Patents

Literature

47results about How to "Easy to sift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

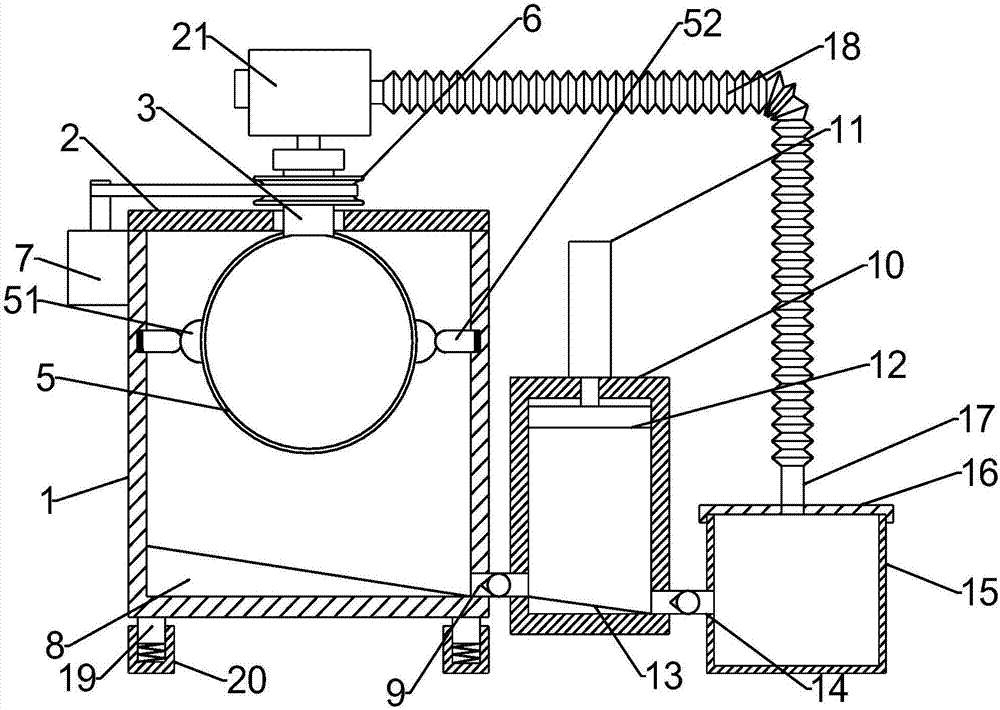

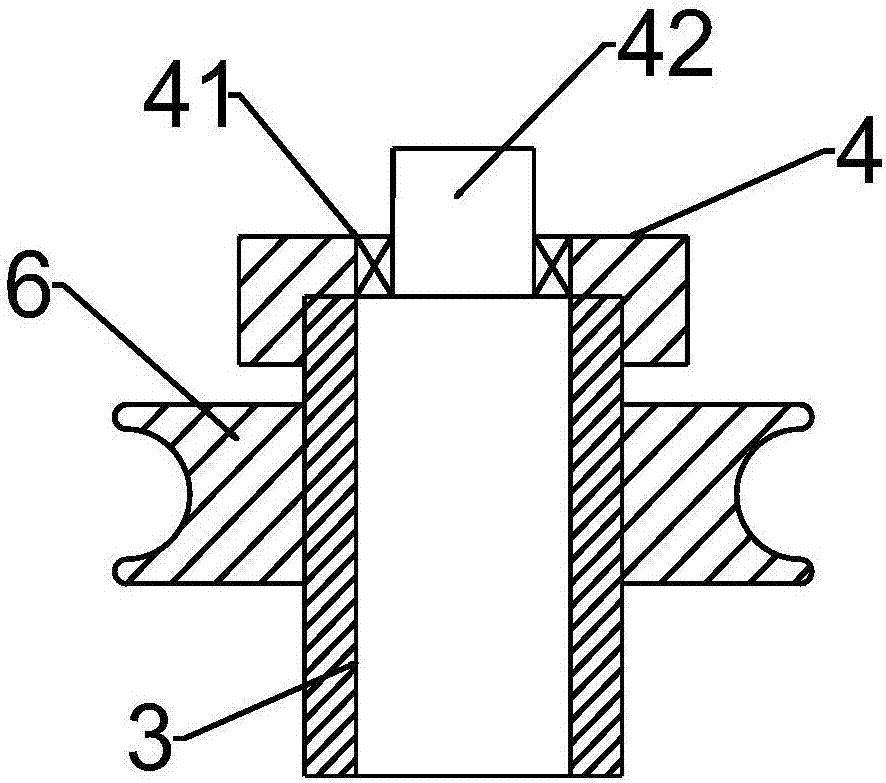

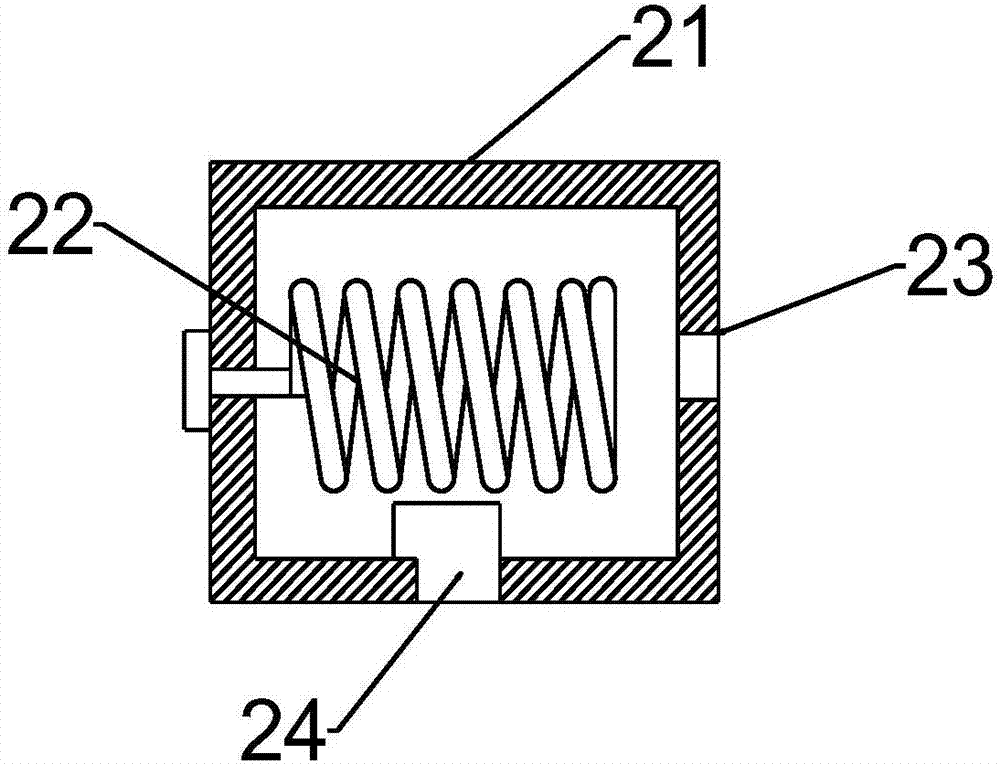

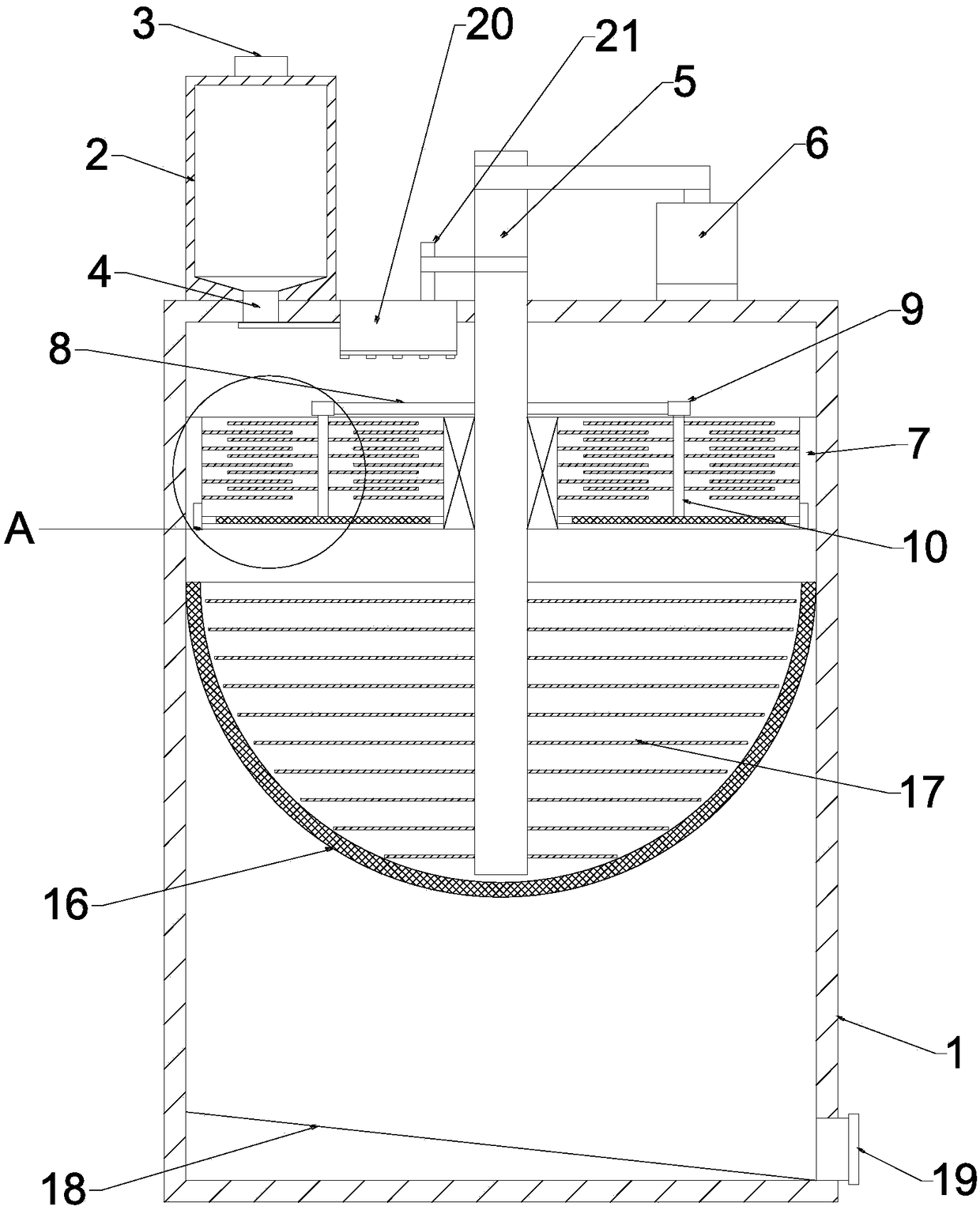

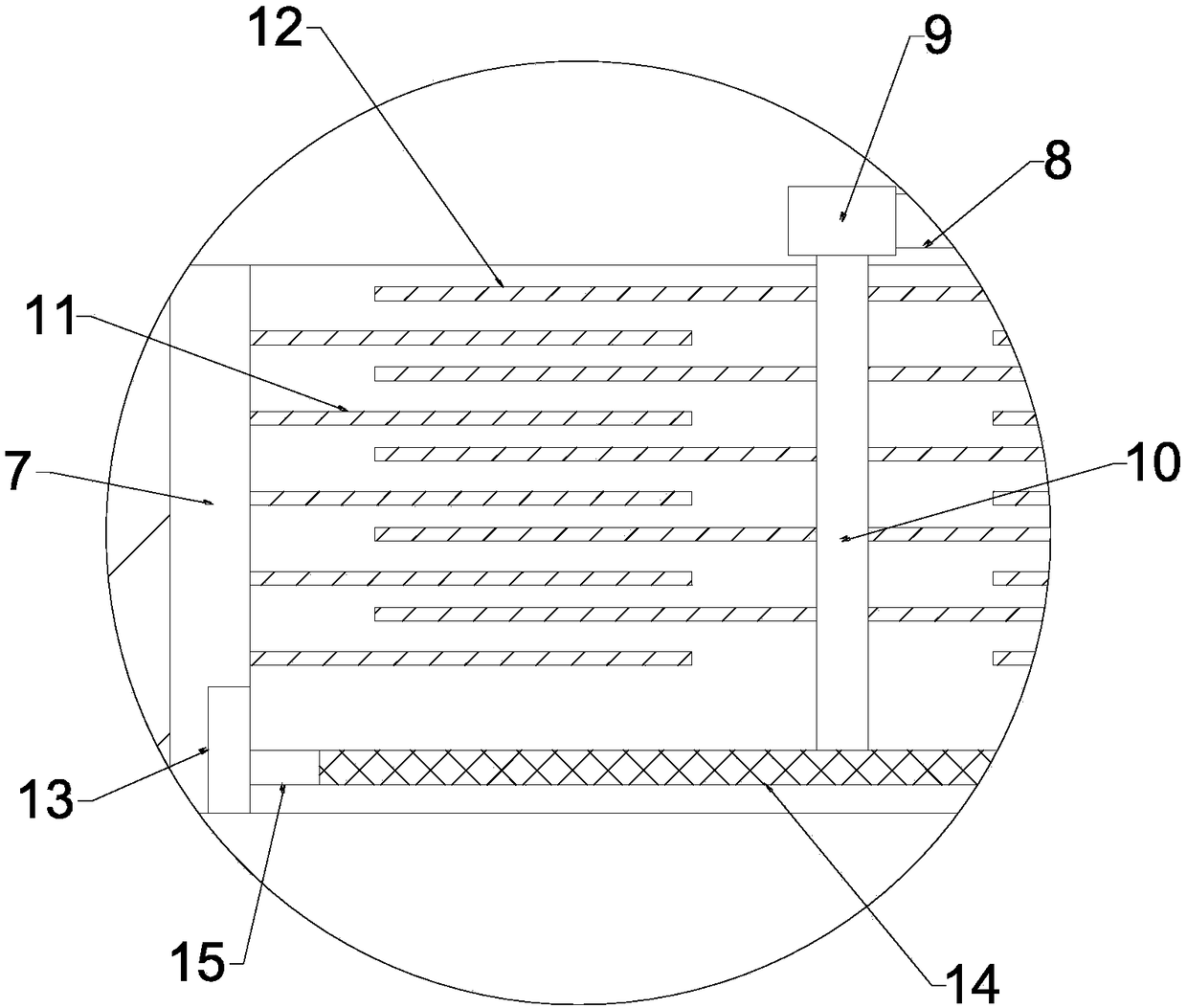

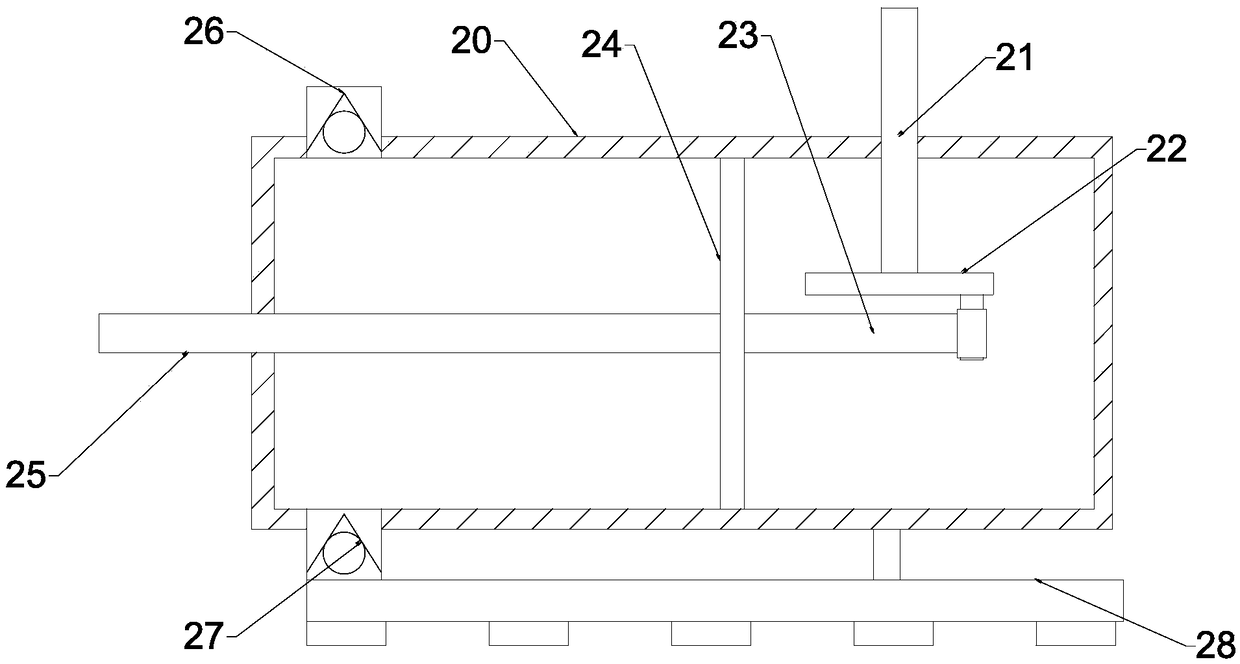

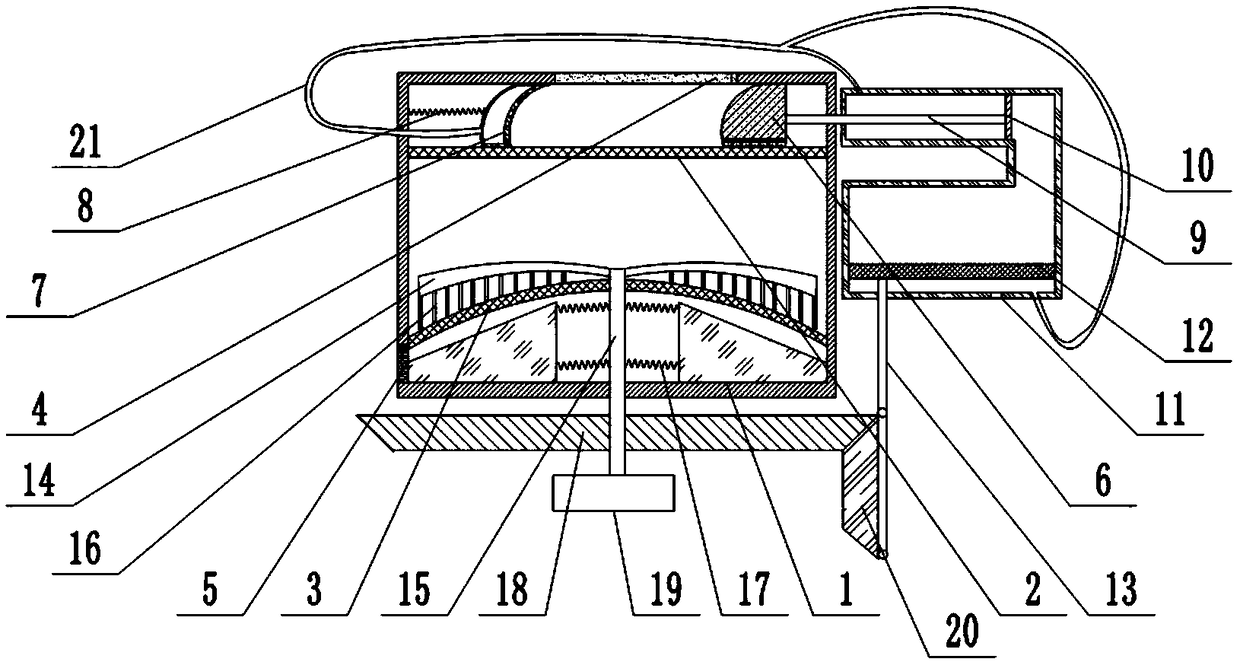

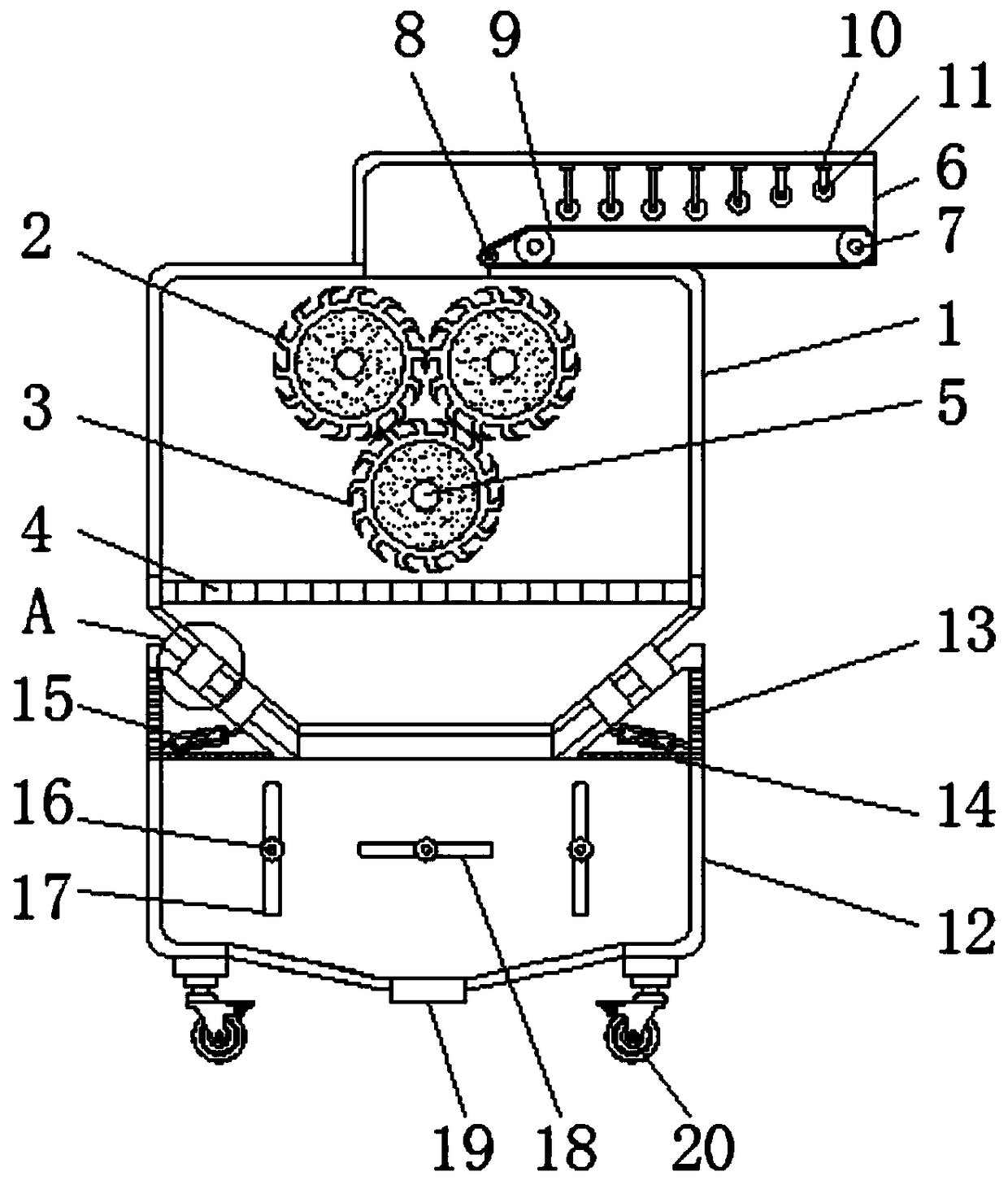

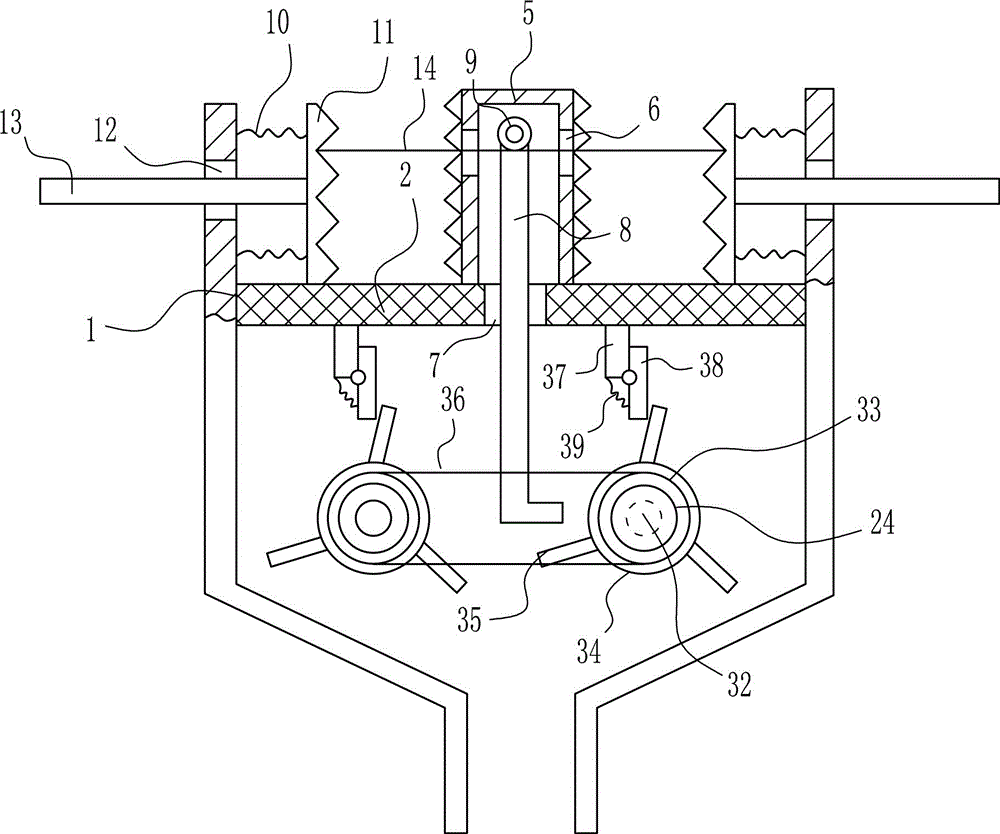

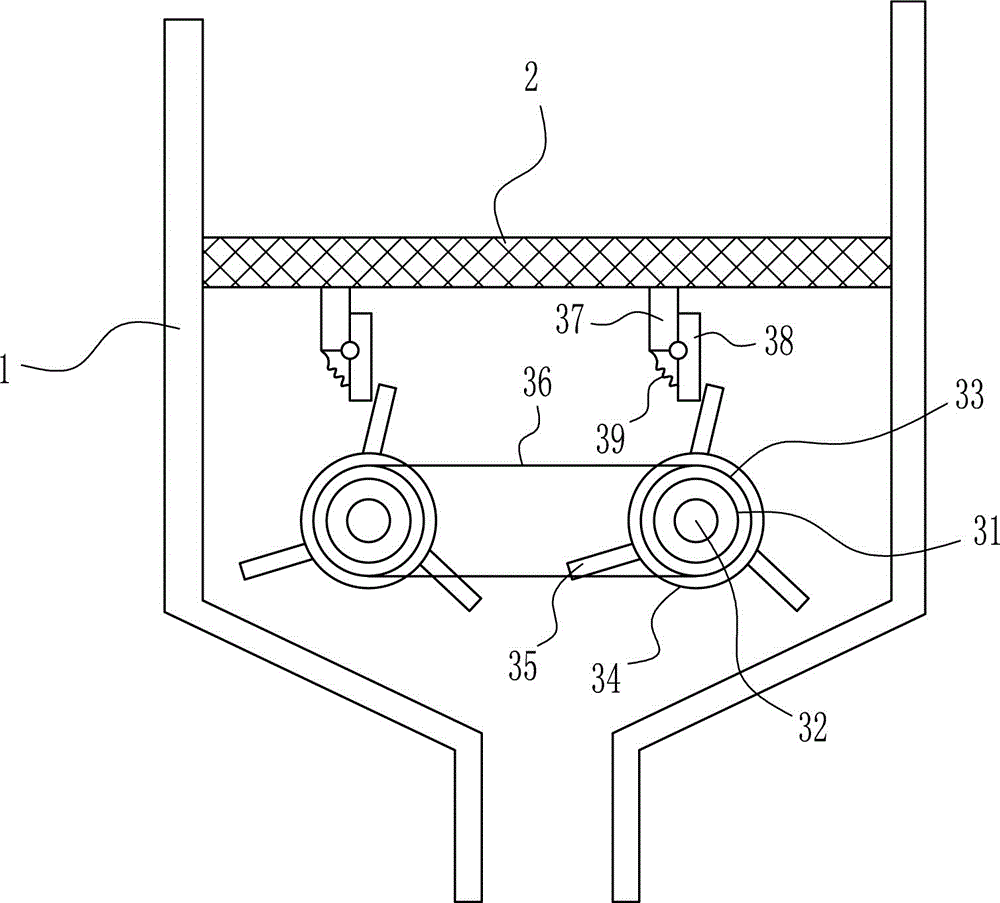

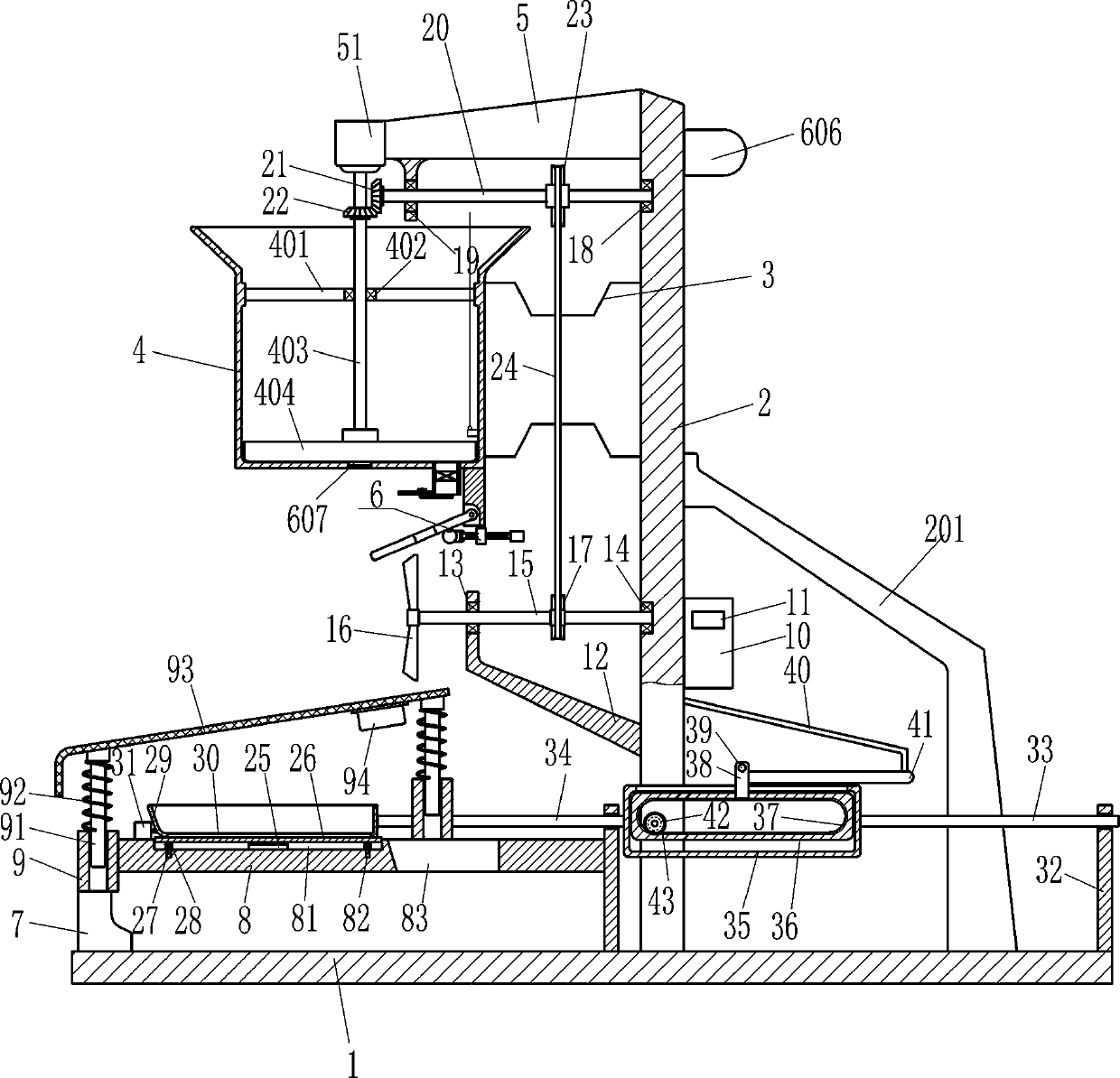

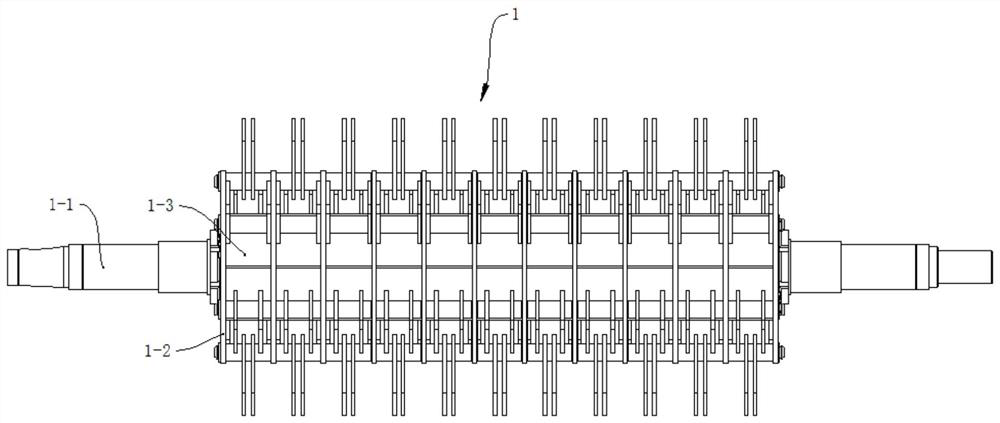

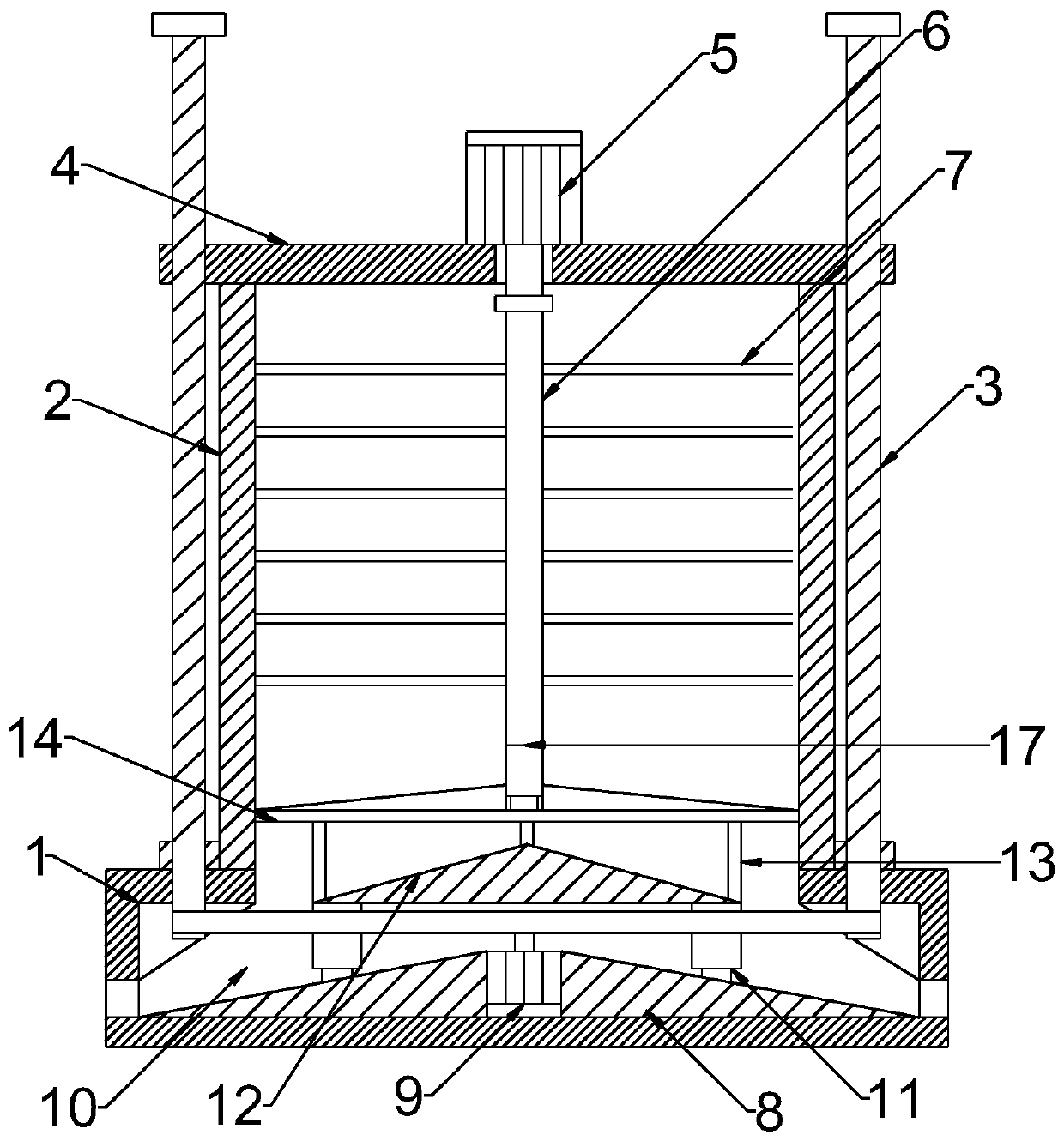

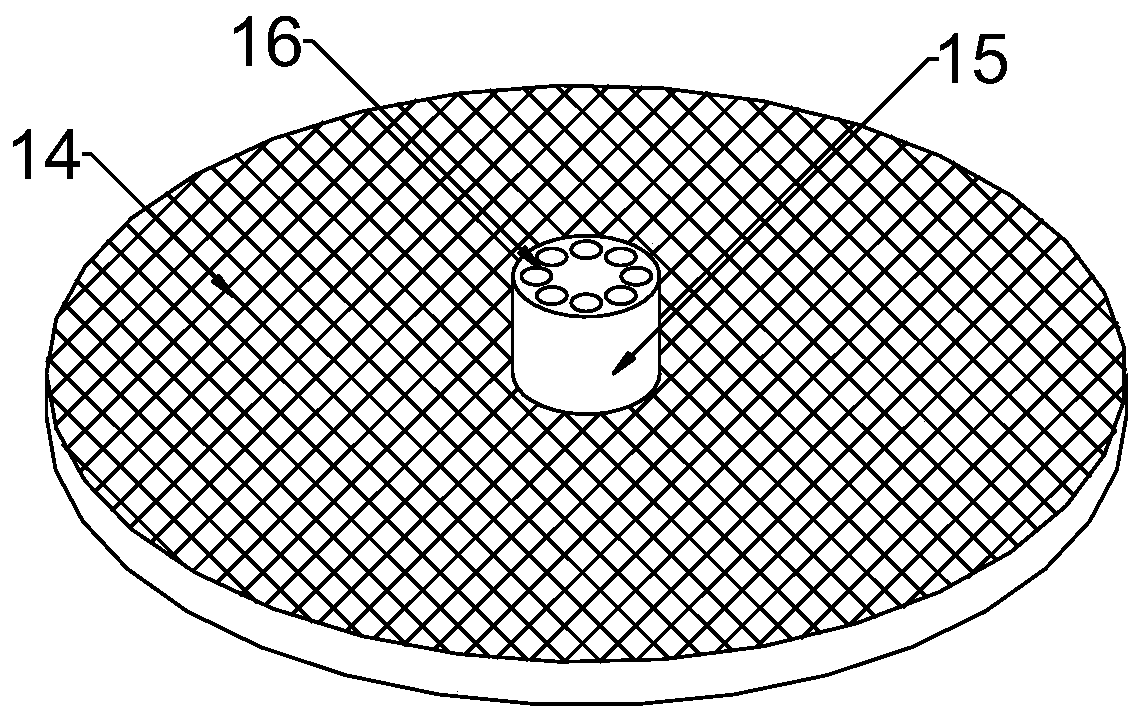

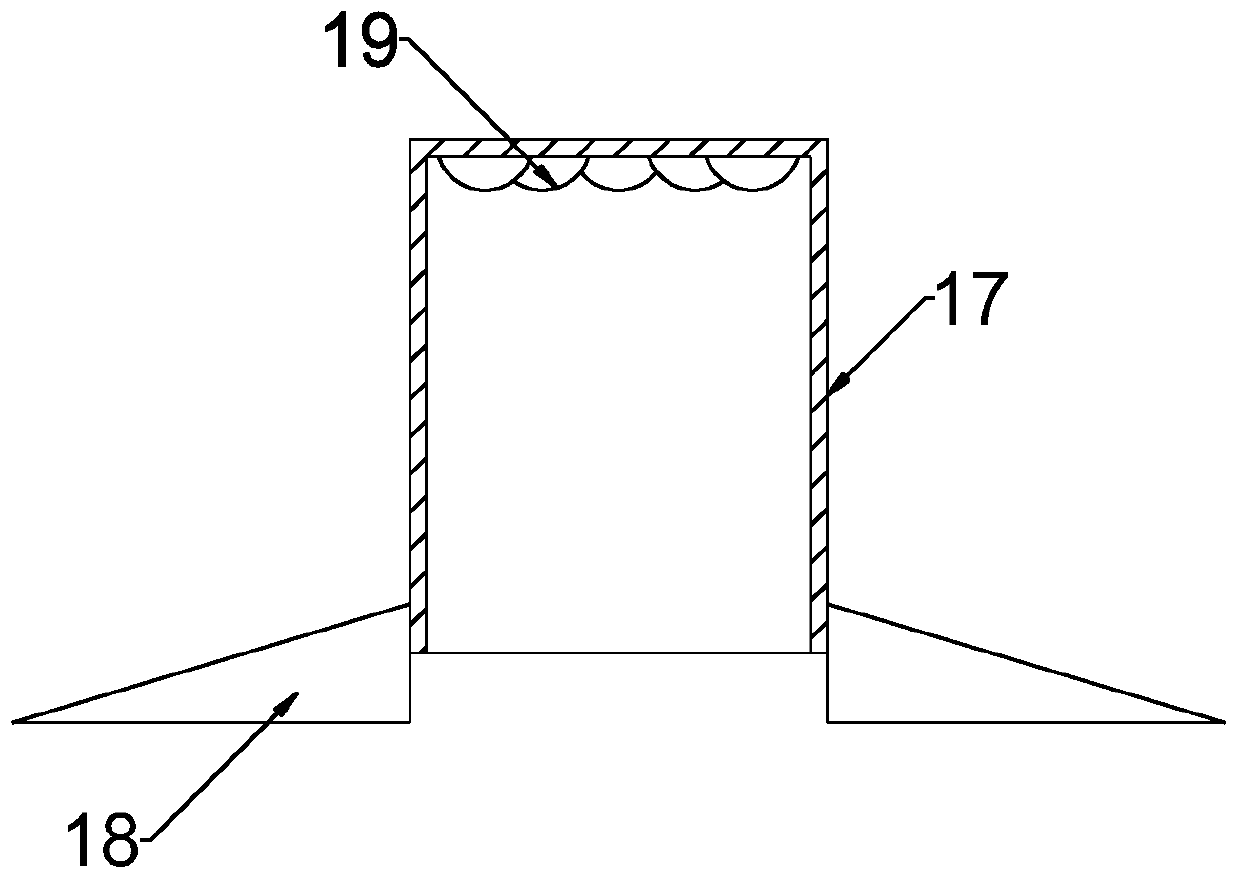

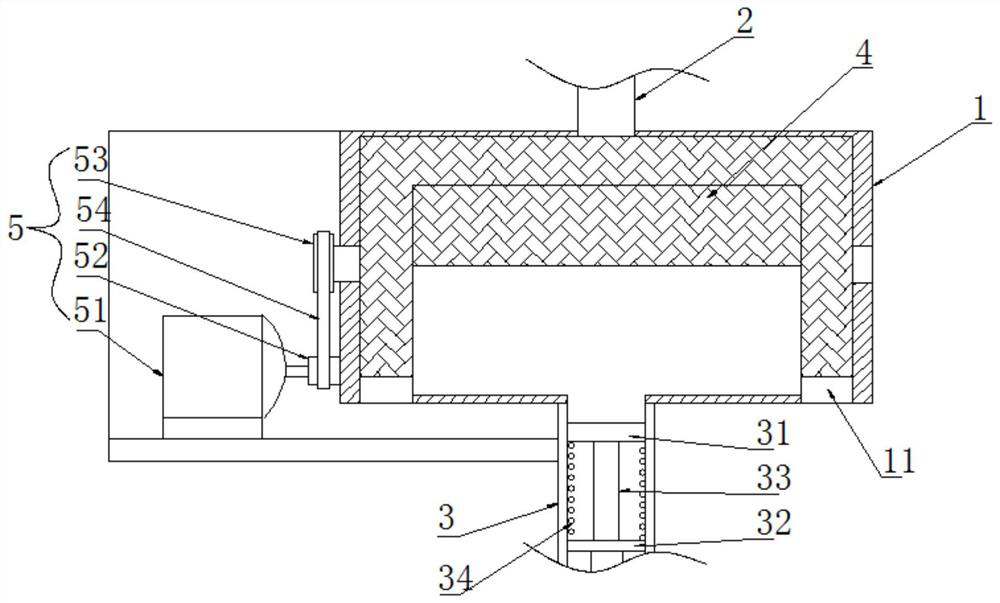

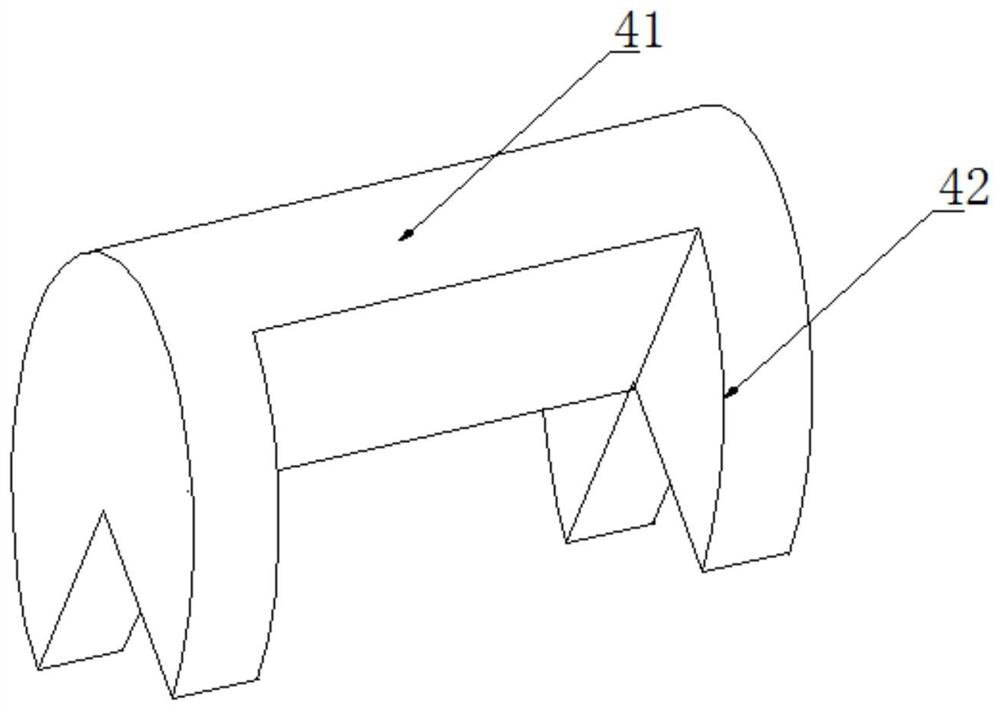

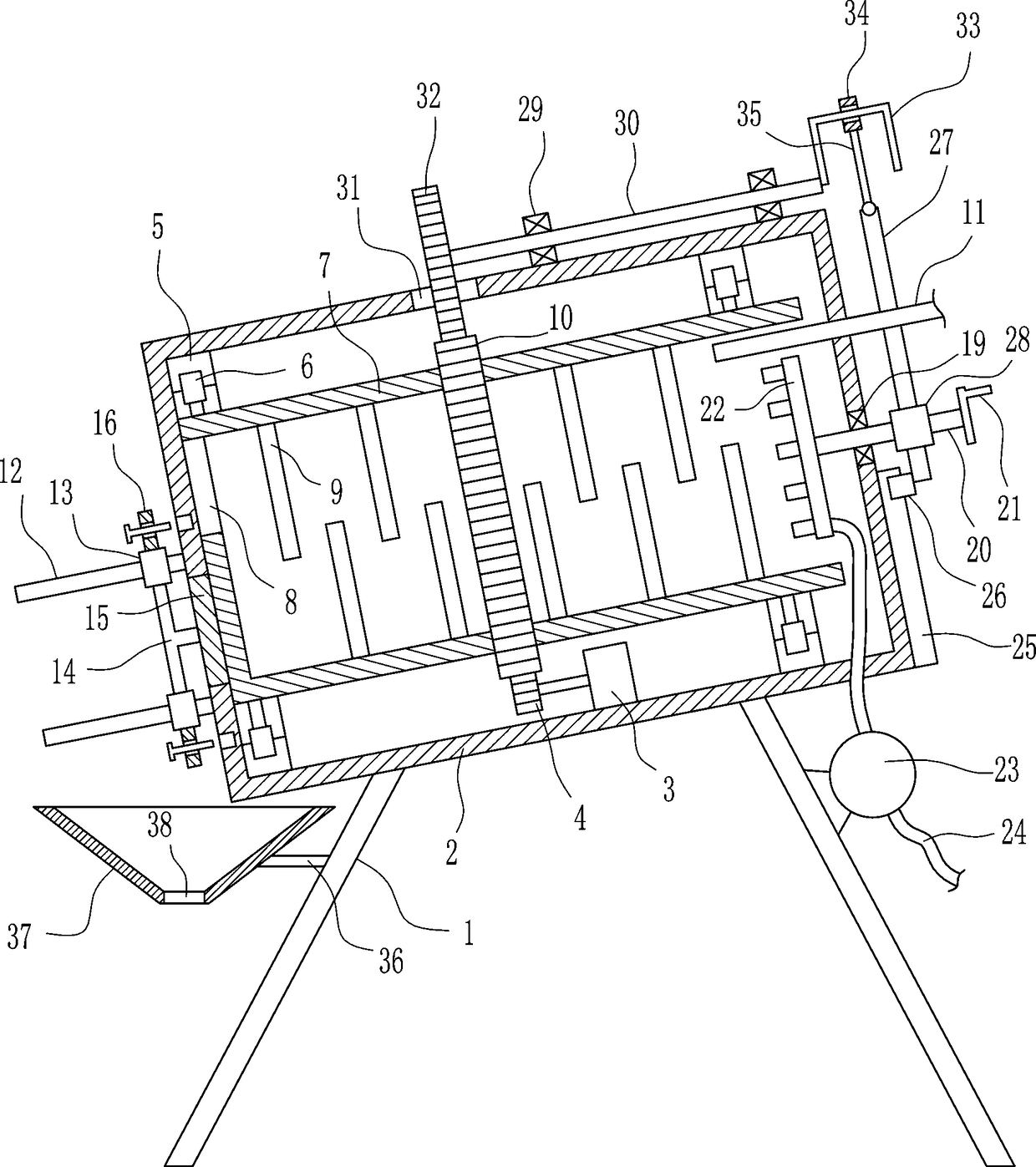

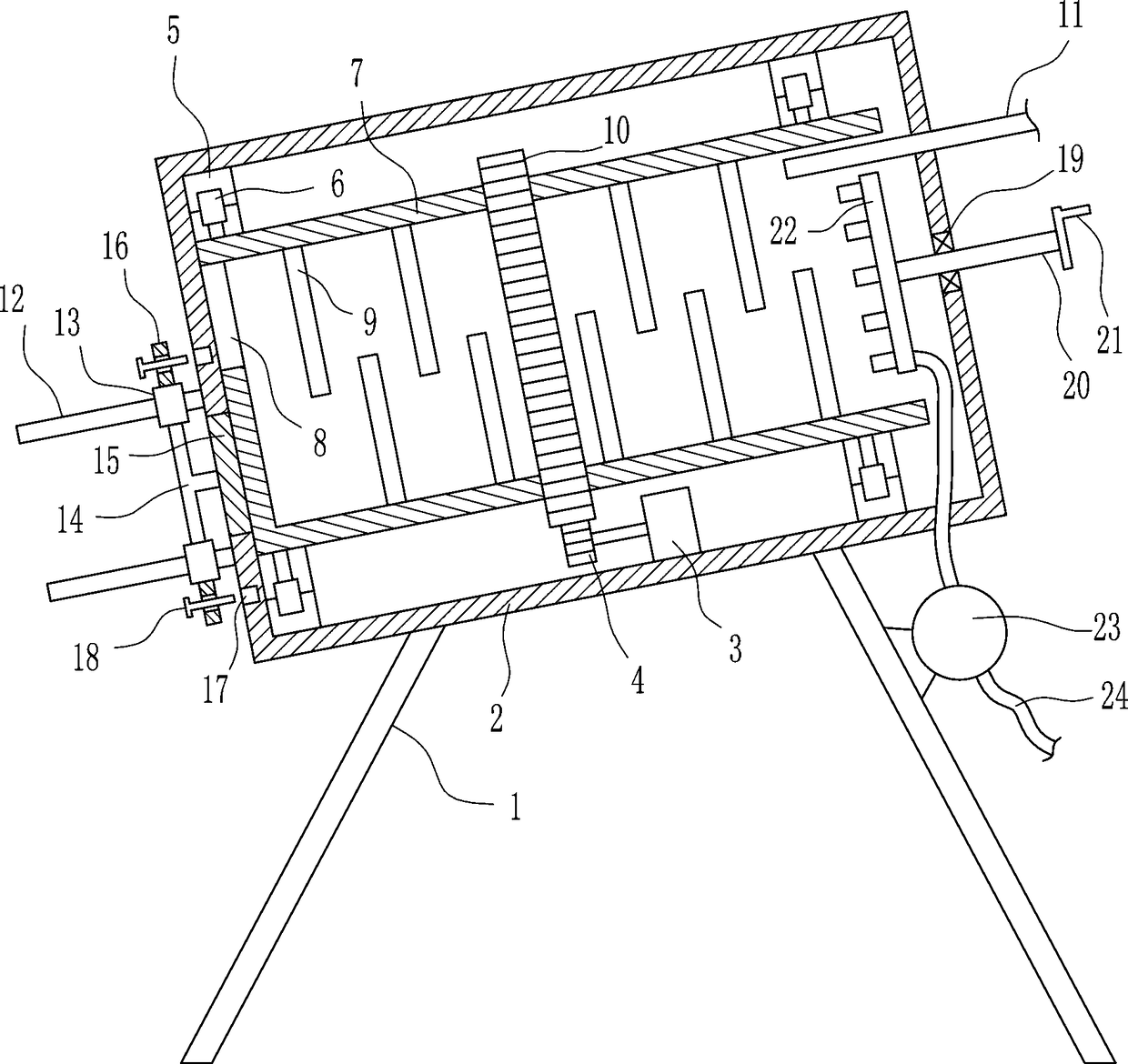

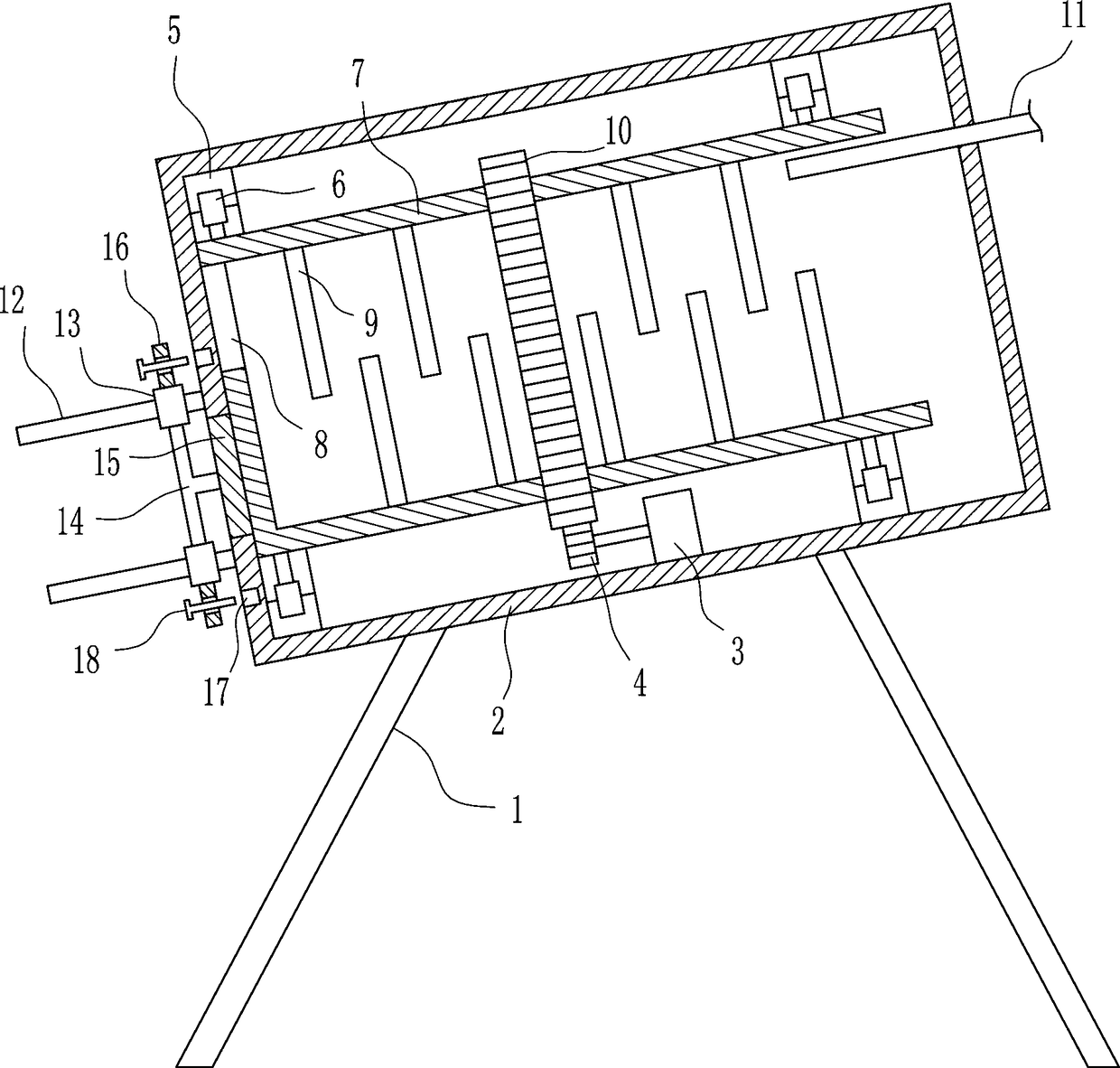

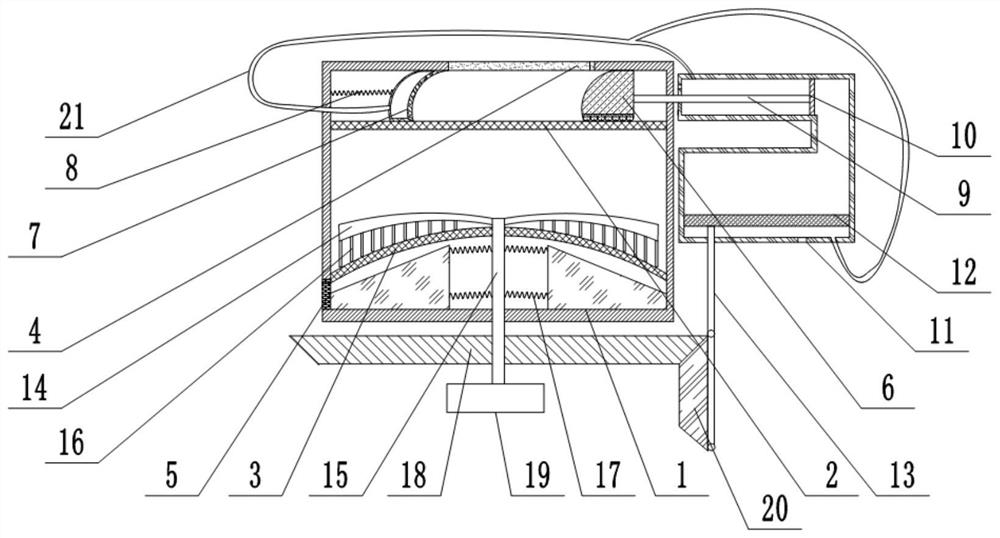

Drying and sieving device for soft magnetic material powder

InactiveCN107127148AEasy to siftImprove sieving efficiencySievingScreeningEngineeringMechanical engineering

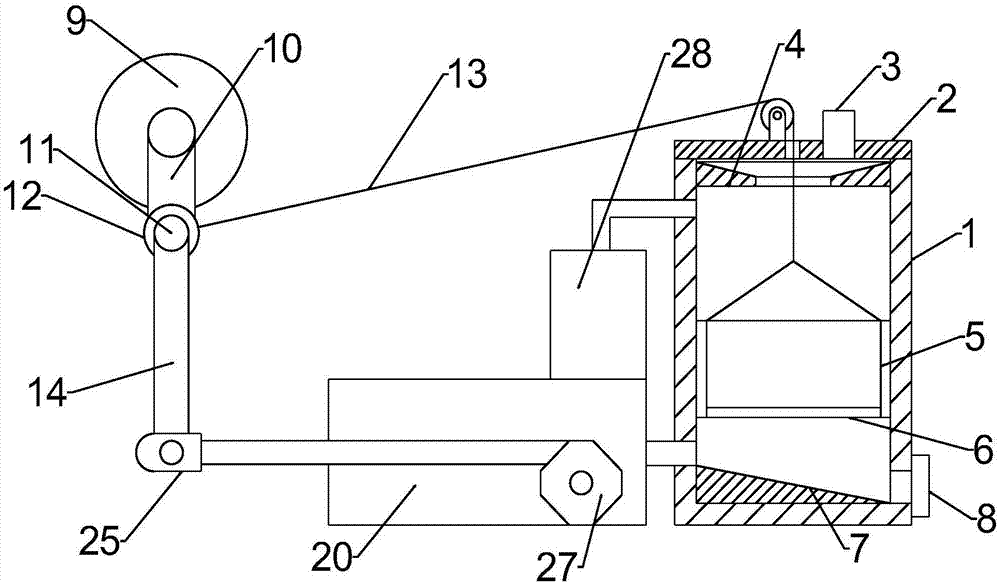

