Water-based unsaturated polyester resin and preparation method thereof

A polyester resin, unsaturated technology, applied in the field of water-based unsaturated polyester resin and its preparation, can solve the problems of environmental pollution, body poisoning, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

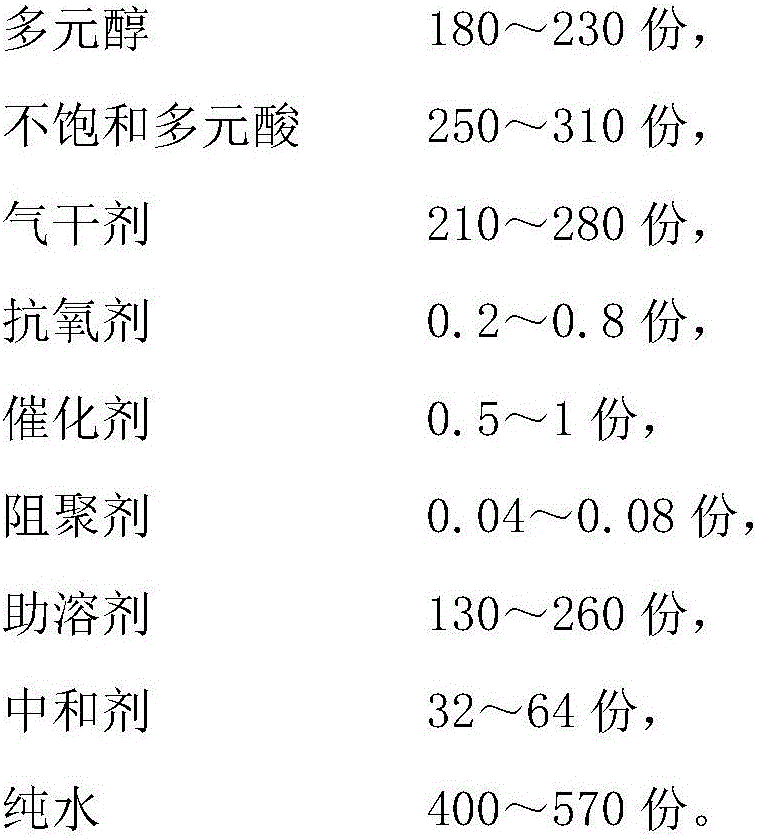

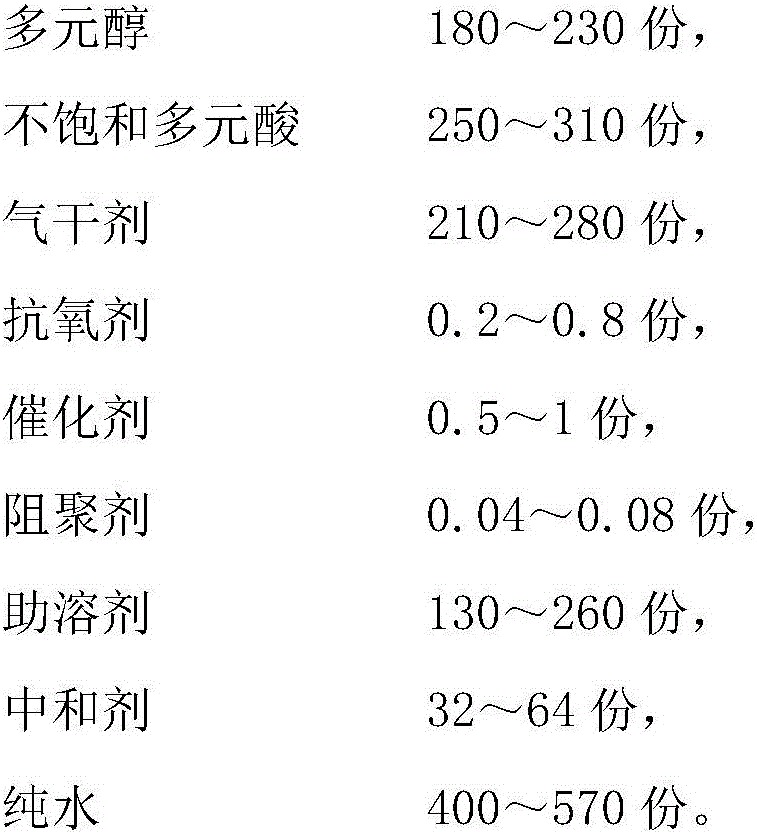

Method used

Image

Examples

Embodiment 1

[0033] Weigh 250 parts of maleic anhydride, 40 parts of pure water, 0.2 parts of 2,6-di-tert-butylcresol, and 18 parts of 1,2-propanediol into the kettle, blow in nitrogen gas, raise the temperature to 110°C, and dissolve 210 parts of dicyclopentanyl Diene drops in 1 hour, keep warm for 1 hour, add 162 parts of neopentyl glycol, 0.5 parts of tetrabutyl titanate, 0.04 parts of methyl hydroquinone into the kettle, heat up to 180 ° C for esterification reaction to an acid value of 30 mgKOH / g, the viscosity of the lamina is 450mPa.s / 120°C, cool down to 80°C, add 65 parts of ethylene glycol monobutyl ether and 65 parts of isopropanol respectively, cool down to about 50°C, add 35.5 parts of triethylamine to adjust the pH value Prepare 7-8, add 360 parts of pure water, and filter to obtain the finished product. The finished product has a solid content of 55% and a viscosity of 650mPa.s / 25°C.

Embodiment 2

[0035] Weigh 310 parts of maleic anhydride, 57 parts of pure water, 0.8 parts of hypophosphorous acid, and 22 parts of 1,2-propylene glycol into the kettle, blow in nitrogen, raise the temperature to 130°C, and drop 270 parts of dicyclopentadiene in 3 hours Finish, keep warm for 3 hours, add 150 parts of 1,3-propanediol, 48 parts of trimethylolpropane, 10 parts of trimethylolpropane diallyl ether, 30 parts of phthalic anhydride, 1 part of dilauric acid di Put butyltin and 0.08 parts of hydroquinone into the kettle, raise the temperature to 210°C for esterification reaction until the acid value is 45mgKOH / g, the viscosity of the vertebral plate is 800mPa.s / 120°C, cool down to 100°C, add 130 parts of ethylene glycol methyl ether, 130 parts of ethanol, 50 parts of diethylamine, and 513 parts of pure water are filtered to obtain the finished product. The finished product has a solid content of 50% and a viscosity of 400mPa.s / 25°C.

Embodiment 3

[0037] Weigh 250 parts of fumaric acid, 170 parts of dipropylene glycol, 10 parts of 1,3-butanediol, 140 parts of ethylene glycol monoallyl ether, 70 parts of trimethylolpropane diallyl ether, 50 parts 1 part of pure water, 0.2 part of triphenyl phosphite, 0.5 part of tetrabutyl titanate, and 0.04 part of tert-butyl hydroquinone were put into the kettle, and nitrogen gas was introduced, and the temperature was raised to 170°C for esterification reaction until the acid value was 30 mgKOH / g. The viscosity of the lamina is 450mPa.s / 120°C, cool down to 80°C, add 65 parts of ethylene glycol methyl ether and 65 parts of isopropanol respectively, cool down to about 50°C, add 32 parts of triethylamine to adjust the pH value to 7-8 , Add 450 parts of pure water, and filter to get the finished product. The finished product has a solid content of 52.5% and a viscosity of 600mPa.s / 25°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com