Patents

Literature

175results about How to "Fast coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

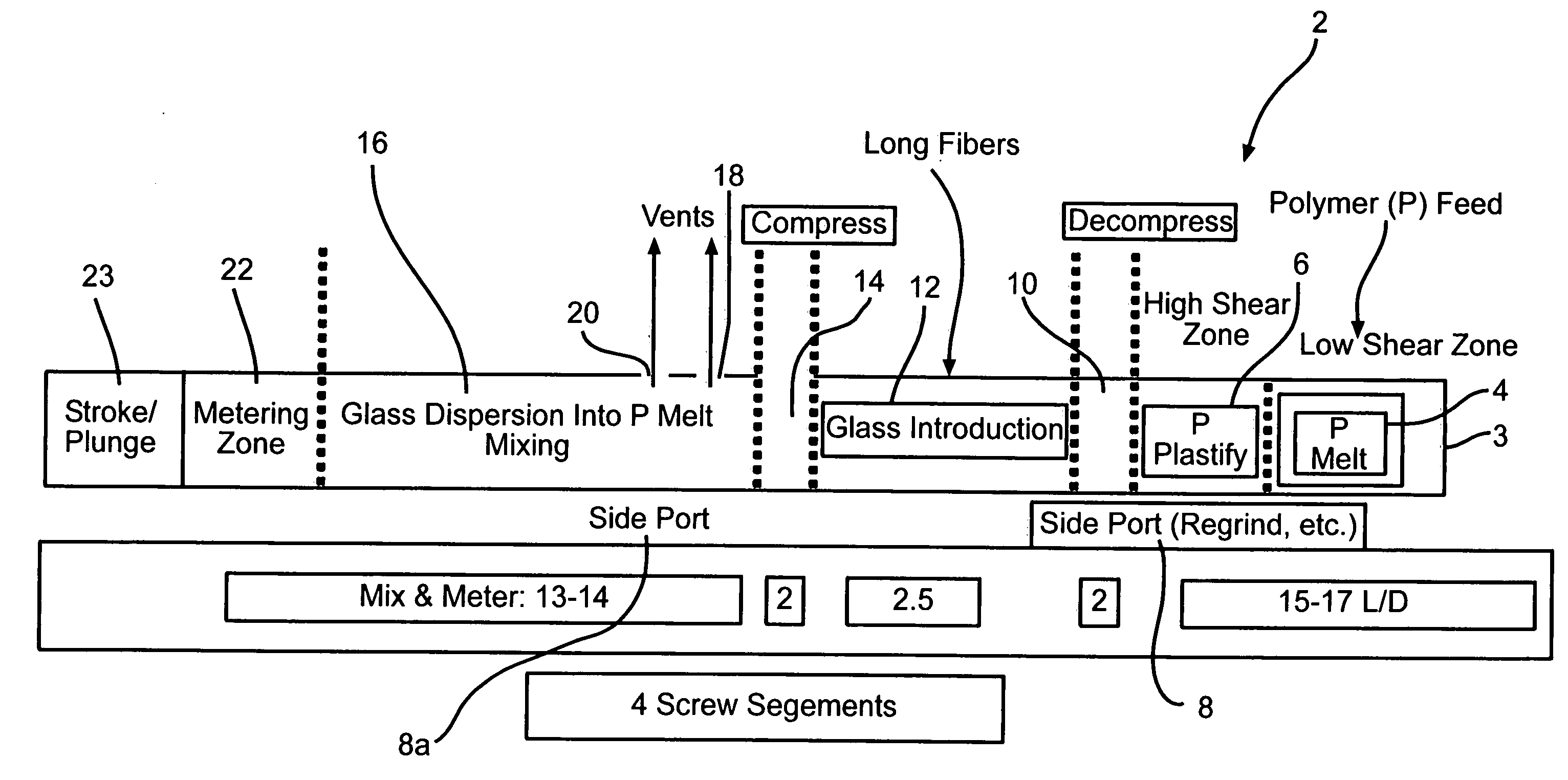

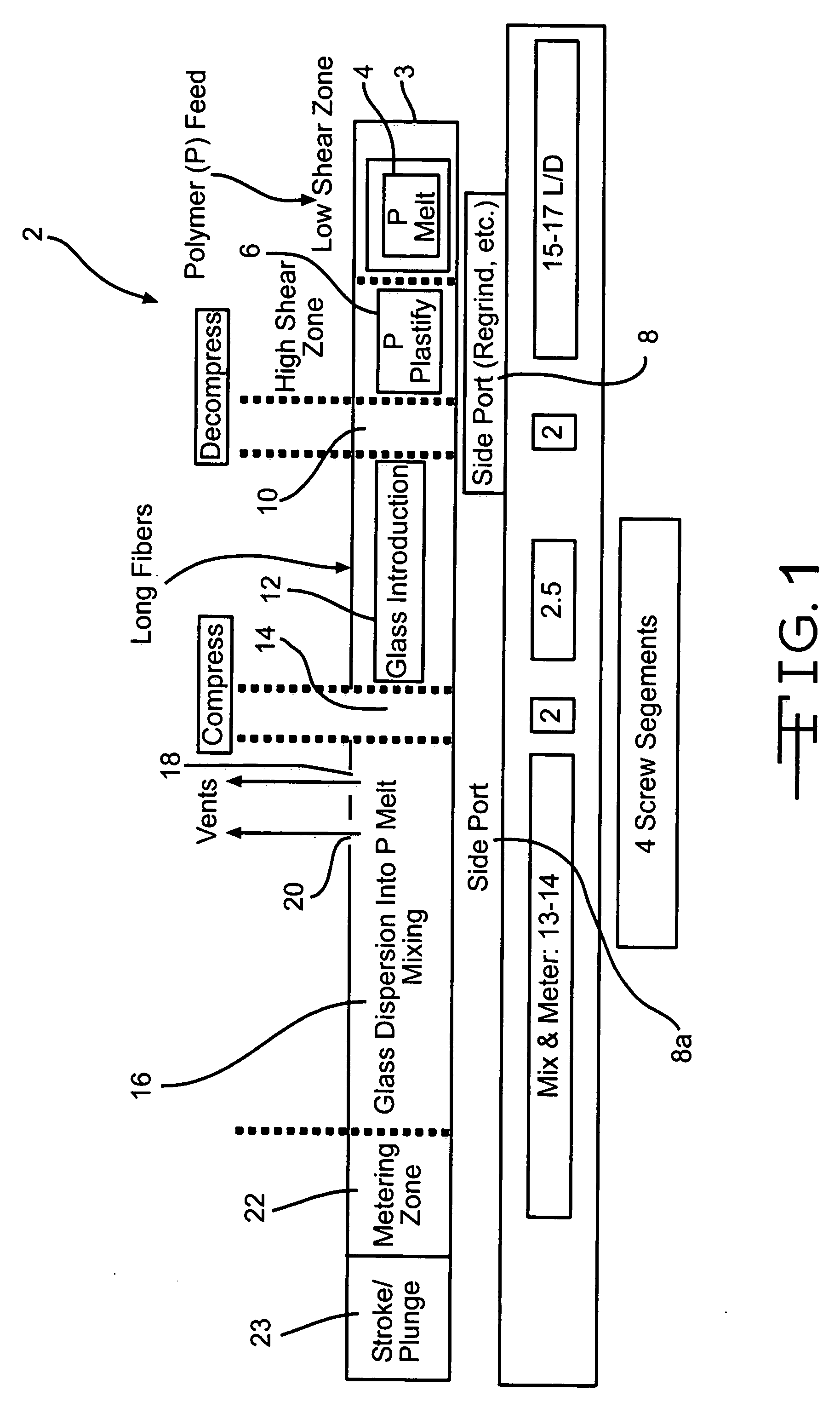

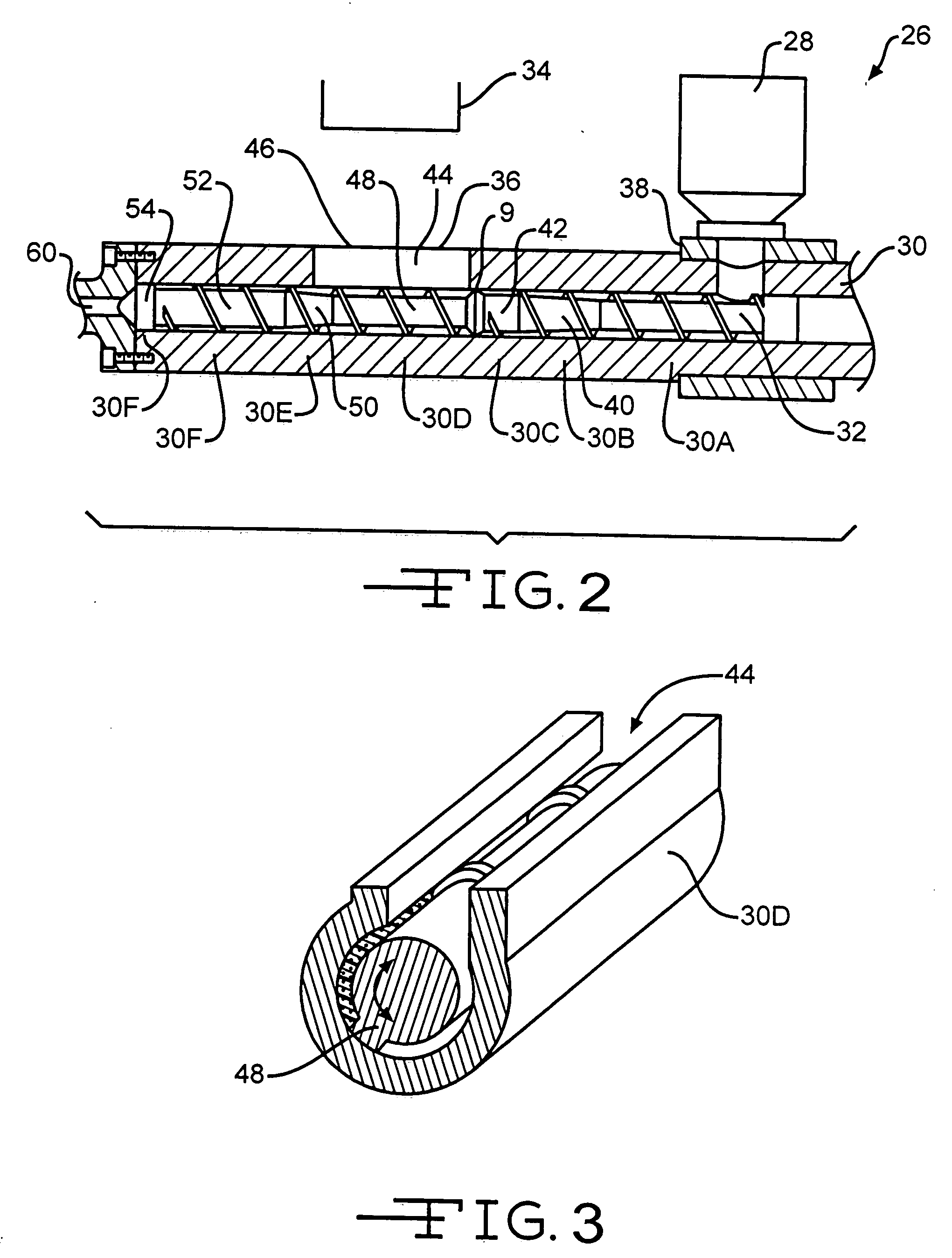

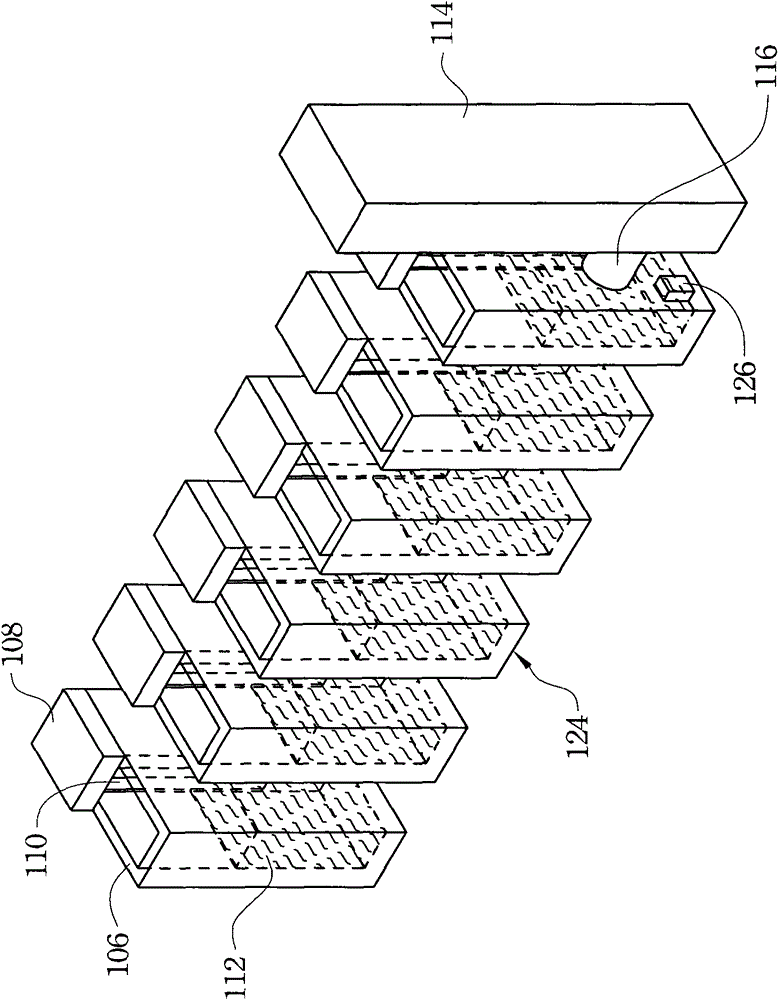

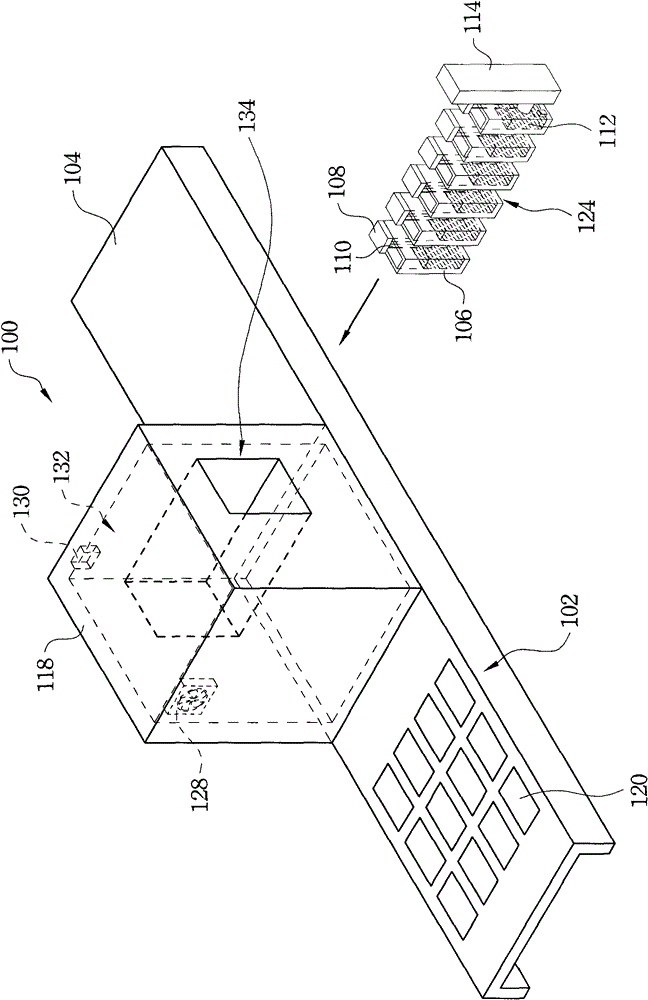

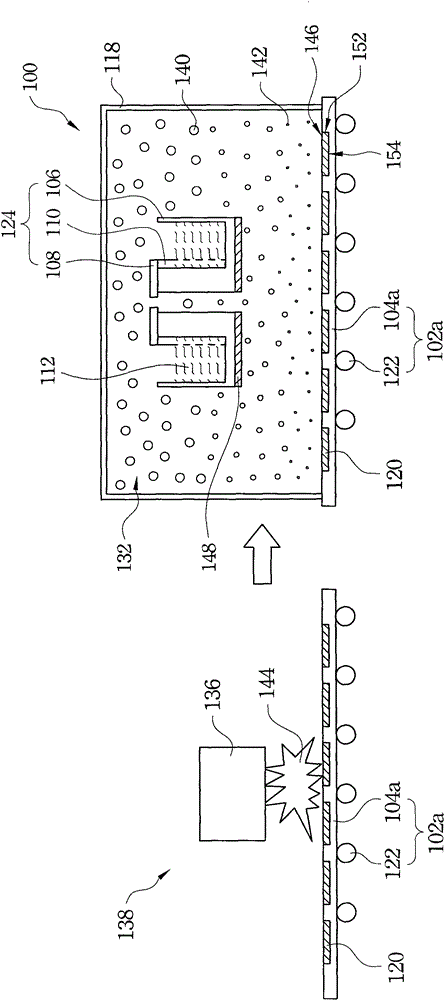

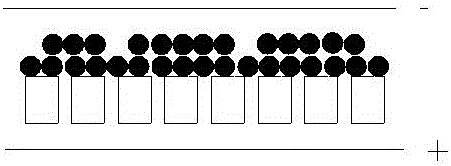

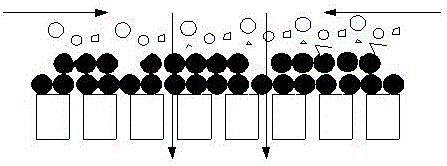

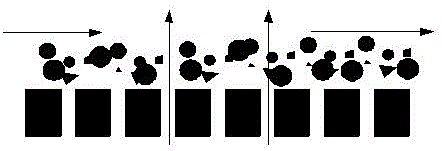

Methods and systems for making long fiber reinforced products and resultant products

InactiveUS20070007685A1Low costGood fiber dispersionDough homogenizationLayered productsProduct systemLow density

Systems and methods are disclosed for making a moldable polymer mixture containing long reinforcing fibers that suffered no significant damage during plastication. The system and method produces a mixture in which the long fibers are longer and have encountered less damage than moldable mixtures made in previous plasticators. The plasticator system has a single screw, but with multiple zones for treating the materials differently. The long fibers, wet or dry, are fed into a downstream zone, distributed over a large port in a low density concentration, and heated and dispersed with low shear to separate the long fibers and surround them with polymer for protection before subjecting them to medium to high shear to finalize the dispersion of the long fibers.

