Patents

Literature

378 results about "Color glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

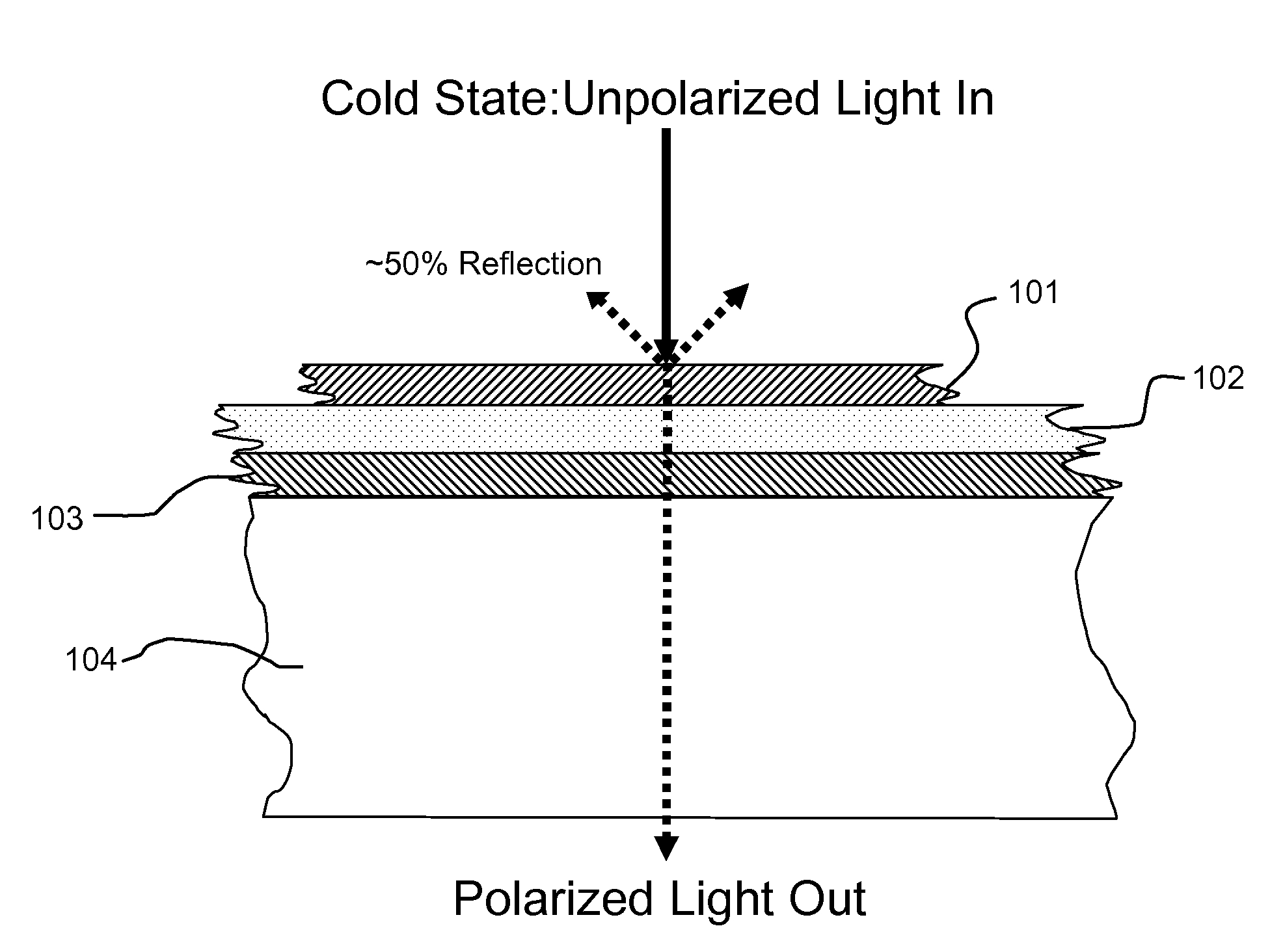

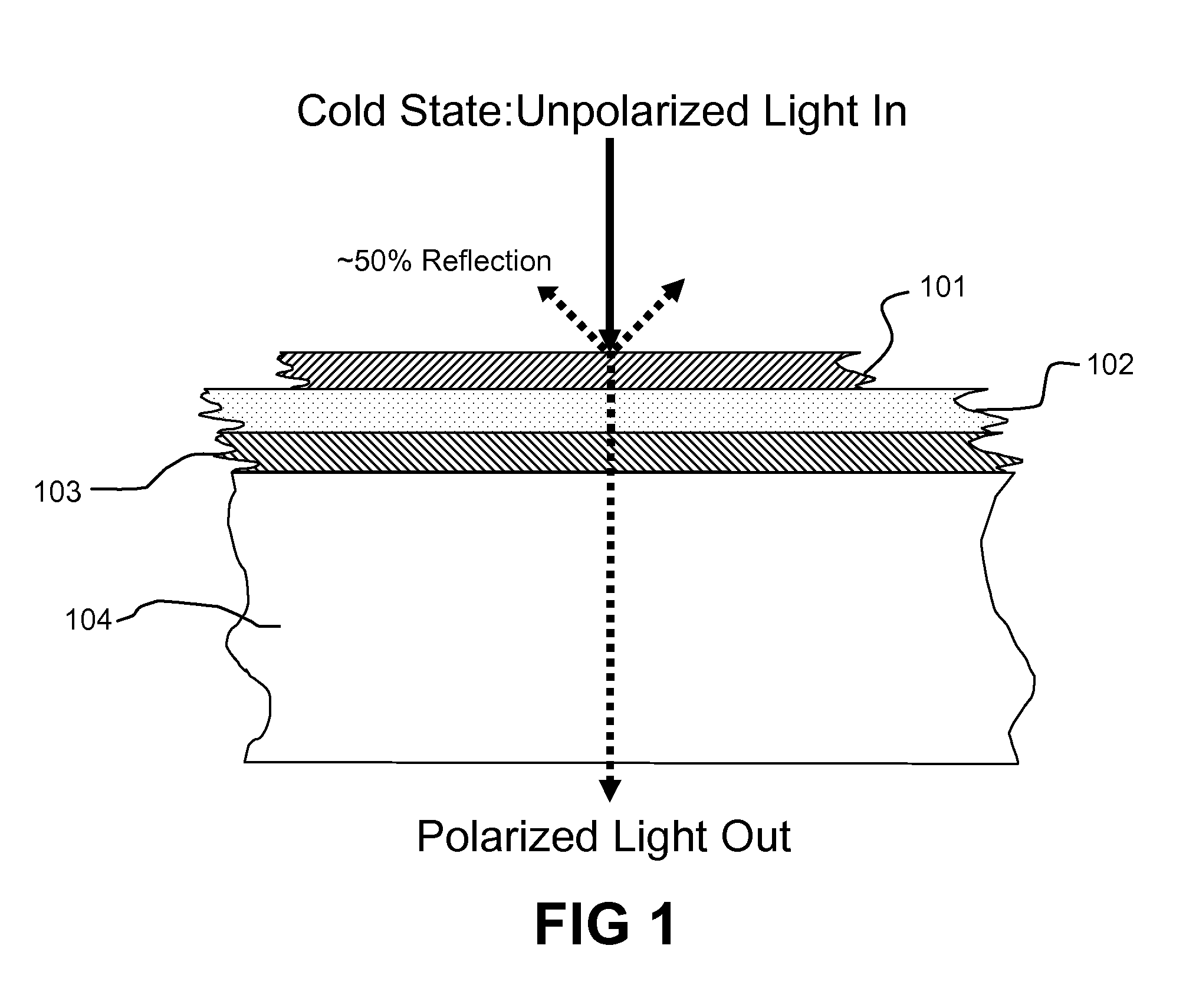

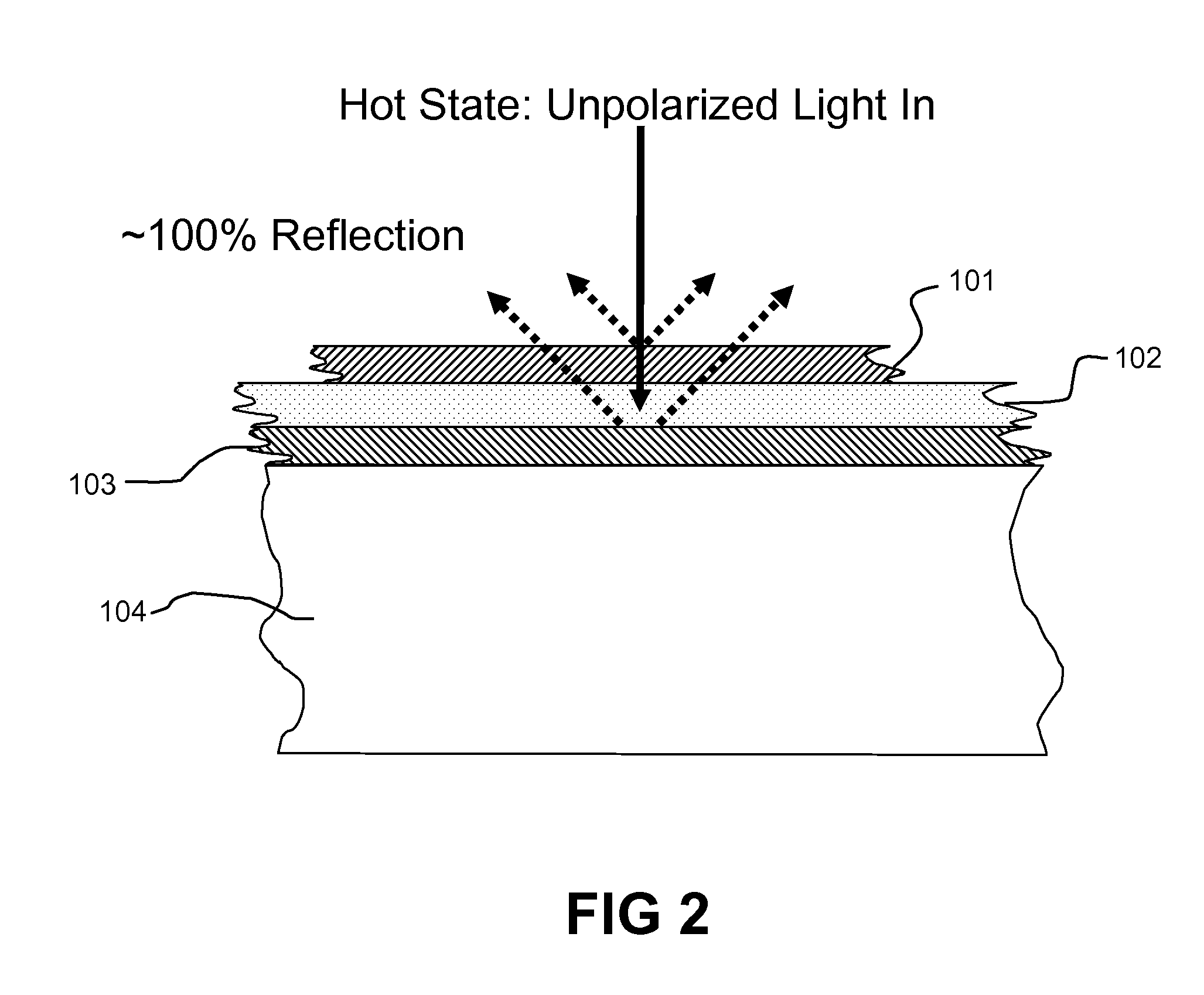

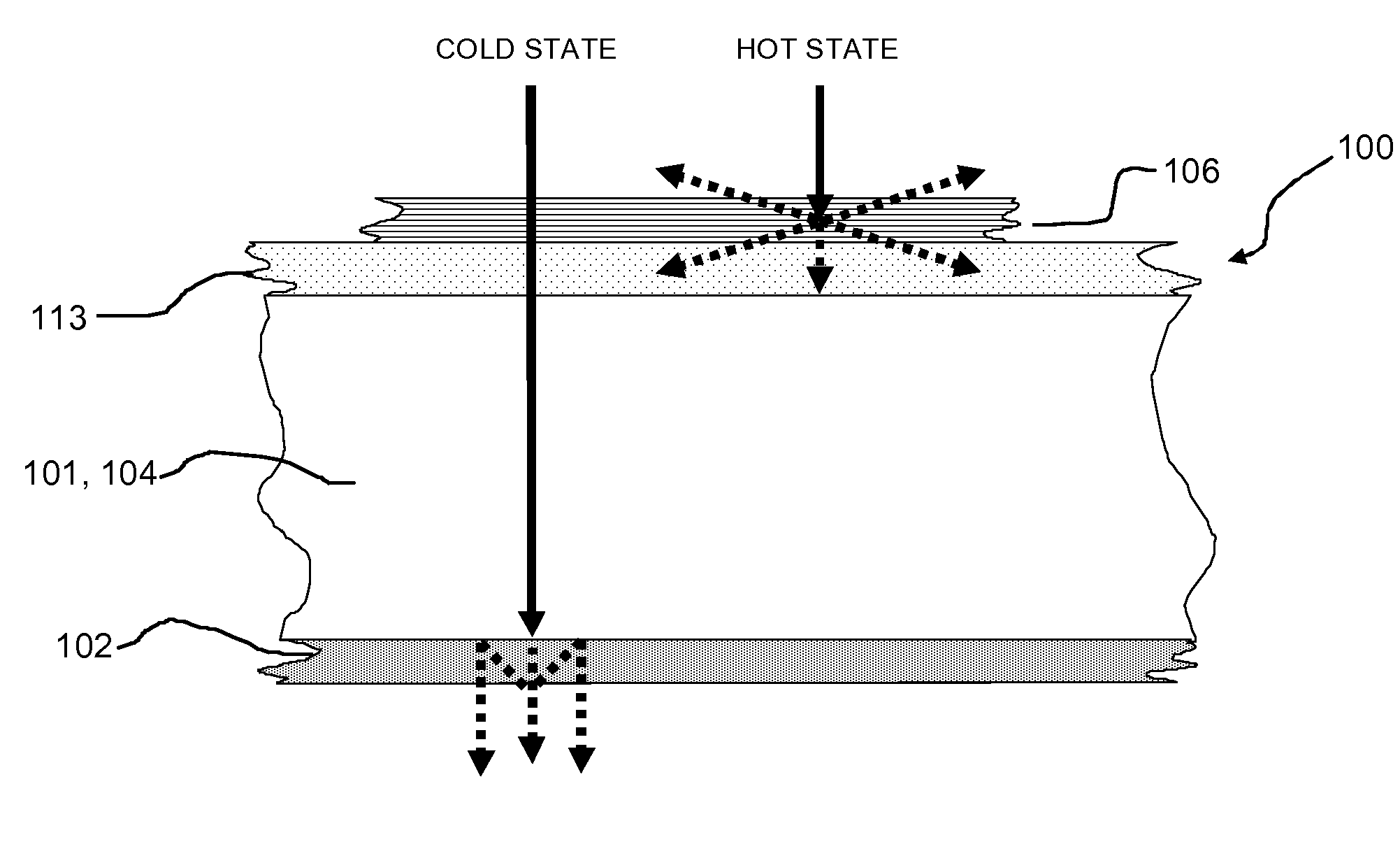

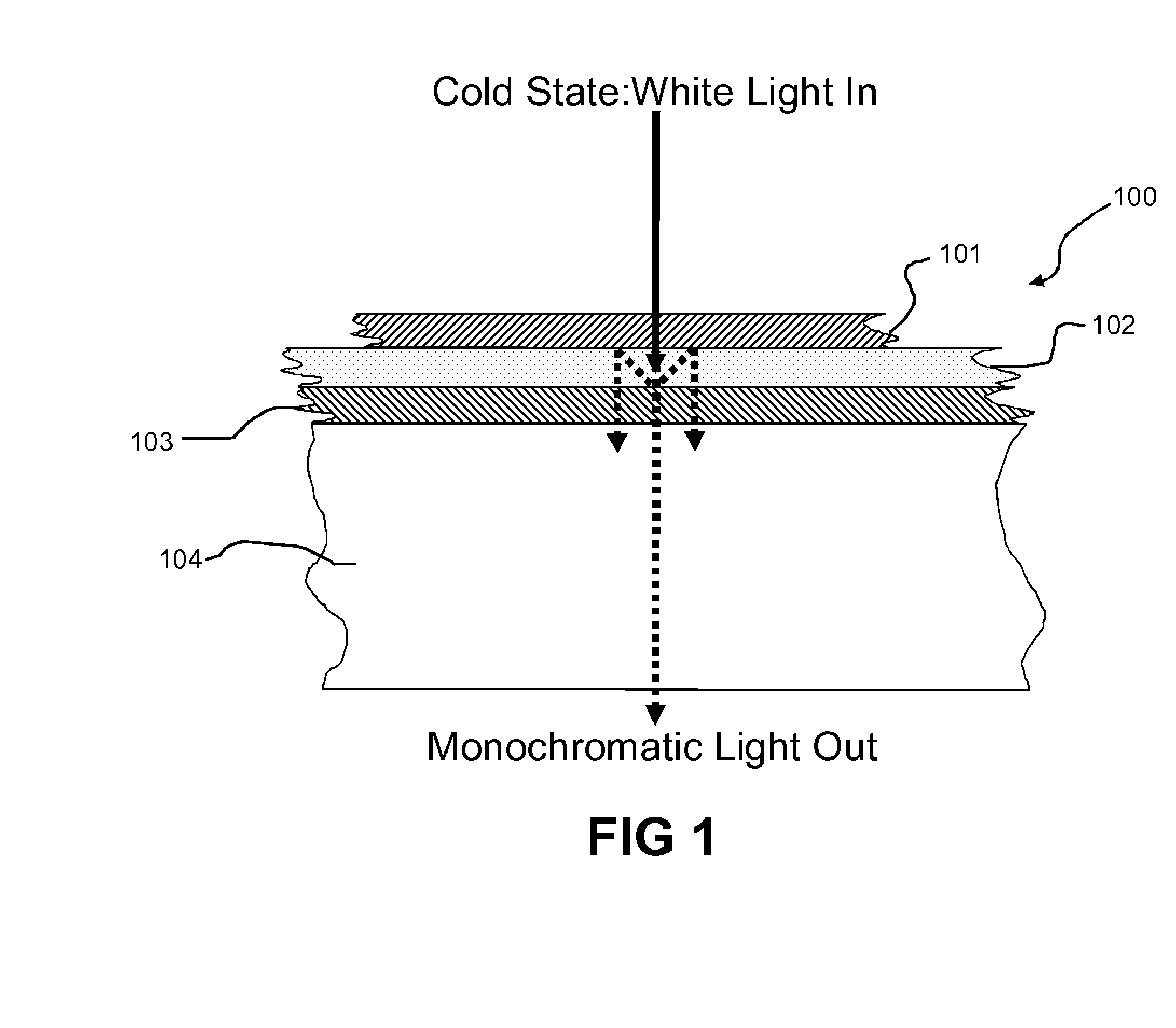

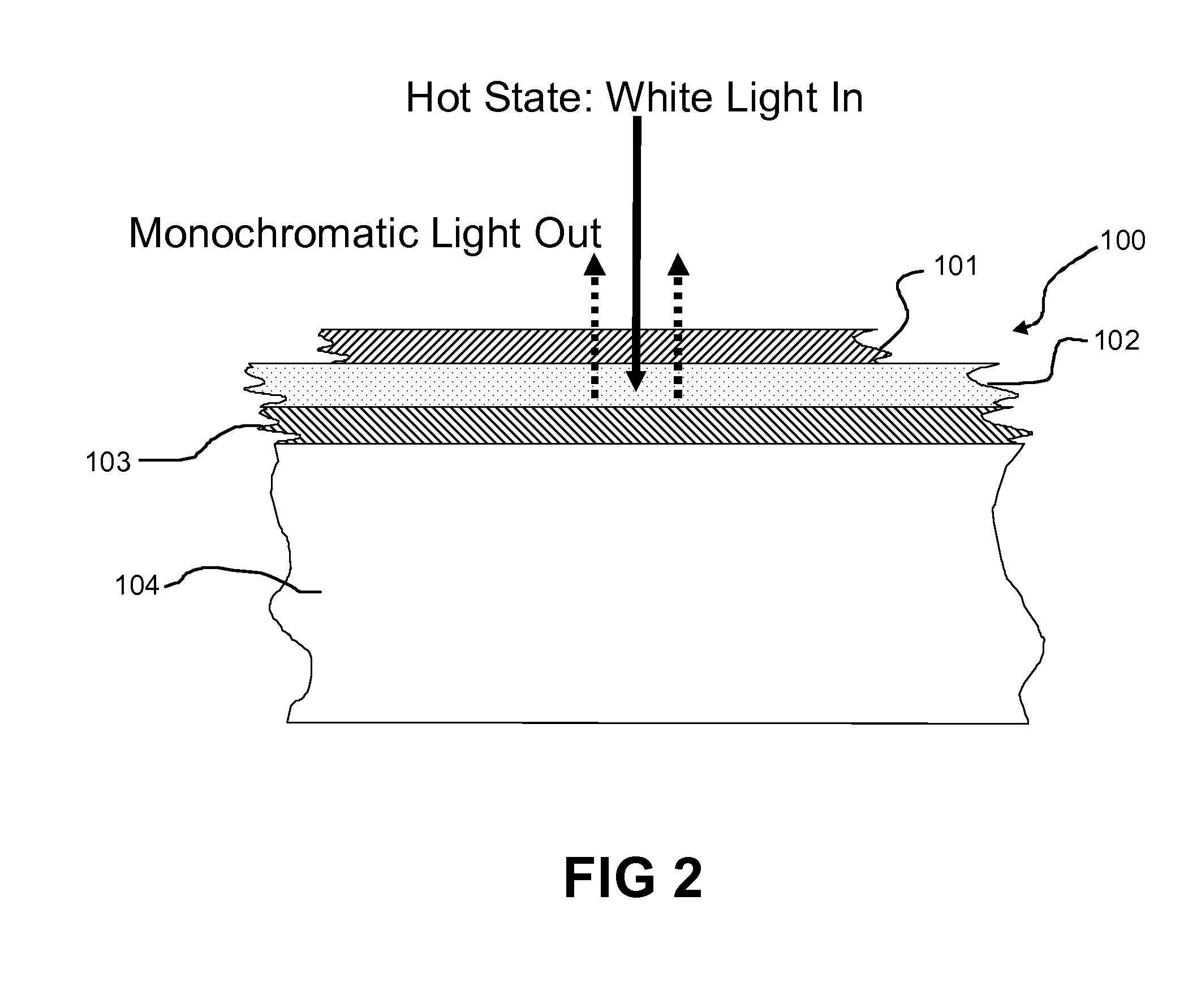

Thermally Switched Reflective Optical Shutter

The thermally switched reflective optical shutter is a self-regulating “switchable mirror” device that reflects up to 100% of incident radiant energy above a threshold temperature, and reflects up to 50% of incident radiant energy below a threshold temperature. Control over the flow of radiant energy occurs independently of the thermal conductivity or insulating value of the device, and may or may not preserve the image and color properties of incoming visible light. The device can be used as a construction material to efficiently regulate the internal temperature and illumination of buildings, vehicles, and other structures without the need for an external power supply or operator signals. The device has unique aesthetic optical properties that are not found in traditional windows, skylights, stained glass, light fixtures, glass blocks, bricks, or walls. The device can be tailored to transmit sufficient visible light to see through in both the transparent and reflective states, while still providing significant control over the total energy transmission across the device.

