Vinyl chloride-vinylidene chloride (VDC)/acrylic acid (AA)/methyl methacrylate (MMA)/acrylonitrile (AN) copolymerized polyvinyl dichloride (PVDC) emulsion and preparation method thereof

An emulsion and copolymerization technology, which is applied in the field of VDC/AA/MMA/AN copolymerized PVDC emulsion and its preparation, can solve the problems of discoloration and poor thermal stability of products, and achieve the effects of good elasticity, good water resistance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

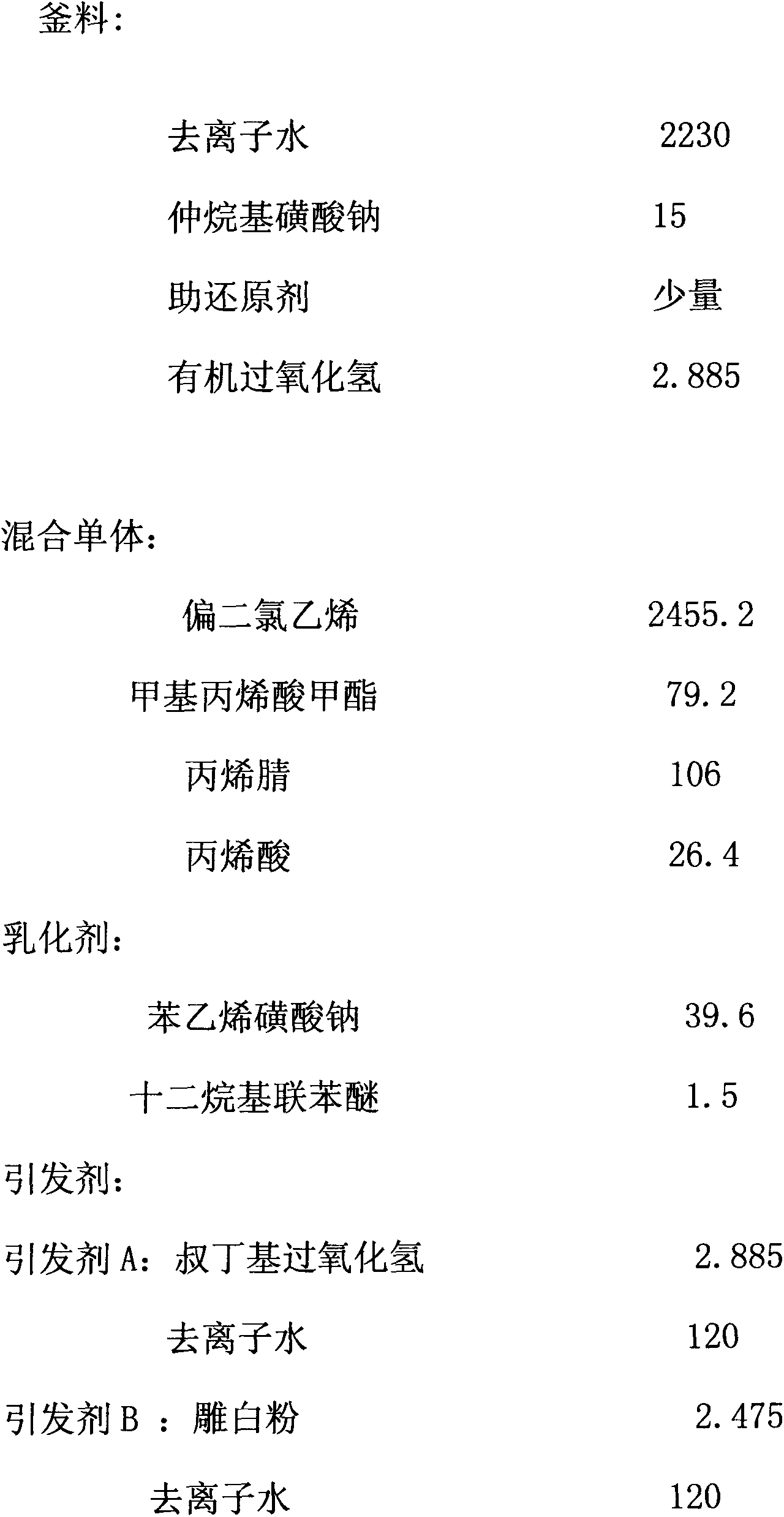

[0024] Raw material and content:

[0025]

[0026]

[0027] The specific operation process: first add 2230 kg of deionized water, a small amount of co-reducing agent, 15 kg of sodium alkane sulfonate and 2.885 kg of organic hydrogen peroxide into the reactor to fully replace the air inside with nitrogen, and inhale 10% of the mixed Monomer, then heat up, add initiator A and B solutions when the temperature rises to 30°C, when the temperature rises to 55°C, when the pressure drops significantly, the remaining mixed monomers are continuously added to the In the reaction kettle, keep the temperature at 50-55°C at the same time, control the injection time of the mixed monomer to 7 hours, and the injection time of the initiator to 8 hours. After the addition of the mixed monomer, continue to add the initiator for 1 hour. At this time, the pressure will drop to a certain level and remain unchanged. After the pressure remains unchanged for 30 minutes, stop adding the initiator,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com