Patents

Literature

1321 results about "Oil paint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil paint is a type of slow-drying paint that consists of particles of pigment suspended in a drying oil, commonly linseed oil. The viscosity of the paint may be modified by the addition of a solvent such as turpentine or white spirit, and varnish may be added to increase the glossiness of the dried oil paint film. Oil paints have been used in Europe since the 12th century for simple decoration, but were not widely adopted as an artistic medium until the early 15th century. Common modern applications of oil paint are in finishing and protection of wood in buildings and exposed metal structures such as ships and bridges. Its hard-wearing properties and luminous colors make it desirable for both interior and exterior use on wood and metal. Due to its slow-drying properties, it has recently been used in paint-on-glass animation. Thickness of coat has considerable bearing on time required for drying: thin coats of oil paint dry relatively quickly.

General water-based quick-drying anti-rust paint and preparation method thereof

InactiveCN102993810AAdvanced Technology FormulaAdvanced DesignRosin coatingsAnti-corrosive paintsWater basedLacquer

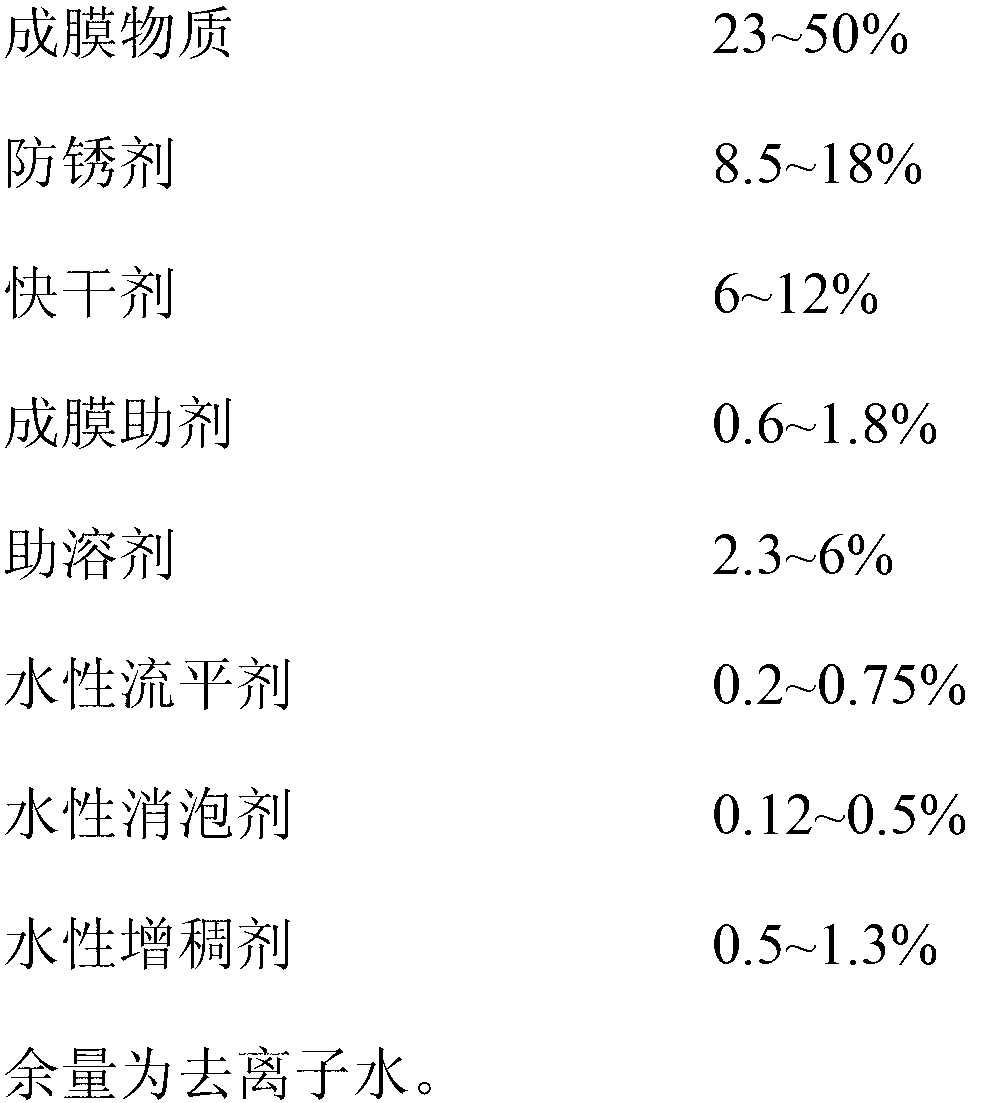

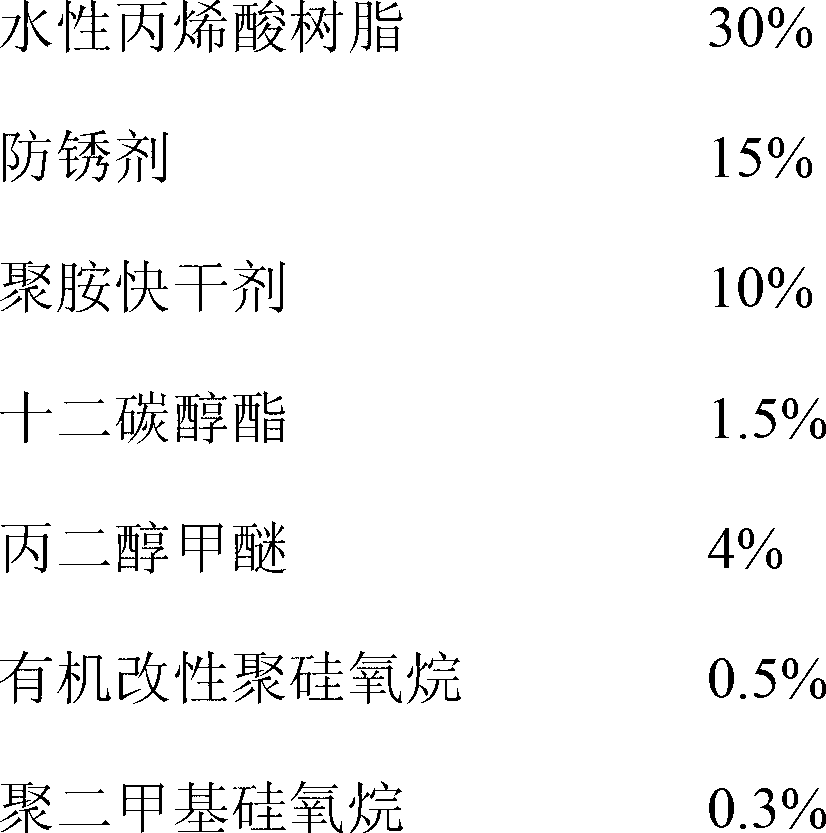

The invention relates to a general water-based quick-drying anti-rust paint and a preparation method thereof. The general water-based quick-drying anti-rust paint comprises the following components in percentage by weight: 18%-55% of film-forming substance, 6%-22% of anti-rust agent and the balance of water. The preparation method comprises the following steps of: firstly pre-dispersing the components except the anti-rust agent according to the formula ratio; then adding the anti-rust agent according to the formula ratio; and re-dispersing to obtain the general water-based quick-drying anti-rust paint. The general water-based quick-drying anti-rust paint disclosed by the invention is safe and nontoxic, contains no lead, chromium or other hazard pigments and derivatives, can not burn or explode, is suitable for safe production, has the advantages of plump paint film, excellent decoration and protection, excellent adhesive force and adjustable glossiness, and is simpler in production process compared with an oil paint.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Waterborne residual rust antirust coating and preparation method thereof

ActiveCN103897510AExcellent physical and chemical anti-rustFunction increaseAnti-corrosive paintsEpoxy resin coatingsAcrylic resinMechanical equipment

The invention discloses a waterborne residual rust antirust coating and a preparation method thereof. The waterborne residual rust antirust coating is prepared from styrene-acrylic emulsion, water soluble epoxy resin, water soluble acrylic resin, iron oxide red, graphene, zinc oxide, barium sulphate, transforming agents, a transformation accelerator, a levelling agent, a defoaming agent, a dispersing agent, a thickening agent and water. The waterborne residual rust antirust coating contains no organic solvent, is environment-friendly and pollution-free, has the characteristic that bottom and surface are combined and has an excellent physical and chemical antirust and rust transforming function, is applicable to rust protection of the surface of steel with rust, a hard oxidation skin layer or an oil paint film and is also applicable to rust protection of the surface of rust-free steel, the preparation method is simple, construction is easy, two transforming agents are complexed in the waterborne residual rust antirust coating, so that a binding force between the waterborne residual rust antirust coating and rust is increased, the waterborne residual rust antirust coating can be directly brushed and coated on the surface of rusty steel and is applicable to multiple construction ways such as spraying, brushing and showering, the coating cost is low, and the rust protection requirements of urban road facilities, bridges, oil and gas pipelines, engineering mechanical equipment, ships and the like can be met.

Owner:重庆南方漆业有限公司

Method for manufacturing transfer film and transfer aluminum-plating paper

The invention discloses a method for manufacturing a transfer film. The method comprises the steps of (1) manufacturing a master die with Fresnel lens patterns and laser graph patterns, and then electroforming to form a die-pressing working plate; (2) mounting the die-pressing working plate on a die-pressing roller, coating a layer of ultraviolet curing embossed coating on a lower surface of a plastic film and enabling the ultraviolet curing embossed coating to be closely contacted with the die-pressing roller, and then curing the coating layer; (3) separating the ultraviolet curing embossed coating layer from the die-pressing working plate to obtain a transfer film. A method for manufacturing transfer aluminum-plating paper comprises the follow-up steps on the basis of the transfer film: (4) plating aluminum on the ultraviolet curing embossed coating layer to form an aluminum-plating layer; (5) coating a layer of oil paint on the aluminum-plating layer and then drying; (6) compounding the transfer film with printing paper, and then separating the ultraviolet curing embossed coating layer from the aluminum-plating layer to obtain the transfer aluminum-plating paper. According to the method, clear Fresnel lens patterns and laser graph patterns can be formed on the transfer film and the transfer aluminum-plating paper.

Owner:汕头市龙湖昌丰化工有限公司

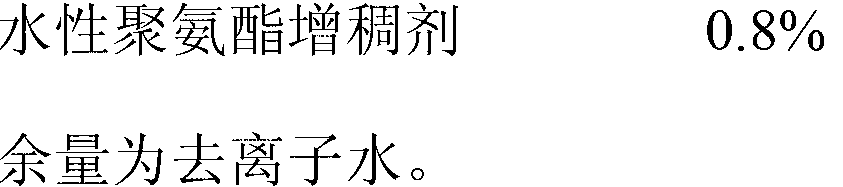

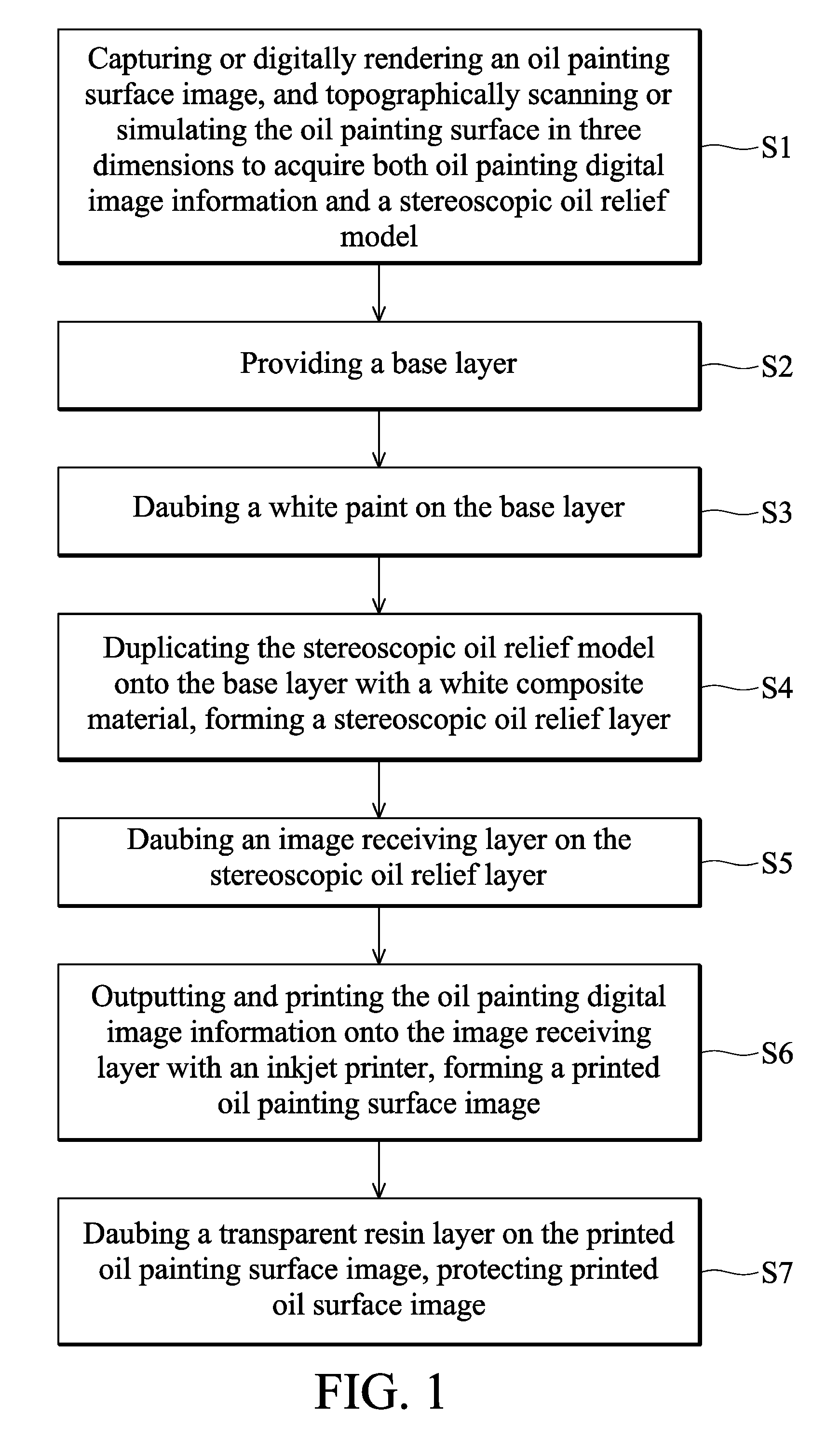

Method for simulating, fabricating, or duplicating an oil painting

A method for simulating, fabricating, or duplicating an oil painting is provided. The oil painting digital image information is acquired by scanning or capturing an oil painting surface image, and / or digitally simulating or rendering an oil painting surface image. A white paint is daubed on a base layer. A stereoscopic oil relief model, forming a stereoscopic oil relief layer, is acquired by topographically scanning the oil painting surface in three dimensions, and simulated or duplicated onto the base layer with a white or colorless transparent composite material. An image receiving layer is daubed on the stereoscopic oil relief layer. The oil image information, forming a printed oil painting surface image, is output and printed onto the image receiving layer with an inkjet printer. A transparent resin layer is daubed on the printed oil painting surface image, protecting the printed oil painting surface image with stereoscopic oil relief layer.

