Patents

Literature

718results about "Preparation by hydrocarbon ammoxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

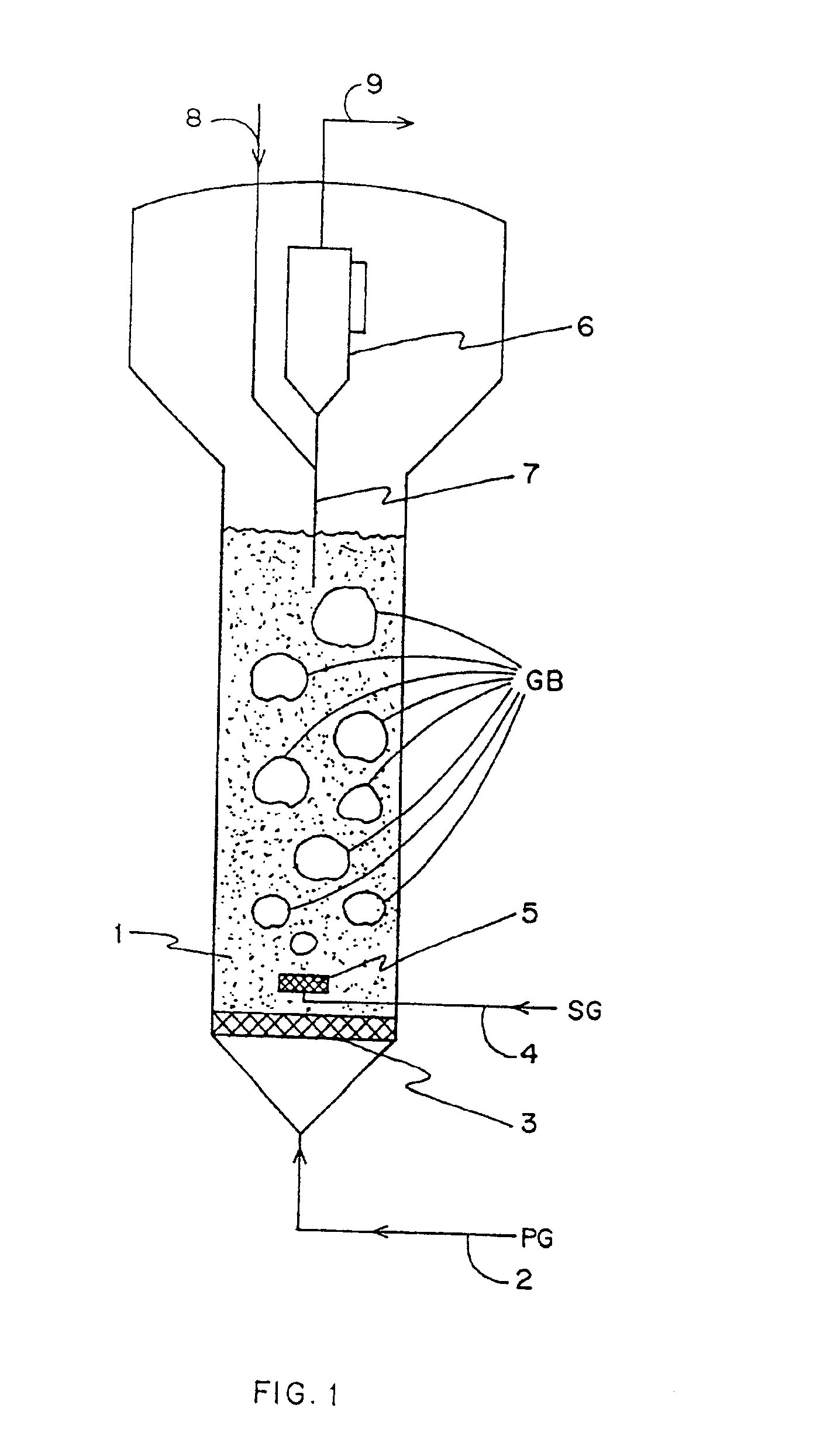

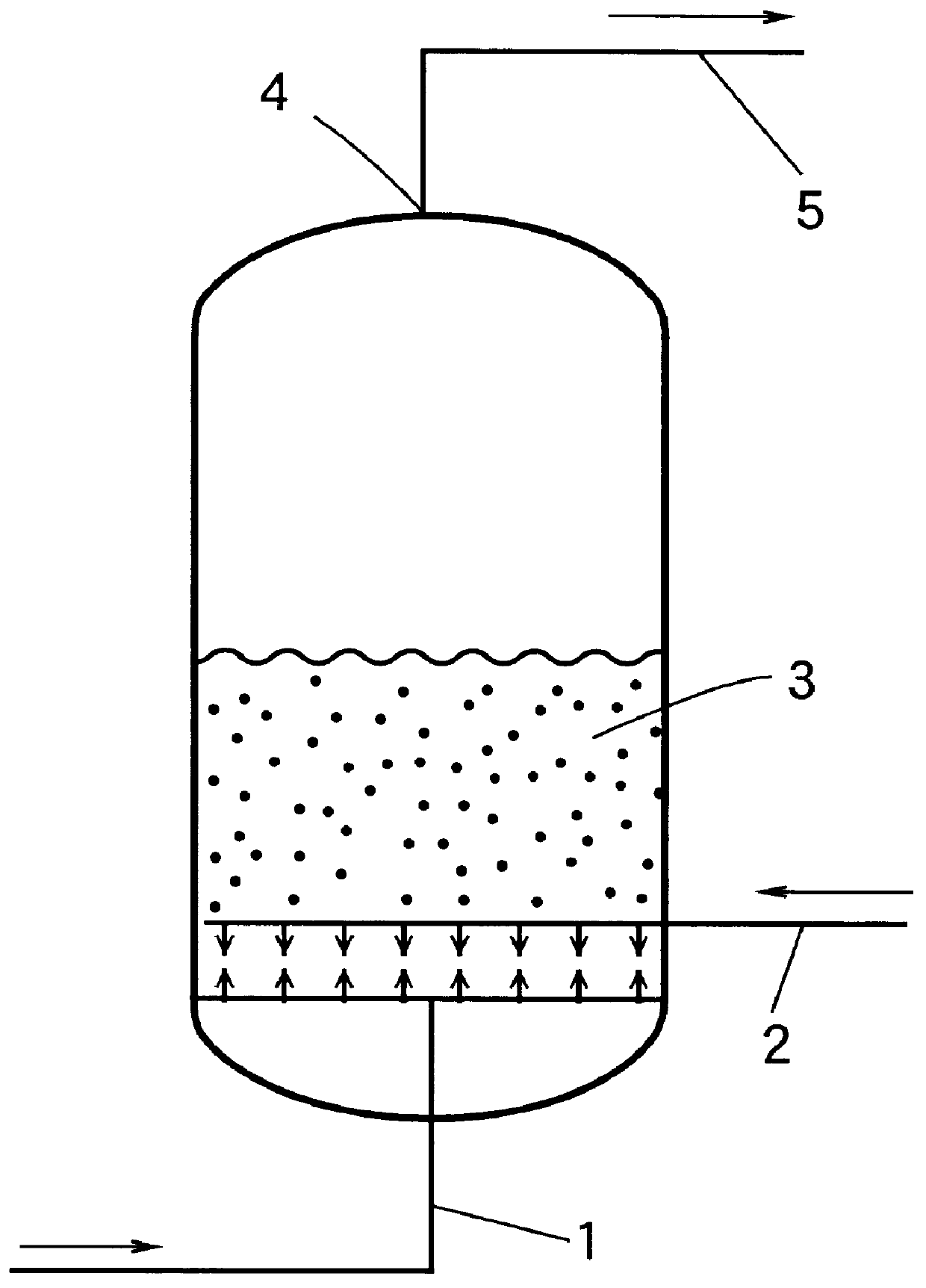

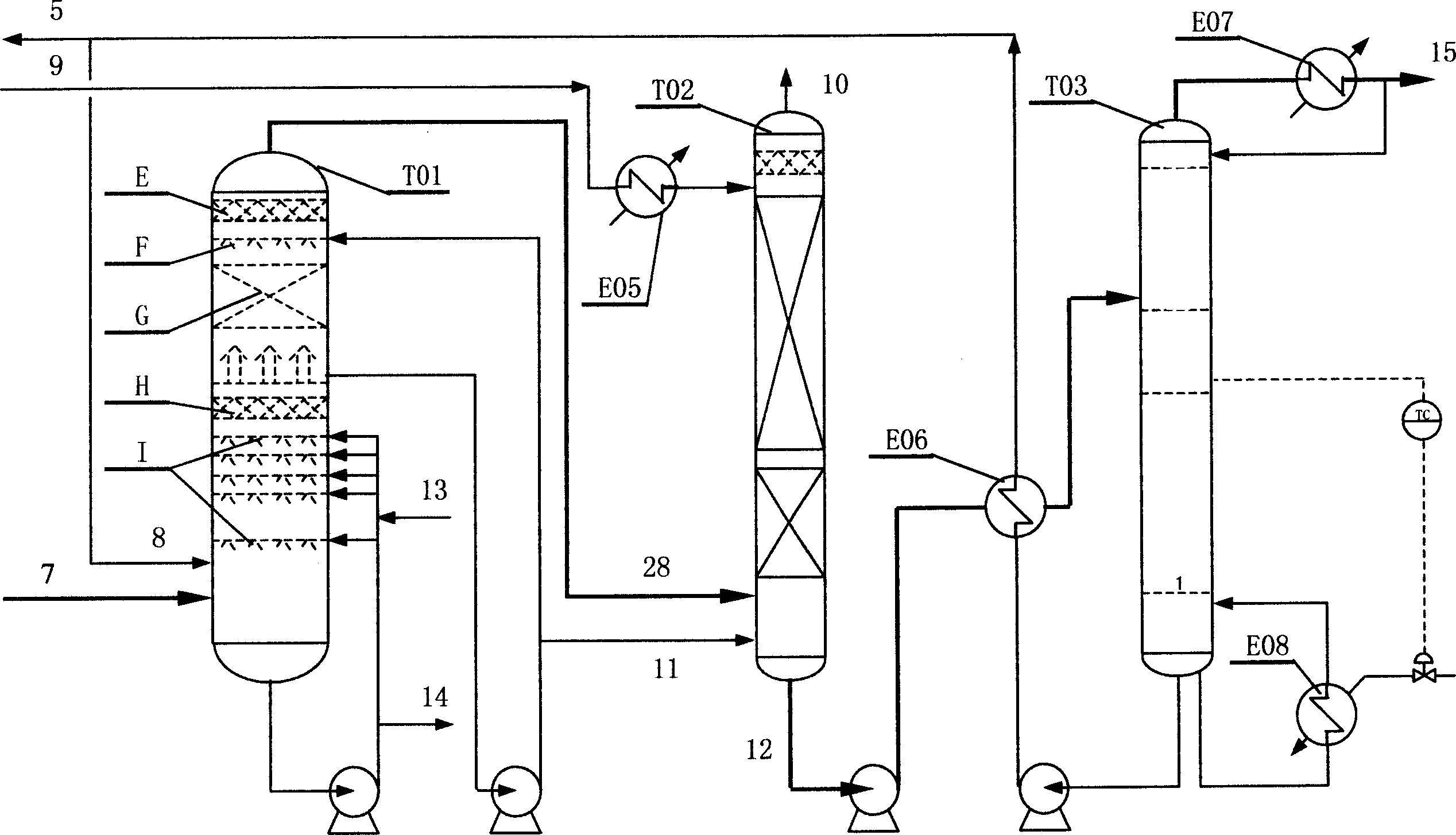

Method for gas-solid contacting in a bubbling fluidized bed reactor

InactiveUS6894183B2Eliminate and drastically reduce bypassEffective contactThermal non-catalytic crackingCatalytic crackingForming gasSolid particle

Owner:COUNCIL OF SCI & IND RES

Multimetal oxide materials

Owner:BASF SE

Method for the oxidative dehydrogenation of ethane

InactiveUS7319179B2Organic compound preparationHeterogenous catalyst chemical elementsAlkaline earth metalDehydrogenation

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC) +1

Fluid bed catalyst in use for oxidizing reaction of olefin ammonia

InactiveCN1600422AImprove wear resistanceHigh activityPreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsFluidized bedActive component

A fluidized-bed catalyst for the ammoxidation reaction of olefin is composed of the carrier consisting of nano-SiO2 and silica sol, and the active component Mo(12-g)BiaFebNicXdZfOgOx, where X is chosen from Mg, Co, Ca, Be, Cu, Zn, Pb, Sb, Mn and Cr, Y is chosen from La, Ce and Sm, Z is chosen from Li, K, Rb, Na and Cs, Q is chosen from B, W, P and V, a=0.1-6, b=0.01-10, c=0.01-10, d=0.01-10, e=0.01-10, g=0-2 and f is more than (0-0.5).

Owner:CHINA PETROLEUM & CHEM CORP

Oxidative reactions using membranes that selectively conduct oxygen

InactiveUS6730808B2Eliminate the problemNot possibleAlkali metal oxides/hydroxidesFunctional group formation/introductionLanthanideOxygen

Reactor membranes for used in oxidation reactions of hydrocarbons involving oxygen comprising a selective oxidation catalyst on a mixed conducting, oxide ion selective ceramic membrane of the composition (Sr1-xCax)1-yAyMn1-zBzO3-delta, whereA is Ba, Pb, Na, K, Y, an element of the lanthanide group or a combination thereof,B is Mg, Al, Ga, In, Sn, an element of the 3d or 4d period or a combination thereof,x is from 0.2 to 0.8,y is from 0 to 0.4,z is from 0 to 0.6, anddelta is a number, dependent on x, y and z, that renders the composition charge neutral.

