Patents

Literature

144 results about "Vinylidine chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

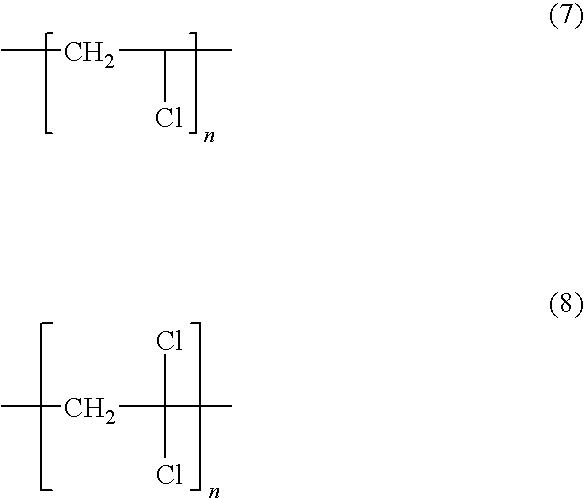

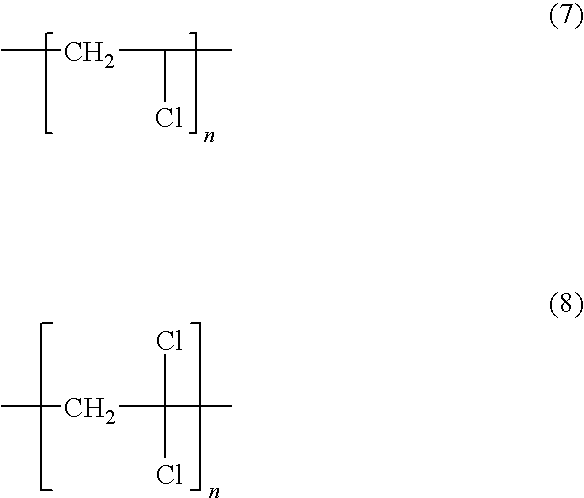

Definition of vinylidene chloride. : a low-boiling flammable liquid compound CH2=CCl2 prepared usually from trichloroethane and used in making saran by polymerization; 1,1-dichloro-ethylene — see polyvinylidene chloride.

Method for preparing polyvinylidene chloride and acrylic ester copolymerization latex

The invention provides a preparation method of copolymerization latex of polyvinylidene chloride and acrylate, which comprises that reacts raw materials polyvinylidene chloride monomer, second monomer, functional monomer, composite emulsifier, pH adjuster, initiator, seed latex, and water in inertia gas, 0.08-0.12MPa and 50-60DEG C, collects polyvinylidene chloride and acrylate copolymerization latex from reaction product. The inventive PVDC latex is white stably, without changing into yellow after coating, with high stability. The latex can be directly coated on surface of base material as BOPP, BOPET and PVC hard sheet, while the coated or coated and dried film has barrier property, damp proofness, fragrance protectiveness, chemical drug resistance, and fireproof or the like. The film is transparent for long time, without changing into yellow. The inventive product can be used in one-time environment-friend dinnerware and inner layer of paper package, as tobacco, food and drug.

Owner:SHANGHAI CHLOR ALKALI CHEM

High-obstruct multiple-layer film for packaging liquid and manufacturing method thereof

InactiveCN101081653AReduce consumptionReduce thicknessFlexible coversWrappersPolyesterPolymer science

The present invention discloses one kind of multilayer high blocking film for packing liquid material, the multilayer high blocking film includes polyethylene-based heat sealing layer(s), blocking polymer layer(s) preferably of ethylene-vinyl alcohol copolymer, PVA or polyvinylidene dichloride; and protecting layer(s) of polypropylene, polyester, etc. It has the total thickness below 80 micron, preferably of 55-65 micron. The present invention discloses also the making process of the multilayer high blocking film.

Owner:刘建林

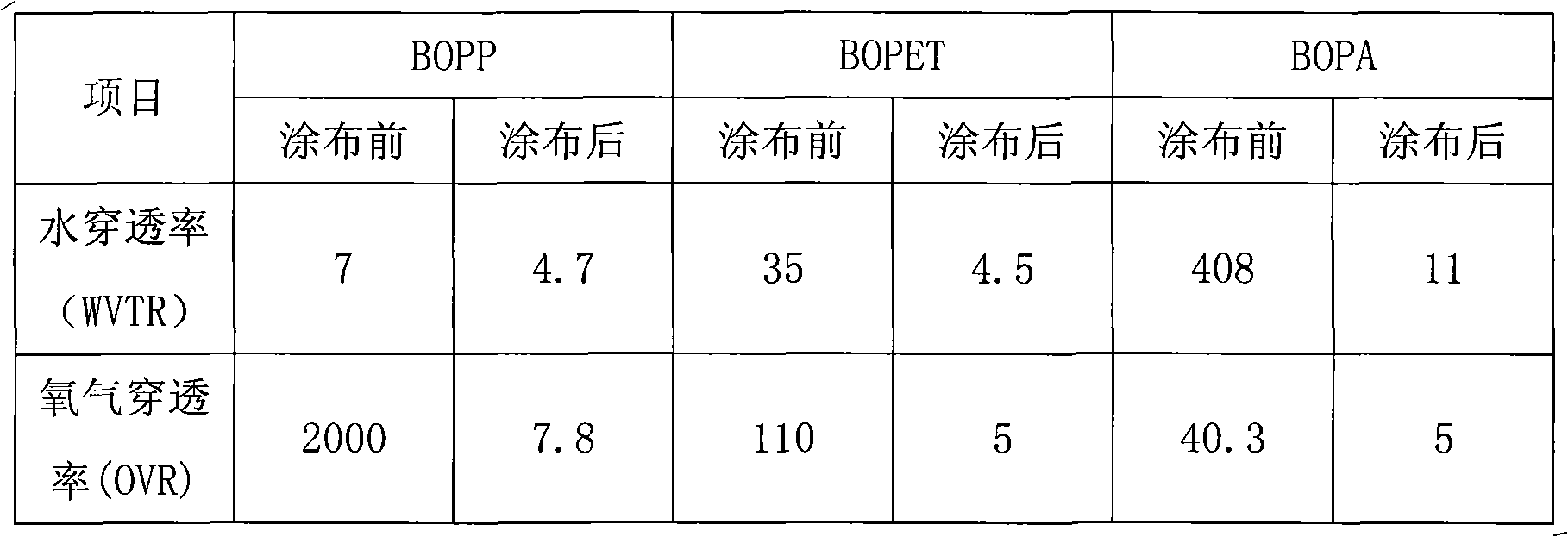

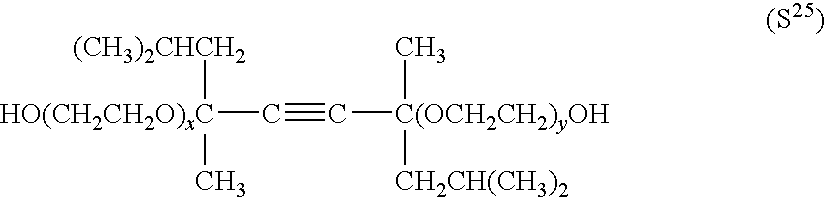

High barrier food package coated membrane latexes by thermal sealing at low temperature and preparation method

InactiveCN101358054AExtended shelf lifeHigh barrierFlexible coversWrappersCoated membraneVinylidine chloride

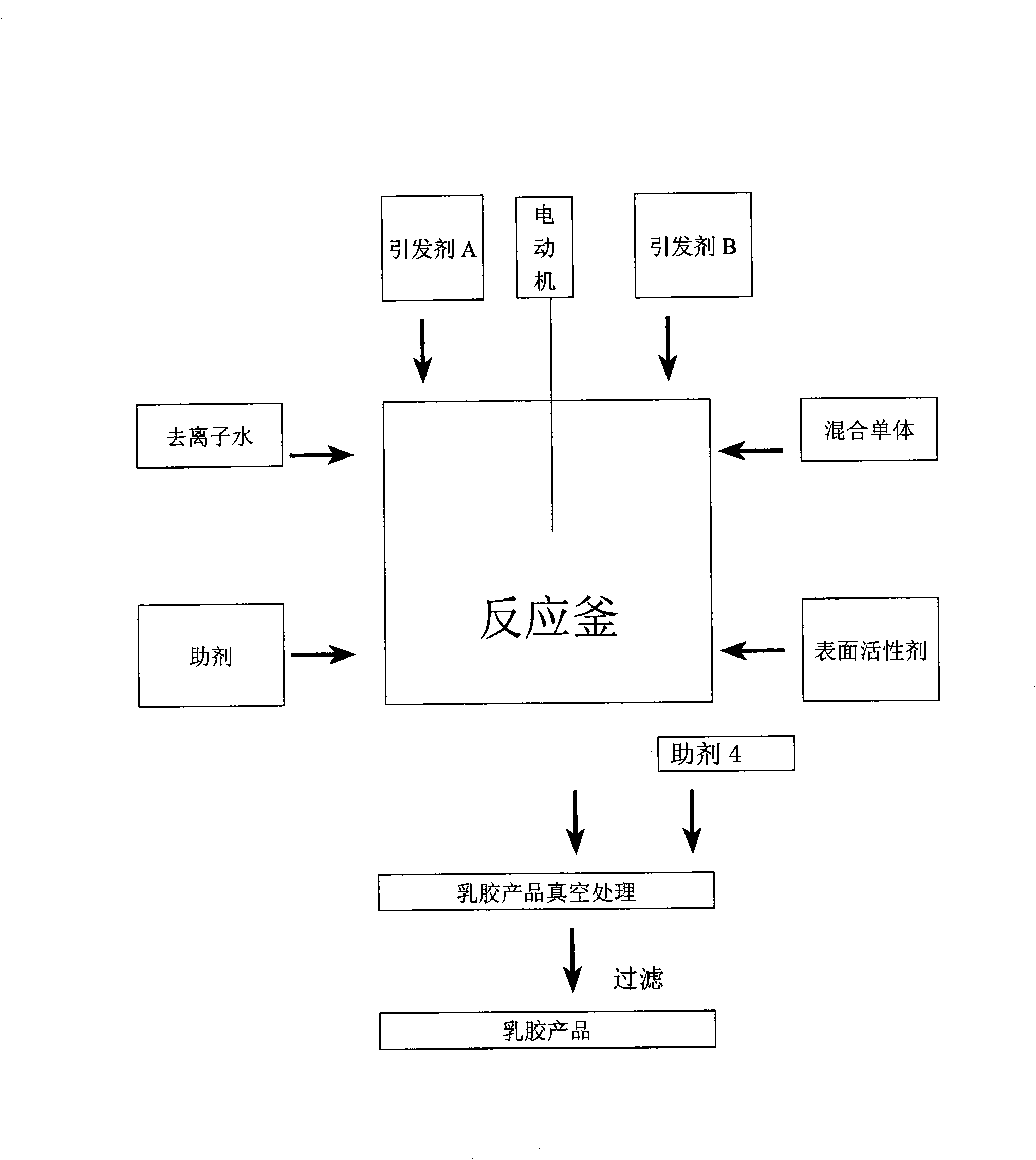

The invention relates to a low-temperature heat-sealing high-barrier food packaging film coating latex. The composition points of the mixed monomer of the latex is that vinylidene chloride accounts for 80 to 93 percent of the total amount of the mixed monomer; methyl acrylate, methyl ethyl oxalate, methyl methacrylate, butyl ester, acrylonitrile or methacrylonitrile account for 2 to 10 percent of the total amount of the mixed monomer; itaconic acid, acrylic acid, methacrylic acid account for 0.5 to 5 percent of the total amount of the mixed monomer; the surfactants added are 0.7 portion of SAS and 0.3 portion of sodium dodecyl sulfate; the additive 3 is 0.01 portion of metallic salt. The preparation method includes the following steps: deionized water, surfactant and additive are added in a reactor; the reactor is vacuumized and the gas is replaced by nitrogen gas; the mixed monomer is added. The product of the invention has the advantages of low temperature heat sealing and high barrier performance, and the food using the product has longer shelf life.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

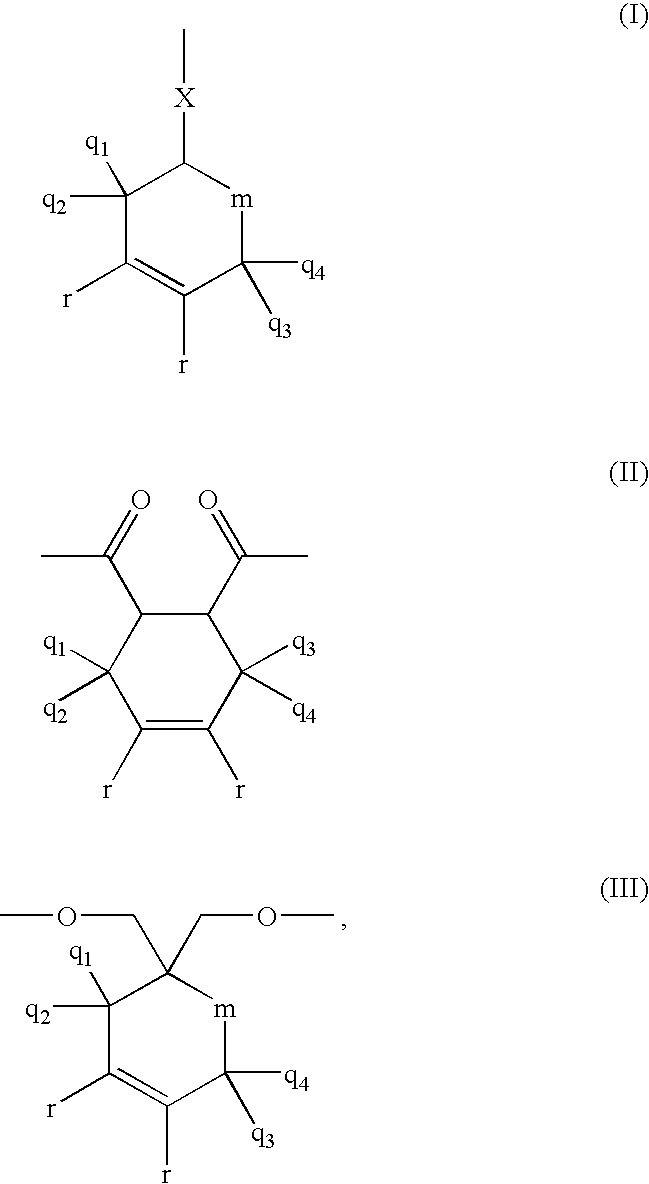

Compatible blend systems of oxygen barrier polymers and oxygen scavenging polymers

