Banana brandy and preparation method thereof

A brandy and banana technology, applied in the field of banana brandy and its preparation, can solve the problems of banana browning and easy precipitation, etc., and achieve the effects of improving production efficiency, shortening aging time, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

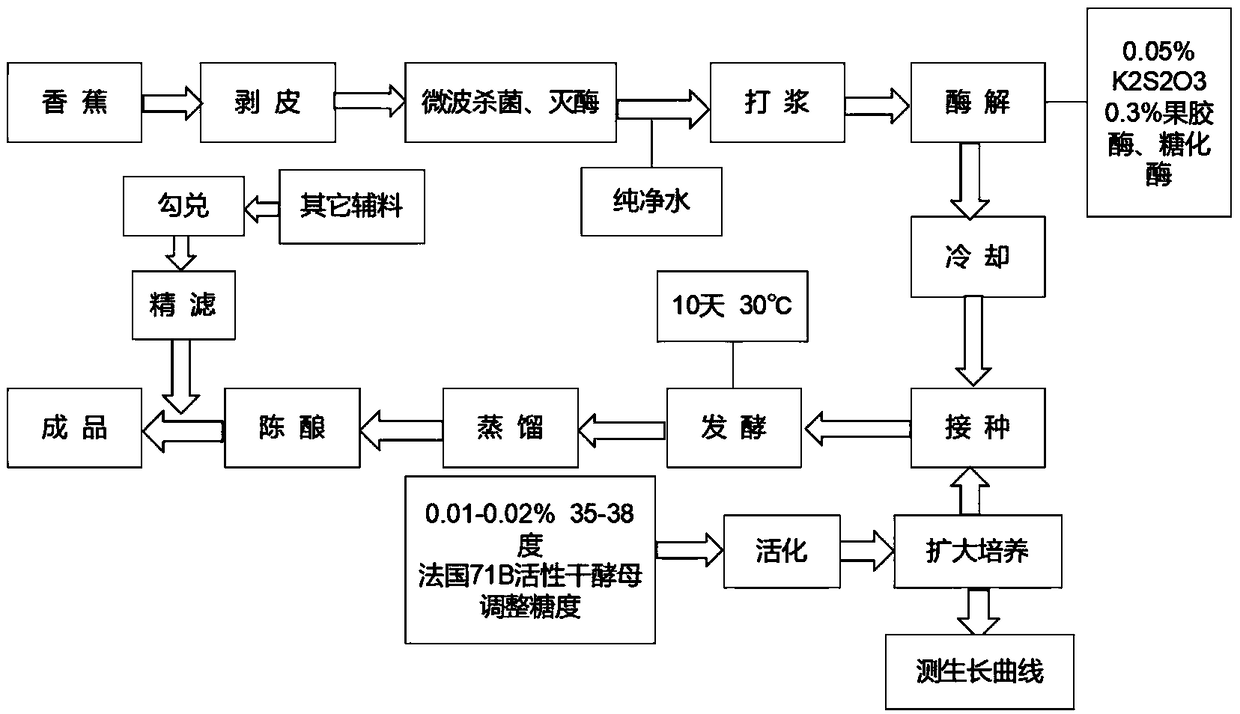

[0058] The preparation method of banana brandy according to the present invention may comprise:

[0059] The screened bananas are removed from the head and tail and screened;

[0060] Roughly beating the screened bananas to obtain banana coarse pulp;

