High-weather-resistant anti-aging glass fiber reinforced polypropylene material and preparation method thereof

An anti-aging and polypropylene technology, which is applied in the field of high weather resistance and anti-aging glass fiber reinforced polypropylene material and its preparation, can solve the problems such as the influence of material color and color difference, and achieve the effect of solving product discoloration, high production efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

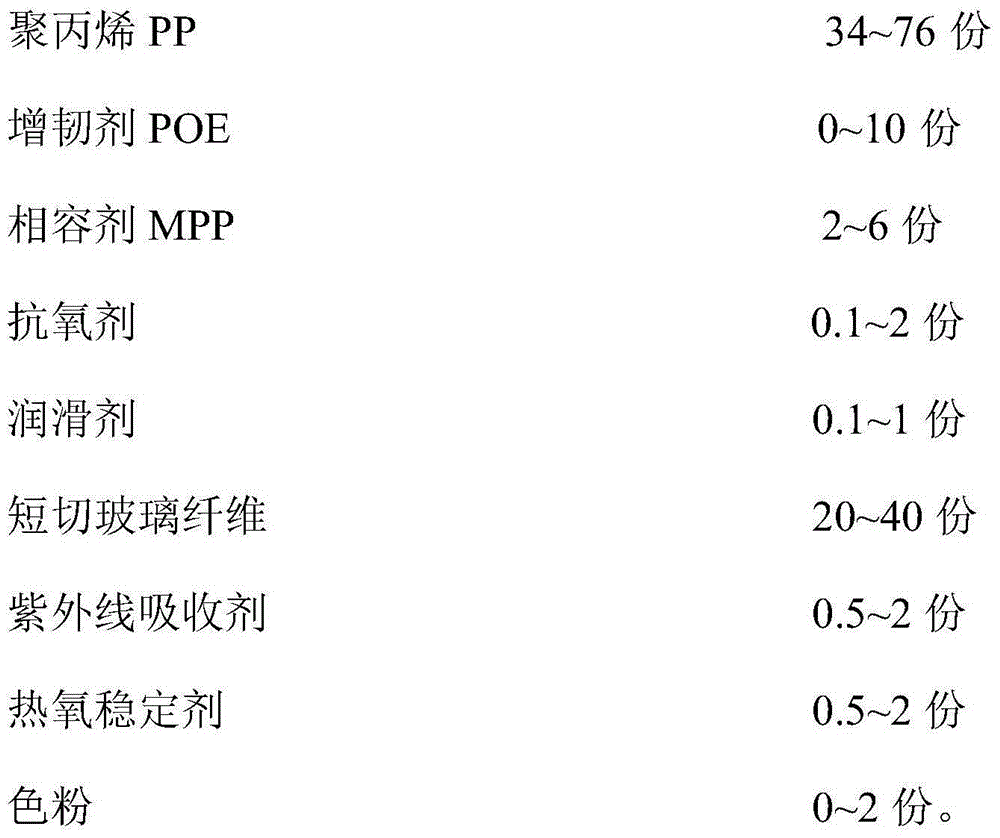

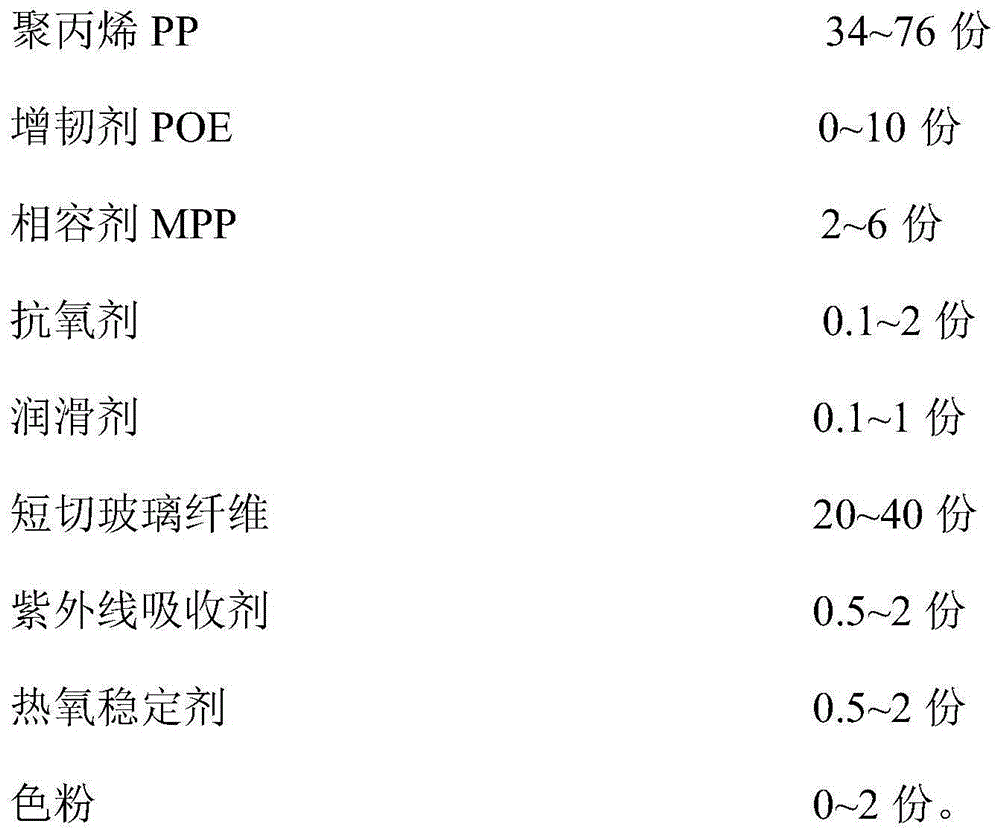

Method used

Image

Examples

Embodiment 1

[0021] The high weather resistance and anti-aging glass fiber reinforced polypropylene material of this embodiment is composed of the following components by weight: 76 parts of polypropylene PP, 1 part of POE, 2 parts of maleic anhydride grafted PP, 20 parts of chopped glass fiber ( Length: 3~4.5mm; Diameter: 8~15μm), 0.1 part of hindered phenolic antioxidant, 0.1 part of phosphite ester synergistic antioxidant, 0.2 part of lubricant, 0.6 part of ultraviolet absorber, 0.5 part of organic amine Phenolic thermal oxygen stabilizer, 0.0052 part of 10000 mesh ultrafine titanium dioxide, 0.0032 part of azo condensation type Yellow3G yellow, 0.0041 part of monoazo orange, 0.001 part of organic silicon light diffuser.

[0022] The preparation method of the high weather resistance and anti-aging glass fiber reinforced polypropylene material of this embodiment includes the following steps:

[0023] S1. Mix polypropylene, compatibilizer, toughening agent, antioxidant, lubricant, ultraviolet ...

Embodiment 2

