Patents

Literature

287 results about "Methacrylonitrile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methacrylonitrile (or 2-Methylprop-2-enenitrile), MeAN in short, is a chemical compound that is an unsaturated aliphatic nitrile, widely used in the preparation of homopolymers, copolymers, elastomers, and plastics and as a chemical intermediate in the preparation of acids, amides, amines, esters, and other nitriles. MeAN is also used as a replacement for acrylonitrile in the manufacture of an acrylonitrile/butadiene/styrene-like polymer. It is a clear and colorless (to slightly yellow) liquid, that has a bitter almond smell.

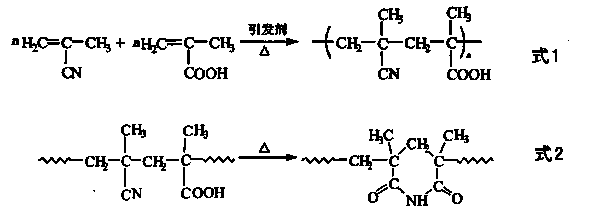

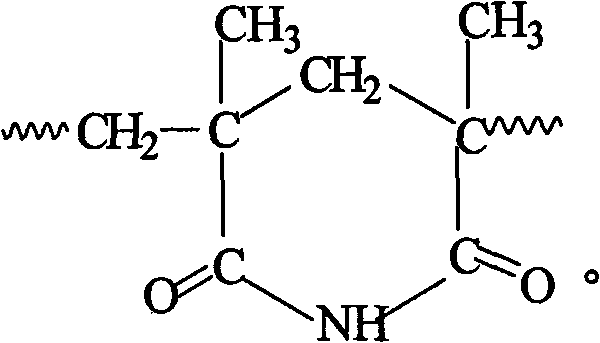

Expandable particles for producing polymethacrylimide foamed material and application thereof

The invention discloses expandable particles for producing a polymethacrylimide foamed material and application thereof. The expandable particles are prepared by the following steps of: putting acrylic acid or methacrylic acid, acrylonitrile or methacrylonitrile, an initiator, a molecular weight regulator, a foaming agent, a foam stabilizer, a cross-linking agent and an additive into a mold; performing a primary bulk polymerization reaction at the temperature of between 30 and 50 DEG C for 10 to 72 hours; performing a further bulk polymerization reaction at the temperature of between 50 and 100 DEG C for 1 to 30 hours to obtain a copolymer plate; smashing and screening the copolymer plate to obtain the expandable particles for producing the polymethacrylimide foamed material. Pre-foamed particles can be prepared by pre-foaming the expandable particles at the temperature of between 150 and 230 DEG C for 0.1 to 2 hours, and polymethacrylimide foam particles can be prepared by foaming the pre-foamed particles at the temperature of between 190 and 260 DEG C and curing the foamed particles at the temperature of between 150 and 230 DEG C. The expandable particles expand the use range of the polymethacrylimide foamed material.

Owner:SICHUAN UNIV

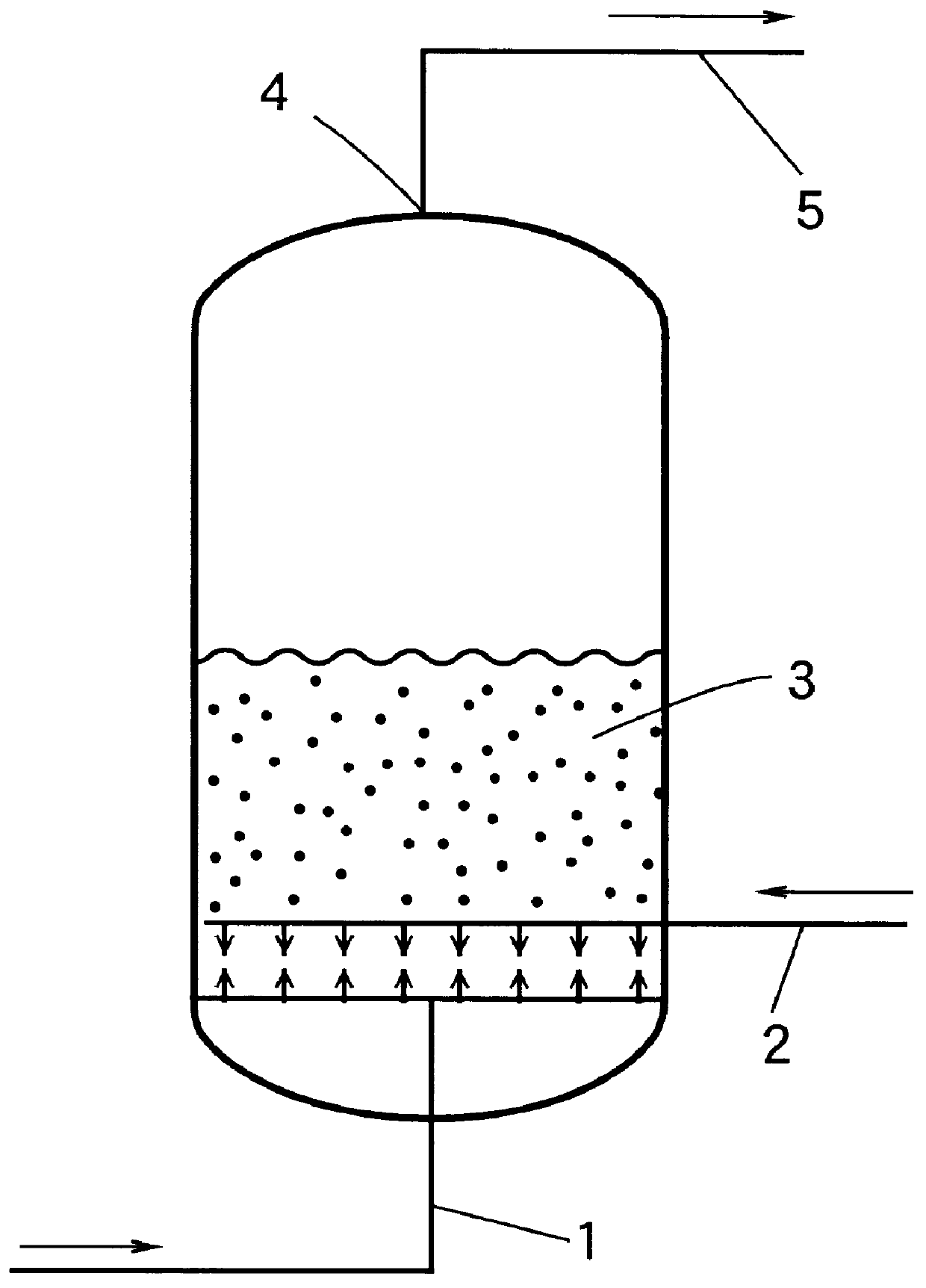

Fluidized-bed catalyst for ammoxidation of propylene or isobutylene

InactiveCN1736592AEasy loadingIncrease reaction pressurePreparation by ammonia-carboxylic acid reactionMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureHigh load

The invention provides a fluid-bed catalyst, which can withstand high voltage and high load, contains non corrosive halide, and has a high single-pass yield. The catalyst comprises metal oxide containing multi active component of Mo, Bi, Fe, Ni and Sm, and a carrier of SiO2, Al2O3 or the mixture. It can be used to prepare the high selective acrylic with propone. Comparing with the prior technique, in the condition of keeping the single- pass yield of acrylic, with the invented catalyst, production capacity of fluid-bed reactor can be improved by 20- 30%, and the usage of the catalyst can decreases by 35%.

Owner:YINGKOU XIANGYANG CATALYST

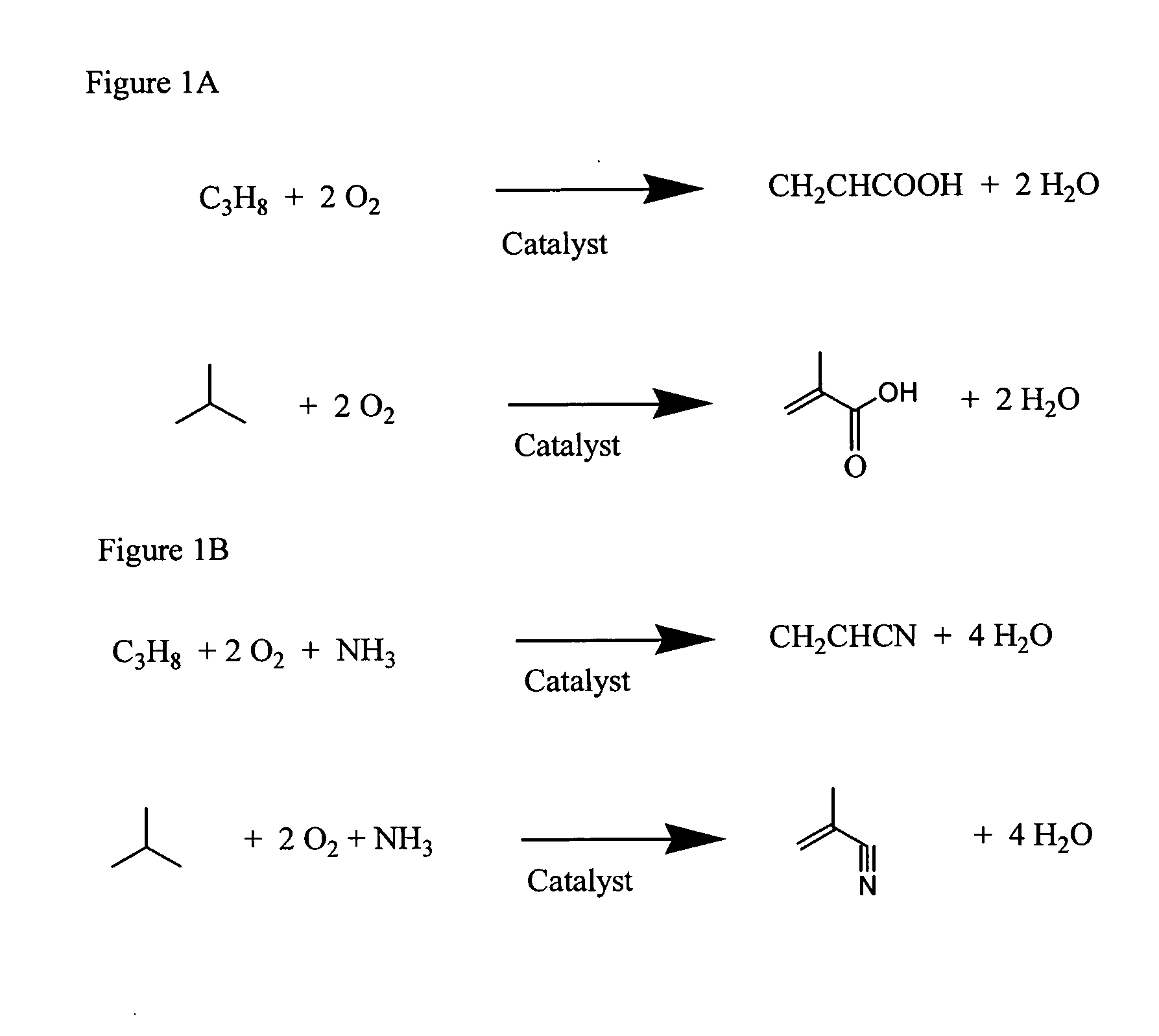

Process for producing acrylonitrile or methacrylonitrile from propane or isobutane by ammoxidation

Owner:ASAHI KASEI KK

Slurry composition, electrode and secondary cell

ActiveUS7316864B2Degree of swelling decreasedImprove the bonding force between layersLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithiumLiquid medium

Owner:ZEON CORP

Mixed metal oxide catalysts for propane and isobutane oxidation and ammoxidation, and methods of preparing same

InactiveUS20050054869A1Increase productionOrganic compound preparationHeterogenous catalyst chemical elementsNiobiumGas phase

Compositions of matter and catalyst compositions effective for gas-phase conversion of propane to acrylic acid (via oxidation) or to acrylonitrile (via ammoxidation) and isobutane to methacrylic acid (via oxidation) and isobutane to methacrylonitrile (via ammoxidation) are disclosed. Preferred catalyst compositions comprise molybdenum, vanadium, niobium, antimony and germanium and molybdenum, vanadium, tantalum, antimony, and germanium. Methods of preparing such compositions and related compositions, including hydrothermal synthesis methods are also disclosed. The preferred catalysts convert propane to acrylic acid and / or to acrylonitrile and isobutane to methacrylic acid / methacrylonitrile with a yield of at least about 50%.

