Patents

Literature

43results about How to "Superhydrophobic stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

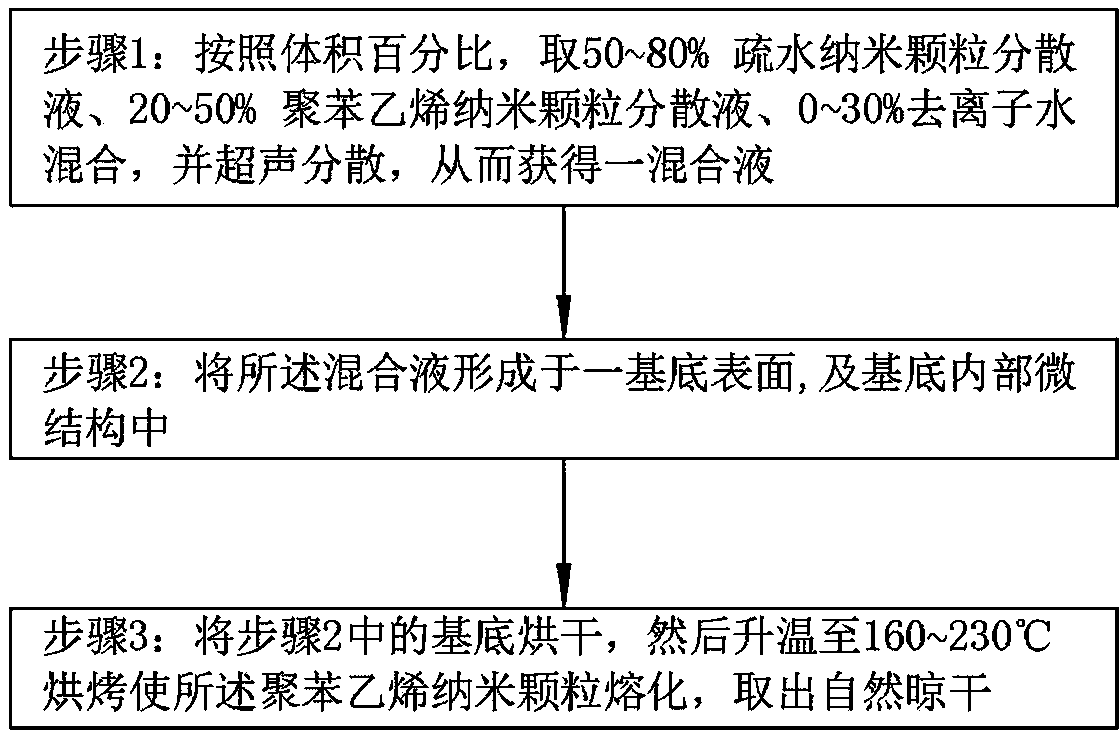

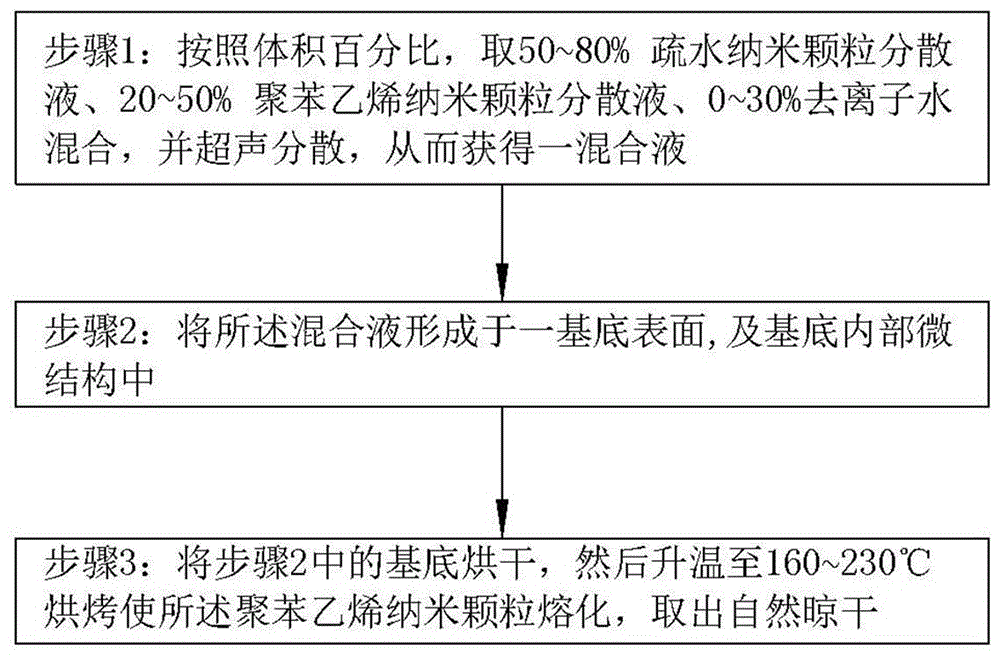

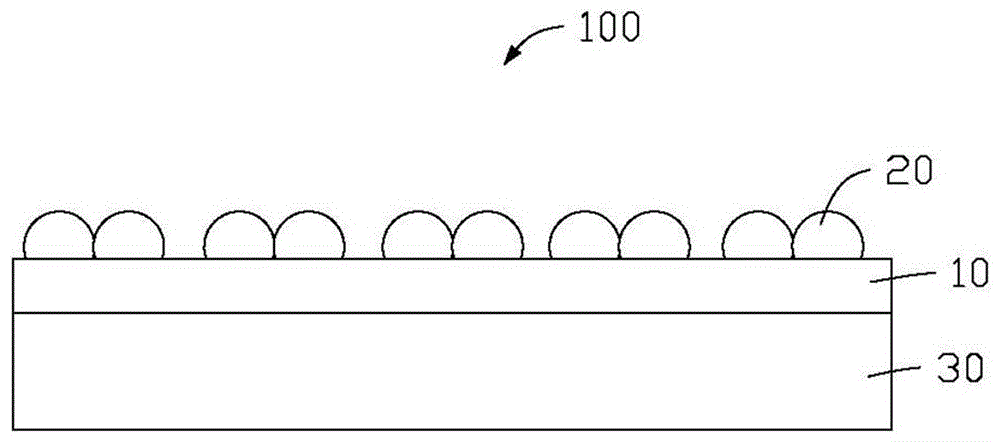

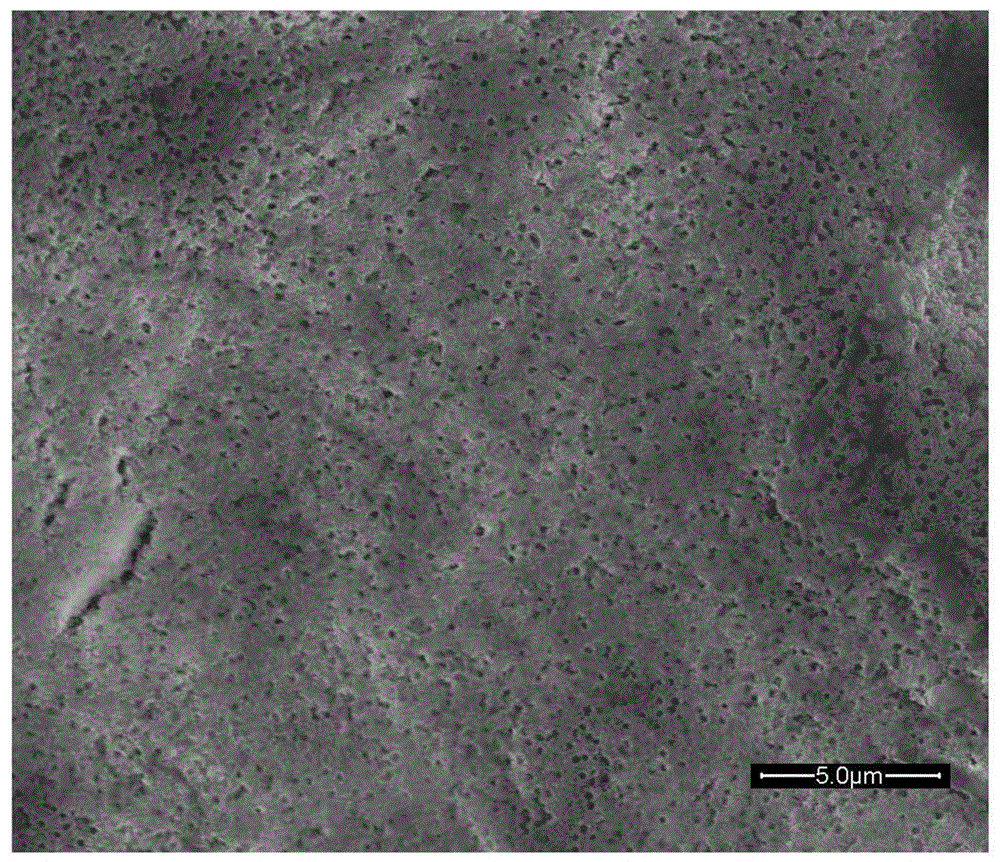

Superhydrophobic paint, superhydrophobic coating and preparation method thereof

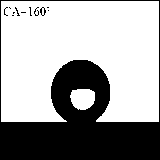

The invention provides a preparation method of a superhydrophobic coating. The preparation method comprises the steps of 1, mixing 50-80 parts of hydrophobic nanoparticle dispersing liquid with the mass percentage of 2-15%, 20-50 parts of polystyrene nanoparticle dispersing liquid with the mass percentage of 1-10% and 0-30 parts of solvent according to the volume part ratio, and ultrasonically dispersing the mixture to obtain a mixed solution; 2, forming the mixed solution on the surface of a substrate and in a microstructure in the substrate; 3, drying the substrate obtained in the step 2, then, raising the temperature to 160-230 DEG C, baking to melt polystyrene nanoparticles, and taking out for naturally airing. The invention also relates to a superhydrophobic paint and the superhydrophobic coating.

Owner:TSINGHUA UNIV

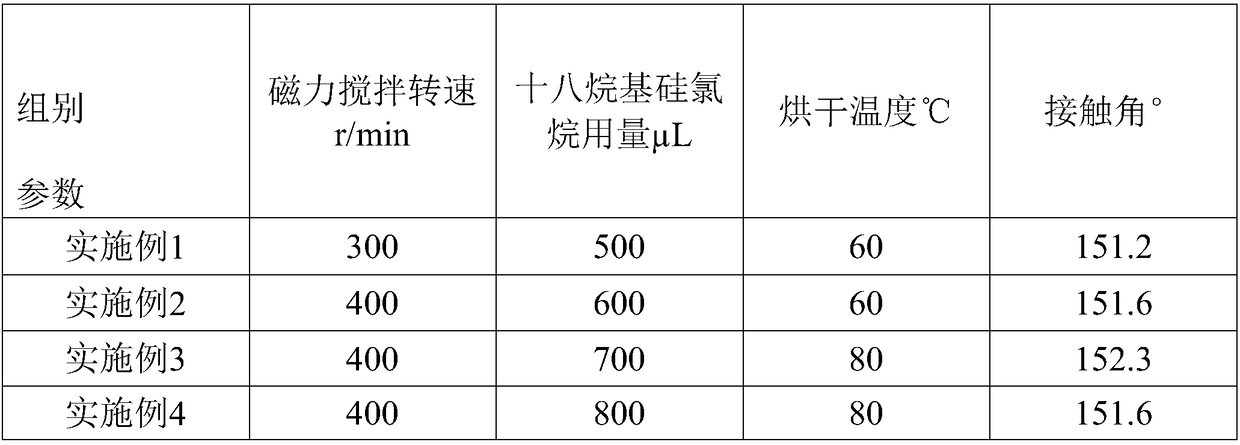

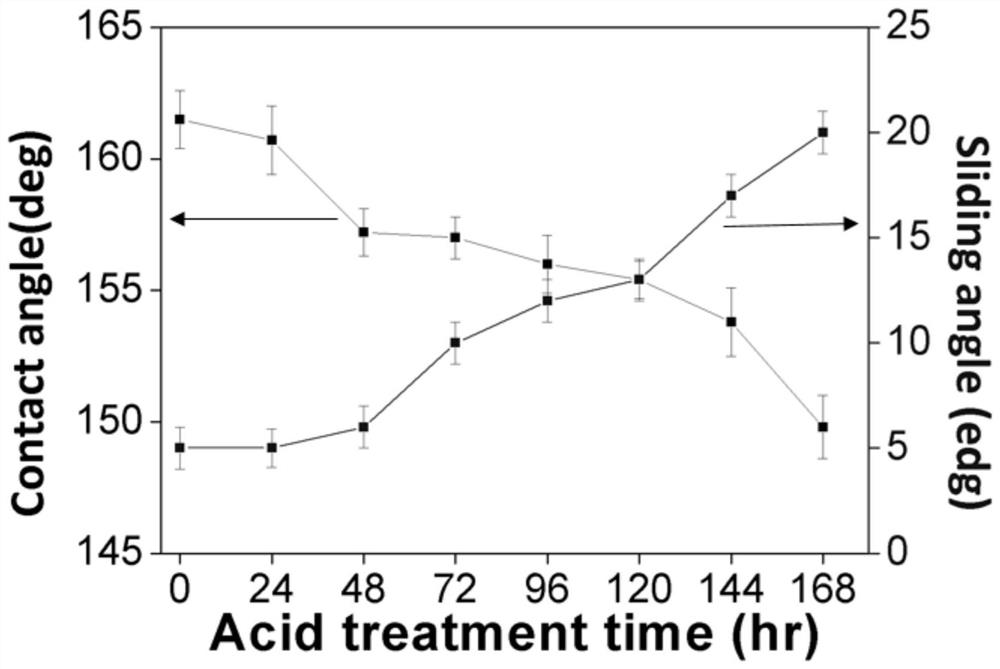

Method for preparation of superhydrophobic timber on the basis of sol-gel method

InactiveCN105599077AHas a superhydrophobic surfaceEasy to operateWood treatment detailsPretreated surfacesSilica nanoparticlesSilanes