Owner:GLEICH KLAUS FRIEDRICH +3

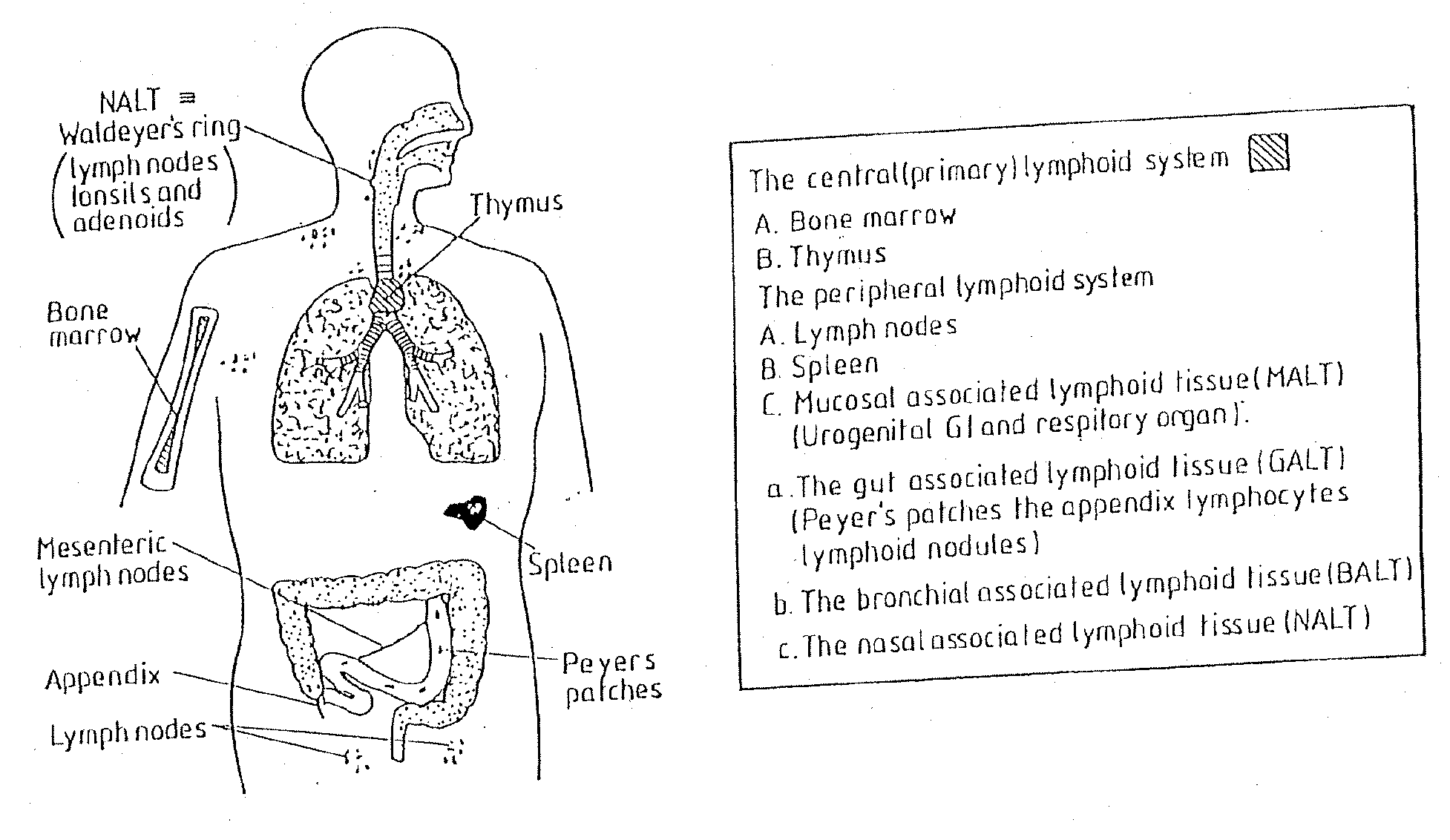

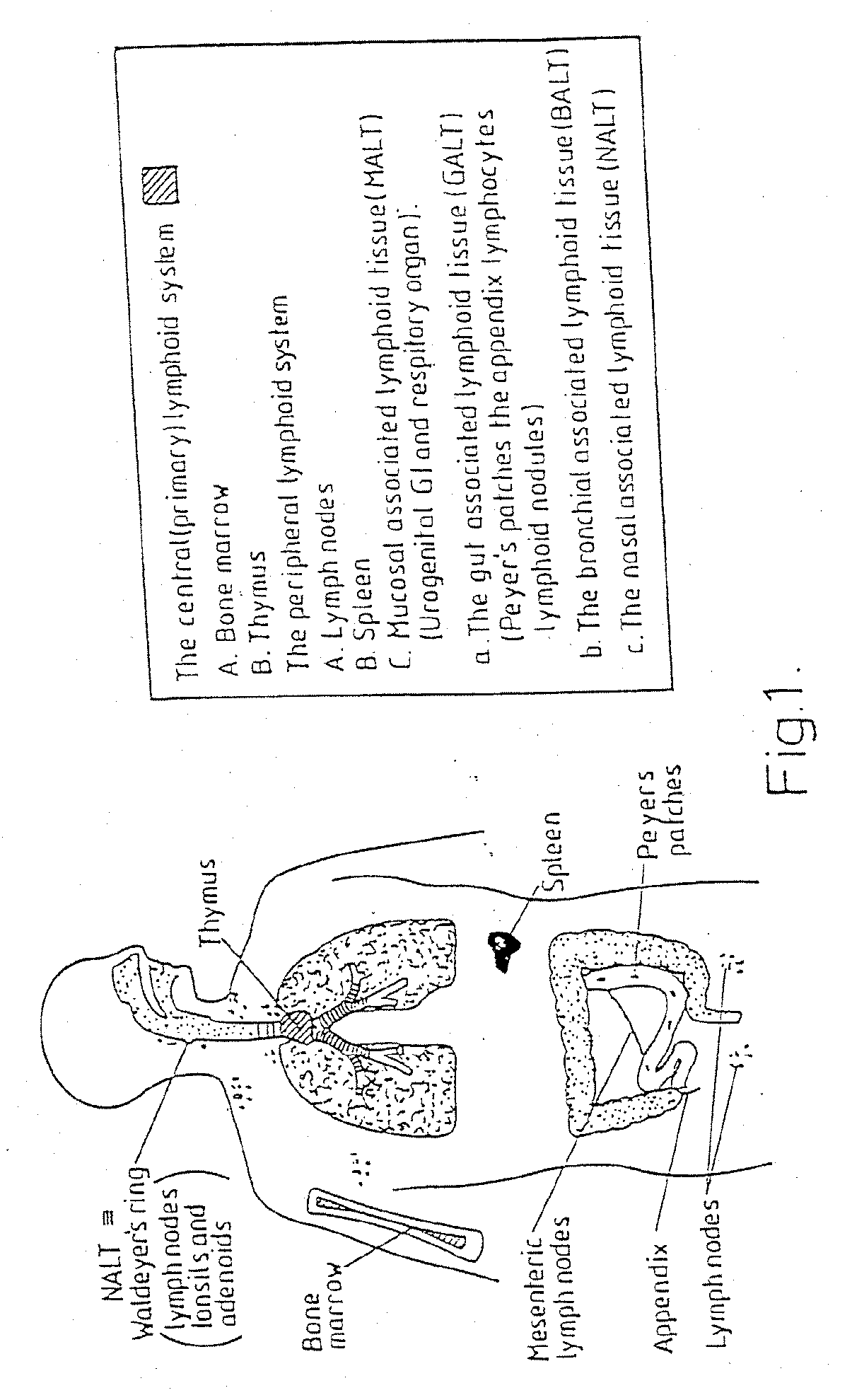

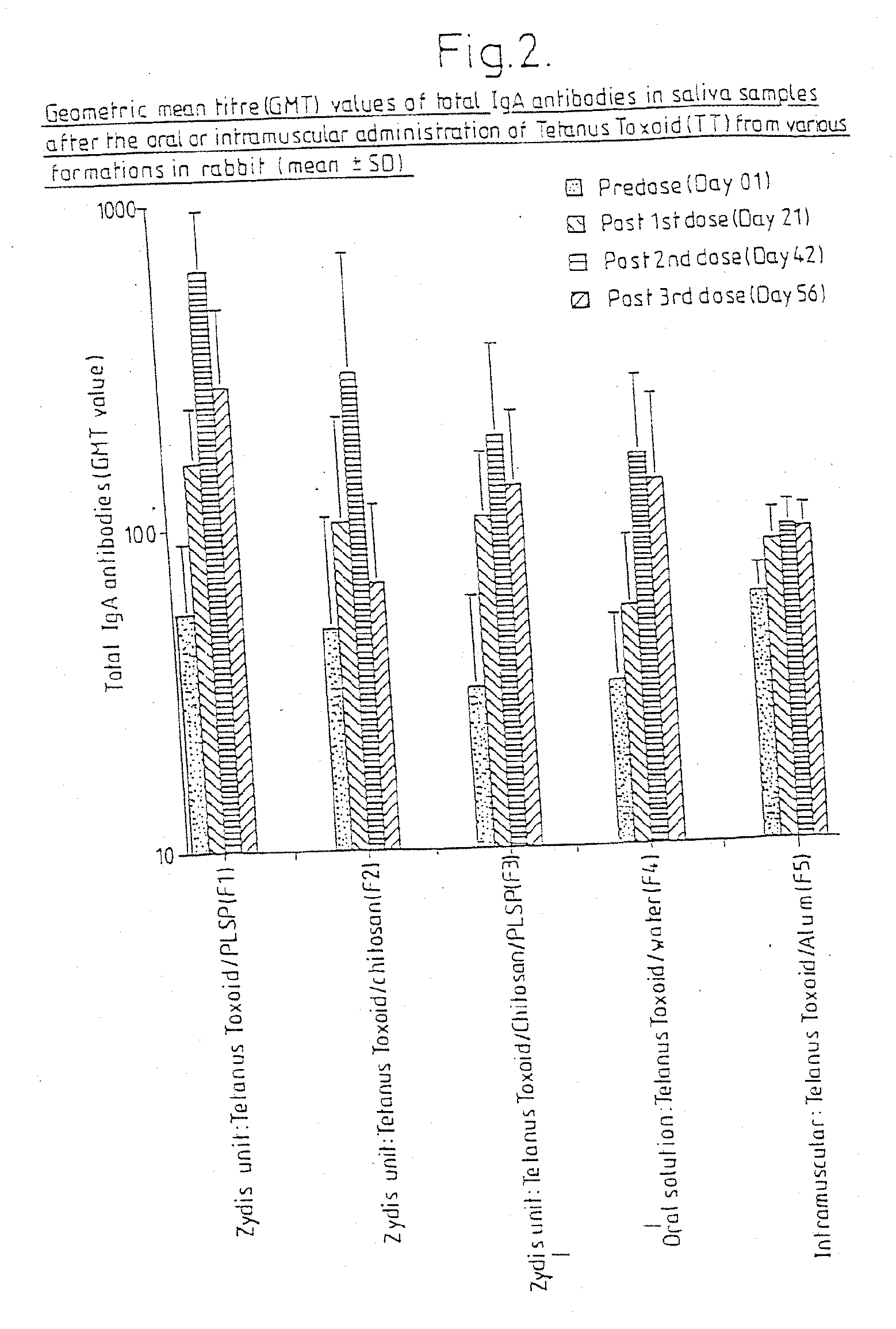

Solid dispersing vaccine composition for oral delivery

InactiveUS20080014260A1Promote absorptionPotentiate immunogenic responseBacterial antigen ingredientsPharmaceutical delivery mechanismAdjuvantMicrosphere

The invention disclosed herein relate to an oral vaccine in which the vaccine composition and adjuvant(s) are carried on a solid fast-dispersing dosage form. The vaccines are targeted toward mucosal tissue and the adjuvant serves to ensure sufficient residence time for the vaccine composition on the mucosal tissue to facilitate its absorption thereby. The fast-dispersing oral solid vaccine dosage form of the invention is particularly useful to administer the vaccine to patients that have difficulty swallowing medications. In one embodiment, the invention provides a fast disintegrating oral solid vaccine dosage form comprising: an immunogenic amount of an antigenic preparation, the antigenic preparation comprising a microsphere-antigen complex; an adjuvant, wherein the adjuvant enhances the absorption of the antigen or potentiates the immunogenic response; a mucoadhesive substance; and a low density dosage form matrix.

Owner:SEAGER HARRY

Magnesium cell with improved electrolyte

ActiveUS20100310933A1Loss of capacityLoss of powerAlkaline accumulatorsElectrolytic capacitorsMagnesium salt1-Butyl-3-methylimidazolium hexafluorophosphate

An improved electrolyte for a cell having an anode comprising magnesium or magnesium alloy. The cell's cathode may desirably include iron disulfide (FeS2) as cathode active material. The improved electrolyte comprises a magnesium salt, preferably magnesium perchlorate dissolved in an organic solvent which preferably includes acetonitrile or mixture of tetrahydrofuran and propylene carbonate. The electrolyte includes an additive to retard the buildup of deleterious passivation coating on the magnesium anode surface, thereby enhancing cell performance. Such additive may preferably include 1-butyl-3-methylimidazolium tetrafluoroborate (BMIMBF4), 1-butyl-3-methylimidazolium hexafluorophosphate (BMIMPF6), lithium hexafluorophosphate (LiPF6), or aluminum chloride (AlCl3)

Owner:DURACELL U S OPERATIONS

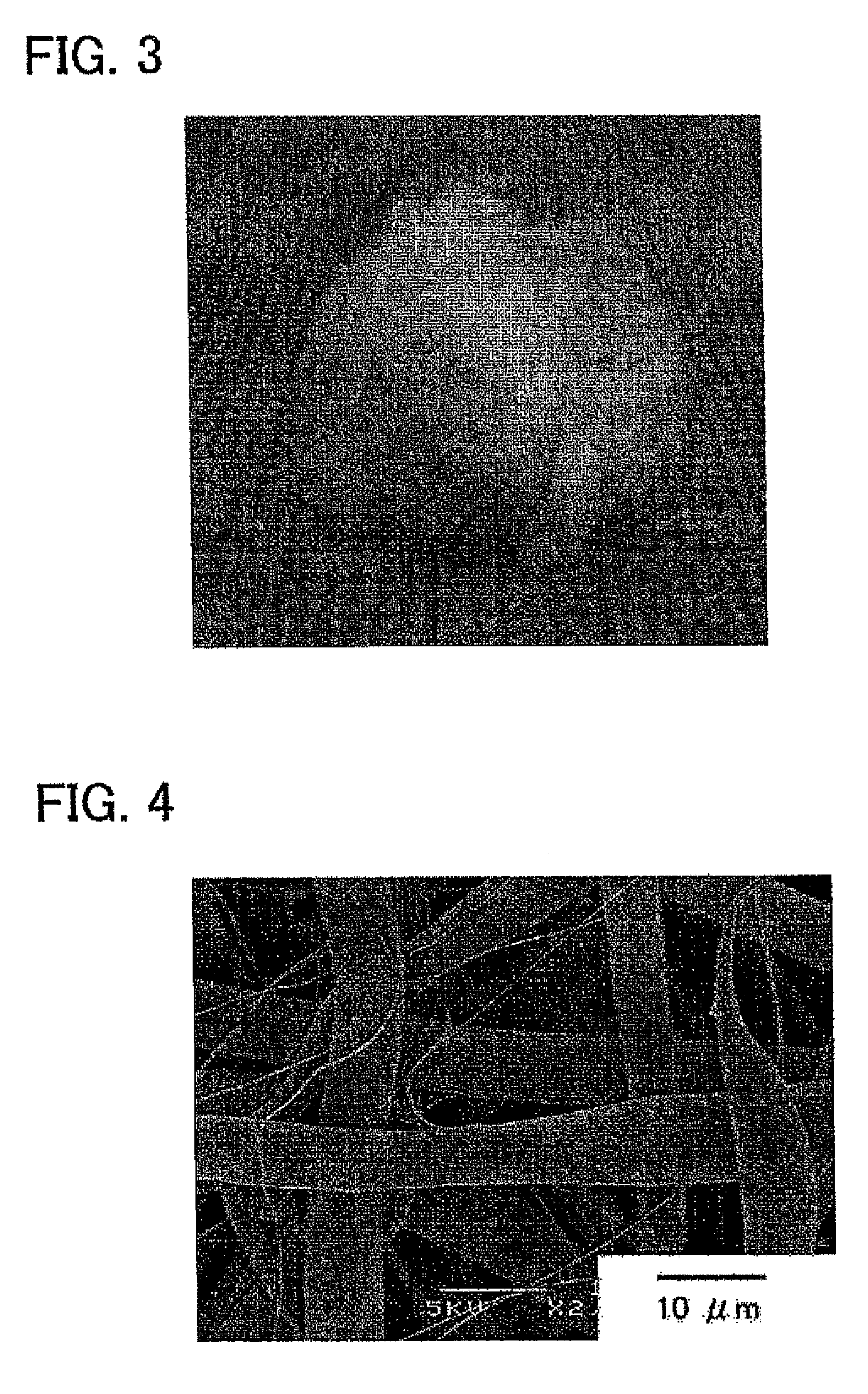

Fiber wadding for filling bone defects

ActiveUS8853298B2Speedup (acceleration)Improve adhesionImpression capsSurgical adhesivesFiberWadding

A fiber wadding for filling bone defects having a flocculent three-dimensional structure is disclosed. The fiber wadding includes a plurality of fibers that contain a biodegradable resin as a principal component and a siloxane. Outside diameter of the plurality of fibers of the wadding is from about 0.05 μm to about 30 μm. Bulk density of the fiber wadding is about 0.005-0.3 g / cm3.

Owner:NAGOYA INSTITUTE OF TECHNOLOGY +1

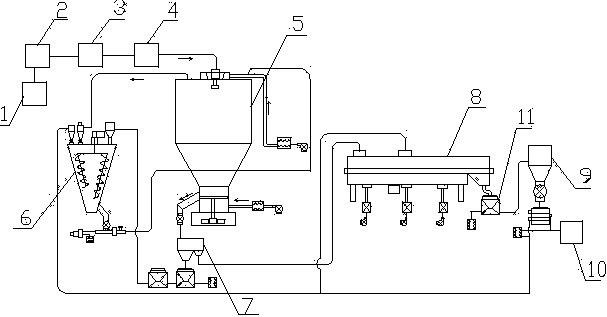

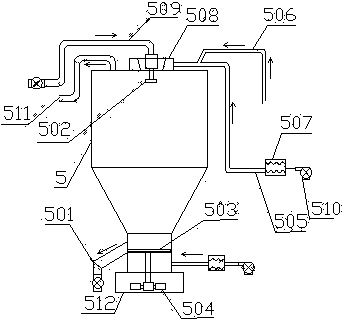

Preparation process and device of vitamin D3 microcapsule powder

ActiveCN104306353AImprove liquidityGreat tasteOrganic active ingredientsPressurized chemical processCalcium biphosphateSolubility

The invention relates to a preparation process and a preparation device of vitamin D3 microcapsule powder. In the preparation process, VD3 oil, sunflower seed oil or corn oil, medicinal starch, maltodextrin, modified starch, white sugar, calcium phosphate and 2,6-di-t-buty-4-methylphenol (BHT) are used as main raw materials. The preparation process and the preparation device are reasonably improved and optimized, the production time is greatly shortened and the whole production process is controlled; through layer-by-layer drying and step-by-step recycling, the prepared vitamin D3 microcapsule powder has smooth and flat surface, and the safety, the fluidity, the mouth feel and the water solubility of the vitamin D3 microcapsule powder are greatly improved; the waste of resources is reduced, the continuous large-scale production is implemented, and the production cost is reduced.