Owner:INEOS USA LLC

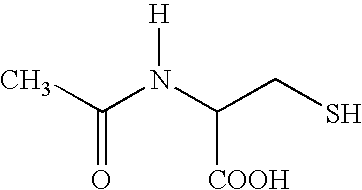

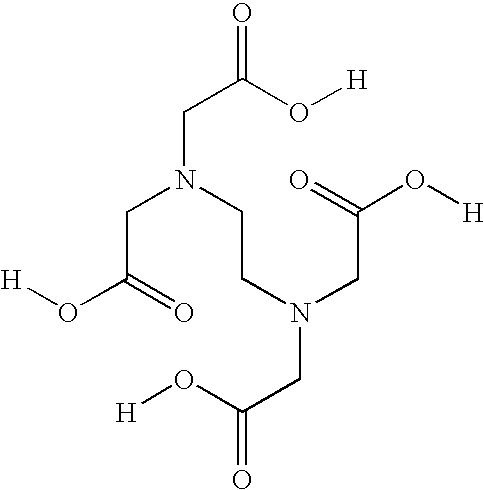

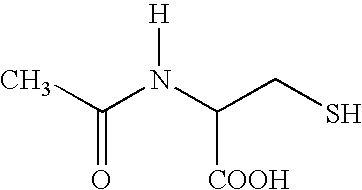

Acetylcysteine composition and uses therefor

This invention relates to novel acetylcysteine compositions in solution, comprising acetylcysteine and which are substantially free of metal chelating agents, such as EDTA. Further, this invention relates to methods of making and using the acetylcysteine compositions. The present compositions and methods are designed to improve patient tolerance and compliance, while at the same time maintaining the stability of the pharmaceutical formulation. The compositions and methods of this invention are useful in the treatment of acetaminophen overdose, acute liver failure, various cancers, methacrylonitrile poisoning, reperfusion injury during cardio bypass surgery, and radiocontrast-induced nephropathy, and can also be used as a mucolytic agent.

Owner:CUMBERLAND PHARM INC

Maleimide modified polymethacrylimide foam and preparation method thereof

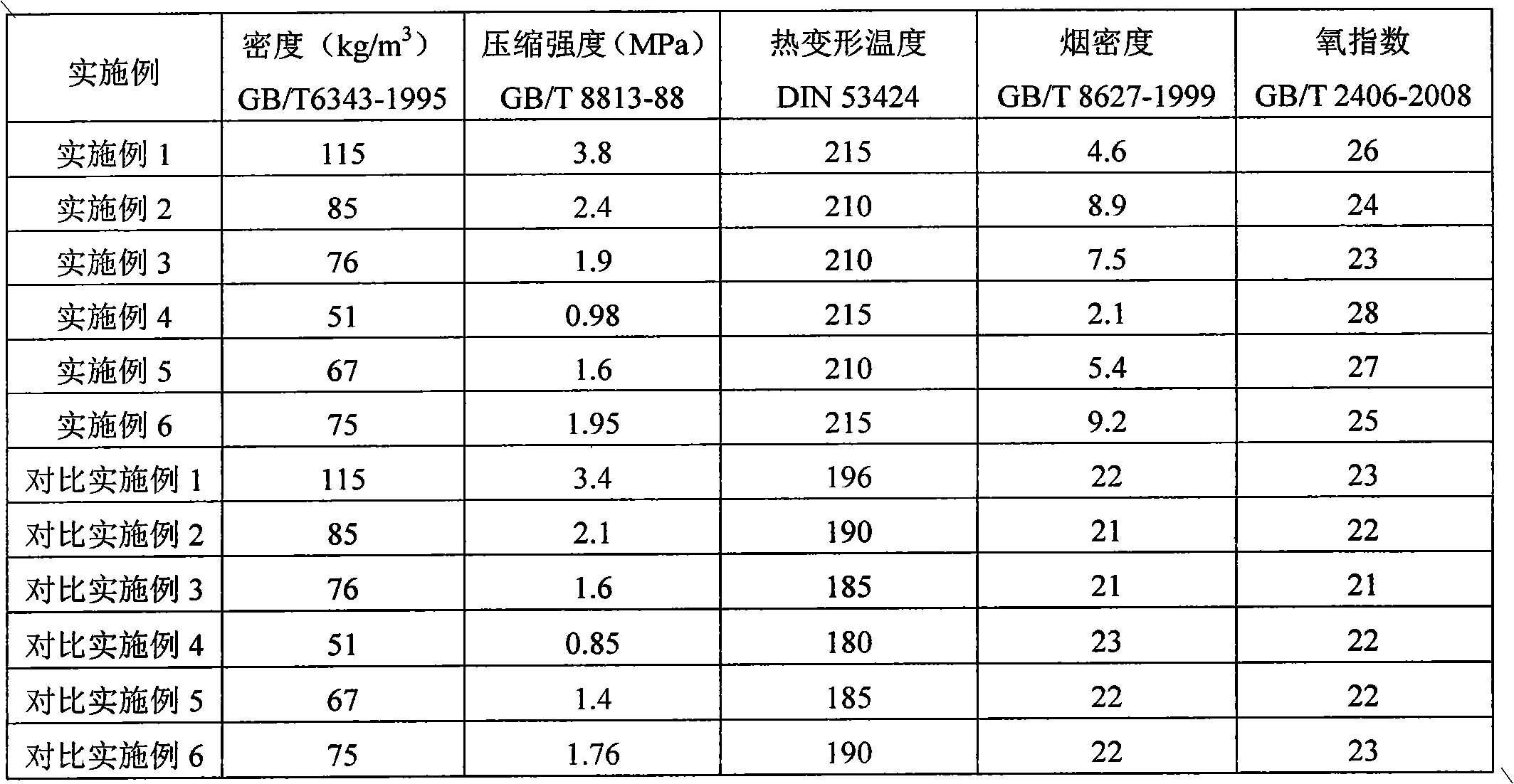

ActiveCN101550215AImprove heat resistanceImprove mechanical propertiesHeat deflection temperatureFoaming agent

The invention relates to high-performance copolymer foam, in particular to maleimide modified polymethacrylimide foam and a preparation method thereof. The maleimide modified polymethacrylimide foam is obtained by the mixed reaction of the components according to the weight proportions: 35-60 of methyl acrylic acid (MAA), 65-40 of methacrylonitrile (MAN), 0.1-50 of maleimide modifier, 0.10-2.0 of initiator, 1.0-20 of foaming agent, 0.1-8 of nucleating agent and 0.1-5 of crosslinking agent. The maleimide modified polymethacrylimide foam has high heat resistance, is not changed in color by heating under the temperature of 220 DEG C for long time, has the heat distortion temperature higher than 200 DEG C, and has the highest mechanical performance in all foams under the same intensity.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Polymethacrylimide foam/inorganic nano composite material and method for preparing same

The invention provides polymethacrylimide foam / inorganic nano-composite material and a preparation method thereof. The composite material takes polymethacrylimide as a base body and inorganic nano-material as reinforcing material. The preparation method is as follows: high-speed stirring and power ultrasound are used to evenly disperse the inorganic nano-material into a system of methacrylic acid, methacrylamide and methacrylonitrile monomers containing auxiliary agents such as evocating agent, vesicant, polymerization inhibitor, cross linker, surfactant, parting agent and so on, the evocating agent evocates copolymerization under certain conditions to form methacrylic acid-methacrylamide-methacrylonitrile copolymer / inorganic nano-composite material with light crosslinking, and the composite material undergoes temperature rising with certain procedures, is foamed at a high temperature and produces an imide ring reaction to produce the polymethacrylimide foam / inorganic nano-composite material. The inorganic nano-material is added, so the mechanical property and the heat resistance of the composite material are apparently improved.

Owner:NAT UNIV OF DEFENSE TECH +1

Particulate porous ammoxidation catalyst

ActiveUS7473666B2High yieldIncrease productionOrganic compound preparationHeterogenous catalyst chemical elementsPore distributionNiobium

A particulate porous ammoxidation catalyst for use in producing acrylonitrile or methacrylonitrile by reacting propylene, isobutene or tert-butyl alcohol with molecular oxygen and ammonia in a fluidized-bed reactor, the catalyst comprising a metal oxide and a silica carrier having supported thereon the metal oxide, wherein the metal oxide contains at least two elements selected from the group consisting of molybdenum, bismuth, iron, vanadium, antimony, tellurium and niobium, and the catalyst having a particle diameter distribution wherein the amount of catalyst particles having a particle diameter of from 5 to 200 μm is from 90 to 100% by weight, based on the weight of the catalyst, and having a pore distribution wherein the cumulative pore volume of pores having a pore diameter of 80 Å or less is not more than 20%, based on the total pore volume of the catalyst and wherein the cumulative pore volume of pores having a pore diameter of 1,000 Å or more is not more than 20%, based on the total pore volume of the catalyst. A method for efficiently producing this catalyst.