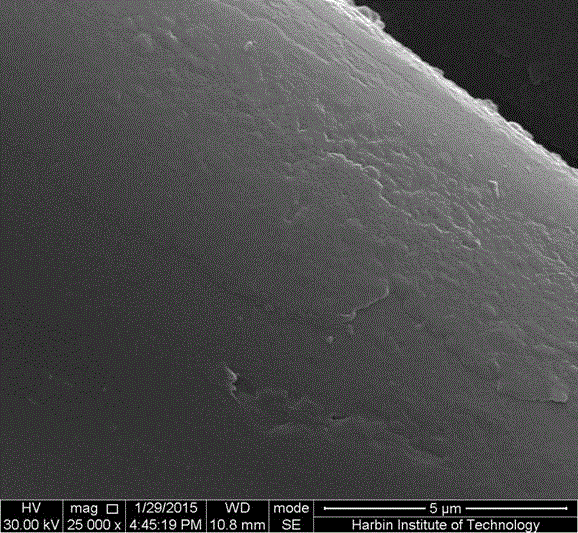

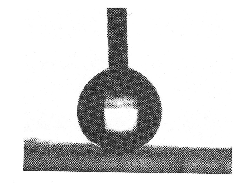

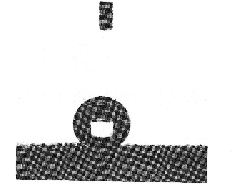

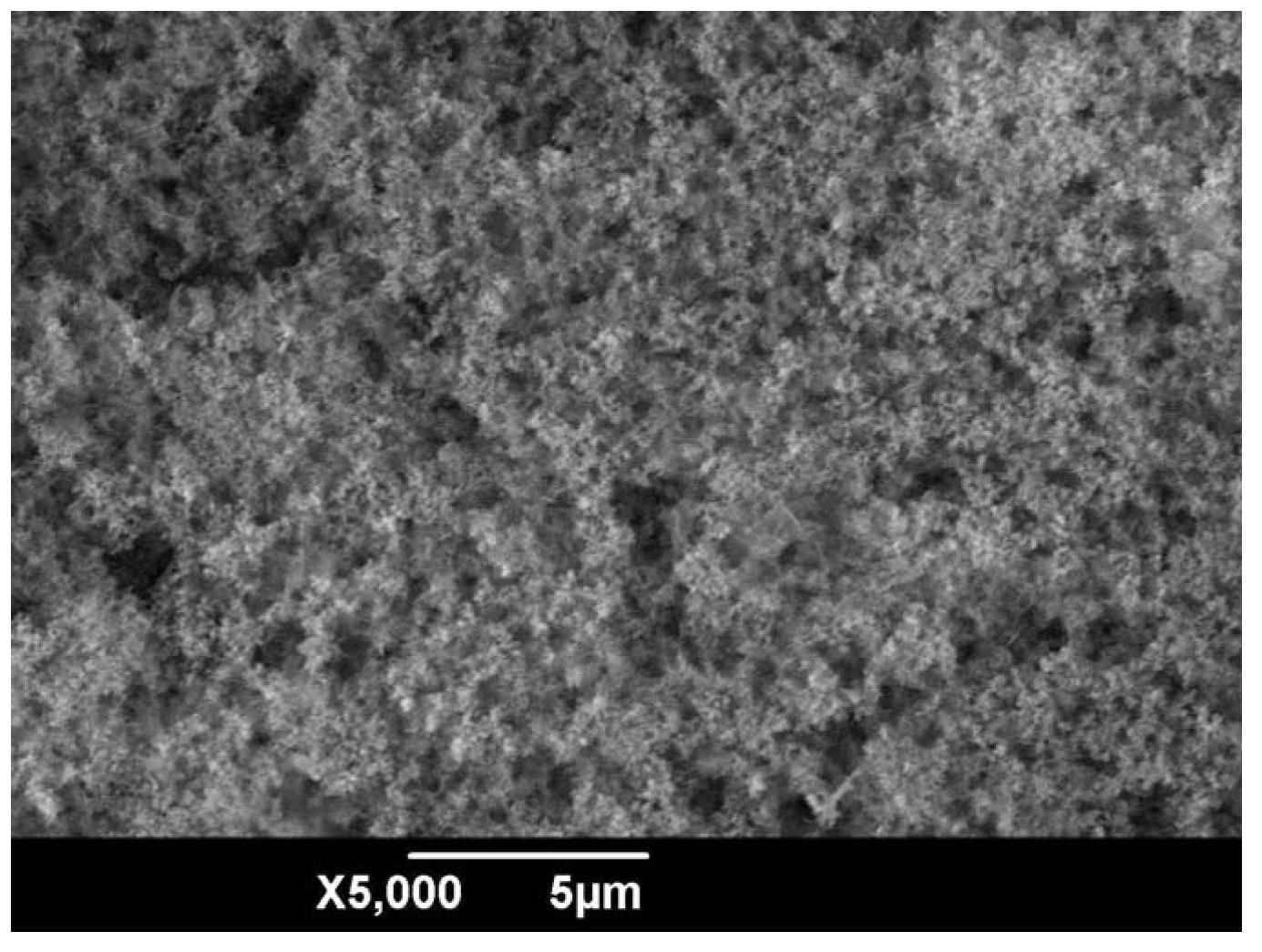

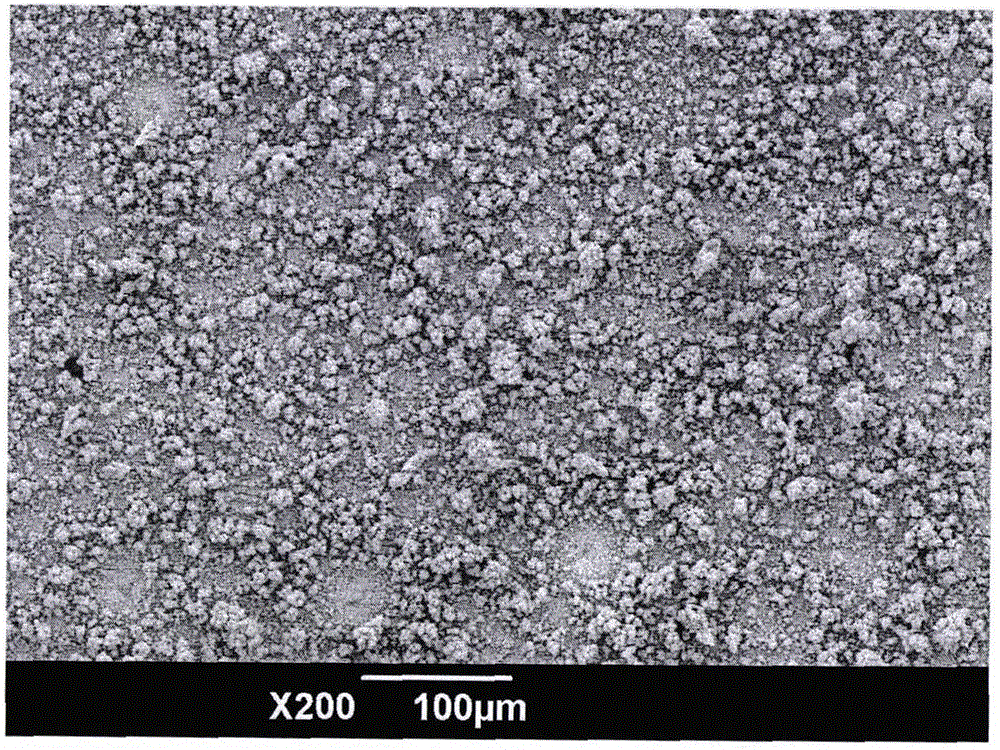

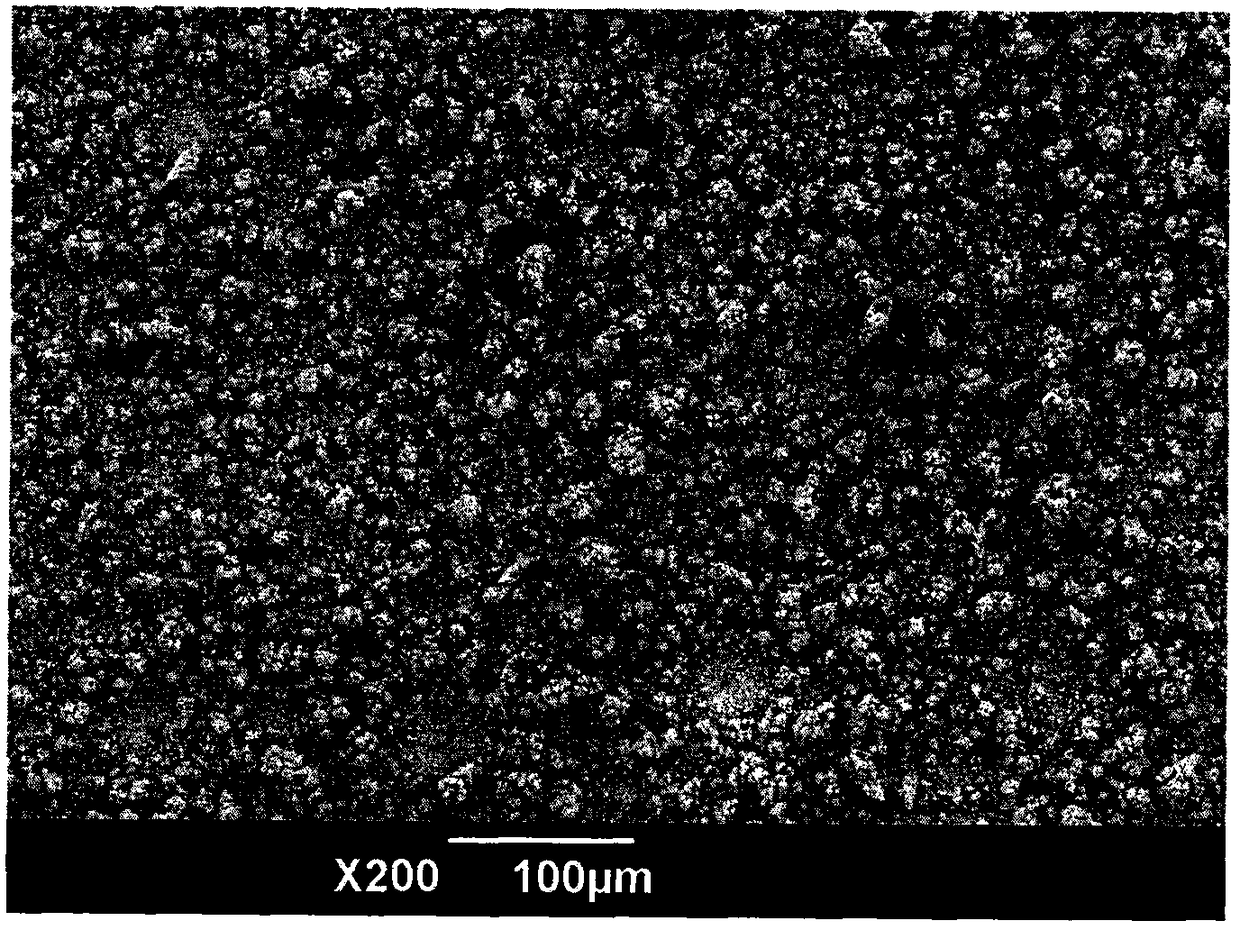

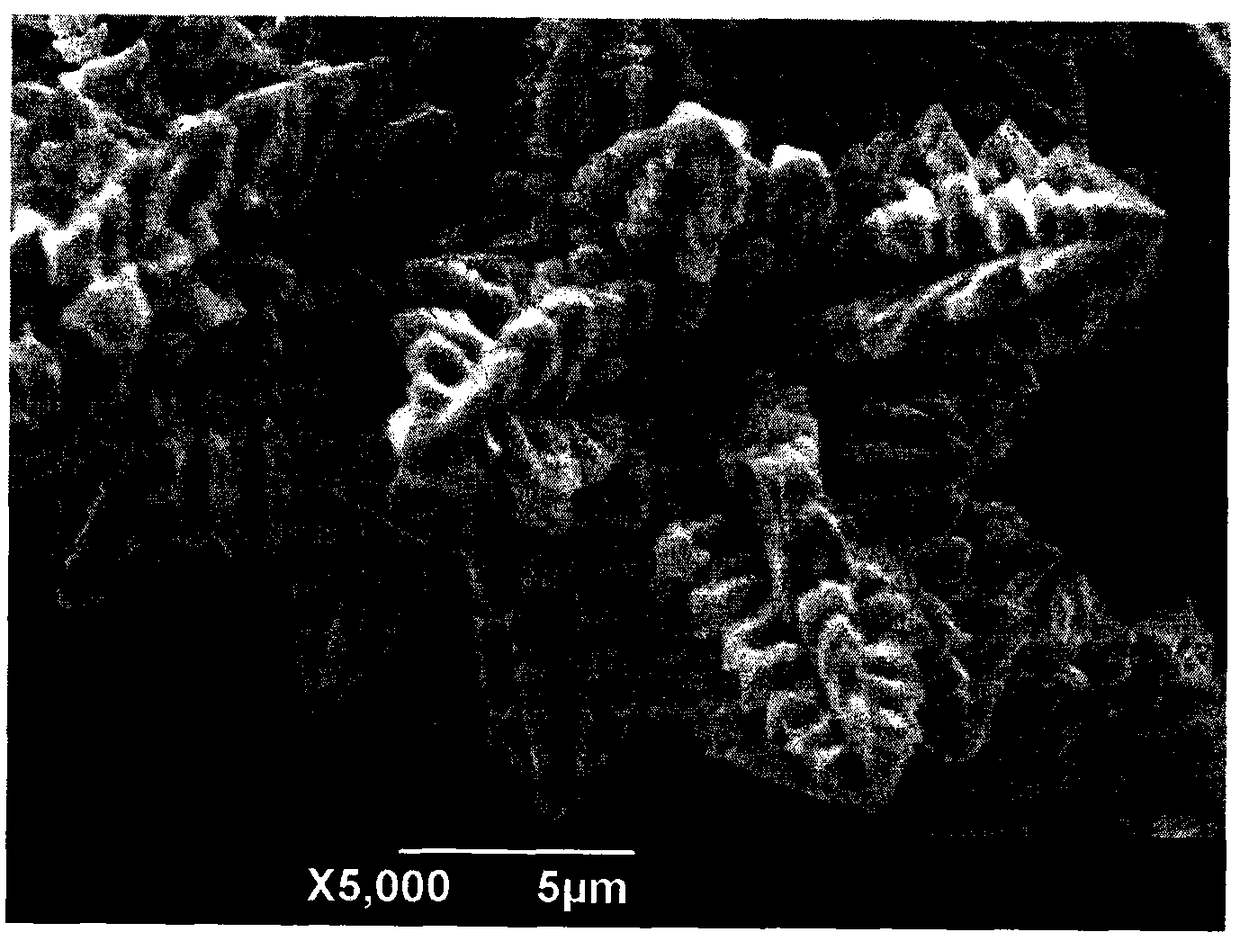

The present invention pertains to a method for preparation of superhydrophobic timber on the basis of a sol-gel method, and the method is as follows: (1), silica sol synthesis, to be more specific, materials are prepared in the volume ratio of ammonia to anhydrous ethanol to ethyl orthosilicate of 1:15 to 17:1; (2), hydrophobic modification of monodispersed nano silica sol, to be more specific, hexadecyl trimethoxysilane, or triethoxysilane-1H, 1H, 2H, 2H-heptadecafluorodecyl silane is used for hydrophobic modification of the synthesized monodispersed nano silica sol, and the hydrophobic agent promotes mutual aggregation of nanoparticles to promote the formation of aggregates of silica nanoparticles; and (3) timber coating processing, to be more specific, the timber surface is coated with the hydrophobically modified silica sol solution by dipping or spraying process. Contact angles of the processed timber surface and water droplets are greater than 150 degrees, roll angles are less than 10 degrees, and a superhydrophobic film has good resistance to acid and alkali erosion and stability in high-humidity environment. The method is simple in operation, less demanding on equipment, and capable of scale production, and has wide market prospects.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

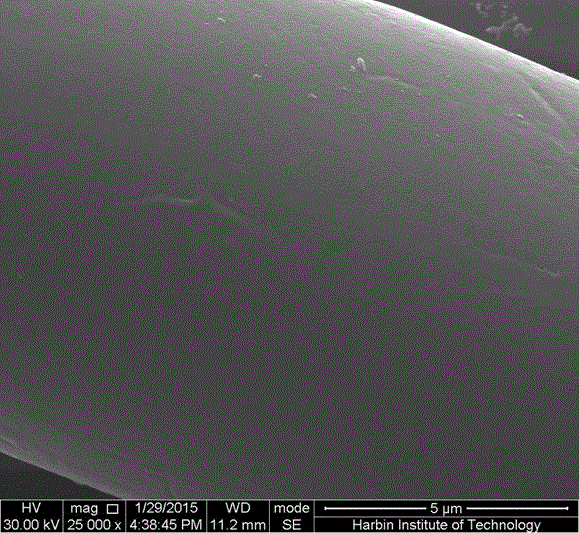

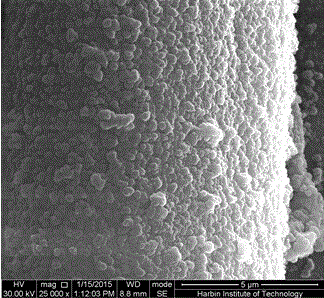

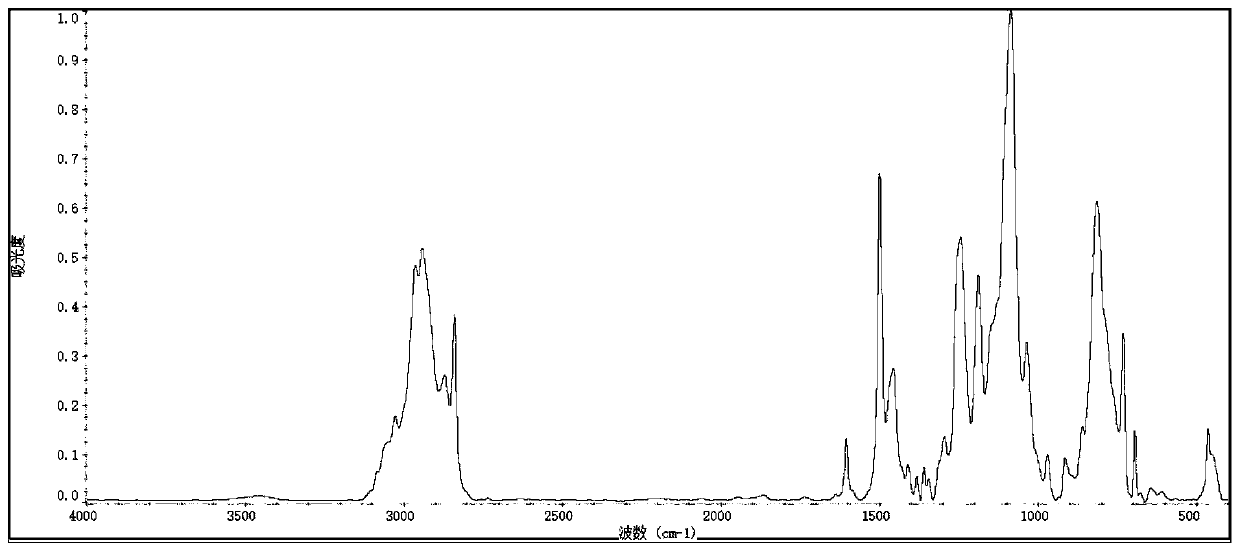

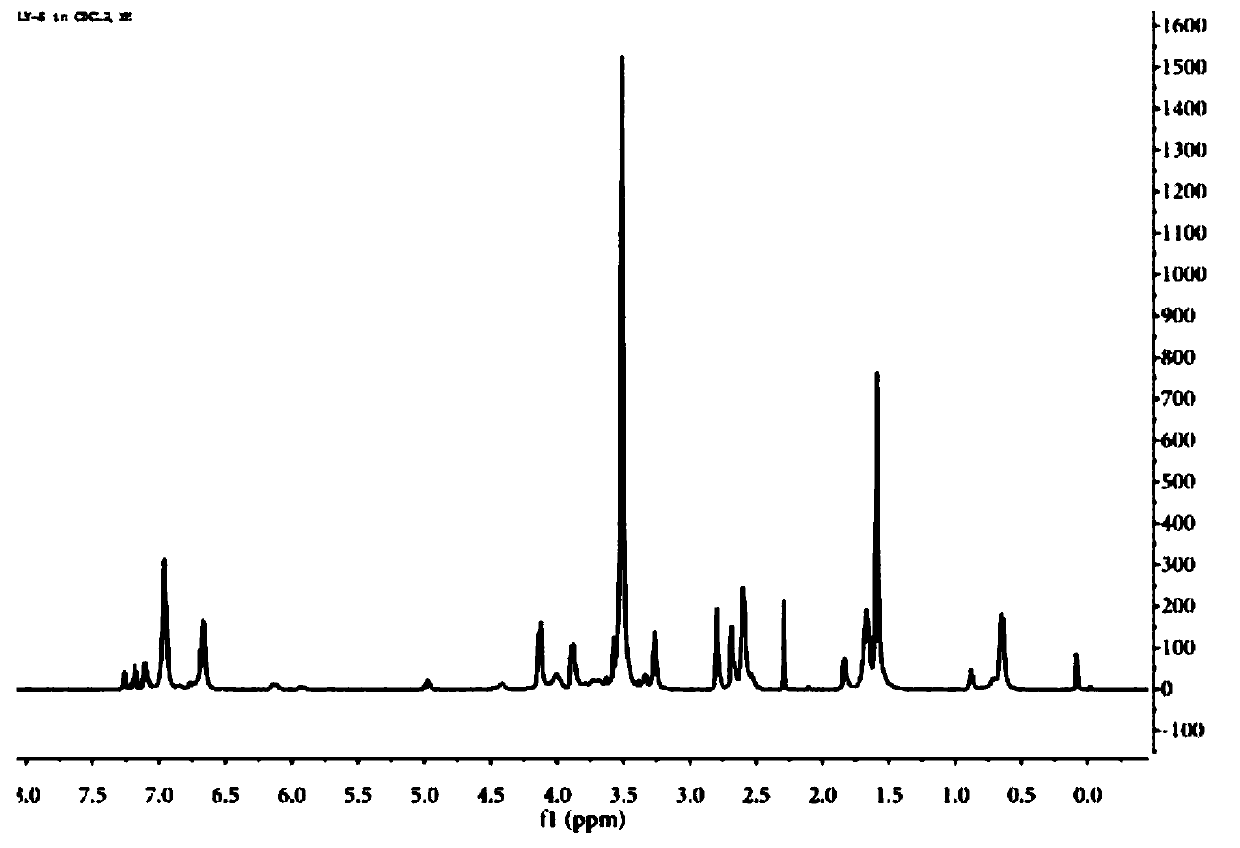

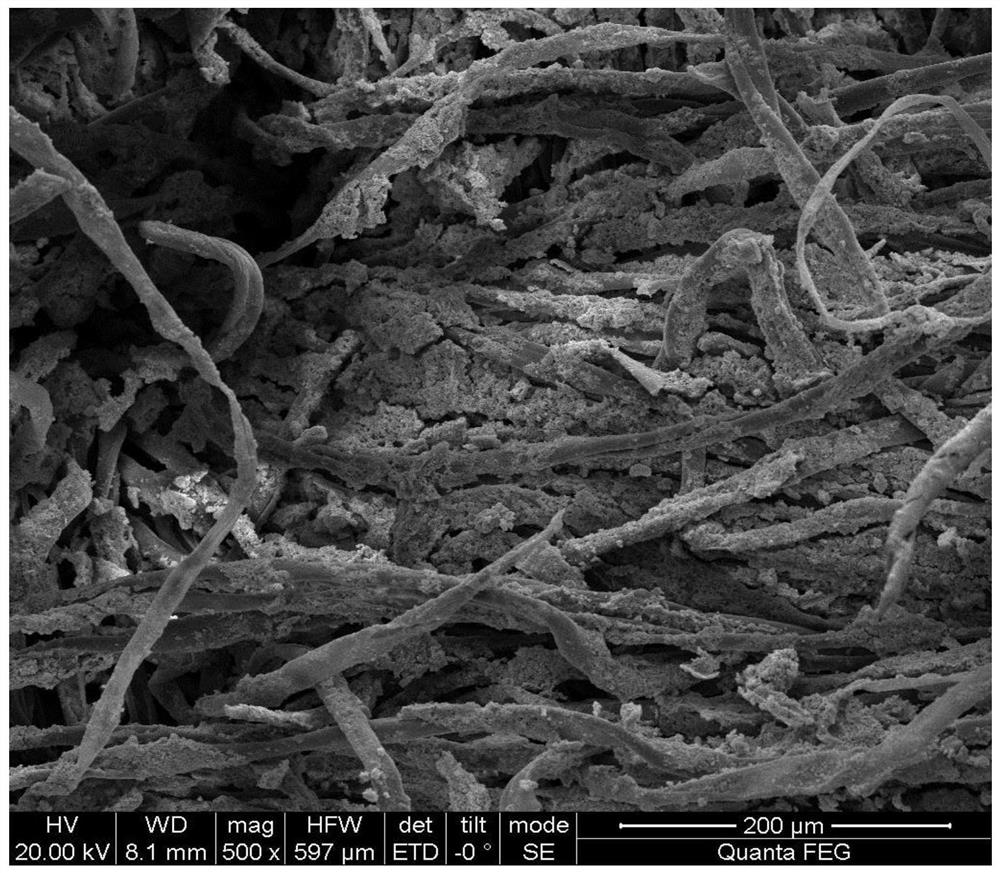

Super-hydrophobic and -oleophylic cloth producing method

A super-hydrophobic and -oleophylic cloth producing method is characterized by comprising following steps: (A) cleaning a cloth and air-drying the cloth; (B) dissolving dopamine hydrochloride and folic acid in water with stirring and pre-treating the water solution to obtain a uniform mixed solution; (C) regulating the pH of the mixed solution with an alkaline medium, adding the cleaned and air-dried cloth in the mixed solution, and performing a stirring reaction to obtain a cloth having a micro-nano structure; (D) adding the cloth in an ethanol solution of octadecylamine and carrying out a reaction to obtain the super-hydrophobic and -oleophylic cloth for oil-water separation, wherein the concentration of the dopamine hydrochloride is 0.5-2.0 mg / mL, the concentration of the folic acid is 0.2-1.0 mg / mL, the pre-treatment temperature is in the range from room temperature to 60 DEG C, and the pre-treatment time is 6-24 h. The producing method is low in cost, is simple in steps, is mild in reaction conditions and is beneficial to amplified production. The cloth is stable in super-hydrophobic property and has an application potential in the fields of oil-water separation, waterproof materials and self-cleaning materials.