Owner:NAT TAIWAN UNIV OF SCI & TECH

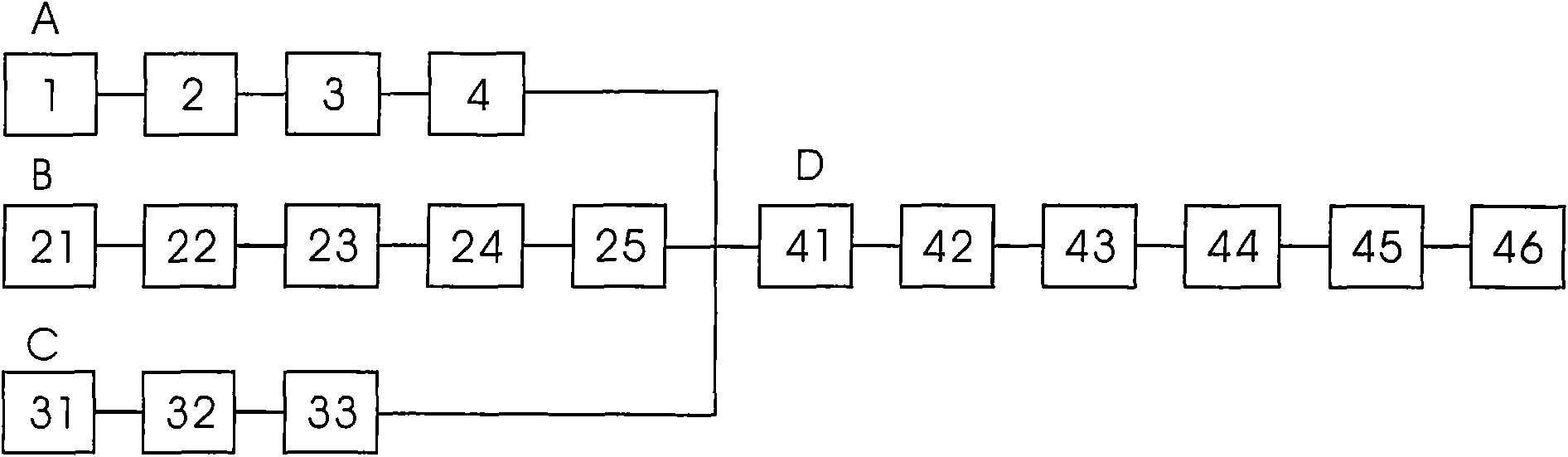

Method for achieving oil painting three-dimensional duplication through ultraviolet-light-emitting diode (UV-LED) ink-jet printer

InactiveCN105128589ANo pollution in the processExact Stereomorphic ReplicationDecorative surface effectsDuplicating/marking methodsPrinting inkEngineering

The invention discloses a method for achieving oil painting three-dimensional duplication through an ultraviolet-light-emitting diode (UV-LED) ink-jet printer. The method comprises the following steps that (1) colored image information of an oil painting is obtained through two-dimensional non-contact scanning equipment; (2) pigment height information of the oil painting is obtained through three-dimensional scanning equipment, and a surface configuration three-dimensional model of the oil painting is established; (3) the number of layers of printing is determined according to the Z-axis height of the model, and the number of the layers is obtained by dividing the maximum value of the Z-axis by the average thickness of a single layer of white ultraviolet (UV) printing ink; (4) the cross section of each layer is extracted, and the cross sections of the layers are introduced into the UV printer to be printed after being subjected to vectorization treatment; (5) stacking printing is conducted through the white UV printing ink according to layer data, and a white three-dimensional oil painting entity is obtained; and (6) colored images are printed on the white three-dimensional oil painting entity, and a three-dimensional oil painting duplicate is formed. By means of the method, the concave-convex undulating characteristics of pigment on the surface of an oil painting original manuscript can be reproduced veritably, the three-dimensional impression of a real oil painting is achieved, the deficiency that the three-dimensional duplication of the oil painting cannot be achieved through an ordinary paint spraying and printing method is remedied, and the requirements for high-fidelity oil painting duplication can be met.

Owner:SOUTH CHINA UNIV OF TECH

Bottom unified aqueous anticorrosive paint and preparation method

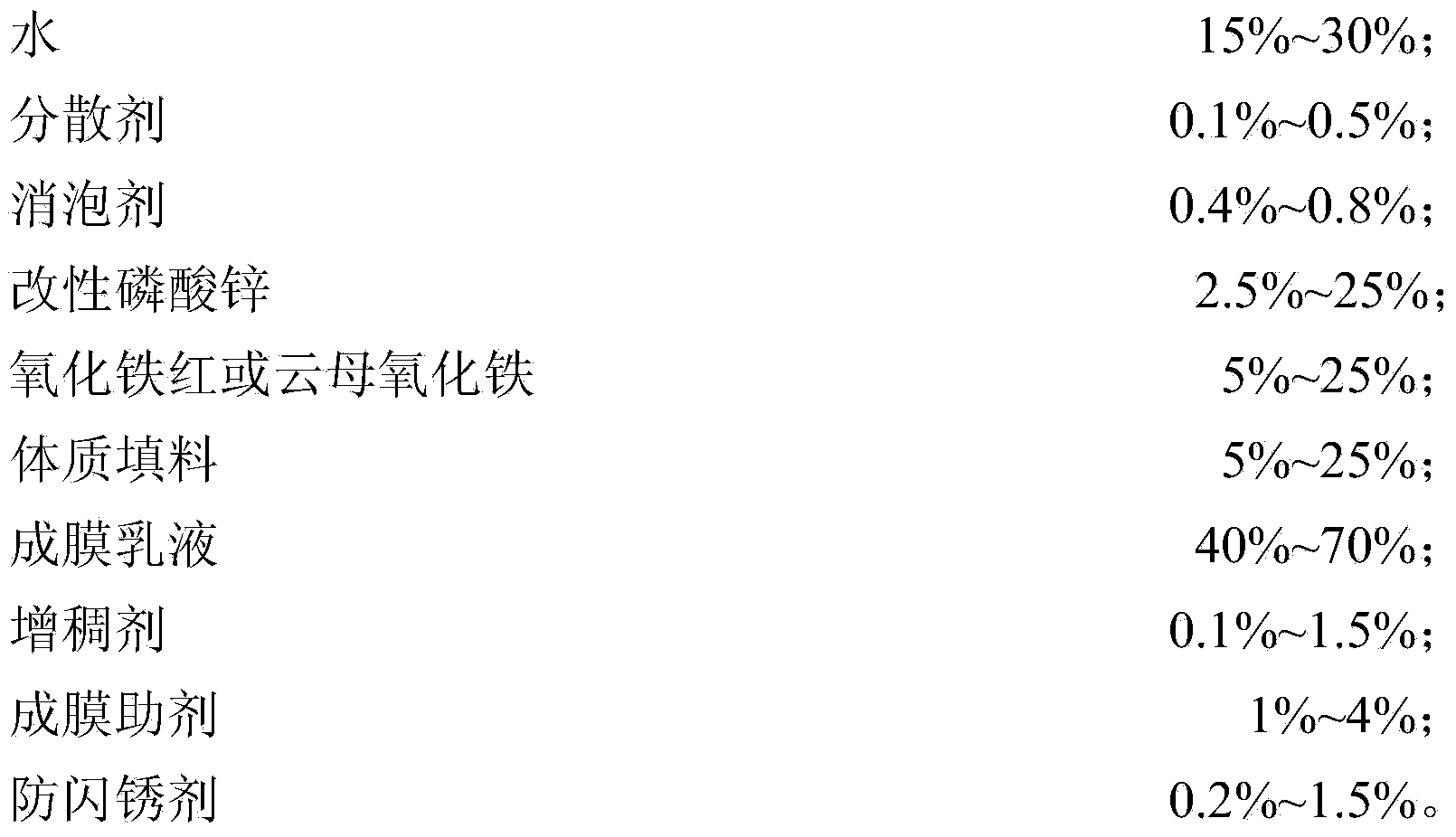

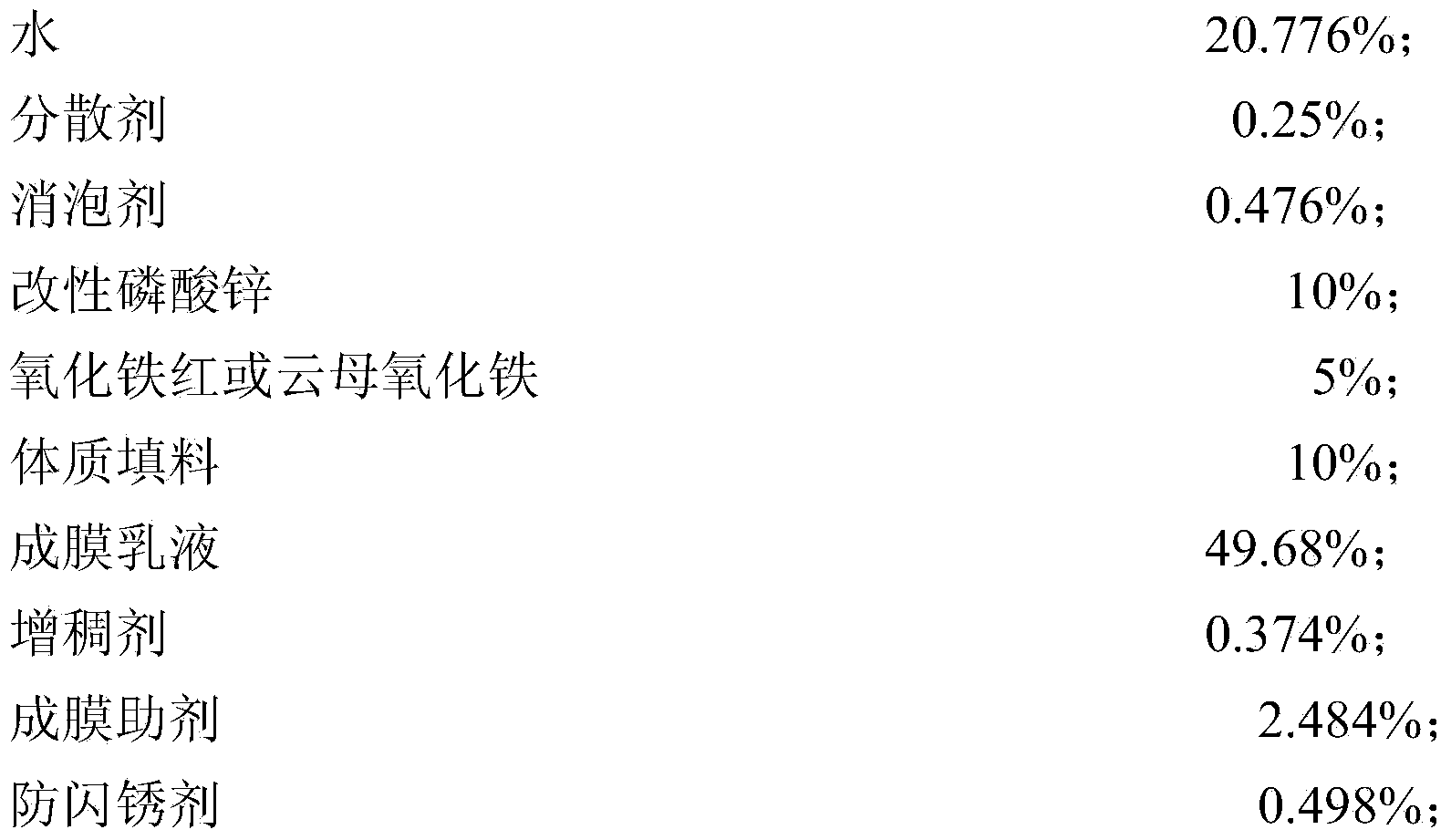

The invention discloses a bottom unified aqueous anticorrosive paint and its preparation method. the paint is composed of the following ingredients, by weight, 15-30% of water, 0.1-0.5% of a dispersant, 0.4-0.8% of an antifoaming agent, 2.5-25% of modified zinc phosphate, 5-25% of iron oxide red or mica iron oxide, 5-25% of a body filler, 40-70% of a film-forming emulsion, 0.1-1.5% of a thickening agent, 1-4% of a film-forming auxiliary agent and 0.2-1.5% of a flash-rust inhibitor. According to the bottom unified aqueous anticorrosive paint, each ingredient with specific weight percentage interacts with each other. Thus, comprehensive performance of the paint is raised, and in particular, anticorrosive performance of the paint is excellent. The paint is environmentally friendly. Problems of heavy odor, high pollution and the like existing in a traditional oil paint are solved. Meanwhile, each anticorrosion index is guaranteed. The product has simple preparation and construction technologies, is easy to carry out, is easy for large-scale industrial production, and has a wide application prospect.

Owner:ZHEJIANG UNIV

Beijing opera facial mask 3D (three-dimensional) printing and forming method

ActiveCN103624985ASimple structureDispersed denseTurbinesOther manufacturing equipments/toolsMaterial resourcesRapid prototyping

The invention discloses a Beijing opera facial mask 3D (three-dimensional) printing and forming method. The method comprises the steps of scanning an opera actor face by a 3D scanner to obtain facial feature point information and establish a corresponding 3D face model; decomposing the corresponding 3D face model into a plurality of layers of plane data by special 3D data processing software; sintering adhesive materials such as powdery metal or plastics according to the plane data by a 3D printer and accumulating layer by layer to print a 3D face mold; and evenly coating one layer of conductive graphite on the mold and applying 50kv voltage to the mold after obtaining the face mold, manufacturing one transparent non-woven fabric mask by an electrostatic spinning device, spraying a Beijing opera facial mask on the transparent non-woven fabric mask by the electrostatic spinning device, and covering the sprayed transparent Beijing opera facial mask on a face part when the Beijing opera facial mask is used to form a thin Beijing opera facial mask. The method makes the rapid forming of the Beijing opera facial mask possible, labor and material resources are saved and damage of oil paint to facial skin is reduced.

Owner:BEIJING UNIV OF CHEM TECH

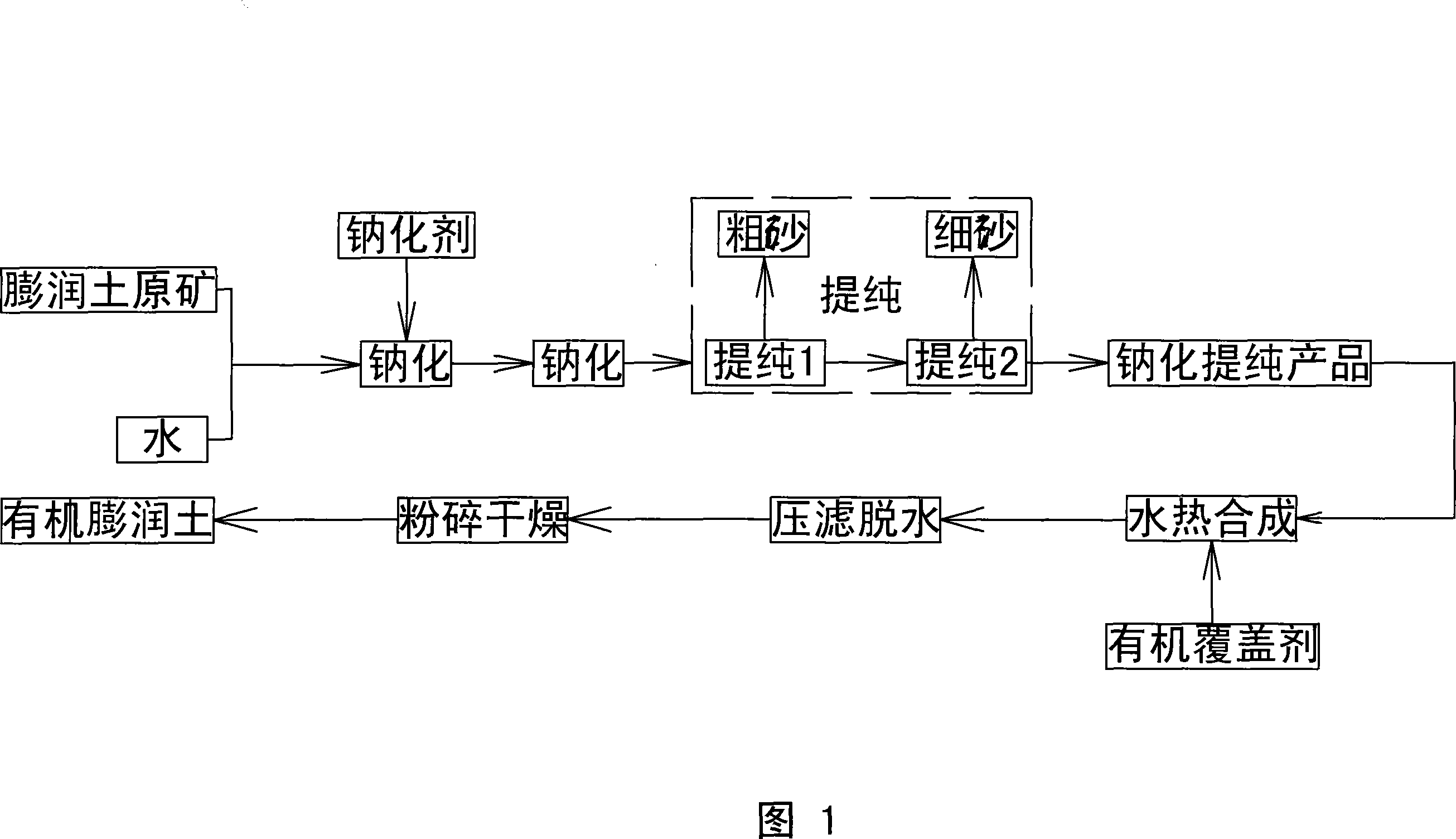

Method for preparing heavy-viscous organophilic bentonite

InactiveCN101224894AContinuously workingImprove stabilityPigmenting treatmentSilicon compoundsSodium BentonitePrinting ink

The invention provides a method for preparing high viscosity organophilic bentonite, which carries out steps of sodium treatment, purification, hydrothermal synthesis, dewatering by filter pressing, crashing and drying operation to bentonite raw ore to obtain the high viscosity organophilic bentonite. The invention can be directly applied to oil paint, printing ink, petroleum drilling slurry and heavy polymer and so on as a thickening suspension agent, a fluid deformation agent and an anti-sagging agent. Through systematic study on technologies of the sodium treatment modification, purification, organic compound and so on of the bentonite, the invention prepares organophilic bentonite jelly glue with stable product quality and excellent performance and determines a proper technical process flow and technical parameters.