Owner:ASAHI KASEI CHEM CORP

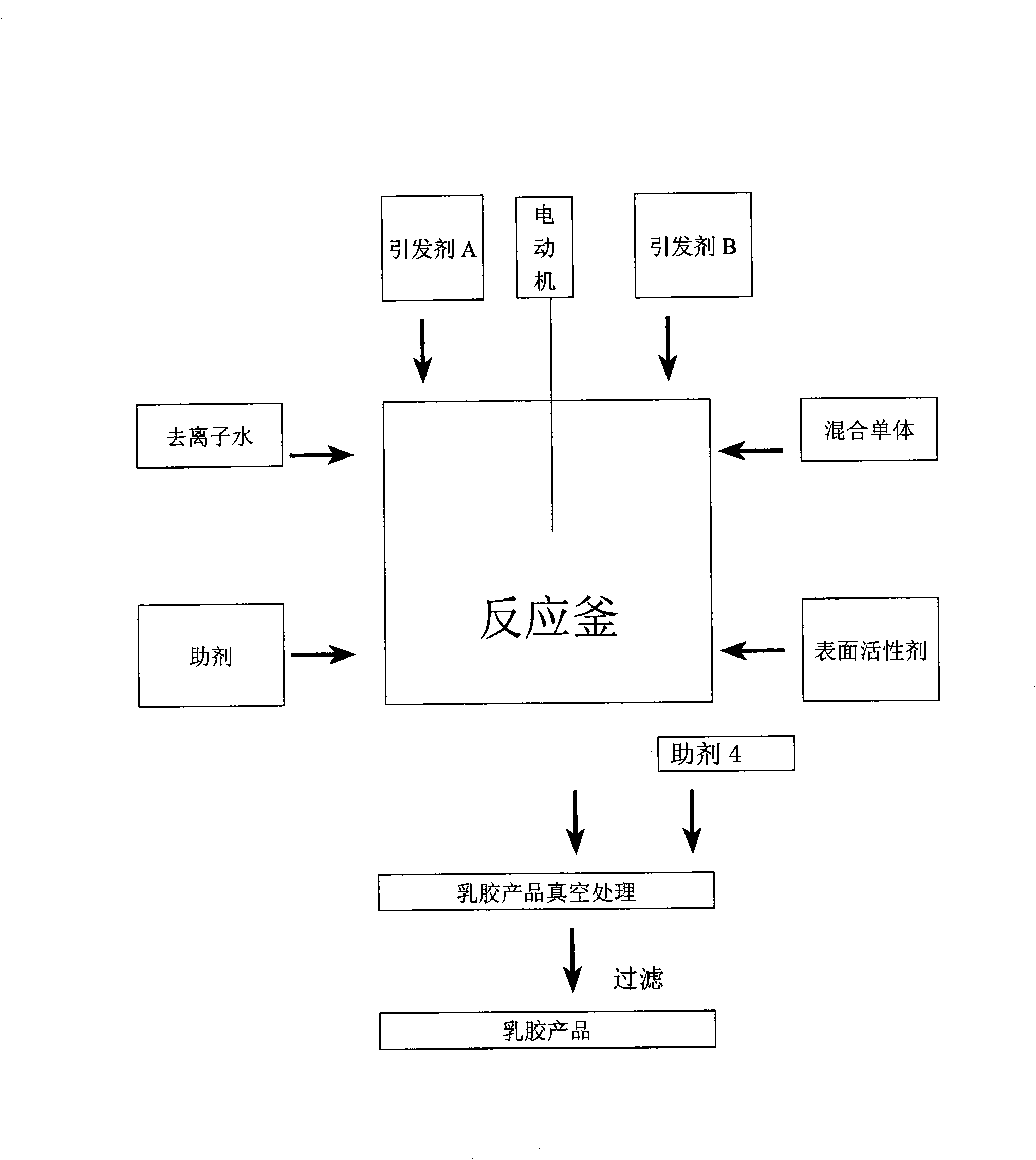

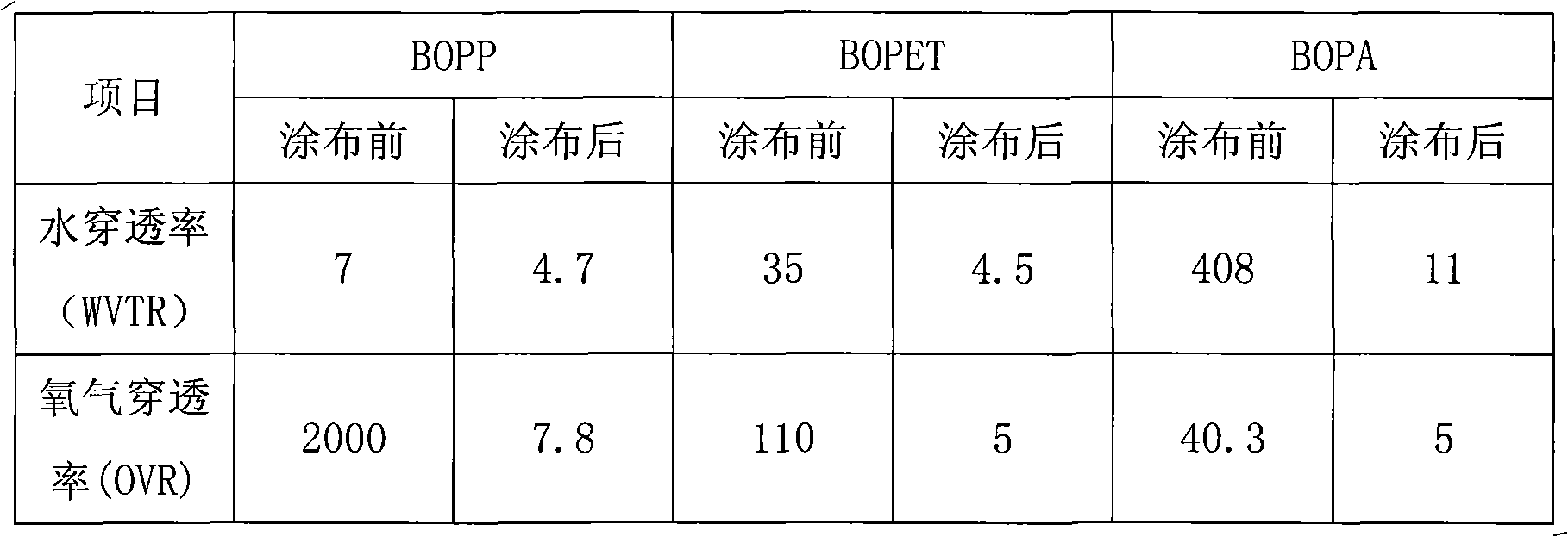

High barrier food package coated membrane latexes by thermal sealing at low temperature and preparation method

InactiveCN101358054AExtended shelf lifeHigh barrierFlexible coversWrappersCoated membraneVinylidine chloride

The invention relates to a low-temperature heat-sealing high-barrier food packaging film coating latex. The composition points of the mixed monomer of the latex is that vinylidene chloride accounts for 80 to 93 percent of the total amount of the mixed monomer; methyl acrylate, methyl ethyl oxalate, methyl methacrylate, butyl ester, acrylonitrile or methacrylonitrile account for 2 to 10 percent of the total amount of the mixed monomer; itaconic acid, acrylic acid, methacrylic acid account for 0.5 to 5 percent of the total amount of the mixed monomer; the surfactants added are 0.7 portion of SAS and 0.3 portion of sodium dodecyl sulfate; the additive 3 is 0.01 portion of metallic salt. The preparation method includes the following steps: deionized water, surfactant and additive are added in a reactor; the reactor is vacuumized and the gas is replaced by nitrogen gas; the mixed monomer is added. The product of the invention has the advantages of low temperature heat sealing and high barrier performance, and the food using the product has longer shelf life.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Composition with increased stress cracking resistance

InactiveUS20100174022A1Improved stress crack resistanceImprove heat deformation resistanceInksOrganic dyesMeth-Crack resistance

Composition containing, based in each case on its total weight,A) 50.0% by weight to 99.5% by weight of at least one (meth)acrylate (co)polymer andB) 0.5% by weight to 50.0% by weight of at least one copolymer obtainable by polymerisation of a monomer mixture comprisingi. 70% by weight to 92% by weight of a vinylaromatic monomer andii. 8% by weight to 30% by weight of acrylonitrile or methacrylonitrile or mixtures thereof andiii. 0% by weight to 22% by weight of at least one further monomer, the composition having a haze according to ASTM D1003 of less than 2.0% at 23° C. and a haze according to ASTM D1003 of less than 4.0% at 40° C. and the composition containing at least one (meth)acrylate (co)polymer a) having a solution viscosity in chloroform at 25° C. (ISO 1628—part 6) of greater than 55 ml / g.The mouldings obtainable from the composition are distinguished in particular by improved stress cracking resistance and are suitable in particular for coverings, finishes or films.

Owner:EVONIK ROEHM GMBH

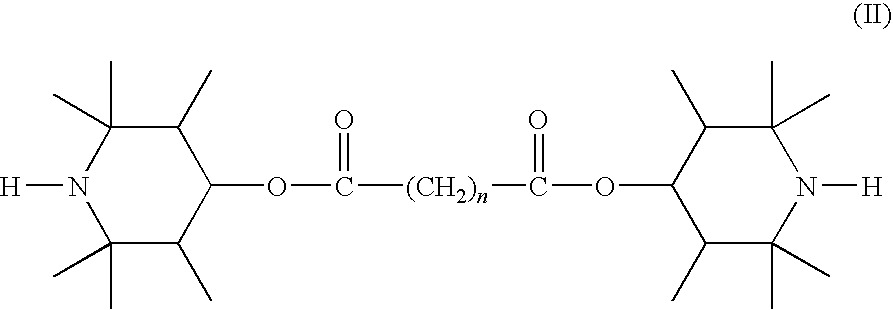

Whisker modified polymethacrylimide foamed plastic and preparation method thereof

InactiveCN102051012AImprove mechanical propertiesHigh heat distortion temperaturePolymer scienceFoaming agent

The invention relates to whisker modified polymethacrylimide foamed plastic, which is prepared from the following raw materials in part by weight: 30 to 70 parts of acrylic acid or methacrylic acid, 30 to 70 parts of acrylonitrile or methacrylonitrile, 0.1 to 20 parts of whisker material, 0.1 to 5 parts of thixotropic agent, 0.1 to 6 parts of nucleating agent, 0.05 to 2 parts of initiator, 0.1 to 15 parts of foaming agent, 0.01 to 2 parts of cross-linking agent and 0.01 to 0.7 part of retarding agent. The invention also relates to a preparation method of the foamed plastic, which comprises the following steps of: (1) mixing the raw materials; (2) performing polymerization reaction on the materials obtained in the step (1); (3) heating a plate prepared in the step (2), and preheating and foaming; and (4) heating the foamed plate prepared in the step (3). The combustibility and smoke density of the foamed plastic are reduced, and the foamed plastic is a plastic material with high performance.

Owner:湖南兆恒材料科技有限公司

Coloured composition with increased stress cracking resistance

InactiveUS20100148401A1Improved stress crack resistanceImprove heat deformation resistanceOrganic dyesCeramic shaping apparatusCrack resistanceMeth-

The invention relates to a composition containing, in relation to the total weight of said composition, A) between 50.0% by weight and 99.5% by weight of at least one (meth)acrylate (co)polymer and B) between 0.5% by weight and 50.0% by weight of at least one copolymer, obtained by the polymerisation of a monomer mixture consisting of i. between 70% by weight and 92% by weight of a vinyl aromatic monomer and ii. between 8% by weight and 30% by weight of acryl nitrile or methacryl nitrile or mixtures thereof iii. between 0% by weight and 22% by weight of at least one other monomer, the composition having at 50° C. a ΔE of less than 0.15, ΔE being defined according to the relationship (1): (1) in which ΔL*: the modification of the colour co-ordinates L* compared with the colour co-ordinates L* at 23° C., Δa*: the modification of the colour co-ordinates a* compared with the colour co-ordinates a* at 23° C., Δb*: the modification of the colour co-ordinates b* compared to the colour co-ordinates b* at 23° C., and the composition contains at least one (meth)acrylate (co)polymer a) with a solution viscosity in chloroform at 25° C. (ISO 1628 part 6) greater than 55 ml / g. The moulded bodies that can be obtained from the composition are characterised in particular by improved stress cracking resistance and are suitable in particular for use in coatings, paints or films.

