Patents

Literature

55results about How to "Little change in chromatic aberration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal salt-free sealing agent for aluminum alloy anodic oxide film

ActiveCN101864589AImprove corrosion resistanceGood gloss and color retentionSurface reaction electrolytic coatingCobaltOrganic compound

The invention provides a metal salt-free sealing agent for an aluminum alloy anodic oxide film, belonging to the technical field of aluminum alloy anodic oxide film post treatment. The sealing agent of the invention is prepared by water solution composed of 1.0-10g / L of a hydration accelerator, 0.01-2g / L of a wetting agent, 0.01-3g / L of an ash inhibitor and 1-15g / L of a pH buffering agent, wherein the pH of workpiece fluid is 5.5-6.5, the operating temperature is 70-90 DEG C, and the sealing speed is 1.0-2.0min / um. The metal salt-free sealing agent creatively adopts organic compounds which are easily subject to biodegradation, does not contain any metal ions of nickel, cobalt, magnesium, calcium, lithium and the like as well as fluorinions, and obtains satisfactory sealing effect of the nano-pores of the aluminum alloy anodic oxide film by virtue of the scientific and coordinated component formula of the water solution; the aluminum alloy anodic oxide film obtained by seal treatment through the sealing agent has the advantages of good corrosion resistance, capability of meeting the requirements of GB 14952.1-94, good light-protection and color-protection properties of a film layer, no ash and pruina, no water stain after drying as well as light flowing color and small color difference change in case of sealing the organic dyeing film; and the metal salt-free sealing agent is widely applicable to sealing treatment of an original-color anodic oxide film, an electrolytic coloring anodic oxide film, a hard oxide film and a dyeing anodic oxide film.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

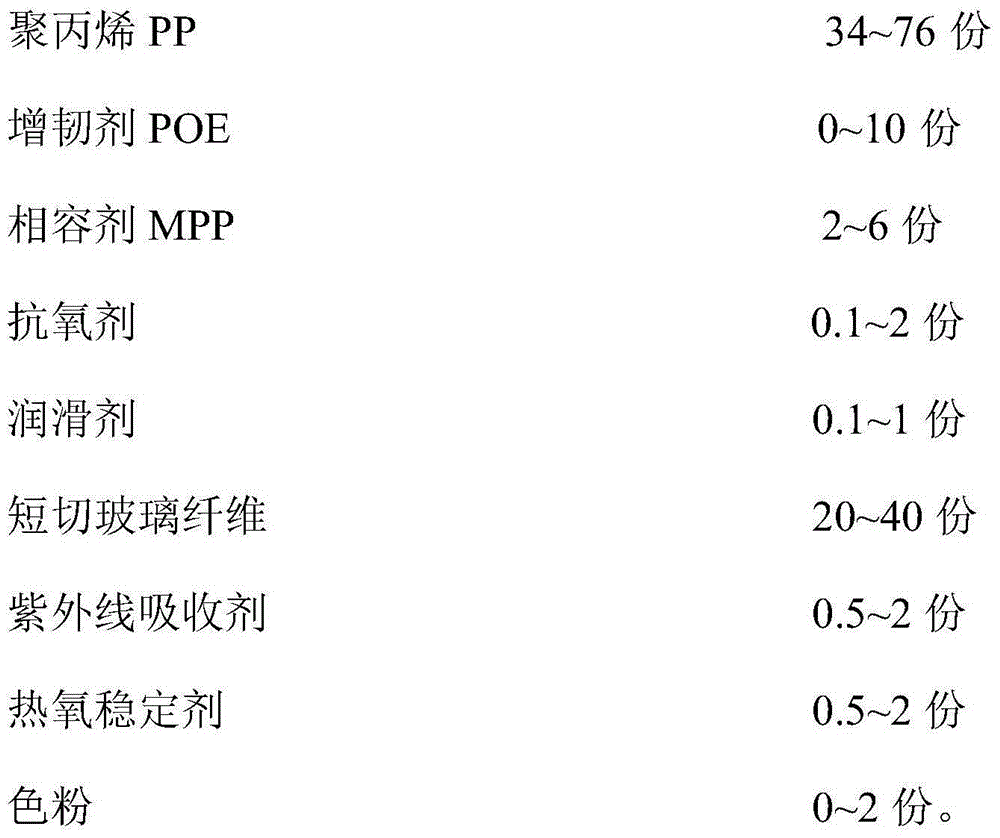

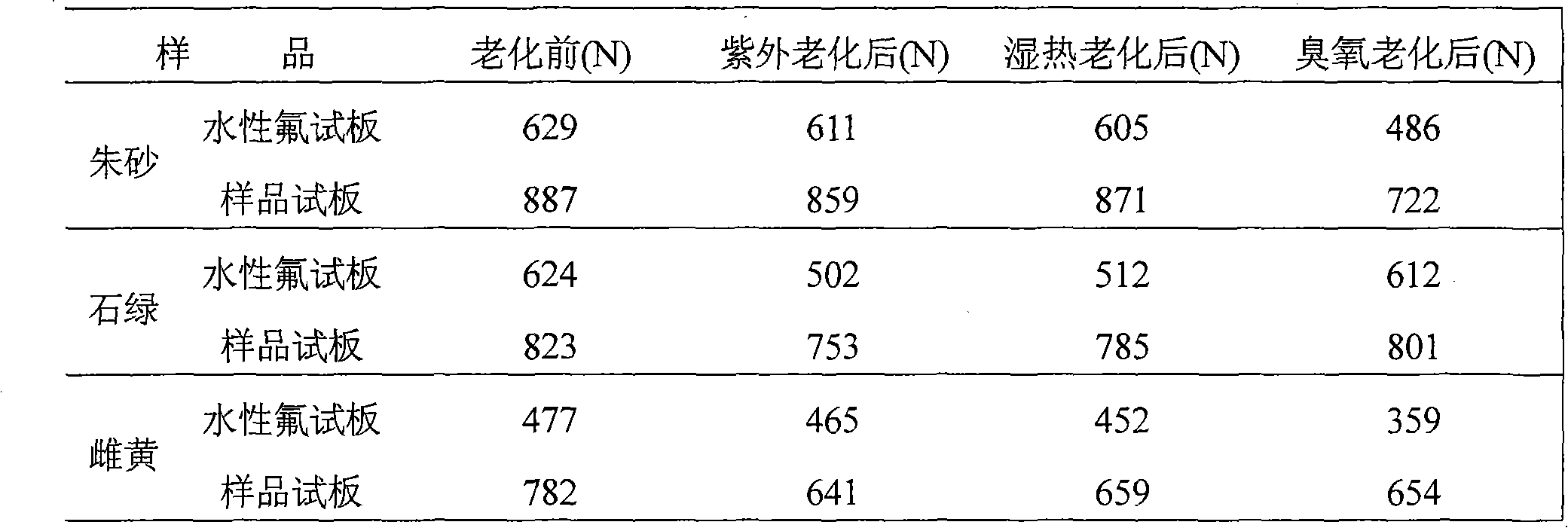

High-weather-resistant anti-aging glass fiber reinforced polypropylene material and preparation method thereof

The invention discloses a high-weather-resistant anti-aging glass fiber reinforced polypropylene material. Through the synergistic action of such components of the material as polypropylene (PP), a chopped glass fiber, a compatible flexibilizer, an anti-oxidant, a lubricant, a coupling agent, one or more ultraviolet light absorbers, a thermo-oxidative stabilizer and one or more toners, as well as reasonable selection of specific components in parts by weight, changes in the color difference of color glass fiber reinforced PP can be greatly reduced under the light-heat aging condition, and the mechanical property retention rate can be high; when the material is applied to automobile parts, household appliances and other products, the problems that the product properties are degraded and the product colors are changed due to long-term exposure of such products in the open air or a high-temperature environment can be effectively solved. The invention further discloses a preparation method of the material. The preparation method is simple to operate, low in cost and high in production benefit; the material obtained according to the preparation method is high in mechanical property, retention rate and color stability, and very suitable for industrialized production; through the preparation method, not only can the service life of the material be prolonged, but also environmental pollution can be reduced.