Owner:BASF AG

Process for converting a hydrocarbon to an oxygenate or a nitrile

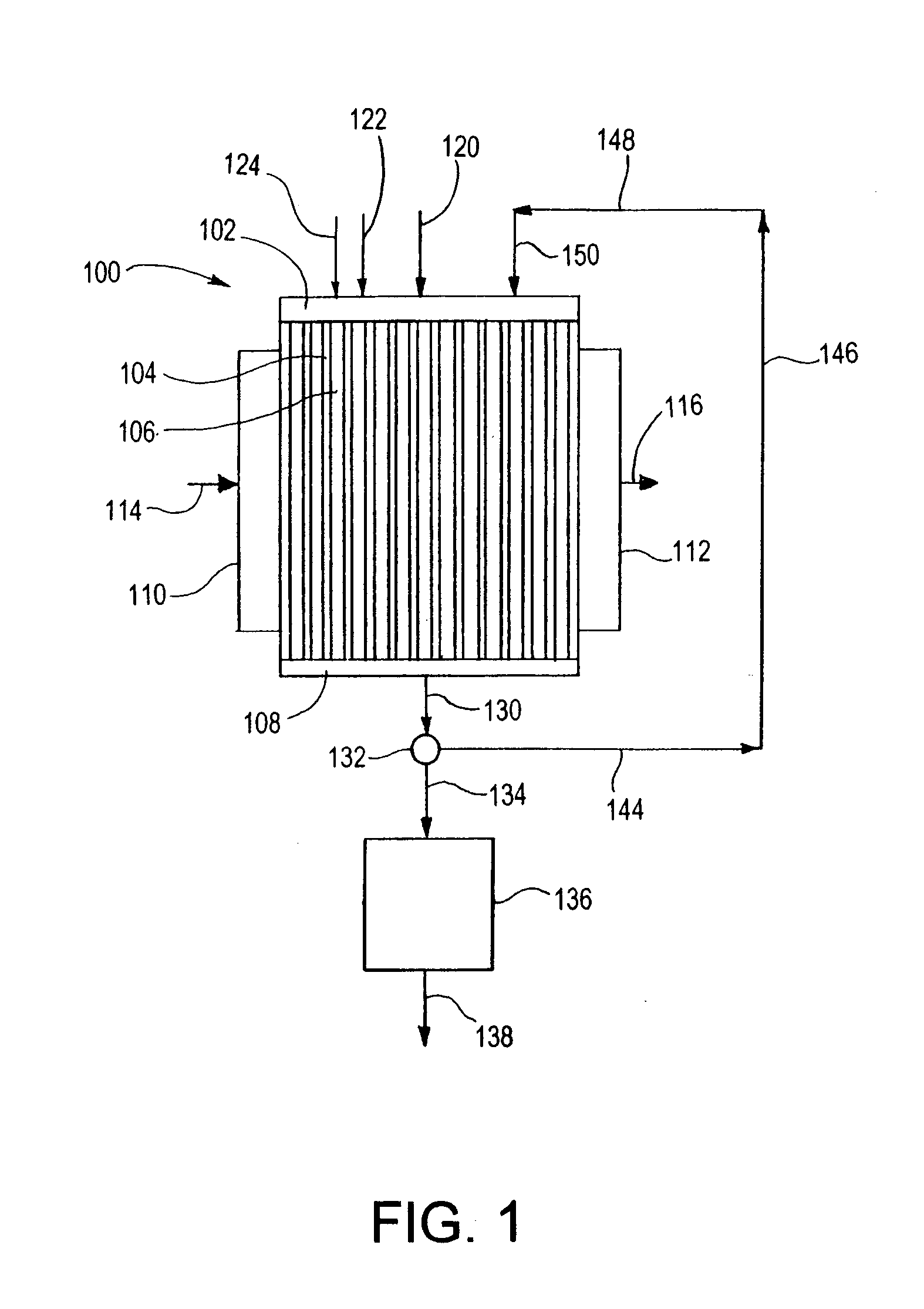

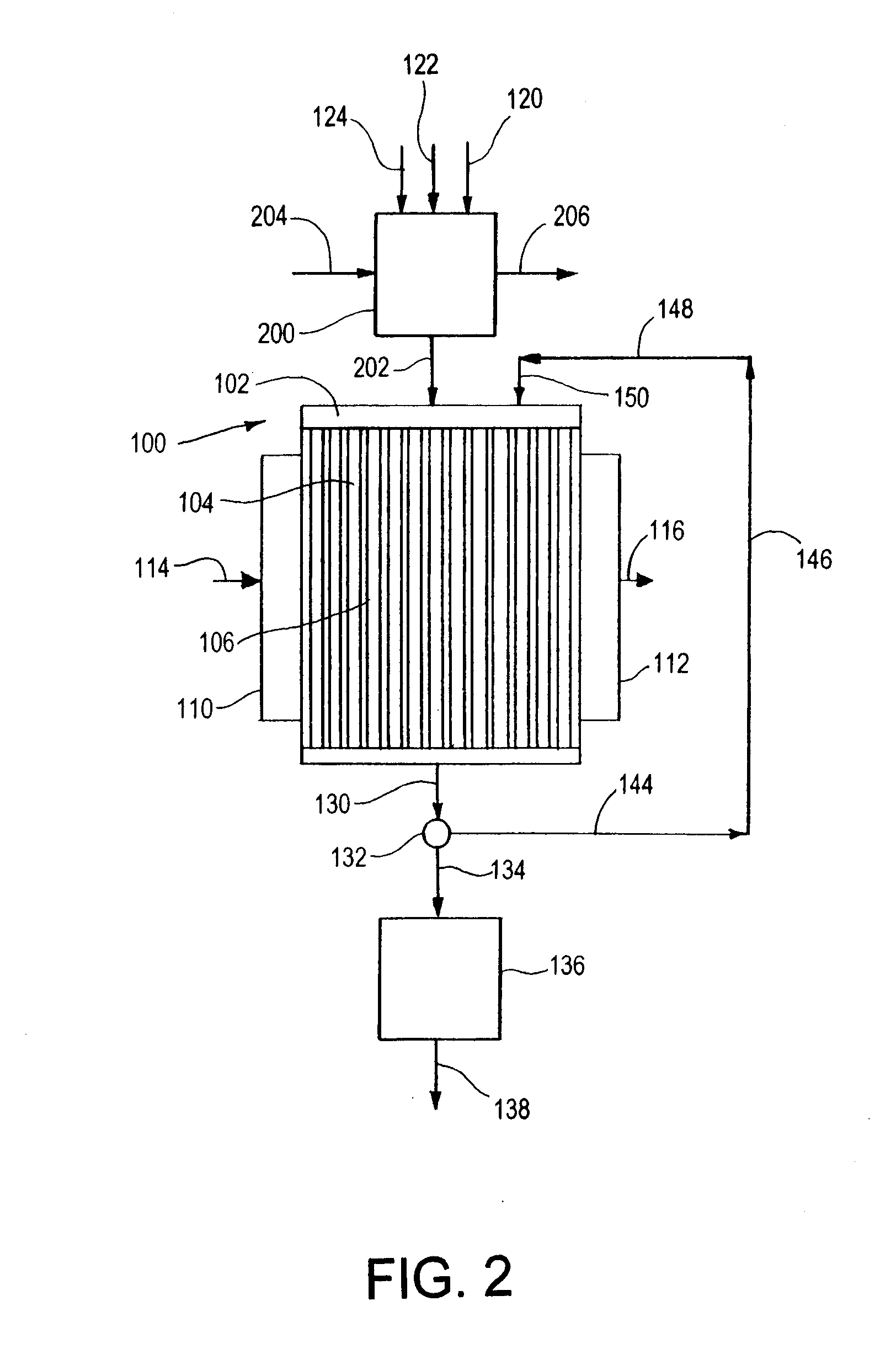

InactiveUS7294734B2Maximize contactOrganic compound preparationCarboxylic acid esters preparationOxygenateOxygen

