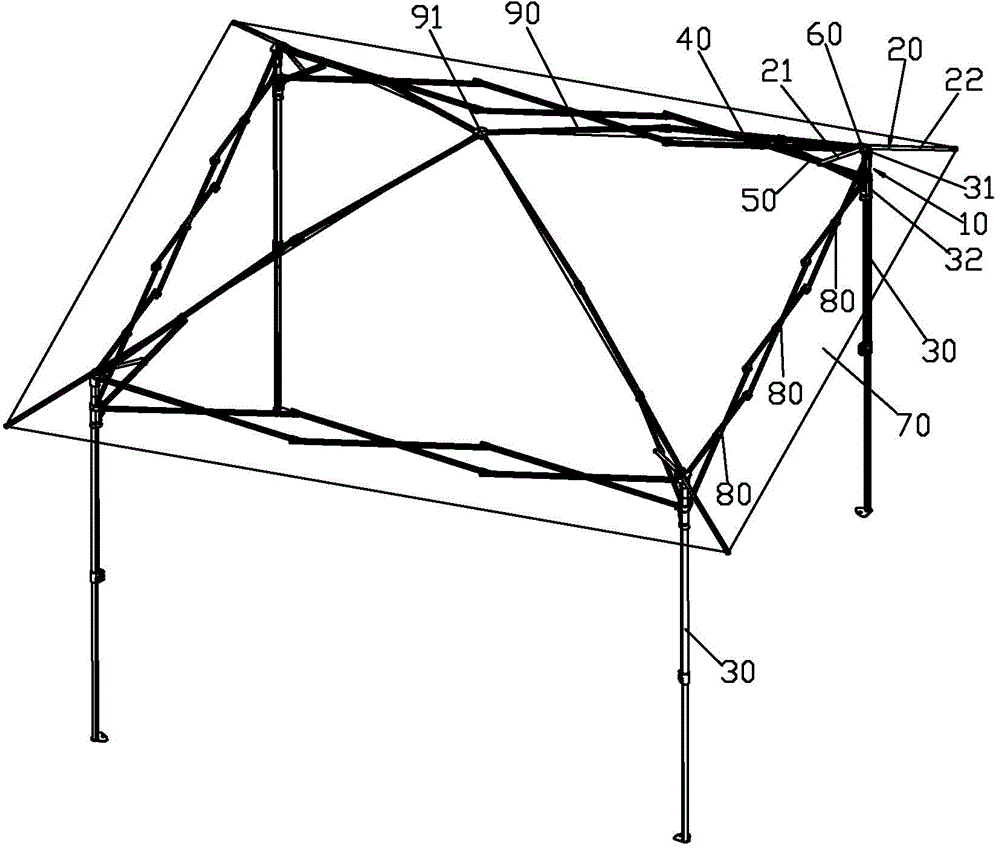

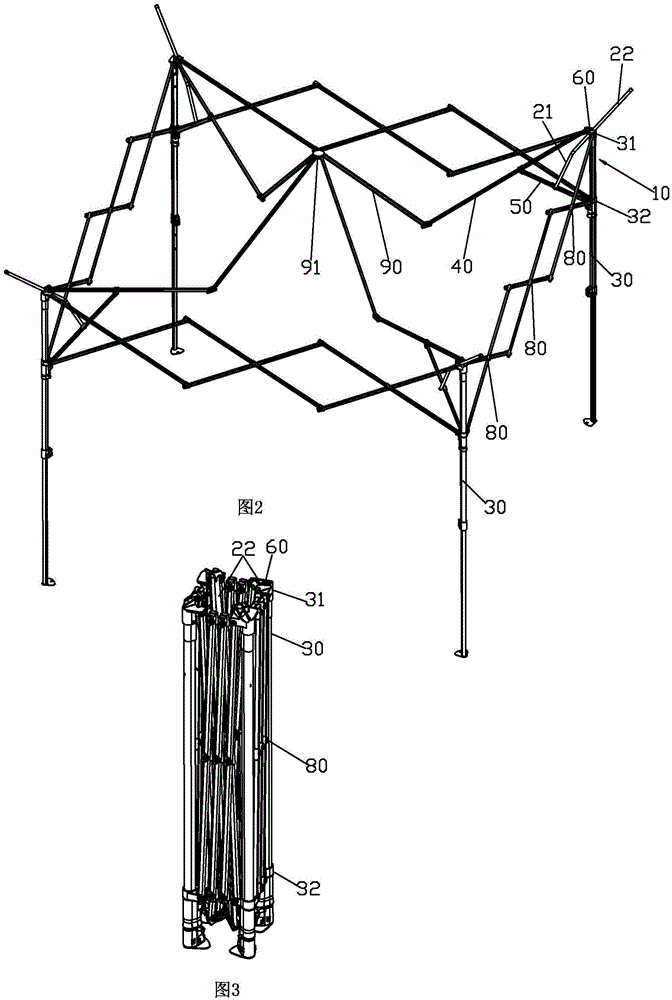

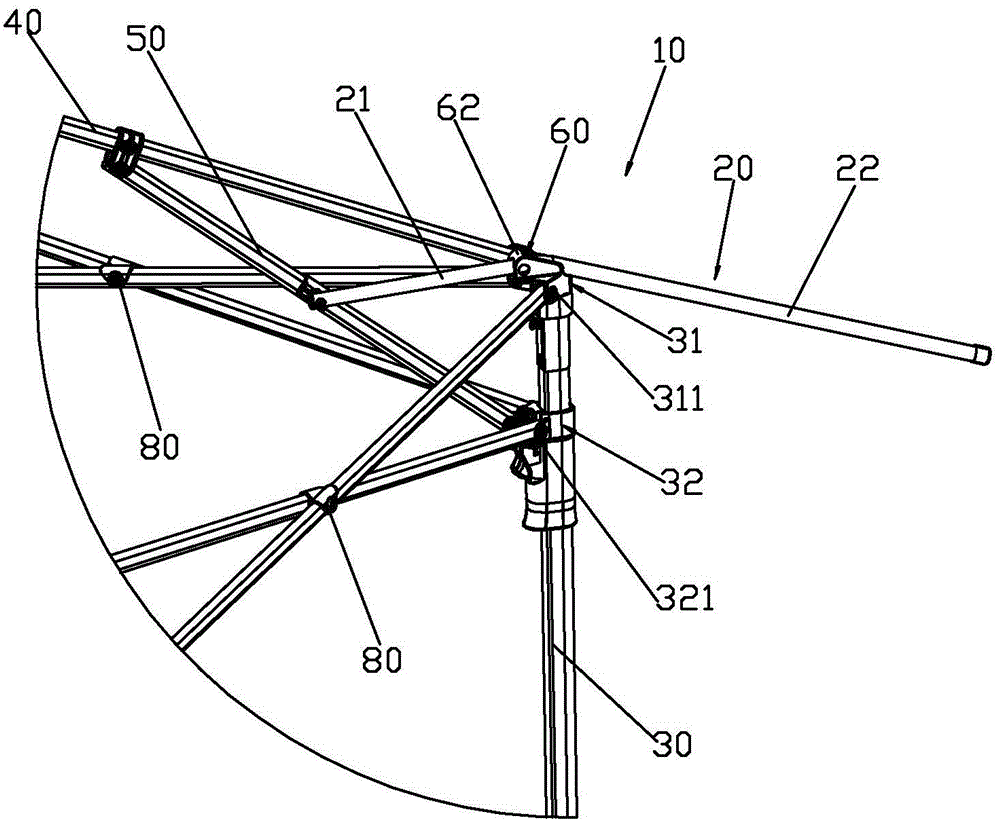

Folding tent eave frame mechanism

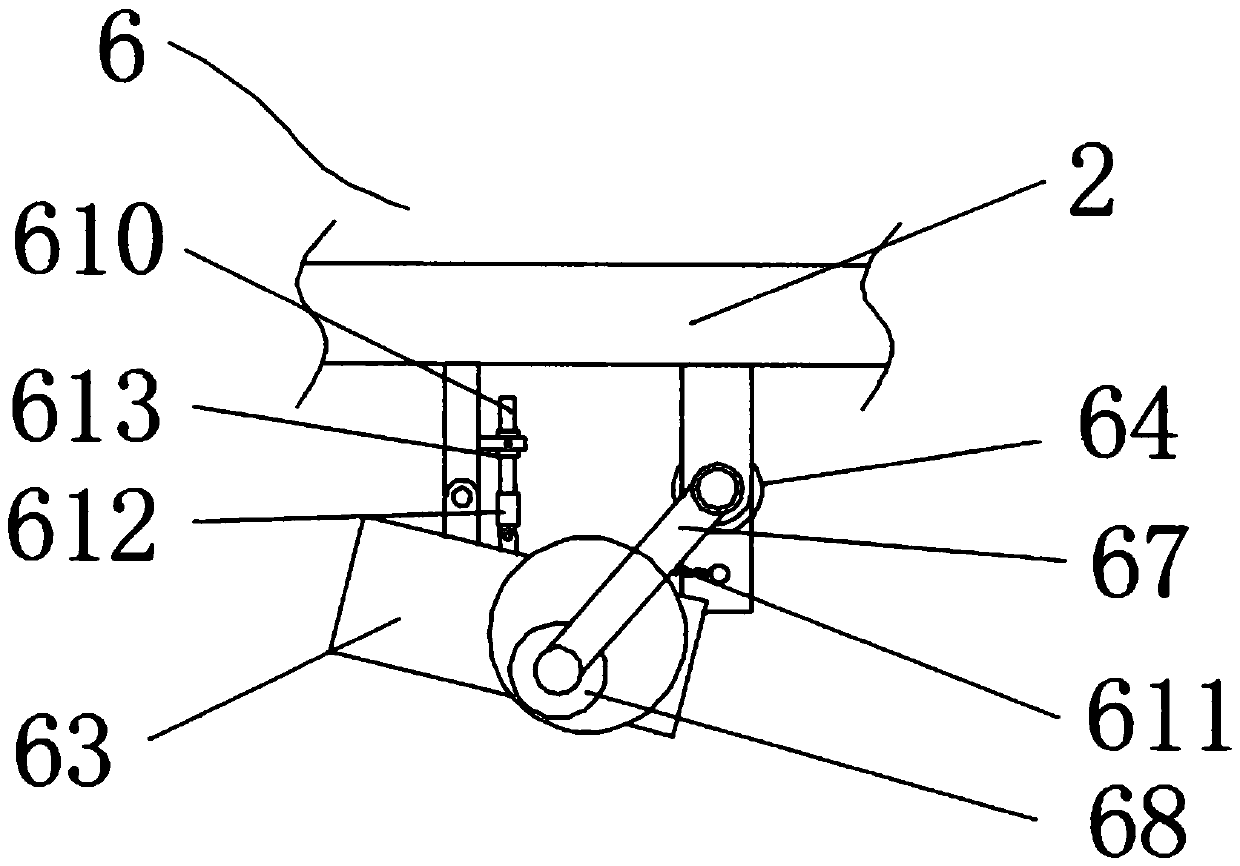

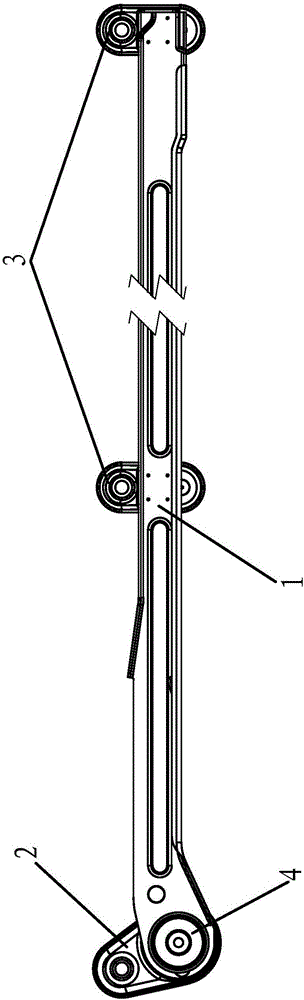

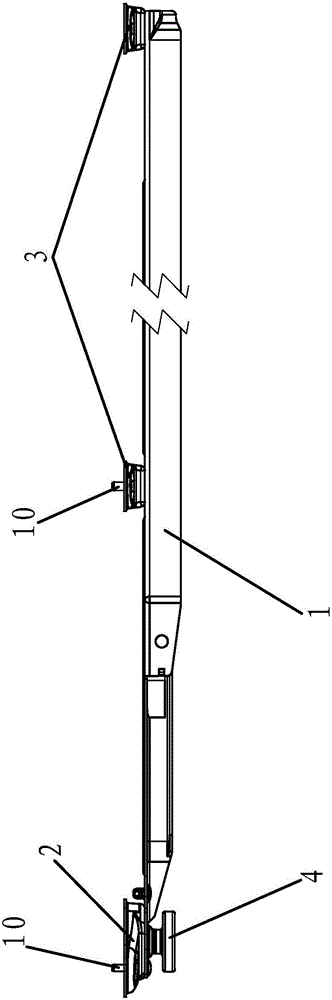

ActiveCN103590650AGuaranteed Relative Swipe ActivityStable and reliable supportTents/canopiesEavesEngineering

Owner:XIAMEN ROADZUP OUTDOOR PROD

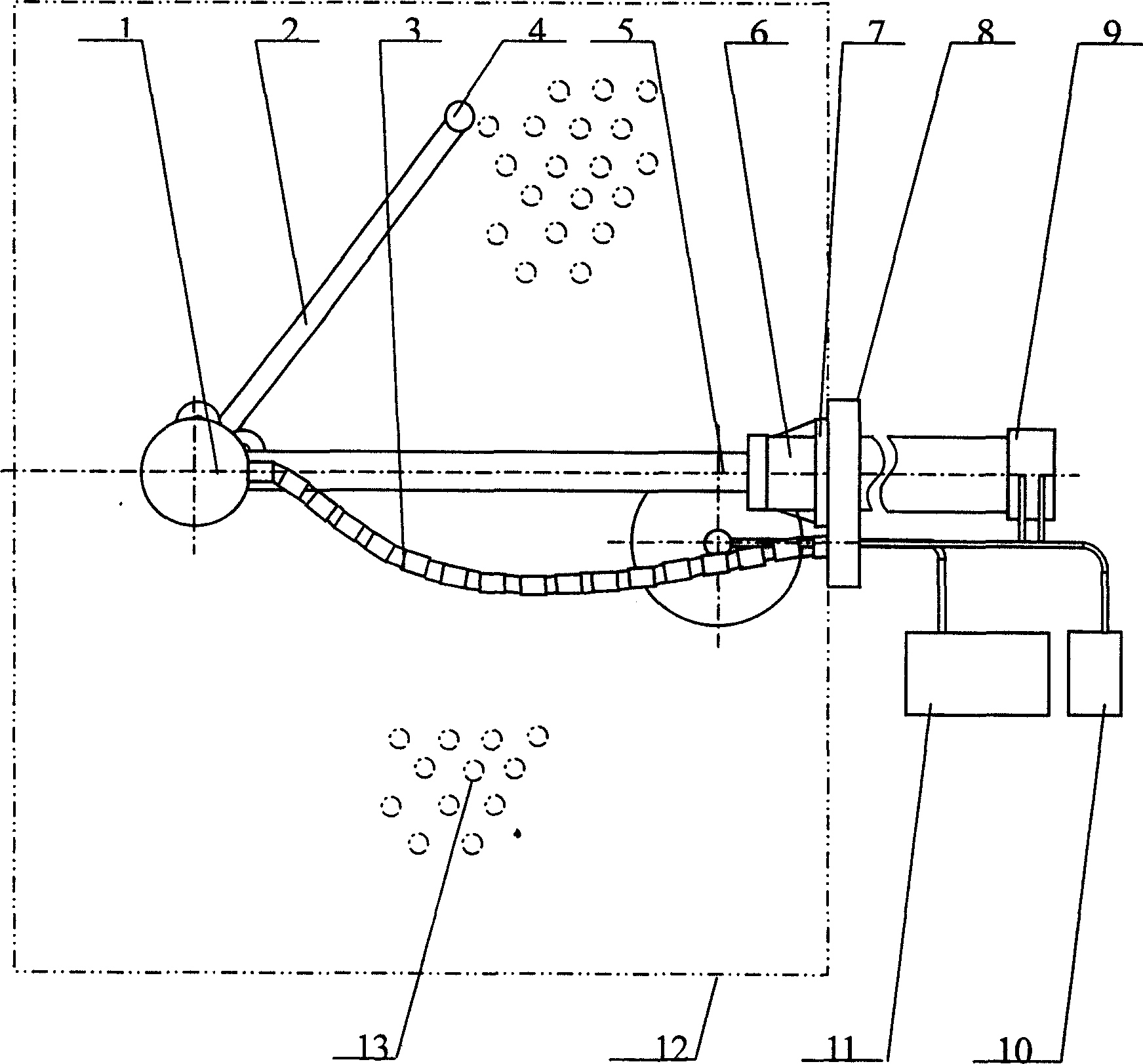

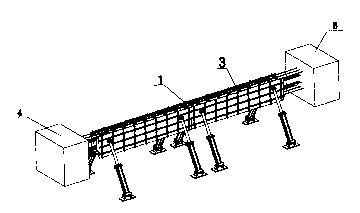

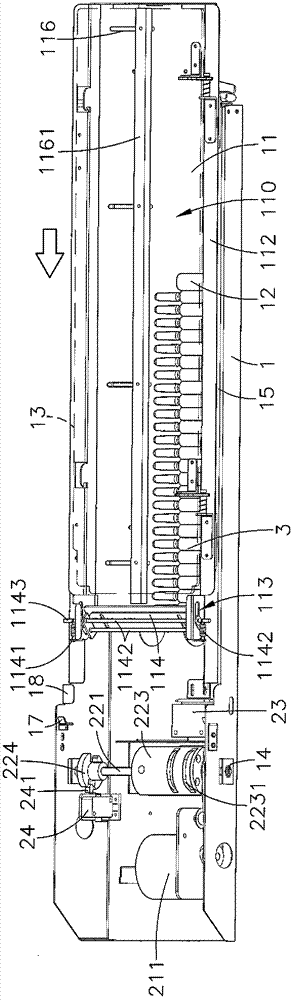

Robot technology of on-line cleaning power plant steam condenser using high pressure water jet

InactiveCN1664486AImprove operational efficiencyMaximize coverage areaRotary device cleaningNon-rotary device cleaningDevice formHigh pressure water

The invention relates to an electric power plant condenser high pressure water shooting flow online washing robot technology that cleans the electric power plant condenser by high pressure water shooting flow. Setting the mechanism arm locating device and high pressure soft tube into the condenser by using the combination method and install structure of locating mechanism arm orientation device formed by extending mechanism arm and rotating mechanism arm, high pressure soft tube manage device, and high pressure spray head control device, locates the spray head on the rotating mechanism arm by computer control system, sends to the inner of the condenser copper pipe, and cleans the dirt in the inner of the condenser copper pipe by high pressure water shooting flow. The generating set needs not stop while cleaning. The invention has advantage of simple structure, no pollution and high reliability.

Owner:CHINA UNIV OF MINING & TECH

Hydraulic variable-diameter centralizer

InactiveCN103541666ASmall starting forceEasy to driveDrilling rodsDrilling casingsTriangular prismEngineering

The invention relates to a hydraulic variable-diameter centralizer used for convention oil gas well drilling and solid mineral resource well drilling, and the hydraulic variable-diameter centralizer solves the problems that an underground variable-diameter centralizer is large in starting force and short in installation distance. According to the technical scheme, sliding blocks penetrate through lower cylindrical body through grooves and are embedded into inner central tube annular grooves, an outer central tube is arranged in a revolving cylindrical body in a sleeved mode, protrusive splines outside the outer central tube are embedded into spiral grooves in the revolving cylinder body, a spring c is arranged outside the outer central tube in a sleeved mode, an upper cylindrical body is in threaded connection with a lower cylindrical body, a spring b is arranged outside the upper cylindrical body in a sleeved mode, and a sliding sleeve is arranged in the upper cylindrical body in a sleeved mode. A centralizing arm a is hinged to the triangular prism surface of the sliding sleeve, a centralizing arm b is hinged to the triangular prism surface of the lower cylindrical body and hinged to the centralizing arm a, a locking cylinder is placed in an upper cylindrical body through hole, a spring a is put in the locking cylinder, and a press plate and the upper cylindrical body are fixed through screws a. The hydraulic variable-diameter centralizer converts axial motion of the inner central tube and the outer central tube into circumferential direction rotation of the revolving cylindrical body, converts axial thrust generated by hydraulic pressure into circumferential direction centralizing force, and is reliable in supporting and large in installation distance.