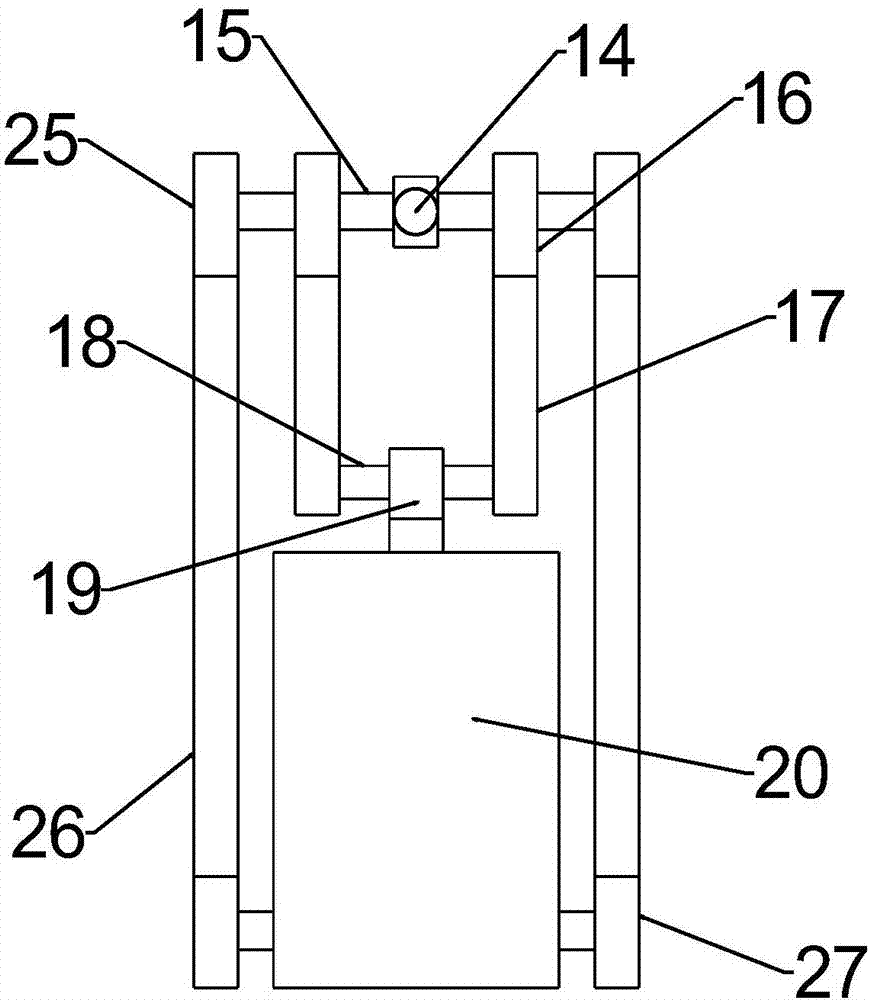

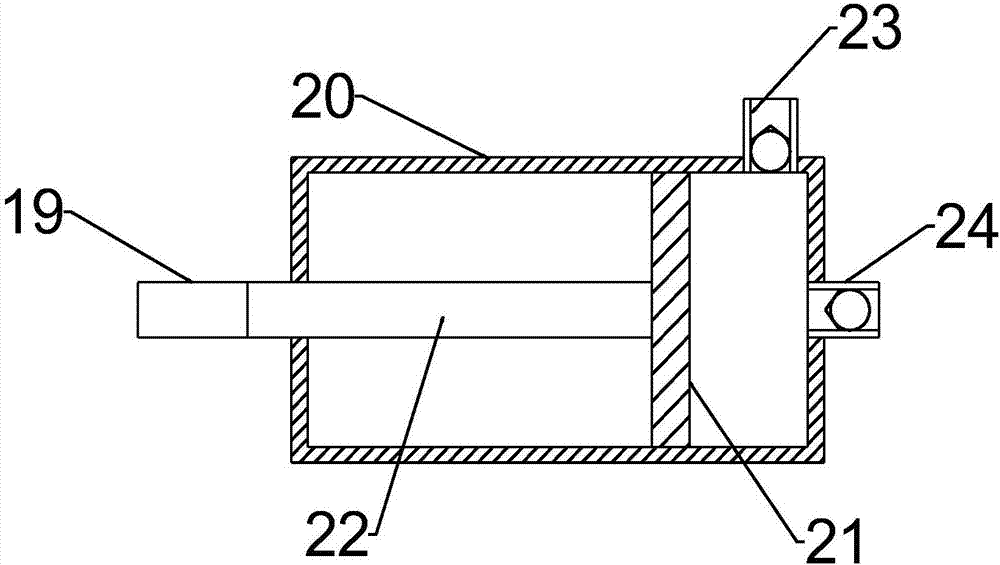

The invention discloses a drying and screening device for soft magnetic material powder, which comprises a screening box, a material guide cylinder, a material storage tank and a heating box. The screening box is provided with a movable upper cover, a feeding pipe, a threaded connection cover, Sealed bearing, air pipe, filter bag, collision protrusion, telescopic protrusion, transmission wheel, motor, first guide bottom plate and first material guide pipe; the material guide cylinder is equipped with electric telescopic rod, piston plate, second guide The bottom plate and the second material guide pipe; the storage tank is provided with a threaded sealing cover, an exhaust pipe and a connecting hose; the lower end of the screening box is provided with a support rod and a support sleeve; There are heating pipes, air intake holes and air guide pipes. In the present invention, through the filter bag, the collision protrusion and the telescopic protrusion, the passing efficiency is improved by collision and friction during rotation, the piston is driven by the electric telescopic rod to produce a circulation effect, and the air is heated by the heating tube, thereby drying the powder and improving the screening efficiency.

