Patents

Literature

1014results about How to "Easy to scale up production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

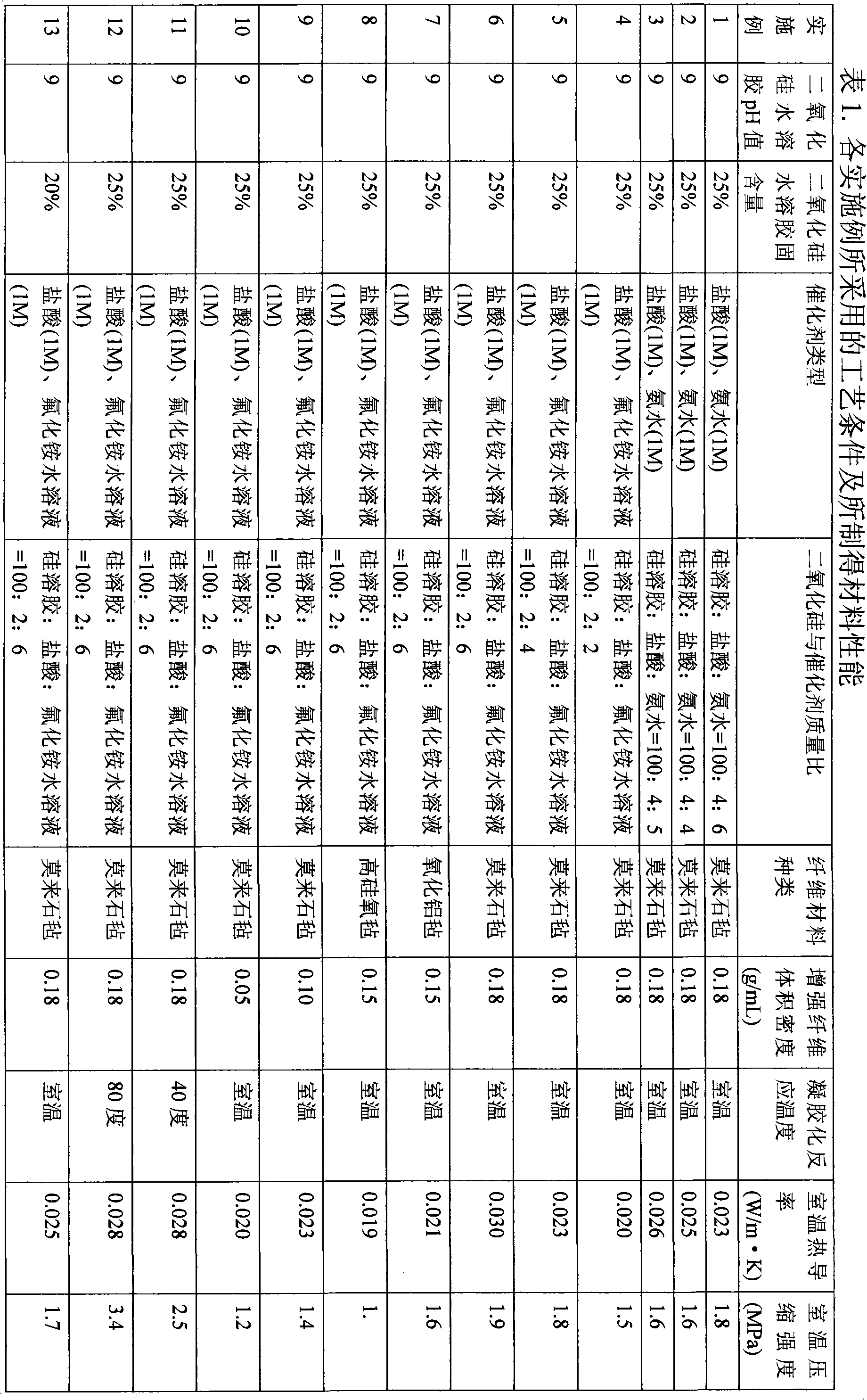

High-performance thermal insulation material and preparation method thereof

The invention provides a high-performance thermal insulation material and a preparation method thereof. The thermal insulation material comprises silicon dioxide aerogel and a fiber material, wherein, the silicon dioxide aerogel takes silicon dioxide hydrosol as a raw material, and is prepared by adding a catalyst. The method comprises the following steps: sol preparing, sol dipping, gelating, gel ageing, hydrophobization treating and drying and the like. The method can conveniently and selectively prepare the materials of planes, abnormal-shape surfaces and multiple sizes, has simple and convenient operation and small environmental pollution. The material has excellent mechanical performance, good high-temperature stability and heat insulation performance, and has wide application prospect in the fields of civilian industries, space flight and aviation industries, military industries and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

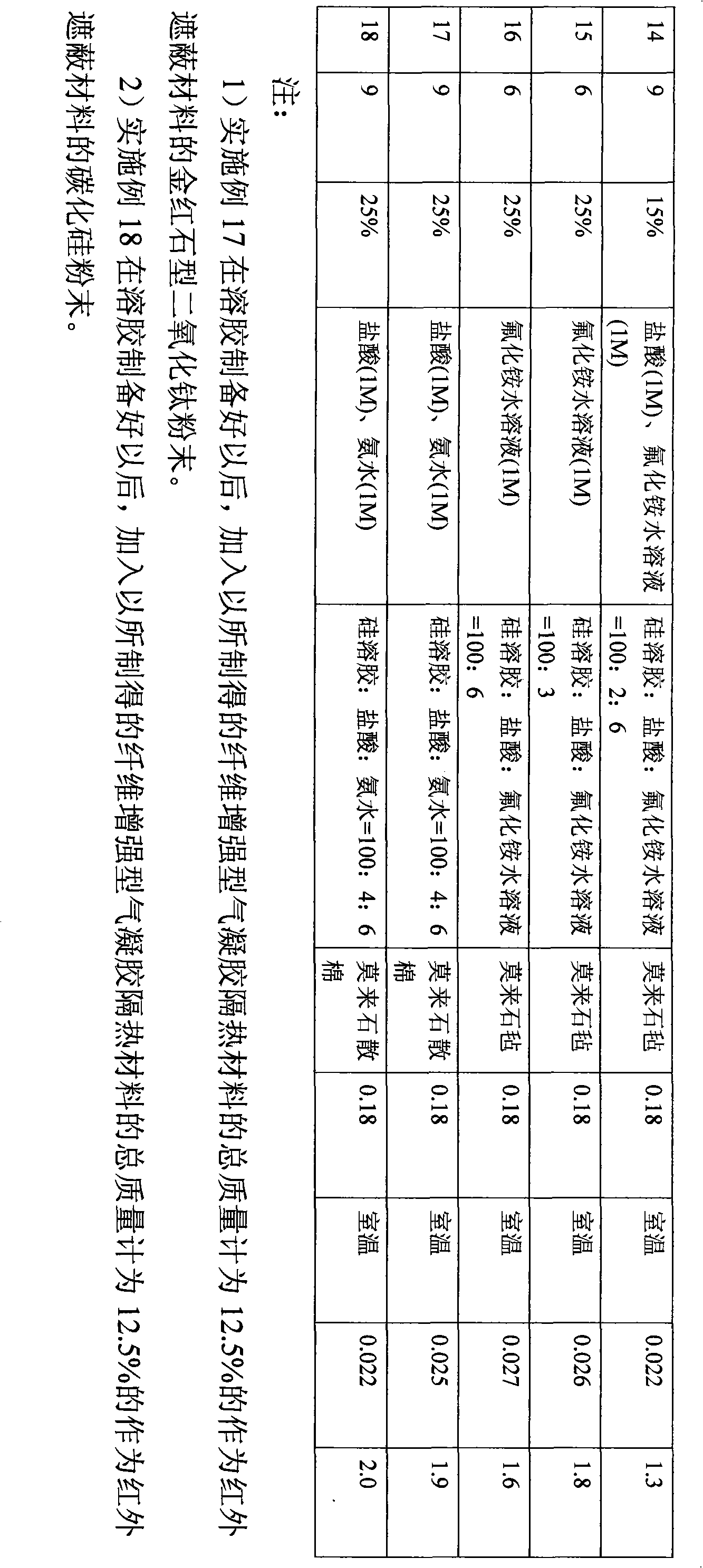

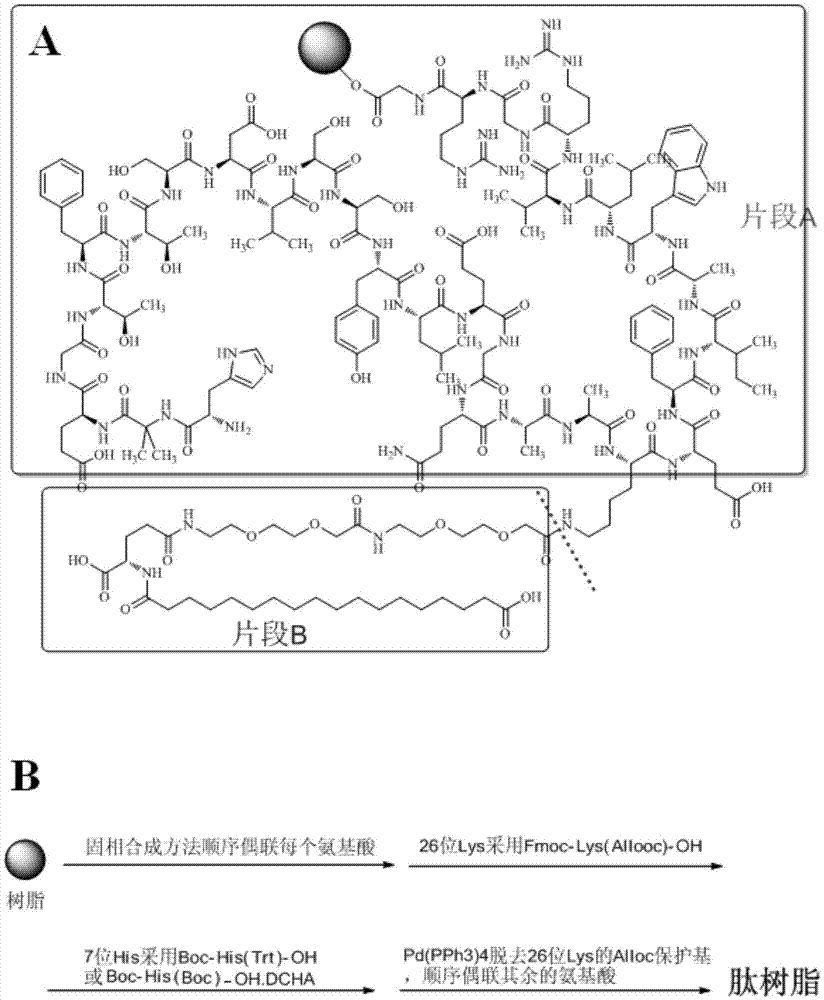

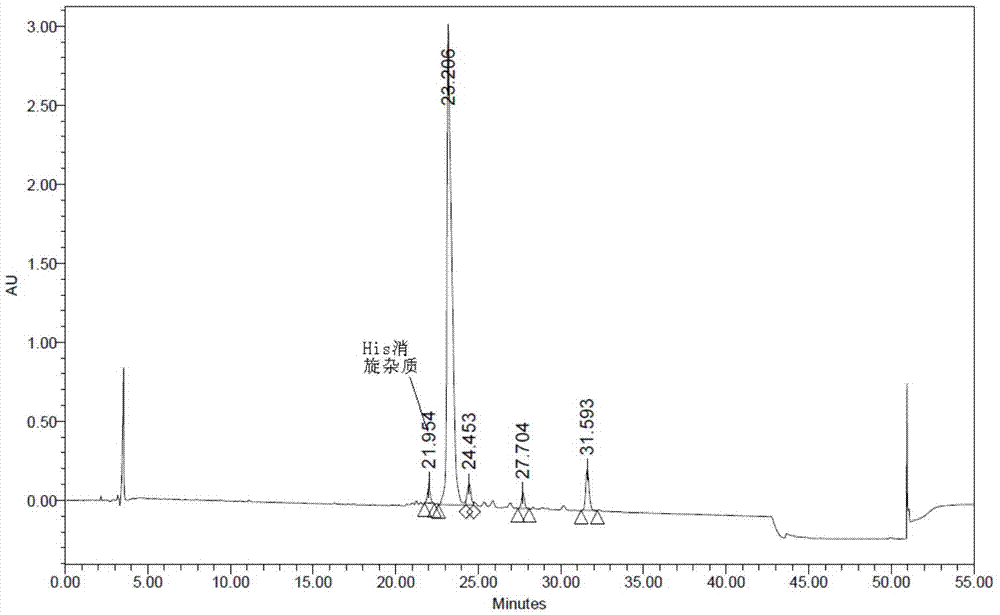

Method for preparing semaglutide

InactiveCN106928343AEasy to operateNo side effectsPeptide-nucleic acidsPeptide preparation methodsSide reactionSemaglutide

The invention relates to the field of polypeptides, in particular to a method for preparing semaglutide. The method has the advantages that Fmoc-Lys (Alloc)-OH protection amino acid is used as a raw material, de-protection is carried out by the aid of selected Pd (PPh3) 4, accordingly, operation procedures are simple, only 1-2 times of simple elimination reaction operation are required, each elimination reaction operation is carried out for 10-30 min, side reaction is prevented, the operation procedures are safe, and enlarged production can be facilitated; Boc-His (Boc)-OH. DCHA and Boc-His (Trt)-OH are used as raw materials in the procedures, and accordingly His racemization risks can be reduced to the greatest extent; special fragments are coupled, and accordingly the synthesis efficiency can be improved.

Owner:HYBIO PHARMA

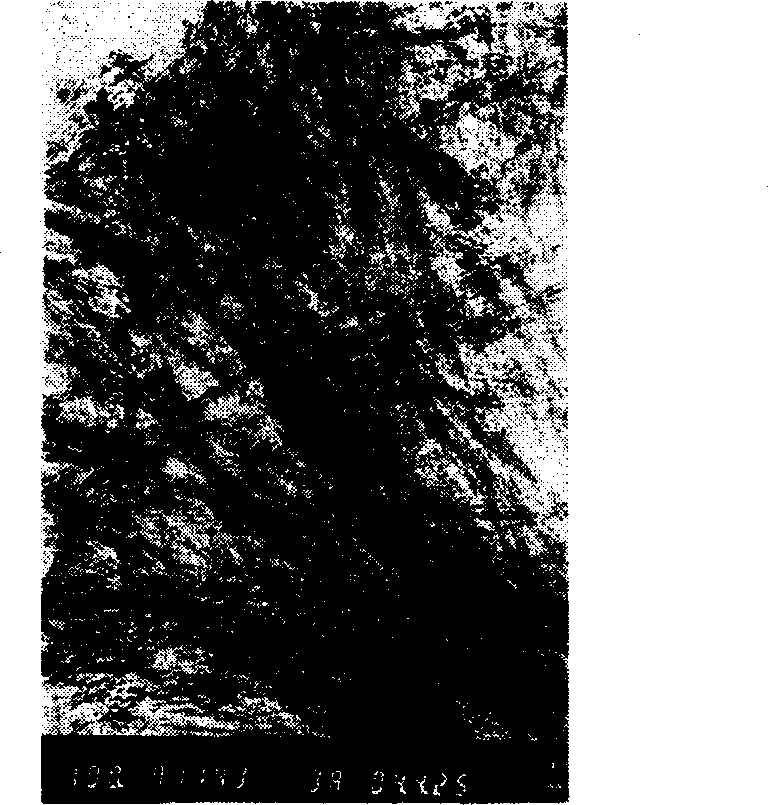

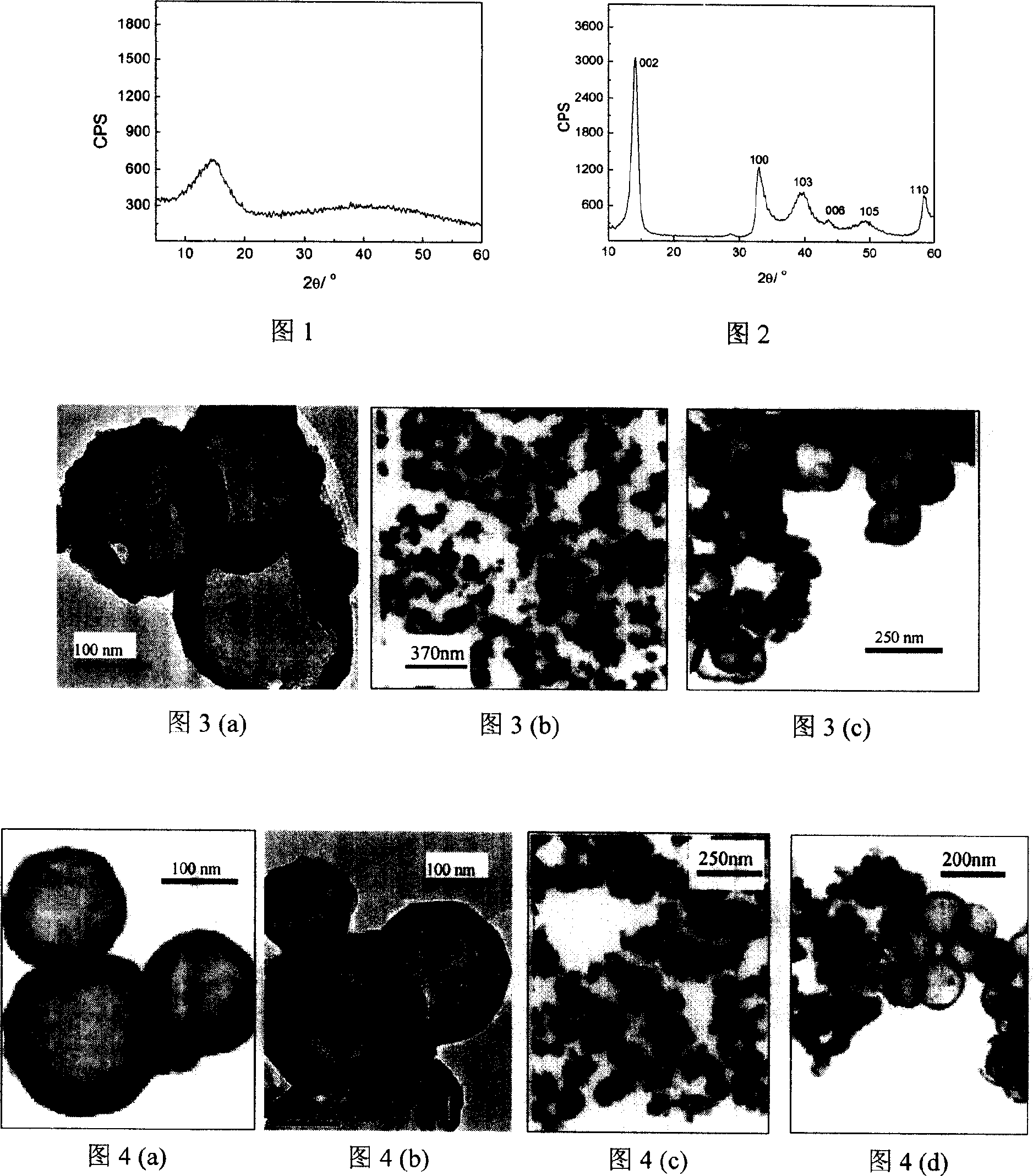

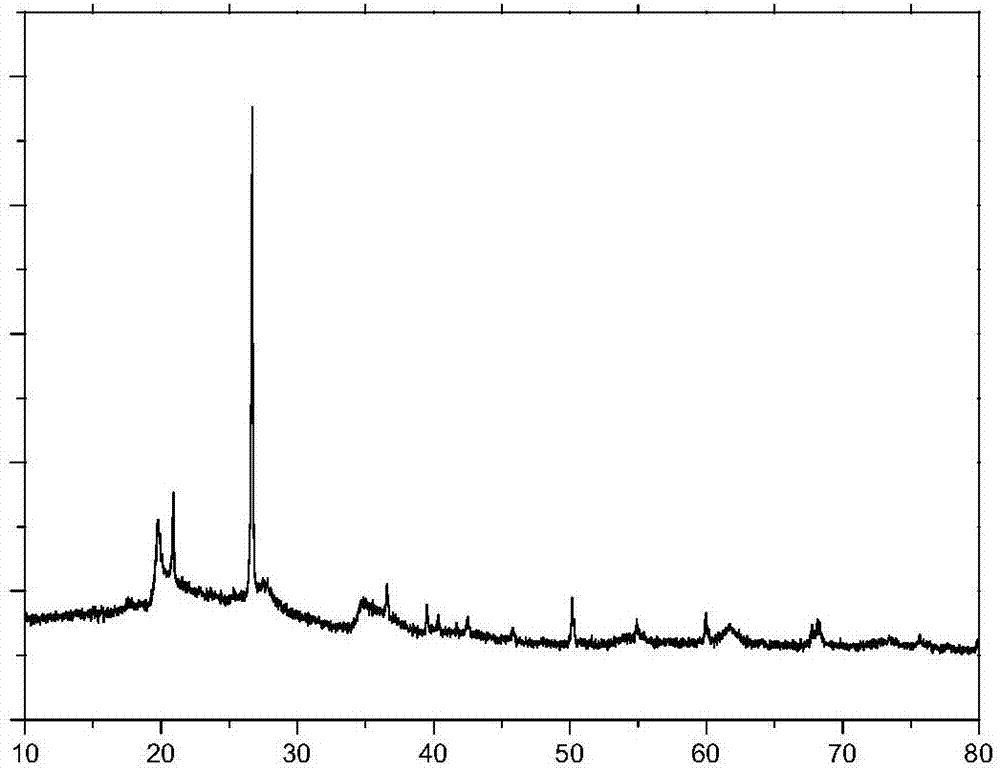

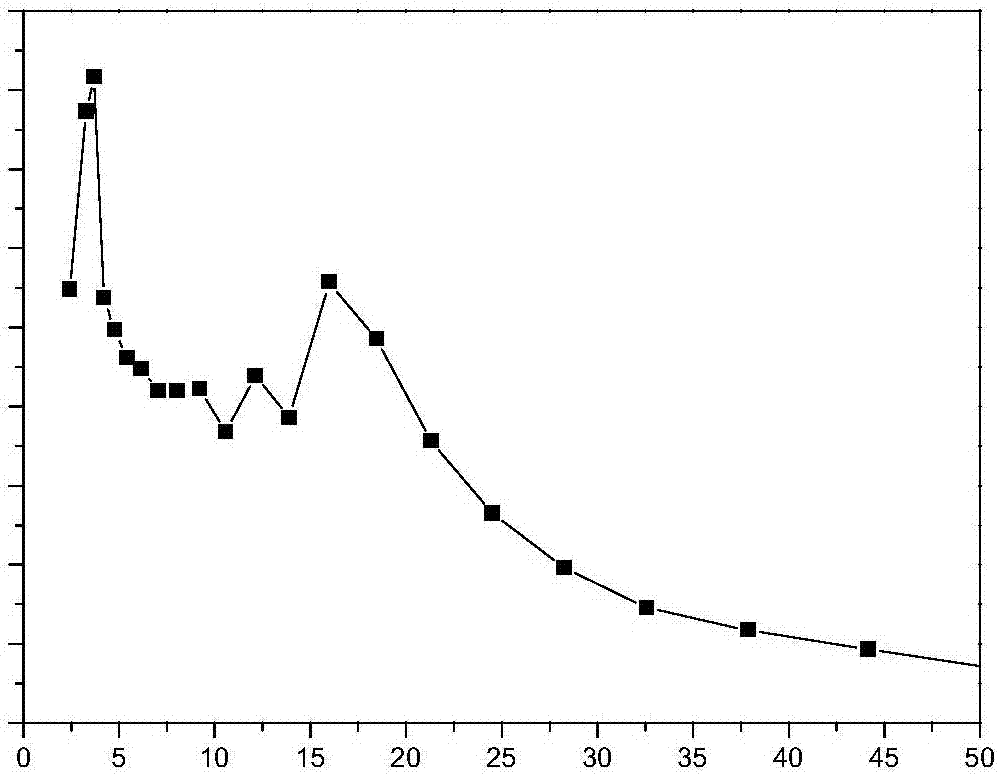

Process for preparing hydrated sodium titanate and nano titanate tube series

InactiveCN1378977AWith ion exchangeLarge specific surface areaTitanium compoundsSodium titanateThermal stability

