A powder coating mixing vibrating screen

A powder coating and vibrating sieve technology, applied in mixers, sieves, grain processing, etc., can solve problems such as low production efficiency, poor continuity, and low degree of automation, and achieve simplified equipment structure, uniform raw material mixing, and reduced additional processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is further described in detail through specific implementation methods:

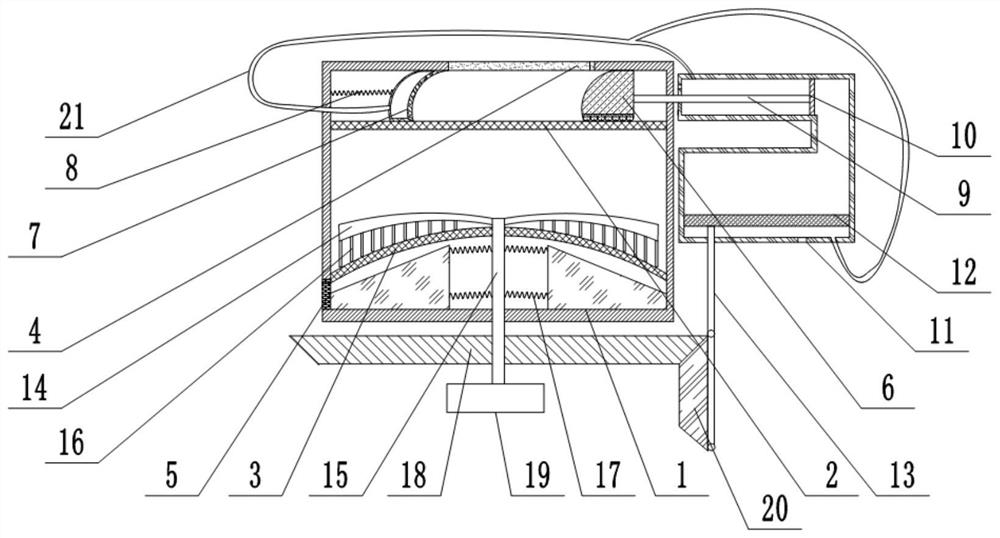

[0028] The reference signs in the accompanying drawings of the specification include: box body 1, first sieve plate 2, second sieve plate 3, feed port 4, discharge port 5, milling hammer 6, stopper 7, return spring 8, second sieve plate One piston rod 9, first piston plate 10, piston cylinder 11, second piston plate 12, second piston rod 13, stirring fan blade 14, rotating shaft 15, stirring teeth 16, compression spring 17, main bevel gear 18, motor 19 , Secondary bevel gear 20, air pipe 21.

[0029] Examples are attached figure 1 Shown: a powder coating mixing vibrating screen, including a box body 1, a feed port 4 is provided at the center of the top of the box body 1, and a door panel that can be opened outward is hinged at the 4 places of the feed port, and the box body 1 is built with a first Sieve plate 2 and second sieve plate 3, the first sieve plate 2 is located above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com