Owner:苏州中材非金属矿工业设计研究院有限公司

Process for covering water transfer printing on wood plastic, plastic and metallic products

The invention discloses a water-coated transfer printing process for wood, plastic, and metal products, which comprises the following steps: according to the necessary background color, spraying oil paint on the surfaces of the wood, the plastic, and the metal products; spreading a water-coated transfer printing film on the water surface by putting the surface with printing ink patterns to face upwards; spraying an activator on the water-coated transfer printing film evenly through a spray gun when the water-coated transfer printing film is softened and spread levelly; and according to the positions of the patterns floating on the water surface, pressing an obtained product downwards into the water for 2 to 10 seconds and taking out the product, and transferring the patterns on the water-coated transfer printing film to the surface of the product under the action of water pressure. The process further comprises the following steps: washing the obtained product clean by water and then putting the product into a drying furnace to be dried at a temperature between 50 and 70 DEG C; or using a blowing gun to blow off the water, drying the product at room temperature, spraying a layer of transparent oil paint on the surface of the product, putting the product in the drying furnace and curing the product at a temperature between 50 and 160 DEG C. The compositions of the activator are as follows according to percentage by weight: 33 percent of xylene, 15 percent of butyl acetate, 15 percent of methyl acetate, 10 percent of methyl isobutyl ketone, 5 percent of isobutanol, 8 percent of isophorone, 5 percent of methyl methacrylate, 7 percent of cyclo ethyl ketone, and 2 percent of nitrocellulose resin.

Owner:张艳 +1

Waterborne wood paint

The invention provides waterborne wood paint, which comprises the following components in percentage by weight: 72 to 88 percent of polyurethane waterborne dispersion, 5 to 10 percent of water, 0.20 to 0.80 percent of dispersant, 0.20 to 0.80 percent of wetting agent, 0.10 to 0.60 percent of leveling agent, 0.20 to 0.80 percent of defoamer, 2 to 5 percent of nanometer silicon carbide, 1 to 4 percent of polyethylene waterborne wax liquid, 0.10 to 0.50 percent of fungicide, 0.5 to 3 percent of thickener, 2 to 6 percent of film-forming additive and 0.10 to 0.50 percent of pH regulator. The invention also provides a method for preparing the waterborne wood paint. In contrast to the prior art, the paint has the advantages that paint film hardness and wear resistance are greatly improved, and the wear resistance is close to the level of oil paint, so that the common problem that waterborne paint is difficult to defoam is solved. The paint also has the characteristics of good leveling property, plump attractive paint film, easy construction and the like.

Owner:广东大中三联科技有限公司

Combined process for manufacturing door

InactiveCN101797763AReduce areaReduce consumptionWood mortising machinesFlat articlesConnection formOil paint

The invention relates to the technical field of wood doors and metal (plastic) doors outside which wooden materials are wrapped, in particular to a combined process for manufacturing a door, which is characterized by comprising the following process steps: a, a door frame manufacturing process; b, a surface board or door core manufacturing process; c, an edge strip manufacturing process; and d, a door assembling process. Compared with the prior art, the invention has the key of changing the production process of a surface material, firstly, the surface material and an economically suitable lining material (thickness is determined by design) are compounded (hot pressing) in advance, and then cutting and machining (plain end, rabbet, V-shaped and other plug connection forms) are carried out to obtain designed width or length dimensions and painting is carried out. The whole production process has high degree of mechanization, high production efficiency, esthetic exterior appearance, little manual work and reduction of dependence on people. The production factory area is reduced and the consumption of oil paint (process waste part) is reduced. The concave and convex phenomena of finished product appearances of the existing wood doors can be avoided.