Owner:许晶

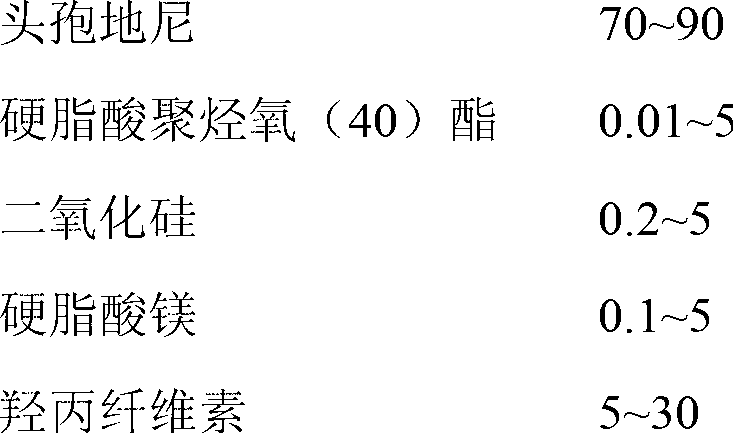

Cefdinir capsule and preparation method thereof

ActiveCN102935075AGood dissolution effectImprove liquidityAntibacterial agentsOrganic active ingredientsMedicineQuality control

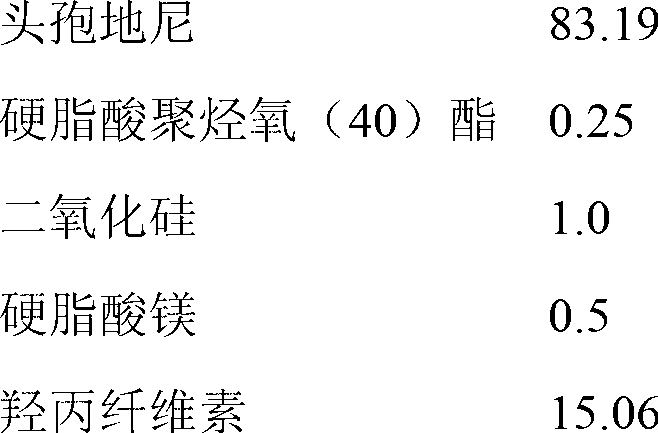

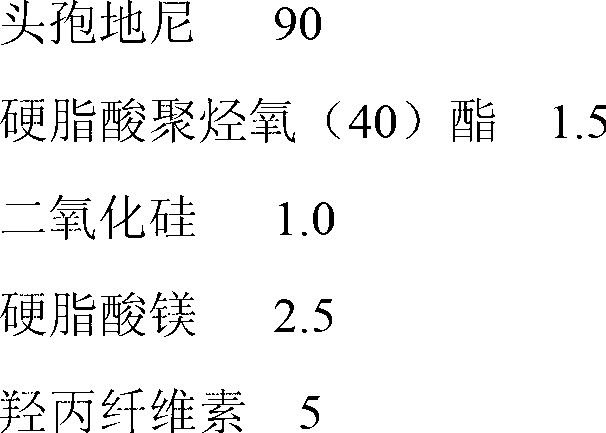

The invention provides a cefdinir capsule and a preparation method of the cefdinir capsule. The content of the cefdinir capsule comprises the necessary components based on parts by weight: 70-90 parts of cefdinir, 0.01-5 parts of polyoxyl (40) ester stearate, 0.2-5 parts of silicon dioxide, 0.1-5 parts of magnesium stearate and 5-30 parts of hydroxypropyl cellulose. The medicine prepared by cefdinir capsule prescription is good in dissolution effect and fluidity, and stable in medicine effect; the provided preparation method is simple in technology; the product is less in introduced impurity, easy in quality control and good in reproducibility and uniformity; and the preparation method saves the energy and reduces the consumption, thus easily meeting the demand of mass production.