Owner:SOUTHWEST PETROLEUM UNIV

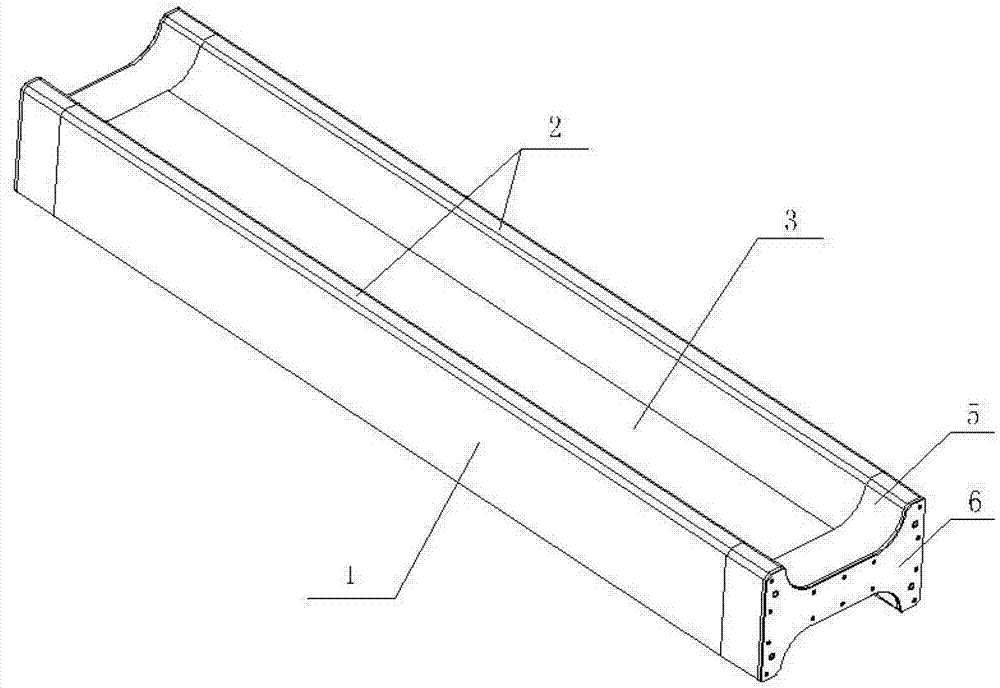

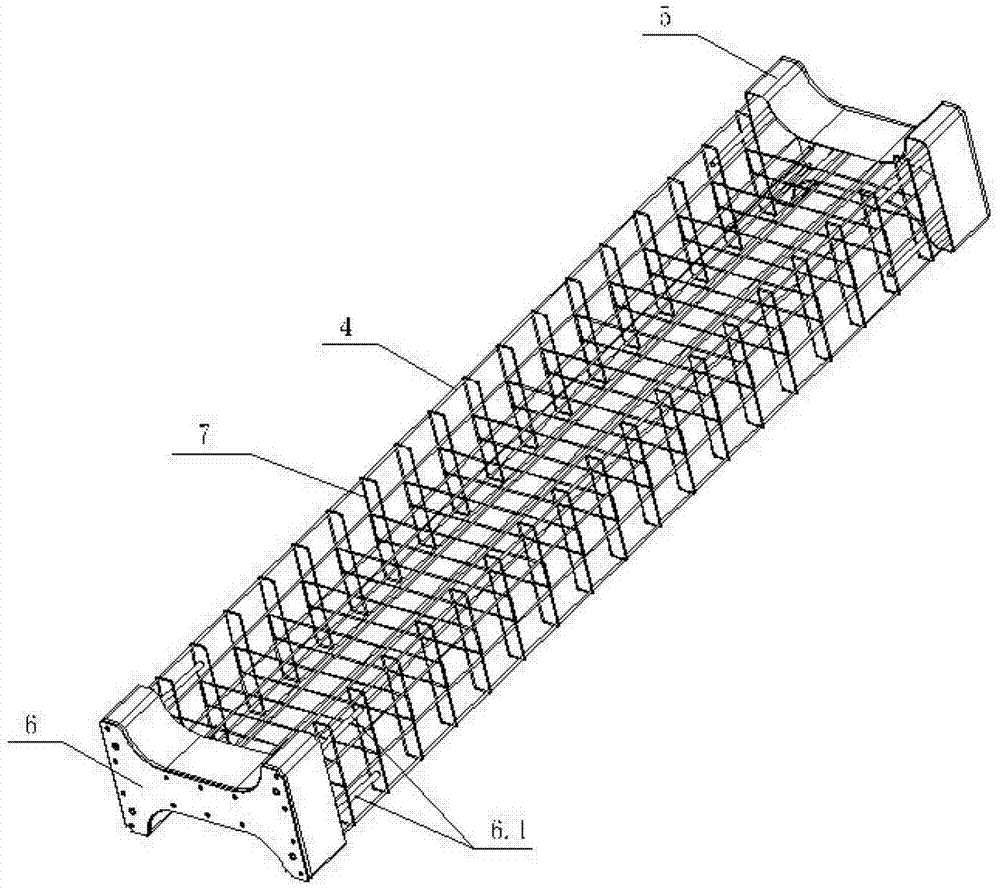

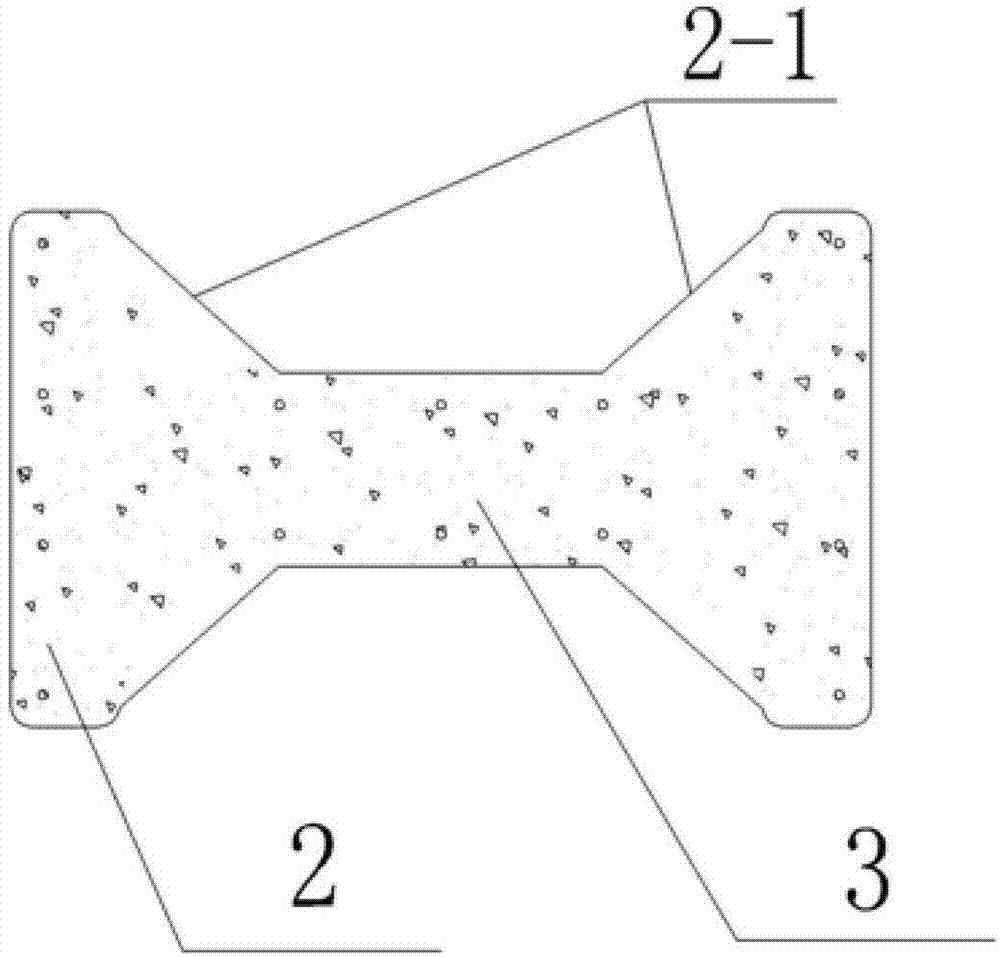

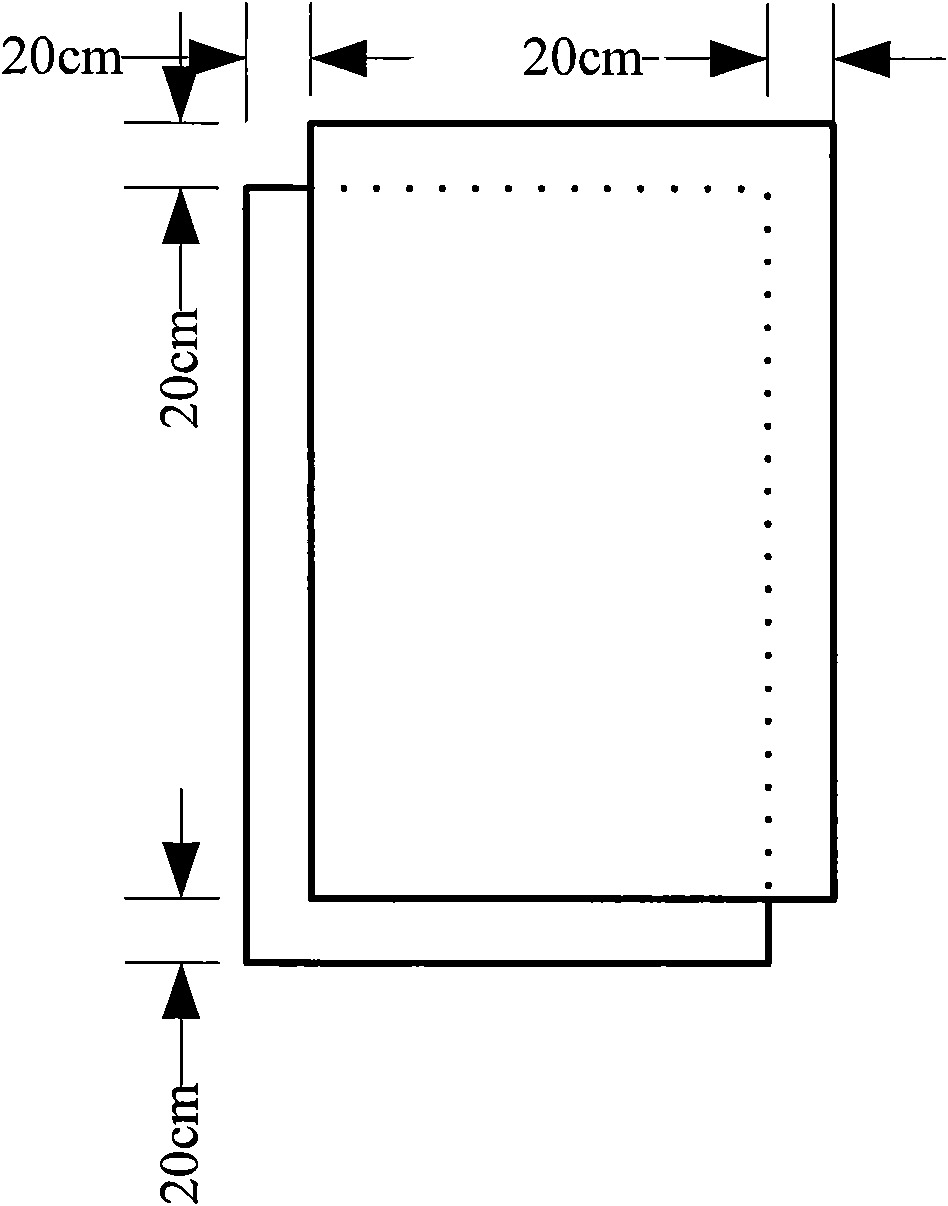

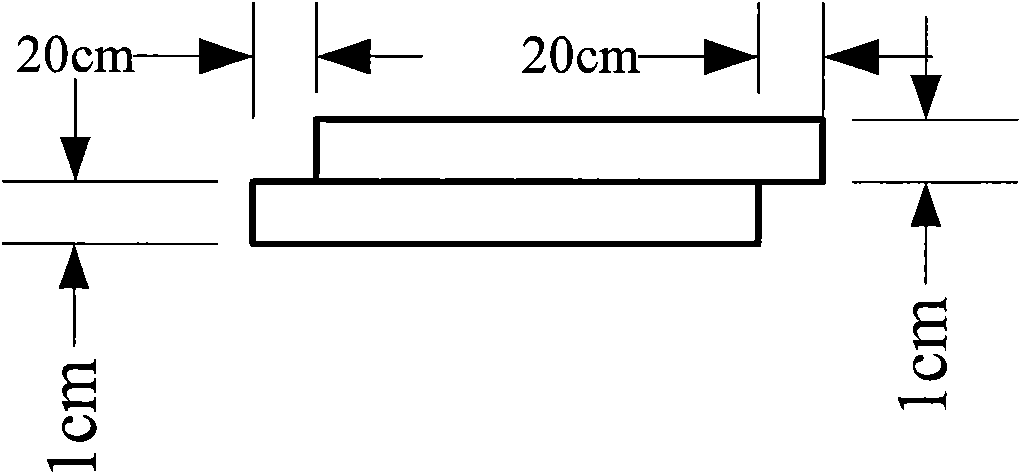

H-shaped support pile and preparation method thereof

ActiveCN102828510AAvoid stuck problemsReduce the anchoring processBulkheads/pilesRebarUltimate tensile strength

The invention discloses an H-shaped support pile which comprises a support pile body poured by prestressed reinforcement, hooping and concrete. The cross section of the support pile body is an H-shaped structure formed by two flanges and a web connected between the two flanges. An end plate and a pile hoop are arranged on at least one end of the support pile body. The end plate is arranged on the end face of the support pile and is provided with a hole. The prestressed reinforcement is contained in the hole. The pile hoop and the end plate are fixedly connected or integrally formed and sleeved on the end part of the support pile body. An anchoring rib extending into the support pile body is fixedly connected on the pile hoop or the end plate. The invention further discloses a preparation method of the H-shaped support pile. The H-shaped support pile provided by the invention has the advantages of low cost, fast construction, and high bending resistance and shear strength.

Owner:谢建富 +1

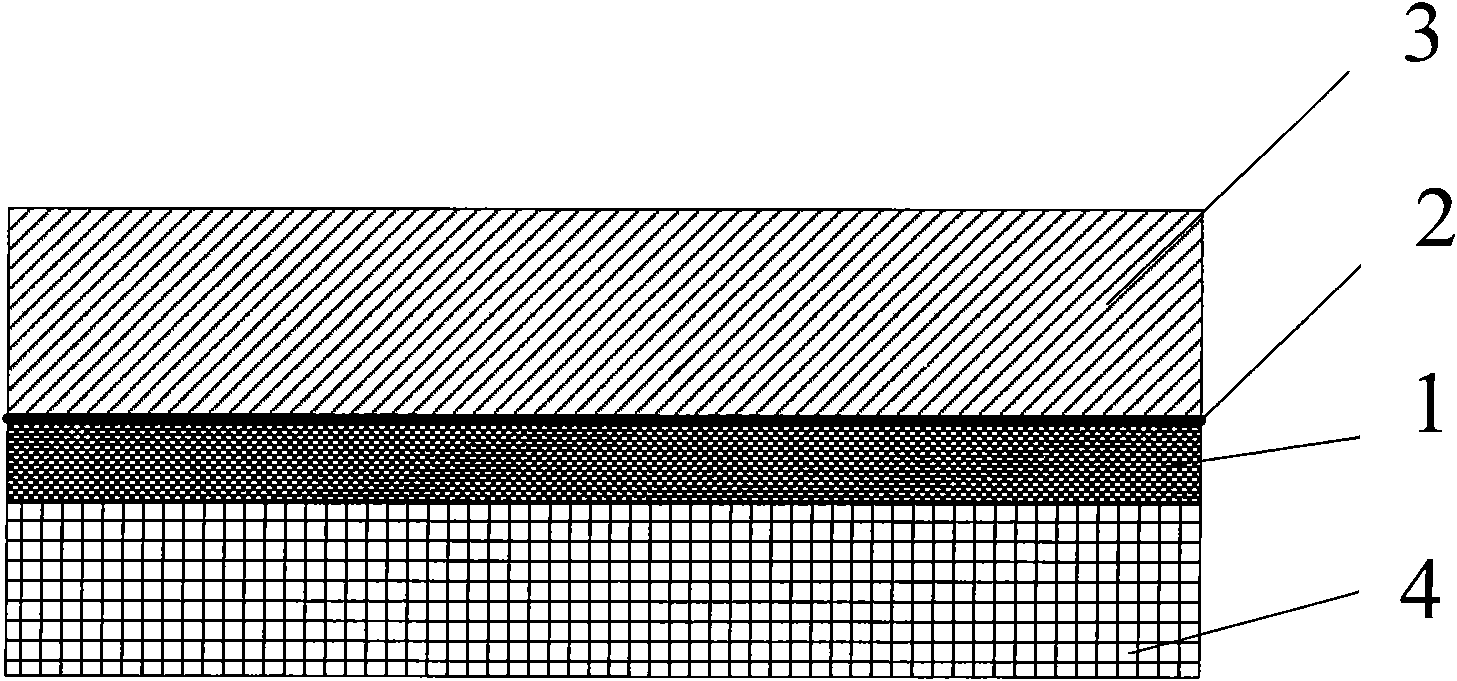

Composite type pavement structure and pavement method thereof

ActiveCN101597878AImprove fatigue resistanceIncrease stiffnessIn situ pavingsBridge structural detailsSheet steelRoad engineering

The invention discloses a composite type pavement structure and a pavement method, and relates to a road engineering structure and a construction method thereof. In the invention, the thermal expansion coefficient, the cement concrete and the fiber-reinforced composite material substrate which performance is near to the steel plate are adopted to reinforce for the bottom surface of the asphalt layer; thus improving the performance of anti-fatigue and anti-reflecting crack of the asphalt surface course, effectively preventing the lower bearing layer from being eroded due to infiltration of the rain water from the asphalt surface course, avoiding bonding problem between the asphalt surface course and the cement concrete or the steel plate, increasing stiffness of the steel bridge surface, and particularly reinforcing the steel bridge surface the steel plate of which has insufficient thickness, so as to reduce the thickness of the asphalt surface course, avoid the damages, such as cracking and falling of the asphalt pavement layer caused by the insufficient thickness of the steel bridge surface and the like.

Owner:广州大象超薄路面技术开发有限公司

Method for praparing varek specimen

InactiveCN101548670AEliminate breaksAvoid breakingDead plant preservationBiochemical engineeringNatural state

The invention discloses a method for praparing varek specimen, including steps of specimen washing, specimen immersing, specimen paper sleeve lining and specimen drying in turns, the specimen immersing step is immersing the specimen into immersion in natural state, the specimen paper sleeve lining step is holding the specimen out of the immersion and lining the specimen onto specimen paper in natural state, in one of the steps before the specimen drying step, the specimen is covered with plastic film, the specimen drying step is padding 6 to 10 pieces of absorbent paper under the specimen paper and using a sample slip to clamp for drying, and in the first three days drying the absorbent paper shoule be replaced once a day, and after the three days drying the absorbent paper should be replaced once for every two to five days. The invention is a method for praparing varek specimen of little specimen damage, good specimen surface gloss and tight cementation between the specimen and the specimen paper, and the method also reduces labor intensity of specimen prepartion.