Owner:张建岩

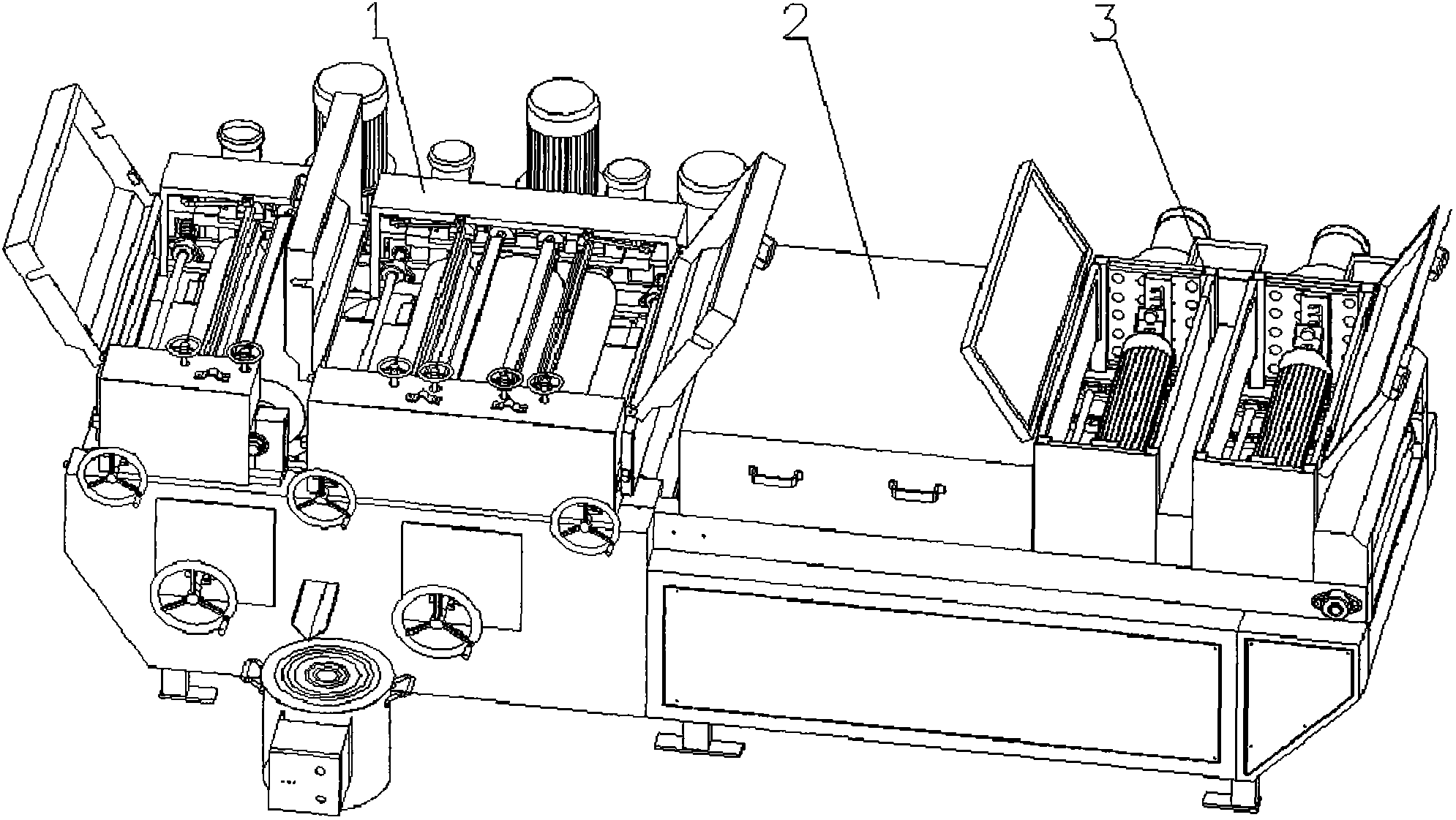

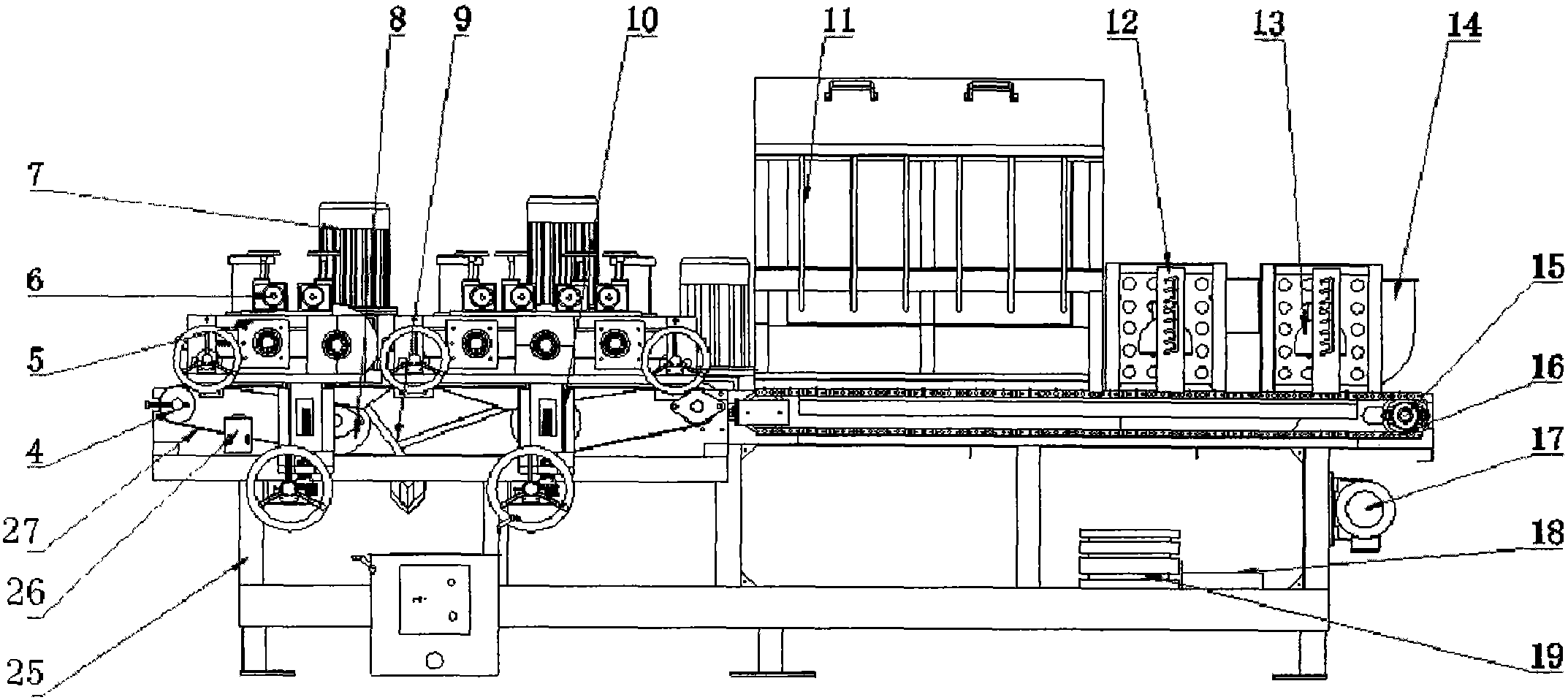

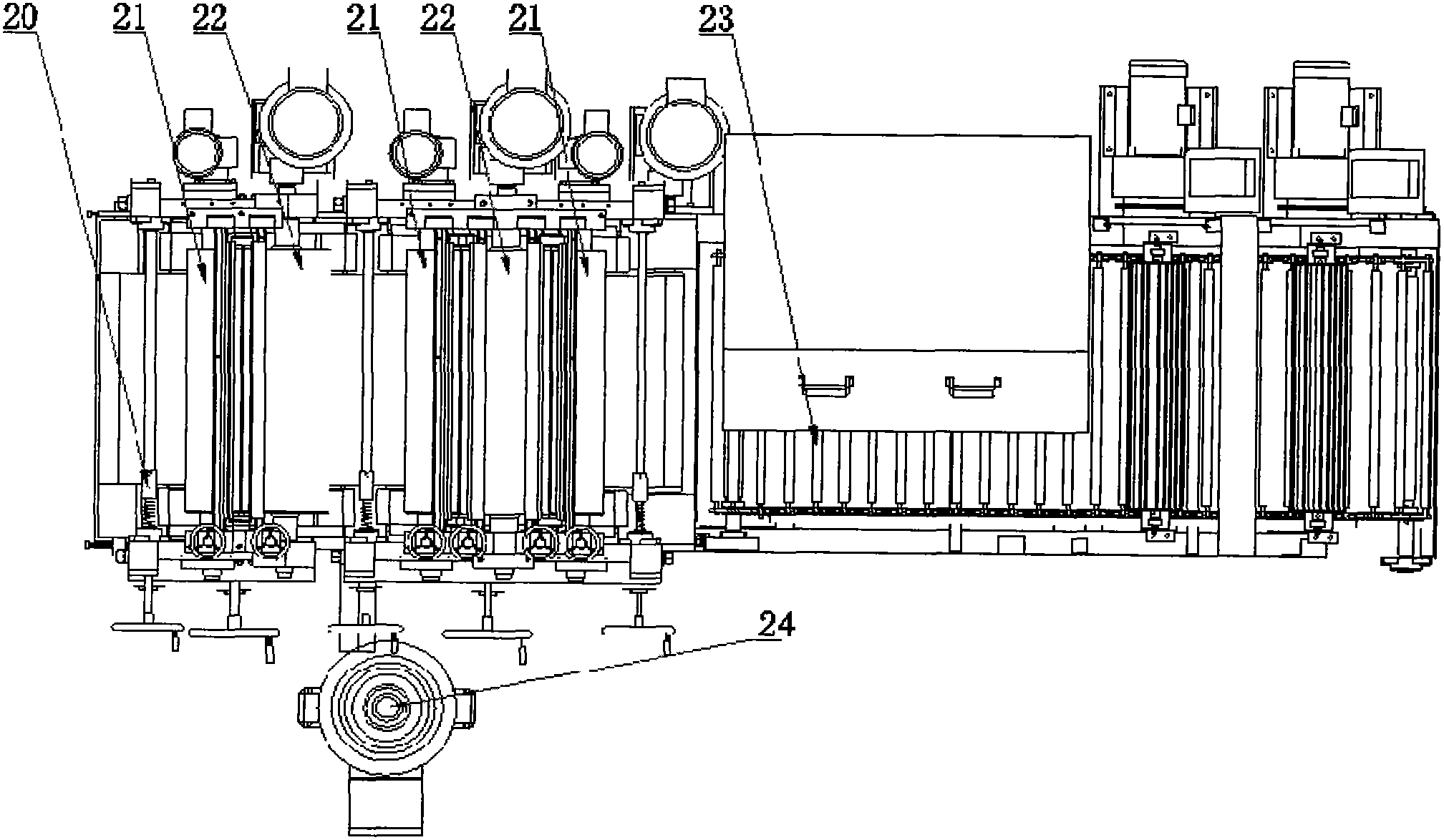

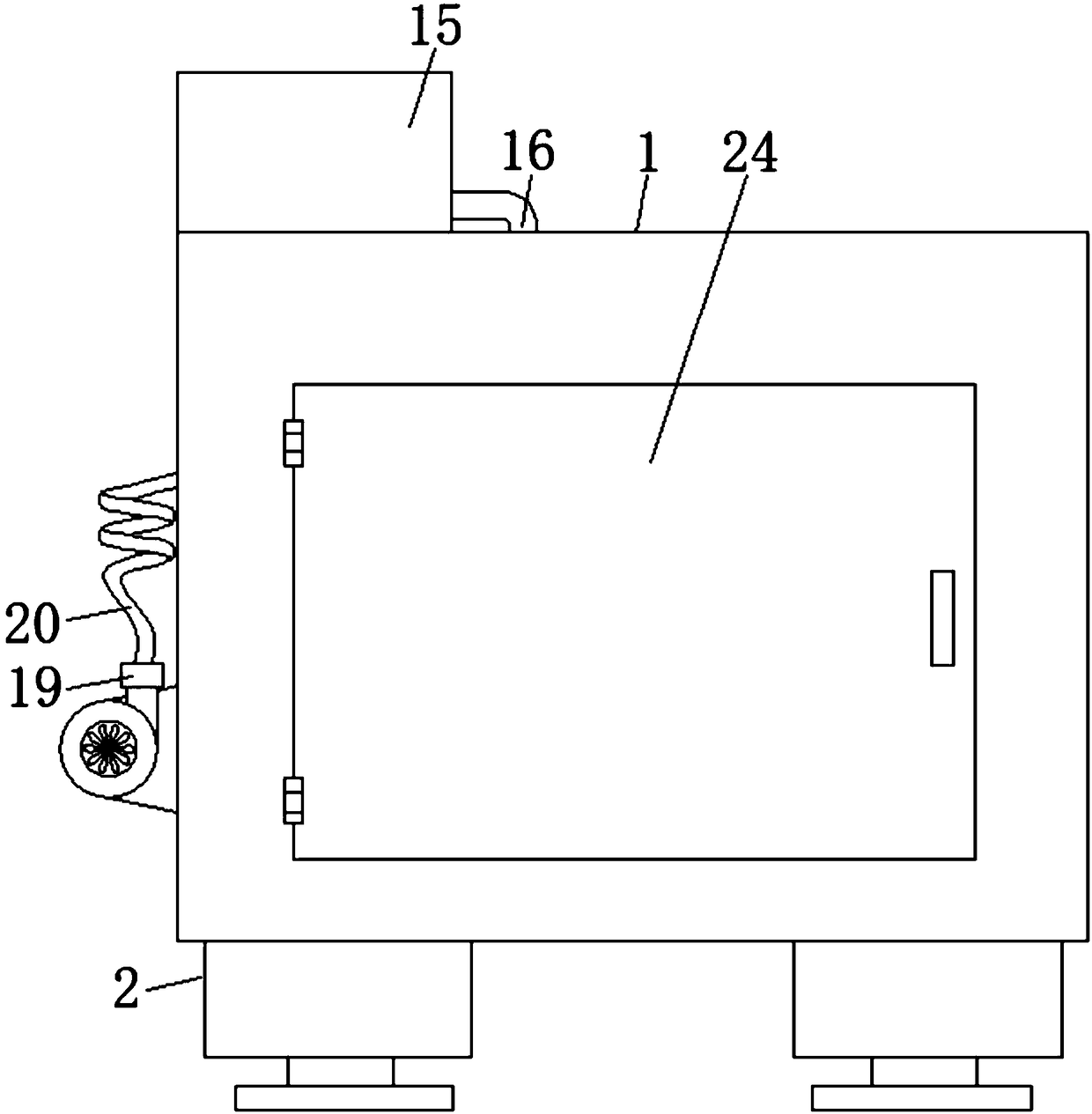

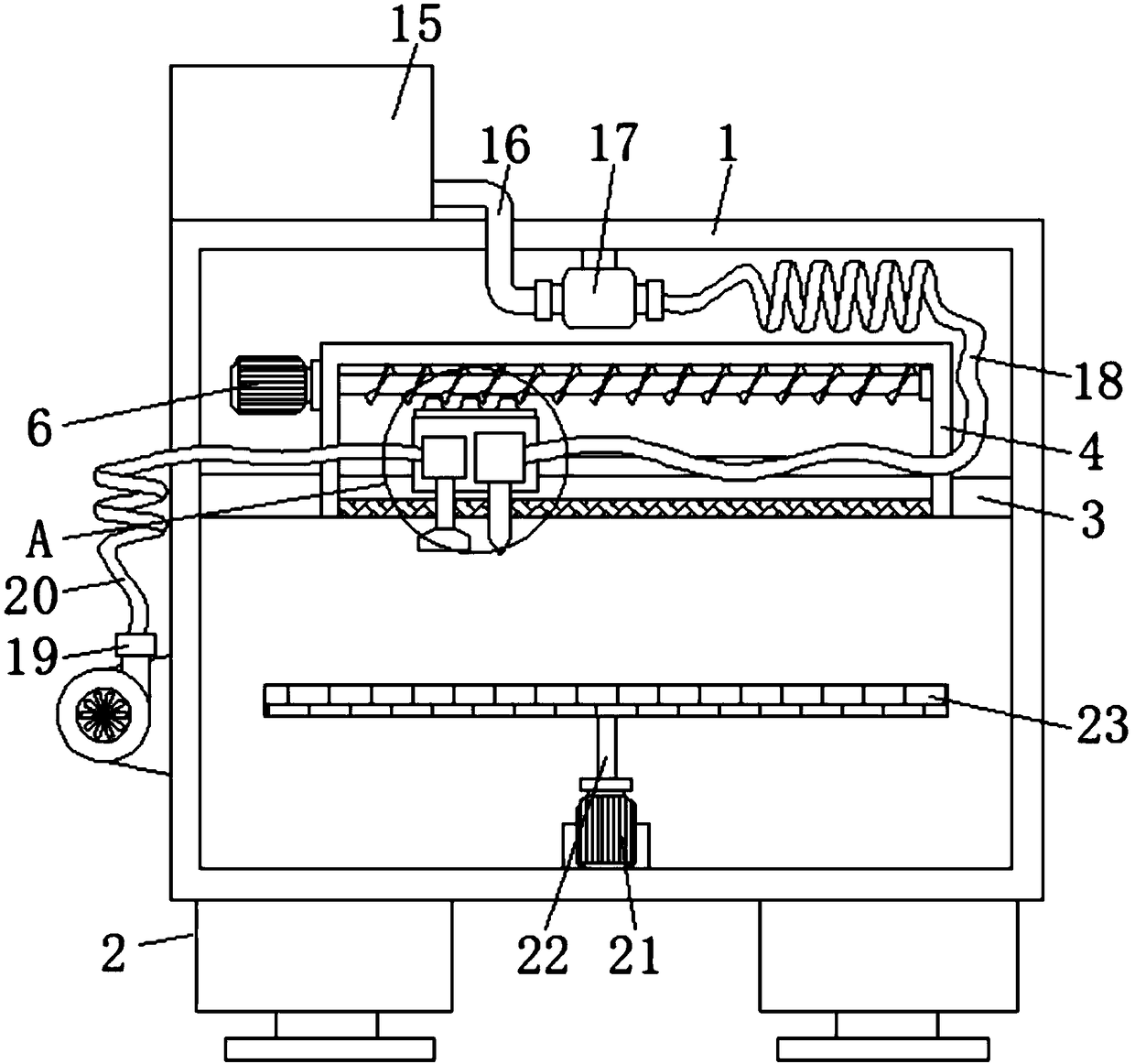

Integration machine with roll coating, leveling and drying

InactiveCN103447198AHigh precisionStrong adhesion to paintLiquid surface applicatorsCoatingsUV curingBiochemical engineering

The invention provides an integration machine with roll coating, leveling and drying. The integration machine comprises double reversible roll-coating equipment, heating and leveling equipment, UV (Ultra Violet) drying equipment and a rack, wherein the double reversible roll-coating equipment, the heating and leveling equipment and the UV drying equipment are arranged on the rack; one end of the heating and leveling equipment is connected with the double reversible roll-coating equipment, and the other end of the heating and leveling equipment is connected with the UV drying equipment; one side of the double reversible roll-coating equipment is provided with an oil-paint warming barrel; the heating and leveling equipment is internally provided with a plurality of quartz heating pipes. The integration machine provided by the invention has the advantages of simple operation, high efficiency, large yield and the like, and has multiple functions by combination of the roll coating equipment, the heating and leveling equipment and the UV curing machine, so that the production efficiency is greatly improved and the processing cost is saved.

Owner:安徽纪兴源科技股份有限公司

Crayon and manufacturing method thereof

InactiveCN101993636AFeel smoothFeel goodPencil leadsNon-propelling pencilsParaffin waxEthylene Polymers

The invention discloses a crayon and a manufacturing method thereof. The crayon is prepared by the following steps: taking paraffin wax, ethylene polymer, stearic acid, pigment and assistants as raw materials; adding the ethylene polymer and stearic acid in the paraffin wax to prepare into a synthetic wax; adding toner and fillers into mineral oil for grinding to prepare into color paste; mixing, melting and evenly stirring the synthetic wax and the color paste to prepare into crayon pulp; and sizing the crayon pulp to prepare into the crayon. The crayon prepared by the invention has the color concentration similar to that of the oil painting stick product and good coloring performance, has no crayon scraps in use, and can not cause pollution to users; in addition, the strength of the crayon can improved.

Owner:LOTUS STATIONERY

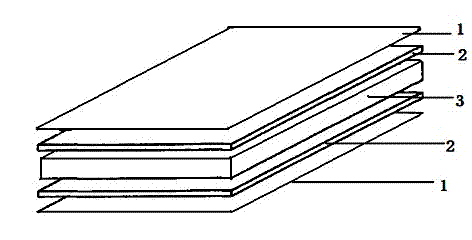

Preparation method of ecological plate

InactiveCN102198675AReduce usageConserve non-renewable resourcesSynthetic resin layered productsWood veneer joiningRenewable resourceNon-renewable resource

The invention discloses a preparation method of an ecological plate, which comprises the following steps of: step 1, preparing melamine impregnated cellophane paper, wherein glue content is increased by 15-20% in the preparation process in comparison with a traditional formula; step 2, attaching the melamine impregnated cellophane paper on special-shaped veneers; step 3, preparing an intermediate substrate; step 4, respectively adhering the veneers attached with the melamine impregnated cellophane paper to two surfaces of the intermediate substrates, and pressing and heating the two surfaces of the intermediate substrate to get the ecological plate. In the preparation method provided by the invention, a grainy paper for printing substitutes a natural wood material to serve as a decorative finish of the plate, so that usage amount of wood is greatly reduced, and non-renewable resource is saved; oil paint is substituted after the surface of the plate is impregnated by melamine, so that cost on processing is greatly saved, processing time is greatly shortened, and environmental performance of the preparation method is far better than that of the conventional production method; and the prepared ecological plate is excellent in surface abrasive resistance, scratch resistance, stain resistance and fire resistance, and is fashionable in design and color expression, so that the prepared ecological plate can meet the requirements of different consumers.

Owner:上海荷雨木业有限公司

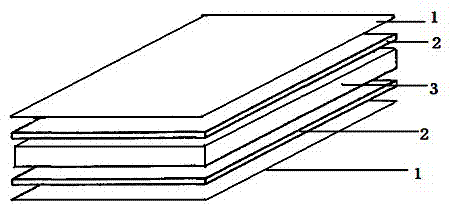

Ink-jet oil painting canvas and manufacturing method thereof

The invention discloses an ink-jet oil painting canvas. The oil painting canvas comprises a base material, a bottom coating layer and a surface coating layer from bottom to top in sequence, wherein the bottom coating layer comprises the following components in parts by weight: 35-45 parts of filler, 1-3 parts of polyvinyl alcohol, 30-40 parts of a bonding agent, 0.5-2 parts of an additive and 10-30 parts of water; the surface coating layer comprises the following components in parts by weight: 10-15 parts of silicon dioxide, 1-3 parts of polyvinyl alcohol, 30-40 parts of a special bonding agent, 0.5-2 parts of an additive, 1-5 parts of an anti-bleeding agent, and 30-50 parts of water. The ink-jet oil painting canvas disclosed by the invention has the advantages that the matching and the bonding strength of the ink-jet oil painting canvas with latex used in Latex ink are good, and when the Latex ink is used for ink-jet printing, the ink can be cured on the surface coating layer at low temperature, and high color fastness can be obtained; simultaneously, the extra anti-bleeding agent is added into the surface coating layer, so that the bleeding of ink can be prevented, the edges of a painting are clear and the color expressiveness is excellent.

Owner:JIANGSU GEMEIGAO DEV CO LTD +1

Anti-sticking anti-scribbling paint composition

InactiveCN101275056AGood stain resistanceGood self-cleaning abilityCoatingsPolymer resinAnti-graffiti coating

The present invention provides an antisticking doodle proof coating, the main component includes 20-70% fluorine polymer resin, 1-7% fluorine-containing surfactant, 2-7% silicon-containing surfactant, 1-5% nano-powder, 0.1-2% metal drier, 20-80% solvent. The antisticking doodle proof coating is coated on the outdoor facilities of all kinds of material of metal, porcelain, cement, coating, oil paint, frp, wood, the antisticking doodle proof coating plays a best important role in sticking and coating resistance, used for outer wall coating decoration at the same time, having strong self-clearing impact, making dust and dirt automatically flush by rain or washing cleanlily by water.

Owner:HARBIN JINTUYUAN SCI & TECH

Water-based imitated marble multi-color paint and preparation and construction method thereof

InactiveCN104830184AImprove waterproof performanceReduce dosageCovering/liningsCoatingsWater basedCrack resistance

The invention relates to water-based imitated marble multi-color paint which comprises the following components in parts by weight: 200-300 parts of deionized water, 3.5-5.5 parts of hydroxyethyl cellulose, 3.5-5.5 parts of multifunctional additives, 0.5-2.0 parts of a wetting agent, 1.5-2.5 parts of an antifoaming agent, 8.5-10.5 parts of ethylene glycol, 17.5-20.5 parts of a coalescing agent, 2.5-5.5 parts of a polyurethane thickener, 350-450 parts of silicone acrylic emulsion, 2.5-4.5 parts of an alkali soluble thickener, 2.5-4.5 parts of a flatting agent, 2.0-3.0 parts of a suspending agent, 2.0-3.0 parts of a preservative and 200-300 parts of colored slices. The water-based imitated marble multi-color paint disclosed by the invention can be used for brush coating and spraying, has an innovative special technical formula, is resistant to washing, mildew and moss and has excellent fouling resistance, extremely high self-cleaning property, crack resistance and attractive daubing appearance.

Owner:田雪

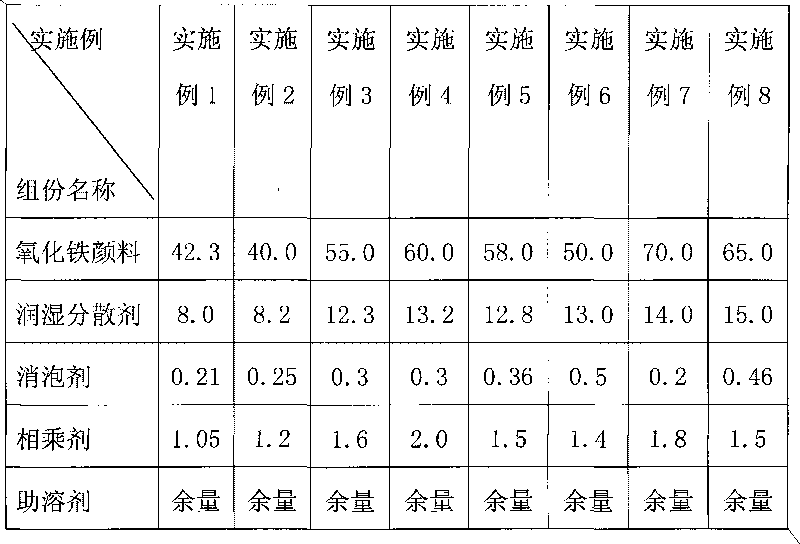

Water and oil applicable iron oxide color paste

ActiveCN101760083ALow production costReduce manufacturing costPigment pastesSolventUltimate tensile strength

The invention discloses a water and oil applicable iron oxide color paste, which is consisting of iron oxide pigment, wet dispersing agent, multiplying agent, foam killer and latent solvent, which are proportioned in gross weight percent as follows: 40.0-70.0 percent of iron oxide pigment, 8.0-15.0 percent of wet dispersing agent, 0.2-0.5 percent of foam killer, 1.0-2.0 percent of multiplying agent, and the rest percent of latent solvent. The ratio of each component in the invention is appropriate, so that the water and oil applicable iron oxide color paste have good compatibility with water or oil paint color; adding a proper amount of the multiplying agent, the iron oxide color paste may have wide universality with good storage stability. In summary, the water and oil applicable iron oxide color paste according to the invention has the advantages of high pigment content, good fluidity, high tinting strength, excellent storage stability, low cost, powerful versatility, simple preparation process, and is suitable for water or oil paint color system mixing; and the color paste has a simple preparation process and is convenient for industrial production, thus overcoming limitation that traditional color paste requires one to one corresponding tinting.