InactiveUS7247390B1Improve compatibilityGood compatibilitySynthetic resin layered productsThin material handlingEpoxyPolyester

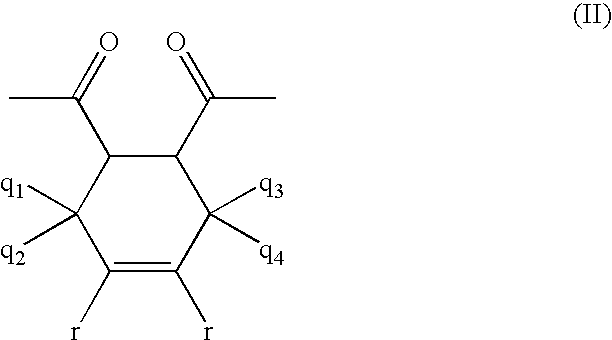

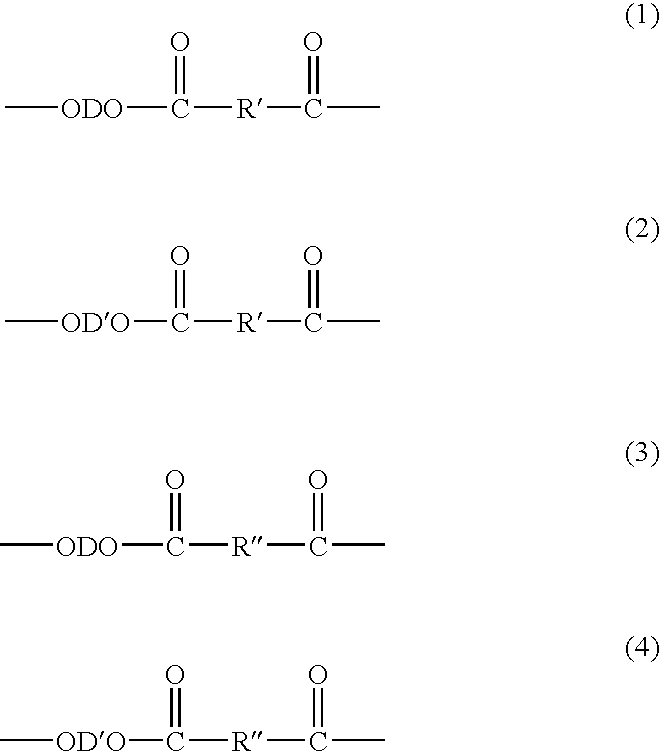

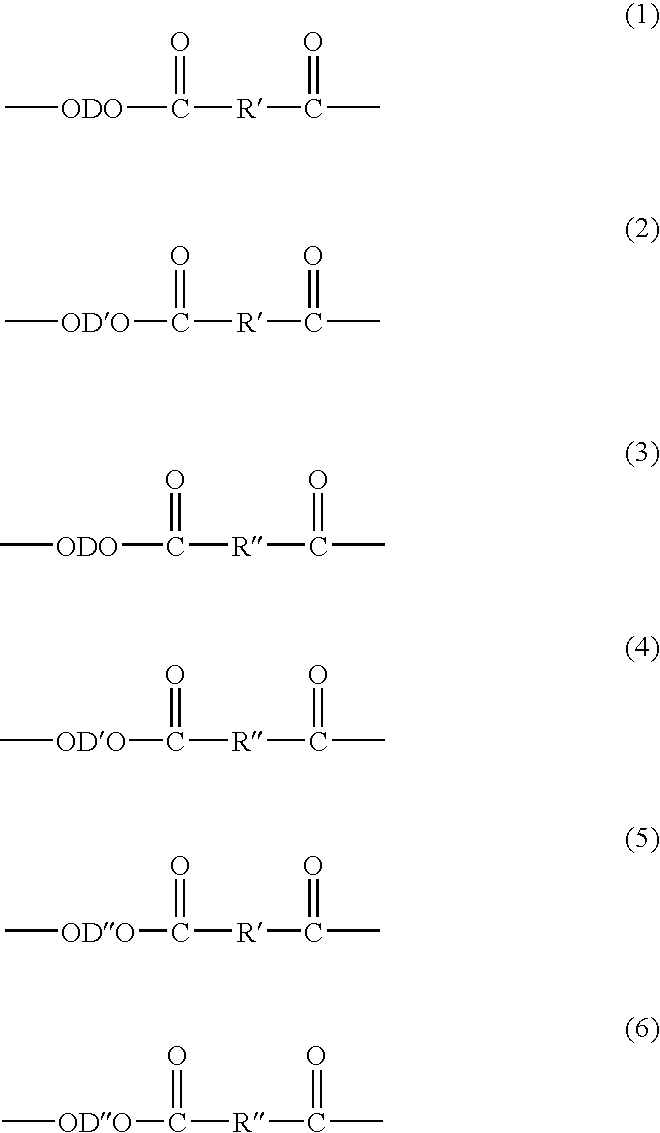

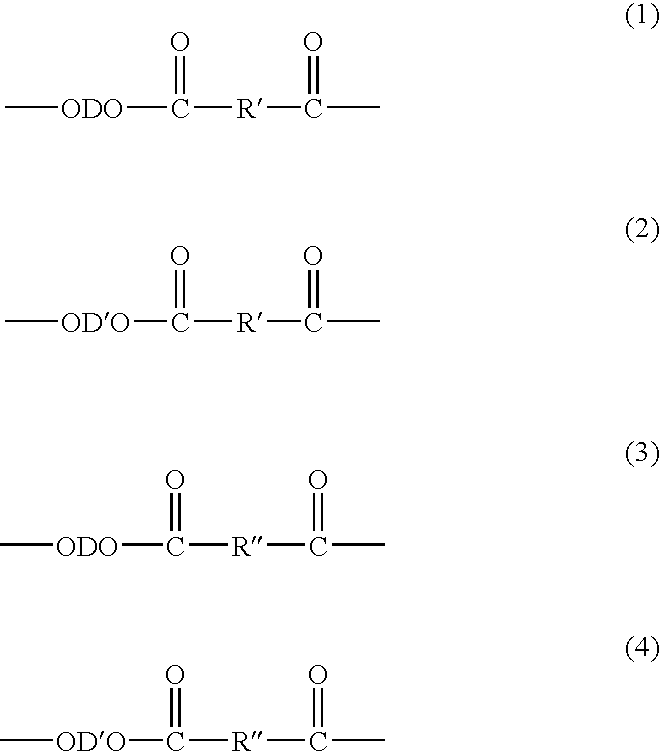

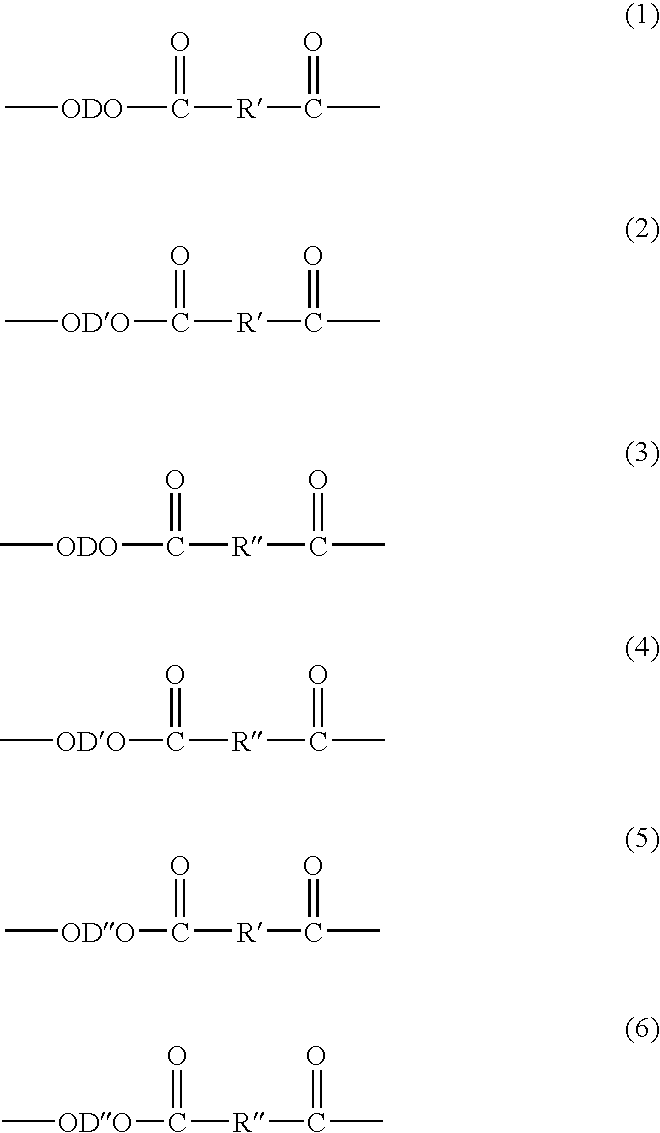

Herein is disclosed an oxygen barrier composition comprising an oxygen barrier polymer and an oxygen scavenging polymer. Preferably, the oxygen barrier polymer is selected from polymers or copolymers of vinyl alcohol, polyesters, polymers or copolymers of vinylidene dichloride, polymers or copolymers of epoxies, polysulfones, polymers or copolymers of acrylonitrile, polymers or copolymers of isocyanates, or polyamides other than MXD6; and the oxygen scavenging polymer either comprises an ethylenic backbone and a cyclic olefinic pendant group of structure I, or a polyester group of structure II or structure III:wherein q1, q2, q3, q4, and r are independently selected from hydrogen, methyl, or ethyl; m is —(CH2)n—, wherein n is an integer from 0 to 4, inclusive; X is null or a linking group; and, when r is hydrogen, at least one of q1, q2, q3, and q4 is also hydrogen. The oxygen barrier composition can be formed into an oxygen barrier layer of a packaging article. Such layers and articles, and methods for making same, are also disclosed.

Owner:CRYOVAC ILLC

Process for the manufacture of polybutylene terephthalate copolymers from polyethylene terephthalate, and compositions and articles thereof

ActiveUS20100168336A1Improved flow and mechanical propertyEfficient recyclingPlastic recyclingPolymer recoveryPolytetramethylene terephthalatePolymer science

A process comprises depolymerizing, with 1,4-butane diol, a first polymer comprising a polyethylene terephthalate component in the presence of at least one second polymer selected from the group consisting of polyvinyl chlorides, polyvinylidene chlorides, polyamides, polylactic acid, and combinations thereof to produce a molten mixture; and polymerizing the molten mixture under conditions sufficient to form a modified polybutylene terephthalate copolymer. The modified PBT comprises (a) at least one polyethylene terephthalate component residue, and (b) a member selected from the group consisting of (i) the at least one second polymer selected from the group consisting of polyvinyl chlorides, polyvinylidene chlorides, polyamides, polylactic acid, and combinations thereof; (ii) the at least one residue derived from the second polymer; and (iii) combinations thereof.

Owner:SHPP GLOBAL TECH BV

Water PVDC latex specially for painting special cloth and its preparing method

InactiveCN1986583AReduce contentImprove water resistanceTextiles and paperPolymer scienceNonwoven fabric

The present invention relates to water-thinned PVDC latex, and is especially a kind of water-thinned PVDC latex for painting special cloth and its preparation process. The water-thinned PVDC latex is prepared with mixed monomer through emulsion polymerization in the presence of emulsifier and initiator. The mixed monomer includes vinylidene chloride 75-90 %, acrylate monomer 8-20 % and unsaturated fatty acid 1-5 %. The water-thinned PVDC latex is used in treating non-woven fabric, and the treated non-woven fabric is hard, elastic, waterproof, heat resistant and crease resistant and may be used widely. In addition, the water-thinned PVDC latex has excellent compatibility with acrylic acid emulsion.

