Poly(3,4-ethylenedioxythiophene)/sulfonated graphene composite hydrogel and preparation method thereof

A technology of ethylenedioxythiophene and sulfonated graphene, which is applied in the direction of electrolytic capacitors, electrical components, circuits, etc., can solve the problems of high specific capacitance and unobtainable conductivity, and achieve easy operation, easy scale-up production, and wide-ranging The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of PEDOT / sulfonated graphene composite hydrogel, the steps are as follows:

[0033] (1) At room temperature, mix 0.309g sodium polystyrene sulfonate (20.6g / L, purchased from Aldrich, Germany) and 1mg sulfonated graphene (67mg / L) (see Zhao G, Jiang L, He Y for the preparation method) , Li JX, Dong HL, Wang XK, et al. Sulfonated graphene for persistent aromatic pollutant management . Advanced Materials, 2011,23:3959. ) was added to 15mL of water, stirred and dispersed by ultrasonic waves to form a dispersion;

[0034] (2) Add 770 μL (7 mmol) of 3,4-ethylenedioxythiophene monomer (purchased from Suzhou Bohong Chemical Technology Co., Ltd.) into the above dispersion liquid, stir and disperse with ultrasonic wave for 1 hour, and disperse evenly;

[0035] (3) 14.1g Fe (NO 3 ) 3 9H 2 O (purchased from Sinopharm Chemical Reagent Co., Ltd.) was dissolved in 5 mL of water, and added to the reaction system formed in step (2) at one time, and continued to st...

Embodiment 2

[0037] Embodiment 2. A kind of preparation method of PEDOT / sulfonated graphene composite hydrogel, its difference with embodiment 1 is that the concentration of sodium polystyrene sulfonate becomes 103g / L, the concentration of sulfonated graphene becomes 6.7mg / L, the static reaction time changed from 6 hours to 12 hours, and the purification equilibrium time changed from 2 days to 4 days.

Embodiment 3

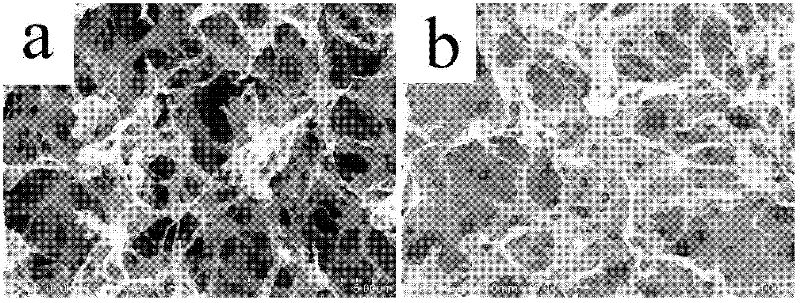

[0038] Embodiment 3. A preparation method of PEDOT / sulfonated graphene composite hydrogel, its difference from Example 1 is that the concentration of sodium polystyrene sulfonate becomes 206g / L, and the concentration of sulfonated graphene becomes 133mg / L L ,14.1g Fe (NO 3 ) 3 9H 2 O becomes 9.5g FeCl 3 ·6H 2 O (purchased from Sinopharm Chemical Reagent Co., Ltd.), the standing reaction time changed from 6 hours to 10 hours, the purification equilibrium time changed from 2 days to 3 days, and the pore size was 3 μm-10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com