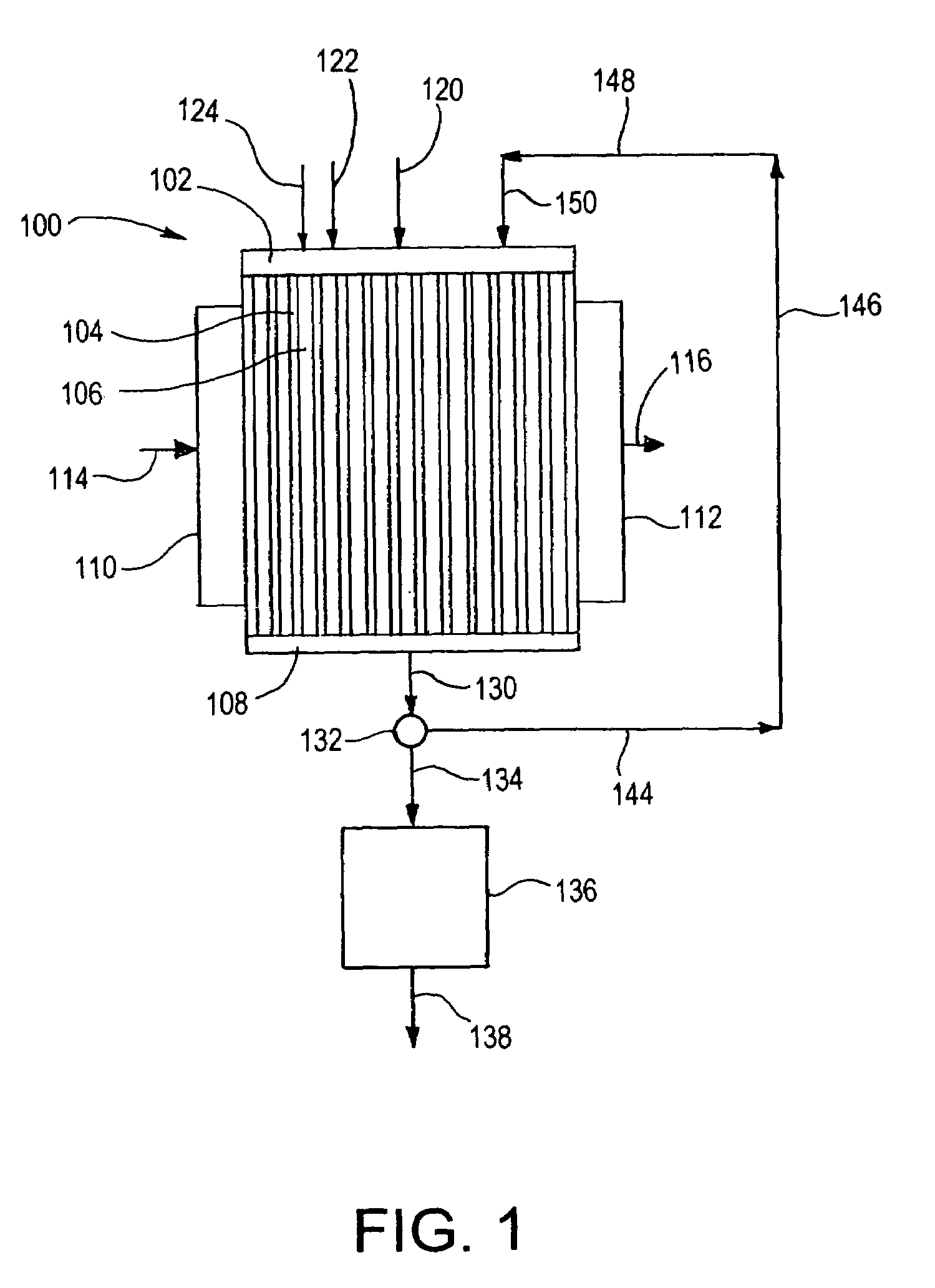

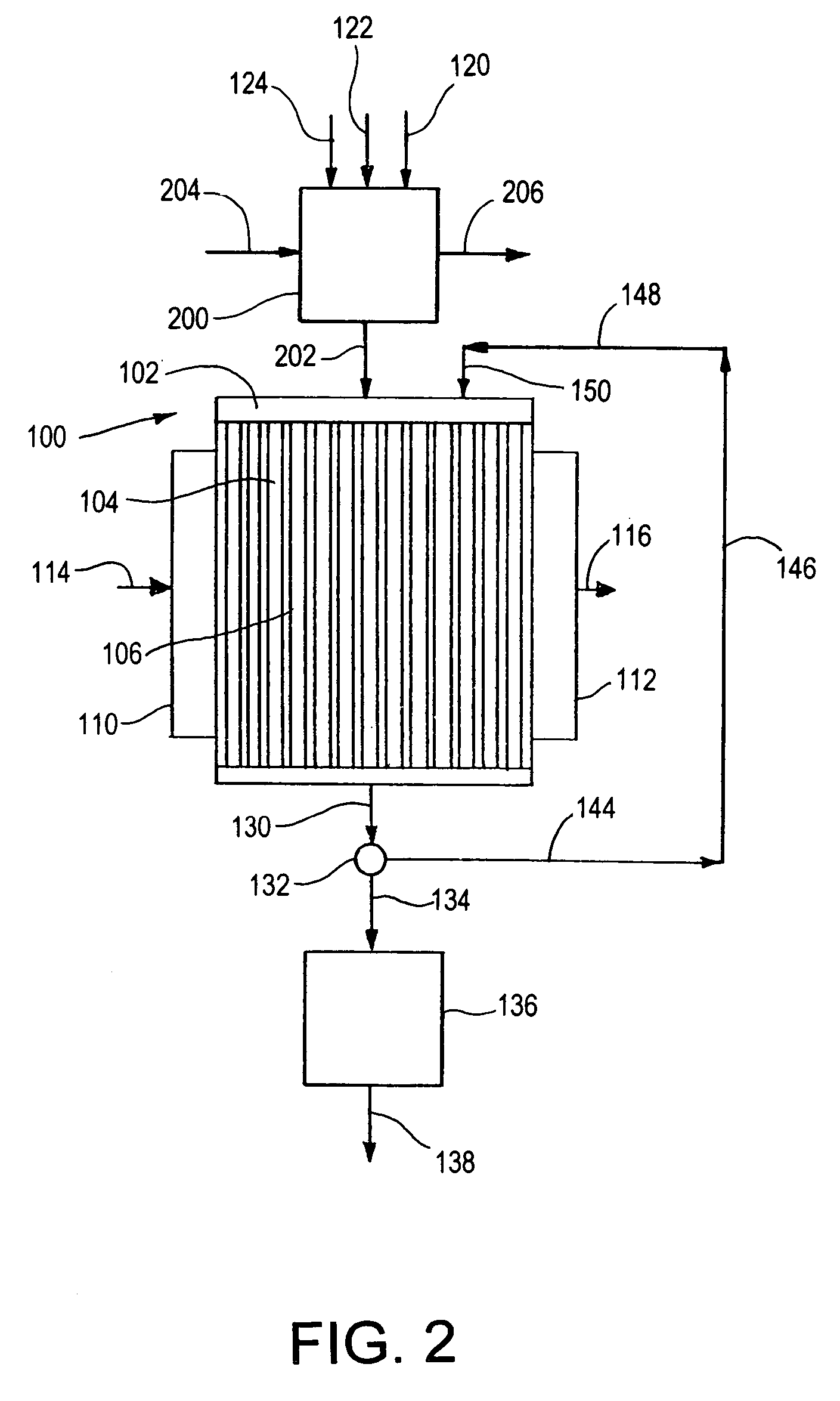

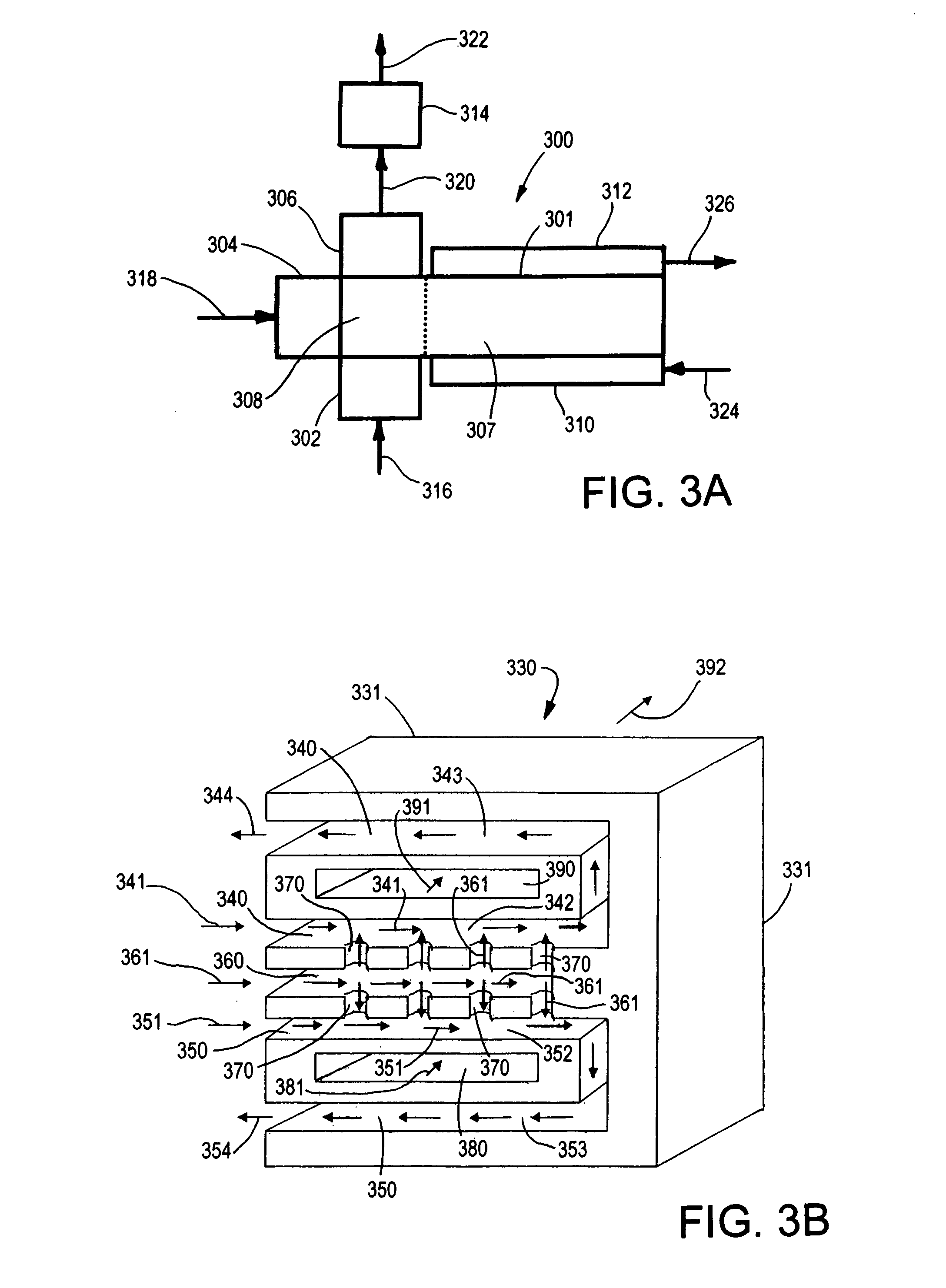

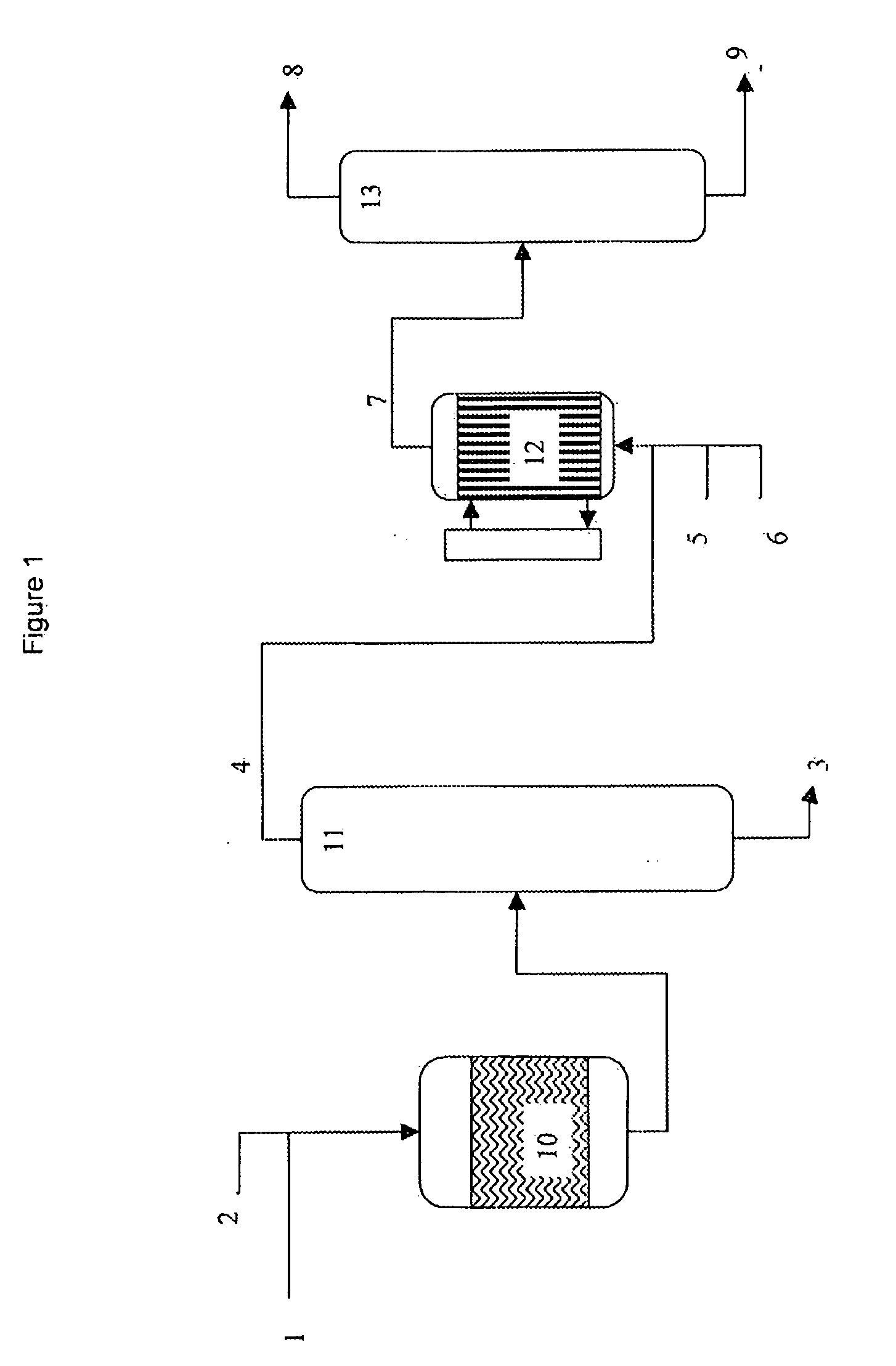

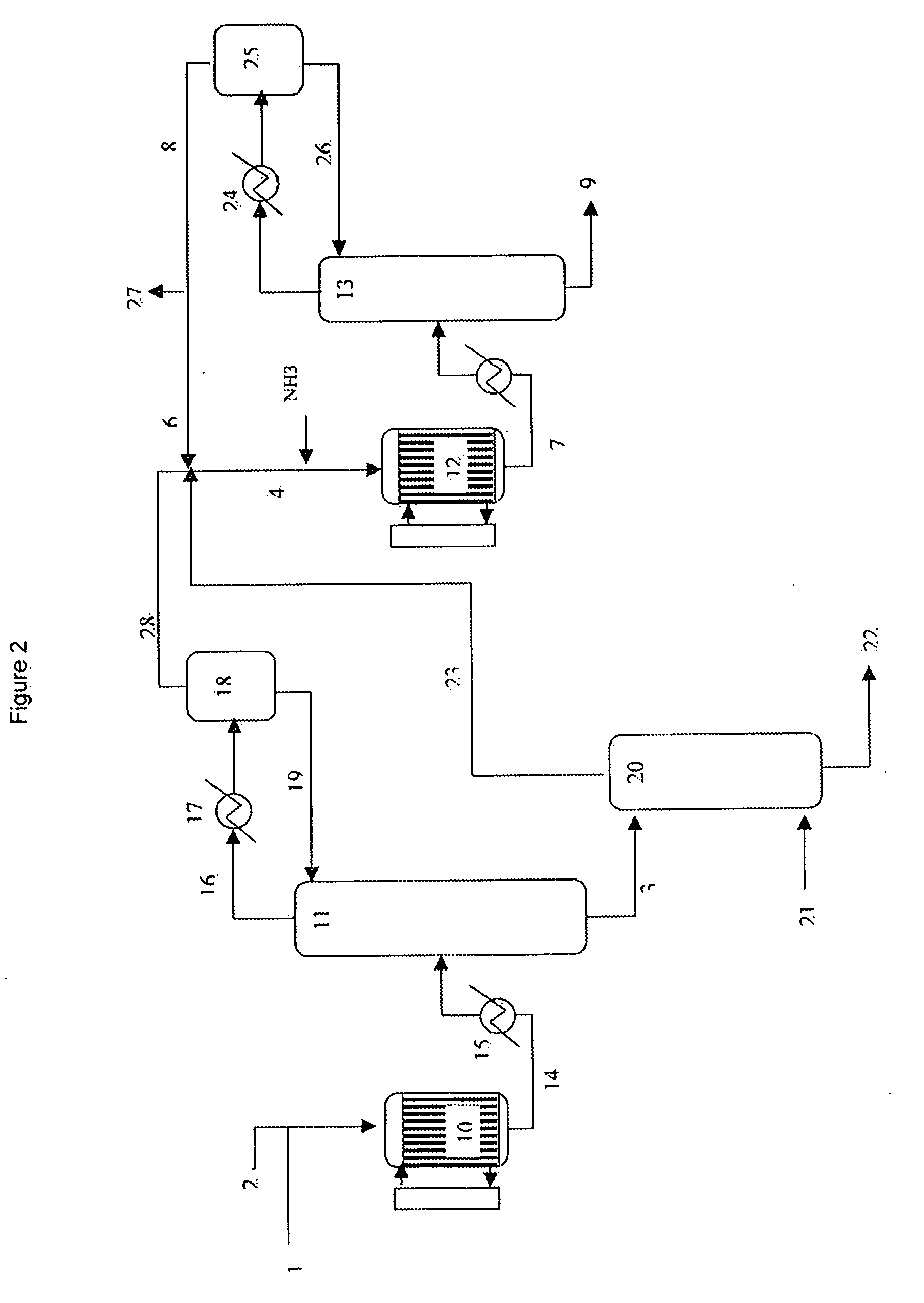

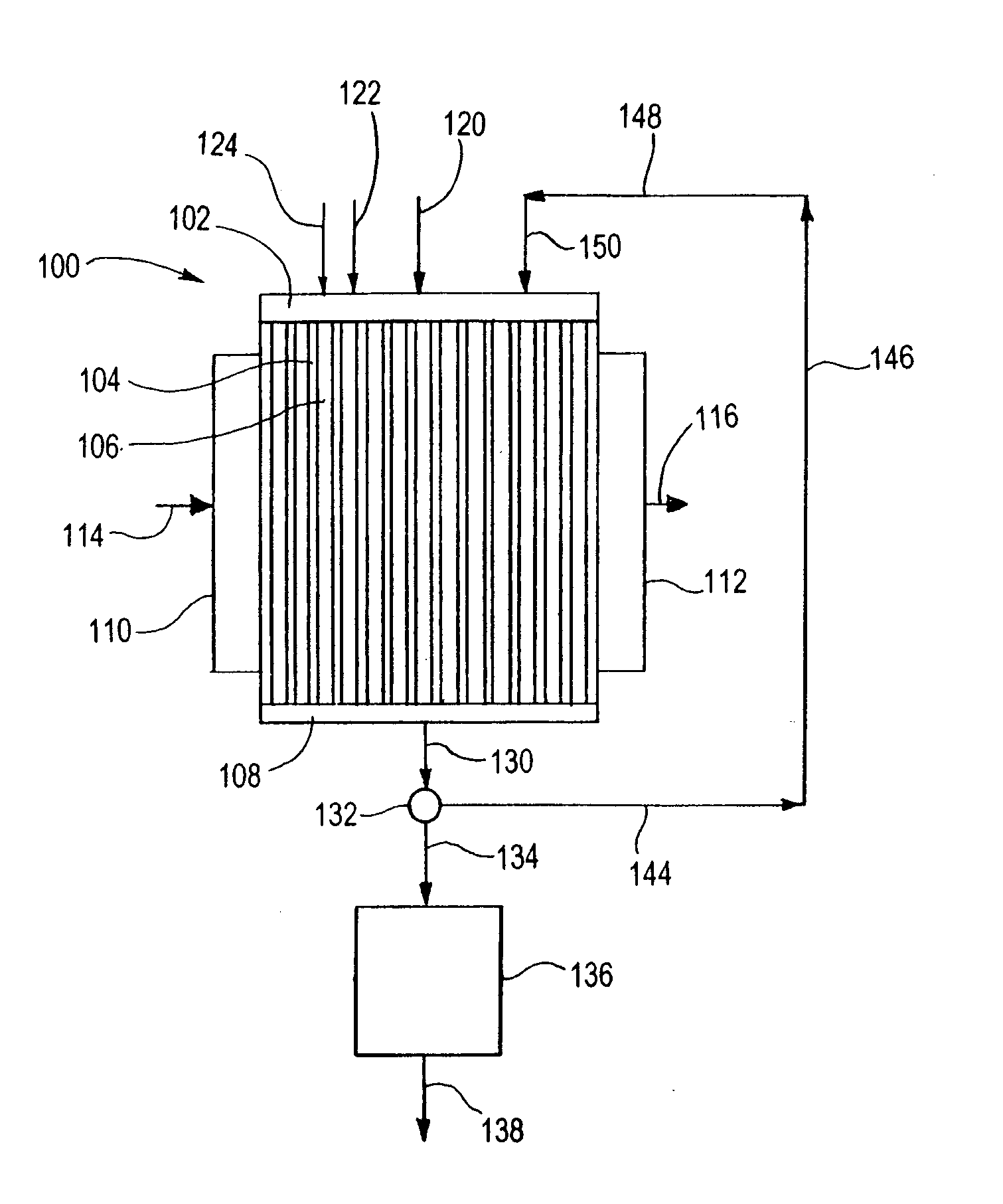

This invention relates to a process for converting a hydrocarbon reactant to a product comprising an oxygenate or a nitrile, the process comprising: (A) flowing a reactant composition comprising the hydrocarbon reactant, and oxygen or a source of oxygen, and optionally ammonia, through a microchannel reactor in contact with a catalyst to convert the hydrocarbon reactant to the product, the hydrocarbon reactant undergoing an exothermic reaction in the microchannel reactor; (B) transferring heat from the microchannel reactor to a heat exchanger during step (A); and (C) quenching the product from step (A).

Owner:VELOCYS CORPORATION

Method for the synthesis of acrylonitrile from glycerol

InactiveUS20100048850A1Less heat releaseIncrease partial pressureOrganic compound preparationPreparation by hydrocarbon ammoxidationGas phaseGlycerol

The invention relates to a novel way to synthesize acrylonitrile from a renewable raw material and more particularly relates to a method for producing acrylonitrile by the ammoxidation of glycerol in gaseous phase. The method can be implemented in a single step, or the glycerol can be previously submitted to a dehydration step. The acrylonitrile thus obtained meets the requirements of green chemistry.

Owner:ARKEMA FRANCE SA

Process for converting a hydrocarbon to an oxygenate or a nitrile

InactiveUS20080031788A1Maximize contactOrganic compound preparationCarboxylic acid esters preparationHydrocotyle bowlesioidesOxygenate

This invention relates to a process for converting a hydrocarbon reactant to a product comprising an oxygenate or a nitrile, the process comprising: (A) flowing a reactant composition comprising the hydrocarbon reactant, and oxygen or a source of oxygen, and optionally ammonia, through a microchannel reactor in contact with a catalyst to convert the hydrocarbon reactant to the product, the hydrocarbon reactant undergoing an exothermic reaction in the microchannel reactor; (B) transferring heat from the microchannel reactor to a heat exchanger during step (A); and (C) quenching the product from step (A).

Owner:VELOCYS INC

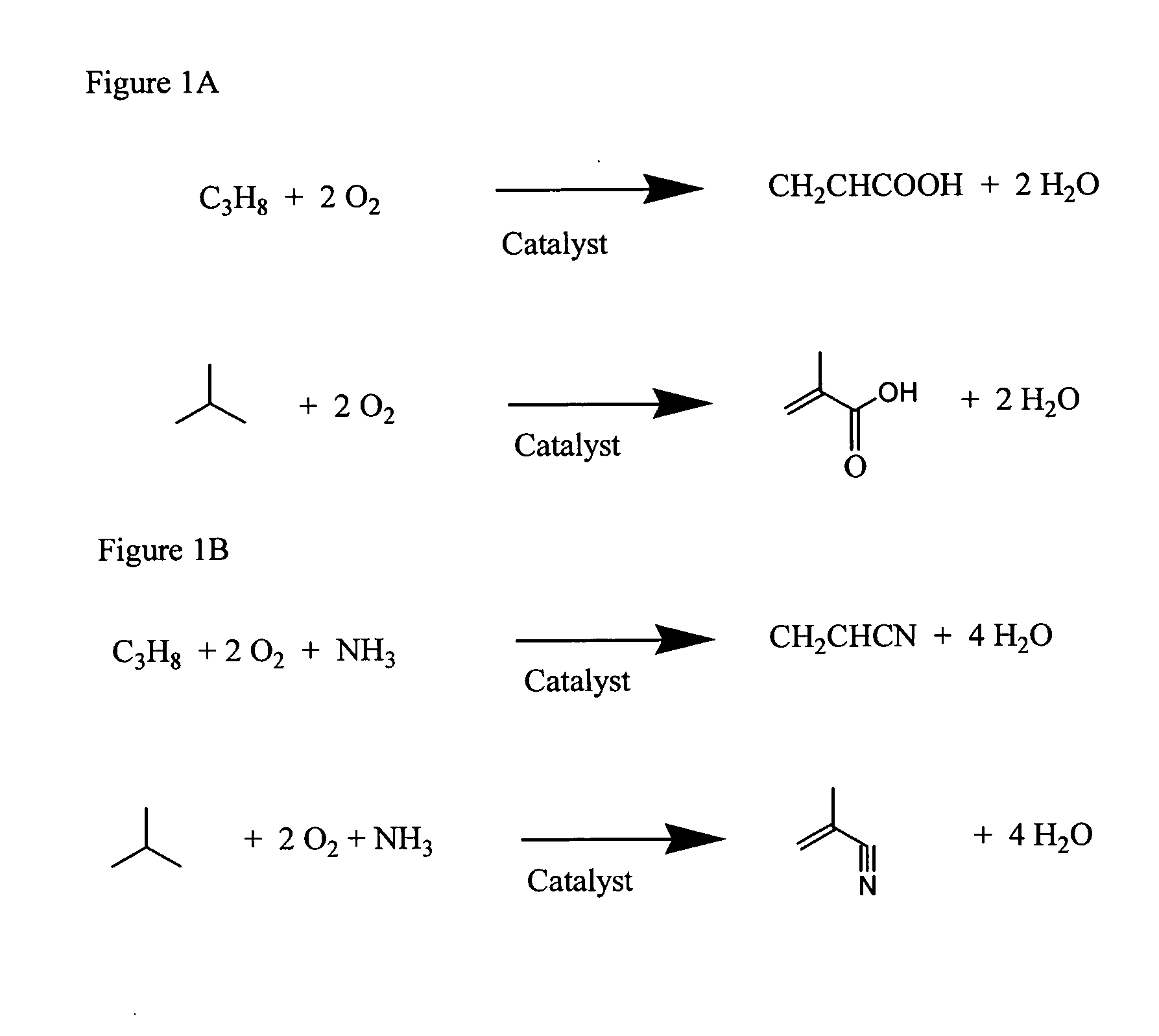

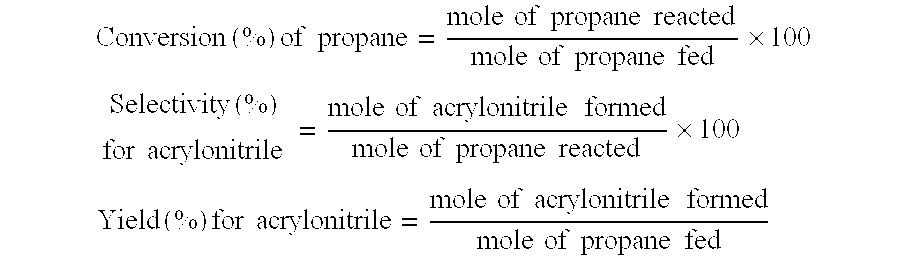

Process for producing acrylonitrile or methacrylonitrile from propane or isobutane by ammoxidation

Owner:ASAHI KASEI KK

Mixed metal oxide catalysts for propane and isobutane oxidation and ammoxidation, and methods of preparing same

InactiveUS20050054869A1Increase productionOrganic compound preparationHeterogenous catalyst chemical elementsNiobiumGas phase

Compositions of matter and catalyst compositions effective for gas-phase conversion of propane to acrylic acid (via oxidation) or to acrylonitrile (via ammoxidation) and isobutane to methacrylic acid (via oxidation) and isobutane to methacrylonitrile (via ammoxidation) are disclosed. Preferred catalyst compositions comprise molybdenum, vanadium, niobium, antimony and germanium and molybdenum, vanadium, tantalum, antimony, and germanium. Methods of preparing such compositions and related compositions, including hydrothermal synthesis methods are also disclosed. The preferred catalysts convert propane to acrylic acid and / or to acrylonitrile and isobutane to methacrylic acid / methacrylonitrile with a yield of at least about 50%.

Owner:INEOS USA LLC

Fluidized bed catalyst for prodn. of acrylonitrile

ActiveCN1751790AHigh purityPromote oxidationPreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsFluidized bedAcrylonitrile

A fluidized-bed catalyst for preparing acrylonitrile by ammoxidizing propene is composed of SiO2 as carrier and the composition AaBbCcNidFeeBifM012Ox, where A is chosen from Li, Na, K, Rb and Cs, B is chosen from W, P, B, Ga, Cr, Sb, Al, Ge, Nb and V, and C is chosen from Ag, Cu and their mixture. Its advantages are high power to bear high reaction pressure and propene load, and high conversion rate and output rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

