Intermittent swing material screening device

A screening device and material technology, applied in the direction of sieve, solid separation, removal of smoke and dust, etc., can solve the problems of low efficiency of manual screening and low passing efficiency, and achieve the effect of improving the effect, promoting sieving and avoiding dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

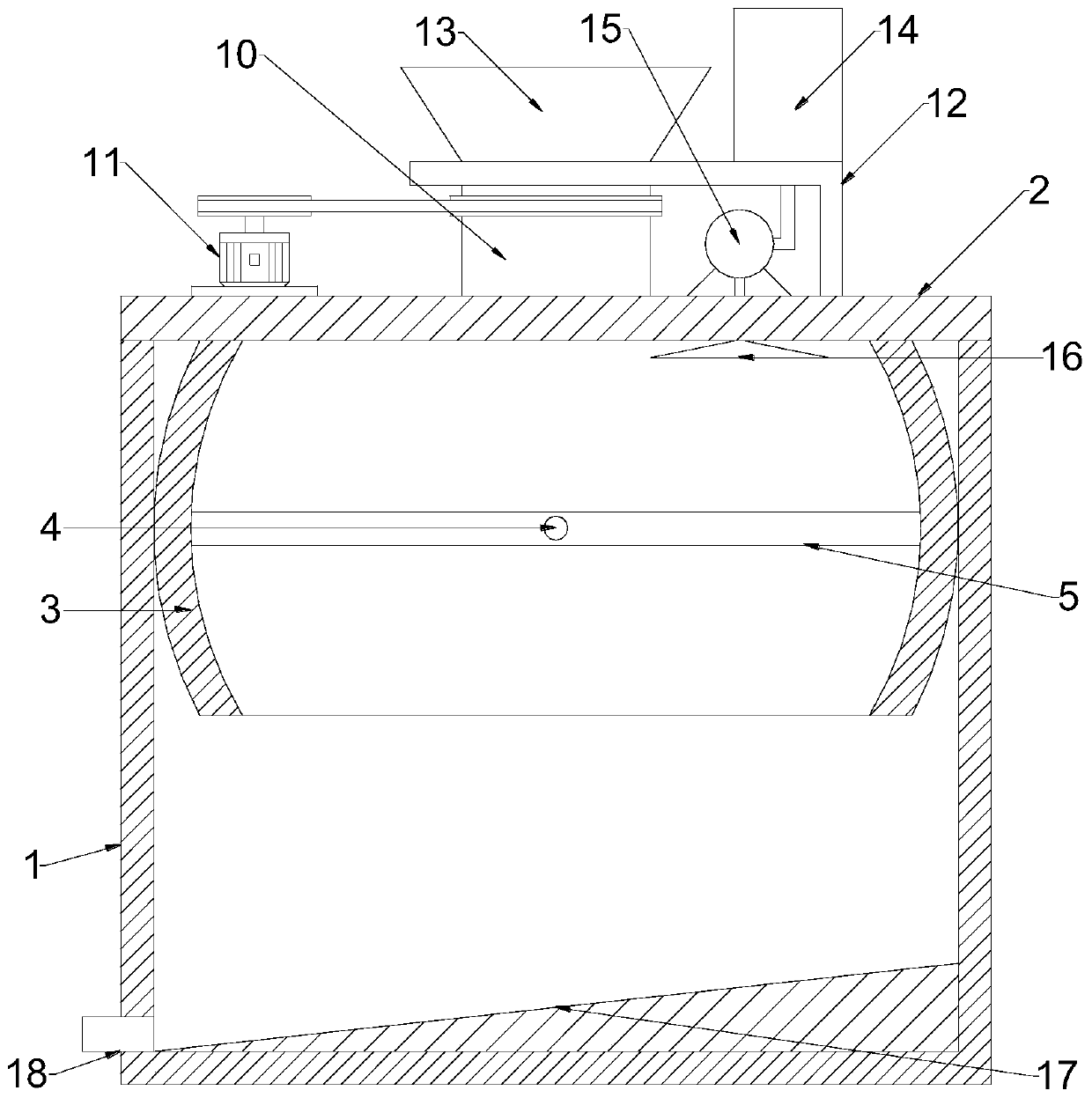

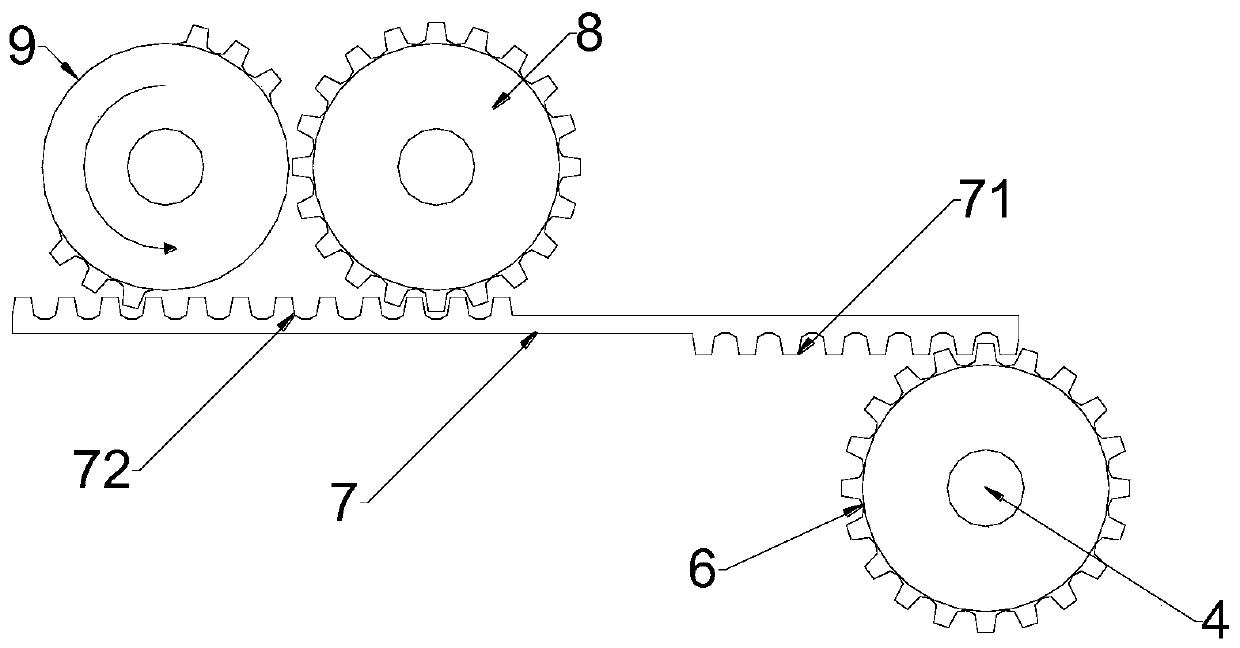

[0024] see Figure 1~3 , in an embodiment of the present invention, an intermittent swing material screening device includes a housing 1 and an upper cover 2, the housing 1 is provided with a screening structure driven by a reciprocating drive structure, and the upper cover 2 is riveted and arranged on The upper end of the housing 1 and the upper cover 2 are also provided with a rotating fabric structure driven by the drive motor 11 and a dust collection structure for preventing dust. The screen plate 5, the second gear 8 and the third gear 9 are composed.

