Graphene-based super-hydrophobic fabric and preparation method thereof

A graphene-based, super-hydrophobic technology, applied in physical treatment, textile and papermaking, fiber treatment, etc., can solve the problems of time-consuming reaction, harsh reaction conditions, complex equipment and process, etc., and achieve the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

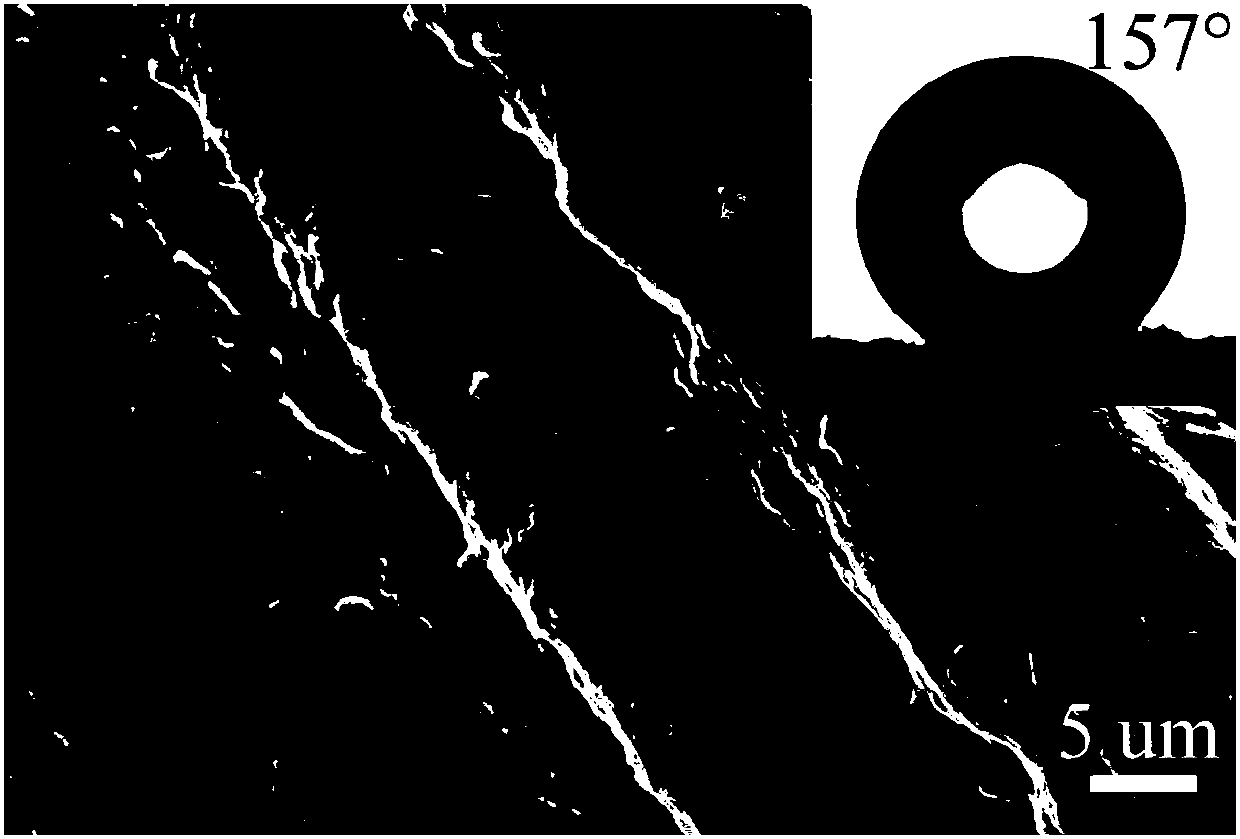

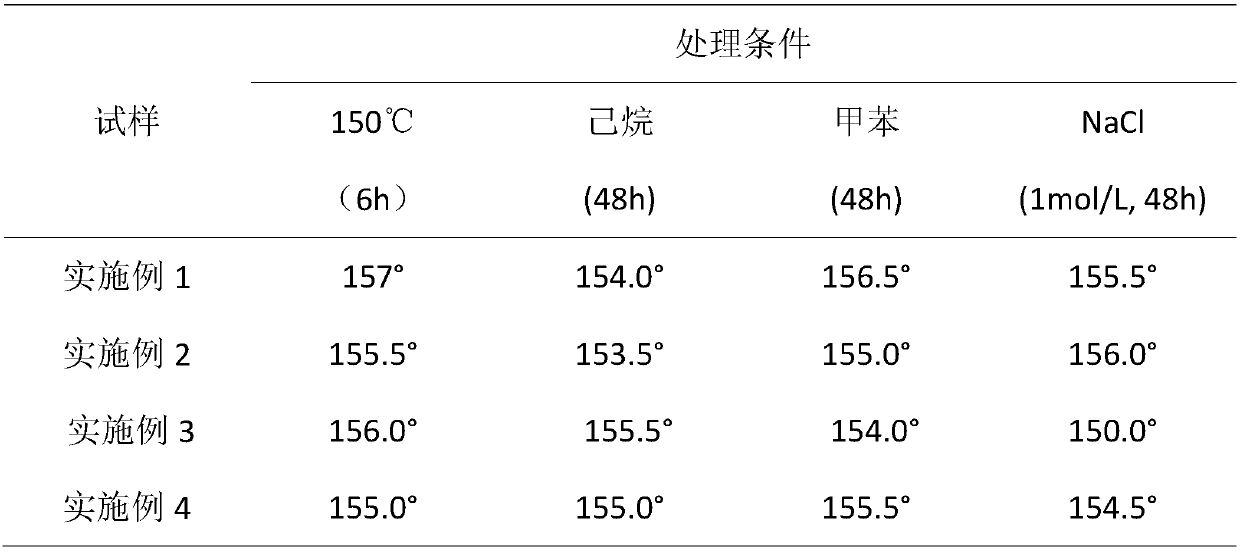

Embodiment 1

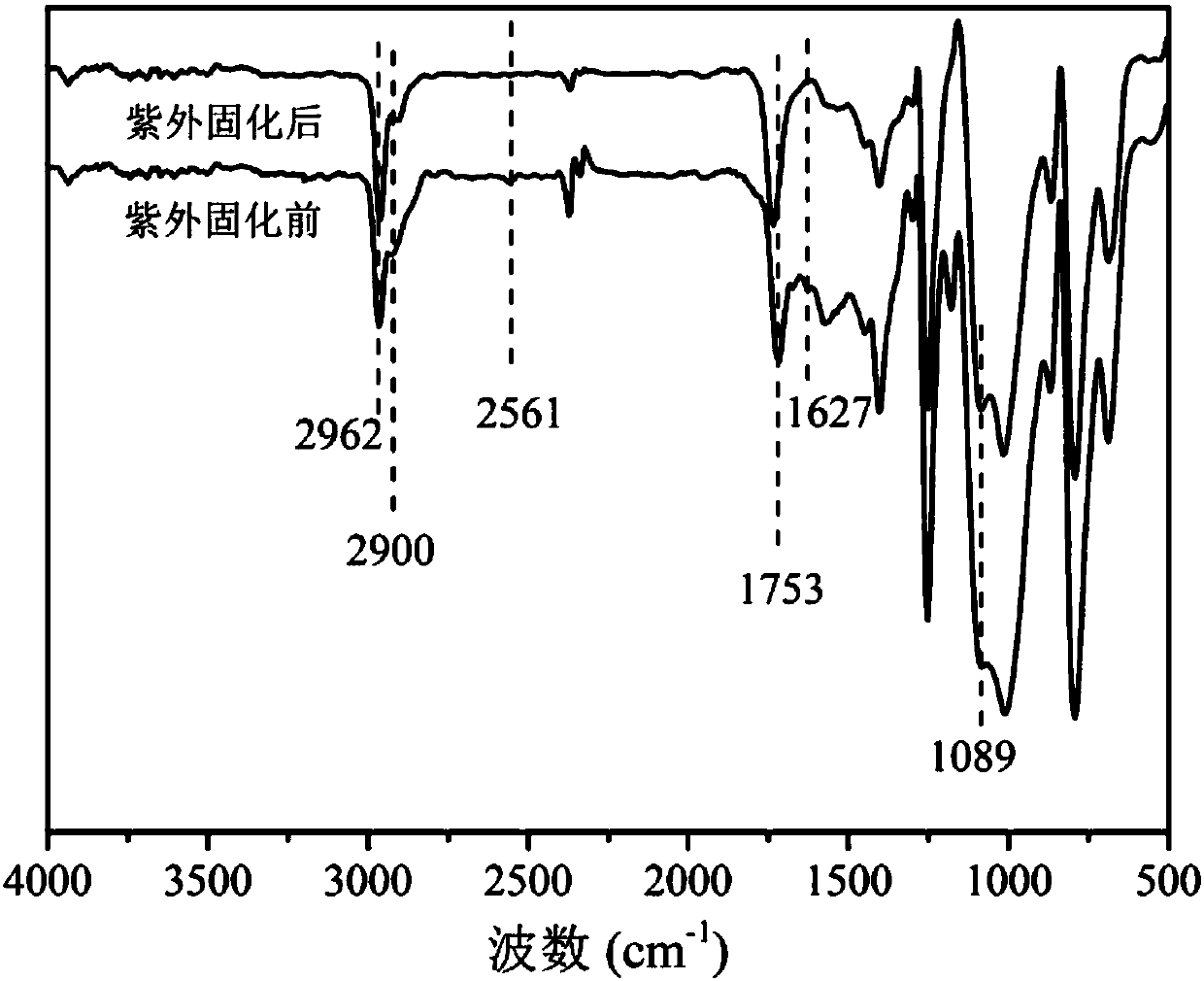

[0027] Disperse 5mL of 3‐mercaptopropyltriethoxysilane in 100mL of deionized water, adjust its pH value to 4‐5 with hydrochloric acid solution (mass fraction: 37wt%), then add 70mL of graphene oxide solution (concentration 3.0 mg / mL), stirred thoroughly, and heated to 100°C for 4 hours, finally centrifuged at 6000r / min for 20 minutes, washed with ethanol for 3 times, and dried in an oven at 80°C for 2 hours to obtain a surface containing S‐H groups modified graphene oxide.

[0028] At room temperature, the modified graphene oxide and vinyl-terminated polydimethylsiloxane (molecular weight is 7000) that mass ratio is 0.25 are dispersed in the acetone of 30g (the