Anode material of lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, electrode manufacturing, active material electrodes, etc., can solve the problems of high AC internal resistance, poor cycle performance, and easy freezing of positive electrode slurry to achieve AC internal The effect of improving resistance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

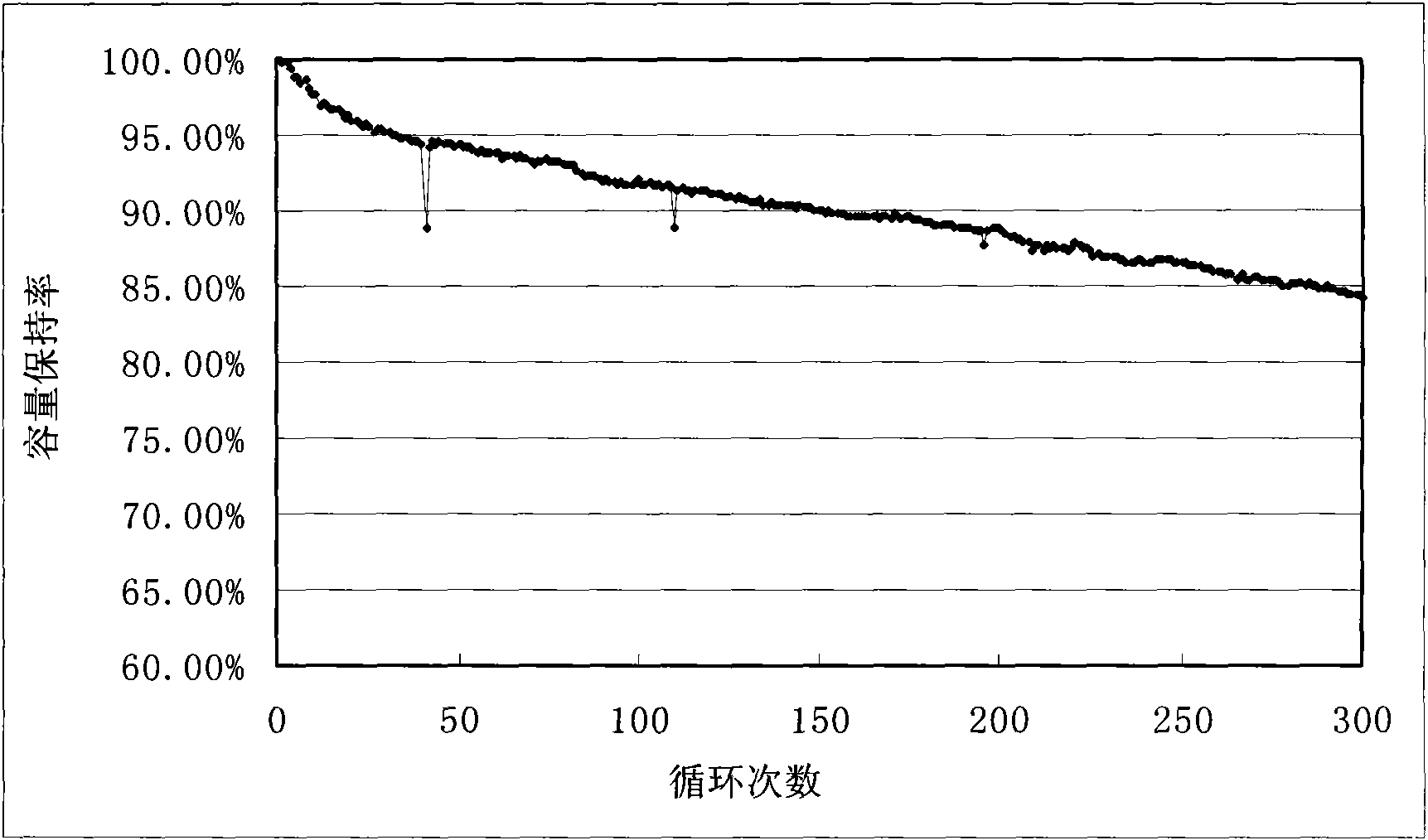

Embodiment 1

[0031] The positive electrode active material is lithium nickel cobaltate and lithium manganate (lithium manganate is the second active material), the carboxylic acid compound is malonic acid, the silane compound is methyltrioxymethylsilane, and the solvent is N-methyl arsenic Rolidone (NMP). The conductive agent used to prepare the positive electrode slurry is conductive carbon black SP, and the binder is polyvinylidene fluoride (PVDF).

[0032] The weight ratio is: lithium nickel cobaltate: lithium manganate: SP: PVDF: NMP: malonic acid: methyltrioxymethylsilane = 100:60:4.5:4.5:60:2:2.

[0033] Mix PVDF and 70% solvent in an egg beater and stir for 90 minutes, then add conductive agent SP and continue stirring for 90 minutes to complete the preparation of the conductive adhesive.

[0034] Dry-mix the baked lithium nickel cobaltate and lithium manganate in a vacuum mixer at 15Hz revolution for 90 minutes; then add 20% solvent and stir for 60 minutes; dissolve malonic acid i...