Owner:海南三叶美好制药有限公司

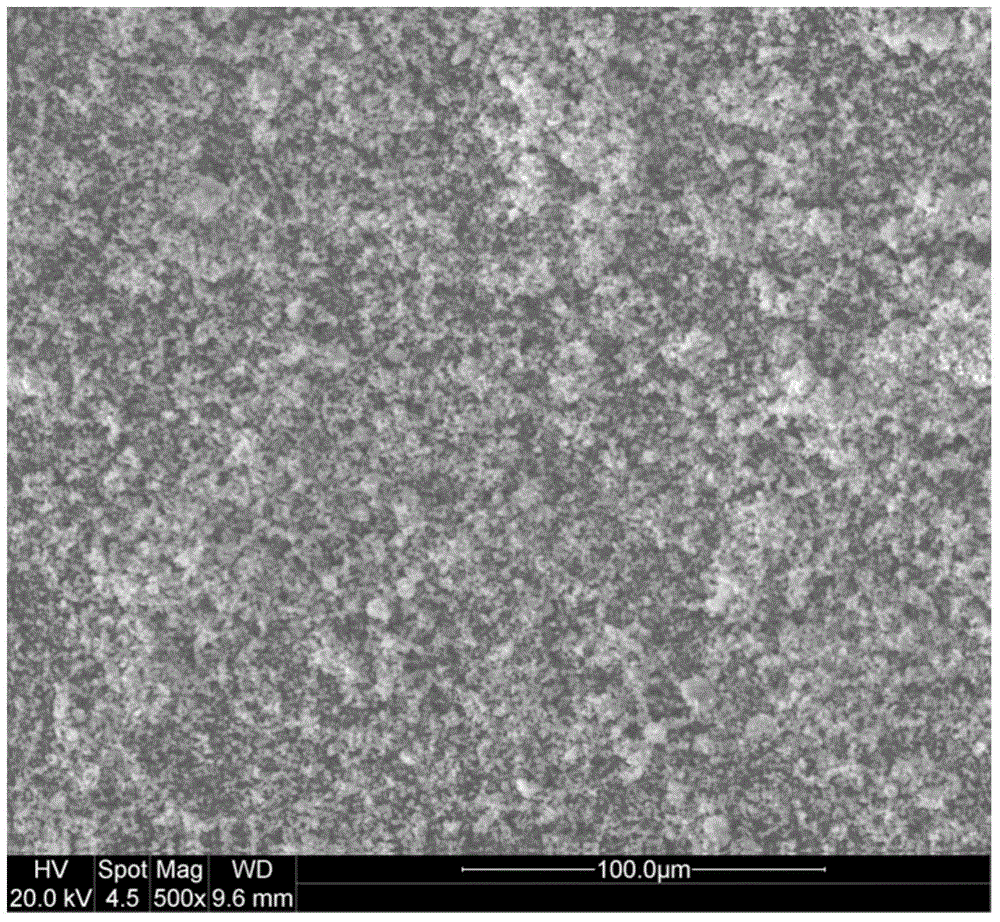

Lithium titanate composite material and preparation method thereof

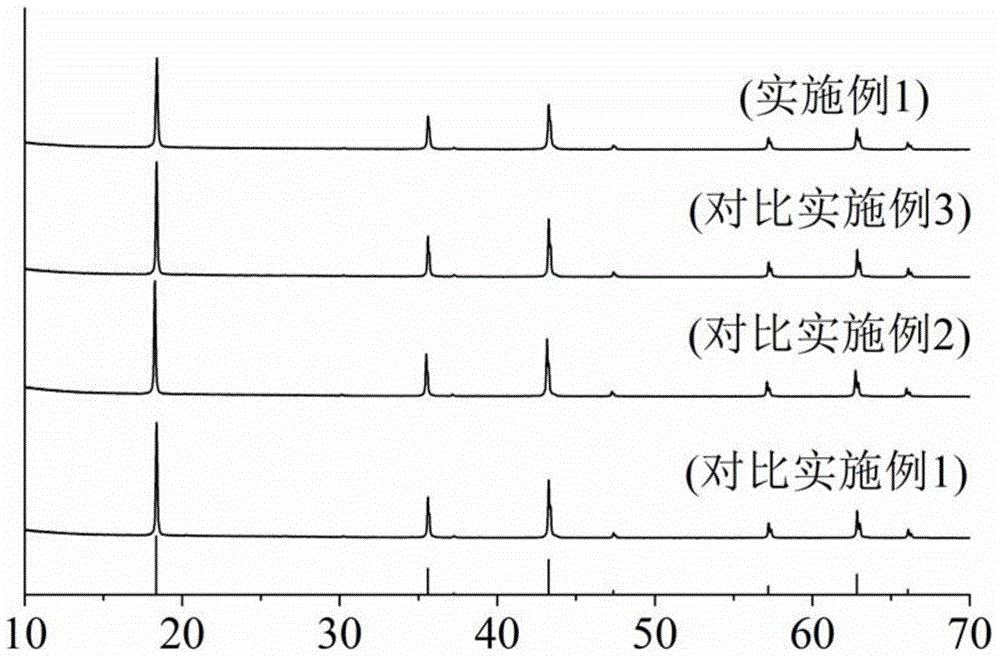

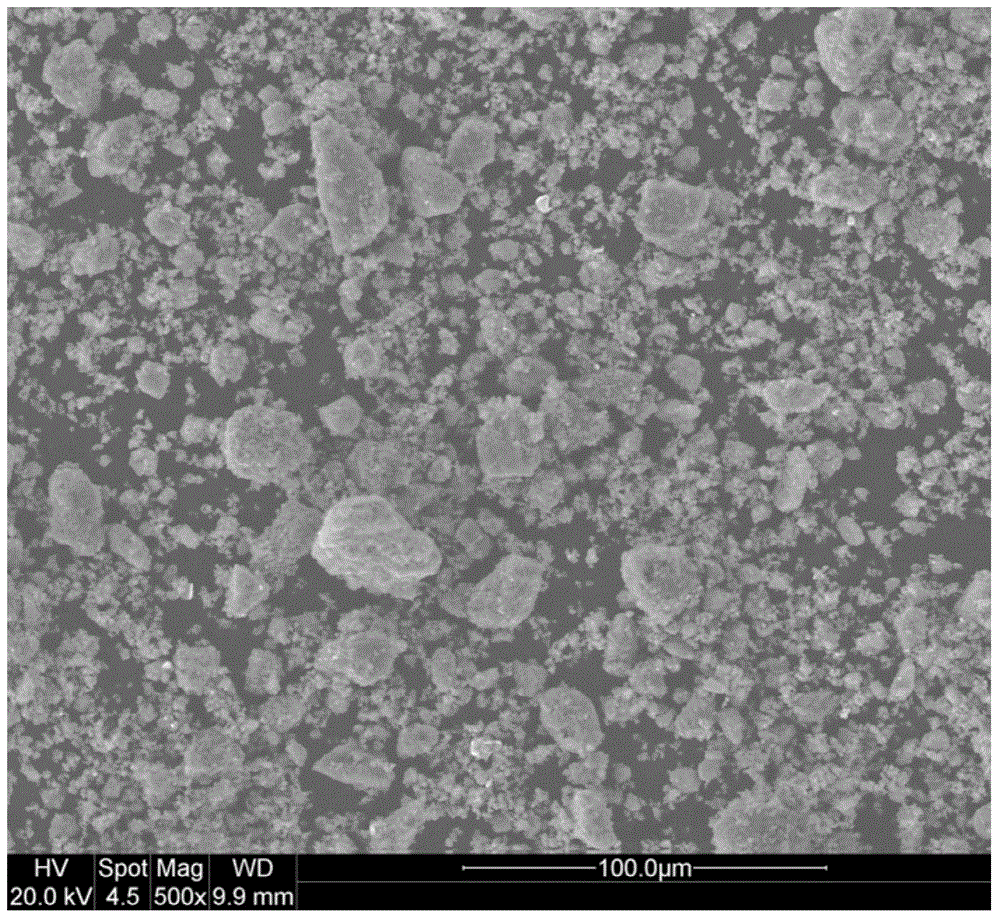

The invention discloses a lithium titanate composite material and a preparation method thereof, wherein the lithium titanate composite material includes a composite particle I, which is formed by coating the surface of Li4Ti4.94Al0.06O12 primary particles by nano carbon, and / or, a composite particle II, which is formed by a plurality of the composite particle I, wherein the structure of the composite particle II is a structure formed among the composite particles I. The nano carbon accounts for 0.2-1.8% of the total weight of the lithium titanate composite material. The particle size of the lithium titanate composite material is 0.1-50 [mu]m. The preparation method is low in raw material cost, is controllable in substance phase and is high in yield, and is suitable for large-scale industrial production. The lithium titanate composite material is stable in performance and can reach a 10 S / m magnitude order in electronic conductivity, is good in rate capability, is small in particle size, is easy to sieve, is good in processability and usability, and can be used in various energy-storage lithium ion batteries which require a long service life and various dynamic lithium ion batteries which require quick charging and discharging.

Owner:SHANGHAI SHANSHAN TECH CO LTD

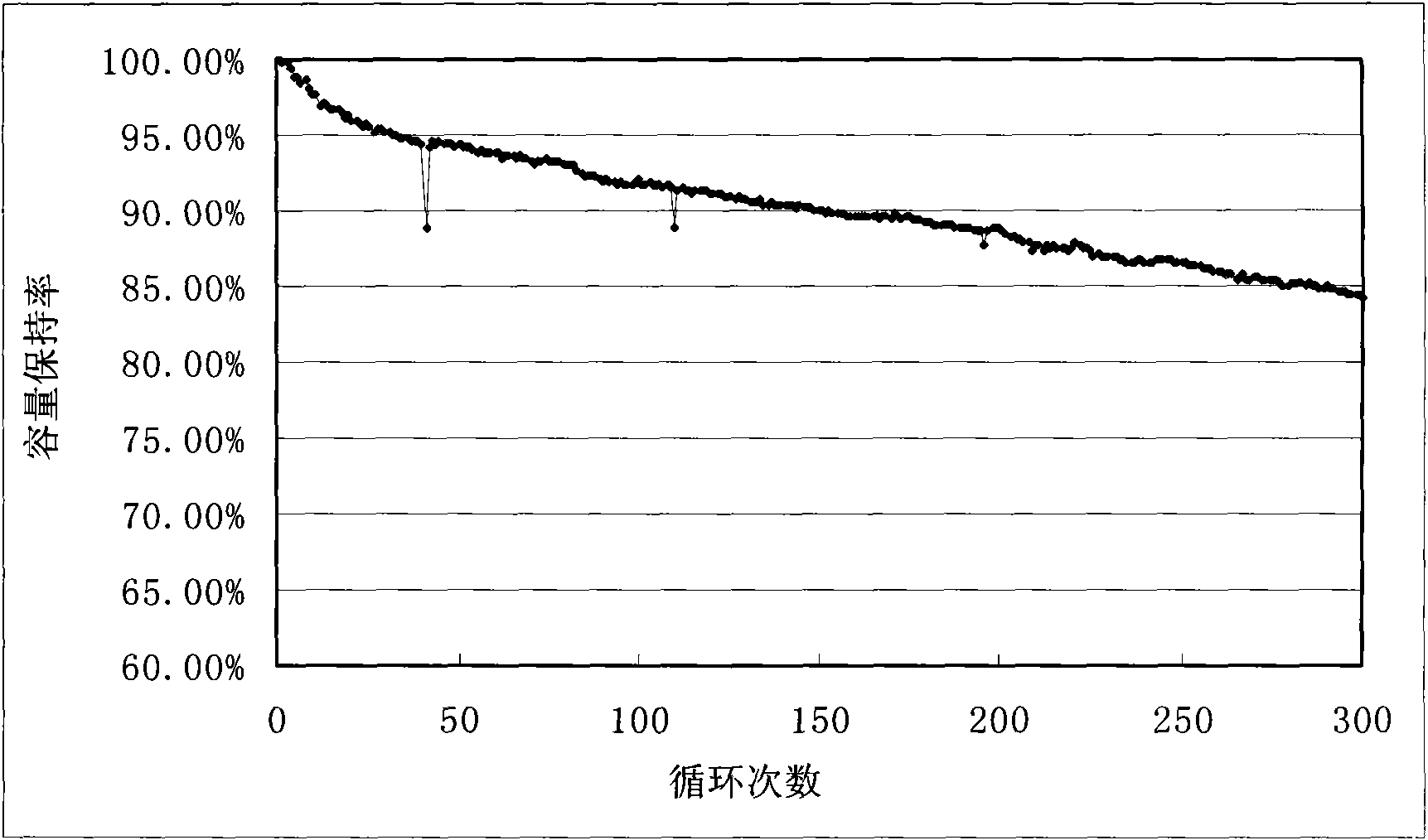

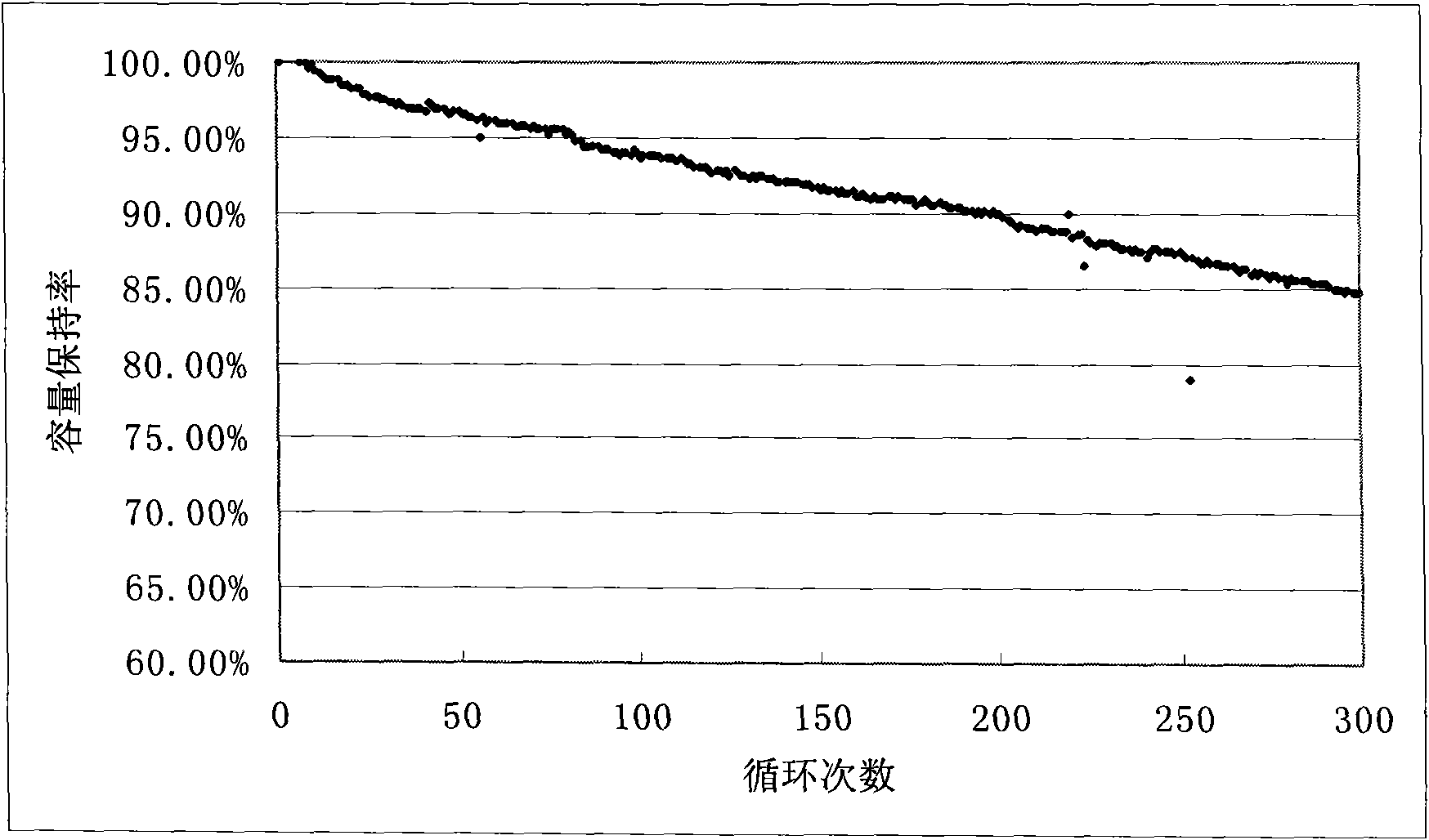

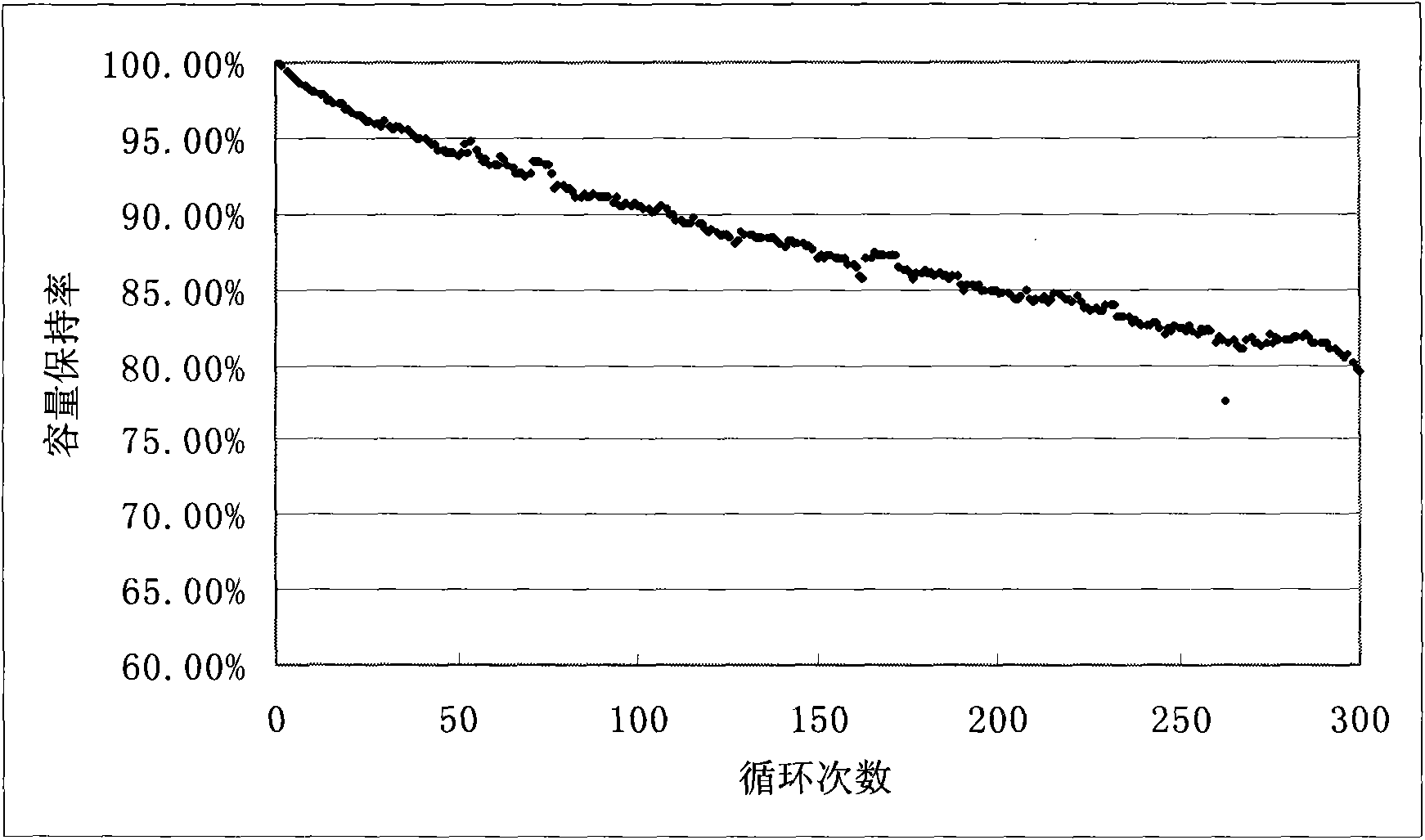

Anode material of lithium ion battery

ActiveCN101640262AEasy to siftNot easy to freezeElectrode manufacturing processesActive material electrodesSilane compoundsInternal resistance

The invention provides an anode material of a lithium ion battery, which comprises the following compositions in proportion by weight that: an anode active substance: a carboxylic acid compound: a silane compound in the ratio of 40-160: 0.01-2:0.01-2, wherein the anode active substance comprises lithium nickel cobalt oxide. The invention also provides a method for preparing the anode material of the lithium ion battery, which is to mix the anode active substance, the carboxylic acid compound and the silane compound, wherein the anode active substance comprises the lithium nickel cobalt oxide;and the weight proportion of the battery is that the anode active substance: the carboxylic acid compound: the silane compound is 40-160:0.01-2:0.01-2. The method adds the carboxylic acid compound and the silane compound into the anode active substance to modify the particle surface of the anode active substance by the carboxylic acid compound and the silane compound. A sizing agent prepared by the method can be easily screened, and is prevented from wrap frozen, and can remarkably improve the alternating current internal resistance and circulation performance of the prepared battery.

Owner:DALIAN CBAK POWER BATTERY CO LTD

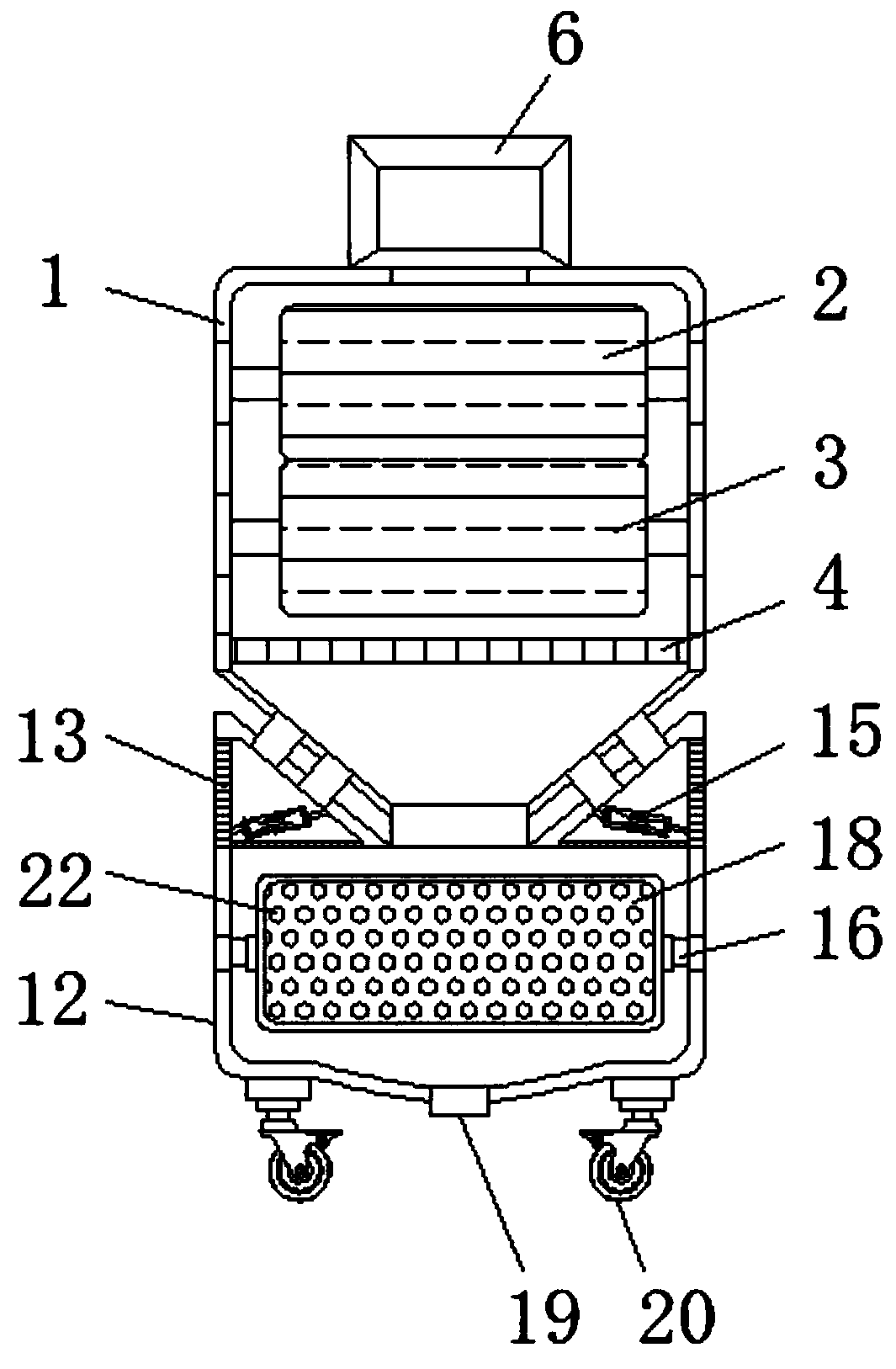

Intermittent-feeding pulverizing and screening device of feed

InactiveCN108095165AEasy to siftAvoid stuck problemsFeeding-stuffGrain treatmentsEngineeringInjection air

The invention discloses an intermittent-feeding pulverizing and screening device of feed. The intermittent-feeding pulverizing and screening device comprises a shell, wherein a storing cavity and a motor are arranged on the shell; a filling pipeline and a feeding pipeline are arranged on the storing cavity; a stirring shaft is arranged on the upper wall of the shell; an annular groove and an innergear are arranged at the upper part in the shell; a fixed blade is arranged in the annular groove; a rotating connecting rod, a rotating sleeve, an auxiliary rotating shaft, a first rotating blade, afilter screen plate and a driving gear are arranged on the periphery of the stirring shaft; a filter screen cover is arranged at the middle part of the inner wall of the shell; a plurality of groupsof second rotating blades are arranged in the filter screen cover on the periphery of the stirring shaft by welding; a driving cavity is arranged at the upper end of the shell; and a driving rotatingshaft, a rotating plate, a swinging connecting rod, a piston plate, a movable baffle plate, an air inlet pipeline, an air outlet pipeline and an air injection pipeline are arranged on the driving cavity. The intermittent-feeding pulverizing and screening device of feed improves the pulverizing processing efficiency by virtue of multistage pulverizing, thereby quickly and stably ensuring processing; and the intermittent-feeding pulverizing and screening device of feed performs intermittent discharging by virtue of coordination of the movable baffle plate and forms continuous downward paint spraying accompanied by movement in the driving cavity to promote feed processing.