Owner:RAVENBRICK

Thermally switched optical downconverting filter

A thermally switched optical downconverting (TSOD) filter is a self-regulating device including a downconverter that converts incoming light at a variety of wavelengths into longer-wavelength radiation and then directs it using one or more bandblock filters in either the inward or outward direction, depending on the temperature of the device. This control over the flow of radiant energy occurs independently of the thermal conductivity or insulating properties of the device and may or may not preserve the image and color properties of incoming visible light. The TSOD filter has energy-efficiency implications, as it can be used to regulate the internal temperature and illumination of buildings, vehicles, and other structures without the need for an external power supply or operator signals. The TSOD filter also has aesthetic implications, since the device has unique optical properties that are not found in traditional windows, skylights, stained glass, light fixtures, glass blocks, bricks, or walls. The TSOD filter has particular, but not exclusive, application as a building material.

Owner:RAVENBRICK

Chemically stabilized light selective element for imaging applications

InactiveUS6163026ARadiation pyrometryAnalysis using chemical indicatorsSignal processing circuitsControl signal

An imaging system having an imaging sensor providing sensor signals in response to incident light and control signals, control circuitry configured to generate control signals for controlling said imaging sensor, signal processing circuitry for generating image data in response to said sensor signals, and a light selective element for selecting the incident light encountered by said imaging sensor, the light selective element comprising an ionically-colored glass having a surface that is treated with a chemical stabilizer.

Owner:INTEL CORP

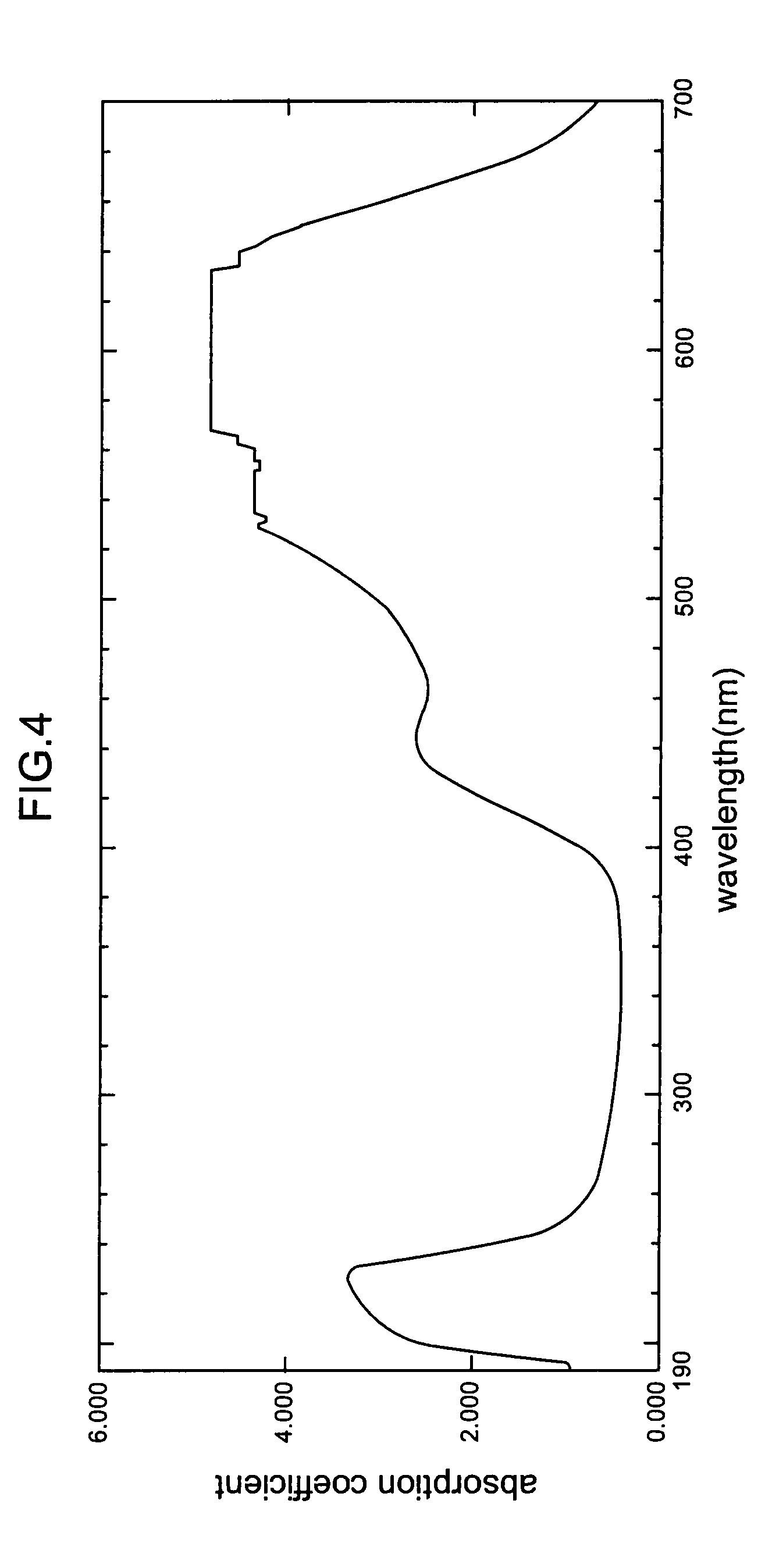

Filter function-equipped optical sensor and flame sensor

ActiveUS7361948B2Good wavelength selectivityEffective shieldingSolid-state devicesMaterial analysis by optical meansPhotodetectorColor glass

In order to provide a filter device capable of maintaining stable optical characteristics for an extended period of time and to provide also a photosensor using the filter device, a photosensor having a filter function includes a filter device having a colored glass filter and configured for permitting transmission of light of a predetermined wavelength range including a detection target wavelength range and a light receiving device for receiving the light transmitted through the filter device. The filter device includes a first interference filter structure comprised of a plurality of light transmitting layers stacked on each other, the first interference filter structure being deposited on a face of the colored glass filter. The light receiving device includes a semiconductor photodetector structure having one or more semiconductor layers, a light receiving area being formed in the one or more semiconductor layers within the semiconductor photodetector structure. The one or more semiconductor layers forming the semiconductor photodetector structure contain InxAlyGa1-x-yN (0≦x≦0.21, 0≦y≦1).

Owner:SOKO KAGAKU

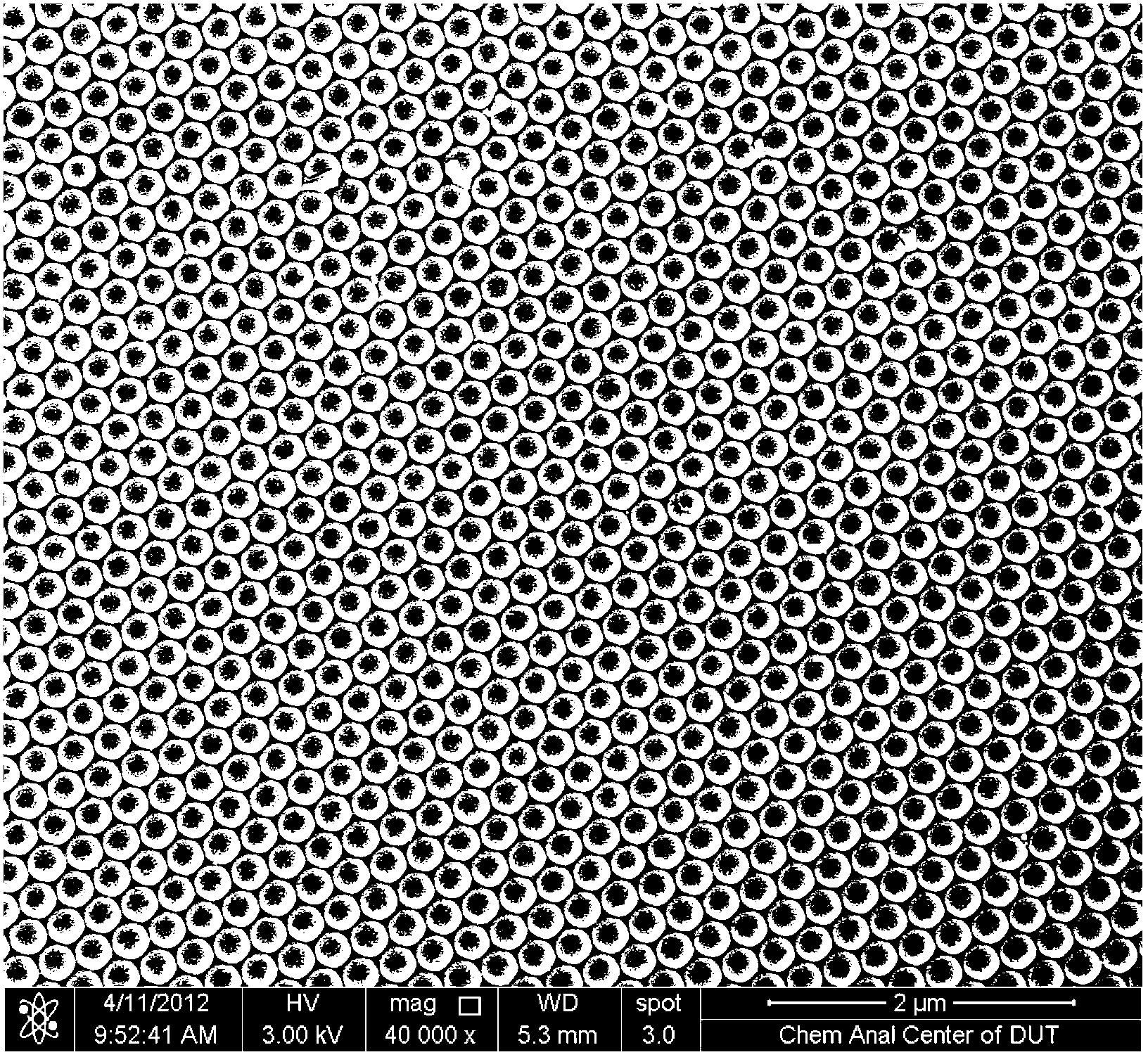

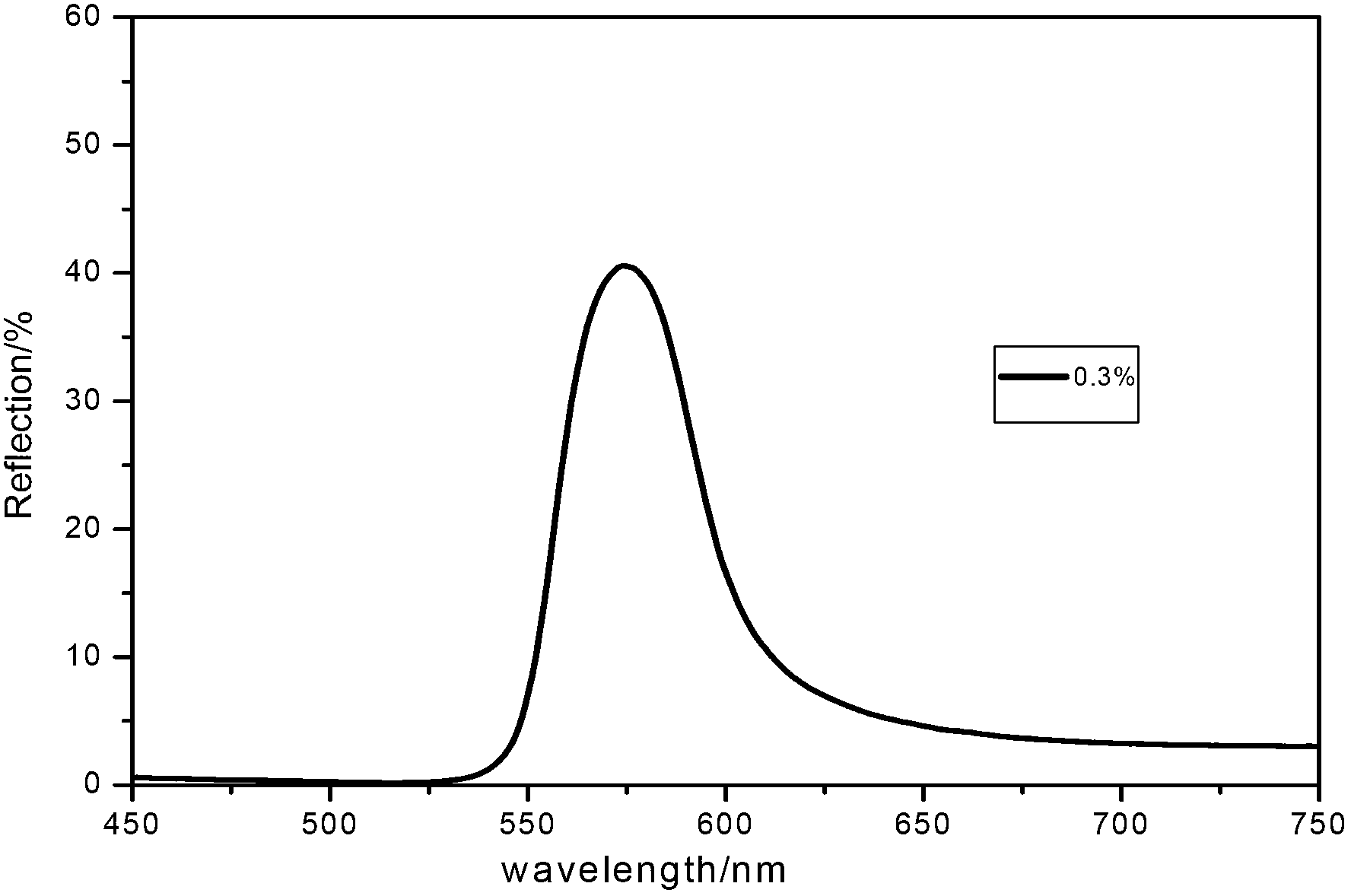

Color producing material with photonic crystal structure and preparation method thereof

The invention relates to color producing material with a photonic crystal structure and a preparation method thereof, belonging to a new material preparation field and specifically belonging to a new color producing material preparation field; the color producing material with a photonic crystal structure contains a little of black dye in a gap between micro-balls which are made of high-refractivity material and are distributed on a substrate periodically; according to the invention, the color producing material with the photonic crystal structure has an advantage of beautiful colors and is suitable to color glasses, silica slices, steel sheets, copper sheets, aluminum sheets, cotton cloth, silk, plastic films or papers and has wide application prospect.

Owner:DALIAN UNIV OF TECH

Crystal color ceramic, crystal color glass, composite material for crystal color illuminating layer and technical method thereof

The invention discloses a crystal colorized ceramic and crystal colorized glass, substantially composite materials and process method of crystal colorized decorative layer, which comprises the following weight materials: dry-powder glaze 6-60, bond 15-50, additive 0-70, glass micro-ball 20-90; in the invention the surfaces of the ceramic and glass product adopt the crystal colorized materials and then are ornamented with patterns, and then sintered for a plurality of times at 400-860 DEG C so as to form a crystal colorized decorative layer. The product has the advantages of brocade-like straight light, wool-like side light, light-shift color-change, and special optical effect with strong solid feeling.

Owner:邓念东 +1

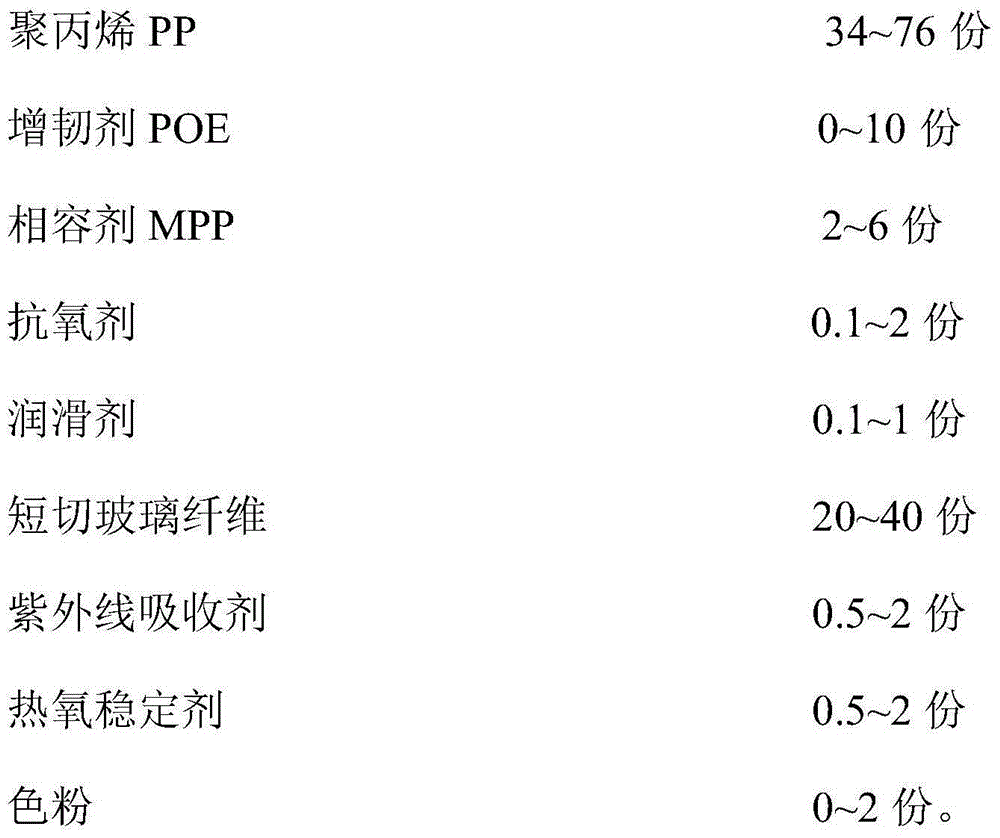

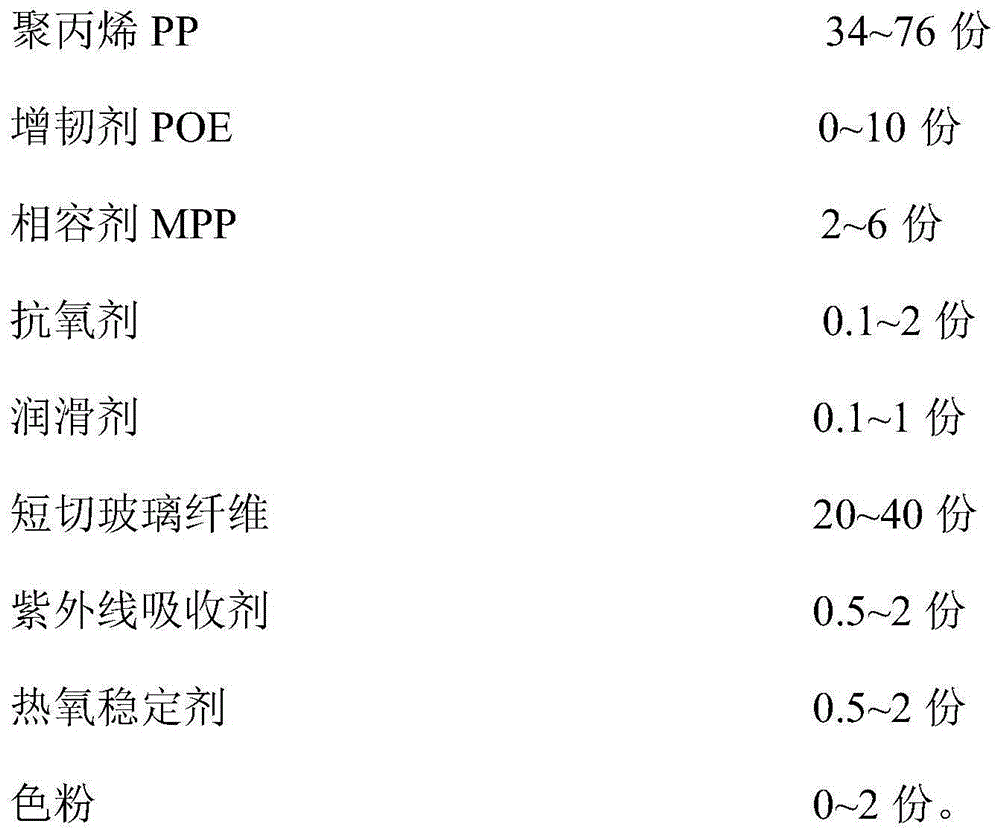

High-weather-resistant anti-aging glass fiber reinforced polypropylene material and preparation method thereof

The invention discloses a high-weather-resistant anti-aging glass fiber reinforced polypropylene material. Through the synergistic action of such components of the material as polypropylene (PP), a chopped glass fiber, a compatible flexibilizer, an anti-oxidant, a lubricant, a coupling agent, one or more ultraviolet light absorbers, a thermo-oxidative stabilizer and one or more toners, as well as reasonable selection of specific components in parts by weight, changes in the color difference of color glass fiber reinforced PP can be greatly reduced under the light-heat aging condition, and the mechanical property retention rate can be high; when the material is applied to automobile parts, household appliances and other products, the problems that the product properties are degraded and the product colors are changed due to long-term exposure of such products in the open air or a high-temperature environment can be effectively solved. The invention further discloses a preparation method of the material. The preparation method is simple to operate, low in cost and high in production benefit; the material obtained according to the preparation method is high in mechanical property, retention rate and color stability, and very suitable for industrialized production; through the preparation method, not only can the service life of the material be prolonged, but also environmental pollution can be reduced.