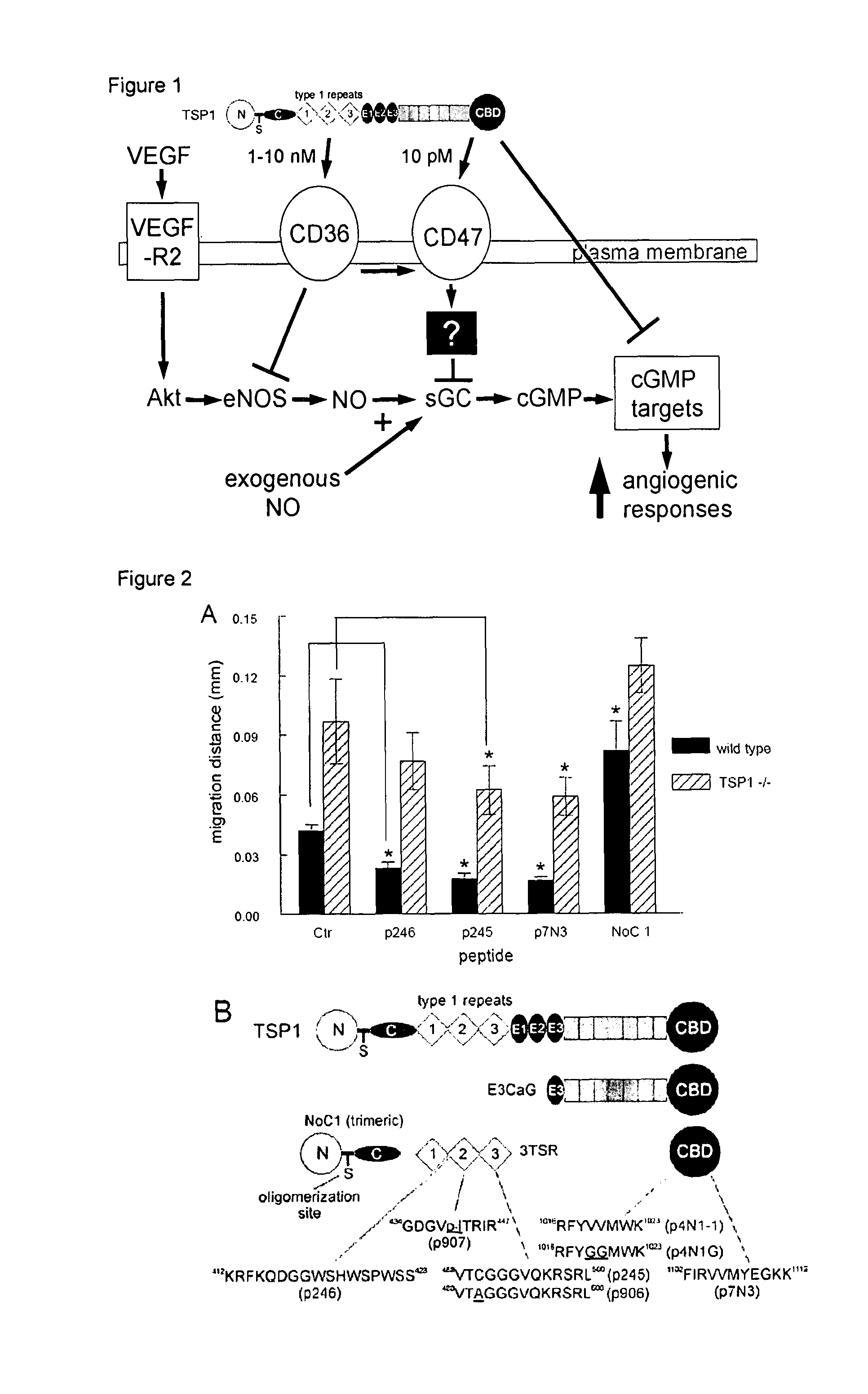

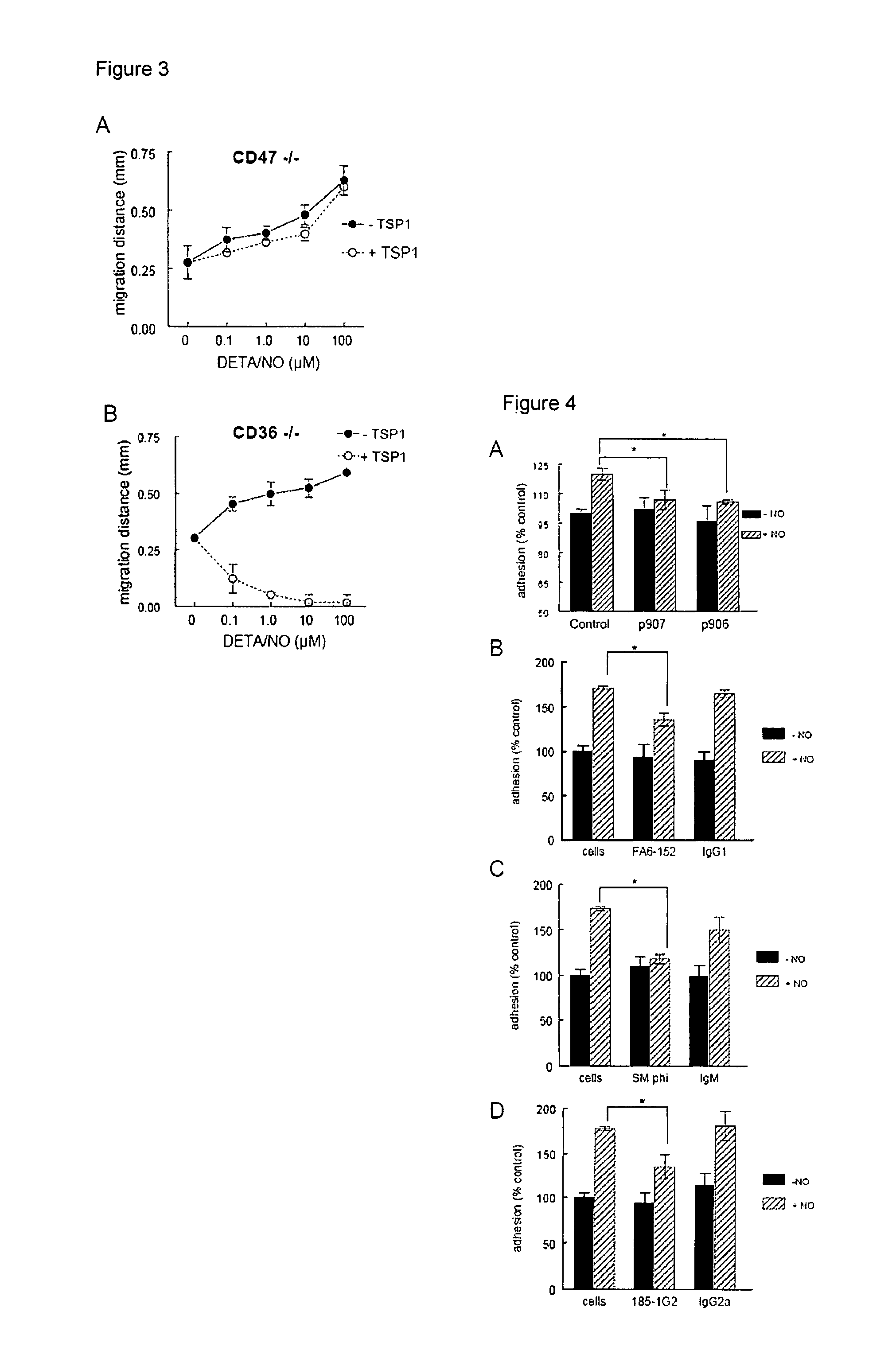

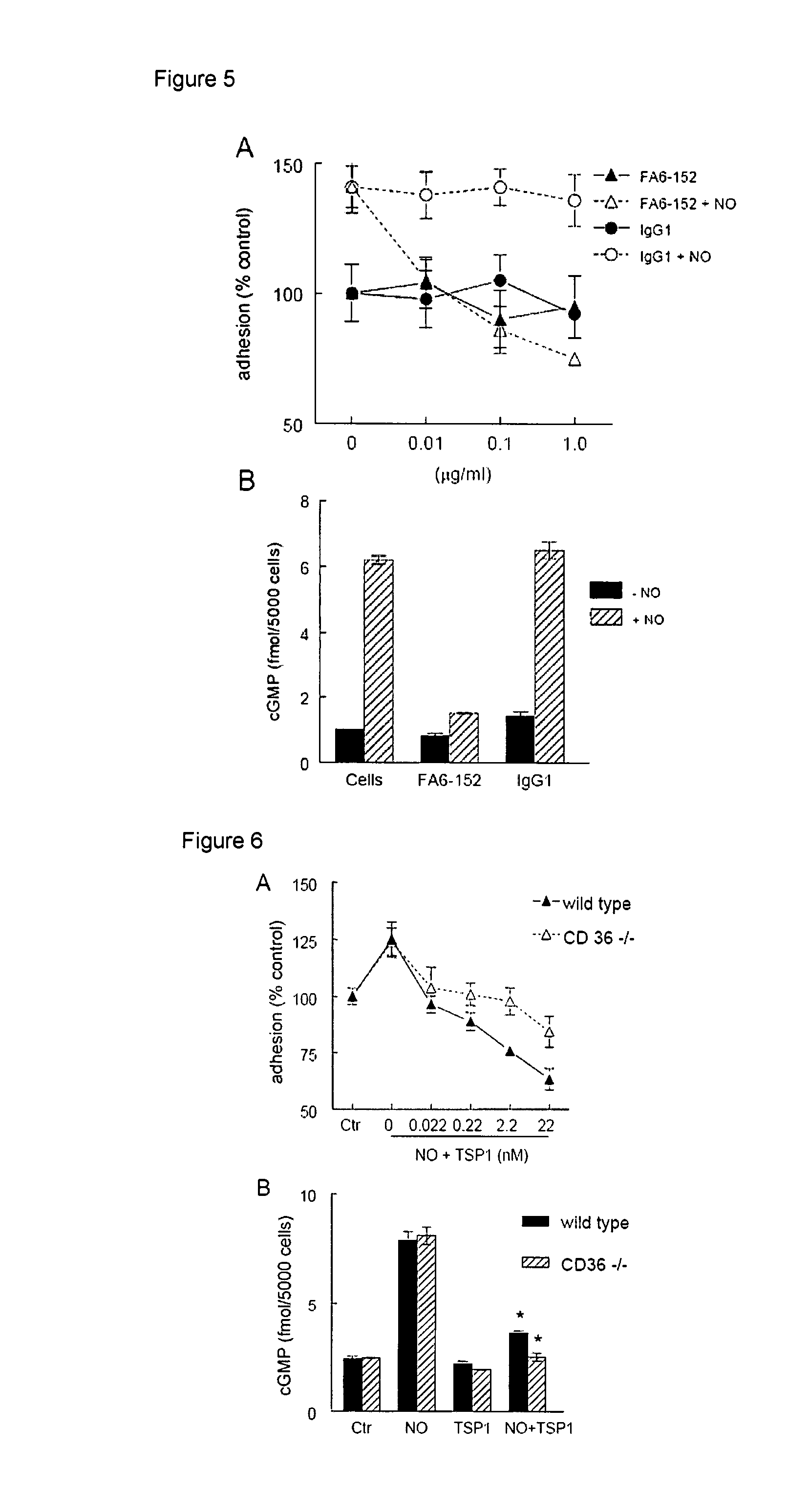

Prevention of tissue ischemia, related methods and compositions

ActiveUS8236313B2Increase blood flowIncrease oxygenationPeptide/protein ingredientsGenetic material ingredientsCoronary artery diseaseWhole body

Provided herein are compositions and methods for preventing, ameliorating, and / or reducing tissue ischemia and / or tissue damage due to ischemia, increasing blood vessel diameter, blood flow and tissue perfusion in the presence of vascular disease including peripheral vascular disease, atherosclerotic vascular disease, coronary artery disease, stroke and influencing other conditions, by suppressing CD47 and / or blocking TSP1 and / or CD47 activity or interaction. Influencing the interaction of CD47-TSP1 in blood vessels allows for control of blood vessel diameter and blood flow, and permits modification of blood pressure and cardiac function. Under conditions of decreased blood flow, for instance through injury or atherosclerosis, blocking TSP1-CD47 interaction allows blood vessels to dilate and increases blood flow, tissue perfusion and tissue survival. This in turn reduces or prevents tissue necrosis and death. The therapeutics identified herein allow for precise regulation of blood flow to tissues and organs which need it, while substantially avoiding systemic complications. Methods and compositions described herein can be used to increase tissue survival under conditions of trauma and surgery, as well as conditions of chronic vascular disease. Also disclosed are methods for the treatment of elderly subjects using agents that affect TSP1 and CD47 and thereby affect tissue perfusion. Additionally, provided herein are compositions and methods for influencing blood coagulation, allowing for controlled increased or decreased blood clotting. Additionally, provided herein are compositions and methods for decreasing blood flow, as in the case of cancer through mimicking the effects of TSP1 and CD47 on blood vessel diameter and blood flow.

Owner:WASHINGTON UNIV IN SAINT LOUIS +1

Particulate porous ammoxidation catalyst

ActiveUS7473666B2High yieldIncrease productionOrganic compound preparationHeterogenous catalyst chemical elementsPore distributionNiobium

A particulate porous ammoxidation catalyst for use in producing acrylonitrile or methacrylonitrile by reacting propylene, isobutene or tert-butyl alcohol with molecular oxygen and ammonia in a fluidized-bed reactor, the catalyst comprising a metal oxide and a silica carrier having supported thereon the metal oxide, wherein the metal oxide contains at least two elements selected from the group consisting of molybdenum, bismuth, iron, vanadium, antimony, tellurium and niobium, and the catalyst having a particle diameter distribution wherein the amount of catalyst particles having a particle diameter of from 5 to 200 μm is from 90 to 100% by weight, based on the weight of the catalyst, and having a pore distribution wherein the cumulative pore volume of pores having a pore diameter of 80 Å or less is not more than 20%, based on the total pore volume of the catalyst and wherein the cumulative pore volume of pores having a pore diameter of 1,000 Å or more is not more than 20%, based on the total pore volume of the catalyst. A method for efficiently producing this catalyst.

Owner:ASAHI KASEI CHEM CORP

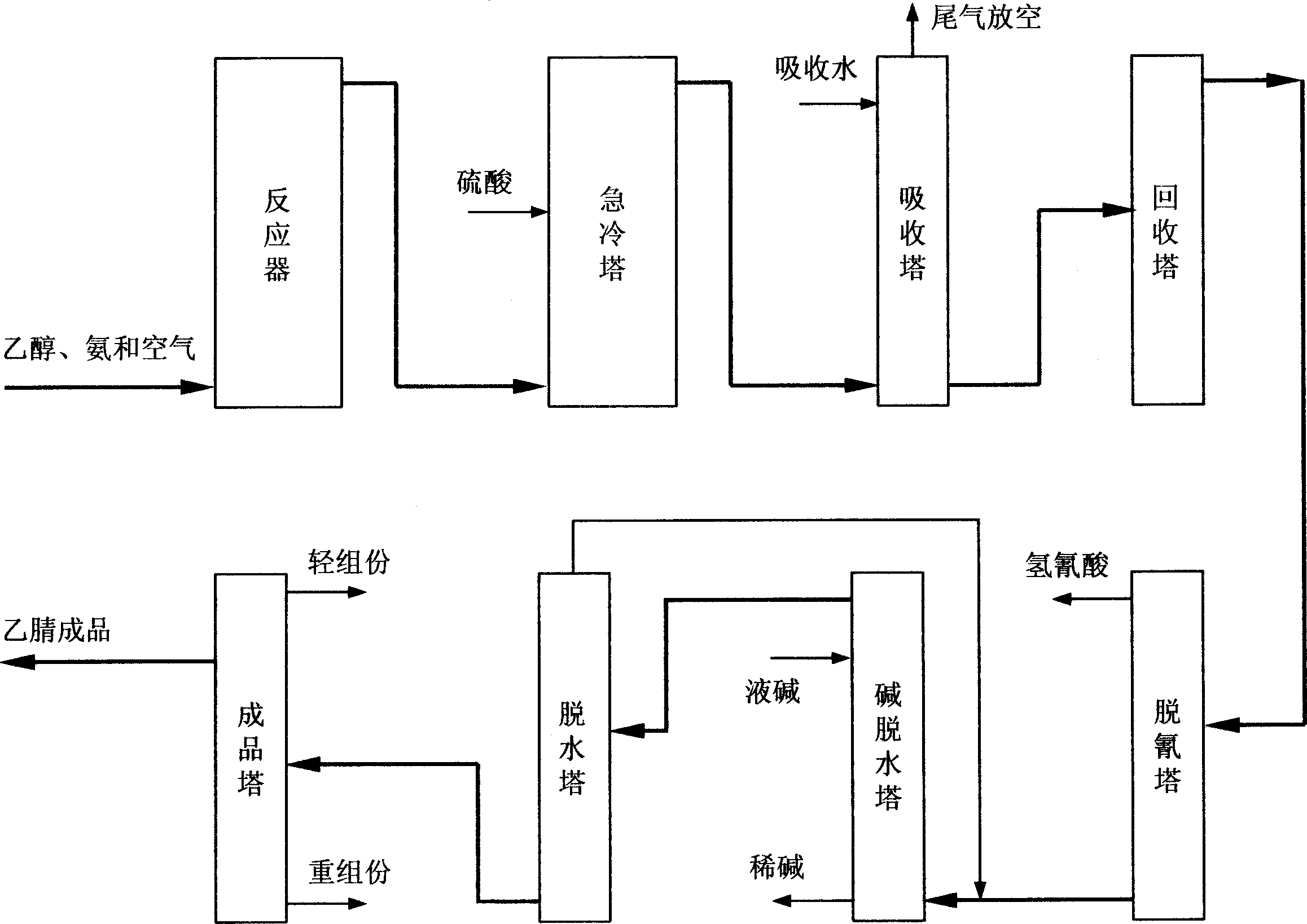

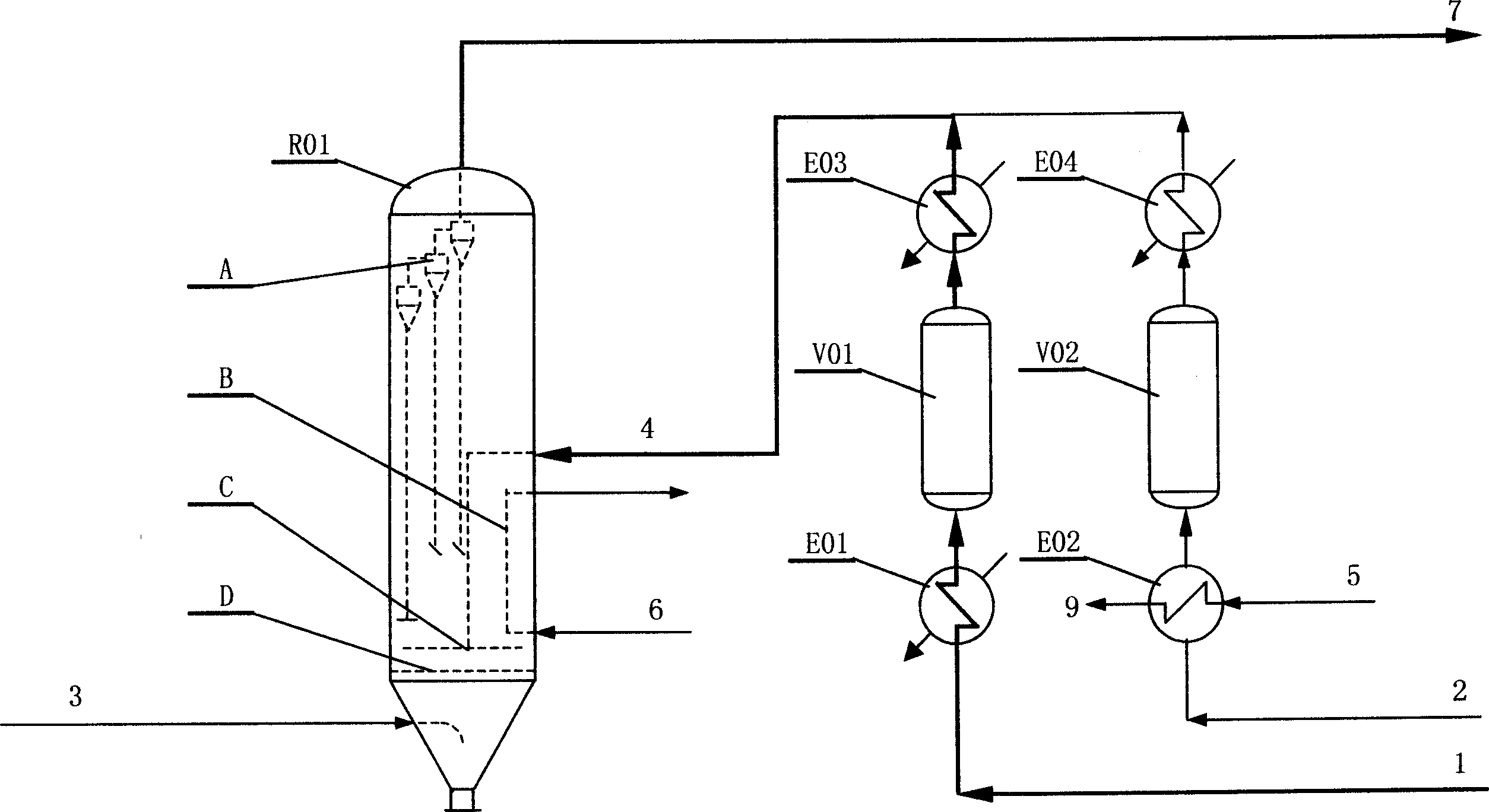

Ethanol ammoxidizing process to synthesize high-purity acetonitrile

InactiveCN1440963AReduce typesReduce contentPreparation by hydrocarbon ammoxidationChemical treatmentSide chain

The present invention belongs to preparation of aliphatic nitrile or carbocycle and heterocycle compound side chain nitrile, and is especially ethanol ammoxidizing process to synthesize high-purity acetonitrile. Fluidized bed catalytic reaction technology and continuous recovering and refining technology are adopted; and the process features the utilization of ethanol, ammonia and air as main material. Compared with available technology, the acetonitrile product has purity has high as 99.9% and less kinds of impurity, lower power consumption and less waste and waste gas prdouced. The product may be further processed into chromatographic product.