Owner:吴烨程

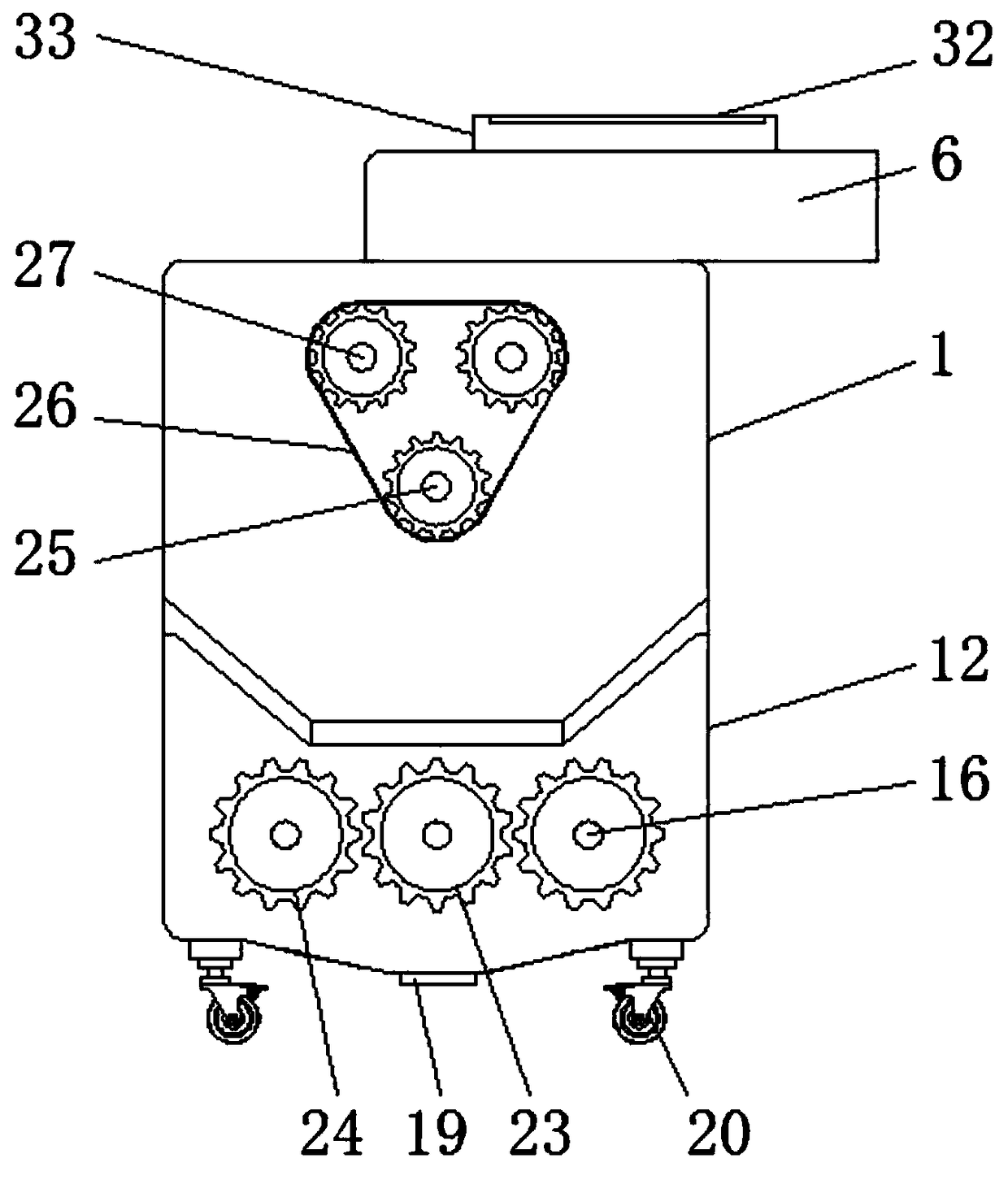

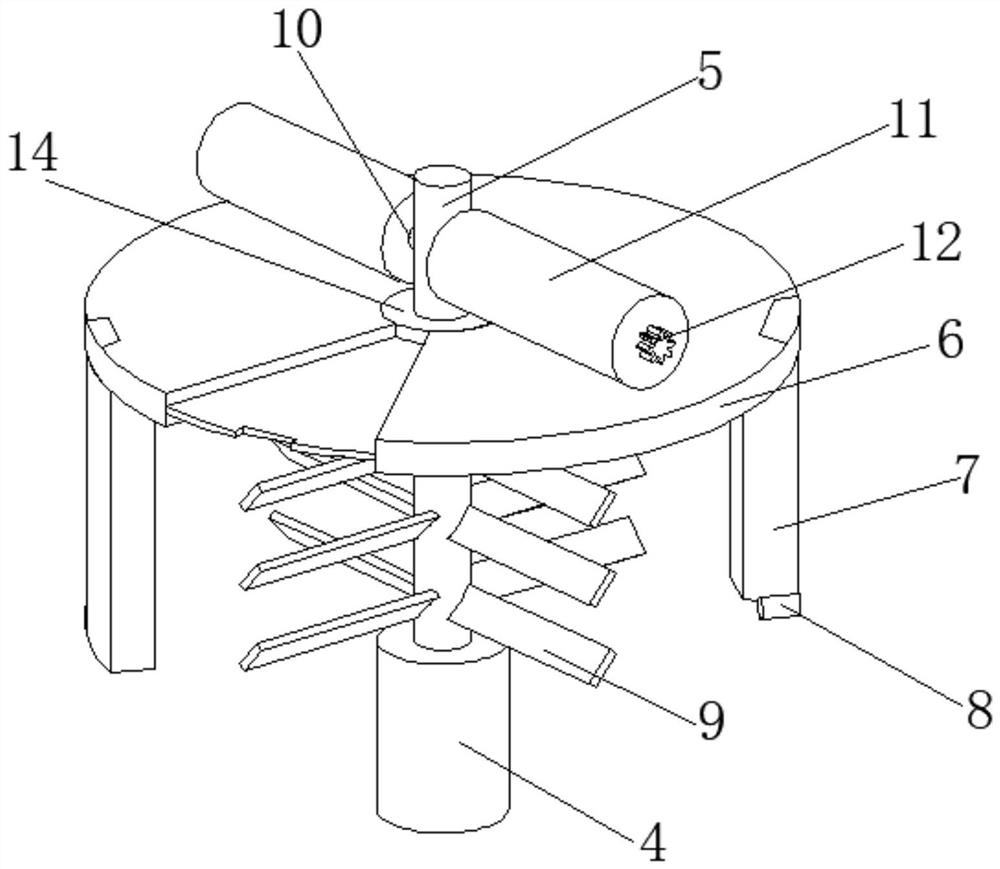

Powder coating mixing vibration screen

The invention belongs to the technical field of powder coating production, and particularly discloses a powder coating mixing vibration screen. The screen comprises a box, a feeding inlet is formed inthe top of the box, a discharging outlet is formed in the side wall of the box, a first screen plate and a second screen plate are arranged inside the box, the first screen plate is located above thesecond screen plate, a grinding hammer is arranged on the first screen plate, a grinding roller is arranged at the bottom of the grinding hammer, a driving device for driving the grinding hammer to move left and right is connected to the grinding hammer, a rotating shaft is rotationally connected to the axis of the second screen plate, stirring fan blades are arranged at the periphery of the topof the rotating shaft, and a power source for driving the rotating shaft to rotate is connected to the bottom of the rotating shaft. By adopting the technical scheme, raw materials are ground into powder by means of the grinding hammer, the raw materials are screened through the first screen plate and the second screen plate, meanwhile, the raw materials are mixed to be uniform, powder coating mixing, grinding and screening are combined into a whole, working procedures are simplified, and the working efficiency is improved.

Owner:CHONGQING QICAIHONG CHEM

Material screening device capable of efficiently preventing dust and blockage

The invention discloses a high-efficiency dust-proof and anti-blocking material screening device, which includes a screening tank, a motor, an air cylinder and a dust collection tank. The screening tank is provided with an upper cover, a feeding pipe, an annular plate, a movable frame, and a screen. , deflector and discharge port; the left side of the screening tank is provided with a motor, and the periphery of the output end of the motor is provided with a rotating rod, a rotating protrusion, a rotating pulley, a first connecting rod and a first rotating shaft; between the rotating pulley and the movable frame A traction rope is provided; a first rotating bearing, a second connecting rod, a second rotating shaft, a second rotating bearing, a third rotating bearing and a third connecting rod are arranged on the periphery of the first rotating shaft; There is an air cylinder; the air cylinder is equipped with a piston plate, a push rod, an air intake pipe, an air outlet pipe and the fourth rotating bearing; the upper end of the air cylinder is provided with a dust collection cylinder, and the dust collection cylinder is equipped with a dust suction pipe, a baffle plate, a support plate and a filter cloth . The invention improves the screening efficiency by lifting the movable frame and the filter screen, and the circulating airflow collects dust and promotes material discharge.

Owner:孙小春

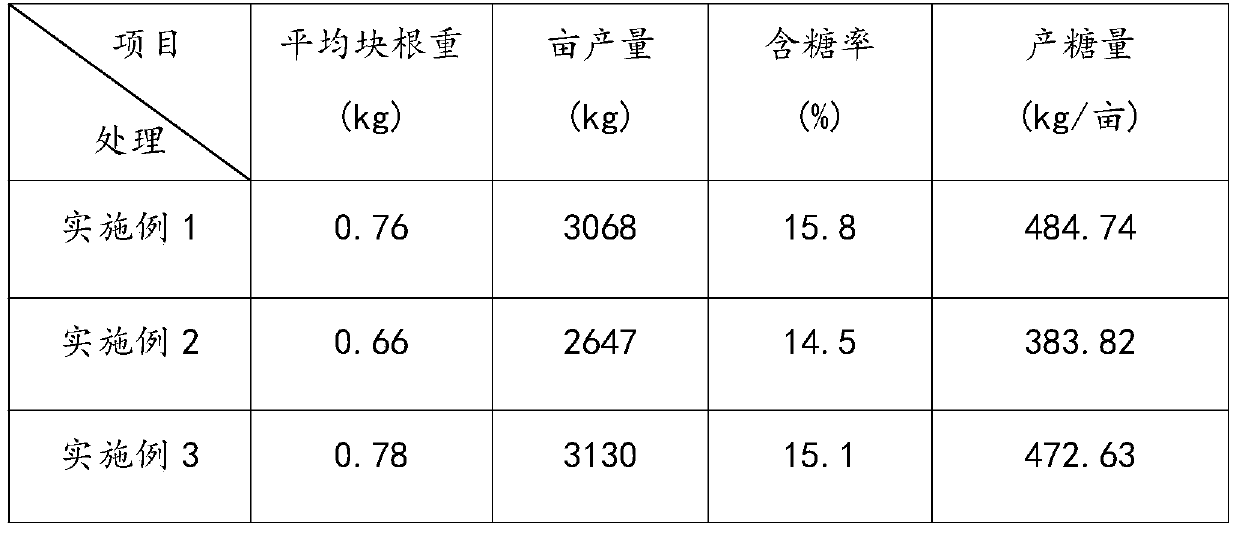

Beet paper tube seedling culture transplanting and multiple-cropping method

InactiveCN110073928AIncrease production valueAbundant photothermal resourcesGrowth substratesCulture mediaResource utilizationBed management

The invention belongs to the technical field of plant seedling culture, and particularly relates to a beet paper tube seedling culture transplanting and multiple-cropping method. The multiple-croppingmethod comprises the following steps of seedling culture bed manufacturing, seedling culture soil manufacturing, seedling culture soil pretreatment, paper tube seeding, seedling culture bed management, transplantation following wheat harvest and field management. A warm area for planting winter wheat is used; the light and heat resources are rich; the land after the wheat harvest is unused; a paper tube seedling culture transplanting technology can be used for multiple-sowing of one season of beet; the effective resource utilization can be realized; the multiple-cropping index can be improved; the goal of increasing the agricultural production value is achieved; meanwhile, the multiple-cropping method is simple; the implementation is easy.

Owner:ECONOMIC CROPS RES INST XINJIANG ACAD OF AGRI SCI

Intermittent swing material screening device

InactiveCN110369276AEvenly distributedImprove screening effectSievingScreeningScreening effectDistributed structure

The invention discloses an intermittent swing material screening device. The intermittent swing material screening device comprises a shell and an upper cover. A screening structure driven by a reciprocating drive structure to swing is arranged in the shell, the upper cover is riveted to the upper end of the shell, a rotary distributing structure driven by a drive motor and a dust collecting structure for preventing dust raising are further arranged on the upper cover, and the drive structure is formed by the cooperation of a sliding rod slidingly arranged on the rear side of the shell, a screen plate, a second gear and a third gear. When material pass through a guide pipe, the materials are divided into multiple parts through distributing blocks, the materials are thrown out during rotation of the guide pipe, by means of the design, distribution can be better achieved, the materials are evenly distributed, and the screening effect can be improved; and by means of the cooperative arrangement, reciprocating and intermittent stop rotation can be formed, and screening of the materials can be better promoted in an irregular swing manner.

Owner:何平姣

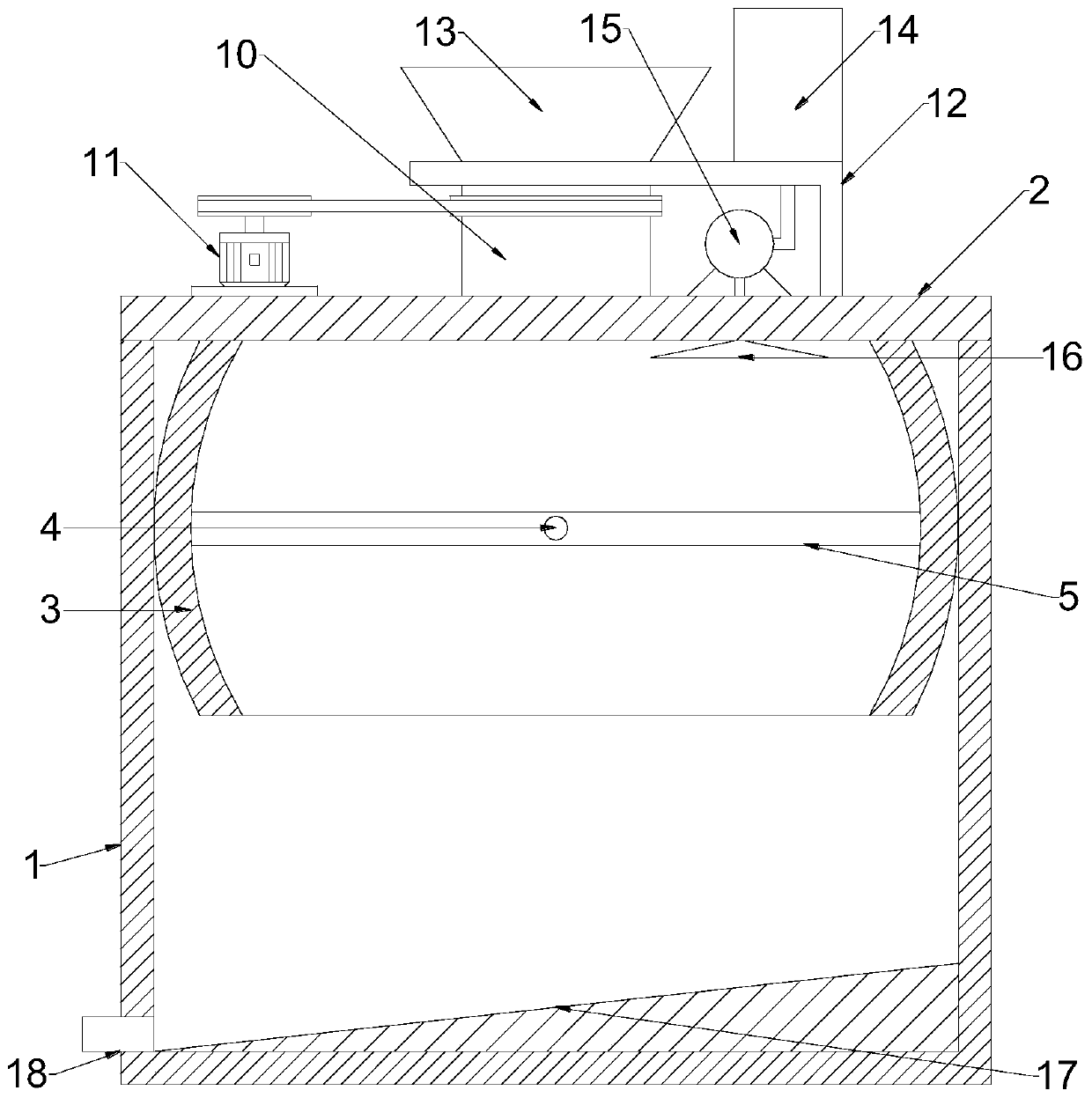

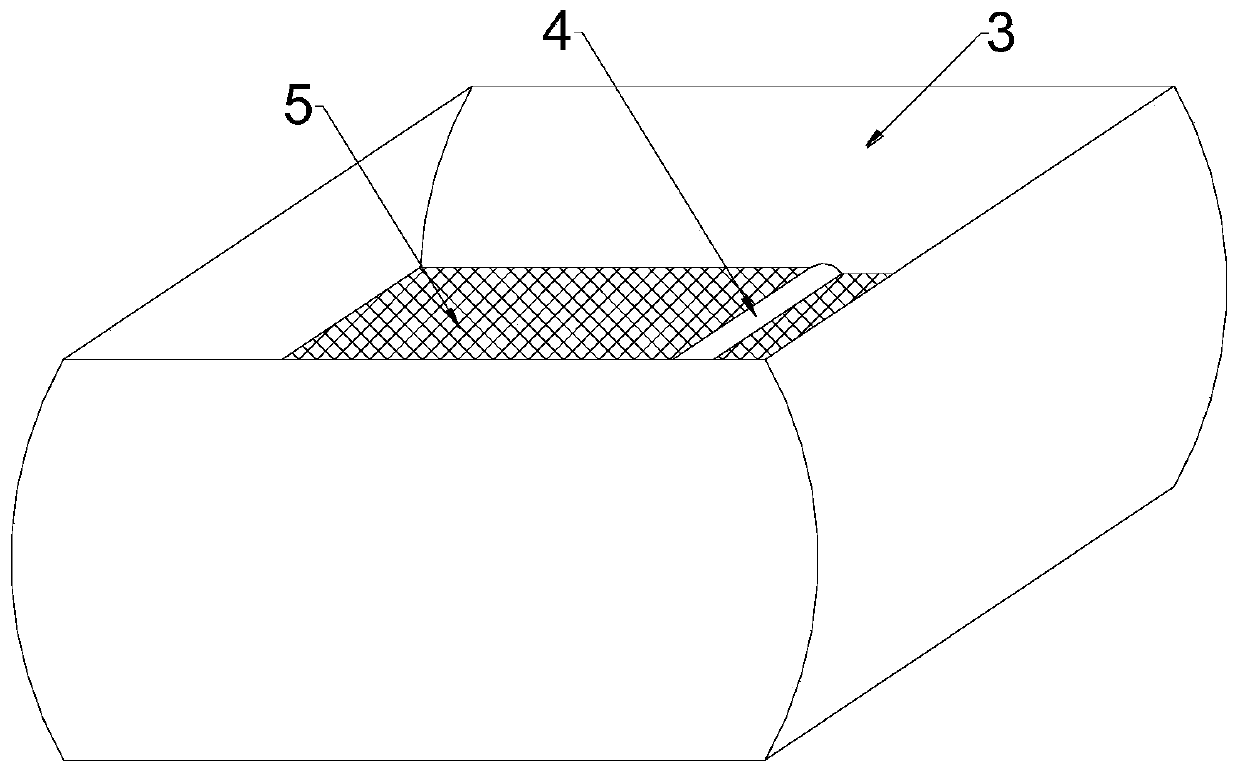

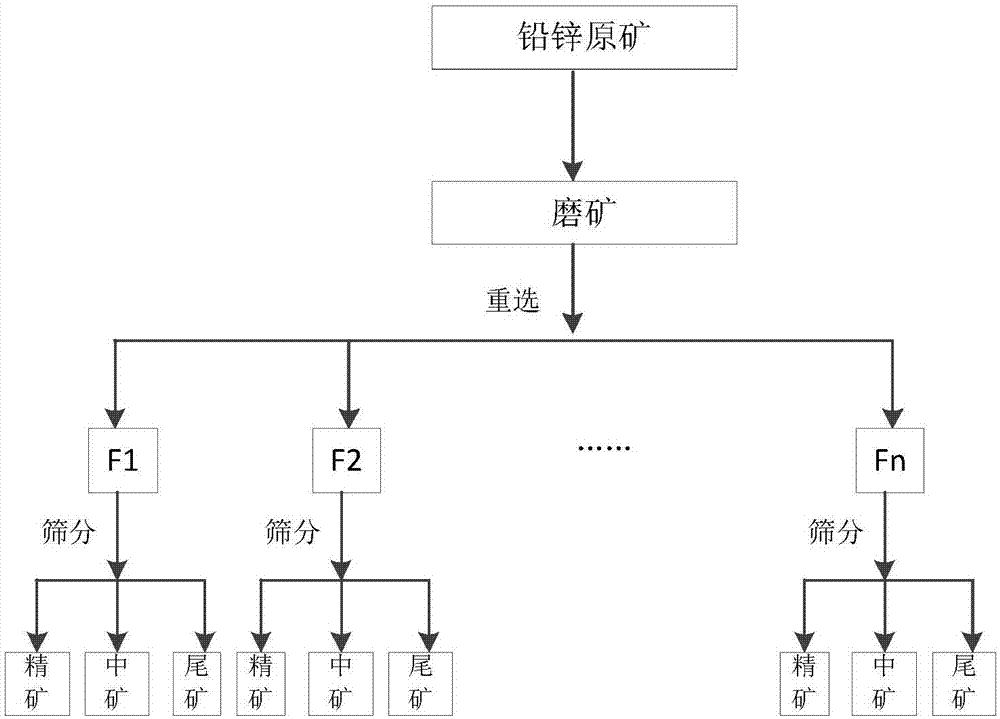

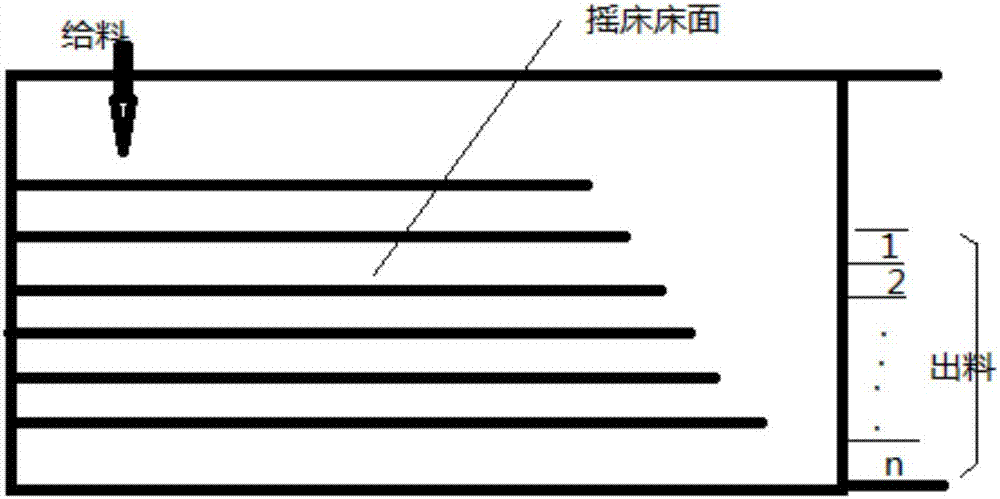

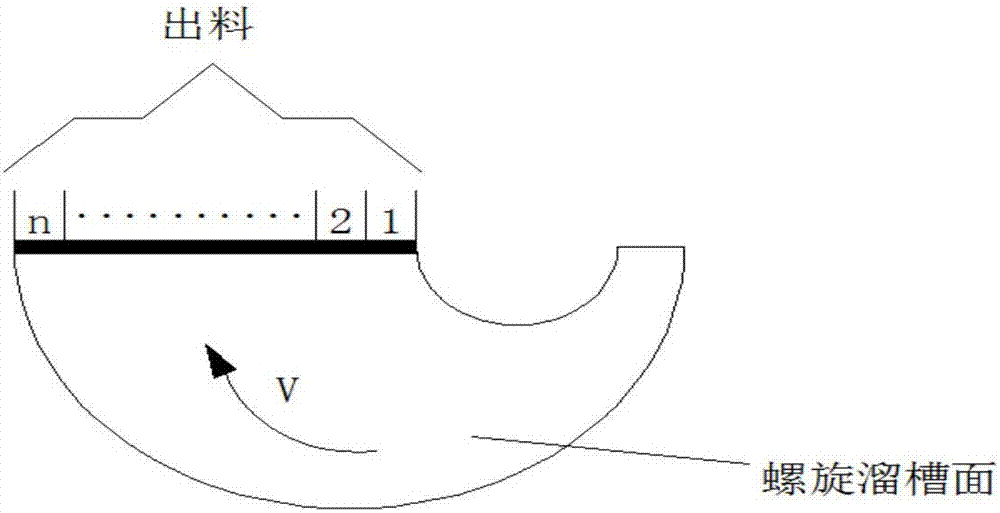

Repeated stratifying, zoning-screening gravity concentration method

The invention provides a repeated stratifying, zoning-screening gravity concentration method. The gravity concentration method comprises the steps of minerals are ground; and the ground minerals are sorted by adopting gravity concentration equipment and are orderly discharged according to the same settling speed at the discharge end of the gravity concentration equipment, and the discharged materials are equally divided into n parts at the discharging end along a discharging belt, wherein n is not less than 4, and the n parts of the discharged materials are screened respectively so as to obtain high-grade concentrates, middlings and tailings. According to the gravity concentration method, by the adoption of the technical scheme, the concentrate grade can be high, the recovery rate can be high, operation can be convenient, and the conventional gravity concentration equipment can be used; and compared with screening and grading of the minerals without being subjected to gravity concentration treatment, the gravity concentration method has the advantage that the screening efficiency is higher by 30-70%.

