Resin granule cleaning and conveying discharge machine unit

A technology of resin pellets and units, applied in the directions of transportation and packaging, packaging, packaging protection, etc., can solve the problems of poor weighing accuracy, reduced packaging efficiency, non-standard, etc., to facilitate cleaning and sieving, and improve product quality , the effect of hindering the production of mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

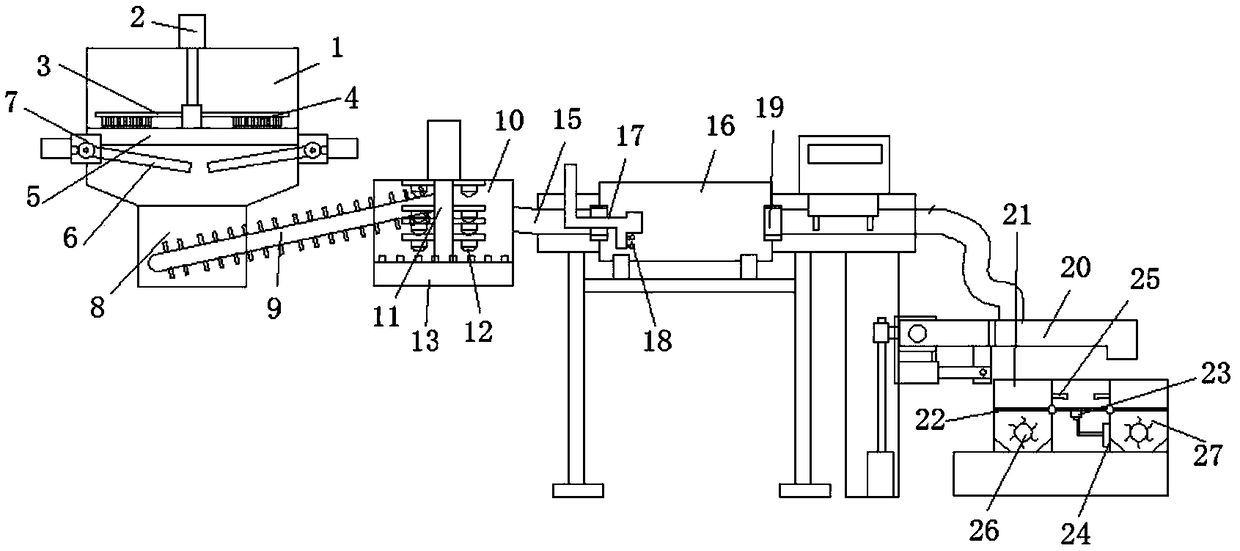

[0010] Referring to the accompanying drawings, a resin pellet cleaning and conveying and unloading unit includes a cleaning tank 1, the upper end of the cleaning tank 1 is provided with a stirring device 2, and the lower end of the stirring device 2 is connected with a brush bar 3, and the brush bar The side wall of 3 is provided with bristle 4, and the lower end of described brush bar 3 is provided with filter net layer 5, and the bottom of described filter net layer 5 is provided with left and right sealing gate 6, and described sealing gate 6 is turned over The device 7 is connected to realize opening and closing. The bottom of the cleaning tank 1 is provided with a feeding channel 8, and the bottom of the feeding channel 8 is provided with a conveying track 9, and the conveying track 9 is connected to the drying mixing drum 10. The drying mixing drum 10 is provided with a stirring shaft 11, the side wall of the stirring shaft 11 is provided with an ultraviolet germicidal la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com