Owner:豆源和(山东)食品饮料有限公司

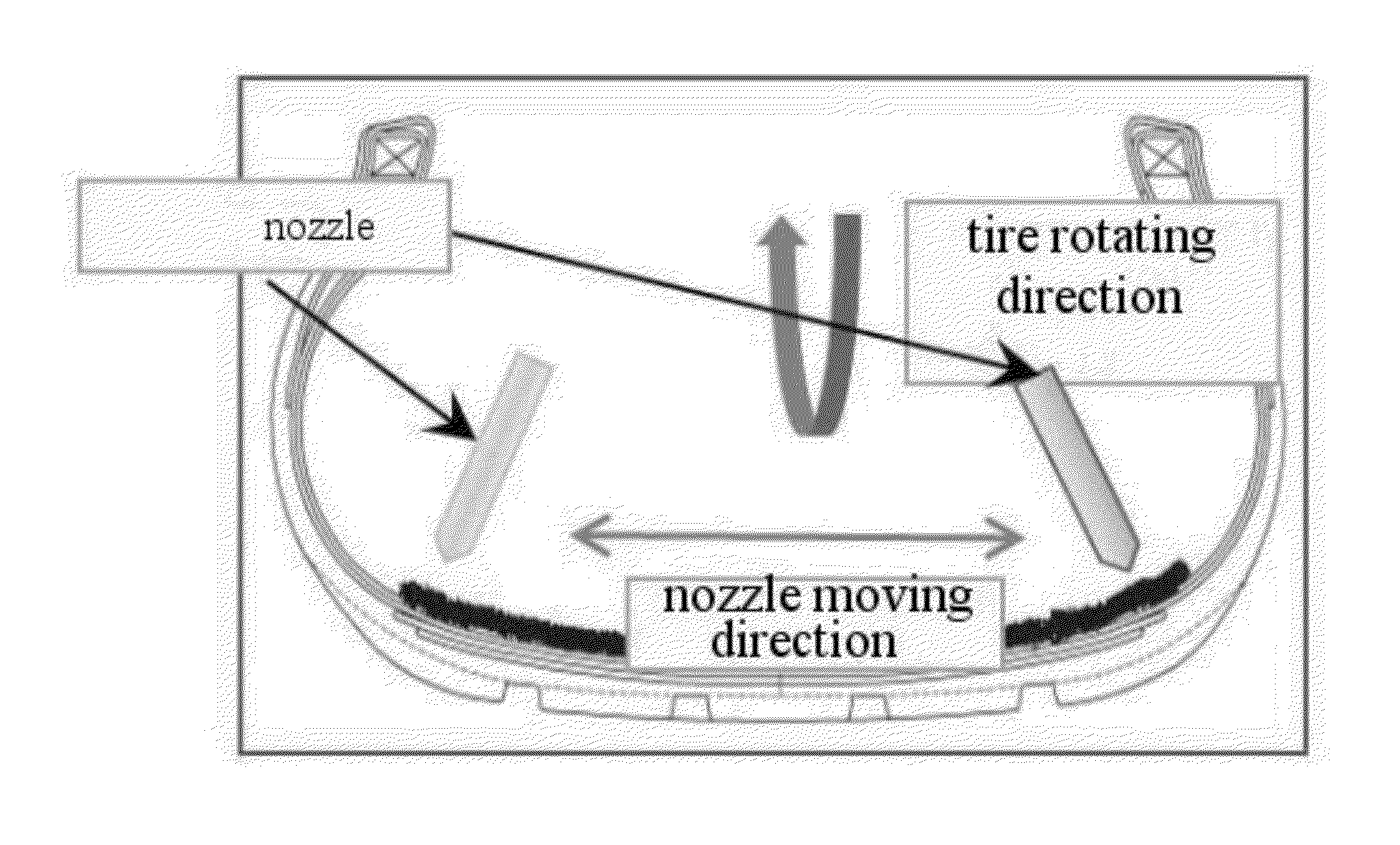

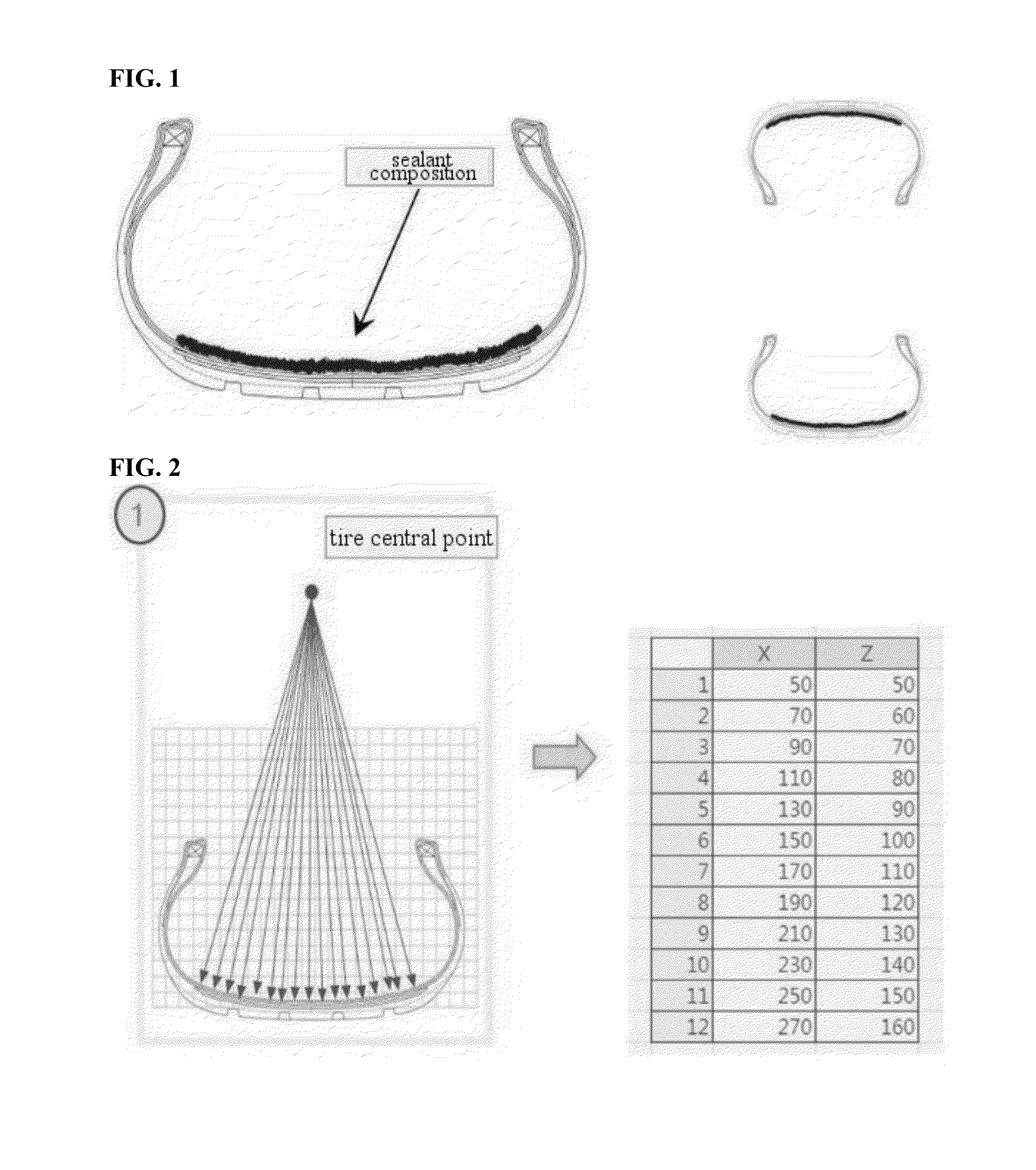

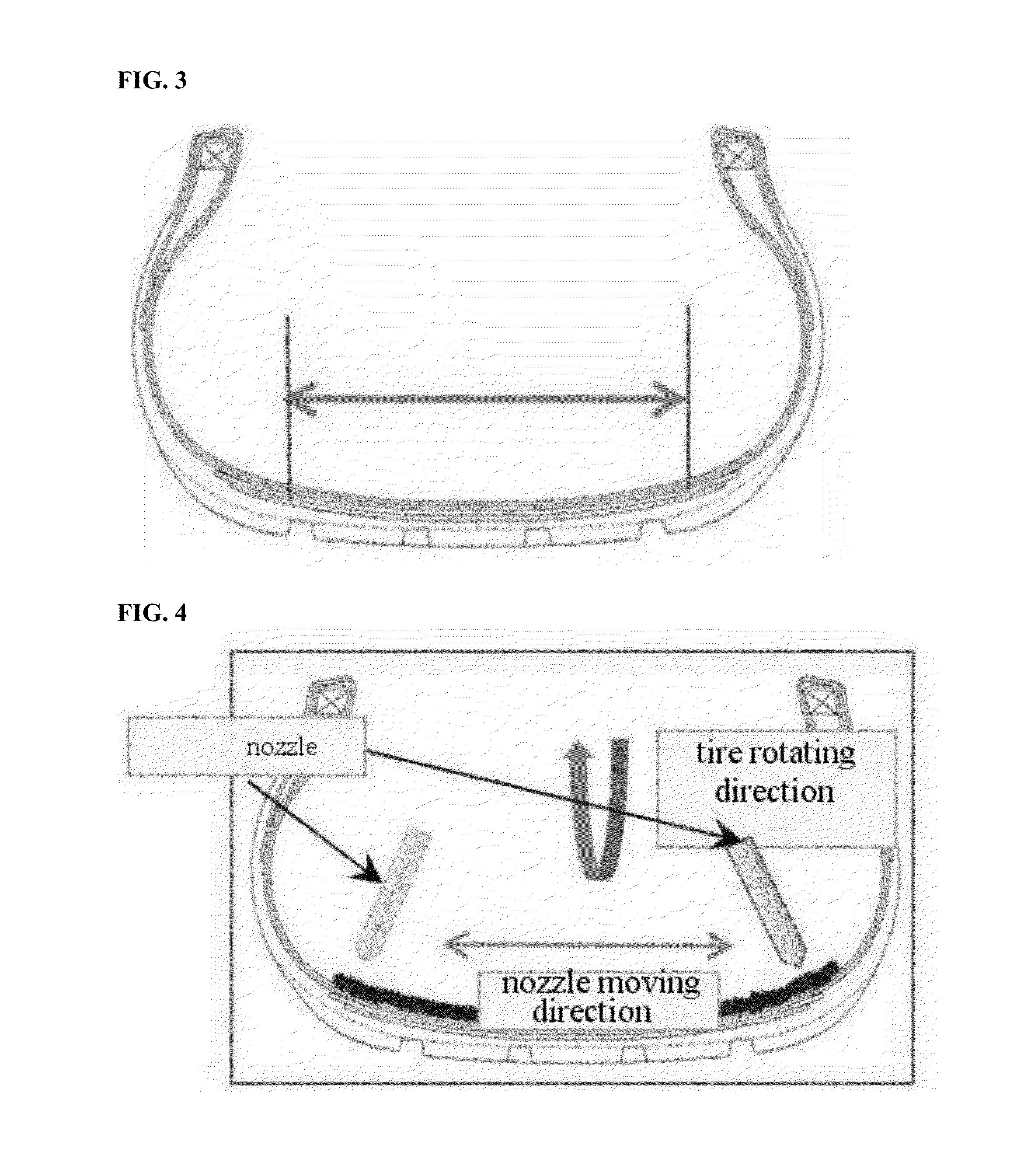

Method of coating sealant composition to inner surface of tire and tire manufactured by the same

ActiveUS20150107743A1Short working hoursQuick compositionTyre partsLiquid surface applicatorsComputer Aided DesignSpray nozzle

Disclosed herein are a method of coating a sealant composition to an inner surface of a tire, and a tire manufactured by the same. The method includes extracting coordinates for coating a sealant composition with reference to a central point of a target tire using a computer-aided design (CAD) file of the target tire; setting robot moving coordinates and setting a coating width based on the extracted coordinates; and coating the sealant composition while moving a nozzle provided to a robot arm and ejecting the sealant composition toward the set coordinates.

Owner:HANKOOK TIRE WORLDWIDE

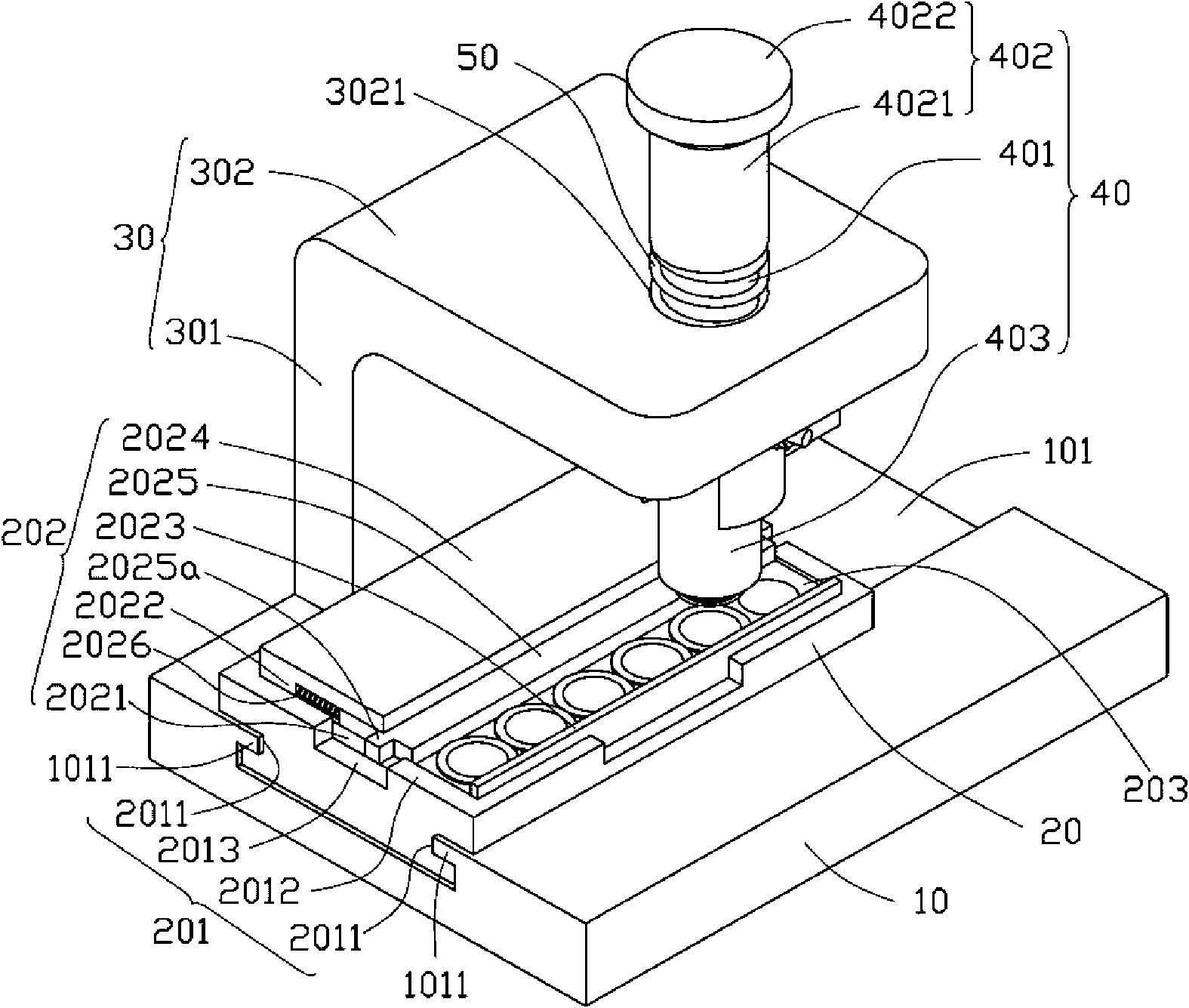

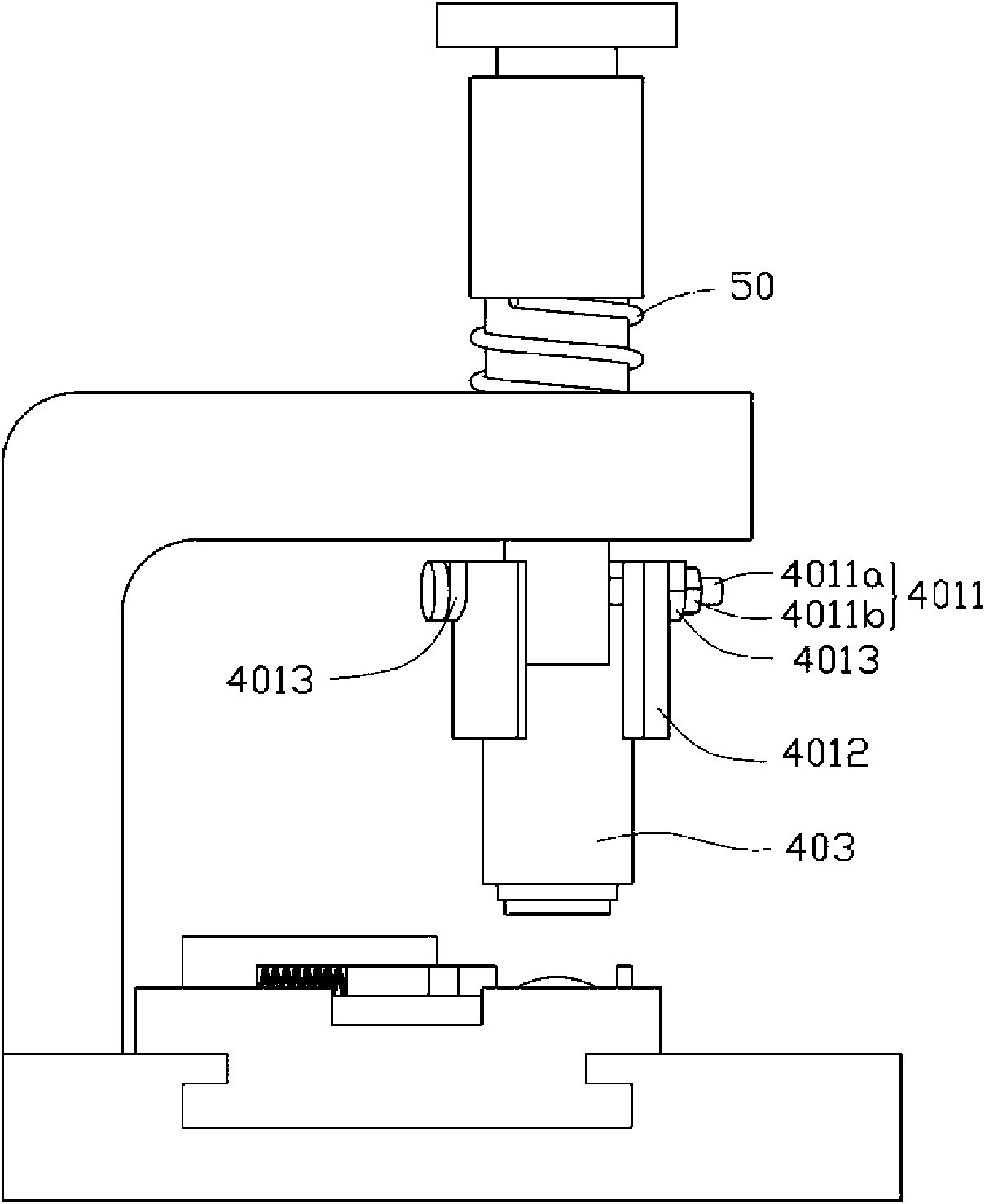

Coating device

InactiveCN101648175AFast coatingApply evenlyLiquid surface applicatorsCoatingsBiochemical engineeringCoating