Owner:NANJING LIHUA ENG PLASTIC

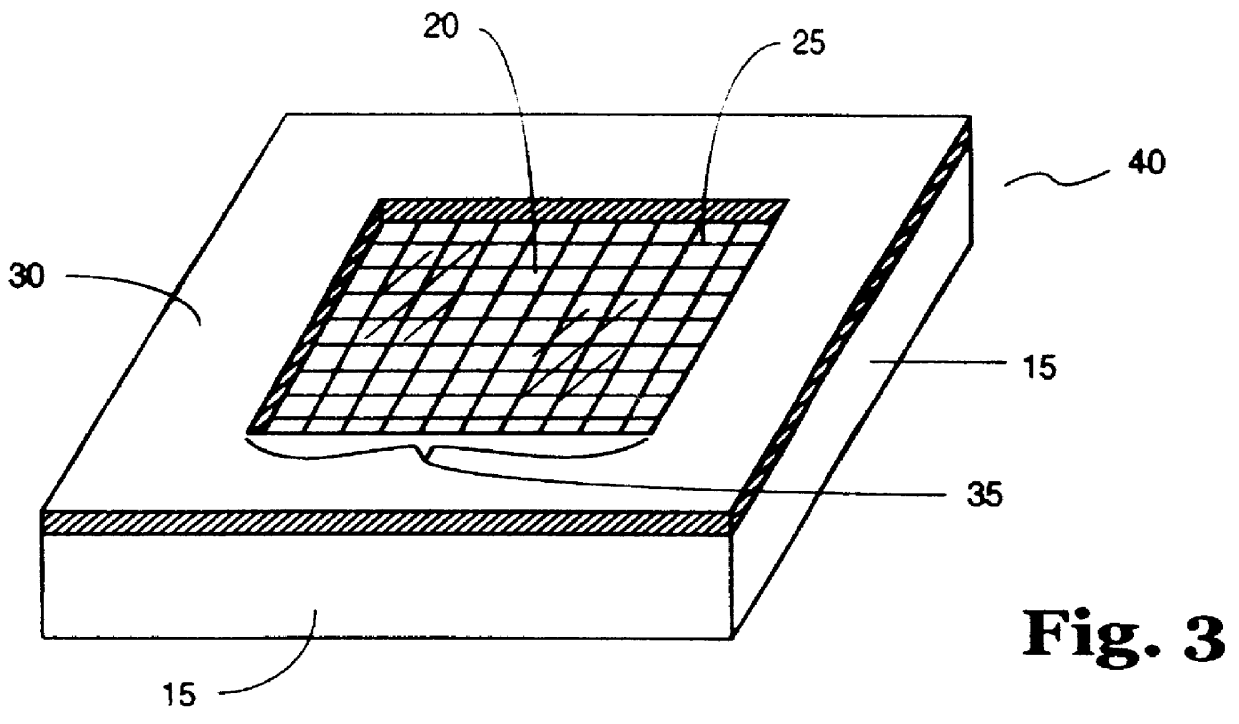

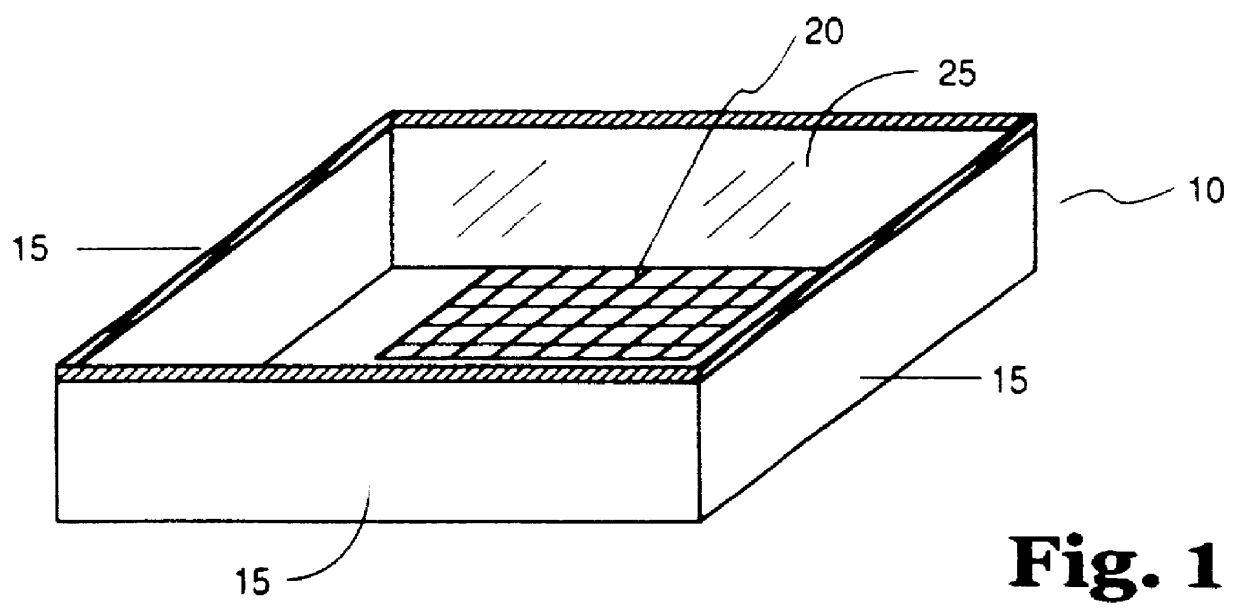

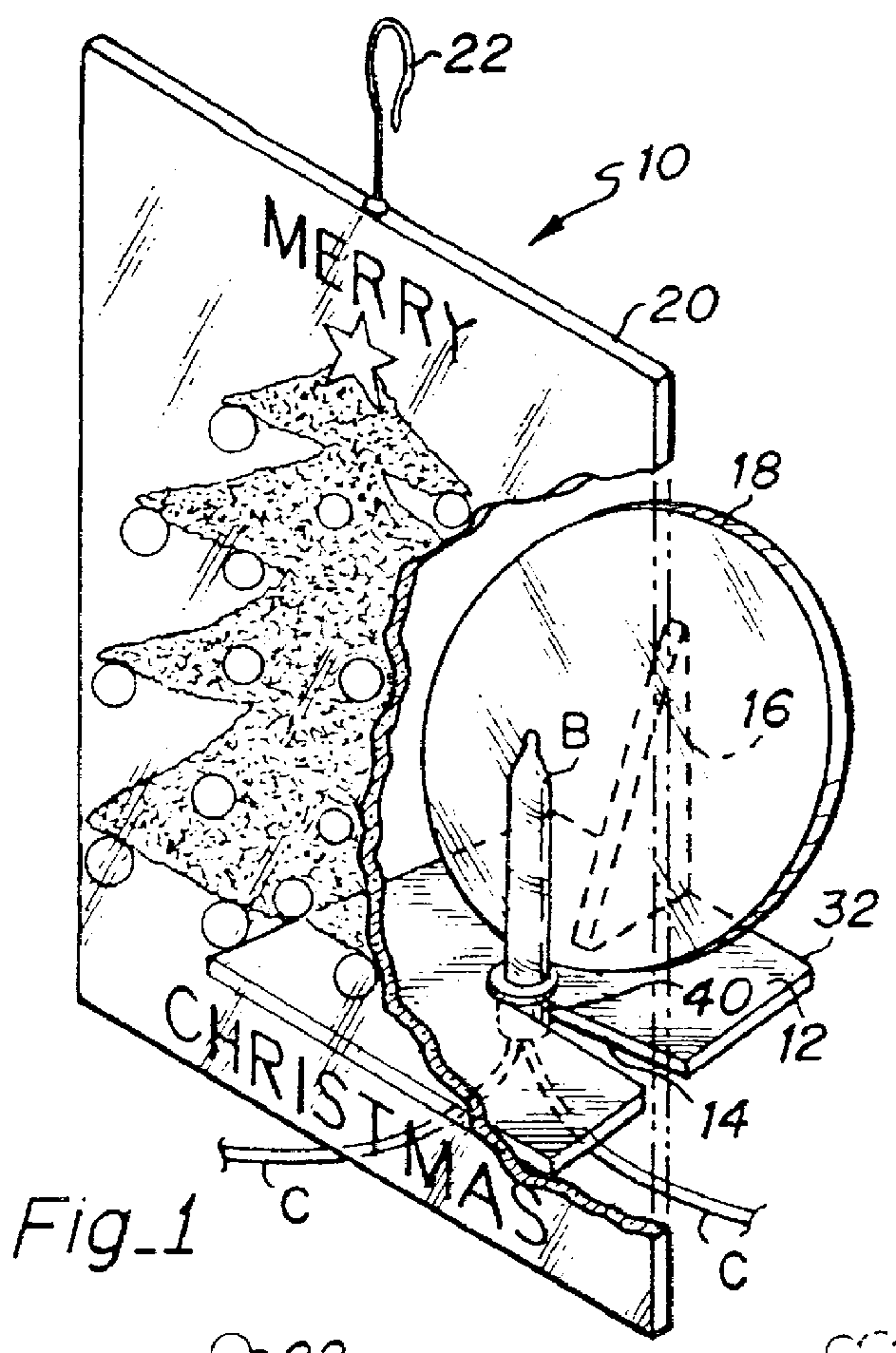

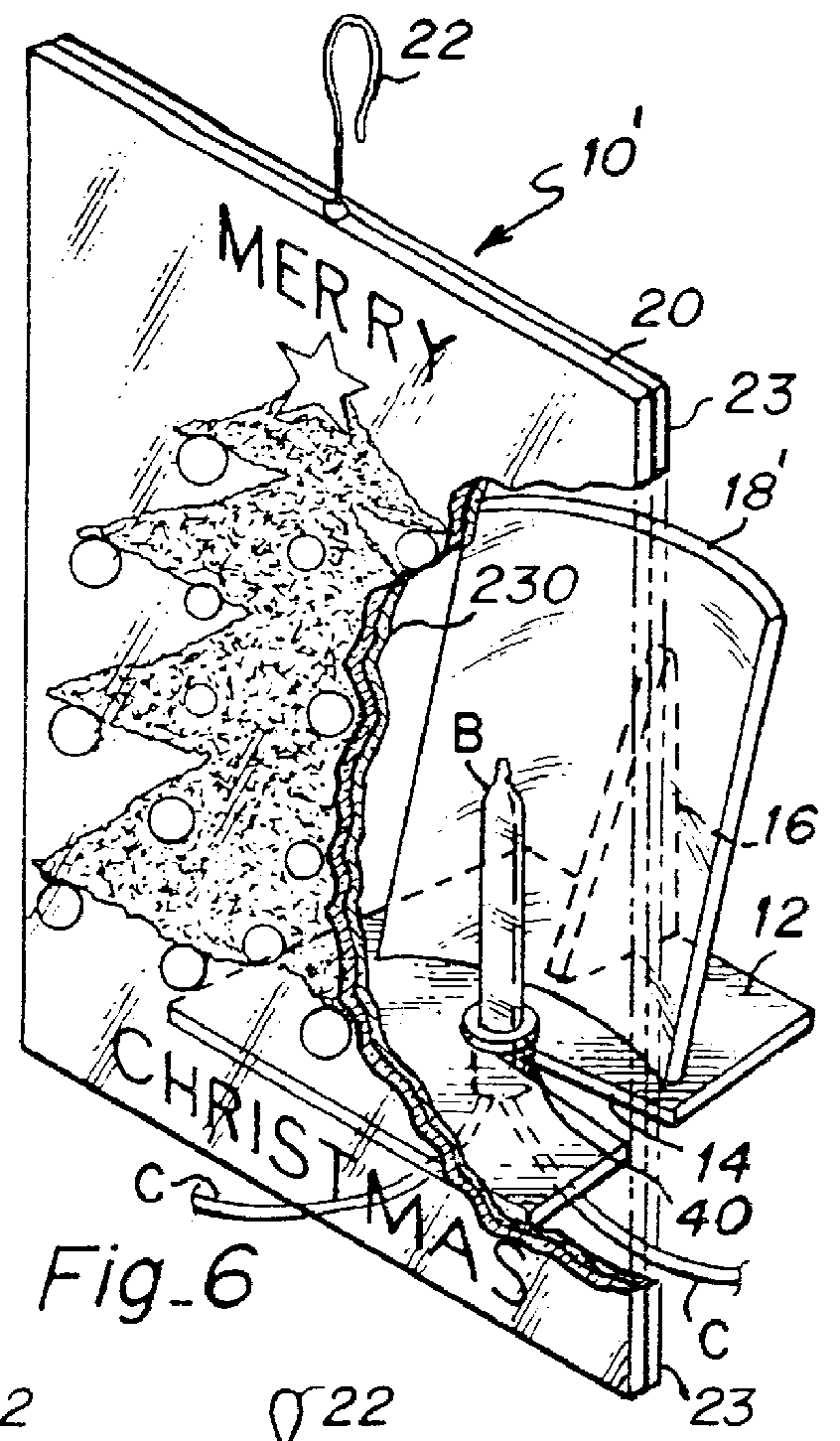

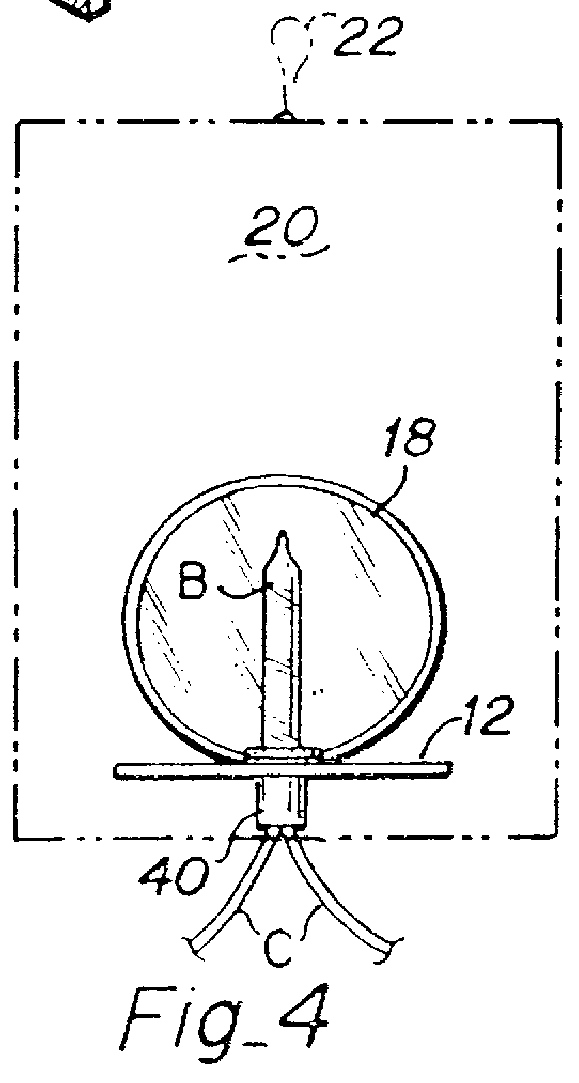

Backlighting apparatus for a light transmissive ornament

An apparatus for backlighting a stained glass ornament, on a Christmas tree, or the like, is disclosed. A platform is provided with a slotted or "keyhole" opening adapted to slidingly receive the base of a standard Christmas tree light. Attached at one side of the base, and perpendicular thereto, is a focal reflective surface to direct the light of the miniature electric lamp common to such strings of lights toward a decorative light transmissive panel located on the opposite side of the base. In one embodiment described herein, the reflective, or mirror, portion of the apparatus is round or oval: in a second embodiment it is generally rectangular in shape. The slotted opening in the preferred embodiment is of the keyhole type to secure the miniature lamp in the desired position and the device is further equipped with an attachment member to attach the unit to a tree or other object that the user wishes to adorn.