Owner:张华堂

Oxide catalyst for oxidation or ammoxidation

InactiveUS7109144B2High selectivityEasy to useOrganic compound preparationOrganic chemistry methodsAlkaline earth metalIndium

Disclosed is an oxide catalyst for use in catalytic oxidation or ammoxidation of propane or isobutane in the gaseous phase, which comprises a composition represented by the Mo1VaSbbNbcZdOn (wherein: Z is at least one element selected from the group consisting of tungsten, chromium, titanium, aluminum, tantalum, zirconium, hafnium, manganese, iron, ruthenium, cobalt, rhodium, nickel, palladium, platinum, zinc, boron, indium, germanium, tin, lead, bismuth, yttrium, gallium, rare earth elements and alkaline earth metals: and a, b, c, d, and n are, respectively, the atomic ratios of V, Sb, Nb, Z and O, relative to Mo), wherein 0.1≦a<0.4, 0.1<b≦0.4, 0.01≦c≦0.3, 0≦d≦1, with the proviso that a<b, and n is a number determined by and consistent with the valence requirements of the other elements present. Also disclosed is a process for producing an unsaturated carboxylic acid or an unsaturated nitrile by using the above-mentioned oxide catalyst.

Owner:ASAHI KASEI KK

Mixed metal oxide ammoxidation catalysts

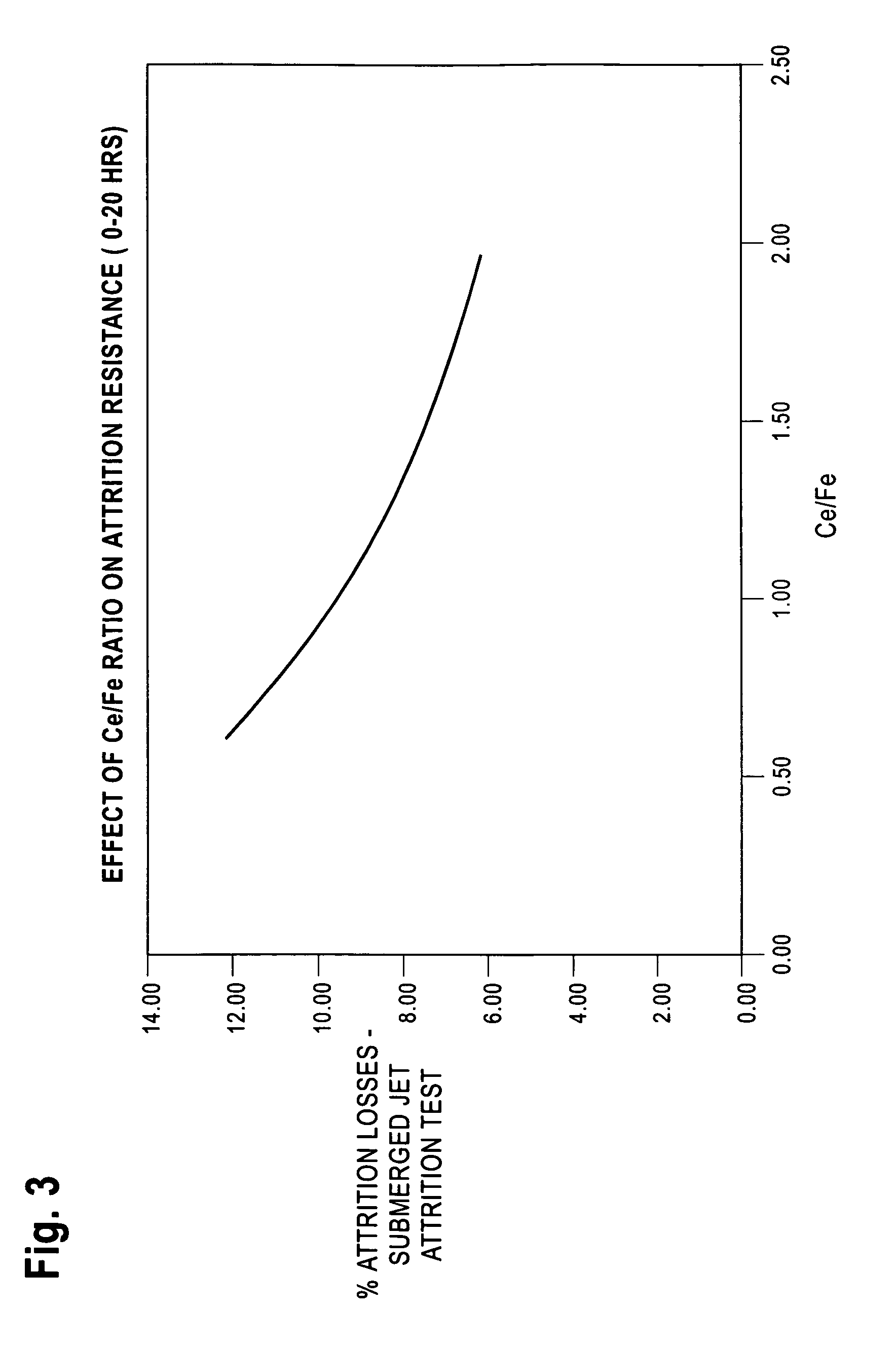

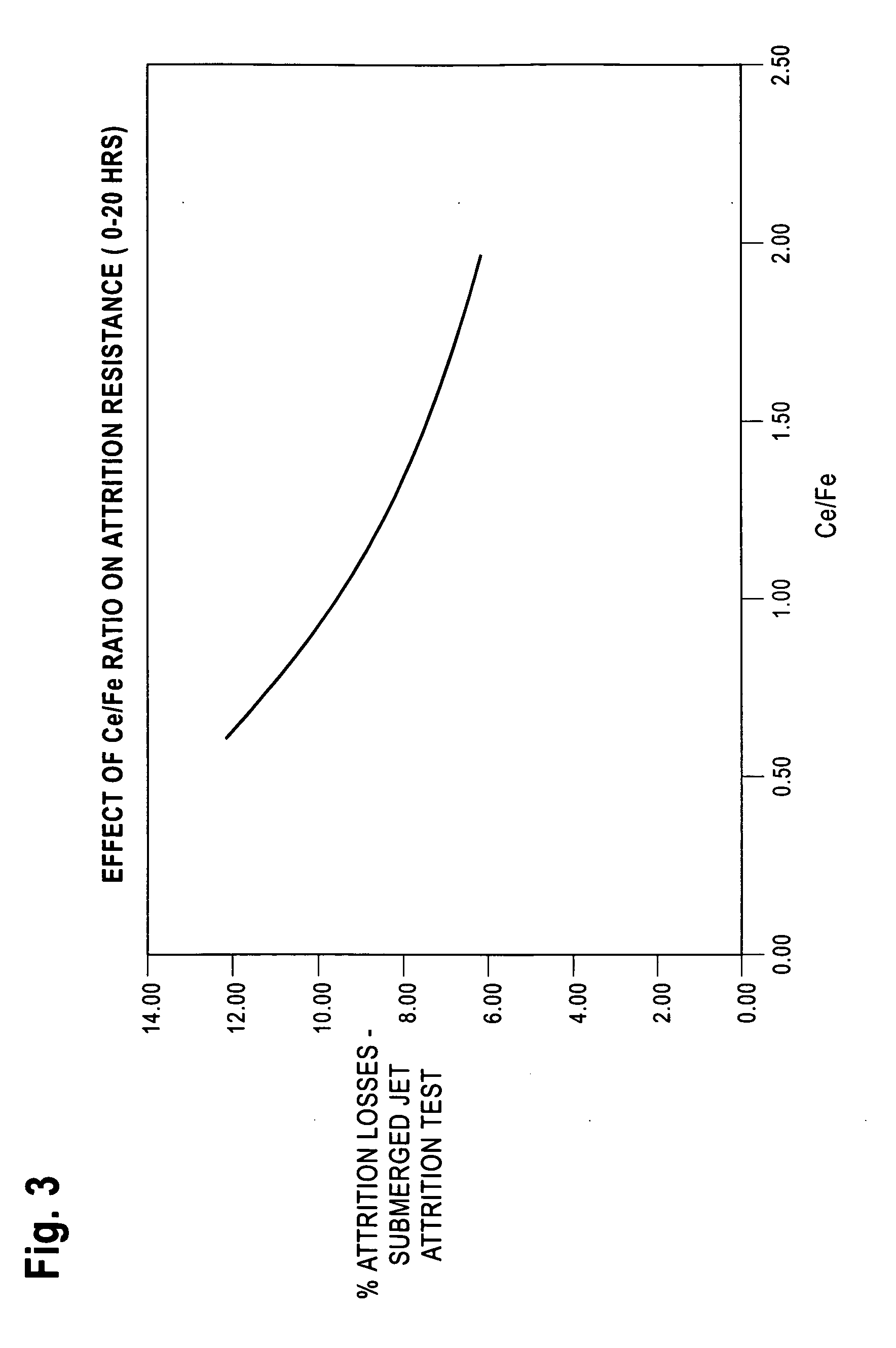

ActiveUS8153546B2Promote conversionHeterogenous catalyst chemical elementsCatalyst activation/preparationCrystallographyCerium

Owner:INEOS EURO LTD

Composition and method for improving density and hardness of fluid bed catalysts

InactiveUS20060199730A1Heterogenous catalyst chemical elementsPreparation by hydrocarbon ammoxidationOxidation stateVolumetric Mass Density

A catalyst composition for the oxidation and ammoxidation of hydrocarbons comprising a plurality of silica sol particles with different average particle sizes, and a complex of metal catalytic oxides having the formula: AaBbCcBidMOeOx, wherein (i) A is one or more of Li, Na, K, Cs, Rb, In, and TI B is one or more of Ni, Mn, Co, Mg, Ca, and Zn C is one or more of Fe, Cr, Ce, Cu, V, W, Sb, Sn, Ge, P, B, Ga, Te, Nb, and Ta, a is 0.0-1.0 b is 0.0-12.0 c is 1.0-12.0 d is 0.0-2.0 e is 12.0-14.0; or AaBbSb12Ox, wherein (ii) A is one or more of Fe, Cr, Ce, V, U, Sn, Ti, Ga, and Nb B is one or more of Mo, W, Co, Cu, Te, Bi, Ni, Ca, and Ta a is 0.1-16 b is 0.0-12.0. In both (i) and (ii), the value of x depends on the oxidation state of the metals used. Furthermore, a process for producing said ammoxidation catalyst is disclosed.

Owner:YKK CORP +1

Cocatalytic polymetallic oxide catalyst

A catalyst comprising an In promoted mixed metal oxide is useful for the vapor phase oxidation of an alkane, or a mixture of an alkane and an alkene, to an unsaturated carboxylic acid and for the vapor phase ammoxidation of an alkane, or a mixture of an alkane and an alkene, to an unsaturated nitrile.

Owner:ROHM & HAAS CO

Catalyst for the manufacture of acrylonitrile

ActiveUS20040110978A1Organic compound preparationHeterogenous catalyst chemical elementsRare-earth elementCerium

A catalyst comprising a complex of catalytic oxides comprising potassium, cesium, cerium, chromium, cobalt, nickel, iron, bismuth, molybdenum, wherein the relative ratios of these elements is represented by the following general formula AaKbCscCedCreCofNigXhFeiBijMo12Ox wherein A is Rb, Na, Li, Tl, or mixtures thereof, X is P, Sb, Te, B, Ge, W, Ca, Mg, a rare earth element, or mixtures thereof, a is about 0 to about 1, b is about 0.01 to about 1, c is about 0.01 to about 1, d is about 0.01 to about 3, e is about 0.01 to about 2, f is about 0.01 to about 10, g is about 0.1 to about 10, h is about 0 to about 4, i is about 0.1 to about 4, j is about 0.05 to about 4, x is a number determined by the valence requirements of the other elements present, and wherein the catalyst is substantially free of manganese and zinc. The catalyst is useful in processes for the ammoxidation of an olefin selected from the group consisting of propylene, isobutylene or mixtures thereof, to acrylonitrile, methacrylonitrile and mixtures thereof, respectively.