Owner:NINGBO UNIV

A folding tent eaves frame mechanism

Owner:XIAMEN ROADZUP OUTDOOR PROD

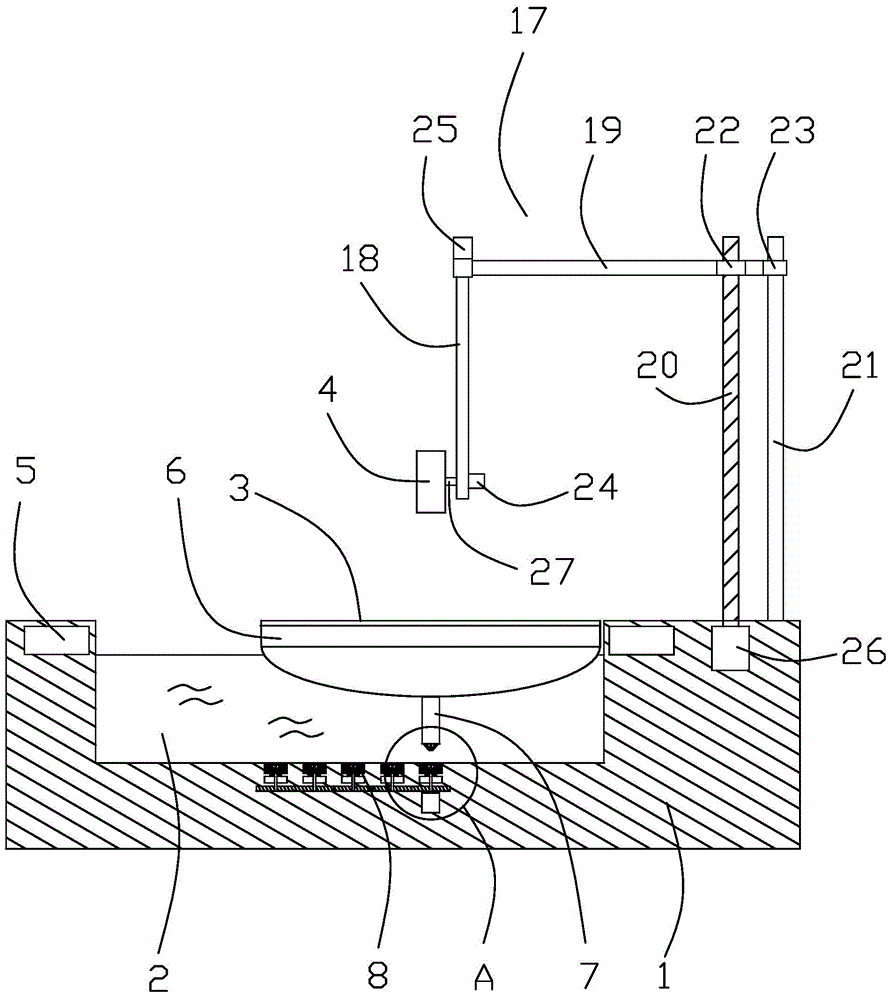

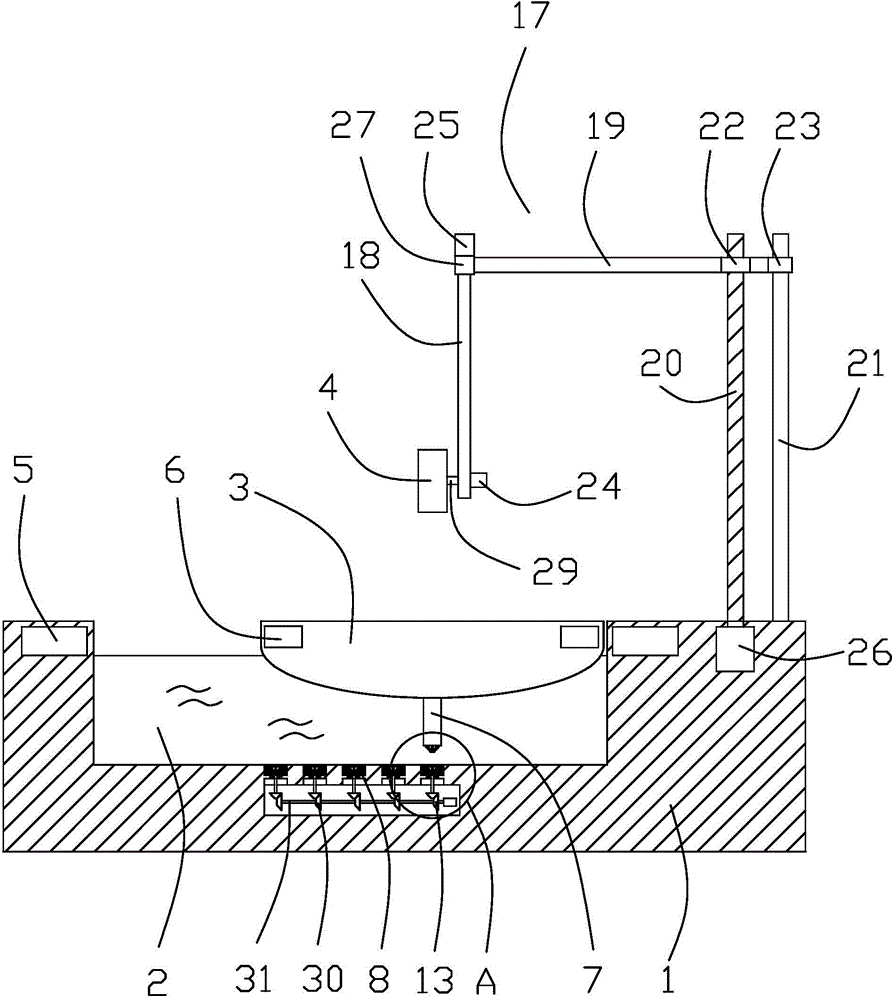

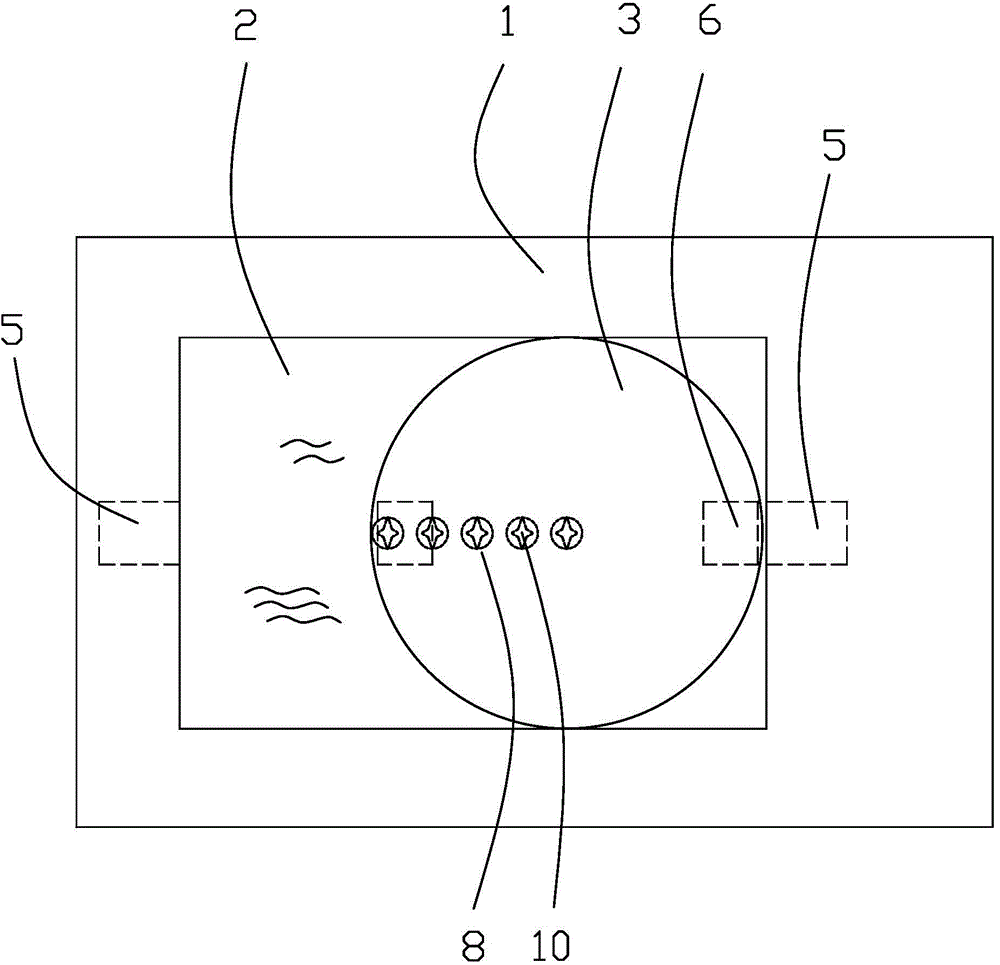

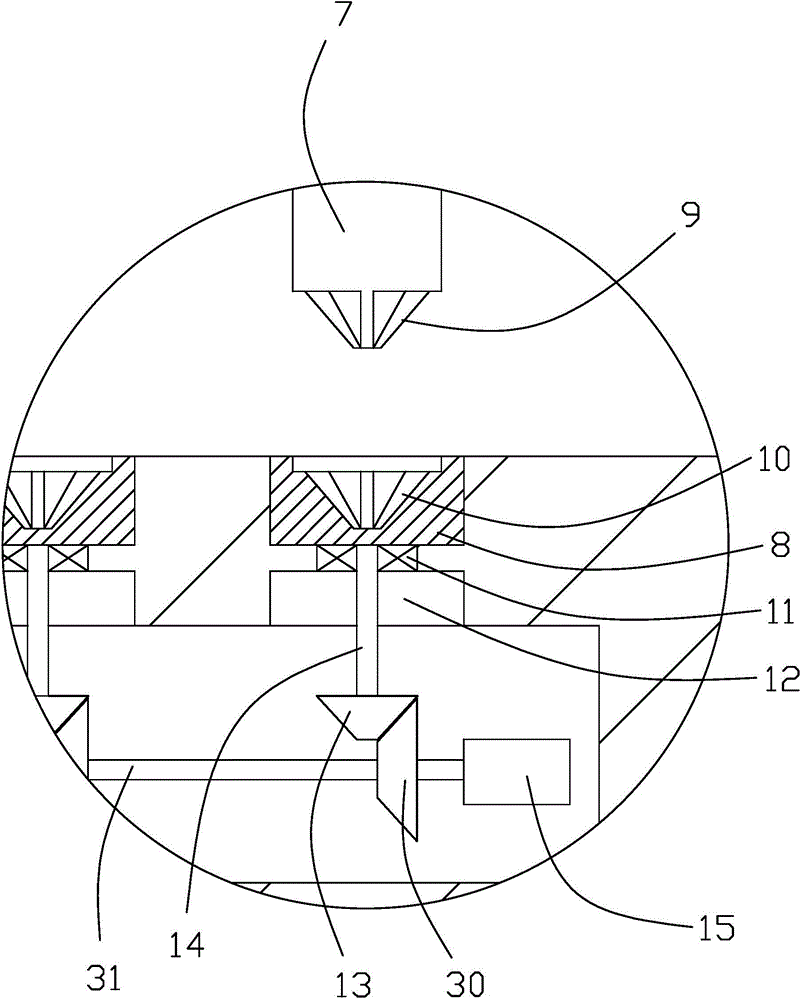

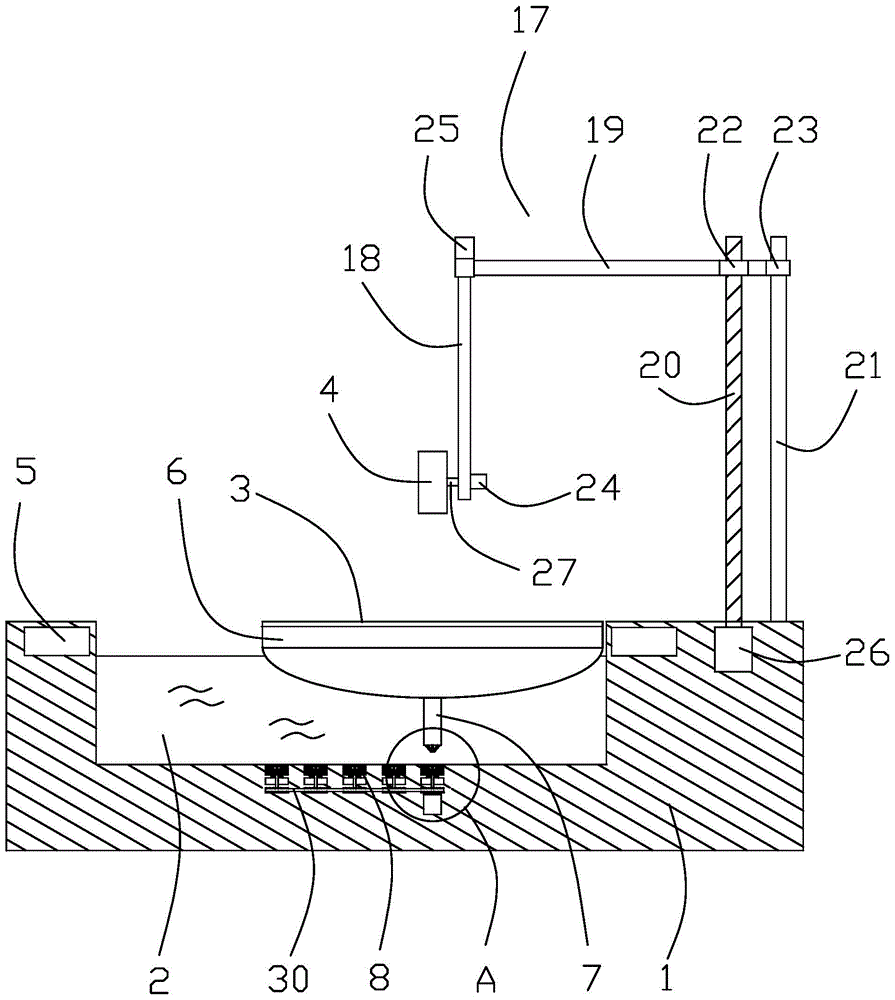

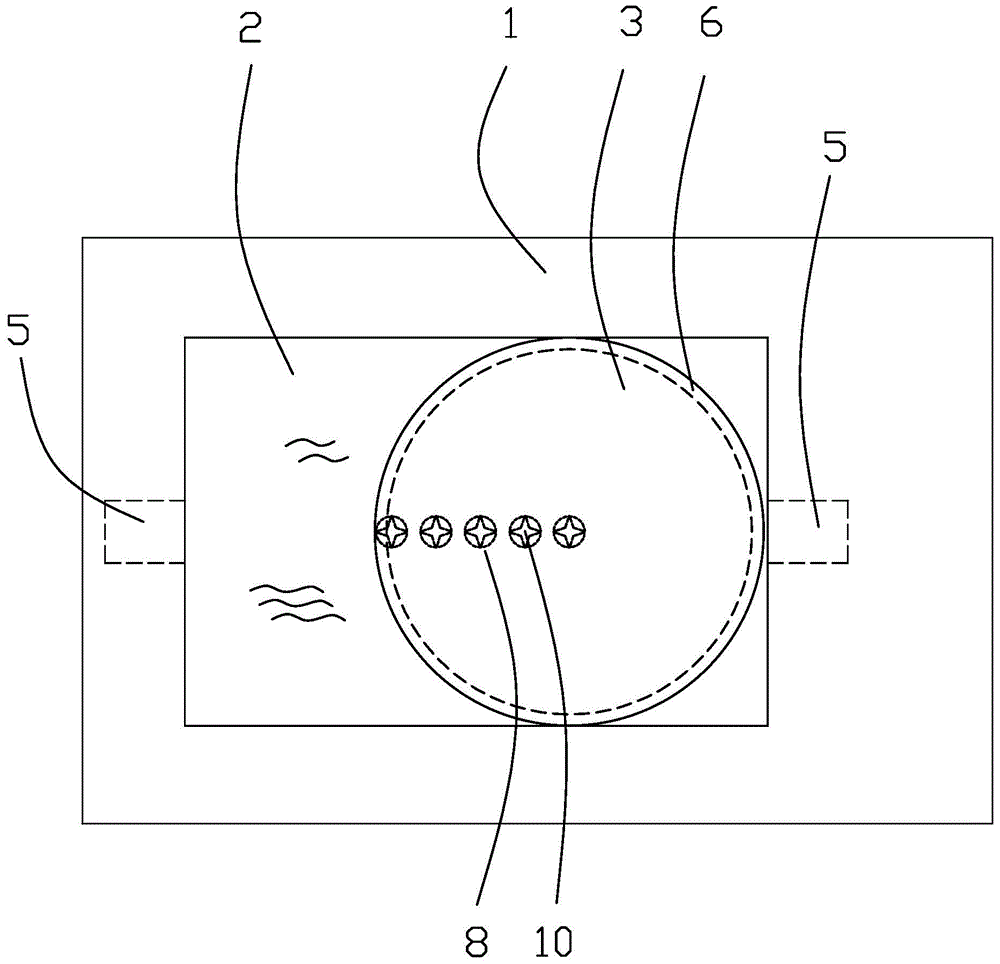

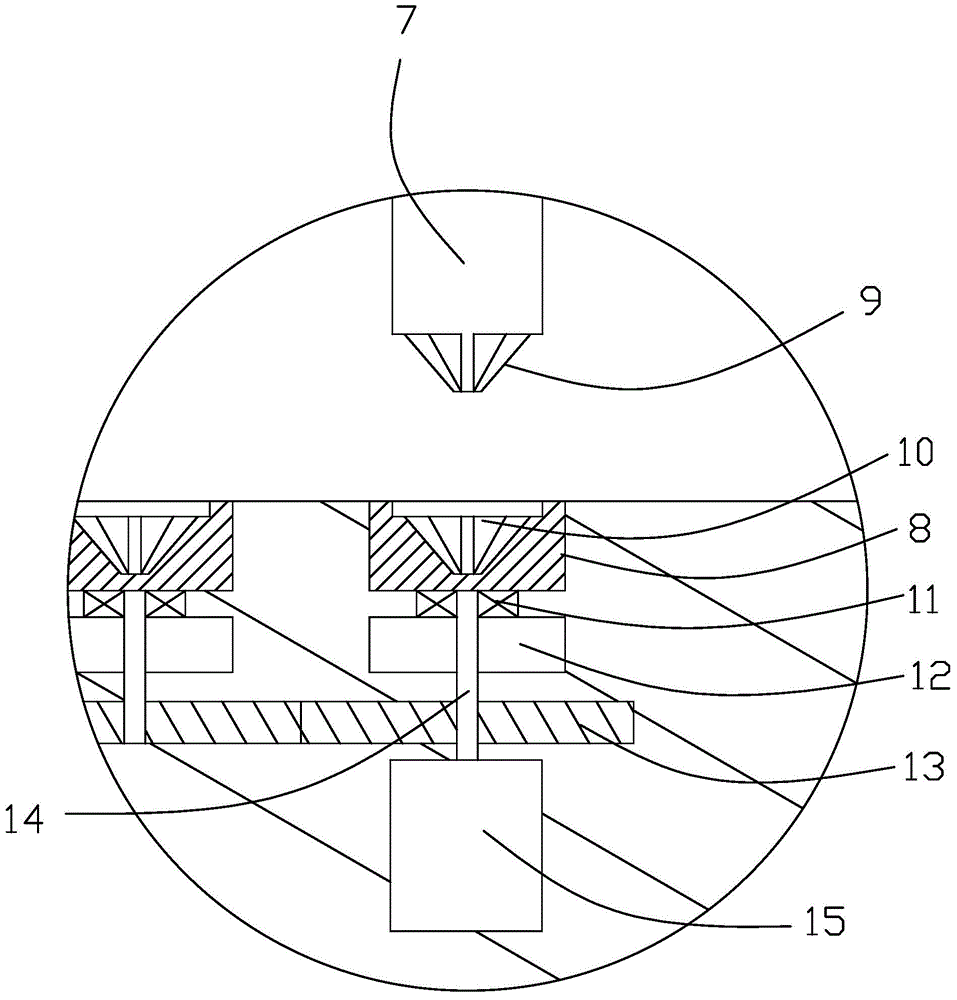

New beef freshness rapid nondestructive detection device and detection method

InactiveCN104374702APrecisely control the moving distanceMove preciselyColor/spectral properties measurementsEngineeringNondestructive testing

The invention relates to a new beef freshness rapid nondestructive detection device and detection method, and solves the problems, in the prior art, of subjective inaccuracy of beef freshness detection and complex detection equipment and detect process. The device comprises a seat body, the seat body is provided with a floating pool, a tray floats in the floating pool, the tray is controlled to move through magnetic force, an adjustment bracket is arranged above the seat body, the adjustment bracket is provided with a light source, and the seat body is also provided with a control unit. The control unit analyzes sample reflectance spectra data to judge the degree of beef freshness. The advantages of the new beef freshness rapid nondestructive detection device are that, by using a spectral detection mode, nondestructive testing of samples can be carried out; the new beef freshness rapid nondestructive detection device is reasonable in structure, the seat body moving resistance is small, and the new beef freshness rapid nondestructive detection device does not jam, and is convenient in operation and maintenance, and accurate in detection data.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

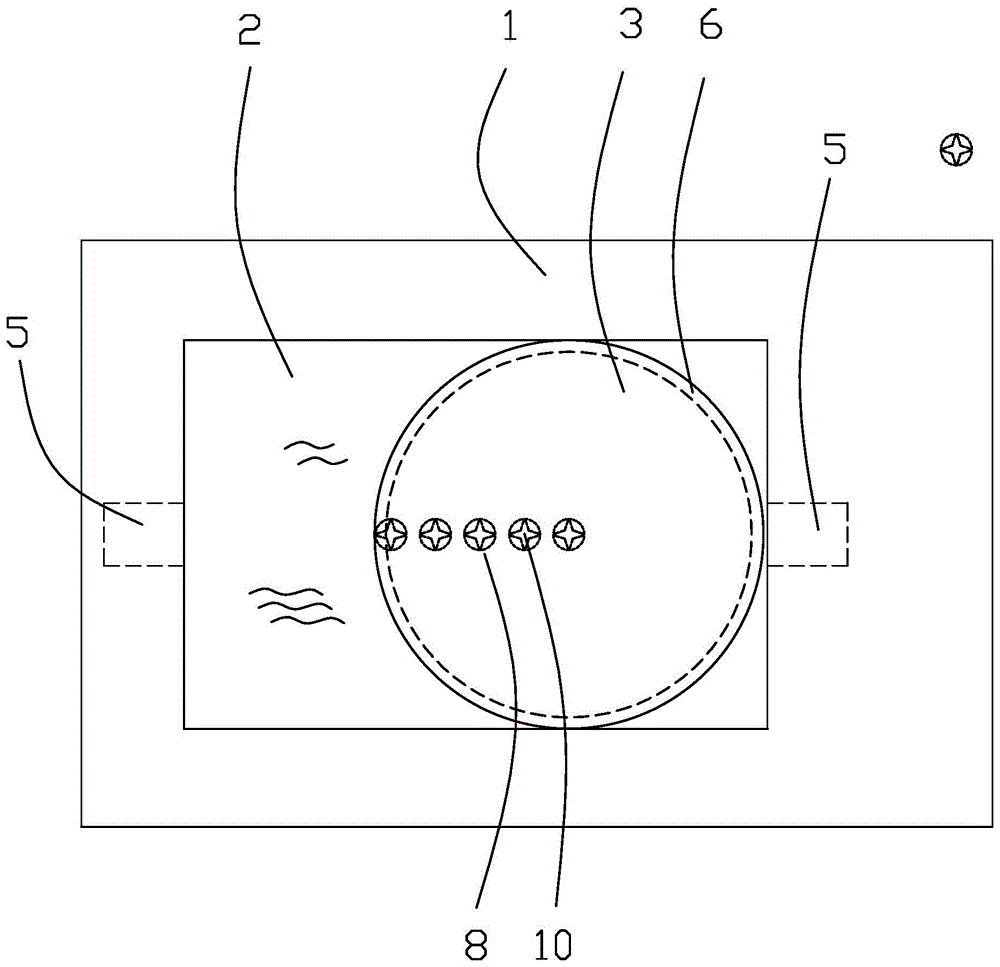

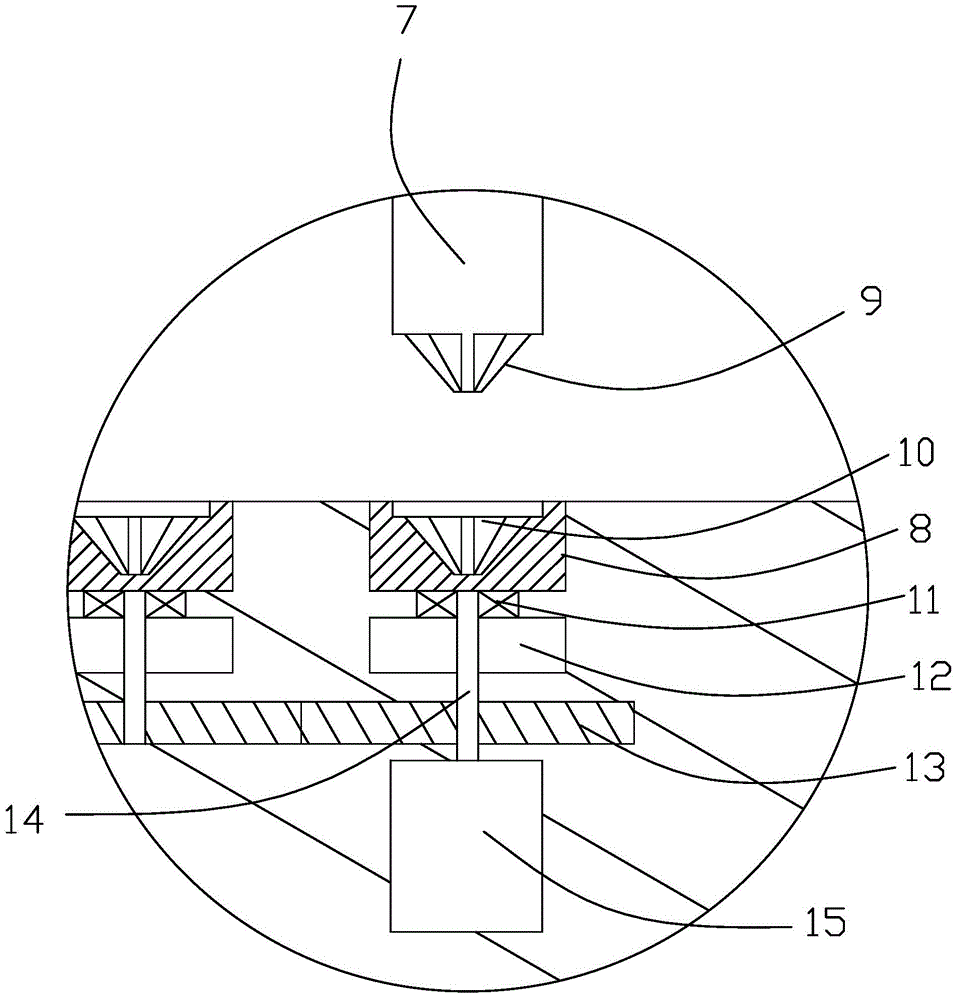

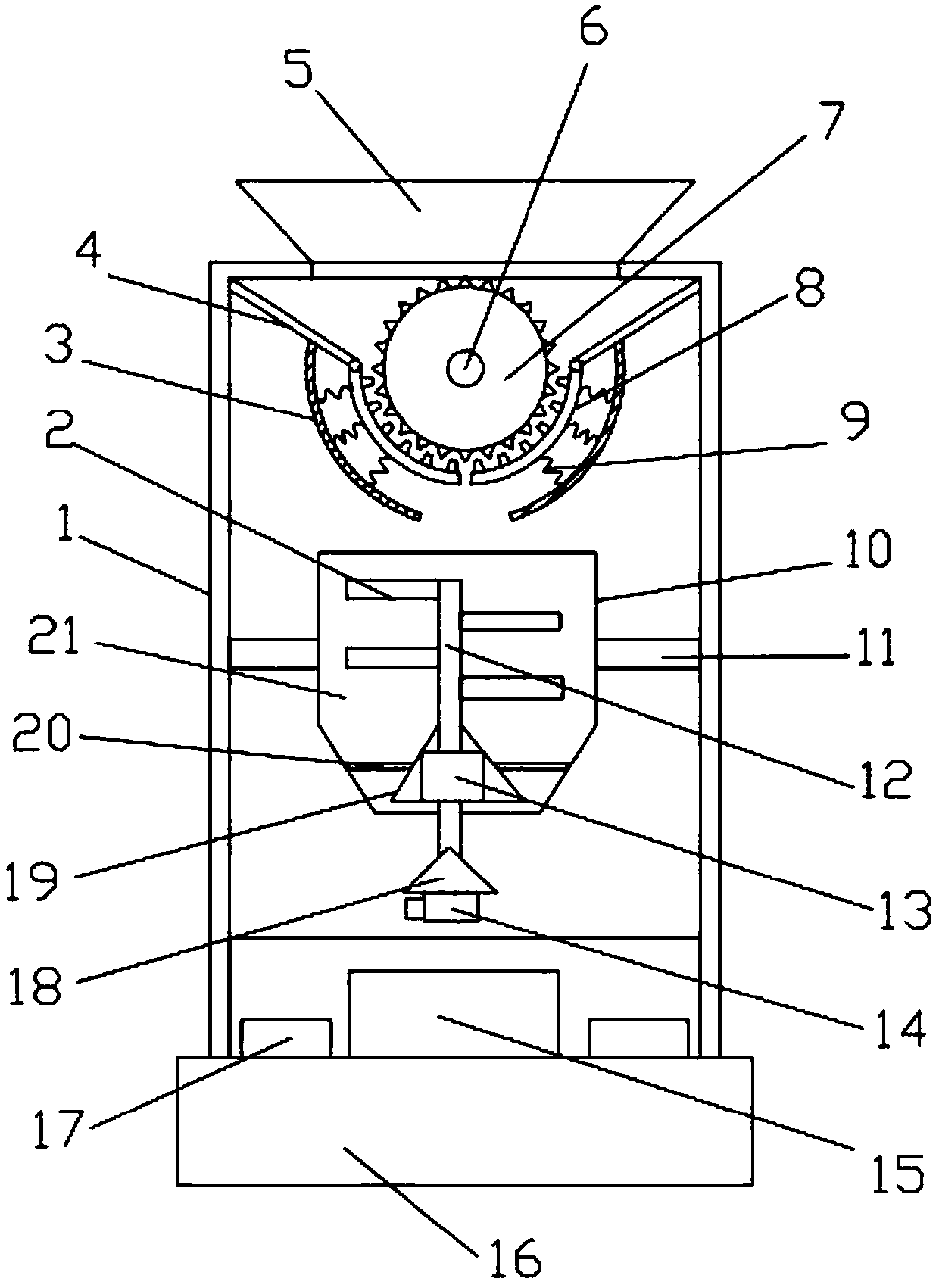

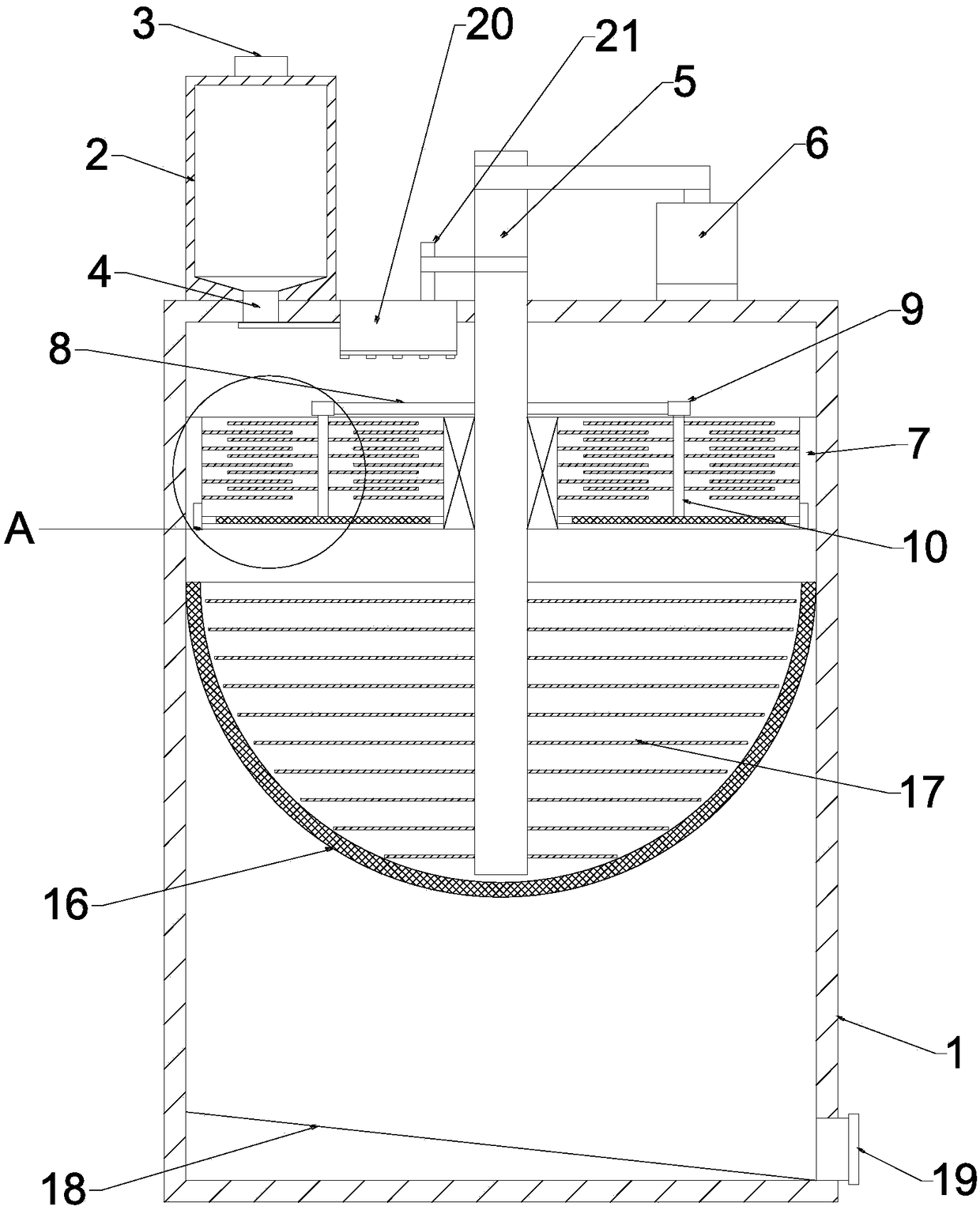

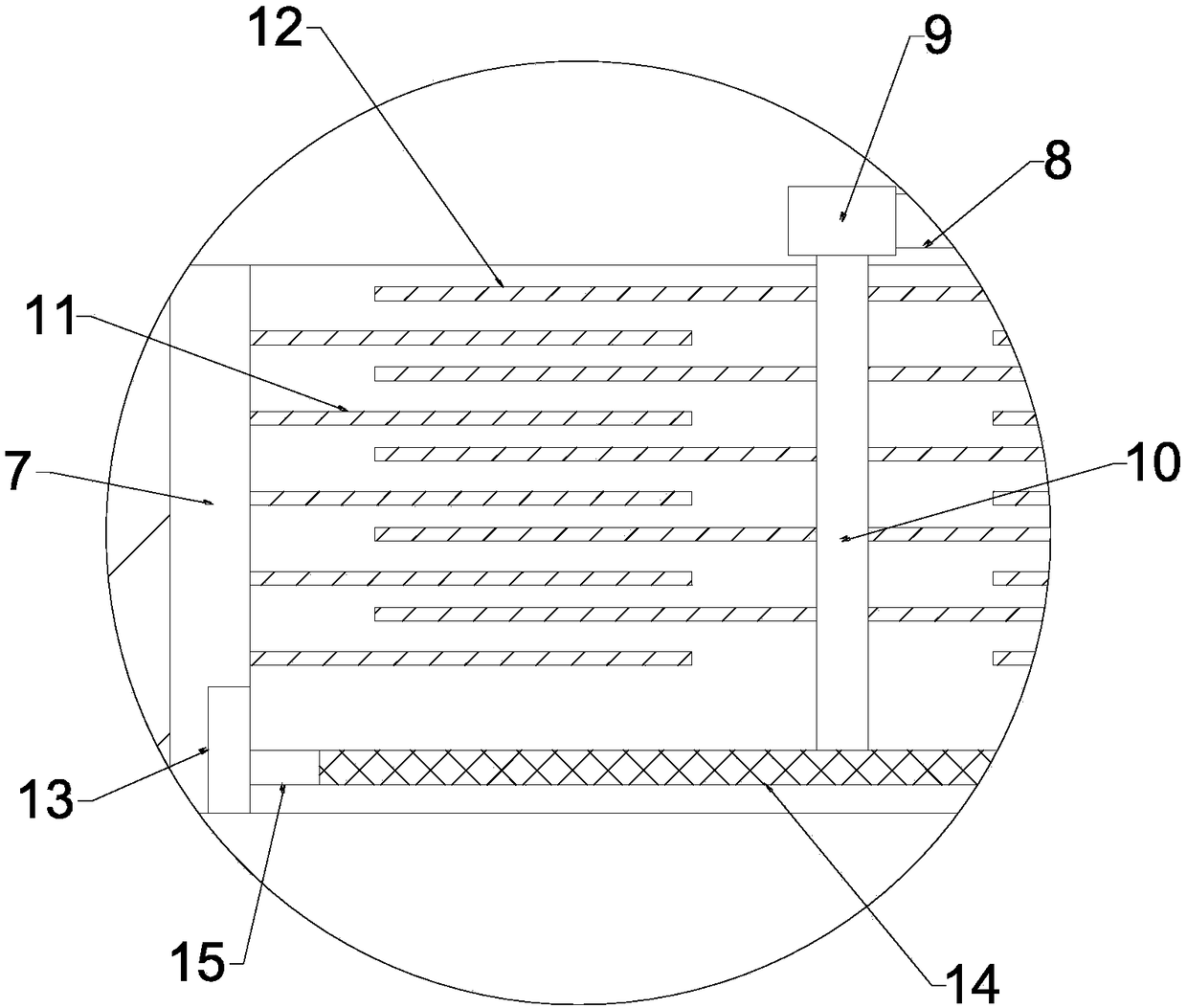

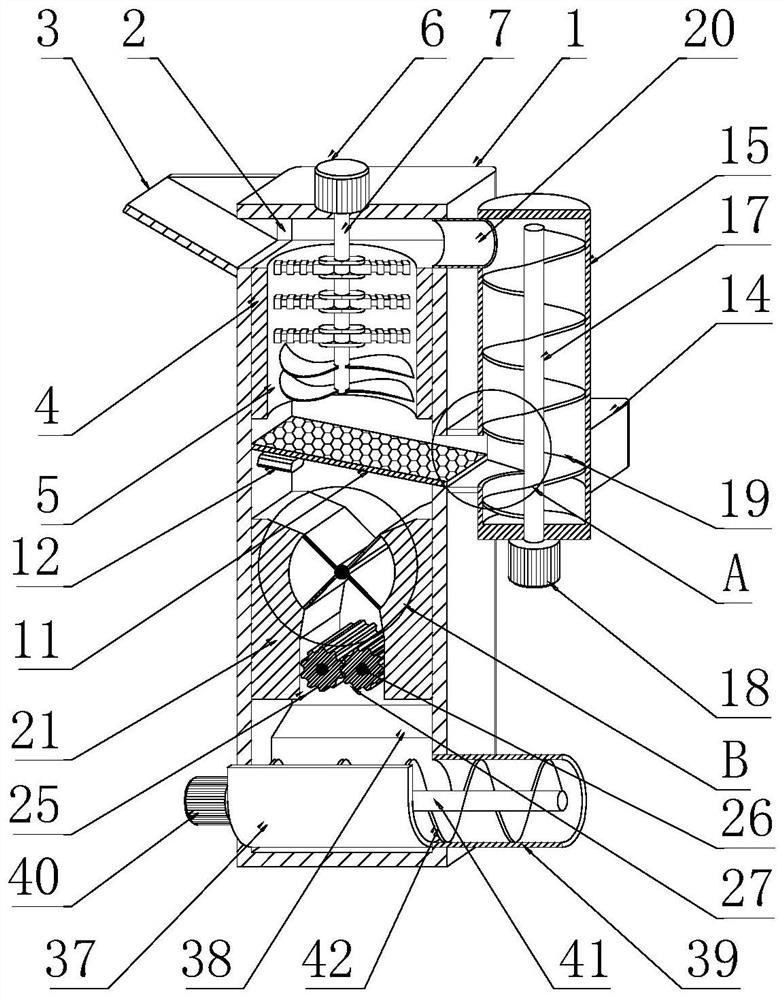

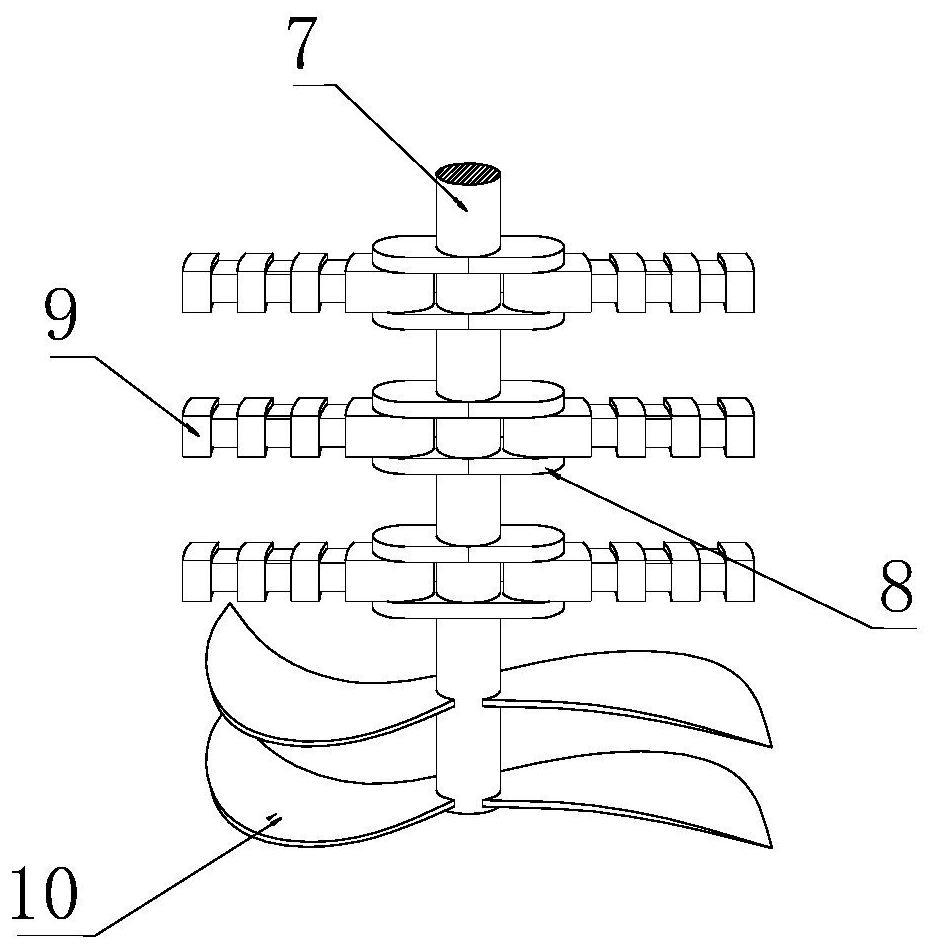

High-efficiency hulling and separating device of camellia oleifera fruit device

ActiveCN107822153AIngenious structureReasonable arrangementHuskingHullingCamellia oleiferaEngineering