Owner:NANJING LIHUA ENG PLASTIC

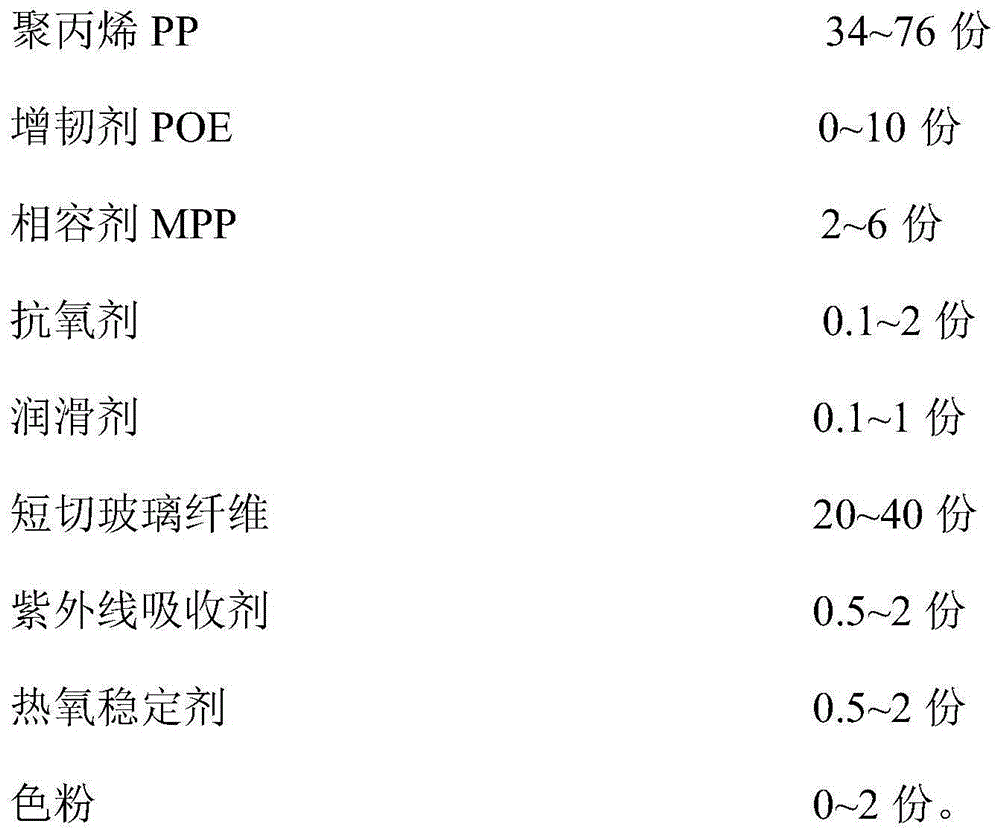

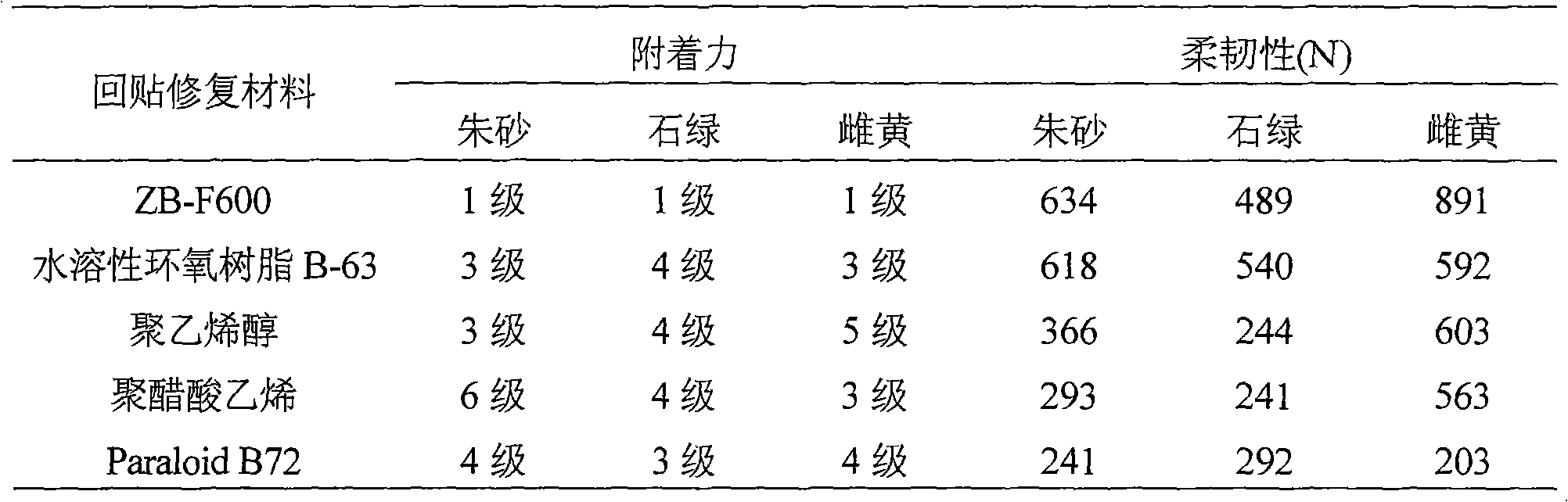

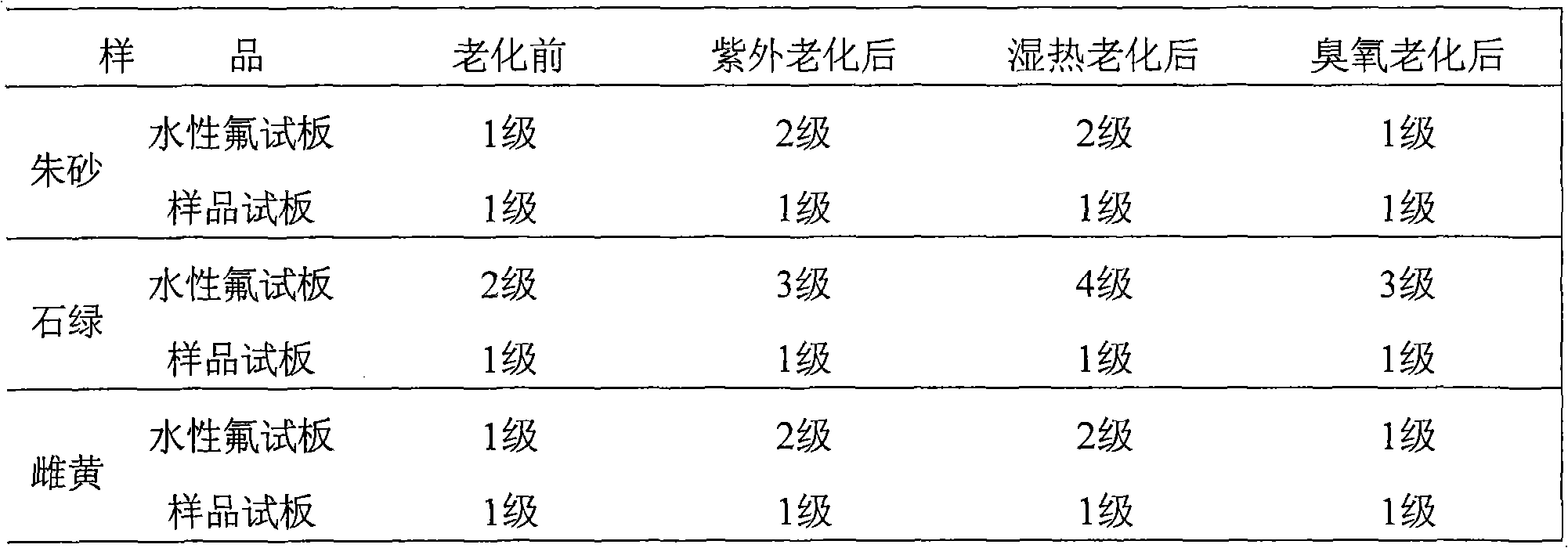

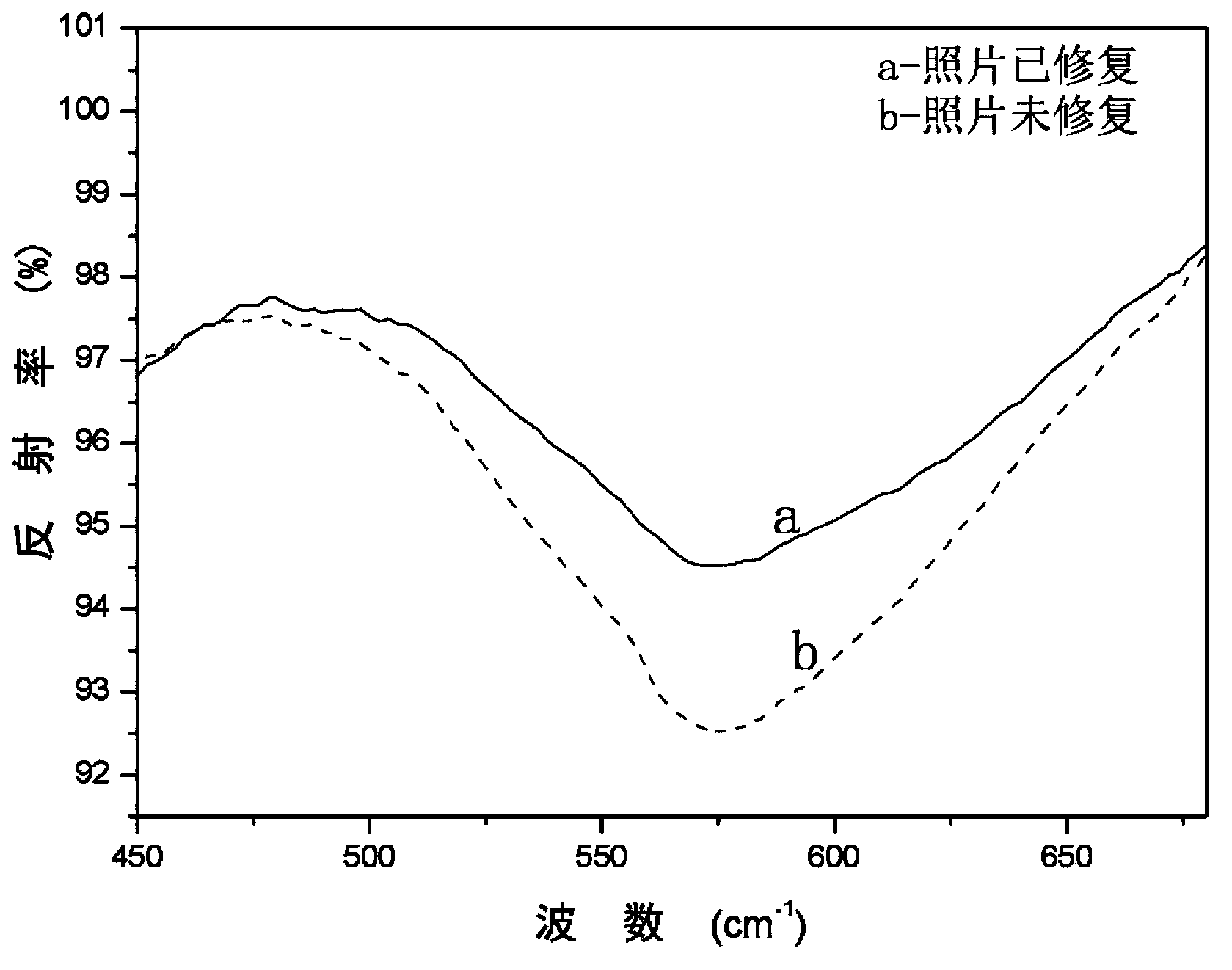

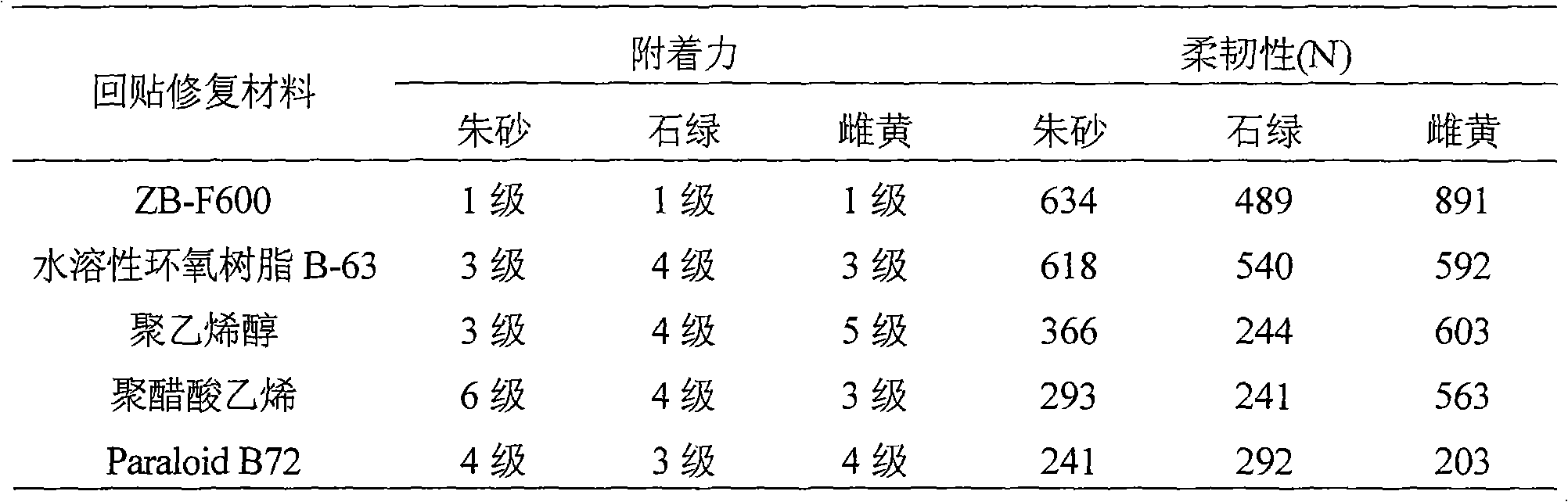

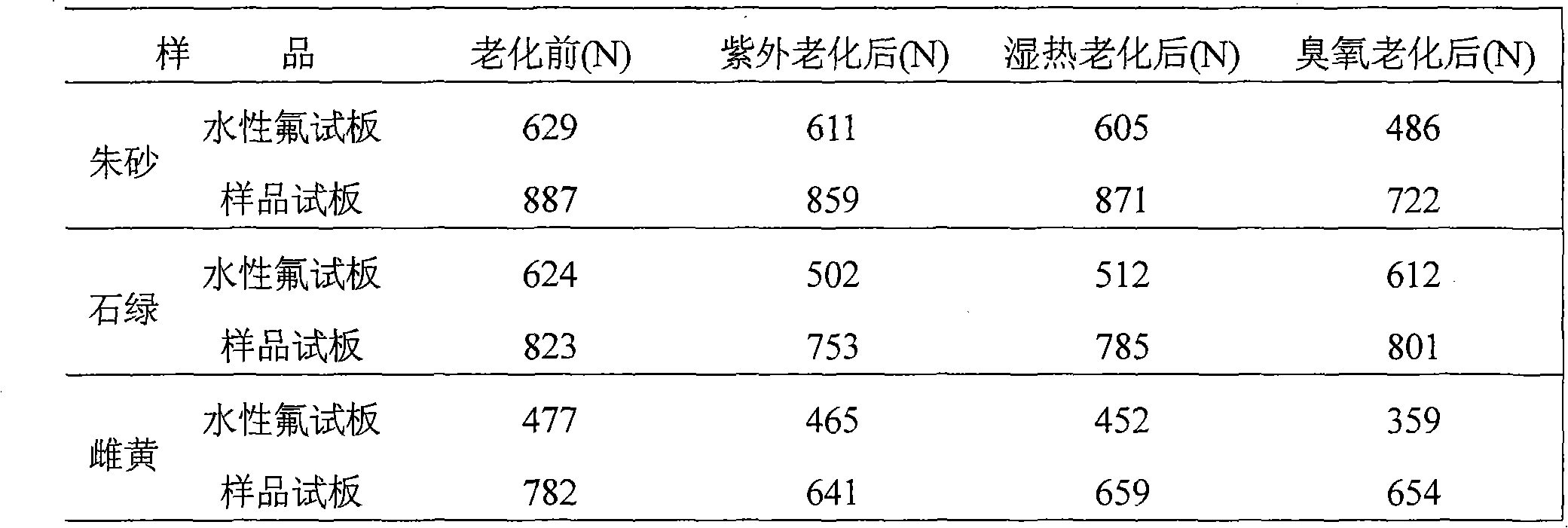

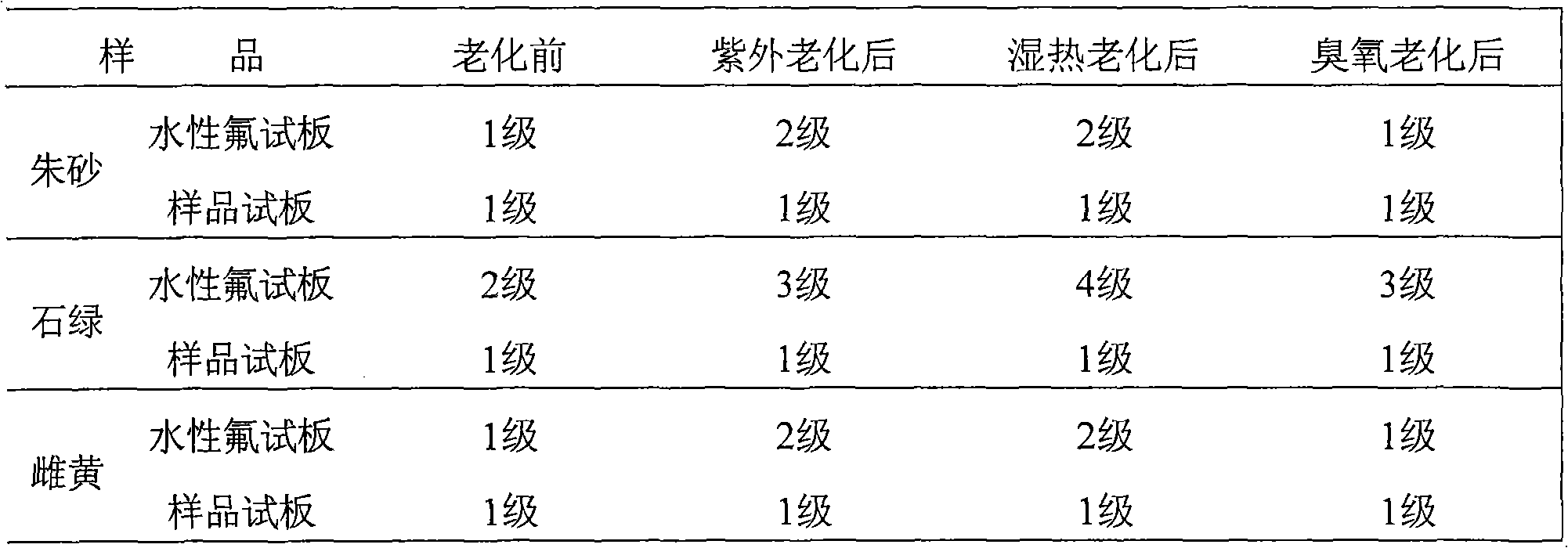

Sizing color painting reattachment restoration agent for ceramic relics

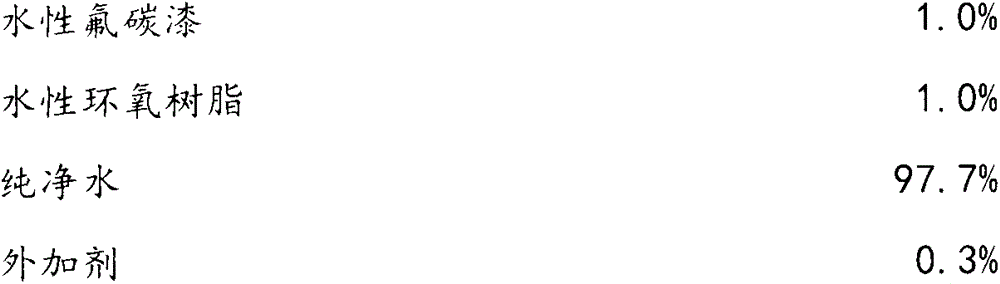

The invention relates to a sizing color painting reattachment restoration agent for ceramic relics, which is prepared from 9% to 35% of ZB-F600 dual FEVE waterborne fluorocarbon resin, 1% to 5% of water-soluble epoxy resin and 60% to 90% of water. After being restored by the agent, a sample test panel has good flexibility, strong adhesion force and little color difference change. After being tested by ultraviolet aging, hygrothermal aging and ozone aging tests, the flexibility and the adhesion force can be maintained well, and the color difference change is little, thereby representing that the agent can enhance the bonding strength of the sample test panel, and strengthen the endurance and the capability of resisting external force impact. The attachment restoration agent carries out attachment restoration on the cracked, wrapped and fallen color painting terro-cotta of Western Han Dynasty in Xianyang Museum. After the terro-cotta is restored by the agent, the color paintings are adhered to the terro-cotta, the strength of the color paintings is enhanced, the surface is smooth and the original feature is restored. The color paintings do not generate the phenomena of falling and wrapping after being traced and investigated for four years, and the agent has good restoration effect.