Owner:ZHEJIANG SENLANDE PACKAGING TECH

Preparation method of binary acid refined adsorbing material

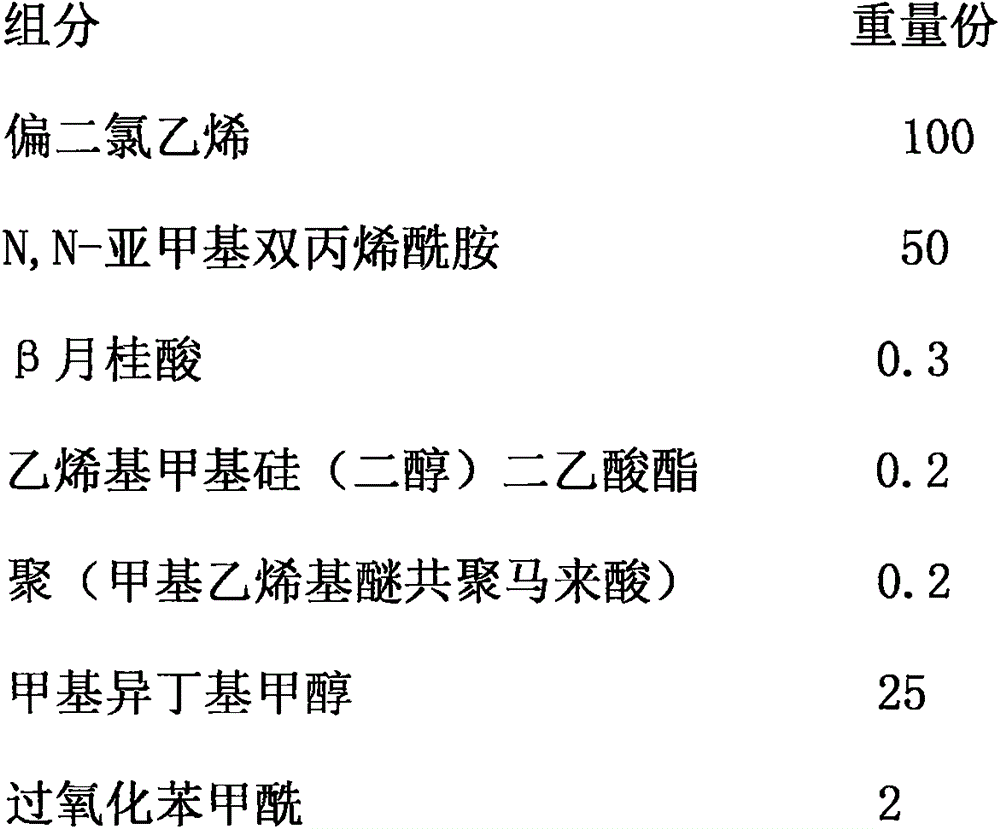

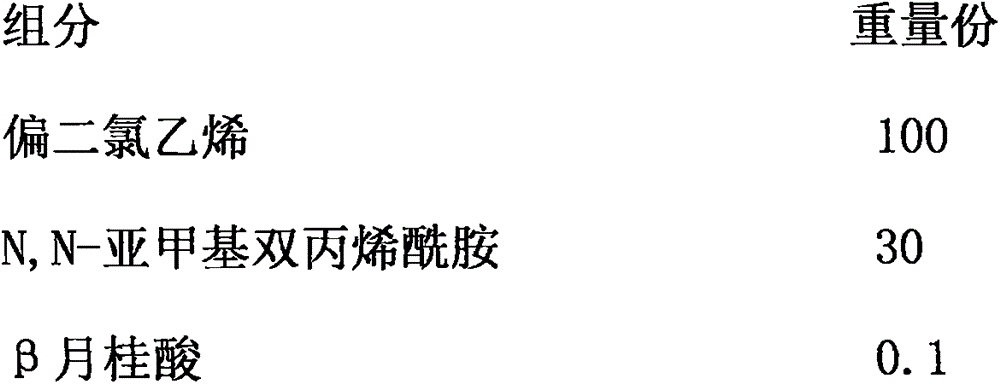

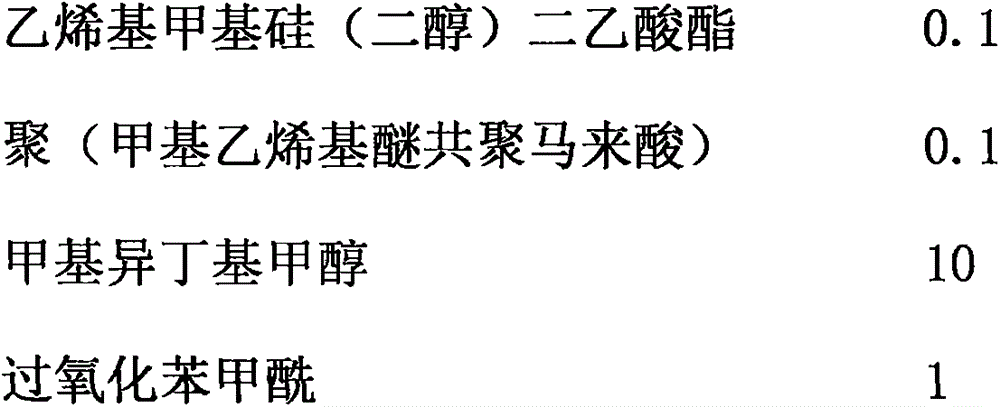

The invention relates to a preparation method of a binary acid refined adsorbing material. According to the preparation method, co-monomers, namely beta-myrcene, vinyl methyl silicone (diol) diacetate and N,N-methylene bisacrylamide, are added into vinylidene chloride, a dispersing aid (methyl vinyl ether copolymerized maleic acid) is added to generate a polymer, and the polymer is utilized for extracting decolored binary acid with a long carbon chain. The preparation method has the advantages that the adsorbing capacity is high, and the loss of binary acid caused by the repeated crystallization and filtration can be reduced.

Owner:XUZHOU HONGFENG HIGH MOLECULAR MATERIAL CO LTD

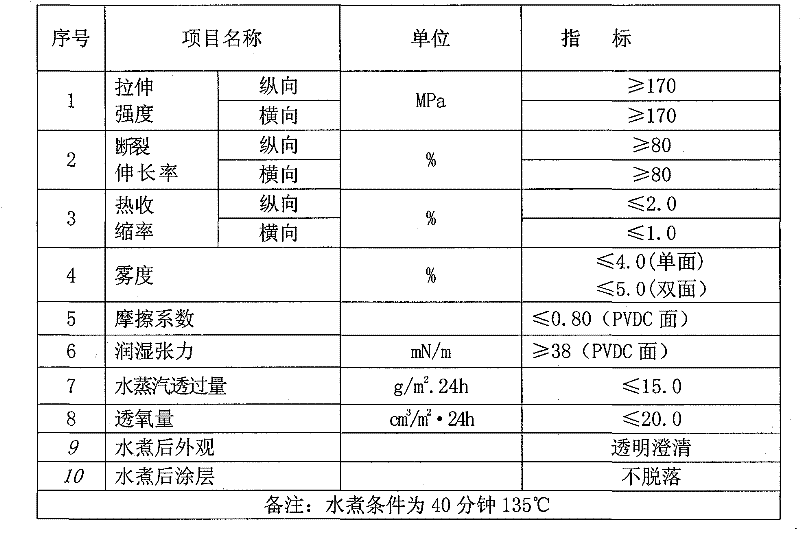

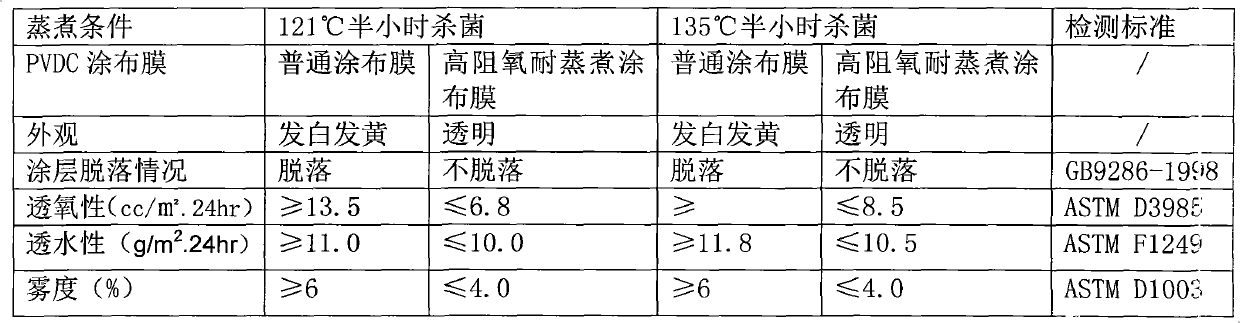

Cooking-resistant polyvinylidene chloride coating film and preparation method thereof

ActiveCN102380998AEasy to break awaySynthetic resin layered productsPretreated surfacesEmulsionAdhesive

The invention relates to a cooking-resistant polyvinylidene chloride coating film and a preparation method thereof. The cooking-resistant polyvinylidene chloride coating film comprises a substrate and a coating layer on the surface of the substrate, wherein a primer layer is formed between the coating layer and the substrate; the coating layer is a modified polyvinylidene chloride coating which is formed by coating a cooking-resistant polyvinylidene chloride emulsion on the surface of the primer layer and drying; the cooking-resistant polyvinylidene chloride coating film is prepared from the following raw materials in parts by weight: 25-95 parts of polyvinylidene chloride blending emulsion, 0-70 parts of softened water, 0-15 parts of slip agent and 0.1-5 parts of adhesive; and the polyvinylidene chloride blending emulsion is prepared form the following raw materials in parts by weight: 88-98.5 parts of polyvinylidene chloride emulsion and 1.5-12 parts of tetraethylenepentamine. The coating film has the advantages of cooking resistance, transparency, environment friendliness, safety, innocuity and low cost and can be used for packaging foods directly through compounding; the foods and a packaging bag are cooked together and subjected to high-temperature disinfection, and a customer can directly eat after opening the packaging bag.

Owner:HAINAN SHINER IND

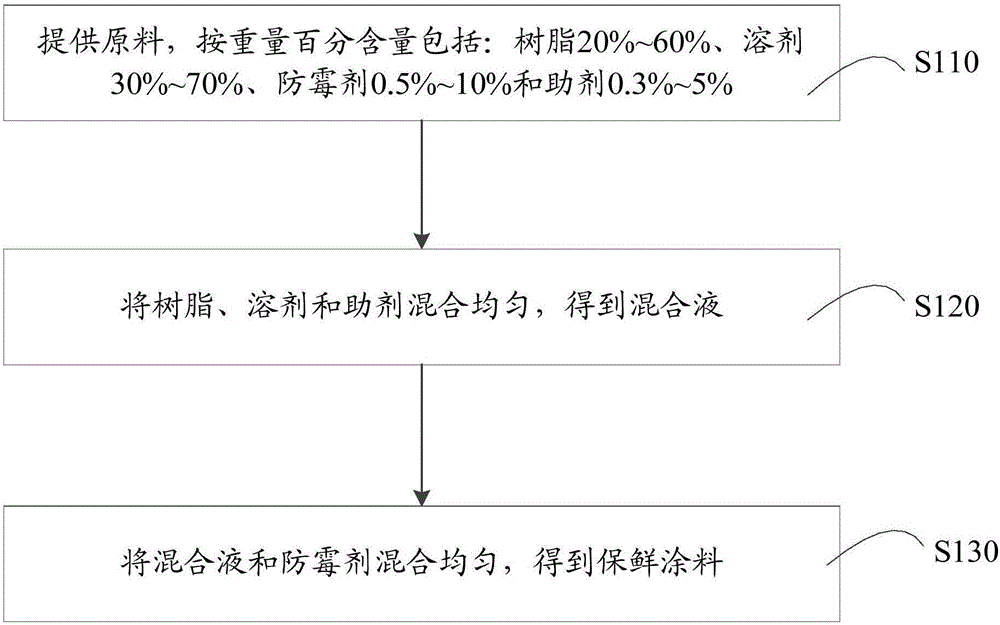

Mildew-proof fresh-keeping paint and preparation method and application thereof

InactiveCN106634517AEvenly dispersedGood fresh-keeping effectAntifouling/underwater paintsPaints with biocidesCarvacryl acetateSolvent

The invention provides mildew-proof fresh-keeping paint and a preparation method and application thereof. The mildew-proof fresh-keeping paint is prepared from the following ingredients in parts by weight: 20 to 60 percent of resin, 30 to 70 percent of solvents, 0.5 to 10 percent of mildew-proof agents and 0.3 to 5 percent of auxiliary agents, wherein the resin is at least one from polyurethane, acrylate copolymers, polyvinyl alcohol, polyvinylidene chloride, modified polyvinylidene chloride, ethylene-vinyl acetate copolymers, polyvinyl acetate copolymers and vinyl acetate-butyl ester coplymers; the solvent is at least one from water and ethyl alcohol. Therefore the resin is dissolved into the solvent; the film forming performance of the resin is regulated through an auxiliary agent; the ingredient mixture ratio is controlled, so that a pore-free coating with the compact surface is formed; therefore the moisture is effectively inhibited from entering or going out of the coating; the effects of maintaining the moisture constancy, keeping fresh and preserving the moisture can be achieved. The intersolubility of the resin and the mildew-proof agents is good, so that the mildew-proof agents are sufficiently dispersed into the resin; the mildew-proof agents can enter the cells through microbial cell membranes; the microbes can be eliminated, or the germination is prevented so as to prevent the mycete growth; the long-time stable fresh keeping effect is achieved.