A process for preparing the nanometre tubes of hydrated sodium titanate and titanate series includes such steps as hydrothermal reaction of TiO2 or metatitanic acid to obtain the nanometre tubes of hydrated sodium titanate, mixing them with the solution containing one or two kinds of metal ions to convert them to the nanometre tubes of hydrated titanate or composite hydrated titanates of the saidmetal ions, and thermal dewatering to obtain the nanometre tubes of corresponding titanate or composite titanates. Its advantages are uniform shape, large specific surface area, high thermal stability and regulatable catalytic performance.

Owner:TSINGHUA UNIV

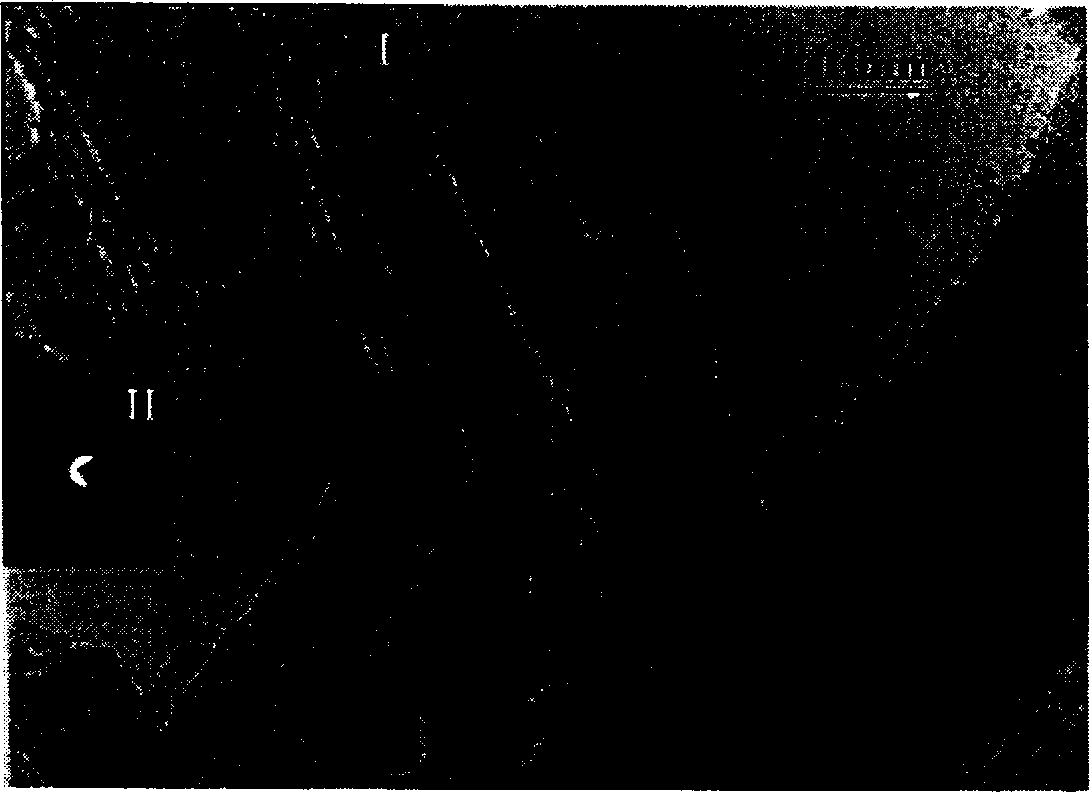

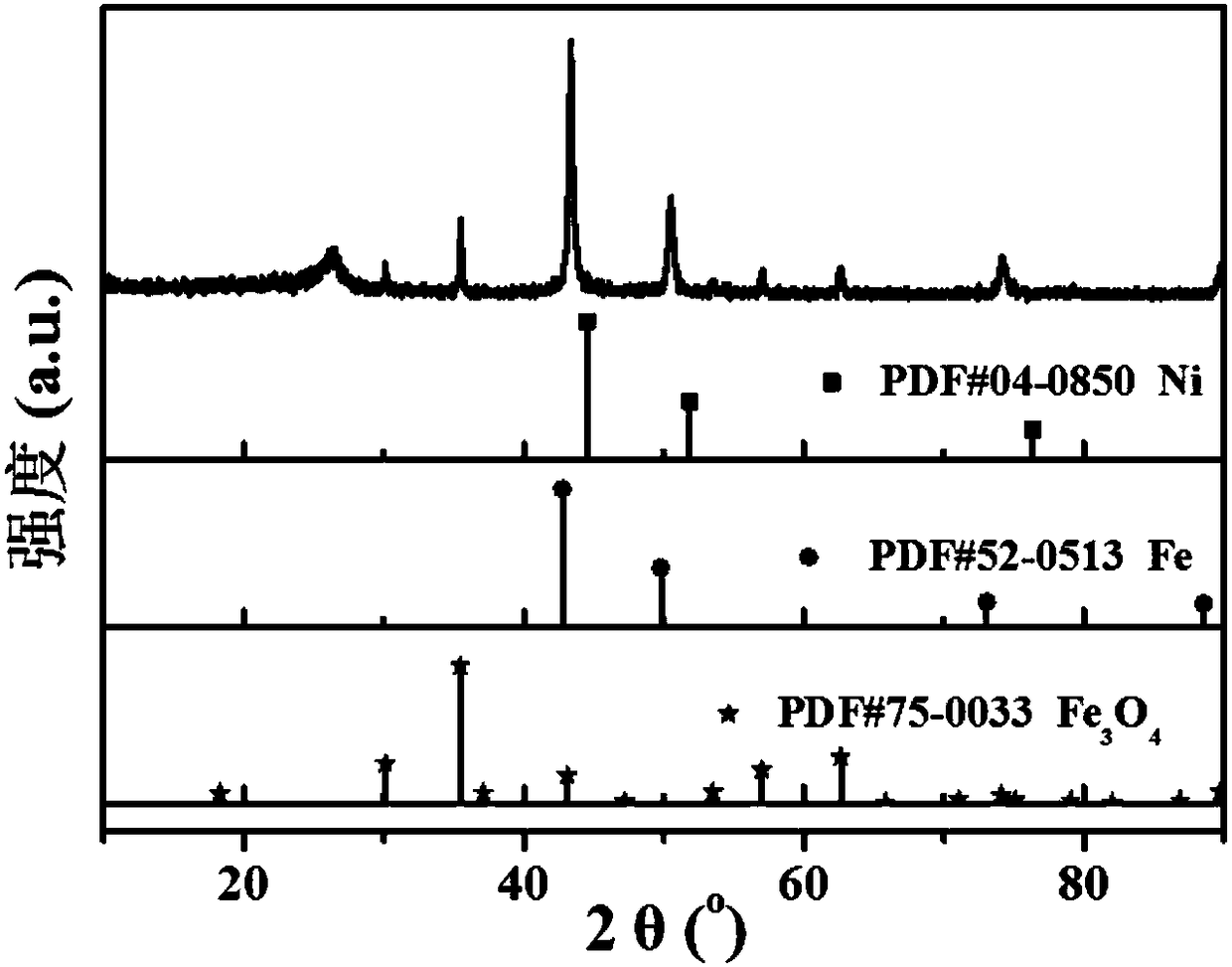

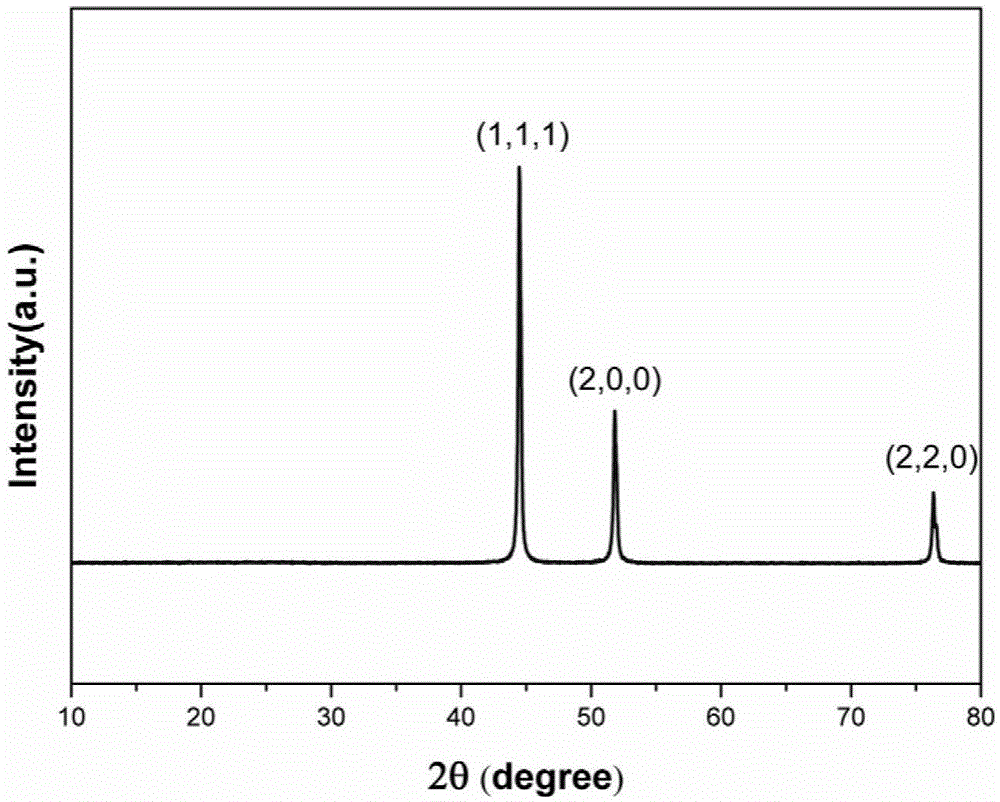

Fe, Ni and N three-doped carbon nanotube coated type FeNi@NCNT catalyst as well as preparation method and application thereof

InactiveCN108543545AIncrease the areaImprove conductivityPhysical/chemical process catalystsCell electrodesMetal particleOxygen

The invention discloses a Fe, Ni and N three-doped carbon nanotube coated type FeNi@NCNT catalyst as well as a preparation method and application thereof, and belongs to the fields of energy materialsand electrochemistry. The catalyst is prepared by using dicyandiamide as a C source and N source and ammonium ferric citrate and NiCl2.6H2O as metal sources, adopting one pot method and performing pyrolysis in two steps; and a plurality of Fe and Ni metal particles in the catalyst are uniformly wrapped in walls of ''bamboo-like'' N-doped carbon nanotubes, and a small number of the particles are distributed at the tip ends of the carbon nanotubes. Compared with a common metal alloy oxygen reduction reaction and oxygen evolution reaction bifunctional catalyst, the catalyst disclosed by the invention exhibits good oxygen evolution reaction activity and stability under alkaline conditions; the preparation method is simple, and raw materials used in the method have low costs and wide sources;and the catalyst can be widely used in the fields of proton exchange membrane fuel cells, electrolyzed water, metal-air batteries and the like, and has higher practical value.

Owner:DALIAN UNIV OF TECH

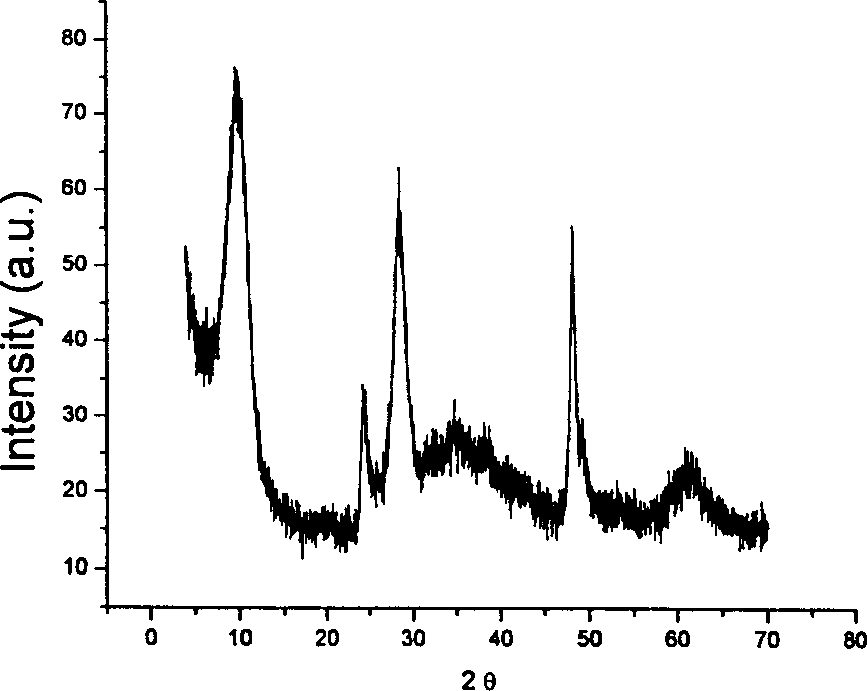

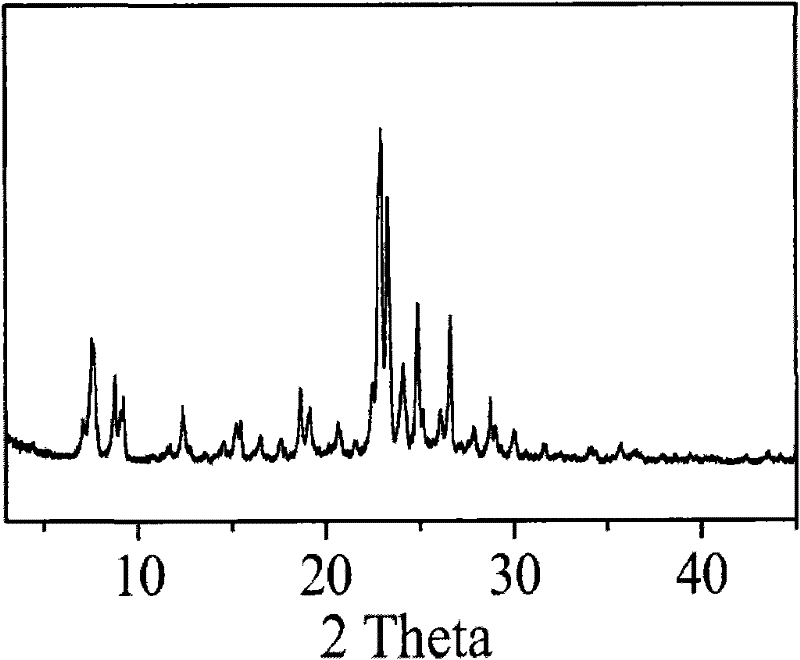

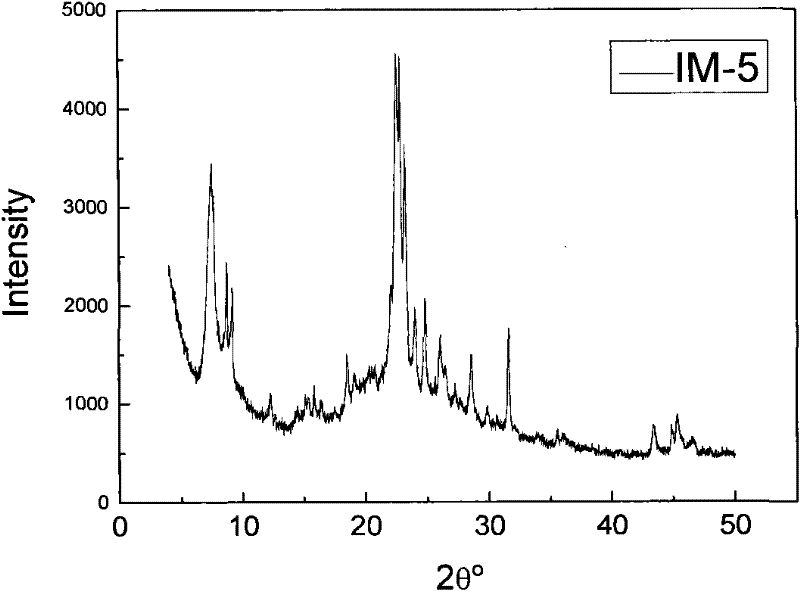

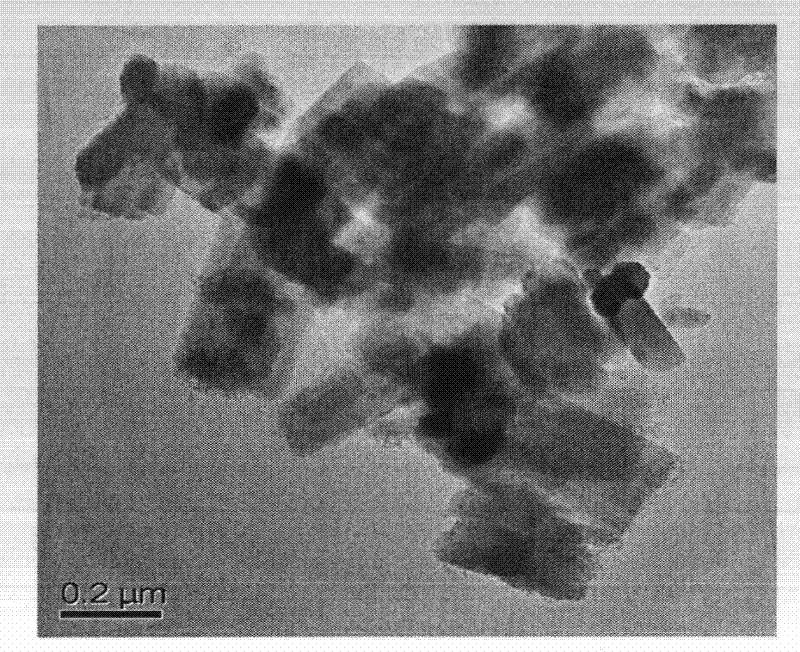

Method of synthesizing IM-5 molecular sieve by using composite template

ActiveCN102452667AReduced nucleation timeShorten crystallization timeCrystalline aluminosilicate zeolitesMolecular sieveAlkali metal oxide

The invention provides a method of synthesizing IM-5 molecular sieve by using a composite template. The method comprises the following steps: (1) dissolving an inorganic base, an aluminum source and two templates in deionized water and carrying out uniform mixing so as to prepare a mixed solution; (2) adding a silicon source into the mixed solution obtained in step (1), optionally adding an additive and carrying out uniform mixing so as to prepare colloid or a solid-liquid mixture; (3) transferring the colloid or the solid-liquid mixture obtained in step (2) to a crystallization kettle, carrying out hydrothermal crystallization at a temperature of 120 to 200 DEG C for 1 to 10 d, carrying out cooling after crystallization and rinsing, filtering and drying the obtained mixed liquor so as to obtain raw powder of the IM-5 molecular sieve. A mole ratio of reactants satisfies the equation of SiO2: Al2O3: M2O: R1: R2: H2O = 60: 0.4-6: 6-21: 0.6-18: 0.6-12: 300-1800, wherein M2O is an alkali metal oxide, R1 is a first template, and R2 is a second template. The method provided in the invention widens the range of mixing ratios of raw materials, improves yield of a single kettle and enables time for crystallization to be further shortened and enlarged production to be easier.