Owner:SHAANXI NORMAL UNIV

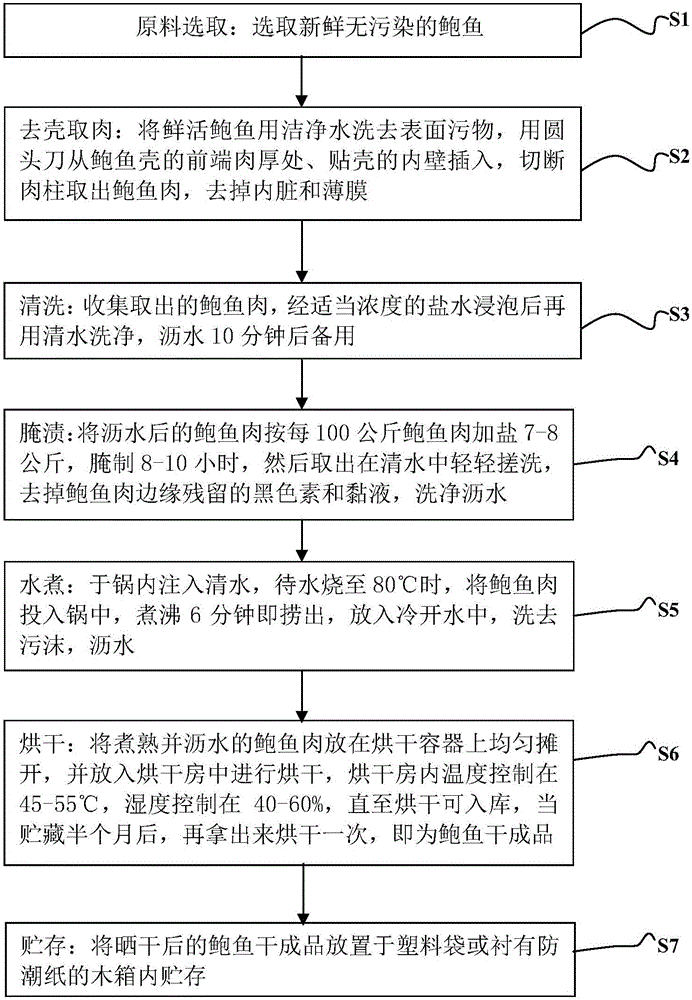

Preparation method for dry abalone

InactiveCN106262034ARetain nutrientsSimple processFood dryingFood ultrasonic treatmentSolar heatHeat pump

The invention discloses a preparation method for dry abalone, relating to the technical field of drying processing of marine products. The method comprises the following steps: selecting raw materials; removing shells to take meat; cleaning; pickling; cooking with water; drying; and storing, thereby acquiring the end product. According to the preparation method for dry abalone, the operation is simple; the special fresh fragrance of the abalone is maintained and the abalone drying efficiency and the abalone drying quality are improved. According to the preparation method, the ultrasonic and solar-heat pump combined drying modes are combined, the respective functions and advantages are utilized in sections and the method has a great significance in increasing the abalone drying efficiency and abalone drying quality and saving cost.

Owner:PUTIAN HUILONG SEAFOOD

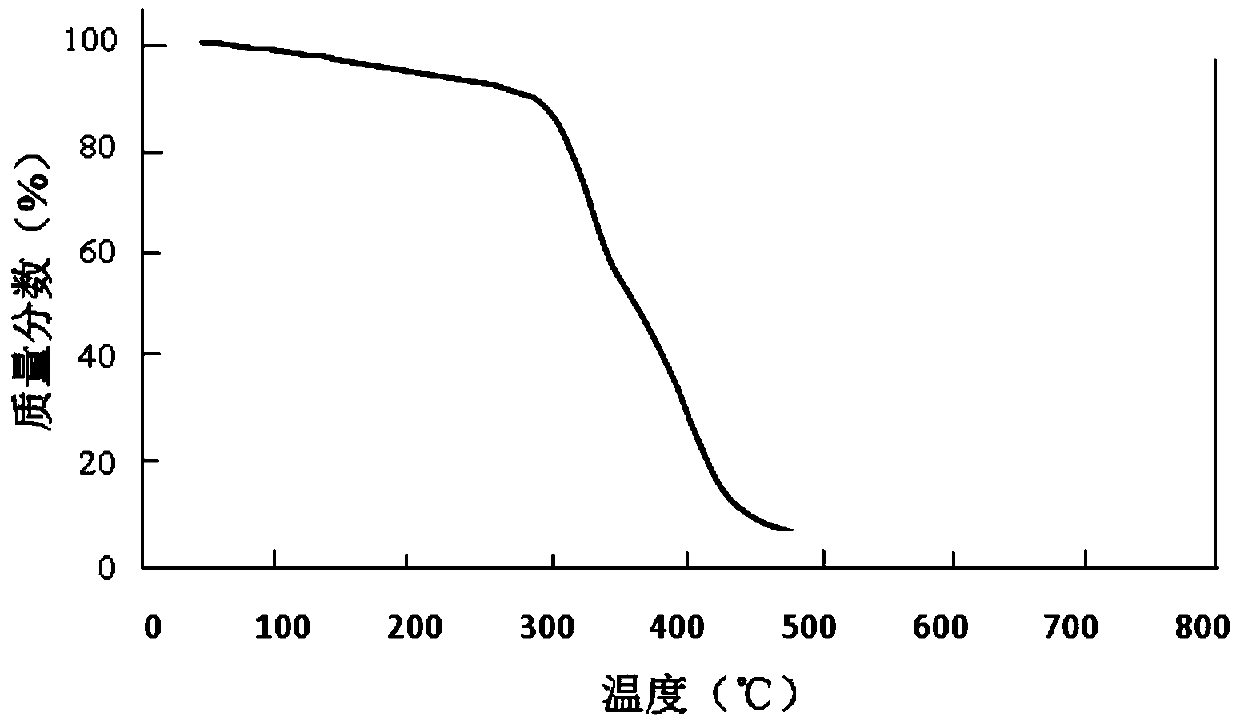

Preparation method of aluminum iron oxide red ceramic pigment

The invention discloses a preparation method of an aluminum iron oxide red ceramic pigment. The method comprises the following steps: putting a mixture of 70% to 80% of calcined aluminum hydroxide, 20 to 30% of ferric oxide and a sodium salt as a mineralization agent by weight percent into a ball miller in a crossing manner to carry out a ball-milling treatment for 25 to 40 hours, wherein the adding amount of the sodium salt accounts for 1% to 5% of the total weight of calcined aluminum hydroxide and ferric oxide, and high-aluminum balls are adopted as ball-milling materials; calcining the material mixture in a kiln at the high temperature of 1050 to 1100 DEG C for 6 to 15 hours; and finally crushing the obtained material to reach the granularity of less than 50 mu m. According to the method, the price of the raw materials is low, so that the cost is saved; and on the premise that the calcining temperature for aluminum iron oxide red in the body kiln reaches 1250 DEG C, the produced architectural ceramic is less in color aberration change, good in stability and bright in forming color, thereby commendably satisfying the aesthetic requirements of people in daily life.

Owner:石家庄高砂新材料有限公司

Reinforcing agent for crisp powder ceramic painted cultural relic

InactiveCN103992729AGood sealingGood flexibilityPolyurea/polyurethane coatingsEpoxy resin coatingsDistilled waterWater soluble

The invention discloses a reinforcing agent for a crisp powder ceramic painted cultural relic. The reinforcing agent comprises, by mass, 6.0%-10.0% of ADM-Z719 waterborne polyurethane resin, 0.3%-1.0% of ZB-F600 bi-component FEVE waterborne fluroresin, 1.0%-3.0% of water soluble epoxy resin B-63, 1.0%-3.0% of C8-10 fatty alcohol-polyoxyethylene ether JFC-6, 2.0%-5.0% of ethanol, 10.0%-20.0% of distilled water, and 65.0%-75.0% methanol. The reinforcing agent provided by the invention has good thermal stability, not only can reinforce the painted layer of the ceramic painted cultural relic, but also can reinforce the ceramic tire. The reinforced painted layer has a primitively simple appearance, small color difference change, strong water resistance, and simple implementation process, significant strengthening effect, so that it can be used for reinforcing a crisp powder pottery crisp powder layer and makes good basis preparation for subsequent desalination.

Owner:SHAANXI NORMAL UNIV

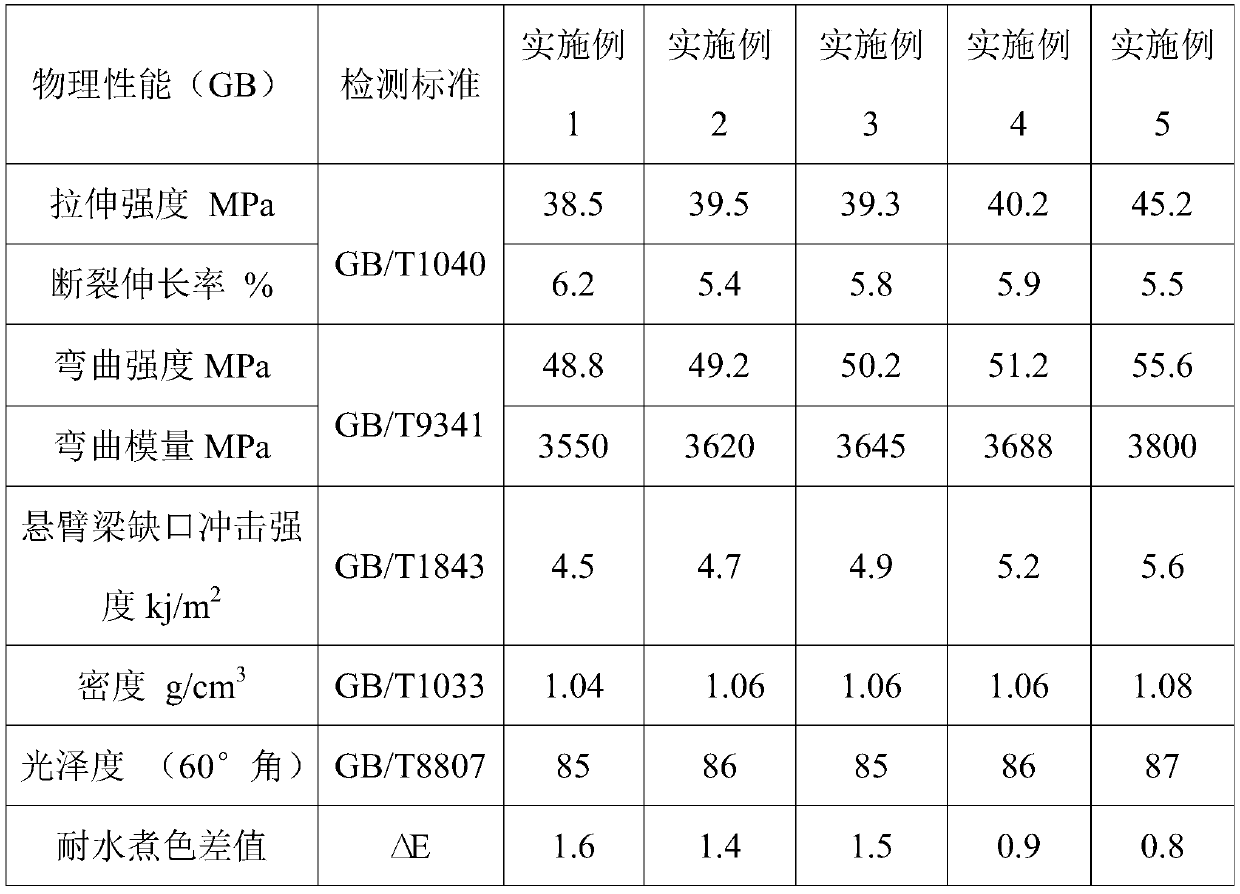

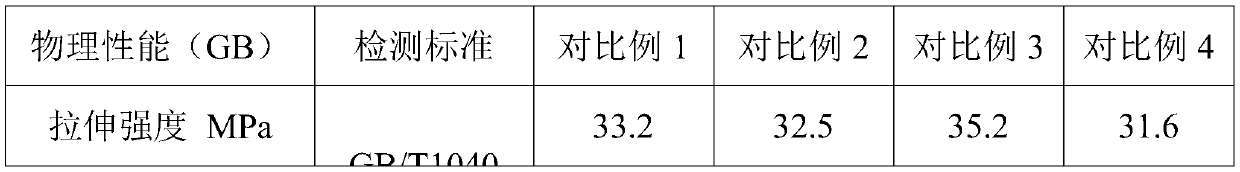

ABS material and preparation method and application thereof

The invention relates to an ABS material and a preparation method and application thereof. The ABS material comprises the following components in parts by weight: 50-200 parts of ABS resin, 1-30 partsof a heat-resistant modifier, 0.01-5 parts of an antibacterial agent, 0.1-5 parts of an anti-UV agent, 0.1-5 parts of a brightener and 1.4-40 parts of an assistant. The ABS material with excellent antibacterial property, heat resistance, UV resistance, mechanical properties and glossiness can be obtained by adopting an ABS resin, heat-resistant modifier, antibacterial agent, anti-UV agent and brightener blending system and combining the ABS resin, the heat-resistant modifier, the antibacterial agent, the anti-UV agent and the brightener in a specific ratio, and can be used in high-temperatureand high-humidity environments and occasions with antibacterial and anti-UV requirements.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