Owner:CHANGDE JINRUN NEW MATERIAL TECH CO LTD

Multicomponent lubricant composition for processing rigid vinyl chloride polymers

Lubricant compositions and processes for producing such lubricant compositions. More specifically, low viscosity lubricant compositions for the working surface of an extrusion die during the processing of plastics that require lubricants to render them processable, such as polyvinyl chloride, chlorinated polyvinyl chloride, polyvinylidene chloride and copolymers thereof. The lubricant composition may include up to about 70% by weight of at least one metal salt while maintaining a melt viscosity low enough to process on conventional finishing equipment such as prill towers or pastillating equipment.

Owner:HONEYWELL INT INC

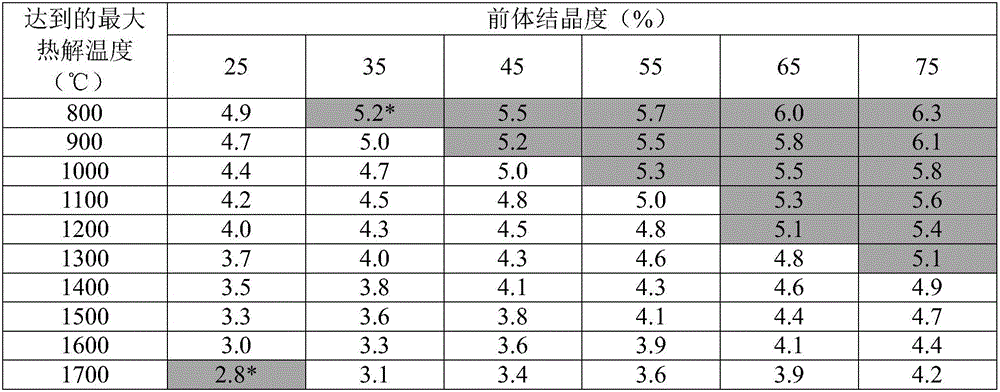

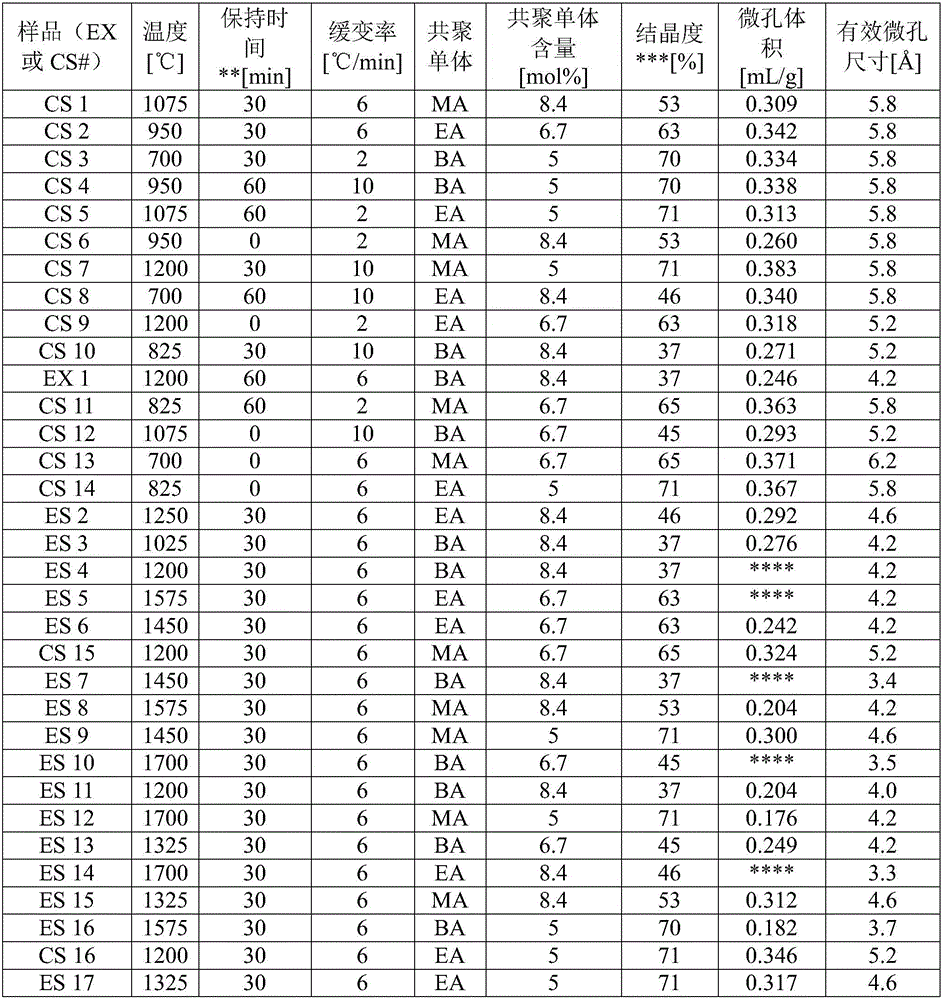

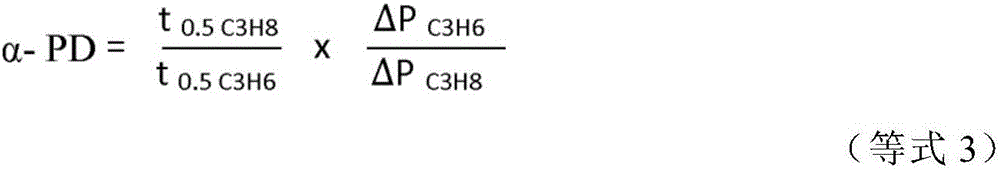

Vinylidene chloride copolymer-based carbon molecular sieve adsorbent compositions and processes therefor

Novel carbon molecular sieve (CMS) compositions comprising carbonized vinylidene chloride copolymer having micropores with an average micropore size ranging from 3.0 to 5.0 angstroms. These materials offer capability in separations of gas mixtures including, for example, propane / propylene; nitrogen / methane; and ethane / ethylene. Such may be prepared by a process wherein vinylidene chloride copolymer beads, melt extruded film or fiber are pretreated to form a precursor that is finally carbonized at high temperature. Preselection or knowledge of precursor crystallinity and attained maximum pyrolysis temperature enables preselection or knowledge of a average micropore size, according to the equation sigma= 6.09 +(0.0275*C) - (0.00233*T), wherein sigma is the average micropore size in Angstroms, C is the crystallinity percentage and T is the attained maximum pyrolysis temperature in degrees Celsius, provided that crystallinity percentage ranges from 25 to 75 and temperature in degrees Celsius ranges from 800 to 1700. The beads, fibers or film may be ground, post-pyrolysis, and combined with a non-coating binder to form extruded pellets, or alternatively the fibers may be woven, either before or after pre-treatment, to form a woven fiber sheet which is thereafter pyrolyzed to form a woven fiber adsorbent.

Owner:DOW GLOBAL TECH LLC

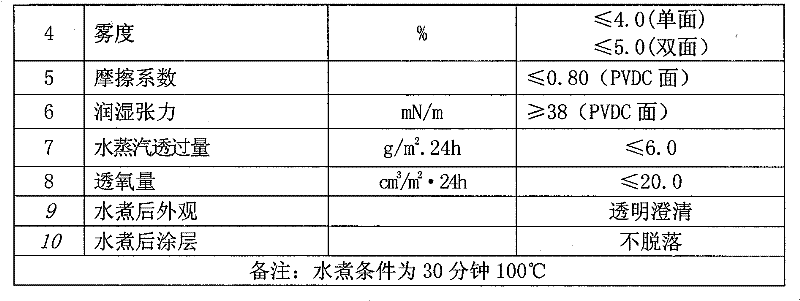

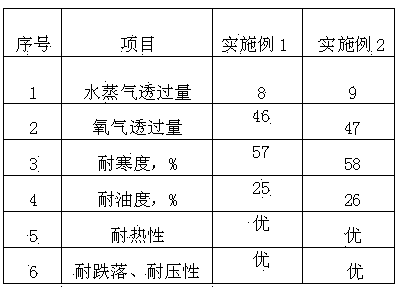

High-oxygen resistant steaming-resistant polyvinylidene chloride coating film and manufacturing method thereof

ActiveCN102848673AUnique appearance qualitySynthetic resin layered productsPretreated surfacesEmulsionSoftened water

The invention relates to a high-oxygen resistant steaming-resistant polyvinylidene chloride coating film and a manufacturing method thereof. The high-oxygen resistant steaming-resistant polyvinylidene chloride coating film comprises a base, a coating layer on the surface of the base, and a base glue layer between the coating layer and the base. The coating layer is a coating obtained by coating modified high-oxygen resistant steaming-resistant polyvinylidene chloride latex. The modified high-oxygen resistant steaming-resistant polyvinylidene chloride latex comprises: by weight, 30 to 38% of a high-oxygen resistant steaming-resistant polyvinylidene chloride blended emulsion, 1.5 to 6% of a nano-material filler, 1 to 8% of a slip agent, 0.1 to 5% of an abherent and 5 to 60% of softened water. The high-oxygen resistant steaming-resistant polyvinylidene chloride blended emulsion comprises: by weight, 40 to 94% of a vinylidene chloride monomer, 1.5 to 10% of an acrylate, 1 to 6% of one or more of acrylic acid and acrylonitrile, 0.5 to 2% of an initiator, 0.1 to 0.8% of an emulsifier, 0.5 to 1% of a stabilizer and 0 to 55% of soft water.

Owner:HAINAN SHINER IND

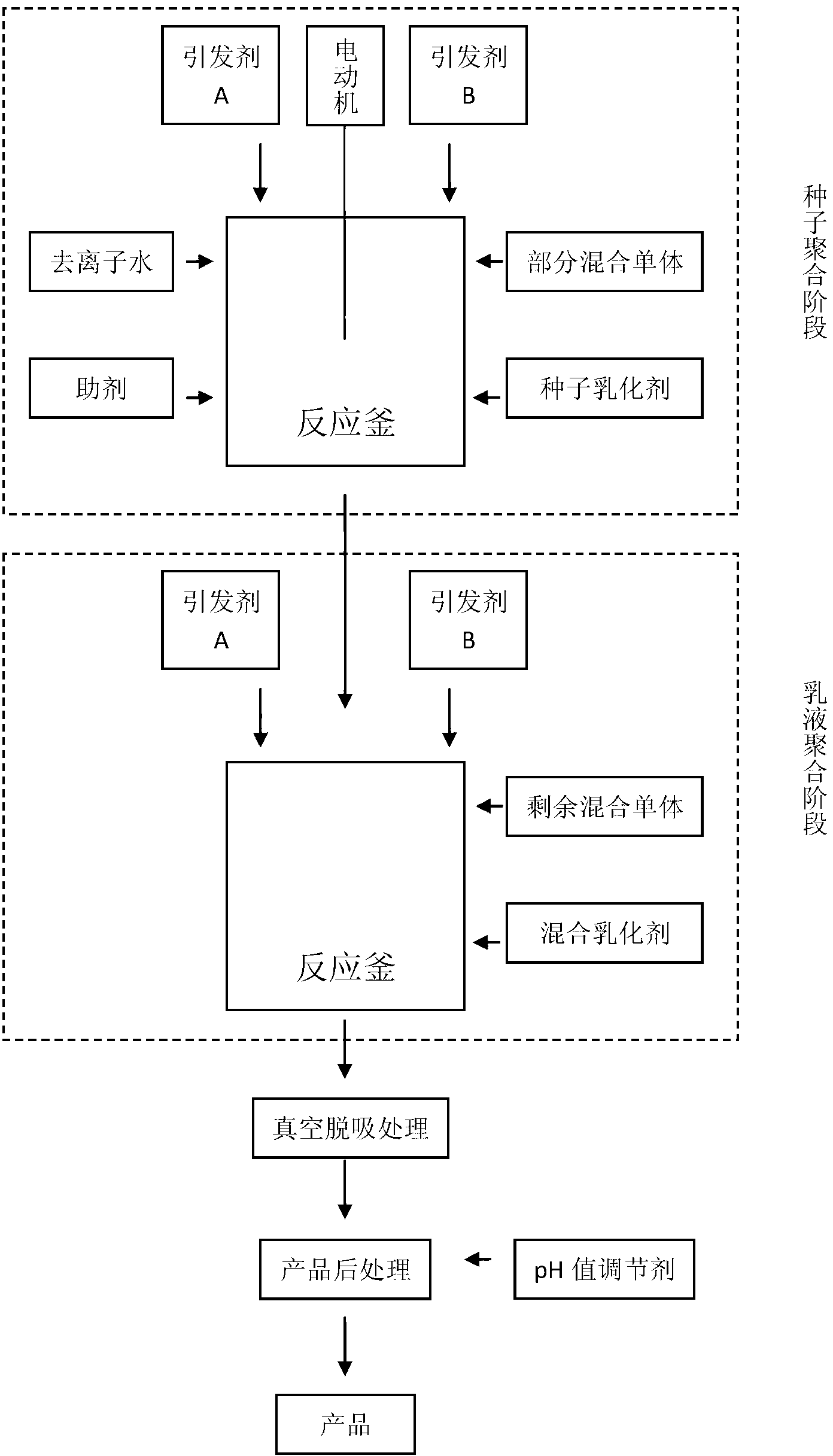

Preparation method of aqueous vinylidene chloride base glue used in high-barrier plastic film

The invention relates to a preparation method of aqueous vinylidene chloride glue used in a high-barrier plastic film. The preparation method comprises the following steps: taking cheap and available vinylidene chloride as a main comonomer, and selecting the vinylidene chloride, polymerizable functional monomer, acrylic monomer and part of unsaturated fatty acid to be copolymerized in the presence of various emulsifiers by seeded semi-continuous emulsion polymerization to obtain an aqueous vinylidene chloride adhesive with good property. When the base glue is applied to the bottom layer of the plastic film (polypropylene, polyethylene, polyester and polyamide), the base glue has the advantages of good wettabilityand strong cohesive force, and the base glue is especially suitable for replacing a polyurethane adhesive as the base glue when coating the high-barrier plastic film.