Owner:HAWKINS VICTOR J

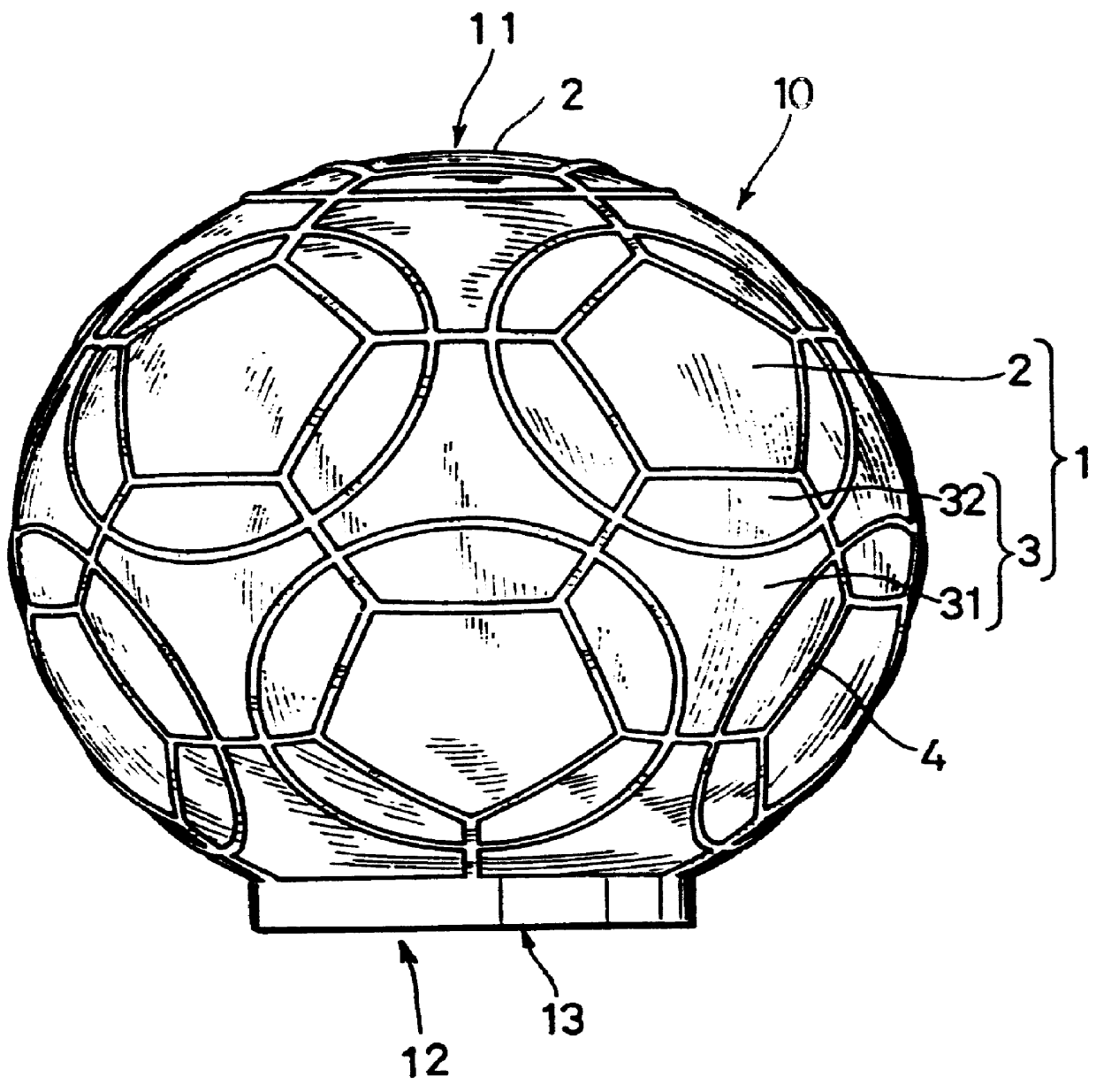

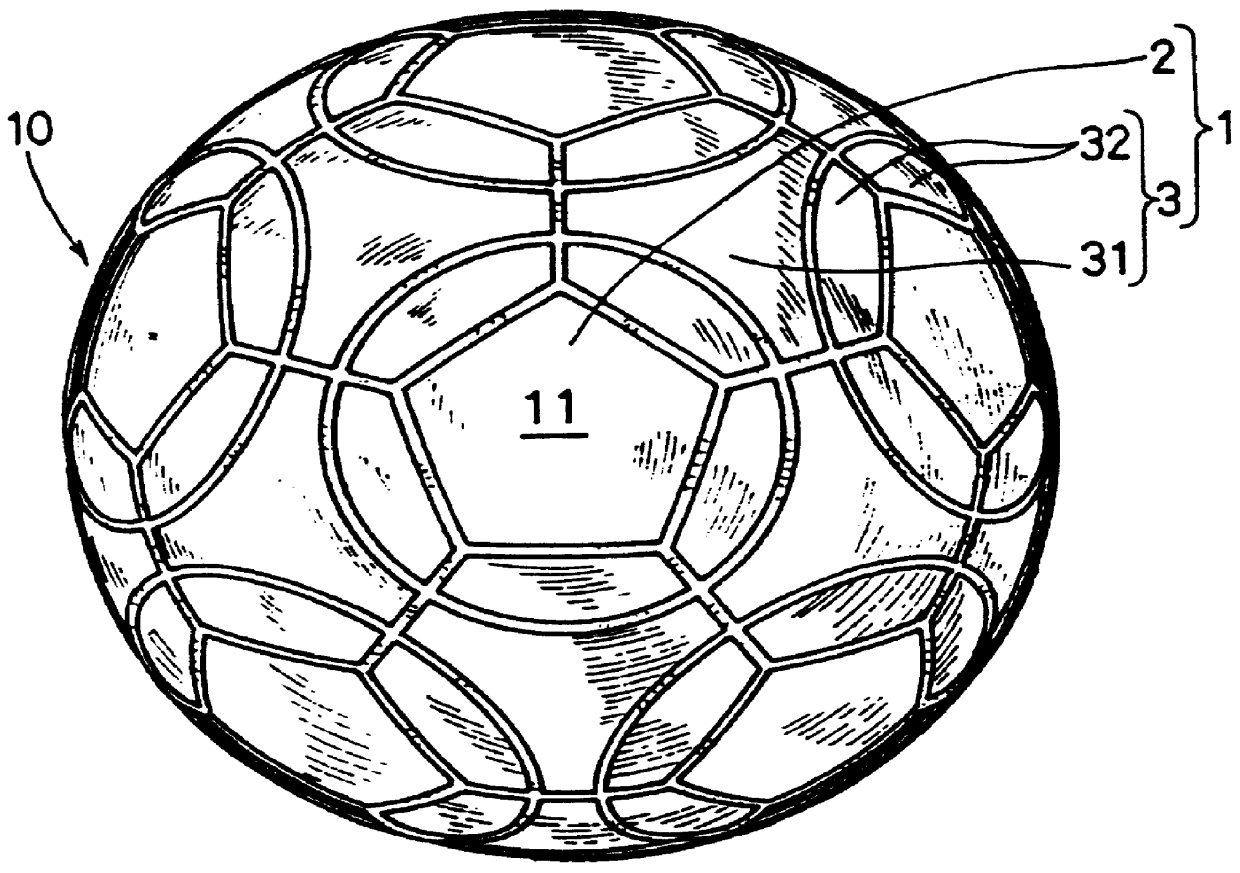

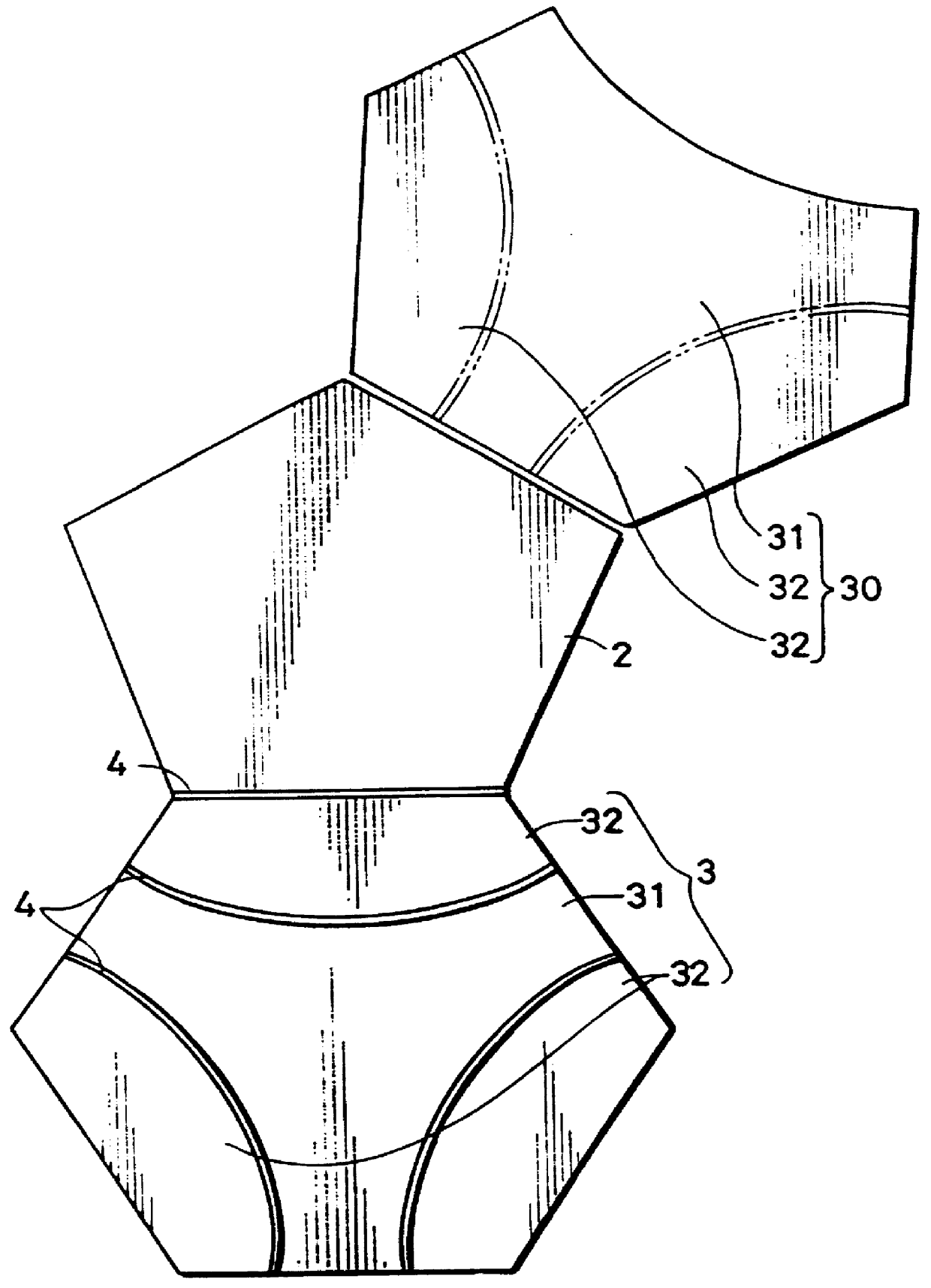

Three dimensional stained glass article and method for producing the same

InactiveUS6117504AEasy to shapeEasy to transformInlaying equipmentDecorative surface effectsThree dimensional shapeEngineering

This invention relates to a stained glass article of a three dimensional shape and a method for producing the same. A glass plate is cut into glass pieces of a certain shape including a pentagon member and a hexagon member. The hexagon member consists of one six-sided irregular member and three four-sided irregular members. The glass pieces of the certain shape are united together via a bonding agent to obtain the three dimensional stained glass imitating the shape of a soccer ball. The glass piece has a curved surface whose radius of curvature is set substantially equal to the radius of the soccer ball.

Owner:YOSHIKAWA KAZUHIDE

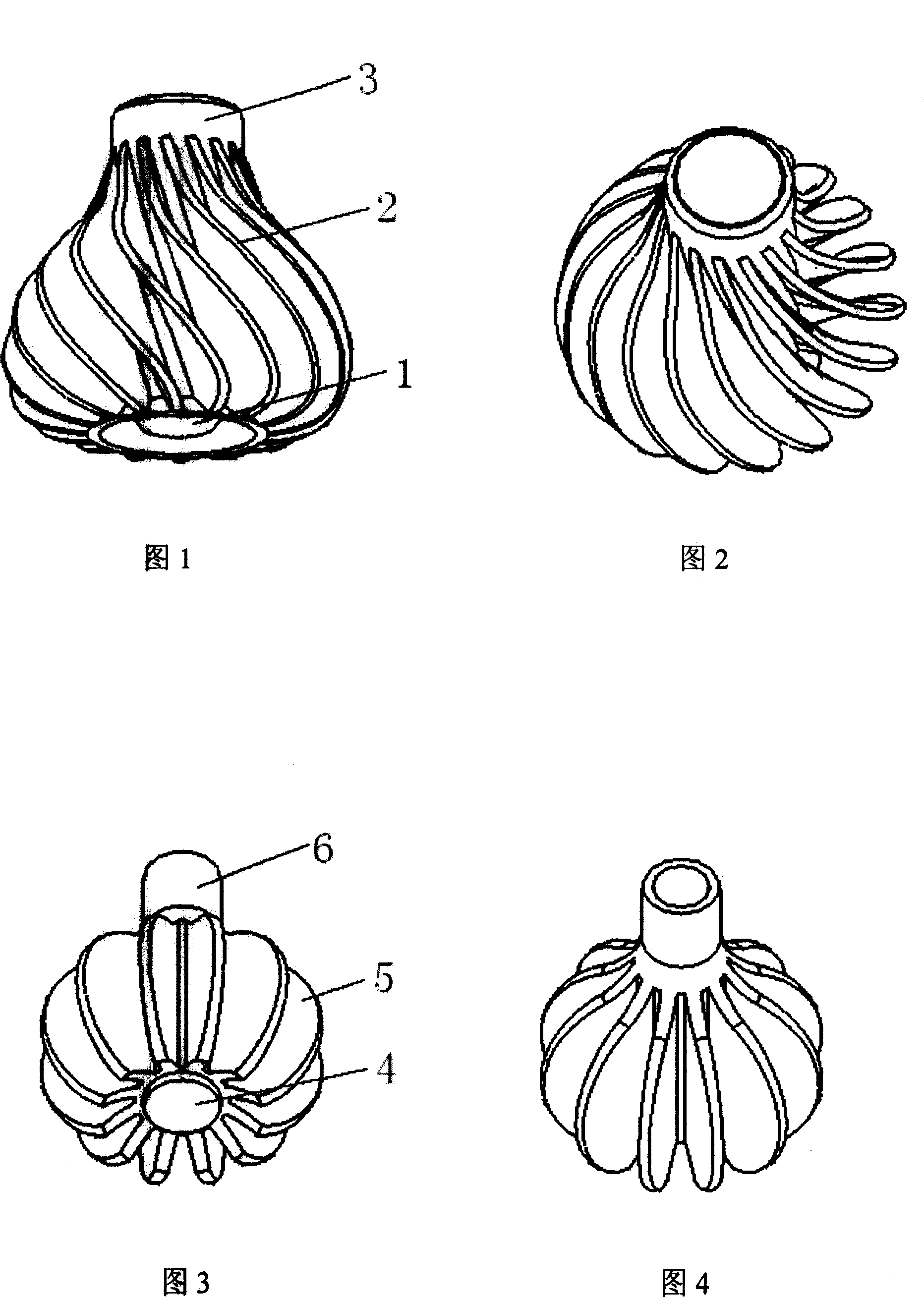

LED lamp having spiral heat dissipation fin

The invention discloses a LED lamp whose ceramic lamp frame adhered with light source is distributed with radiation fins. The invention provides a screw radiation fin LED lamp, comprising the frame of several screw radiation fins. And the frame is made from ceramic, with beautiful appearance, while the invention can use glass, as colorful glass. The inventive LED lamp has better radiation and high light efficiency, with long service life and low cost.

Owner:吕大明

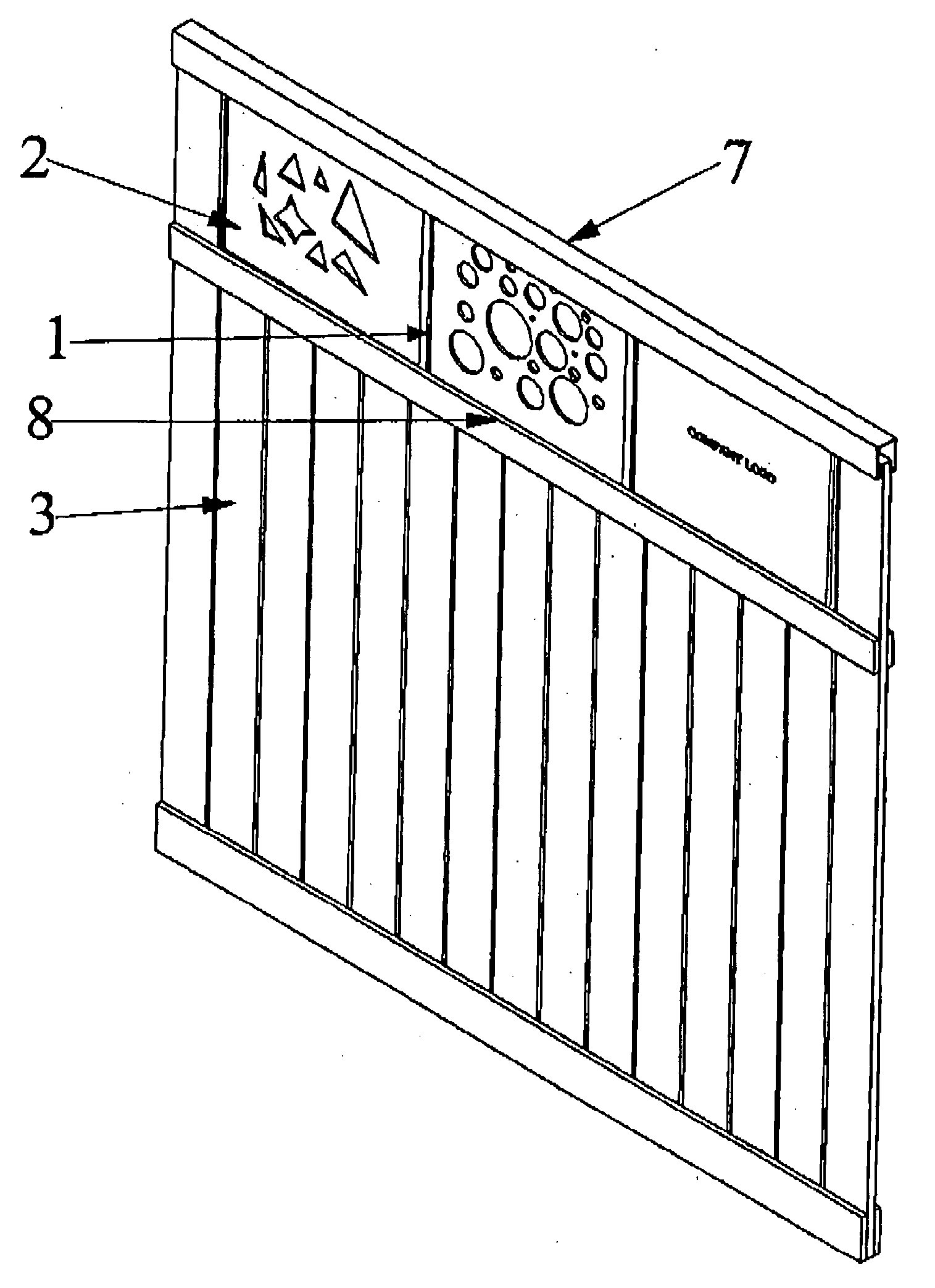

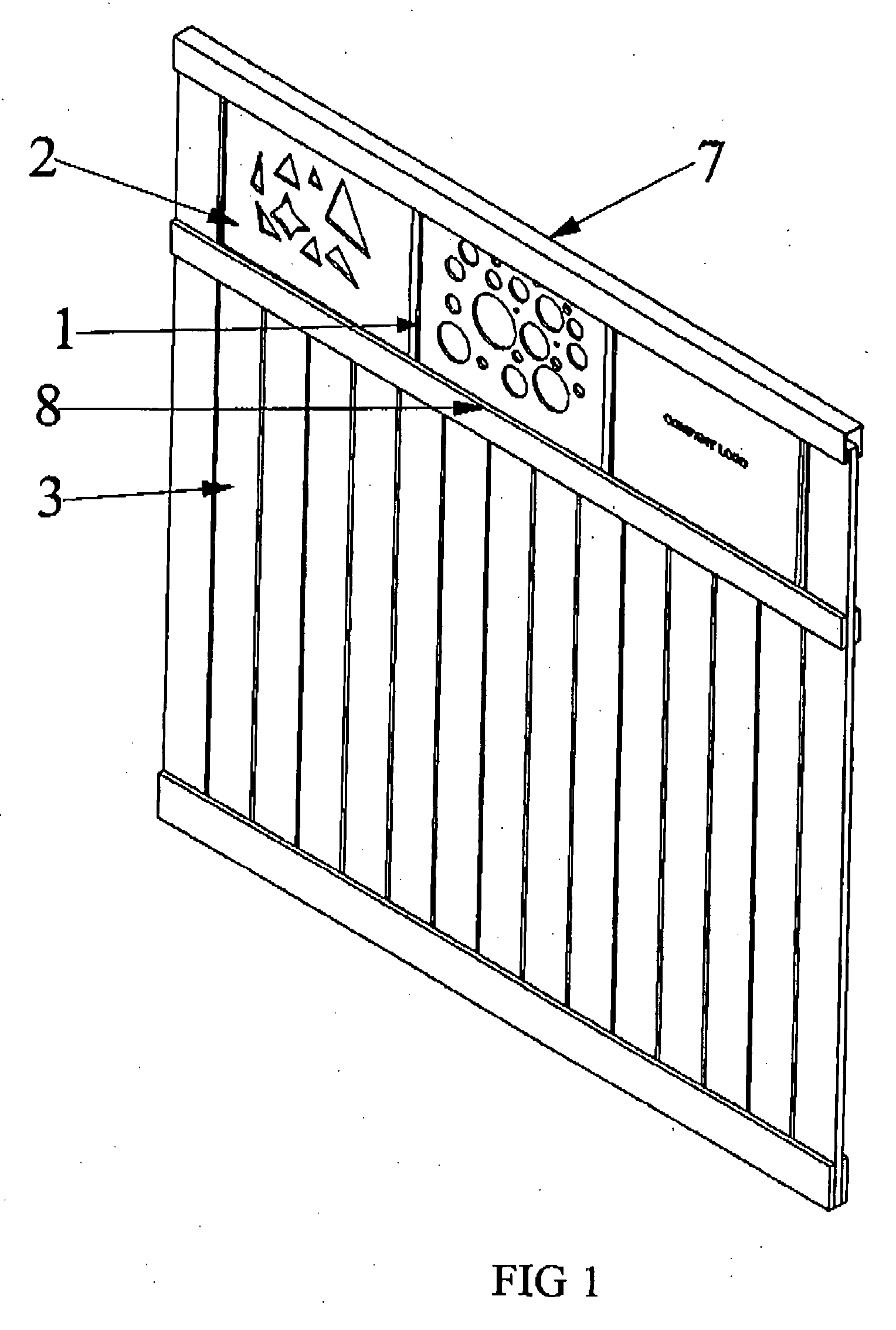

Novel modular molded frame with interchangeable design panels for vinyl fencing and its method of fabrication

An interchangeable aesthetic window panel embellishment system to be attached within an existing fence. The system is composed of a support frame (20) that is to be attached within the upper portion of a fence in place of the existing lattice and an aesthetic window panel (30) made of translucent plastic. The window panel may be of any variety of aesthetic designs, such as stained-glass patterns, home addresses, sport, school, or business logos, holiday designs, or advertising. The panels may be replaced at any time. The number of panels within each support frame may vary.