Owner:HIT YIXING ACAD OF ENVIRONMENTAL PROTECTION

Superhydrophobic inorganic organic nano composite polymeric coating material and preparation method thereof

InactiveCN101824278AWide range of usesReduce resistancePretreated surfacesSpecial surfacesChemical reactionFunctionalized nanoparticles

The invention discloses a superhydrophobic inorganic organic nano composite polymeric coating material and a preparation method thereof. The coating material is prepared from 30 to 98 mass percent of thermosetting polymeric precursor and 10 to 70 mass percent of surface functionalized nanoparticle under the action of 0 to 5 mass percent curing agent, wherein the obtained surface water contact angle and rolling angle of the material are 120 to 180 DEG and 1 to 20 DEG respectively; and a falling water drop which is spherical can bounce up and can freely roll on the surface. The method has the characteristic of simple preparation process by using the chemical reaction between organic groups on the surfaces of the polymeric precursor and the modified nanoparticle in the solution. The coating material has the functions of stain resistance, dust prevention and self cleaning.

Owner:NANJING UNIV OF TECH

Graphene-based super-hydrophobic fabric and preparation method thereof

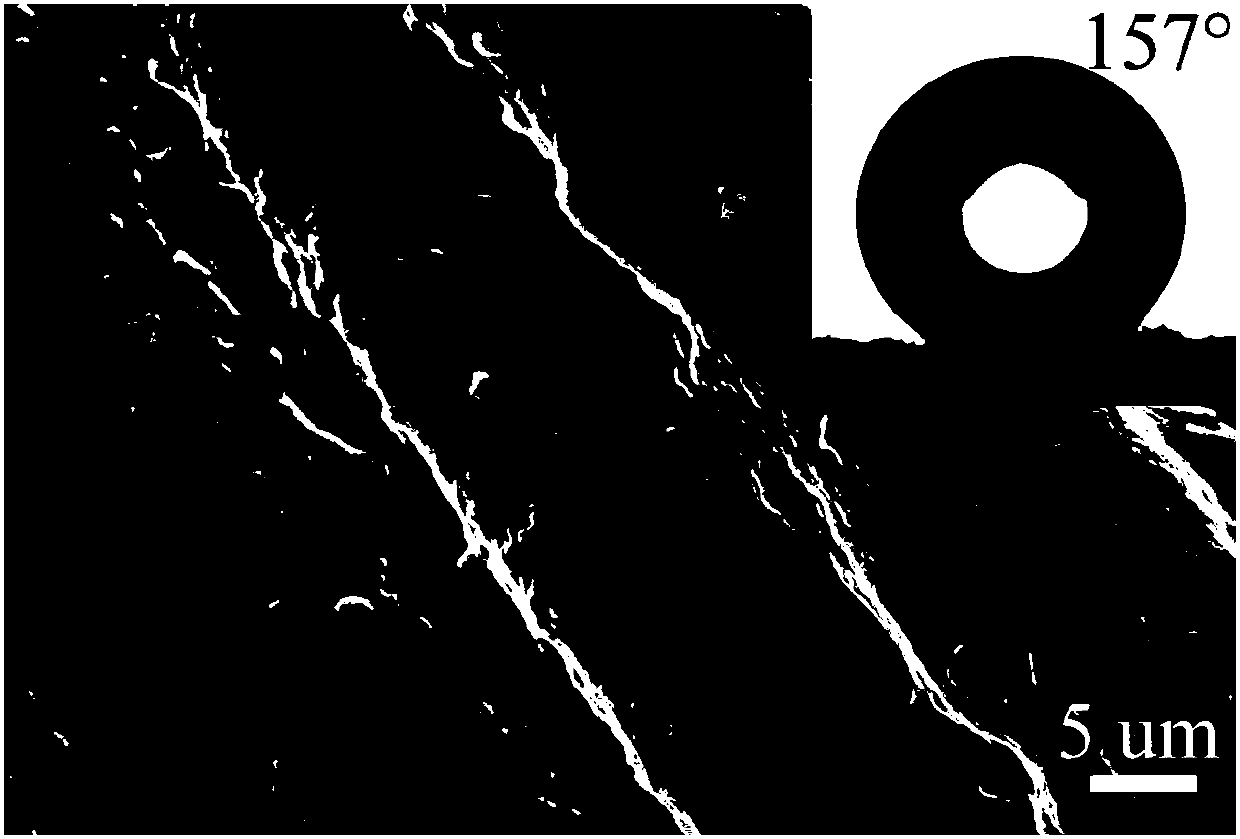

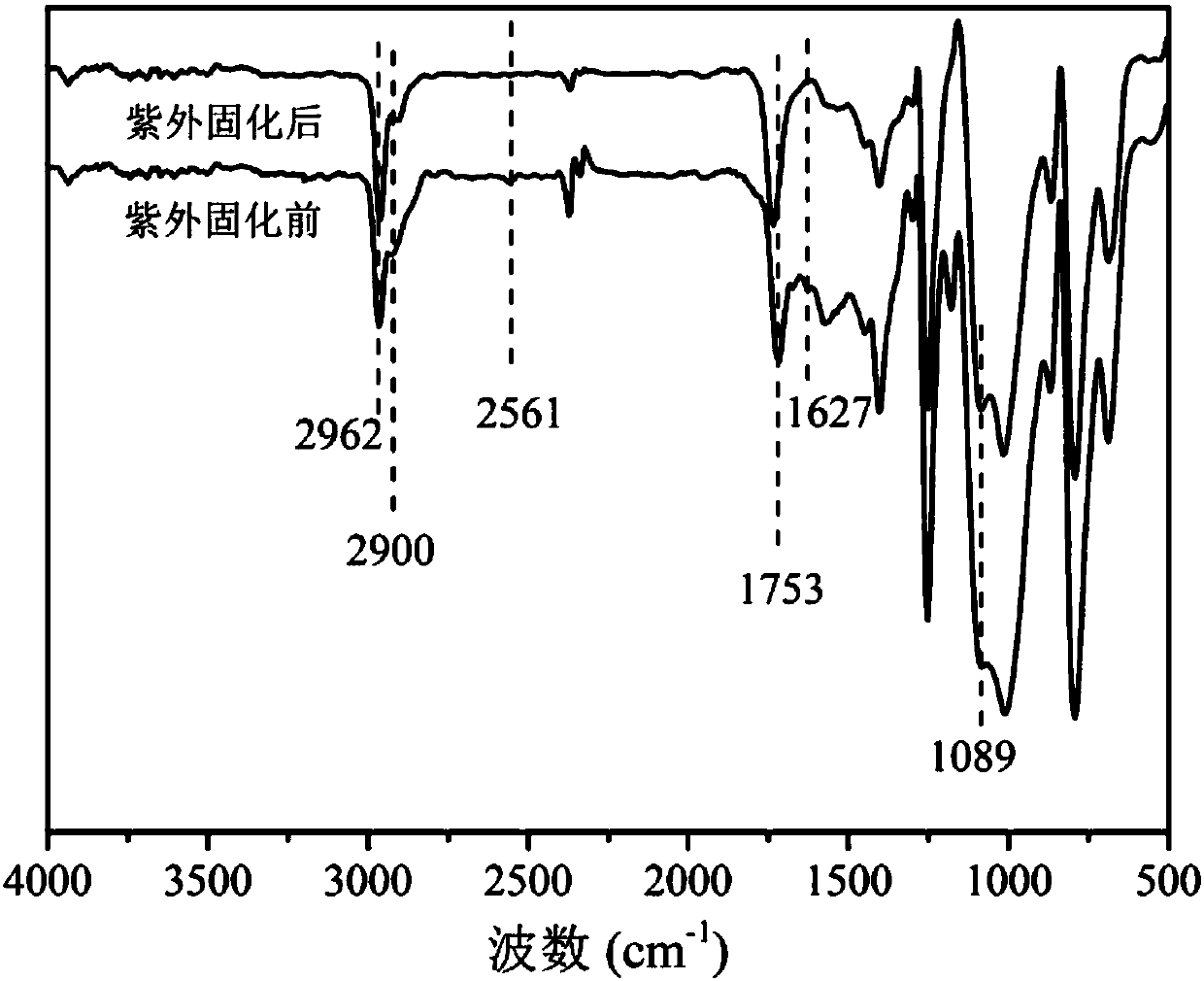

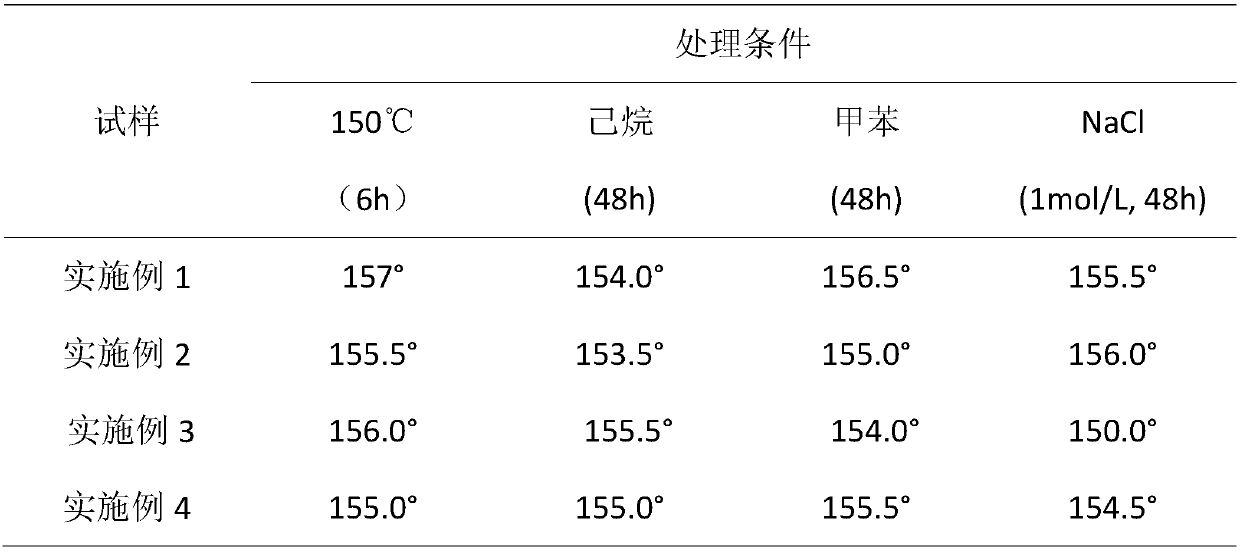

The invention discloses graphene-based super-hydrophobic fabric and a preparation method thereof. The preparation method comprises the following steps: firstly, performing surface modification on graphene oxide by a silane coupling agent containing an S-H group to obtain modified graphene oxide with the surface containing the S-H group; secondly, dispersing the modified graphene oxide and terminated vinyl polydimethylsiloxane into a solvent at room temperature, stirring uniformly, adding a crosslinking agent and a photoinitiator, and continuously stirring to form a uniform solution; finally, soaking the fabric in the prepared mixed solution by a dip-coating method, taking out, performing ultraviolet irradiation to enable the S-H group on the modified graphene oxide attached to the fabric and C=C double bond on the terminated vinyl polydimethylsiloxane to perform mercapto ene reaction to finally prepare the graphene-based super-hydrophobic fabric. The method is simple and convenient andthe surface water drop static contact angle of the prepared fabric is more than 150 degrees; meanwhile, the fabric has excellent heat resistance and chemical resistance.

Owner:SOUTH CHINA UNIV OF TECH

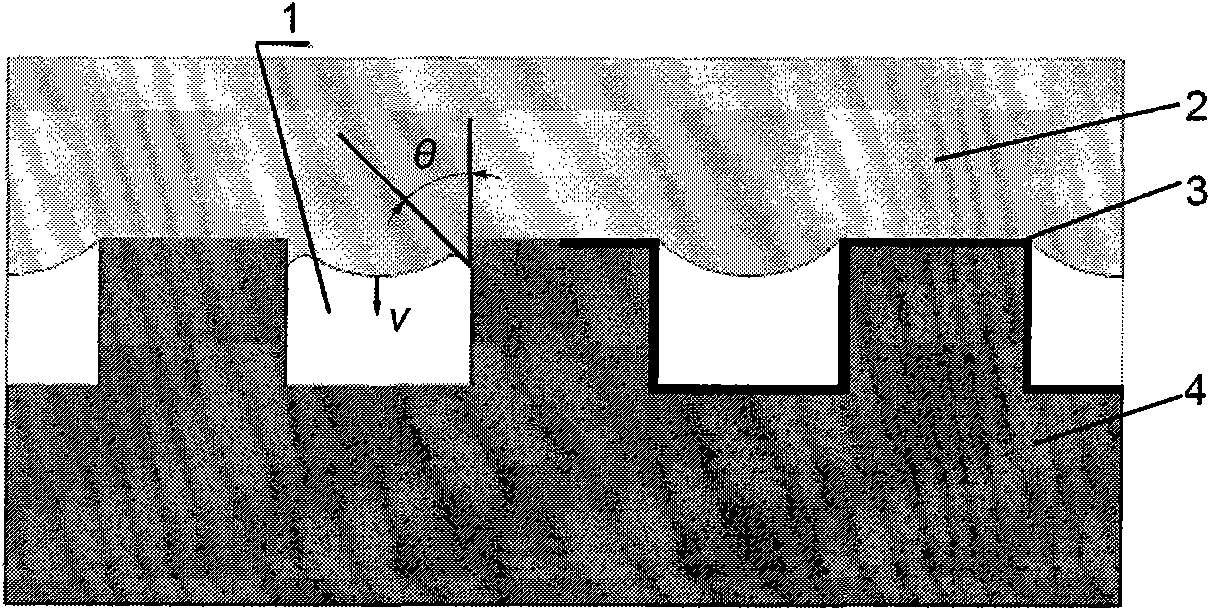

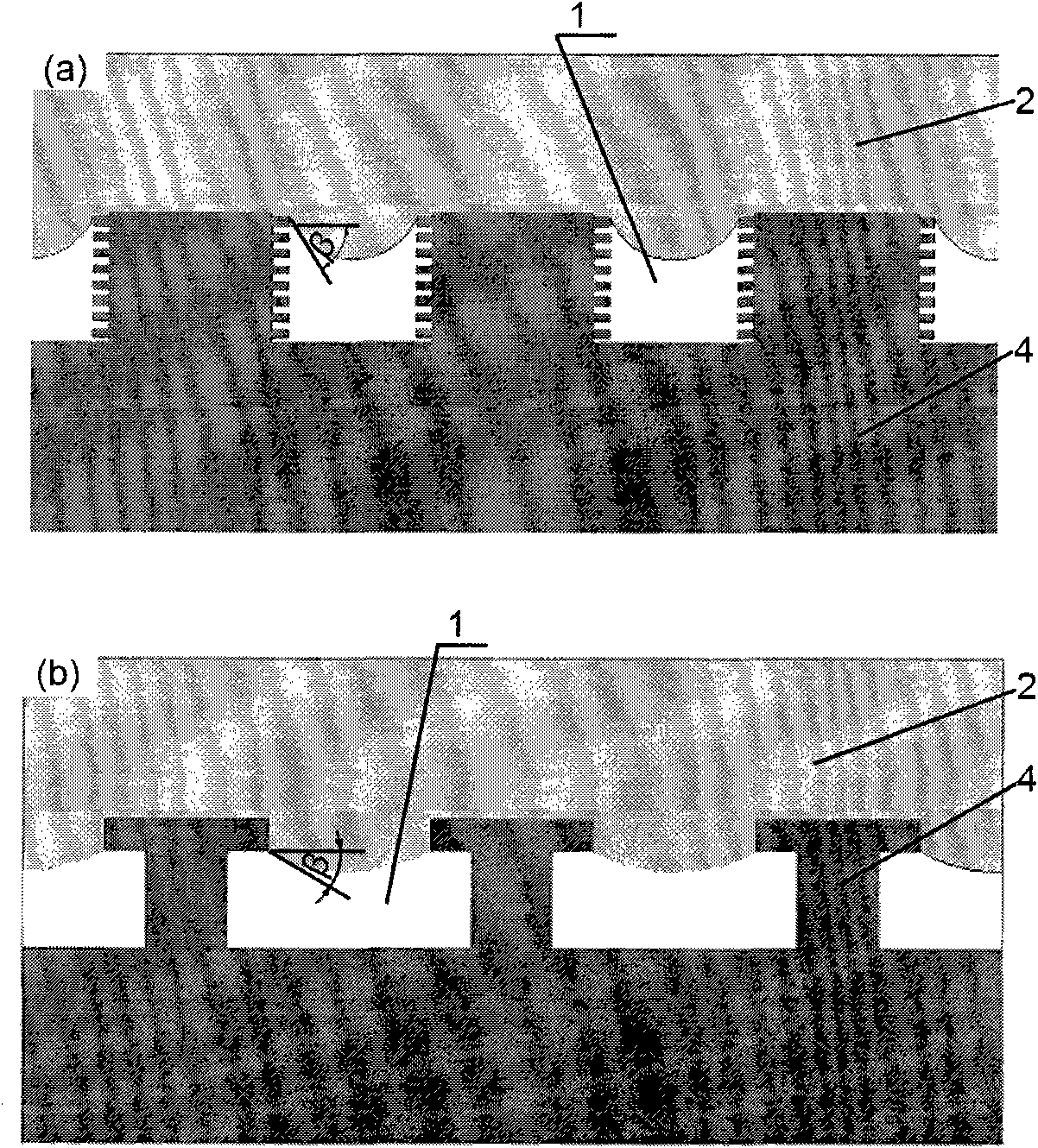

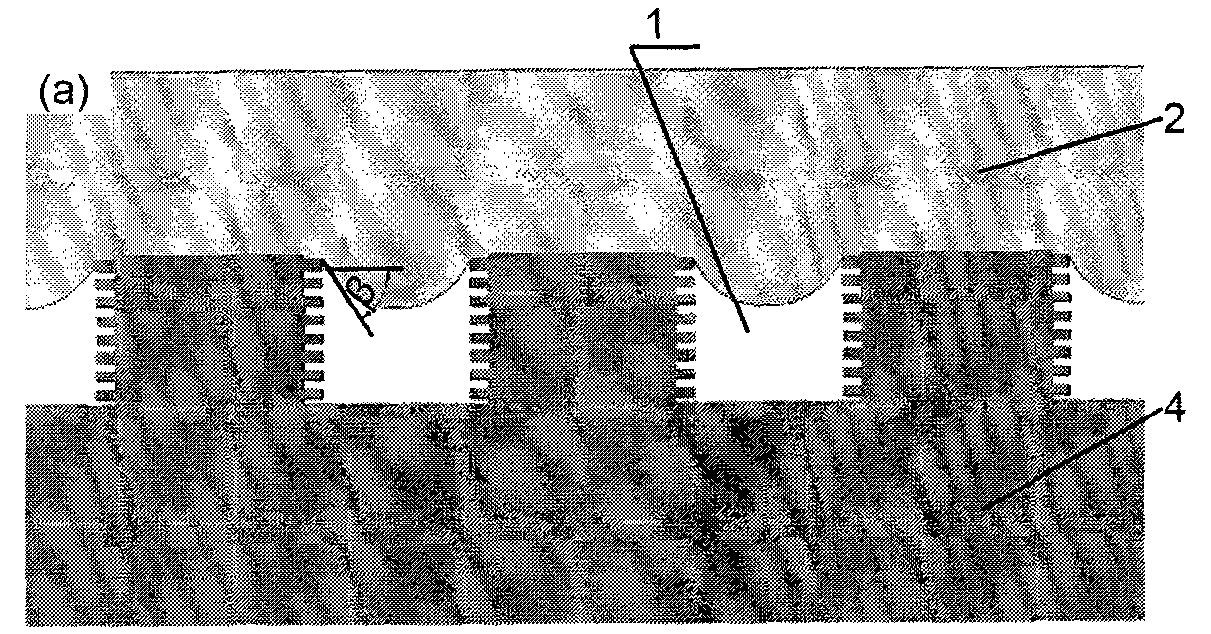

Hydrophilic material surface super hydrophobic functional shift micro structure design method

InactiveCN101817500ASuperhydrophobic effectSuperhydrophobic stabilityNanostructure manufactureMicrostructural devicesMicro structureMicro nano

The invention provides a hydrophilic material super hydrophobic surface micro nano structure design method, relating to the micro nano structure function surface design preparation technical field. Protuberance ratio of micro structure is calculated according to super hydrophobic contact angle requirement; and meanwhile maximum period of micro structure is determined according to use condition; and finally, contact status of liquid and micro structure surface is verified according to the designed micro structure and structure parameter. The invention realizes surface super hydrophobic performance by controlling the form of micro structure without carrying out coating treatment on the surface, thus the super hydrophobic performance of micro structure surface can not be influenced when the structure form of the interior of micro structure is not changed even if the material is partially abrased, super hydrophobic surface has stable performance, and the performance is effective for long term.