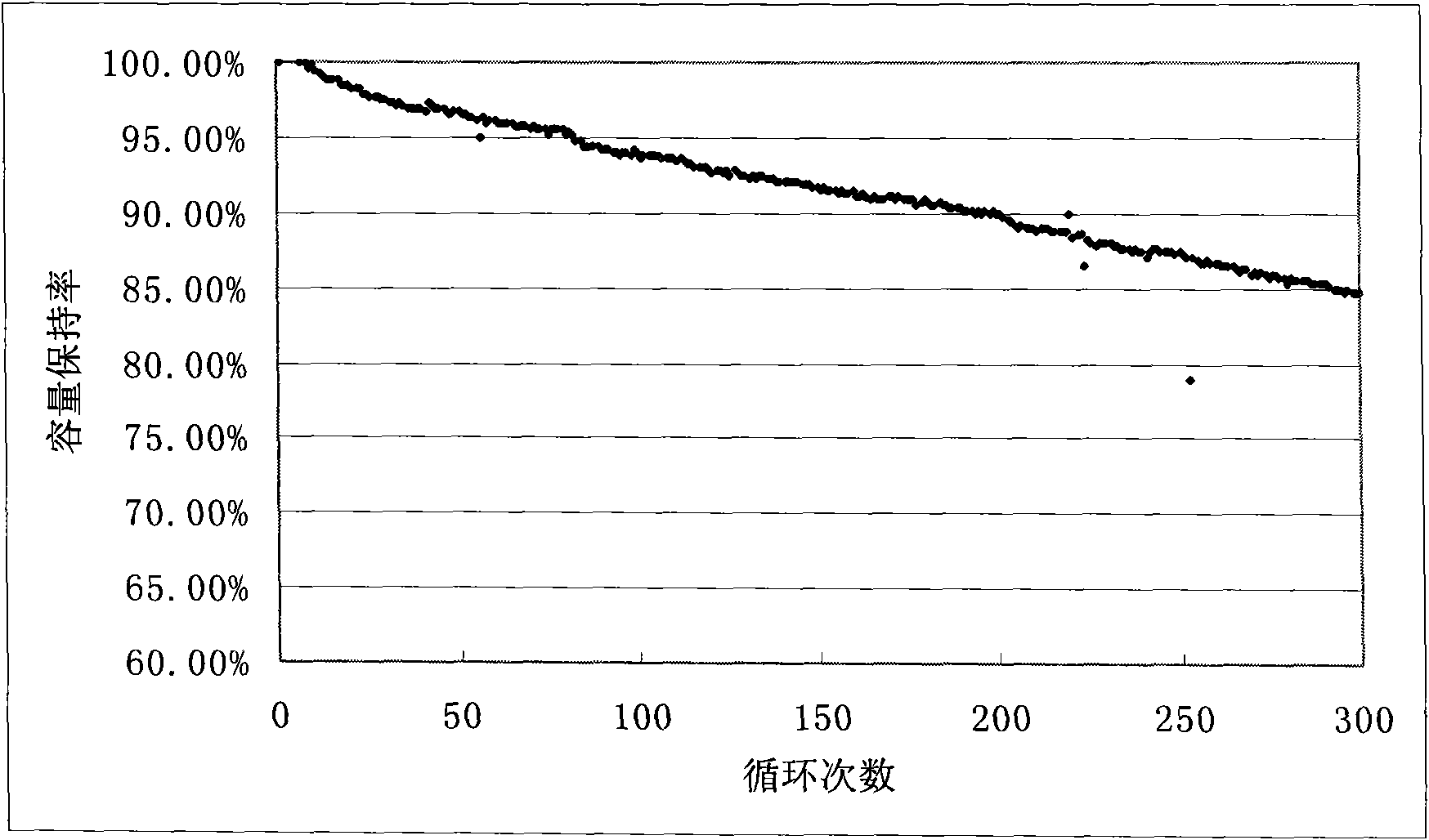

Embodiment 2

[0037] The positive electrode active material is lithium nickel cobaltate and lithium cobaltate + lithium manganate (lithium cobaltate + lithium manganate is the second active material), the carboxylic acid compound is oxalic acid, the silane compound is tetramethoxysilane, and the solvent It is diethyl carbonate (DEC). The conductive agent used to prepare the positive electrode slurry is conductive carbon black SP, and the binder is polyvinylidene fluoride (PVDF).

[0038] The weight ratio is: lithium nickel cobaltate: lithium cobaltate + lithium manganate: SP: PVDF: DEC: oxalic acid: tetramethoxysilane = 40:60:5:5:30:0.01:0.01.

[0039] Mix PVDF and 50% solvent in an egg beater and stir for 90 minutes, then add conductive agent SP and continue stirring for 90 minutes to complete the preparation of the conductive adhesive.

[0040] Dry-mix the baked lithium nickel cobaltate, lithium cobaltate + lithium manganate in a vacuum mixer at 15Hz for 90 minutes; then add 40% solvent ...