Owner:ANHUI UNIVERSITY +1

Textile finishing agent modified from Nano material and preparation method

InactiveCN1539860AConvenient sourceThe process method is simpleFibre treatmentChemistryIsooctyl acrylate

A nano material modified finishing agent for fabric is prepared through synthesizing the fluoric monomer by electrolysis, and copolymerization between 2-perfluoro octylamido ethyl acrylate, isooctyl acrylate, hydroxyethyl acrylate and metadichloroethylene. Its advantages are high antibacterial, hydrophobic and oleophobic power.

Owner:吉林省长吉图教育发展有限公司

VDC/MA copolymerized PVDC composition

ActiveCN101560276AThe color of the film surface is whiteImprove thermal stabilityChange colorMembrane surface

The invention discloses a VDC / MA copolymerized PVDC composition, which comprises the following components in portion by weight: 88 to 95 portions of vinylidene chloride monomer, 5 to 12 portions of methyl acrylate monomer, 0.005 to 0.02 portion of chelating agent, 0.05 to 0.25 portion of dispersant, 0.03 to 0.12 portion of pH modifying agent, 0.30 to 4.0 portions of thermal stability plasticizing agent, 0.15 to 0.40 portion of evocating agent, and 2.33 to 14.5 portions of post processing assistant. The weight average molecular weight MW of the composition is 75,000 to 90, 000. The VDC / MA copolymerized PVDC composition solves the problem that a PVDC resin has poor post processing thermal stability and is easy to decompose and change colors, and can keep the luster of an membrane surface unchanged for long term when the composition as a multilayer co-extrusion membrane or a co-extrusion cast membrane is used for packing low-medium temperature food.

Owner:ZHEJIANG QUZHOU JUSU CHEM IND CO LTD +1

Controlled release pesticide and fertilizer briquettes

InactiveUS6225258B1Simple compositionEasy to useBiocideAgriculture gas emission reductionAdhesiveFosetyl-Al

An attrition and shatter resistant plant nutrient / pesticide briquette composition which slowly releases the nutrients and biologically active materials over long periods of time, comprising slow release plant nutrient particles, pesticide sorption particles, liquid systemic pesticide sorbed on the pesticide sorption particles to reduce pesticide leachability, an adhesive, coating the slow release plant nutrient and pesticide sorption particles, the composition formed into briquettes by pressing into dies at elevated pressures and temperatures to make briquettes resistant to attrition and shattering. A six step method is provided for the preparation of the slow releasing briquettes from slow release fertilizers, such as magnesium ammonium phosphate; pesticide sorption particles, such as activated carbon; liquid systemic pesticides emulsions, such as imidachloprid fosetyl-Al, and metalaxyl; and adhesives, such as a vinylidine chloride, 2-ethylhexyl acrylate, acrylic acid resin emulsion.

Owner:AGRINUTRIENTS TECH GRP INC

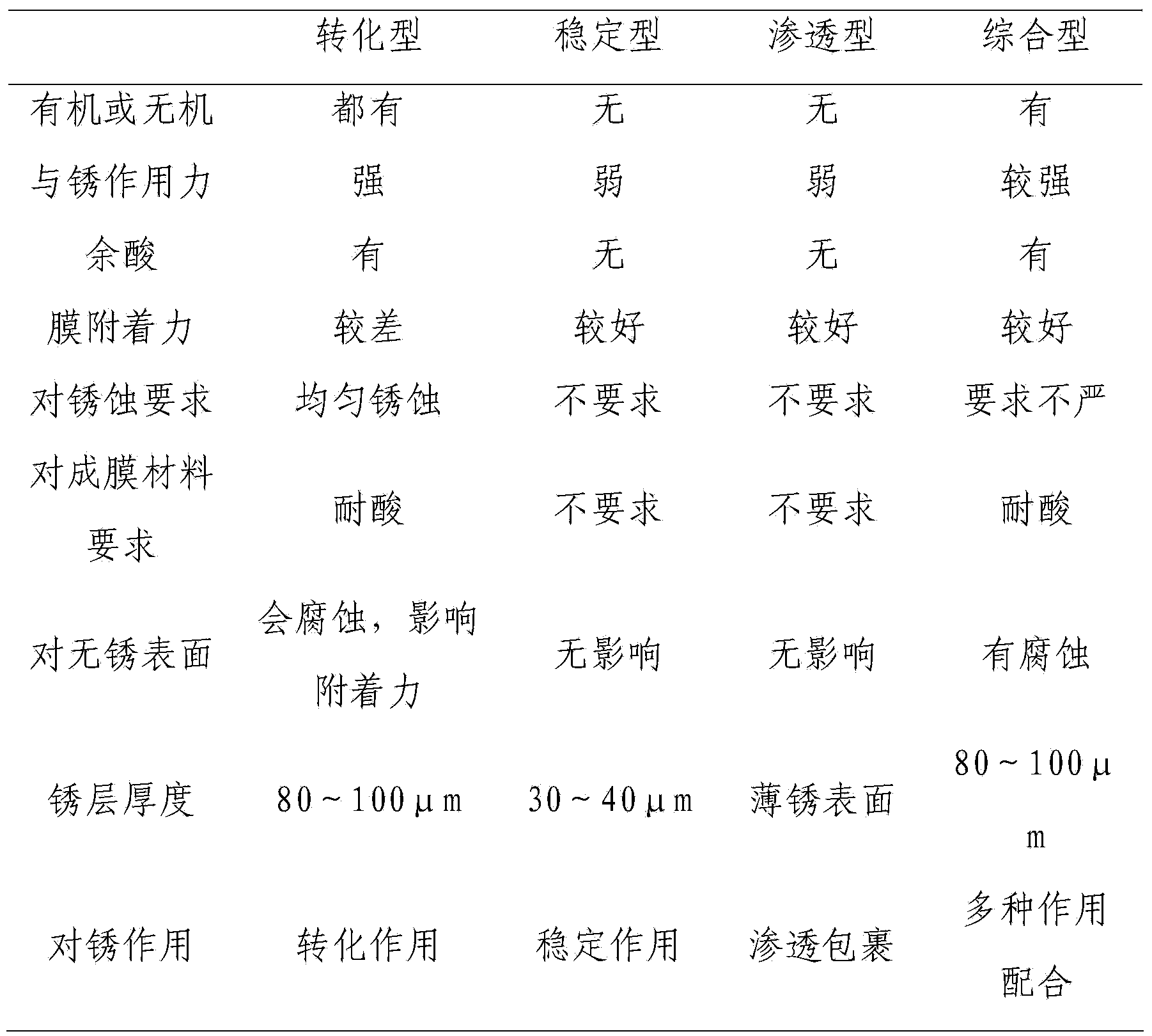

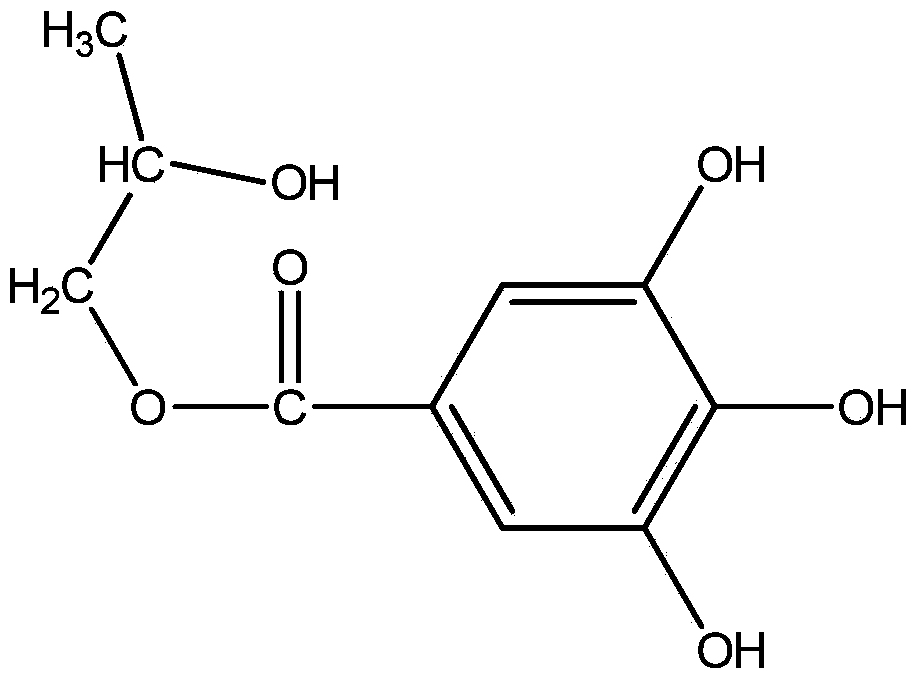

Rust transforming agent and preparation method thereof, water-based iron rust conversion coating and preparation method thereof

InactiveCN103849862AImprove water resistanceImprove stabilityAnti-corrosive paintsMetallic material coating processesWater basedGallic acid ester

The invention belongs to the technical field of a metal anti-corrosion coating, and particularly relates to a rust transforming agent and a preparation method thereof, a water-based iron rust conversion coating and a preparation method thereof. The rust transforming agent comprises a step of synthesizing 2-hydroxypropyl 3,4,5-trihydroxybenzoic acid by taking a gallic acid, 1,2-propylene glycol and a p-toluenesulfonic acid as initial raw materials, wherein the rust transforming agent contains 18.5-26.7% of gallic acid, 66.6-74% of 1,2-propylene glycol, and 6.6-7.5% of p-toluenesulfonic acid; the water-based iron rust conversion coating is prepared from a vinylidene chloride composite polymer emulsion, ethylene glycol butyl ether, filling slurry prepared in the step (1) and the rust transforming agent. The prepared rust transforming agent disclosed by the invention is good in water tolerance, strong in stability, and good in matching property with a water paint and an oil paint.

Owner:SHANDONG UNIV OF SCI & TECH

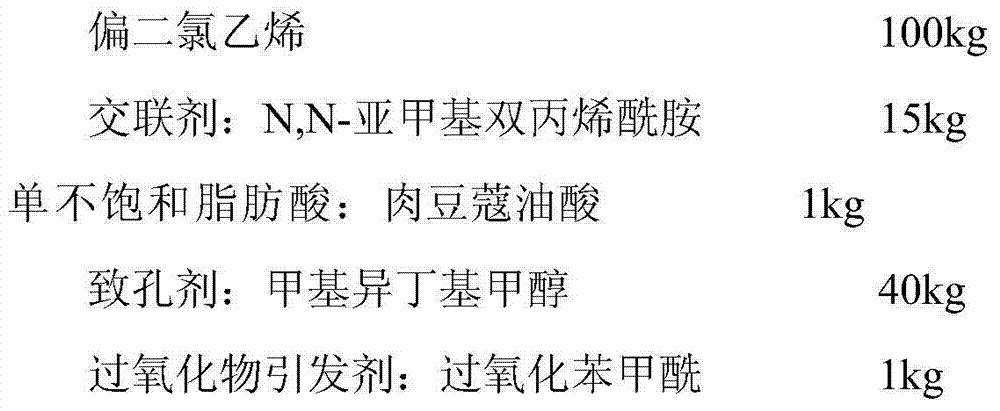

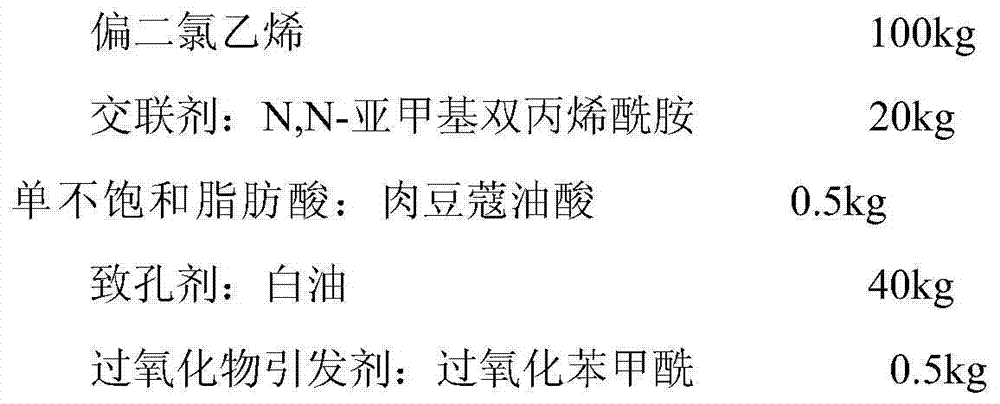

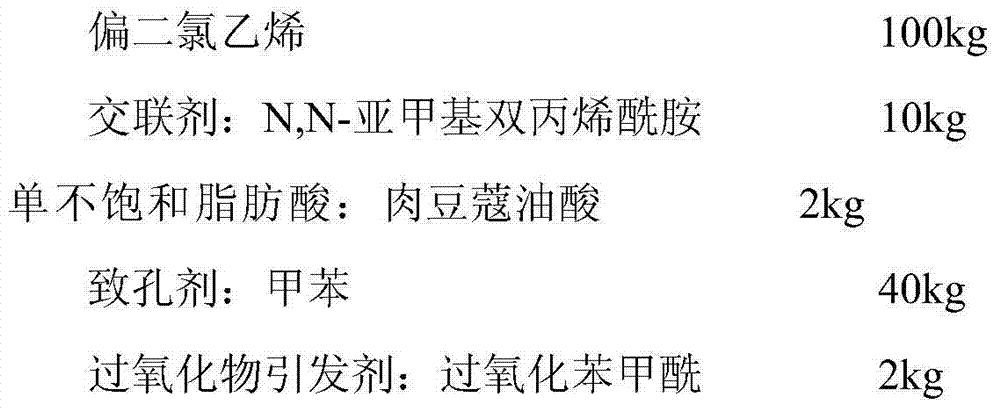

Preparation method of spherical polyvinylidene chloride resin with micropore structures