The invention discloses a high-efficiency hulling and separating device of a camellia oleifera fruit device. The high-efficiency hulling and separating device comprises a housing, wherein a base is arranged at the bottom of the housing; a feeding hopper is arranged at the top of the housing; flow-guiding plates are arranged at the inner top of the housing in a bilateral symmetry manner; arc-shapedtooth grooves which are in bilateral symmetry are respectively formed in the bottom end of each flow-guiding plate; a crushing roller is arranged between the two arc-shaped tooth grooves; crushing teeth which are meshed with the arc-shaped tooth grooves are arranged on the outer side of the crushing roller; and the crushing roller is mounted on a crushing shaft arranged in the housing in a sleeving manner. The high-efficiency hulling and separating device of a camellia oleifera fruit device provided by the invention is ingenious in structure and reasonable in arrangement; a hulling mechanismis ingeniously arranged, so that the hulling efficiency is high, and in addition, shell blocking can be effectively avoided; a kneading mechanism is ingeniously arranged, so that shells of crushed camellia oleifera fruits are thoroughly separated from kernels of the crushed camellia oleifera fruits through the centrifuging flexible extruding and kneading of a kneading belt; and a sorting mechanismis ingeniously arranged, so that the high-efficiency sorting of the shells and the kernels is realized.

Owner:ANHUI LONGMIANSHAN FOOD

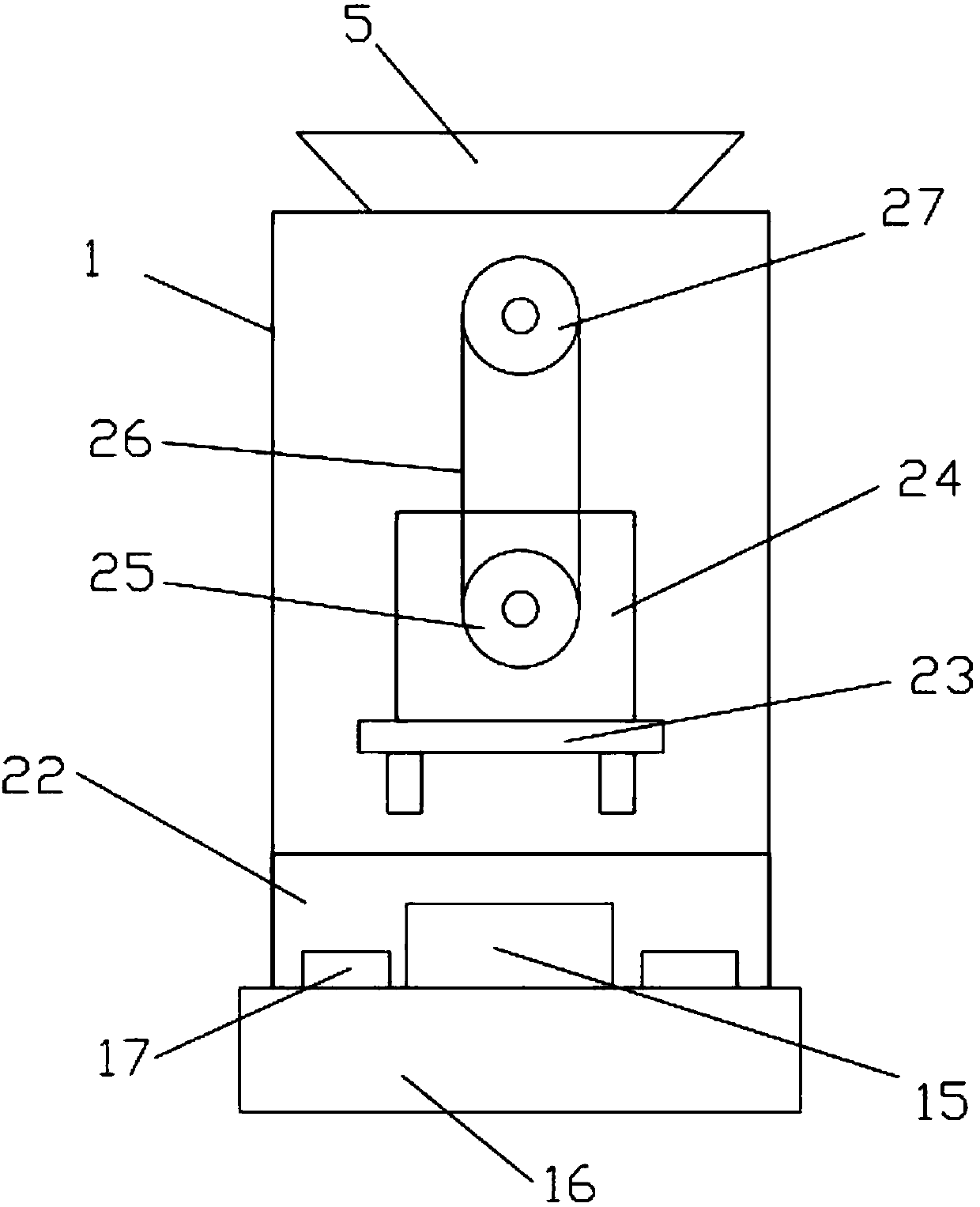

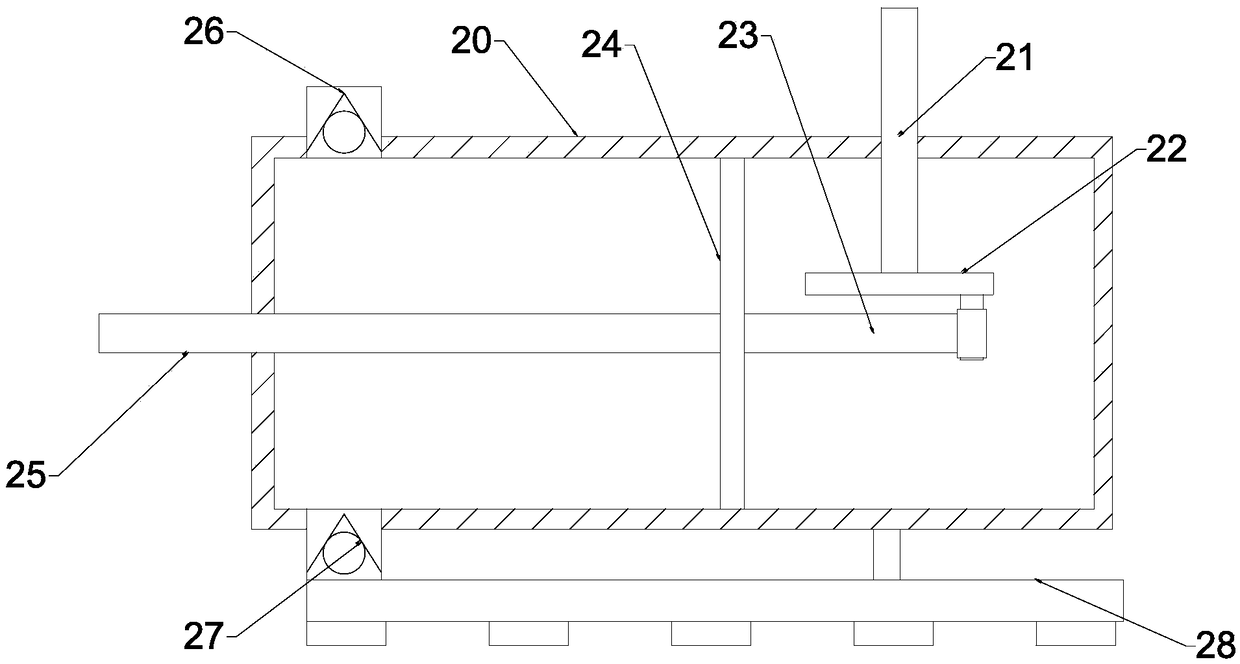

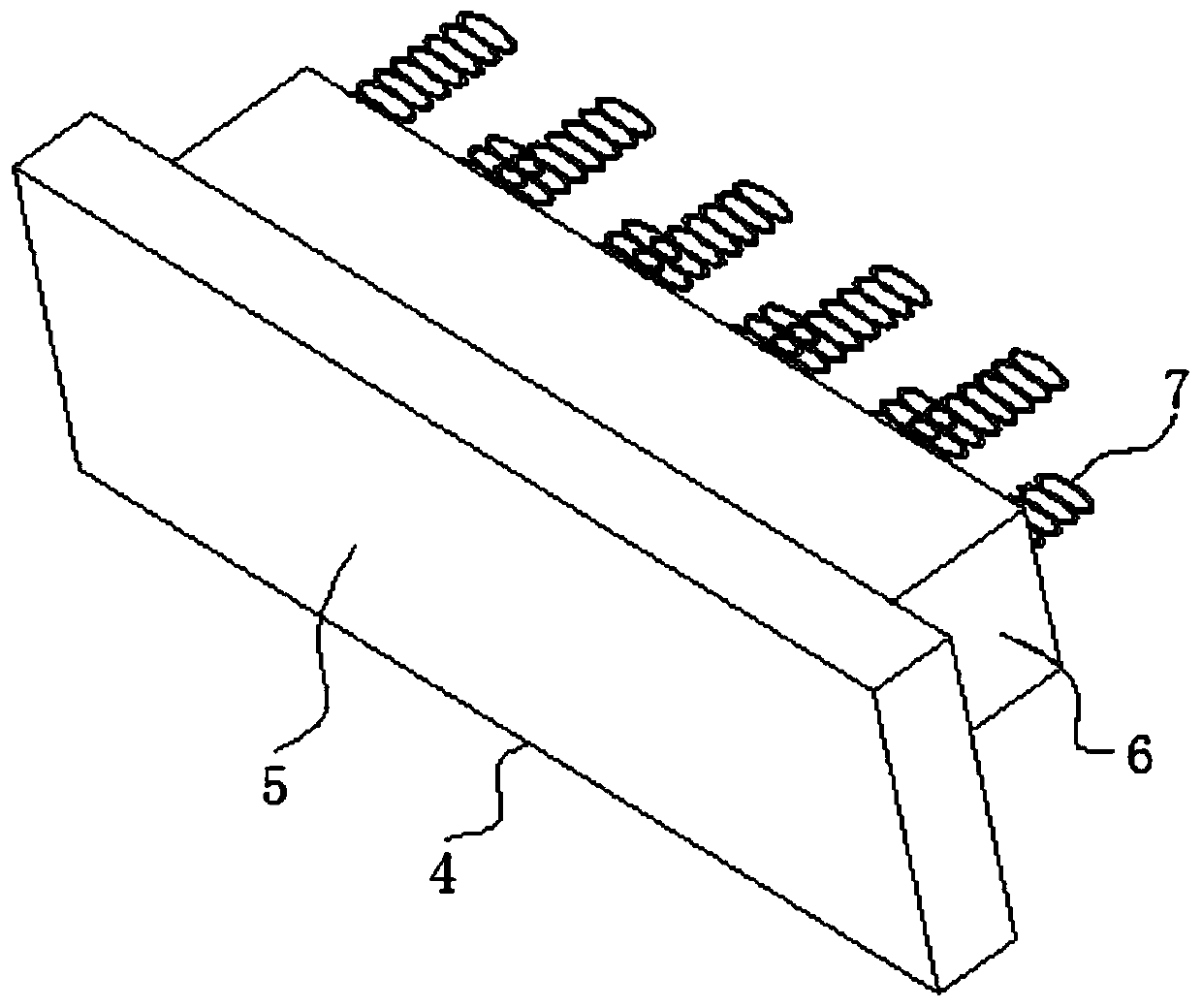

Intermittent-feeding pulverizing and screening device of feed

InactiveCN108095165AEasy to siftAvoid stuck problemsFeeding-stuffGrain treatmentsEngineeringInjection air

The invention discloses an intermittent-feeding pulverizing and screening device of feed. The intermittent-feeding pulverizing and screening device comprises a shell, wherein a storing cavity and a motor are arranged on the shell; a filling pipeline and a feeding pipeline are arranged on the storing cavity; a stirring shaft is arranged on the upper wall of the shell; an annular groove and an innergear are arranged at the upper part in the shell; a fixed blade is arranged in the annular groove; a rotating connecting rod, a rotating sleeve, an auxiliary rotating shaft, a first rotating blade, afilter screen plate and a driving gear are arranged on the periphery of the stirring shaft; a filter screen cover is arranged at the middle part of the inner wall of the shell; a plurality of groupsof second rotating blades are arranged in the filter screen cover on the periphery of the stirring shaft by welding; a driving cavity is arranged at the upper end of the shell; and a driving rotatingshaft, a rotating plate, a swinging connecting rod, a piston plate, a movable baffle plate, an air inlet pipeline, an air outlet pipeline and an air injection pipeline are arranged on the driving cavity. The intermittent-feeding pulverizing and screening device of feed improves the pulverizing processing efficiency by virtue of multistage pulverizing, thereby quickly and stably ensuring processing; and the intermittent-feeding pulverizing and screening device of feed performs intermittent discharging by virtue of coordination of the movable baffle plate and forms continuous downward paint spraying accompanied by movement in the driving cavity to promote feed processing.

Owner:吴烨程

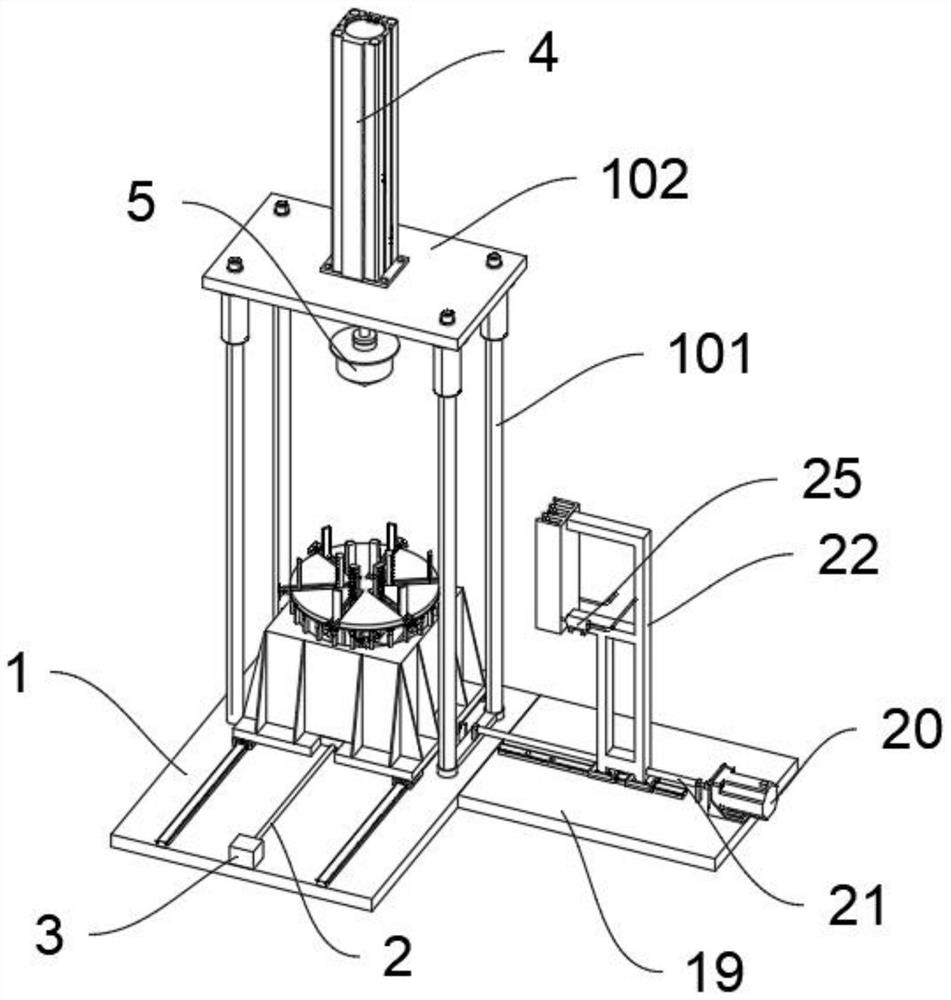

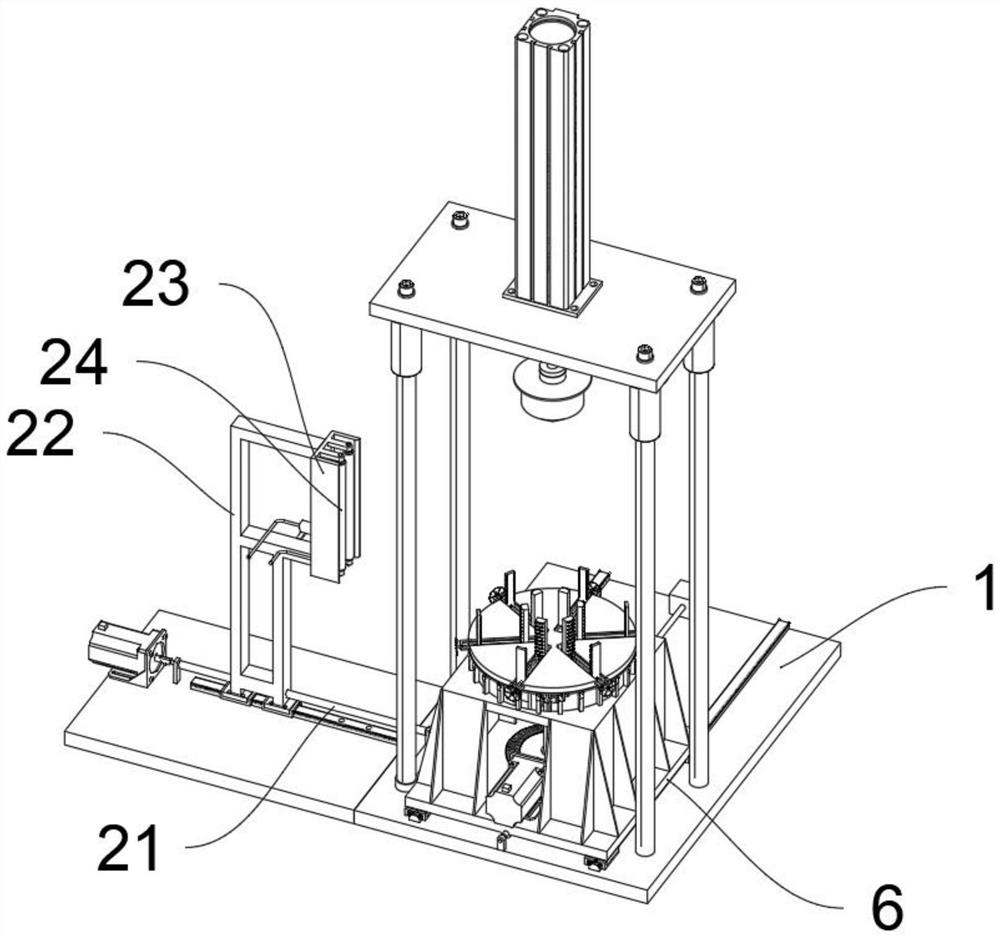

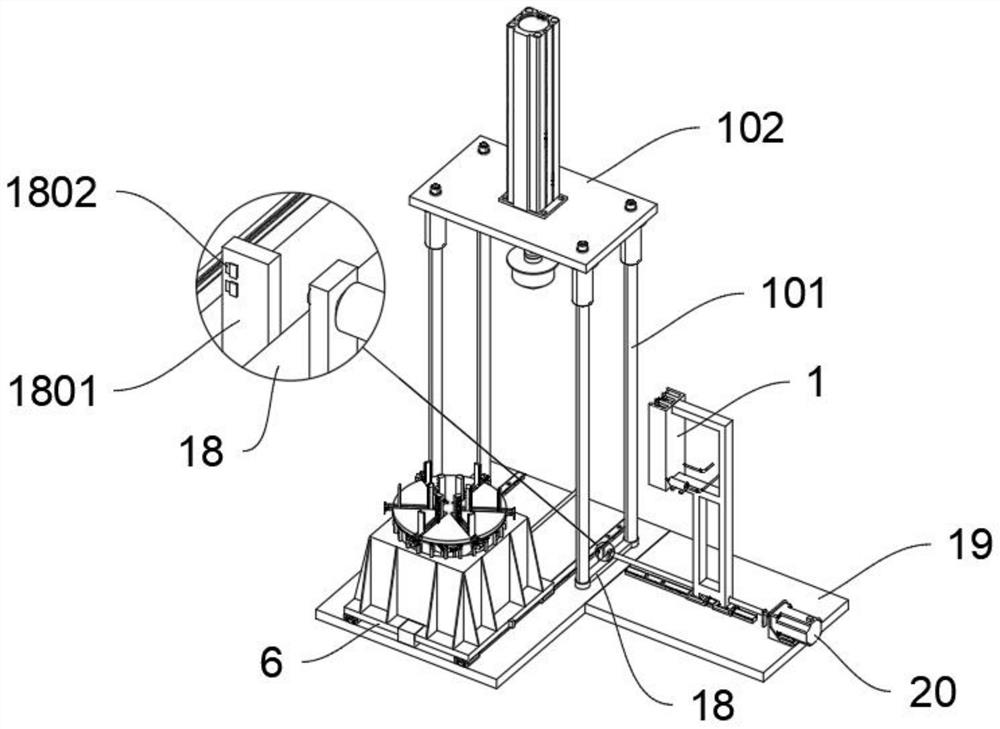

Straight pipe fitting reducing machining equipment for automobile accessory machining

InactiveCN112371853AEasy to processAvoid stuck problemsShaping toolsMetal-working feeding devicesStraight tubePipe fitting

The invention discloses straight pipe fitting reducing machining equipment for automobile accessory machining, relates to the technical field of automobile accessory machining, and solves the problemsthat currently-used reducing machining equipment is mainly a punching machine, only provides expanding and supporting functions, does not have automatic conveying and feeding functions and does not have functions of automatically aligning and centering pipe fittings. The straight pipe fitting reducing machining equipment for automobile accessory machining comprises a base; a lead screw A is rotationally arranged at the top of the base; a motor shell is fixedly arranged on the front side of the top of the base; and a motor is arranged in the motor shell and is in transmission connection with the front end of the lead screw A. A supporting bin shell is arranged, so that the function of automatically conveying the pipe fittings is provided for the pipe fittings; meanwhile, a connecting shaftsliding disc is arranged at the top of the supporting bin shell, so that assistance can be provided for rotation of a pipe fitting base, and the supporting capacity is provided for the pipe fitting seat, and the pipe fitting seat can be matched with the pipe fittings for reducing punching.

Owner:孙祖善

Method for producing H-shaped support piles

The invention provides a method for producing H-shaped support piles which are low in cost, bending resistant, shearing resistant and high in intensity. The technical scheme includes that the method specifically includes: (1) placing stop plates on the baseplate of an H-shaped support pile die or at two ends of the baseplate, serially connecting the stop plates on prestressed steel via holes on the stop plates, serially connecting a plurality of stirrups on the prestressed steel, connecting one end of the prestressed steel on a first tensioning device, and connecting the other end of the prestressed steel on a second tensioning device; and (2) adjusting distributing distance of the stop plates and the stirrups, closing the H-shaped support pile die to tension the prestressed steel, and the like.