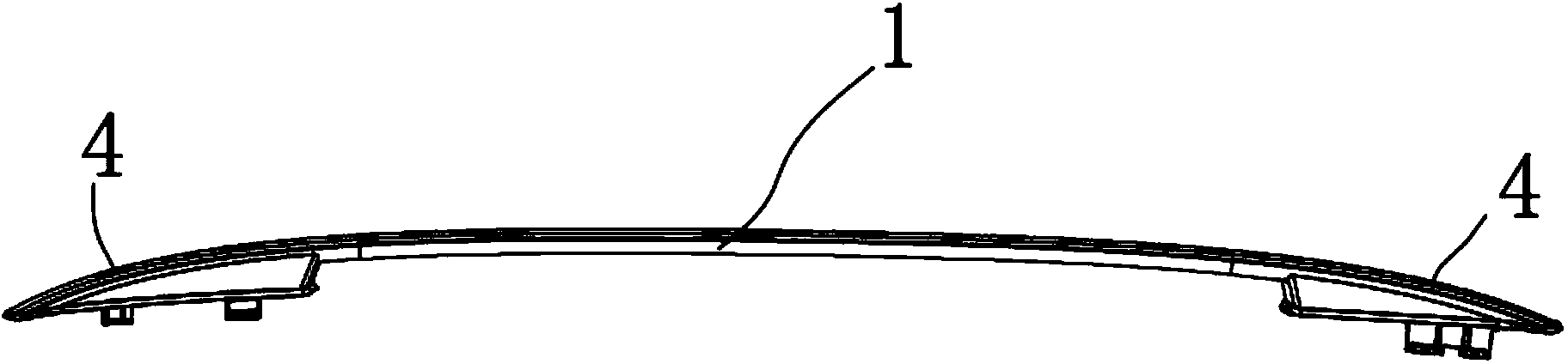

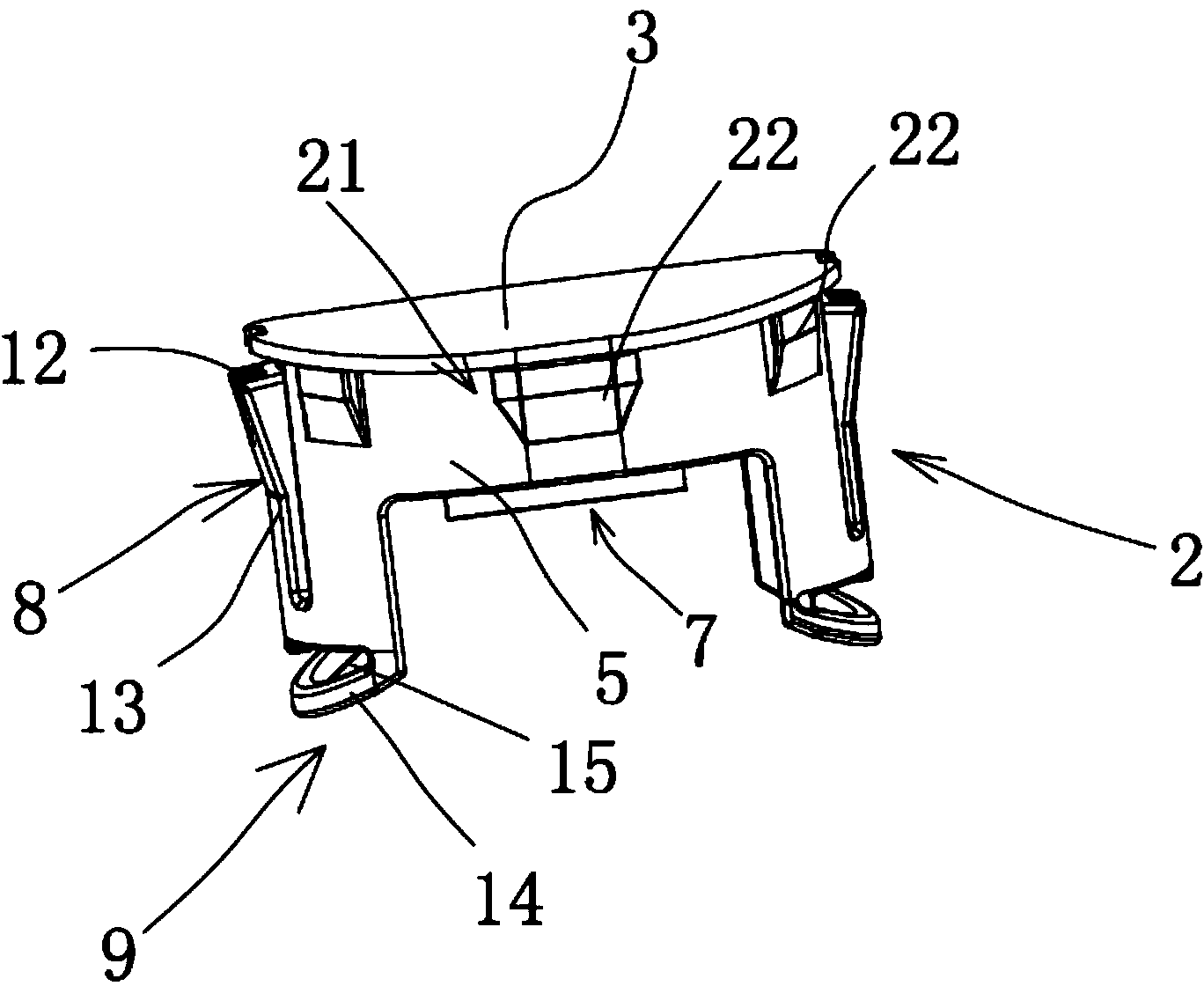

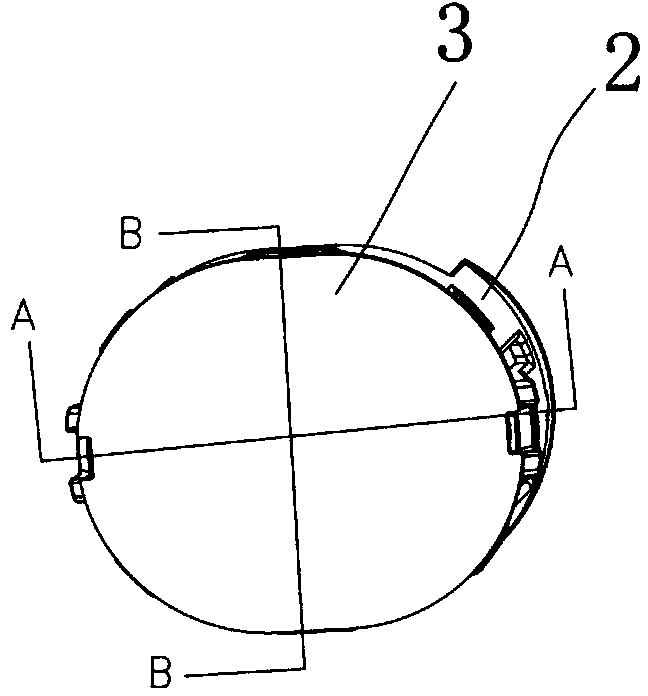

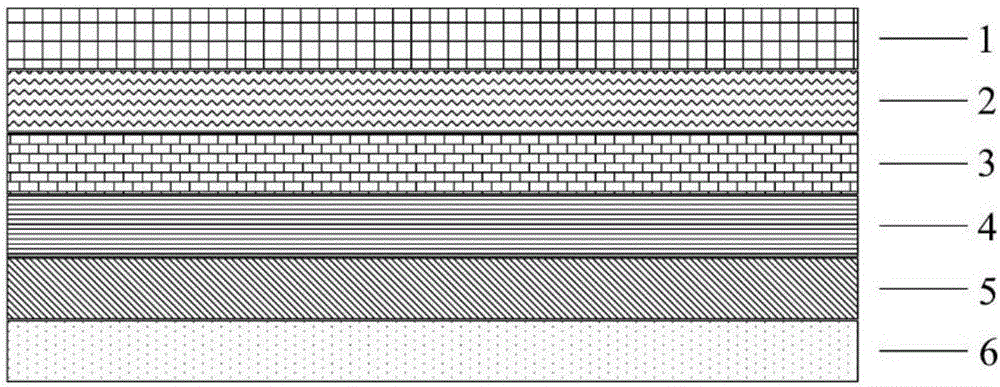

Covering device for aluminum tube installing hole of automobile roof rack

InactiveCN103707816ALittle change in chromatic aberrationSimple structureSupplementary fittingsEngineeringChromatic aberration

The invention belongs to the technical field of automobile spare parts, and provides a covering device for an aluminum tube installing hole of an automobile roof rack. The covering device is arranged in the aluminum tube installing hole of the roof rack and comprises a plastic supporting part and a metal covering piece which are assembled together, and the plastic supporting part comprises the following components: a body part, a surface attaching part, a covering piece clamping-connection part, an elastic piece part and an elastic foot. The covering device for the aluminum tube installing hole of the automobile roof rack has the advantages of being simple in structure and convenient to use and install, the split structure is adopted, the metal coveting piece is assembled in the aluminum tube installing hole through the plastic supporting part, and the metal covering piece is made of the same material and manufactured through the same anode technology as an aluminum tube body, so that chromatic aberration on the installing hole is small in change, and beauty of overall appearance is ensured.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

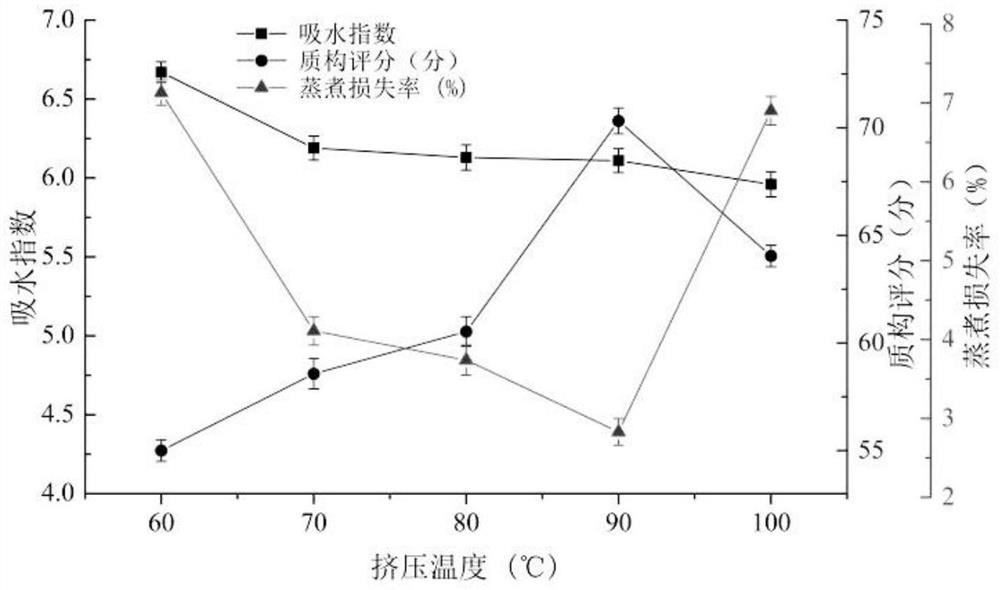

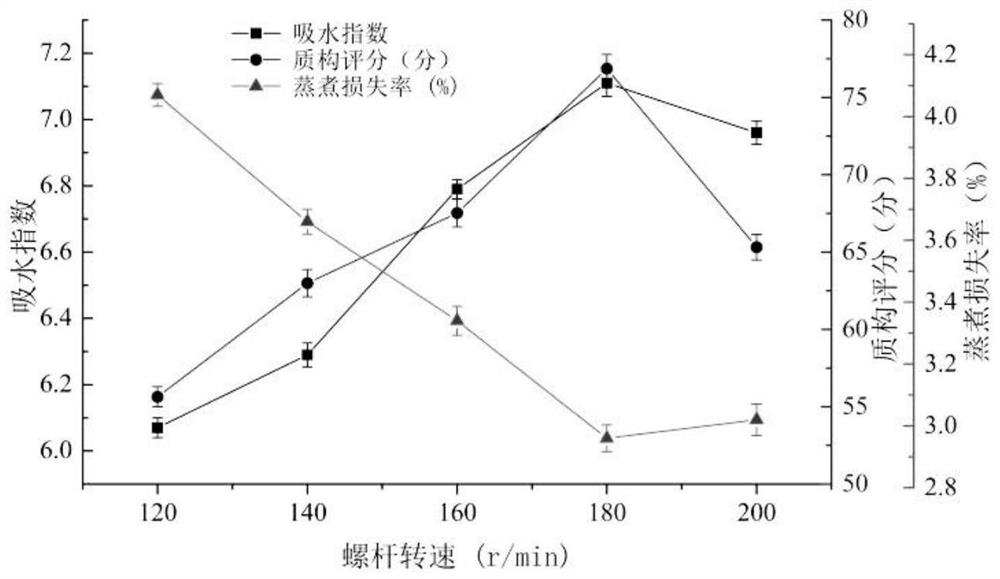

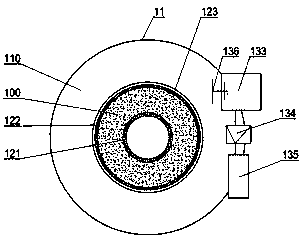

Preparation method of selenium-rich and zinc-rich whole-grain recombinant rice

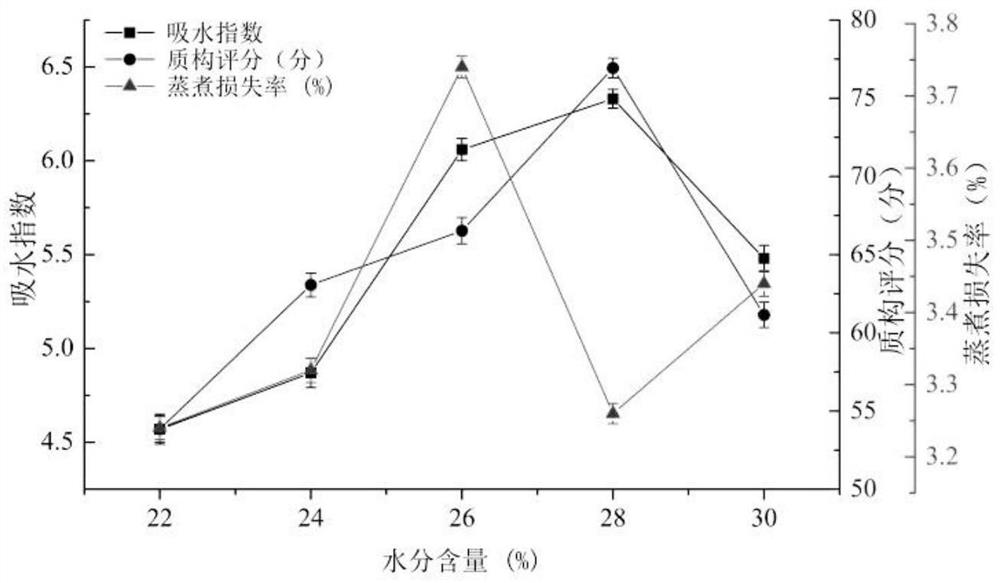

PendingCN114468225ASmall color changeLittle change in chromatic aberrationFood ingredientsBiotechnologyDigestion

The invention relates to the technical field of food processing, in particular to a preparation method of selenium-rich and zinc-rich whole grain recombinant rice, and the preparation method specifically comprises the steps of crushing and sieving, mixing and tempering, extrusion forming, drying and the like. According to the method, the cooking loss rate, the water absorption index and the texture score are taken as measurement indexes, and the influence of the moisture content, the screw rotating speed, the extrusion temperature and the number of raw material meshes on the recombinant rice is researched. Results show that when the moisture content is 28%, the screw rotating speed is 180r / min, the extrusion temperature is 92 DEG C and the mesh number of the raw materials is 80, the SZER has a high comprehensive score, and the selenium content and the zinc content are 193.03 + / -10.98 mu g / kg and 21.53 + / -0.31 mg / kg respectively. Meanwhile, the physical and chemical properties and structure of the SZER, the quality characteristics and digestion characteristics of the SZER and the storage stability of the SZER are researched and analyzed.

Owner:HARBIN UNIV OF COMMERCE

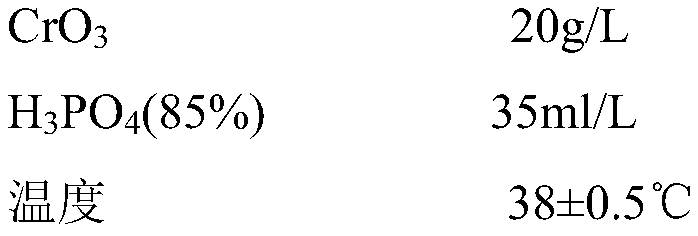

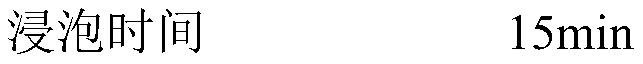

Aluminum alloyanode oxide film hole sealing agent and hole sealing method thereof

The invention provides an aluminum alloy anode oxide film hole sealing agent and a hole sealing method thereof. The aluminum alloy anode oxide film hole sealing agent is prepared from the components with the following concentration: 5-10 g / L of nickelous acetate, 2-8 g / L of a PH stabilizer, 0.5-5 g / L of a corrosion inhibitor, 0.1-5 g / L of a surface active agent, 10-50 mg / L of an antisludging agent, 0.2-0.8 g / L of a complexing agent, and the balance of deionized water. The aluminum alloy anode oxide film hole sealing agent has the beneficial effects that 1, the hole sealing effect is great, escaped dye is less, the color difference change is small, and the aluminum alloy anode oxide film hole sealing agent can be used for dyeing anode oxide film sealing holes; 2, a hole sealing agent solution is stable, the impurity tolerance ability is strong, it is only needed that the content of the nickelous acetate is analyzed everyday, medicinal liquid is added according to the proportion, and thePH value of the solution is monitored periodically; 3, the anode oxide film is strong is corrosion resistance after being subjected to hole sealing, and a neutral salt spray test is conducted for 72hours according to the ASTM B-117 standard, and corrosion is avoided on the surface; and 4, the hole sealing effect meets the requirement of GB14952.1-94, and hole sealing ash is avoided on the surface of the oxide film.