Owner:CHINA PETROLEUM & CHEM CORP +1

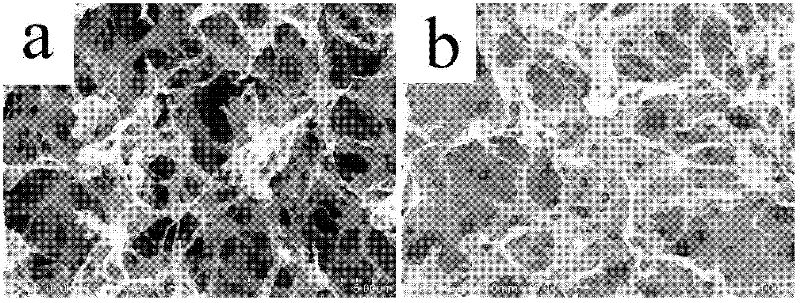

Preparation method of metal-organic framework material/polymer composite proton exchange membrane

ActiveCN105789668AStrong penetrating powerImprove performanceRegenerative fuel cellsVanadium redox batteryMetal-organic framework

The invention relates to a preparation method of a metal-organic framework material / polymer composite proton exchange membrane. The method is characterized by comprising the following steps: dissolving a polymer matrix and a certain amount of metal-organic framework material with an organic solvent and carrying out ultrasonic dispersion to form a uniform membrane liquid; coating the flat and smooth surface of a glass plate with the obtained membrane liquid, and then removing the organic solvent to obtain a composite membrane; and carrying out vacuum drying on the composite membrane for 24 hours to prepare the composite proton exchange membrane for an all-vanadium redox flow battery. The composite proton exchange membrane is smooth in surface; the internal structure of the membrane is regular; the membrane is uniform in thickness and free of a defect; and the thickness is 10-300 microns. The composite proton exchange membrane provided by the invention has excellent vanadium ion permeation blocking ability, keeps excellent proton transfer performance, overcomes the defect of relatively high vanadium ion permeability of an existing all-vanadium redox flow battery membrane, and has the advantages of being simple in preparation process, high in proton transmittance, excellent in vanadium blocking property, excellent in oxidative resistance, easy to industrially amplify and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

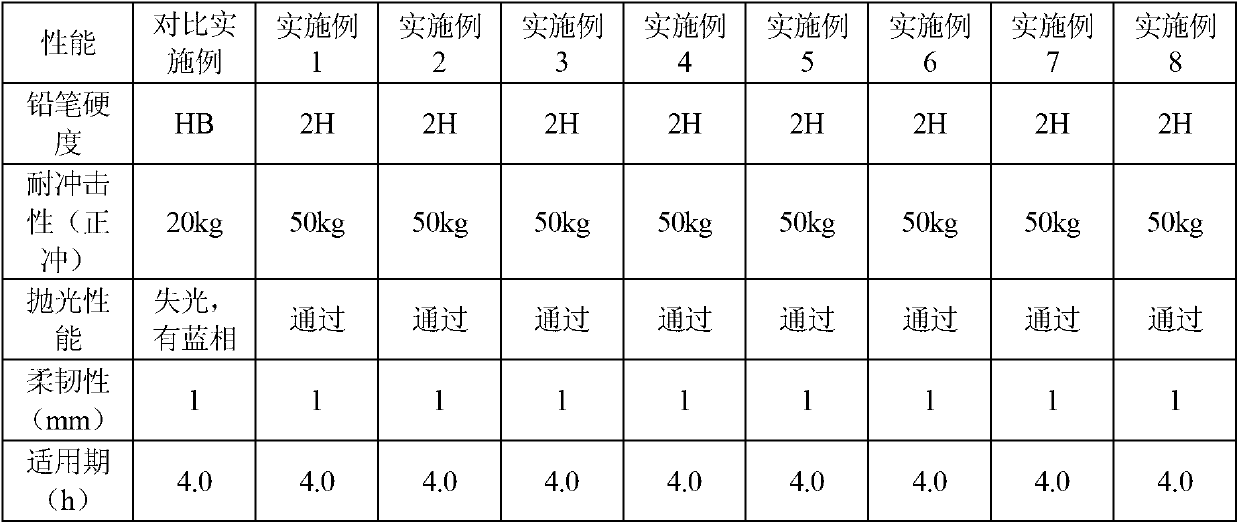

Preparation method of high-reaction-activity hydroxyl acrylic resin

InactiveCN103130944AImprove molecular structureHigh glass transition temperaturePolyurea/polyurethane coatingsAcrylic resinSolvent

The invention relates to a preparation method of high-reaction-activity hydroxyl acrylic resin. According to the invention, a solvent in a reactor is heated to a preset temperature under the protection of an inert gas; a mixture of a monomer component A with hard monomer as a main component (and comprising a small amount of soft monomer, hydroxyl monomer and carboxyl monomer) and an initiation agent is slowly added; a reaction is carried out for a certain period of time with maintained temperature; a mixture of a monomer component B with soft monomer as a main component (and comprising a small amount of hard monomer, hydroxyl monomer and carboxyl monomer) and an initiation agent is slowly added; and reaction is carried out for a certain period of time with maintained temperature, such that acrylic resin comprising hydroxyl is obtained. The invention has the characteristic that common monomers are adopted, and only the synthesis process is changed wherein monomer dropping sequence is changed, such that resin molecular structure is substantially changed, and the synthesized hydroxyl acrylic resin shows high reaction activity during a curing reaction. The method provided by the invention also has the advantages of low cost, simple process, and suitability for industrialized productions.

Owner:XI AN JIAOTONG UNIV +1

Poly(3,4-ethylenedioxythiophene)/sulfonated graphene composite hydrogel and preparation method thereof

InactiveCN102558772APorous Structure RegulationEasy to controlElectrolytic capacitorsCapacitanceIron salts

The invention relates to a method for preparing poly(3,4-ethylenedioxythiophene) / sulfonated graphene composite hydrogel with a porous structure through supramolecular self-assembly. The method comprises the following steps of: dissolving sodium polystyrene sulfonate and sulfonated graphene in water, stirring, performing ultrasonic dispersion to ensure that the sodium polystyrene sulfonate and thesulfonated graphene are dissolved, adding a 3,4-ethylenedioxythiophene monomer, uniformly stirring, adding polyvalent iron salt, standing at room temperature and reacting to obtain blocky poly(3,4-ethylenedioxythiophene) / sulfonated graphene composite hydrogel. The poly(3,4-ethylenedioxythiophene) / sulfonated graphene composite hydrogel with a controllable and porous structure is prepared by using the interaction and electrostatic action of a hydrogen bond and a pi-pi bond among the sulfonated graphene, the sodium polystyrene sulfonate and 3,4-ethylenedioxythiophene through supramolecular self-assembly. The prepared composite hydrogel has high electrical conductivity and mechanical strength, and high specific capacitance and cycle stability in electroactive electrolyte.

Owner:HOHAI UNIV

Hydrogenated pyridine derivative and method for preparing salt thereof

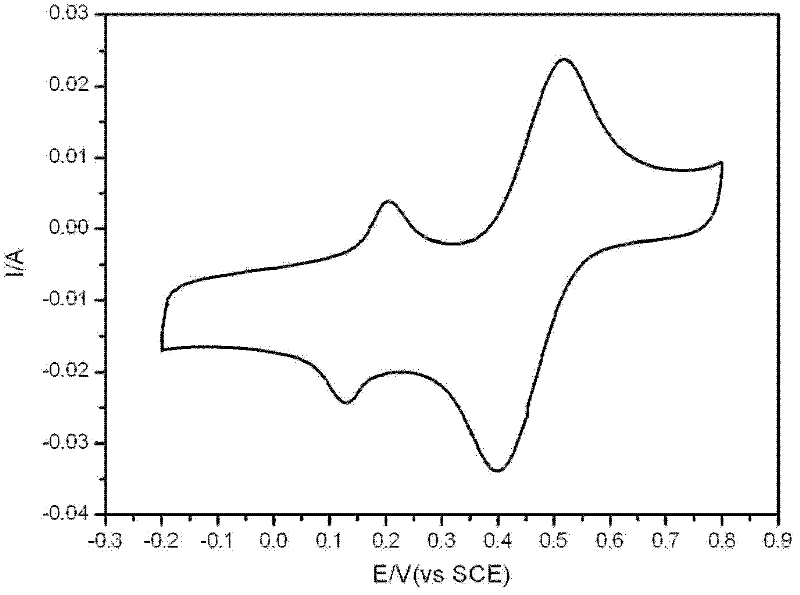

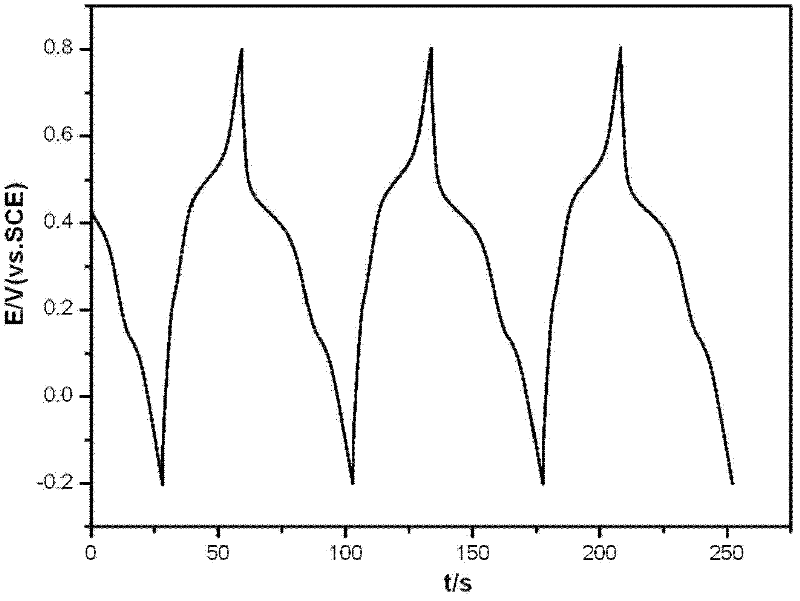

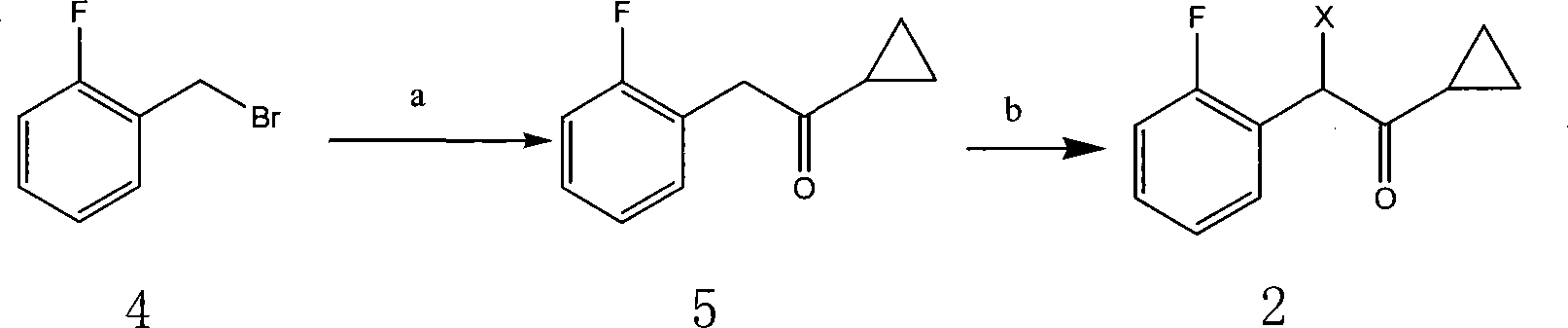

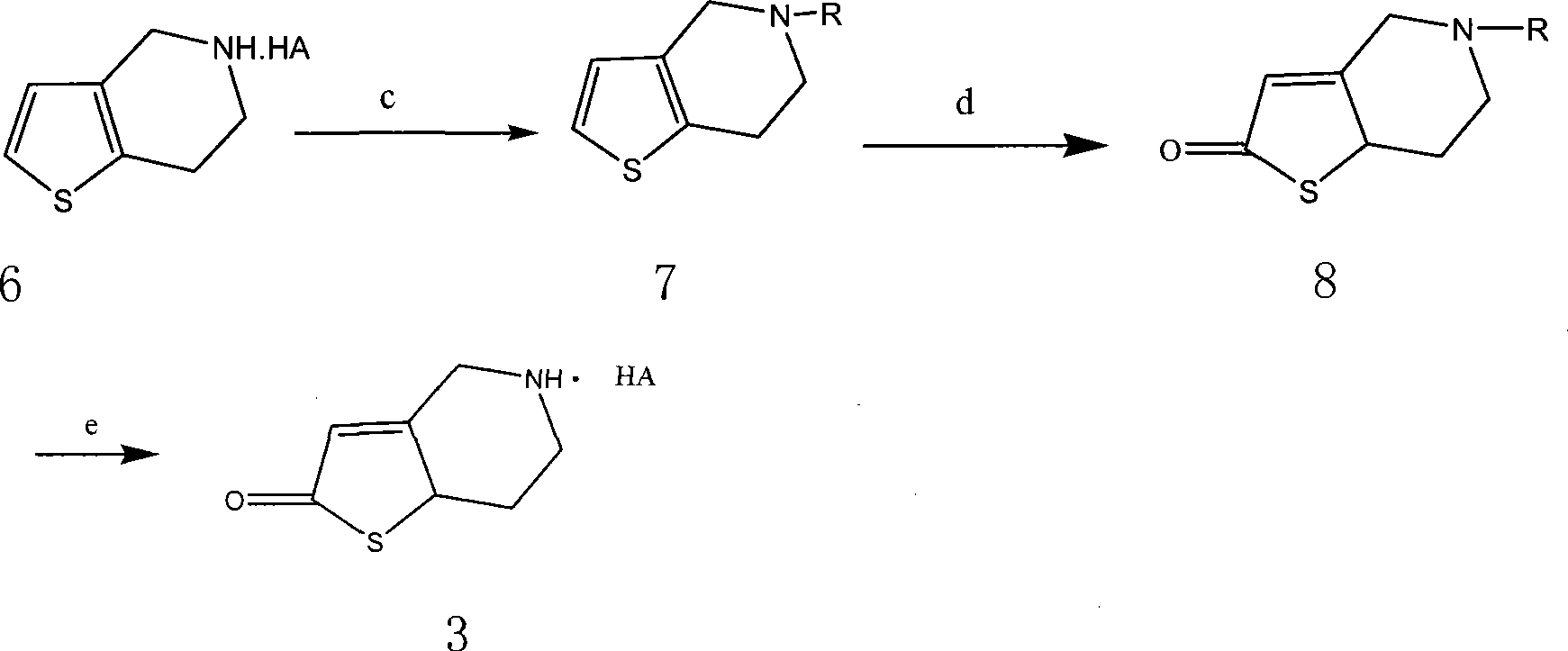

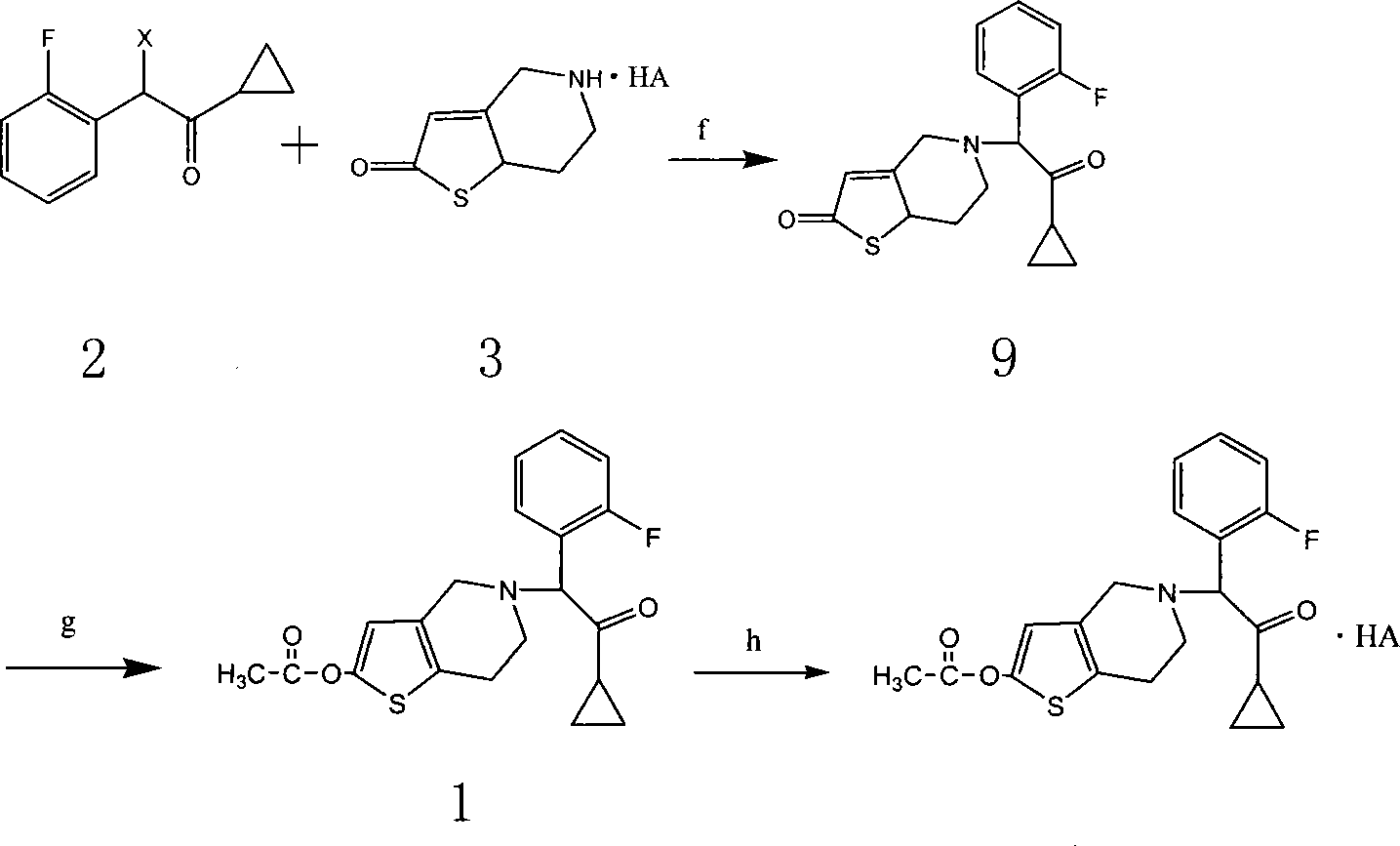

InactiveCN101177430AMild reaction conditionsEasy to scale up productionOrganic active ingredientsOrganic chemistryPyridiniumHalogen

The invention relates to the hydropyridine derivatives of 2-acetoxy-5- (Alpha-cyclopropyl carbonyl-2-fluorobenzyl) -4, 5, 6, 7-tetrahydrothiophene plus [3, 2-C] pyridine and salts of the hydropyridine derivative as well as the preparation method. The invention comprises following steps: preparing two main intermediates: Alpha-cyclopropyl carbonyl-2 fluorobenzyl halogen 2 (wherein, X=F, CL, Br, I) and 2-oxygen-2, 4, 5, 6, 7, 7 Alpha-hexahydrothiophene plus [3, 2-C] pyridinium salt 3 (wherein, HA=HCL, H2SO4, HBr, HI); esterifying the product obtained through condension of the two main intermediates using acetic anhydride to get target product. The target product and the needed acid are combined to be salts via addition reaction; during the process of crystallization, necessary crystal seed is added to achieve single-morphic crystals.