Owner:EVONIK ROEHM GMBH

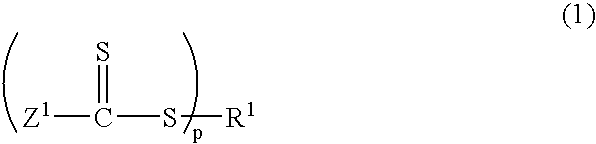

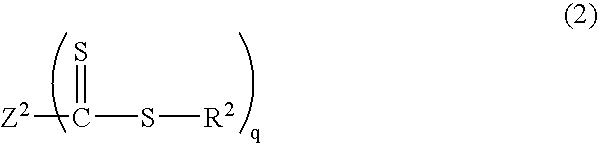

Block copolymer

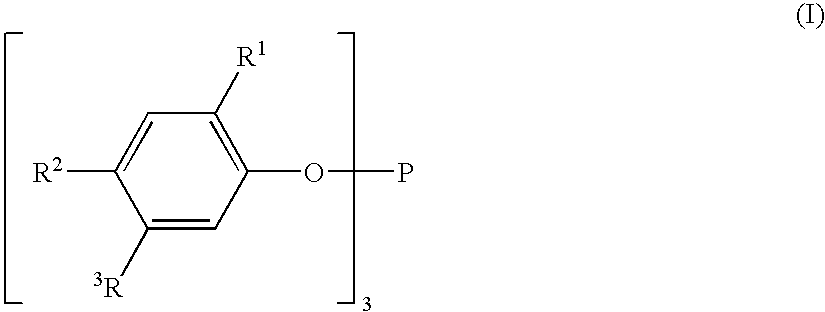

InactiveUS20040236020A1Improve flame retardant performanceImprove heat resistanceElastomerPolymer science

Provided are a block copolymer including a polymer block containing acrylonitrile or methacrylonitrile as a principal constituent, which is excellent in heat resistance, weatherability, oil resistance, flame retardancy, and low-temperature resistance and which can be economically produced; and a thermoplastic resin composition and an elastomer composition each containing the block copolymer. The block copolymer is produced by reversible addition-fragmentation chain transfer polymerization in the presence of a thiocarbonylthio group-containing compound.

Owner:KANEKA CORP

Acetylcysteine composition and uses therefor

This invention relates to novel acetylcysteine compositions in solution, comprising acetylcysteine and which are substantially free of metal chelating agents, such as EDTA. Further, this invention relates to methods of making and using the acetylcysteine compositions. The present compositions and methods are designed to improve patient tolerance and compliance, while at the same time maintaining the stability of the pharmaceutical formulation. The compositions and methods of this invention are useful in the treatment of acetaminophen overdose, acute liver failure, various cancers, methacrylonitrile poisoning, reperfusion injury during cardio bypass surgery, and radiocontrast-induced nephropathy, and can also be used as a mucolytic agent.

Owner:CUMBERLAND PHARM INC

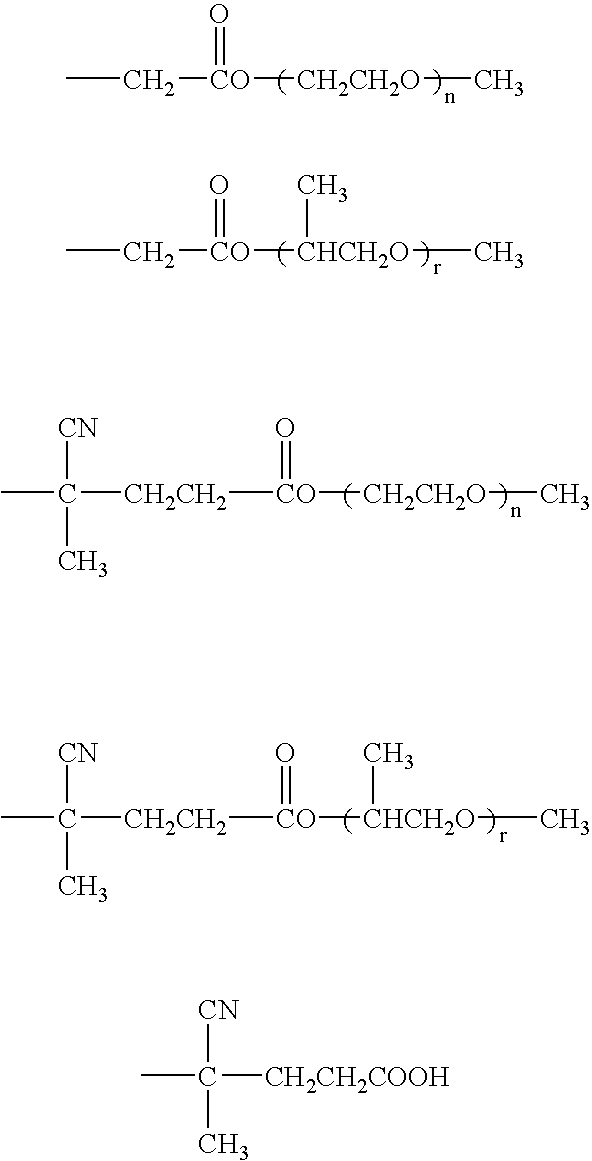

Slurry composition, electrode and secondary cell

ActiveUS20050069769A1Degree of swelling decreasedImprove the bonding force between layersLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithiumLiquid medium

A slurry composition for electrode comprising a binder, an active material, and a liquid medium, characterized in that the binder comprises a polymer (X) comprising 60 to 95 mole % of repeating units derived from acrylonitrile or methacrylonitrile and 5 to 30 mole % of repeating units derived from at least one kind of a monomer selected from 1-olefins and compounds represented by the following general formula (1): CH2═CR1—COOR2 wherein R1 represents a hydrogen atom or a methyl group and R2 represents an alkyl group; and the liquid medium is capable of dissolving the polymer (X). The slurry composition allows the manufacture of a lithium ion secondary battery having enhanced capacity and good charge-discharge cycle characteristics and good charge-discharge rate characteristics.

Owner:ZEON CORP

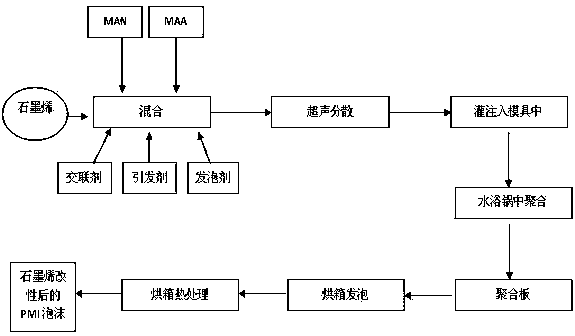

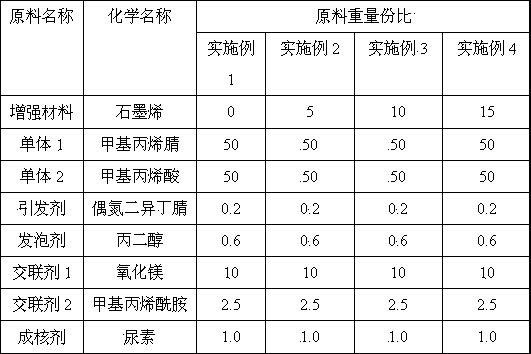

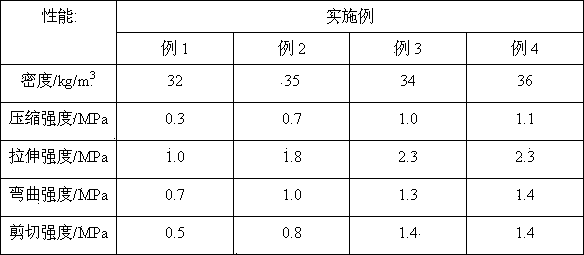

Method for preparing graphene reinforced PMI (polymethacrylimide) foam material

The invention discloses a method for preparing a graphene reinforced PMI (polymethacrylimide) foam material. Graphene is taken as a reinforcing material, methacrylonitrile and methacrylic acid are taken as a comonomer, an initiator, a crosslinking agent, a foaming agent, a nucleating agent and the like are added to prepare a foamable polymerized plate, and finally the foamable polymerized plate is freely foamed and subjected to thermal treatment in a drying oven so as to prepare polymethacrylimide rigid foam. Reactions of crosslinking, cyclization and the like are sufficiently conducted in the foaming and thermal treatment process, so as to harden copolymer molecular chain, and finally the foam plastic with excellent property is prepared. Due to adoption of the method, the tensile strength, the bending strength, the compression strength and the shearing strength of PMI are improved, and the electromagnetic shielding property and the anti-static property of the PMI foam are also improved. The PMI foam with excellent mechanical property can be widely applied to manufacturing of foam interlayer components in the fields of spaceflight, aviation, vessels, trains and the like.

Owner:江苏美赫家居有限公司

Mixed metal oxide ammoxidation catalysts

ActiveUS8153546B2Promote conversionHeterogenous catalyst chemical elementsCatalyst activation/preparationCrystallographyCerium

Owner:INEOS EURO LTD

Catalyst for the manufacture of acrylonitrile

ActiveUS20040110978A1Organic compound preparationHeterogenous catalyst chemical elementsRare-earth elementCerium

A catalyst comprising a complex of catalytic oxides comprising potassium, cesium, cerium, chromium, cobalt, nickel, iron, bismuth, molybdenum, wherein the relative ratios of these elements is represented by the following general formula AaKbCscCedCreCofNigXhFeiBijMo12Ox wherein A is Rb, Na, Li, Tl, or mixtures thereof, X is P, Sb, Te, B, Ge, W, Ca, Mg, a rare earth element, or mixtures thereof, a is about 0 to about 1, b is about 0.01 to about 1, c is about 0.01 to about 1, d is about 0.01 to about 3, e is about 0.01 to about 2, f is about 0.01 to about 10, g is about 0.1 to about 10, h is about 0 to about 4, i is about 0.1 to about 4, j is about 0.05 to about 4, x is a number determined by the valence requirements of the other elements present, and wherein the catalyst is substantially free of manganese and zinc. The catalyst is useful in processes for the ammoxidation of an olefin selected from the group consisting of propylene, isobutylene or mixtures thereof, to acrylonitrile, methacrylonitrile and mixtures thereof, respectively.