Owner:安徽华淮新材料有限公司

Method for preparing colorized imitation metal wiredrawn film through UV transfer process

InactiveCN106240214AStable to boilStable performance in aging resistance testNatural patternsDecorative surface effectsAging resistancePrinting ink

The invention discloses a method for preparing a colorized imitation metal wiredrawn film through a UV transfer process. Specifically, the method comprises the following steps that (a) colorized UV glue is prepared; (b) a UV transferred colorized wiredrawn film is prepared; (c) corona and vacuum aluminizing are conducted; and (d) bottom sealing is conducted. Components are formed into a pointed cone shape in an injection molded mode after high temperature mixing, and a final product is obtained through degreasing and sintering. The UV transferred colorized imitation metal wiredrawn film is free of printing ink printed layers, and no influence is caused to an aluminum coating; the boiling resistance and ageing resistance testing performance are stable, and color difference changes before and after tests are small; and by means of the preparation method, the production process for the imitation metal wiredrawn film is simplified, the cost is lower than that of printing ink, and the method is suitable for large-scale production.

Owner:CHANGZHOU HUAWEI ADVANCED MATERIAL

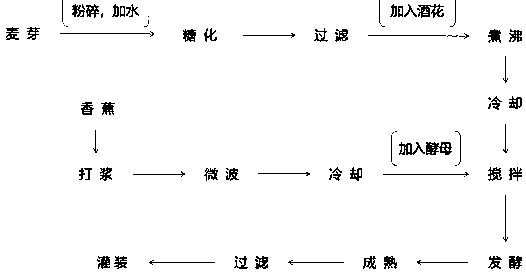

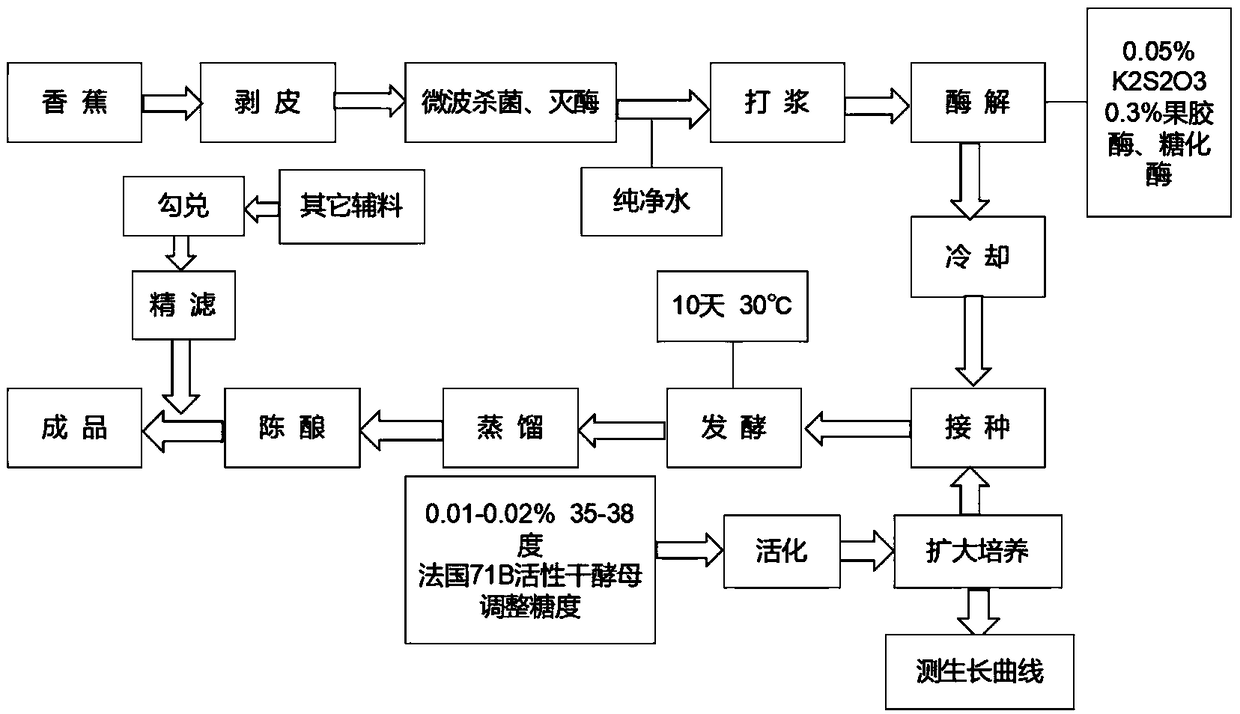

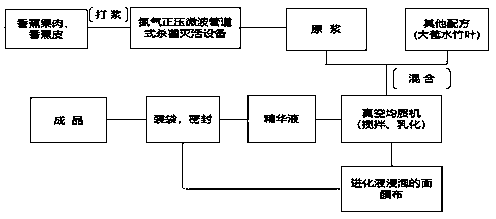

Method for preparing banana beer and beer prepared by method

The invention discloses a method for preparing the banana beer. The process of the method is simple, easy to run, and suitable for large-scale production. The method for preparing the banana beer comprises the steps of weighing and pulverizing malt, adding purified wat, preparing malt crude juice, saccharifying malt crude juice, filtering, and collecting supernatant clear juice to obtain malt clear juice, mixing that supernatant clear juice with the supernatant clear juice, and mixing the supernatant clear juice with the supernatant clear juice to obtain malt clear juice. the malt juice is added into the hops, evenly mixed, boiled, and cooled to the fermentation temperature; (2) removing head and tail and peeling the selected banana to obtain banana pulp; Carrying out coarse beating on banana pulp to obtain coarse banana pulp; The banana coarse pulp is transferred to a nitrogen positive pressure closed pipe microwave treatment device through an airtight pipe for microwave enzyme inactivation treatment, wherein the banana coarse pulp is heated while being stirred and conveyed by a spiral stirrer while being heated by microwave, and is conveyed forward while stirring to obtain the banana coarse pulp treated by microwave enzyme inactivation; 3) adding that banana crude pulp and the malt clear juice into the yeast and fermenting; (4) Mature, canned.

Owner:广西香蕉谷科技有限公司

Red ceramic pigment and preparation method thereof

InactiveCN105419394ANarrow particle size distributionColor stablePigmenting treatmentSodium fluorideDiiron Trioxide

The invention relates to red ceramic pigment and a preparation method thereof and belongs to the technical field of ceramic pigment preparation. The red ceramic pigment is prepared from, by weight, 0.1-0.5 part of ferric oxide, 1-5 parts of chromic nitrate, 1-5 parts of aluminum nitrate, 0.5-1 part of silicon dioxide, 5-10 parts of zinc oxide, 25-35 parts of urea, 0.1-0.5 part of sodium fluoride and 15-20 parts of sodium fluosilicate. The preparation method includes the steps that the raw materials are evenly mixed and stirred to obtain a uniform mixture, and the mixture is fully ground for 2.5-3 hours; the mixture is forged for 5-6 hours at the temperature of 700-750 DEG C; after forging, the powder is added into pure water with the weight 20-25 times that of the powder, stirred for 30-60 min, drained and dried; the dried solid is ground through a ball mill, passes a screen with 300-350 meshes, and the red ceramic pigment is obtained. The ceramic pigment is narrow in particle size distribution, stable in color generation, little in color difference change and good in stability at high temperature. Meanwhile, the production technology is simple in process, equipment requirements are low, and industrial production is easy to achieve.

Owner:赖清甜

Preparation and application of cultural-relic color-painting reinforcing material

InactiveCN104693915AWith dustproofWater resistantLiquid surface applicatorsEpoxy resin coatingsEpoxyEmulsion

The present invention relates to preparation and application of a cultural-relic color-painting reinforcing material. The preparation comprises the following steps: pouring a waterborne fluorocarbon coating with a solid content of 47% and waterborne epoxy resin with the solid content of 20% into pure water in proportion, carrying out constant stirring, and then adding an additive for reaction so as to obtain an ultraviolet-light-absorbing protective glue solution which forms an emulsion. The cultural-relic color-painting reinforcing material of the invention overcomes the defects that the values of the cultural relics are influenced and the like because single usage of conventional color-painting reinforcing materials like an inorganic reinforcing material, an organic reinforcing material and a novel reinforcing material influences the appearance, strength, life and the like of color paintings. The cultural-relic color-painting reinforcing material prepared in the invention has the properties of dust prevention performance, water resistance, acid resistance, strong anti-aging ability, strong adhesive force and appropriate hardness and can reinforce and protect fragile, crisp and loose cultural-relic color-painting layers, so various mechanical strengths and mechanical properties of the color-painting layer bodies are effectively improved.

Owner:NANJING MUSEUM

Method for manufacturing red ceramic pigment of silicoferrite

ActiveCN101318838ALittle change in chromatic aberrationImprove stabilityCeramic colorantsFerrosilicon

The invention discloses a production method for an environmentally friendly, cheap and stable ceramic colorant which is a ferrosilicon red ceramic colorant. The key point of the method is: lanthanum carbonate is introduced into a formulation and is used to effectively and completely enwrap ferric oxide together with silicon dioxide through high-activity lanthana decomposed from the lanthanum carbonate at a temperature of 900 DEG C and the property of having a greater atomic radius of the lanthanum carbonate, thereby enabling the ferric oxide to show stable colors without impacts from ambient surroundings. In addition, the ferrosilicon red ceramic colorant adapted to different temperatures is manufactured through changing the processing conditions.

Owner:肇庆市欧陶新型材料有限公司

Boiling-resistant color-changing polypropylene composite material and preparation method thereof

ActiveCN111187468AImprove mechanical propertiesImprove heat resistancePolypropylene compositesAntioxidant

The invention discloses a boiling-resistant color-changing polypropylene composite material, which is prepared from the following raw materials in parts by weight: 47 to 90 parts of a polypropylene resin, 2 to 15 parts of an acrylonitrile-styrene copolymer, 2 to 10 parts of a compatilizer, 1 to 8 parts of a filler modifier, 5 to 20 parts of a filler, 0.2 to 1.0 part of an antioxidant, 0.2 to 1.0 part of a weather-resistant agent, 0.1 to 2.0 parts of a heat-resistant modifier and 0.5 to 2.0 parts of a lubricant. The invention also discloses a preparation method of the boiling-resistant color-changing polypropylene composite material. Compared with the existing polypropylene composite material, the polypropylene composite material disclosed by the invention has high boiling discoloration resistance, high hardness, high heat resistance and good gloss, can be widely applied to household appliance shell parts such as tableware, electric cookers, electric kettles, induction cookers and the like as daily necessities, and has a wide market application prospect.

Owner:ORINKO NEW MATERIAL CO LTD

Coffee ceramic pigment and preparation method thereof

InactiveCN105399446ANarrow particle size distributionColor stableManufacturing technologySodium fluoride

The invention relates to a coffee ceramic pigment and a preparation method thereof and belongs to the technical field of preparation of ceramic pigments. The coffee ceramic pigment comprises the following components in parts by weight: 0.1-0.3 part of manganese dioxide, 0.3-0.5 part of iron oxide, 0.5-1 part of silicon dioxide, 5-10 parts of zinc oxide, 25-35 parts of urea, 0.1-0.5 part of sodium fluoride and 5-10 parts of sodium fluosilicate. The preparation method comprises the following steps: uniformly mixing and stirring raw materials to obtain a uniform mixture, and then fully grinding the uniform mixture for 1-2 h; calcining the mixture for 8-10 h at 600-650 DEG C; after calcination, adding the calcined powder into purified water which is 30-35 times of the calcined powder in weight, stirring for 30-60 min, filtering out water and drying; grinding a dried solid by a ball mill, and screening with a sieve of 300-350 meshes to obtain the coffee ceramic pigment. The coffee ceramic pigment is narrow in particle size distribution, stable in color generation, small in chromatic difference change, good in stability at high temperature, meanwhile, simple in manufacturing technology and process, low in equipment requirement and easy for realizing industrial production.

Owner:赖清甜

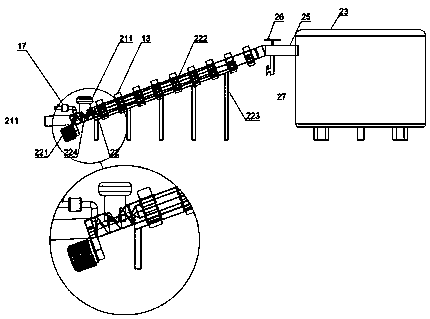

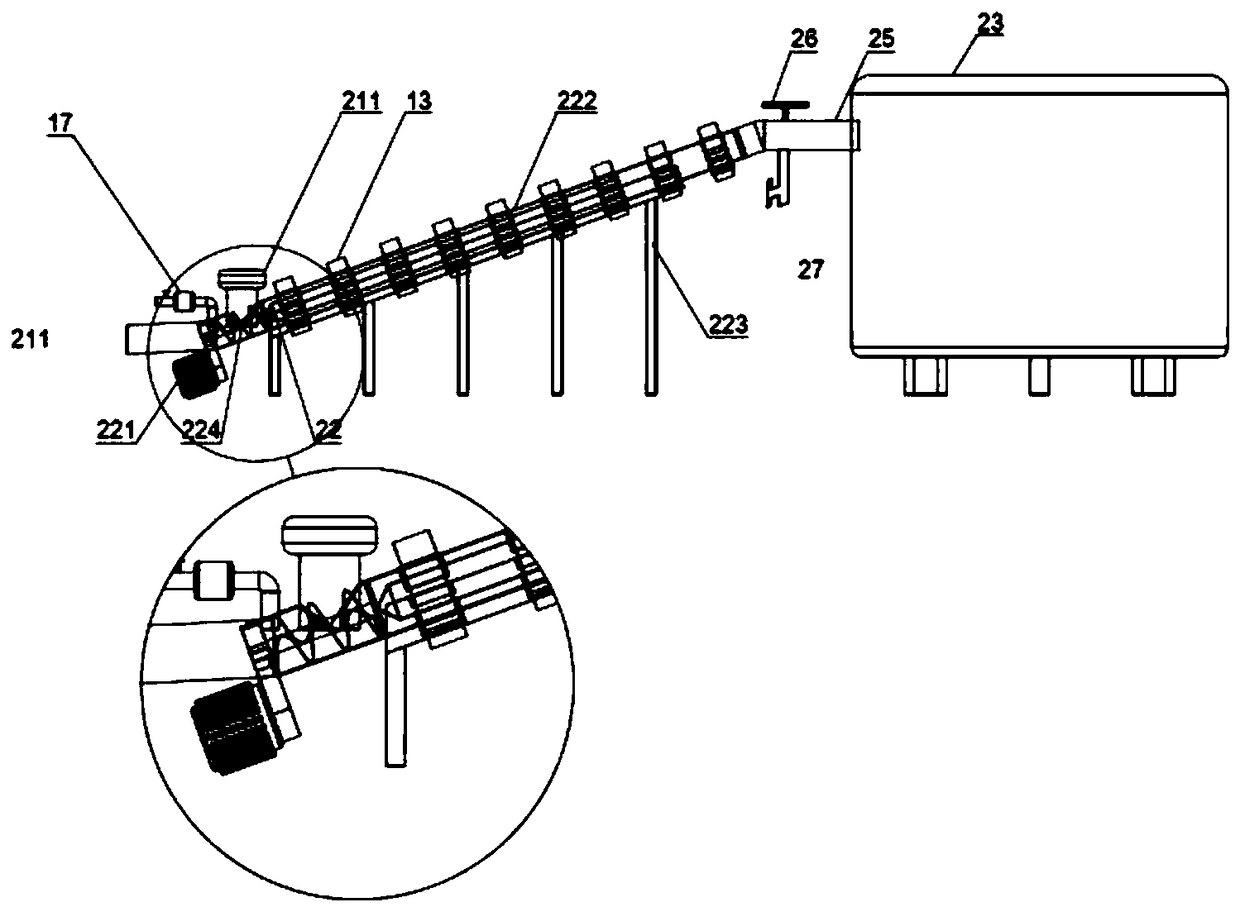

Banana brandy and preparation method thereof

PendingCN108841481AReduce Methanol ContentAddressing the Risk of High MethanolAlcoholic beverage preparationYeastPectinase