Owner:俞晓东 +2

Bayonet connection type fluid connector

InactiveCN103557393AImprove sealingExtended service lifeJoints with fluid cut-off meansCouplingsConnection typeRabbet

The invention discloses a bayonet connection type fluid connector. The bayonet connection type fluid connector comprises a socket and a plug matched with the socket, wherein the plug consists of a valve body at the front part and a casing at the rear part; a first fluid guide hole is formed in the plug, and a first spring and a first valve core are arranged in the first fluid guide hole; a first stopping shoulder is located at the rear part of the first fluid guide hole, and the first spring is arranged between the first stopping shoulder and the first valve core; the casing is sleeved with a first connecting sleeve, a screwed rabbet is formed in the side wall of the first connecting sleeve, and a limiting groove is formed in the tail end of the screwed rabbet; a second fluid guide hole is formed in the socket, and a clamping ring, a fluid guide column, a second spring and a second valve core are arranged in the second fluid guide hole; a third stopping shoulder matched with the clamping ring is arranged at the front part of the fluid guide column, a fourth fluid guide hole is formed in the fluid guide column, the second spring is arranged between the third stopping shoulder and the second valve core, and limiting claming nails matched with the screwed rabbet and the limiting groove are fixed on the outer wall of the socket. According to the bayonet connection type fluid connector, quick positioning of the plug and the socket is facilitated through utilizing the bayonet type matching, and furthermore, the joint of the plug and the socket can be protected.

Owner:中国电子科技集团公司第四十研究所

New beef freshness detection device and detection method

InactiveCN104374710APrecisely control the moving distanceMove preciselyColor/spectral properties measurementsTesting foodEngineeringNondestructive testing

The invention relates to a new beef freshness detection device and detection method, and solves the problems, in the prior art, of subjective inaccuracy of beef freshness detection and complex detection equipment and detect process. The device comprises a seat body, the seat body is provided with a floating pool, a tray floats in the floating pool, the tray is controlled to move through magnetic force, an adjustment bracket is arranged above the seat body, the adjustment bracket is provided with a light source, and the seat body is also provided with a control unit. The control unit analyzes sample reflectance spectra data to judge the degree of beef freshness. The advantages of the new beef freshness detection device are that, by using a spectral detection mode, nondestructive testing of samples can be carried out; the new beef freshness detection device is reasonable in structure, the seat body moving resistance is small, and the new beef freshness detection device does not jam, and is convenient in operation and maintenance, and accurate in detection data.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

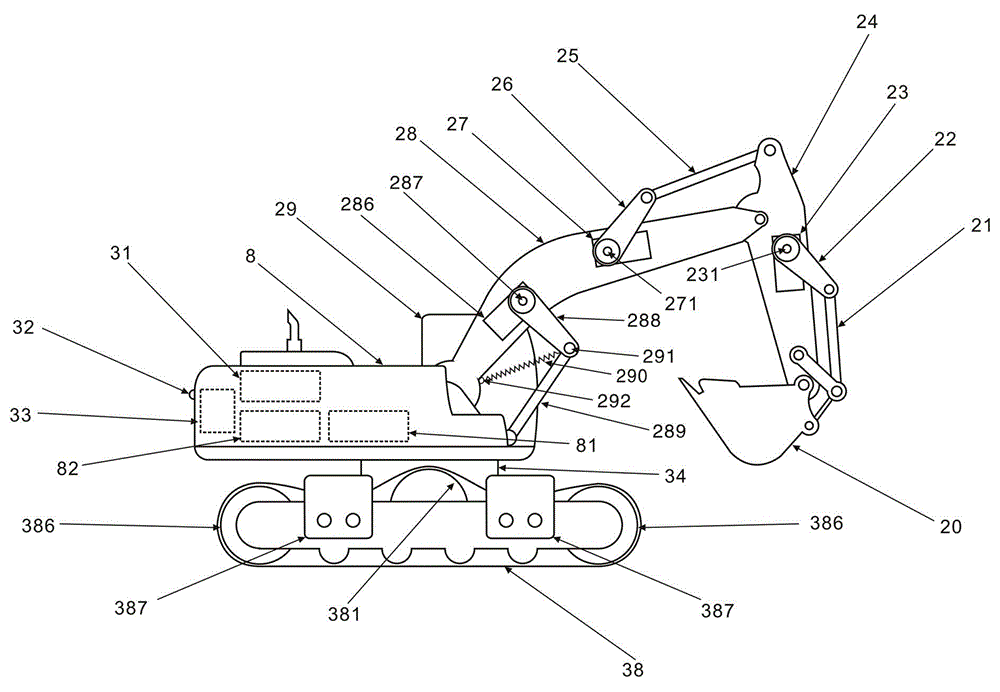

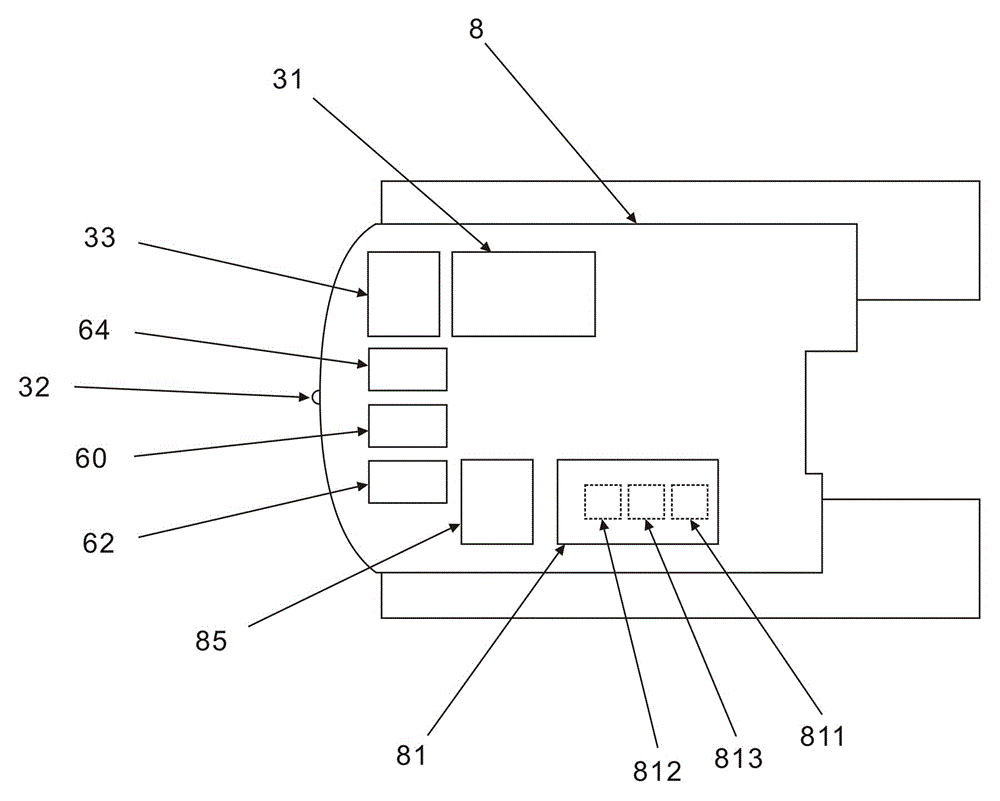

Crank-type wireless remote control device and excavator toy controlled by same

ActiveCN105126351ASolid workmanshipSimple and flexible operationRemote-control toysToy vehiclesPotentiometerEngineering

The invention discloses a crank-type wireless remote control device which comprises a digital remote control emission board, a counter, a timing circuit board and a timing display, wherein the digital remote control emission board comprises an emission master board as well as an action control module and an emission module connected with the emission master board, the action control module comprises a forward-walking, backward-walking, leftward-walking and right-walking control module, a bucket rod and bucket action control module, and a central rotation and movable arm action control module, the emission module is used for sending out actuating signals of an eight-direction walking rocker potentiometer, a bucket rod and bucket action rocker potentiometer, and a central rotation and movable arm action rocker potentiometer, and the emission module further comprises an emission module antenna. The crank-type wireless remote control device is easy and flexible to operate, and is sturdy and durable. The invention further discloses an excavator toy. After being provided with a bucket rod steering engine, a bucket engine, a movable arm steering engine and a central rotation gear limiting device, the excavator toy has the advantages that the excavating action is smooth, the shell clamping is avoided during rotation of the machine body, the wheel clamping is avoided during walking of a caterpillar track, and a battery can be replaced in time.

Owner:蔡迪

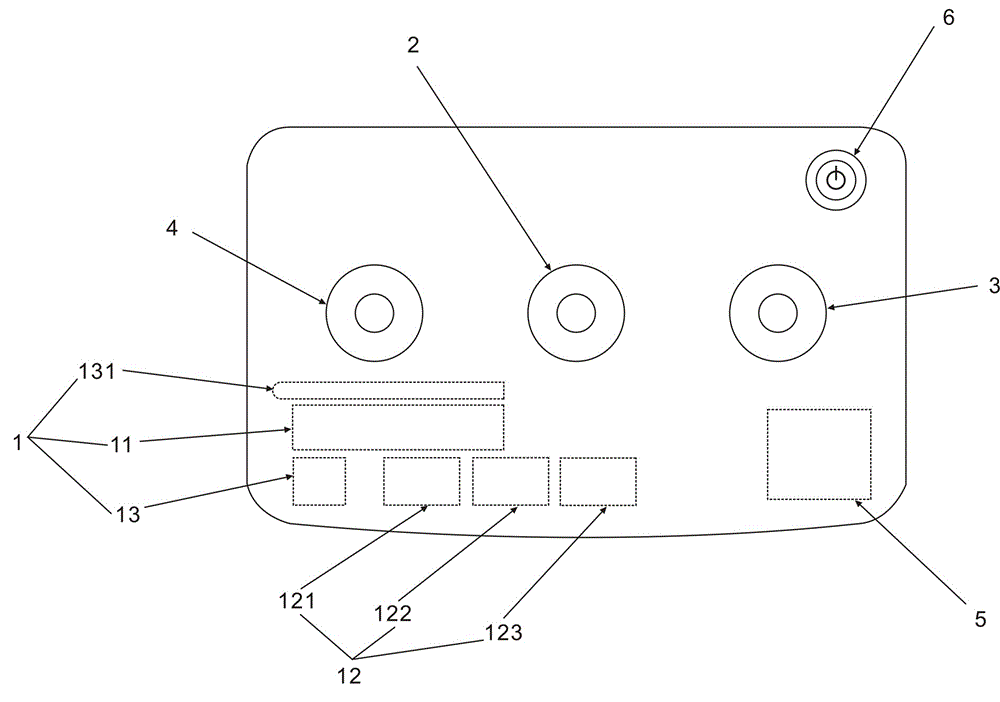

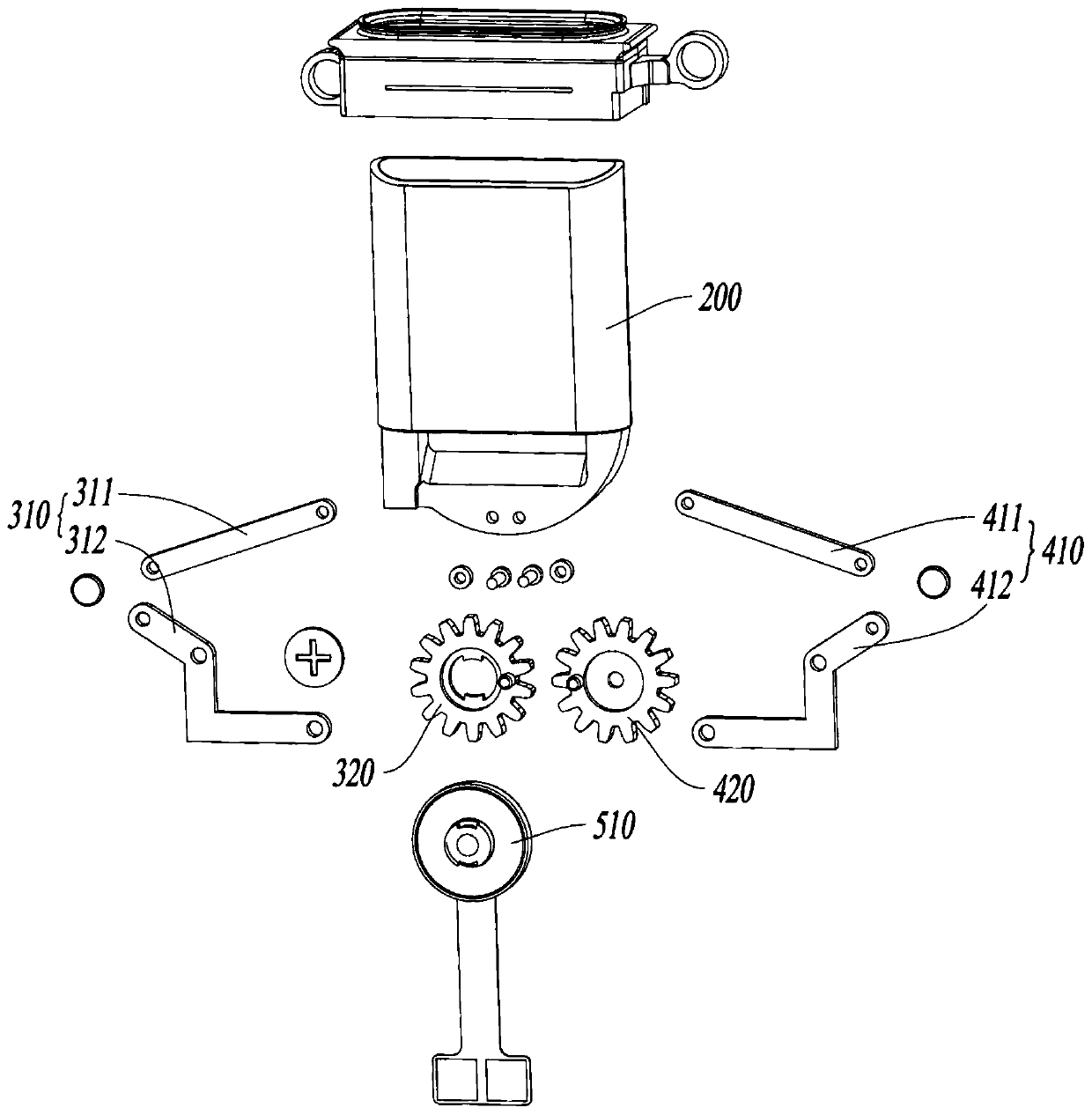

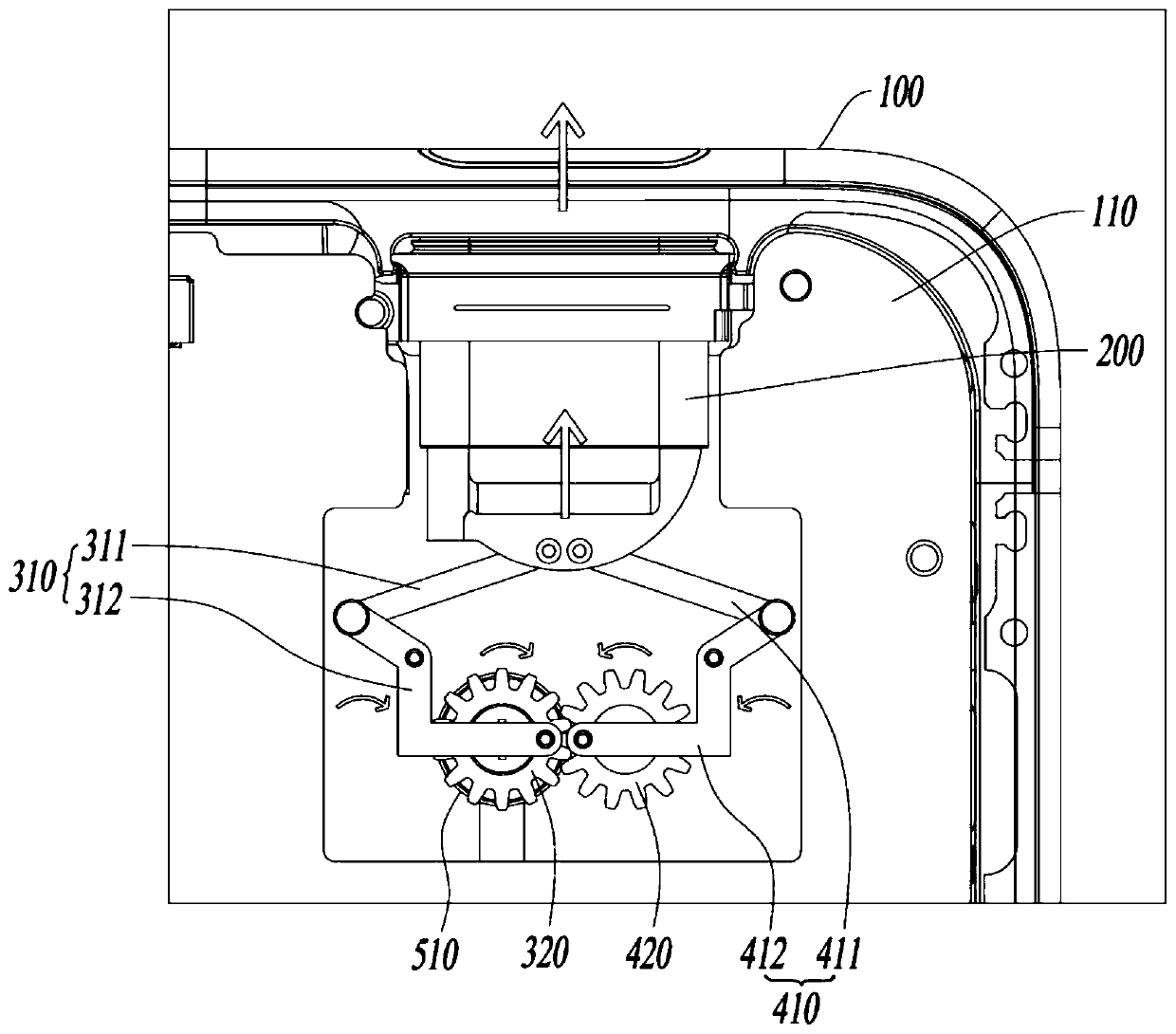

Electronic equipment

ActiveCN111163198AAvoid stuck problemsTelephone set constructionsCrankElectrical and Electronics engineering

The invention discloses electronic equipment which comprises a shell, a functional device, a transmission mechanism and a first driving mechanism, the shell is provided with an inner cavity and a through hole, and the through hole is communicated with the inner cavity; the functional device is movably arranged on the shell between a first position and a second position, and at least part of the functional device extends out of the shell through the through hole at the first position; at the second position, the functional device is accommodated in the inner cavity; the transmission mechanism is mounted in the inner cavity and is in transmission connection with the functional device; the transmission mechanism comprises a first transmission assembly and a second transmission assembly, the first transmission assembly comprises a first connecting rod and a first crank, the first end of the first connecting rod is rotationally matched with the functional device, and the second end of the first connecting rod is rotationally matched with the first crank; the second transmission assembly comprises a second connecting rod and a second crank; and the first driving mechanism drives the first crank and the second crank to reversely rotate at the same speed. According to the scheme, the problem that the functional device is easy to clamp in the telescopic process can be solved.