Owner:INEOS USA LLC

Mixed metal oxide ammoxidation catalysts

ActiveUS20110237753A1Promote conversionHeterogenous catalyst chemical elementsCatalyst activation/preparationCrystallographyCerium

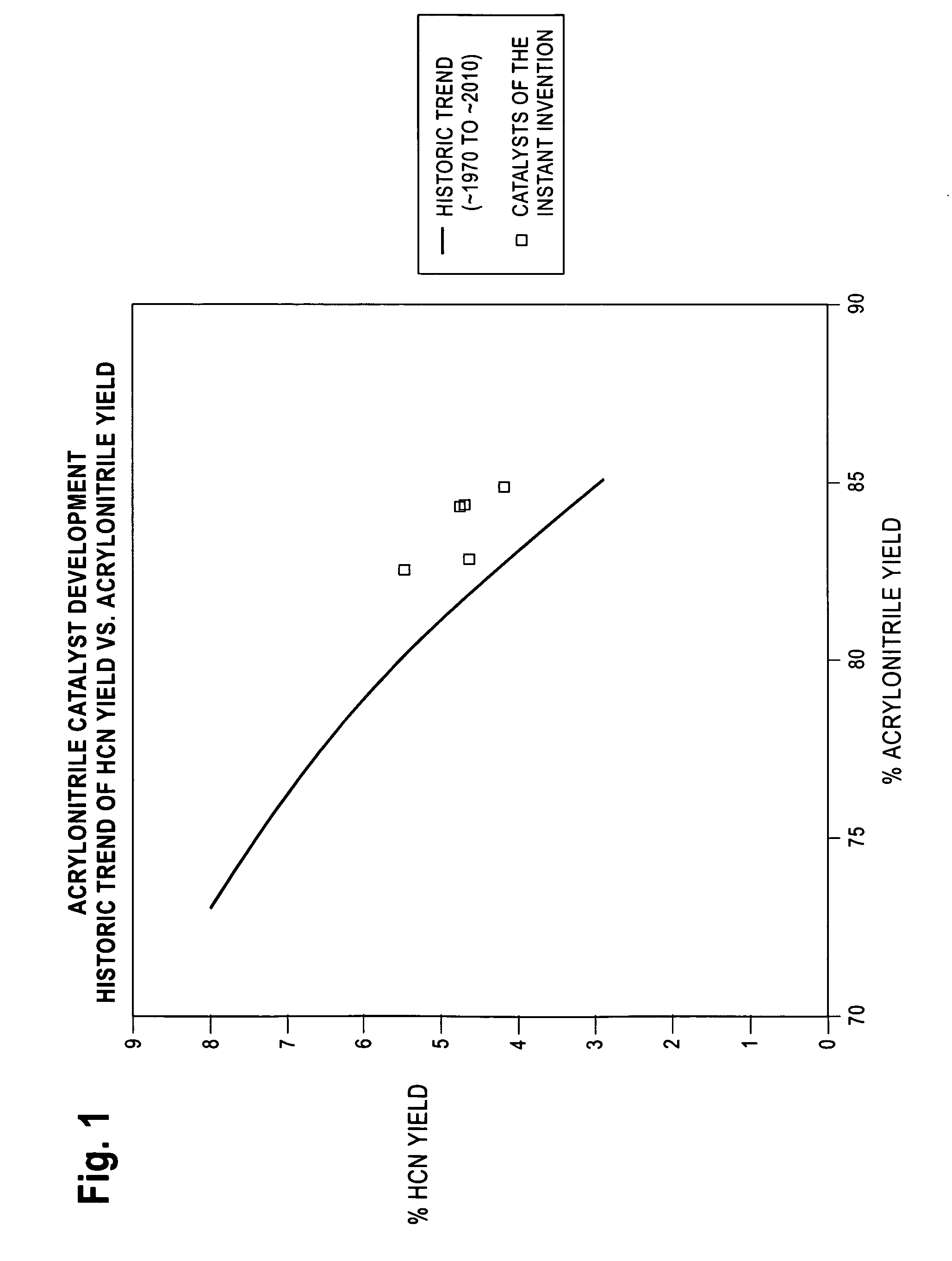

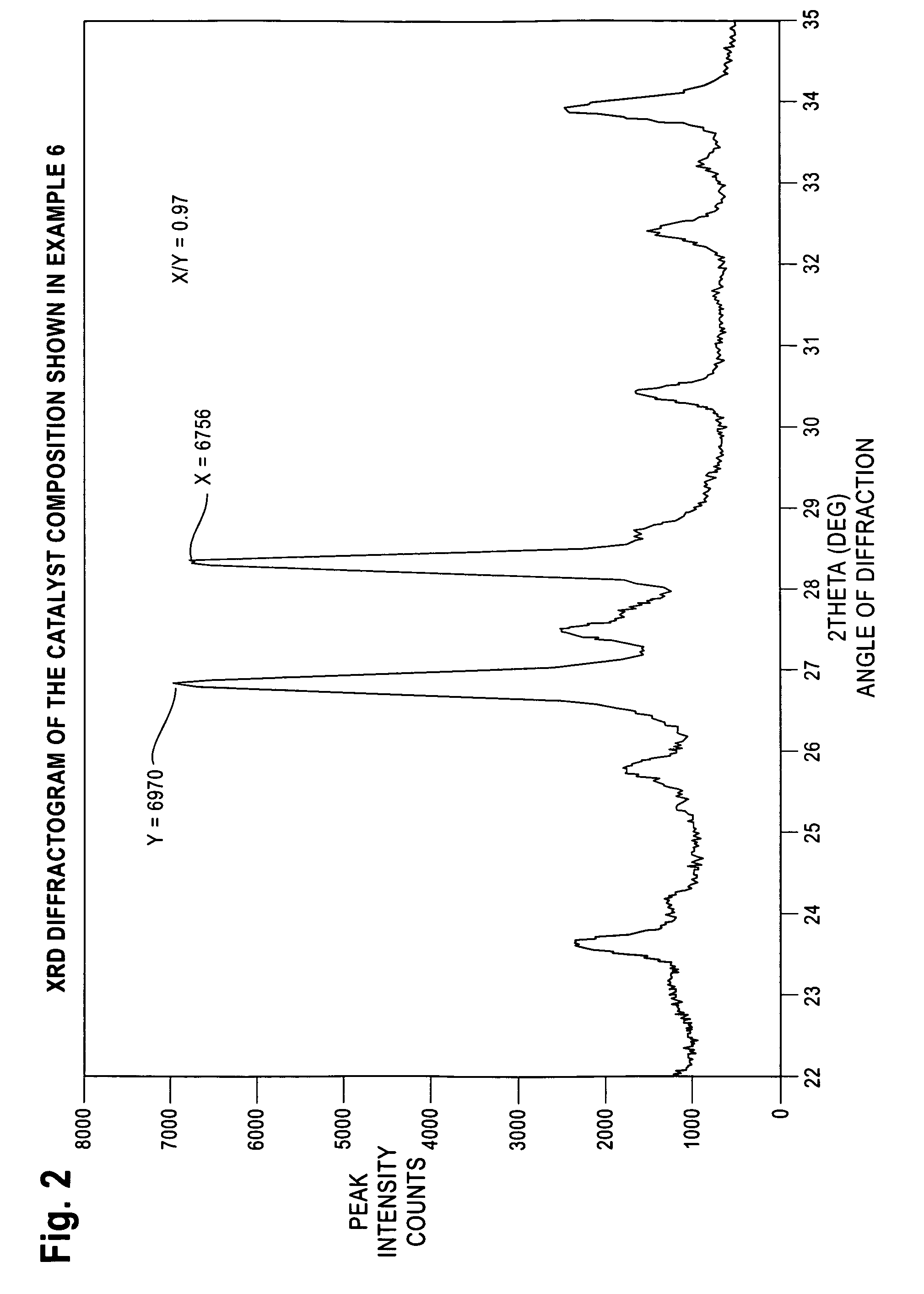

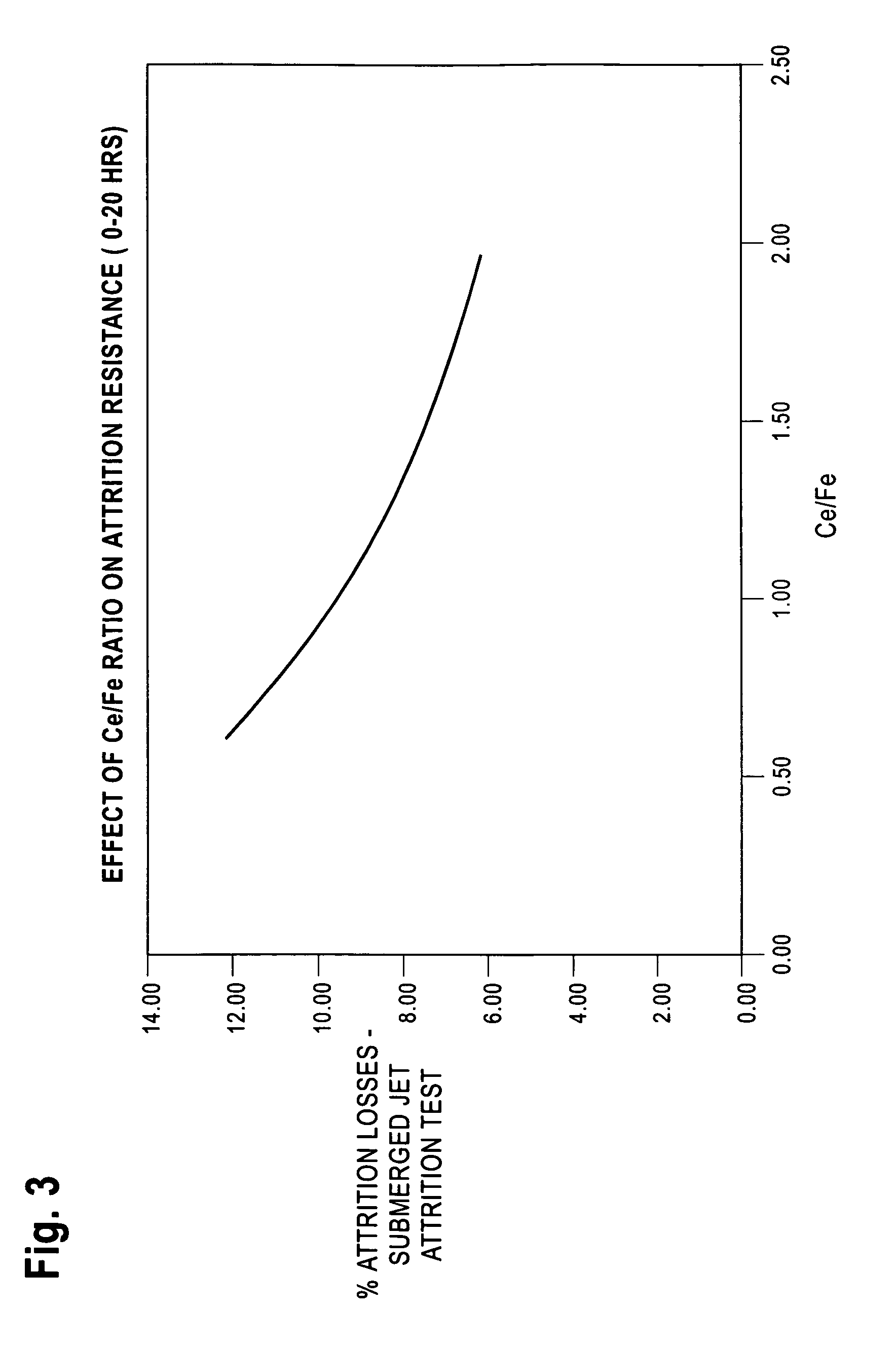

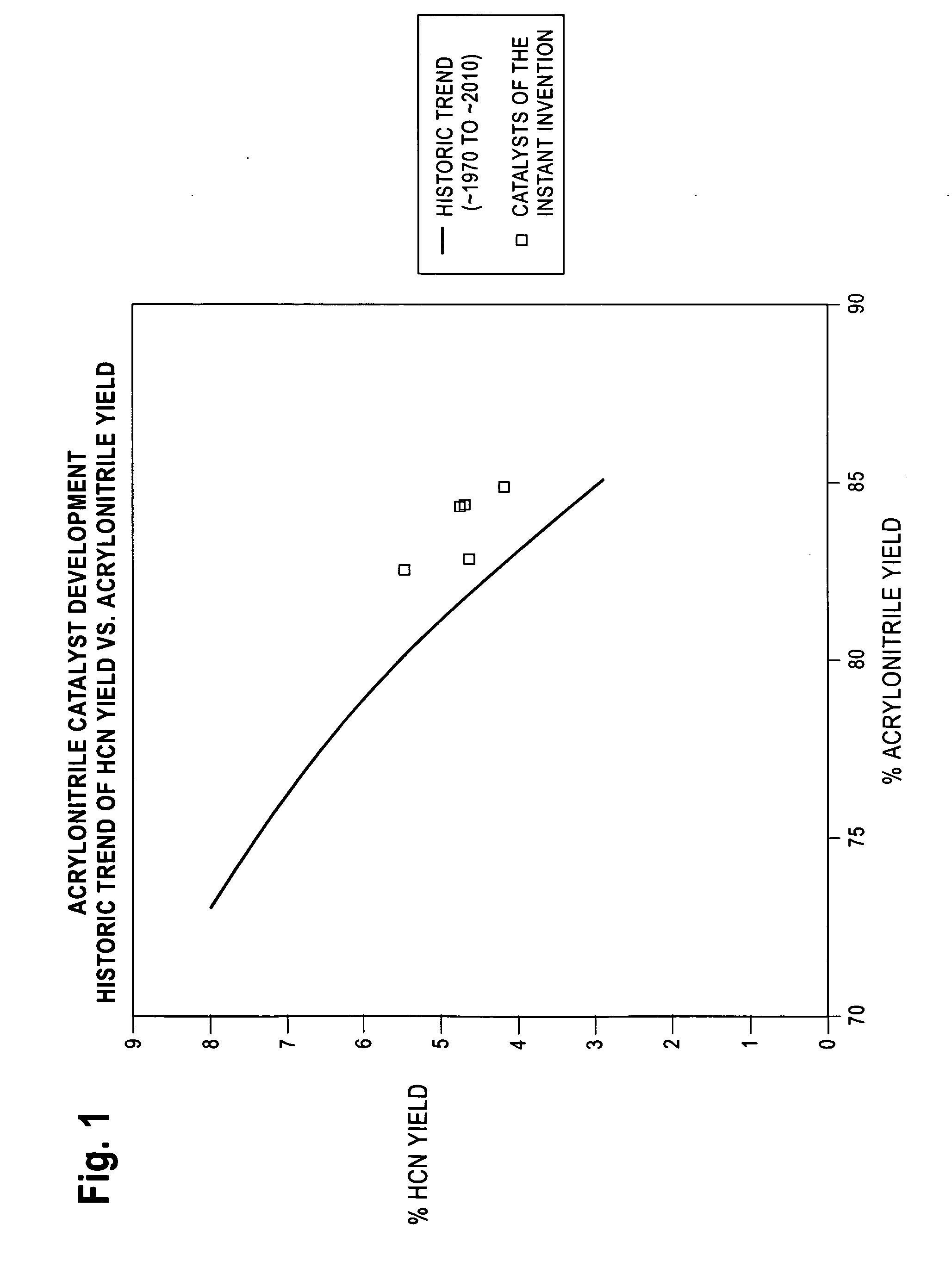

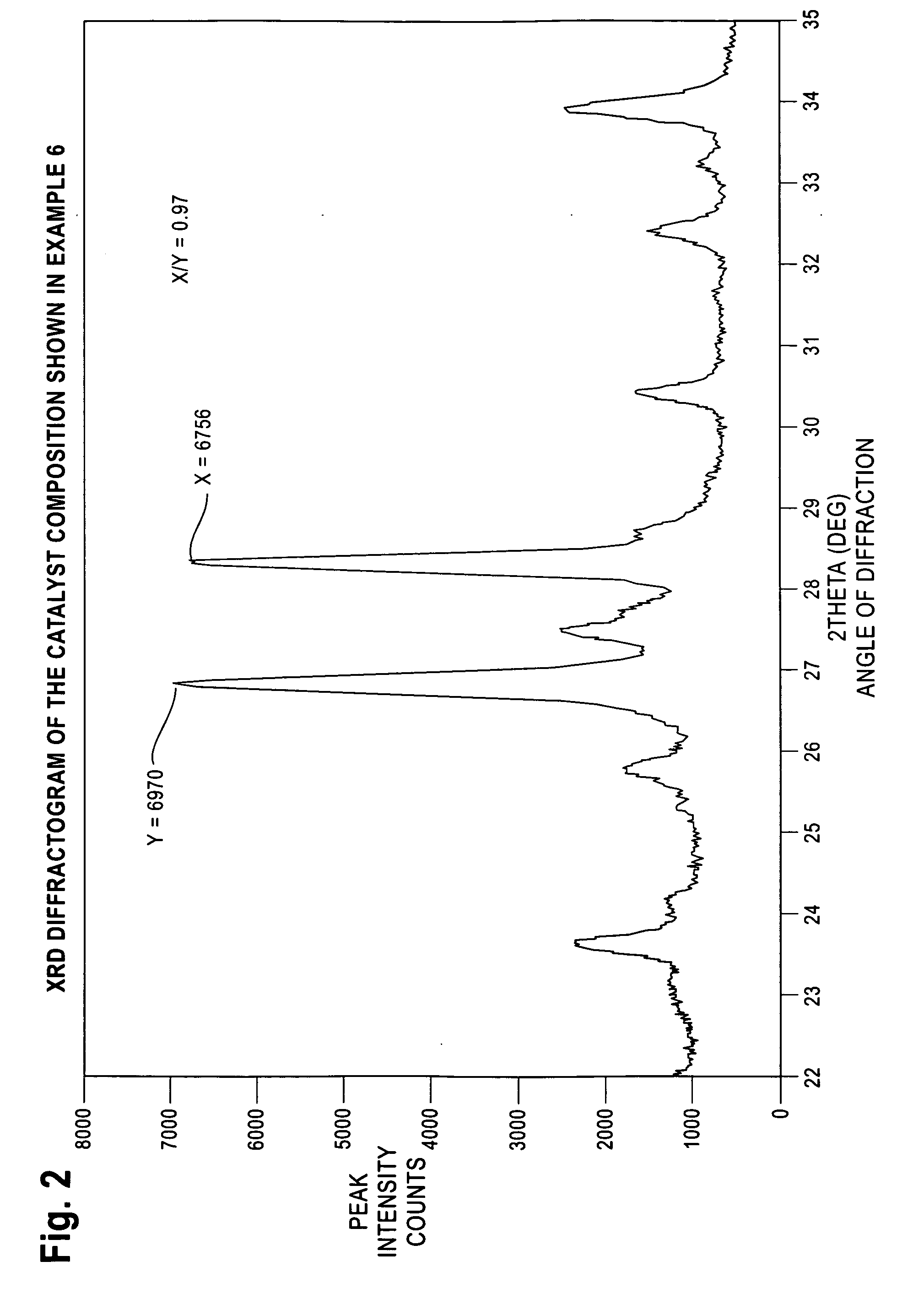

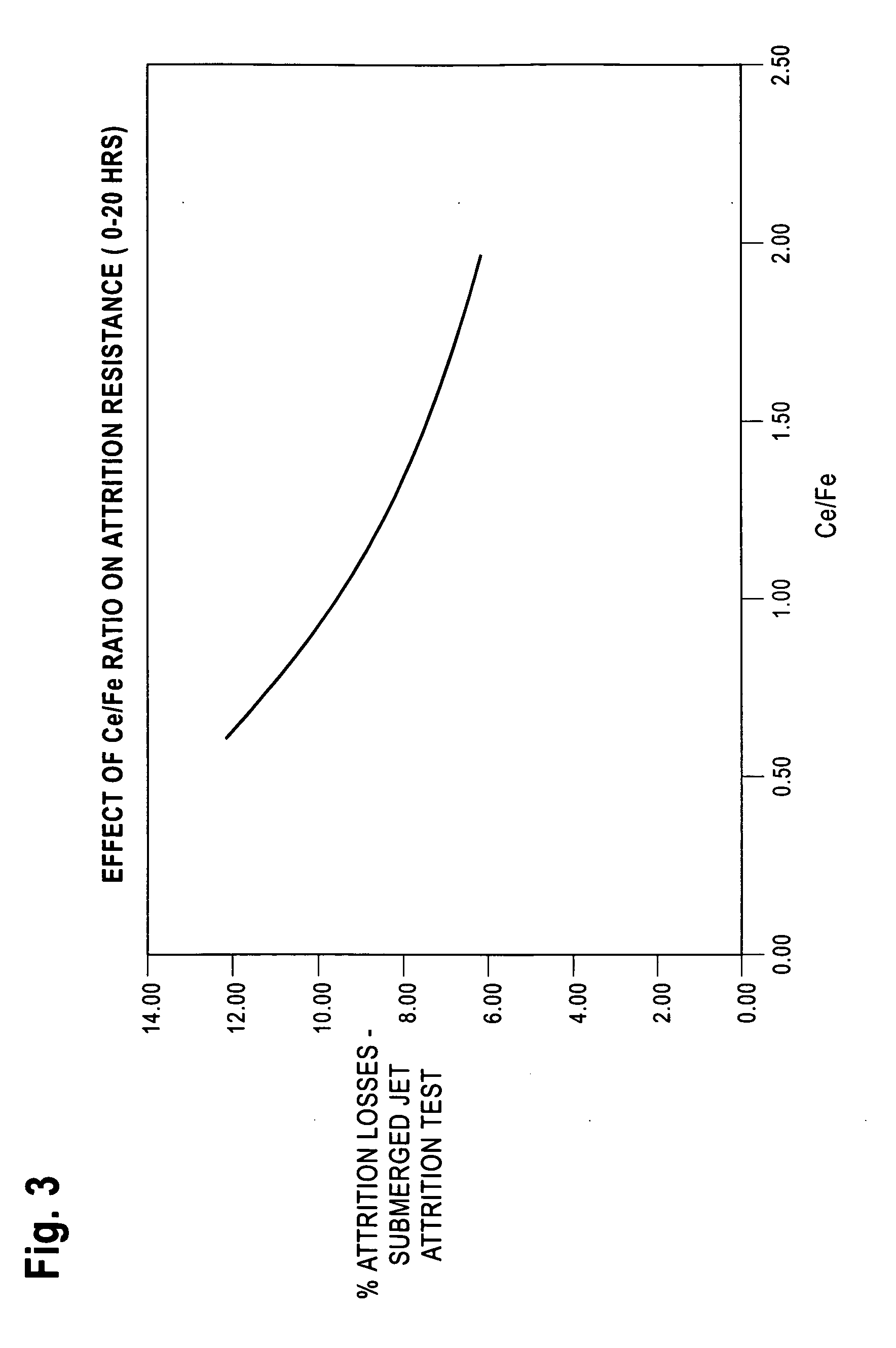

A catalytic composition useful for the conversion of an olefin selected from the group consisting of propylene, isobutylene or mixtures thereof, to acrylonitrile, methacrylonitrile, and mixtures thereof. The catalytic composition comprising a complex of metal oxides comprising bismuth, molybdenum, iron, cerium and other promoter elements, wherein the X-ray diffraction pattern of the catalytic composition has X-ray diffraction peaks at 2θ angle 28±0.3 degrees and 2θ angle 26.5±0.3 degrees, and wherein the ratio of the intensity of the most intense x-ray diffraction peak within 2θ angle 28±0.3 degrees to the intensity of most intense x-ray diffraction peak within 2θ angle 26.5±0.3 degrees is defined as X / Y, and wherein X / Y is greater than or equal to 0.7.