Owner:LUNAN PHARMA GROUP CORPORATION

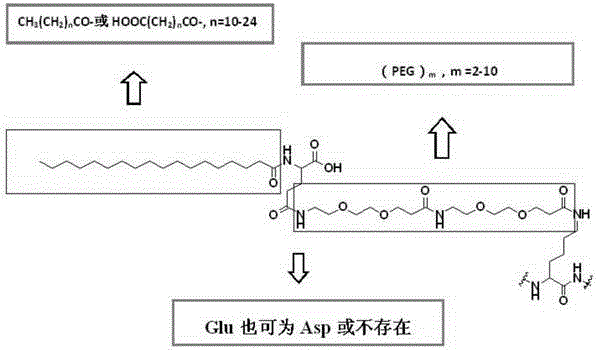

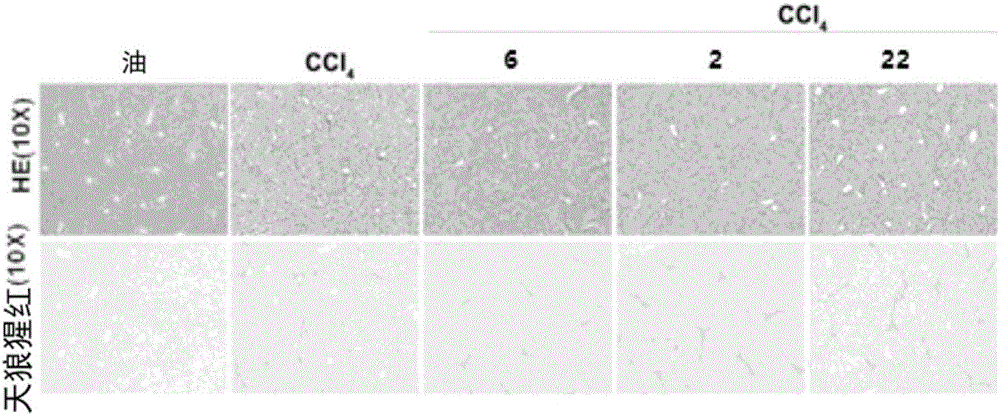

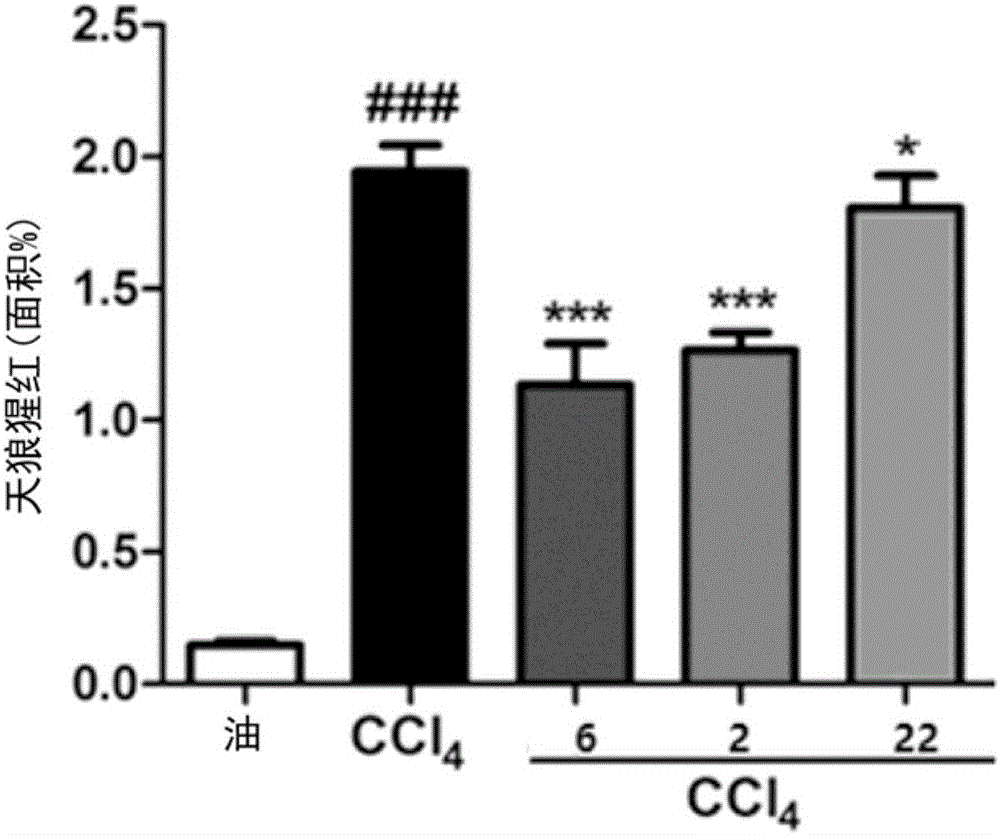

Application of GLP-1R/GCGR double-target agonist polypeptide to treatment of fatty liver diseases, hyperlipidemia and arteriosclerosis

ActiveCN106046145AImprove biological activityExtended half-lifePeptide/protein ingredientsMetabolism disorderFibrosisDrug biological activity

The invention relates to application of a polypeptide compound having double agonist effects on a glucagon-like peptide-1 receptor and a glucagon receptor. The polypeptide compound has the characteristics of high enzymolysis stability, high bioactivity, no adverse reaction, etc., can alleviate abnormal rise in the levels of total cholesterol and triglyceride in blood induced by diabetes and high-meal diet, lowers the level of liver enzyme, improves liver damage and fibrosis stage and is applicable to prevention or treatment of diseases like non-alcoholic fatty liver diseases, hyperlipidemia and arteriosclerosis.

Owner:SHENZHEN TURIER BIOTECH CO LTD

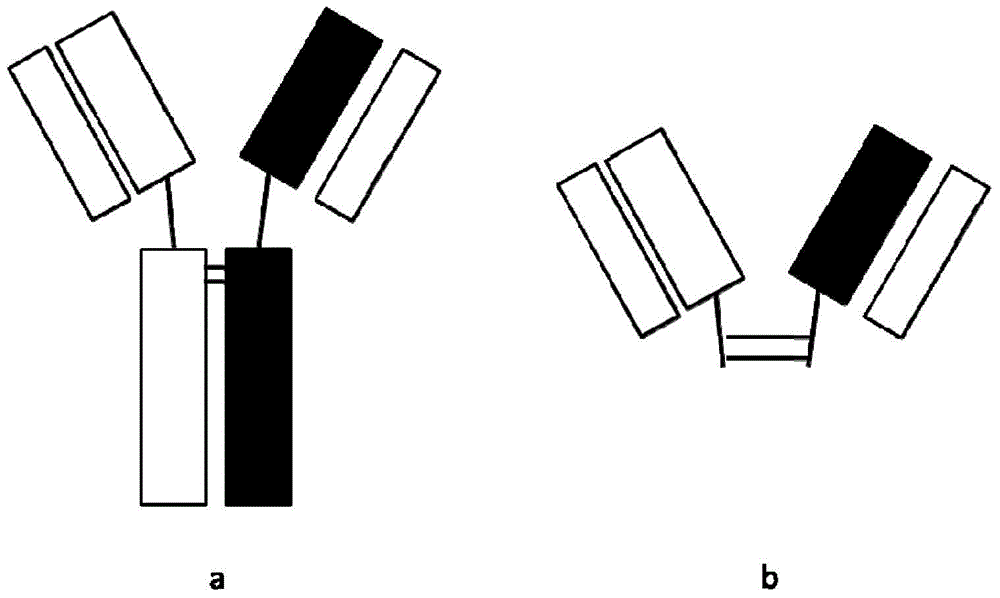

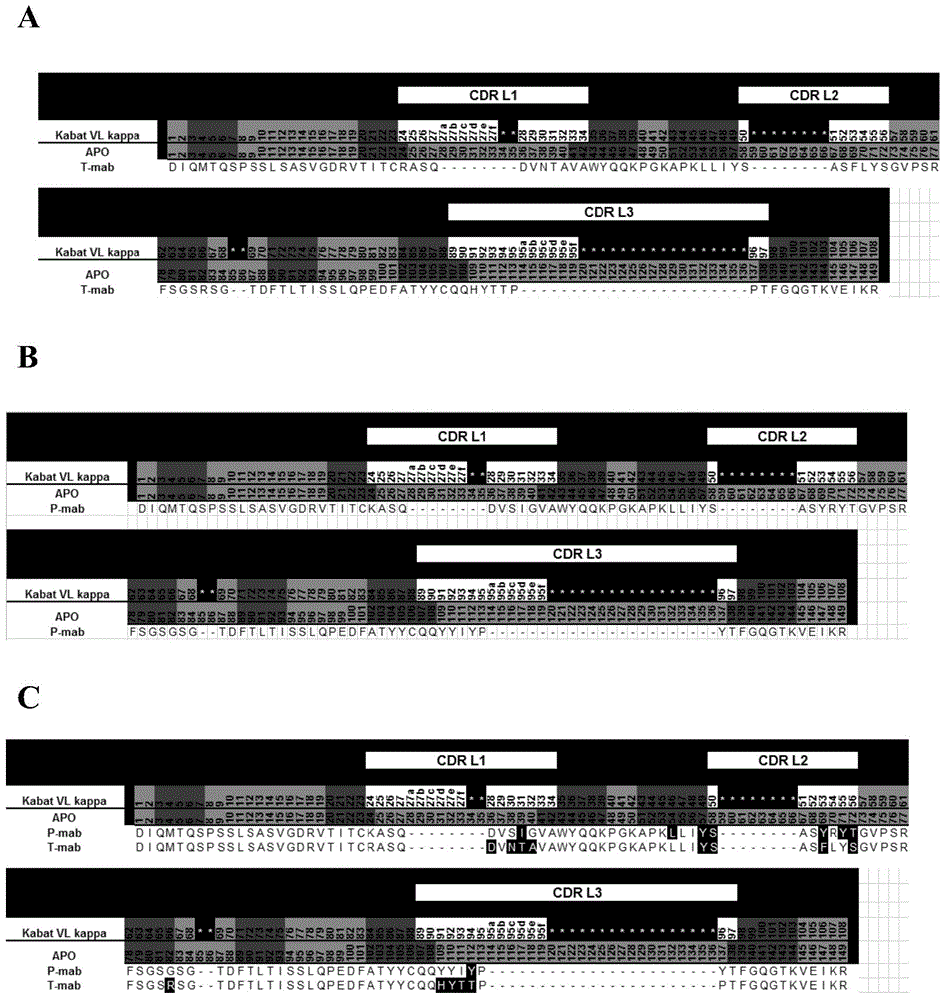

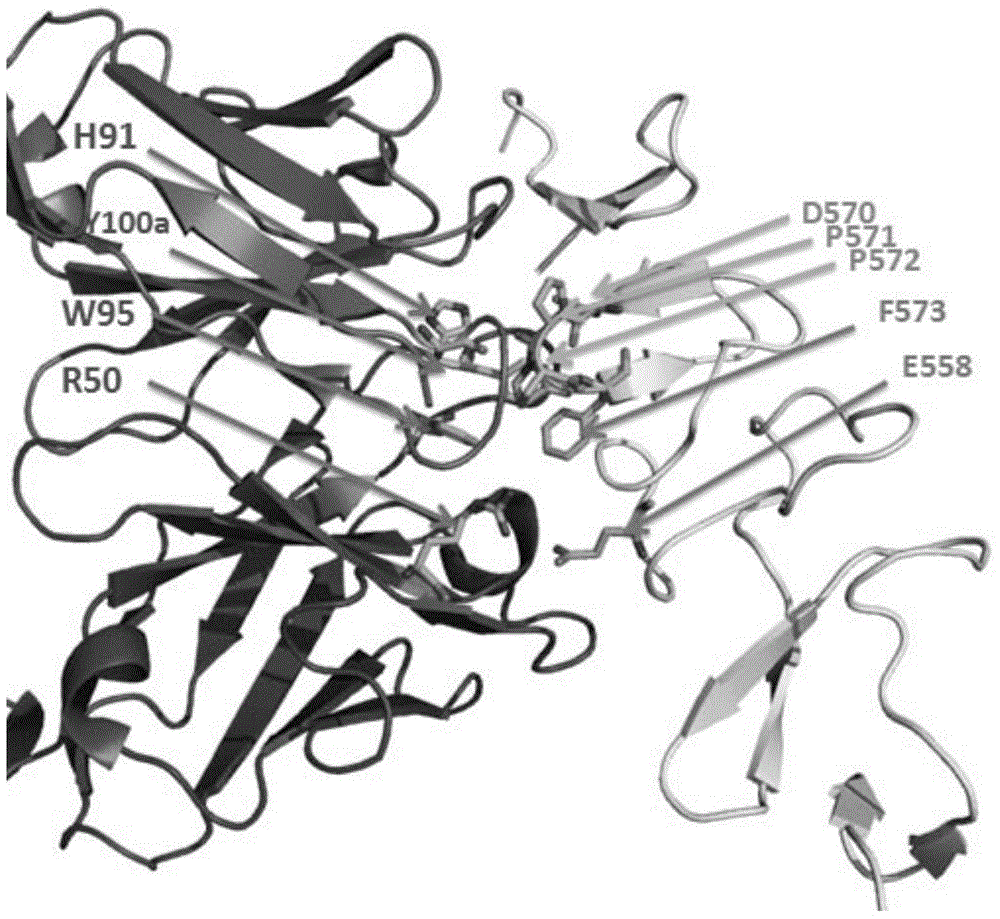

Bispecific antibody or antibody mixture having common light chain

ActiveCN105820251AStability is not affectedSolving the problem of heavy and light chain mismatchesHybrid immunoglobulinsImmunoglobulins against cell receptors/antigens/surface-determinantsBispecific antibodyMixed Cellular Population

The invention relates to a bispecific antibody or antibody mixture, and more specifically relates to the bispecific antibody or the antibody mixture having a common light chain, and a preparation method of the bispecific antibody or the antibody mixture. The invention also relates to nucleic acid molecules for coding the bispecific antibody or the antibody mixture, a recombinant vector containing the nucleic acid molecules and recombinant cells, and a detection and quantification method for the bispecific antibody or the antibody mixture. The bispecific antibody or the antibody mixture is prepared by a common light chain technology, the preparation method is simple and controllable, mismatching of the light chains in the bispecific antibody can be avoided, the antibody mixture can be expressed in same host cell, difficulty for culturing the mixed cell groups is reduced, and the amplification production is easily achieved.

Owner:JIANGSU ALPHAMAB BIOPHARMACEUTICALS CO LTD

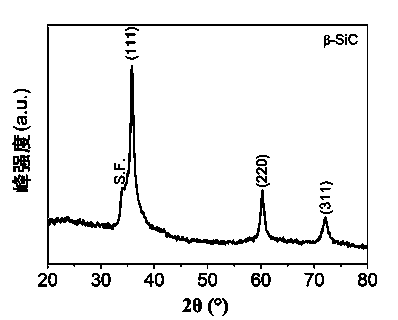

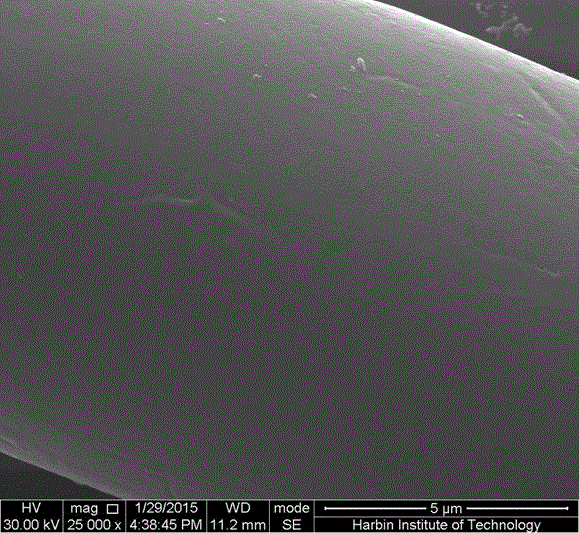

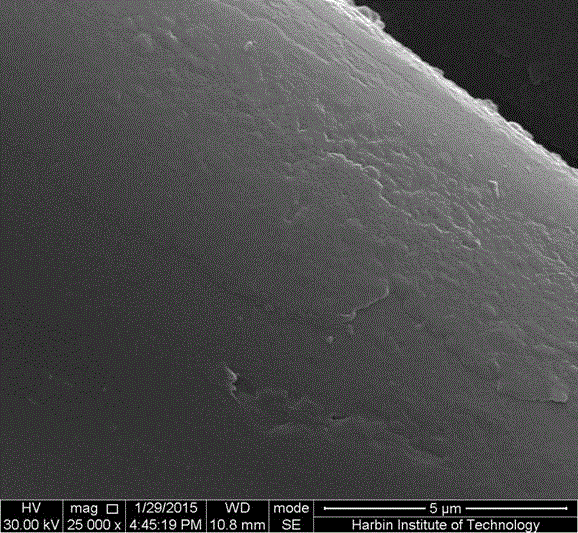

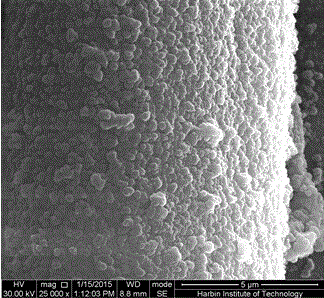

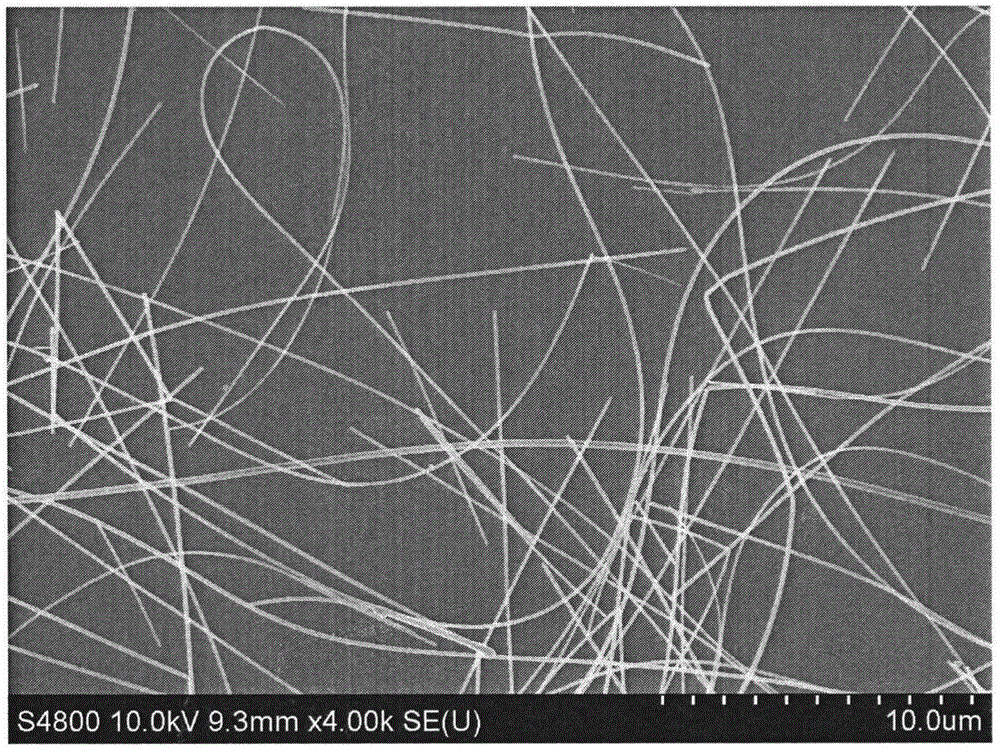

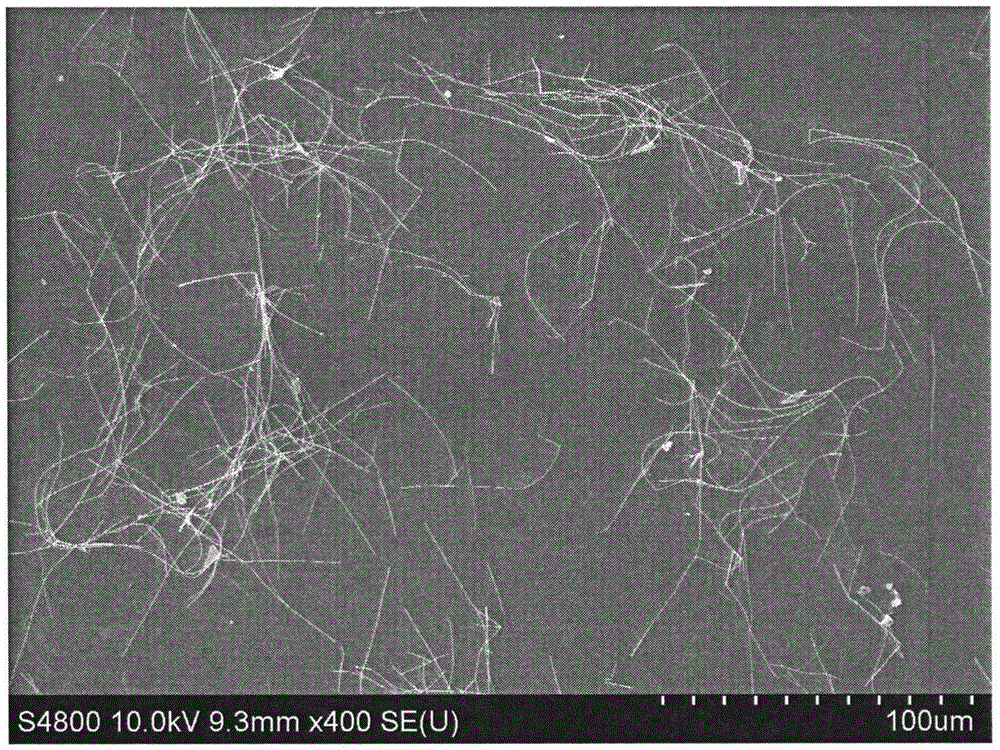

Preparation method of porous silicon carbide nanofiber

ActiveCN103966701AUniform diameterLarge specific surface areaArtificial filament chemical after-treatmentFiltrationElectrospinning

The invention discloses a preparation method of a porous silicon carbide nanofiber. The preparation method comprises the following steps of: (1) preparing a carbon nanofiber precursor polymer spinning solution; (2) performing electrostatic spinning to prepare a polymer nanofiber; (3) carrying out pre-oxidization crosslinking on the polymer nanofiber; (4) carrying out high-temperature firing on the pre-oxidized polymer nanofiber to prepare a carbon nanofiber; and (5) carrying out carbon thermal reduction on the carbon nanofiber and silicon powder to obtain the porous silicon carbide nanofiber. According to the preparation method, the morphology, the diameter and the ordering of the obtained silicon carbide nanofiber can be effectively regulated and controlled through simple means; the production cycle is relatively short so that expanded production can be conveniently realized and the preparation process is simple so that the industrial production can be conveniently realized; the porous silicon carbide nanofiber has wide application prospect in the fields of high-temperature filtration, high-temperature catalysis, catalyst carriers, heat insulation and sound insulation, gas separation, chemical sensors and the like.