The invention provides a coating device. The coating device comprises an operating platform, a carrier plate which can be slidably arranged on the operating platform, a support arm which is positionedat one side of the carrier plate and fixed on the operating platform, and a coating rod which is arranged on the support arm in a penetrating manner and can slide in relation to the support arm. Thesurface of the carrier plate is provided with a lens fixing area and the lower end of the support arm is just opposite to the lens fixing area. The coating device has the advantages of quick and evencoating after replacing traditional artificial coating, thus improving coating efficiency.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Velvet fabric and production method thereof

ActiveCN105178043AAdjust the clearanceImprove general performanceMechanical cleaningPressure cleaningAntioxidantEngineering

The invention provides a velvet fabric and a production method thereof, and is used for solving the technical problems that the existing velvet fabric is too simple, has no characteristic such as abrasion resistance, electrostatic resistance, high-low temperature resistance and the like, is single in function, has no production method and the like. The velvet fabric comprises a velvet layer, and is characterized in that a reinforcing layer is fixed on the velvet layer, and the reinforcing layer consists of the following components in parts by weight: 25 to 30 parts of polytetrafluoroethylene, 1.2 to 1.6 parts of antioxidant, 2 to 3 parts of cross-linking agent, 2 to 4 parts of catalyst and 30 to 50 parts of water. The invention also provides a production method of the velvet fabric. The velvet fabric has advantages of high functionality and simple process.

Owner:HAINING JBL TEXTILE

An addition type silicone pressure-sensitive adhesive used for medicines and a preparing method thereof

ActiveCN107338020ALow shrinkageReduce pollutionNon-macromolecular adhesive additivesFilm/foil adhesivesHydrogenSilicone oil

An addition type silicone pressure-sensitive adhesive used for medicines and a preparing method thereof are disclosed. Raw materials of the addition type silicone pressure-sensitive adhesive include, by weight, 100 parts of vinyl silicone oil, 5-10 parts of hydrogen-containing silicone oil, 3-5 parts of a filler, 0.03-0.3 part of an inhibitor and 0.03-0.3 part of a catalyst. The pressure-sensitive adhesive is nontoxic, nonirritant, waterproof and breathable, has good initial adhesive force, holding power and peel strength, can be uncovered and adhered repeatedly, and is a pressure-sensitive adhesive material having ideal properties for medicines.

Owner:南宁市六分仪生物科技有限责任公司

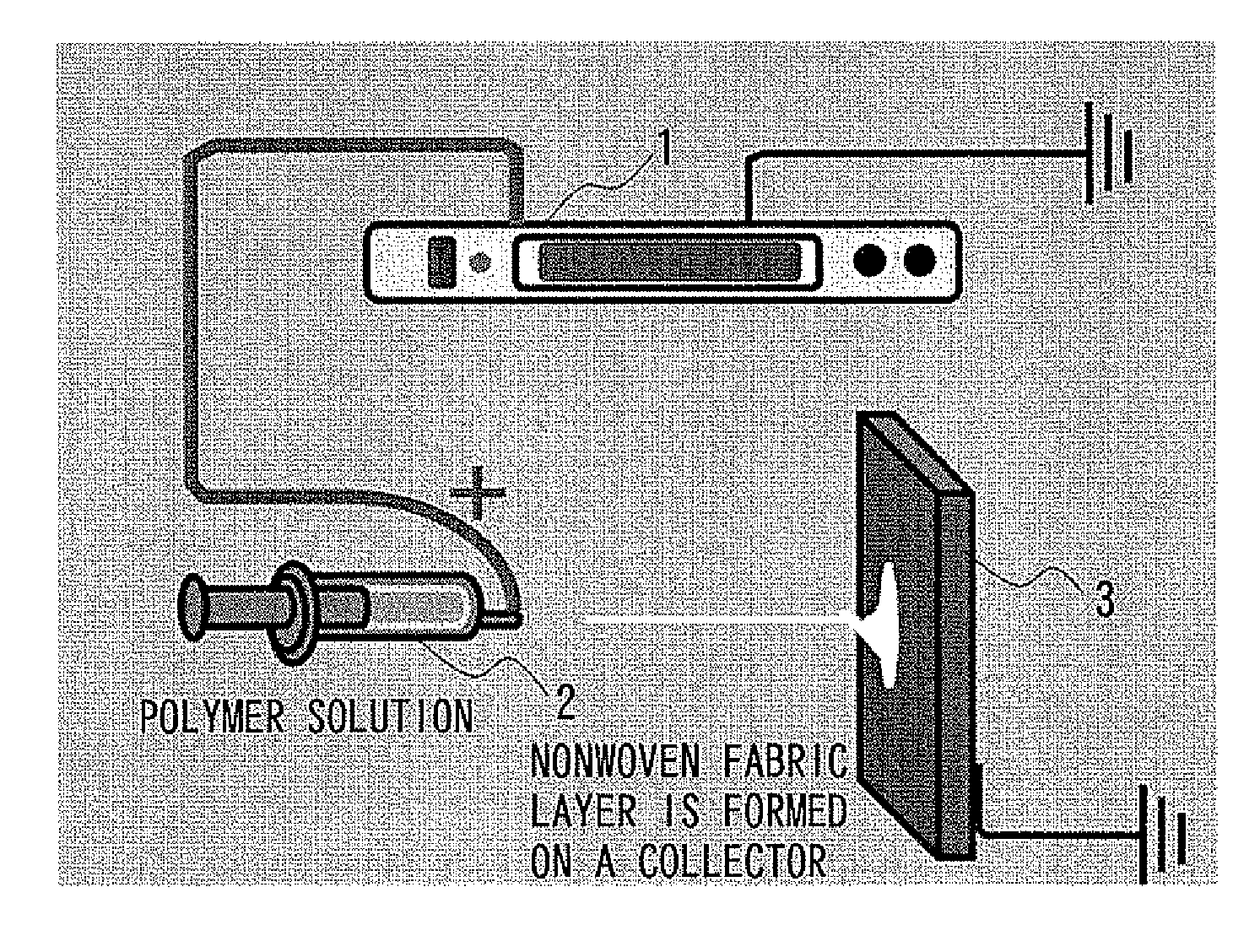

Material for filling bone defects and production method thereof

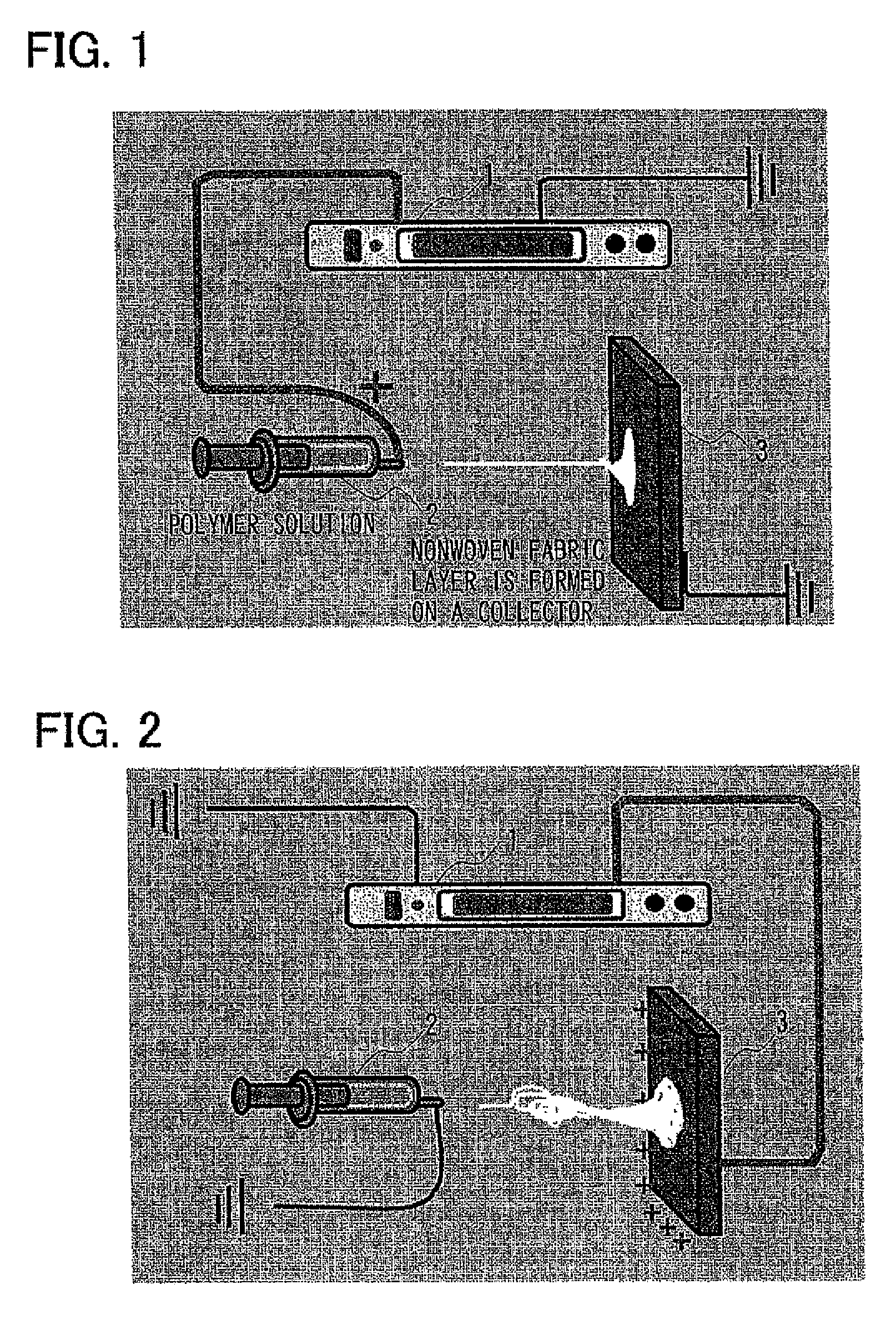

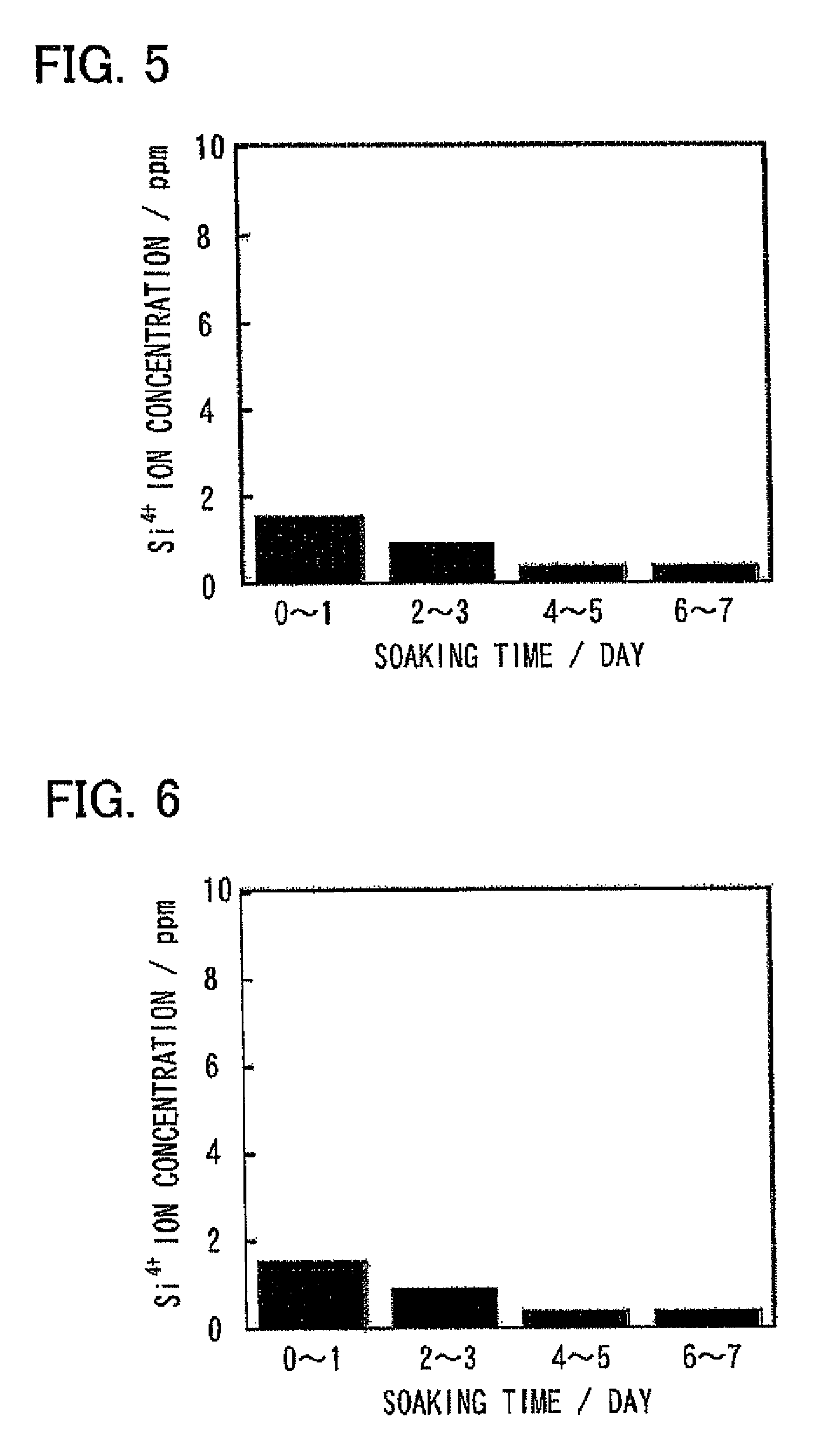

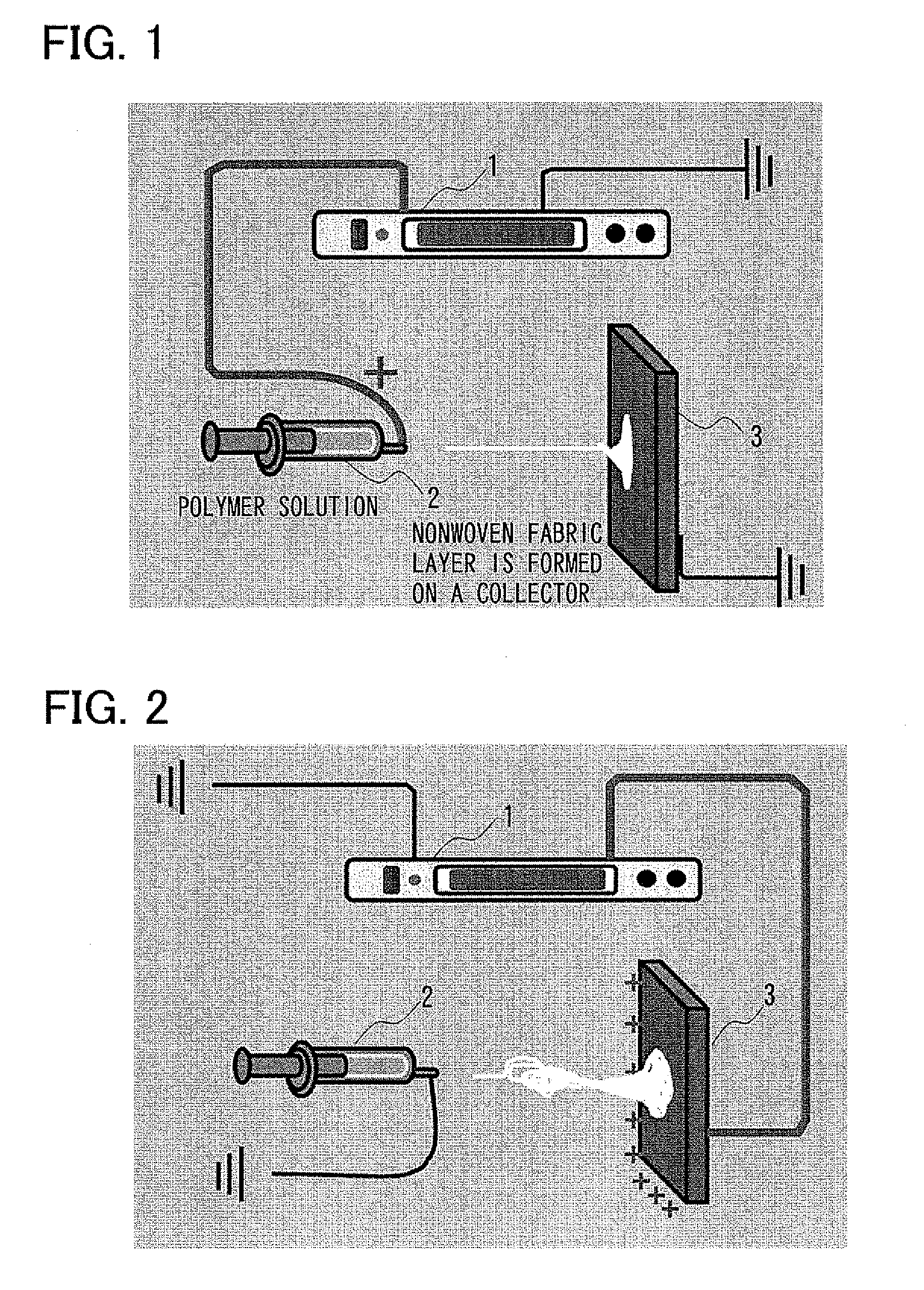

InactiveUS20110009522A1Low viscosityHigh viscosityImpression capsElectric discharge heatingElectrospinningSlurry

Disclosed is a material for filling bone defects having a three-dimensional steric structure. This material is produced by dissolving or suspending a substance in a solvent to give a solution or slurry, the substance containing a biodegradable resin as a principal component and bearing a siloxane; adding water to the solution or slurry to give a spinning solution, the water having a relative dielectric constant larger than that of the biodegradable resin; subjecting the spinning solution to electrospinning while applying a positive charge to a collector by a voltage supply and grounding a nozzle of a syringe without applying a charge thereto; thereby yielding the material on the collector.