Owner:SUZHOU SUNMUN TECH CO LTD

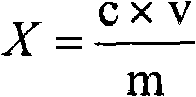

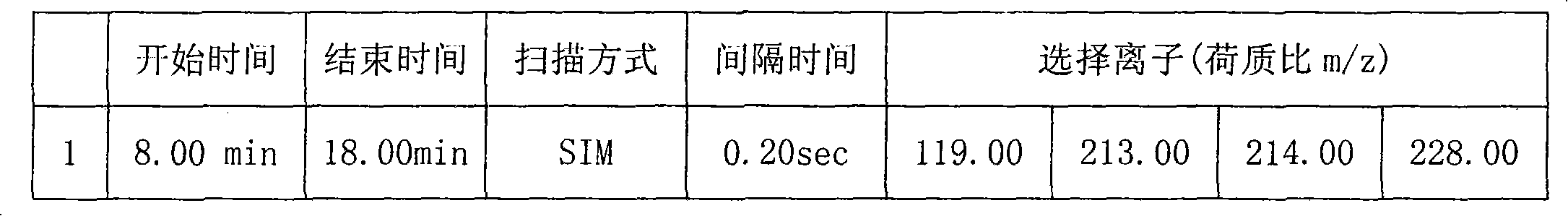

Method for detecting content of bisphenol A

The invention provides a method for detecting the content of bisphenol A, comprising the steps: extracting a sample to be detected with organic solvent, condensing the obtained extraction solution, purifying the extraction solution through a C18 solid phase extraction column, taking the organic solvent as leacheate, collecting, condensing and metering the volume of the leacheate and finally filtering the leacheate to obtain sample test solution; then, detecting the sample detecting solution through a gas chromatograph-mass spectrometer according to an external reference method; when the sampleto be measured is a solid sample, crushing the sample to be measured first and carrying out Soxhlet extraction on the sample to be detected; and when the sample to be detected is liquid, and ultrasound extraction is carried out. The method for detecting the content of the bisphenol A is quick and effective and ensures that the error rate is not more than 3 percent and the detection limit is 0.05mg / kg. The method is used for detecting the content of bisphenol A in rubber, plastic, ink and oil paint products, is reliable and convenient to implement and can meet the requirements on research andproduction.