Owner:SHENZHEN NONFEMET TECH

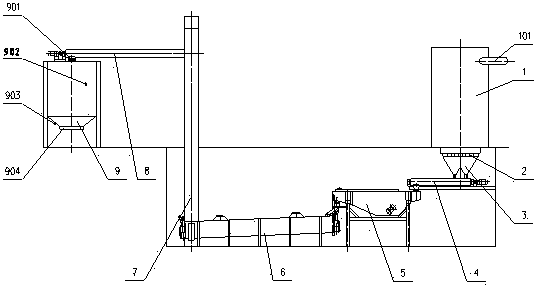

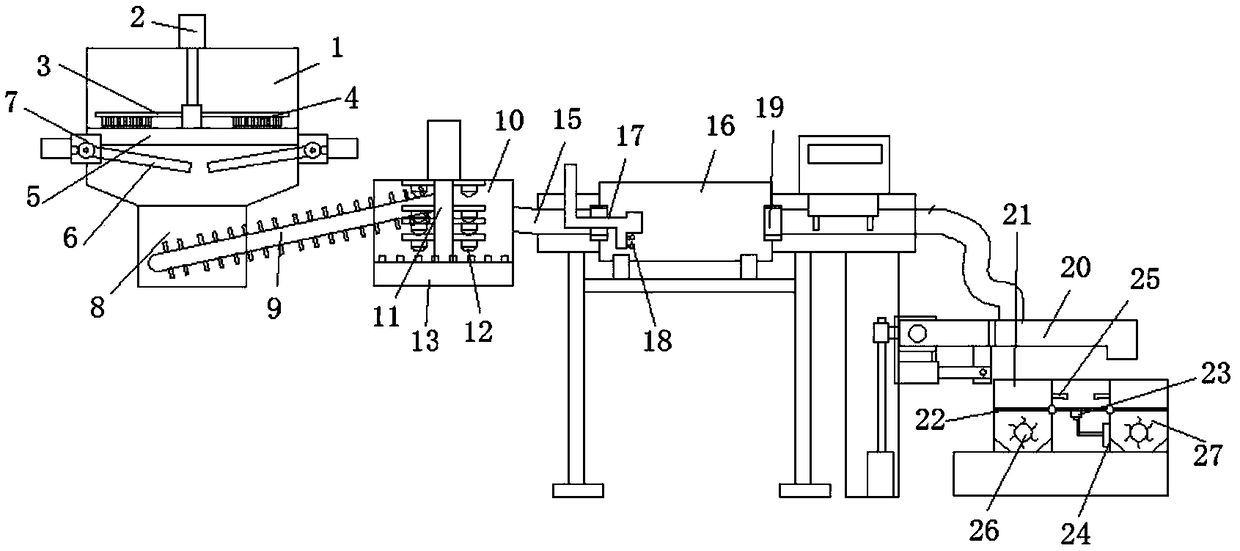

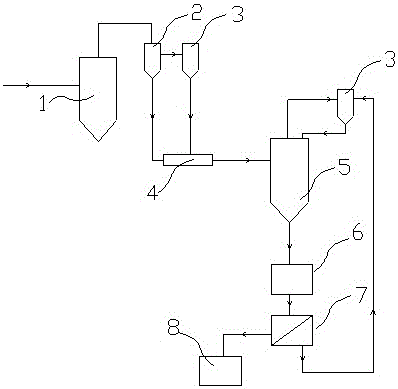

V-method molding sand processing system and method

ActiveCN104162629AImprove qualityEfficient removalMould handling/dressing devicesCooling effectImpurity

The invention relates to a V-method molding sand processing system and method. With the V-method molding sand processing system, sand subjected to pouring and shakeout by virtue of V-method sand processing is firstly conveyed to a sieving device to be sieved, iron-containing impurities in the sand are sorted out, and then the sand is cooled and is lifted and conveyed to a modeling part, thereby solving the problems that during V-method sand processing with magnetic separation first and then cooling on hot sand subjected to pouring and shakeout, iron-containing impurities in the sand are difficult to clean, and if sand is subjected to cooling first and then magnetic separation, iron-containing impurities in the sand are heavy, a cooling effect of a boiling cooling bed is influenced, and the cooling bed is blocked and cannot be used.

Owner:HENAN UNIV OF SCI & TECH

Extrusion-cutting-type smashing device for biomass energy raw material capable of being conveniently stored

ActiveCN109220255AEasy to storeAvoid taking up spaceSievingNon-rotating vibration suppressionBiomassEngineering

The invention discloses extrusion-cutting-type smashing device for a biomass energy raw material capable of being conveniently stored. The device comprises a smashing box body, a filtering screen, a material receiving box body, a ventilator, a second screening plate and a discharging port, a first cutting blade is arranged on the upper side in the smashing box body, and the lower side of the firstcutting blade is meshed with a second cutting blade; a first rotating wheel is connected with a second rotating wheel through a belt, a limit rolling wheel is rotatably connected with a slide groove,and the filtering screen is located at the lower end in the smashing box body; a big rotating wheel is arranged at the right end in a feeding box body, and a fixed rod is fixedly connected to the upper surface of the inner wall of the feeding box body. The extrusion-cutting-type smashing device for the biomass energy raw material capable of being conveniently stored can conveniently extrude and cut the biomass energy raw material of straw and the like thoroughly, therefore the biomass energy raw material is convenient to store and is prevented from occupying large space, the cut biomass energy raw material can be conveniently turned over and sieved, moisture can be quickly removed, and it is avoided that due to the fact that the material goes mouldy, the using is influenced.

Owner:睢宁宝源新能源发电有限公司

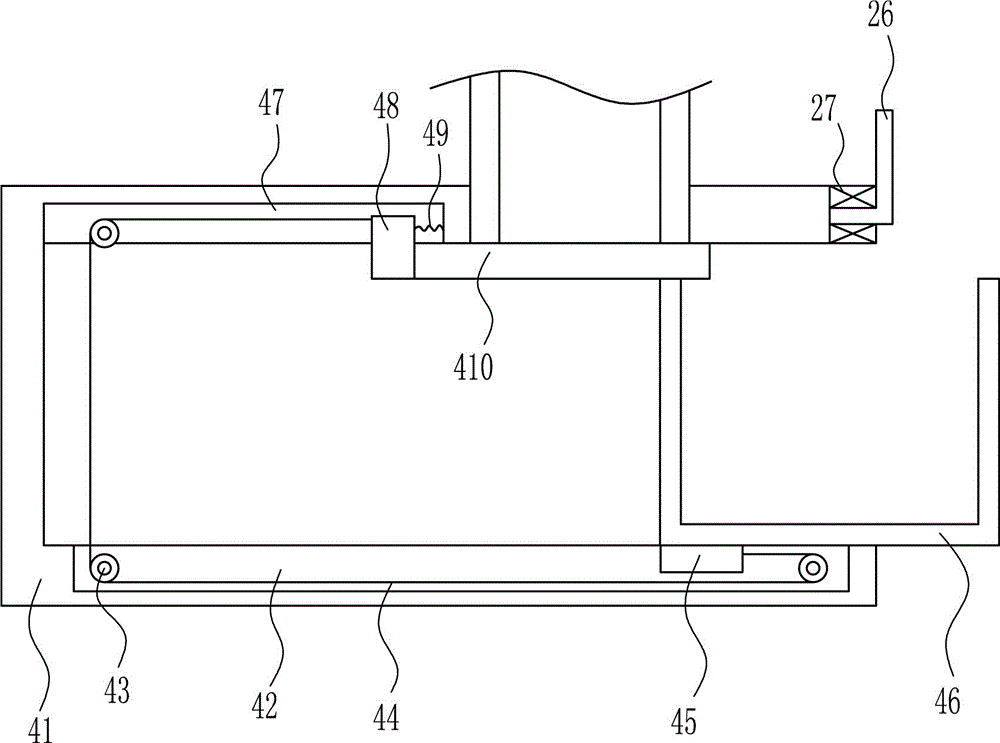

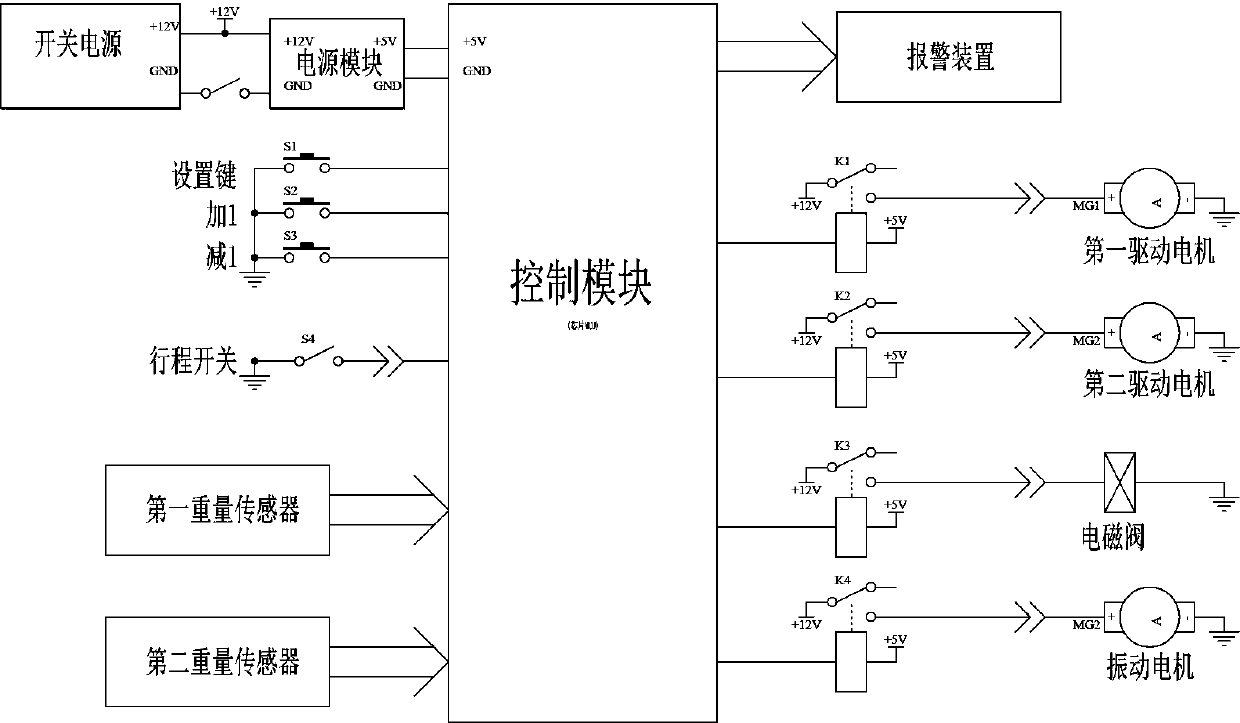

Convenient weighing and sieving integrated device for talc powder for production of household water purifier

ActiveCN106824766AAchieve the effect of sievingThe effect of effective screeningSievingScreeningEngineeringTalc

The invention relates to a weighing and sieving integrated device, in particular to a convenient weighing and sieving integrated device for talc powder for production of a household water purifier. The convenient weighing and sieving integrated device for talc powder for production of the household water purifier can sieve industrial talc powder and take out the industrial talc powder easily. The convenient weighing and sieving integrated device for talc powder for production of the household water purifier comprises a sieving box and the like, a filter net is connected between left and right sides of the upper side in the sieving box, and a sieving mechanism is connected between the left and right sides of the middle in the sieving box and located on the lower side of the filter net. The sieving mechanism is firstly arranged to knock the filter net to sieve the talc powder, the talc powder is effectively sieved, and a weighing mechanism is arranged.

Owner:XUZHOU FANGBO ENVIRONMENTAL PROTECTION EQUIP

Acesodyne capsule for heart and stomach

ActiveCN101559100AImprove curative effectGood curative effectHydroxy compound active ingredientsDigestive systemBorneolBiomedical engineering

The invention discloses an acesodyne capsule for heart and stomach, which is prepared by Cinnamomum migao H.W.Li, borneol and auxiliary materials, wherein the auxiliary material is aluminium hydroxide. Compared with the prior art, the invention improves the compounding of the acesodyne capsule for heart and stomach, changes the existing auxiliary material starch into the aluminium hydroxide; the naphtha rich in the Cinnamomum migao H.W.Li is dispersed in the aluminium hydroxide in the form of micro-grains; the mixed medicated powder is not bonded again, can be crushed, sieved and filled with capsule conveniently, is extremely suitable for practical industrial production and is convenient for the medicine production enterprises to execute the GMP standard strictly. Simultaneously, the medical function of the aluminium hydroxide also improves the curative effect of the acesodyne capsule for heart and stomach.

Owner:GUIZHOU YIBAI PHARMA CO LTD

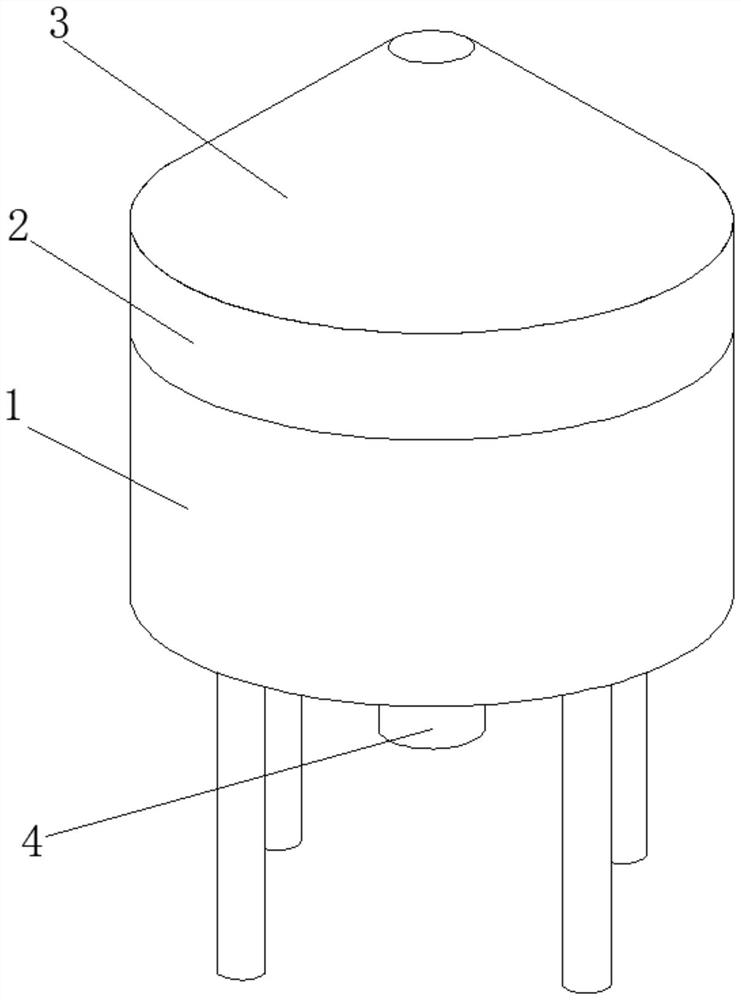

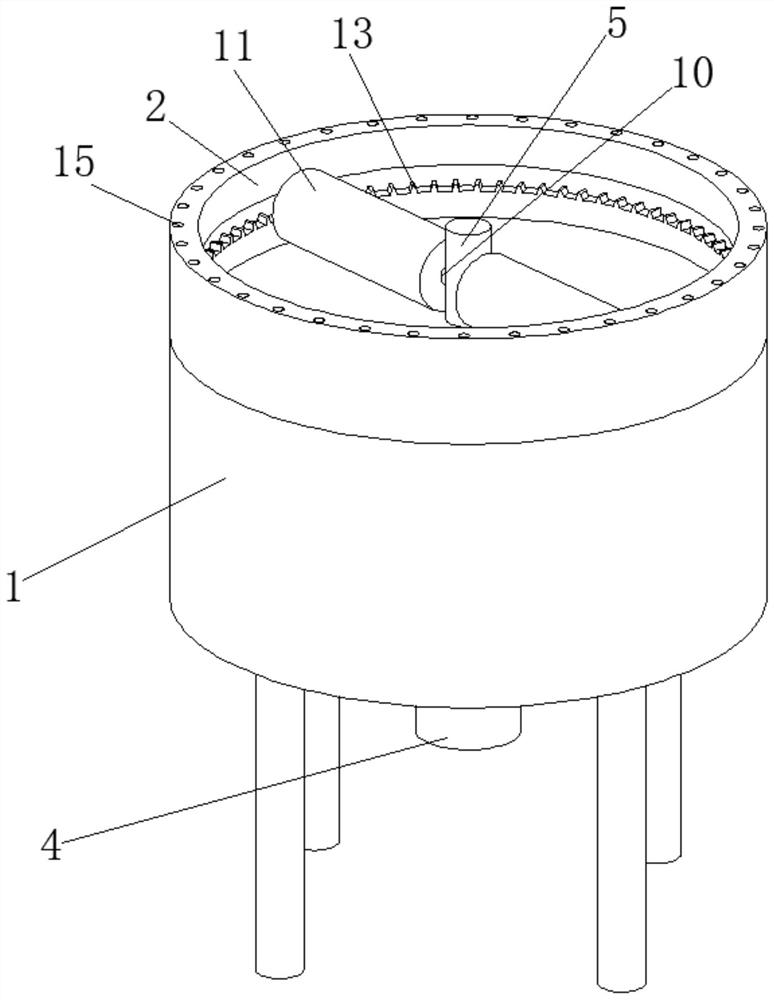

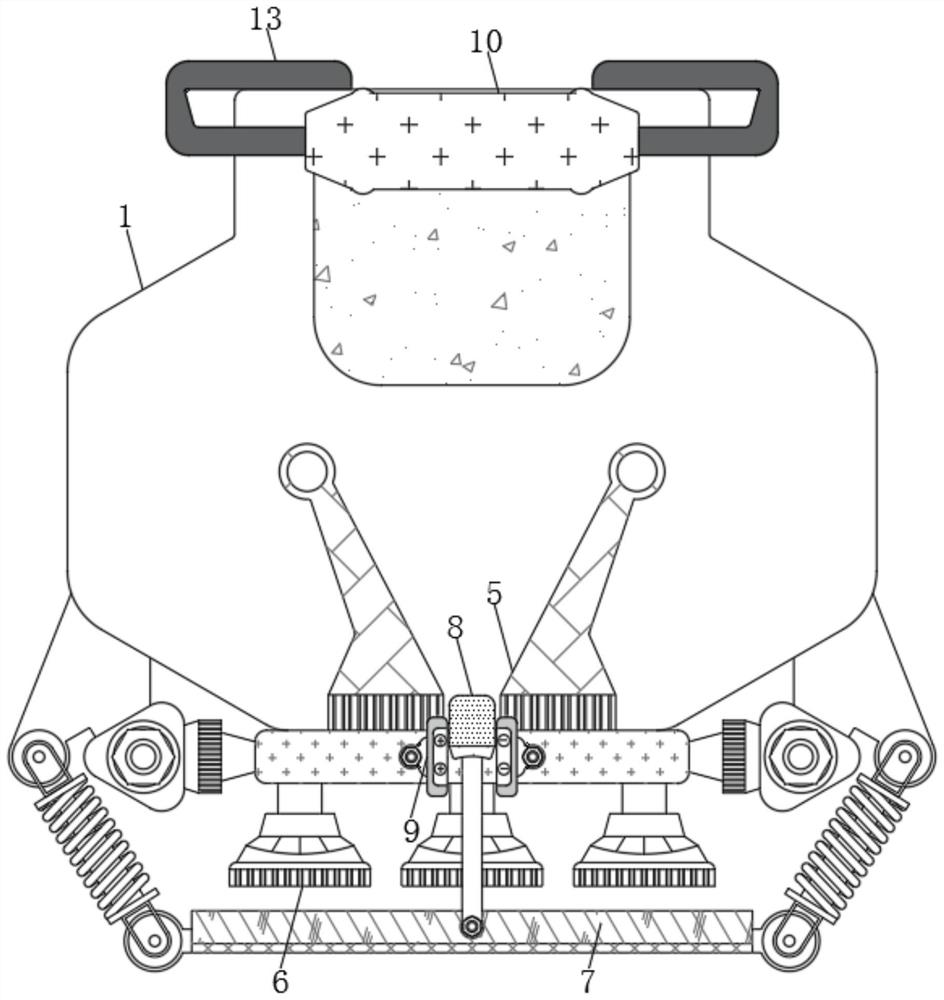

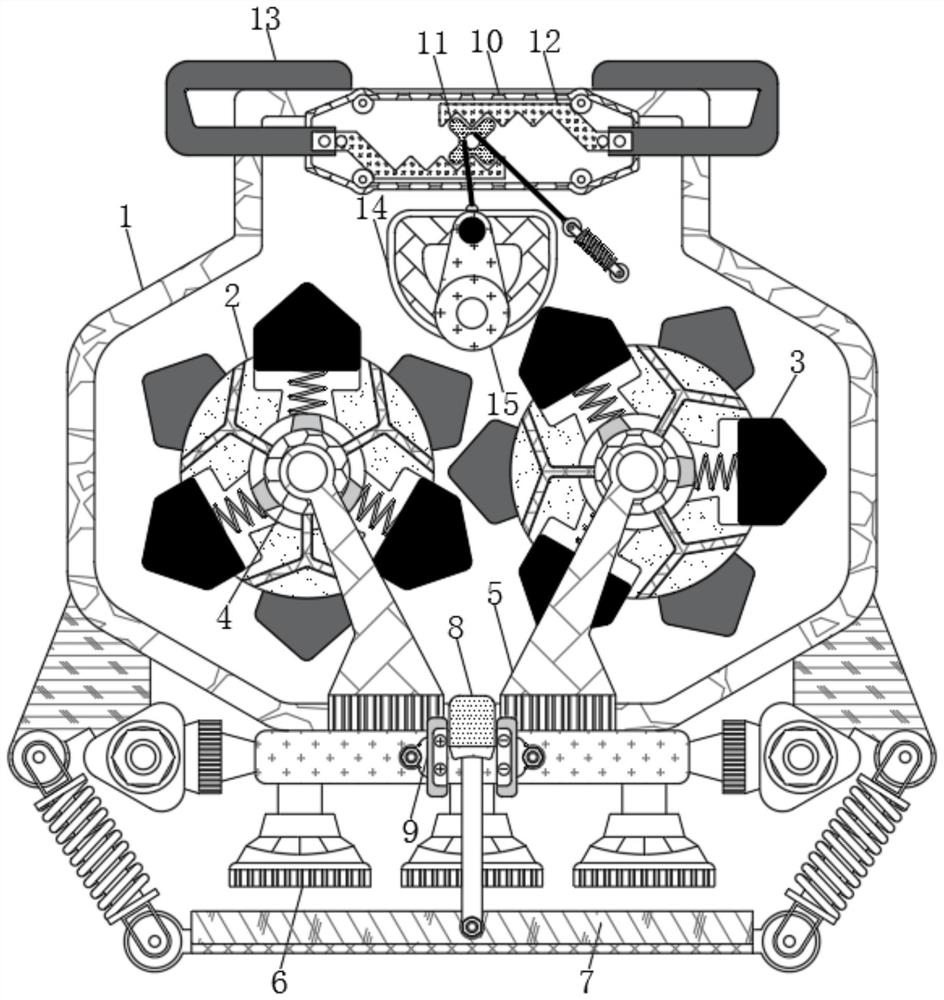

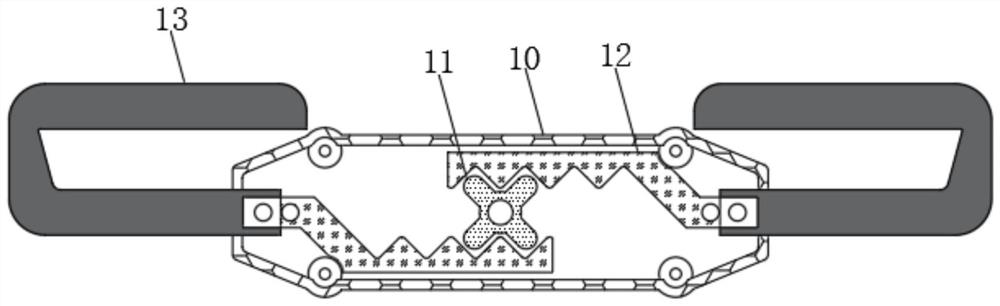

Intelligent sieving device for oil sunflower seeds

InactiveCN110142212APrevent fallingAvoid accumulationSievingGas current separationFixed frameEngineering

