Rust transforming agent and preparation method thereof, water-based iron rust conversion coating and preparation method thereof

A rust conversion agent and rust conversion technology are applied in coatings, anti-corrosion coatings, and metal material coating processes. The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

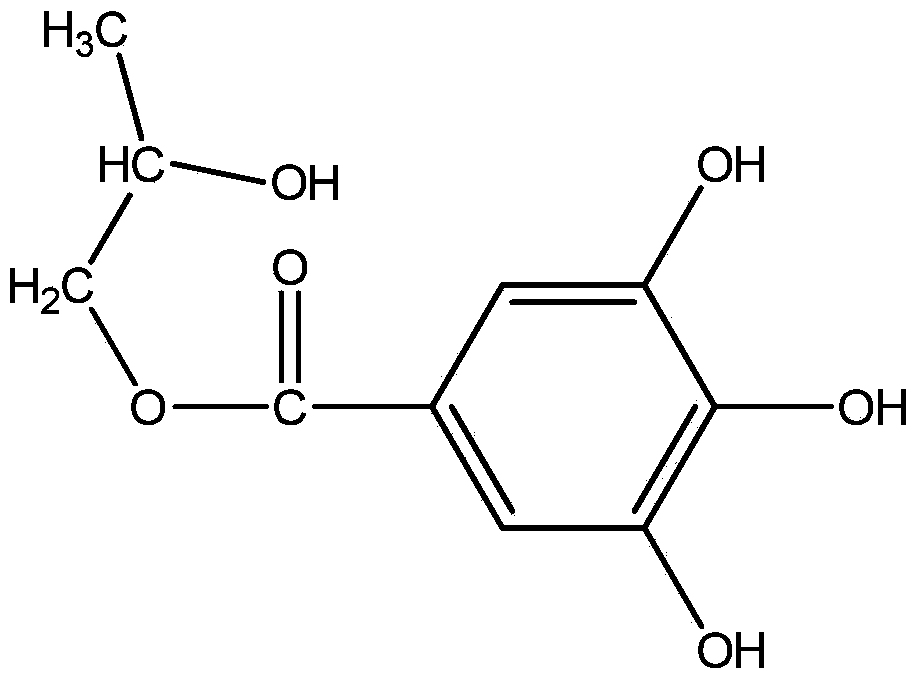

[0050] Synthetic rust conversion agent: add 30.6g 1-2 propylene glycol to a four-neck flask and place it in a cold water bath, add 10.2g gallic acid and 1.02g p-toluenesulfonic acid in proportion under stirring conditions, raise the temperature of the water bath to 70°C, and stir to react After about 1 hour, when the solid matter is completely dissolved, the system turns light yellow; raise the temperature of the system to 105°C, maintain a constant temperature, stir with a stirrer for 2.5-3 hours, cool down and discharge to obtain the rust conversion agent.

example 2

[0052] Synthesis of rust converting agent: Add 27g of 1-2 propylene glycol in a four-neck flask and place it in a cold water bath, add 6.75g of gallic acid and 0.7g of p-toluenesulfonic acid in proportion under stirring conditions, raise the temperature of the water bath to 75°C, and stir for 1h After the solid material is completely dissolved, the system turns light yellow; raise the temperature of the system to 110°C, maintain a constant temperature, stir with a stirrer for 2.5-3 hours, cool down to room temperature and discharge to obtain the rust conversion agent.

example 3

[0054] Preparation of water-based rust conversion primer: add 22.0g deionized water to a beaker, add 9.0g aluminum tripolyphosphate, 9.0g sericite, 4.0g talcum powder, 2.0g barium sulfate and 1.5g nano-silica in turn under stirring , evenly dispersed and ground on the equipment until the particle size is less than 20 microns, the resulting pigment paste. Add 48.0g of vinylidene chloride composite polymer emulsion into the beaker, add 1.0g of ethylene glycol butyl ether under stirring, add 2.0g of PH regulator after stirring, and stir evenly; add the above-mentioned pigment filler slurry into the emulsion, stir About 15 minutes, add 1.5g of the rust conversion agent prepared in Example 2, add an appropriate amount of defoamer depending on the bubbles during the stirring process, add an appropriate amount of thickener to thicken, and stir for 30 minutes. A water-based rust conversion primer that can be painted with rust is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com