Owner:PONY TESTING INT GRP SHANGHAI CO LTD

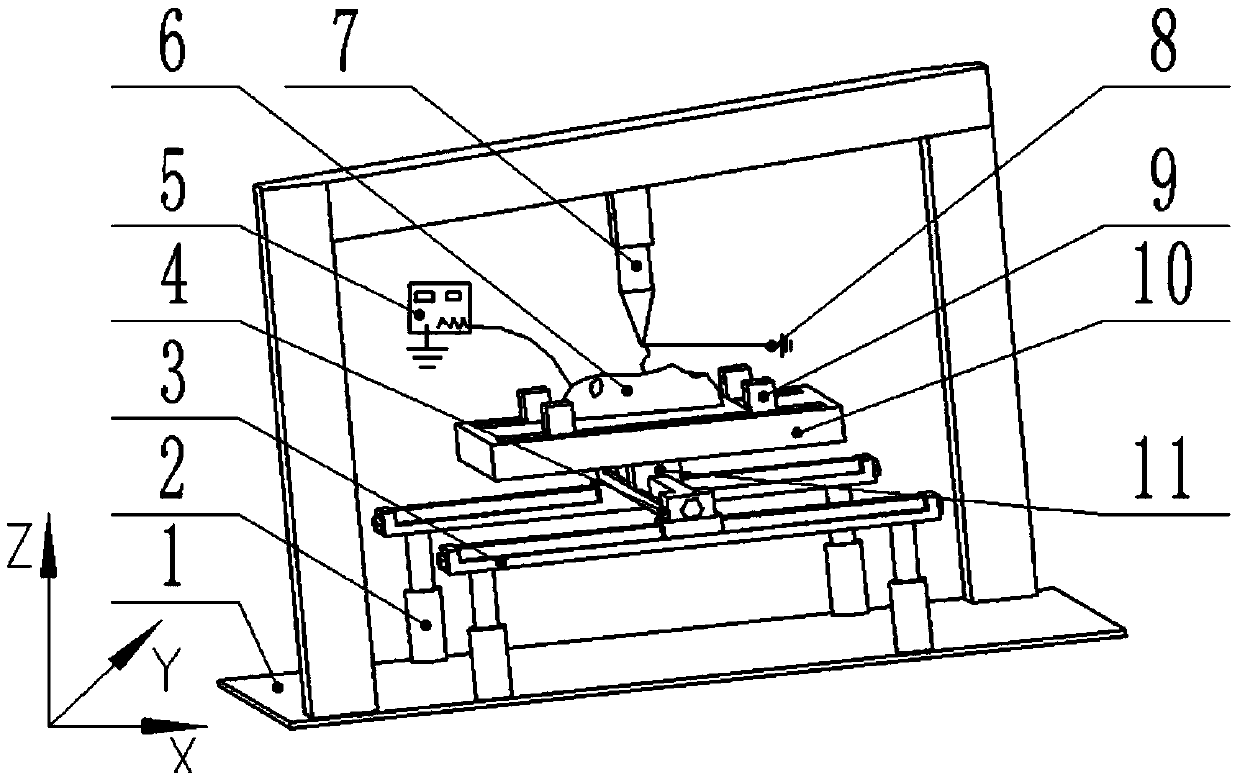

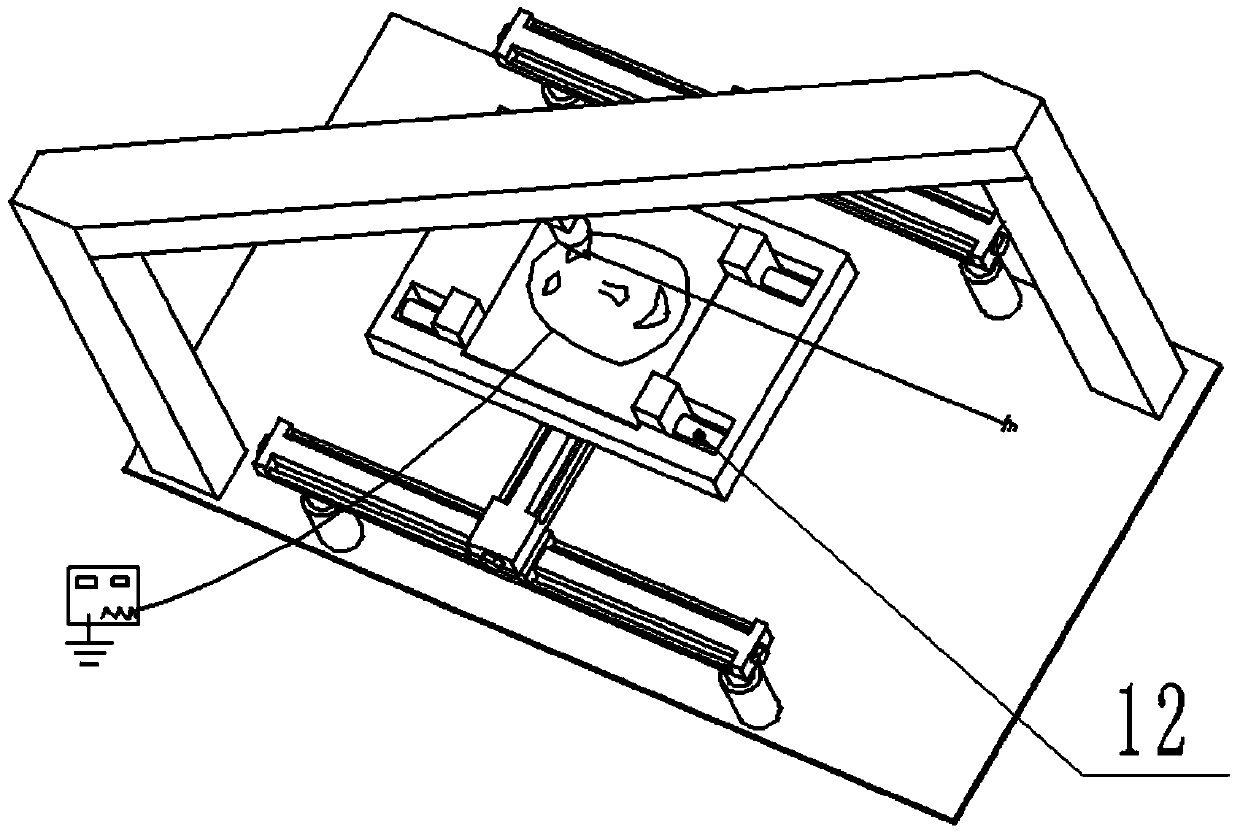

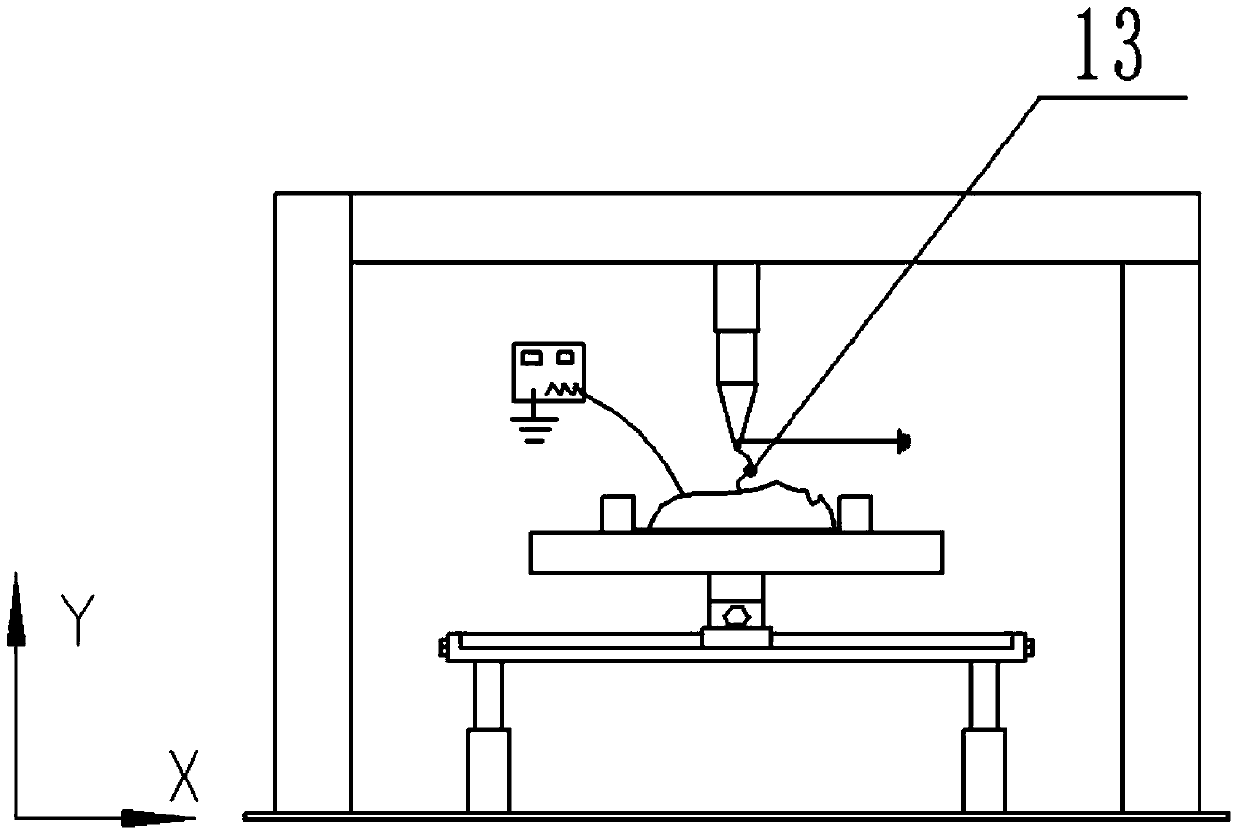

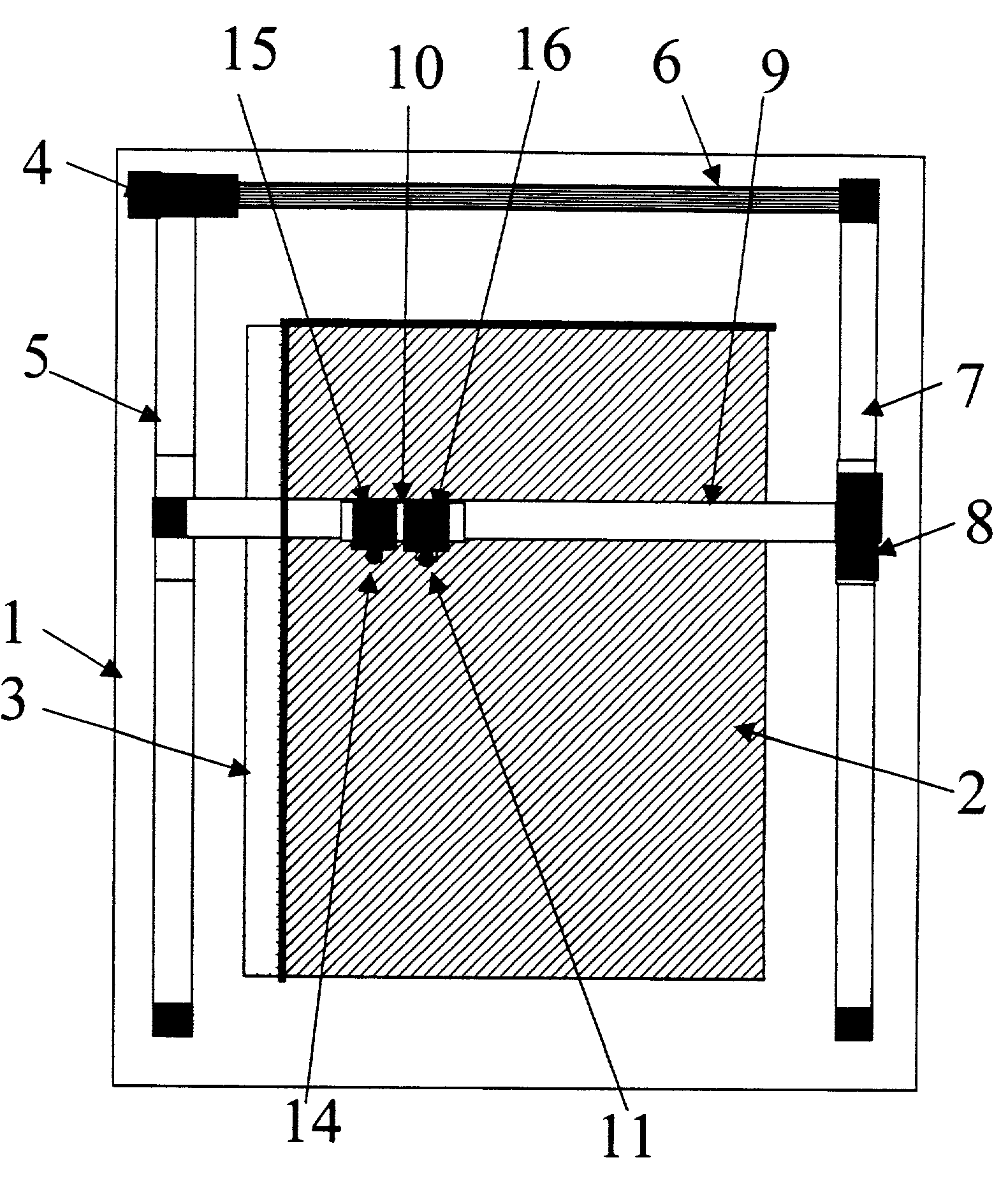

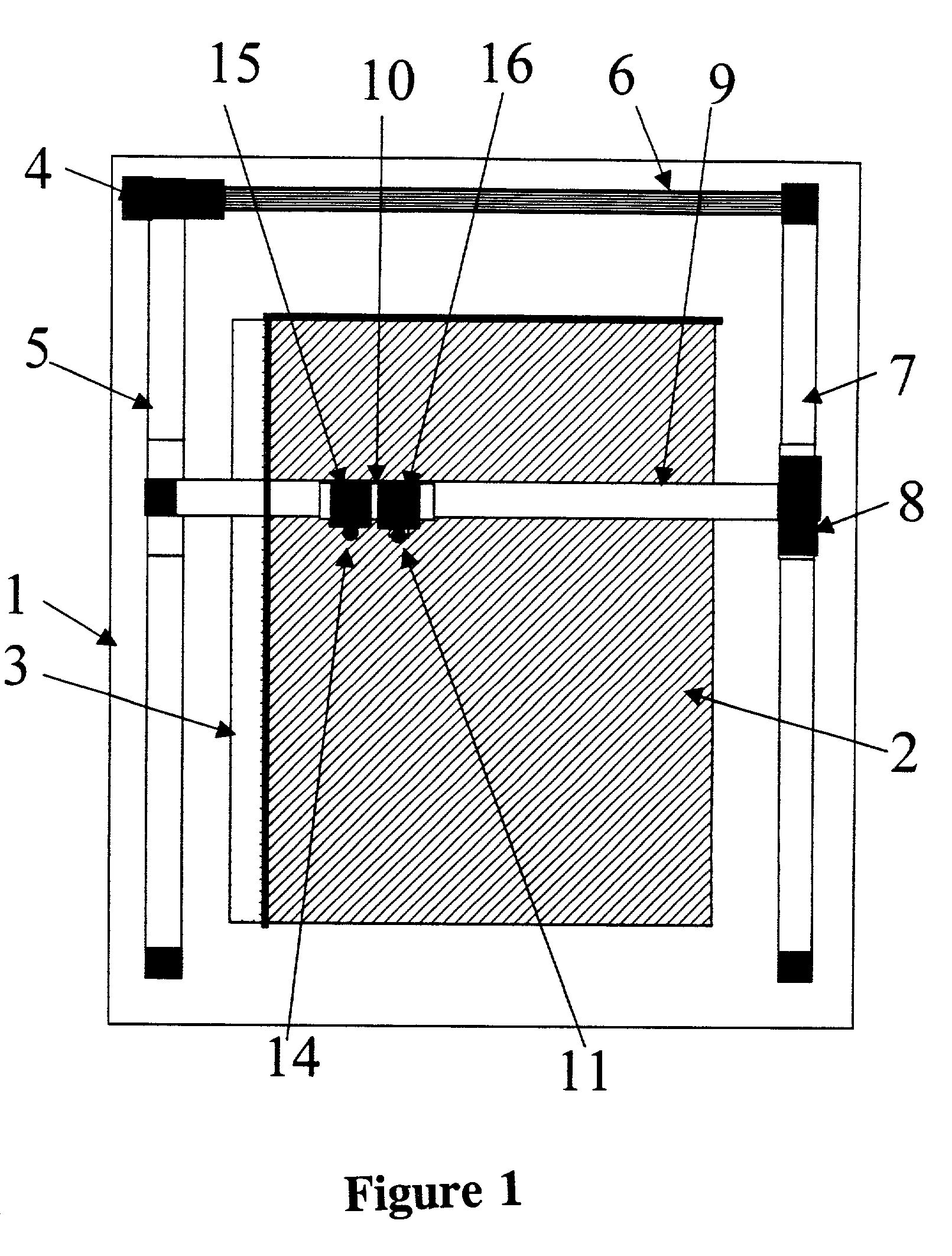

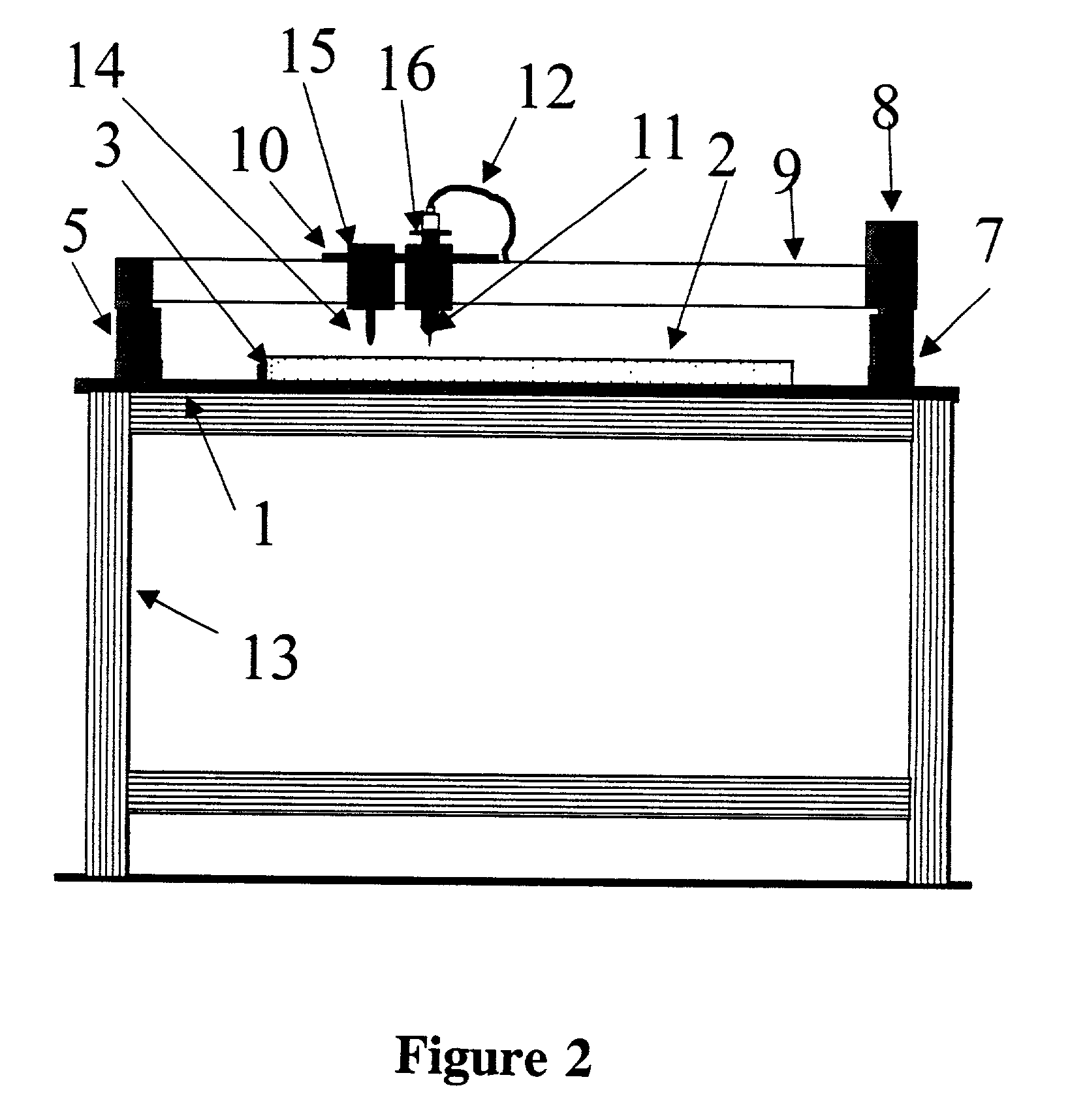

Mechanism for applying paint to canvas

InactiveUS7094292B2Efficient productionLiquid surface applicatorsMovable spraying apparatusOil paintMechanical engineering

Owner:RANDALL JOHN N +1

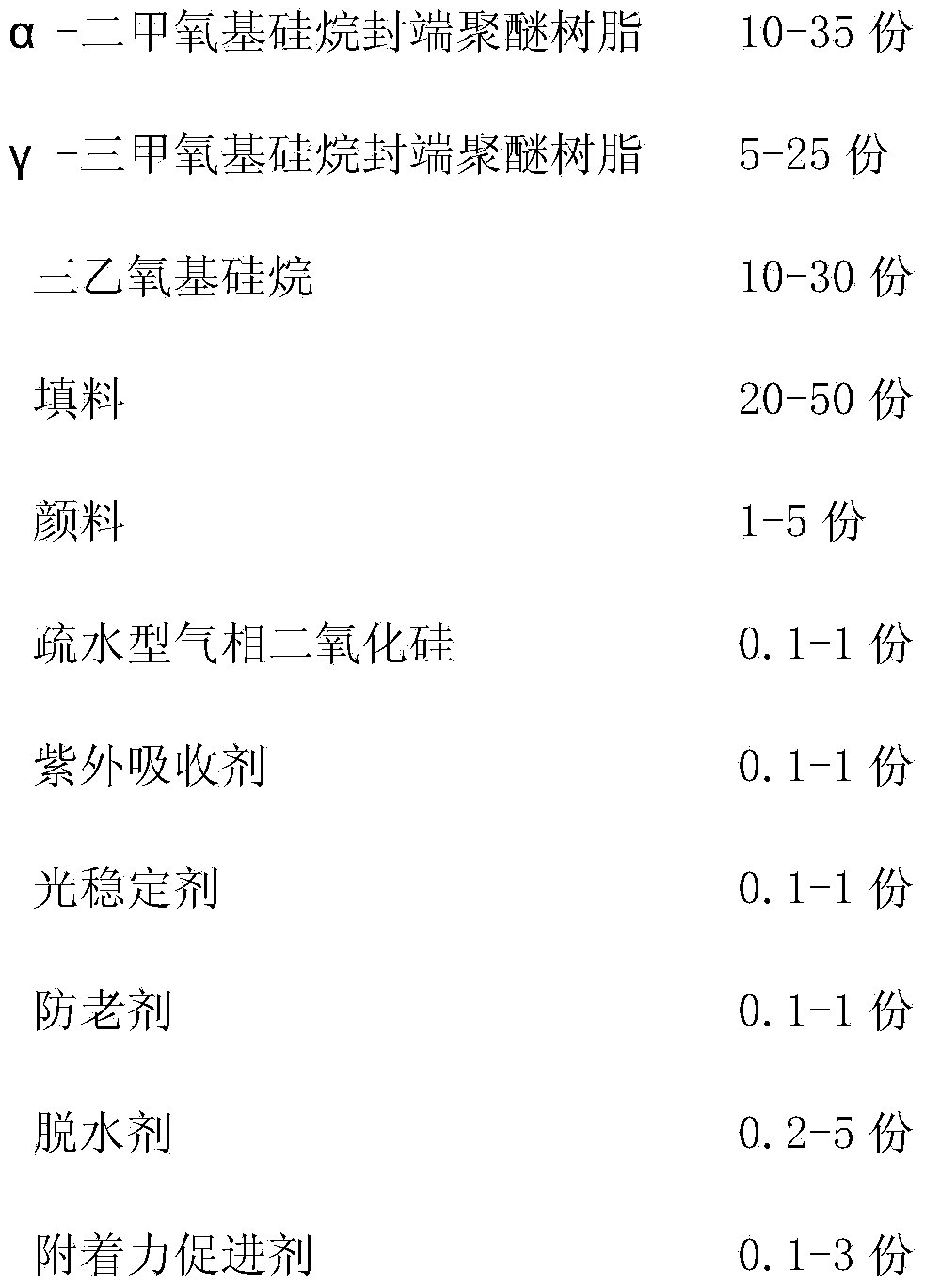

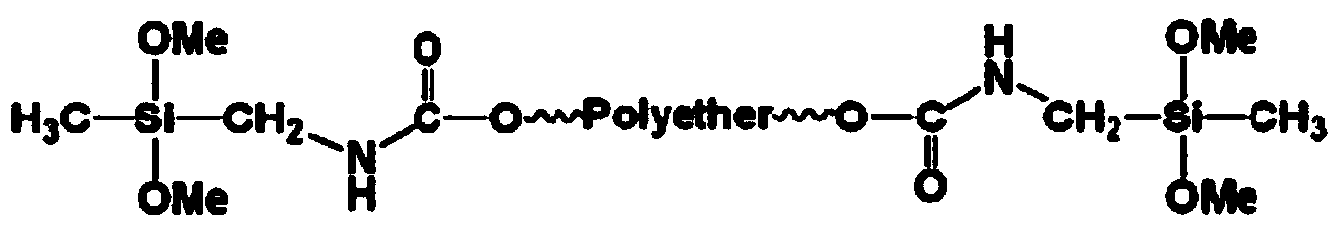

Waterproof paint

ActiveCN103642376AImprove mechanical propertiesImprove waterproof performanceFireproof paintsAnti-corrosive paintsGas phaseAntioxidant

The invention discloses a waterproof paint. The raw materials are, by weight, 10-35 parts of alpha-dimethoxy silane terminated polyether resins, 5-25 parts of gamma-trimethoxy silane terminated polyether resins, 10-30 parts of triethoxy silane, 20-50 parts of filling materials, 1-5 parts of pigments, 0.1-1 part of hydrophobic gas-phase silica, 0.1-1 part of ultraviolet absorbents, 0.1-1 part of light stabilizers, 0.1-1 part of antioxidants, 0.2-5 parts of dehydrating agents and 0.1-3 parts of adhesion promoters. The waterproof paint is environmentally friendly and non-poisonous, has excellent mechanical properties, waterproof performance and anticorrosion performance, and has good adhesion with oil paint, steel, concrete and the like. In addition, inorganic flame retardants of aluminum hydroxide or magnesium hydroxide can be added, thus the waterproof paint has good flame retardant effects, and the application range of the waterproof paint is further widened.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