The invention discloses a simple and feasible banana brandy production process and aims to solve the problems of fermentation and methanol reduction in case of a high pectin content. The banana brandyproduction method comprises the following steps: cutting off heads and ends of screened bananas, and screening; performing rough pulping on the screened bananas so as to obtain crude banana pulp; conveying the crude banana pulp into a nitrogen positive pressure sealed pipeline type microwave treatment device for microwave enzyme deactivation treatment through a sealed pipeline, and performing stirring and conveying on the crude banana pulp in the microwave treatment device by using a spiral thruster while microwave heating is performed, so as to obtain crude banana pulp after microwave enzymedeactivation treatment; performing enzymolysis on the crude banana pulp after microwave enzyme deactivation treatment with pectinase and glucoamylase, performing rough filtration, and removing dregsso as to obtain banana juice; putting yeast into the banana juice to carry out fermentation, so as to obtain crude banana wine; distilling the crude banana wine, so as to obtain crude banana brandy; aging the crude banana brandy, and blending, thereby obtaining the banana brandy.

Owner:广西香蕉谷科技有限公司

Preparation method of yellow-green pigment for plastic

InactiveCN103483865AGood stabilityLittle change in chromatic aberrationOrganic dyesSodium carboxymethylcelluloseIron oxide

The invention relates to a preparation method of yellow-green pigment for plastic. The preparation method comprises the following steps: (1) putting 12-15 parts of polyoxypropylene glycerol ether into a constant-temperature container, and heating to 55 DEG C; (2) grinding yellow pigment 181 powder and yellow pigment 183 powder into 0.5-1 micron by a grinding miller; (3) orderly adding 3-4 parts of grinded yellow pigment 181 powder and 4-5 parts of grinded yellow pigment 183 powder to the polyoxypropylene glycerol ether, and evenly stirring by a stirrer; (4) adding 7-8 parts of ferric oxide green powder to the constant-temperature container to evenly stir; (5) finally adding 5-7 parts of sodium carboxymethylcellulose to the container, and evenly mixing all ingredients; (6) homogenizing the evenly mixed pigment by a homogenizer, wherein the homogenizing pressure is 20-25 MPa, and the homogenizing time is 20 minutes. The prepared yellow-green pigment can be applied to the plastic, and has excellent color stability.

Owner:苏州冰心文化用品有限公司

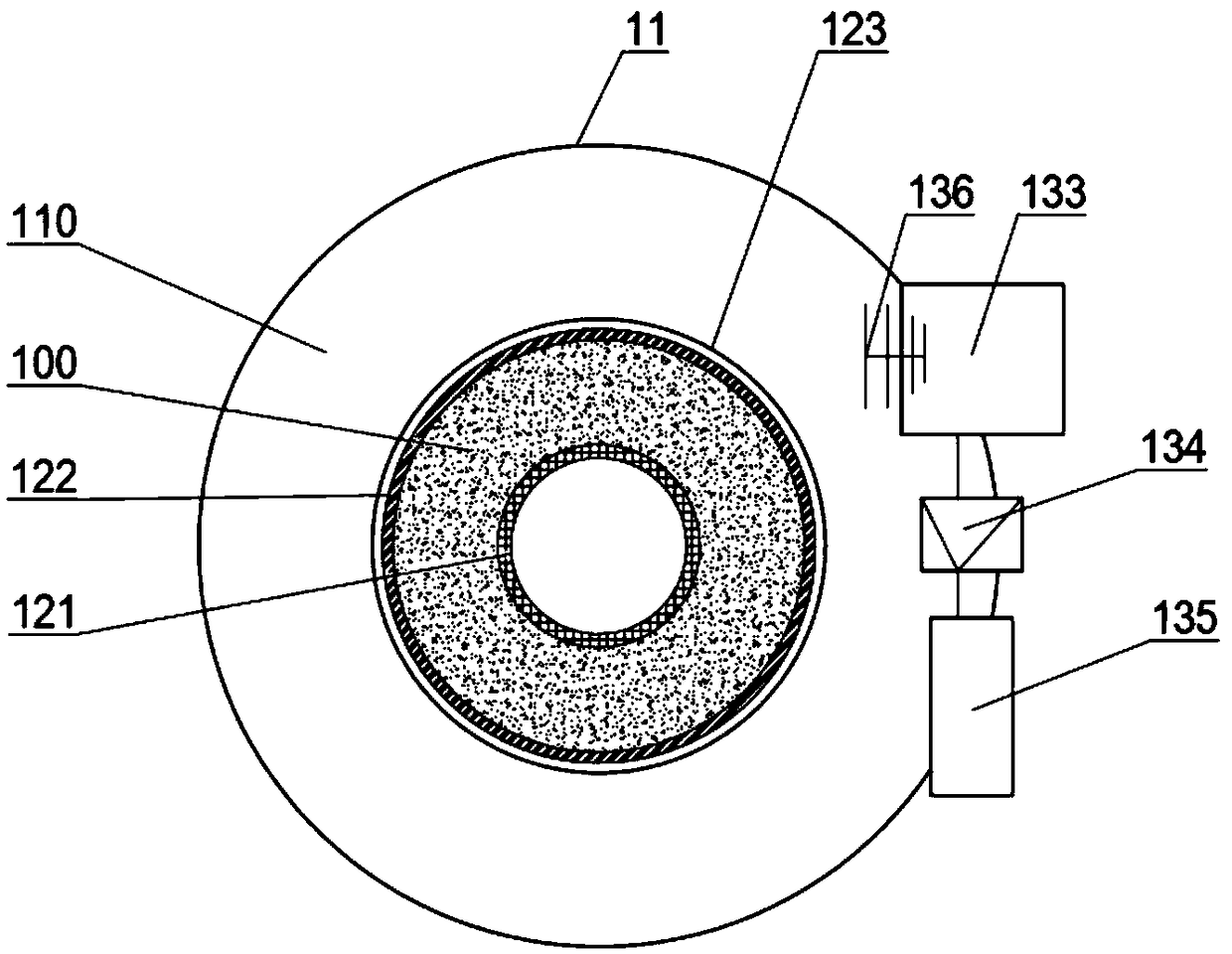

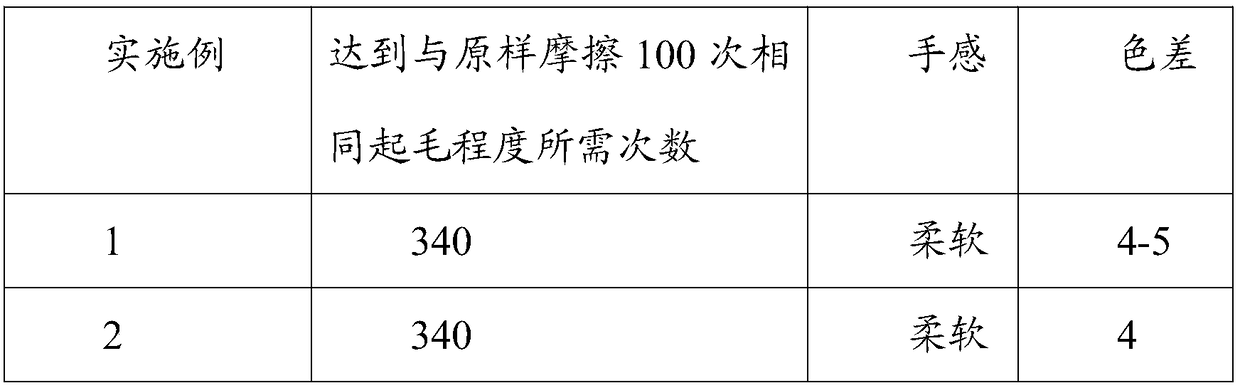

Finishing agent for preventing fluffiness of embroideries and preparation method and utilization method of finishing agent

ActiveCN109440467AImprove controllabilityAnti-pilling effect is obviousAbrasion resistant fibresCross-linkOperability

The invention discloses a finishing agent for preventing fluffiness of embroideries and a preparation method and a utilization method of the finishing agent. The finishing agent is prepared from, by weight, 2-5 parts of polyvinyl alcohol, 2-5 parts of polyacrylic acid, 0.2-0.5 part of cross-linking agent borax, 0.2-0.5 part of a colorless water-soluble penetrating agent, 0.2-0.5 part of a colorless water-soluble softening agent and deionized water added to obtain solution in total parts by weight of 100. The preparation method of the finishing agent for preventing fluffiness of the embroideries includes steps: weighing 2-5 parts by weight of polyvinyl alcohol, swelling in an appropriate amount of deionized water, heating to dissolve to obtain polyvinyl alcohol water solution. The preparation method of the finishing agent for preventing fluffiness of the embroideries is simple, and the utilization method of the finishing agent for preventing fluffiness of the embroideries is convenient,high in operability and controllability and free of pollution. The finishing agent for preventing fluffiness of the embroideries is evident in fluffiness resistance, the embroideries are low in colordifference after processing, and intrinsic color, pattern texture, hierarchical effect and soft handfeel of the embroideries are kept.