Owner:ZACARIAS FELIX +3

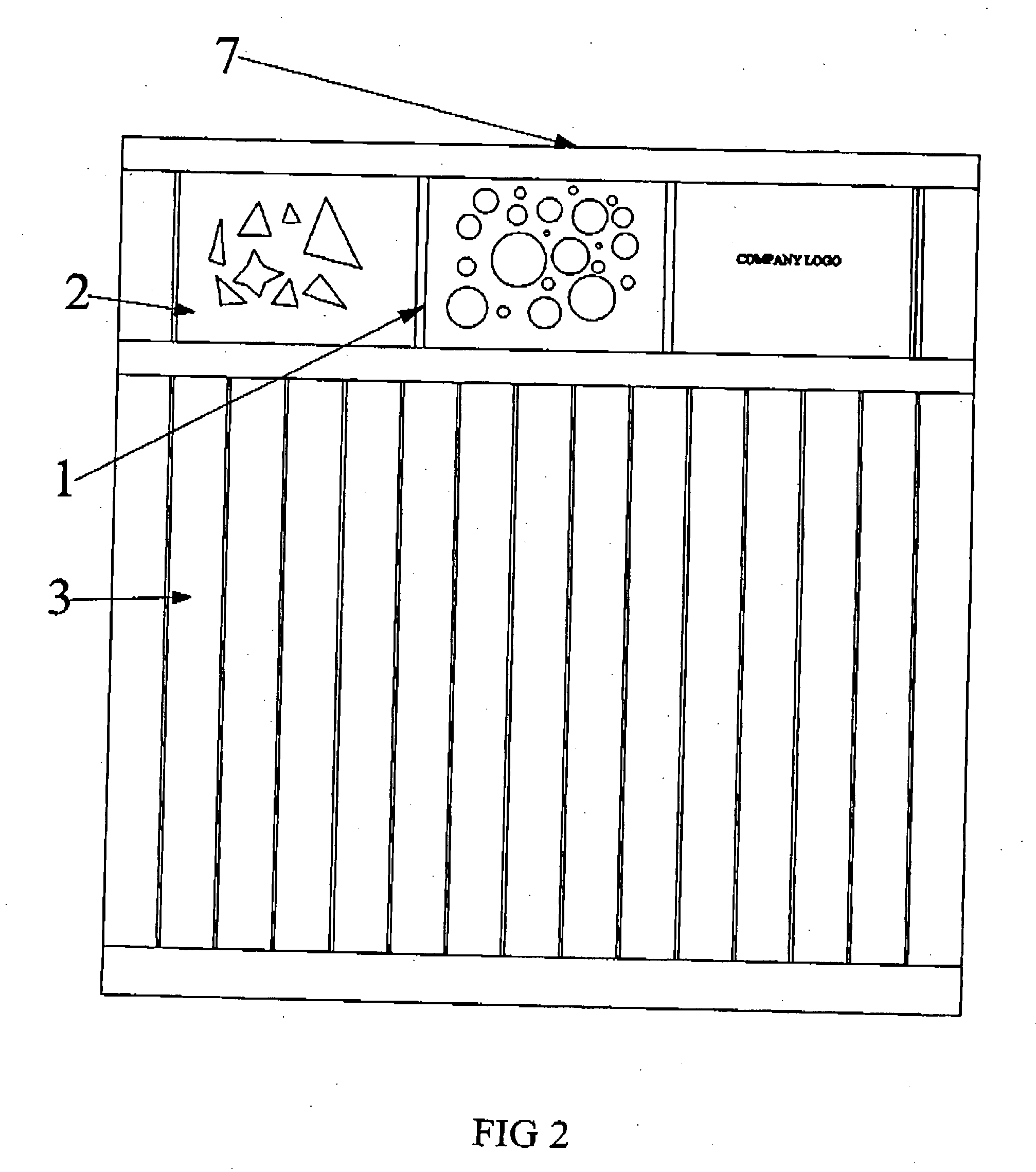

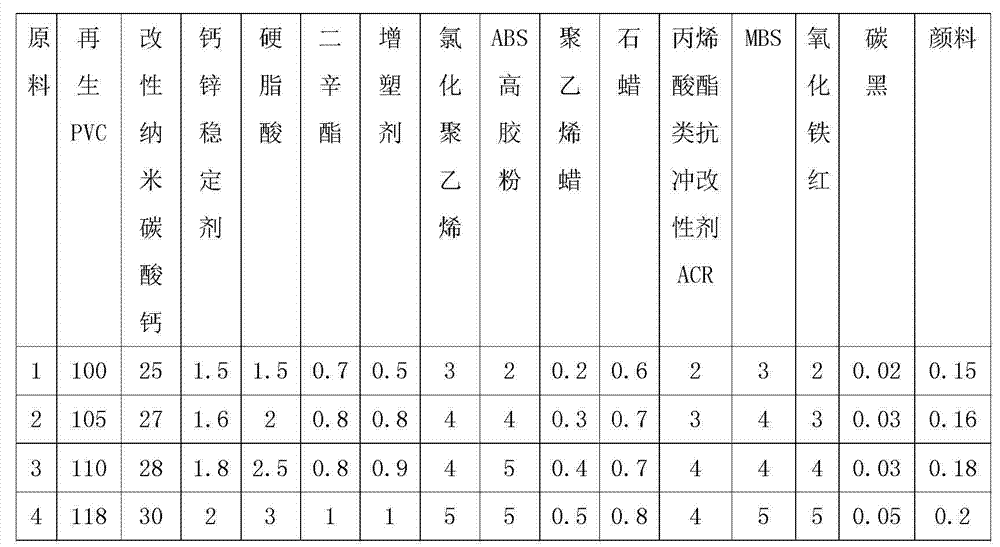

Color glass-reinforced plastic profile material made from novel reclaimed material

The invention discloses a color glass-reinforced plastic profile material made from a novel reclaimed material. The color glass-reinforced plastic profile material is made from raw materials, such as recycled PVC (polyvinyl chloride), modified nano calcium carbonate, a calcium zinc stabilizer, stearic acid, di-n-octyl phthalate, plasticizer, chlorinated polyethylene, ABS (acrylonitrile-butadiene-styrene) high rubber powder, polyethylene wax, paraffin, acrylate impact modifier ACR, MBS (methyl methacrylate), iron oxide red, carbon black and a pigment. According to the color glass-reinforced plastic profile material, the calcium zinc stabilizer substitutes a lead salt stabilizer, so that the color glass-reinforced plastic profile material is safer and harmless and does not affect the health of human bodies. A waste glass-reinforced plastic profile material or an unqualified glass-reinforced plastic profile material is effectively utilized, so that the reutilization of the glass-reinforced plastic profile material is realized, a large number of raw materials are also saved in a production process, white pollution is reduced, our natural environment is more protected, and the policy requirements of energy conservation and environment friendliness are met. The profile material made from the recycled PVC has all the characteristics of the profile material made from the raw materials as well as the characteristics of smoother surface, better density, better toughness and the like.

Owner:SHUCHENG ANTAI PLASTIC PROD

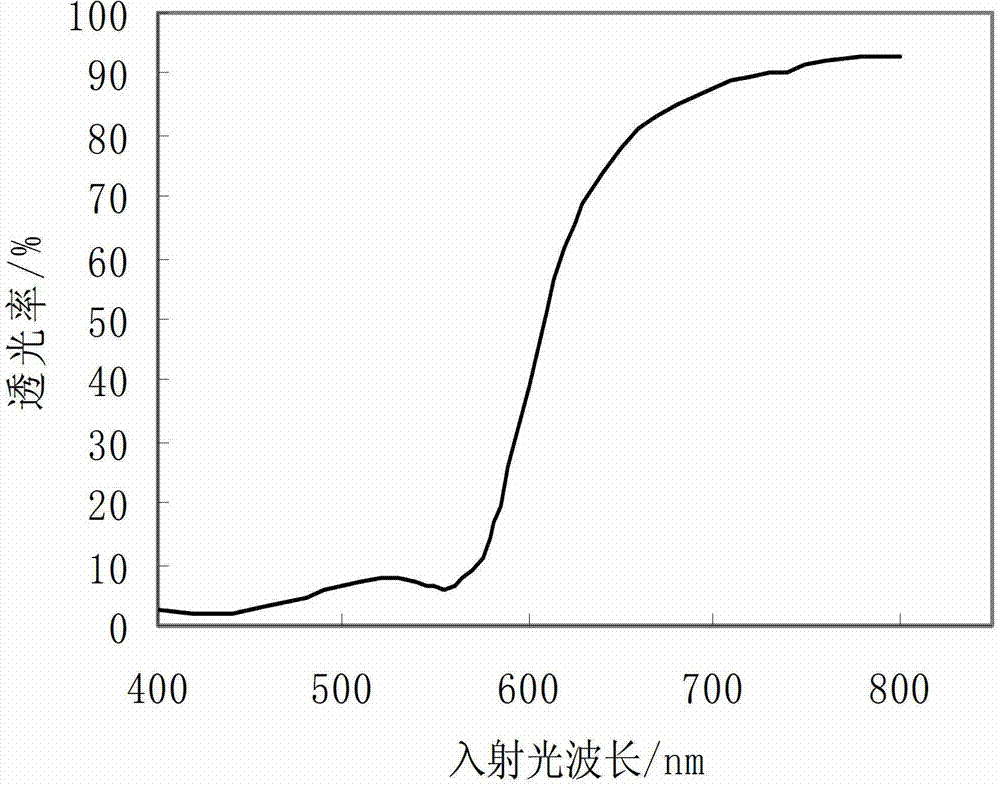

High-strength colored glass ceramics as a cooktop, smooth on both sides

InactiveUS20130140293A1Improve sealingGood application effectDomestic stoves or rangesLighting and heating apparatusTransmittanceHigh intensity

A glass-ceramic cooktop is provided that is made of glass-ceramic material with a flat upper side and an underside. The glass-ceramic material has transmittance values of greater than 0.1% in the visible light range in the total wavelength region greater than 420 nm, a light transmittance in the visible range of 0.8-2.5%, and a transmittance of 0-85% in the infrared at 1600 nm, and wherein the glass-ceramic material has high quartz mixed crystals as the prevalent crystal phase. The underside is flat, unstructured, and coplanar with the upper side.

Owner:SCHOTT AG

Colored powdered glass printing ink, oil paint and coating

A color glass powder printing ink / lacquer / paint comprises staining compound, thinner, forming agent, polymerization inhibitor and addition agent. The staining compound adopts color glass powder or screen printing glaze powder.

Owner:王广武

Method for preparing color glass fibers by on-line coating

The invention relates to a method for preparing color glass fibers by on-line coating, which comprises the following steps: (1) diluting glacial acetic acid, a silane coupling agent, a dye-fixing agent and water-soluble epoxy respectively with deionized water at room temperature, then orderly mixing, uniformly stirring, adding an inorganic coloring material, finally adding the balance of water to obtain an impregnating agent containing the coloring material; (2) adding the impregnating agent containing the coloring material into equipment on a glass fiber production line, preparing glass fiber protofilaments by on-line wire drawing, and finally drying to obtain the color glass fibers. The method of the invention can realize dyeing directly in the glass fiber preparation process, is simple in process, convenient for operation, energy-saving, and suitable for industrial production; the method of the invention can prepare glass fibers with various colors; dyed samples have good sunning resistance and high temperature color fastness; the color does not diffuse when the glass fiber is combined with resin to prepare composite materials; and the color is bright and not indistinct.

Owner:DONGHUA UNIV +1

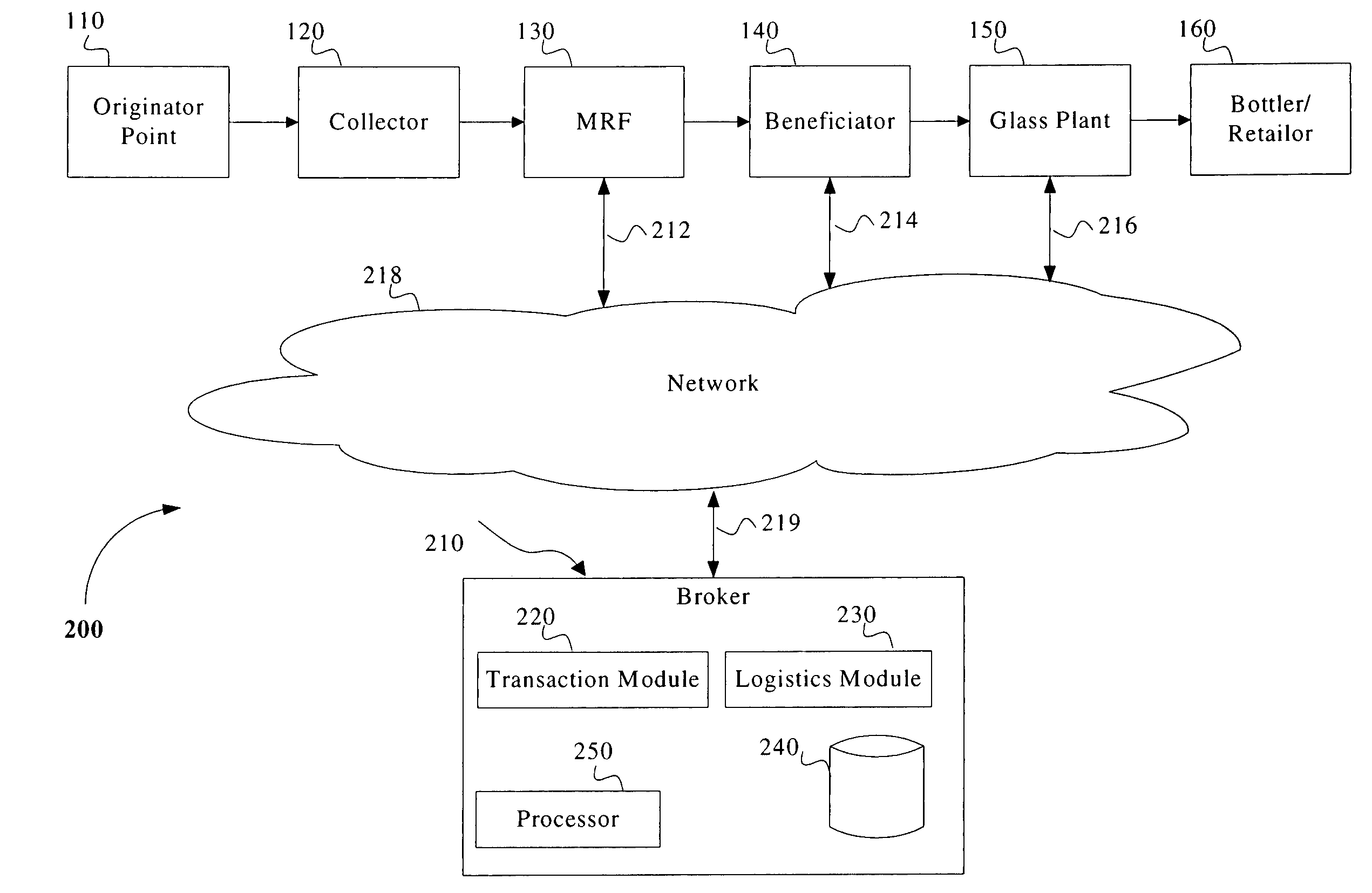

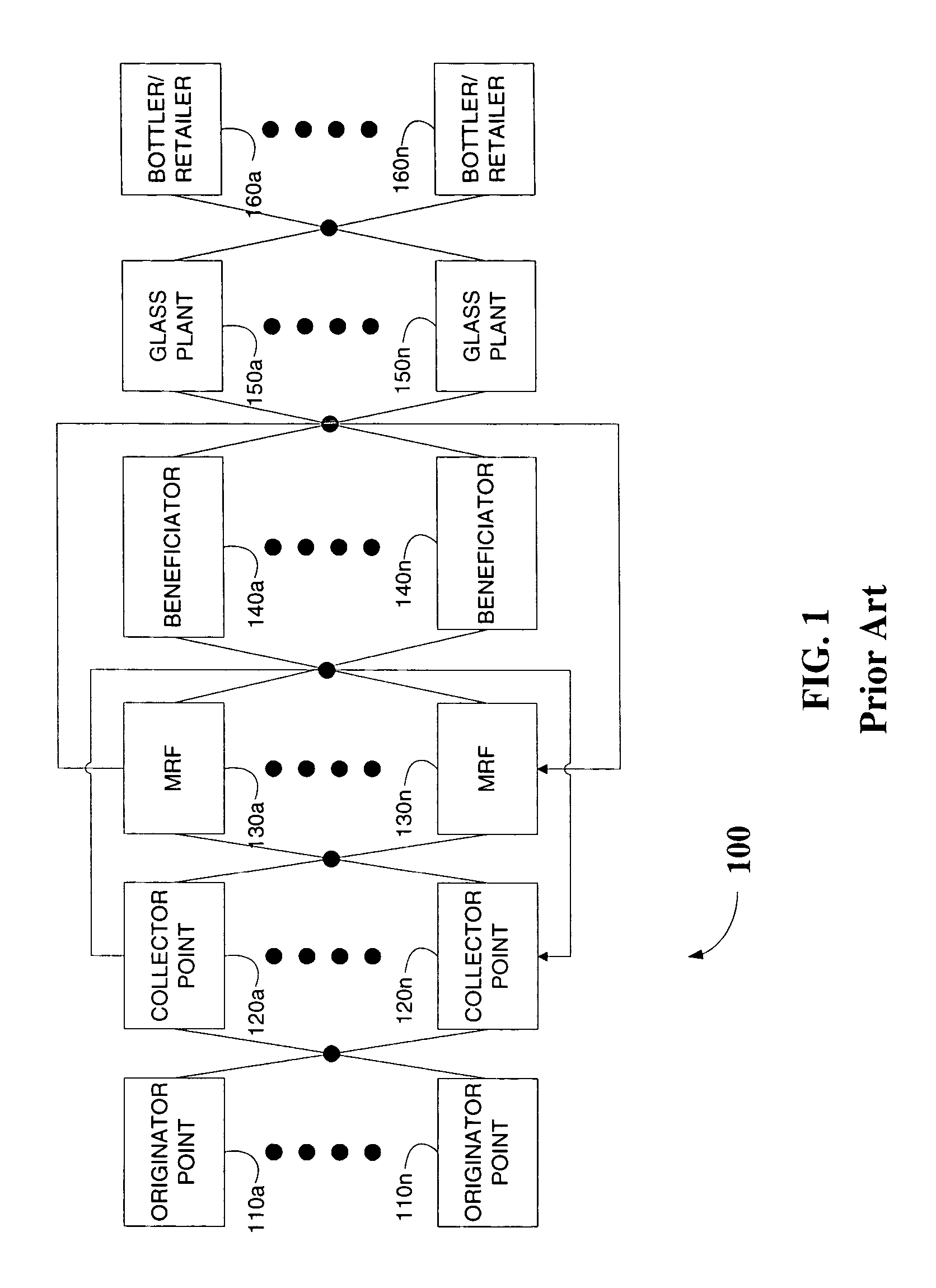

Method, system and computer readable medium for brokering the purchase and sale of glass cullet

Owner:RE COMMUNITY HLDG II INC

Preparation method for colored glass beads

InactiveCN102898003AAvoid the disadvantages of single color, unstable color, high production cost, etc.Improve efficiencyGlass shaping apparatusGlass productionGlycerolSlurry

The invention provides a preparation method for colored glass beads; and the preparation method comprises the following steps of: after uniformly mixing SiO2 powder, CaO powder, Na2O powder, K2O powder, Al2O3 powder, ZnO powder and Sb2O3 powder, forming a batch material; pouring a glass liquid after the batch material is melted into water, quenching the glass liquid in the water; grinding water-quenched glass fragments to a particle size of 10-200 microns; and then nodulizing the ground glass fragments in a bead forming furnace, so as to obtain a parent glass bead; pouring water, glycerol and dextrin into a beaker; after uniformly mixing the water, the glycerol and the dextrin, adding a mixture to a mixture of AgNO3, CuCl, Cu2O, SnO, FeSO4.7H2O, zinc powder and pulverized coal; uniformly mixing the two mixtures; and ball-milling the mixtures so as to obtain a coloring ion diffusion slurry for a colored glass bead; and mixing the parent glass bead and the coloring ion diffusion slurry so as to form a mixed material; pouring the mixed material into a stainless steel mold; heating the stainless steel mold to 550-650 DEG C; preserving the heat of the stainless steel mold for 5-10 minutes; and cooling the stainless steel mold so as to obtain ion diffused and colored glass bead. According to the invention, defects of single color, instable color, high production cost and the like in the traditional preparation method are avoided.