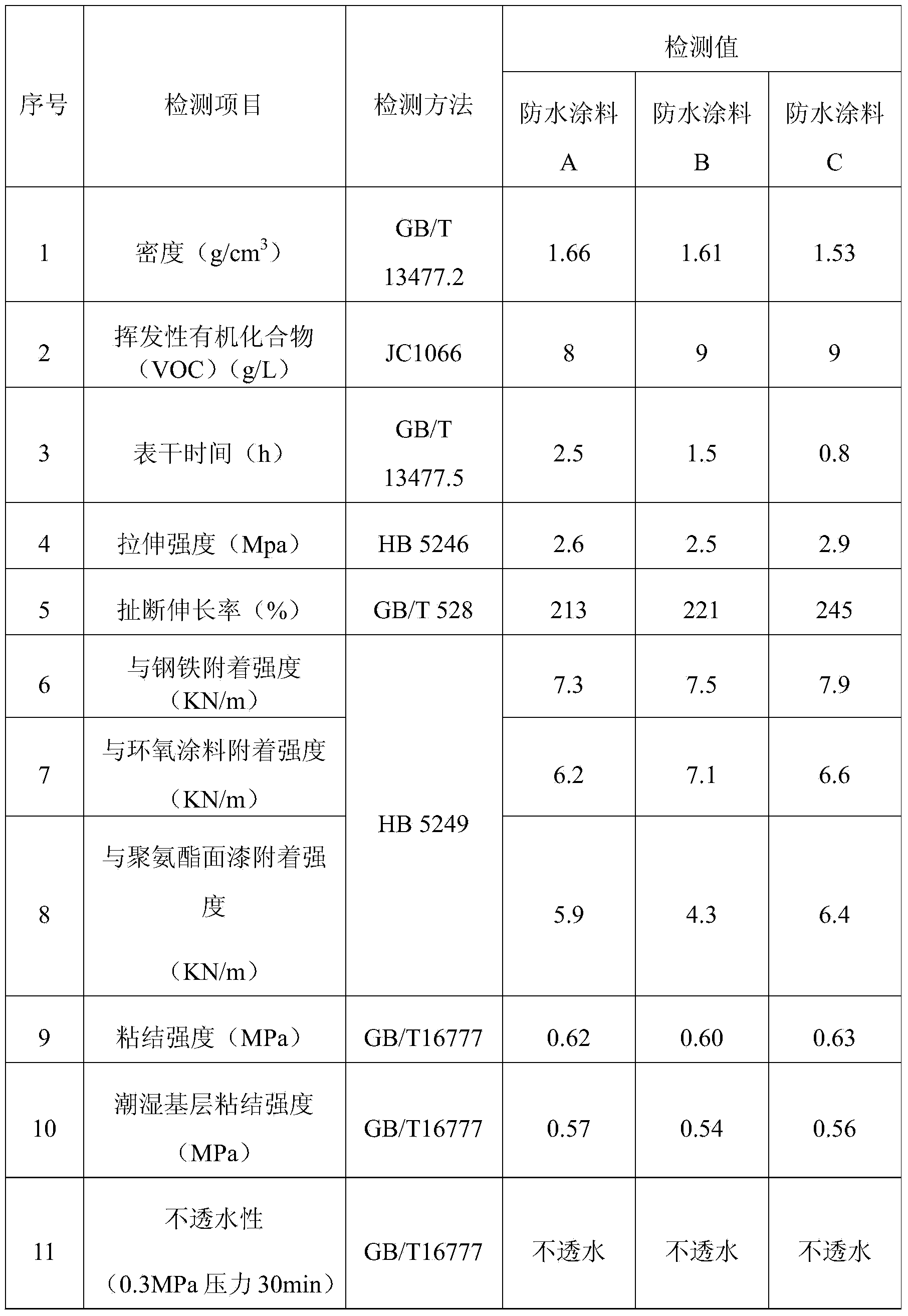

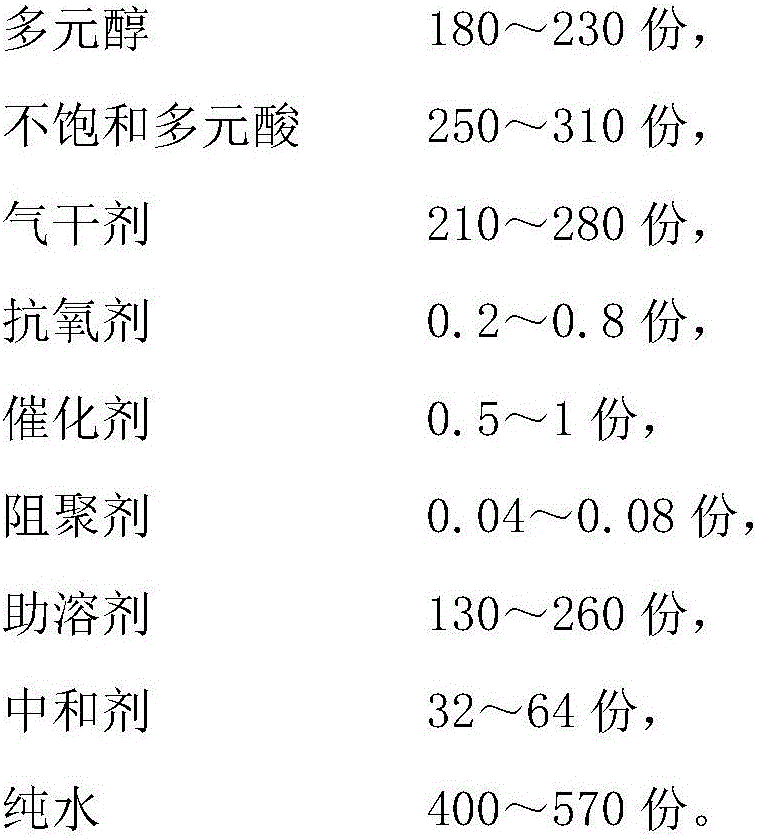

Water-based unsaturated polyester resin and preparation method thereof

The invention belongs to the technical field of high molecular materials and relates to water-based unsaturated polyester resin and a preparation method thereof. The water-based unsaturated polyester resin is prepared from the following raw materials in parts by weight: 180-230 parts of polylol, 250-310 parts of unsaturated polyacid, 0-40 parts of saturated polyacid, 210-280 parts of air drying agent, 0.2-0.8 part of antioxidant, 0.5-1 part of catalyst, 0.04-0.08 part of polymerization inhibitor, 32-65 parts of neutralizing agent, 130-260 parts of cosolvent and 400-570 parts of pure water. The water-based unsaturated polyester resin has the advantages that the water-based unsaturated polyester resin can be diluted with water; the prepared lacquer is low in VOC discharge and flexible in construction; the water-based unsaturated polyester resin has low cost, net flavor and air drying property and can be cured at normal temperature or cured by heating; and the water-based unsaturated polyester resin is used for replacing the traditional resin for traditional oil paint products and has wide application prospects.

Owner:CHENGDU SUPPON CHEM IND CO LTD

Robot skin

ActiveCN102555394AEasy to makeImprove antioxidant capacitySynthetic resin layered productsInorganic adhesivesEngineeringResin adhesive

The invention relates to robot skin, which comprises a glass cement mixture layer, a sponge resilient layer and a resin adhesive layer which are adhered together in sequence from outside to inside. The root skin is constricted by the glass cement mixture layer, the sponge resilient layer and the resin adhesive layer, and the robot skin can be easily and conveniently manufactured, wherein the oxidation resistance of the robot skin is enhanced by means of oxidation resistance and certain extensibility of glass cement, and the robot skin does not break or the normal operation of machinery is not influenced along with mechanical movement of a robot. Due to the use of the sponge resilient layer, the thickness of the robot skin can be increased, and the weight of the robot skin can be reduced. Further, an oil paint is mixed in the glass cement mixture layer, so that colorization at a later period can be easily and conveniently realized; and in addition, the effects of reinforcement and expansion of tensile force can be achieved by integrating an elastic fabric layer in the robot skin.

Owner:SHENZHEN HUANGQIANG CULTURE TECH GROUP

Colored powdered glass printing ink, oil paint and coating

A color glass powder printing ink / lacquer / paint comprises staining compound, thinner, forming agent, polymerization inhibitor and addition agent. The staining compound adopts color glass powder or screen printing glaze powder.

Owner:王广武

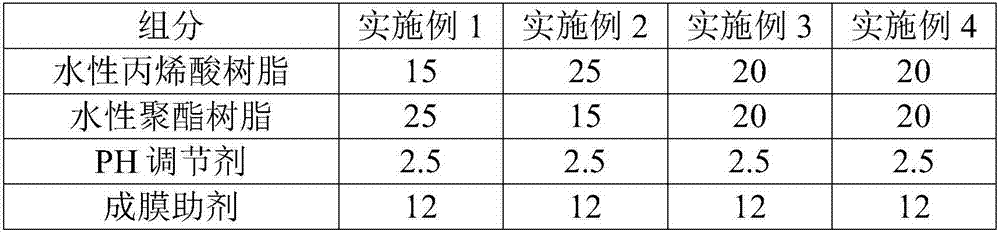

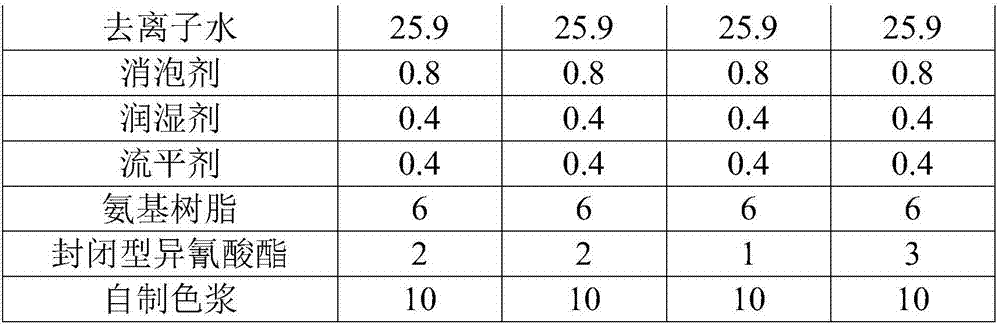

Glazing-free high-temperature baked finishing coat for sharing bicycle and preparation method thereof

The invention relates to the technical field of coatings and specifically discloses a glazing-free high-temperature baked finishing coat for a sharing bicycle and a preparation method thereof. The finishing coat contains the following components in parts by weight: 15-25 parts of water-based acrylic resin, 15-25 parts of water-based polyester resin, 2-3 parts of pH regulator, 0.5-1 part of de-foaming agent, 10-15 parts of coalescing agent, 0.2-0.5 part of wetting agent, 0.2-0.5 part of flatting agent, 25-35 parts of deionized water, 5-7 parts of amino resin, 1-3 parts of closed isocyanate and 5-10 parts of color paste. The coating technology according to the invention becomes a twice-coating twice-baking technology; the production efficiency is increased, the energy consumption is reduced, the cost is lowered and the VOC emission is reduced; the finishing coat after being baked has the effect of the paint film after being glazed and the weather fastness, glossiness and fullness all are comparable with those of the oil paint.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Color smoking treatment technology for wood modification face layer

ActiveCN105729597ADrying helpsGood for smokingWood treatment detailsThermal wood treatmentVacuum pumpingSmoking treatment

The invention discloses a color smoking treatment technology for a wood modification face layer. The color smoking treatment technology comprises the specific steps that firstly, to-be-treated wood is stacked and is blown through hot air; secondly, a layer of alcohol is brushed on the surface of the wood, cleaning is conducted through a sodium carbonate solution, then thorough scrubbing is conducted through water, and the wood modification face layer is obtained; thirdly, the overall wood is immersed in a phosphoric acid solution and taken out to be aired dry; fourthly, the wood is subjected to smoking, and the wood is subjected to further baking smoking through fuel materials; fifthly, the wood is placed in a heat treatment box to be tidily placed, rapid temperature rising is conducted, vacuum pumping is carried out, then slow temperature rising is conducted, and drying is conducted till absolute dry is achieved; sixthly, the surface of the wood subjected to heat treatment is wiped thoroughly through water; seventhly, the surface of the modification face layer is coated with a wood modification agent; and eighthly, the surface of the wood modification agent is coated with a layer of protective paint again. According to the color smoking treatment technology, physical treatment and oil paint treatment are combined, the permanency of the wood color is guaranteed, the wood waterproofness is guaranteed as well, and the wood is free of toxicity, environment-friendly, safe and sanitary.

Owner:JIANGSU KENTIER WOOD

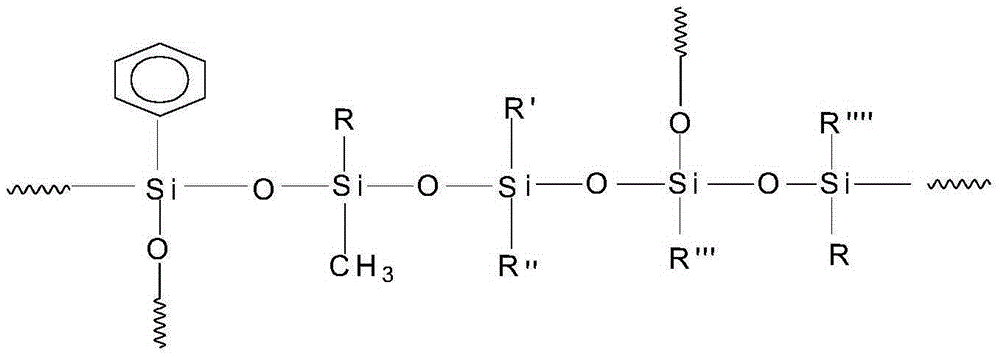

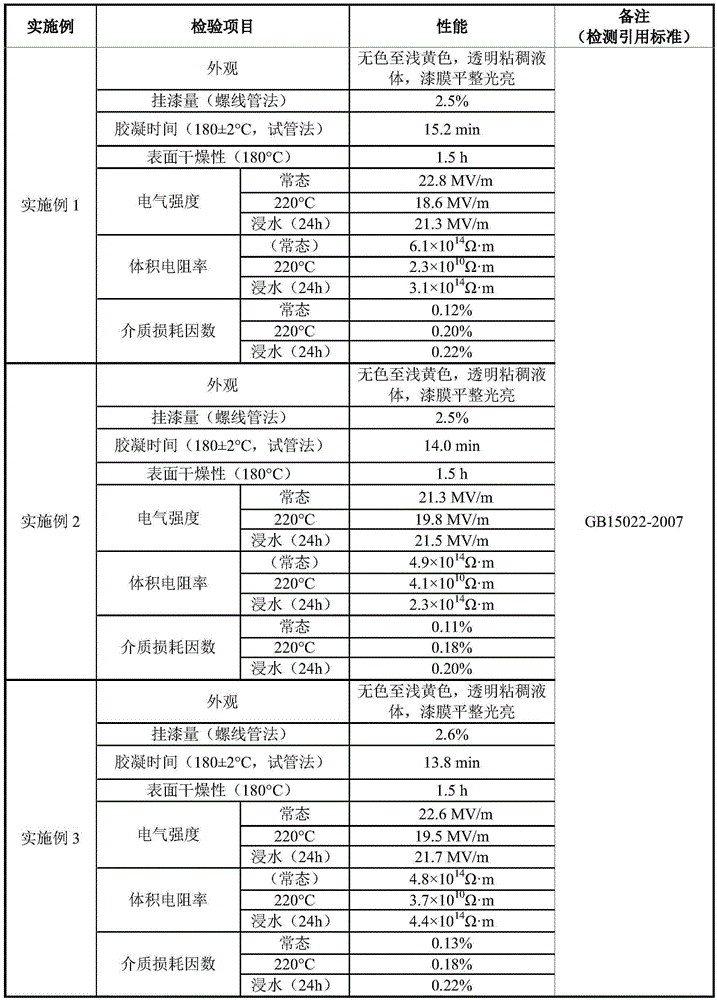

Preparation method for organic silicon impregnating varnish

The invention relates to the field of oil paint chemical engineering and especially relates to organic silicon impregnating varnish, and a preparation method and an application thereof. The organic silicon impregnating varnish is acquired through the hydrolytic condensation of silane monomers and is further acquired through the hydrolytic condensation of the silane monomers containing full alkoxy. The pure resin type organic silicon impregnating varnish not only has the advantages of excellent insulating properties, such as, high heat resistance, hydrophobic property, pressure-withstanding anti-corona property, and the like, and environmental protection, but also has the advantages of excellent adhesive force and bonding strength to the impregnated substrates, so that the phenomena of cracking and insulating painting falling caused by vibration of machinery (such as, high-speed running locomotive, mining machinery, wind power generation equipment, and the like) and heat effect are resisted and avoided.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

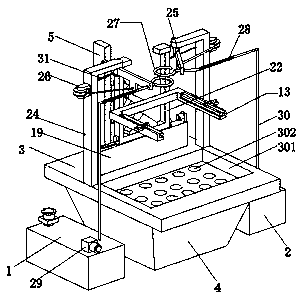

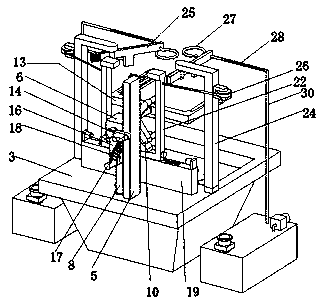

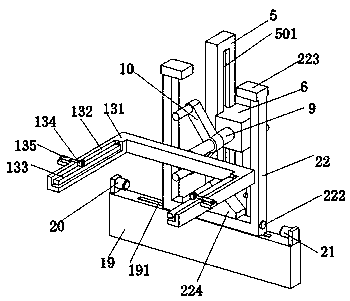

Double-sided paint spraying equipment for machined vehicle door of electric automobile

ActiveCN111330764AReduce workloadHigh degree of automationLiquid spraying apparatusElectric vehicleOil paint

The invention relates to the technical field of electric vehicles, in particular to double-sided paint spraying equipment for a machined vehicle door of an electric automobile. The double-sided paintspraying equipment comprises a first paint box, a second paint box and a paint spraying platform, wherein the first paint box and the second paint box are respectively arranged on the left side and the right side of the paint spraying platform, a machine box is arranged at the lower end of the paint spraying platform, a stand column is arranged at the rear end of the upper surface of the paint spraying platform, a stand sliding groove is formed in one side face of the stand column, and a lifting block is arranged on the side face, close to the stand sliding groove, of the stand column. According to the double-sided paint spraying equipment, the automation degree is high in the 180-degree overturning process, the overturning angle is accurate, manual fixing is not needed after overturning,and the workload of operators is reduced; and meanwhile, through the linkage function of each component, a paint spraying mechanism for paint spraying can be automatically switched in the door overturning process, the whole action is rapid, the problem that existing equipment needs to manually and frequently switch oil paint is solved, the linkage effect is excellent, the working efficiency is high, and the practicability is high.