Owner:ORTHOREBIRTH

Atmospheric pressure evaporation method for anti-fouling film, atmospheric pressure evaporation apparatus and device for manufacturing anti-fouling film

InactiveCN102747327AOmit the step-down and vacuum procedureLow costVacuum evaporation coatingSputtering coatingEvaporationAtmospheric pressure

The present invention relates to an atmospheric pressure evaporation method for an anti-fouling film, an atmospheric pressure evaporation apparatus and a device for manufacturing an anti-fouling film, wherein the atmospheric pressure evaporation method for an anti-fouling film comprises steps of: providing a base material, gasifying an anti-fouling coating solution to form a plurality of vapour molecules, and depositing the vapour molecules on one surface of the base material to form an anti-fouling film.

Owner:CREATING NANO TECH INC

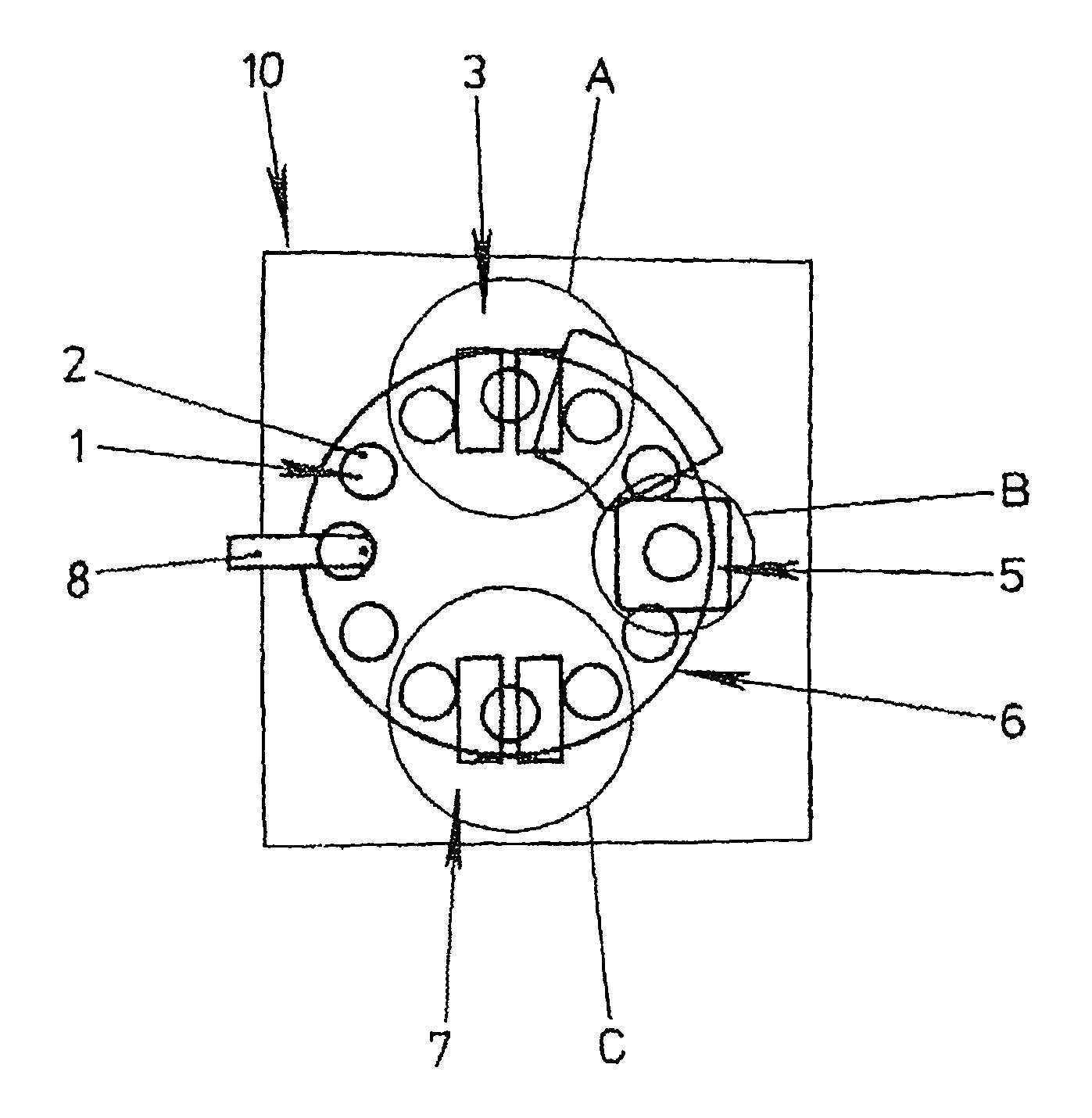

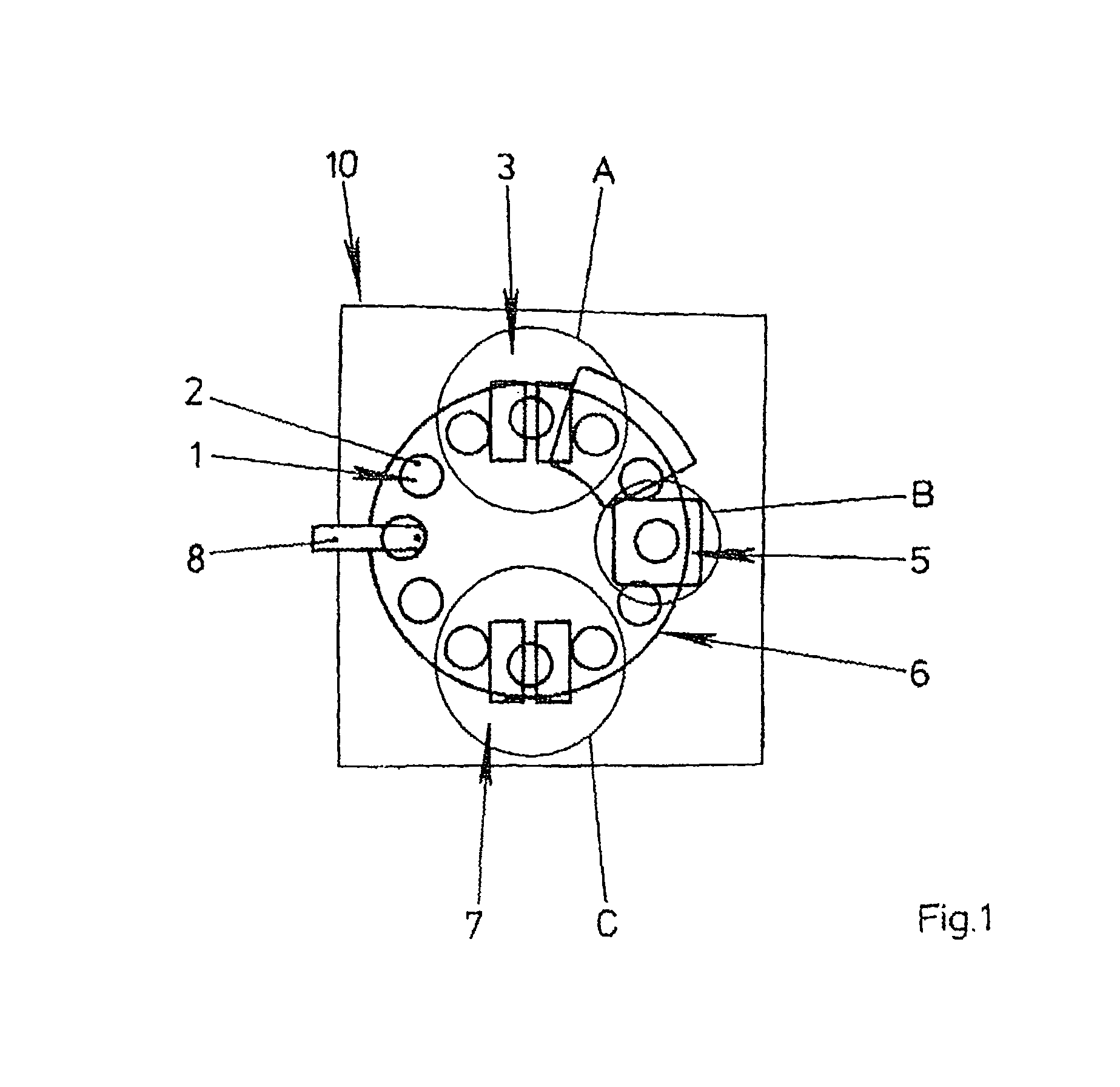

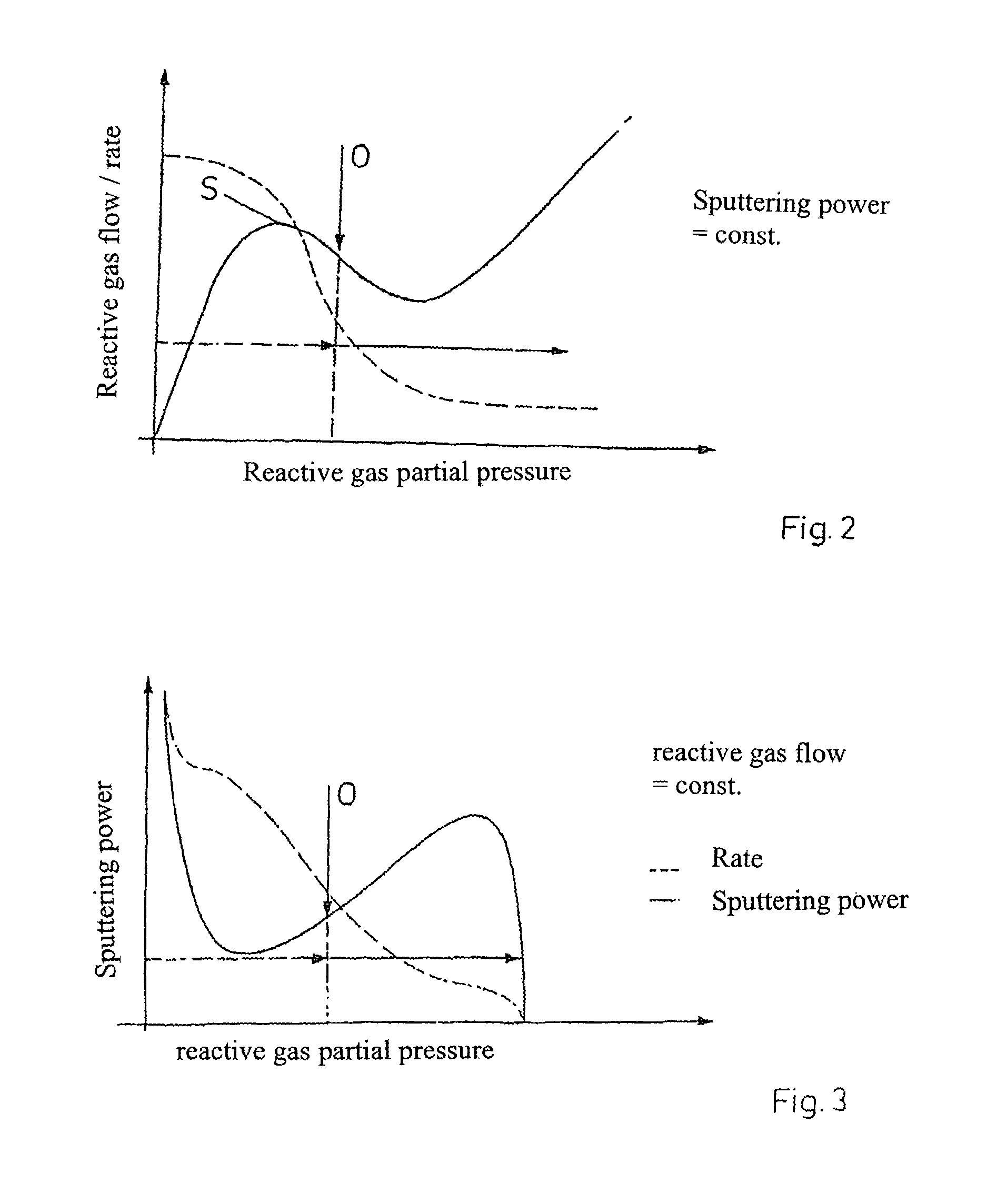

Method for producing a multilayer coating and device for carrying out said method

ActiveUS8956511B2High spreading rateLess timeCellsElectric discharge tubesStoichiometryReactive components

A method for reducing the optical loss of the multilayer coating below a predetermined value in a zone by producing coating on a displaceable substrate in a vacuum chamber with the aid of a residual gas using a sputtering device. Reactive depositing a coating on the substrate by adding a reactive component with a predetermined stoichiometric deficit in a zone of the sputtering device. Displacing the substrate with the deposited coating into the vicinity of a plasma source, which is located in the vacuum chamber at a predetermined distance from the sputtering device. The plasma action of the plasma source modifying the structure and / or stoichiometry of the coating, preferably by adding a predetermined quantity of the reactive component to reduce the optical loss of the coating.