Owner:SUZHOU VOCATIONAL UNIV

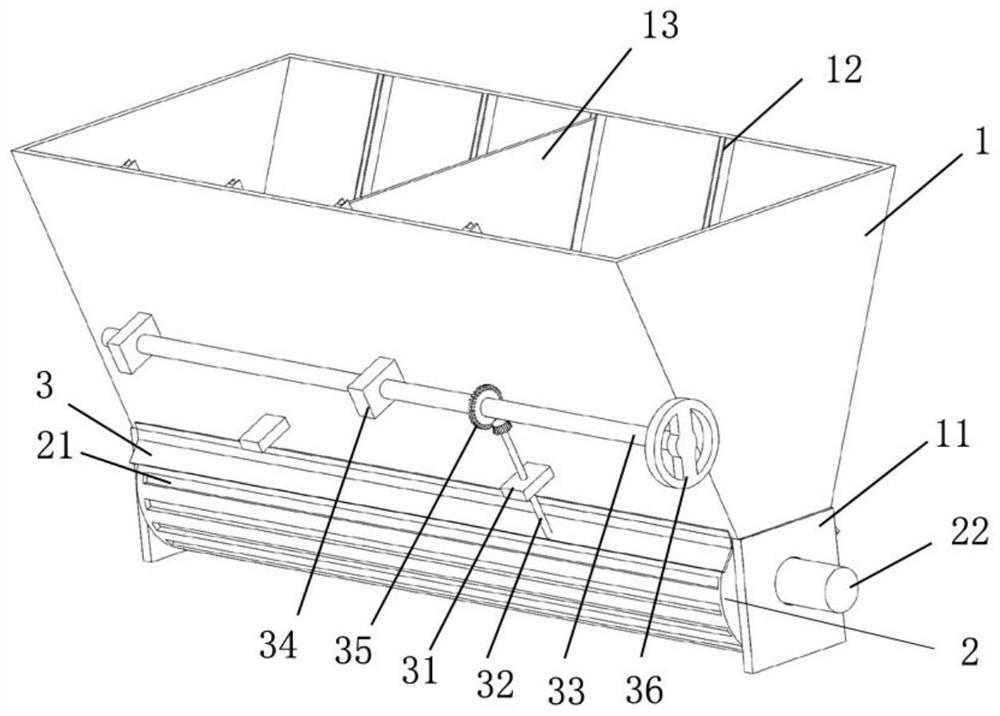

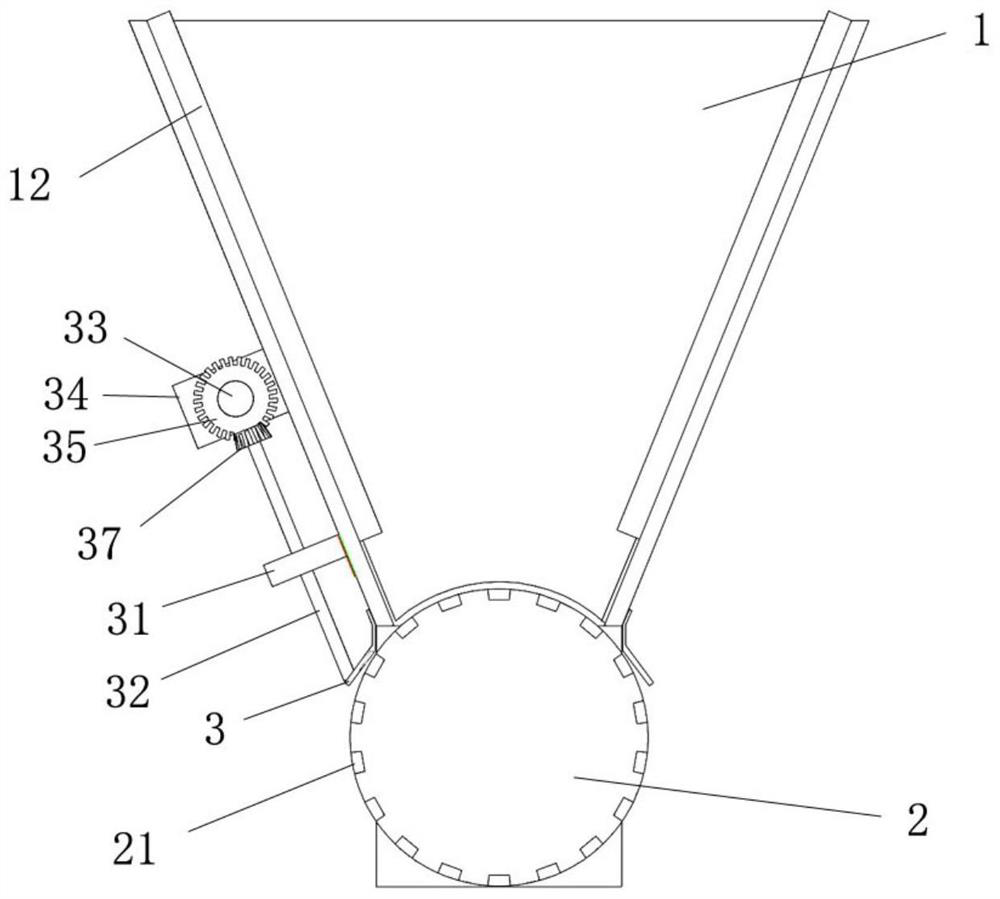

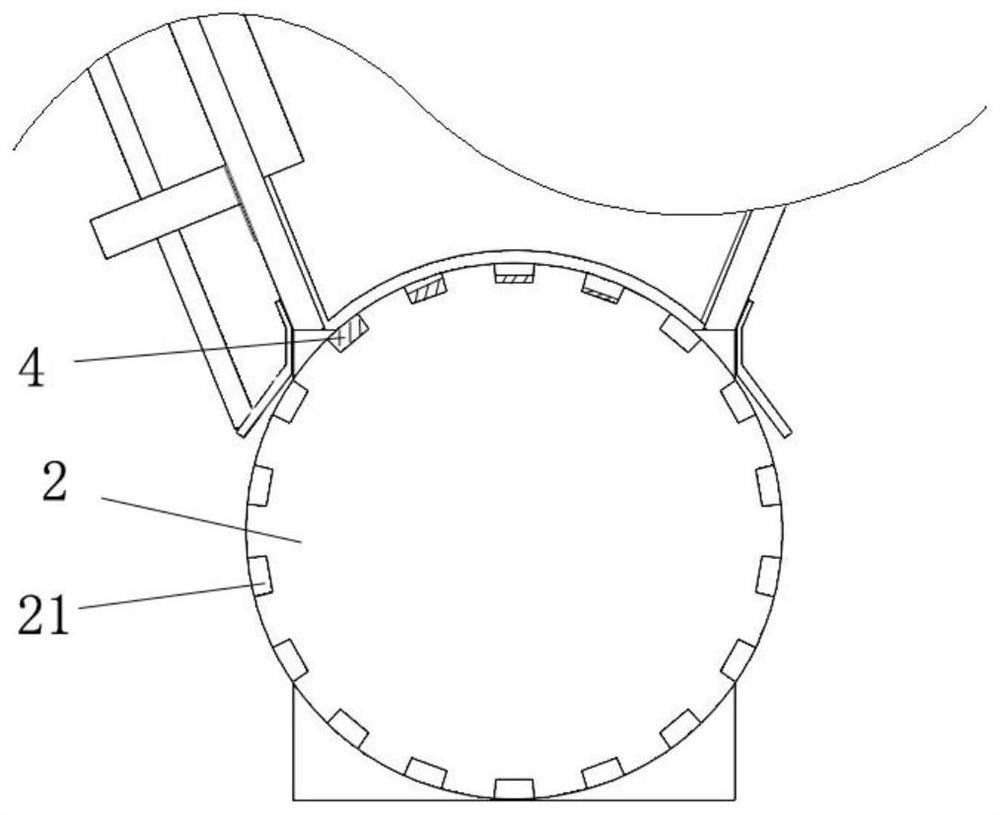

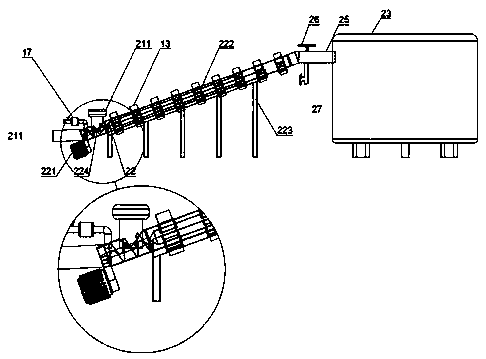

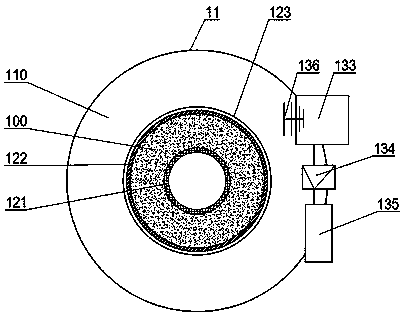

Fiberglass tile sand spreading device

PendingCN111646239ALittle change in chromatic aberrationSimple structureLoading/unloadingSoil scienceMechanical engineering

The invention provides a fiberglass tile sand spreading device which comprises a sand hopper and a spreading roller. A sand outlet is formed in the lower end of the sand hopper, the spreading roller is rotatably mounted below the sand outlet, and at least two sand storage grooves are formed in the outer side wall of the spreading roller, and extend along the axial direction of the spreading roller. The spreading roller rotates anticlockwise, the sand hopper is filled with primary color sand, as the spreading roller rotates, the primary color sand is aggregated on the left side of the sand hopper, as the primary color sand is consumed, the content of the primary color sand in the sand storage grooves is gradually reduced from left to right, then auxiliary color sand is added, the content ofthe auxiliary color sand in the sand storage grooves is gradually increased from left to right, and thus the gradient of the primary color sand and the auxiliary color sand is formed. As the spreading roller rotates, the sand in the sand storage grooves falls from the sand outlet, so that gradient-ramp mixed sand is spread between sand of different colors, the color difference change is reduced,and products are more attractive.

Owner:浙江荣平建材科技有限公司

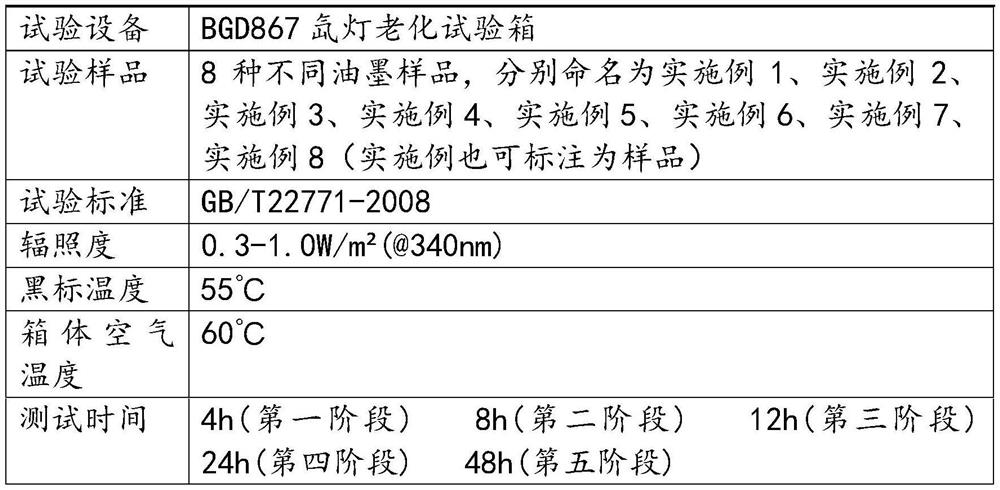

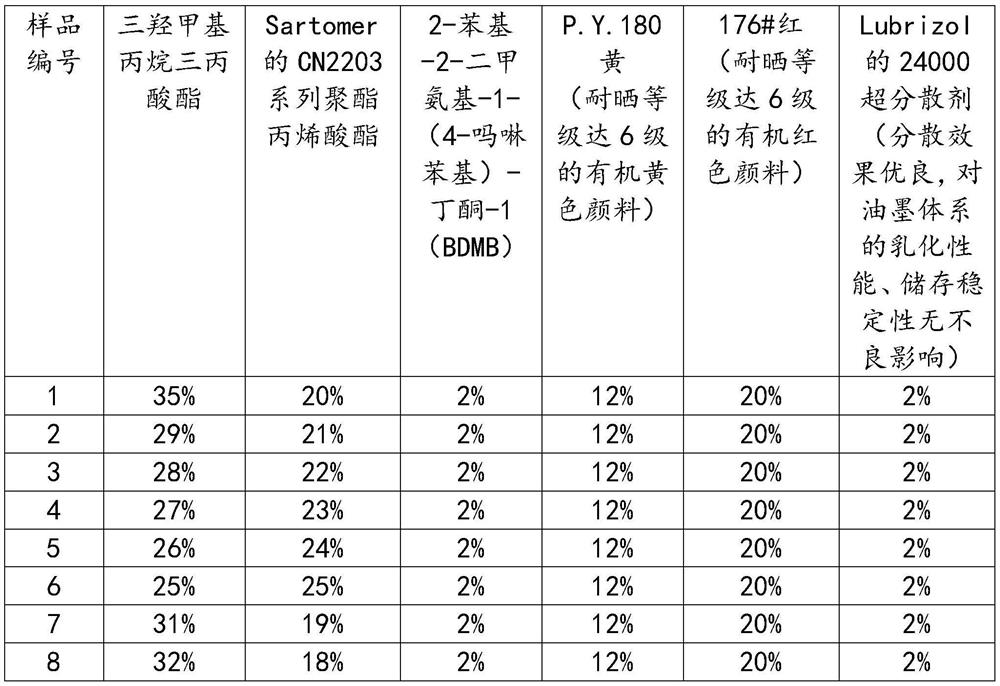

Weather-resistant printing ink, manufacturing method and testing method of weather-resistant printing ink

InactiveCN113214704AImprove visibilityModerate drying speedWeather/light/corrosion resistanceInksPolyesterPolymer science

The invention discloses weather-resistant printing ink, a manufacturing method and a testing method thereof, and the weather-resistant printing ink is mainly prepared from the following raw materials in parts by weight: 40-60 parts of polyacrylate oligomer, 8-15 parts of reactive diluent, 4-10 parts of photoinitiator, 10-15 parts of pigment, 3-6 parts of filler, 1-3 parts of dispersing agent and 1-2 parts of assistant. And the degree of functionality of the polyester acrylate oligomer is between 3 and 7. The higher the functionality of the polyester acrylic acid is, the stronger the reaction activity is, so that the curing speed can be improved, but the too high functionality can cause the increase of the viscosity and the reduction of the flexibility. The printing ink has the advantages of favorable toughness, appropriate drying speed, favorable filler wetting effect, favorable oleophylic-hydrophilic balance and favorable chroma resistance. Through the matching of the components and the manufacturing method, the weather-resistant printing ink has better weather resistance, the color difference change is smaller in different areas and different temperatures, and the distinguishing degree of printed matters is effectively improved.

Owner:东莞智源彩印有限公司

Novel light-resistant and weather-resistant pigment formula for textile

InactiveCN107190531AGood light and weather resistanceImprove light fastnessDyeing processEmulsionButyrate

The invention relates to a novel light-resistant and weather-resistant pigment formula for textile. The novel light-resistant and weather-resistant pigment formula for textile is prepared from the following ingredients in parts by weight: 30 to 90 parts of branch chain acrylic emulsion, 40 to 85 parts of auxiliary agents, 3 to 12 parts of monastral blue, 1.5 to 8 parts of sweet potato starch, 14 to 19 parts of glycerol, 5 to 8 parts of span, 4 to 9 parts of propyl butyrate and 2 to 4 parts of polypropylene glycerol ether. The novel light-resistant and weather-resistant pigment formula has the advantages that blue pigments obtained through the preparation by the formula have good light-resistant and weather-resistant effects; the light-resistant grade can reach grade 6 to 7; good light-resistant color fastness is realized; the high-temperature test and the water spraying test are alternately circulated; after the circulation times of 40 times, the color difference change is very small; a good weather-resistant effect is achieved.

Owner:南通祥升纱业有限公司

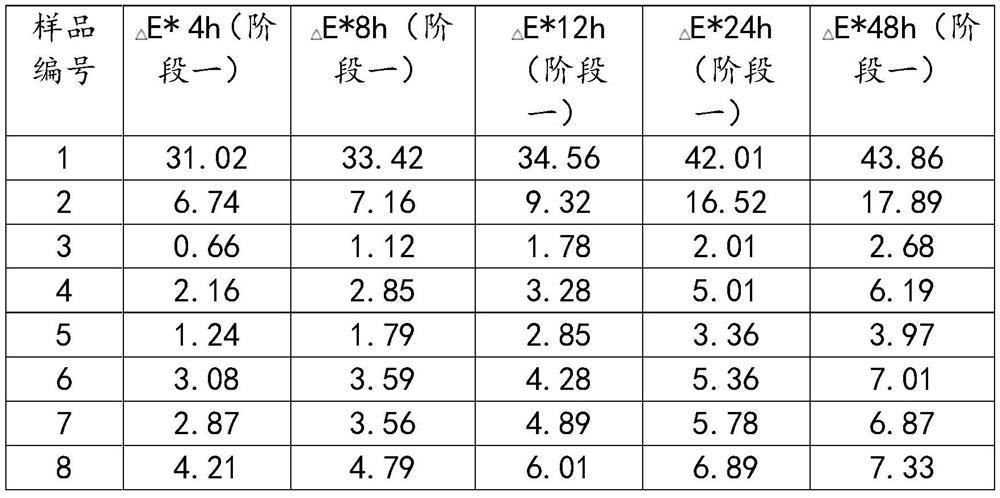

A banana facial mask preparing method and a banana facial mask prepared by the method

PendingCN108938515AColor unchangedFully microwavedCosmetic preparationsToilet preparationsMedicinePositive pressure

The invention discloses a preparing method of a banana beautifying product, particularly a banana facial mask preparing method. The method is simple in process and feasible, and can achieve large-scale industrial production. In particular, the method can overcome a problem that banana facial masks are liable to brown and essence substances are difficult to extract. The banana facial mask preparingmethod includes (1) subjecting screened bananas to head and tail removing and peeling treatment to obtain banana flesh, subjecting the banana flesh to coarse pulping to obtain coarse banana pulp, conveying the coarse banana pulp through a sealed pipeline to a nitrogen positive-pressure sealed pipeline type microwave treatment device, and performing microwave enzyme deactivation in which the coarse banana pulp is subjected to microwave heating while being stirred and conveyed by a screw propeller in the microwave treatment device to obtain coarse banana pulp subjected to microwave enzyme deactivation; (2) subjecting Murdannia bracteata (C. B. Clarke) J. K. Morton ex Hong to three times of extraction with water, and mixing extract liquids; (3) mixing the coarse banana pulp subjected to microwave enzyme deactivation and the extract products of the Murdannia bracteata (C. B. Clarke) J. K. Morton ex Hong into a vacuum homogenizer and performing homogenizing emulsification; (4) preparing anessence liquid; and (5) performing microwave sterilization, bagging and sealing.