Owner:INEOS USA LLC

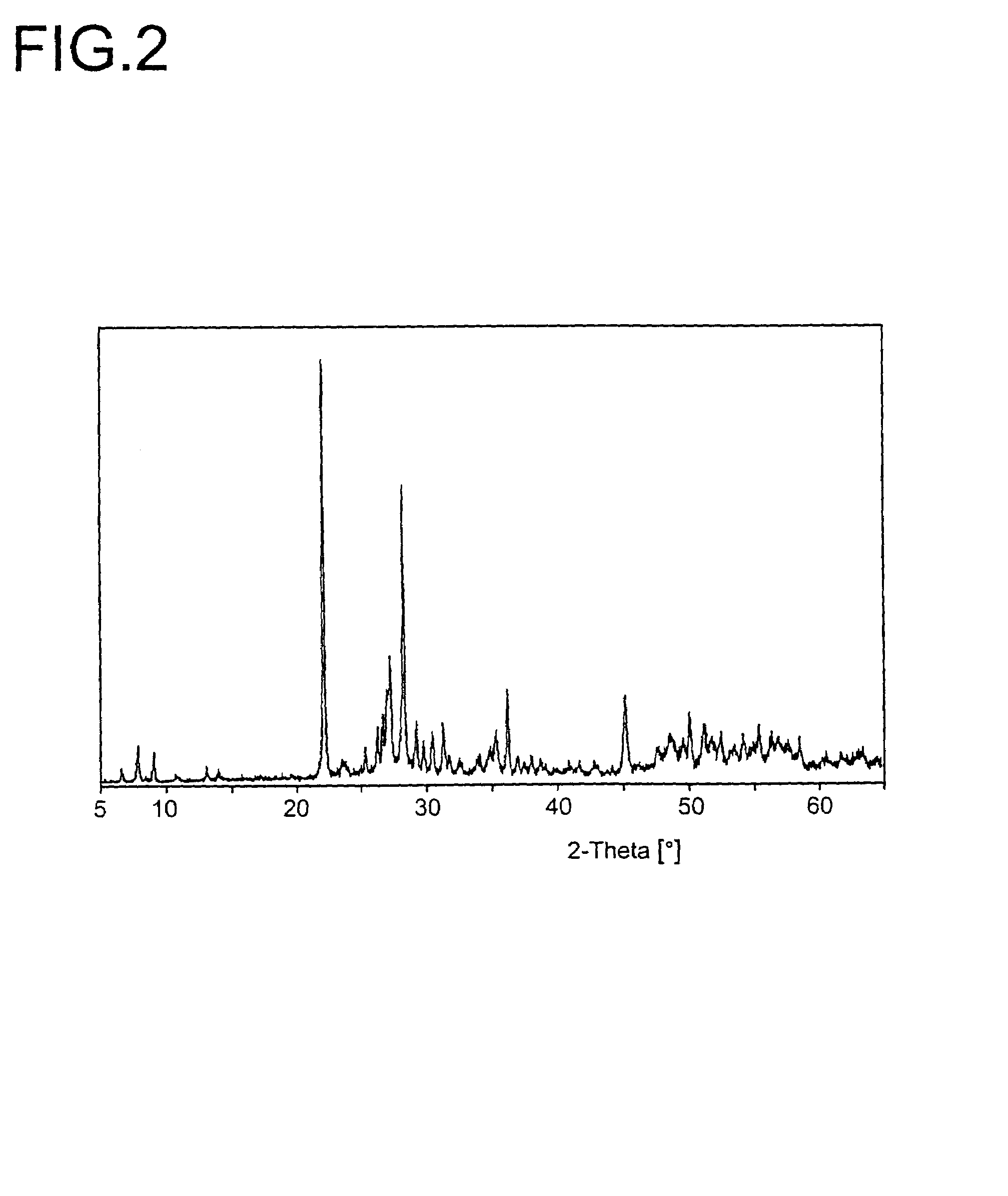

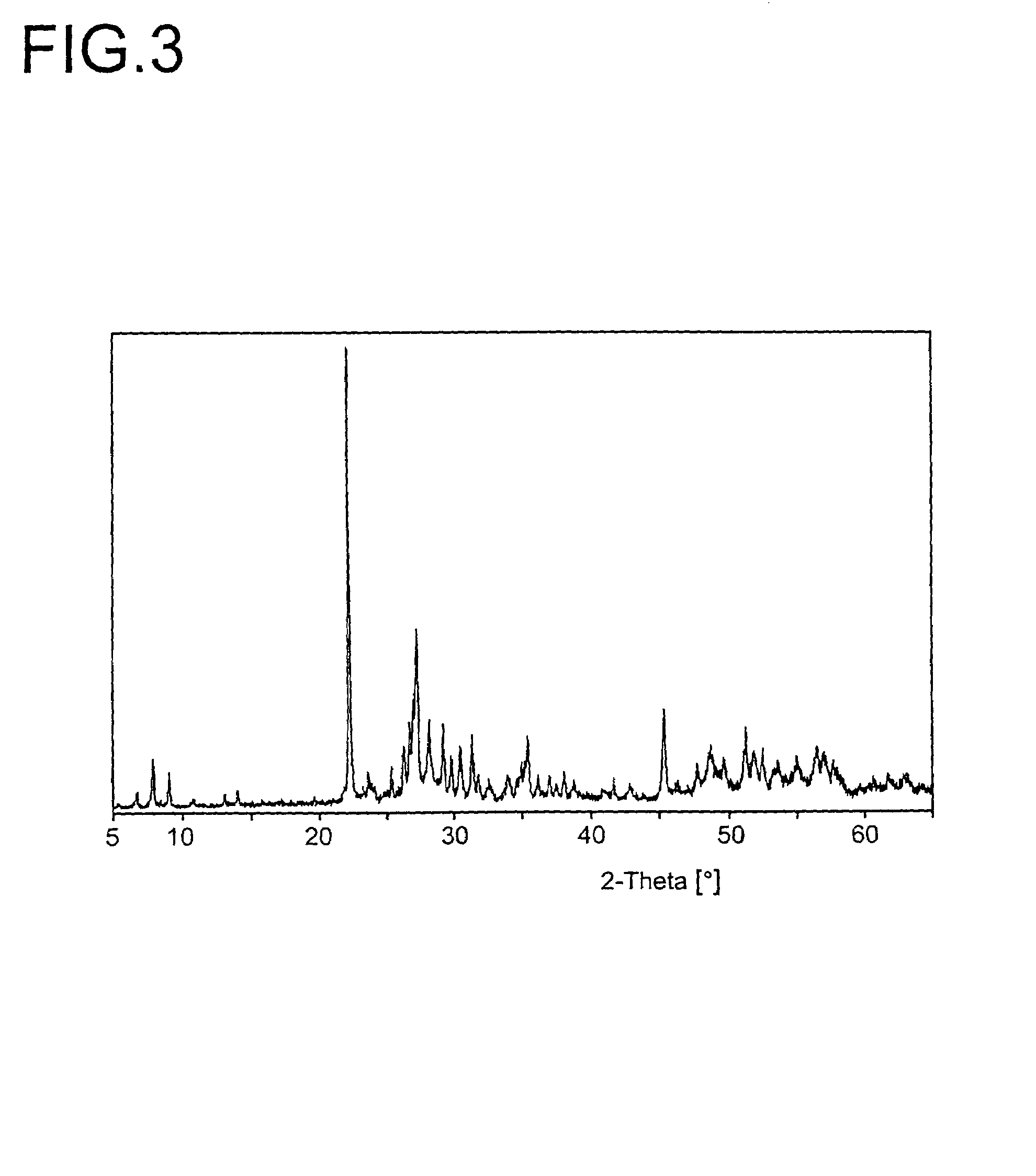

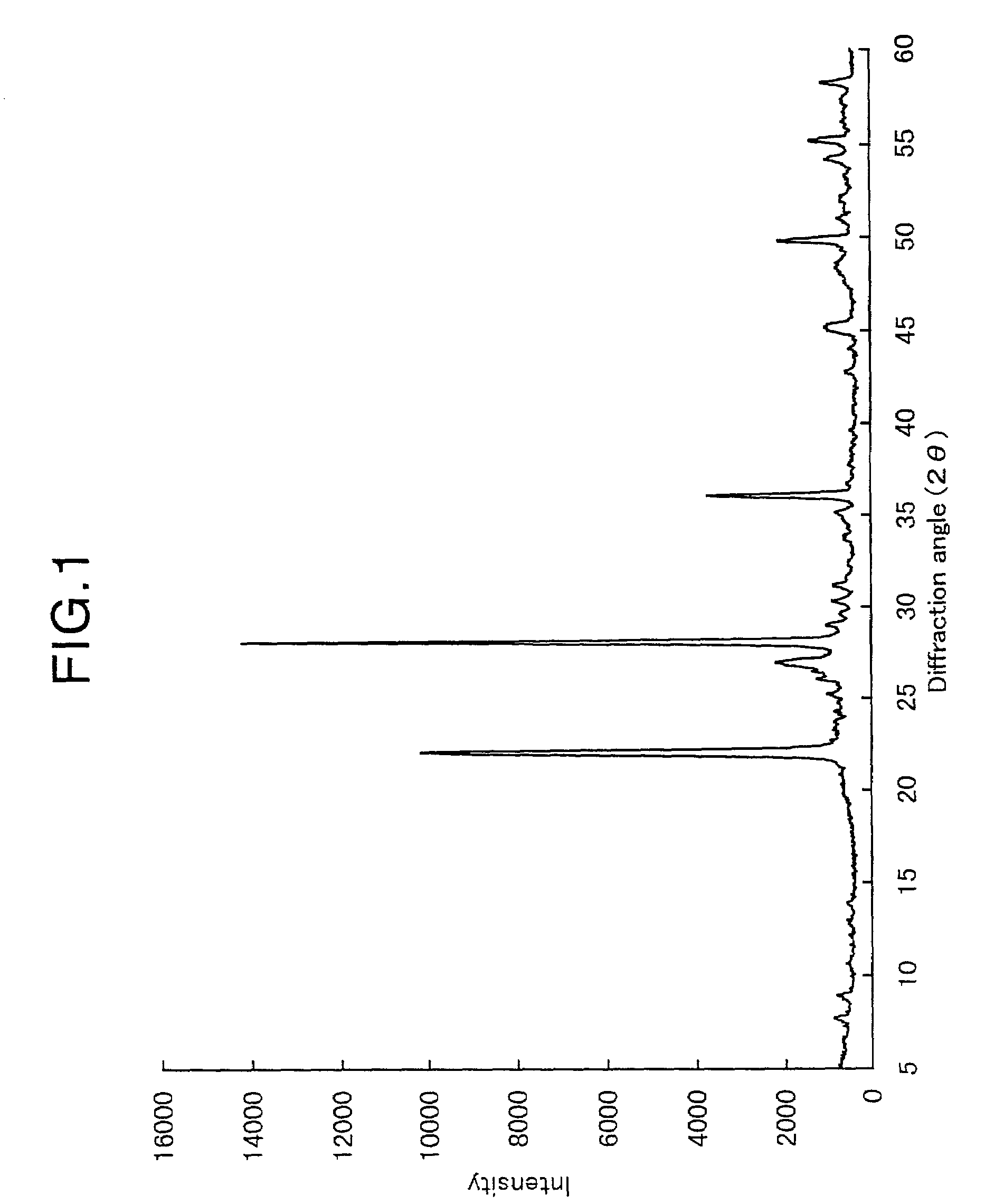

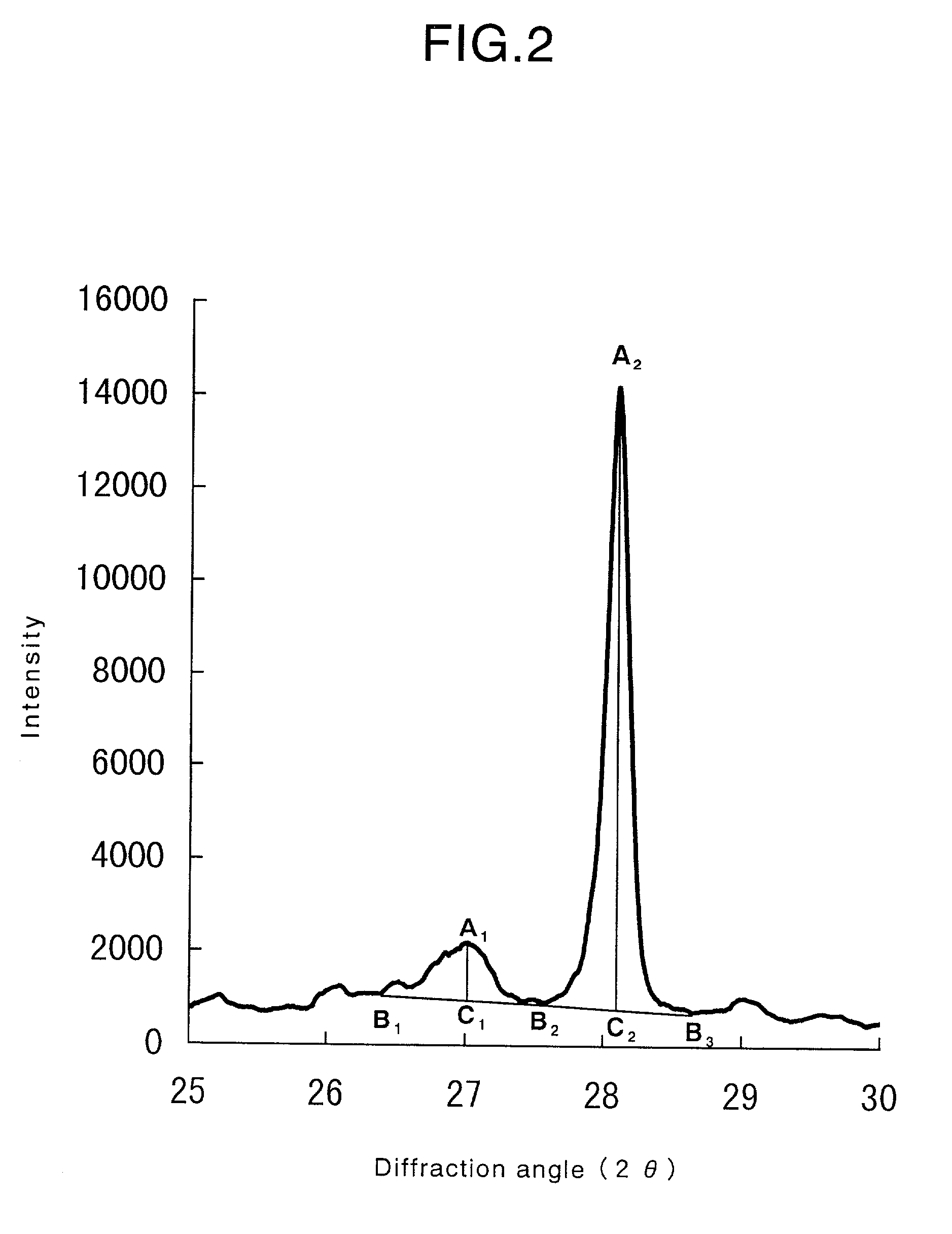

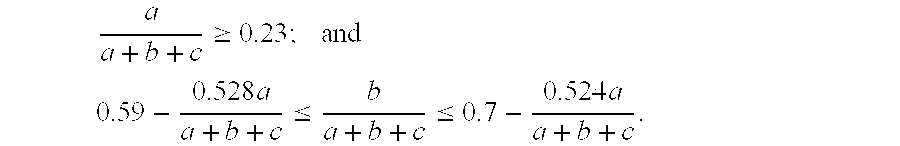

Mixed metal oxide ammoxidation catalysts

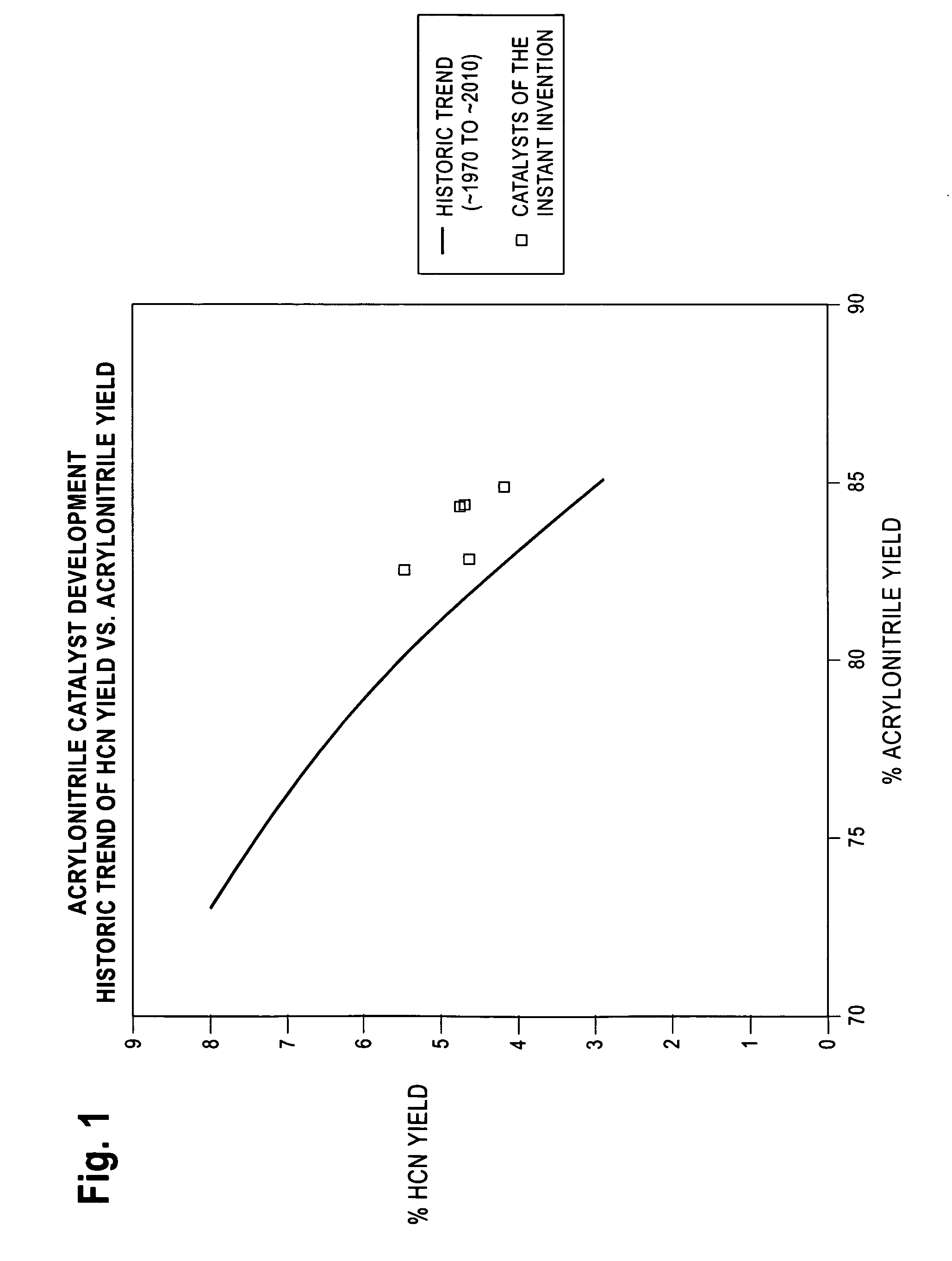