Owner:VIVO MOBILE COMM CO LTD

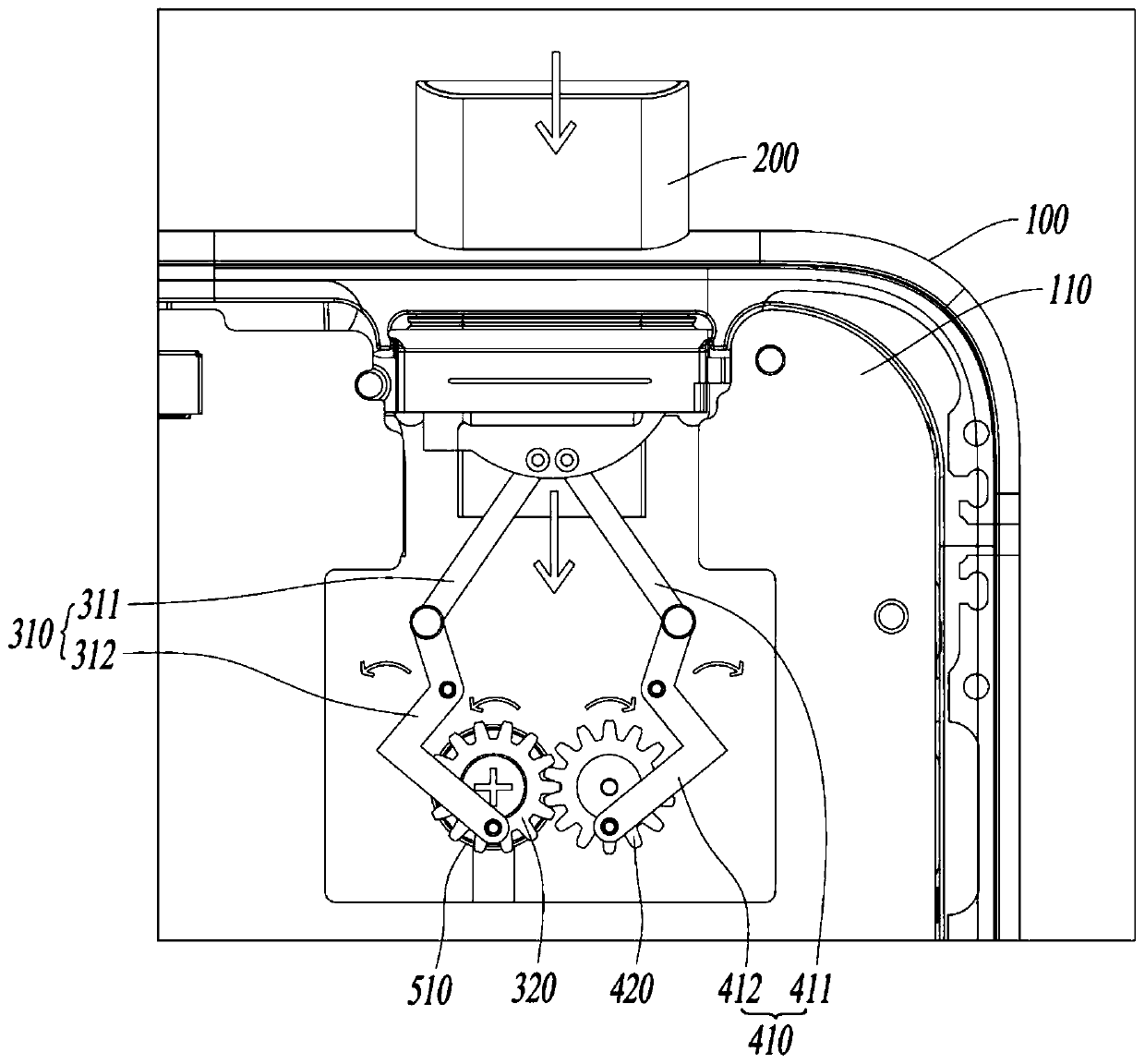

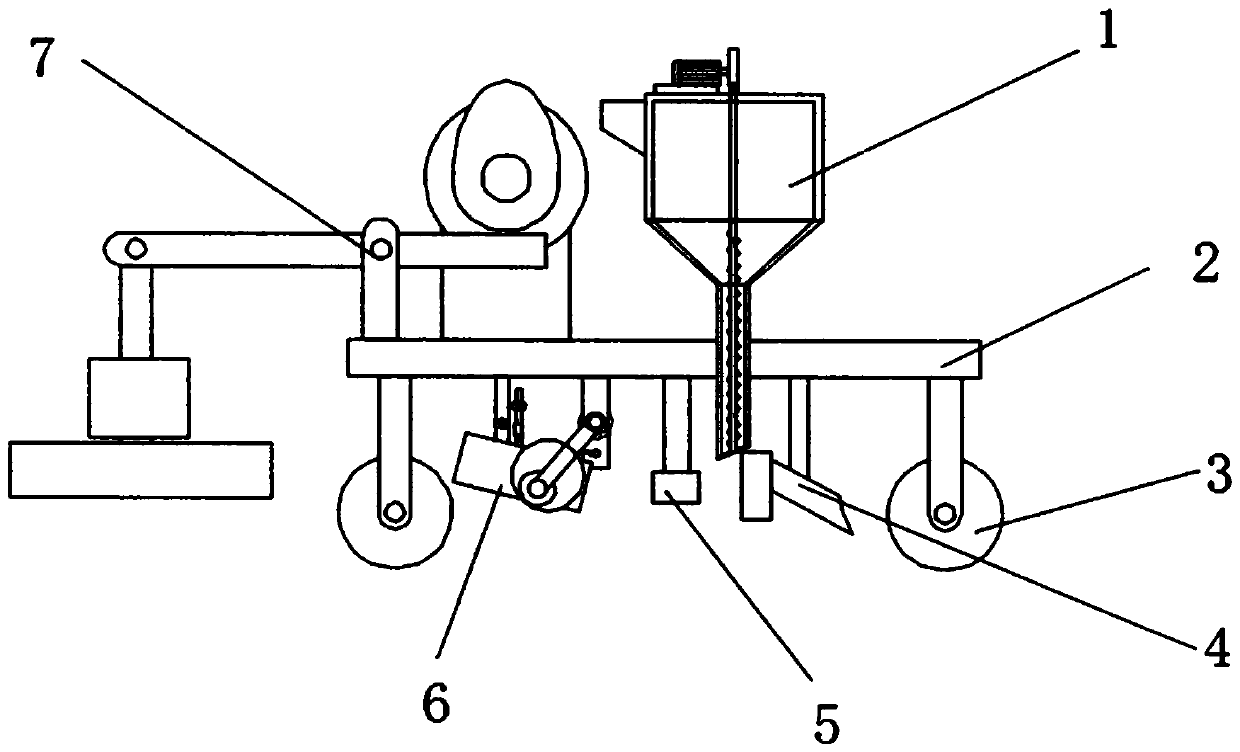

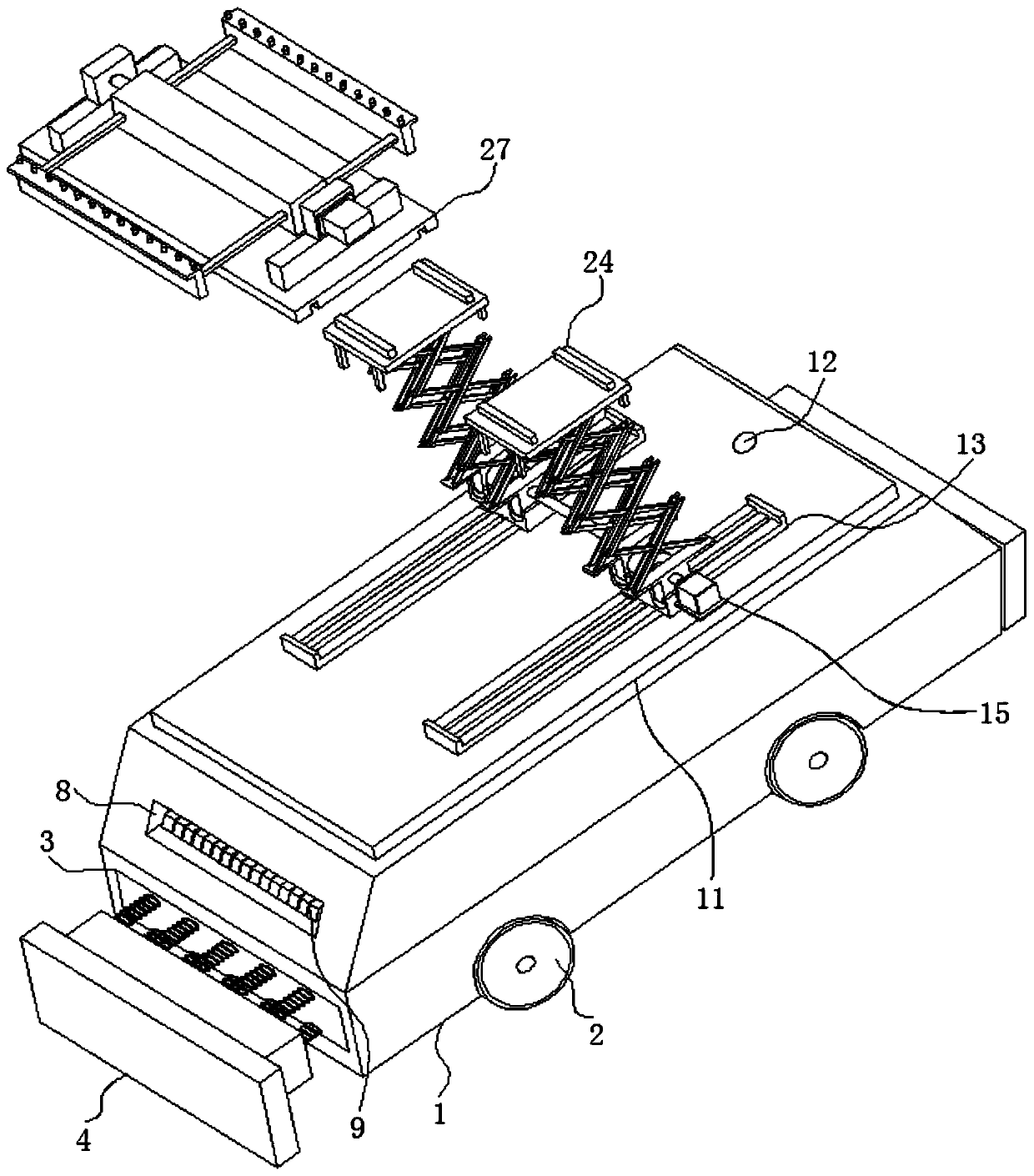

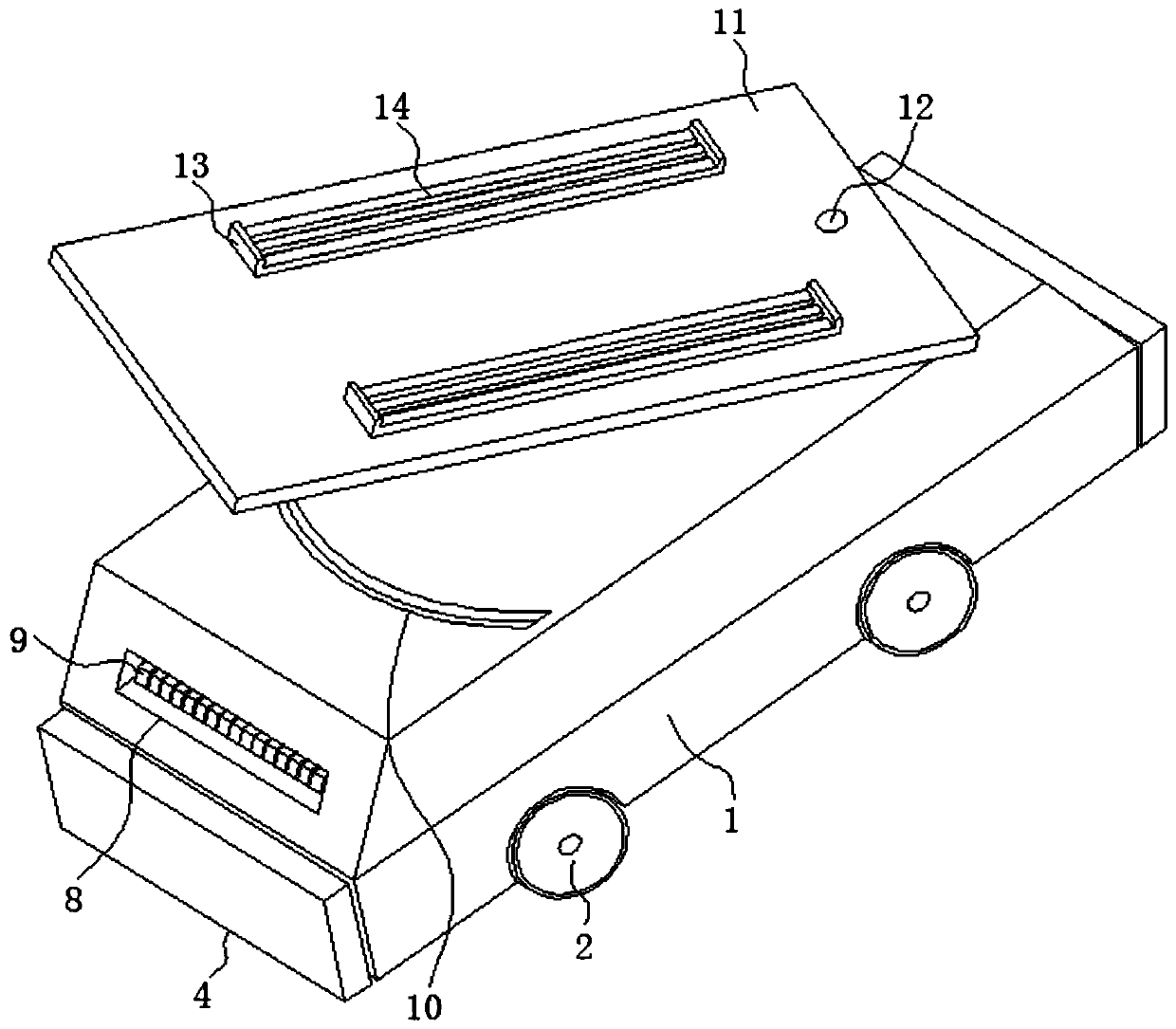

Agricultural production seeding device and method

InactiveCN110199624AMeet plantingAvoid stuck problemsDibble seedersMetal working apparatusAgricultural engineeringCam

The invention discloses an agricultural production seeding device and method. The device comprises a seed dibbling assembly, a machine frame, moving wheels, a grooving knife, a soil covering plate, afilm covering assembly and a hole opening assembly, wherein the seed dibbling assembly is vertically mounted in the machine frame; the seed dibbling assembly comprises a material storage box, a movable rod, a material storage pipe, a feed inlet, a material discharging motor, a sealing plate, a first cam and a return spring; and the material storage pipe is vertically inserted in the machine frame.Through the arrangement of the seed dibbling assembly, interval sowing can be realized, the planting of crops with large spacing can be met, the seeds can be further avoided from jamming in a seed box, the sowing rate is ensured, and the yield is improved; through the arrangement of the film covering assembly, the function of sowing and covering a film can be realized, the covering film positioncan correspond to the sowing position, so that the labor amount of covering the film is reduced, and the sowing efficiency is improved; and through the arrangement of the hole opening assembly, a holecan be opened accurately and uniformly, and the aperture standard can better meet the planting requirements.

Owner:续建花

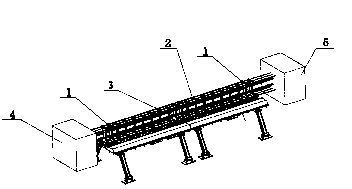

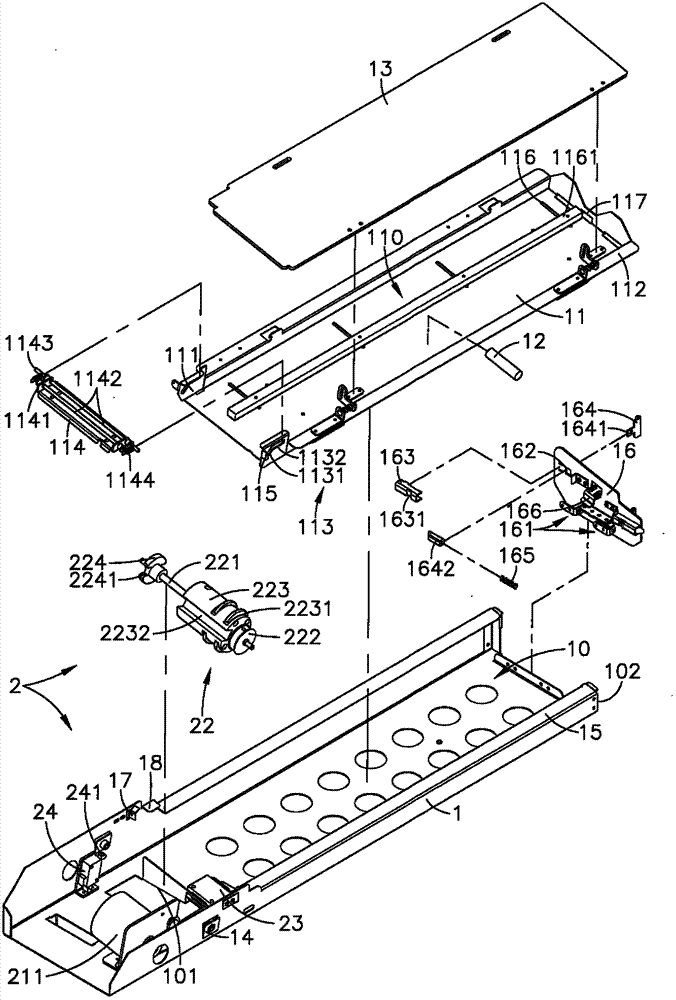

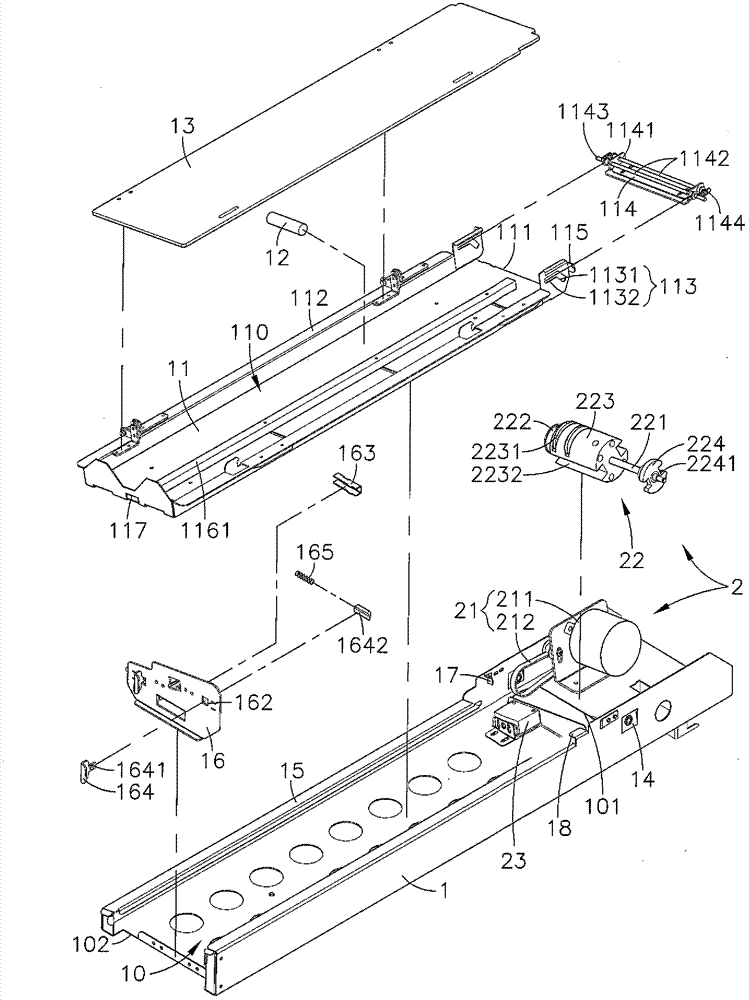

Novel sliding rail and detection device thereof

ActiveCN105686420ASmooth slidingAvoid stuck problemsMachine part testingDrawersHinge angleEngineering

The invention provides a novel sliding rail and a detection device thereof. The novel sliding rail comprises a strip-shaped sliding rail body. The sliding rail body is a frame body. The frame body is provided with a concave track. One end of the sliding rail body is a fitting end, and the other end of the sliding rail body is a positioning end. A first installation base is arranged on the rear wall of the fitting end. A second installation base is arranged on the rear wall of the positioning end. A second installation base is arranged on the rear wall of the middle of the sliding rail body. A pulley is arranged on the front side wall of the fitting end. A hinge hole is formed in the fitting end. A center shaft penetrates through the hinge hole and is sleeved with the pulley. A spring connected to the center shaft in a sleeving mode is arranged between the pulley and the fitting end. Gear rivets are riveted to the two ends of the center shaft. A gasket is arranged on the outer side of the pulley. Proper avoiding space is provided for elastic displacement, so that slippage is smooth and continuous, the clamping problem is effectively avoided, meanwhile, the using comfort is improved, slippage stability is ensured, and noise is lowered.

Owner:HAINING JINMAO HARDWARE

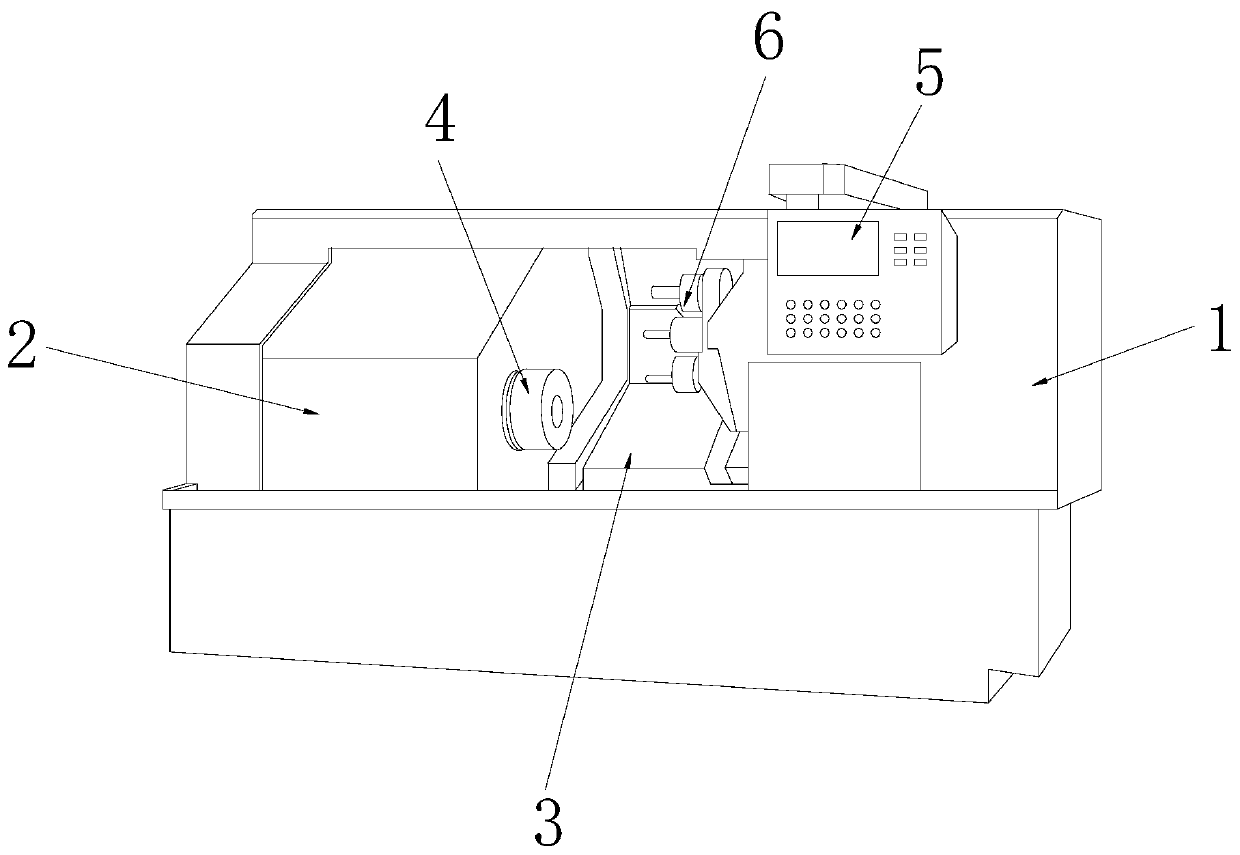

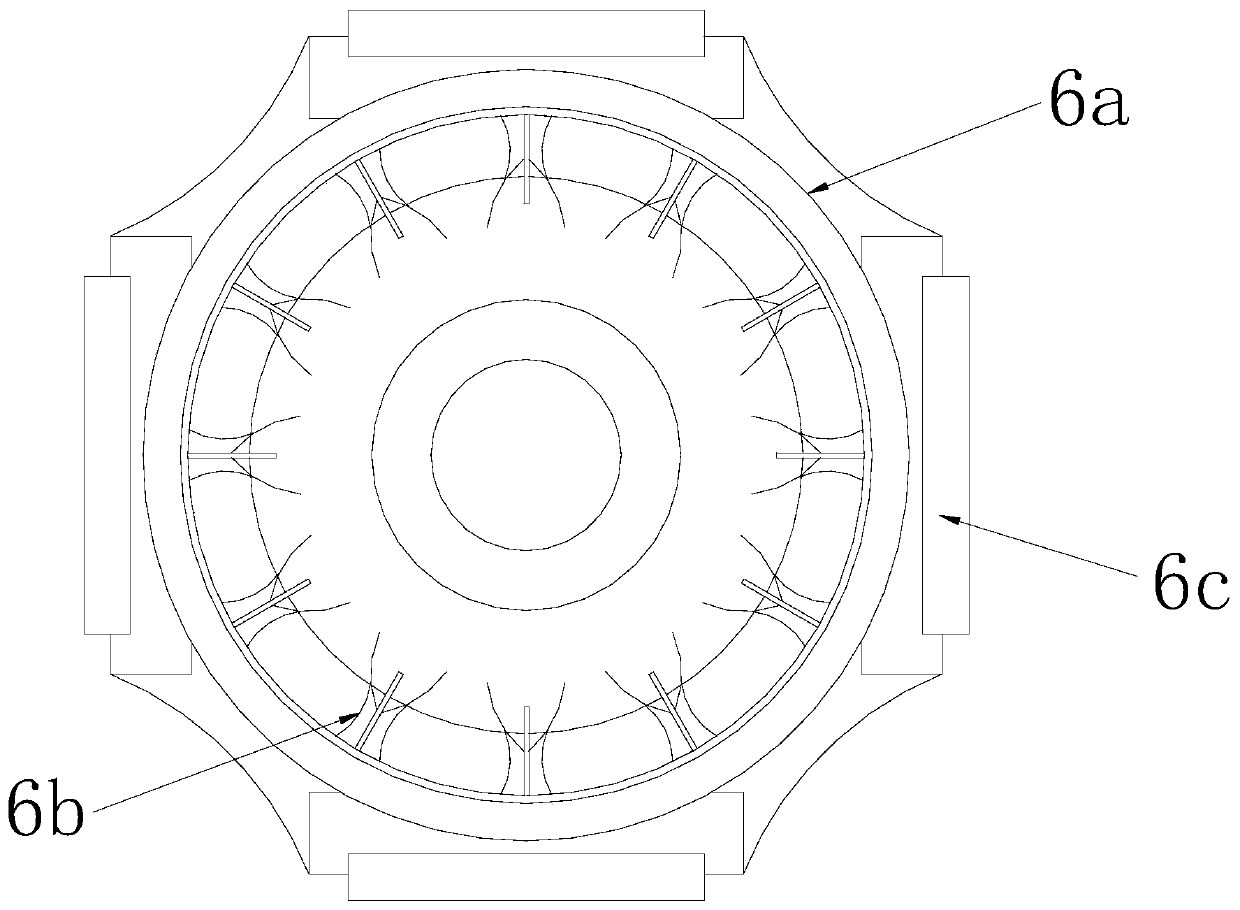

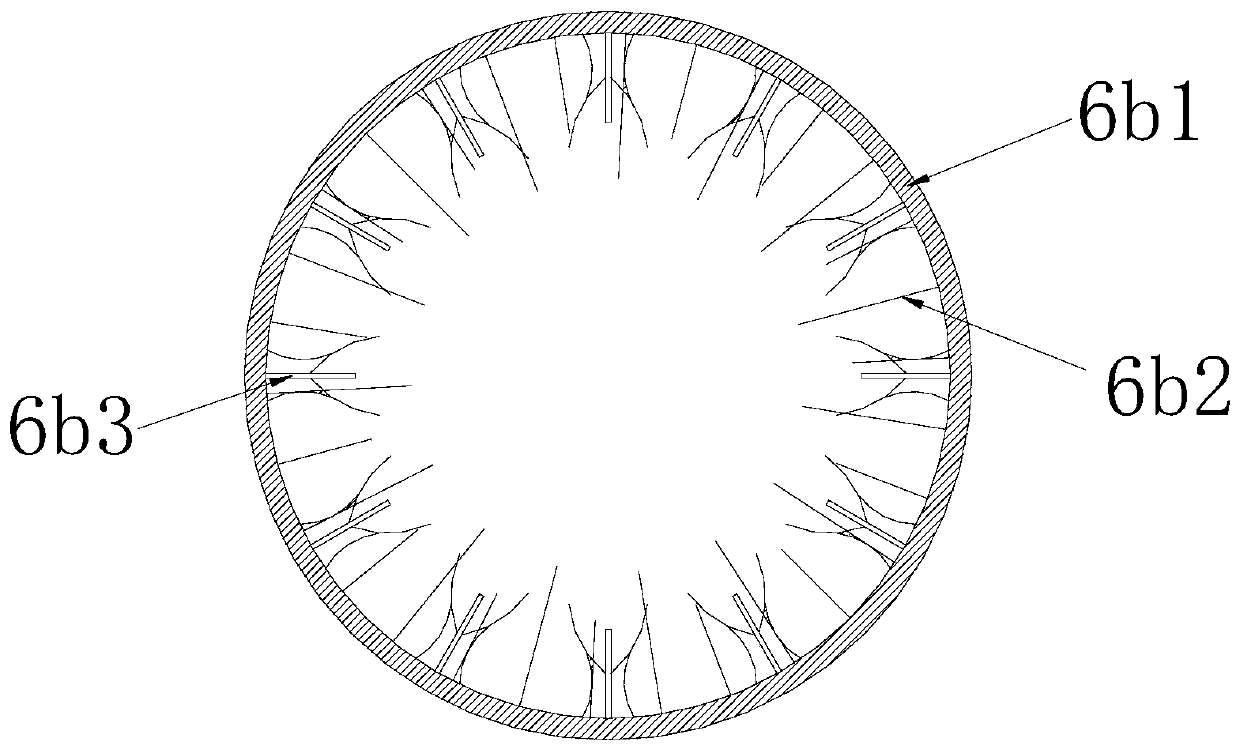

Numerical control turning machining center based on flexible manufacturing

InactiveCN111300239AAvoid stuck problemsAvoid the phenomenon of rotation freezeGrinding machinesGrinding/polishing safety devicesNumerical controlStructural engineering

The invention discloses a numerical control turning machining center based on flexible manufacturing. The numerical control turning machining center structurally comprises a device main body, a driving box, a workbench, a connecting disc, a controller and a machining assembly. The numerical control turning machining center has the beneficial effects that a cleaning and smoothing mechanism is arranged, thus under the action of lubricating oil permeated by a permeating strip, the phenomena of stuck and rotation jamming of a grinding assembly due to metal chips are advantageously avoided, meanwhile under the matching effect of a cleaning assembly between shafts, the metal chips which are produced by grinding and attached to the surface of the grinding assembly are effectively scraped, so as to avoid the rotating load of the grinding assembly caused by the attachment of the large amount of the metal chips and oil stains, and the widened grinding of the grinding assembly caused by the attachments, resulting in an inaccurate phenomenon, a collecting and storing structure is arranged, thus the metal chips produced during grinding are further collected concentratedly, thus the metal chipsare prevented from sticking gaps of the grinding assembly, and normal operation cannot be conducted.