Owner:NAT UNIV OF DEFENSE TECH

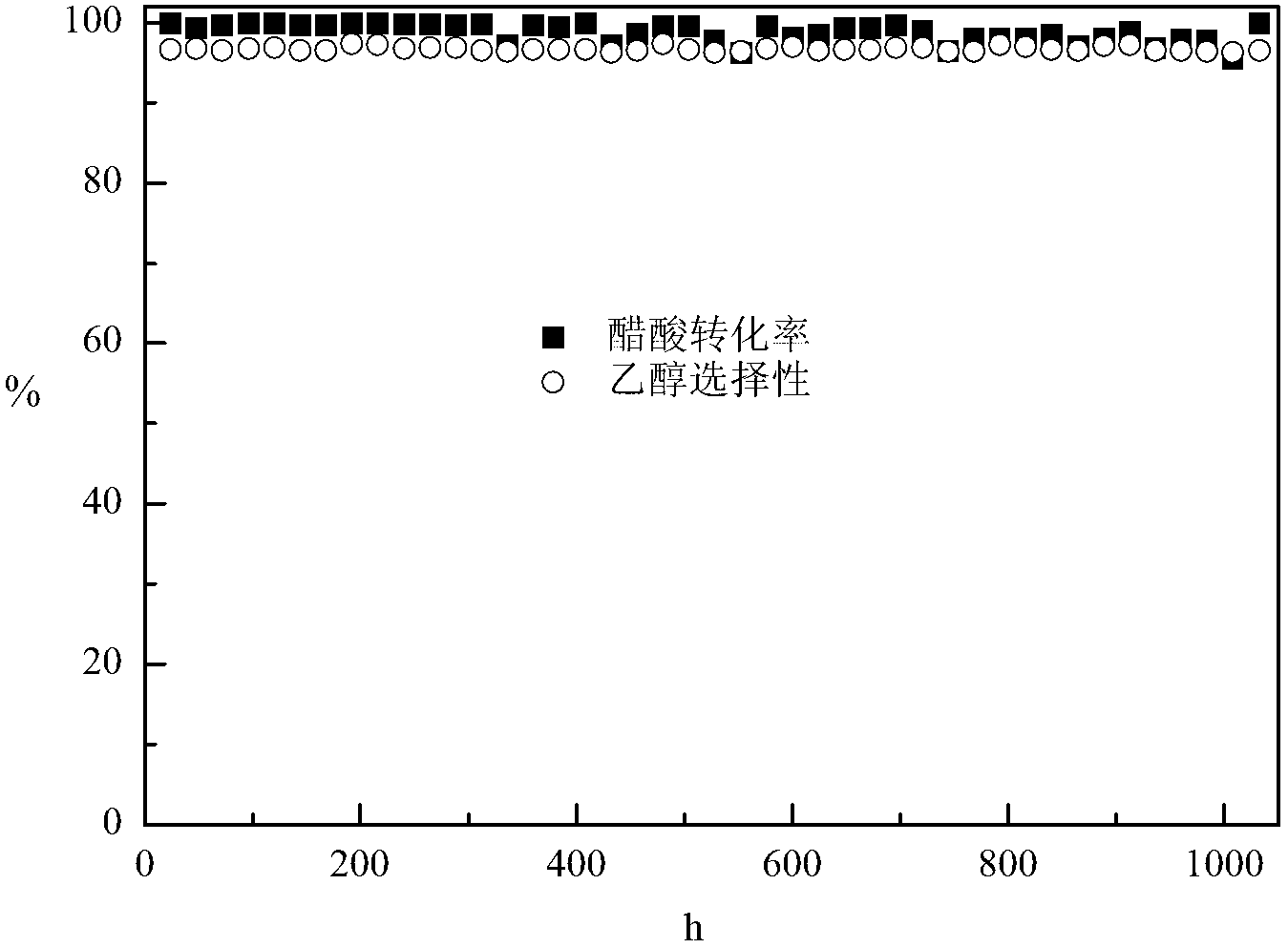

Catalyst for producing ethanol and preparation method thereof

ActiveCN103170337AImprove thermal stabilityAvoid inactivationOrganic compound preparationHydroxy compound preparationHydrogen pressureReaction temperature

The invention relates to a catalyst for producing ethanol and a preparation method thereof. The weight ratio of reactive metal to aid to a protective agent to a carrier in components of the catalyst is (5-30):(0-20):10:100, wherein the reactive metal is any one of nickel, cobalt, copper and manganese; the aid is any one of iron, molybdenum, cerium, barium, zinc and tin; the protective agent is aluminium nitrate or silica sol; and the carrier is carbon nano tube or silica. By taking glacial acetic acid hydrogenation ethanol production reaction as an example, the acetic acid conversion rate is more than 99 percent, the ethanol selectivity is more than 95 percent, the service life of the catalyst exceeds 1000 hours, and the space time yield of the ethanol is more than 1000mg / g-cat. / h under the conditions of the reaction temperature of 225 DEG C and the hydrogen pressure of 2.5MPa. According to introduction of the protective agent, the heat stability of the catalyst is greatly improved, and the series of catalysts are low in cost, simple in preparation, excellent in performance and high in stability and have good industrial application prospects.

Owner:XIAMEN UNIV +1

Method for preparing non-crystal molybdemum sulfide nano powder

InactiveCN101024517ARapid and uniform precipitation reactionShort reaction timeNanostructure manufactureMolybdenum sulfidesSolubilityStrong acids

The invention relates to a manufacture method for amorphous form molybdenum sulphide nanometer powder. The feature is that: it uses solubility molybdenate, thiacetamide, strong acid and dispersing agent as raw material, dissolving solubility molybdenate and thiacetamide into deionized water, adding dispersing agent, adding strong acid in a short time, reacting at constant temperature, absorbing tail gas hydrogen disulfide by NaOH sulotion, filtering, washing, drying the depositing to gain MoSx(=2-4) nanometer powder, using it as precursor, burning and gaining amorphous form molybdenum sulphide nanometer powder that has widely application prospect in lubrication, catalyst and photo-electric-magnetism field.

Owner:HEFEI UNIV OF TECH

Super-hydrophobic and -oleophylic cloth producing method

A super-hydrophobic and -oleophylic cloth producing method is characterized by comprising following steps: (A) cleaning a cloth and air-drying the cloth; (B) dissolving dopamine hydrochloride and folic acid in water with stirring and pre-treating the water solution to obtain a uniform mixed solution; (C) regulating the pH of the mixed solution with an alkaline medium, adding the cleaned and air-dried cloth in the mixed solution, and performing a stirring reaction to obtain a cloth having a micro-nano structure; (D) adding the cloth in an ethanol solution of octadecylamine and carrying out a reaction to obtain the super-hydrophobic and -oleophylic cloth for oil-water separation, wherein the concentration of the dopamine hydrochloride is 0.5-2.0 mg / mL, the concentration of the folic acid is 0.2-1.0 mg / mL, the pre-treatment temperature is in the range from room temperature to 60 DEG C, and the pre-treatment time is 6-24 h. The producing method is low in cost, is simple in steps, is mild in reaction conditions and is beneficial to amplified production. The cloth is stable in super-hydrophobic property and has an application potential in the fields of oil-water separation, waterproof materials and self-cleaning materials.

Owner:HIT YIXING ACAD OF ENVIRONMENTAL PROTECTION

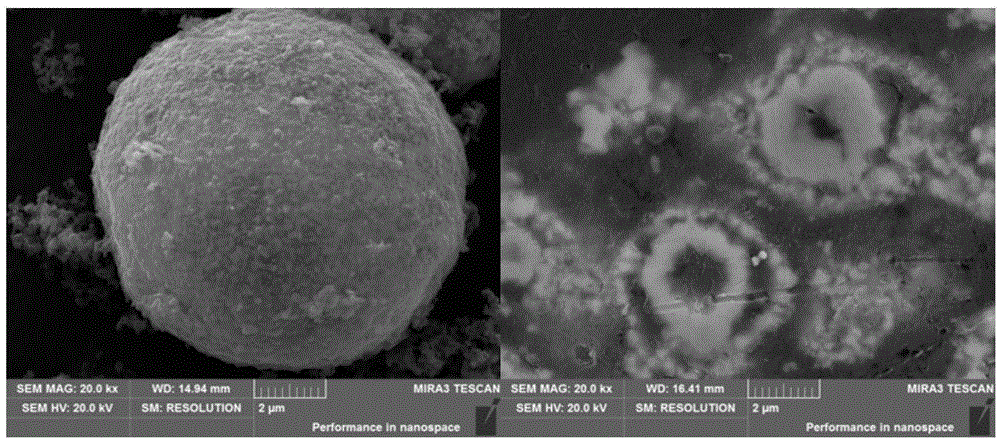

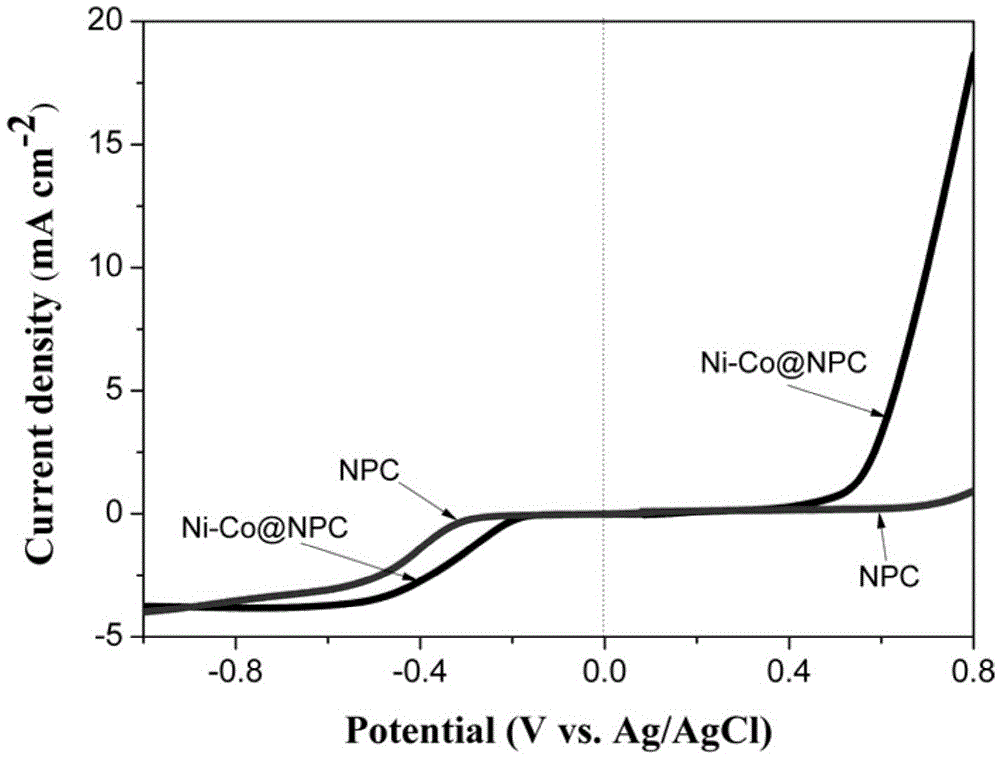

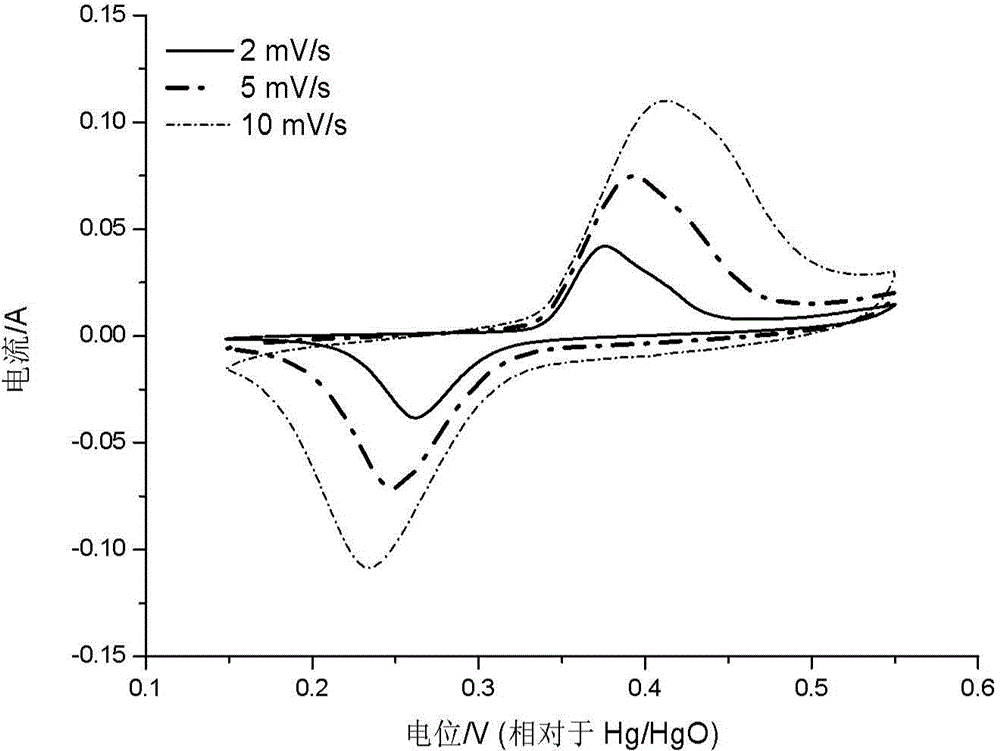

Bi-functional catalyst for alkaline water system metal/air battery and preparation method thereof

ActiveCN105552393AImprove stabilityHas bifunctional catalytic activityFuel and primary cellsCell electrodesIn situ polymerizationControllability

The invention discloses a bi-functional catalyst for an alkaline water system metal / air battery and a preparation method thereof. The catalyst is a core-shell structure material formed by coating transition metal simple substance particles by nitrogen doped carbon; the preparation process is: taking transition metal salt and urea as raw materials, obtaining precursors of transition metal simple substance particles through a hydrothermal method, coating nitrogen contained polymers on the surfaces of the precursors through in situ polymerization, and carrying out high-heat treatment to obtain the catalyst. The catalyst is good in stability, has bi-functional catalytic activity (ORR and OER) and has high catalytic activity in alkaline environment; the preparation technology is strong in controllability and easy in repetition and satisfies the industrial production demand.

Owner:CENT SOUTH UNIV

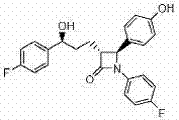

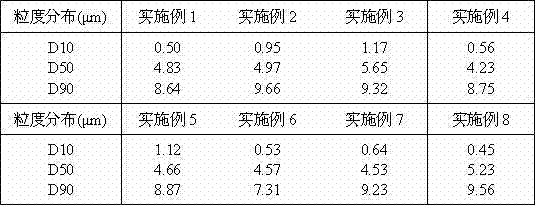

Preparation method of ezetimibe medicine composition

InactiveCN103655453AEasy to operateEasy to scale up productionOrganic active ingredientsMetabolism disorderMedicineEzetimibe

The invention relates to a preparation method of an ezetimibe medicine composition. The preparation method comprises the following steps: 1, suspending ezetimibe in a proper solvent to prepare an uniform ezetimibe micron-sized suspension; 2, adding the suspension into a diluent of the medicine composition in a spraying manner and drying to prepare particles and powder of the ezetimibe medicine composition; and 3, preparing the particles and the powder into the ezetimibe medicinal minimum dose unit. Firstly, the medicine is prepared into the micron-sized suspension, granulation is carried out in a one-step granulation manner, the medicine is added into the diluent and finally, the medicinal minimum dose unit is prepared. The preparation method has the benefits that the effect of the preparation method is superior to that of a method in which micronization is carried out after the slightly soluble medicament is separately micronized; and the operation is simple and the large scale production is easy.

Owner:CHINA RESOURCES SAIKE PHARMA

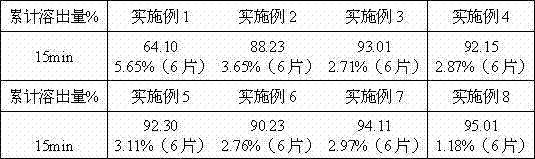

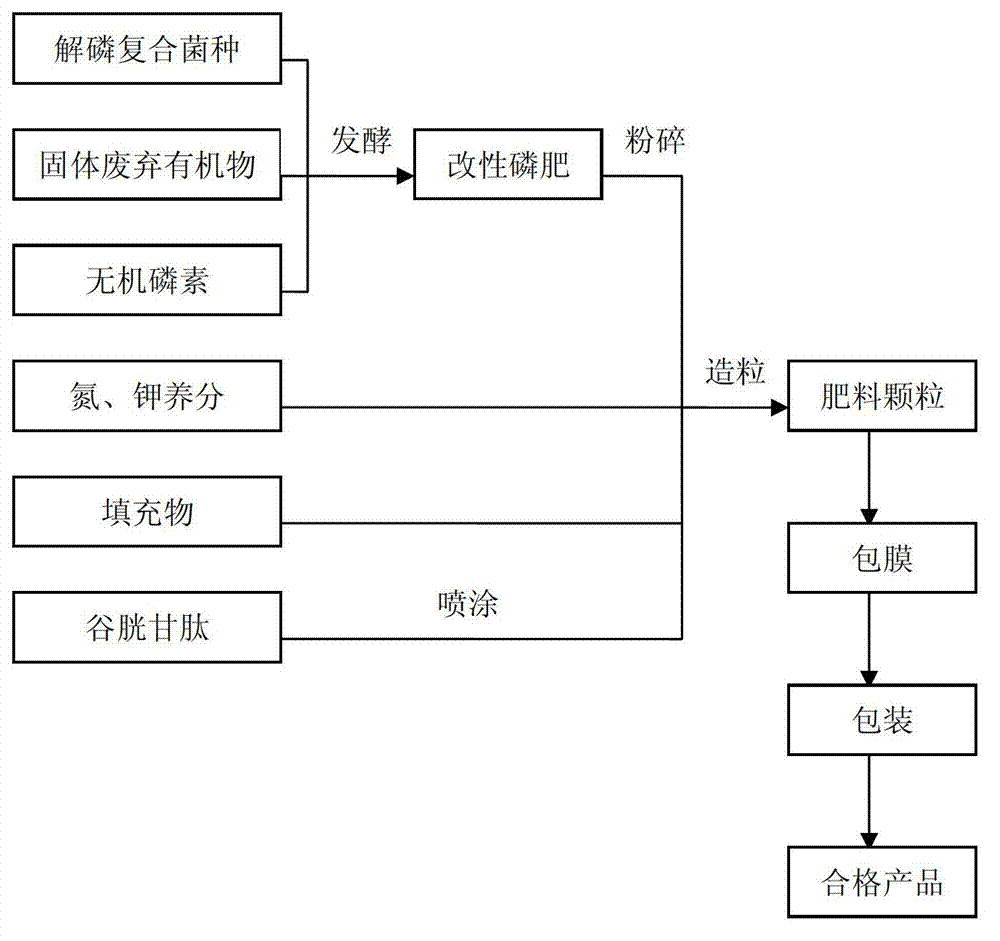

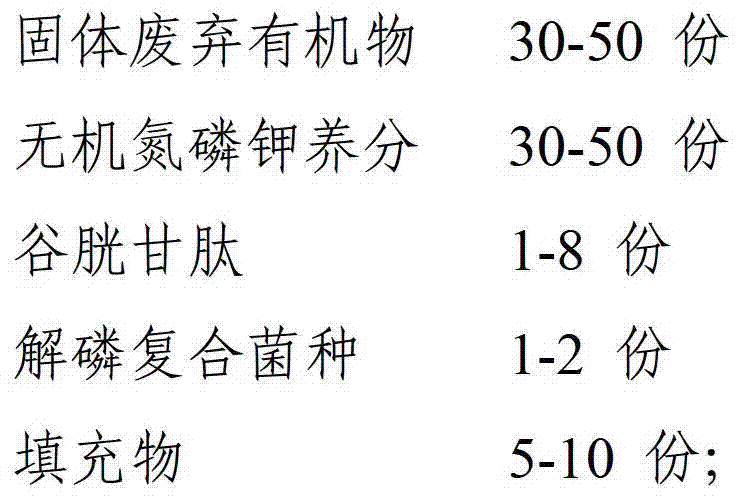

Environment-friendly organic-inorganic compound fertilizer and preparation method thereof

ActiveCN103204744AImprove protectionImprove overall utilizationFertilizer mixturesPotassiumGrossularine-1

The invention provides an environment-friendly organic-inorganic compound fertilizer. The fertilizer comprises the following raw materials in parts by weight: 30-50 parts of solid waste organic, 30-50 parts of inorganic nitrogen phosphorus and potassium nutrient, 1-8 parts of glutathione, 1-2 parts of phosphate-solubilizing compound strain, and 5-10 parts of filler. The organic-matter containing raw material adopted by the fertilizer is from a large amount of solid waste organic from other industries, the byproduct or leftovers are used for providing abundant organic matter so as to produce the organic-inorganic compound fertilizer, the waste is turned into wealth, the environmental protection is realized, the cost is saved, and the enterprise benefit is increased. The detoxication effect of the glutathione is used for producing the organic-inorganic compound fertilizer, so that the blank in China is filled.