Owner:阜阳佳派生产力促进中心有限公司

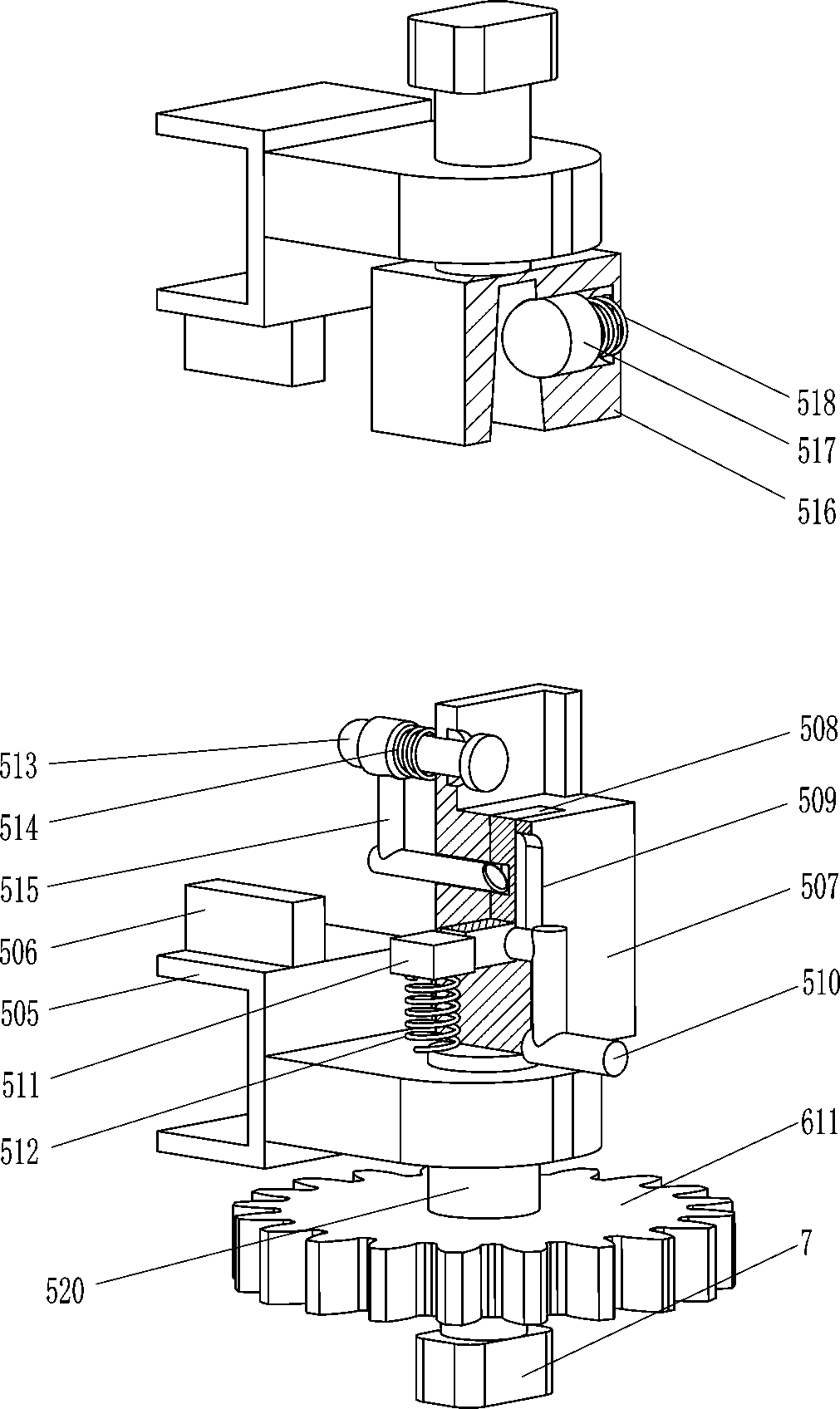

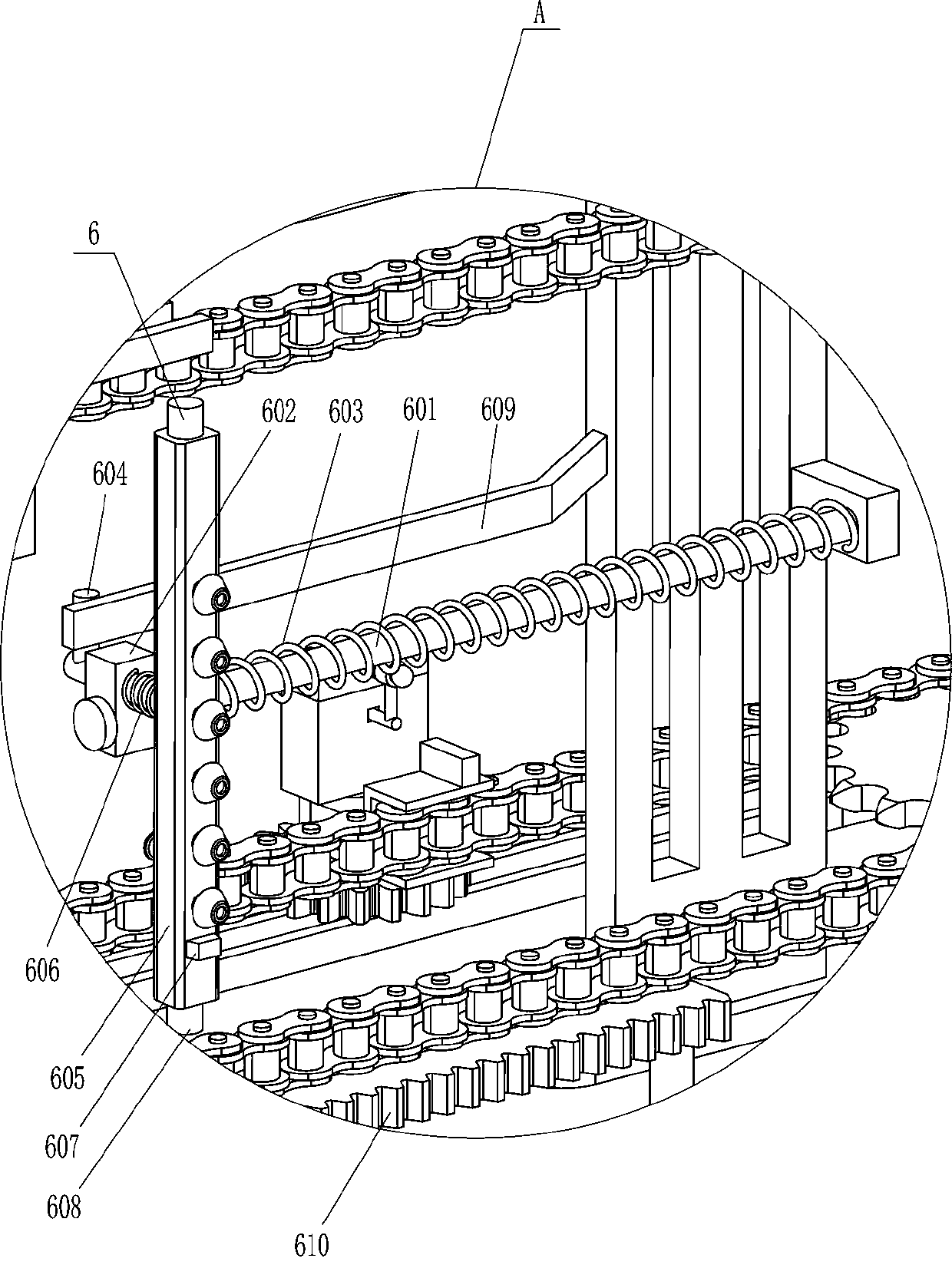

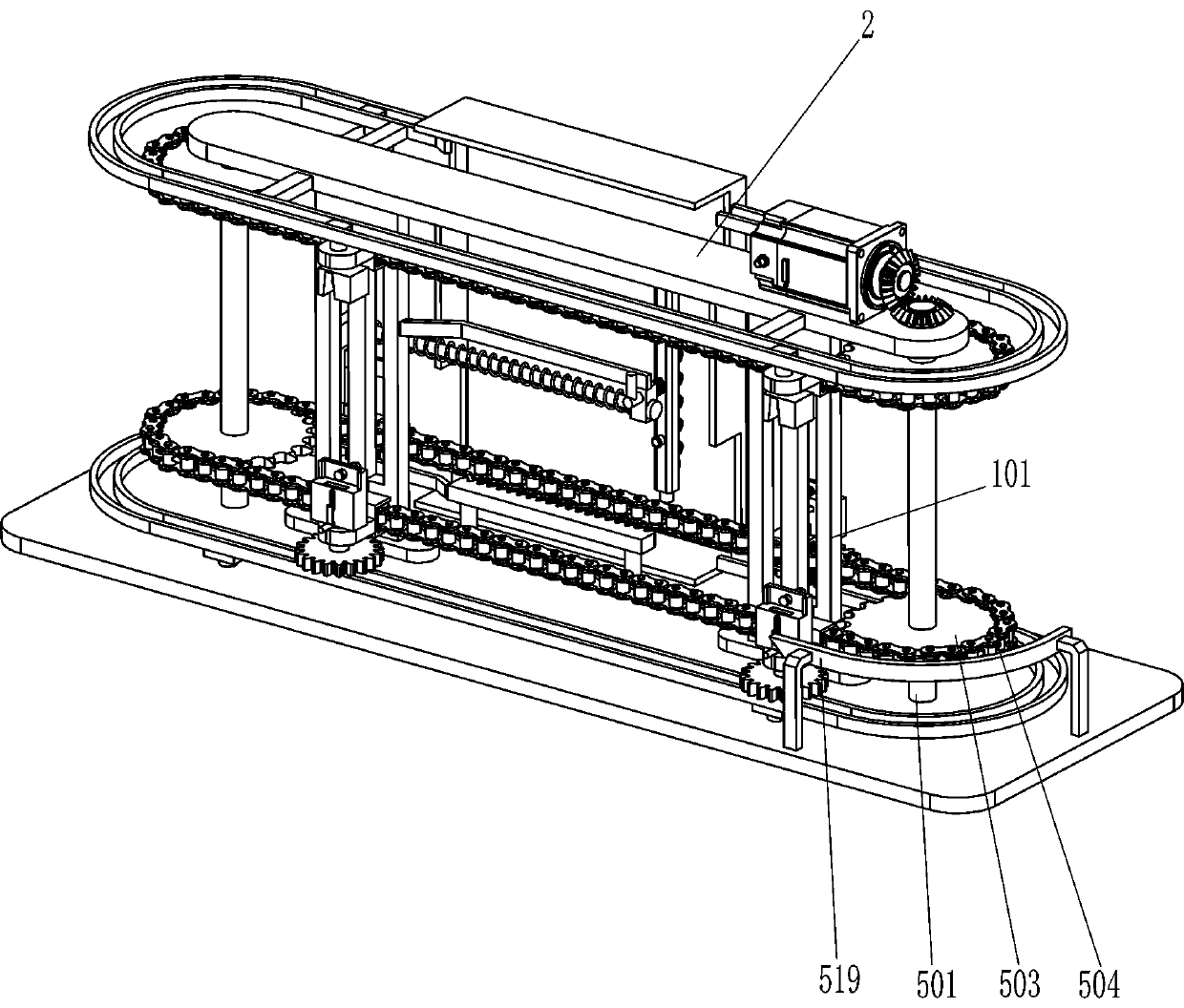

Automatic paint spraying equipment for pickaxe

The invention relates to paint spraying equipment, in particular to automatic paint spraying equipment for a pickaxe. The invention aims at solving the technical problem of how to design the automaticpaint spraying equipment for the pickaxe, which can comprehensively spray paint on the pickaxe without the need of manpower, is effort-saving and convenient, and can prevent flying oil paint from influencing the ambient environment. The automatic paint spraying equipment for the pickaxe comprises a bottom plate and a servo motor, wherein support plates are symmetrically and fixedly connected to one side of the bottom plate; a rack is fixedly connected between the end parts, far away from the bottom plate, of the two support plates; and the servo motor is arranged on one side, far away from the bottom plate, of the rack. According to the automatic paint spraying equipment for the pickaxe provided by the invention, the pickaxe is fixed through a pickaxe moving block and a second clamp rod,and the servo motor is started to rotate forwards, so that the pickaxe can be rotated inversely so as to spray the paint through a paint spraying part; and in addition, through the cooperation of a rotary gear and a rack, the pickaxe is rotated so as to be sprayed with the paint comprehensively and has no need to be sprayed with the paint manually, so that the automatic paint spraying equipment for the pickaxe is effort-saving and convenient.

Owner:赣州圣享区块链技术有限公司

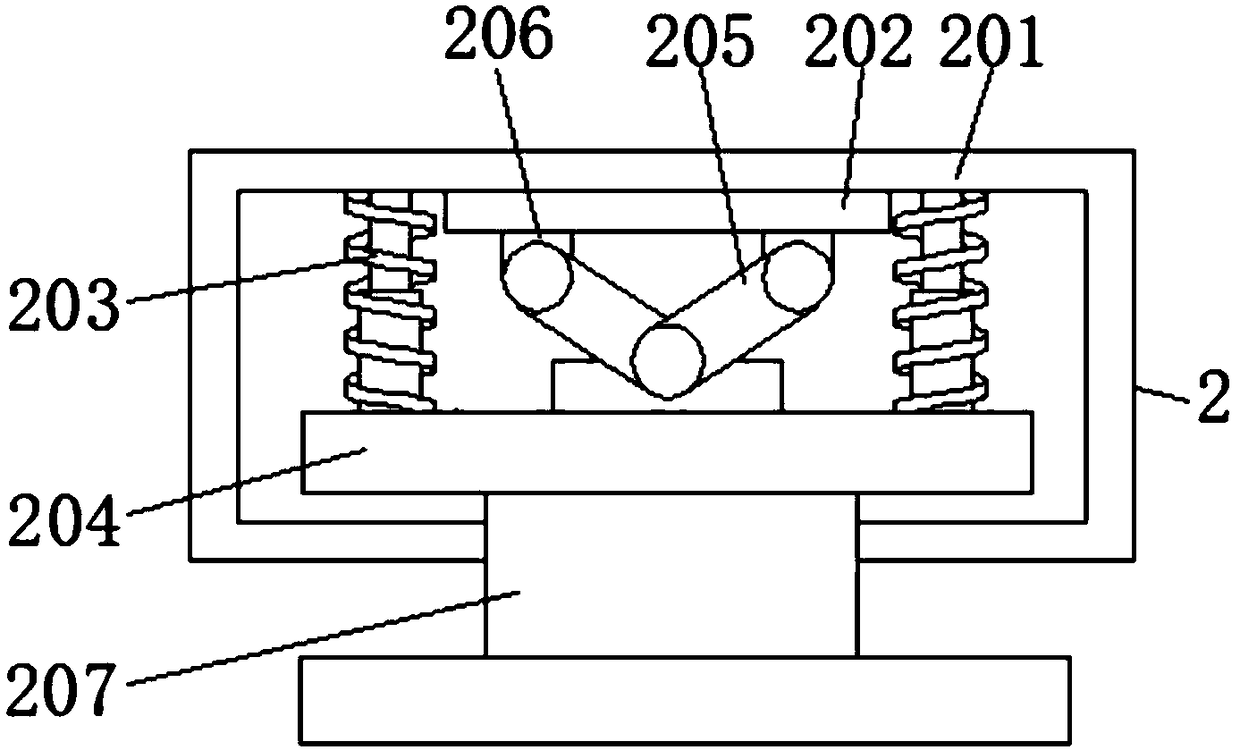

Metal plate surface spraying device

InactiveCN108580142AEven spray jobImprove drying efficiencyPretreated surfacesCoatingsEngineeringOil paint

The invention relates to the technical field of spraying devices and discloses a metal plate surface spraying device. The metal plate surface spraying device comprises a device body. Two symmetric damping mechanisms are fixedly installed at the bottom of the device body. Fixing blocks are fixedly connected with the inner walls of the two sides of the device body. A fixing box is fixedly connectedbetween the opposite ends of the two fixing blocks. A through groove is formed in the bottom of the fixing box, the left side of the fixing box is fixedly connected with a first motor, and an output shaft of the first motor is fixedly connected with a screw rod. The end, away from the first motor, of the screw rod penetrates the fixing block and is movably connected with the right side of the inner wall of the fixing box. By means of the metal plate surface spraying device, the problems that the spraying device conducts spraying unevenly, later-period airing time is long, efficiency is low, dust can stain oil paint, and cleaning is very not convenient are solved, and the effects that spraying is even, the drying efficiency is high, staining of dust is prevented, and noise pollution is alsoreduced are achieved.

Owner:丁奇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com