Owner:INEOS EURO LTD

In situ modification of molybdenum-based catalysts

A process for the conversion of a hydrocarbon selected from the group consisting of propylene, isobutylene, propane, isobutane or mixtures thereof, to acrylonitrile, methacrylonitrile, or mixtures thereof, the process comprising the step of reacting in the vapor phase at an elevated temperature and pressure said hydrocarbon with a molecular oxygen-containing gas and ammonia, in the presence of a molybdenum-based ammoxidation catalyst and a catalyst modifier, wherein said catalyst modifier comprises a molybdate or a polymolybdate of at least one element M selected from the group consisting of cesium, rubidium, potassium, sodium, thallium, lithium, nickel, cobalt, iron, chromium, copper, magnesium, manganese, cerium and phosporus, and wherein the ratio of the M elements to Mo in the molybdate or polymolybdate is greater than the ratio for these M elements to Mo in the molybdenum-based catalyst. The catalyst modifier is useful in modifying the performance of molybdenum-based catalyst and inhibiting molybdenum oxide loss for such catalysts.

Owner:INEOS EURO LTD

Method for preparing high-density polymethacrylimide foam material

The invention discloses a method for preparing a high-density polymethacrylimide foam material. The high-density polymethacrylimide foam material is prepared by taking methacrylic acid and methacrylonitrile as comonomers and N,N'-diamine diphenylmethane type bismaleimide as a density control agent, adding an initiating agent, a foaming agent, a cross-linking agent and a nucleating agent to copolymerize so as to obtain a methacrylic acid and methacrylonitrile copolymer resin matrix, and further performing high-temperature foaming and thermal treatment. By adopting the method, PMI (Polymethacrylimide) foam with the density of 320kg / m<3> at most is prepared, and the difficult problem that foam plastic with the density greater than 200kg / m<3> has less possibility of being prepared from the polymethacrylimide foam is solved. The material can be applied to fields requiring PMI foam plastic with high density, such as airplanes and radar shells.

Owner:JIANGSU ZHAOJUN NEW MATERIAL CO LTD

Acrylic rubber and cross-linkable acrylic rubber composition

InactiveUS7402631B2Well balanced heat resistance and cold resistance and fuel oil resistanceImprove stabilityCross-linkMeth-

An acrylic rubber, comprising an alkoxyalkyl(meth)acrylate monomer unit in an amount of 70.1 to 99.8 wt %, a methacrylonitrile monomer unit in an amount of 0.1 to 9.9 wt % and a butenedionic acid monoester monomer unit in an amount of 0.1 to 20 wt %; and a cross-linkable acrylic rubber composition made by containing the acrylic rubber and a cross-linking agent. According to the invention, it is possible to provide a cross-linkable acrylic rubber composition having excellent scorch stability and an acrylic rubber cross-linked product, which can be obtained by cross-linking the cross-linkable acrylic rubber composition, having excellent heat resistance, cold resistance and fuel oil resistance.

Owner:ZEON CORP

Positive pole of Li-ion battery and the Li-ion battery

InactiveCN101212053AHigh specific capacityImproved magnification performanceCell electrodesSecondary cellsMethacrylatePhysical chemistry

The invention relates to an anode of a lithium ion battery, which comprises a current collector and an anode material on the current collector. The anode material contains an anode active material and a binding agent, wherein the binding agent comprises a first polymer and a second polymer. The first polymer contains fluorine with a functional group, and the second polymer contains at least a cell of acrylonitrile cell, a methylacrylonitrile cell, an acrylic acid ester cell and a methacrylic acid ester cell. The invention also provides the lithium ion battery containing the anode. The anode of the lithium ion battery provided by the invention can improve the specific capacity, rate performance and cycle performance of the battery.

Owner:SHANGHAI BYD

Mixed metal oxide catalysts for the ammoxidation of propane and isobutane

InactiveUS20080103325A1Organic compound preparationHeterogenous catalyst chemical elementsGas phaseHafnium

A catalyst composition comprising molybdenum, vanadium, antimony niobium, at least one element select from the group consisting of titanium, tin, germanium, zirconium, and hafnium, and at least one lanthanide selected from the group consisting of lanthanum, praseodymium, neodymium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium and lutetium; with the proviso that catalyst contains germanium (in the absence of at last one of titanium, tin, zirconium, hafnium) only in combination with neodymium and / or praseodymium and no other lanthanides. Such catalyst compositions are effective for the gas-phase conversion of propane to acrylonitrile and isobutane to methacrylonitrile (via ammoxidation).

Owner:INEOS USA LLC

Polymethacrylimide foam material and preparation method thereof

The invention discloses a polymethacrylimide foam material and a preparation method thereof. The preparation method comprises the following steps: mixing a propylene monomer containing carboxyl, a propylene monomer containing acylamino, a polymerization initiating agent, a foaming agent and a cross-linking agent according to a proportion in parts by weight; electrically stirring or magnetically stirring to obtain uniform mixed liquid; pouring the mixed liquid into a sealed glass container to pre-polymerize so as to obtain a transparent block; and then hot processing to obtain the polymethacrylimide foam material. The propylene monomer containing the carboxyl and the propylene monomer containing the acylamino are used as main monomers to prepare the polymethacrylimide foam material by prepolymerization and hot processing without any virulent (methyl) acrylonitrile after being mixed. The invention has the advantages of simple and convenient working procedures and great production cost reduction. The prepared polymethacrylimide foam material can be directly widely applied to the fields of aerospace, carrier rockets, railway locomotives, ships, wind power generating blades, sports goods, and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Core-shell polymeric particles

The present invention provides a polymeric particle including a core, a first shell, and a second shell is provided: the core including, when dry, at least one void; the first shell polymer having a calculated glass transition temperature('Tg') greater than 50 DEG C and including, as polymerized units, from 15% to 60%, by weight based on the weight of the first shell, monomer selected from the group consisting of acrylonitrile, methacrylonitrile, acrylamide, methacrylamide, and mixtures thereof; and from 0.3% to 10%, by weight based on the weight of the first shell polymer, multiethylenically unsaturated monomer; and the second shell polymer having a Tg of from -60 DEG C to 50 DEG C; wherein the weight ratio of the second shell polymer to the total of all other structures of the polymeric particle is from 0.5:1 to 3:1.The particle provides binding functionality and, when dry, opacity and energy savings. A method for providing a polymeric particle and a method for providing opacity to a dry coating are also provided.