Owner:SHANDONG BAOYUAN BIOTECH CO LTD

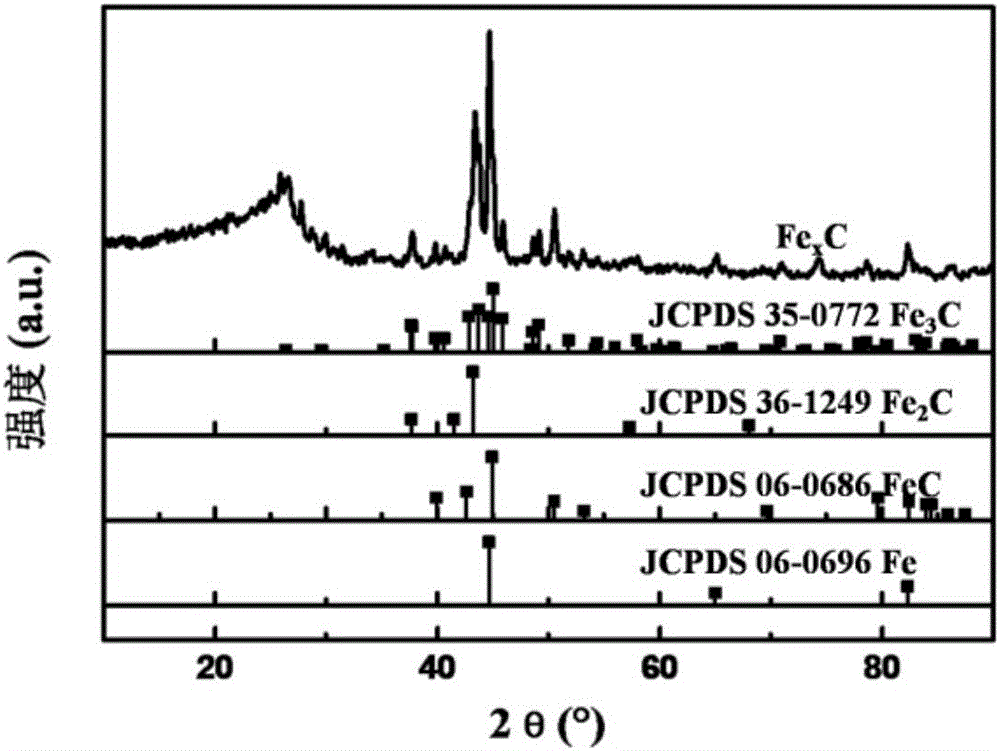

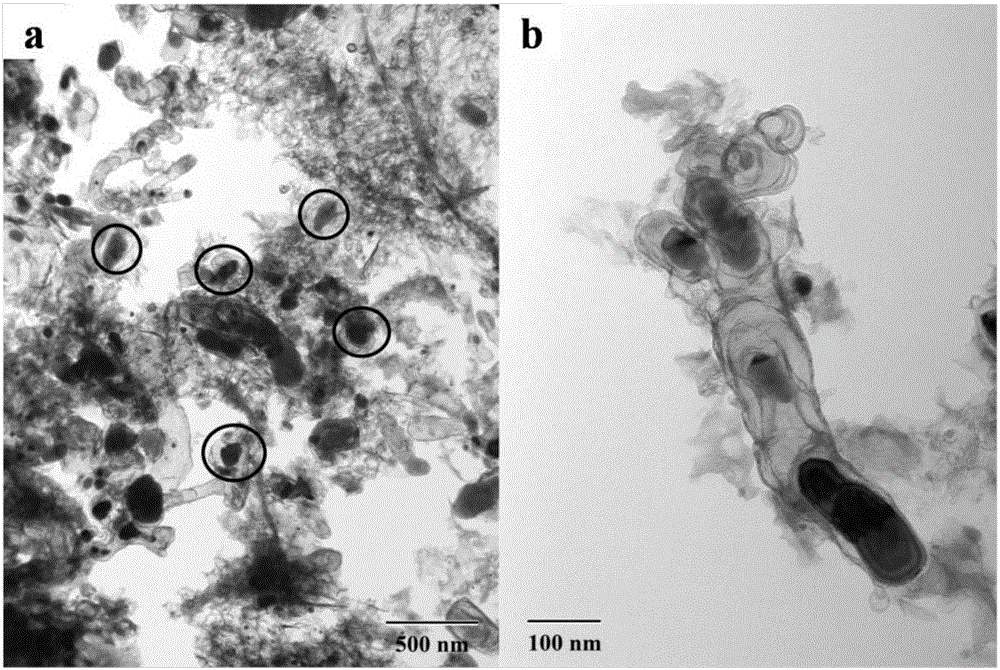

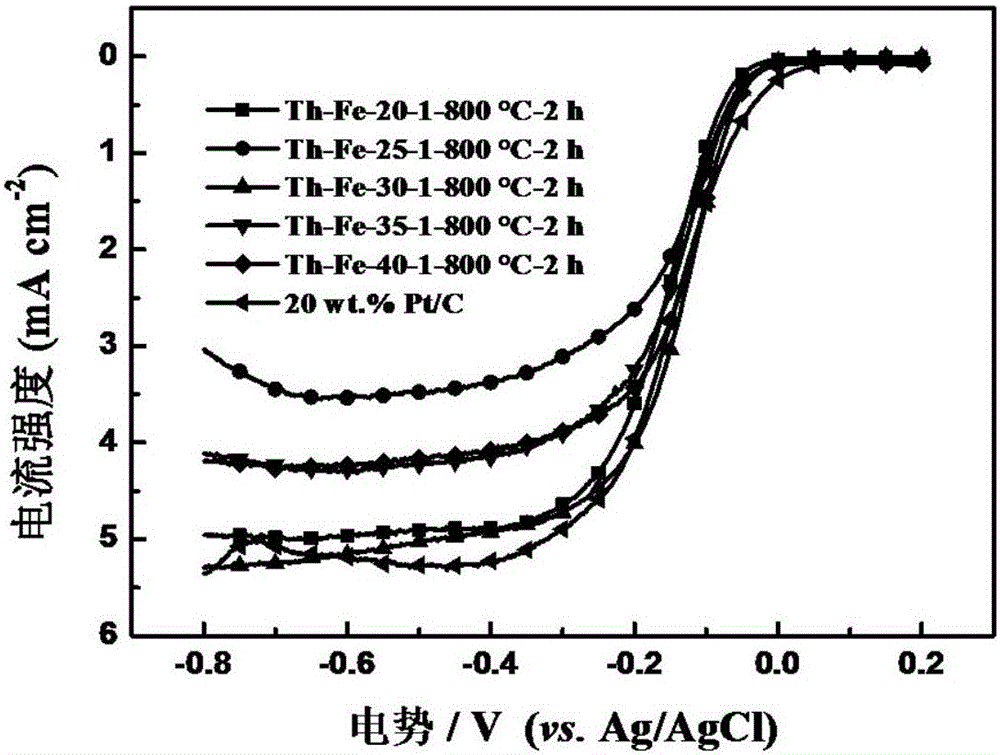

N and S dual-doped carbon nanotube-coated FexC catalyst and preparation method and application thereof

The invention provides a N and S dual-doped carbon nanotube-coated FexC catalyst and a preparation method, and belongs to the field of energy materials and electrochemistry. The N and S dual-doped carbon nanotube-coated FexC catalyst is prepared through pyrolysis in an inert atmosphere by taking thiourea as a C source, a N source and a S source, taking FeCl3.6H2O as a metal source and adopting a one-step method. According to the catalyst, metal particles are coated with N and S dual-doped carbon nanotubes, therefore, direction contact of the metal particles and an electrolyte solution in the reaction process can be effectively avoided, and the catalyst is beneficial for improving the material stability; the catalyst not only shows the oxygen reduction catalyzing performance equivalent to a Pt-C catalyst and the better stability and methanol tolerance under the alkaline condition, but also has the oxygen reduction catalyzing performance under the acidic condition; compared with a common coated-type FexC catalyst, the catalyst has the advantages that the preparation method is simple, the raw materials are easy to obtain, scale production is convenient to achieve, and the high practical value is achieved.

Owner:DALIAN UNIV OF TECH

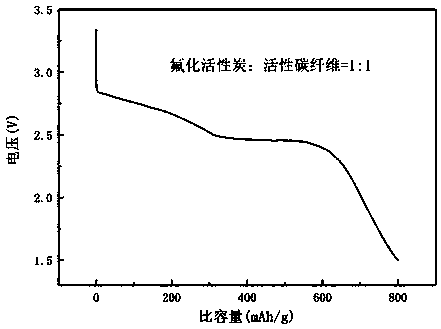

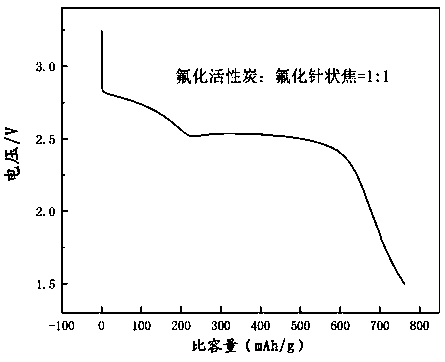

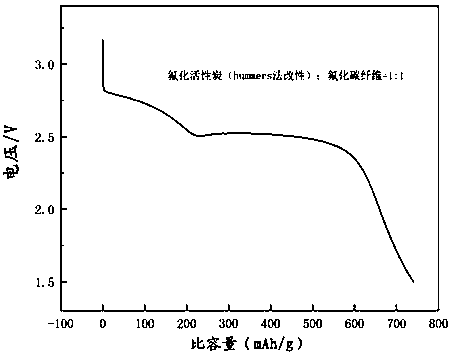

Composite carbon fluoride cathode material for lithium primary battery, preparation method and application thereof

ActiveCN109461923AHigh specific capacityHigh capacity densityCell electrodesNon-aqueous electrolyte cellsMass ratioPorous carbon

The invention belongs to the technical field of a cathode material for a lithium primary battery, particularly relates to the field of preparation of the cathode material for a fluorocarbon battery, and in particular to a composite carbon fluoride cathode material for the lithium primary battery, a preparation method and an application thereof. The material is a composite material prepared by ballmilling and mixing a porous carbon fluoride material having a high tap density and a carbon fluoride material having a high graphitization degree and then fluorinating the mixture. The composite material has a carbon content of 38-60%, a fluorine content of 40-62% and a tap density of greater than 0.8g / ml; the mixing mass ratio is in the range of 1:0.1-1:10; and the composite material has high specific surface area, high tap density and high graphitization degree. Due to the high tap density of the material, the overall high volumetric specific energy of the material is guaranteed; through anion diffusion channel composed of porous carbon fluorides, the voltage hysteresis phenomenon at the initial stage of the battery discharge is effectively improved and the overall discharge performance of the material is improved.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD

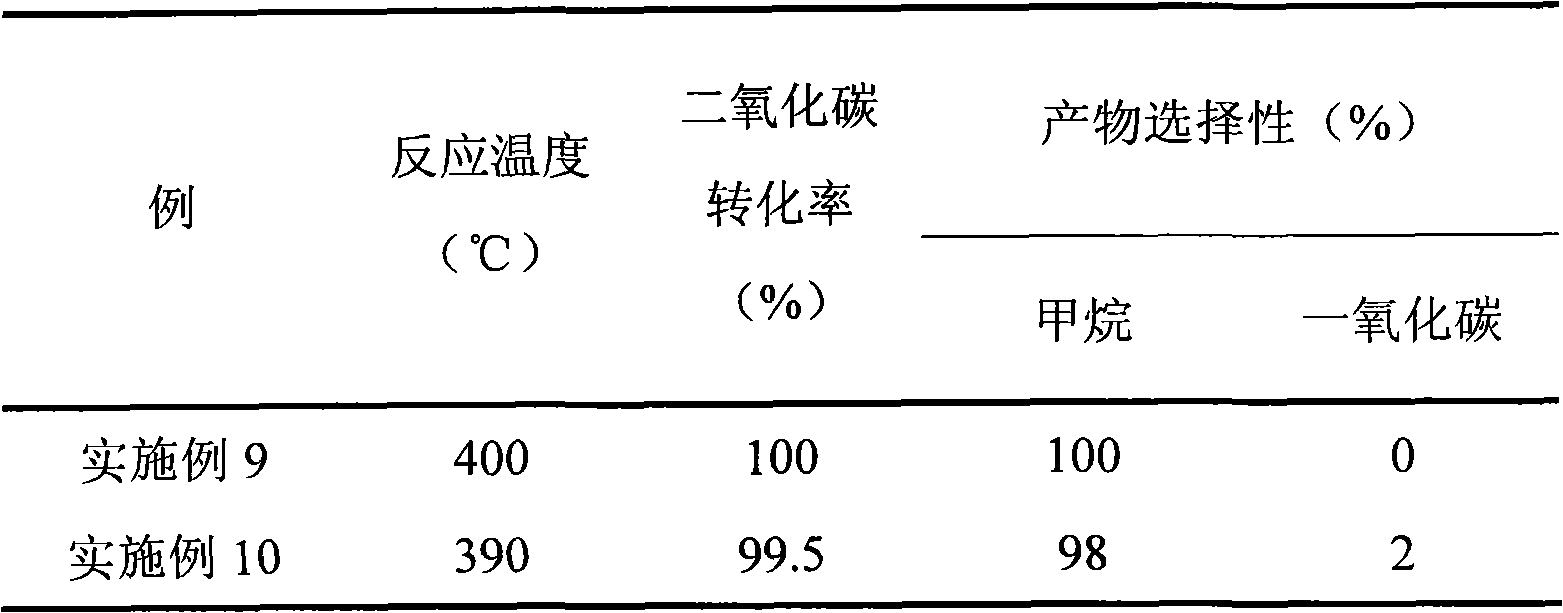

Catalyst for methanation of carbon dioxide

InactiveCN102091629AImprove structural stabilityImprove heat stabilityHydrocarbon from carbon oxidesHydrogen separation using solid contactMethanationActive component

The invention discloses a catalyst for the methanation of carbon dioxide. The carrier of the catalyst is composite oxide of rare earth and other metals, and the composition of the catalyst is represented by a general formula of AxByOz, wherein in the formula, A is a rare metal, B is one or two metals from groups IIB, IIIA, VIA, IVB, VB and VIB, x is 0 to 1, y is 0 to 2, and z is 2 to 4; and the active component of the catalyst is nickel, and the nickel loaded on the carrier accounts for 1 to 15 percent of the total weight of the catalyst. Compared with the conventional carbon dioxide methanation technique, the catalyst technique disclosed by the invention, under the similar reaction conditions, can achieve a carbon dioxide conversion rate of 100 percent, a methane selectivity of 100 percent and a methane time space yield of more than 1,000g / kg.h.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

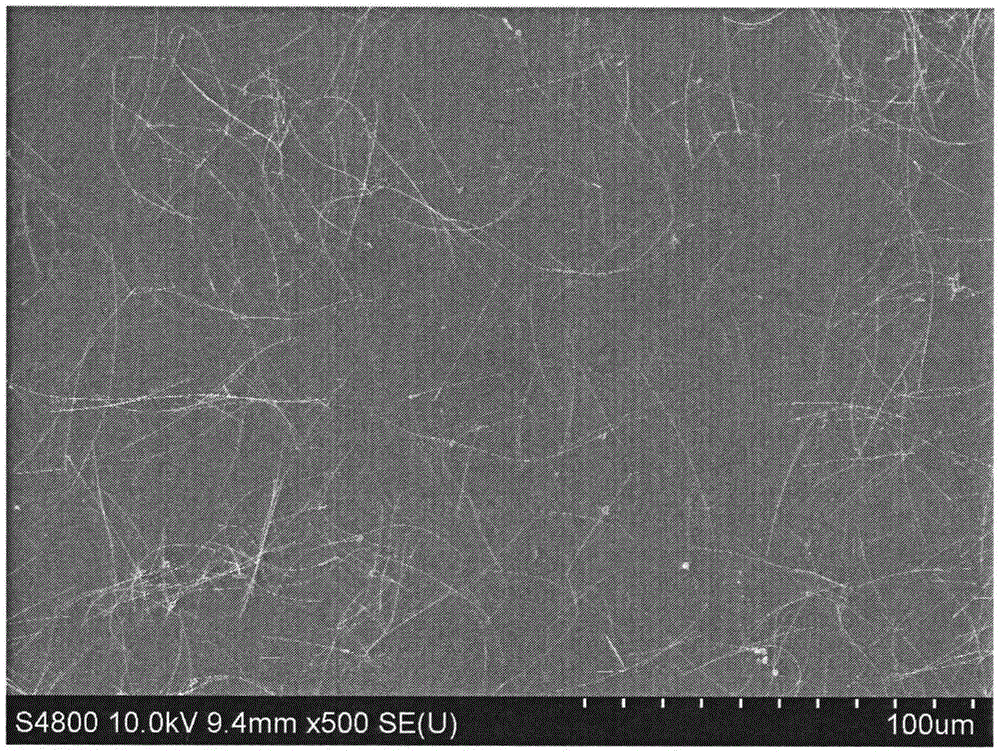

Method for preparing silver nanowires

InactiveCN105537622AEasy to operateAvoid the effects of reactionsNanotechnologyPolymerPhotochemistry

The invention discloses a method for preparing silver nanowires. Under protection of inert gas, a polymer polyhydric alcohol solution and a silver salt and halide polyhydric alcohol solution are sequentially added into a premixing container and are stirred to be completely dissolved, and mixed liquor is transferred to a reaction device which is preheated to 100-180 DEG C to react for 2-5 h; acetone with the volume being 5-9 times that of prepared silver nanowire mother liquor is added into the prepared silver nanowire mother liquor, natural settling is conducted for 10-30 min after acute vibration, supernatant is moved away, sediment is reserved, and the process is repeated 2-3 times; ethyl alcohol with the volume being 5-9 times that of the mother liquor is added into the sediment, centrifugal separation is carried out, supernatant is moved away, sediment is reserved, and the process is repeated 2-3 times; and obtained silver nanowires are stored in the ethyl alcohol in a scattered mode. The preparation method is one-pot, operation is simple, and stability and repeatability are good; stirring is not needed in the reaction process during preparation, and silver wire particles are few; the material adding speed does not need to be strictly controlled in the preparing process, and large-scale production is facilitated; separation and purification are carried out through natural settling of the acetone and then centrifugal sedimentation of the ethyl alcohol, so that the separation efficiency is higher.

Owner:嘉兴禾浦光电科技有限公司

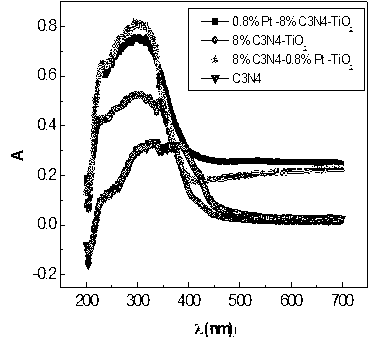

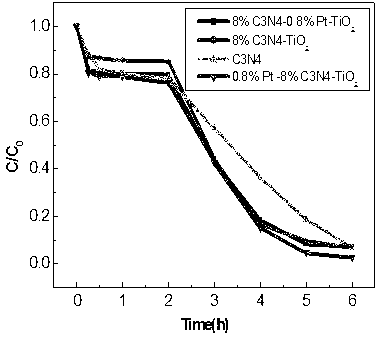

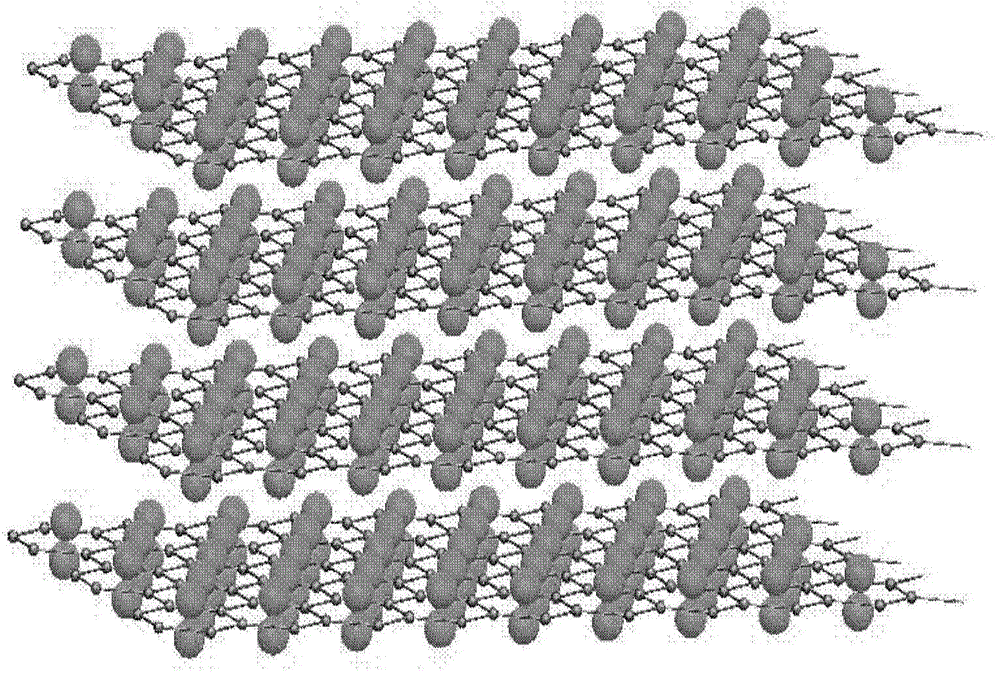

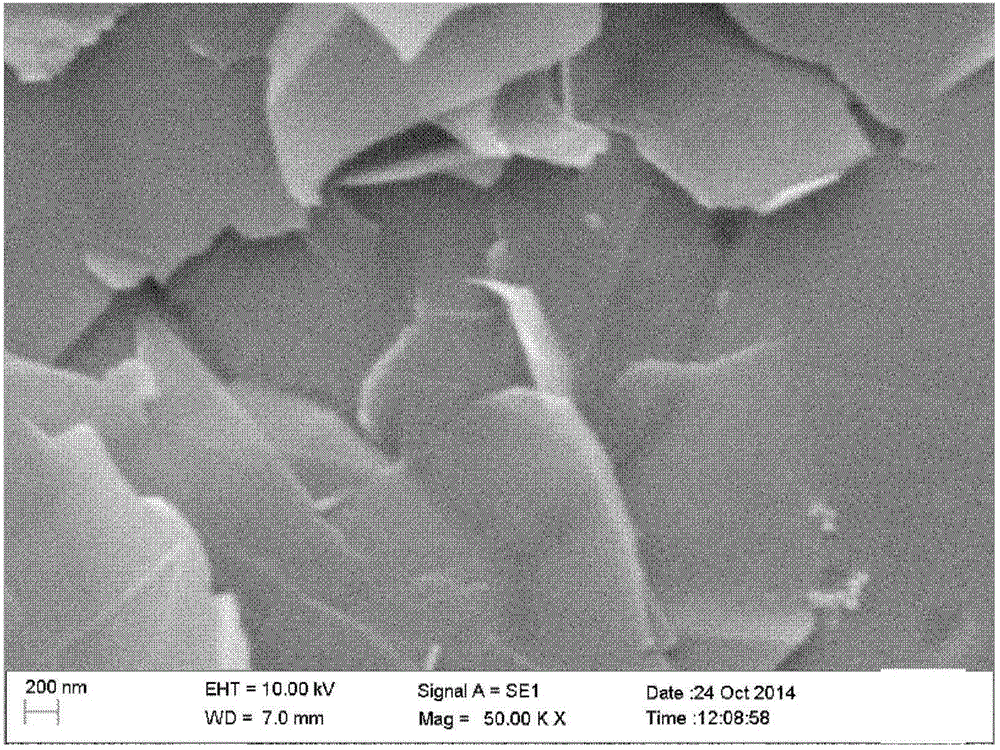

Method for preparing Pt-C3N4-TiO2 three-component visible light photocatalyst

InactiveCN103230808ASimple reaction conditionsMild and stable reactionPhysical/chemical process catalystsLight ActivityCarbide

The invention relates to a method for preparing a Pt-C3N4-TiO2 three-component visible light photocatalyst. The method is characterized by comprising the steps of: firstly heating melamine up to the temperature of 540 DEG C so as to be cracked into graphite-like nitrogen carbide (g-C3N4); then carrying out ultrasonic mixing so as to enable P25 to be loaded with g-C3N4; and finally synthesizing by using an immobilized sol process, thereby preparing the target product. The composite photocatalyst with the structure has high visible light activity, thus the photocatalyst becomes an important sewage treatment agent with a potential research value. The method has the advantages that the reaction conditions are simple, the reaction is mild and stable, and the production enlargement is facilitated.