The invention relates to a sieving device, in particular to an intelligent sieving device for oil sunflower seeds. By adoption of the intelligent sieving device for the oil sunflower seeds, the laborintensity of workers can be relieved, and accumulation of the oil sunflower seeds can be prevented. According to the technical scheme, the intelligent sieving device for the oil sunflower seeds comprises a base, a vertical support, a fastening frame, a fixing frame, a feeding box, a feeding device, a scattering mechanism and the like, wherein the vertical support is fixedly connected to the middleof the top of the base, the fastening frame used for supporting is fixedly connected to the right side of the top of the base, the left side of the fastening frame is connected with the right side ofthe vertical support, the fixing frame and a second mounting plate are connected to the upper portion of the left side of the vertical support, and the second mounting plate is located above the fixing frame. According to the intelligent sieving device for the oil sunflower seeds, a sieve can be vibrated, so that qualified oil sunflower seeds pass through the sieve to fall into a container, and unqualified oil sunflower seeds and impurities directly fall off from the sieve.

Owner:刘泽锋

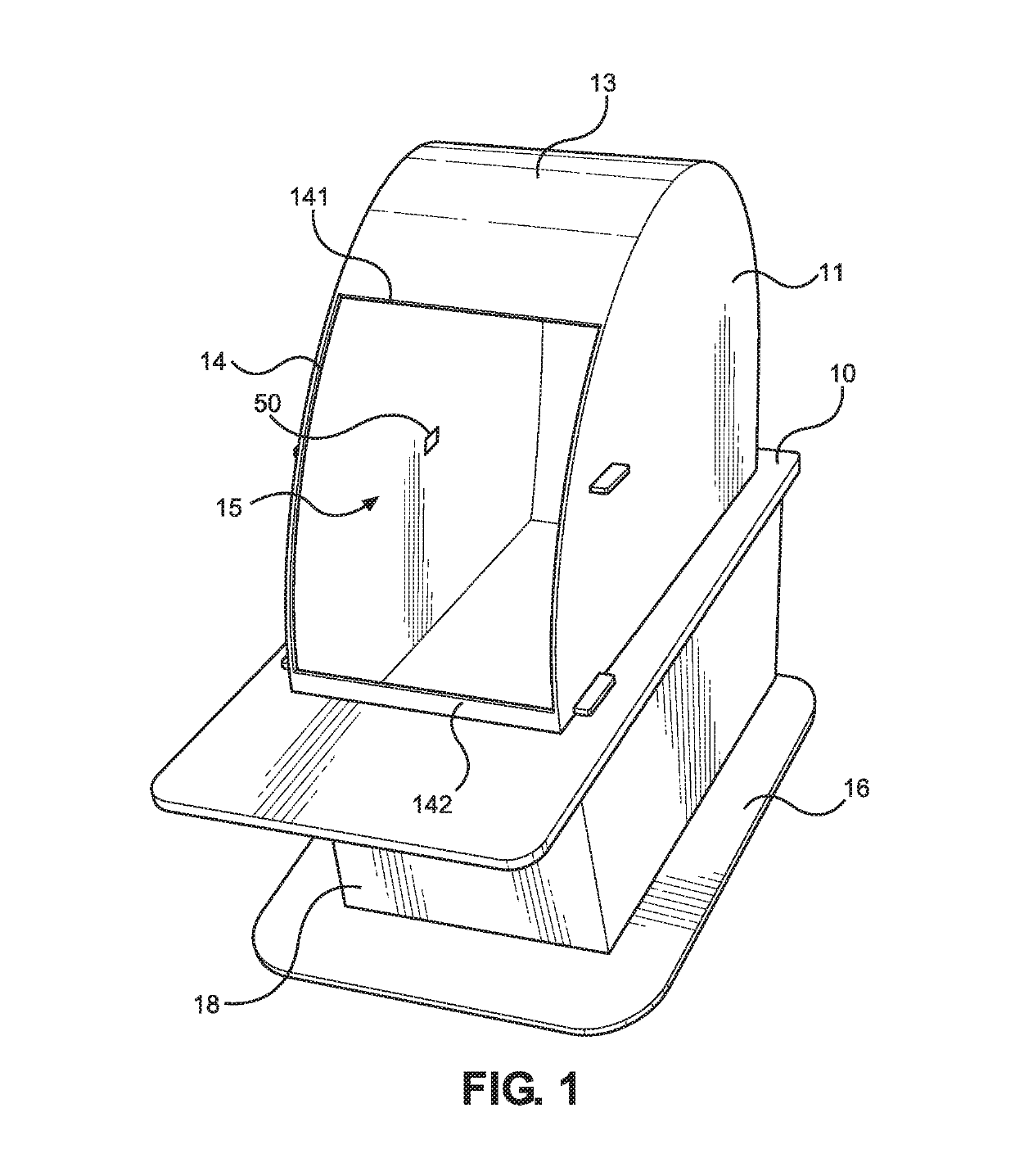

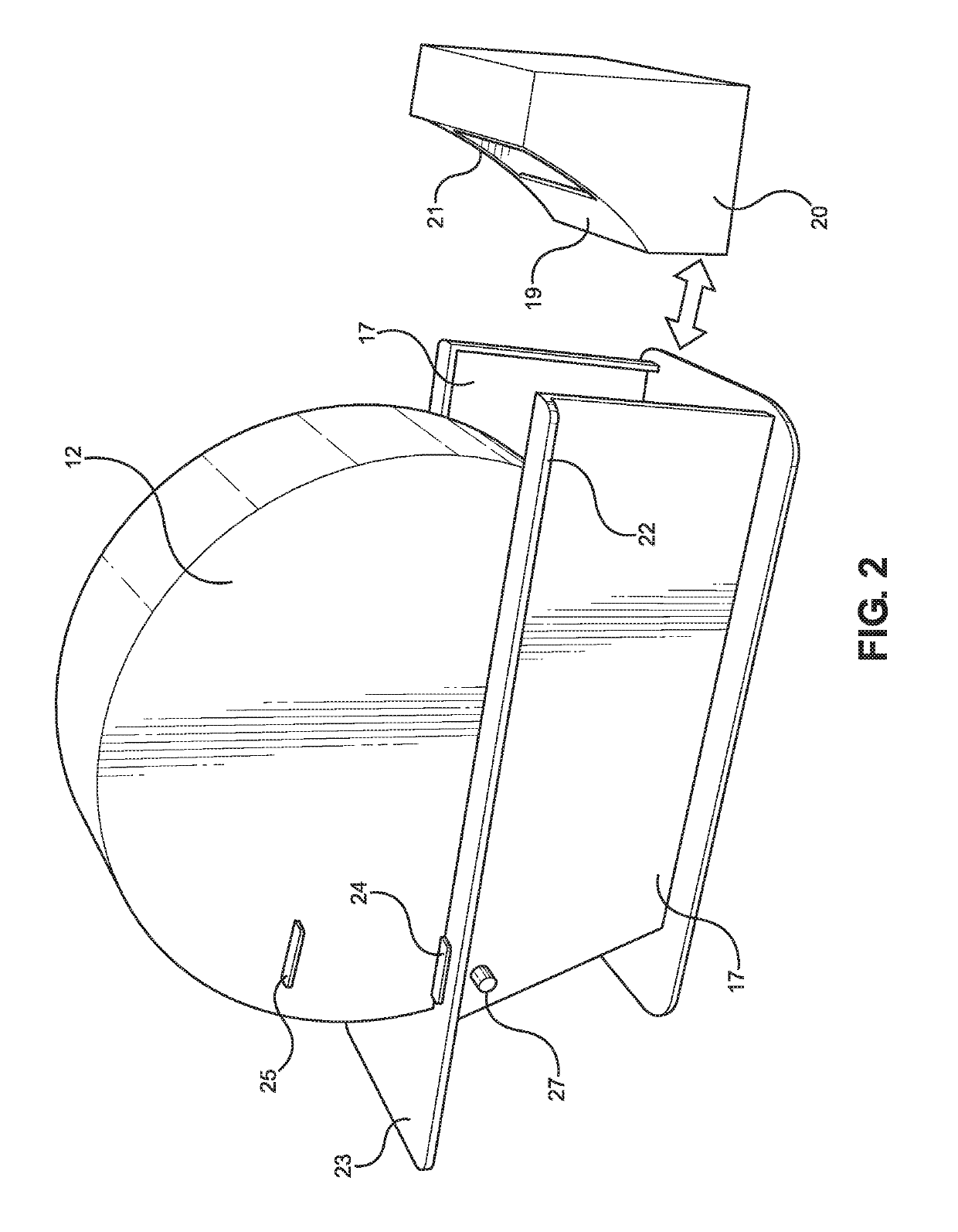

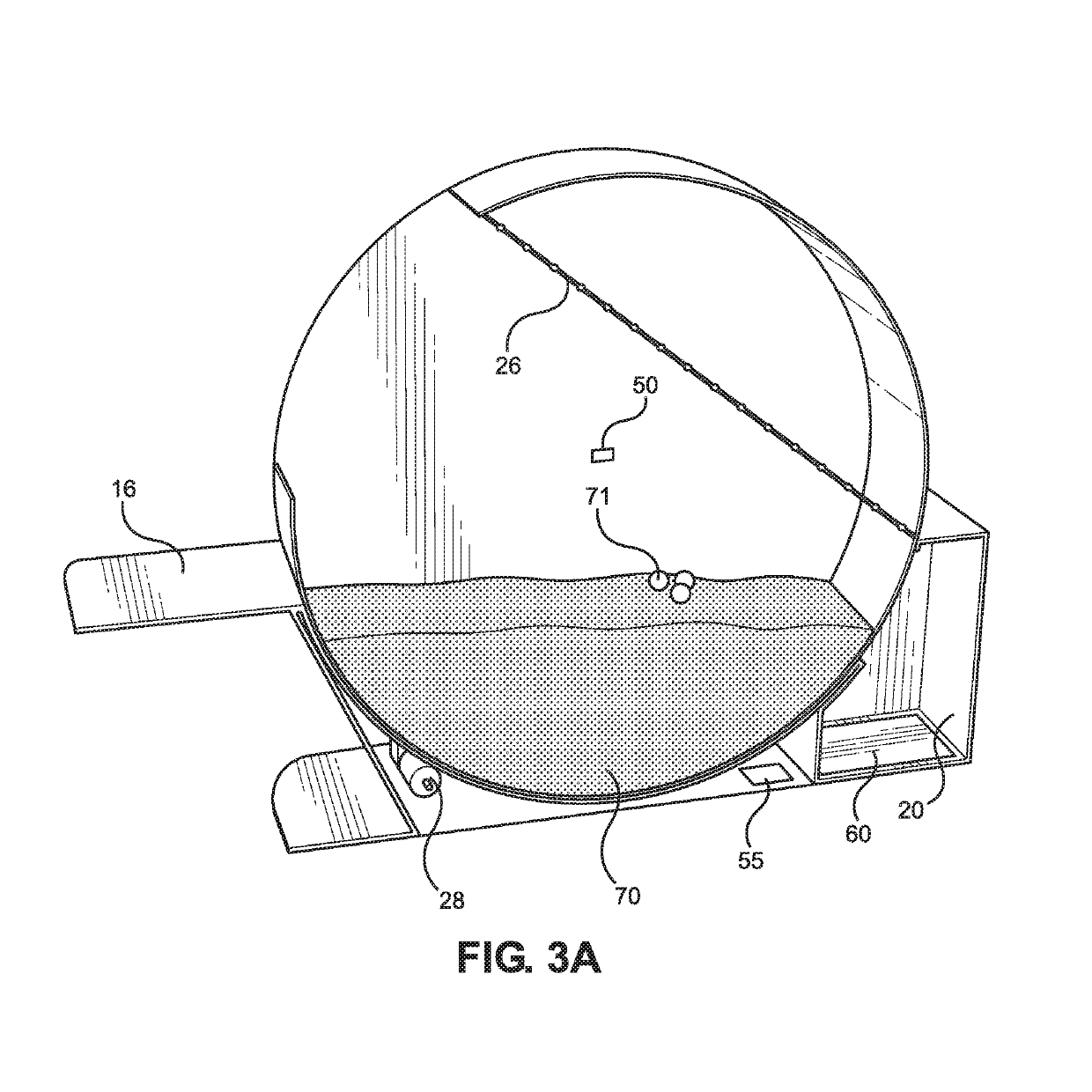

Self-Cleaning Litter Box

A self-cleaning litter box. The self-cleaning litter box includes a basin designed to rotate about an axis, having a hollow center with an interior volume designed to hold litter. An aperture is disposed in the basin designed to provide access to the interior volume. A filter screen disposed within the interior volume and extending across the basin is designed to sift excrement from the litter. The basin is disposed within a base that supports the basin. A waste container is positioned within the base. The waste container includes an opening in communication with the basin such that the aperture of the basin fits flush against the opening of the waste container when the basin is rotated for sifting excrement. In one embodiment, the self-cleaning litter box incorporates a motion sensor, a weight sensor and a wireless transceiver.

Owner:TURNER BRUCE KEITH

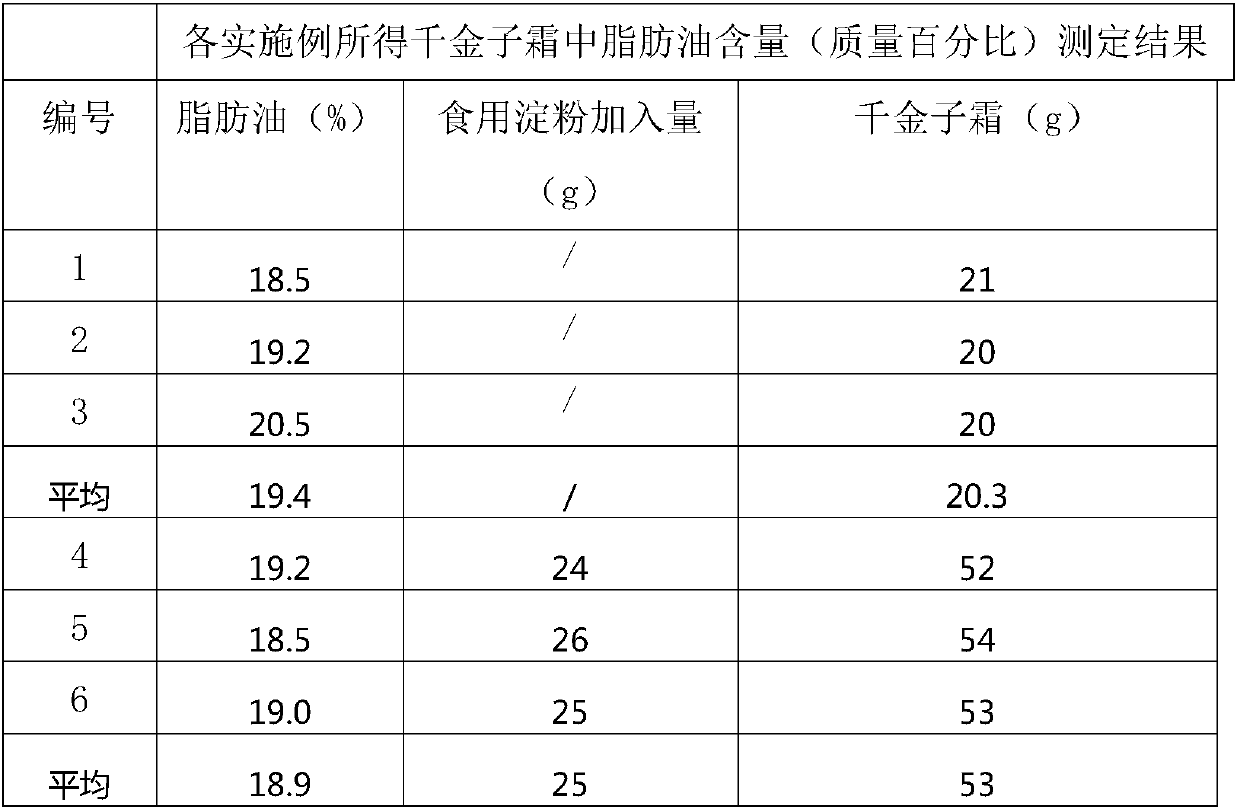

Preparation method of moleplant seed cream

InactiveCN107693568AHigh extraction rateReduce energy consumptionPlant ingredientsMedicineAdemetionine

The invention relates to the technical field of preparation processing of traditional Chinese medicine decoction pieces, and in particular discloses a preparation method of moleplant seed cream. The method comprises the following steps: drying, pulverizing for the first time, extracting for the first time, filtering for the first time, extracting for the second time, filtering for the second time,pulverizing for the second time, drying by evaporating, preparing the cream and the like. The traditional cream preparation process falls behind, the production efficiency is low, the technical indexof the cream preparation process is undefined, the oil-removing degree is difficult to master, and the industrial development of the moleplant seed cream is restricted seriously. By the method, the preparation cycle of the moleplant seed cream is shortened, waste of raw materials is avoided, the oil content can be regulated and controlled accurately, the obtained moleplant seed cream has uniformquality and thinking is provided for modern industrial production of the moleplant seed cream.

Owner:九信(武汉)中药研究院有限公司

Resin granule cleaning and conveying discharge machine unit

PendingCN108438374AEasy to wash and sieveQuality improvementPackage sterilisationEngineeringMechanical engineering

The invention discloses a resin granule cleaning and conveying discharge machine unit which comprises a cleaning tank. The machine unit is characterized in that the upper end of the cleaning tank is provided with a stirring device, the lower end of the stirring device is connected with a brush rod, the side wall of the brush rod is provided with bristles, the lower end of the brush rod is providedwith a filter net layer, left and right sealing flashboards are arranged below the filter net layer and connected through a turnover device so as to achieve opening and closing, a discharge channel is arranged below the cleaning tank, a conveying track is arranged below the discharge channel, and the conveying track is connected with a drying stirring barrel. The structure is simple, resin granules can be rapidly cleaned, mildew is reduced, and the discharging and weighing efficiency is high.

Owner:合肥新思路智能科技有限公司

Raw material pre-sieving device for concrete preparation for civil engineering

InactiveCN111545448AEasy to siftSave human effortSievingScreeningElectric machineConstruction engineering

The invention discloses a raw material pre-sieving device for concrete preparation for civil engineering. The device comprises a base; a sieving mechanism is arranged above the base; a feeding mechanism is arranged above the sieving mechanism; the feeding mechanism comprises a vertical plate, a rotating column and a No.1 motor; the rotating column is arranged on the inner side of the vertical plate; the No.1 motor is arranged at the front part of the vertical plate; a feeding plate is arranged on the rotating column; and a non-slip rubber pad is arranged on the feeding plate. The device is simple in structure, reasonable in design and low in production cost, sieving of raw materials is greatly facilitated, the manpower is saved, the working efficiency is improved, and the device has the high practical value.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

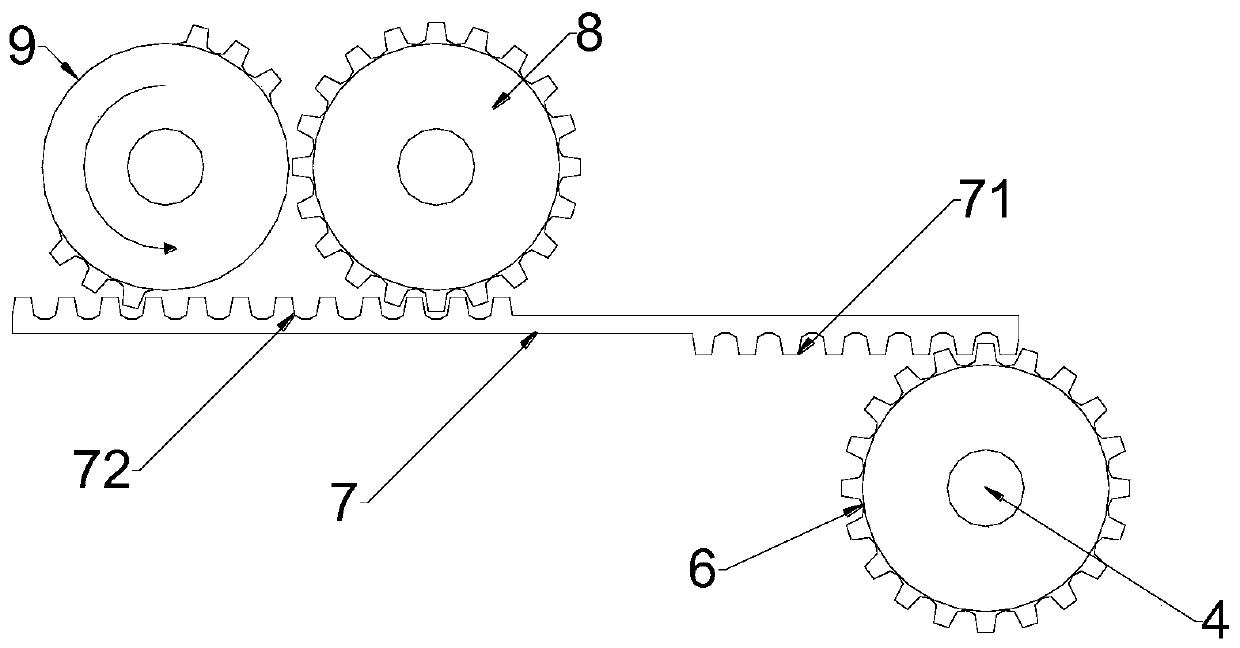

Mixing and stirring equipment for constructional engineering

InactiveCN113715171AAffect siftingGuaranteed intermittent joinSievingScreeningGear wheelElectric machinery

The invention relates to the technical field of constructional engineering, and discloses mixing and stirring equipment for constructional engineering. The mixing and stirring equipment comprises a box body, wherein the top of the box body is fixedly connected with a screen drum; the top of the screen drum is movably connected with a top cover; the bottom of the box body is fixedly connected with a motor; the output end of the motor is welded with a rotary shaft; a planetary gear set is arranged on the surface of the rotary shaft; the surface of the planetary gear set is movably connected with a rotary plate; a scraping mechanism is arranged on the bottom of the rotary plate; the inner wall of the box body is welded with a limiting rod; the surface of the rotary shaft is welded with a plurality of stirring rods; and the surface of the rotary shaft is rotatably connected with a transmission rod. According to the mixing and stirring equipment disclosed by the invention, sand can be rolled through a rotary pressure roller, so that sand which is caked due to water is dispersed; and meanwhile, a heating tube in the pressure roller can dry soaked sand, so that the sand is prevented from being adhered into screen holes due to water, and therefore, a screen is prevented from being blocked, and screening of sand is prevented from being affected.