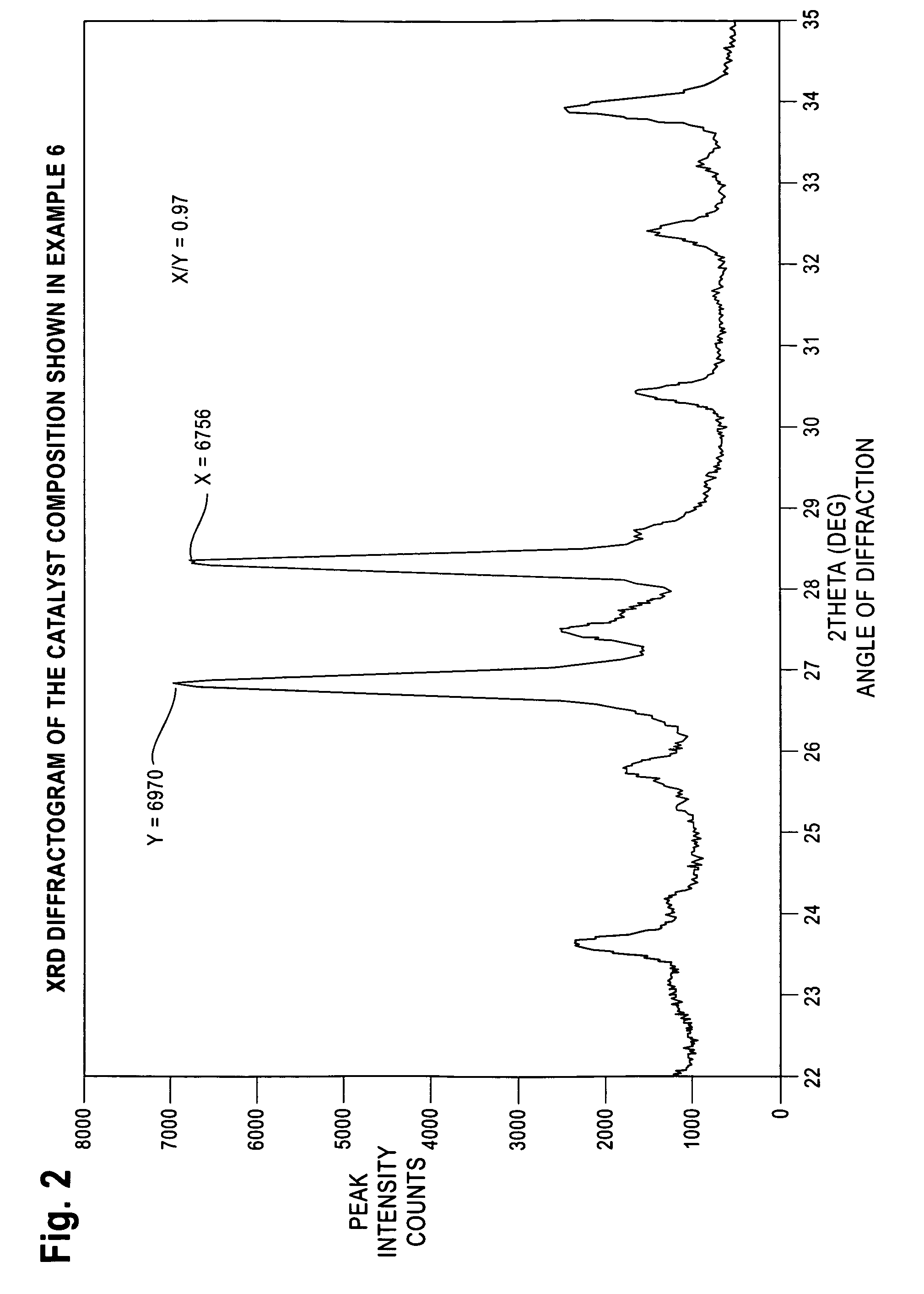

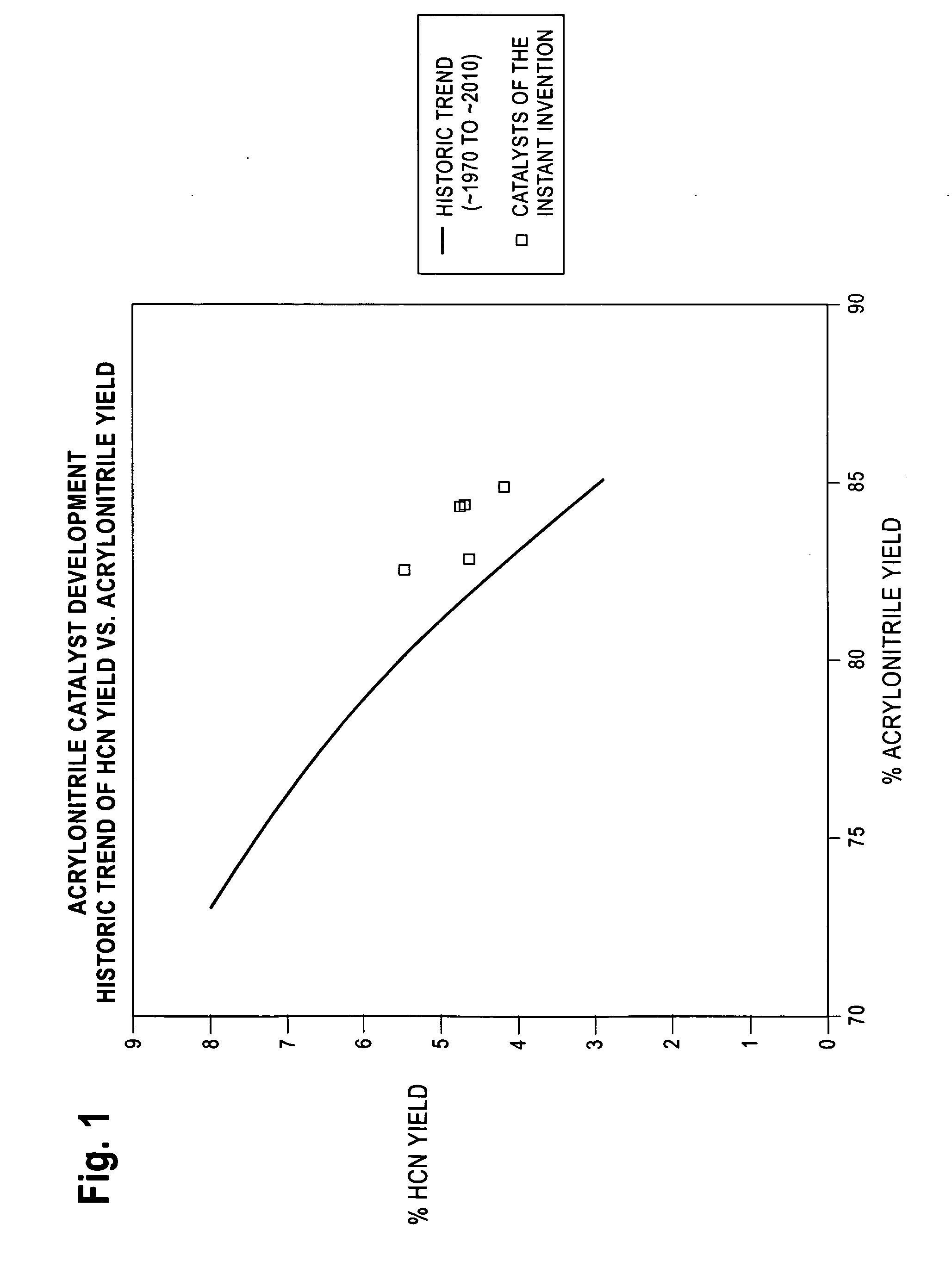

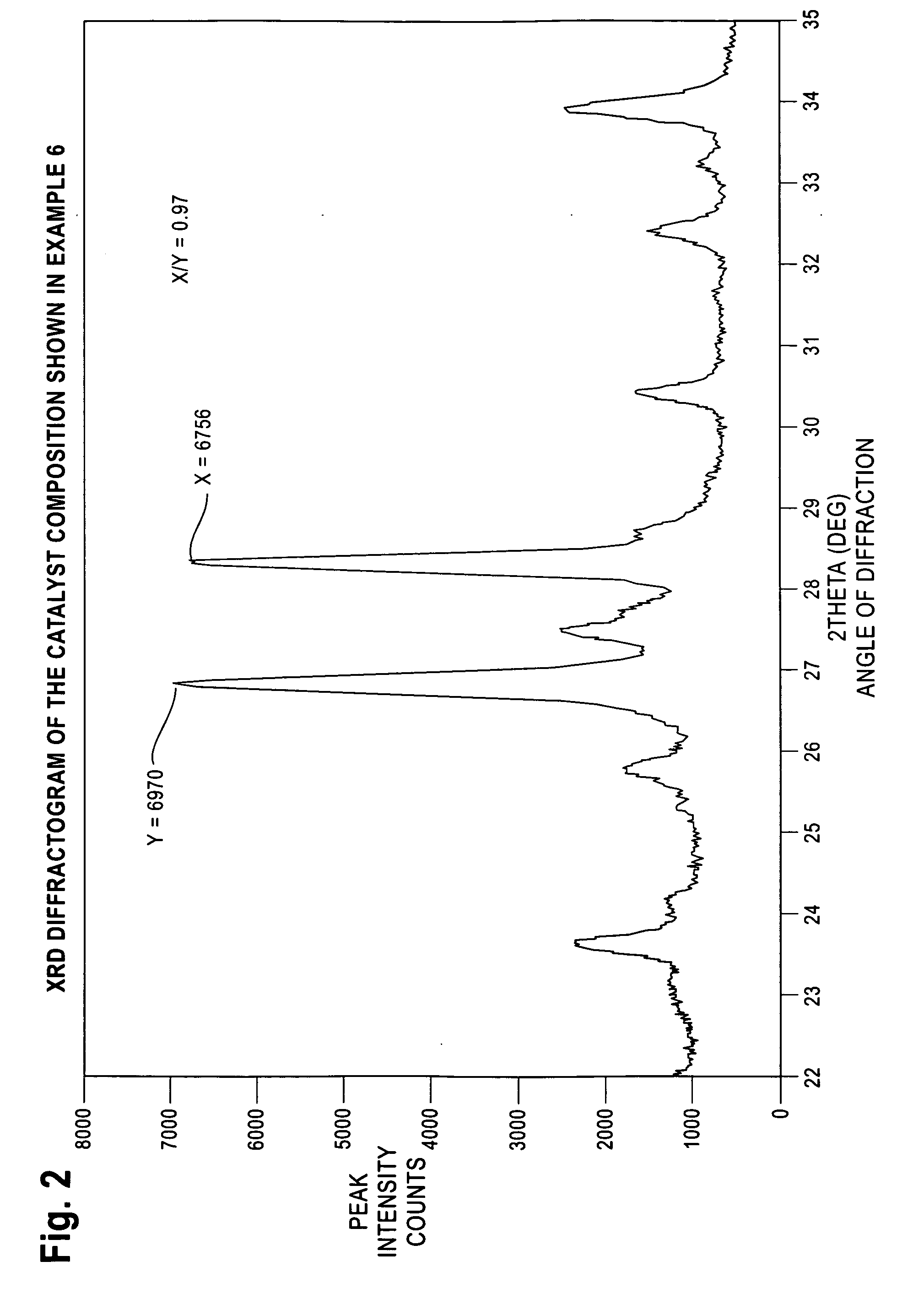

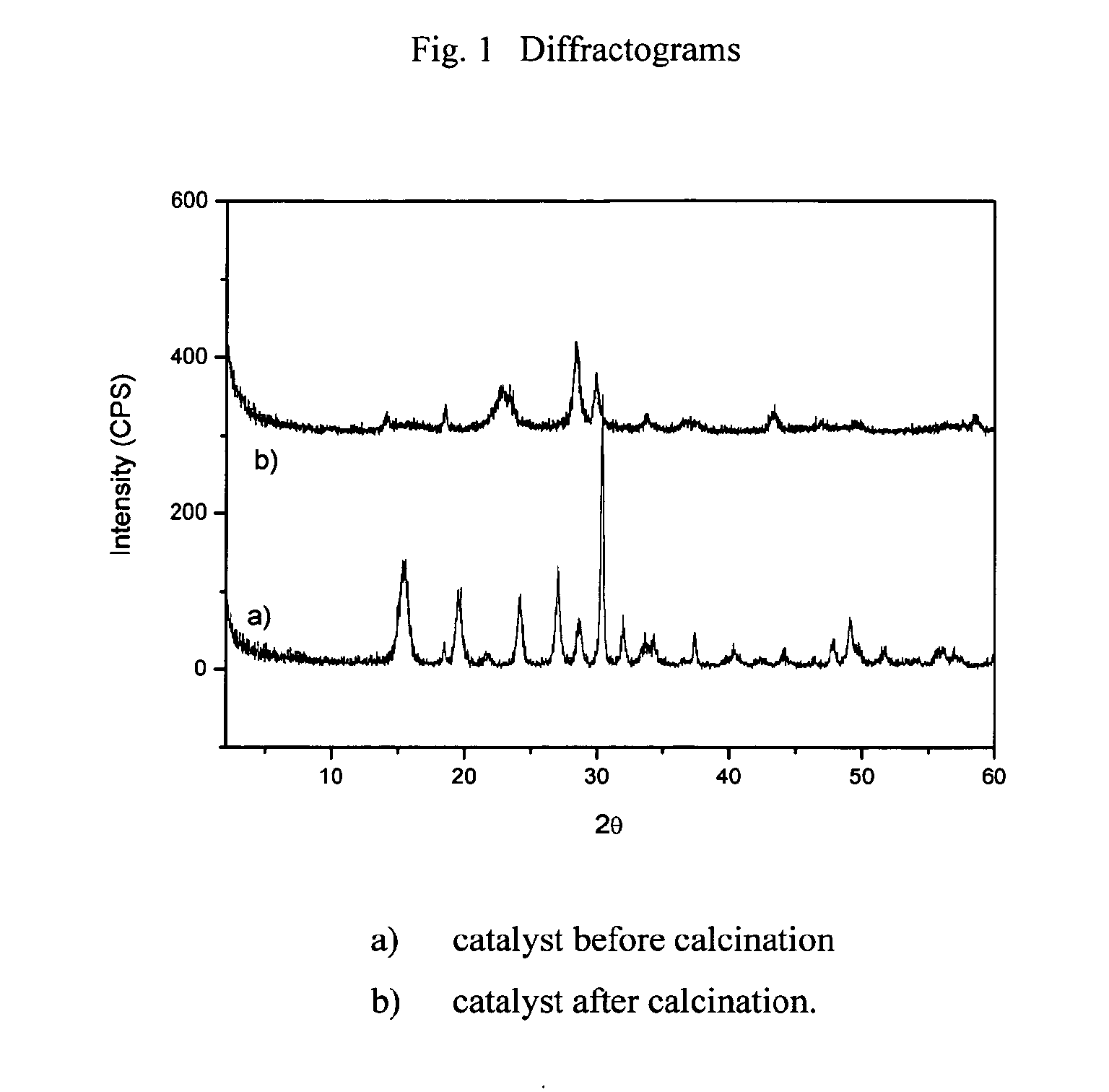

ActiveUS20110237753A1Promote conversionHeterogenous catalyst chemical elementsCatalyst activation/preparationCrystallographyCerium