[0027] This example is roughly the same as Example 1. The difference lies in the weight of each component. The details are as follows: 57.5 parts of polypropylene PP, 5 parts of POE, 4 parts of maleic anhydride grafted PP, 30 parts of chopped glass fiber (long : 3~4.5mm; diameter: 8~15μm), 0.4 part hindered phenolic antioxidant, 0.2 part phosphite synergistic antioxidant, 0.8 part silicone lubricant, 1 part UV absorber, 1 part organic Amine phenolic thermal oxygen stabilizer, 0.0049 parts of 10000 mesh superfine titanium dioxide, 0.0032 parts of azo condensation type Yellow3G yellow, 0.0040 parts of monoazo orange, 0.002 parts of organic silicon light diffusion agent.

[0028] The preparation method is the same as in Example 1, and will not be repeated. Finally, the obtained material is dried in a blower drying oven at 90° C. for 1 to 2 hours, and then injection molded to prepare test samples and products.

Embodiment 3

[0030] This example is roughly the same as Example 1, and the difference lies in the weight of each component, specifically as follows: 34 parts polypropylene PP, 10 parts POE, 6 parts maleic anhydride grafted PP, 40 parts chopped glass fiber (long : 3~4.5mm; diameter: 8~15μm), 0.6 part hindered phenolic antioxidant, 0.6 part phosphite synergistic antioxidant, 0.8 part silicone lubricant, 2 part UV absorber, 2 part organic Amine phenolic thermal oxygen stabilizer, 0.0049 parts of 10000 mesh superfine titanium dioxide, 0.0032 parts of azo condensation type Yellow3G yellow, 0.0040 parts of monoazo orange, 0.002 parts of organic silicon light diffusion agent.

[0031] The preparation method is the same as in Example 1, and will not be repeated. Finally, the obtained material is dried in a blower drying oven at 90° C. for 1 to 2 hours, and then injection molded to prepare test samples and products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com