Owner:李颖煜

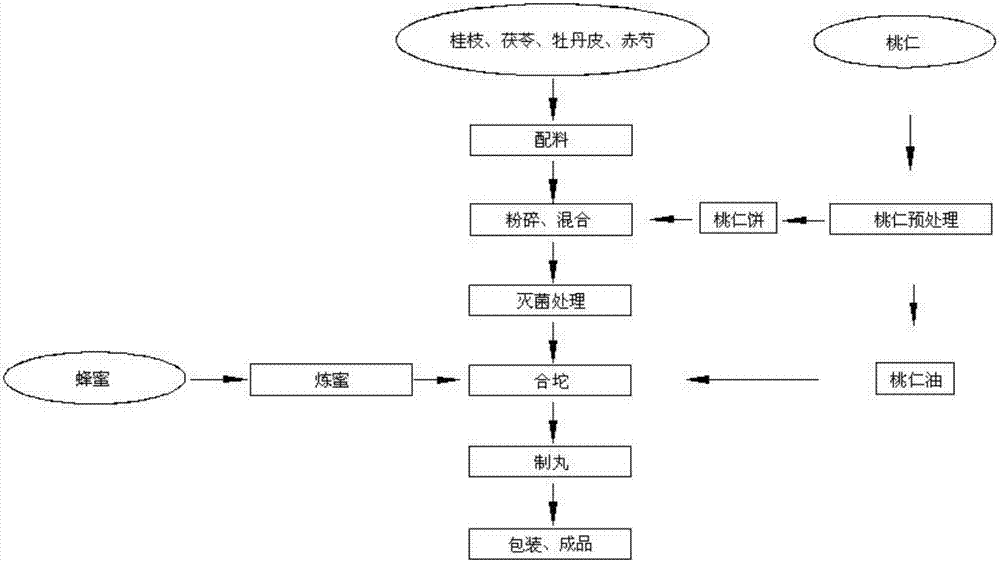

Production technology of cassia twig-poria cocos pill

InactiveCN107137475AEasy to siftHigh recovery ratePill deliverySexual disorderPulverizerAmygdalus persica

The invention belongs to the technical field of traditional Chinese medicine preparations and particularly relates to a production technology of a cassia twig-poria cocos pill. The production technology mainly solves the technical problem that the existing production process of a cassia twig-poria cocos pill has screening difficulty and a low medical powder recovery rate. The production technology comprises 1) material blending: uniformly mixing 1 part of cassia twig, 1 part of poria cocos, 1 part of moutan bark and 1 part of red peony root, 2) peach kernel pretreatment: taking 1 part of peach kernels, putting the peach kernels into an oil press, carrying out oil pressing treatment and separating peach kernel oil and peach kernel cake in the peach kernels, 3) crushing and mixing: putting the mixture in step 1) and the peach kernel cake into a pulverizer together, carrying out crushing to obtain powder of 100 to 200 meshes and then mixing the crushed medical powder through a mixer for 20-30min, 4) sterilization, 5) honey refining, 6) blending, 7) pelleting and 8) packaging for forming finished products. The cassia twig-poria cocos pill has the advantages of easy sieving, high recovery rate of medical powder and low cost.

Owner:SHANXI HUAKANG PHARMA

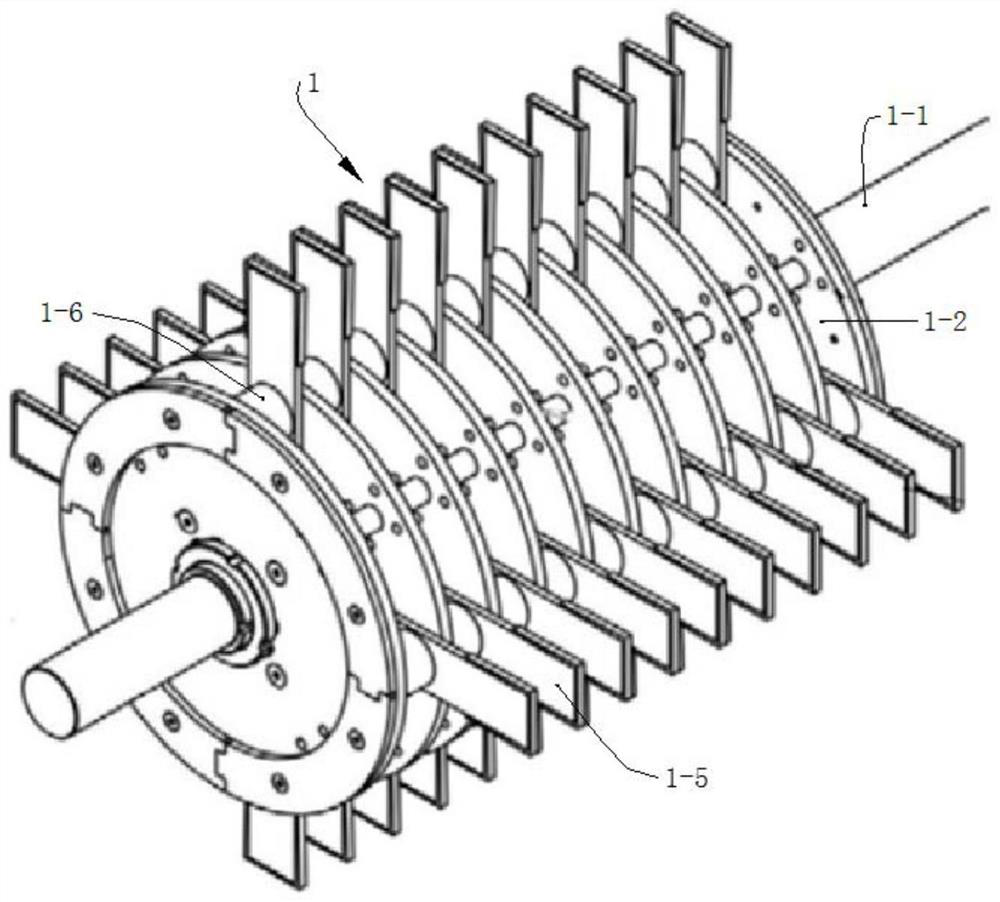

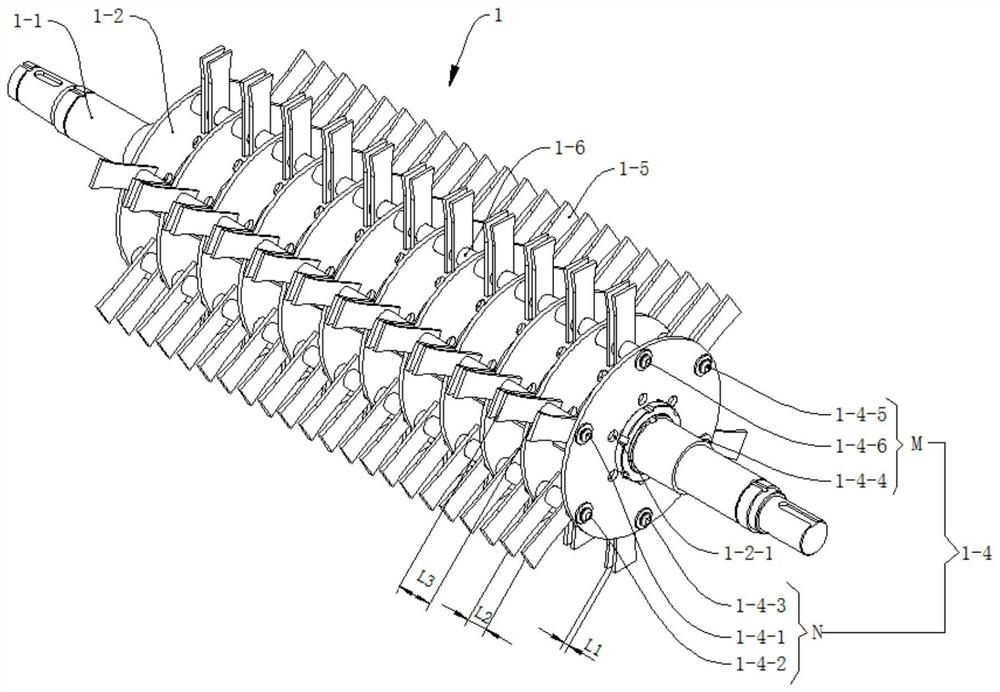

Fiber regeneration machine

PendingCN112844656AConvenient continuous cuttingIncrease cutting frequencyGrain treatmentsFiberEngineering

The invention discloses a fiber regeneration machine. The fiber regeneration machine comprising a machine shell, wherein a rotor is arranged in the machine shell and comprises a rotor shaft, cutter heads, shaft pins and blades; the multiple cutter heads are arranged on the rotor shaft; each of the multiple shaft pins is connected with all the cutter heads; all the shaft pins are evenly distributed along the outer rings of the cutter heads; two blades are arranged on the shaft pin located between every two adjacent cutter heads; at least every two adjacent shaft pins form a group; the two blades on the shaft pin, located between every two adjacent cutter heads, in each group of shaft pins gradually approach the cutter heads in the clockwise direction; and the blades, located between every two adjacent cutter heads, on the same shaft pin are arranged in the same mode. According to the fiber regeneration machine, the crushing effect can be improved, the production efficiency is improved, and the energy consumption is reduced.

Owner:SHANDONG JIEFENG MACHINERY MFG

Herbage crushing and processing device with elastic screening function

The invention discloses a herbage crushing and processing device with an elastic screening function. The device comprises a base and a crushing cavity, wherein the base is communicated with the crushing cavity; an upper cover fits the upper end of the crushing cavity and is provided with a crushing structure extending into the crushing cavity; the crushing structure comprises a rotating shaft rotatably arranged in the middle of the upper cover and groups of crushing blades fixedly connected to the periphery of the rotating shaft; the upper end of the rotating shaft is connected with a first motor for transmission, the bottom of the base is provided with a material guide structure, and the upper end of the material guide structure is connected with a screen through an elastic support structure; lifting rods penetrate through the two sides of the upper cover symmetrically, and the lower end of the rotating shaft is cooperatively connected with the screen through an elastic connection structure. According to the device during processing, the screen stays in an elastic state, and the movement of herbage and the elastic motion of the screen during processing are promoted, so that materials are driven to pass through, and the processing efficiency is thus improved; herbage which does not satisfy a screening standard can be continuously processed during rotation until the standard is satisfied.

Owner:田玉琴

Method and device for preventing m-phthalonitrile from being caked

The invention relates to a method and a device for preventing m-phthalonitrile from being caked. After being gasified, ammonia gas and the m-phthalonitrile enter a fluidized bed to be subjected to an ammoxidation reaction; a resultant enters a thin-wall material collector through an oil cooler and is subjected to cooling and material collection; a product is intermittently washed into a washing tower by water and then is washed, centrifuged and dried; after being dried, the product is conveyed into a stock bin through a packing auger conveyor; after being crushed, the product is added into a granulator by adopting a single-screw-rod charging machine and then is prepared into olive-shaped grains; then the olive-shaped grains are sieved by a vibration sieve device; m-phthalonitrile dried powder blocks are crushed and granulated and then are sieved to obtain finished-product grains; the m-phthalonitrile grains are discharged through a vibration sieve and packaged. According to the method and the device, provided by the invention, the m-phthalonitrile is prepared into the olive-shaped finished-product grains through the granulator and discharged materials of the vibration sieve are automatically packaged; the product is grain-shaped, the density is increased and the product is not caked, so that ton bags are used for packaging; the labor intensity of subsequent work can be alleviated and the labor force is reduced; meanwhile, dust pollution is also alleviated.

Owner:TAIZHOU BAILLY CHEM CO LTD

Medicinal material crushing device capable of solving problems of over-high operating temperature and difficult treatment of blockage

PendingCN113522483AReduce the effects of medicinal propertiesQuality assuranceGrain treatmentsMedicinal herbsThermodynamics

The invention relates to the technical field of crushing, and discloses a medicinal material crushing device for solving the problems of over-high operating temperature and difficult treatment of blockage. The medicinal material crushing device comprises a shell, and the interior of the shell is rotatably connected with a crushing roller. A crushing mechanism is automatically cooled by using the operation of crushing operation and a vortex tube principle, so that the problems that heat generated by long-time operation and heat generated by high-speed friction with medicinal materials cause rising of the surface temperature, and therefore the service life of the crushing mechanism is shortened are avoided. The influence of the temperature of the crushing mechanism on the property of medicinal materials is reduced, the quality of the medicinal materials is ensured, hot air generated by operation of a vortex tube acts on the medicinal materials on the surface of a screening tool, so that the medicinal materials are in a dynamic state, screening of the medicinal materials is promoted, feeding operation is automatically suspended under the gravity action caused when the large-size medicinal materials on the surface of the screening tool are too much, the crushed medicinal materials are prevented from being continuously accumulated on the surface of the screening tool, and sufficient time is provided for treatment of large-specification medicinal materials on the surface of the screening tool, so that the crushing operation can be carried out in order.

Owner:张朔

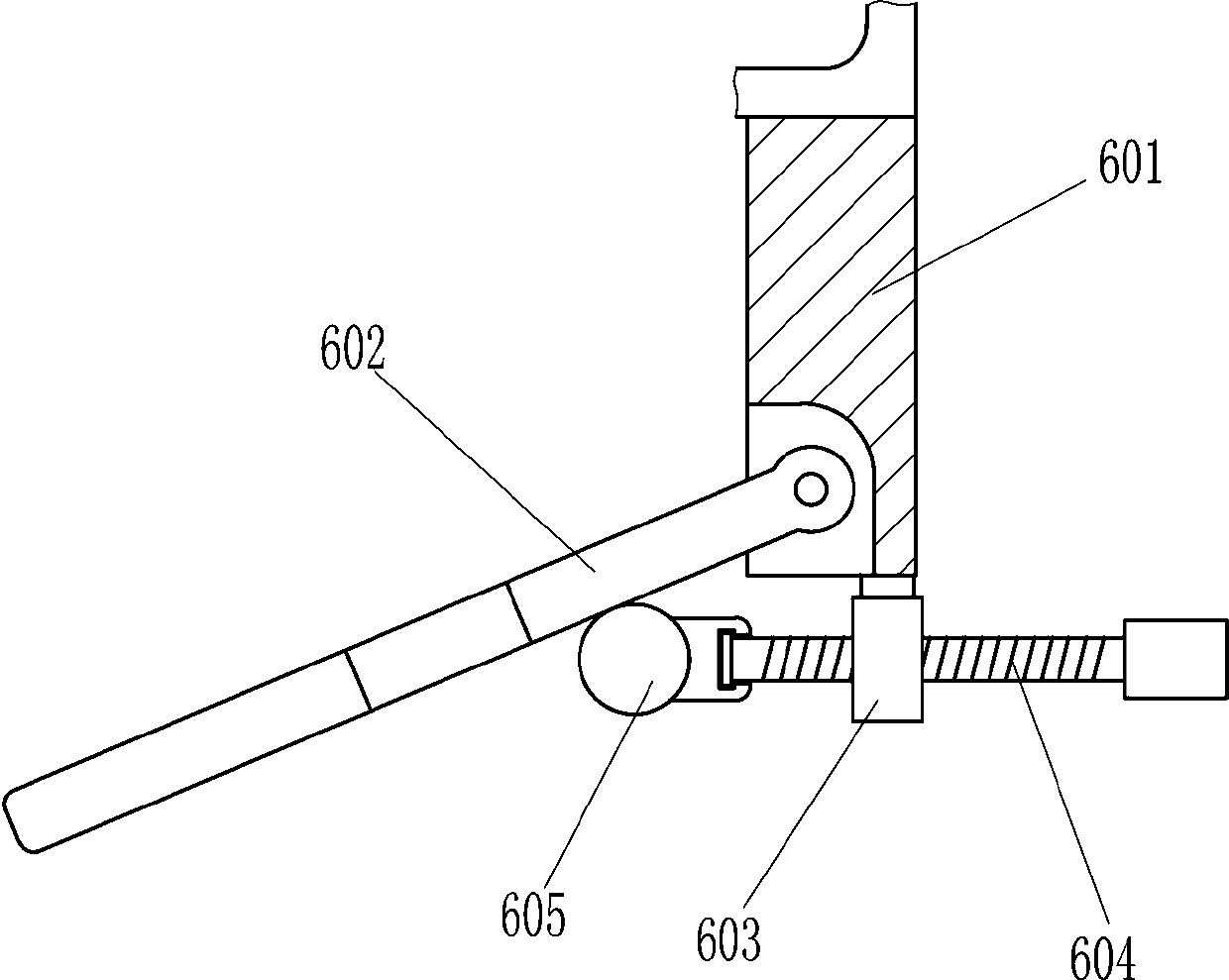

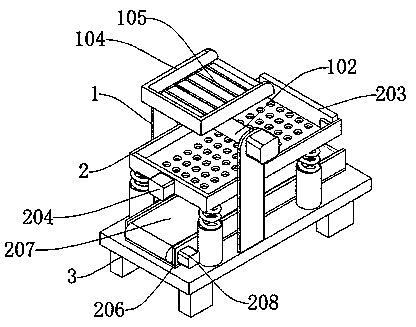

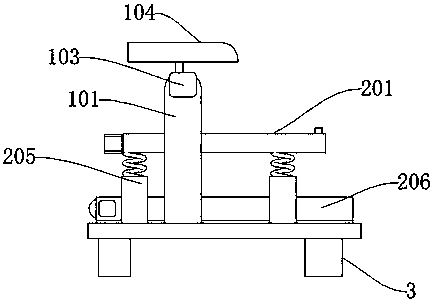

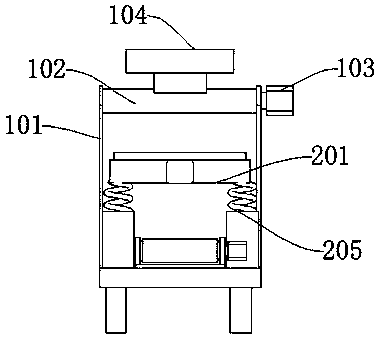

A Pneumatic Intermittent Drive Device

ActiveCN108816748BVibration sieving effect is goodEasy to siftSievingScreeningEngineeringMechanical engineering

The invention belongs to the technical field of drive mechanisms, and provides a pneumatic and intermittent drive device. A drive rod can be pneumatically and intermittently driven to move up and down, the drive rod is connected with a screw, then the screen is pneumatically and intermittently driven to vibrate up and down, and screening of an anode material after sintering is facilitated. The pneumatic drive manner is novel in structure, a gas inlet pipe keeps continuous gas input, a rotating part is driven to rotate to achieve intermittent gas output of a gas outlet pipe, a piston and a spring are combined, and the drive rod is intermittently driven to up and down; and the vibration and screening effect of the screen is good.

Owner:JINGMEN GEM NEW MATERIAL +1

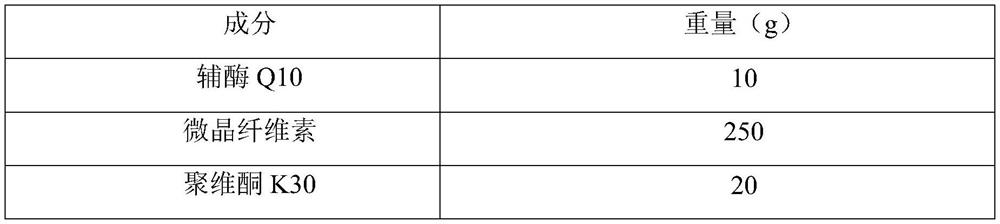

Tablet containing coenzyme Q10 and preparation method thereof

ActiveCN114569571AImprove wear resistanceImprove seismic performanceAntibacterial agentsOrganic active ingredientsMagnesium stearateStearic acid

The invention belongs to the technical field of medicine oral solid preparations, and particularly relates to a coenzyme Q10 tablet and a preparation method thereof. Raw materials and auxiliary materials of the coenzyme Q10 tablet comprise a tablet core and a coating layer, the tablet core comprises coenzyme Q10, microcrystalline cellulose, povidone K30, magnesium stearate, beeswax and xanthophyll, and the coating layer comprises a film coating material, amaranth and aerosil. According to the present invention, the problems of poor compressibility, low hardness, unqualified friability and the like are solved, the content uniformity is improved, the content of the related substance is reduced, and the long-term stability is improved by optimizing the auxiliary material and the use amount in the tablet core, adopting the dry granulation, improving the screening and mixing process in the prescription preparation method, and optimizing the coating process;

Owner:山东正牧生物药业有限公司

Impurity flocculating equipment for treating domestic sewage

ActiveCN108394977AEasy to siftWell mixedSpecific water treatment objectivesWater/sewage treatment by flocculation/precipitationPulp and paper industrySewage

The invention relates to domestic sewage treatment equipment, in particular to impurity flocculating equipment for treating domestic sewage. The invention aims at providing the impurity flocculating equipment for treating the domestic sewage, which enables small particle impurities in the domestic sewage to be coagulated together and be convenient to sieve. The invention provides the impurity flocculating equipment for treating the domestic sewage. The impurity flocculating equipment comprises a mounting rack, a mounting frame, a motor, a first gear, an annular sliding rail, a first sliding block, a cylindrical mixed transparent barrel stirring rod, an outer gear ring, a water inlet pipe, guide rails and the like; the mounting frame is connected to the top of the mounting rack; the motor is connected to the middle-right side of the bottom inside the mounting frame; the first gear is connected to the left side of the motor; the annular guide rail is connected to the left wall and the right wall of the mounting frame. According to the impurity flocculating equipment disclosed by the invention, the effects that small particle impurities in the domestic sewage can be coagulated together and are convenient to sieve are realized; the domestic sewage and a flocculating agent can be fully mixed by continuously rotating the cylindrical mixed transparent barrel and the stirring rod.

Owner:ZHEJIANG HAICHENG DECHANG MACHINERY CO LTD

Acesodyne capsule for heart and stomach

ActiveCN101559100BGood curative effectEasy to crushHydroxy compound active ingredientsDigestive systemNaphthaAluminium hydroxide

The invention discloses an acesodyne capsule for heart and stomach, which is prepared by Cinnamomum migao H.W.Li, borneol and auxiliary materials, wherein the auxiliary material is aluminium hydroxide. Compared with the prior art, the invention improves the compounding of the acesodyne capsule for heart and stomach, changes the existing auxiliary material starch into the aluminium hydroxide; the naphtha rich in the Cinnamomum migao H.W.Li is dispersed in the aluminium hydroxide in the form of micro-grains; the mixed medicated powder is not bonded again, can be crushed, sieved and filled with capsule conveniently, is extremely suitable for practical industrial production and is convenient for the medicine production enterprises to execute the GMP standard strictly. Simultaneously, the medical function of the aluminium hydroxide also improves the curative effect of the acesodyne capsule for heart and stomach.

Owner:GUIZHOU YIBAI PHARMA CO LTD

A powder coating mixing vibrating screen

The invention belongs to the technical field of powder coating production, and specifically discloses a powder coating mixing vibrating screen, which includes a box body, the top of the box body is provided with a material inlet, the side wall is provided with a discharge port, and a first sieve is built in the box body plate and the second sieve plate, the first sieve plate is located above the second sieve plate, the first sieve plate is provided with a milling hammer, the bottom of the milling hammer is provided with a rolling roller, and the milling hammer is connected with a motor to drive it to move left and right In the driving device, a rotating shaft is rotatably connected to the axis of the second sieve plate, stirring fan blades are arranged on the top of the rotating shaft, and a power source for driving the rotation is connected to the bottom of the rotating shaft. With this technical scheme, the raw materials are ground by the milling hammer, the raw materials are sieved through the first sieve plate and the second sieve plate, and the raw materials are mixed evenly at the same time, and the mixing, grinding and sieving of the powder coating are combined into one Integrate, reduce process, improve work efficiency.

Owner:CHONGQING QICAIHONG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com