Owner:LEYBOLD OPTICS

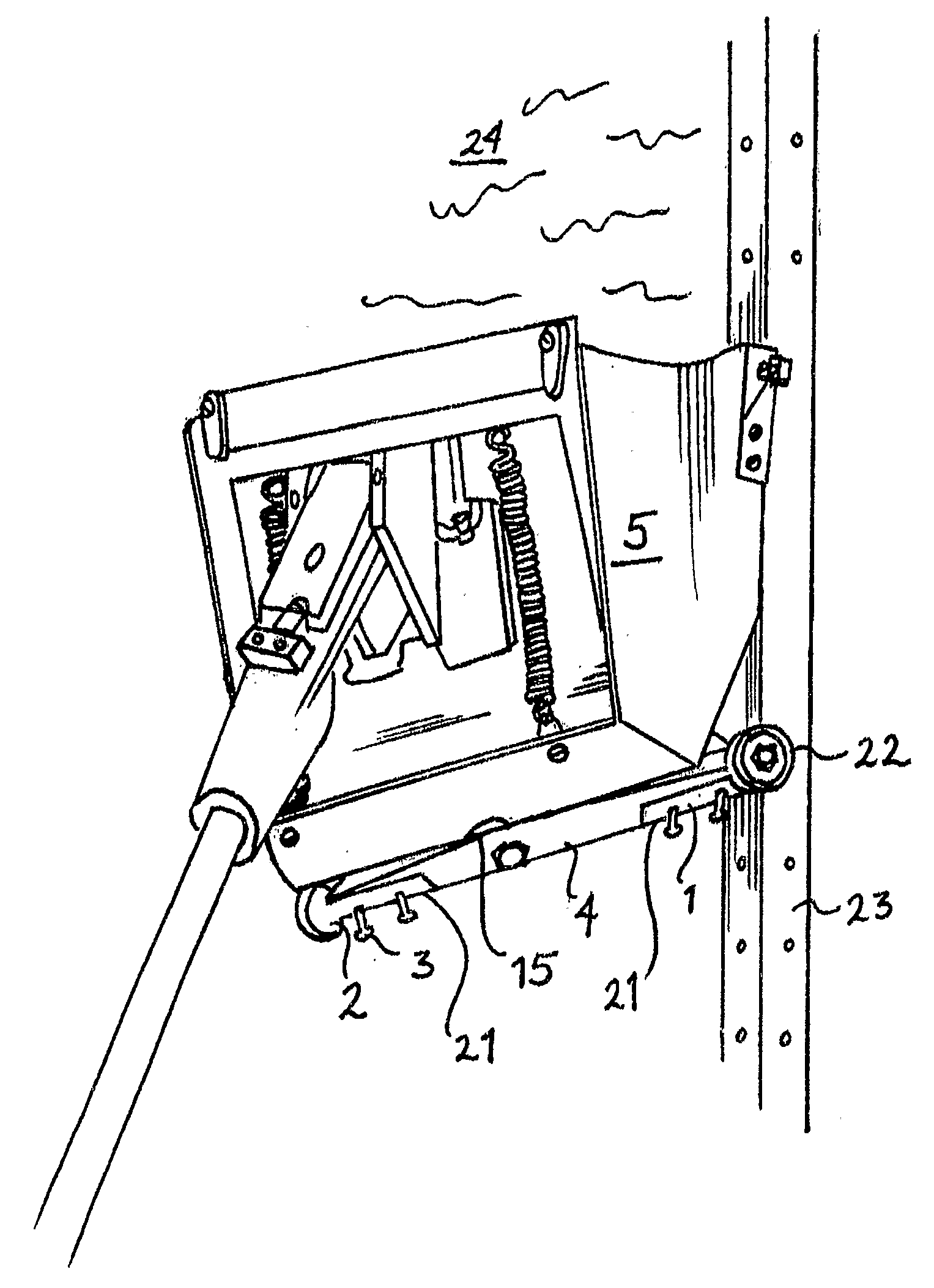

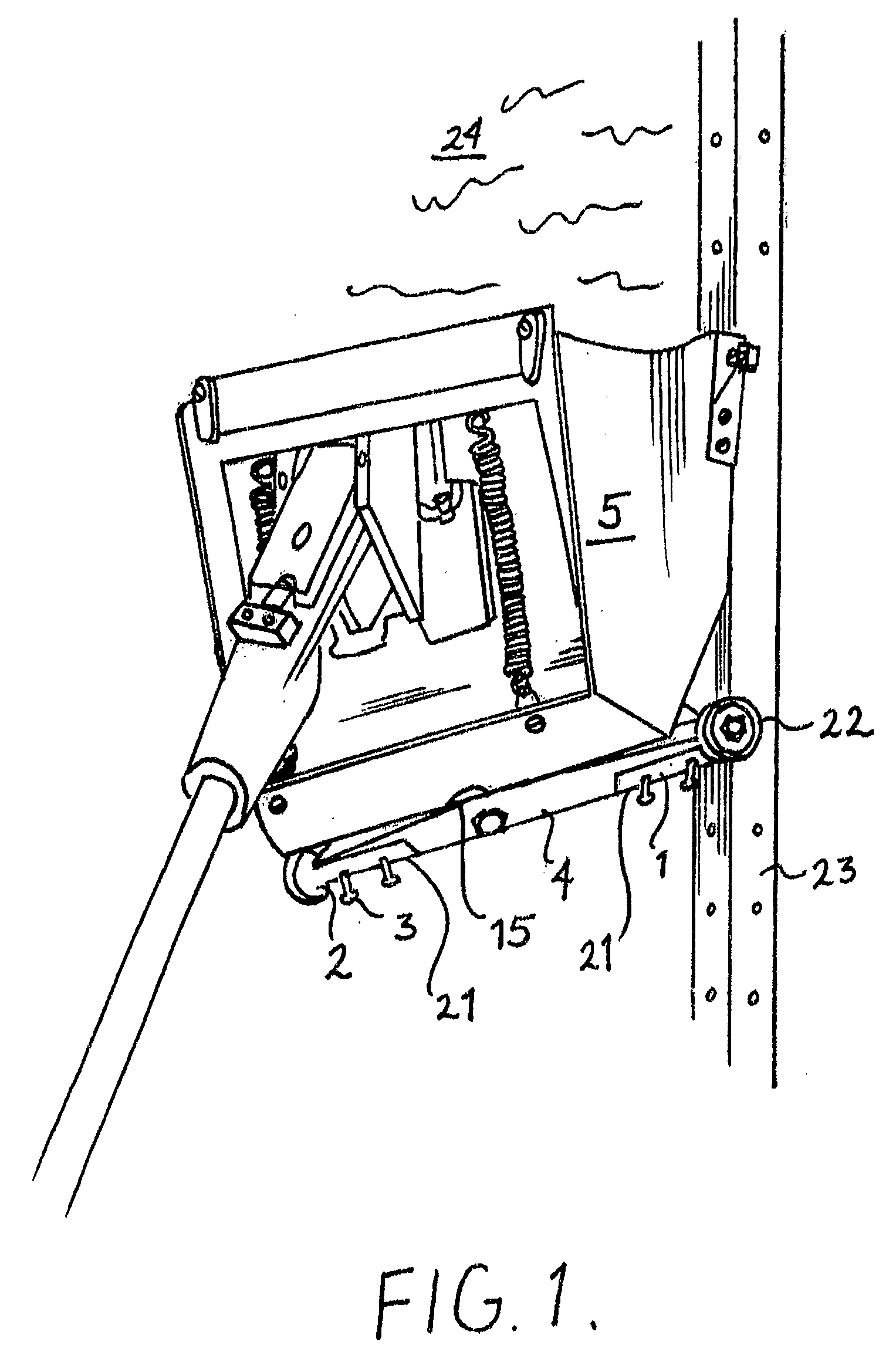

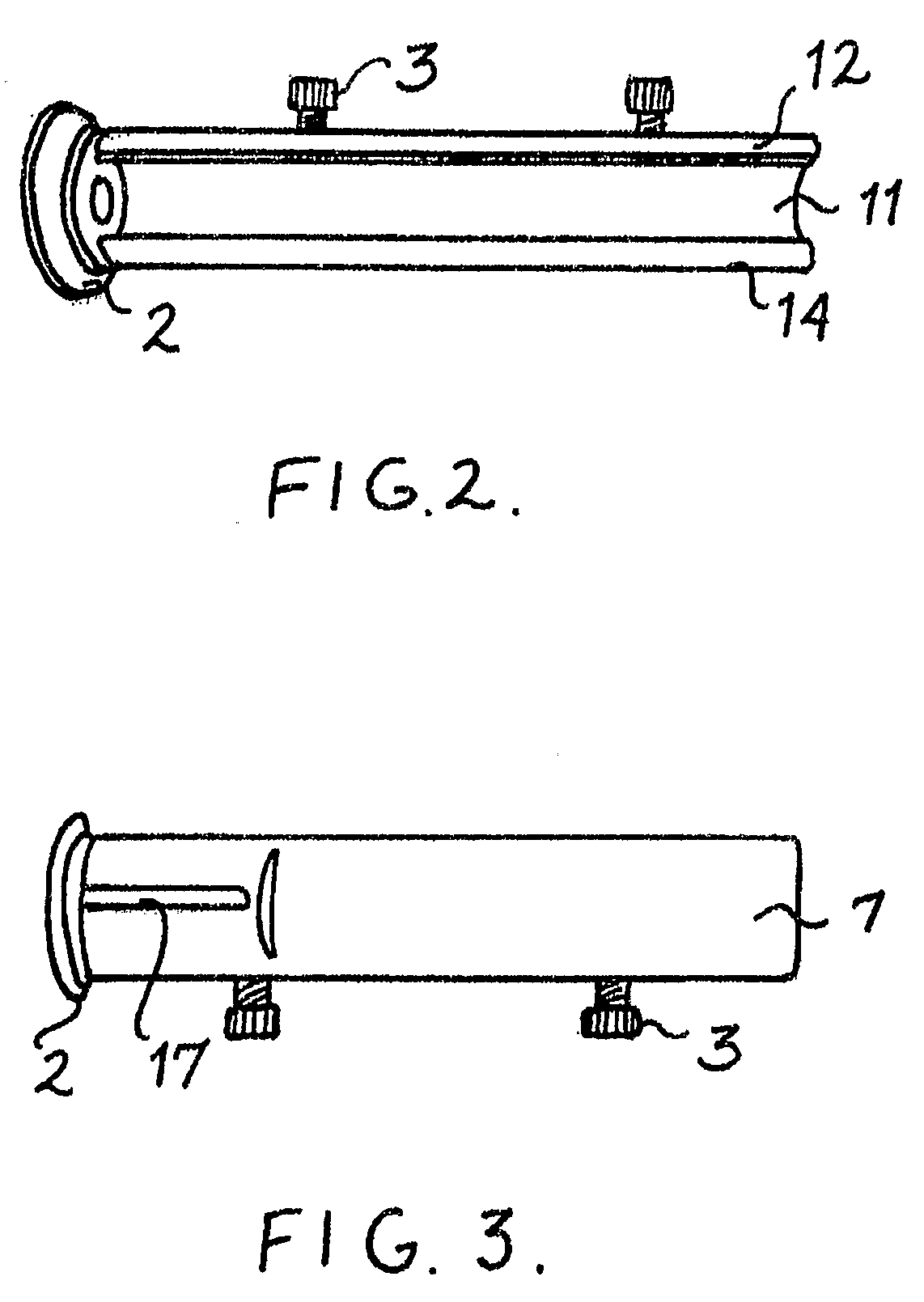

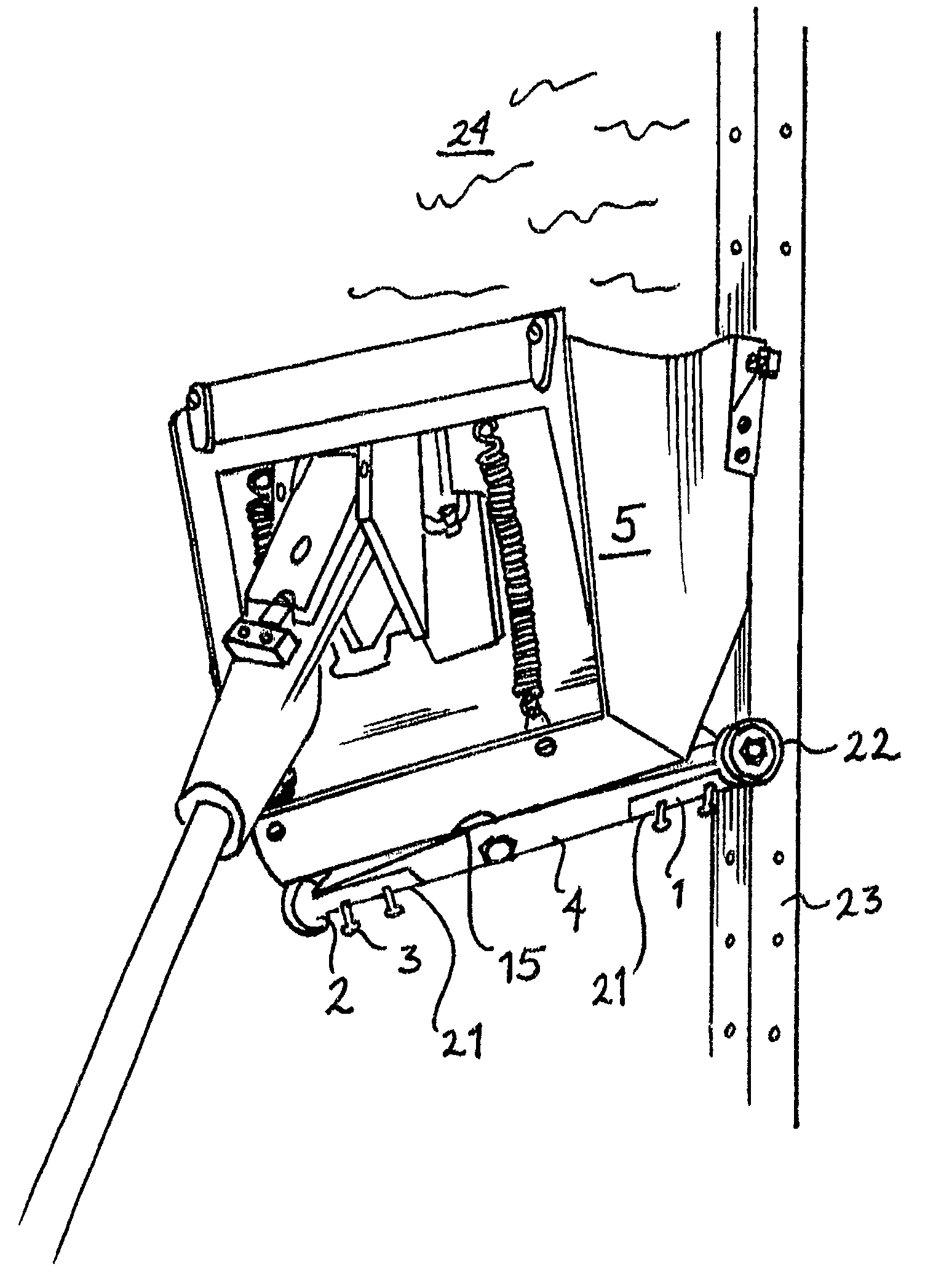

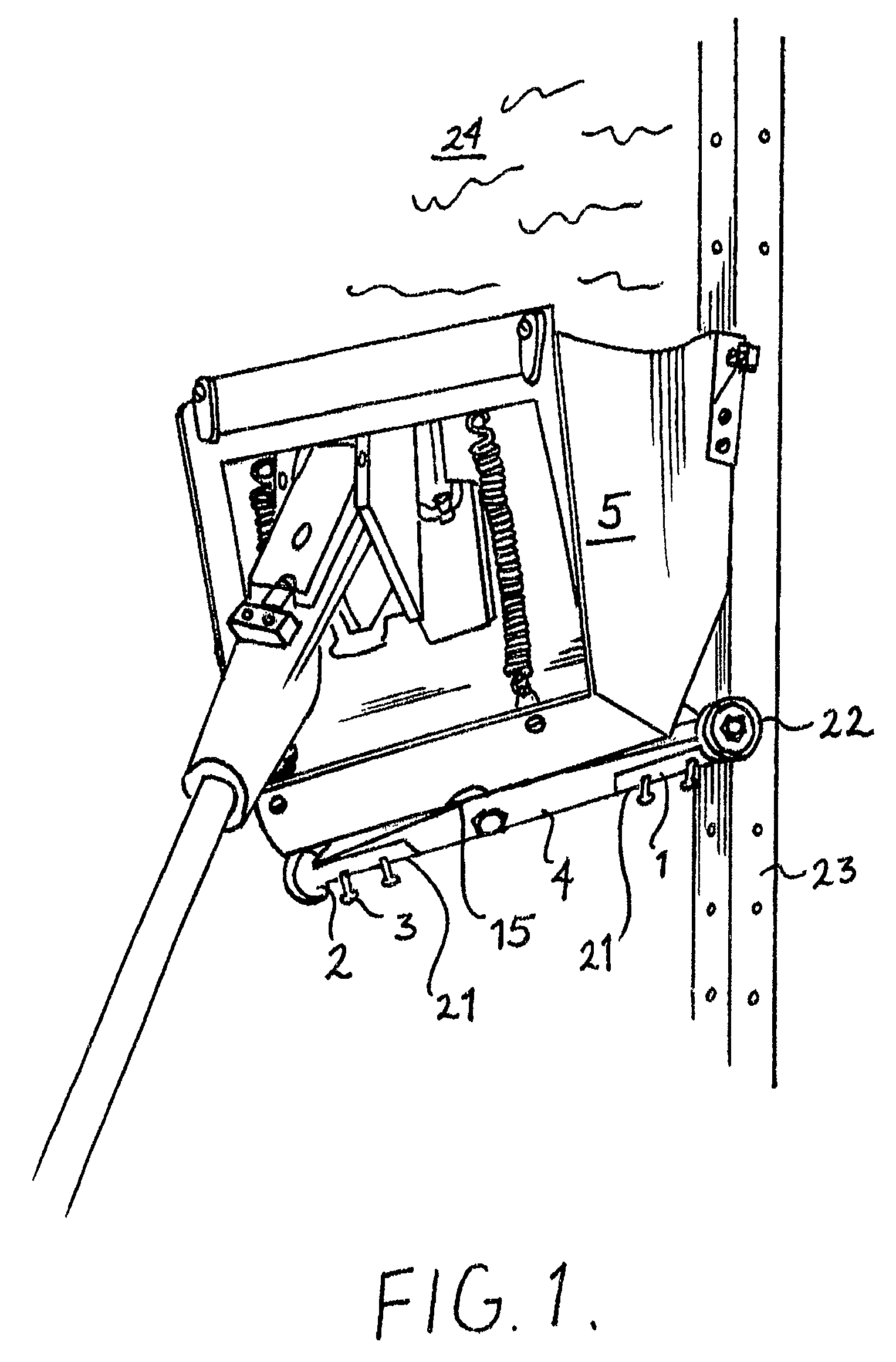

Axle Guide Assembly for Drywall Coating Box

An axle guide assembly for a drywall coating box. The axle guide assembly comprises one or more, preferably two, axle guides. Each axle guide is a clip that fits onto an axle of a drywall coating box in order to allow coating mud to be applied to the outside of a corner bead. As the axle guide assembly is slid down the corner bead, mud is applied to the corner bead.