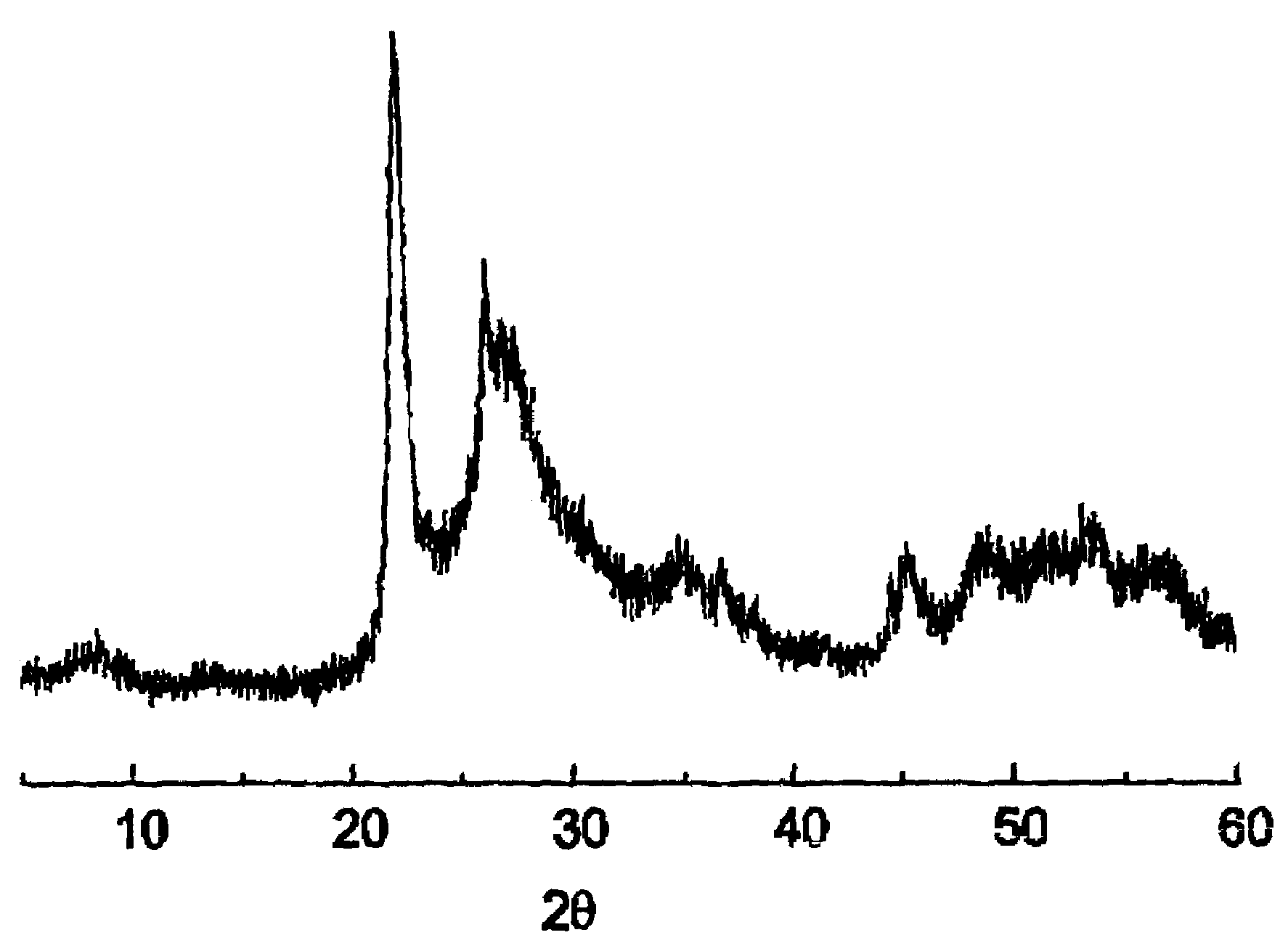

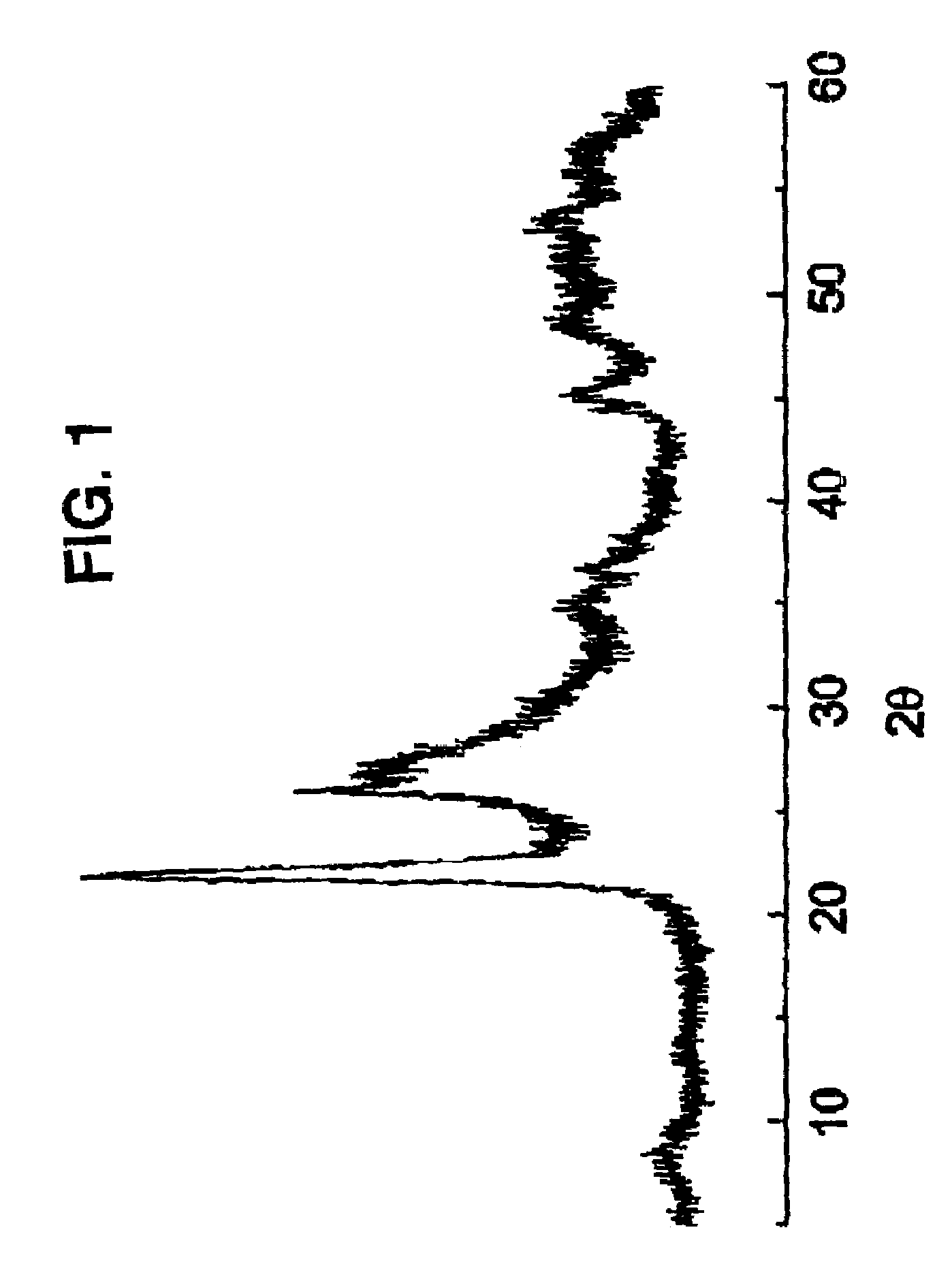

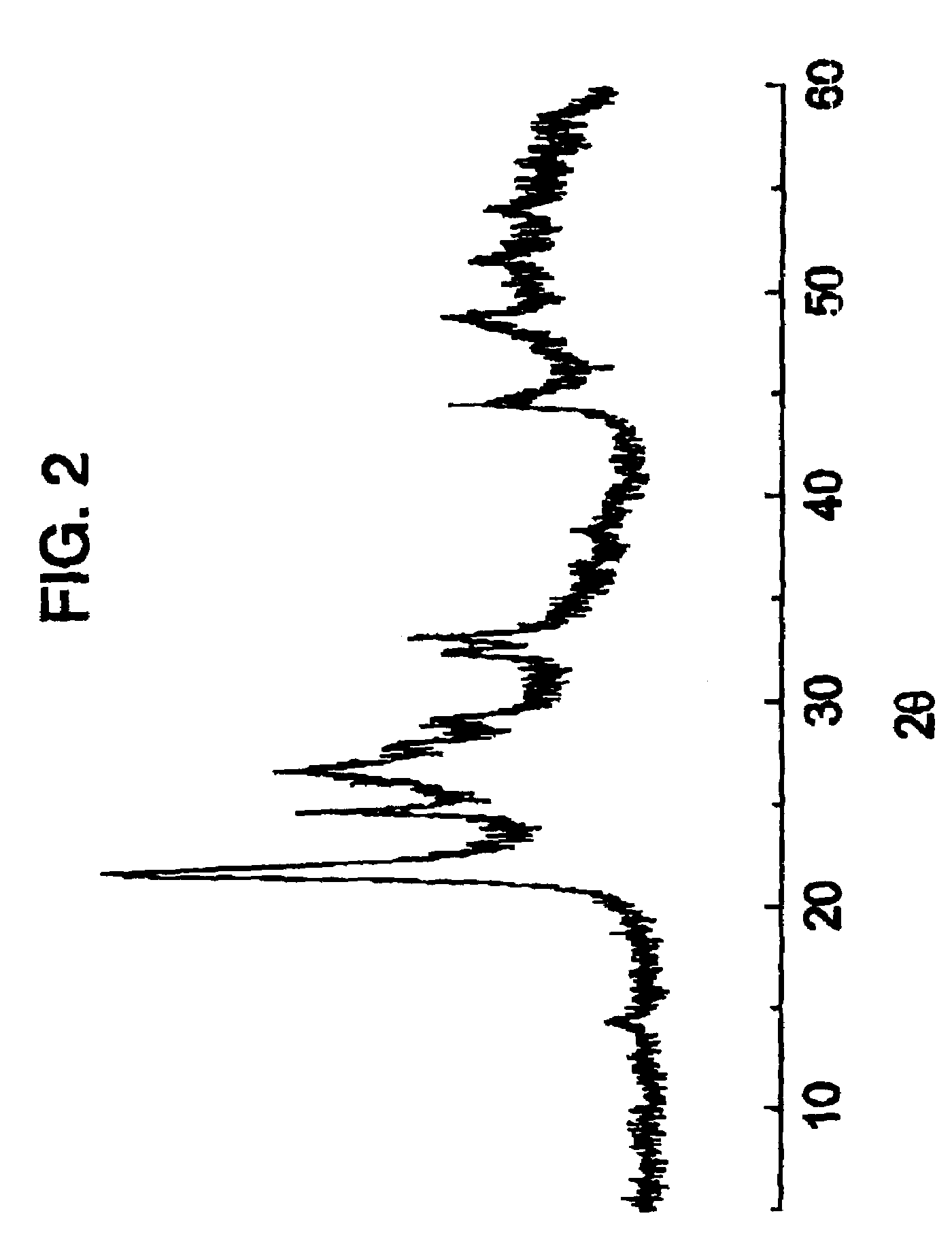

A catalytic composition useful for the conversion of an olefin selected from the group consisting of propylene, isobutylene or mixtures thereof, to acrylonitrile, methacrylonitrile, and mixtures thereof. The catalytic composition comprising a complex of metal oxides comprising bismuth, molybdenum, iron, cerium and other promoter elements, wherein the X-ray diffraction pattern of the catalytic composition has X-ray diffraction peaks at 2θ angle 28±0.3 degrees and 2θ angle 26.5±0.3 degrees, and wherein the ratio of the intensity of the most intense x-ray diffraction peak within 2θ angle 28±0.3 degrees to the intensity of most intense x-ray diffraction peak within 2θ angle 26.5±0.3 degrees is defined as X / Y, and wherein X / Y is greater than or equal to 0.7.

Owner:INEOS EURO LTD

Mixed metal oxide catalysts and catalytic conversions of lower alkane hydrocarbons

InactiveUS20080249328A1Facilitate ammoxidationHigh yieldMolecular sieve catalystsOrganic compound preparationAlkaneNiobium

Catalytic compositions and processes are disclosed for economical conversions of lower alkane hydrocarbons. Broadly, the present invention discloses solid compositions containing mixed metal oxides that exhibit catalytic activity for ammoxidation of lower alkane hydrocarbons to produce an unsaturated nitrile in high yield. Generally, these solid oxide compositions comprise, as component elements, molybdenum (Mo), vanadium (V) niobium (Nb) and at least one active element selected from the group consisting of the elements having the ability to form positive ions. Mixed metal oxide catalytic compositions advantageously comprise one or more crystalline phases at least one of which phases has predetermined unit cell volume and aspect ratio. Also described are methods for forming the improved catalysts having the desired crystalline structure and ammoxidation processes for conversion of lower alkanes.

Owner:INEOS USA LLC

Process for manufactguring acrolein from glycerol

InactiveUS20110213174A1High catalytic activityOrganic compound preparationPreparation by hydrocarbon ammoxidationGas phaseGlycerol

The subject of the present invention is a process for preparing acrolein by dehydration of glycerol in the presence of a catalyst system comprising oxygen, phosphorus and at least one metal chosen from vanadium, boron or aluminium. The process is preferably carried out in the gas phase in the presence of oxygen starting from aqueous solutions of glycerol.

Owner:ARKEMA FRANCE SA

Catalyst for oxidation or ammoxidation

ActiveUS20060235238A1Low yieldEfficient productionOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystGas phase

Disclosed is a catalyst for use in catalytic oxidation or ammoxidation of propane or isobutane in the gaseous phase, which comprises an oxide containing, in specific atomic ratios, molybdenum (Mo), vanadium (V), niobium (Nb) and antimony (Sb), wherein the oxide catalyst has a reduction ratio of from 8 to 12% and a specific surface area of from 5 to 30 m2 / g. Also disclosed is a process for efficiently producing this catalyst.

Owner:ASAHI KASEI CHEM CORP

Vanadium-containing catalysts, process for manufacturing and use of the same

InactiveUS6281378B1Efficient preparationGood dispersionOrganic compound preparationCarboxylic acid esters preparationBenzoic acidPartial oxidation

Vanadium-containing catalysts are obtained by using polyvanadic acid as a source of vanadium. Vanadium-containing catalysts are obtained by mixing catalyst components other than vanadium, or their precursors, with a polyvanadic acid sol which is formed by ion-exchanging a metavanadic acid aqueous solution with a proton-type cation-exchange resin and performing polycondensation, and by drying and / or calcining the mixture. Such vanadium-containing catalysts can fully exhibit their catalytic activity under mild reaction conditions, and can be suitably used for various reactions, such as synthesis of phthalic anhydride by the partial oxidation of o-xylene, synthesis of benzaldehyde by the partial oxidation of toluene, synthesis of benzoic acid by the partial oxidation of toluene, synthesis of anisaldehyde by the partial oxidation of p-methoxy toluene, synthesis of propylene by the oxidative dehydrogenation of propane, synthesis of isobutene by the oxidative dehydrogenation of isobutane, synthesis of methyl formate by the oxidative dehydrogenation of methanol, and synthesis of acrylonitrile by the ammoxidation of propane.

Owner:NIPPON SHOKUBAI CO LTD

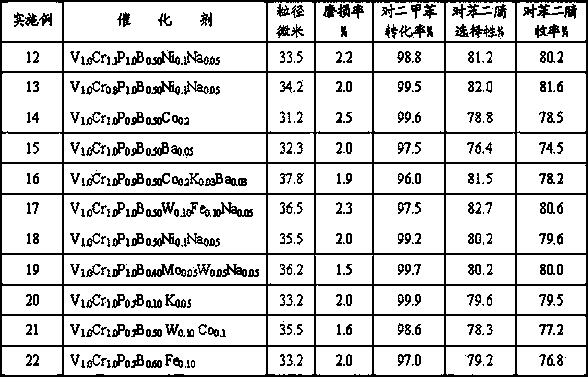

Aromatic ammoxidation fluidized bed catalyst, preparation method and application

ActiveCN106268890AHeterogenous catalyst chemical elementsPreparation by hydrocarbon ammoxidationLoss rateRare-earth element

The invention relates to a high-abrasion-resisting aromaticamm oxidation fluidized bed catalyst and a preparation method thereof. The technical problems of poor abrasion resistance properties, high in catalyst loss rate and high in production cost of an existing aromatic ammoxidation fluidized bed catalyst are mainly solved. The mixed catalyst of V1.0CraAbBcCdMeOx consists of a carrier and the compound shown as a chemical formula based on the atomic ratio, wherein A is selected from at least one of P, B, Bi, Sb and As elements, B is selected from at least one of Mn, Ni, Co, Ti, Sn, Mo or rare earth elements, C is selected from at least one of alkali metal or alkaline earth metal, M is selected from at least one of Zr and W. By the adoption of the technical scheme of the preparation method strictly controlling the component adding sequence, the abrasion resistance of the catalyst is effectively improved, and the obtained catalyst can be used for industrialized production of aromatic ammoxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

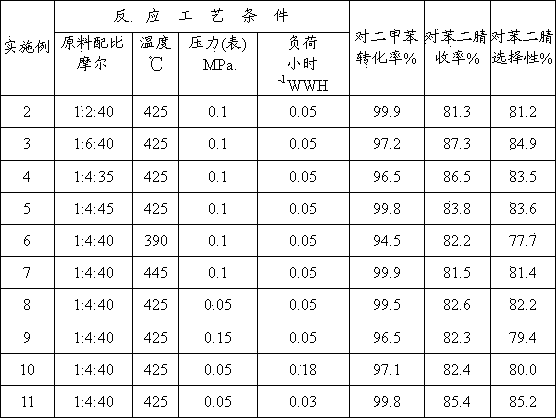

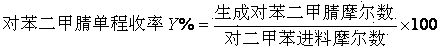

Preparation method of terephthalonitrile through ammonium oxidation

ActiveCN103896807AHigh catalytic efficiencyEasy loadingPreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsAlkali metal oxideFluidized bed

The invention relates a preparation method of terephthalonitrile through ammonium oxidation, and aims to solve the problems of low yield of terephthalonitrile, small reaction load, or difficult reaction heat dissipation in the presence of a conventional catalyst in the prior art. A fluidized bed catalyst is used to solve the problems mentioned above, wherein the fluidized bed catalyst comprises 30 to 80% of silica carrier and 20 to 70% of active component, and the active component is represented by a formula V<1.0>CrPX<c>Y<d>Z<e>O<m>; wherein the X is selected from at least one component of boron oxides and arsenic oxides, Y is selected from at least one component of alkali metal oxides and alkali earth metal oxides, Z is selected from at least one component of oxides of Ni, Co, Pb, Fe, Mo, and W. The fluidized bed catalyst well solves the problems mentioned above and is capable of being applied to the industrial terephthalonitrile production.

Owner:CHINA PETROLEUM & CHEM CORP +1

In situ modification of molybdenum-based catalysts

A process for the conversion of a hydrocarbon selected from the group consisting of propylene, isobutylene, propane, isobutane or mixtures thereof, to acrylonitrile, methacrylonitrile, or mixtures thereof, the process comprising the step of reacting in the vapor phase at an elevated temperature and pressure said hydrocarbon with a molecular oxygen-containing gas and ammonia, in the presence of a molybdenum-based ammoxidation catalyst and a catalyst modifier, wherein said catalyst modifier comprises a molybdate or a polymolybdate of at least one element M selected from the group consisting of cesium, rubidium, potassium, sodium, thallium, lithium, nickel, cobalt, iron, chromium, copper, magnesium, manganese, cerium and phosporus, and wherein the ratio of the M elements to Mo in the molybdate or polymolybdate is greater than the ratio for these M elements to Mo in the molybdenum-based catalyst. The catalyst modifier is useful in modifying the performance of molybdenum-based catalyst and inhibiting molybdenum oxide loss for such catalysts.

Owner:INEOS EURO LTD

Catalyst for use in catalytic oxidation or ammoxidation of propane or isobutane in the gaseous phase

InactiveUS7087551B2High selectivityEasy to useOrganic compound preparationHeterogenous catalyst chemical elementsRheniumIridium

Disclosed is an oxide catalyst comprising an oxide represented by the formula Mo1VaNbbXcYdZeQfOn (wherein: X is at least one element selected from the group consisting of Te and Sb; Y is at least one element selected from the group consisting of Al and W; Z is at least one element selected from the group consisting of elements which individually form an oxide having a rutile structure and a Z oxide having a rutile structure is used as a source of Z for producing the catalyst; Q is at least one element selected from the group consisting of titanium, tin, germanium, lead, tantalum, ruthenium, rhenium, rhodium, iridium, platinum, chromium, manganese, technetium, osmium, iron, arsenic, cerium, cobalt, magnesium, nickel and zinc, and a Q compound not having a rutile structure is used as a source of Q for producing the catalyst; and a, b, c, d, e, f and n are, respectively, the atomic ratios of V, Nb, X, Y, Z, Q and O, relative to Mo). Also disclosed is a process for producing an unsaturated carboxylic acid or an unsaturated nitrile by using the above-mentioned oxide catalyst.

Owner:ASAHI KASEI KK

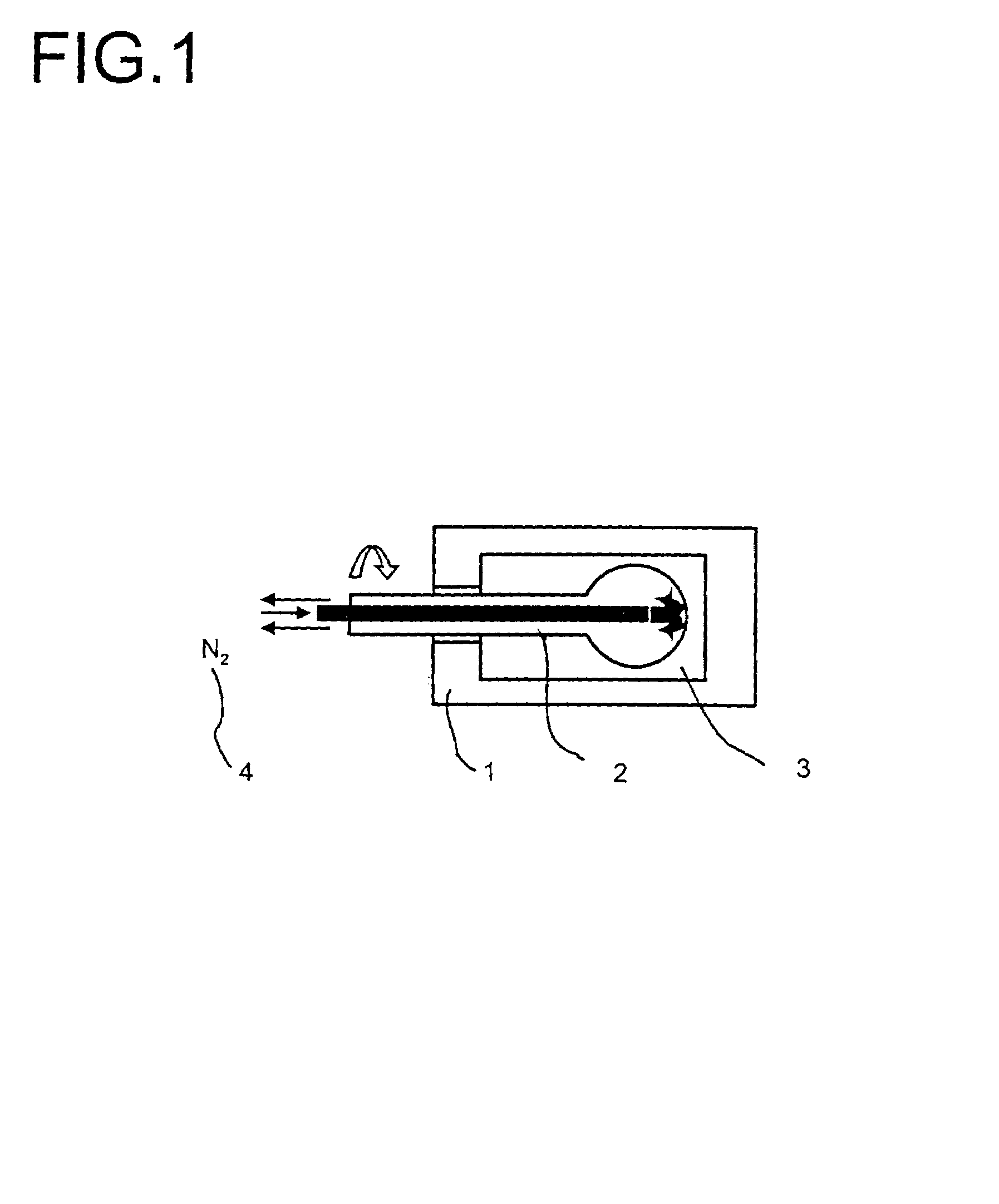

Method for producing ammoxidation catalyst

InactiveUS7365041B2High yieldOrganic chemistry methodsHeterogenous catalyst chemical elementsPtru catalystManganese

An ammoxidation catalyst comprising a molybdenum (component (1)), bismuth (component (2)), at least one element selected from the group consisting of nickel, cobalt, zinc, magnesium, manganese and copper (component (3)) and at least one element selected from the group consisting of lanthanum, cerium, praseodymium and neodymium (component (4)), over which an organic compound is subject to ammoxidation which is a composite oxide fluid bed catalyst, is prepared by i) preparing a first solution that comprises at least a portion of component (1), at least a portion of component (2), and at least a portion of component (3) but none of component (4); ii) preparing a second solution by adding a solution of component (4) to the first solution; and iii) drying the second solution obtained and calcining the solid matter obtained from the drying step.

Owner:MITSUBISHI CHEM CORP

Method for preparing unsaturated nitrile catalyst using with ammoxidation method

InactiveCN101121129AHigh yieldLow ammonia conversionPreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsActive componentOrganic compound

The present invention relates to a preparation method of an unsaturated nitrile catalyst, which is produced by an ammoxidation. The present invention mainly solves the problems in the prior art that in the ammoxidation, an ammonia conversion rate is low; the remnants ammonia is high; carbonyl by-products, such as acrolein etc, are high. The present invention solves the problems well by a technical proposal that SiO2 is used as a carrier, and the catalyst consists of a combination is adopted which contains active components and which is expressed by the following general formula: in the formula of Mo12BiaFebNicXdYeZfOx, the X is selected from at least one of Mg, Co, Ca, Cu, Zn, Pb, Mn, Cr, Nb, Zr, Ti, Sn or Ru; the Y is selected from at least one of La, Ce, Sm or Ge; the Z is selected from at least one of K, Rb, Na, Cs, In, Tl or Ag, and at least one of an organic compound which contains active-oh and can mutually react with a silica sol is added into an initial material in the process of the catalyst preparation. The present invention can be used for the industrial production of unsaturated nitrile, which is produced by an olefin ammoxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com