Owner:JIANGSU UNIV

Preparation method of copolymer grafted carbon nano-tube super-hydrophobic material

The invention discloses a preparation method of a copolymer grafted carbon nano-tube super-hydrophobic surface. The method comprises the following steps: preparing a copolymer of alpha-vinyltoluene and butyl methacrylate by adopting a simple free radical polymerization method; grafting the copolymer to the surface of a multi-wall carbon nano-tube to obtain a alpha-vinyltoluene and butyl methacrylate copolymer grafted multi-wall carbon nano-tube; dispersing the alpha-vinyltoluene and butyl methacrylate copolymer grafted multi-wall carbon nano-tube into an organic solvent in an ultrasonic wave way to obtain a dispersing liquid; preparing resin paste by uisng resin, a promoting agent and an initiator; and coating the resin paste on the surface of a matrix of an inorganic or organic material, and coating the dispersing liquid to form a stable super-hydrophobic surface. The preparation method does not have special requirement on equipment, is low in cost, easy in implementation, and simple in process, has easily available raw materials, is environmental friendly, and can be used as a corrosion-resistance material, a pollution-prevention material, a self-cleaning material and the like.

Owner:QILU UNIV OF TECH

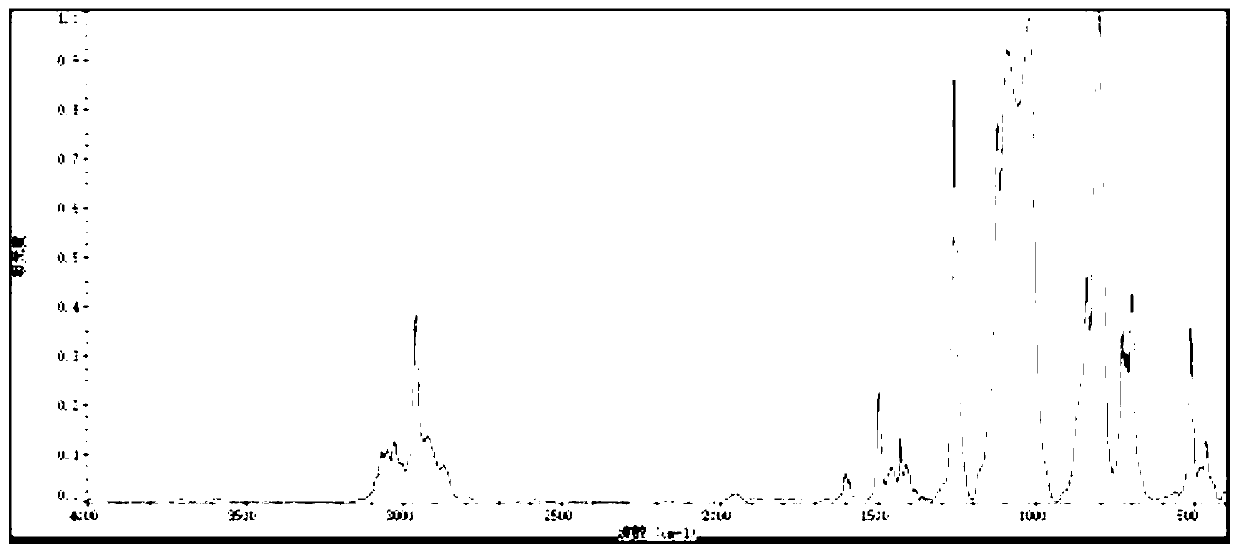

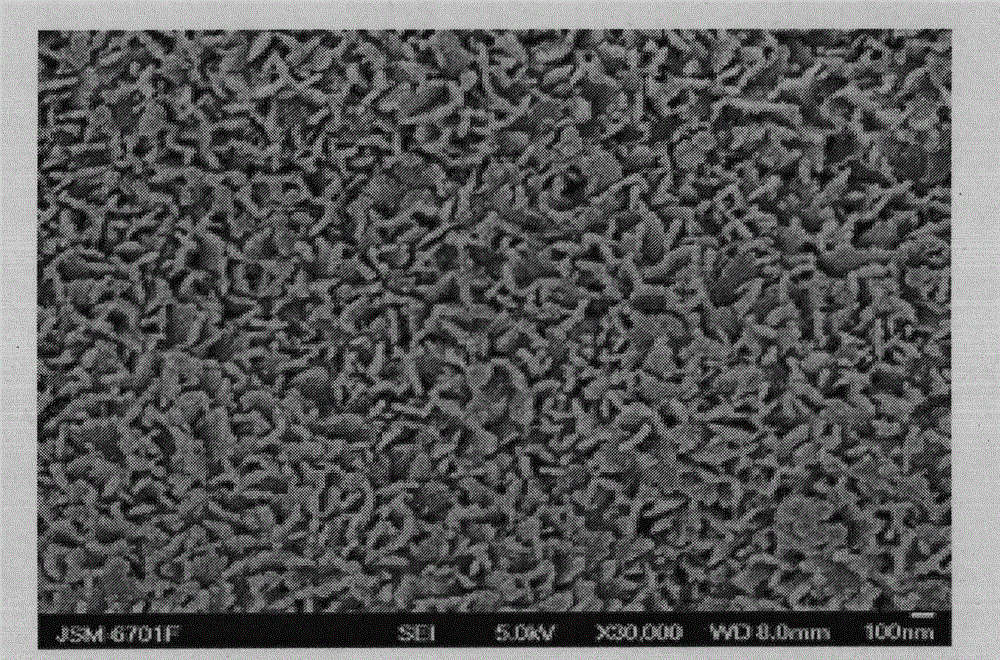

Method for preparing super-hydrophobicity membrane on silicon face

InactiveCN101190435AWon't happenSuperhydrophobic stabilityAntifouling/underwater paintsPretreated surfacesNanostructureChemical modification

The invention discloses a method that a film with ultra-hydrophobic property is prepared on silicon surface. The method prepares a dual-layer structure that micron structure and nanostructure coexist in surface microstructure by adopting a sol-gel method, and chemically modifies the surface through fluoric organics in order to form a contact angle of more than 150 DEG between the surface and the water and a sliding angle of less than 10 DEG that water drop slides on the surface, thus having good ultra-hydrophobic property. The invention provides a new preparation method for the applicable expansion of silicon material in industrial production. The invention has the advantages of simple operation, low requirements to equipment, scale production and having excellent industrial application prospect.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

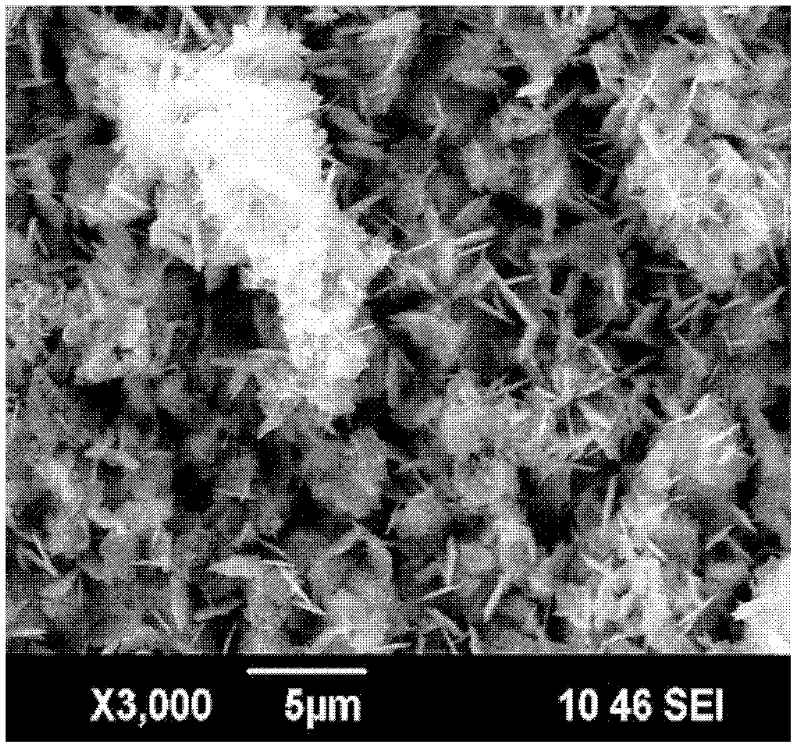

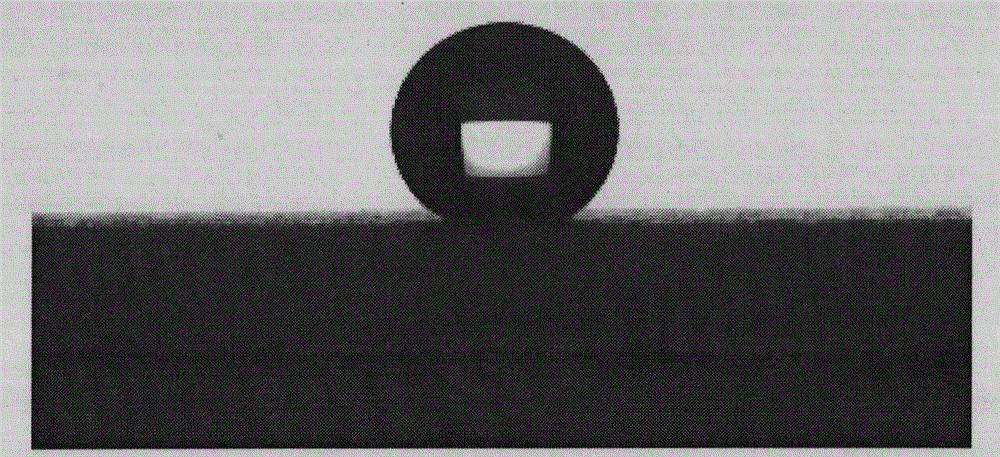

Electrochemical method for preparing superhydrophobic surface on copper substrates by using aqueous electrolyte

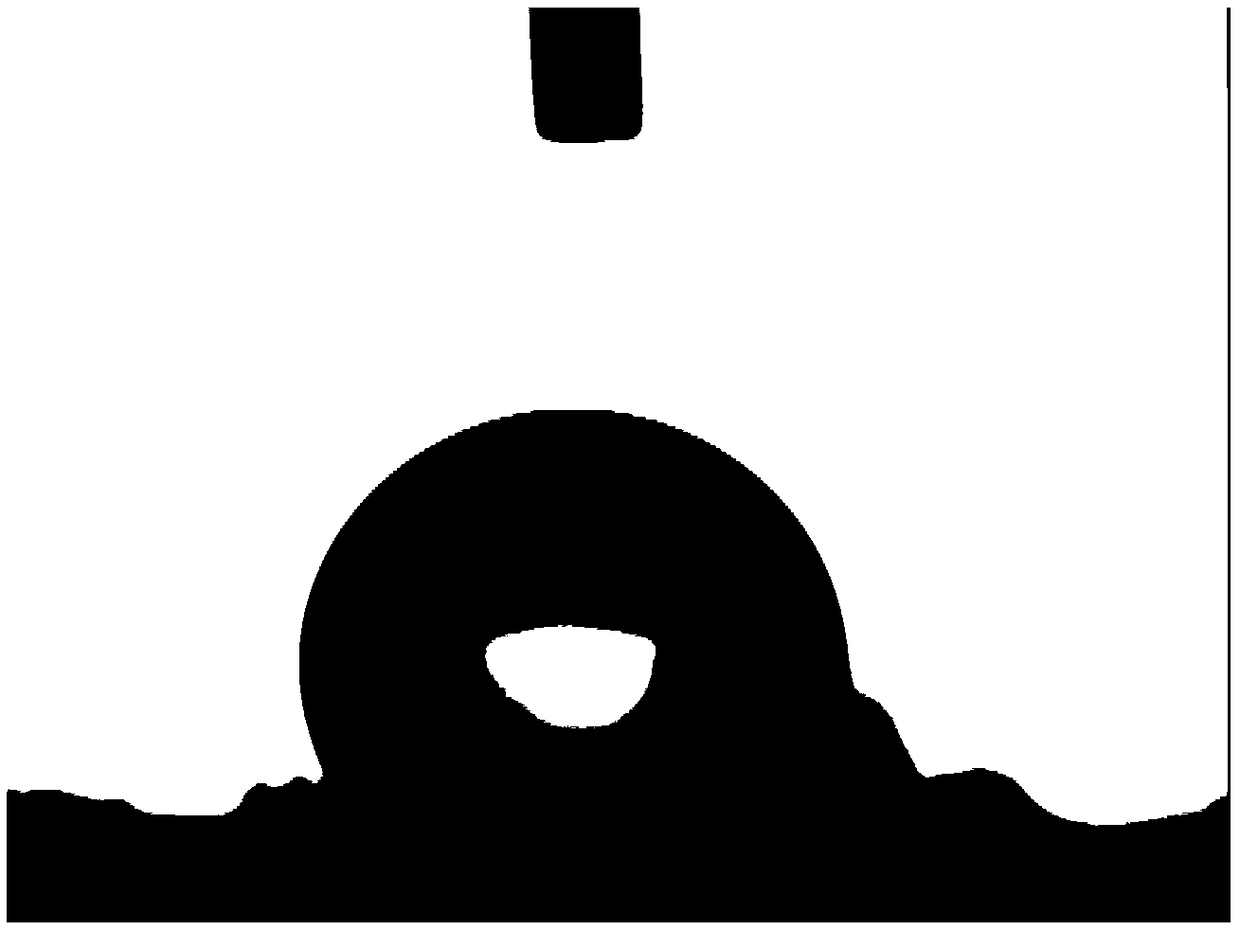

The invention discloses an electrochemical method for preparing a superhydrophobic surface on copper substrates by using an aqueous electrolyte. The method comprises the steps of: I, dissolving potassium hydroxide and potassium peroxydisulfate into distilled water to obtain a solution A; II, dissolving tetradecanoic acid into anhydrous ethanol to obtain a solution B; III, polishing the two copper substrates by using waterproof abrasive paper, then cleanly washing the two copper substrates by sequentially using the distilled water and the anhydrous ethanol, and drying for later use; IV, placing the solution A, as an electrolyte, into an electrolytic cell, and utilizing the two dried copper substrates as an anode and a cathode respectively to electrolyze; and V, cleanly washing the electrolyzed anode copper substrate by sequentially using the distilled water and the anhydrous ethanol, then uniformly smearing the solution B to a surface of the cleanly washed anode copper substrate, and airing to obtain the copper substrates with the super-hydrophobic surface. A contact angle of the super-hydrophobic surface prepared on the copper substrates by using the method can reach more than 152 degrees, and the super-hydrophobic performance keeps stable after the copper substrates are placed in a normal condition for one year.

Owner:XIAN UNIV OF SCI & TECH

Superhydrophobic wood fiber powder and preparation method thereof

InactiveCN109468831AImprove resource utilizationHigh economic valueLiquid repellent fibresVegetal fibresSilica particleCellulose

The invention relates to superhydrophobic wood fiber powder and a preparation method thereof, and belongs to the field of development of functional biomass materials. The invention aims at improving the utilization value of wood fiber biomass raw materials and solving the problems of complex preparation process and relatively high cost of superhydrophobic materials. The invention relates to the superhydrophobic wood fiber powder and the preparation method thereof. The preparation method comprises the following steps: firstly, crushing a lignocellulose raw material into powder by using a crusher; secondly, grafting lignocellulose powder prepared in the first step with silica particles; thirdly, adding a lignocellulose powder solid grafted with the silica particles, prepared in the second step, into a silane coupling agent for carrying out superhydrophobic modification to obtain the superhydrophobic wood fiber powder. The superhydrophobic wood fiber powder prepared with the preparation method disclosed by the invention belongs to a high added value product and has the advantages that resource utilization of the wood fiber biomass raw materials is widened and the production cost of ahydrophobic material is reduced. A preparation process is simple and is easy to control.

Owner:SOUTH CHINA UNIV OF TECH

Long-acting superhydrophobic anticoagulation biovalve and preparation method therefor

ActiveCN112641998ASimple preparation processMild conditionsPharmaceutical delivery mechanismTissue regenerationDouble bondPhenols

The invention discloses a long-acting superhydrophobic anticoagulation biovalve and a preparation method therefor. The method comprises the following steps: (1) treating a biovalve material with glutaraldehyde for 48 to 96 hours; (2) embedding nanoparticles, which are polymerized from polyphenol compounds and metal ions and contain double-bond groups, in the surface of the biovalve material; and (3) grafting surfaces of the nanoparticles with a hydrophobic substance, so as to form a hydrophobic coating. According to the long-acting superhydrophobic anticoagulation biovalve and the preparation method therefor, the superhydrophobic coating with a long-acting high water contact angle and a low roll angle is prepared on the surface of the biovalve through a simple and stable operating process without affecting properties of a valve body in accordance with moderate self-polymerization reaction conditions of polyphenols and elicitation of a reaction mechanism of the metal ions, double bonds and mercapto groups, and the requirements on long-acting anticoagulation are met through impeding adsorption of plasma proteins.