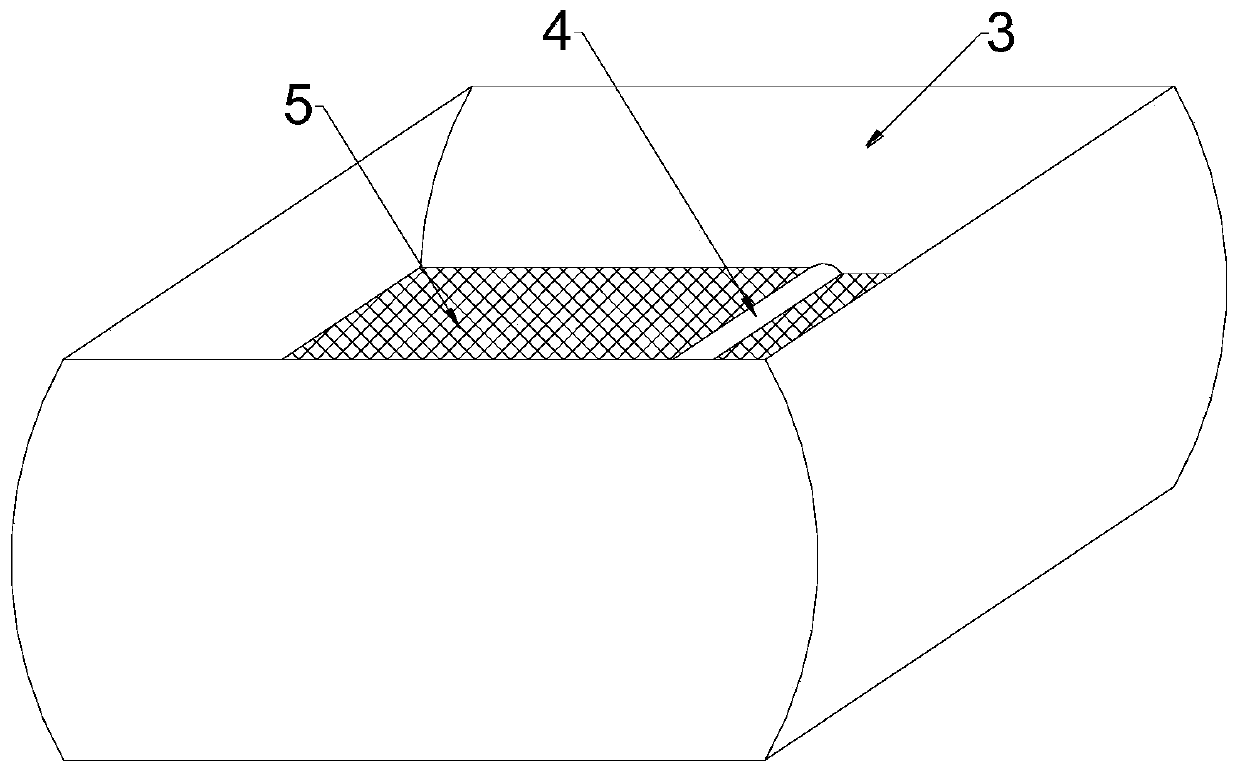

[0025] The screening structure includes a rotating shaft 4 that rotates radially on the front and rear sides of the inner wall of the housing 1 and a screen plate 5 fixed on the rotating shaft 4. The two sides of the screen plate 5 are symmetrically provided with groove plates 3, and the The slot plate 3 is fixed between the front and rear side walls of the housing 1, and the arc center position of the slot plate 3 is flu...

Embodiment 2

[0034] see Figure 4~5 , in the embodiment of the present invention, an intermittent swing material screening device, on the basis of embodiment 1, a cloth block 19 is fixedly connected in the material guide pipe 10, and the cloth block 19 is composed of multiple sets of triangular metal plates , the cloth block 19 forms a polygonal structure, so that when the material passes through the feed pipe 10, it is divided into multiple parts by the cloth block 19 and thrown out during the rotation of the feed pipe 10. This design can better After finishing the cloth, the material is evenly distributed, which can improve the screening effect.

[0035]The working principle of the present invention is: start the drive motor 11 to drive the feed pipe 10 to rotate, put the material into the feed pipe 10 through the feed hopper 13, when the material passes through the feed pipe 10, it is divided into multiple parts by the cloth block 19, and It is thrown out during the rotation of the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com