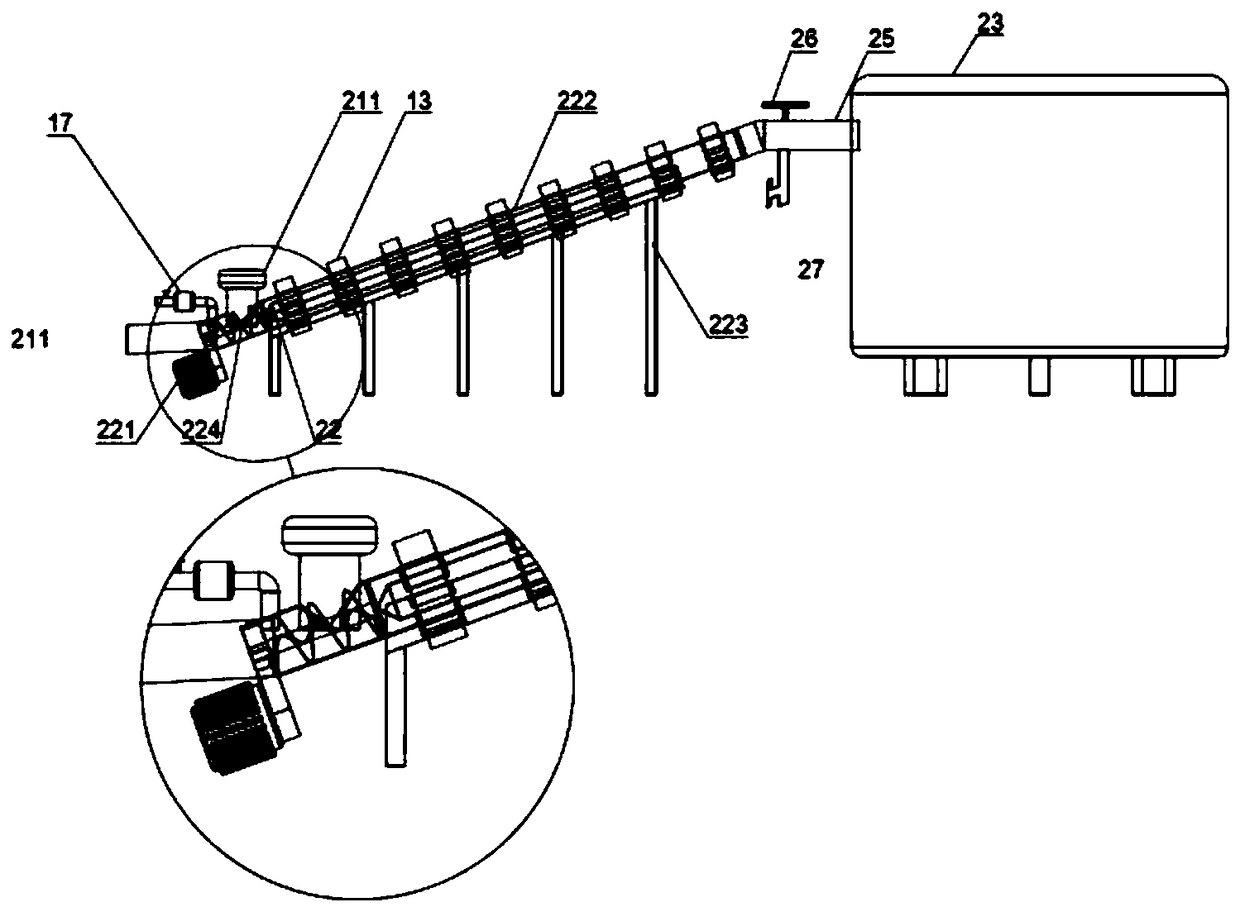

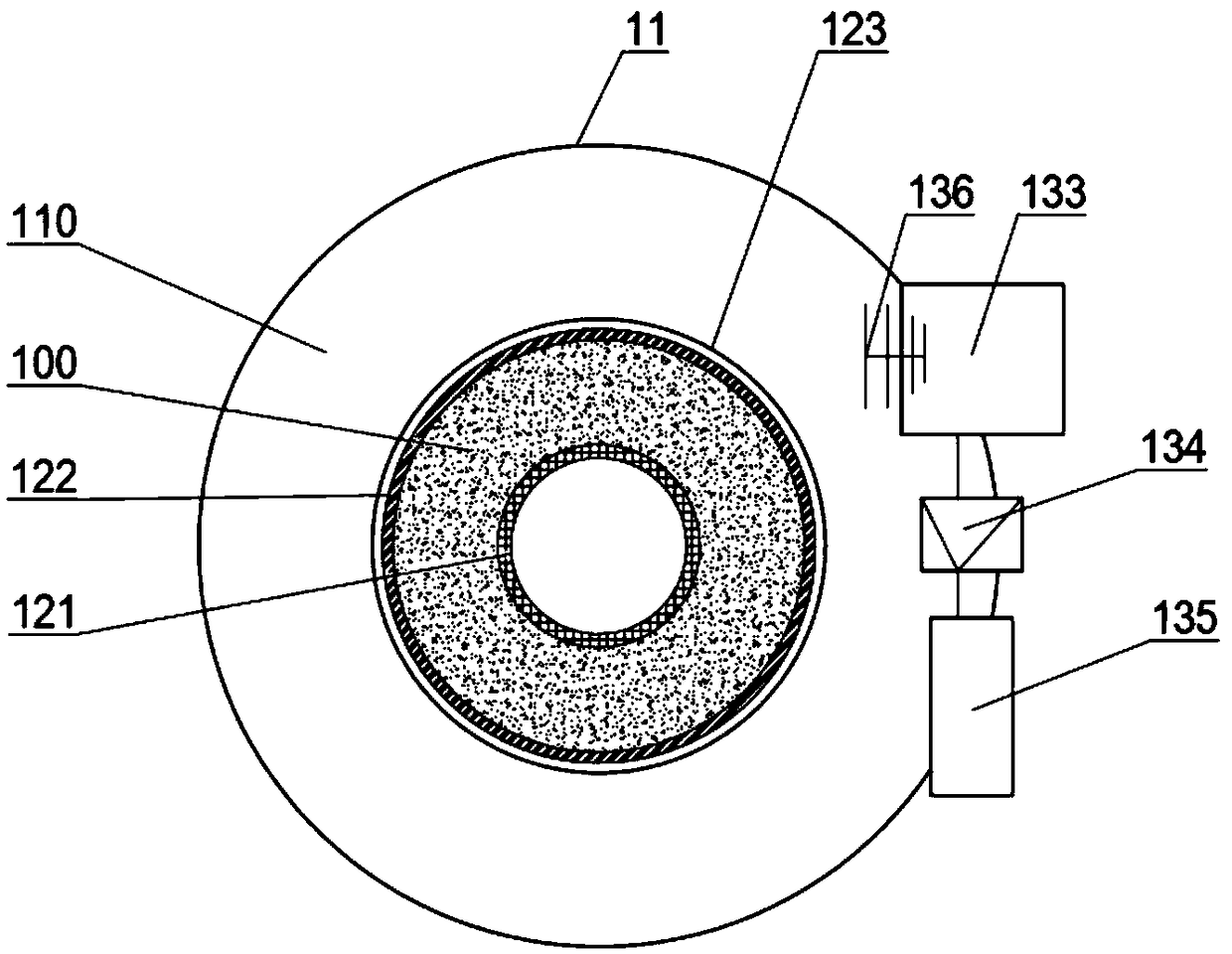

[0061] The banana coarse pulp is transported through a closed pipeline to a nitrogen positive pressure closed pipeline microwave treatment device for microwave enzyme-inactivating treatment, wherein the banana coarse pulp is heated by microwaves while being stirred and conveyed by a screw propeller in the microwave processing device to obtain a microwave enzyme-inactivating product. Processed banana coarse pulp;

[0062] Adding pectinase and glucoamylase to the crude banana pulp treated with microwave inactivation for enzymatic hydrolysis, followed by coarse filtration and slag removal to obtain banana juice;

[0063] Banana juice is added to yeast to ferment to obtain banana crude wine;

[0064] The crude banana wine is dist...

Embodiment 1

[0080] The screened 9 mature bananas are deheaded and screened to obtain banana pulp; the banana pulp is quickly roughly beaten to obtain banana coarse pulp; the banana coarse pulp is transferred to a nitrogen positive pressure sealed pipeline microwave processing device through a closed pipeline Carry out microwave deenzyme treatment, wherein said banana crude pulp is heated by microwave while stirring and transporting with a screw propeller in a microwave treatment device, the microwave power is 60KW, the microwave frequency is 2800MHz, the microwave power density is 8W / g, and the sterilization and inactivation time 12 minutes; the microwave power of heat preservation treatment is 20KW, the microwave density is 8W / g, the microwave frequency is 2800MHz, the sterilization and inactivation time is 9 minutes, and the temperature after deactivation is 85°C;

[0081] Cool the crude banana pulp treated with microwave enzymes to 60°C and keep it warm, add pectinase and glucoamylase o...

Embodiment 2

[0084] The screened 9 mature bananas are deheaded and screened to obtain banana pulp; the banana pulp is quickly roughly beaten to obtain banana coarse pulp; the banana coarse pulp is transferred to a nitrogen positive pressure sealed pipeline microwave processing device through a closed pipeline Carry out microwave deenzyme treatment, wherein said banana crude pulp is heated by microwave while stirring and transporting with a screw propeller in a microwave treatment device, the microwave power is 80KW, the microwave frequency is 2450MHz, the microwave power density is 6W / g, and the sterilization and inactivation time 8 minutes; the microwave power of heat preservation treatment is 60KW, the microwave density is 6W / g, the microwave frequency is 2450MHz, the sterilization and inactivation time is 6 minutes, and the temperature after deactivation is 88°C;

[0085] Cool the crude banana pulp that has been treated with microwave enzymes to 60°C and keep it warm, add pectinase and g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brown coloration index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com