Owner:WATTERS RON

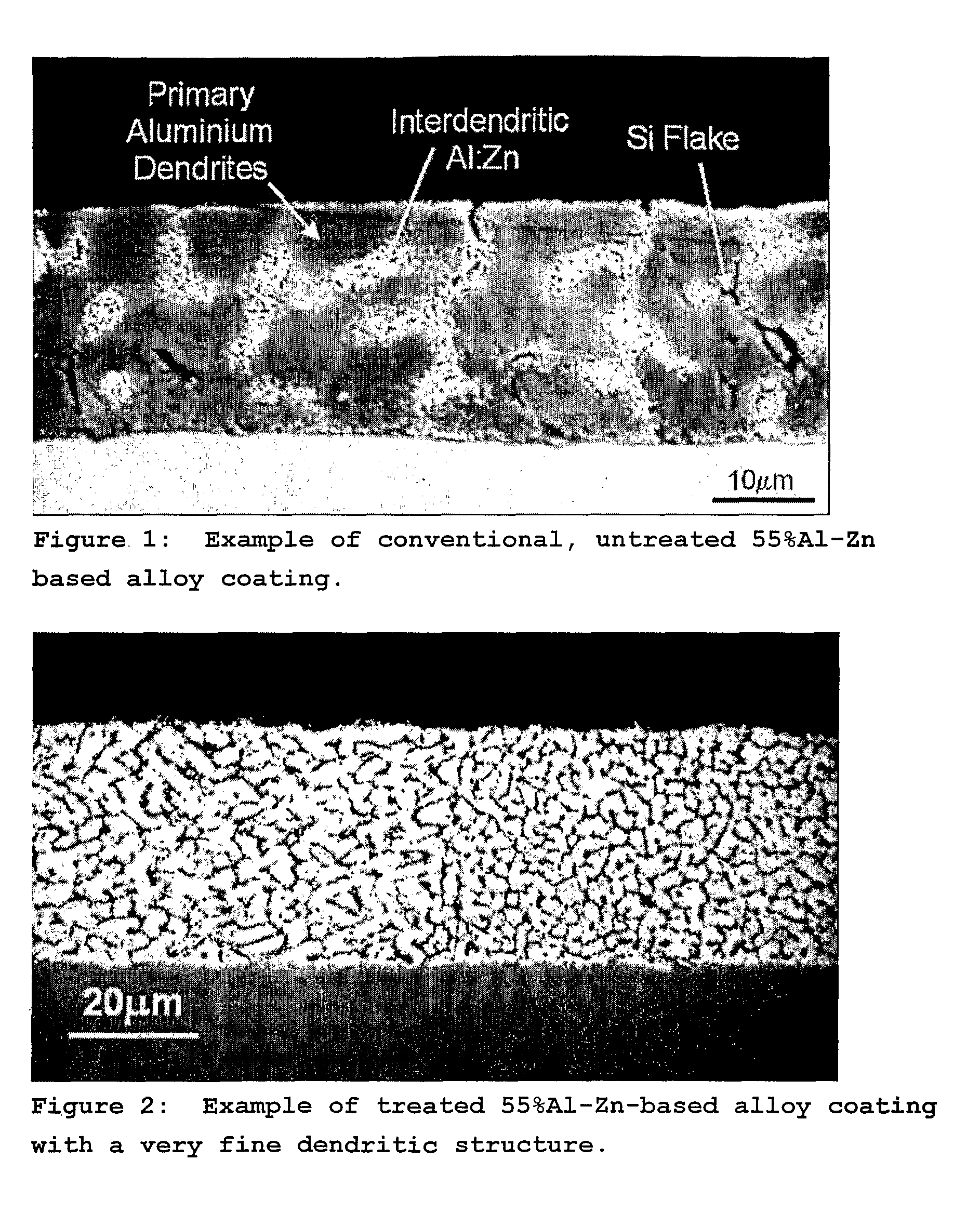

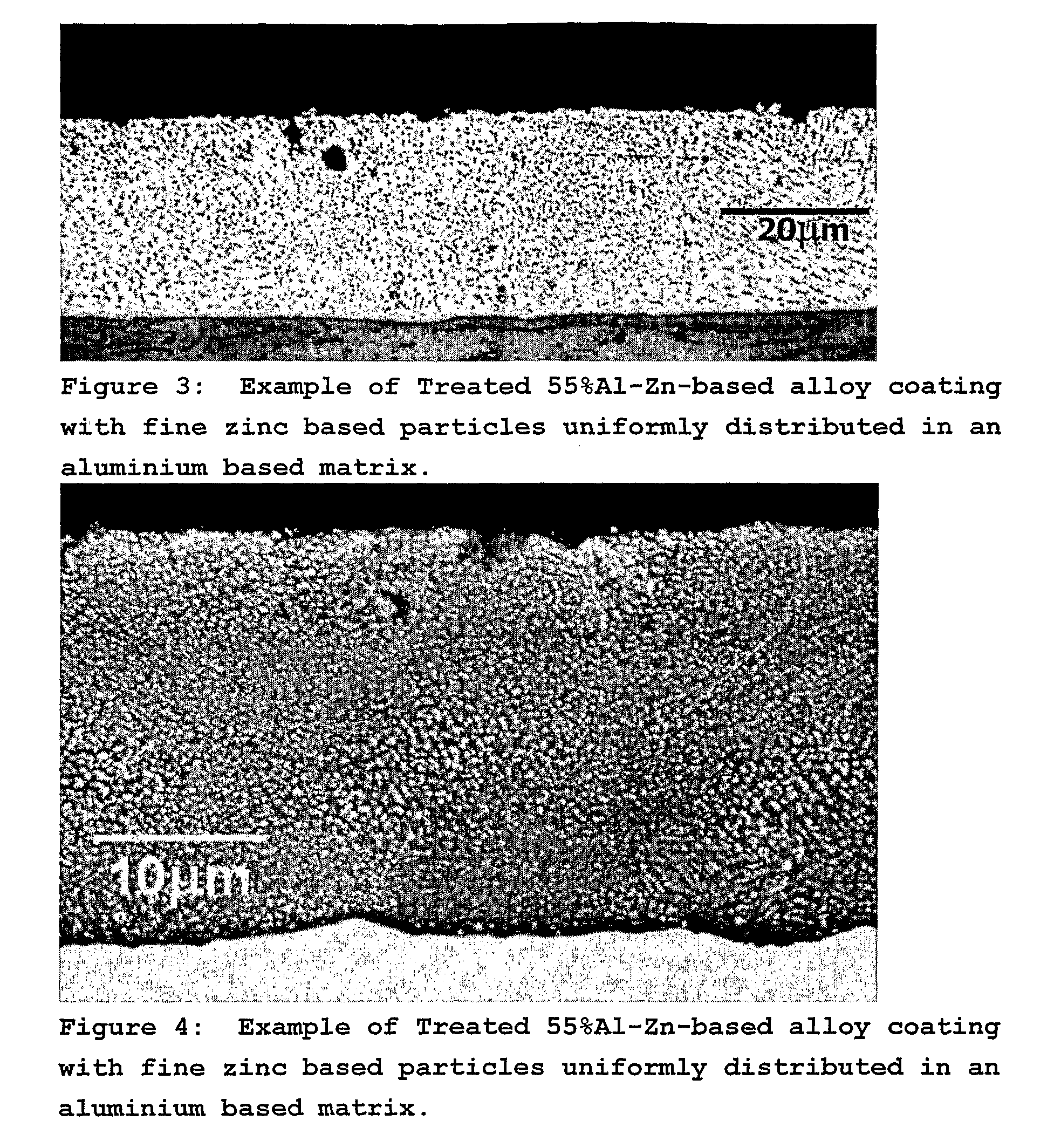

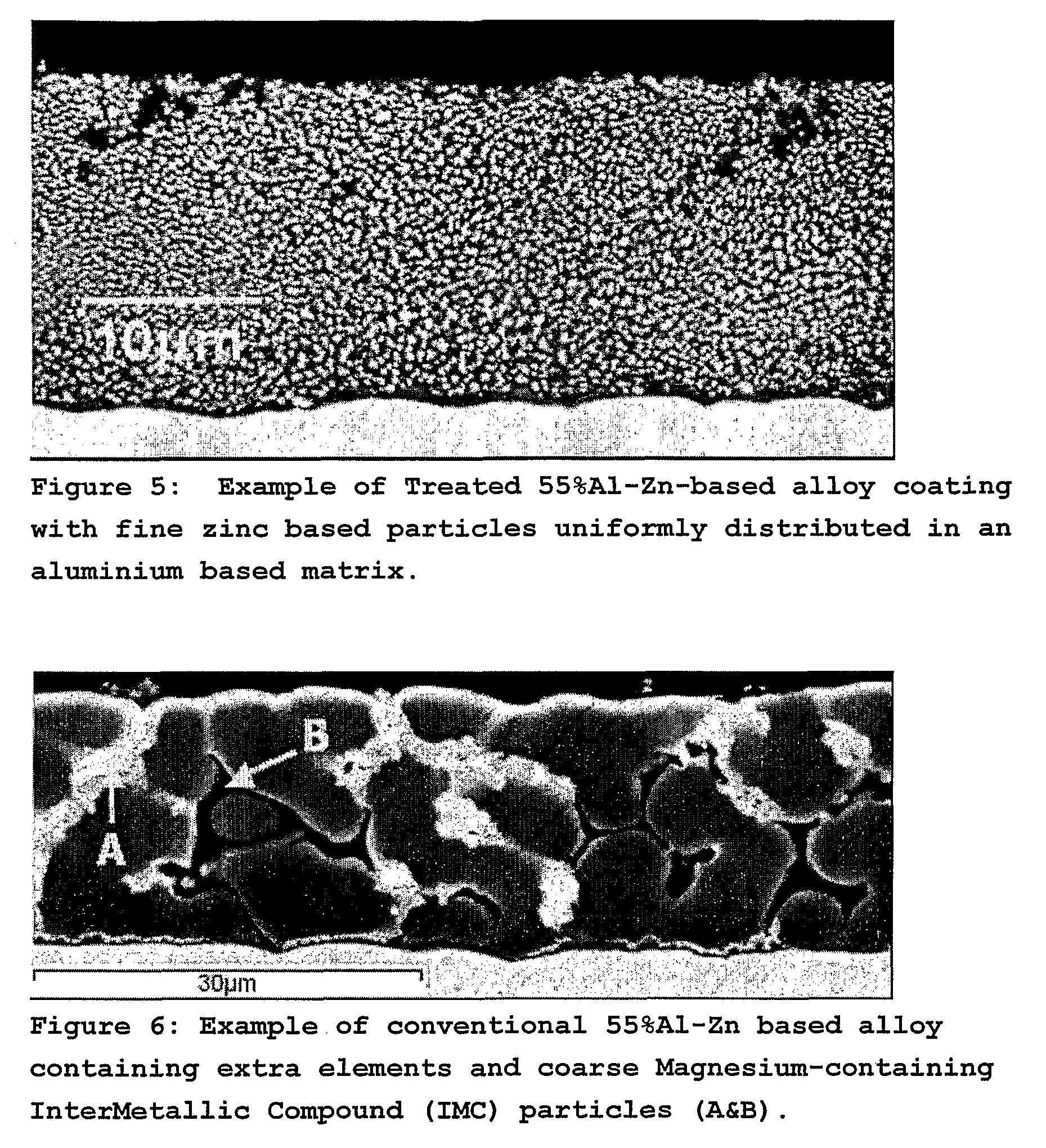

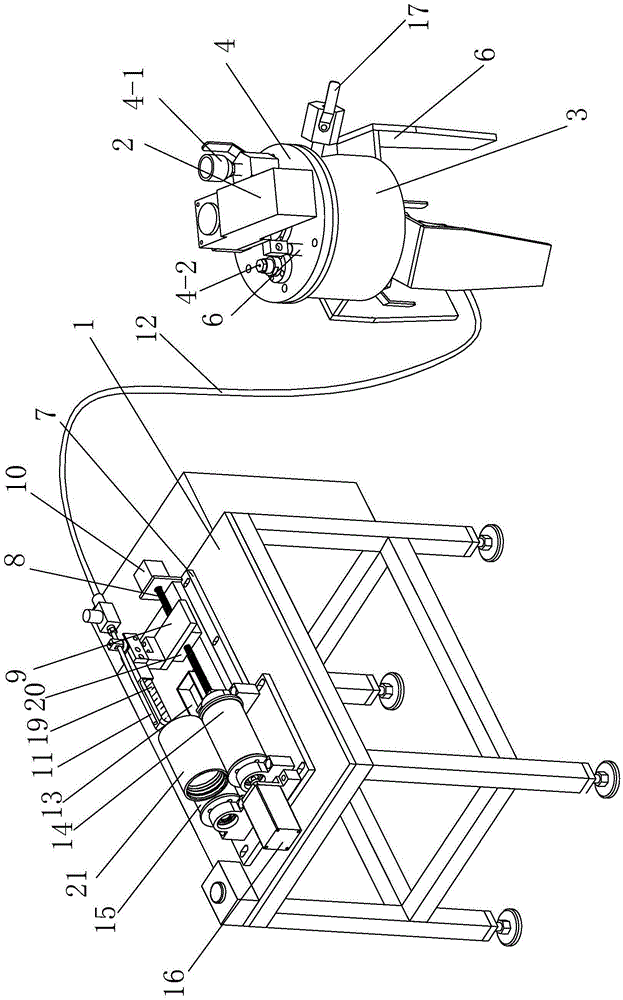

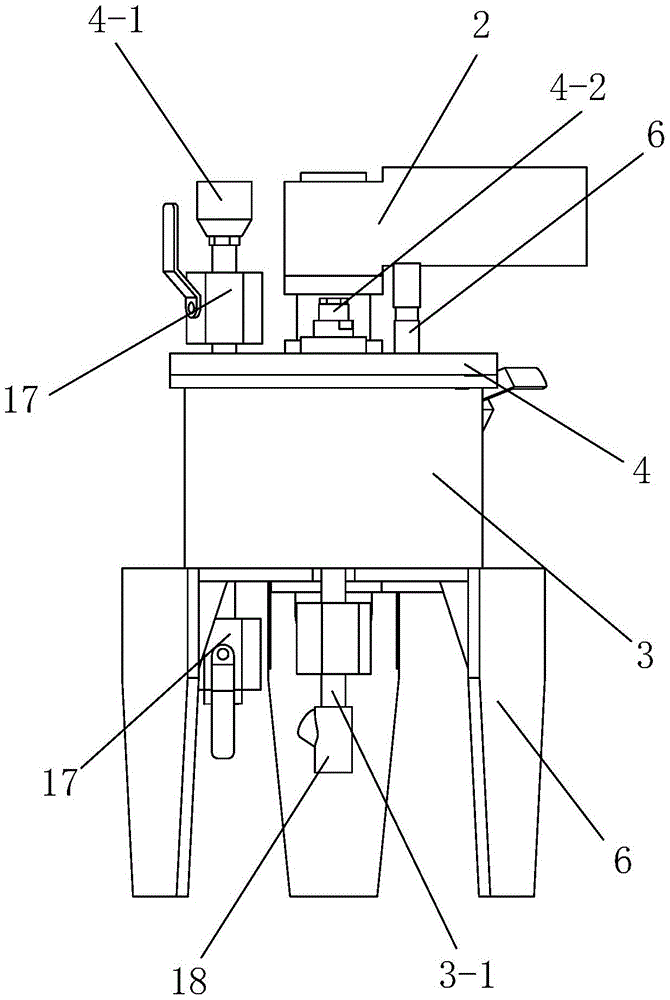

Treating Al/Zn-based alloy coated products

ActiveUS8475609B2Heating fastFast coatingHot-dipping/immersion processesFurnace typesAlloy coatingZinc based alloy

A method of treating an Al / Zn-based alloy coated product that includes an Al / Zn-based alloy coating on a substrate is disclosed. The method includes the steps of rapid intense heating of the alloy coating for a very short duration, and rapid cooling of the alloy coating, and forming a modified crystalline microstructure of the alloy coating.