Owner:SHAANXI UNIV OF SCI & TECH

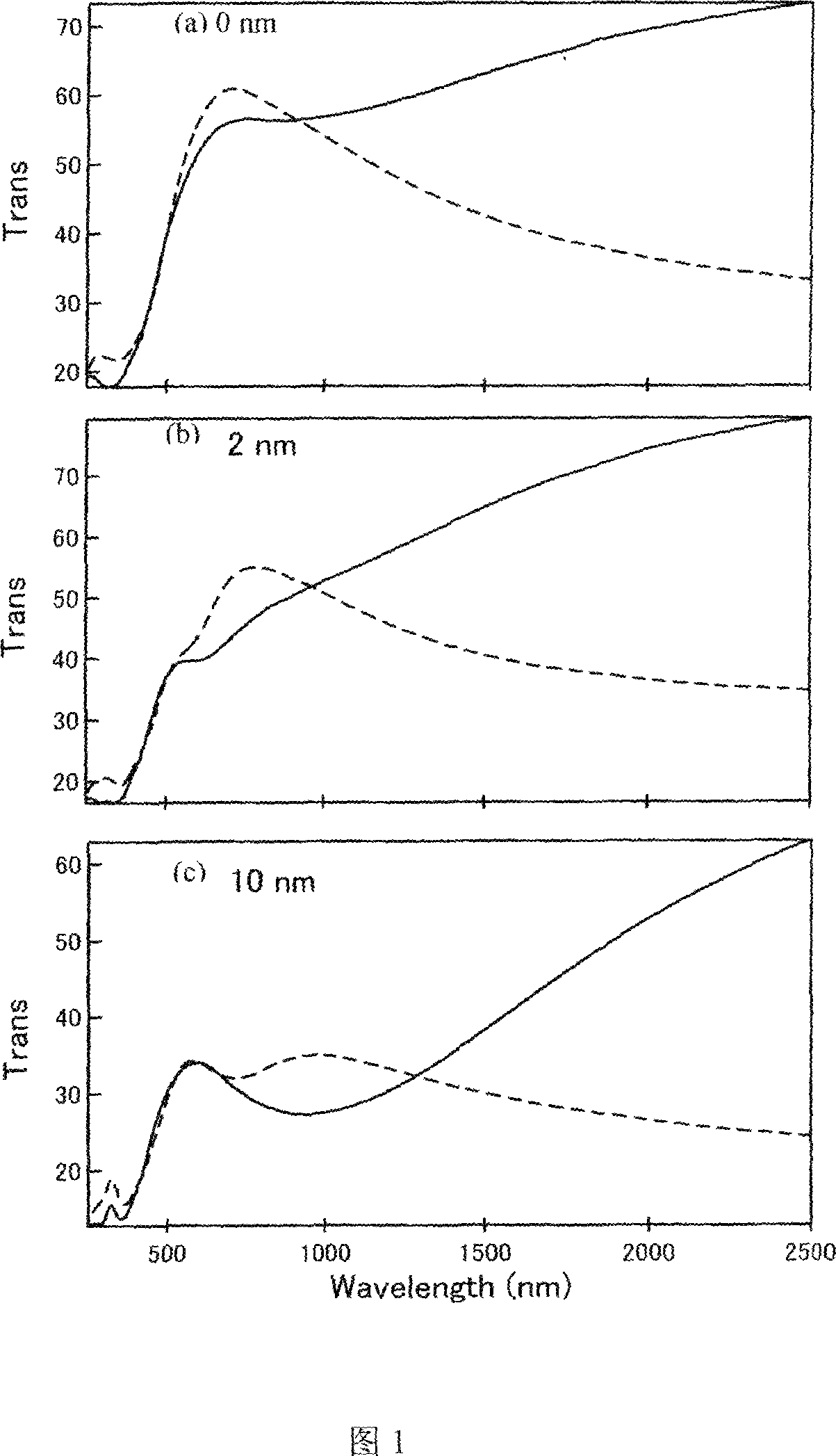

Spectrum local decorated thermocolour glass and method for making same

The invention discloses a thermal-color glass polished partly by a spectrum, which consists of glass substrate, a vanadium dioxide film and nanometer particles of noble metal deposited on the upper surface of the vanadium dioxide film or in the vanadium dioxide filmThe invention also discloses a method for preparing partly polished coating glass of the vanadium dioxide, which includes the following steps: (1) a glass substrate is heated to 500 DGE C and the temperature is kept invariant; (2) a VO2 film is prepared; (3) the nanometer particles of the noble metal are deposited.The method for preparing the thermal-color glass polished partly by spectrum in the invention is easy to be operated and can effectively realize part polishing of thermal-color spectrum of the vanadium dioxide coating glass; the partly polished coating glass of the vanadium dioxide has stronger performance and wider application range.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

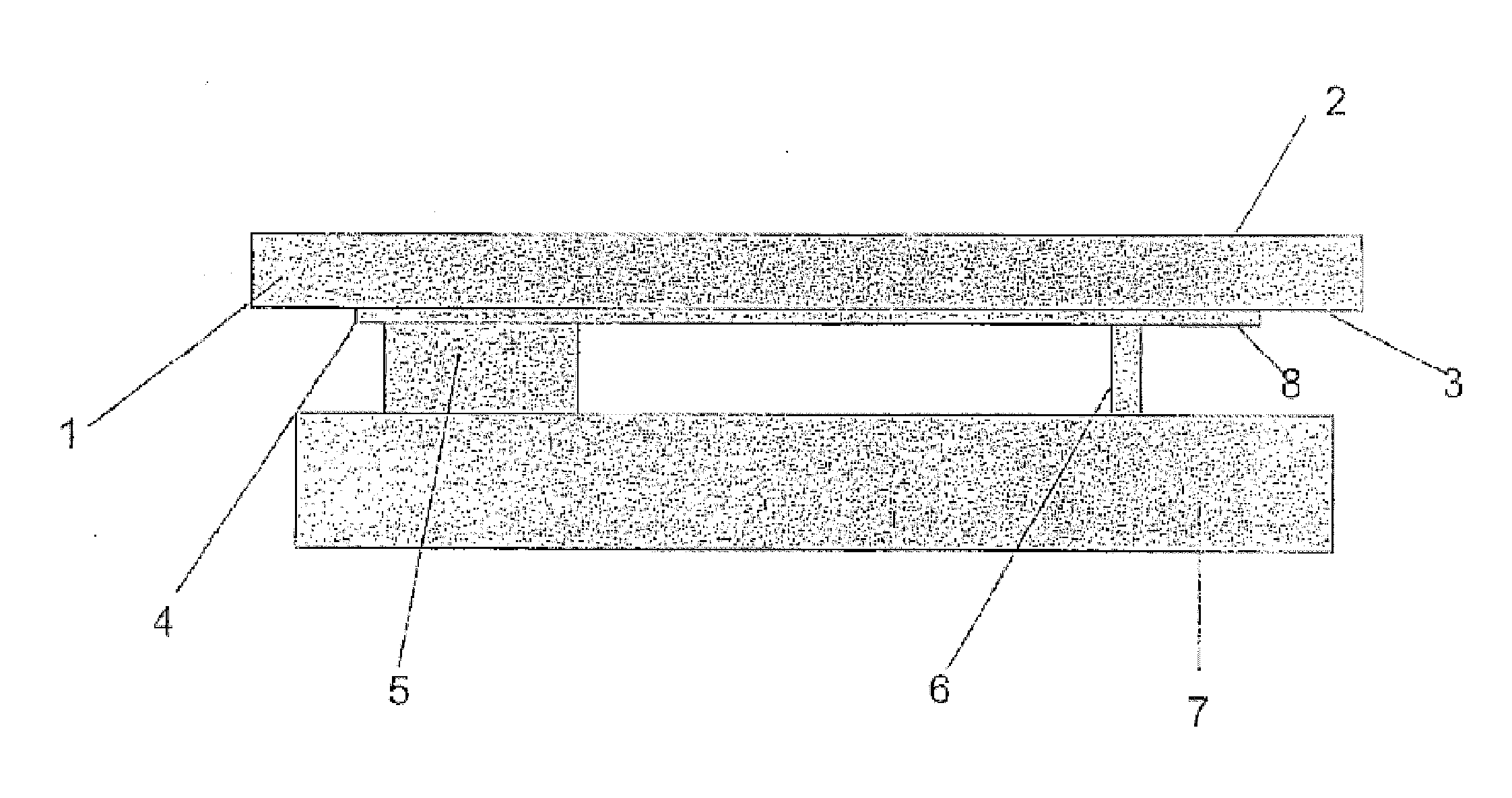

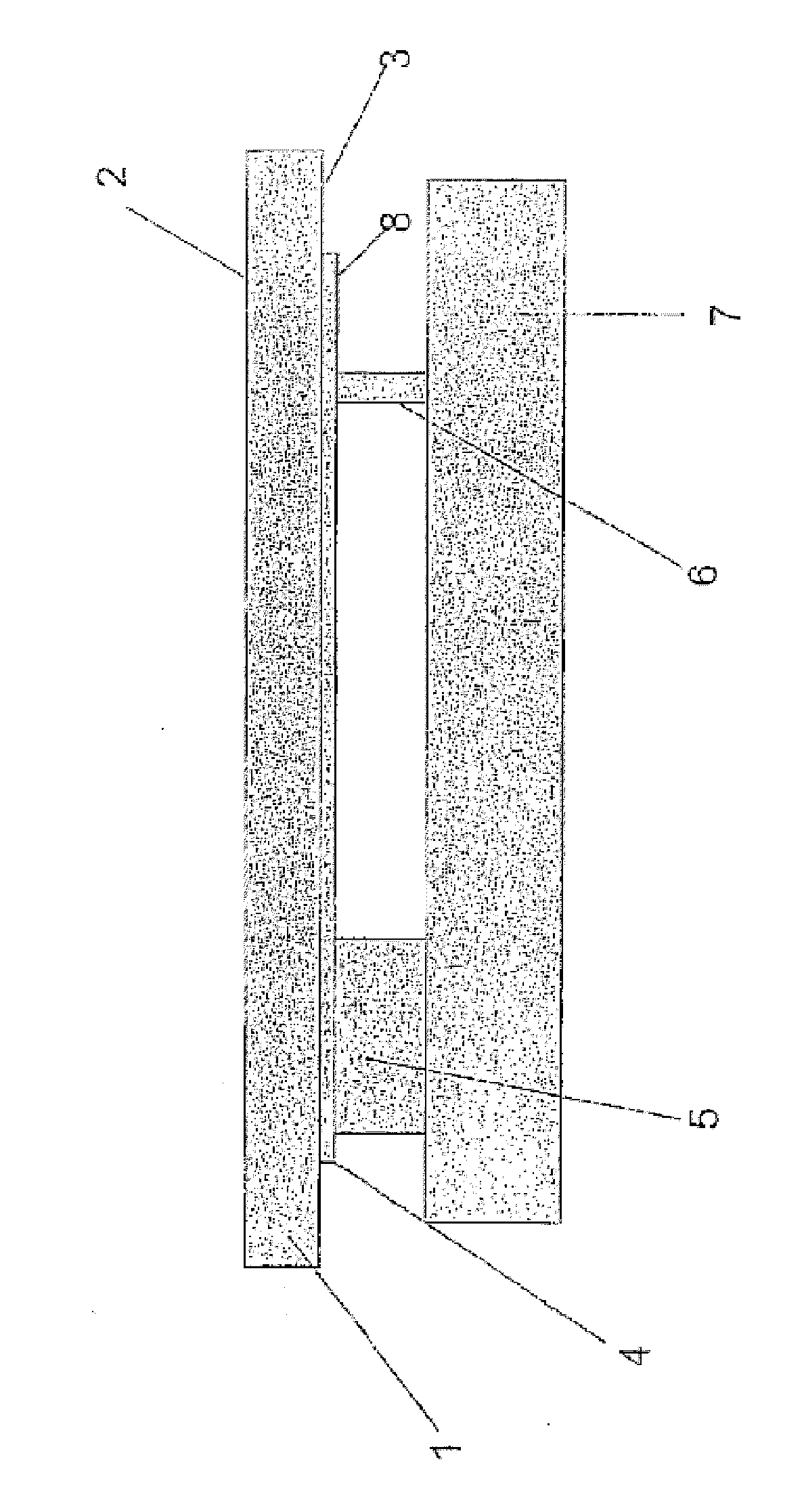

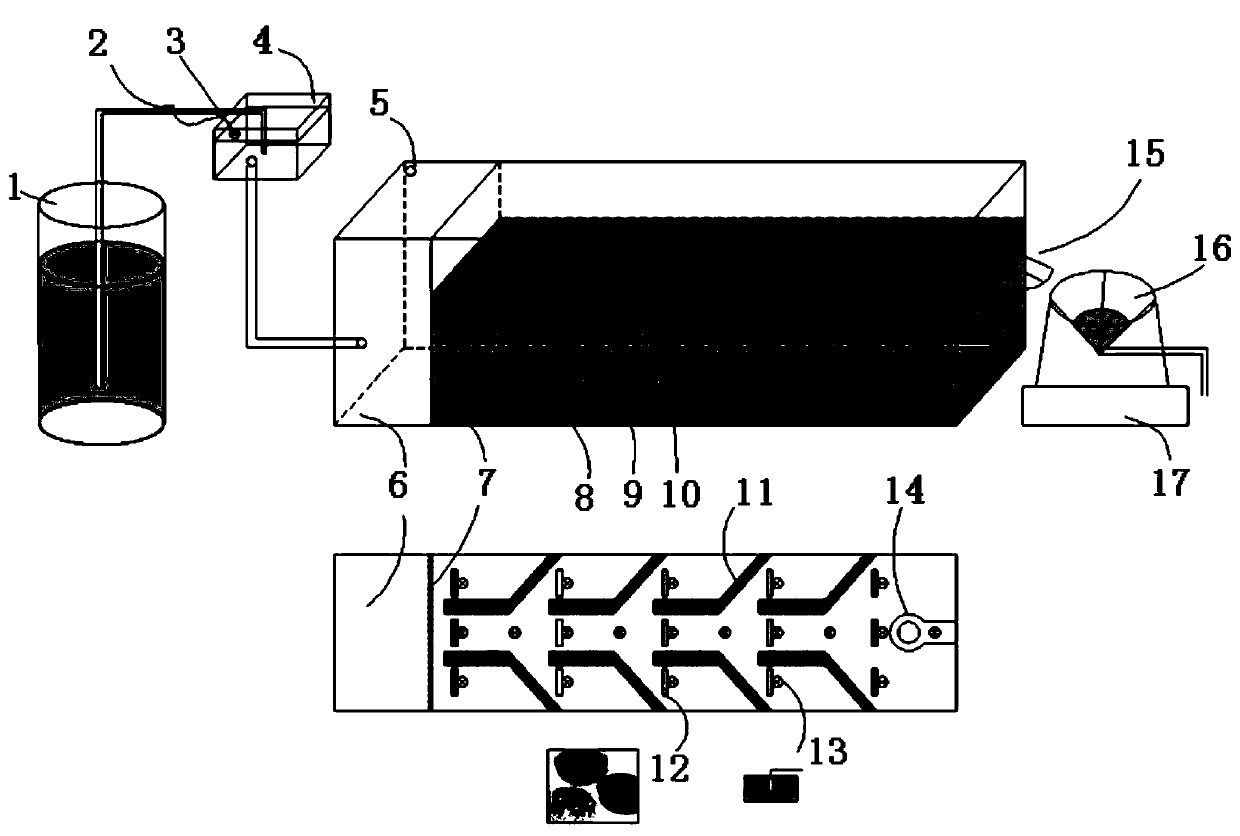

Test device and test method for simulating dam piping under high water-level condition

PendingCN110275009AThe principle is simpleEasy to operateEarth material testingPermeability/surface area analysisWater storagePore water pressure

The invention discloses a test device and test method for simulating dam piping under a high water-level condition. A test box is divided into a water storage chamber and a soil sample filling chamber through a water permeable partition plate; a valve ball is arranged in a pressure regulating water tank; the height of the valve ball can be adjusted; the water inlet of the water storage chamber is communicated with the water outlet of the pressure regulating water tank through a pipeline; the pressure regulating water tank can be adopted to supply water and regulate the pressure of the water; the height of the pressure regulating water tank is adjustable; the switching on and switching off of a water pump are controlled through the valve ball in the pressure regulating water tank; the pressure regulating water tank and the valve ball are matched with each other so as to accurately control the water level height of the water storage chamber; a sand gravel cushion layer is laid at the bottom of the soil sample filling chamber; a test sandy soil layer is arranged on the upper surface of the sand gravel cushion layer; a pore water pressure sensor is buried in the test sandy soil layer; color glass beads are laid on the top of the test sand layer along an axis direction; the colored glass beads are used for tracing the upstream development trajectory of piping; a piping outlet is communicated and led out through a water-sand discharging pipeline; and a funnel for collecting gushing sand is arranged below the outlet of the water-sand discharging pipeline.

Owner:NANJING HYDRAULIC RES INST

Method for preparing colorful vanadium dioxide thermo color glass

The present invention provides a method for producing colorful vanadium dioxide thermo-color glass, which comprises the following steps in turn: (a) glass substrate is washed and dried in blowing way; (b) the glass substrate is arranged into a film deposit chamber and is heated to 400 to 600 DEG C; (c) working gas is ventilated in; (d) the vanadium dioxide thermo-color layer is prepared with the magnetic sputter-control preparation craftwork; (e) the titanium dioxide interference layer is prepared with the magnetic sputter-control preparation craftwork, and the film thickness of the interference layer is precisely controlled to obtain the vanadium dioxide thermo-color glass with different colors. Through the precise control of the film thickness, the reflecting color of the glass can be presented in pink, blue, absinthe green, golden yellow and other colors. With different colors, besides having the function of the high-efficient energy conservation, the vanadium dioxide thermo-color glass also has the decoration effect, thereby being easy to be accepted by the users.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Inner printed color crystal glass and its production process

ActiveCN1739981ASolve the problem of coloringSolve historical problems that cannot be screen-printedDecorative surface effectsRotary pressesScreen printingEngineering

The inner arced color printed glass is for refrigerator, air conditioner and other household product. It is layered structure including base glass, color ink layer and base ink layer. The production process includes the following steps: toughening, cleaning and drying the arced glass base; setting the glass base on arced table and screen printing with color ink, screen plate and arced ink scraper; and printing one layer of base ink; and stoving in far infrared oven at 150-180 deg.c. the arced color glass is novel and fashionable.

Owner:JIANGSU XIUQIANG GLASSWORK CO LTD

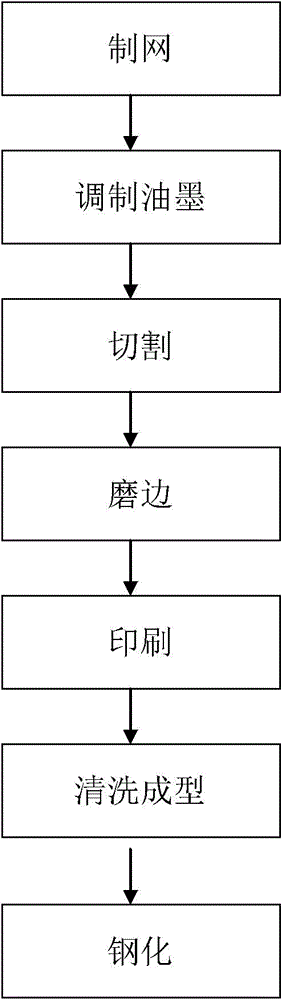

Overprinting glass manufacturing method and multi-color glass product

The invention relates to an overprinting glass manufacturing method and a multi-color glass product. The overprinting glass manufacturing method comprises the following steps: providing glass with a preset size and more than two types of ink; manufacturing a screen printing plate, coating the screen printing plate with a photosensitive material, and exposing, developing and forming a film with a required pattern; printing first ink on the surface of the glass, drying the first ink to form a first ink layer, printing second ink on the first oil layer, drying the second ink to obtain a second ink layer, repeating the printing step to form more than two ink layers, then printing a waterproof material layer on the outermost ink layer according to the required pattern, and performing drying; flushing a printed product, respectively forming the required pattern corresponding to all the layers of ink, and performing thermal treatment to prepare a finished product. The patterns on all the layers of ink are formed in one step and are precisely aligned; the pattern positions are consistent, staggering is avoided, and the patterns are tidy and attractive. Due to thermal treatment, the ink can be more firmly attached to the surface of the glass and is unlikely to decolor and durable; the overprinting glass manufacturing method can be applied to manufacturing of various multi-color glass products.