Owner:JILIN VENUS HAOYUE MEDICAL LTD

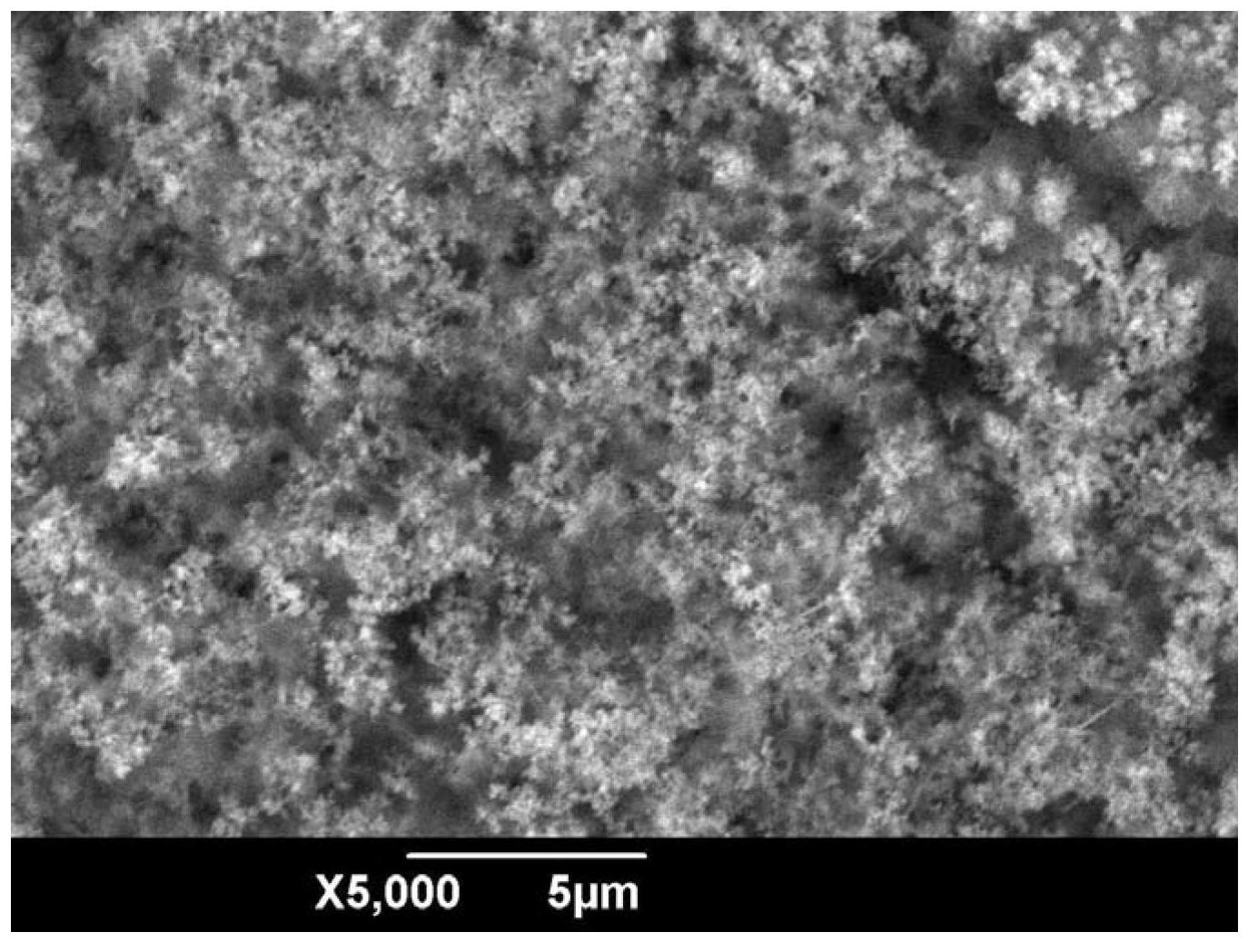

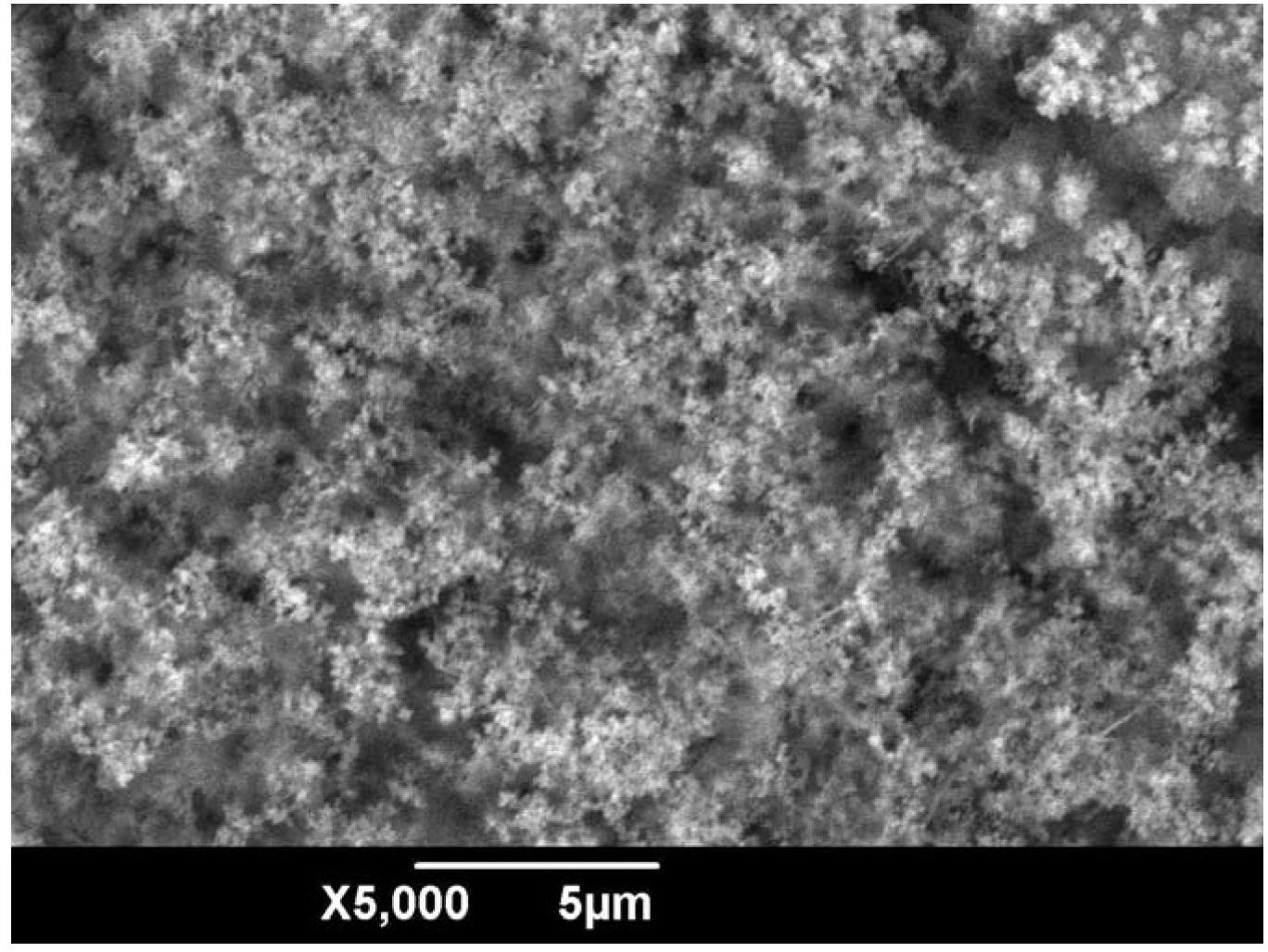

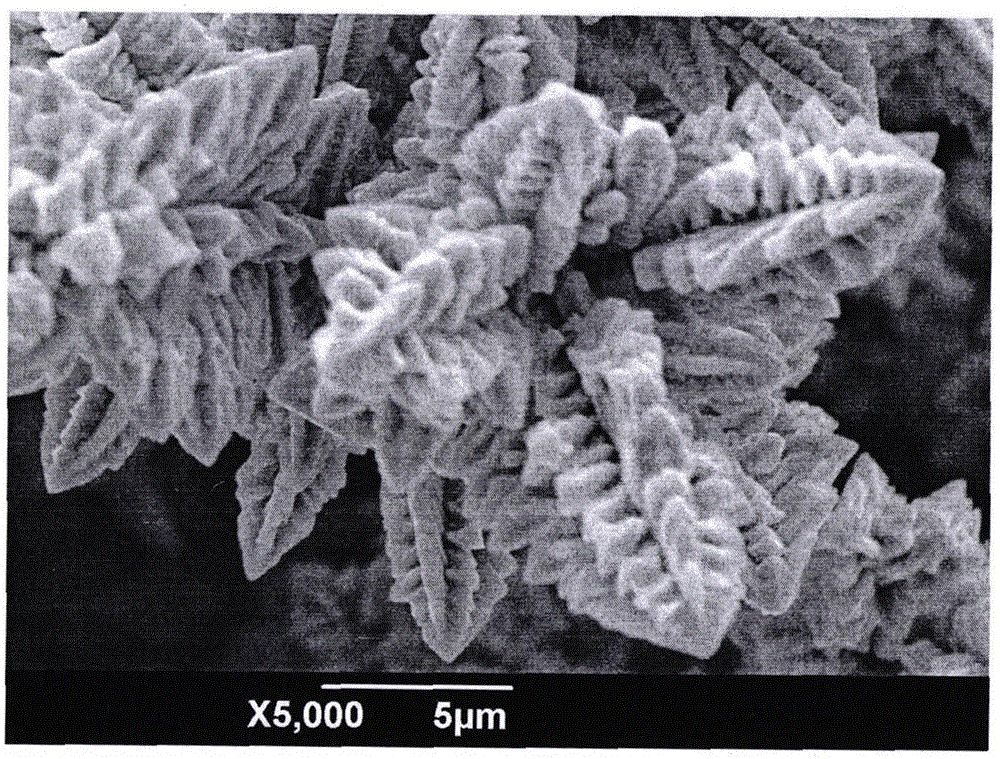

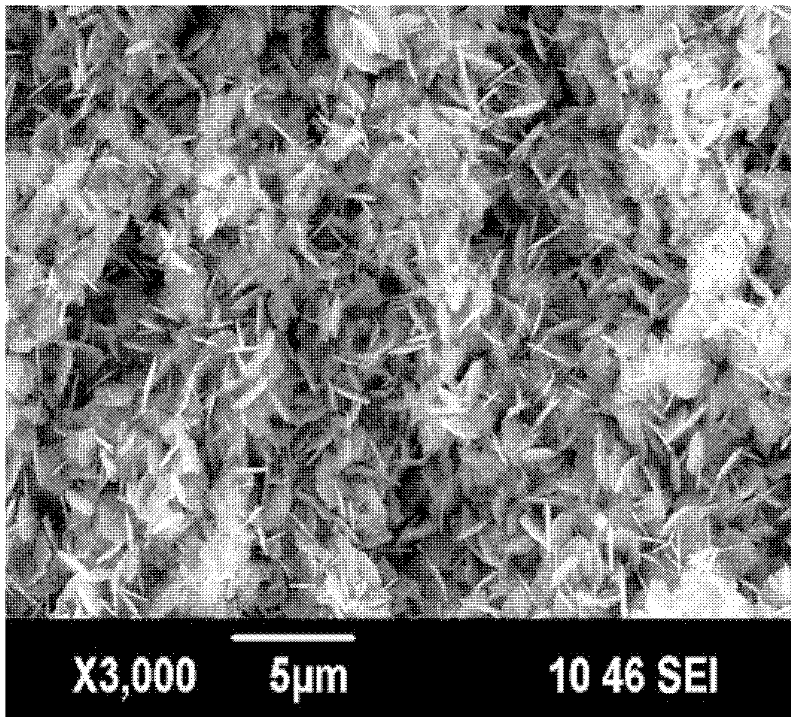

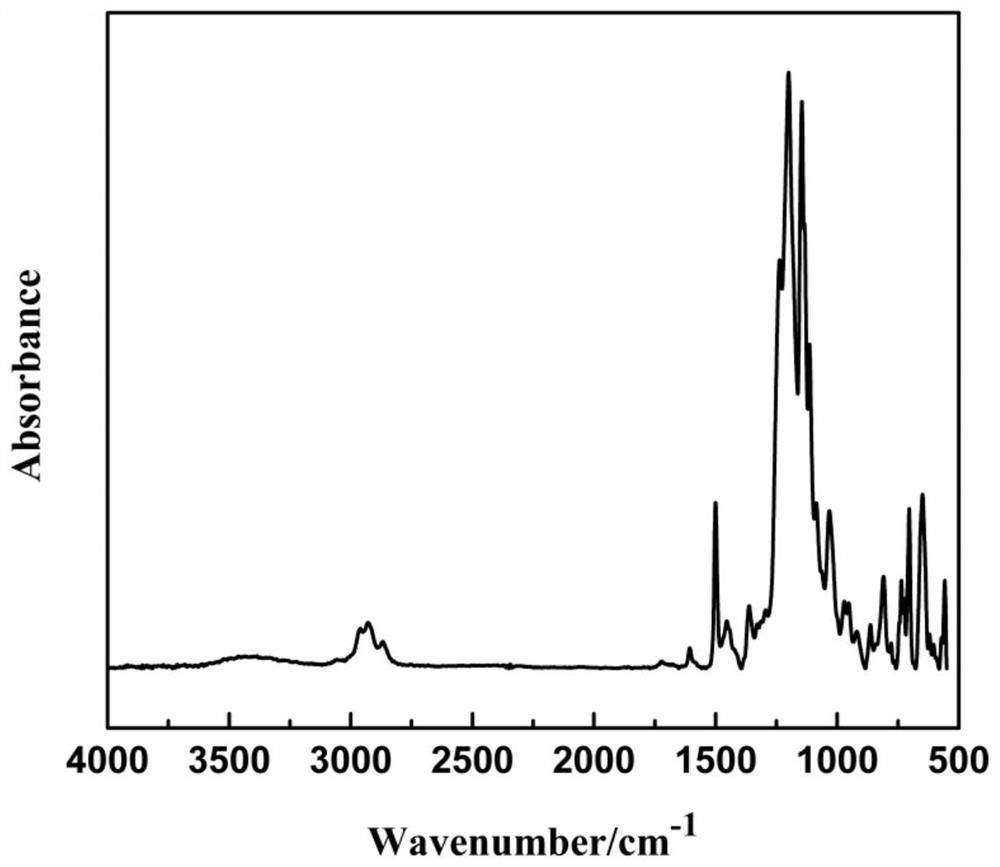

Electrochemical method for preparing super-hydrophobic surface of copper dendritic crystal

The invention discloses an electrochemical method for preparing a super-hydrophobic surface of a copper dendritic crystal. The method comprises the following steps: (1) concentrated sulfuric acid is slowly added in distilled water; and then, a copper sulfate crystal is dissolved in the solution for uniformly stirring to prepare solution A; (2) myristic acid is dissolved in anhydrous ethanol to obtain solution B; (3) oxide layers on the surfaces of two copper substrates are removed, are cleaned by distilled water and anhydrous ethanol in sequence, and are dried for future use; (4) the solution A is put in an electrolytic cell as electrolyte; and the dried two copper substrates are respectively used as an anode and a cathode for electrolysis; and (5) the electrolyzed cathode copper substrate is cleaned by the distilled water and the anhydrous ethanol in sequence; then, the surface of the cleaned cathode copper substrateis uniformly coated by the solution Bfor airing; and then, the surface is lightly wiped by sponge to obtain the super-hydrophobic surface. The super-hydrophobic surface, prepared on the copper substrate by the method, has a contact angle being 152 degrees or above, and keeps stable super-hydrophobic performance after one-year placement under conventional conditions.

Owner:XIAN UNIV OF SCI & TECH

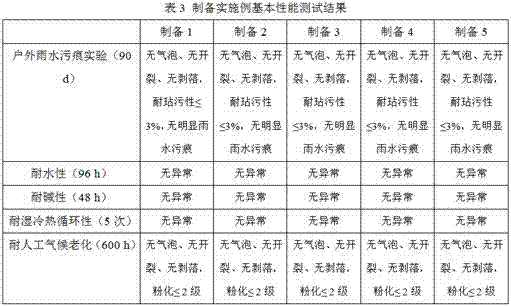

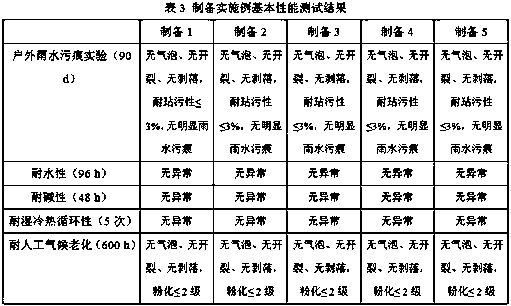

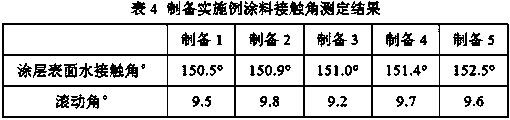

Super-hydrophobic self-cleaning coating for building

InactiveCN109517522ASuperhydrophobic stabilityNot easy to aging failureCoatingsSolventHydrophobic effect

The invention relates to a super-hydrophobic self-cleaning coating for a building. The coating is prepared by dispersing and mixing 2-10% by mass of heptafluorodecyl triethoxysilane, 1-10% by mass ofmethyl triethoxysilane, 1-10% by mass of perhydropolysilazane, 2-15% by mass of solid microparticles and the balance a solvent. The super-hydrophobic self-cleaning coating for the building has the advantages that the super-hydrophobic self-cleaning coating is stable in super-hydrophobic property and unlikely to age and lose effect, and can work normally in severe working conditions such as acid, alkali, high temperature and strong ultraviolet rays; and the super-hydrophobic self-cleaning coating can be cured at a constant temperature, is not high in construction condition and is suitable for various buildings.

Owner:萍乡亨厚新材科技有限公司

Preparation method and application of high-strength superhydrophobic composite material taking block-like organosilicone/epoxy hybrid resin as matrix

The invention provides a preparation method of a superhydrophobic composite material taking two chemically-bonded silanized epoxy resin and block-like organosilicone / epoxy hybrid resin as a matrix. The silanized epoxy resin is prepared by utilizing a reaction of trimethoxysilane and high-purity allyl epoxy resin, the block-like organosilicone / epoxy hybrid resin is prepared by utilizing a reactionof double-hydrogen-terminated organosilicone and the high-purity allyl epoxy resin; and the two organosilicone / epoxy resin hybrid systems and micro-nano particles are blended and compounded to form asuspension, then an epoxy resin curing agent is added for matching, and the generated suspension can be sprayed, brushed or dip-coated on the surfaces of various base materials to obtain a superhydrophobic surface with high adhesive force and high mechanical strength. The preparation method has the advantages of simplicity, easiness in operation and extremely high process stability, and the formedsuperhydrophobic composite material is firm and reliable, still has the superhydrophobic characteristic after being abraded, and has very high practical values.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

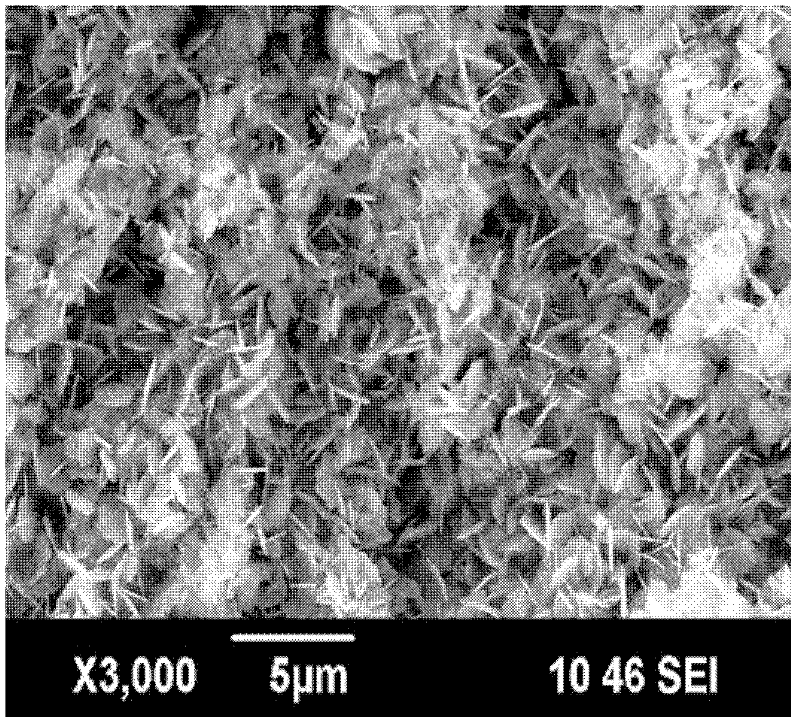

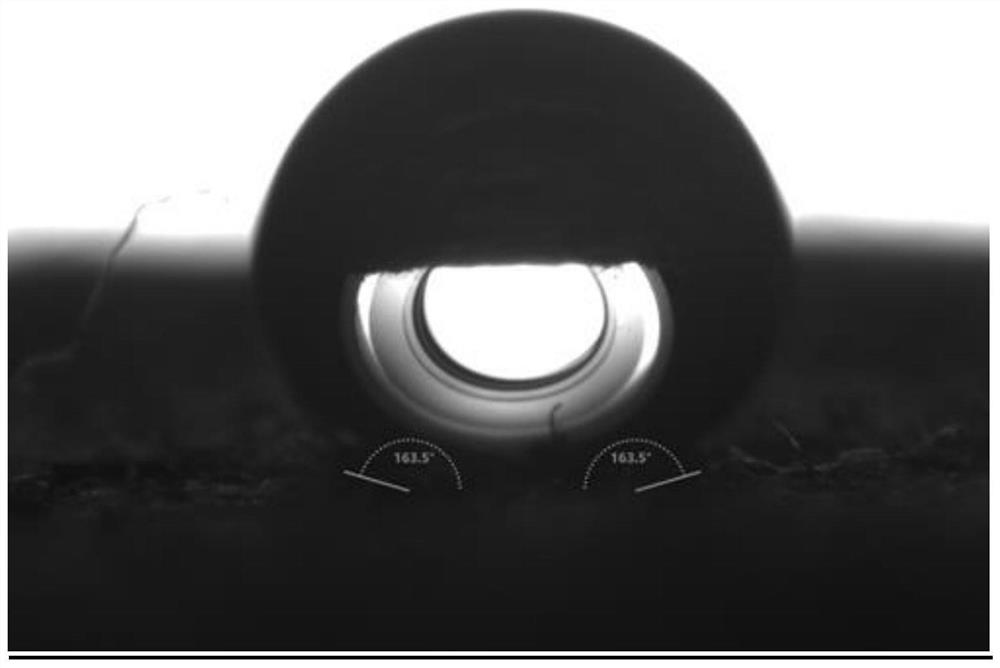

Electrochemical method for preparing super-hydrophobic surface on copper substrate