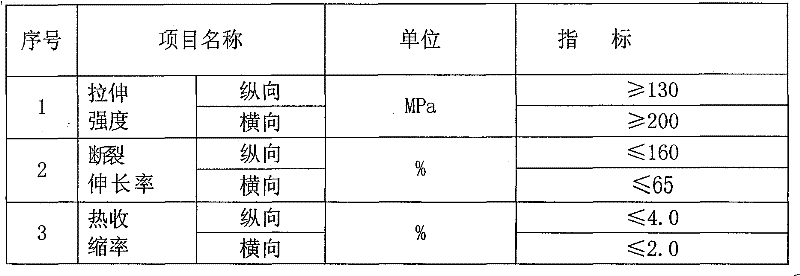

The invention discloses a preparation method of spherical polyvinylidene chloride resin with micropore structures. The preparation method comprises the following steps: (1) adding 100 parts of water and 0.5-2 parts of an organic dispersant in parts by weight into a reaction kettle, and uniformly stirring to obtain aqueous phase liquor; (2) uniformly stirring 100 parts of vinylidene chloride, 10-20 parts of a cross-linking agent, 0.5-2 parts of monounsaturated fatty acids, 0.5-2 parts of a peroxide initiator and 10-40 parts of a pore-foaming agent in parts by weight to obtain oil phase liquor; and (3) adding the oil phase liquor prepared in the step (2) into the reaction kettle filled with the prepared aqueous phase liquor in the step (1) in a weight ratio of (1.5-1.6):1, reacting for 10-20 hours at 70-100 DEG C, discharging after reaction, and water-washing, drying and separating the pore-foaming agent to obtain a spherical polyvinylidene chloride resin product with the micropore structures. The spherical polyvinylidene chloride resin with the micropore structures disclosed by the invention has the advantages of great grain size of the product prepared, high specific surface area, good mechanical property, long service life and the like.

Owner:JUHUA GROUP TECH CENT

Water/oil repellent composition and article

InactiveUS20100179287A1High friction durabilitySmall impactOther chemical processesLiquid repellent fibresChlorideVinylidine chloride

To provide a water / oil repellent composition which can impart water / oil repellency with excellent friction durability to a surface of an article, even though while having structural units based on a monomer having an Rf group having at most 6 carbon atoms, structural units based on a monomer having an Rf group having at least 8 carbon atoms are reduced as much as possible, and an article which has little impact on environment and is less susceptible to deterioration of water / oil repellency by friction.A water / oil repellent composition which comprises polymer (A) having units of monomer (a) and units of monomer (b), having no units of monomer (c) and having at least 15 mass % and less than 45 mass % of fluorine atoms, and polymer (B) having units of monomer (a), having no units of monomer (c) and having at least 45 mass % of fluorine atoms: monomer (a): a monomer having a C4-6 Rf group; monomer (b): a monomer having an alkyl group having at least 12 carbon atoms, vinyl chloride or vinylidene chloride; monomer (c): a monomer having Rf group having at least 8 carbon atoms.

Owner:ASAHI GLASS CO LTD

Vinyl chloride-vinylidene chloride (VDC)/acrylic acid (AA)/methyl methacrylate (MMA)/acrylonitrile (AN) copolymerized polyvinyl dichloride (PVDC) emulsion and preparation method thereof

The invention relates to a vinyl chloride-vinylidene chloride (VDC) / acrylic acid (AA) / methyl methacrylate (MMA) / acrylonitrile (AN) copolymerized polyvinyl dichloride (PVDC) emulsion and a preparation method thereof. The emulsion consists of the following components according to parts by weight: 90-96 parts of a vinylidene chloride monomer, 1-2 parts of an acrylic monomer, 4-5 parts of acrylonitrile, 3-4 parts of a methyl methacrylate monomer, 0.2-0.3 part of am initiator, 1-2 parts of an emulsifier, 90-100 parts of a dispersant and 0.0001-0.0002 part of a pH regulating agent. According to the emulsion, the content of the vinylidene chloride monomer is increased, so that a good water resistance is guaranteed after drying latex, and acrylate soft monomer is added to guarantee a certain softness of processed fabric. A thin film coated by the emulsion disclosed by the invention is comparatively hard, and has good elasticity and barrier property; and in addition, the aqueous latex disclosed by the invention, in comparison with acrylic emulsion, has a good solubility, and has a quite excellent modification effect by combining with an acrylic emulsion-type processing agent.

Owner:NANTONG REPAIR AIR CHEM BIOENG

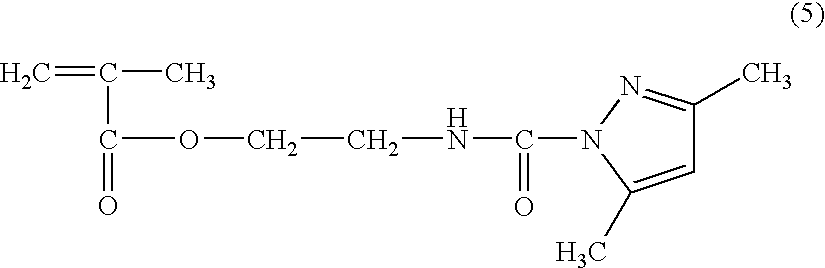

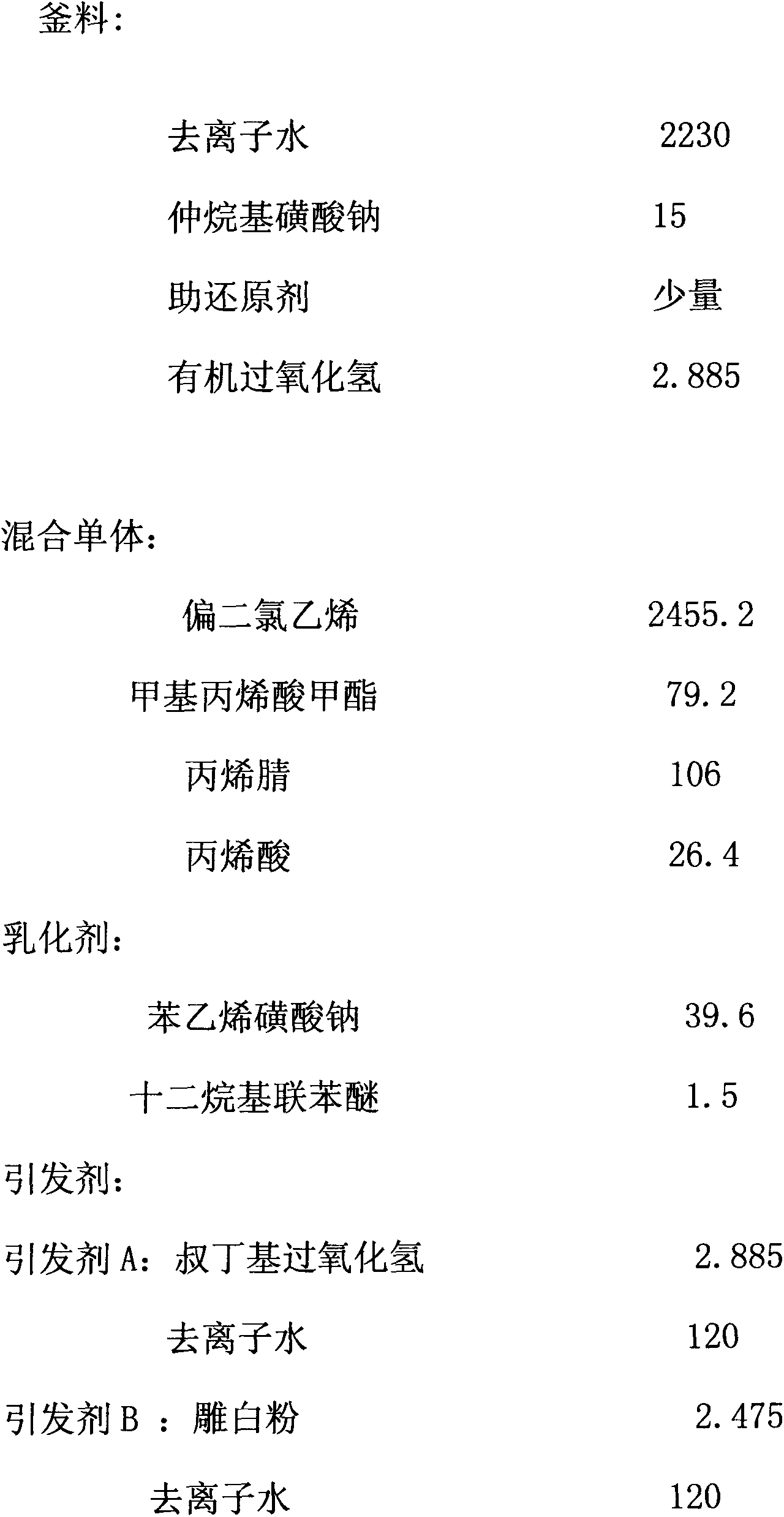

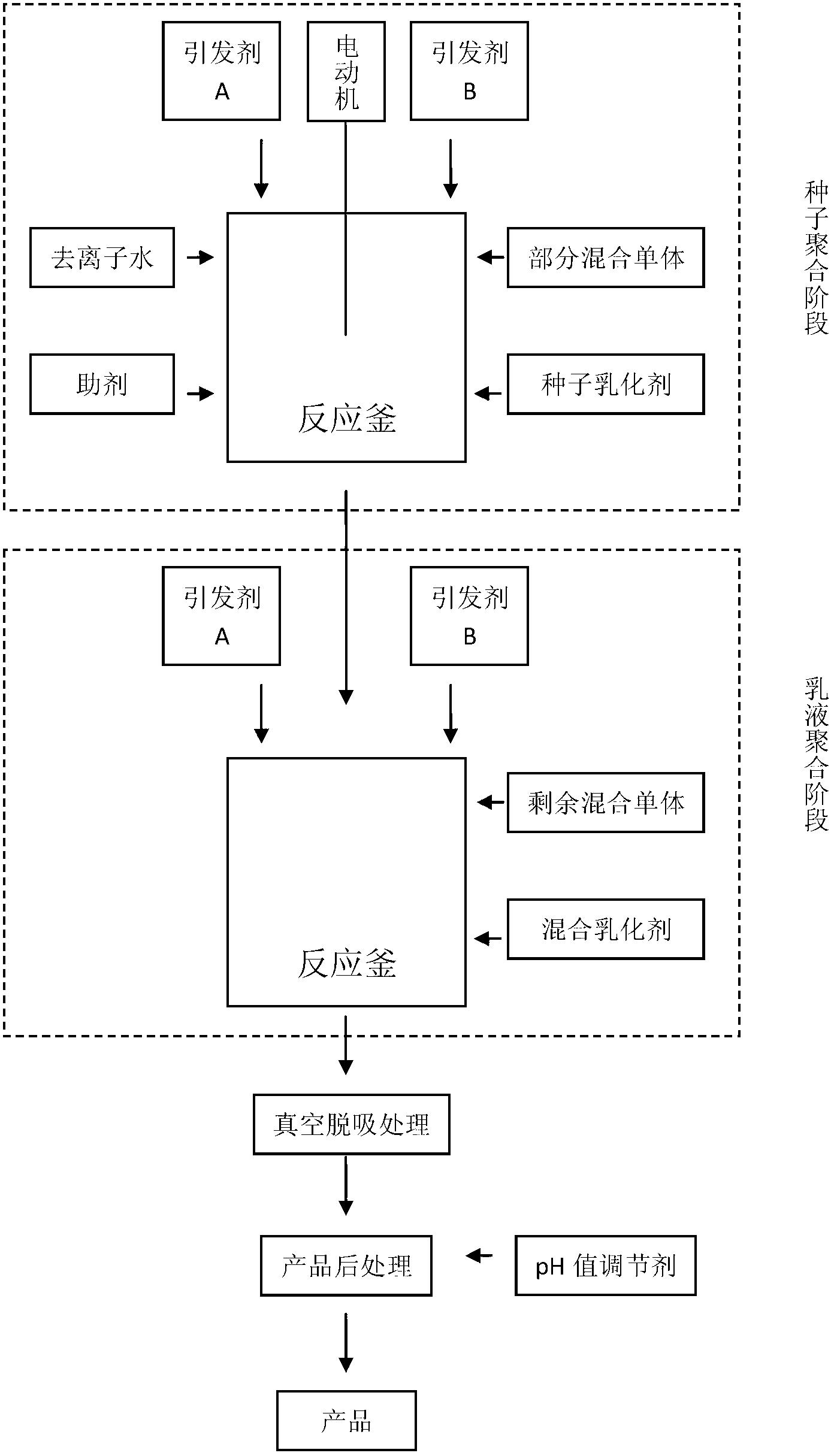

Poaching type special polyvinyl dichloride (PVDC) rubber latex and preparation method thereof and application

ActiveCN103059199AGood heat sealingFlexible coversWrappersPolyethylene terephthalate glycolPolymer science

The invention provides poaching type special polyvinyl dichloride (PVDC) rubber latex which is excellent in poaching resistance and heat-sealing property and a preparation method thereof. According to the preparation method, seeded emulsion polymerization is adopted and proper amount of microcrystalline wax is added before a vacuum desorption aftertreatment process. Parts by weight of each component are calculated by 100 parts and comprise 50 parts of monomer mixtures, initiation agents, mixing and emulsifying agents, seeded emulsifying agents and additives; the monomer mixtures comprise 89.5-92.5 % of vinylidene chloride by weight of the total monomer mixtures, 1.2-1.8 % of (methyl) acrylonitrile, 2.5-3.0 % of methyl butyl acrylate, 2.9-5.9 % of methyl methacrylate and 0.1-0.4 % of methacrylic acid; the initiation agents comprise tert-butyl hydroperoxide and sodium formaldehyde sulfoxylate; the mixing and emulsifying agents comprise sodium dodecylbenzene sulfonate and secondary chain alkyl sulfonate; the seeded emulsifying agents comprise sodium dodecylbenzene sulfonate; and the additives comprise ammonium acetate and ferrous chloride. The poaching type special PVDC rubber latex can be coated on nylon and polyethylene terephthalate (PET), and can be used for packaging poaching food.