Owner:NANCHANG HANGKONG UNIVERSITY

Composite material of nickel hydroxide/graphene or graphite and preparation method for composite material

InactiveCN104616908AIncrease volumetric energy densityLow costMaterial nanotechnologyHybrid capacitor electrodesGraphiteGraphene

The invention discloses a composite material of nickel hydroxide / graphene or graphite which is structurally Ni(OH)2 / graphite or layered Ni(OH)2 / graphene composite material alternated with Ni(OH)2 and graphene, wherein the weight content of the nickel hydroxide is 10-90%. The invention further discloses a method for preparing the composite material. The composite material is simple in process, low in cost, environment-friendly and easy for batch production.

Owner:SOUTHWEST PETROLEUM UNIV

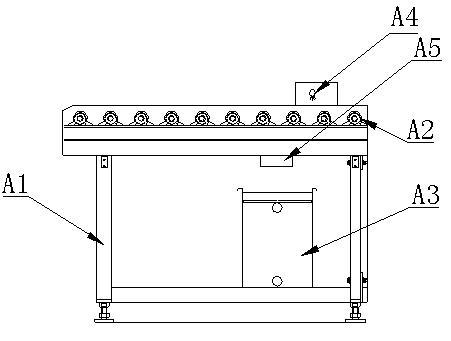

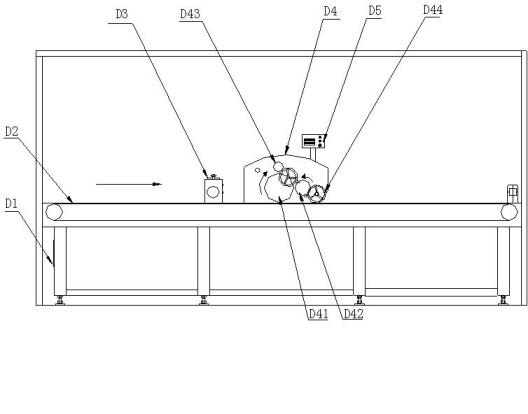

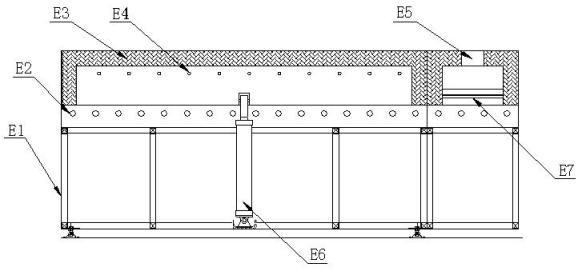

Method and equipment for producing coated glass

The invention belongs to the field of glass coating and discloses a method for producing coated glass. The method comprises the steps of: cleaning the glass; pre-heating the glass; coating the glass; solidifying the glass for 5 to 15 minutes at the temperature of 80 and 350 DEG C; cooling the glass; and the like. The invention also discloses production equipment completing the production method, which comprises a loading machine, a glass washer, a glass pre-heater, a glass coating machine, a coating pre-solidifying machine, a coating high-temperature solidifying machine, a glass cooler and a discharge machine which are arranged on a production line in sequence. The method and the equipment have the characteristics of low production cost and stable glass coating quality; the solar antireflection glass transmittance after a single surface is coated can be increased by over 2.5 percent; and the requirements of solar components can be met.

Owner:HANGZHOU JIELING MACHINERY EQUIP

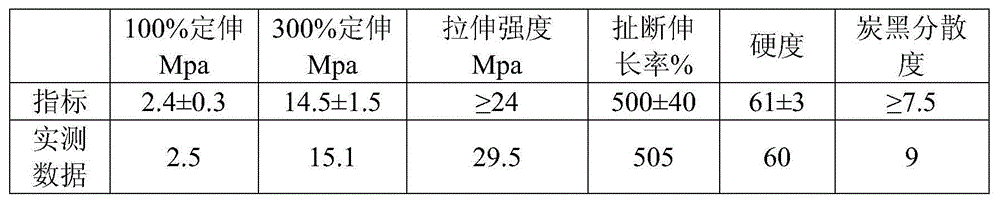

All-steel load radial tire tread base rubber material and preparation method thereof

InactiveCN104530499AImprove dispersion and uniformityImprove processabilitySpecial tyresChemistryCarbon black

The invention relates to an all-steel load radial tire tread base rubber material and a preparation method thereof. The base rubber material comprises the following raw materials in parts by weight: 100 parts of natural rubber, 0-0.3 part of a peptizer, 30-45 parts of carbon black, 7-18 parts of white carbon black, 1-4 parts of a silane coupling agent, 3-5 parts of zinc oxide, 1-3 parts of stearic acid, 1-3 parts of phenolic tackifying resin, 0.5-3 parts of petroleum resin, 0.5-2 parts of an anti-aging agent 6PPD, 0.5-2 parts of an anti-aging agent RD, 1-3 parts of sulfur, 0.8-3 parts of an accelerator and 0-0.3 part of a scorch retarder. Petroleum resin is added to improve the medium-term and long-term viscidity of a tire tread half member so that the tread is well bonded with belt layers during molding and the phenomenon of delamination of a tread crown is improved. The material disclosed by the invention has the advantages of good thermal resistance and aging resistance, low heat generation and tear resistance and the problem of pattern groove cracking of the finished tread is improved.

Owner:RUBBER CO LTD OF SHAANXI YANCHANG PETROLEUM GRP CO LTD

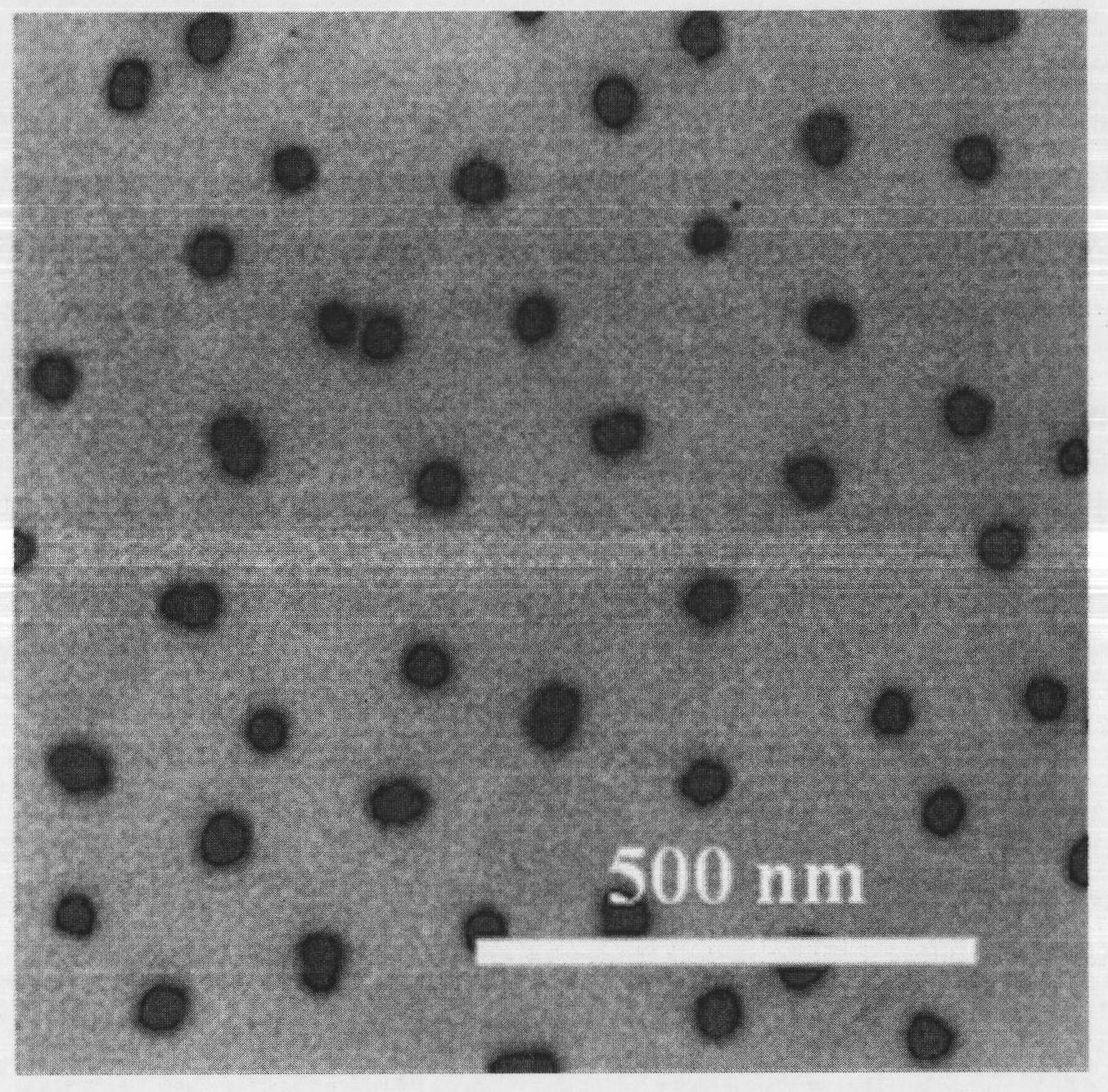

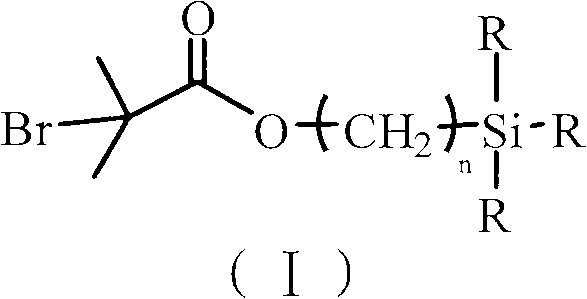

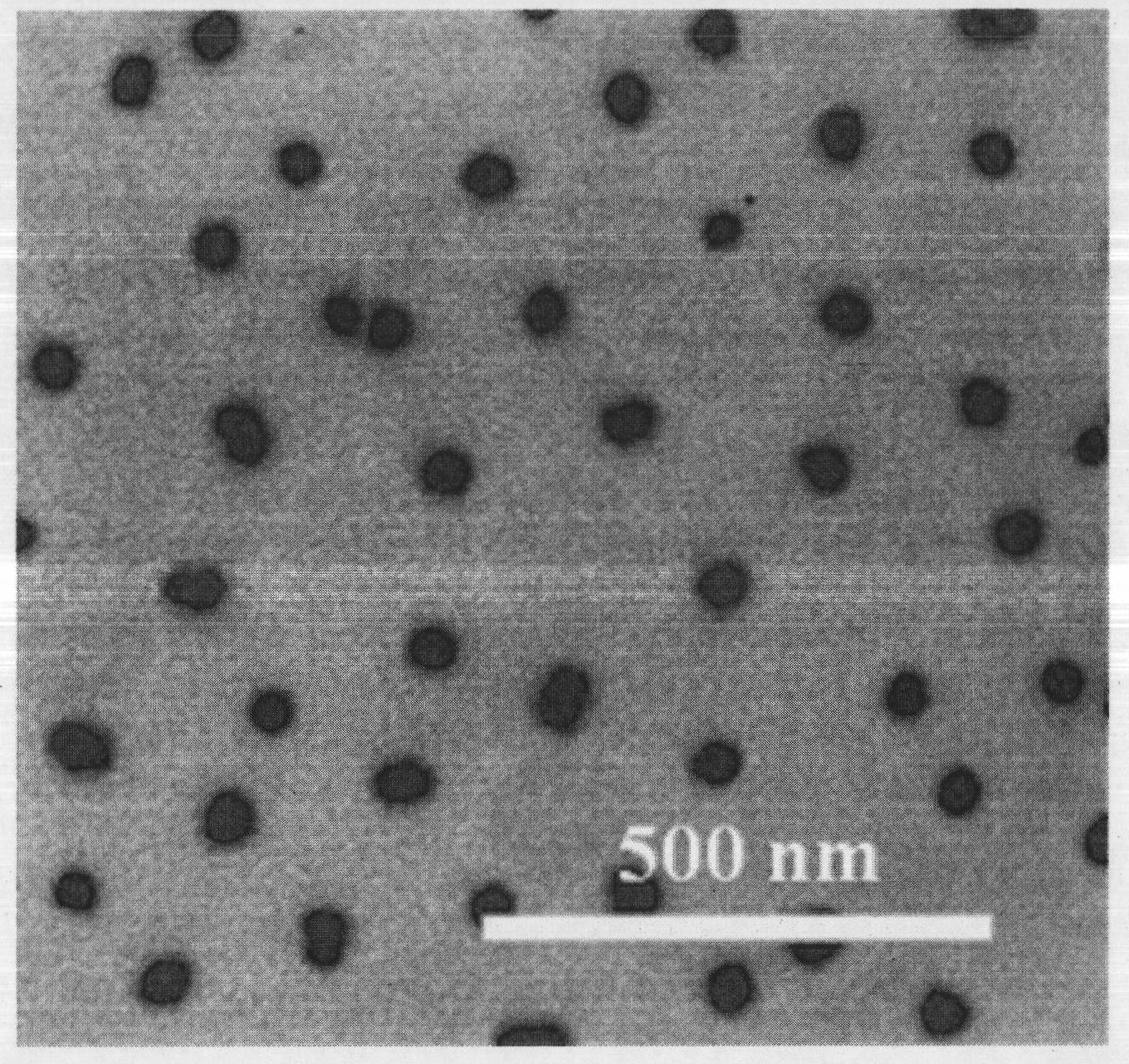

Method for preparing SiO2-poly(dimethylaminoethyl methacrylate) (PDMAEMA) nanoparticles having core-shell structure

ActiveCN101891867AParticle size adjustableNarrow particle size distributionGraft reactionSio2 nanoparticle

The invention relates to the field of nano technology and discloses a method for preparing SiO2-PDMAEMA nanoparticles having a core-shell structure. The method comprises the following steps of: selecting 2-bromideisobutyryl bromide with a higher initiation activity or a compound represented by a formula (I) as an initiator by using an atom-transfer radical-polymerization method; and during reaction, mixing CuX2 serving as a passivator, a ligand, SiO2 nanoparticles modified by the initiator, a solvent and diethylaminoethyl methacrylate at first and then adding CuX to perform a grafting reaction to obtain the SiO2-PDMAEMA nanoparticles with the core-shell structure. Experiments show that: the prepared SiO2-PDMAEMA nanoparticles have the advantages of controllable particle size, narrow particle size distribution and controllable molecular weight of the polymer PDMAEMA grafted on the surface of SiO2. Moreover, the preparation method provided by the invention has the characteristics of mild reaction conditions, convenience, feasibility and short preparation period and is easy for mass production.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