The invention discloses an electrochemical method for preparing a super-hydrophobic surface on a copper substrate. The electrochemical method comprises the following steps: 1) polishing copper substrates by using 800 particle-size and 1200 particle-size waterproof abrasive paper in turn, washing the copper substrates with distilled water and absolute ethyl alcohol in turn, drying the copper substrates by using an electric blower, and standing by; 2) adding potassium hydroxide and potassium peroxydisulfate into the absolute ethyl alcohol, thereby obtaining a solution A; 3) dropwise adding a material with low surface energy into the absolute ethyl alcohol, thereby obtaining a solution B; 4) placing the solution A as electrolyte into an electrolyzer, respectively taking the two dried copper substrates as an anode and a cathode, and electrolyzing; 5) washing the anode copper substrate after being electrolyzed with absolute ethyl alcohol and clean water in turn, and then placing the cleaned anode copper substrate into the distilled water and soaking for more than 2 hours; and 6) uniformly coating the solution B on the soaked anode copper substrate, and then drying in the air, thereby obtaining the copper substrate with the super-hydrophobic surface. A contact angle of the super-hydrophobic surface prepared according to the method provided by the invention is above 162 degrees.

Owner:XIAN UNIV OF SCI & TECH

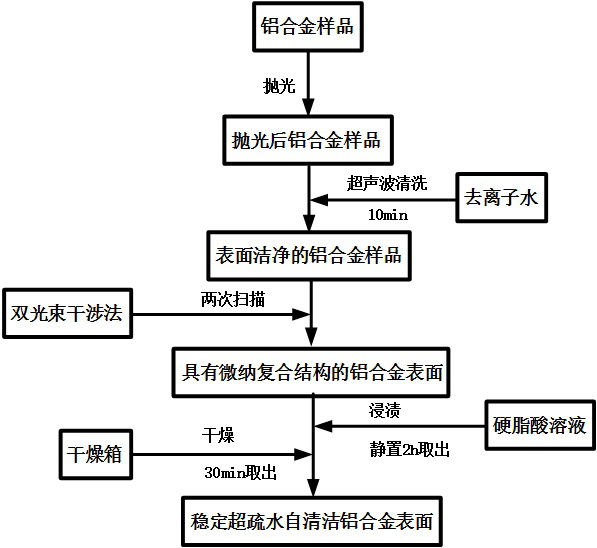

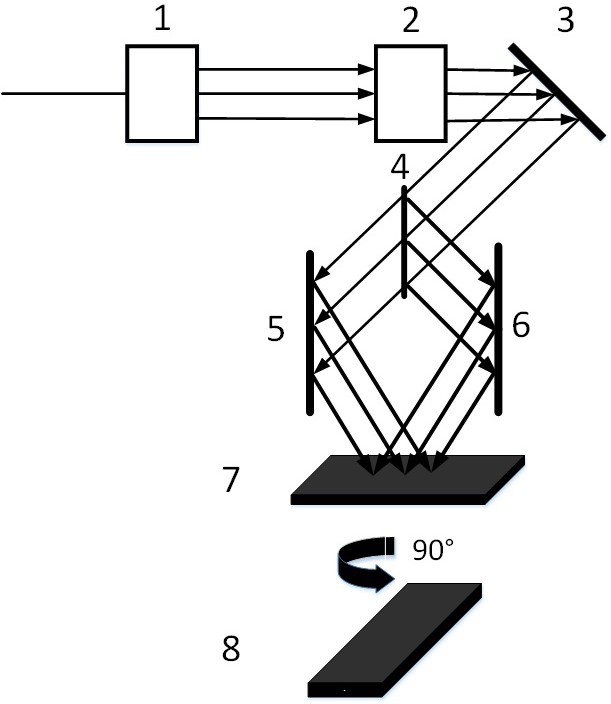

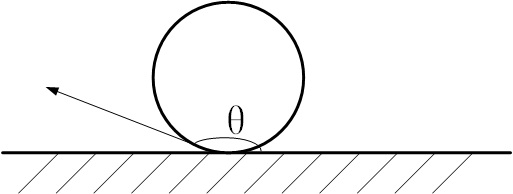

Stable super hydrophobic self-cleaning surface and double-light-beam interference-method preparation method thereof

InactiveCN111805089AImprove stabilitySmall sizeWelding/soldering/cutting articlesLaser beam welding apparatusSurface modificationAlloy surface

The invention provides a stable super hydrophobic self-cleaning surface and a double-light-beam interference-method preparation method thereof. According to the stable super hydrophobic self-cleaningsurface and the double-light-beam interference-method preparation method thereof, a polished and cleaned aluminum alloy sample is fixed on a processing platform, a double-light-beam interference method of interference superposition of two coherent laser beams is adopted to perform erosion on the surface of the aluminum alloy sample, one aluminum alloy sample of a periodicity controllable size micro-nano composite structure is obtained, finally, the aluminum alloy sample is immersed in a stearic acid solution for surface modification treatment, and the stable super hydrophobic self-cleaning aluminum alloy surface is obtained. By means of the stable super hydrophobic self-cleaning surface and the double-light-beam interference-method preparation method thereof, the double-light-beam interference method and surface modification are combined, the stable super hydrophobic self-cleaning surface is prepared, by means of change of double-light-beam laser interference optical parameters, the parameters of the micro-nano composite structure of the surface of a material subjected to double-light-beam interference are adjusted, the micro-nano composite structure periodicity size and microstructure shape size are controlled, and the super hydrophobic performance and cleaning function adaptation requirements are met better.

Owner:XIANGTAN UNIV

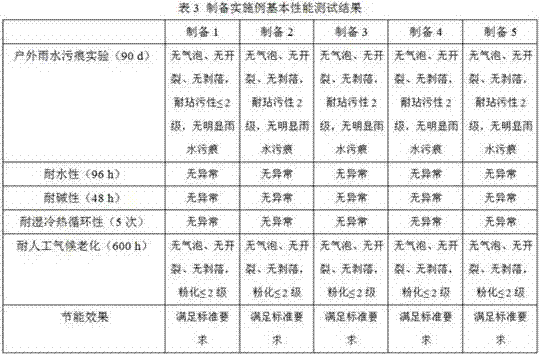

Energy saving super hydrophobic colorful luminous latex paint for exterior walls and preparation method thereof

InactiveCN106905782ASimple componentsSuperhydrophobic stabilityAntifouling/underwater paintsLuminescent paintsEmulsionStearate

The invention relates to the technical field of hydrophobic paint for exterior walls, and discloses energy saving super hydrophobic colorful luminous latex paint for the exterior walls and a preparation method thereof. The energy saving super hydrophobic colorful luminous latex paint comprises the following components by mass: 30-50% of styrene acrylic emulsion, 1-15% of stearate, 1-5% of nano silica, 10-30% of a luminescent pigment, 1-5% of a coloring pigment, 3-5% of an assistant and 20-40% of water. The energy saving super hydrophobic colorful luminous latex paint has the advantages of low cost, simple preparation, stable ultra hydrophobic property, saving energy and environmental-friendliness.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

