Robot skin

A robot and skin technology, applied in inorganic adhesives, chemical instruments and methods, layered products, etc., can solve the problems of inability to spray, poor UV resistance, long production cycle, etc., to achieve enhanced oxidation resistance, high The effect of rebound color and thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

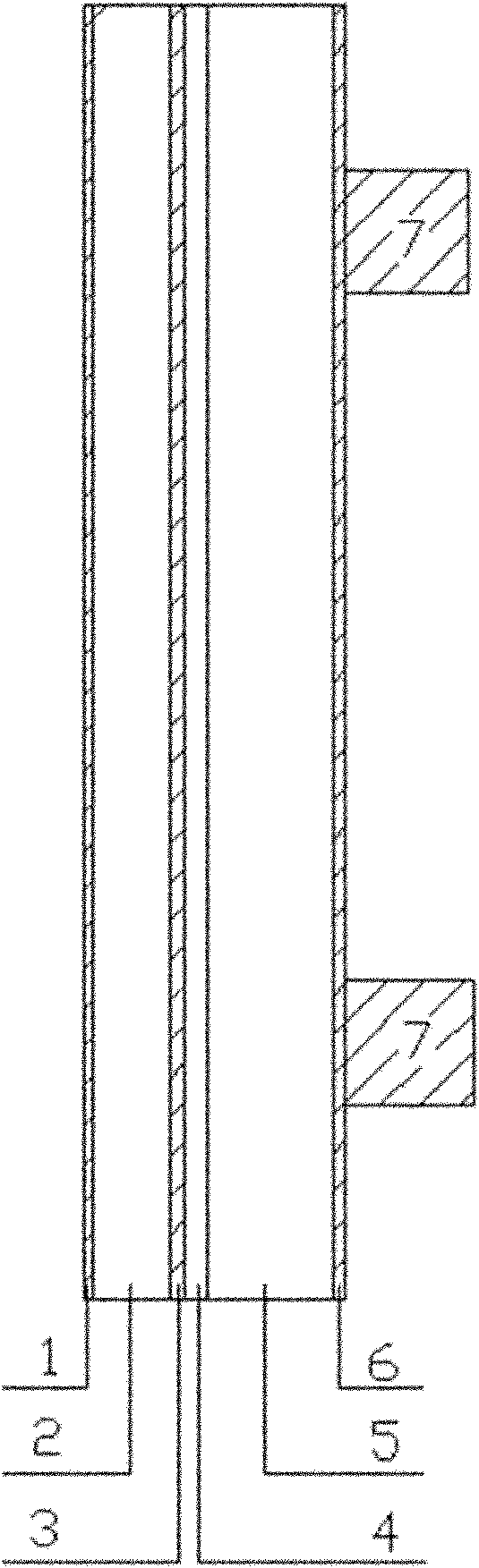

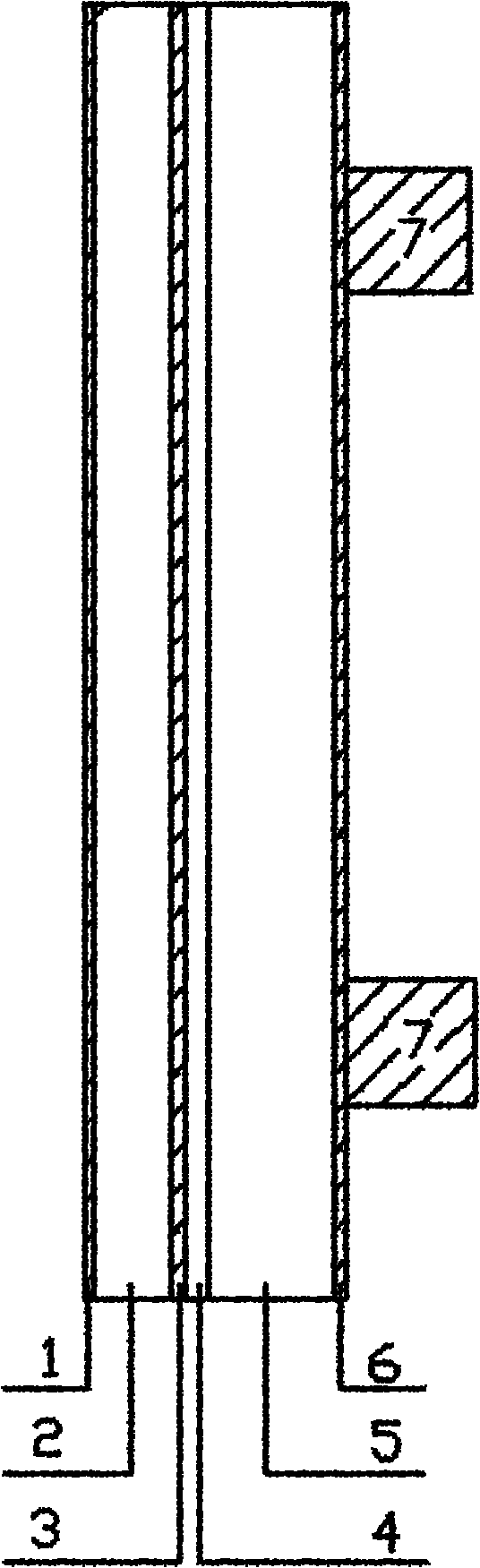

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0036] The robot skin in the entertainment project of the present invention is mainly used for the skin of bionic animals and characters, the skin of popular science bionic education equipment, and outdoor landscapes and decorative materials. It is a new type of robot skin with high-quality characteristics. It includes a glass glue mixture layer, a sponge rebound layer and a resin glue layer pasted together from outside to inside in sequence. Among them, the oxidation resistance and certain extensibility of the glass glue enhance the oxidation resistance of the robot skin, and enable the robot skin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com