Super-hydrophobic and -oleophylic cloth producing method

A super-hydrophobic and super-oleophilic technology, applied in fiber types, textiles and papermaking, fiber treatment, etc., can solve the problems of unfavorable application and cost increase, and achieve the effects of scale-up production, low cost and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Preparation of superhydrophobic superoleophilic cloth

[0032] (1) Put the fabric (polyester) in ethanol for 30 minutes of ultrasonic treatment;

[0033] (2) Dissolve 0.2g of dopamine hydrochloride and 0.1g of folic acid in 100 mL of water, and stir at 60°C for 6 hours;

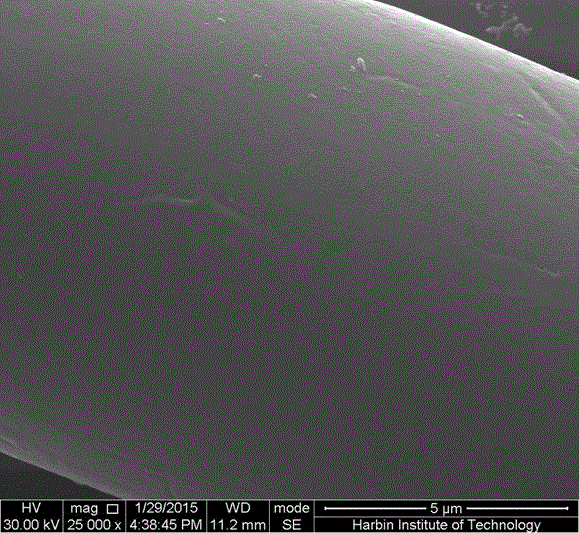

[0034] (3) Use sodium hydroxide to adjust the pH value of the above mixed solution to 8, then add the washed cloth and stir at room temperature for 9 hours to obtain a cloth with obvious hierarchical structure on the surface (such as image 3 shown).

[0035] (4) Take out the cloth, wash it with ethanol, put it in the ethanol solution of octadecylamine, the concentration of octadecylamine is 10 mmol L -1 , after 24 hours of reaction, the superhydrophobic and superoleophilic fabric was obtained with a water contact angle of 162 o (Such as Figure 4 shown), the toluene contact angle is 0 o (Such as Figure 5 shown).

Embodiment 2

[0036] Embodiment 2: Preparation of superhydrophobic superoleophilic cloth

[0037] (1) Put the cloth (cotton) in acetone for 30 minutes of ultrasonic treatment;

[0038] (2) Dissolve 0.1 g of dopamine hydrochloride and 0.1 g of folic acid in 100 mL of water, and stir at 50°C for 6 hours;

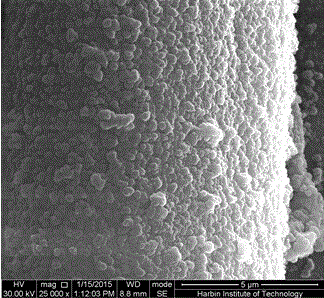

[0039] (3) Adjust the pH value of the above mixed solution to 9 with sodium hydroxide, then add the washed cloth and stir at room temperature for 12 h to obtain a cloth with a uniform and dense micro-nano structure on the surface (such as Image 6 shown);

[0040] (4) Take out the cloth, wash it with ethanol, put it in the ethanol solution of octadecylamine, the concentration of octadecylamine is 15 mmol L -1 , after reacting for 24 h, the superhydrophobic and superoleophilic fabric was obtained, with a superhydrophobic contact angle of 160 o (Such as Figure 7 shown).

Embodiment 3

[0041] Embodiment 3: Preparation of superhydrophobic superoleophilic cloth

[0042] (1) Put the fabric (80% polyester, 20% cotton) in acetone for 40 minutes of ultrasonic treatment;

[0043] (2) Dissolve 0.1 g of dopamine hydrochloride and 0.05 g of folic acid in 80 mL of water, and stir at 30°C for 12 h;

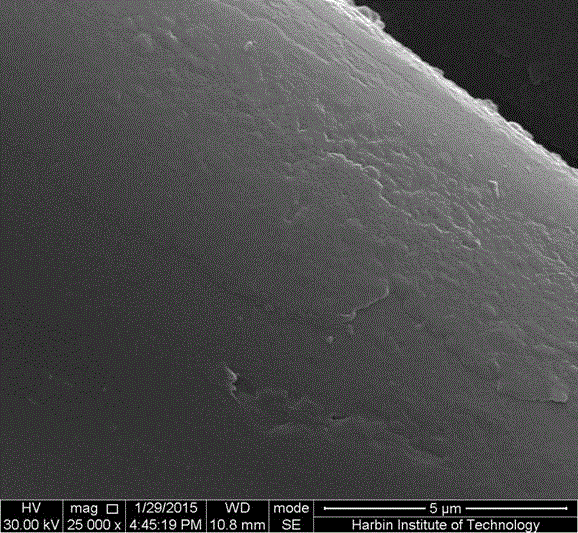

[0044] (3) Adjust the pH value of the above mixed solution to 8.5 with Tris, then add the washed cloth and stir at room temperature for 24 h to obtain a cloth with a micro-nano structure on the surface (such as Figure 8 shown).

[0045] (4) Take out the cloth, wash it with ethanol, put it in the ethanol solution of octadecylamine, the concentration of octadecylamine is 20 mmol L -1 , after reacting for 24 h, the superhydrophobic and superoleophilic fabric was obtained with a water contact angle of 152 o (Such as Figure 9 shown), the oil contact angle is 0 o .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com