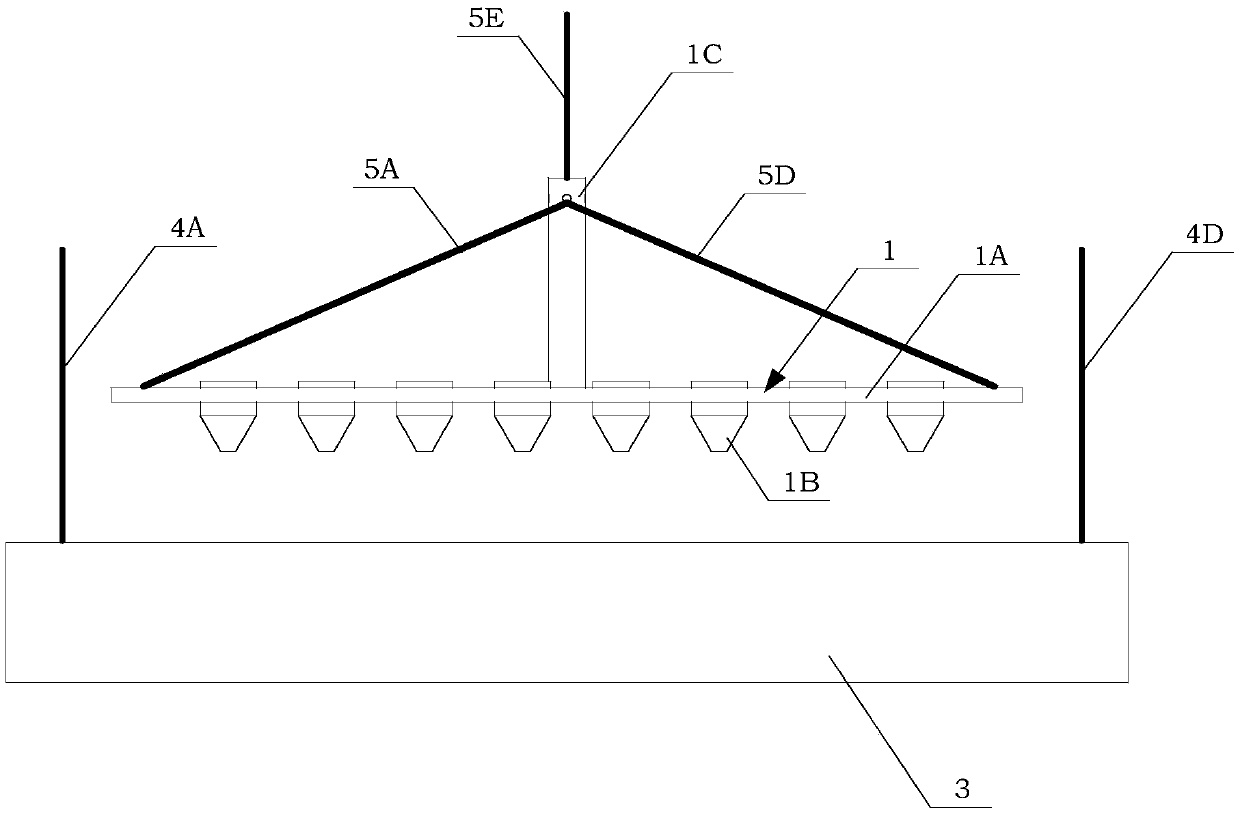

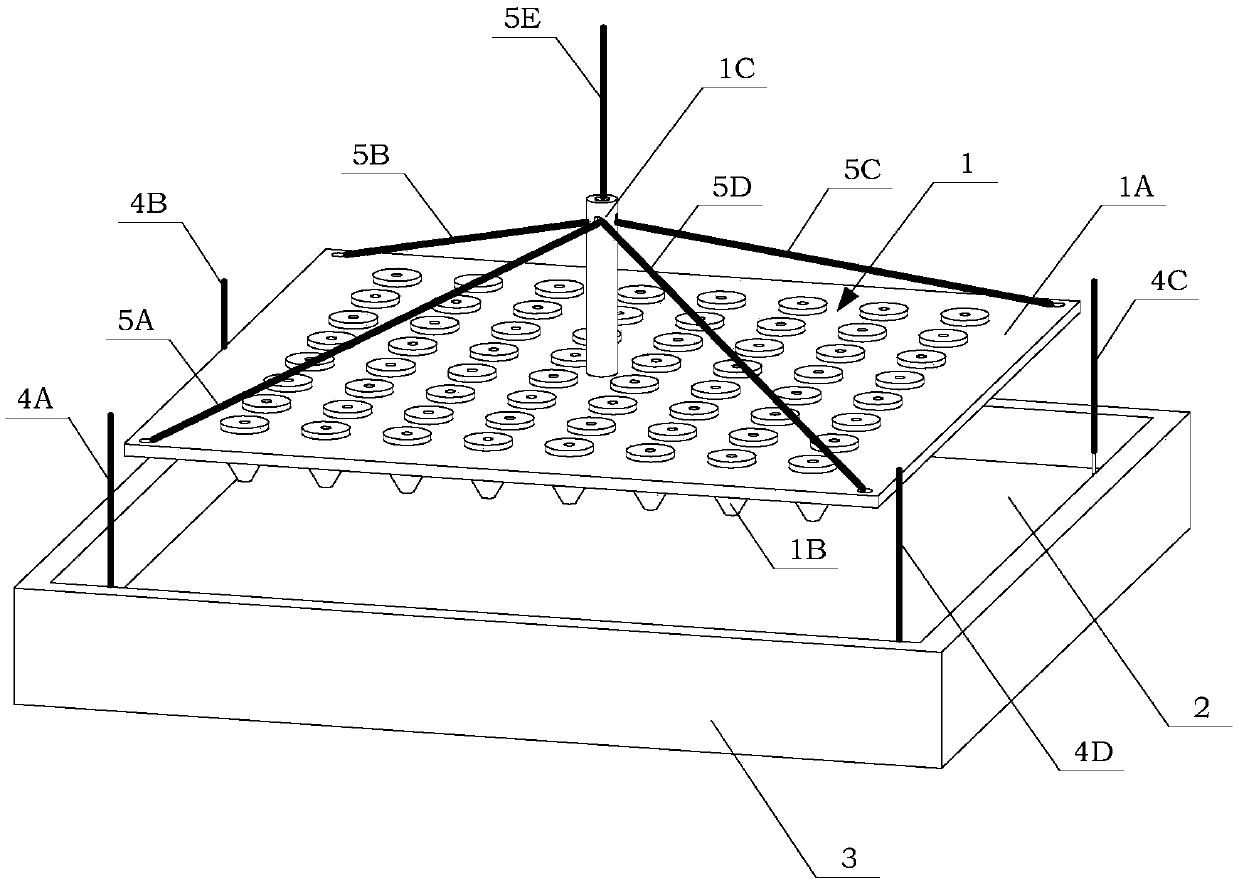

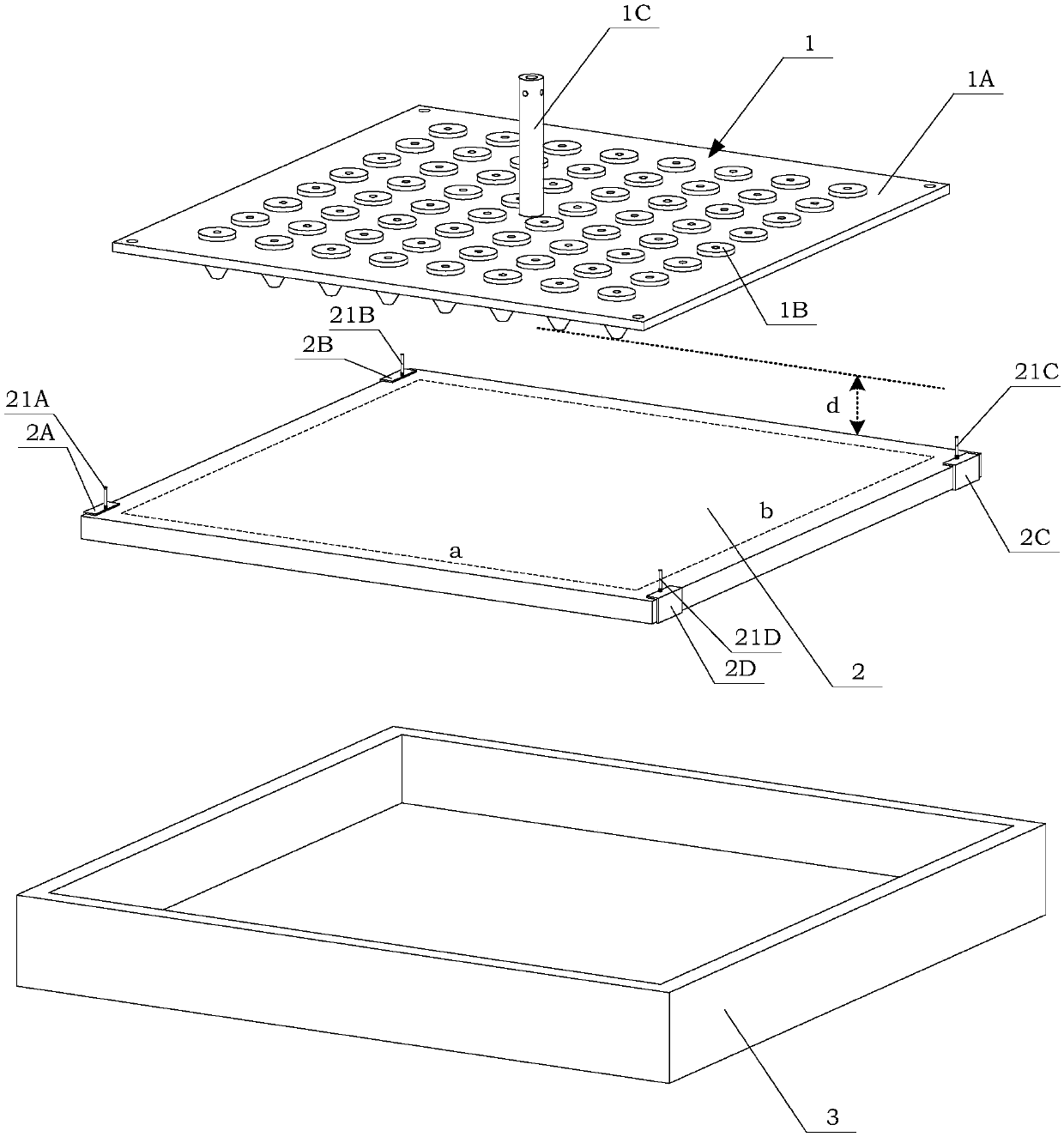

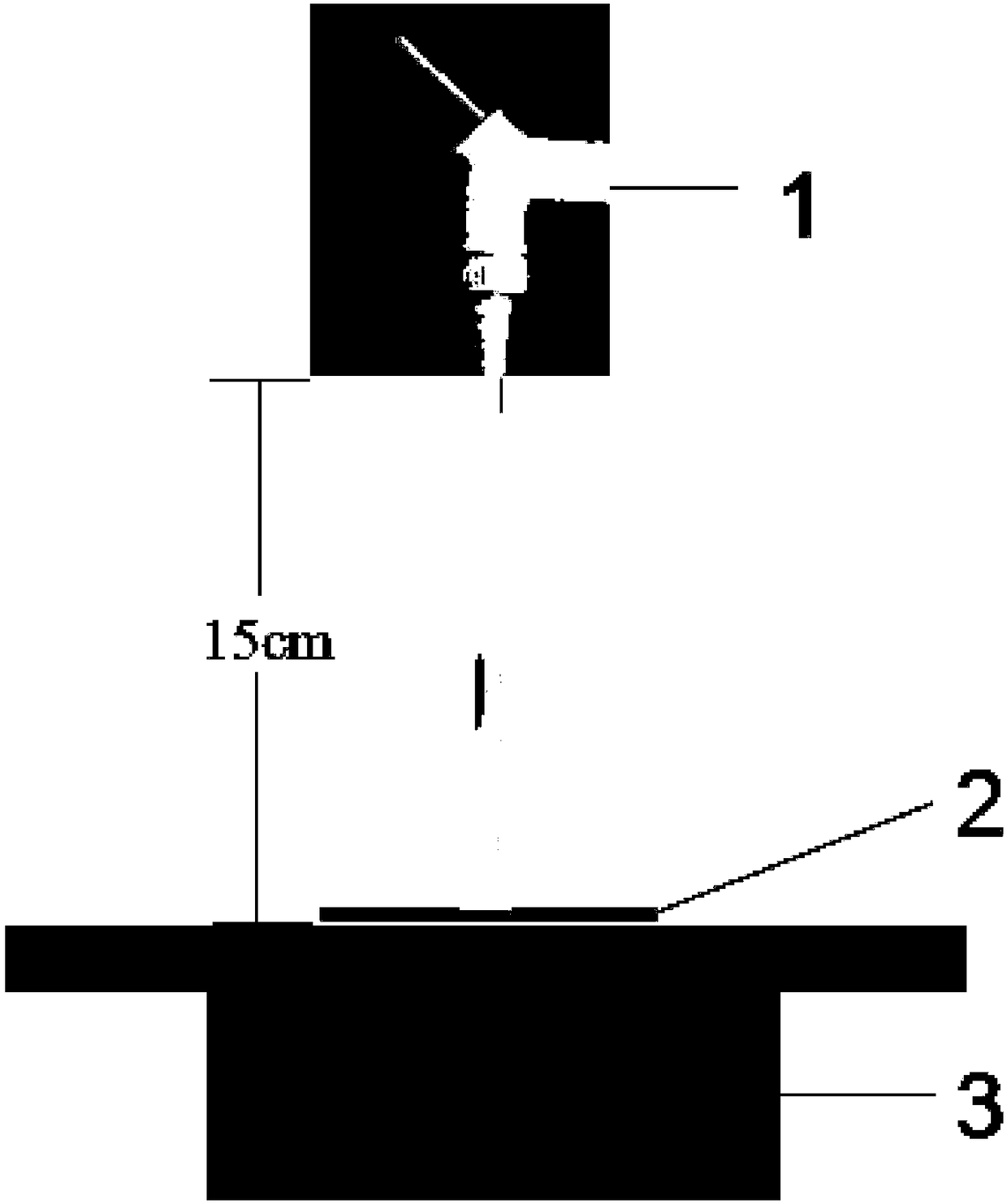

Spray preparation method of industrialized and anti-stripping largesuper-hydrophobic surface

ActiveCN109604127AUniform coatingFast coatingLiquid spraying apparatusSpecial surfacesEpoxyMetallurgy

The invention discloses a spray preparation method of an industrialized and anti-stripping large super-hydrophobic surface. A substrate with a large area is soaked in an epoxy resin solution, and thesubstrate is subjected to lifting and lowering, inclining, and leveling to obtain a pre-coated substrate; a plurality of spraying nozzles are used for ultrasonic atomization spraying; a hydrophobic coating is perpendicularly sprayed on the upper surface of the pre-coated substrate in an ultrasonic mode, and an anti-stripping and large super-hydrophobic coating is obtained on the upper surface of the substrate after low-temperature solidification. Super-hydrophobic surfaces no less than 0.8m*0.8m can be prepared on surfaces of different substrates. The super-hydrophobic performance of the prepared super-hydrophobic coating is stable, the water contact angle is more than 153 degrees, the rolling angle is less than 5 degrees, good anti-stripping performance is achieved, and the utilization rate of the super-hydrophobic coating is improved by ultrasonic atomization spraying.

Owner:承德纳森新材料科技有限公司

Super-hydrophobic transparent luminous latex coating for outer wall and preparation method thereof

InactiveCN106957567ASimple componentsTransparent appearanceAntifouling/underwater paintsLuminescent paintsEmulsionMetallurgy

The invention relates to the technical field of hydrophobic coating for an outer wall, and discloses a super-hydrophobic transparent luminous latex coating for an outer wall and a preparation method thereof. The coating is prepared from the following components in percentage by mass: 35-55 percent of styrene-acrylic emulsion, 10-30 percent of luminous pigment, 3-20 percent of stearate, 1-5 percent of nano-silicon dioxide, 3-5 percent of auxiliary and 20-30 percent of water. The super-hydrophobic transparent luminous latex coating for an outer wall has the advantages of low cost, simplicity in preparation and environmental protection, and can be applied in a large scale.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

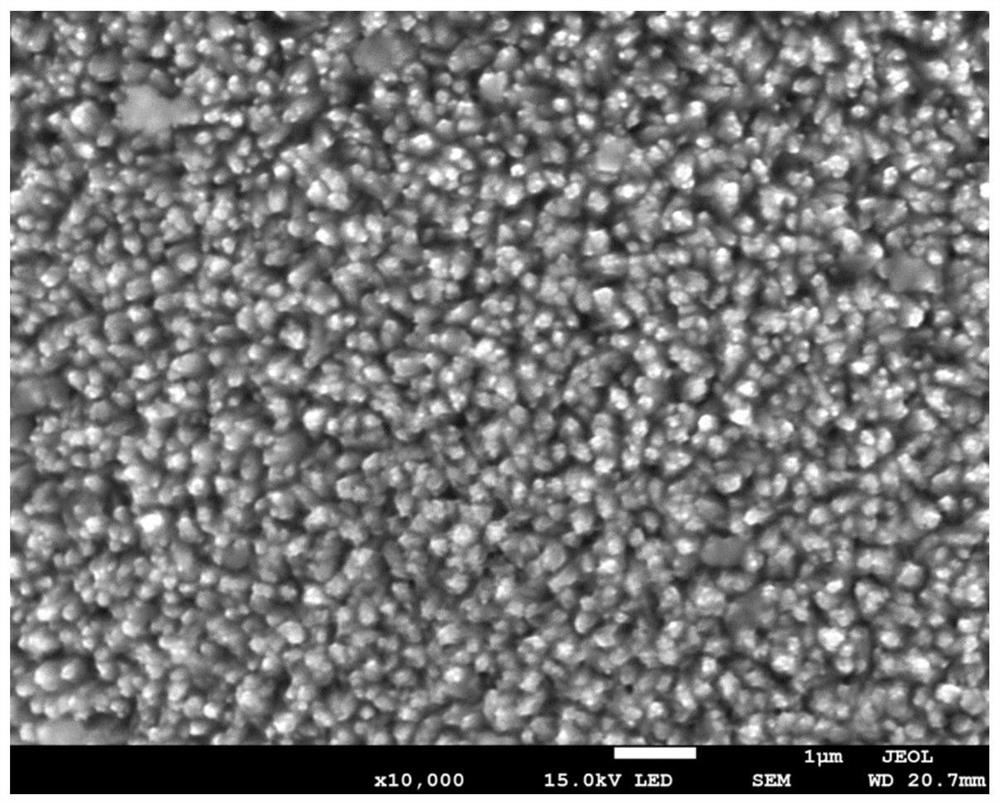

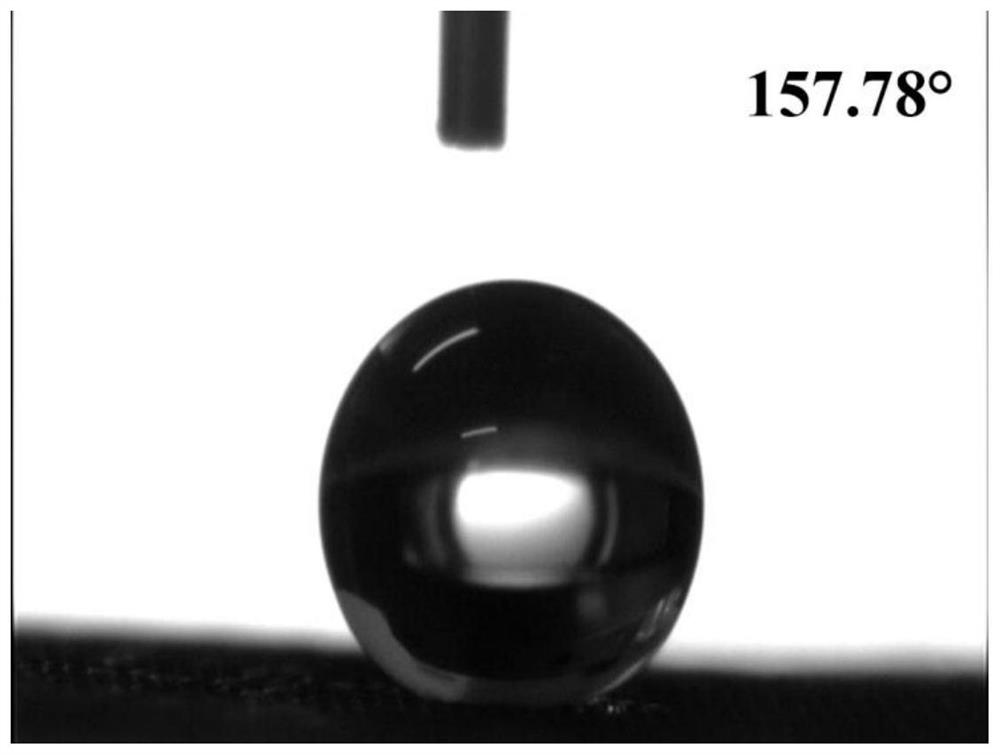

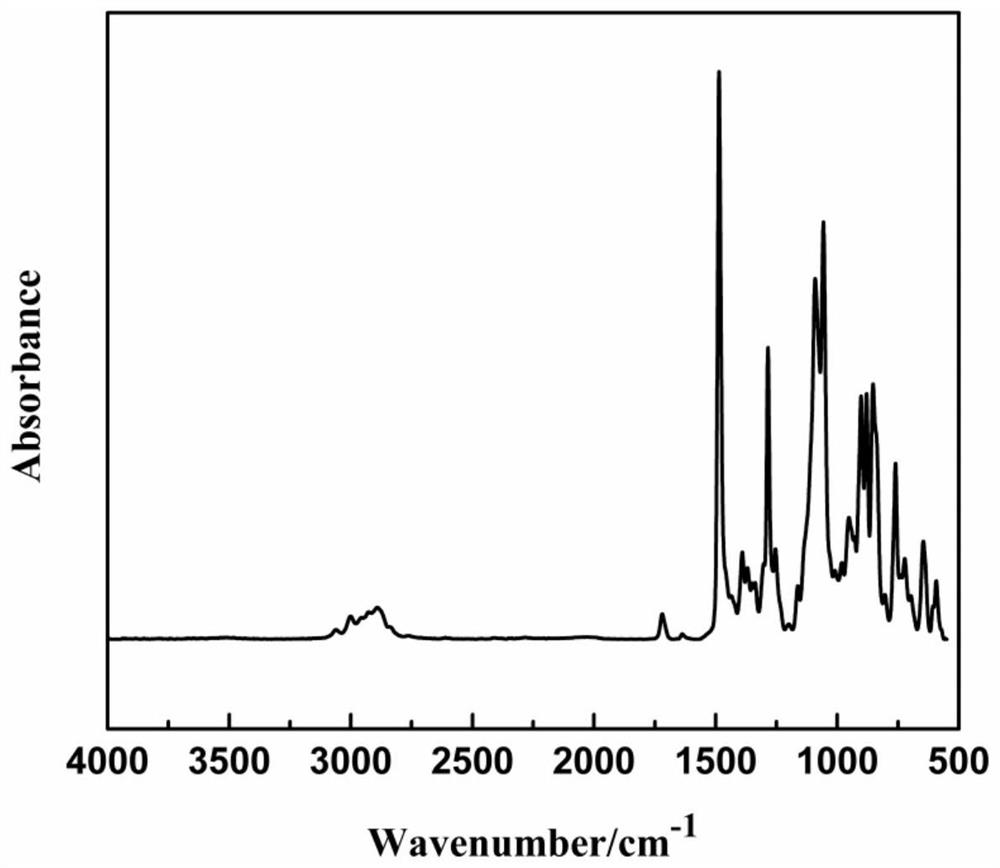

Method for preparing super-hydrophobic nano Ni3S2 coating on surface of nickel mesh

InactiveCN109989056AReduce dependenceThe operation process is simpleMetallic material coating processesIonRolling angle

The invention relates to a method for preparing a super-hydrophobic nano Ni3S2 coating on the surface of a nickel mesh. The method comprises the following steps taht firstly, pretreating the surface of the nickel mesh to remove oil stains and impurities attached to the surface of the nickel mesh; dissolving a proper amount of sodium hydroxide and ammonium persulfate into deionized water, fully stirring and uniformly mixing, soaking the nickel mesh in the solution and heating in a water bath at the temperature of 35-65 DEG c, so that an oxidation layer is formed on the surface of the nickel net, taking out the sample, washing with deionized water and rapidly drying; then preparing a water solution with a certain concentration of sodium sulfate decahydrate and ammonium fluoride, fully stirring and heating to 60-90 DEG c, soaking the nickel mesh subjected to the treatment in the solution, and keeping the temperature for a certain time to obtain a Ni3S2 coating with a nano-protrusion structure; finally, the super-hydrophobic nano Ni3S2 coating is obtained on the surface of the nickel net through tetradecanoic acid modification, the contact angle between the coating and the deionized water is between 151-159 degrees, the rolling angle ranges from 5 degrees to 10 degrees. The method is simple to operate and low in cost, and is easy to realize industrial production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

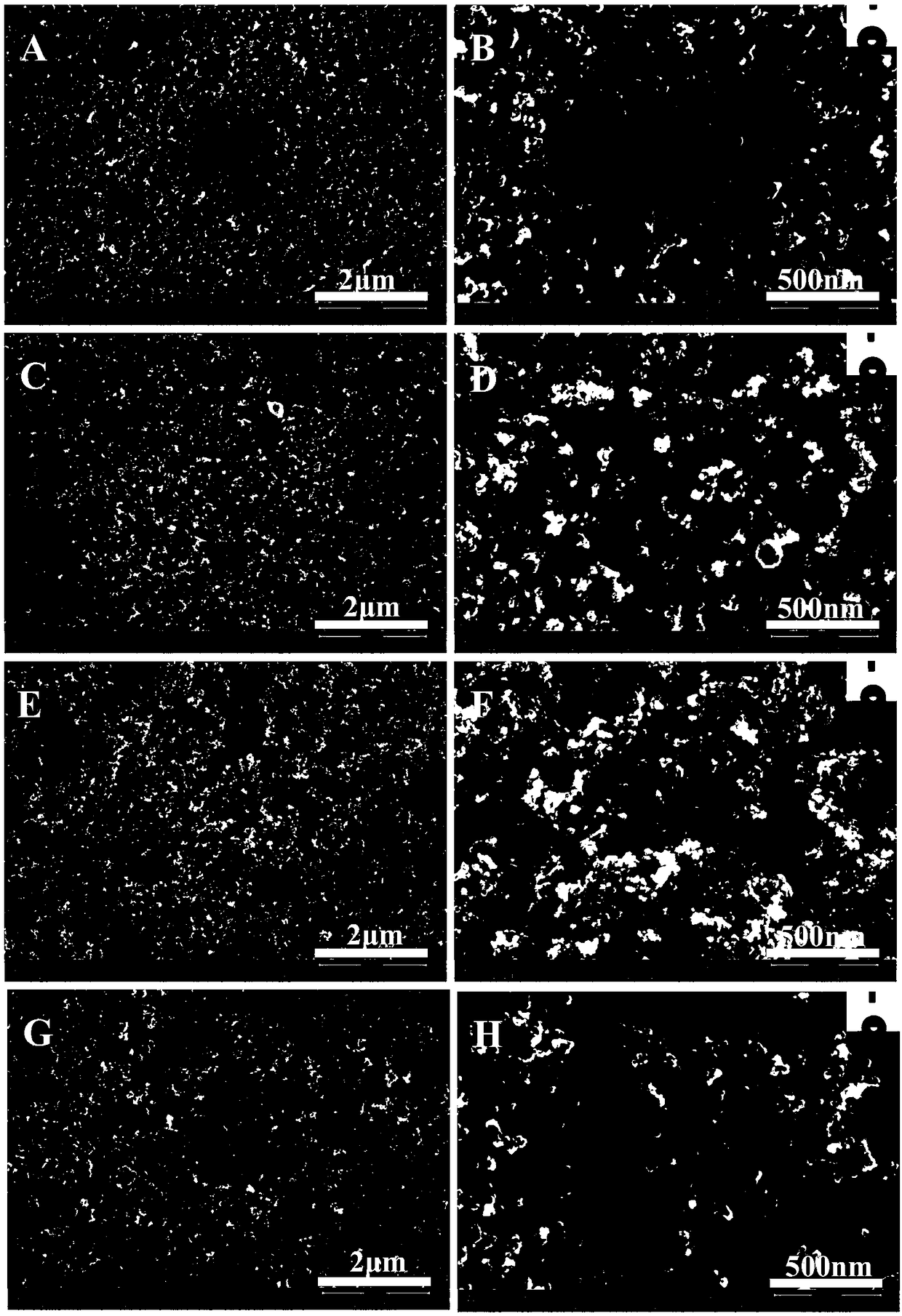

Method for preparing polymer superhydrophobic surface by virtue of hydrophobic nanoparticle spontaneous deposition

InactiveCN108527888AStable super hydrophobic performanceResistance to water shockNanometreHydrophobic surfaces

The invention discloses a method for preparing a polymer superhydrophobic surface by virtue of hydrophobic nano particle spontaneous deposition. The method comprises the following steps: uniformly spraying hydrophobic nanoparticles onto a polymer film-shaped melt surface, so that the hydrophobic nanoparticles can be spontaneously deposited inside the melt surface in a short time at a polymer melting point or the viscous flow temperature or above, forming an insert structure, and cooling, thus obtaining the polymer superhydrophobic film. The polymer superhydrophobic film provided by the invention has the advantages of stable hydrophobic performance, water impact resistance, good friction resistance and the like. The preparation method of the invention is highly matched with the existing polymer casting and spraying process, so that only a row of hydrophobic nanoparticle spraying apparatuses is required nearby a T-shaped machine head of the casting or spraying device; and moreover, the cost is low, the repetition / continuity is good, environmental protection is achieved, and the method is suitable for mass production and wide in market prospect.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of flexible super-hydrophobic surface based on carbon nanotubes

ActiveCN113061942ASuperhydrophobic stabilityAvoid breakingMaterial nanotechnologyVacuum evaporation coatingHigh surfaceChemical vapor deposition

The invention relates to the field of super-hydrophobicity, in particular to a preparation method of a flexible super-hydrophobic surface based on carbon nanotubes. The method comprises the following steps: (a) preparing multi-walled carbon nanotube powder by using a chemical vapor deposition method; (b) performing ultrasonic purification on the multi-walled carbon nanotube powder in a solution; (c) ultrasonically dispersing the multi-walled carbon nanotube powder in an isopropanol solution to form a stable suspension; and (d) adding magnesium nitrate electrolyte salt into the suspension and centrifuging. According to the preparation method, preparation of the large-area super-hydrophobic surface can be realized; a titanium layer on the surface of a carbon nanotube film is stable in super-hydrophobic performance and not prone to being damaged by external force, high-surface-energy Ti on the surface is directly changed into low-surface-energy TiO2 through calcination after electrophoretic deposition, and the surface does not need to be modified by fluorine-containing chemical substances any more; and the preparation process is simple, the cost is low, and large-area continuous preparation can be realized.