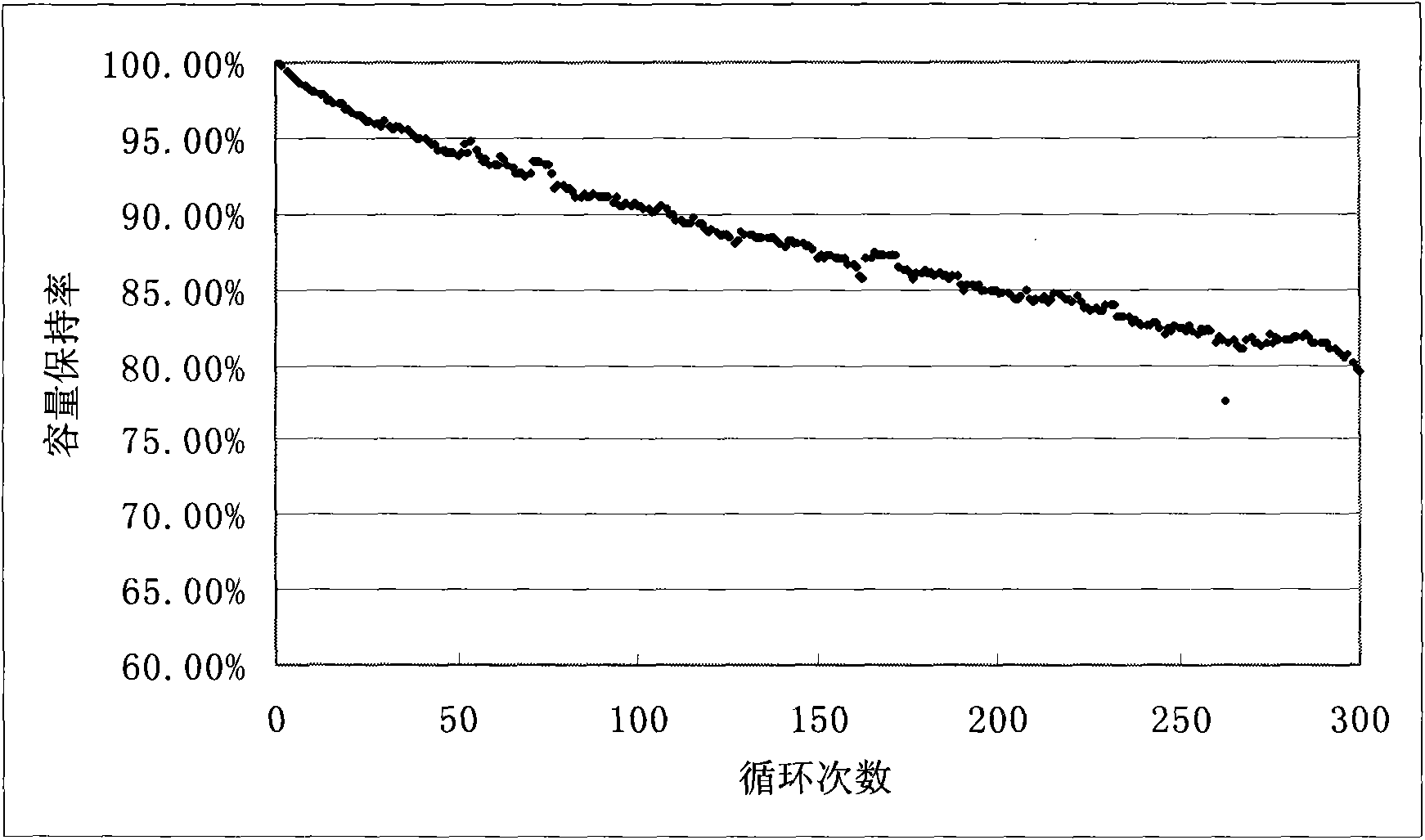

Embodiment 3

[0043] The positive electrode active material is lithium nickel cobaltate, the carboxylic acid compound is propionic acid, the silane compound is methyltriacetoxysilane, and the solvent is methyl ethyl carbonate (EMC). The conductive agent used to prepare the positive electrode slurry is conductive carbon black SP, and the binder is polyvinylidene fluoride (PVDF).

[0044] The weight ratio is: lithium nickel cobaltate: SP: PVDF: EMC: propionic acid: methyltriacetoxysilane = 70:5:5:100:1.5:1.0.

[0045] Mix PVDF and 50% solvent in an egg beater and stir for 90 minutes, then add conductive agent SP and continue stirring for 90 minutes to complete the preparation of the conductive adhesive.

[0046] Dry-mix the baked lithium nickel cobaltate, lithium cobaltate + lithium manganate in a vacuum mixer at 15Hz revolution for 90 minutes; then add 40% solvent and stir for 60 minutes; dissolve propionic acid in 5% solvent and add Put it into a vacuum mixer, and the stirring time is 60 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com