mass concentration that modified graphene oxide accounts for mixed solution is 0.75wt%, vinyl-terminated polydimethylsiloxane accounts for 3wt% mass concentration of the mixed solution) and stirs evenly, then adds crosslinking agent trimethylolpropane trimethacrylate and photoinitiator 2-hydroxyl- 2-methyl-1-phenyl-1-a...

Embodiment 2

[0033] Disperse 5mL of 3‐mercaptopropylmethyldiethoxysilane in 100mL of deionized water, adjust its pH value to 4‐5 with hydrochloric acid solution (37wt%), and then add 60mL of graphene oxide solution (Concentration: 3.5mg / mL) Stir well, and heat to 80°C for 6h, finally centrifuge at 7000r / min for 15min, wash with ethanol for 3 times, dry in an oven at 80°C for 2h, get the surface containing S‐ H-based modified graphene oxide.

[0034] At room temperature, the modified graphene oxide and vinyl-terminated polydimethylsiloxane (molecular weight is 5000) that mass ratio is 0.5 are dispersed in the acetone of 30g (the mass concentration that modified graphene oxide accounts for mixed solution is 1.5wt%, vinyl-terminated polydimethylsiloxane accounts for 1wt% mass concentration of the mixed solution) and stirs evenly, then adds crosslinking agent trimethylolpropane triacrylate and photoinitiator 1‐hydroxycyclohexylbenzene base ketone, and continued to stir to form a uniform solut...

Embodiment 3

[0038] Disperse 5mL of 3‐mercaptopropyltrimethoxysilane in 100mL of deionized water, adjust its pH value to 4‐5 with hydrochloric acid solution (mass fraction: 37wt%), then add 52.5mL of graphene oxide solution (concentration 4.0 mg / mL) and stirred thoroughly, and heated to 90°C for 5h reaction, finally centrifuged at 8000r / min for 10min, washed with ethanol for 5 times, dried in an oven at 80°C for 2h, and obtained surface S‐H group-containing modified graphene oxide.

[0039] At room temperature, the modified graphene oxide and vinyl-terminated polydimethylsiloxane (molecular weight is 4000) with a mass ratio of 0.3 are dispersed in 30 g of butanone (modified graphene oxide accounts for the mass concentration of the mixed solution 0.9wt%, vinyl-terminated polydimethylsiloxane accounts for 3wt% mass concentration of the mixed solution) and stirs evenly, then adds crosslinking agent pentaerythritol triacrylate and photoinitiator 2‐methyl‐1‐(4 ‐Methylthiophenyl)‐2‐morpholine‐1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com