Owner:海南海达丰实业有限公司

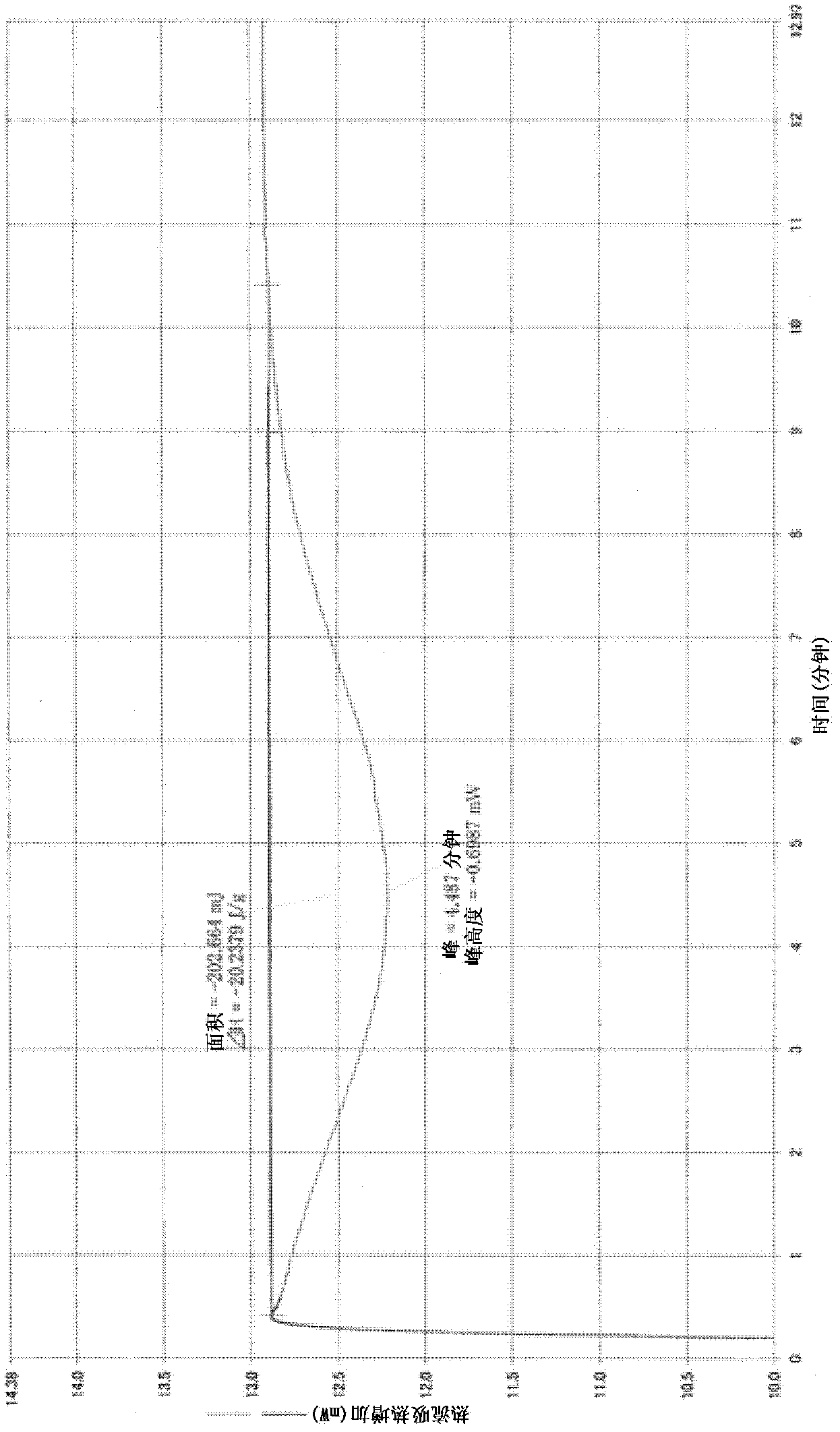

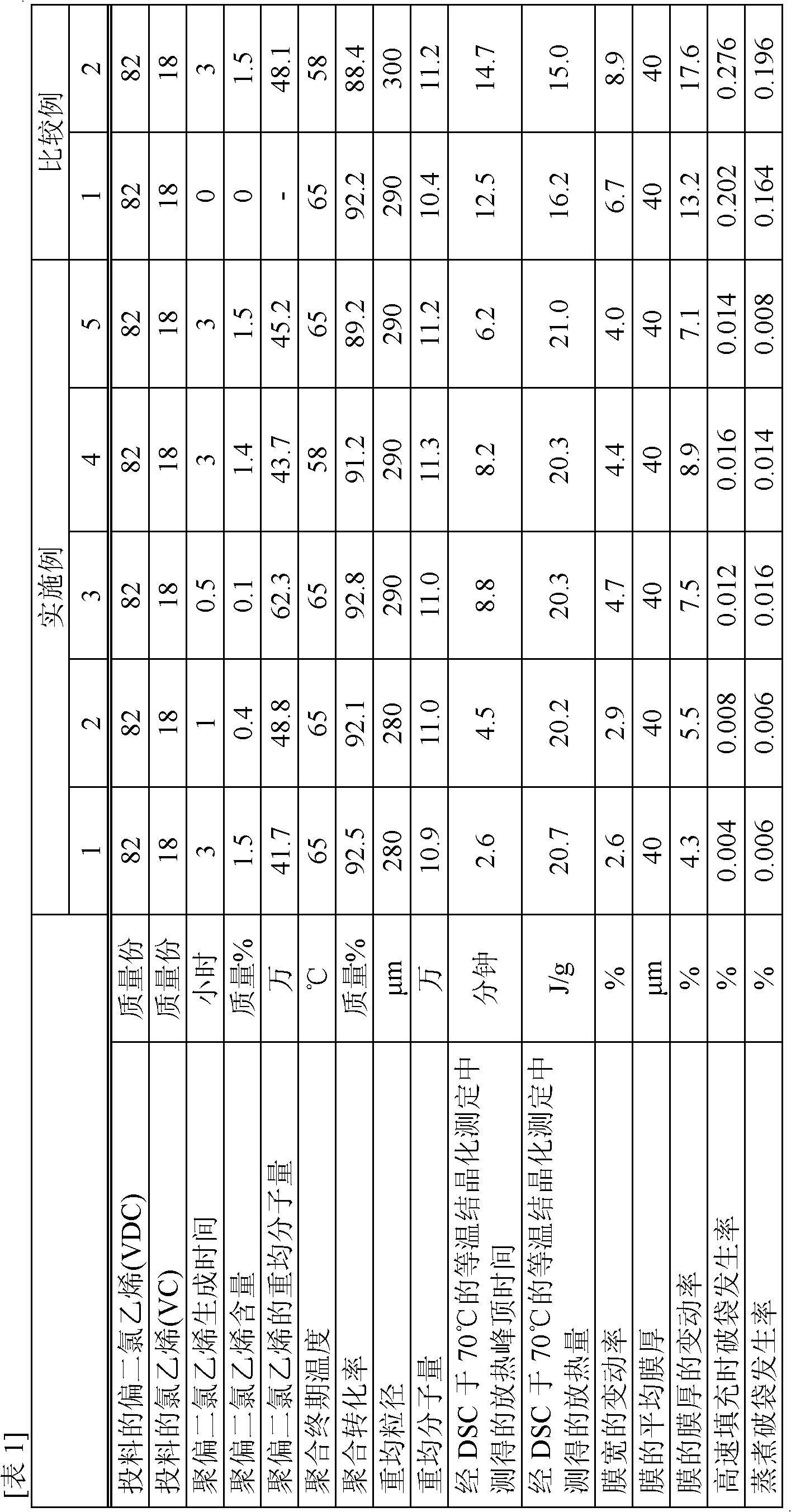

Vinylidene chloride copolymer, and its membrane or sheet material

ActiveCN103224582AExcellent adaptability to drawing processingImprove film thickness uniformityFlexible coversWrappersChlorideIsothermal crystallization

The invention relates to a vinylidene chloride copolymer composition, the stretch processing adaptability during a melt molding process is excellent, thereby membrane thickness uniformity of the obtained membrane or the sheet material is excellent, and the high frequency seal adaptability and heating pressurization sterilization adaptability (so-called boiling adaptability) of the provided membrane or the sheet material are excellent; The vinylidene chloride copolymer is the vinylidene chloride copolymer formed by vinylidene chloride and a polymerism vinyl monomer, wherein, through the differential scanning calorimetry thermal detection (DSC), and the heat release summit time of the vinylidene chloride copolymer detected in an isothermal crystallization detection at 70 DEG C is less than 10 minutes.

Owner:ASAHI KASEI KK

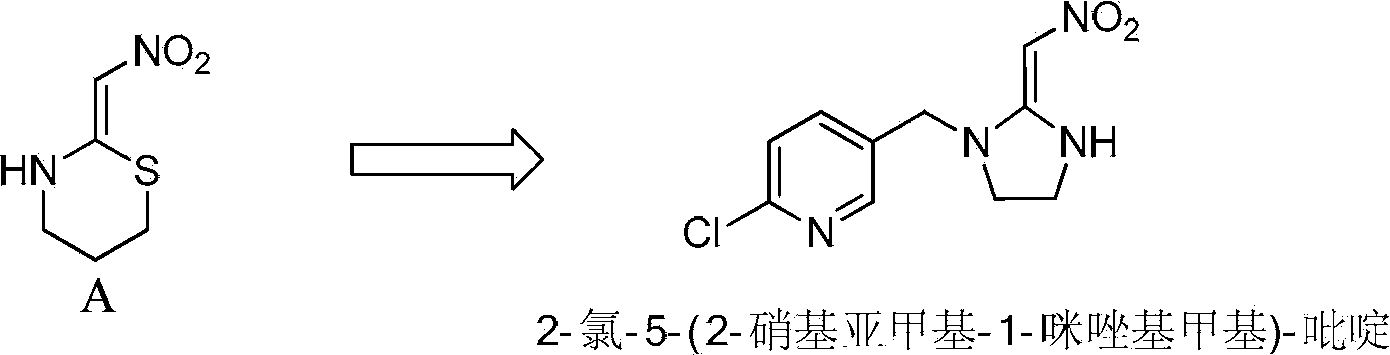

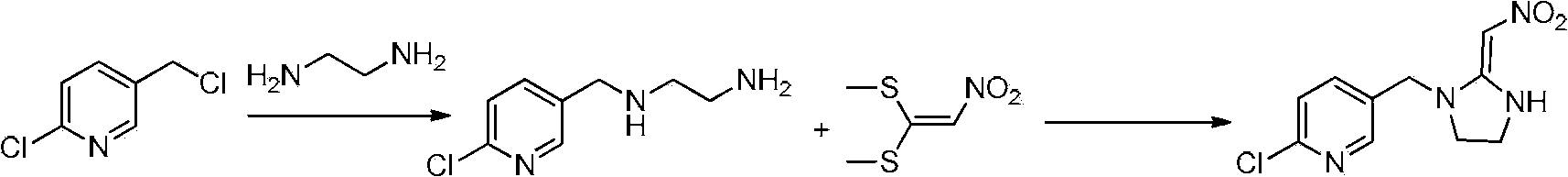

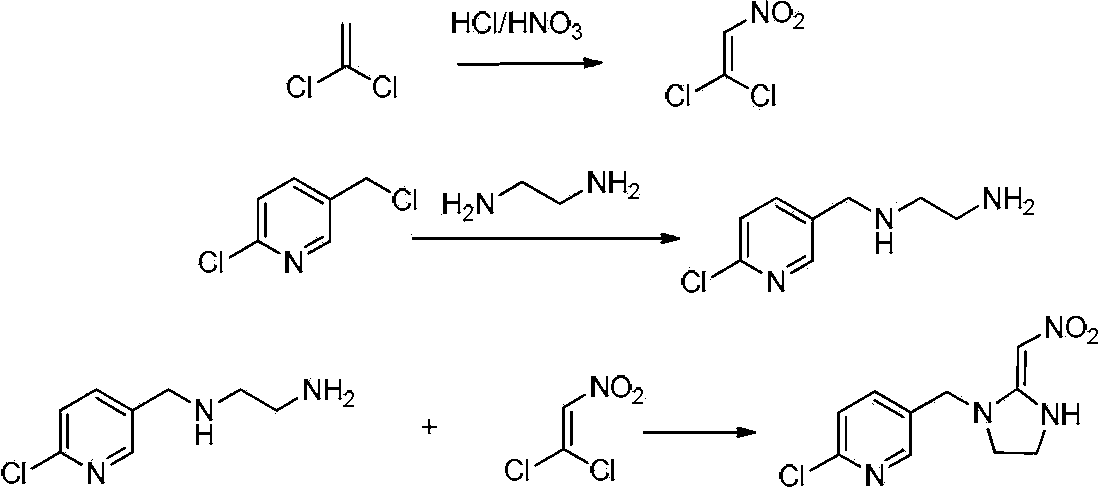

Synthesis process of 2-chlorin-5-((2-(nitryl methylene) imidazoline-1-yl) methyl) pyridine