Owner:ROHM & HAAS CO

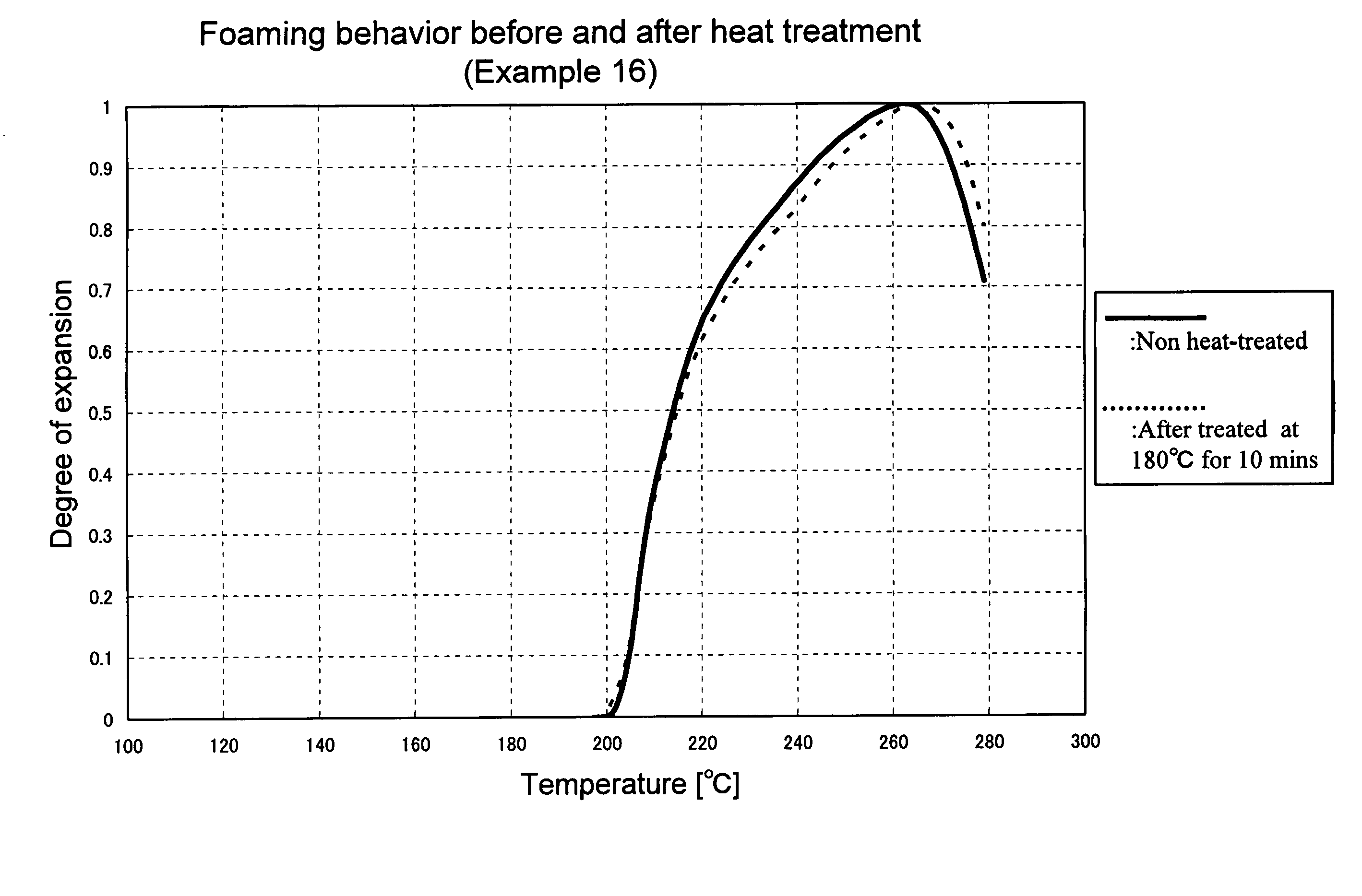

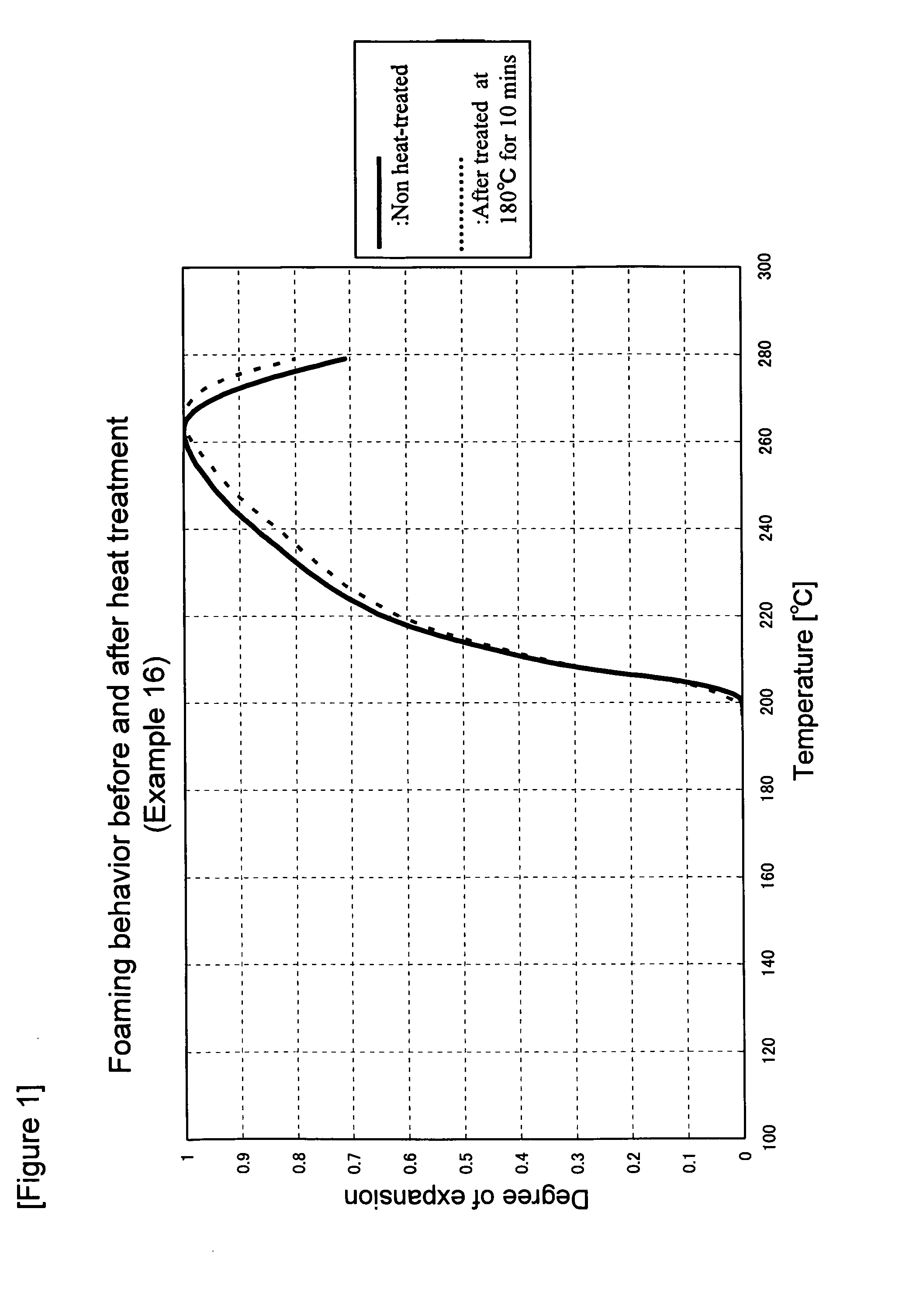

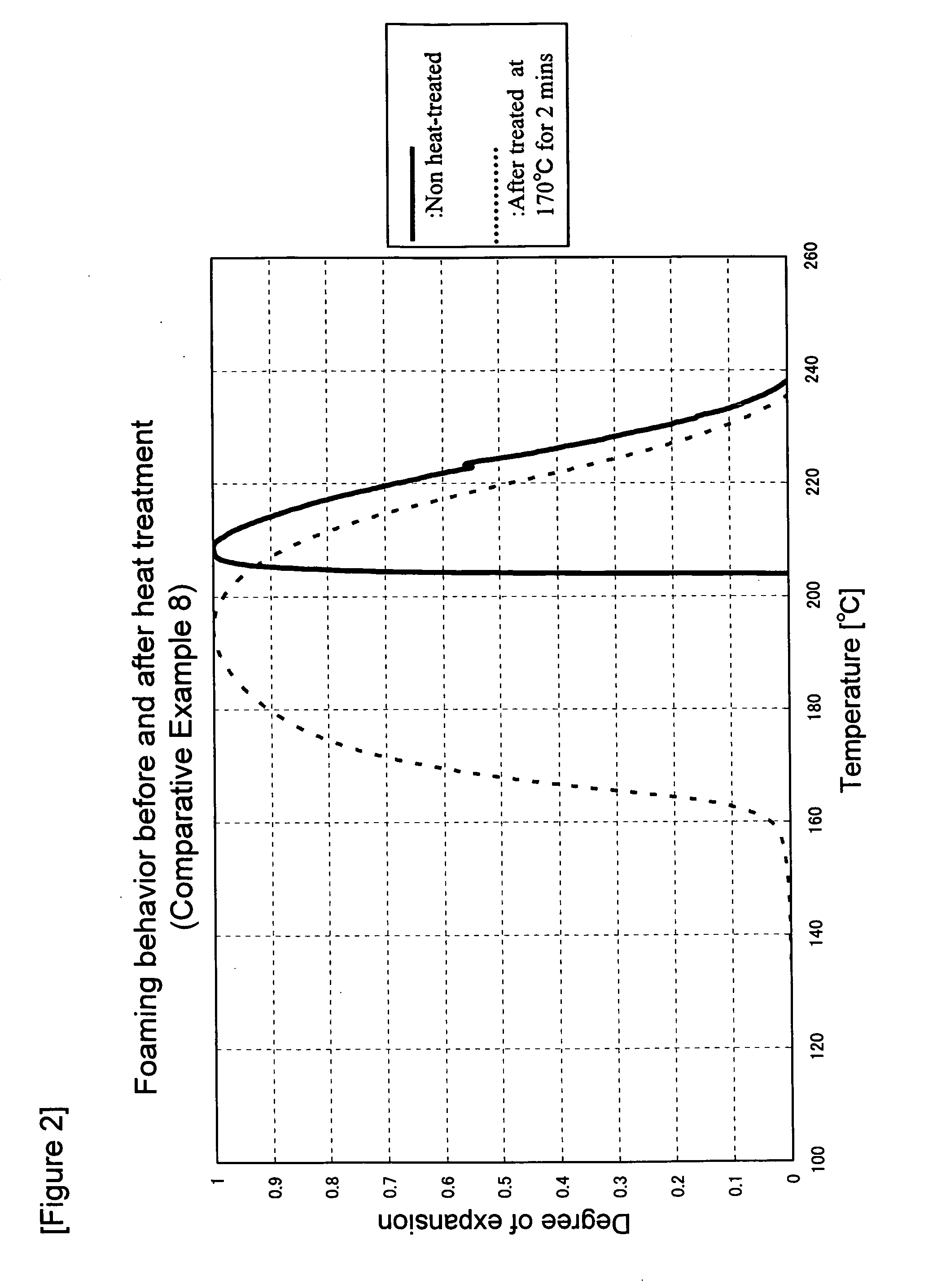

Thermally Foamable Microsphere, Method of Producing the Same, and Use Thereof

ActiveUS20090292031A1Improve heat resistanceHigh expansion rateOther chemical processesExpansion ratioMethacrylonitrile

This invention aims to provide a thermally foamable microsphere which is excellent in heat resistance, has a high expansion ratio, and shows stable foaming behavior; a method of producing the thermally foamable microsphere; and suitable use thereof.This invention provides a thermally foamable microsphere in which an outer shell encapsulating a foaming agent is formed of a copolymer having a polymethacrylimide structure. In particular, this invention provides a thermally foamable microsphere in which monomers capable of forming the polymethacrylimide structure by a copolymerization reaction are methacrylonitrile and methacrylic acid. Moreover, this invention provides a method of producing the thermally foamable microsphere and use of the thermally foamable microsphere as an additive.

Owner:KUREHA KAGAKU KOGYO KK

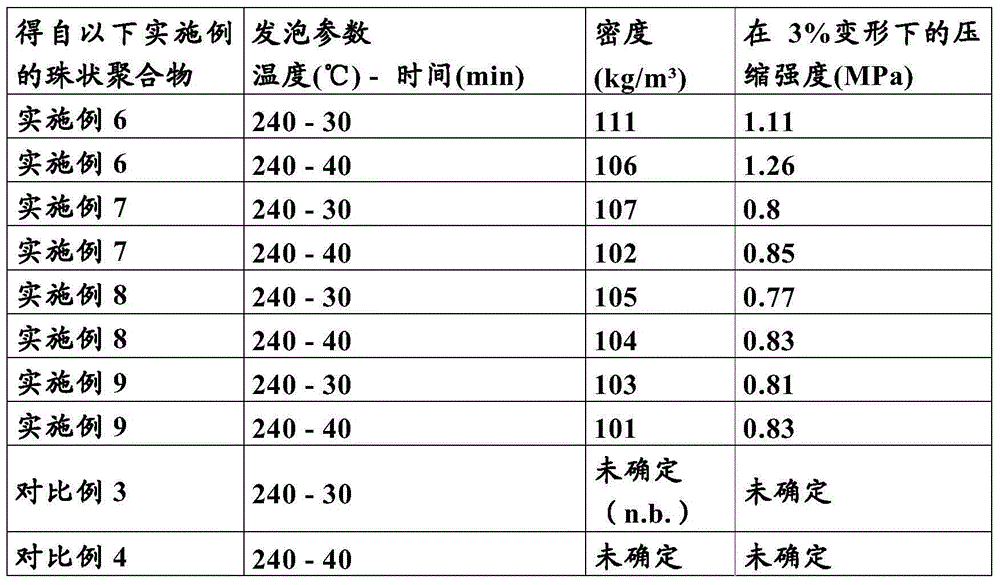

Bead polymer for producing PMI foams

The invention relates to a foamable bead polymer consisting of (meth)acrylonitrile, (meth)acrylic acid, copolymerizable latent expanding agents and optionally (meth)acrylic acid esters, to the production of said polymer by means of suspension polymerization and to the use thereof for producing foams. Using a bead polymer of this type it is possible, for example, to carry out a simple in-mould foaming process to produce products directly in the form of the desired workpiece. These workpieces are particularly suitable for use as components in spacecraft, aircraft, water and land craft and for other construction elements.

Owner:EVONIK ROEHM GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com