Catalyst for catalytic conversion of synthetic gas as well as preparation method and application thereof

A catalytic conversion and catalyst technology, which is applied in the direction of catalyst activation/preparation, preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, etc. It can solve problems such as poor stability, low content of high-carbon alcohols, and poor repeatability of catalysts. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

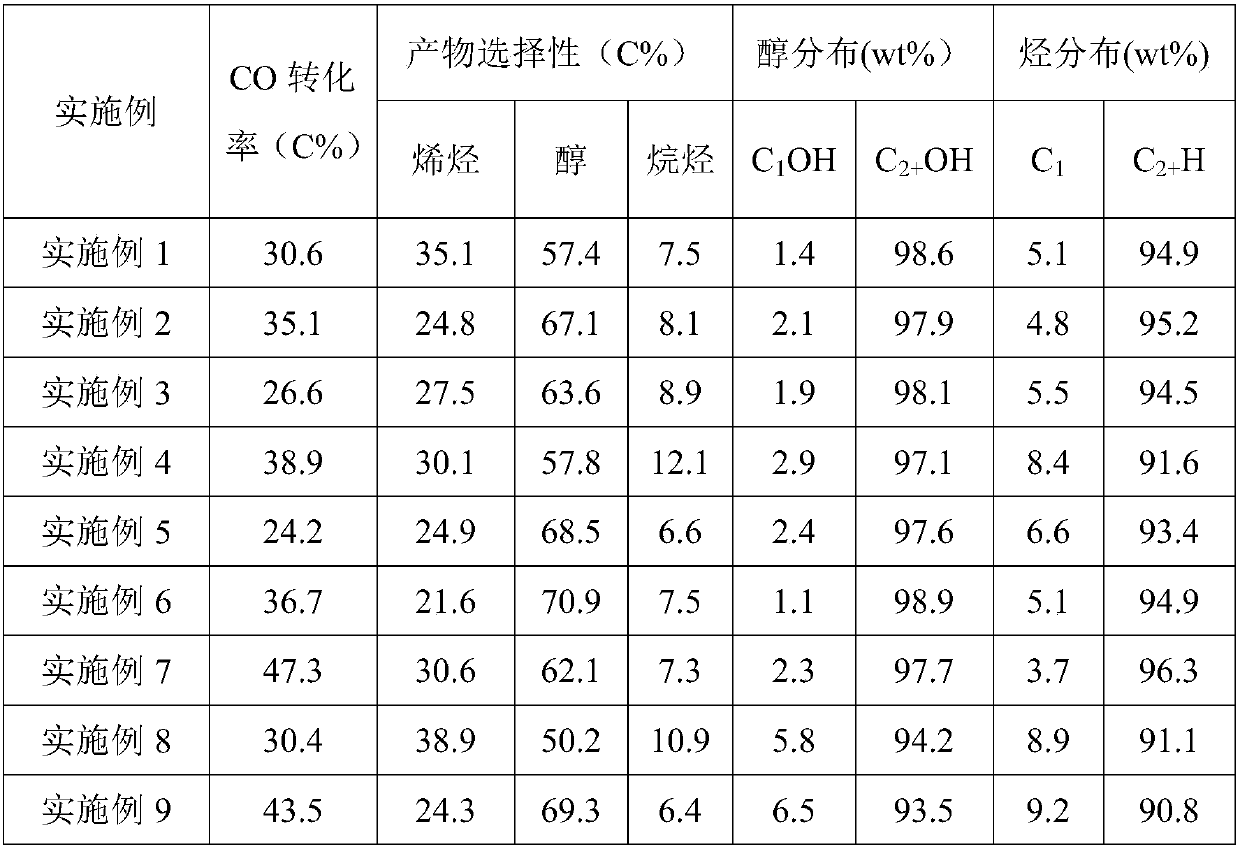

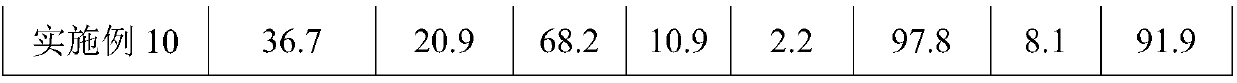

Examples

Embodiment 1

[0090] Will Co(NO 3 ) 2 ·6H 2 O, 50% Mn(NO 3 ) 2 Aqueous solution, Fe(NO 3 ) 3 9H 2 O and Zr(NO 3 ) 4 ·5H 2O is dissolved in a certain amount of deionized water according to the molar ratio of Co / Mn / Fe / Zr=5 / 1 / 1 / 0.5 to form a mixed solution with a total metal concentration of 2mol / L, and then sodium carbonate is dissolved in a certain amount of deionized water In ionized water, a lye with a concentration of 2mol / L is formed. Add mother liquor (water) in the beaker, 10gAl 2 o 3 Add the aerosol to the mother liquor and stir evenly (Co and Al 2 o 3 The molar ratio is 4.9:1), the titration temperature is adjusted to 65°C, the titration pH is controlled to be 8, and the above two solutions are co-precipitated in the stirred mother liquor in a co-current manner. After the titration, it was aged at 65°C for 2 hours, centrifuged and washed 6 times, then dried in an oven at 120°C for 12 hours, then transferred to a muffle furnace and heated to 400°C for 4 hours to obtain a...

Embodiment 2

[0095] Will Co(NO 3 ) 2 ·6H 2 O, 50% Mn(NO 3 ) 2 Aqueous solution, Cu(NO 3 ) 3 ·3H 2 O and Zn(NO 3 ) 4 ·5H 2 O is dissolved in a certain amount of deionized water according to the molar ratio of Co / Mn / Cu / Zn=18 / 4 / 1 / 1 to form a mixed solution with a total metal concentration of 1mol / L, and then ammonium carbonate is dissolved in a certain amount of deionized water In ionized water, a lye with a concentration of 1.5mol / L is formed. Add the mother liquor (water) into the beaker, adjust the titration temperature to 35° C., control the titration pH=9, and co-precipitate the above two solutions in the stirred mother liquor in a co-current manner. After the titration, it was aged at 35°C for 12 hours, centrifuged and washed 6 times, then dried in an oven at 100°C for 24 hours, then transferred to a muffle furnace and heated to 300°C for 6 hours to obtain a Co mass content of 56.1%. Co-based catalysts.

[0096] Take 1.02mg of rhodium chloride, dissolve it in 10ml of deioniz...

Embodiment 3

[0100] Take 10g Co(NO 3 ) 2 ·6H 2 O, 10g 50% Mn(NO 3 ) 2 The aqueous solution and 10g of ammonium molybdate were dissolved in a certain amount of deionized water (molar ratio Co / Mn / Mo=3.4 / 2.8 / 5.1); then 10g of activated carbon was taken as a carrier (the molar ratio of Co to activated carbon was 0.2:1), using Equal volume impregnation, drying at room temperature for 24 hours after impregnation, then drying in an oven at 120°C for 12 hours, and finally calcination in a tube furnace at 500°C for 5 hours, the calcination atmosphere is nitrogen, and a Co-based catalyst with a Co mass content of 11.8% is obtained .

[0101] Get 1.482g rhodium nitrate and 0.08g phosphoric acid, dissolve in 10ml of deionized water to form a mixed solution, then take 10gAl 2 o 3 The carrier was added into the mother liquor containing 20ml of deionized water, and the above mixed solution was dropped into the mother liquor drop by drop under the condition of stirring at room temperature. Stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com