Owner:XINYI GLASS ENG (DONGGUAN) CO LTD

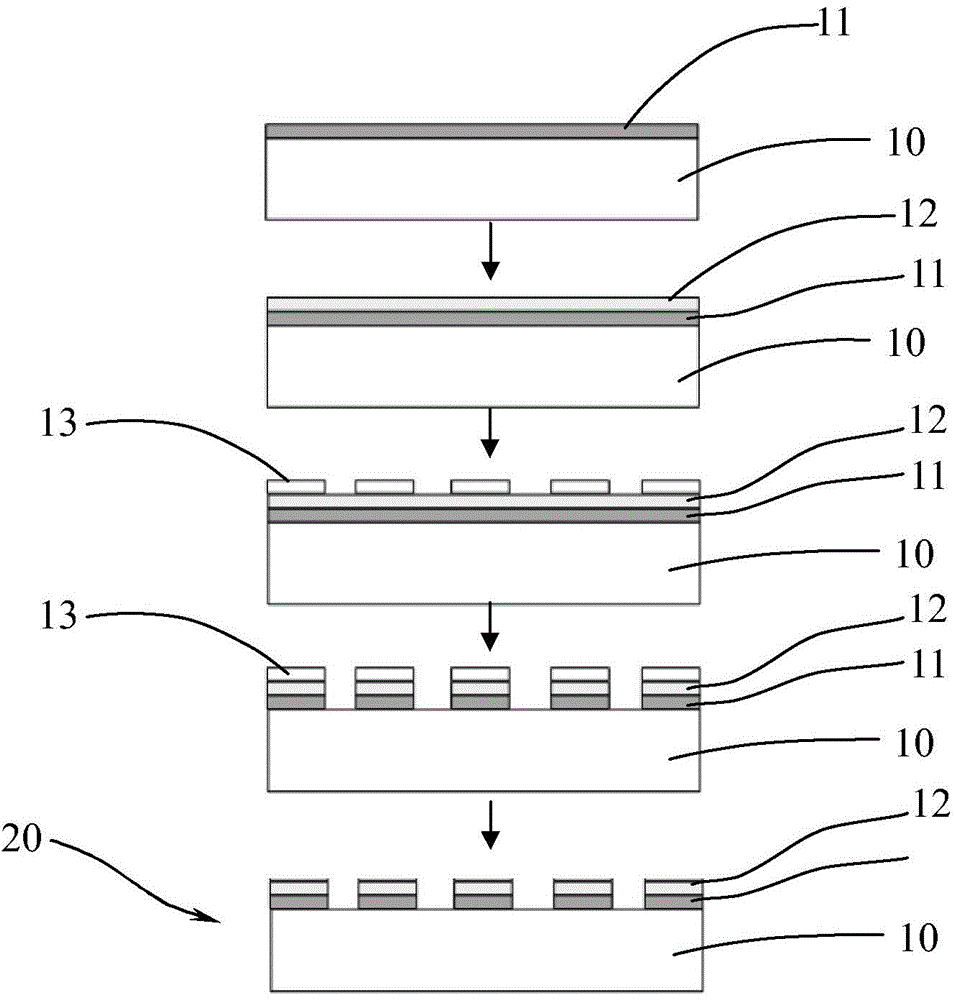

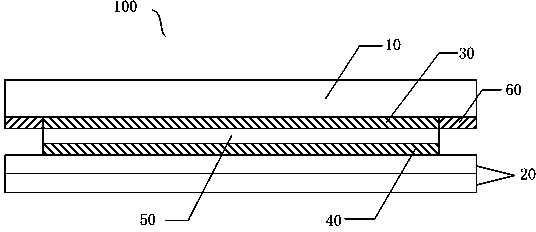

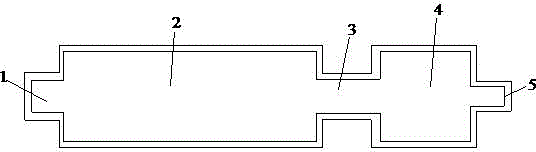

Touch screen and manufacturing method thereof

InactiveCN103744554AThin structureSimple structureInput/output processes for data processingColor glassCover glass

The invention is applicable to the field of display screens and provides a touch screen and a manufacturing method thereof. The touch screen comprises cover plate glass and a thin film transistor (TFT) display. An induction electrode of the touch screen is manufactured on the cover plate glass. A driving electrode of the touch screen is manufactured on the surface of color glass of the TFT display. One side of the cover glass with the induction electrode is bonded with one side of the TFT display with the driving electrode through optical glue. Two structures of OGS and ON-CELL are combined, the induction electrode and the driving electrode of a touch sensor are manufactured on the touch screen cover plate glass and the TFT display color glass respectively, and slimness of touch products and optimization of the touch performance are achieved.

Owner:SHENZHEN ZHENGXING OPTOELECTRONICS TECH

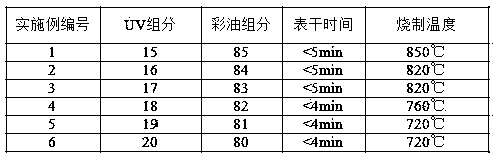

Photo-cured high-temperature colored glass printing ink and preparation method therefor and painting method thereof

The present invention discloses photo-cured high-temperature colored glass printing ink which comprises 15-20% by mass of an UV component and 80-85% by mass of a colored oil component. According the method for introducing an UV coating system into high-temperature colored glass printing ink, by improving the introduced UV coating system and components and component contents in the high-temperature colored glass printing ink, the glass printing ink can achieve an effect of surface dry within a short time after painting, then can be painted for several times repeatedly to form needed complicated patterns, and performs high-temperature tempering after painting, so that the patterns are permanently fixed.