ActiveCN103524489ARaw materials are easy to getReduce manufacturing costOrganic chemistryOrganic compound preparationImidazolidineChloride

The invention provides a synthesis process of 2-chlorin-5-((2-(nitryl methylene) imidazoline-1-yl) methyl) pyridine. Particularly, the method comprises the following steps: preparing 2-nitryl methylene imidazolidine from vinylidene chloride serving as a raw material; and reacting the 2-nitryl methylene imidazolidine with a 2-chlorin-5-chloromethyl pyridine compound so as to form 2-chlorin-5-((2-(nitryl methylene) imidazoline-1-yl) methyl) pyridine. The synthesis process has the advantages that raw materials are easily available, production cost is low, conditions are mild, and the operation is simple and convenient; moreover, synthesis process is environmentally-friendly and suitable for industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Fluoride-contained textile finishing agent and preparation method thereof

The invention discloses a fluoride-contained textile finishing agent and a preparation method thereof. The fluoride-contained textile finishing agent is copolymerized by emulsion via oxa perfluoroalkyl (methyl) acrylate monomer, higher aliphatic alcohol (methyl) acrylate monomer, crosslinking monomer and enhanced monomer in the presence of a complex emulsifying agent, an emulsion accelerator, a chain transfer agent, a stabilizing agent and an initiating agent; vinylidene chloride or chloroethylene is used as the enhanced monomer; the mass of the enhanced monomer is 5-40% of total mass of the monomer; polypropylene glycol or segmented copolymer of the polyethylene glycol and polypropylene glycol is used as the emulsion accelerator; the mass of the emulsion accelerator is 5-50% of total mass of the monomer; stearoylbenzoylmethane is used as the stabilizing agent; and the mass of the stabilizing agent of 0.5-5% of the total mass of the monomer. The fluoride-contained textile finishing agent has the advantages of high washable degree and does not pollute the environment.

Owner:常州化工研究所有限公司

Artificial hair fiber bundle and hair decorative product using the same

ActiveUS20070190322A1Superior in stylabilityGood sensory characteristicsDollsWigsFiber bundlePolyvinyl chloride

An artificial hair fiber bundle comprising: a mixture of a synthetic acrylic base fiber (A) made of an acrylic base copolymer containing acrylonitrile, vinyl chloride and vinylidene chloride and a vinyl monomer copolymerizable therewith, a synthetic acrylic base fiber (B) made of an acrylic base copolymer containing acrylonitrile, vinyl chloride and a vinyl monomer copolymerizable therewith; and a synthetic polyvinyl chloride base fiber having a monofilament fineness of 30 to 90 decitexes, provides a hair decorative product superior in stylability and sensory characteristics and favorable for use as a wig, hairpiece, or the like.

Owner:KANEKA CORP

Oxygen barrier plastic material

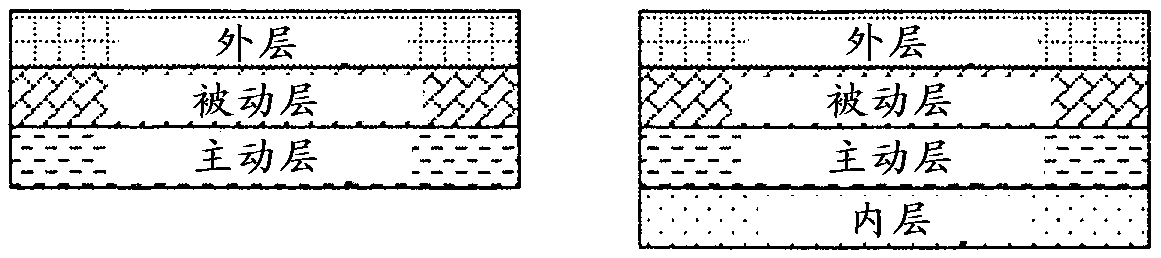

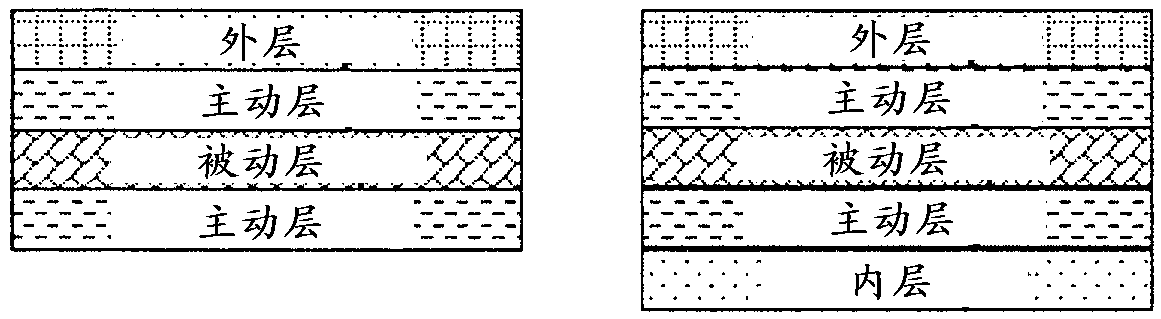

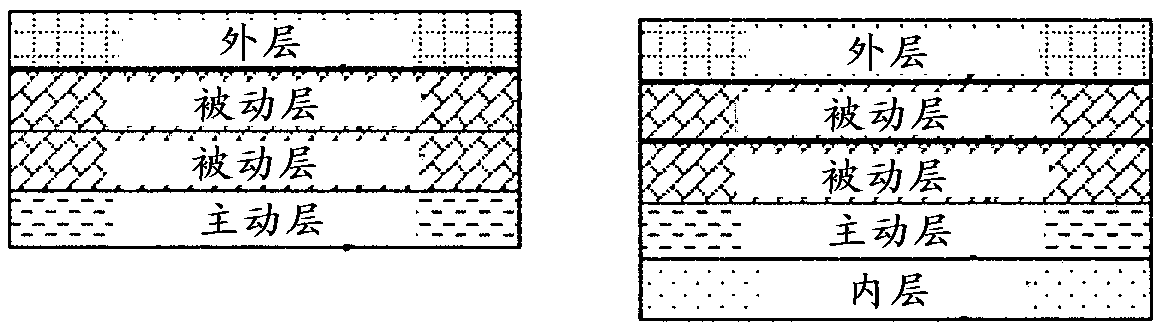

PendingCN109562609ASynthetic resin layered productsDomestic containersPolymer sciencePolyethylene terephthalate glycol

The invention relates to a multilayer packaging film comprising at least three different types of layers (A), (B), and (C): (A) is at least one outer layer, (B) is at least one passive oxygen barrierlayer, (C) is at least one active oxygen scavenging layer, characterized in that - the at least one outer layer (A) is a thermoplastic polymer; - the at least one passive oxygen barrier layer (B) is selected from the group consisting of ethylene vinyl alcohol copolymers, polyvinylchloride, copolymers of polyvinyl chloride, polyvinyl alcohol, polyvinylidene dichloride, copolymers of polyvinylidenedichloride, polyacrylonitrils, copolymers of polyacrylonitrils, polyethylene terephthalate, polyethylene naphthalate, polyethylenefuranoate, polysiloxanes, and polyamides; - the at least one active oxygen scavenging layer (C) comprises a) a plastic material which is a polyolefin, a polyolefin copolymer or a polystyrene, and additives (b) and (c), wherein b) is a polyterpenic resin; and c) is a transition metal catalyst.

Owner:CLARIANT PLASTICS & COATINGS LTD

Process for the manufacture of polybutylene terephthalate copolymers from polyethylene terephthalate, and compositions and articles thereof

ActiveUS7910657B2Improved flow and mechanical propertyEfficient recyclingPlastic recyclingPolytetramethylene terephthalatePolyethylene terephthalate glycol

A process comprises depolymerizing, with 1,4-butane diol, a first polymer comprising a polyethylene terephthalate component in the presence of at least one second polymer selected from the group consisting of polyvinyl chlorides, polyvinylidene chlorides, polyamides, polylactic acid, and combinations thereof to produce a molten mixture; and polymerizing the molten mixture under conditions sufficient to form a modified polybutylene terephthalate copolymer. The modified PBT comprises (a) at least one polyethylene terephthalate component residue, and (b) a member selected from the group consisting of (i) the at least one second polymer selected from the group consisting of polyvinyl chlorides, polyvinylidene chlorides, polyamides, polylactic acid, and combinations thereof; (ii) the at least one residue derived from the second polymer; and (iii) combinations thereof.

Owner:SHPP GLOBAL TECH BV

Composite packaging bag for beverages and production method of composite packaging bag

InactiveCN103434235ALow oxygen permeabilityLight weightSynthetic resin layered productsLaminationLow-density polyethylenePolyamide

The invention discloses a composite packaging bag for beverages and relates to the technical field of beverage packaging bags. Films made of three raw materials, namely low density polyethylene, two-way stretch polyamide and polyvinylidene chloride are subjected to low / high-pressure rolling no-glue compositing, then are cured, cooled and sliced, and are subjected to thermal inductance pressing and cutting to form a bag. A production method has the energy-saving effect and is low in pollution. The produced composite packaging bag is high in tensile strength, low in oxygen permeation rate, resistant to oil, high temperature and low temperature, high in air impermeability, low in specific gravity, low in cost, quick and novel in packaging, and has the environment-friendly effect.

Owner:SHANDONG JUQIANG BIOLOGICAL FOOD

Manufacturing method of cationic water-based vinylidene chloride metal anti-corrosion paint

ActiveCN103044600AImprove mechanical stabilityGood ion toleranceAnti-corrosive paintsWater basedVinylidine chloride

The invention discloses a manufacturing method of cationic room-temperature crosslinking water-based vinylidene chloride metal anti-corrosion paint, which is characterized in that resin of the paint is cationic vinylidene chloride latex; an cationic emulsifier is polymerized with high pressure emulsions of a vinylidene chloride monomer and an acrylate monomer; an initiator is mixed by an oil-soluble initiator and a water-based initiator; the prepared vinylidene chloride latex is good in mechanical stability, and can be grinded together with a rust-resistant pigment; the cationic durability is good; cations dissociated from the rust-resistant pigment do not influence the storage stability of the water-based paint; and the anti-corrosion effect is excellent.

Owner:JIANGSU RONGCHANG NEW MATERIAL TECH

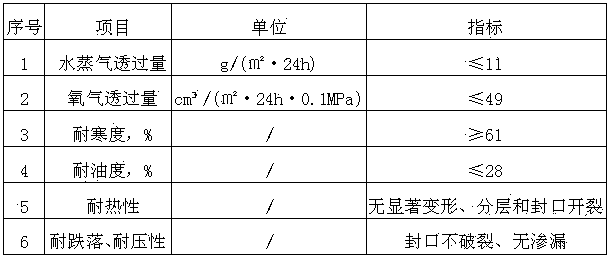

Polyvinylidene chloride copolymer emulsion for pharmaceutical packing coating and preparation method and application thereof

The invention provides polyvinylidene chloride copolymer emulsion for pharmaceutical packing coating and a preparation method and application thereof. The copolymer emulsion is manufactured by adopting of seeded emulsion polymerization and adding of microcrystalline wax in the process of vacuum desorption, and parts by weight of components of the copolymer emulsion are calculated by 100 parts including 60 parts of monomer mixture, initiating agent, seeded emulgato, mixed emulgator and addition agent. The monomer mixture comprises 90-94% vinylidene chloride, 3-5% crylic acid-2-phthalic acid ester, 2-5% metacrylic acid ester monomer and 0.2-1.5% methylacrylic acid, the initiating agent comprises tert-butyl hydroperoxide and sodium formaldehyde sulfoxylate, the seeded emulgator comprises sodium dodecyl benzene sulfonate and non-ionic emulsifier, and the mixed emulgator comprises sodium sulfonate emulgator, non-ionic emulsifier and negative ion reaction type emulsifier. The obtained pharmaceutical packing coating is good in separation performance (west separation and oxygen separation), low in vinylidene chloride residuals, and low in cost, a quality guarantee period of pharmaceutical packing reaches 3 years and is up to an international standard of plastic uptake drug packing, copolymer emulsion stability is good, and a quality guarantee period of the emulsion is more than two years.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com