Owner:赵永伟

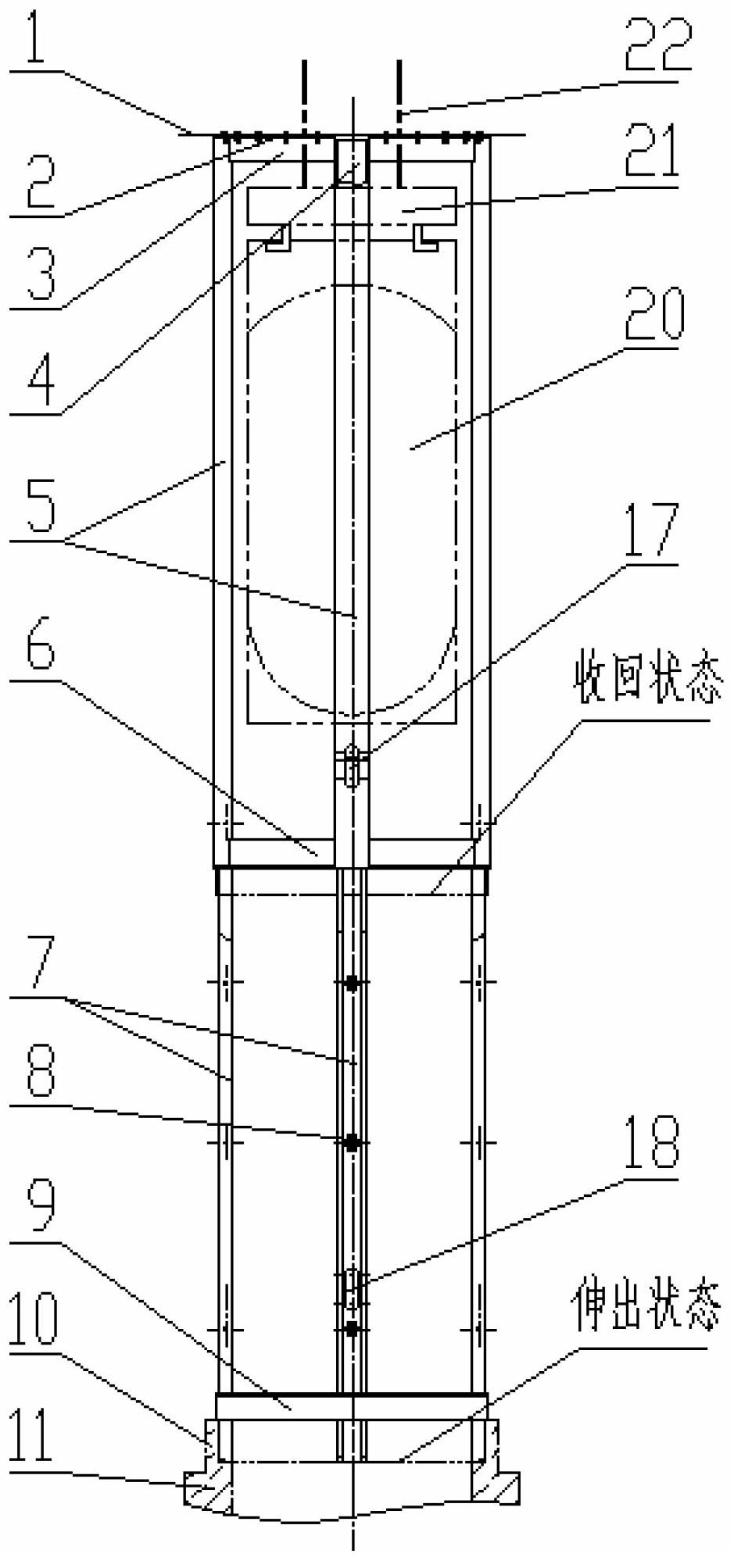

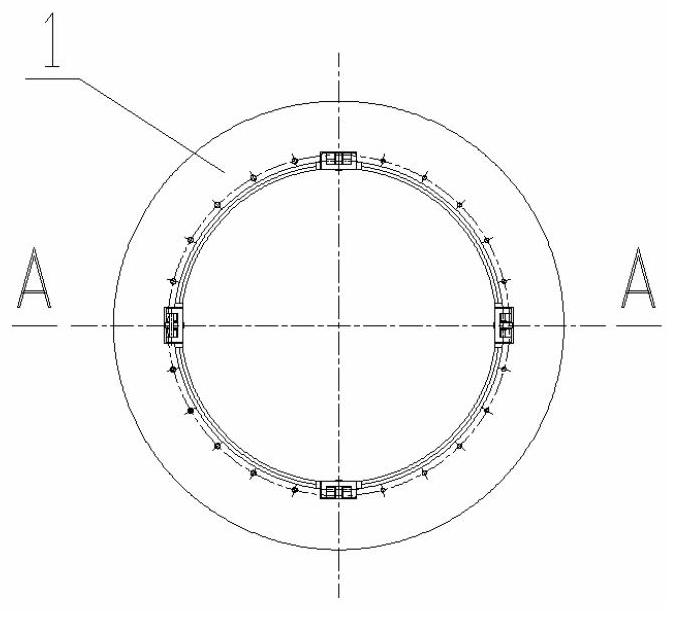

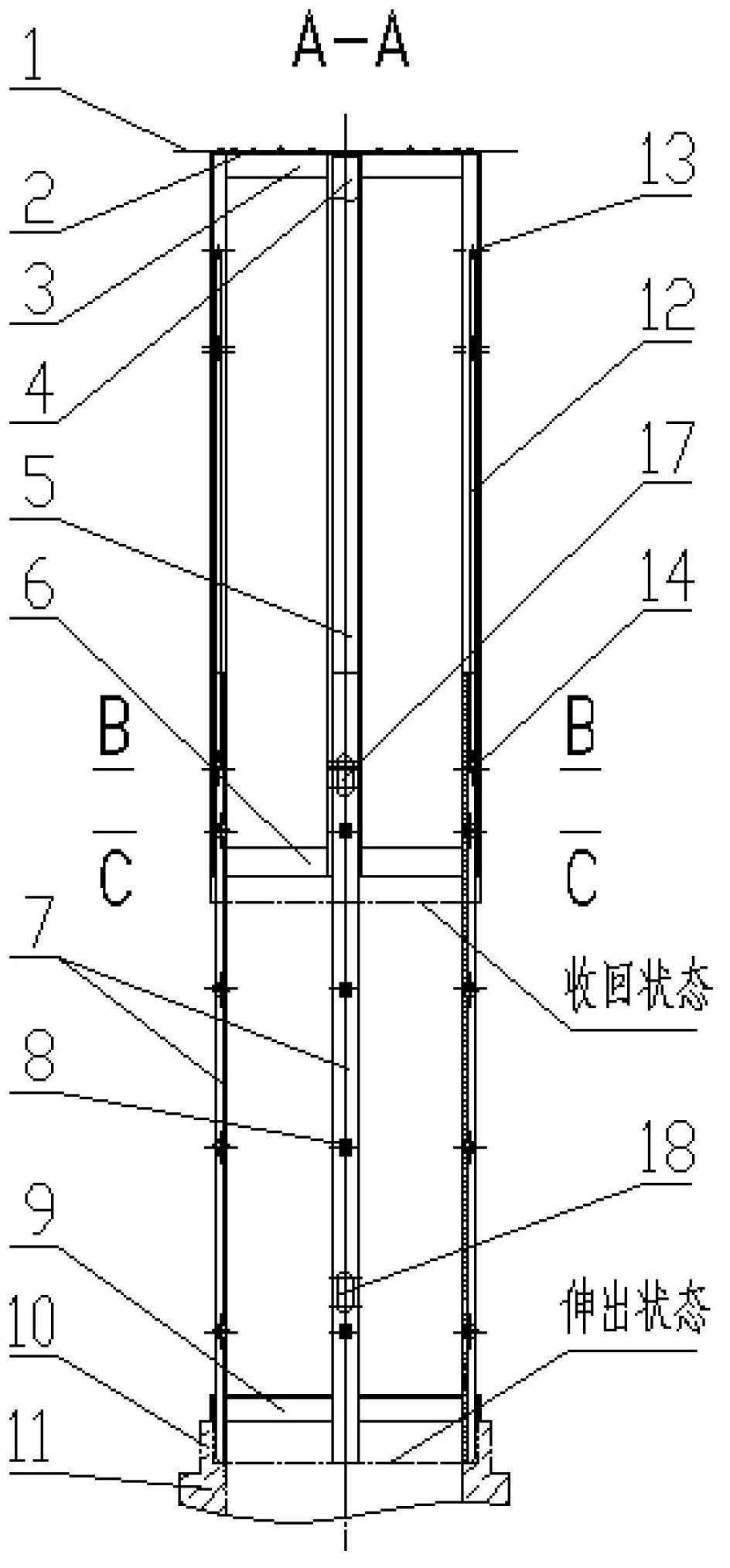

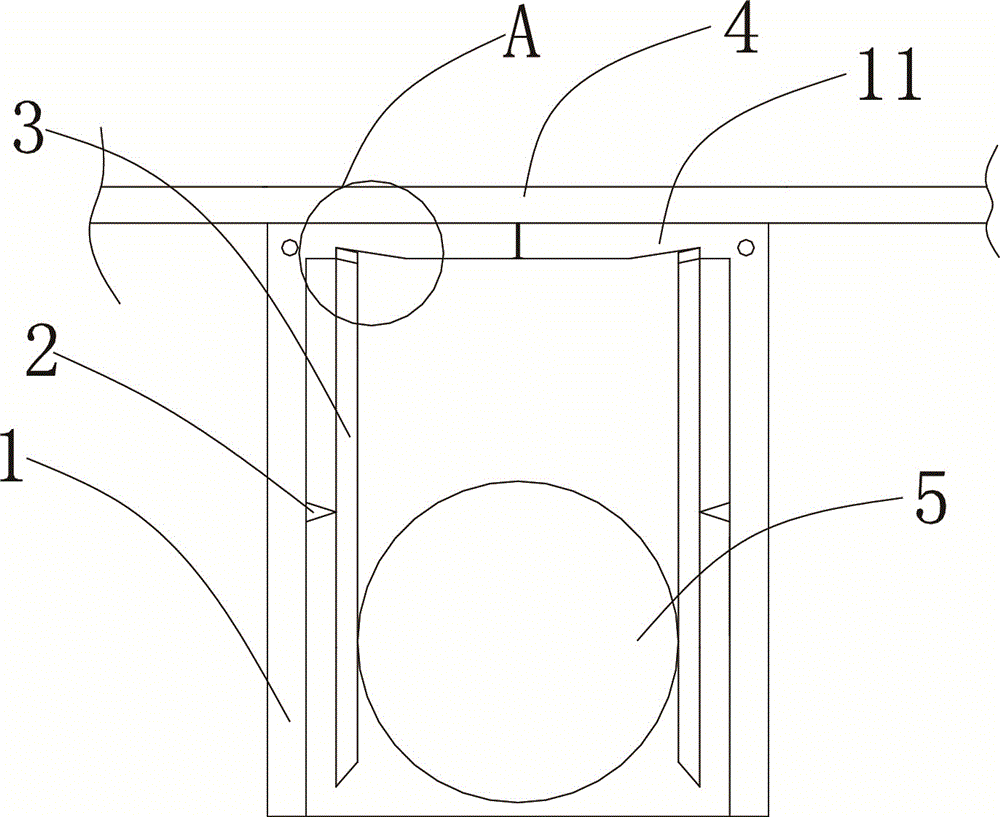

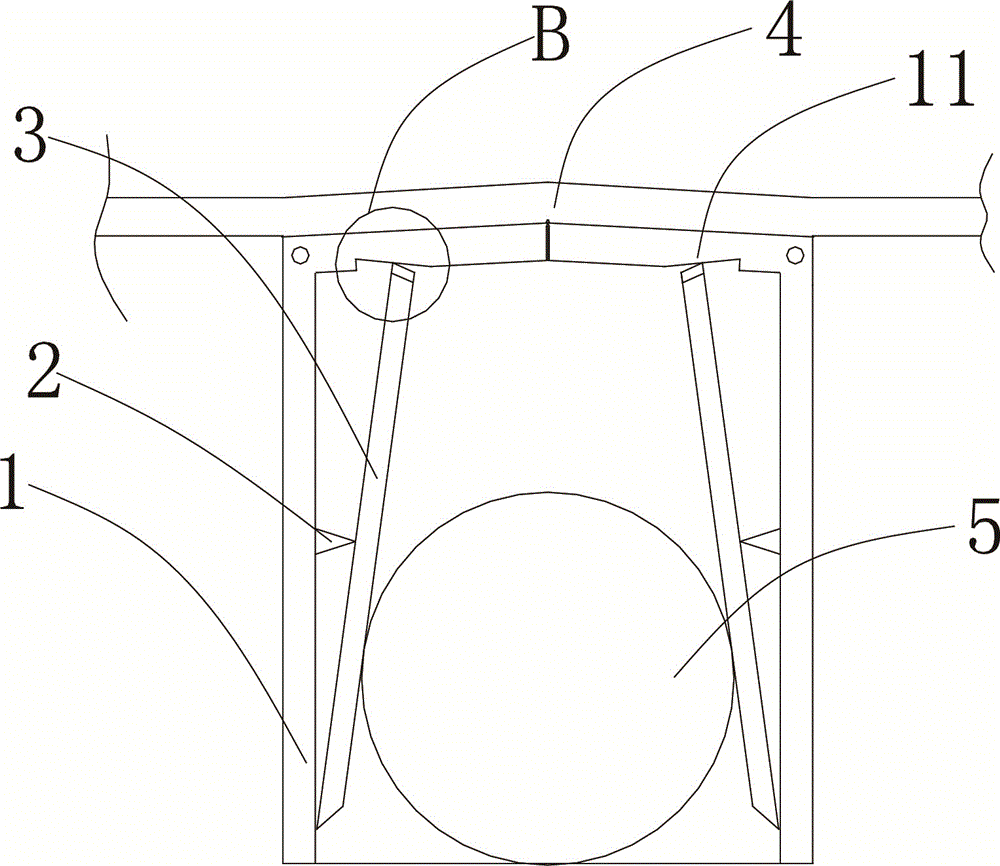

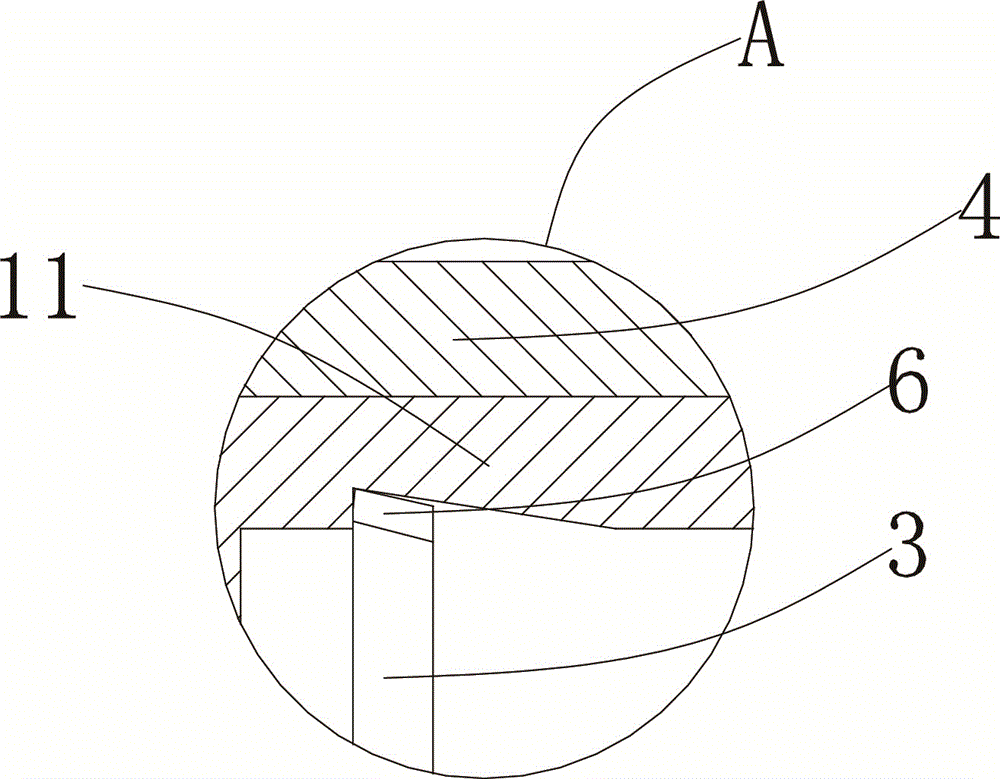

Telescopic spent fuel storage tank hoisting guide device

The invention relates to a telescopic spent fuel storage tank hoisting guide device which comprises a positioning annular plate (1), a top flange (2), an outer guide rib (5), an inner guide rib (7), a top reinforcing ring (3), a middle reinforcing ring (6) and a bottom reinforcing ring (9); the hoisting guide device also comprises a guide wheel assembly (8); the inner guide rib (7) is arranged inside the outer guide rib (5); and the guide wheel assembly (8) is arranged on the inner guide rib (7) and between the inner guide rib (7) and the outer guide rib (5). The telescopic spent fuel storage tank hoisting guide device can be used for hoisting guide and precise positioning of a spent fuel storage tank in a pebble-bed high temperature gas cooled reactor spent fuel storage system, so that the spent fuel storage tank can be hoisted into a shielding transferring container.

Owner:CHINERGY CO LTD

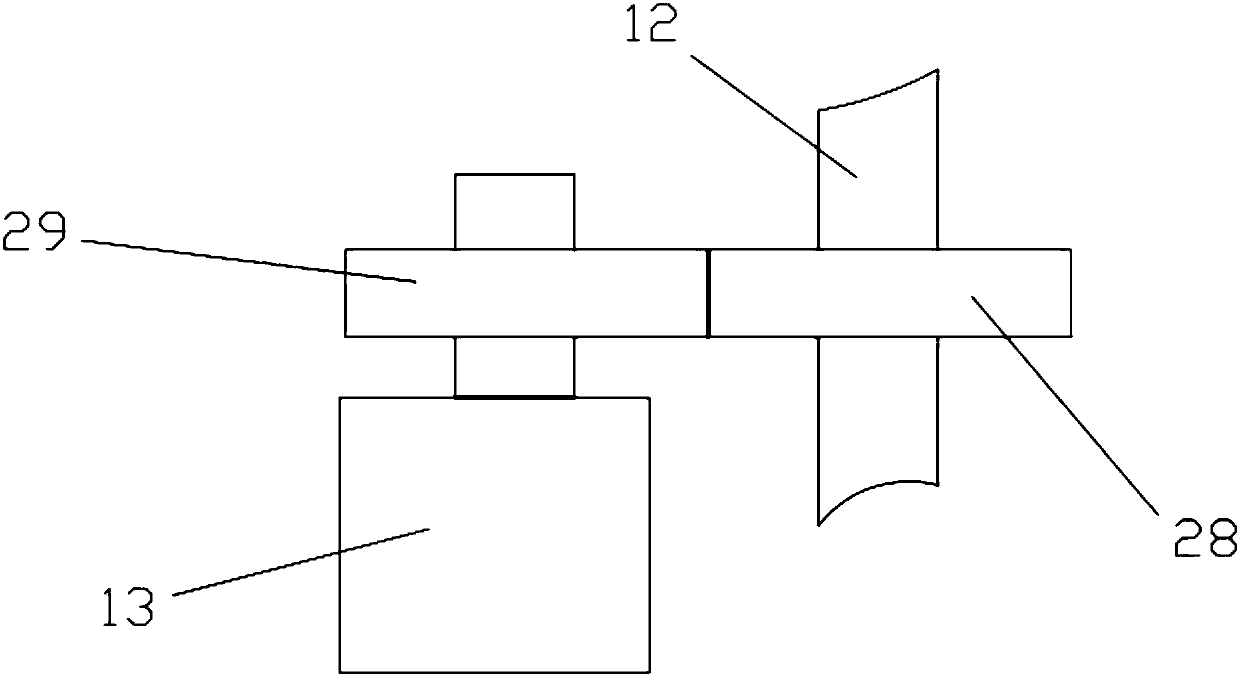

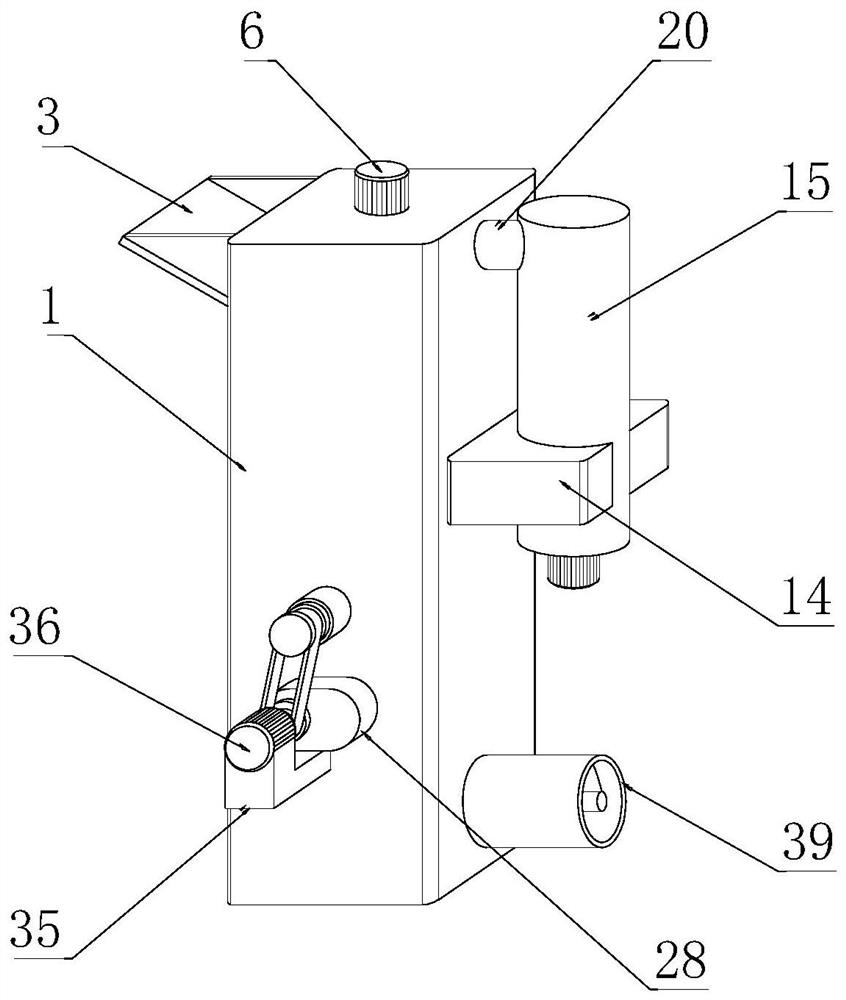

Injection medicine dispensing mechanism

The invention discloses an injection medicine dispensing mechanism comprising an inclined base and an operating mechanism mounted on the base. A holding space and a hollow groove with a lower front end are formed in the base, a seat provided with a containing space and an outlet and capable of being movably disassembled and assembled is assembled in the holding space, two sidewalls of the seat sequentially bend towards the outlet to form support rail plates, slide rails penetrating the sidewalls and stop doors moving by the aid of the slide rails are arranged on the sidewalls, two sidewalls of the holding space are bent to form inclined rails allowing the two support rail plates of the seat to slide, a rotary dispensing device of the operating mechanism is provided with a shaft rod with two ends pivoted on axial portions of the two sidewalls of the base, the shaft rod is provided with a rotary barrel with at least one transverse driving groove, and the rotary barrel is driven to rotate by a driving device. Front preset injection in the containing space of the base is enabled to enter the driving groove, and then is discharged from the hollow groove of the base along the rotation of the driving groove so as to finish the dispensing operation, and multiple preset injections can be moved forwards due to the inclining of the base, so that continuous dispensing action can be performed, and automatic dispensing is realized.

Owner:郝荣华

New beef freshness rapid nondestructive detection device and detection method

InactiveCN104374709APrecisely control the moving distanceMove preciselyColor/spectral properties measurementsEngineeringNondestructive testing

The invention relates to a new beef freshness rapid nondestructive detection device and detection method, and solves the problems, in the prior art, of subjective inaccuracy of beef freshness detection and complex detection equipment and detect process. The device comprises a seat body, the seat body is provided with a floating pool, a tray floats in the floating pool, the tray is controlled to move through magnetic force, an adjustment bracket is arranged above the seat body, the adjustment bracket is provided with a light source, and the seat body is also provided with a control unit. The control unit analyzes sample reflectance spectra data to judge the degree of beef freshness. The advantages of the new beef freshness rapid nondestructive detection device are that, by using a spectral detection mode, nondestructive testing of samples can be carried out; the new beef freshness rapid nondestructive detection device is reasonable in structure, the seat body moving resistance is small, and the new beef freshness rapid nondestructive detection device does not jam, and is convenient in operation and maintenance, and accurate in detection data.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

High-safety car airbag in acceleration popping

ActiveCN106347289APop up fastAvoid stuck problemsPedestrian/occupant safety arrangementFriction weldingEngineering

The invention provides a high-safety car airbag in acceleration popping, comprising an airbag frame, wherein the end of the airbag frame is fixedly connected with a car instrument disk by friction welding; a safety airbag is set in an airbag frame; the two sides of the airbag frame are provided with jacking mechanisms; each jacking mechanism comprises a lever A which is hinged in the safety frame; the end of the lever A is set in an inclined shape; the surface is subjected to polishing treatment; an inclined groove matching with the end is set in the upper end cover of the airbag frame; and the inclination of the groove is gradually shallow from the side to the upper end cover. The car airbag has following effects: during the expansion process of the airbag, the lever A is pressed; the lever A rotates a certain angle to jack the upper end face of the airbag frame; on the one hand, the popping speed of the airbag is quickened to prevent blocking the airbag; on the other hand, the groove at the upper end cover is jacked with the instrument disk after being thinned, and the probability knocking out the chippings is greatly reduced.

Owner:宁波井上华翔汽车零部件有限公司

Industrial solid waste environment-friendly smashing and recycling device and operation method thereof

ActiveCN112237977AConvenient recycling workEasy to fall intoGrain treatmentsElectric machineryCentrifugal force

The invention discloses an industrial solid waste environment-friendly smashing and recycling device and an operation method thereof. The industrial solid waste environment-friendly smashing and recycling device comprises a box body, the top end of one side of the box body is provided with a feeding inlet, a feeding hopper is fixedly installed at the position, corresponding to the first feeding inlet, of the top end of one side of the box body, and a fixing base is fixedly installed at the top end of the inner side of the box body; a cylindrical hole is formed in the top end of the fixing base; one end of an output shaft of a first motor is fixedly connected with a first rotating rod; breaking hammers are hinged to the inner sides of hinge bases, and breaking cutters are evenly installed at the two symmetrical ends of the lower portion of the outer wall of the first rotating rod; the first rotating rod is driven by the first motor to rotate, and accordingly, the breaking hammers and the breaking cutters do circumferential movement in a conical hole; and the breaking hammers are hinged to the first rotating rod, therefore, large solid waste materials falling into the box body can bebroken under the action of centrifugal force, and then, the broken solid waste materials can be further cut up through the breaking cutters below the breaking hammers.

Owner:浙江富星环保科技有限公司

Rotatable and turning Lifting AGV (automatic guided vehicle) with laser guiding function

ActiveCN110962731AMulti-directional deliveryWide range deliveryLoad securingBumpersElectric machineryAutomotive engineering

The invention discloses a rotatable and turning lifting AGV (automatic guided vehicle) with a laser guiding function and relates to the technical field of AGVs. The vehicle specifically comprises a vehicle body, buffering mechanisms, a rotating plate, a sliding mechanism and a bearing mechanism. Wheels are installed at the bottom of the vehicle body. The buffering mechanisms are installed at the front end and the rear end of the vehicle body. A limiting groove is formed in the upper surface of the vehicle body, a rotating shaft is connected between one end of the rotating plate and the rear end of the vehicle body in a penetrating mode, a sliding mechanism is assembled above the sliding seat in a sliding mode, a hydraulic lifting frame is connected above the sliding mechanism, and a bearing mechanism is assembled above the supporting plate in a sliding mode. A stepping motor is used for controlling the rotating shaft to rotate, the rotating shaft drives the rotating plate to rotate bya certain angle together, objects can be turned by a certain angle while the overall advancing direction of the AGV is not adjusted, and therefore the AGV can deliver the objects in multiple directions and in a large range.