Owner:FOSHAN CITY GREEND CHEM

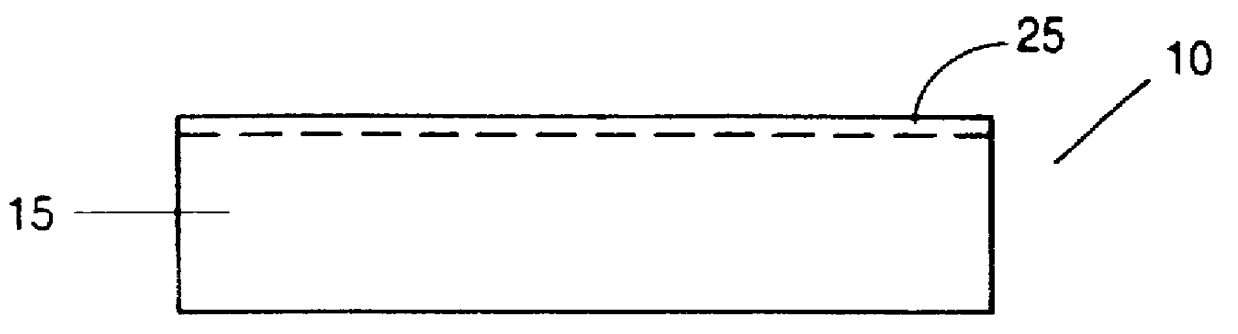

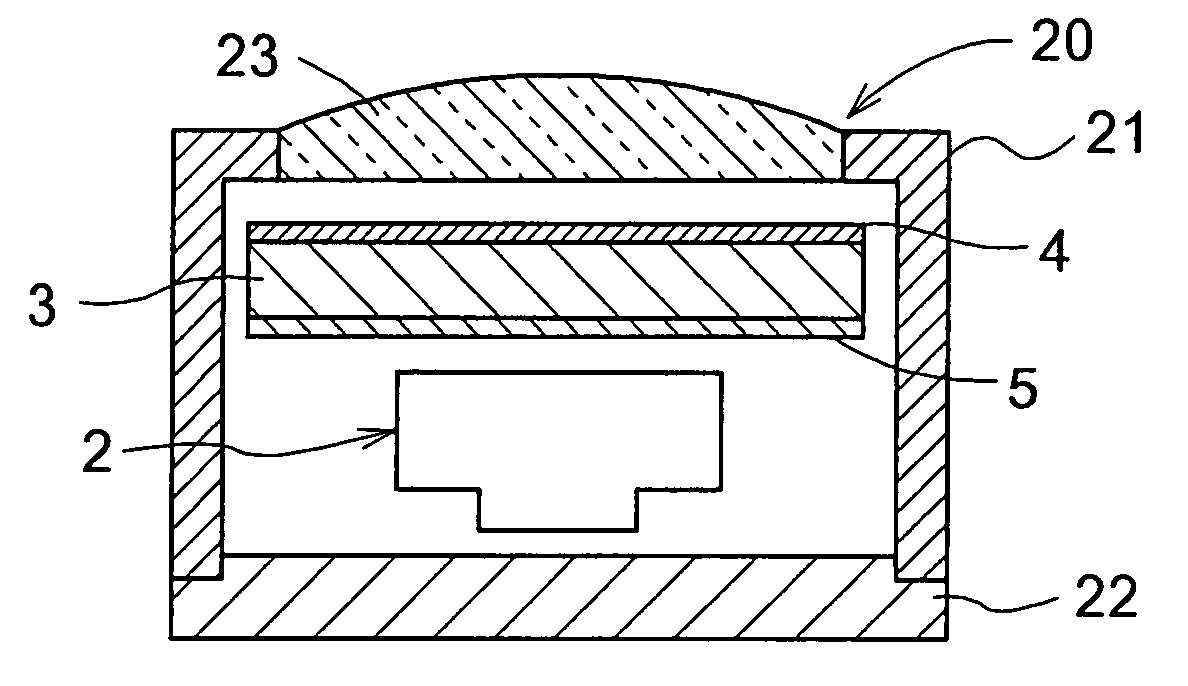

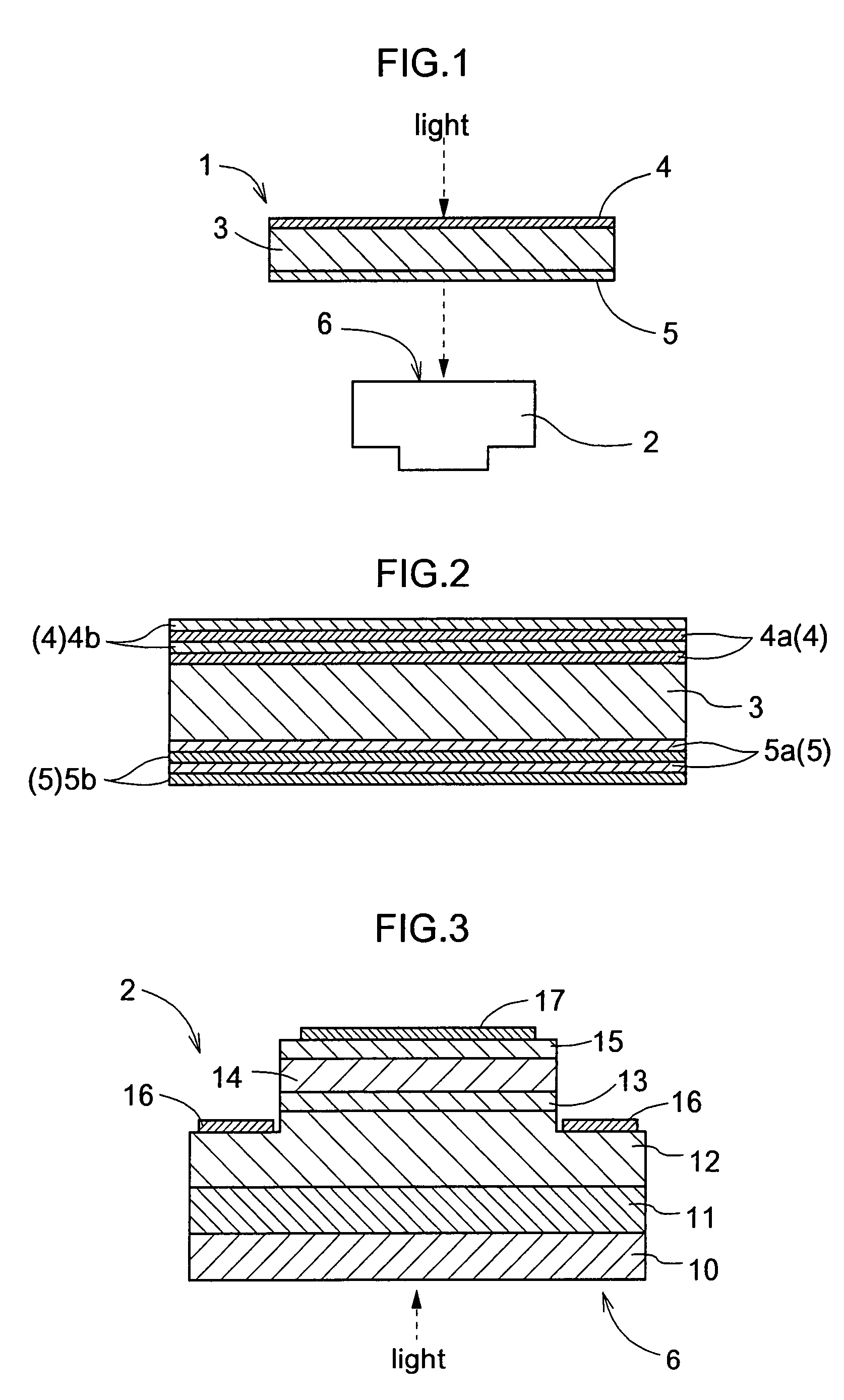

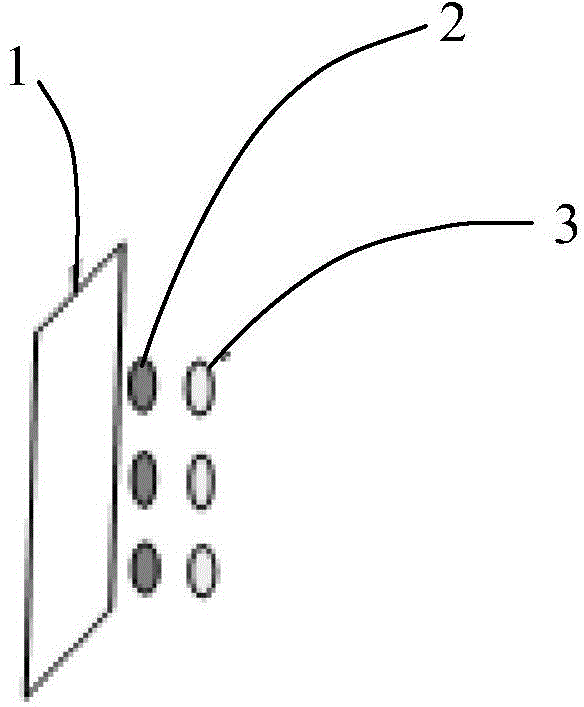

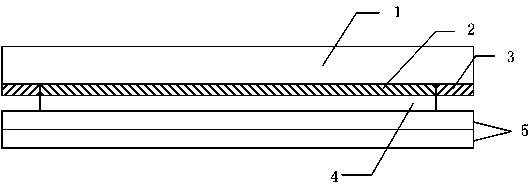

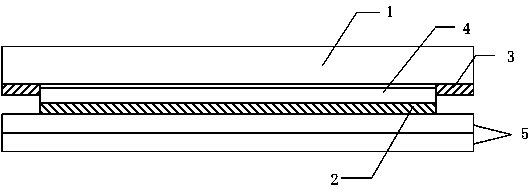

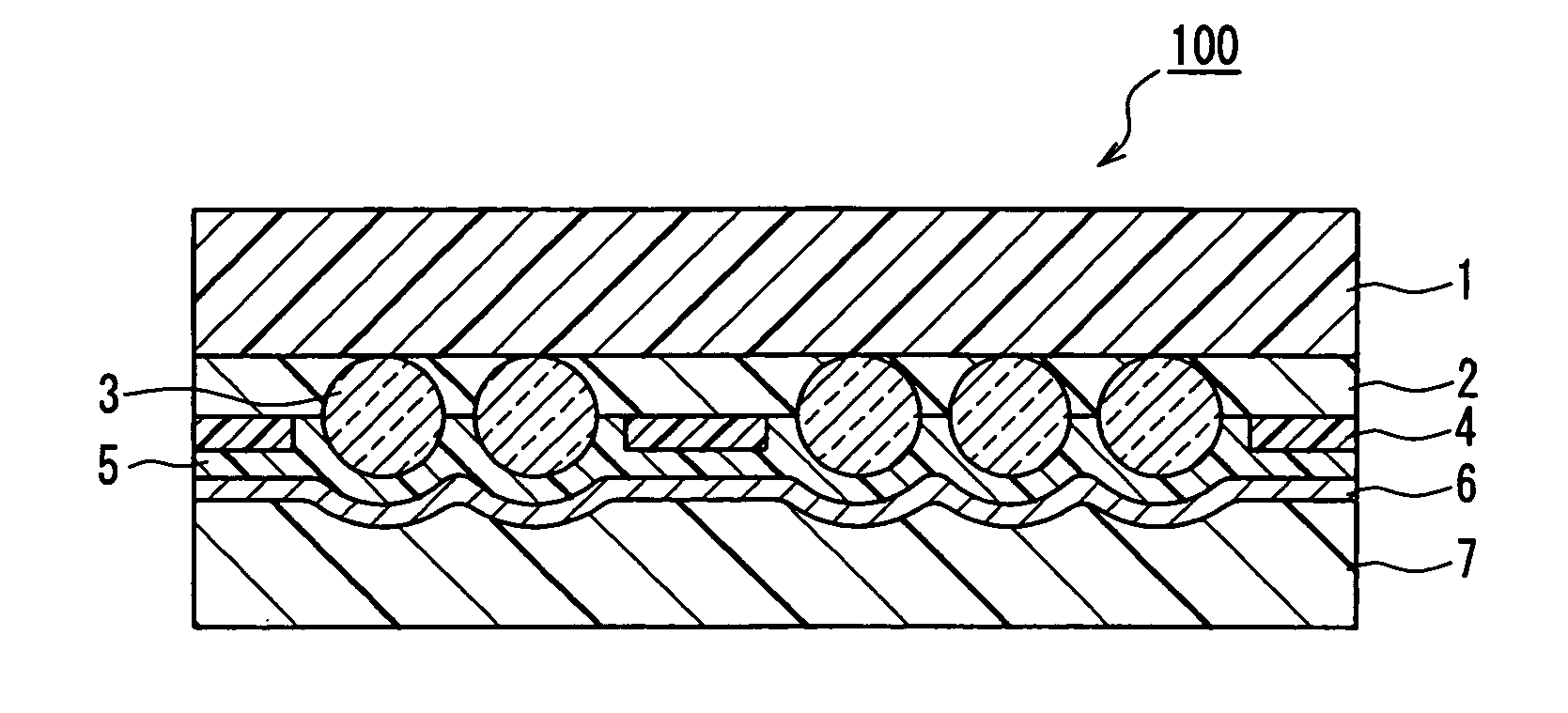

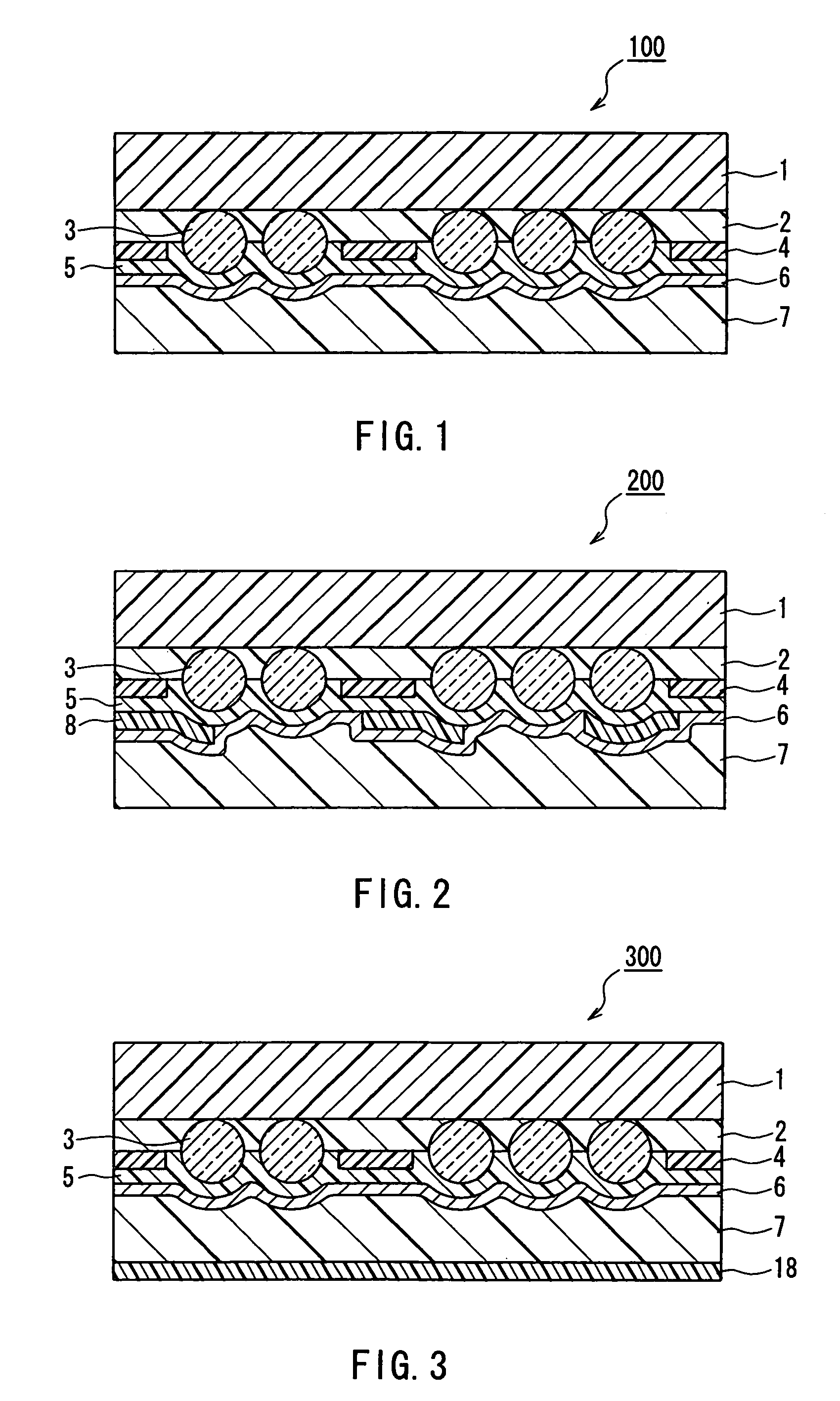

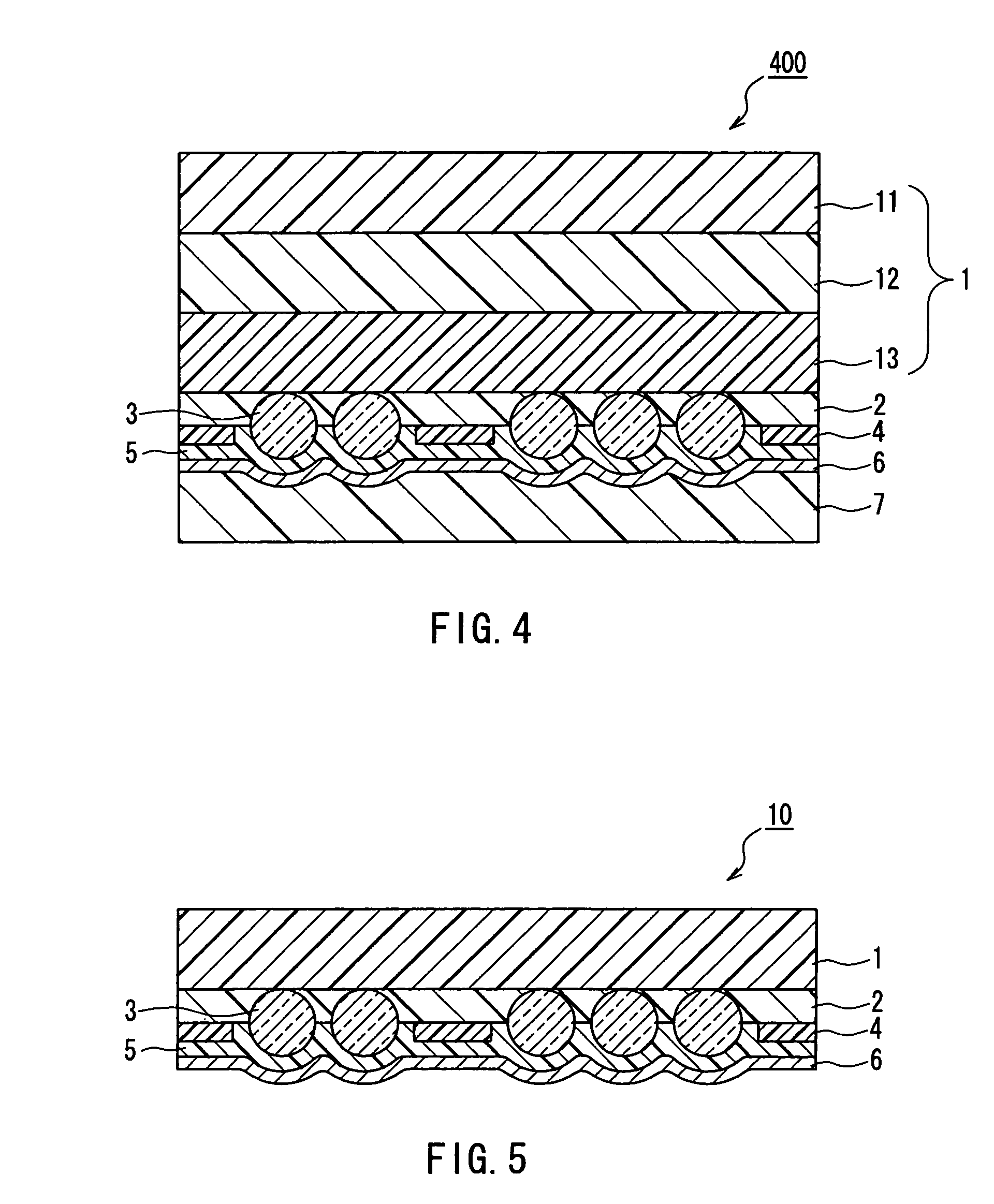

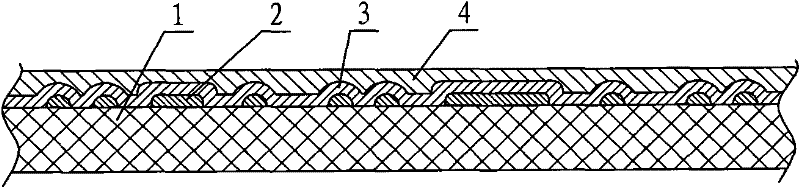

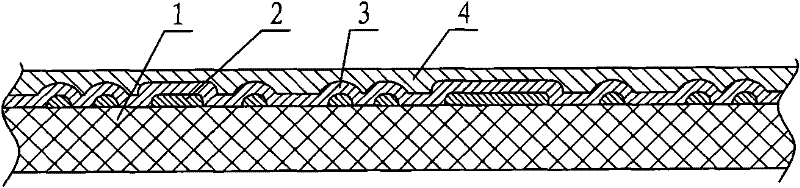

Retroreflective sheet for security and method for manufacturing the same

ActiveUS8003197B2Good effectClearly markedStampsDecorative surface effectsSurface layerRoom temperature

The present invention is directed to providing a retroreflective sheet for security that is difficult to be counterfeited, cannot be reused if once released, includes a printed image that can be identified visually regardless of an object to be attached such as a colored glass and also can be identified visually clearly even in the night time, and is directed to providing a method for manufacturing the same. The retroreflective sheet for security of the present invention includes: a surface layer 1; a binder layer 2; high-refractive-index glass beads 3; a print resin layer 4; a focusing layer 5; a metal layer 6; and a pressure-sensitive adhesive layer 7 in this order, wherein the print resin layer 4 forms a mark, the high-refractive-index glass beads 3 are disposed in the binder layer 2, a position for disposing the high-refractive-index glass beads 3 does not coincide with a position of the print resin layer 4, when being observed from the surface layer 1 side in a thickness direction of the retroreflective sheet for security, and the print resin layer 4 is made of a composition containing a room temperature curing resin as a main component.

Owner:KIWA CHEM IND CO LTD

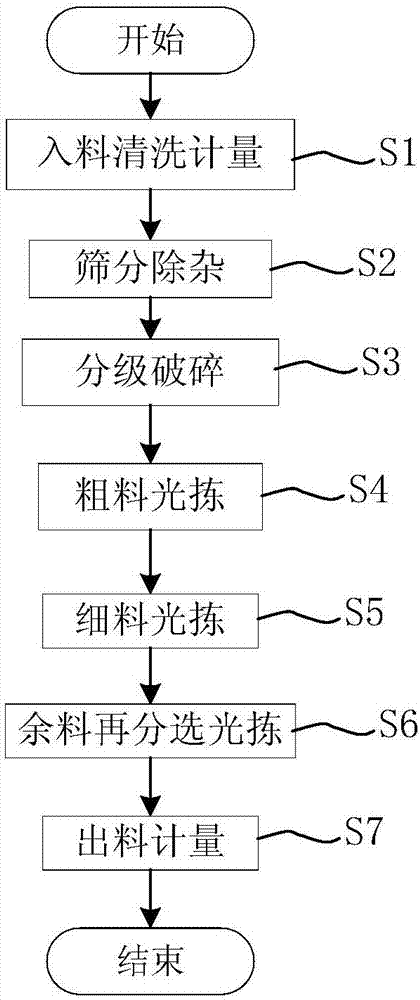

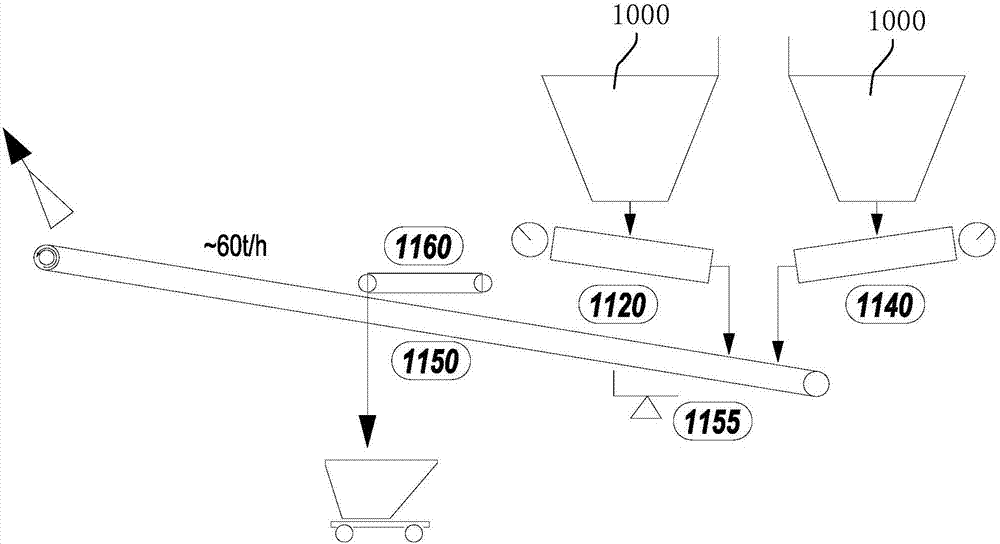

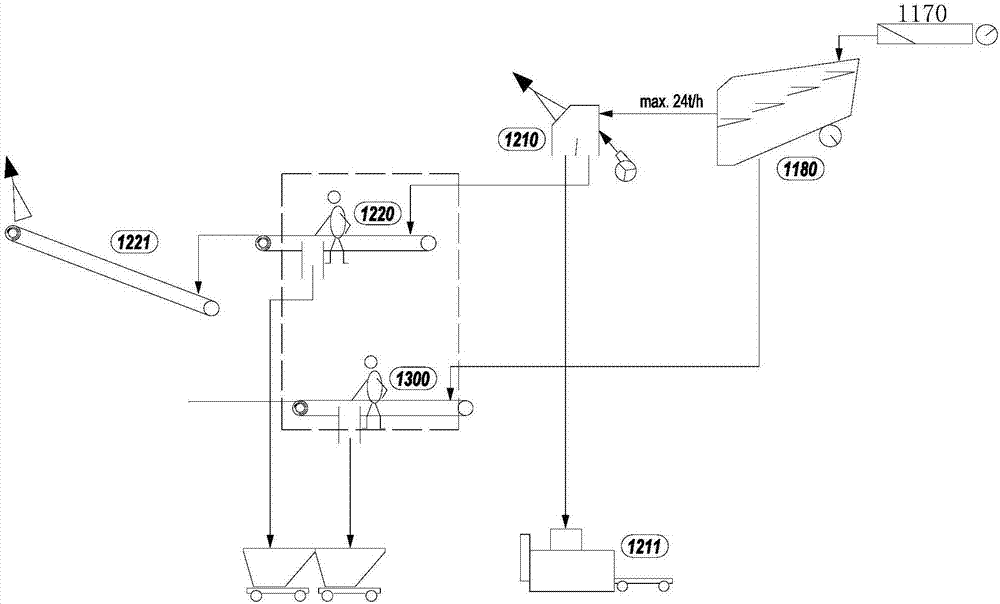

Automatic wet-process sorting control method for waste glass

InactiveCN107952781AImprove sorting qualityImprove sorting efficiencyGas current separationSolid waste disposalThree stageEngineering

The invention discloses an automatic wet-process sorting control method for waste glass. The method comprises the following steps that S1, feeding, cleaning and metering are carried out, specifically,the waste glass is cleaned, water is removed, and then feeding is carried out by adopting a vibration feeding machine; S2, screening and impurity removal are carried out; S3, staged crushing is carried out, specifically, two-stage crushing is carried out on separated materials; S4, optical sorting is carried out on coarse materials, specifically, non-ferrous metals are removed by an eddy currentsorting machine, and three-stage screening is completed according to the granular size of 1-3mm, 3-8mm and 8-50mm; S5, optical sorting is carried out on fine materials; S6, optical sorting is carriedout on excess materials, specifically, screening is carried out continuously on materials with the granular size of 8-50 mm by adopting a three-stage broken glass optical sorting machine to carry outimpurity and mixed-color separation so as to obtain materials with the granular size of 8-16mm, 16-22mm and 22-50mm; and 7, discharging and metering are carried out, specifically, separated main-colorglass, colored glass pieces and stone ceramics are metered and discharged separately. The method has the advantages that various specifications can be subdivided, all the impurities can be removed, the sorting quality can be greatly improved, and the sorting efficiency and the productivity can be improved.

Owner:上海燕龙基再生资源利用有限公司

Processing method of three-dimensional colored ice crystal glass

A method for processing three-dimensional colored ice crystal glass, which includes a glass substrate layer, the technical points of which are: first clean and dry the glass used as the glass substrate layer; then print on one side of the glass substrate layer by a screen printing machine A solid-color skeleton layer capable of forming a pattern is dried for later use; then a paint spraying machine is used to evenly spray a color-modified epoxy resin paint layer having a color contrast effect with the solid-color skeleton layer, and dried; On the epoxy resin layer, apply one layer of primer layer again, and after drying, it will be the finished product of three-dimensional colored decorative glass. Due to mutual repulsion between the solid-color skeleton layer and the colored modified epoxy resin paint layer, the colored modified epoxy resin paint accumulates to both sides of the solid-color skeleton layer, and a transition color is formed between the two; thus in On the basis of the color difference effect, a remarkable three-dimensional color effect is formed. The invention also has the advantages of simple method, long service life, low comprehensive cost, wide application range and the like.

Owner:高维凡

Melting furnace for producing float glass and colorant addition method

The invention relates to a melting furnace for producing float glass and a colorant addition method, belonging to the technical field of glass production. According to the invention, a neck (3) is used as a charging and mixing part; and coloring materials are added into molten glass via a charging channel (8) arranged at the charging area (6) of the neck. Since the melting furnace is filled with colorless basic molten glass, the operation of coloring is performed at the neck, thereby reducing displacement amount of the molten glass and effectively shortening changing time of the molten glass; and the method enables large-size melting furnaces to adapt to features of color glass demand market, and the features of the color glass demand market include demands for various varieties and little demand for a single variety.

Owner:CHINA LUOYANG FLOAT GLASS GROUP

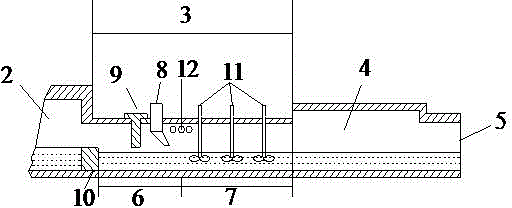

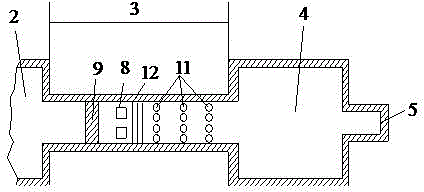

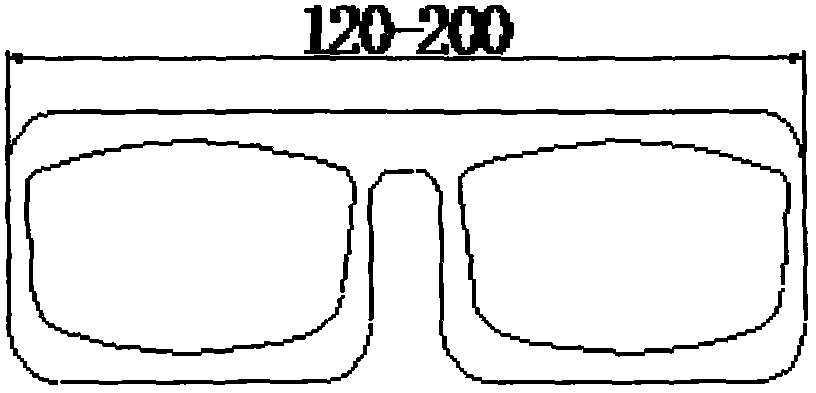

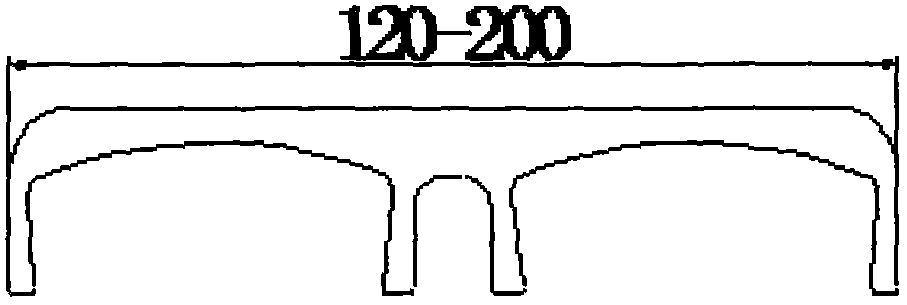

Multi-color glasses frame blank and shell profile shapes blank as well as molding equipment thereof

InactiveCN102692727AReduce wasteReduce one cutting production processNon-optical partsElastomerCellulose diacetate

The invention provides a multi-color glasses frame blank and a shell profile shapes blank as well as molding equipment thereof. The multi-color glasses frame blank is a long-strip profile shapes; the width of the multi-color glasses frame blank is 120-200 mm and the thickness of the multi-color glasses frame blank is 20-66 mm; the length of the multi-color glasses frame blank can be designed and set according to a shearing machine; and the blank can be made of cellulose diacetate, TR90 (Thio Rubber 90) or other nylon materials which are similar with the TR90, a nylon elastic body or a nylon alloy material. According to the multi-color glasses frame blank and the shell profile shapes blank as well as the molding equipment thereof disclosed by the invention, the blank with the width of the glasses frame with the needed shape is molded for one time under other related material profile molding process conditions of using the plastified cellulose diacetate, the TR90 or the other nylon materials which are similar with the TR90, the nylon elastic body or the nylon alloy material, so that a primary cutting production procedure can be reduced and the material waste is reduced; working hours can be saved by flat-bottom and arc-shaped profile shapes and the product quality is improved; and the working hours and the material waste can be saved by hollow and solid shell rods.

Owner:钟沿东 +1

Red coloring agent for low-temperature colored glass, and preparation method and use method thereof

InactiveCN107651834AIncreased diffusion rateHigh stoichiometric ratioDecompositionReaction temperature

The invention belongs to the field of colored glass, and particularly relates to a red coloring agent for low-temperature colored glass, and a preparation method and a use method thereof. The red coloring agent is prepared from the following raw materials in parts by mass: 30 to 50 parts of a quartz powder, 10 to 30 parts of borax, 10 to 25 parts of sodium carbonate and 2 to 30 parts of a coloringadditive, by the steps of mixing the materials, founding at high temperature, performing water quenching and pulverizing, wherein the coloring additive is one of or a mixture of more than one of selenium powder, cuprous oxide and ferric oxide. A large amount of low-melting-point silicon oxide, borax and sodium carbonate are adopted in the coloring agent base material, so that the dispersing speedof the coloring agent in 1200-DEG C glass liquid is greatly enhanced and uniformly colored glass original liquid is formed. In the preparation process of the coloring agent, the composite powder is directly added into a high-temperature frit furnace to perform founding and the reaction temperature is increased from a room temperature to 1350 to 1500 DEG C instantaneously, so that decomposition, volatilization and composition segregation of the materials in the slow heating process are avoided, and a coloring agent product with high stoichiometric ratio and high high-temperature dispersion speed is obtained.

Owner:JIANGSU BAIFU TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com