Water and oil applicable iron oxide color paste

A water-oil universal, iron oxide technology, applied in the direction of pigment slurry, etc., can solve the problem of unsuitable oil-based paint coloring, etc., and achieve good storage stability, energy saving, and good fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

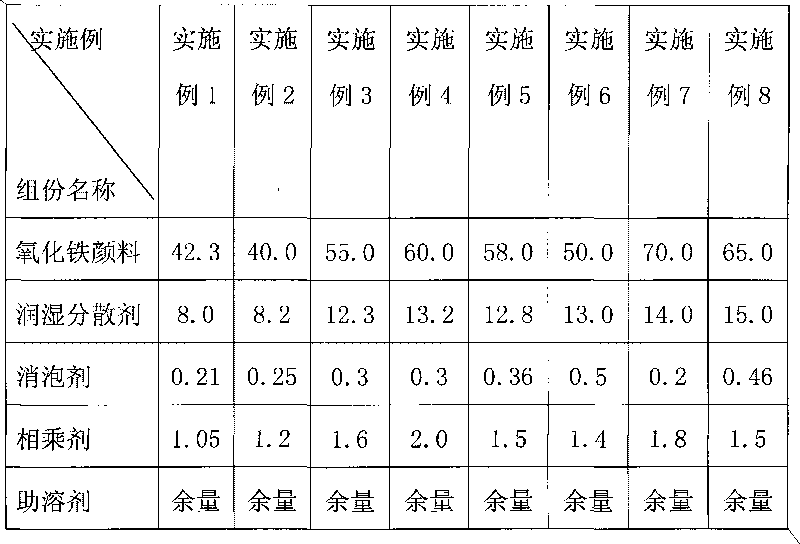

[0019] The formula of the embodiment of the invention is referring to Table 1:

[0020] Table 1: (unit: weight percentage)

[0021]

[0022] When preparing water-oil general-purpose iron oxide color paste, add wetting and dispersing agent, defoamer, and multiplier to the co-solvent and mix evenly, then put in the corresponding amount of iron oxide pigment, disperse at high speed for 45 minutes, and then grind for 2 hours. After reaching a satisfactory fineness, slowly disperse and defoam, filter and pack to obtain the required color paste.

[0023] The production process of water-oil universal iron oxide color paste is the same as the general color paste production process. During the production process, the machine can be cleaned with water or organic solvents, without adding equipment and procedures, and it is easy for industrial production.

[0024] In summary, the water-oil universal iron oxide color paste prepared according to the above formula and steps has good comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com