Owner:广西香蕉谷科技有限公司

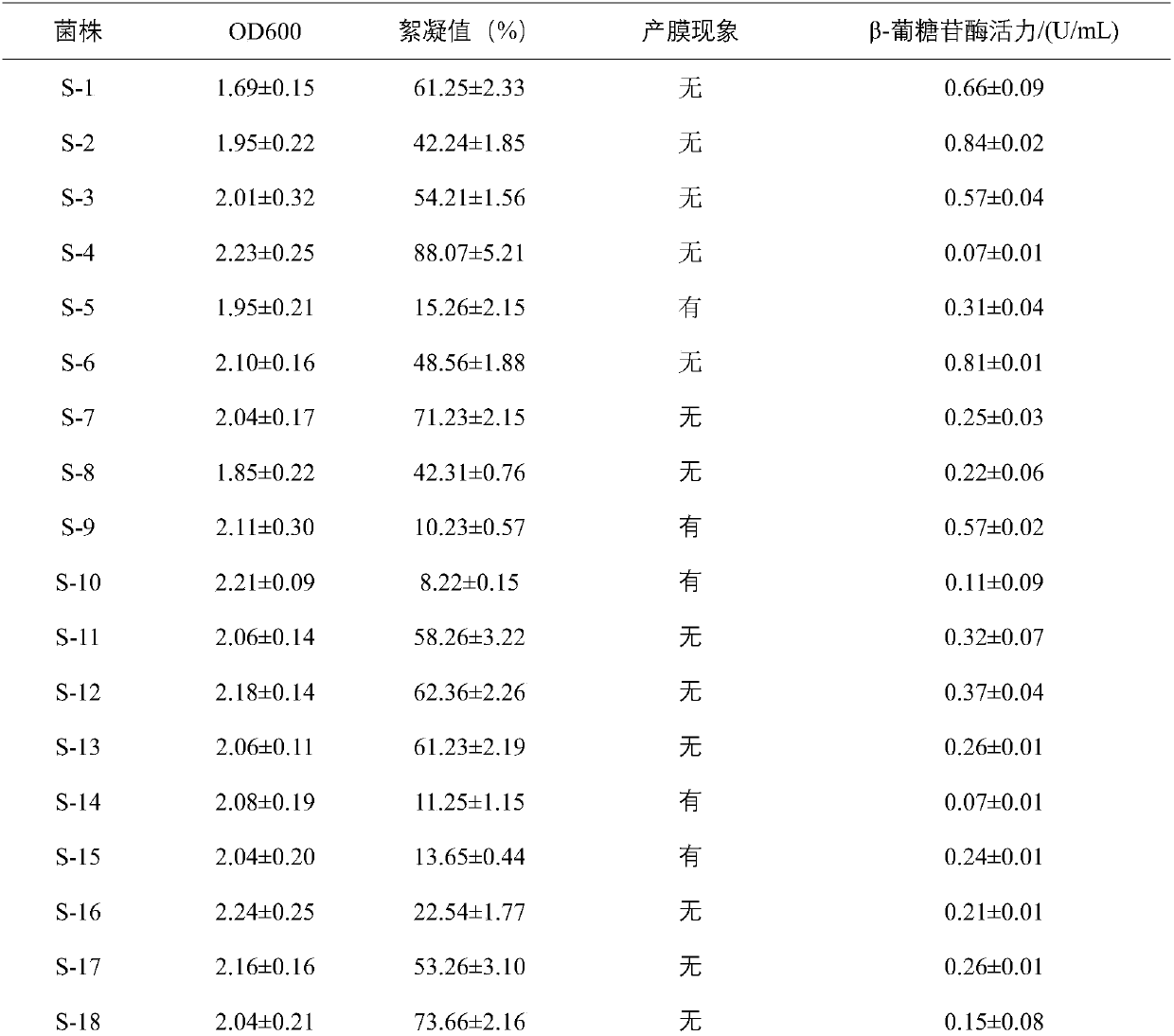

Saccharomyces cerevisiae strain FM-S-4 capable of improving color and luster stability of fruit wine and application

ActiveCN107746814ASecurity resourcesReliable resourceFungiAlcoholic beverage preparationFruit wineFlocculation

The invention relates to a saccharomyces cerevisiae strain FM-S-4 capable of improving the color and luster stability of fruit wine and application and belongs to the technical field of biological engineering. A novel saccharomyces cerevisiae strain with low beta-glucosidase activity, strong flocculation capability and good fermentation performance is screened from a traditional fermented food, namely Kefir grains, is named as FM-S-4 and is identified to saccharomyces cerevisiae. The FM-S-4 is used as a fruit wine fermentation agent of berries including blackberries, blueberries and the like and the reduction of content of phenol substances and anthocyanin substances in fruit wine fermentation and ageing processes can be effectively alleviated; the color and luster stability of the fruit wine is easy to improve; the fermentation and clarification time is shortened and the flavor of the fruit wine is improved, so that the saccharomyces cerevisiae strain FM-S-4 has a wide application prospect.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Composite nano acrylic paint and preparation method thereof

InactiveCN106147332ALittle change in chromatic aberrationImprove light fastnessArtist's paintsAluminatePropylamine

The invention discloses a composite nano acrylic pigment and a preparation method thereof. The preparation method comprises the following steps: step 1: take calcium aluminate and mechanically ball mill it in a ball mill; step 2: take 19-28 parts of acrylate emulsion by weight , Gum Arabic 3‑8 parts, glycerin 2‑6 parts, triethanolamine 4‑7 parts, ethylene glycol butyl ether acetate 2‑6 parts, aminopropylamine dioleate 2‑5 parts, polyoxypropylene glyceryl ether 1 ‑4 parts, mixed in a mixing tank, the temperature in the mixing tank is 40‑60 °C, the stirring speed is 100‑200r / min, stirring for 30‑50min; Step 3: Add cetyl palmitic acid to the mixing tank in step 2 2-6 parts of ester, 1-4 parts of calcium aluminate, 2-5 parts of nano-calcium oxide, 2-5 parts of phthalocyanine green G, and then stirred for 20-40 minutes, cooled to form a composite nano-acrylic pigment.

Owner:苏州冰心文化用品有限公司

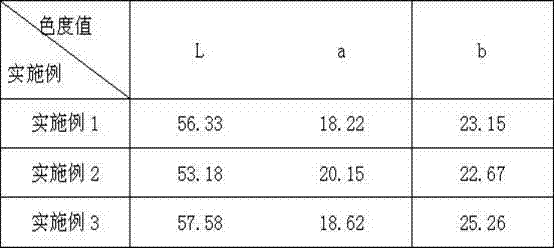

Anti-ultraviolet glass with small color difference and preparation method thereof

ActiveCN112062466ASmall color differenceLittle change in chromatic aberrationUltraviolet lightsGlass melting

The invention discloses anti-ultraviolet glass with small color difference and a preparation method thereof, and relates to the technical field of anti-ultraviolet glass. According to the anti-ultraviolet glass with the small color difference, the anti-ultraviolet effect can be achieved only by adding a small amount of Fe2O3 (0.1-0.2%) and CeO2 (0.04-0.1%), the color difference change is small, and the cost is low. According to the glass prepared by the preparation method provided by the invention, added materials can be uniformly dispersed in a glass body in the glass melting process, so thatthe effects of uniform color and small color difference change are achieved. Compared with common glass, the anti-ultraviolet glass with the small color difference has the advantages that the color values (including brightness L, a* and b*) of the glass are slightly changed after the anti-ultraviolet glass with small color difference is added with materials, so that the glass can hardly be distinguished by naked eyes, and the appearance of the glass is not influenced. According to the anti-ultraviolet glass with small color difference provided by the invention, the ultraviolet light transmittance can be effectively reduced from 65-75% to 44-50% under the condition that the visible light transmittance of the glass is not greatly reduced.

Owner:深圳南玻科技有限公司 +1

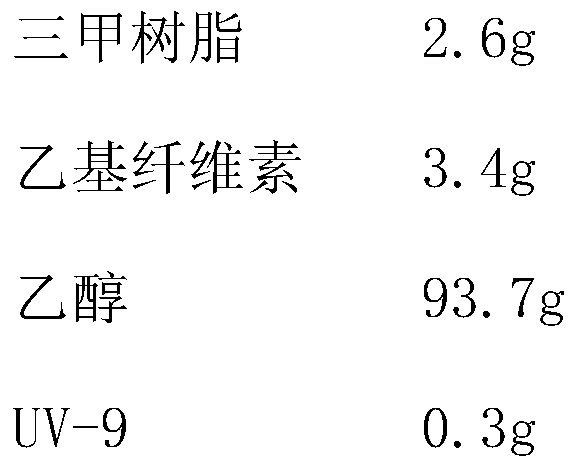

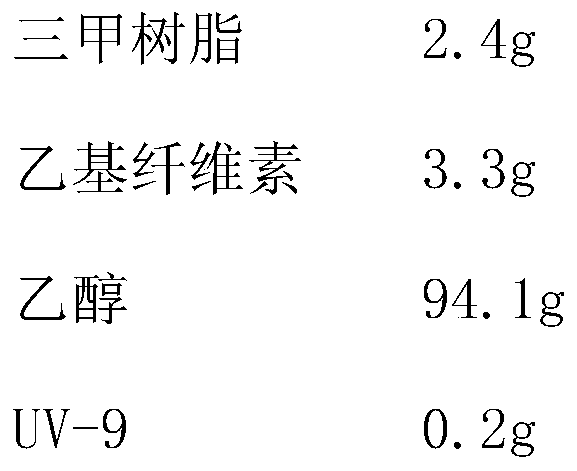

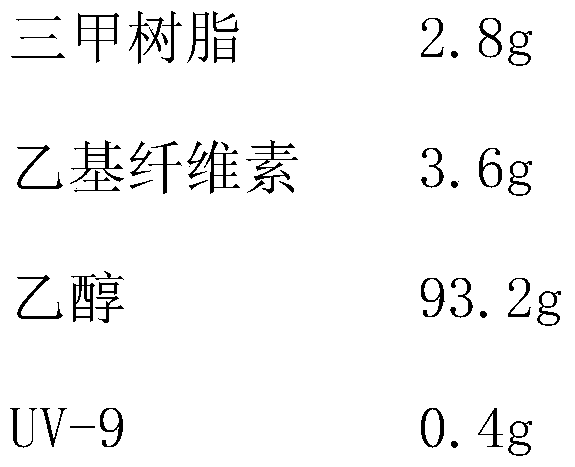

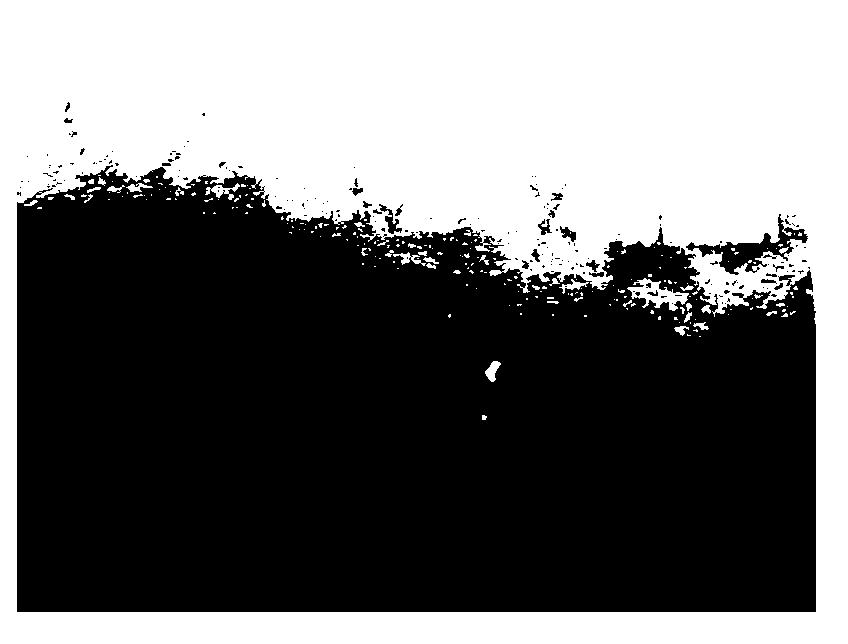

A kind of pottery painted cultural relic reinforcement coating and preparation method thereof

The invention discloses a ceramic painted relic reinforcing paint, which comprises the following components in percentage by weight: 2.2 to 2.8% of three methyl resin, 3.2 to 3.6% of ethyl cellulose, 91.7 to 96.2% of ethanol, and 0.2 to 0.4% of UV-9. The invention also discloses a preparation method of the reinforcing paint. The preparation method comprises the following steps: according to the total weight of needed paint, calculating the amounts of the components (three methyl resin, ethyl cellulose, ethanol, and UV-9); completely dissolving ethyl cellulose into ethanol, then adding three methyl resin and UV-9 into the ethanol solution of ethyl cellulose, stirring to completely dissolve three methyl resin and UV-9, and filling the solution into containers to obtain finished products. The reinforcing paint has the functions of penetrating water and salts, and preventing oxidation, can be used to reinforce the powdery layers of ceramic painted relics, and has a strong performance on sealing and protecting the painted layers; the UV and aging resistant property of the reinforcing paint is strong, the color difference change of the processed painted layer is small, and the reinforcing effect is prominent.

Owner:SUZHOU JIREN HIGH TECH MATERIAL CO LTD

Black and white photo development reinforcing agent

ActiveCN102786847BHigh mechanical strengthImprove mechanical propertiesPhotography auxillary processesCoatingsPolymer scienceSilicon dioxide

The invention relates to a black and white photo development reinforcing agent which is prepared by mixing banana oil solution of ethyl cellulose with nanometer silicon dioxide, banana oil solution of vinylidene fluoride-chlorotrifluoroethylene copolymer, di(1,2,2,6,6-pentamethyl-4-piperidyl)sebate and diisooctyl phenyl phosphate according to certain mass proportions. The black and white photo development reinforcing agent is mildew-proof, waterproof and acid-proof and has the properties of strong anti-aging capability, strong adhesive force and high hardness; the original appearance of seriously or slightly fuzzy or faded black and white photos can be revealed; the stability can be kept; various mechanical strength and mechanical properties of the photos can be effectively improved; and long-term storage of historical relics is more benefited.

Owner:SHAANXI NORMAL UNIV

Sizing color painting reattachment restoration agent for ceramic relics

The invention relates to a sizing color painting reattachment restoration agent for ceramic relics, which is prepared from 9% to 35% of ZB-F600 dual FEVE waterborne fluorocarbon resin, 1% to 5% of water-soluble epoxy resin and 60% to 90% of water. After being restored by the agent, a sample test panel has good flexibility, strong adhesion force and little color difference change. After being tested by ultraviolet aging, hygrothermal aging and ozone aging tests, the flexibility and the adhesion force can be maintained well, and the color difference change is little, thereby representing that the agent can enhance the bonding strength of the sample test panel, and strengthen the endurance and the capability of resisting external force impact. The attachment restoration agent carries out attachment restoration on the cracked, wrapped and fallen color painting terro-cotta of Western Han Dynasty in Xianyang Museum. After the terro-cotta is restored by the agent, the color paintings are adhered to the terro-cotta, the strength of the color paintings is enhanced, the surface is smooth and the original feature is restored. The color paintings do not generate the phenomena of falling and wrapping after being traced and investigated for four years, and the agent has good restoration effect.

Owner:SHAANXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com