Tablet containing coenzyme Q10 and preparation method thereof

A coenzyme and tablet technology, applied in the field of coenzyme Q10-containing tablets and its preparation, can solve the problems of low hardness, low hardness, poor compressibility, etc., reduce the content of related substances, solve the problem of poor content uniformity, enhance wear resistance and The effect of the ability to resist vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

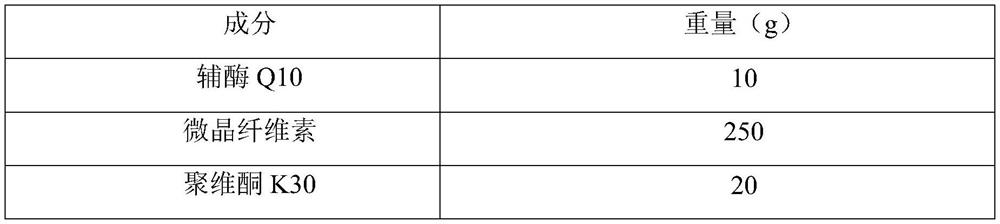

[0033] Embodiment 1: a kind of coenzyme Q10 tablet, its components and preparation process are as follows:

[0034] Chip composition, calculated in 1000 pieces

[0035]

[0036]

[0037] Preparation Process:

[0038] (1) pulverizing and sieving: pulverize coenzyme Q10, microcrystalline cellulose, povidone K30, magnesium stearate, and lutein in the recipe quantities, respectively, pass coenzyme Q10 and lutein through a 65-mesh sieve, and the microcrystalline Cellulose, povidone K30, and magnesium stearate were respectively passed through a 24-mesh sieve;

[0039] (2) mixing; the coenzyme Q10 and lutein sieved in step (1) were placed in a mixer and mixed for 5min, added microcrystalline cellulose, povidone K30, magnesium stearate and continued to mix for 10min, and then added Beeswax mixed for 10min;

[0040] (3) Granulation: use a dry granulator for granulation;

[0041] (4) drying and tableting;

[0042] (5) Coating: prepare a coating aqueous solution containing 4% ...

Embodiment 2

[0043] Embodiment 2: a kind of coenzyme Q10 tablet, its components and preparation process are as follows:

[0044] Chip composition, calculated in 1000 pieces

[0045] Element Weight (g) Coenzyme Q10 5 microcrystalline cellulose 220 Povidone K30 30 Magnesium stearate 15 beeswax 10 Lutein 1

[0046] Preparation Process:

[0047] (1) pulverizing and sieving: pulverize coenzyme Q10, microcrystalline cellulose, povidone K30, magnesium stearate, and lutein in the recipe quantities, respectively, pass coenzyme Q10 and lutein through a 65-mesh sieve, and the microcrystalline Cellulose, povidone K30, and magnesium stearate were respectively passed through a 24-mesh sieve;

[0048] (2) mixing; the coenzyme Q10 and lutein sieved in step (1) were placed in a mixer and mixed for 5min, added microcrystalline cellulose, povidone K30, magnesium stearate and continued to mix for 10min, and then added Beeswax mixed for 10min;

[0049] (3)...

Embodiment 3

[0052] Embodiment 3: a kind of coenzyme Q10 tablet, its components and preparation process are as follows:

[0053] Chip composition, calculated in 1000 pieces

[0054] Element Weight (g) Coenzyme Q10 15 microcrystalline cellulose 290 Povidone K30 10 Magnesium stearate 5 beeswax 20 Lutein 3

[0055] Preparation Process:

[0056] (1) pulverizing and sieving: pulverize coenzyme Q10, microcrystalline cellulose, povidone K30, magnesium stearate, and lutein in the recipe quantities, respectively, pass coenzyme Q10 and lutein through a 65-mesh sieve, and the microcrystalline Cellulose, povidone K30, and magnesium stearate were respectively passed through a 24-mesh sieve;

[0057] (2) mixing; the coenzyme Q10 and lutein sieved in step (1) were placed in a mixer and mixed for 5min, added microcrystalline cellulose, povidone K30, magnesium stearate and continued to mix for 10min, and then added Beeswax mixed for 10min;

[0058] (3) G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com