Owner:CHANGZHOU UNIV +1

A method for superhydrophobicizing the surface of aluminum material

InactiveCN101935834BGood antifoulingEffective protectionMetallic material coating processesMetal layered productsSuperhydrophobeMetallic aluminum

Owner:LANZHOU JIAOTONG UNIV

Coating material

InactiveCN102408762ASuperhydrophobic stabilityGood reproducibilityCoatingsRepeatabilityParameter control

The utility discloses a coating material which is prepared from a thermosetting high molecular pre-polymer having a reaction active center and surface functionalized nano-particles under the action of a curing agent, wherein the mass percentage contents of all the components therein are as follows: 23-85% thermosetting high molecular pre-polymer having the reaction active center, 9-77% surface functionalized nano-particles, and 0-5% curing agent. The preparation method of the coating material disclosed in the invention is simple in process and free of complex parameter control; the preparation method causes no pollution during preparation and thereby is environment-friendly; and simultaneously, the coating material prepared in the invention is stable in super hydrophobicity, good in repeatability, and also low in cost; therefore, the coating material has excellent industrial application prospect.

Owner:DANCHEN TECH DALIAN

One-pot method for preparing stable superhydrophobic antibacterial fabrics

ActiveCN112538762BShort polymerization timeIncreased durabilityBiochemical fibre treatmentLiquid repellent fibresSuperhydrophobeAnti bacterial

The invention relates to a method for preparing a stable super-hydrophobic antibacterial fabric by a one-pot method. Add fluorine-free silane modifier, ultrasonically treat and mix evenly to obtain a treatment solution; then soak the washed and dried fabric in the treatment solution, perform ultrasonic treatment, take out the fabric treated with the treatment solution and place it in the treatment solution. Dry in a heated oven; and then repeat the operation for at least 3 times to obtain a stable superhydrophobic antibacterial fabric. The method of the invention is simple and time-saving, shortens the polymerization time of dopamine and simplifies the process, and enables the obtained fabric to have higher durability and better super-hydrophobicity.

Owner:JIANGSU UNIV OF TECH

A kind of preparation of superhydrophobic nanometer Ni on the surface of nickel mesh 3 s 2 method of coating

InactiveCN109989056BReduce dependenceEasy to realize industrial productionMetallic material coating processesPhysical chemistryPre treatment

The invention relates to a method for preparing a super-hydrophobic nano Ni3S2 coating on the surface of a nickel mesh. The method comprises the following steps taht firstly, pretreating the surface of the nickel mesh to remove oil stains and impurities attached to the surface of the nickel mesh; dissolving a proper amount of sodium hydroxide and ammonium persulfate into deionized water, fully stirring and uniformly mixing, soaking the nickel mesh in the solution and heating in a water bath at the temperature of 35-65 DEG c, so that an oxidation layer is formed on the surface of the nickel net, taking out the sample, washing with deionized water and rapidly drying; then preparing a water solution with a certain concentration of sodium sulfate decahydrate and ammonium fluoride, fully stirring and heating to 60-90 DEG c, soaking the nickel mesh subjected to the treatment in the solution, and keeping the temperature for a certain time to obtain a Ni3S2 coating with a nano-protrusion structure; finally, the super-hydrophobic nano Ni3S2 coating is obtained on the surface of the nickel net through tetradecanoic acid modification, the contact angle between the coating and the deionized water is between 151-159 degrees, the rolling angle ranges from 5 degrees to 10 degrees. The method is simple to operate and low in cost, and is easy to realize industrial production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A kind of superhydrophobic composite material with fluorinated epoxy resin as matrix, preparation method and superhydrophobic surface

ActiveCN111138938BImprove performanceSuperhydrophobic stabilityEpoxy resin coatingsSuperhydrophobePolymer science

The invention discloses a superhydrophobic composite material with fluorine-containing epoxy resin as a matrix, a preparation method and a superhydrophobic surface. The preparation method comprises: using 2,3,5,6-tetrafluoro-tere-phenylenedimethanol and epichlorohydrin to react to obtain low-viscosity fluorine-containing epoxy resin; in the presence of a photoinitiator, 4,4'-diallyl Bisphenol A type epoxy resin and 1H, 1H, 2H, 2H-perfluorodecanethiol are photoreacted to obtain room temperature crystalline fluorine-containing epoxy resin; the nanoparticles are treated with a coupling agent, and low-viscosity fluorine-containing epoxy resin and Crystallize fluorine-containing epoxy resin at room temperature, ultrasonically disperse and stir for 2 to 3 hours. Add a curing agent to the super-hydrophobic composite material, and spray, brush or roll-coat it on the surface of the substrate to obtain a super-hydrophobic surface. The preparation method of the invention is simple and convenient, the reaction rate is fast, the preparation period is short, and the obtained composite material has stable superhydrophobic performance and no pollution.

Owner:BEIJING UNIV OF CHEM TECH

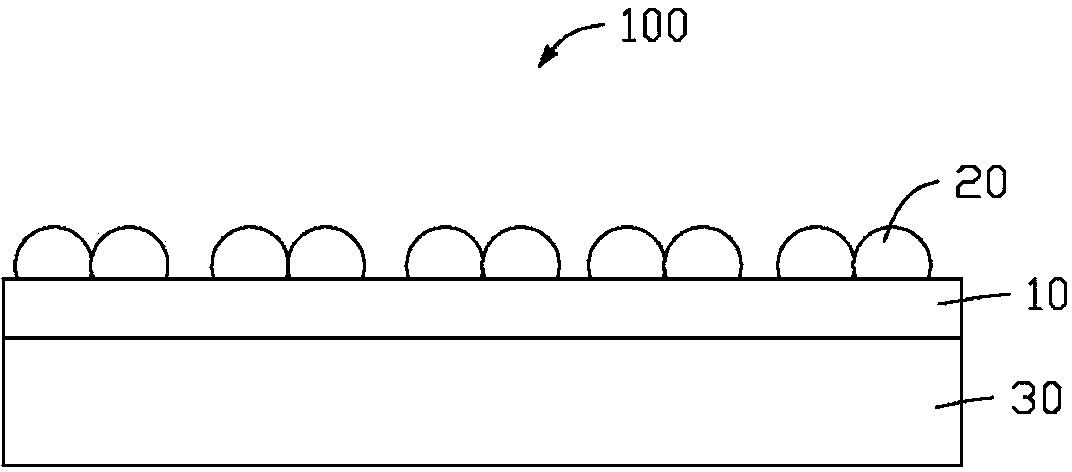

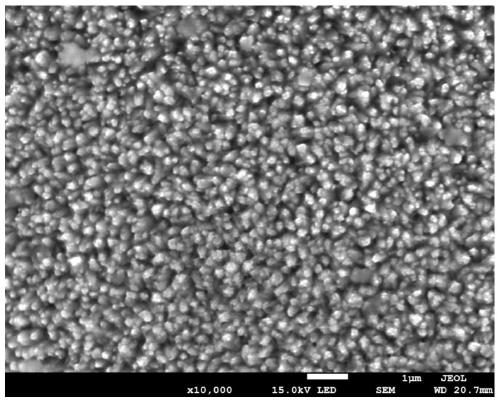

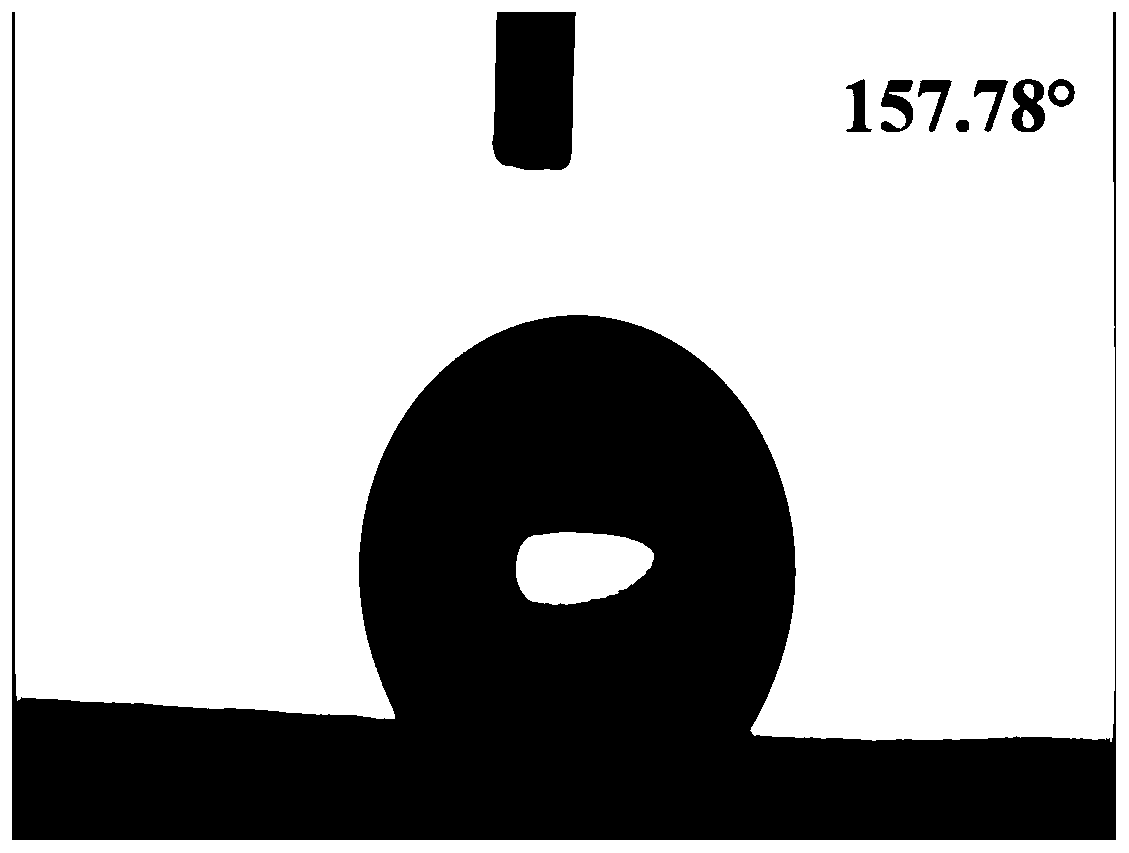

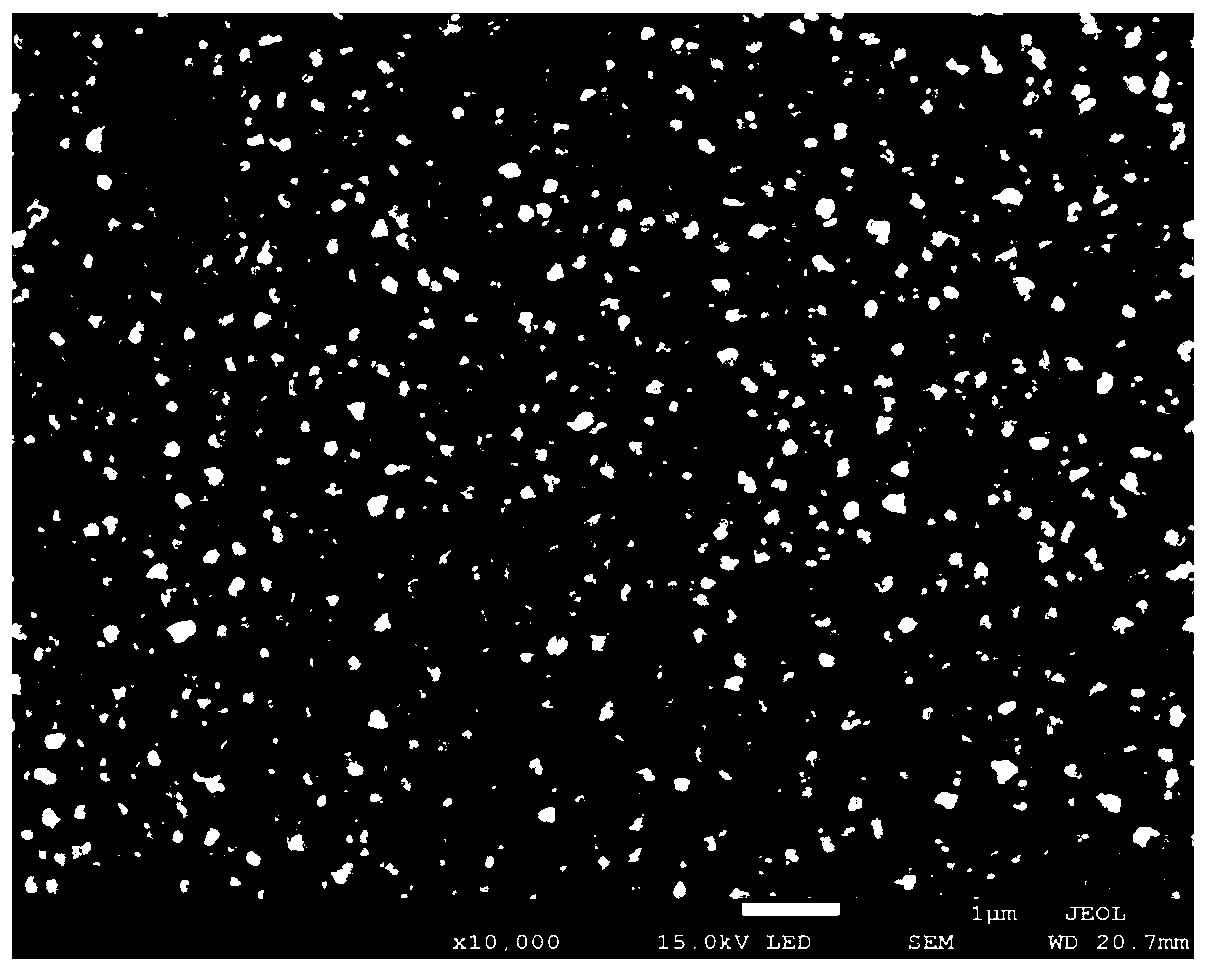

Superhydrophobic coating, superhydrophobic coating and preparation method of the superhydrophobic coating

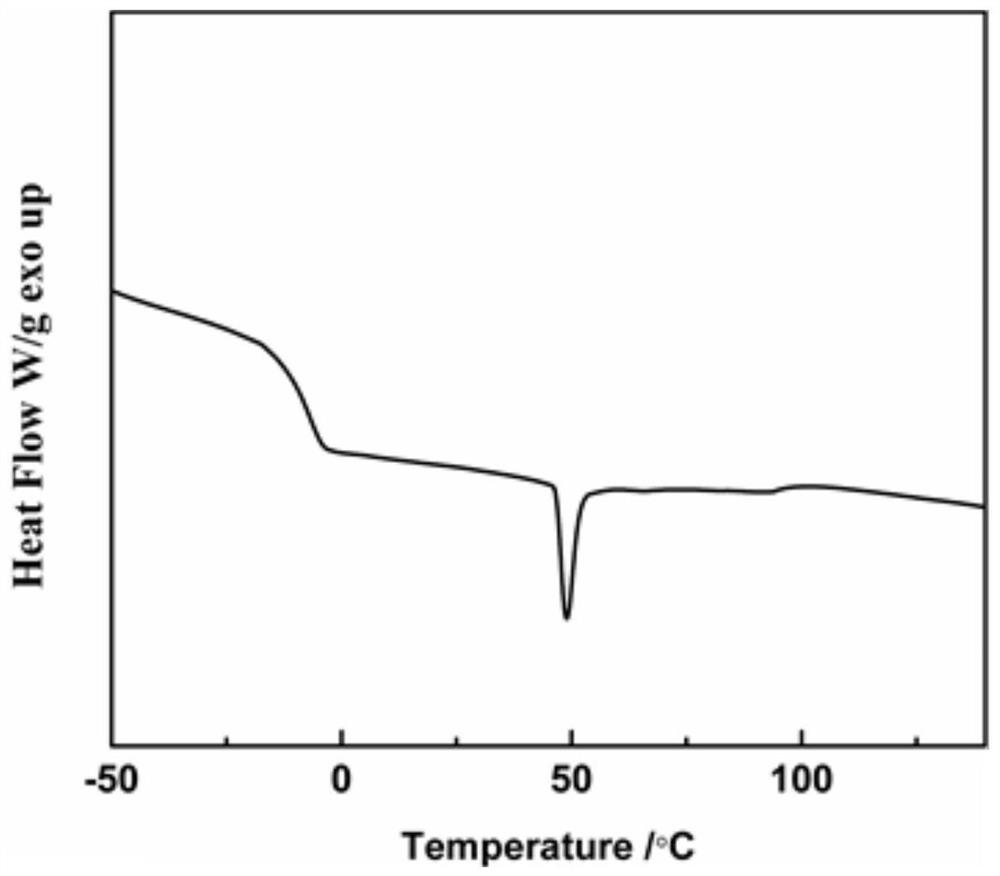

ActiveCN104046152BSuperhydrophobic stabilityNot easy to aging failureCoatingsNanoparticlePolystyrene nanoparticles

The invention provides a preparation method of a superhydrophobic coating. The preparation method comprises the steps of 1, mixing 50-80 parts of hydrophobic nanoparticle dispersing liquid with the mass percentage of 2-15%, 20-50 parts of polystyrene nanoparticle dispersing liquid with the mass percentage of 1-10% and 0-30 parts of solvent according to the volume part ratio, and ultrasonically dispersing the mixture to obtain a mixed solution; 2, forming the mixed solution on the surface of a substrate and in a microstructure in the substrate; 3, drying the substrate obtained in the step 2, then, raising the temperature to 160-230 DEG C, baking to melt polystyrene nanoparticles, and taking out for naturally airing. The invention also relates to a superhydrophobic paint and the superhydrophobic coating.

Owner:TSINGHUA UNIV

An electrochemical method for preparing copper dendrite superhydrophobic surface

The invention discloses an electrochemical method for preparing a superhydrophobic surface of copper dendrites. The method comprises the following steps: 1. Slowly add concentrated sulfuric acid to distilled water, then dissolve copper sulfate crystals in the solution, and obtain solution A after stirring evenly 2. Dissolve myristic acid in absolute ethanol to obtain solution B; 3. Remove the oxide layer on the surface of the two copper substrates, then rinse them with distilled water and absolute ethanol successively, and dry them for later use; 4. Dissolve the solution A is placed in the electrolytic cell as the electrolyte, and the two dried copper substrates are respectively used as the anode and the cathode, and electrolyzed; 5. Rinse the electrolyzed cathode copper substrate with distilled water and absolute ethanol in turn, and then the solution B Apply evenly on the surface of the cathode copper substrate after washing, let it dry, and then wipe the surface lightly with a sponge. The contact angle of the superhydrophobic surface prepared on the copper substrate by the method of the present invention can reach more than 152°, and the superhydrophobic performance remains stable after being placed for one year under conventional conditions.

Owner:XIAN UNIV OF SCI & TECH

Superhydrophobic transparent luminous latex paint for exterior walls and preparation method thereof

InactiveCN106957567BSimple componentsTransparent appearanceAntifouling/underwater paintsLuminescent paintsEmulsionMetallurgy

The invention relates to the technical field of hydrophobic coating for an outer wall, and discloses a super-hydrophobic transparent luminous latex coating for an outer wall and a preparation method thereof. The coating is prepared from the following components in percentage by mass: 35-55 percent of styrene-acrylic emulsion, 10-30 percent of luminous pigment, 3-20 percent of stearate, 1-5 percent of nano-silicon dioxide, 3-5 percent of auxiliary and 20-30 percent of water. The super-hydrophobic transparent luminous latex coating for an outer wall has the advantages of low cost, simplicity in preparation and environmental protection, and can be applied in a large scale.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com