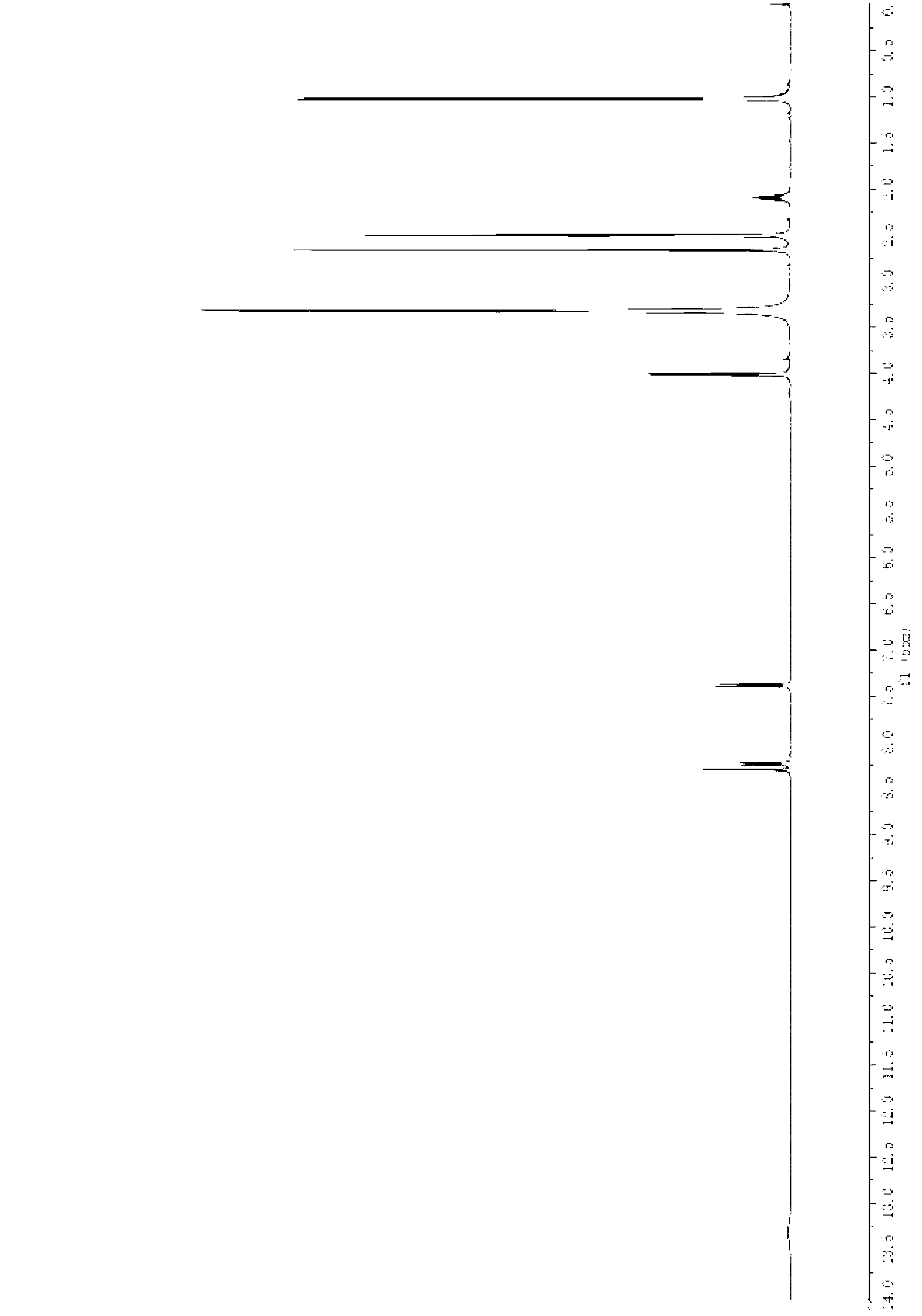

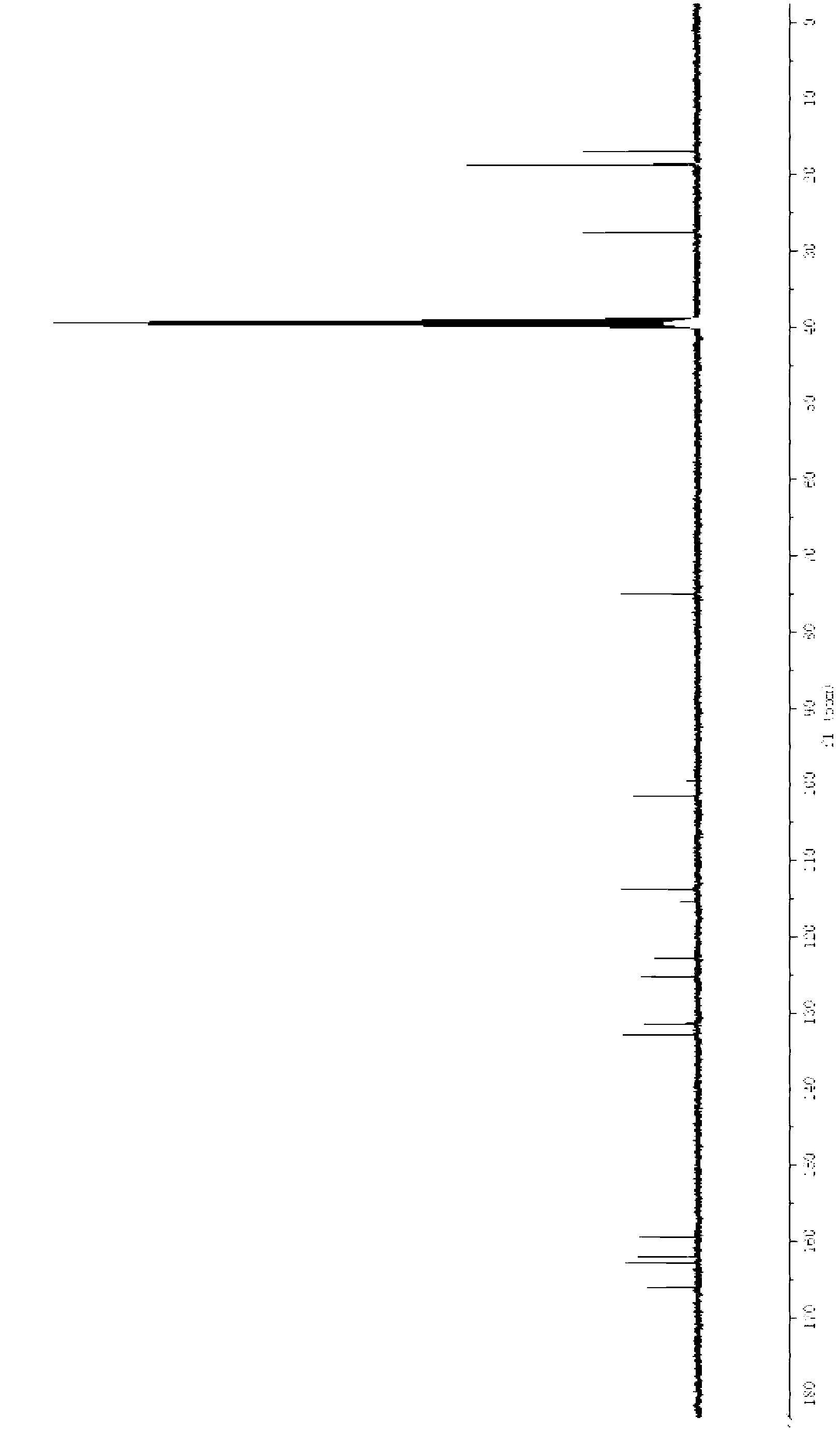

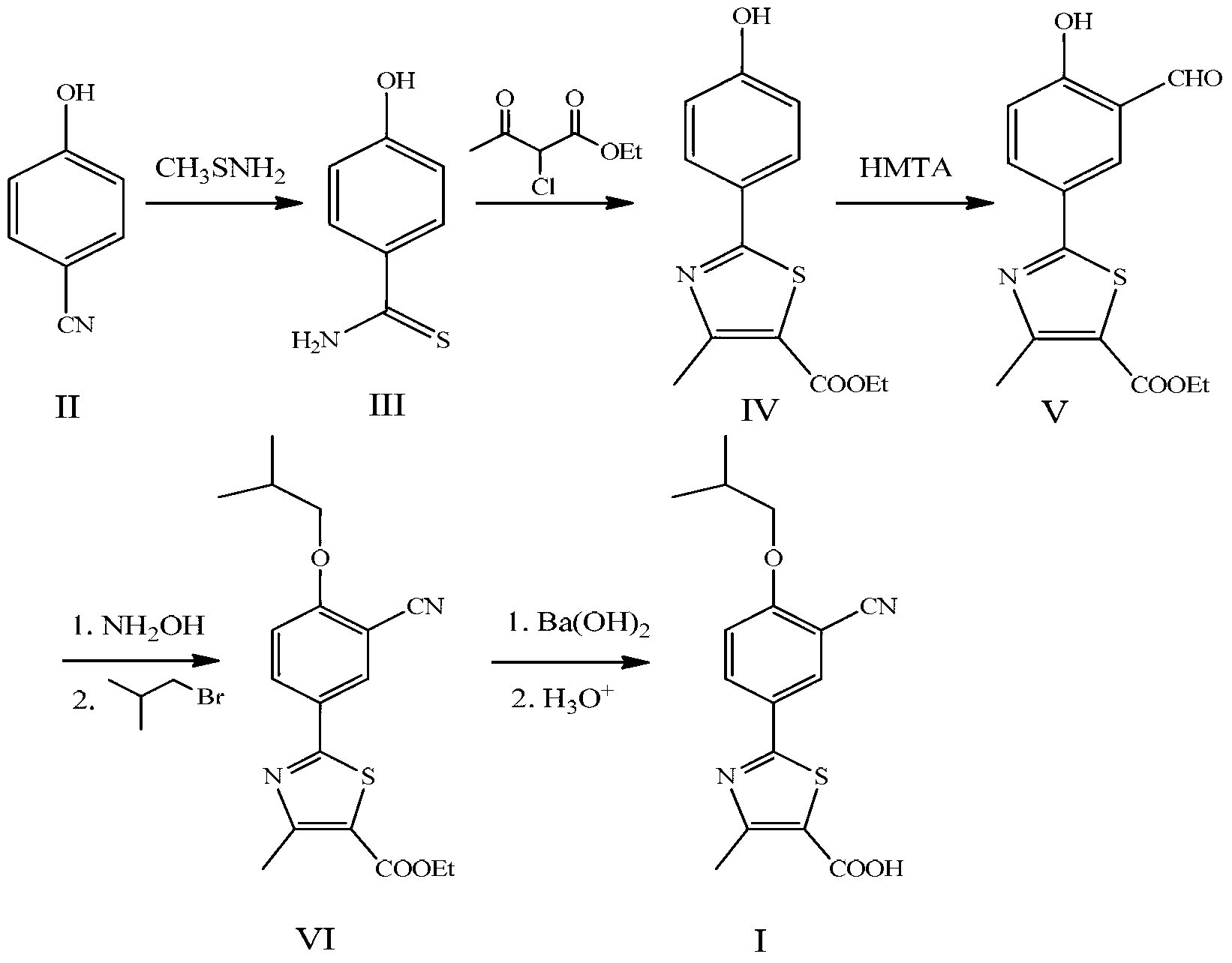

Preparation method for febuxostat

InactiveCN103304512ALow costReduce operation processOrganic chemistryHydroxylamine HydrochlorideToxic material

The invention discloses a preparation method for febuxostat. The preparation method for febuxostat comprises the following steps of: by using 4-hydroxybenzonitrile and thioacetamide as raw materials, and reacting in hydrochloric acid solution to prepare 4-hydroxythiobenzamide; carrying out a reaction on 4-hydroxythiobenzamide and 2-chloroacetoacetic acid ethyl ester to prepare 2-(4-hydroxylphenyl)-4-methylthiazol-5-carboxylic acid ethyl ester; carrying out a reaction on the obtained compound and hexamine in the mixed acid system of methanesulfonic acid and trifluoroacetic acid to prepare 2-(3-formyl-4-hydroxylphenyl)-4-methylthiazole-5-carboxylic acid ethyl ester; synthesising 2-(3-nitrile-4-isobutoxylphenyl) -4-methylthiazole-5-carboxylic acid ethyl ester from the compound, hydroxylamine hydrochloride, potassium carbonate, iso-butyl bromide and the like in a polar protonic solvent via a one-pot method; and finally hydrolyzing in an alkaline condition to obtain the target product, namely, febuxostat. The total yield of the preparation method for febuxostat disclosed by the invention is increased to 66%, the separation steps are reduced, any extremely toxic substance is not involved, and the environmental pollution is less.

Owner:SOUTH CHINA UNIV OF TECH

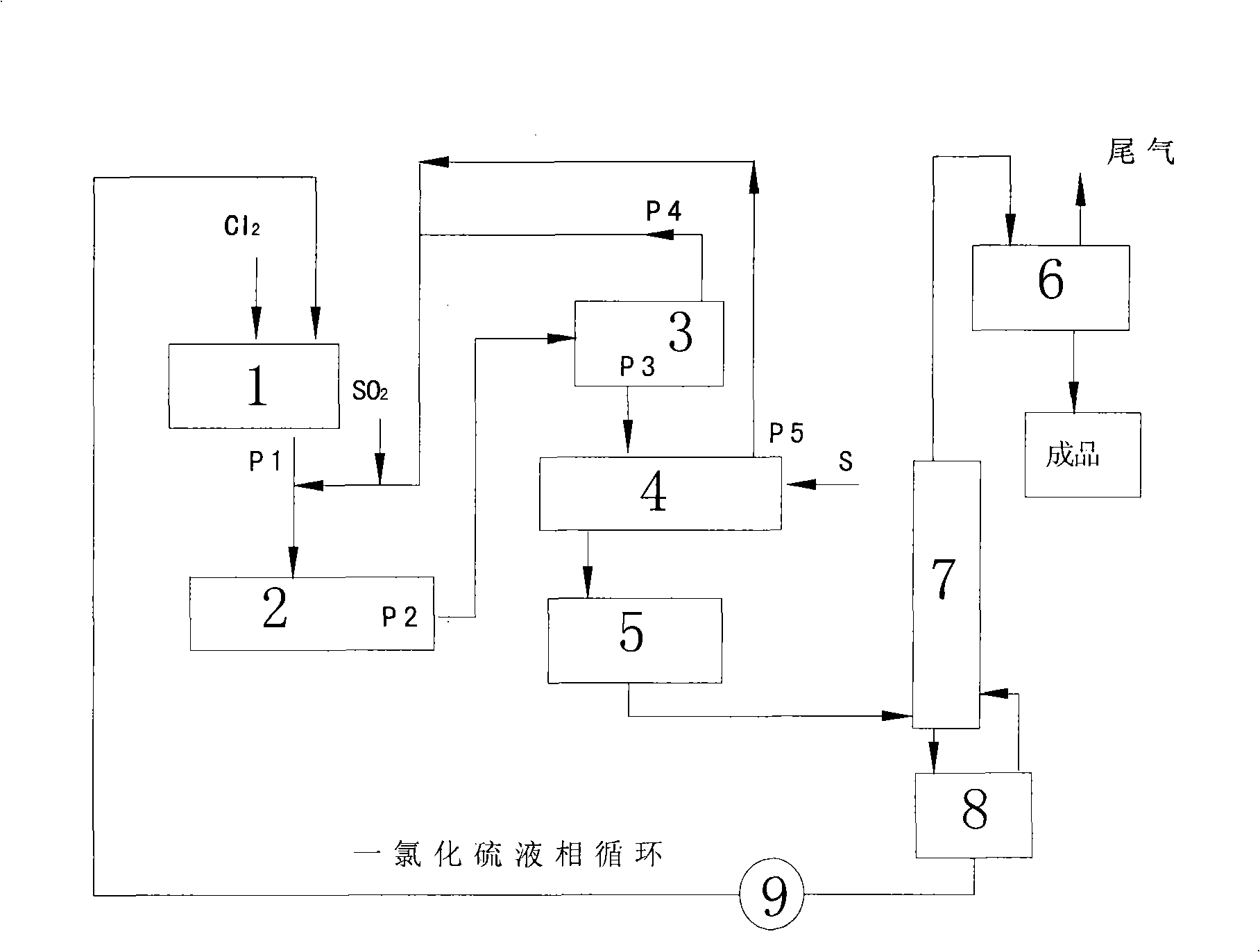

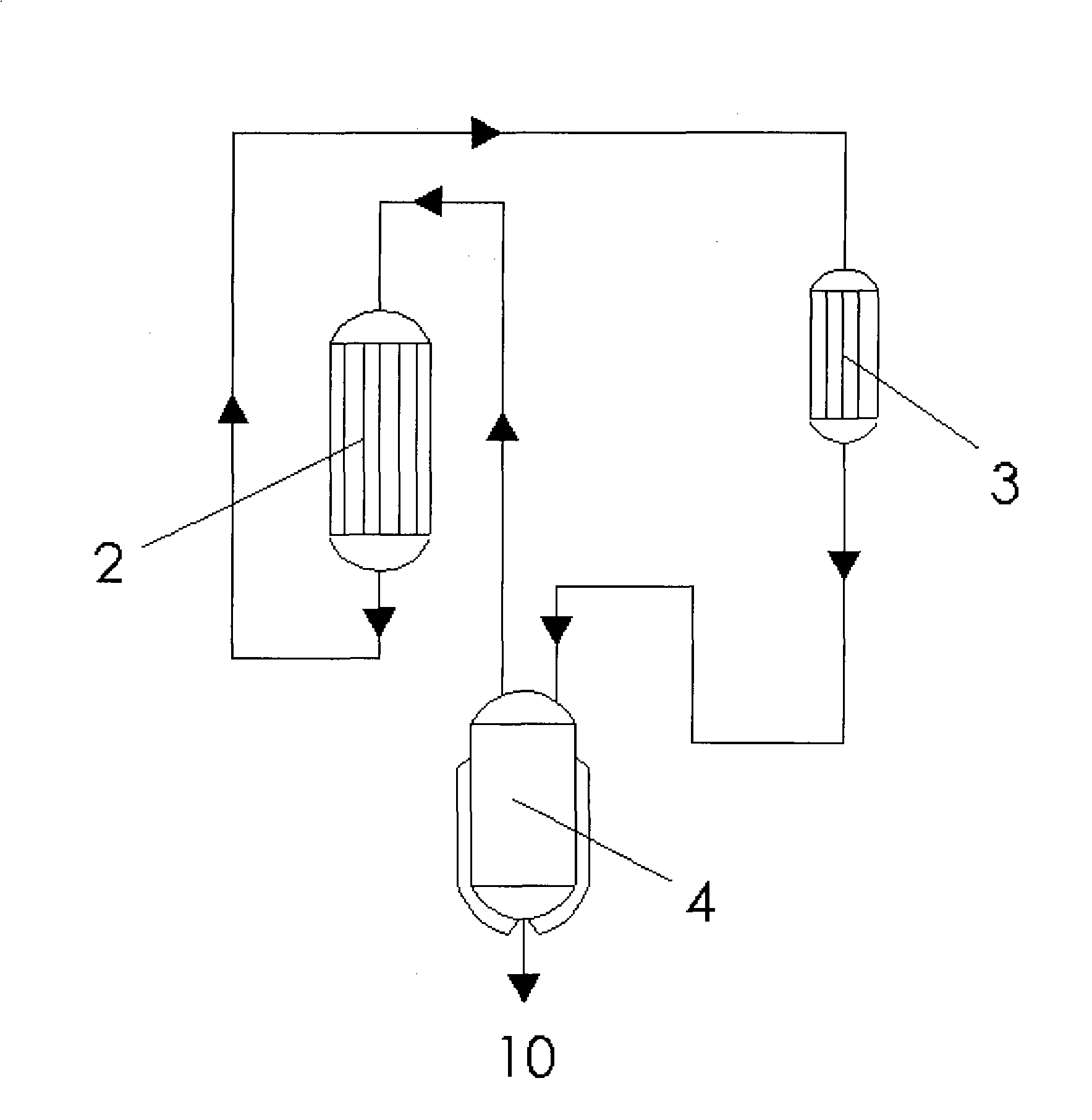

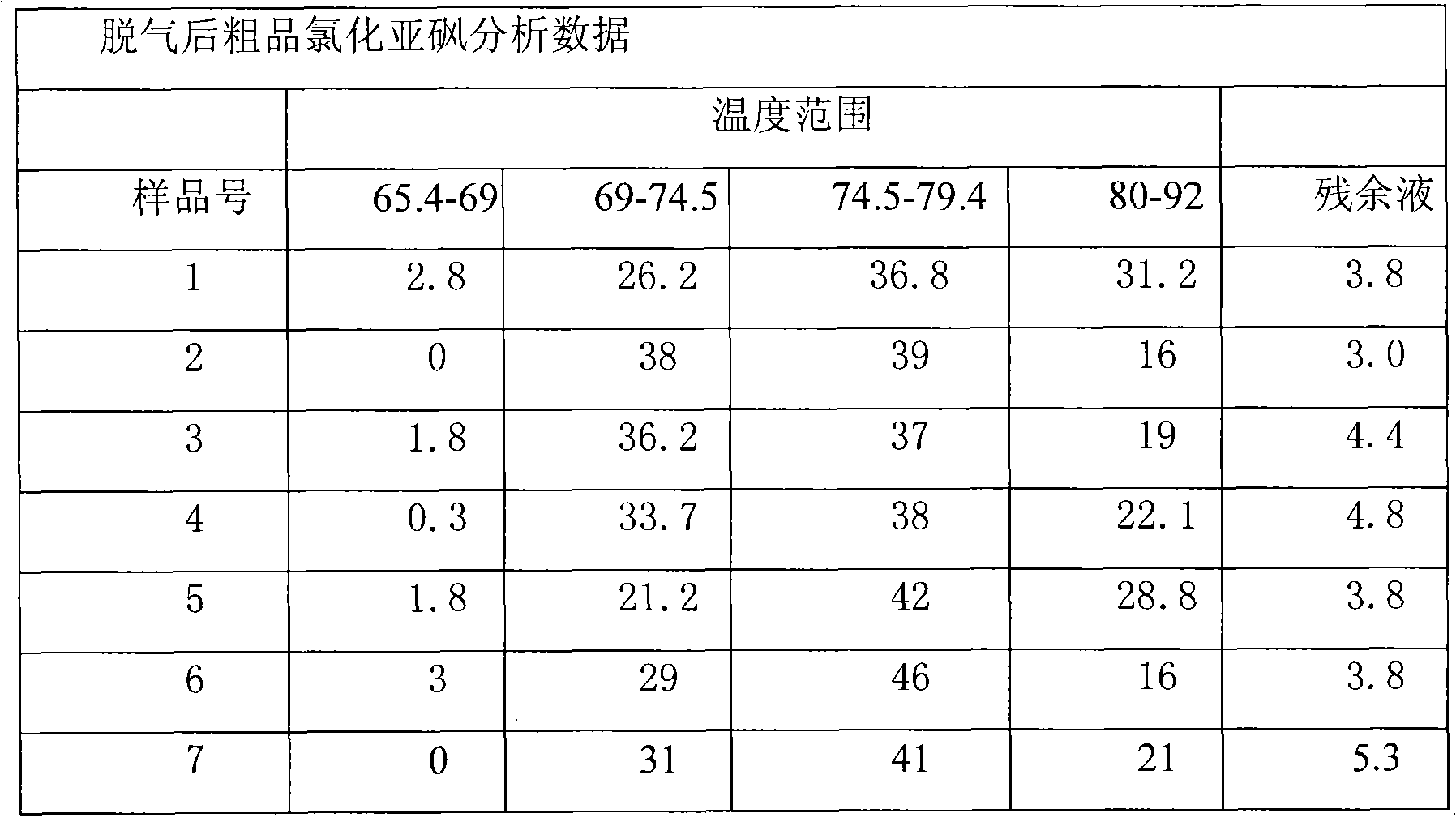

Liquid phase circulation method in synthesis of thionyl chloride

ActiveCN101284652AEasy to scale up productionGuaranteed uptimeSulfur and halogen compoundsSulfur dichlorideLiquid phase

The invention relates to a liquid phase circulation method for synthesizing thionyl chloride. Specifically, the method comprises a process that the condensate of a crude product of the thionyl chloride and the purified mixed liquid of the crude product of the thionyl chloride in a degassing device are vulcanized and distilled, and then the distilled tower bottom residual liquid is again pumped to the sulfur dichloride for synthesis, thereby forming the fully-closed and full-circulation method for synthesizing the thionyl chloride.

Owner:JIANGXI SELON INDAL

Non-noble metal composite oxide monolithic catalytic combustion catalyst as well as preparation method and application thereof

ActiveCN107008254AGood dispersionNot easy to fall offIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsAlcoholHoneycomb

The invention discloses a non-noble metal composite oxide monolithic catalytic combustion catalyst and a preparation method thereof. The preparation method comprises the following steps: preferably selecting soluble salt solutions of more than two of Mg, Ti, Mn, Co, Cu, La, Ce and Zr and loading onto modified attapulgite (ATP); drying and roasting to prepare a composite oxide powder type catalyst; then uniformly grinding the prepared powder type catalyst and adding an additive and water; after sufficiently stirring, mixing, kneading and ageing to obtain plastic mud; and extruding and molding by a mold, cutting, drying and roasting to finally obtain the honeycomb-shaped composite oxide monolithic catalytic combustion catalyst. The catalyst provided by the invention has the advantages of high mechanical strength, good chemical stability, low raw material cost, simple preparation process and the like and has a good removal effect on catalytic combustion of low-concentration organic waste gas, especially alcohols, benzene compounds and carboxylates.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com