Owner:SHENZHEN OKAGV COMPANY

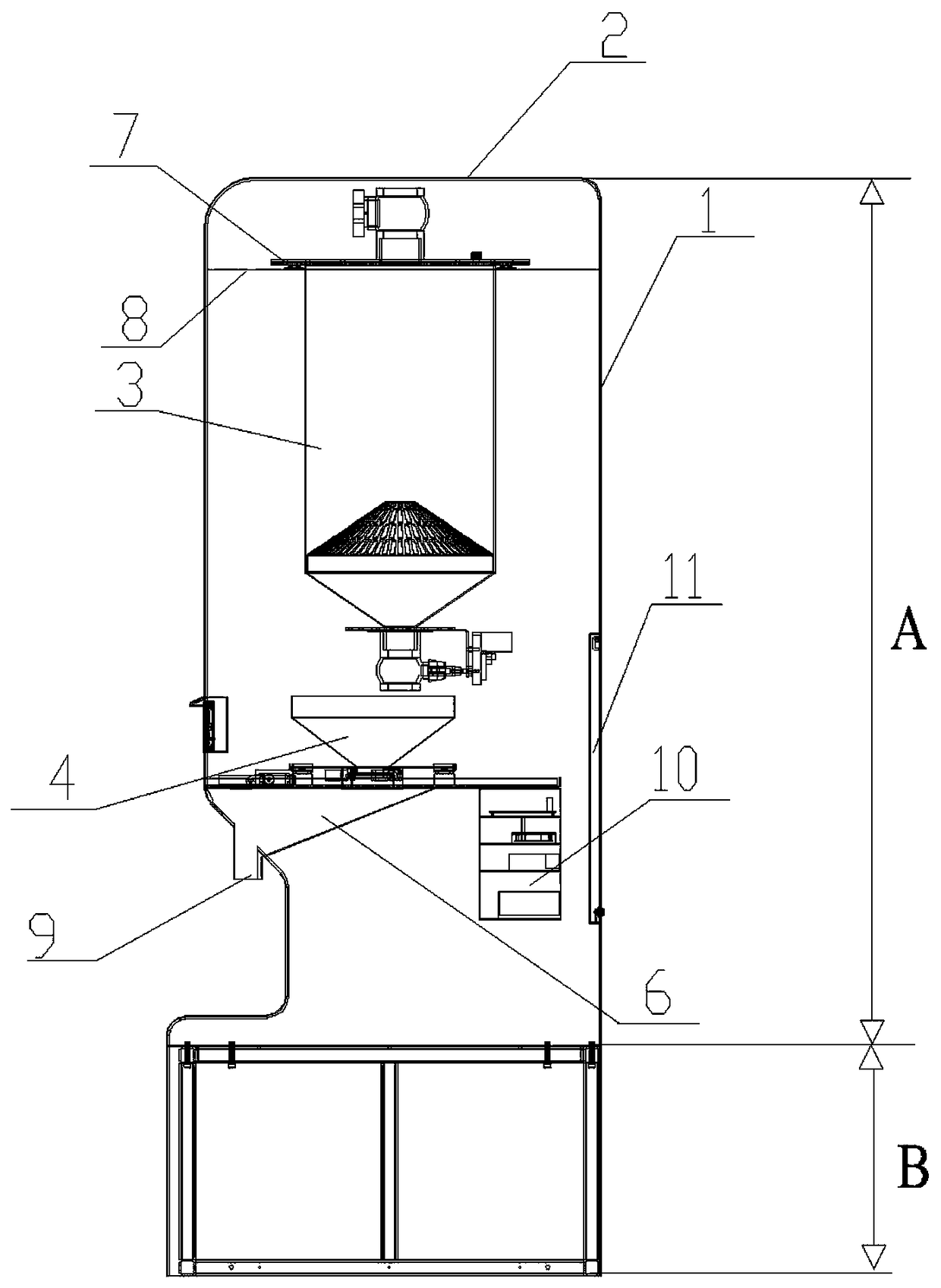

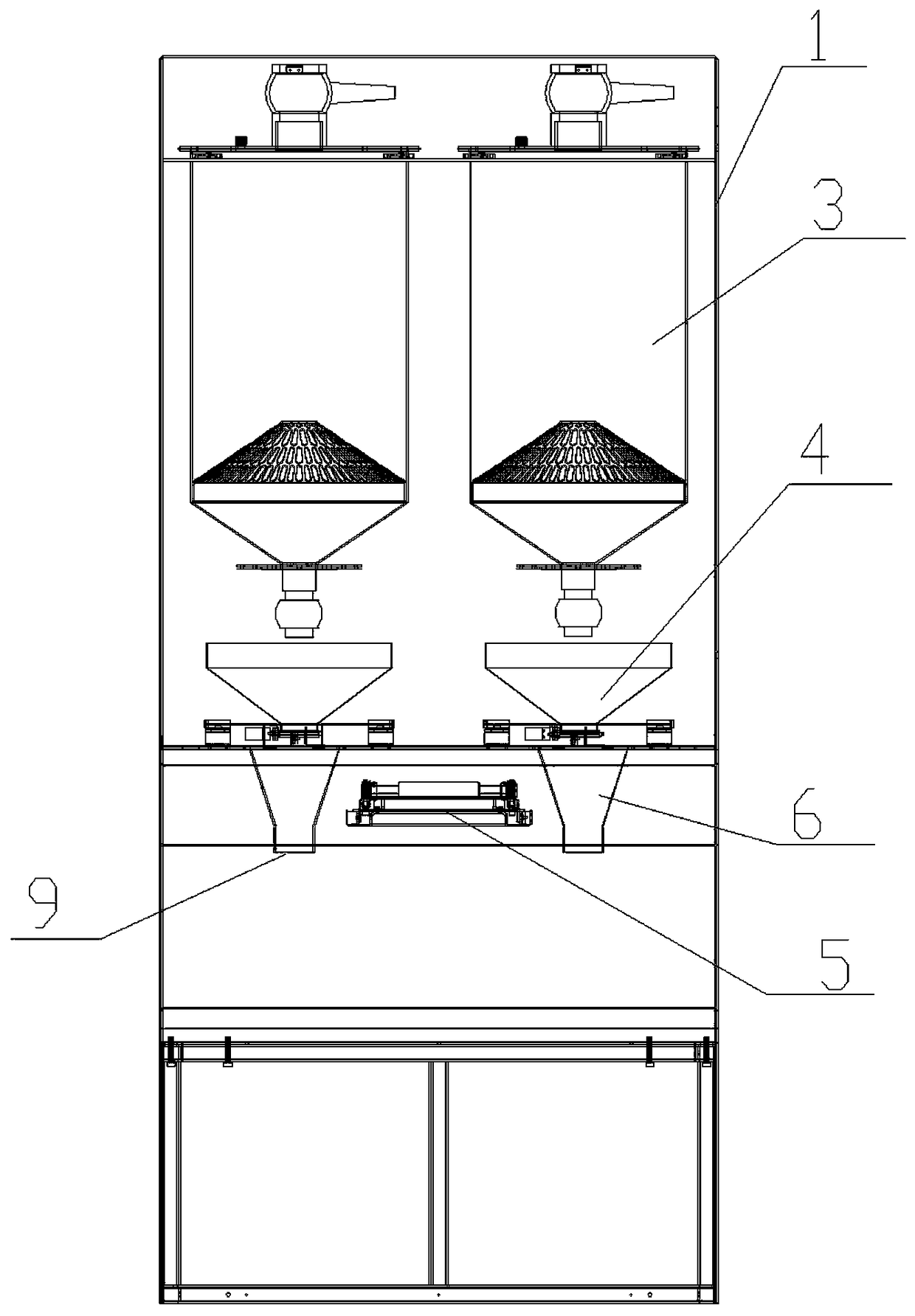

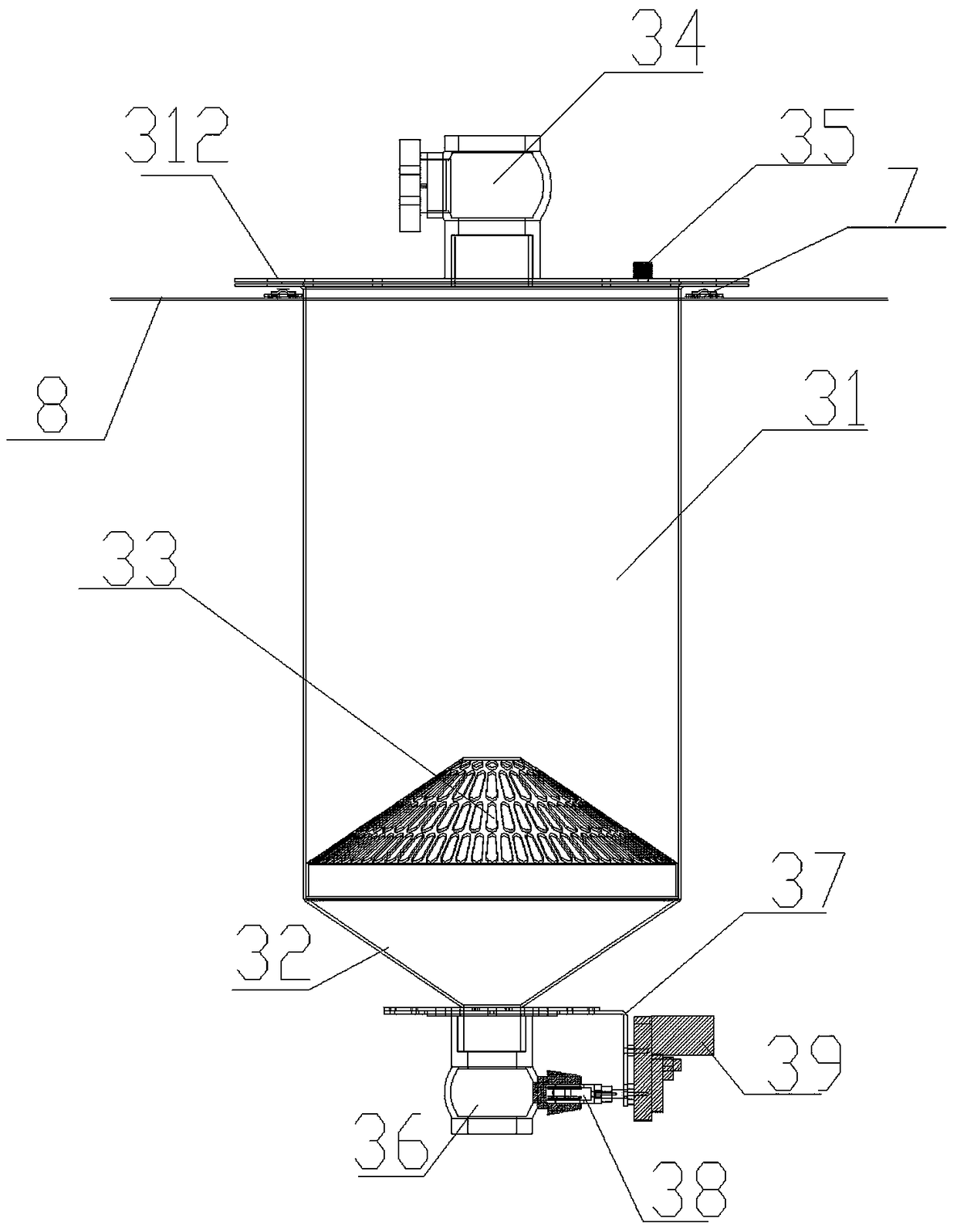

Portable grain vending machine

PendingCN108922040AControl the discharge situationPrevent moisture deteriorationApparatus for dispensing fluids/granular materialsGrain storageComputer engineering

The invention discloses a portable grain vending machine. The portable grain vending machine comprises a computer case; a top cover is arranged at the upper end of the computer case; a shopping bag extracting device and at least a grain storage bin are arranged in the computer case; a shopping bag extracting mouth and a grain taking mouth as many as the grain storage bin are arranged at the frontside of the computer case; and the downside of the outputting mouth of each grain storage bin is correspondingly communicated with a grain taking mouth through each obliquely arranged discharging channel. The portable grain vending machine is simple in structure, convenient to install, easy to transport, small in volume and more practical.

Owner:河南省天天粮仓科技有限公司

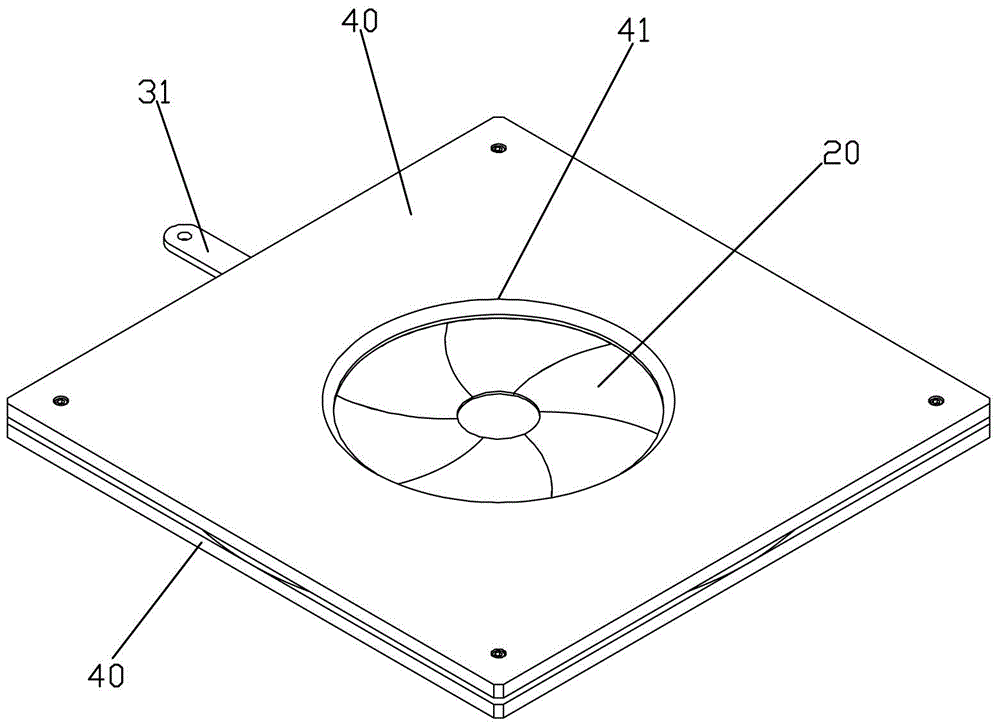

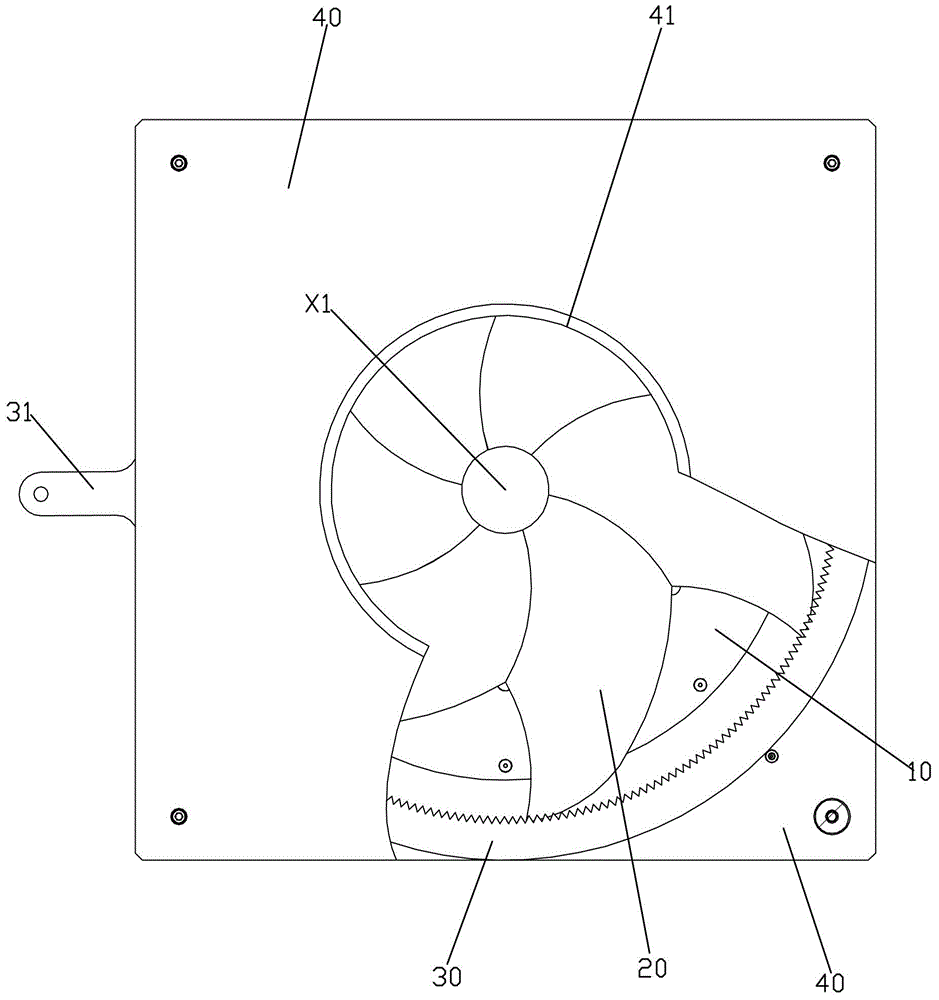

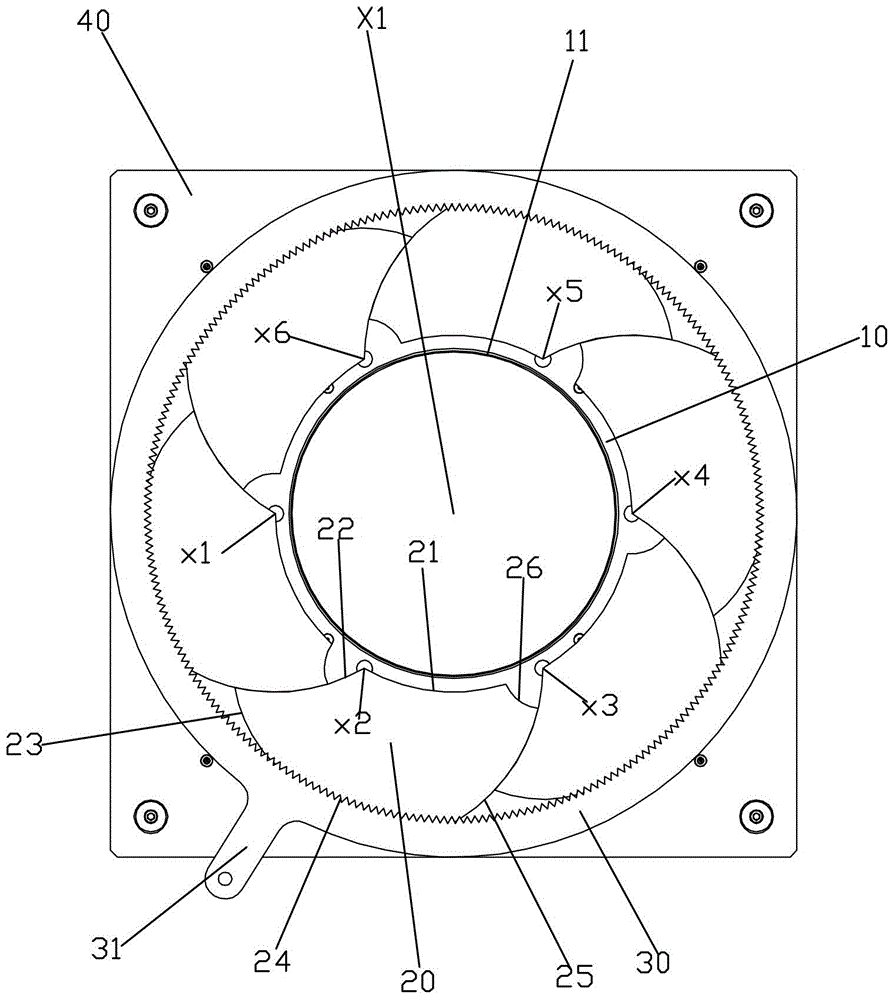

Necked-opening bionic mechanical hand and sheltering device

The invention discloses a necked-opening bionic mechanical hand and a sheltering device. The mechanical hand comprises a base plate, a plurality of fan-shaped plates and a tooth ring. The base plate is provided with a trough hole. The tooth ring can rotate relative to the base plate. The fan-shaped plates are connected to the base plate in a pivot joint mode and arranged in an annular mode and can rotate between the opening position and the closing position. The tooth ring inner diameter is R. The interval of the pivot joint axes of every two adjacent fan-shaped plates is S, and the annular arrangement radius is S. The outer peripheral edge of each fan-shaped plate at least comprises five arc segments connected sequentially. The fan-shaped outer peripheral edge is formed according to the following conditions: according to each fan-shaped plate at the opening position, the circle center of the first arc segment is located at X1 and the radius is S, the circle center of the second arc segment is located at the pivot joint axis of the previous adjacent fan-shaped plate and the radius is S, the circle center of the fourth arc segment is located at X1 and the radium is R, and the circle center of the fifth arc segment is located at pivot joint axis of the corresponding fan-shaped plate and the radium is S; according to each fan-shaped plate at the closing position, the circle center of the third arc segment is located at the pivot joint axis of the corresponding fan-shaped plate and the radium is R-S. The third arc segments and the fourth arc segments can be meshed with the tooth ring in a matched mode. The necked-opening bionic mechanical hand and the sheltering device have the following advantages that a necked-opening can be totally opened and closed automatically, the necked-opening bionic mechanical hand and the sheltering device are used for packing, simple in process and free of manual operation, the cost is reduced, and efficiency is improved.

Owner:倍施力(厦门)智能装备有限公司

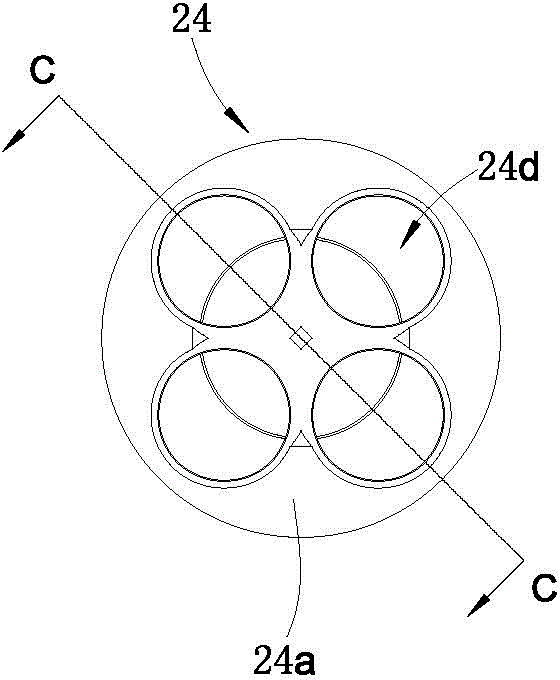

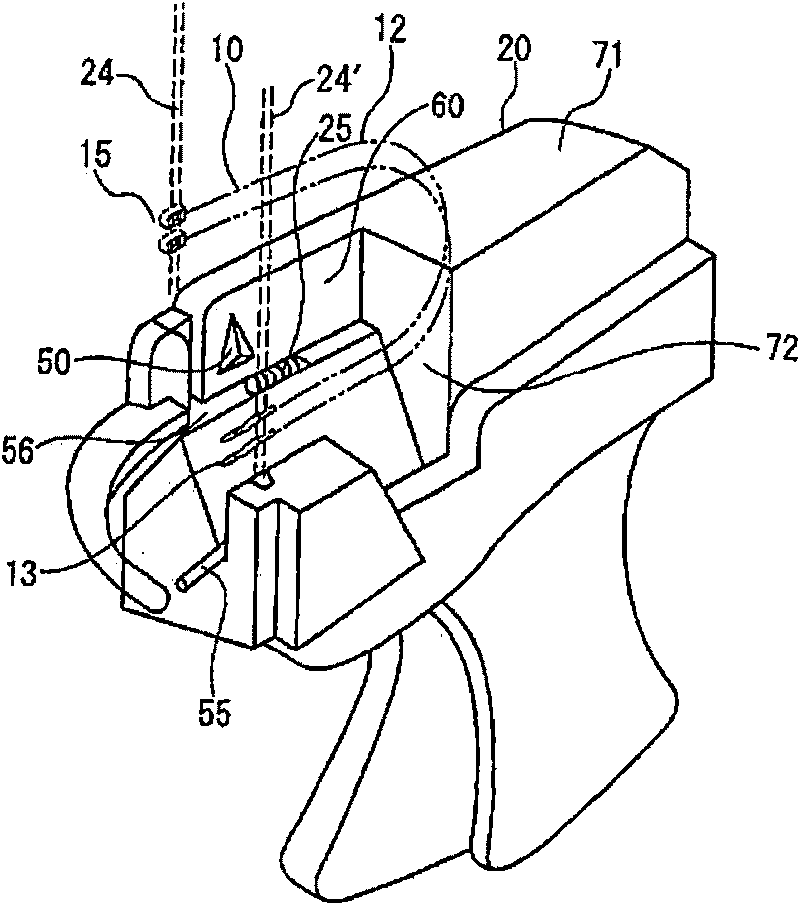

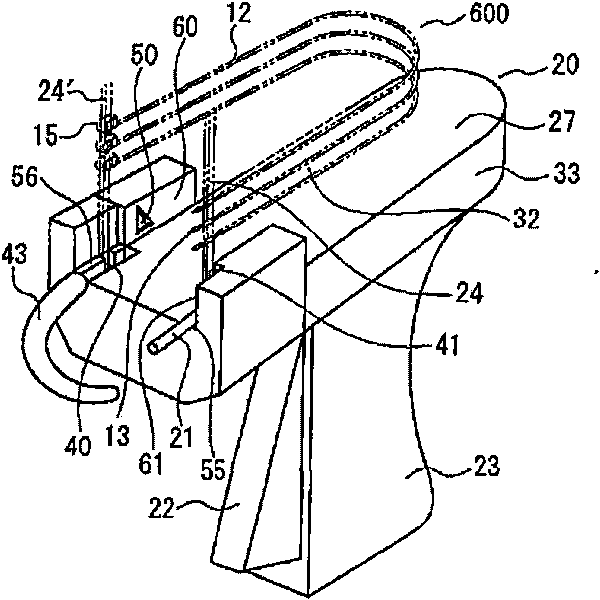

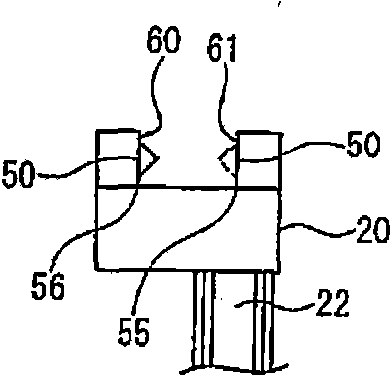

Circular pin combination device and circular pin ejection method

ActiveCN101734392ARemove intertwiningAvoid getting stuckAffixing tagsConductor CoilMechanical engineering

The present invention relates to a circular pin combination device which is provided with a winding releasing mechanism that actively release the winding part when winding of circular pin sheets occurs on the circular pin combination device. On the circular pin combination device (20), a random part selected from a part near an ejection part (56) of a socket (15) and a part near an ejection part (55) of an insertion-through part (13) is provided with the winding releasing mechanism (50) which exerts a pressing force in a direction crossed with an axial direction of a filament part (12) to one part of the filament part (12) that is next to the socket (15) or the insertion-through part (13).

Owner:克铁库存斯股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com