Owner:BLUESCOPE STEEL LTD

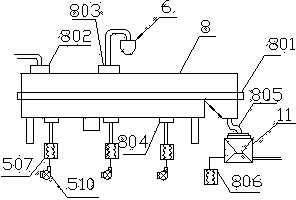

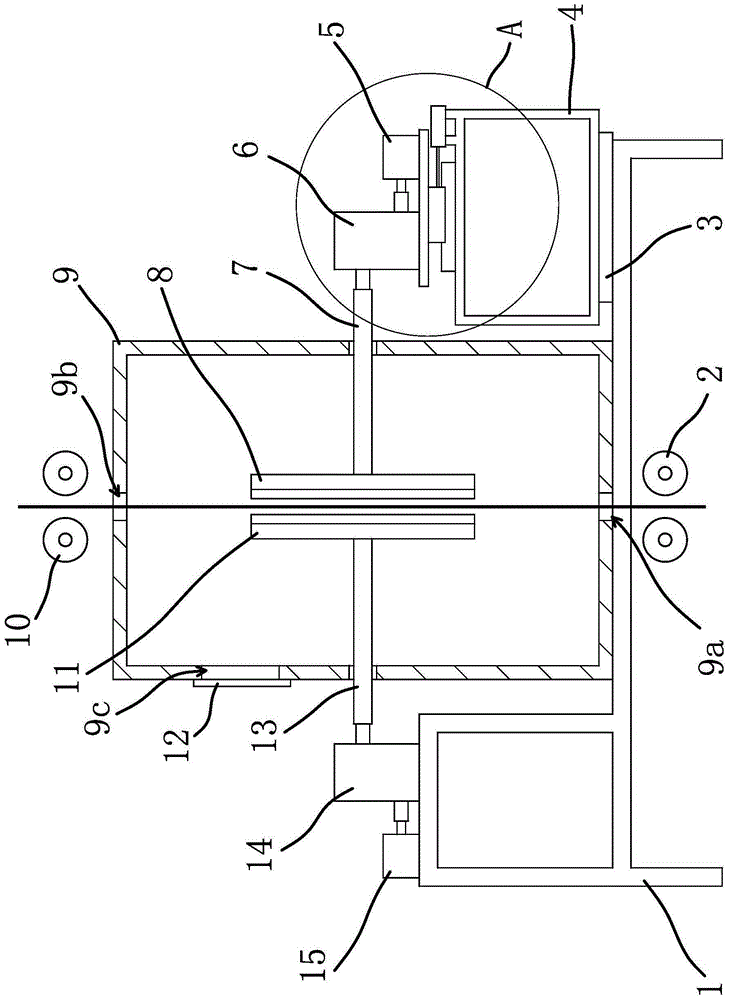

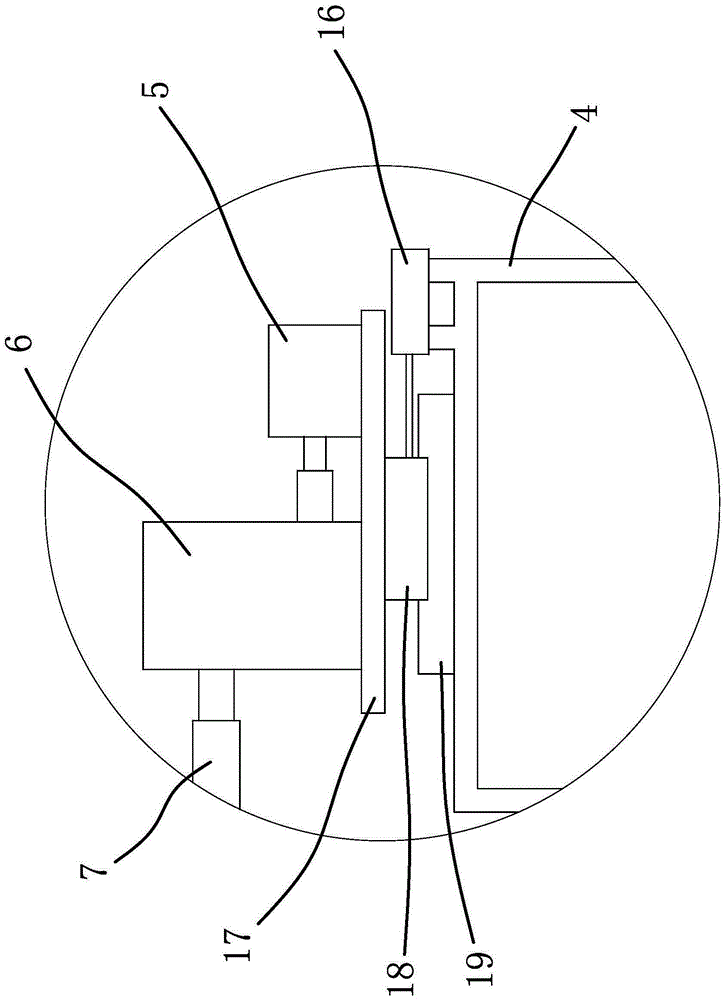

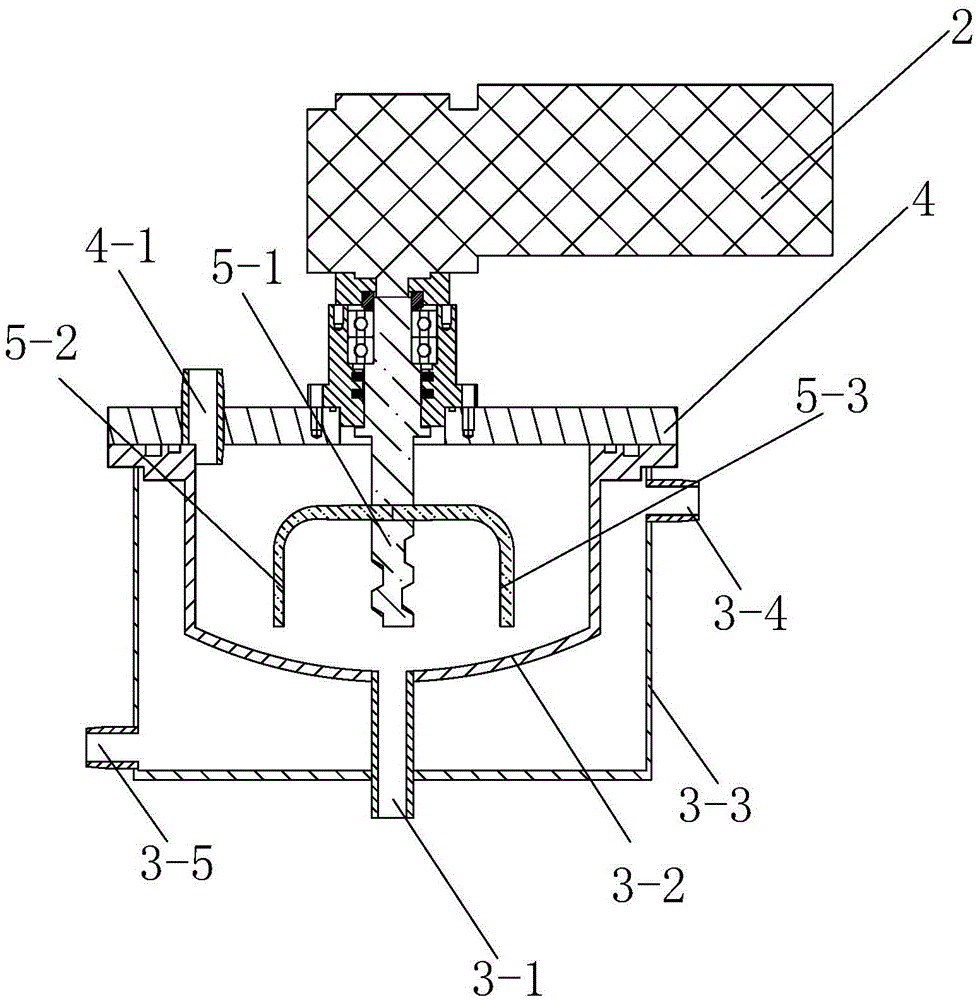

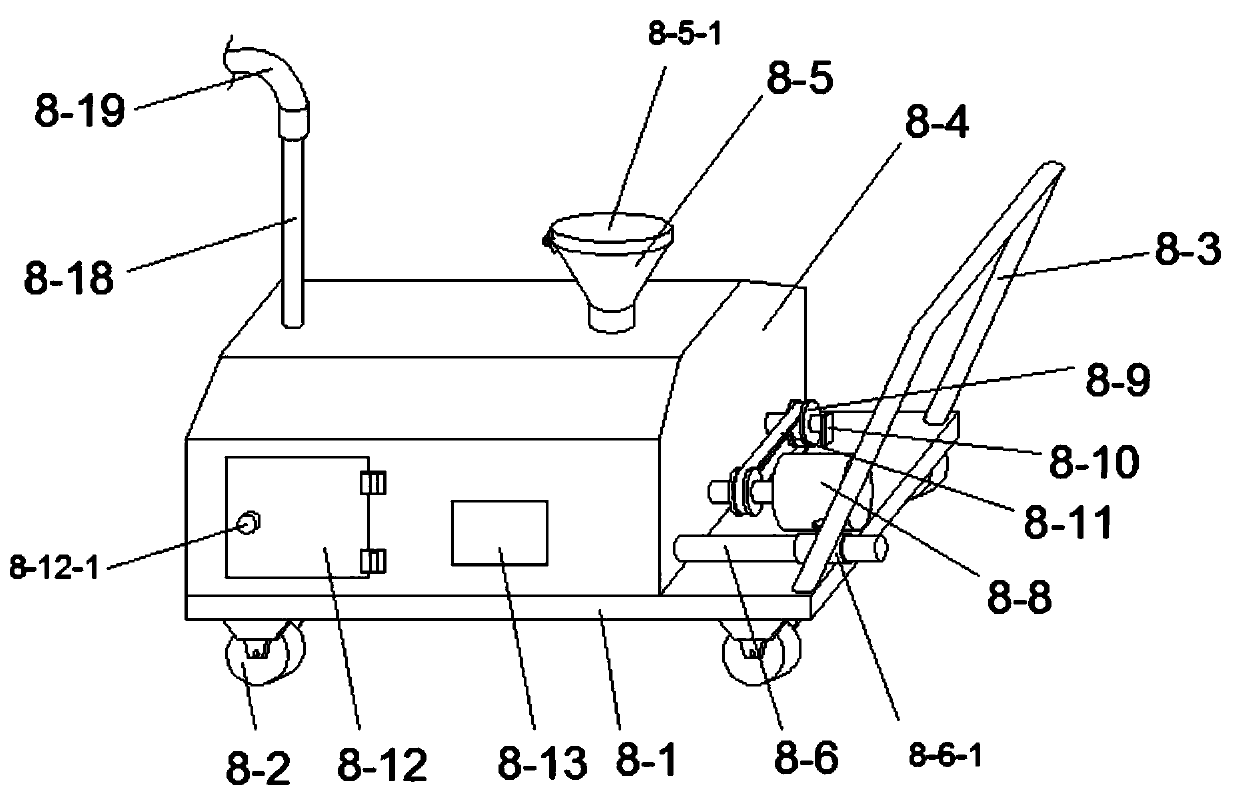

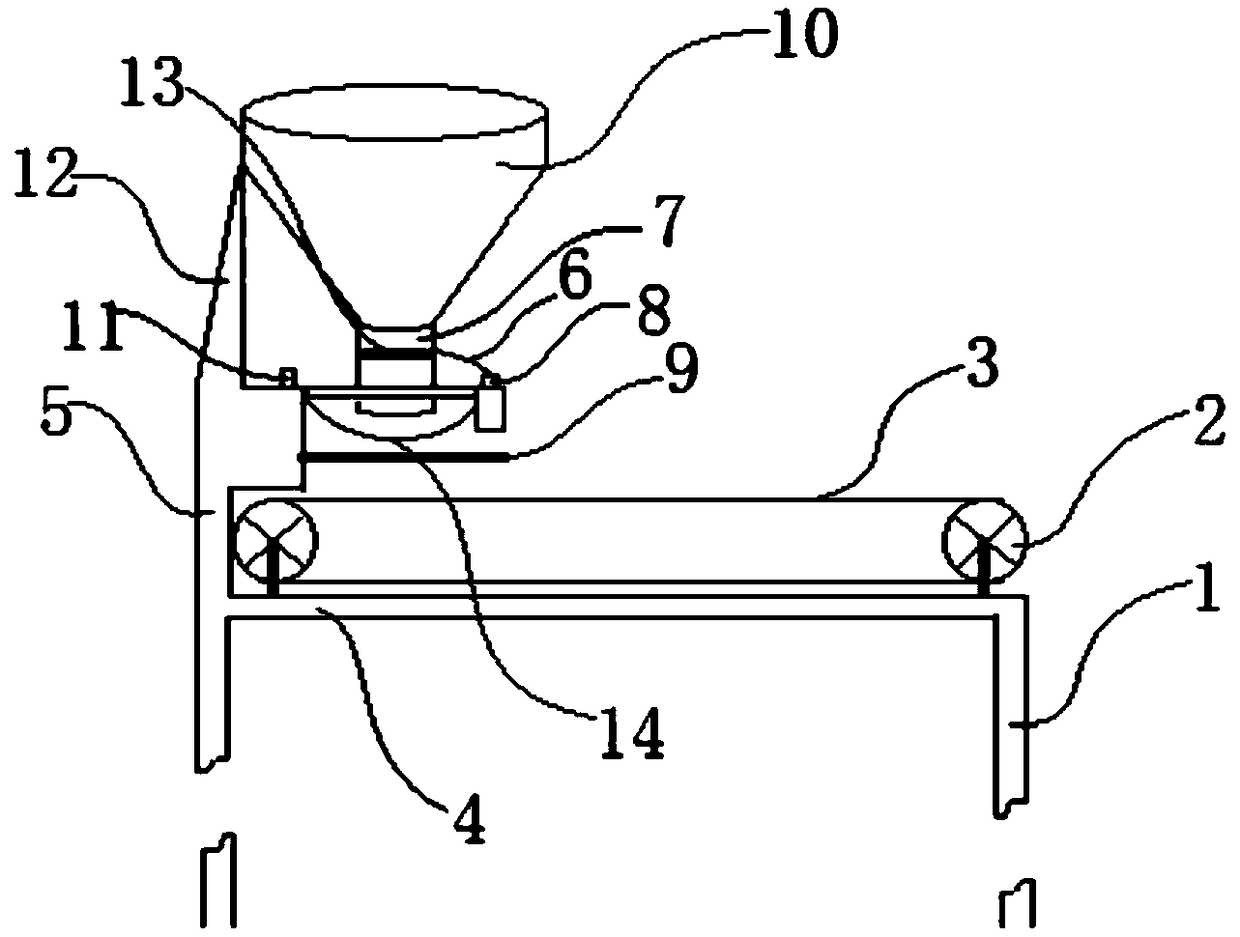

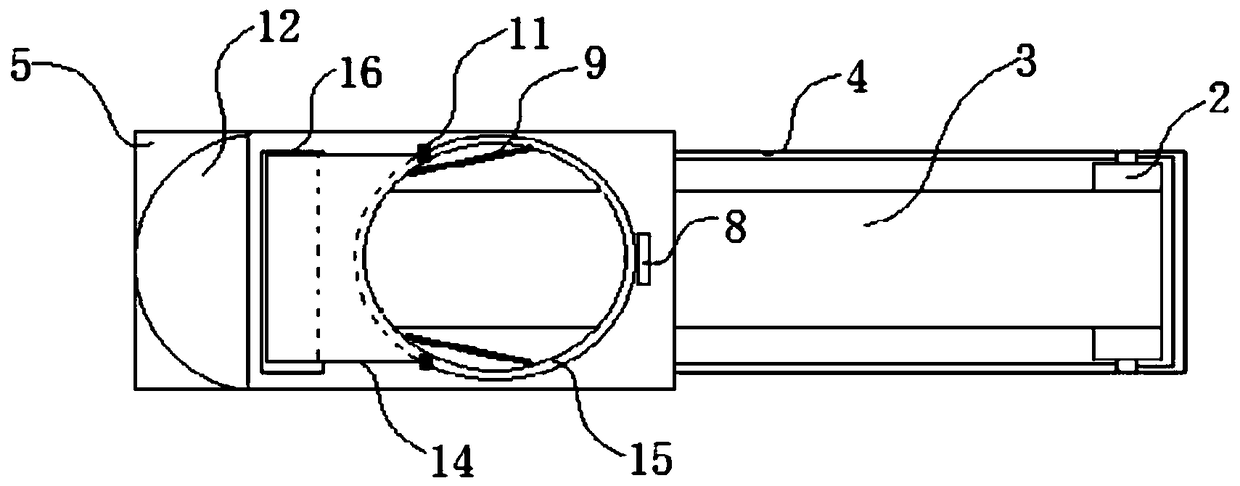

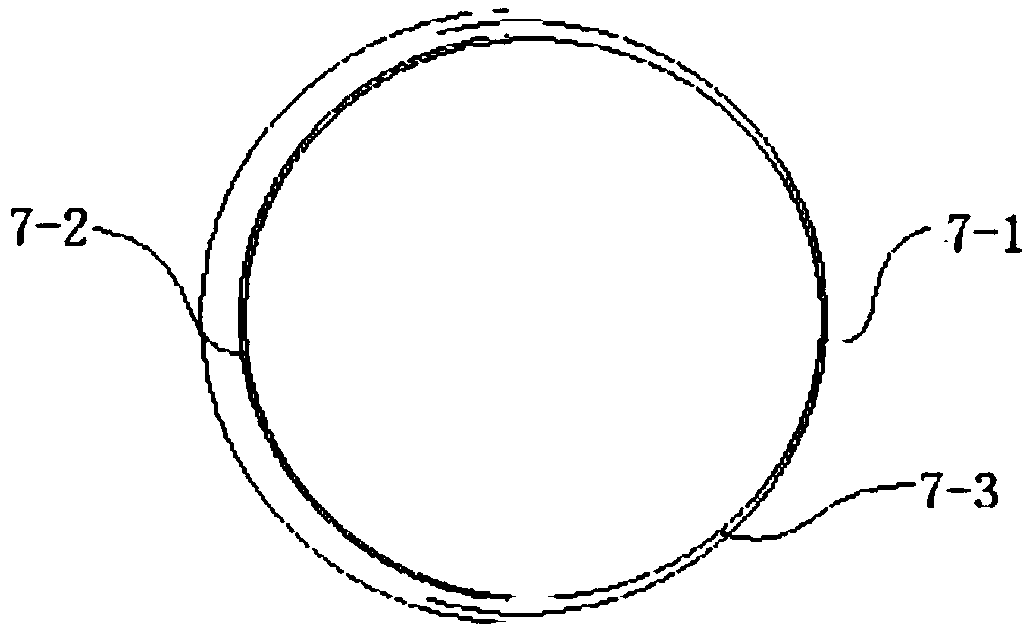

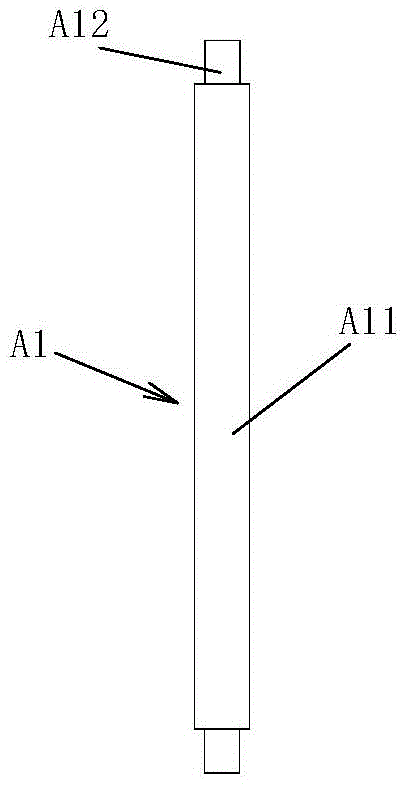

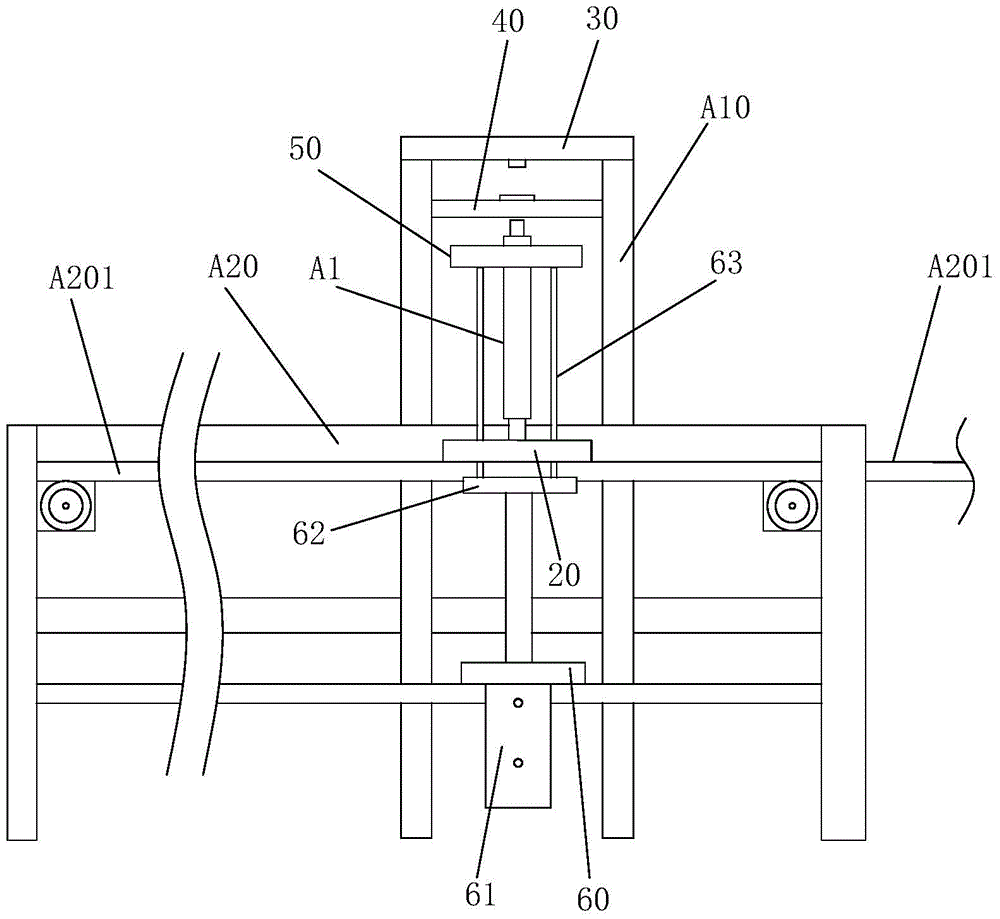

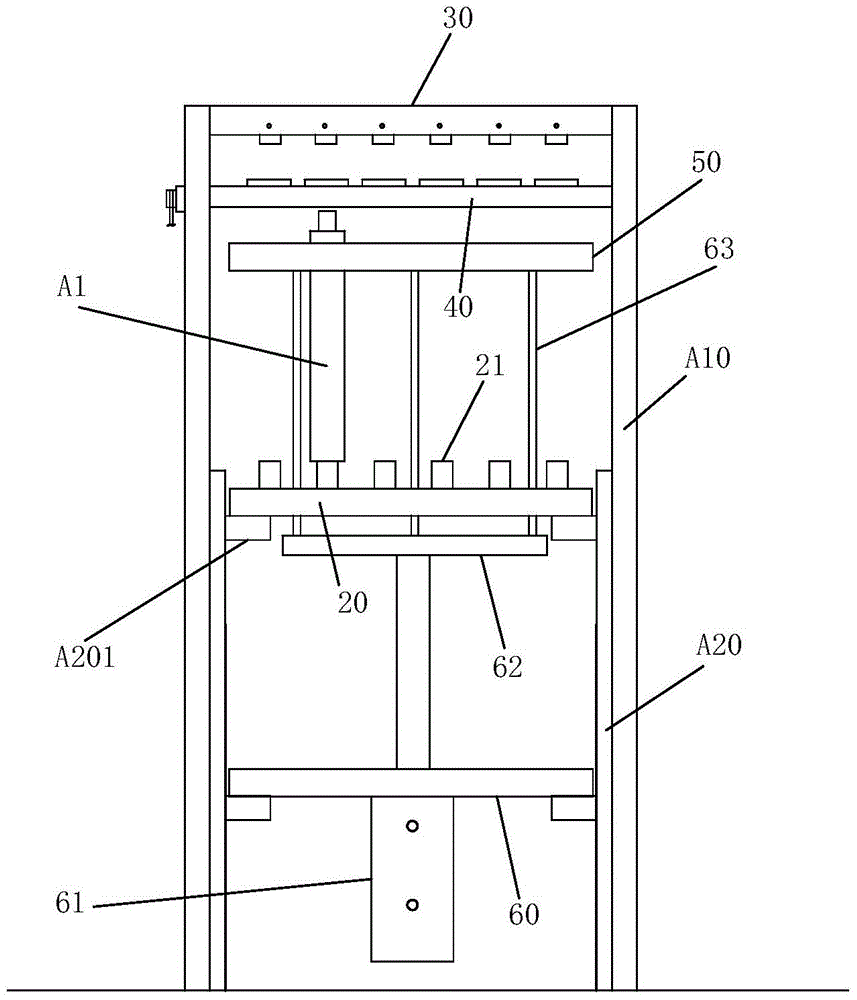

Device and method for coating inner wall of oil casing coupling with anti-friction nano coating

InactiveCN105583126ASimple structureNovel and reasonable designLiquid surface applicatorsCoatingsCouplingReciprocating motion

The invention discloses a device for coating the inner wall of an oil casing coupling with an anti-friction nano coating. The device for coating the inner wall of the oil casing coupling with the anti-friction nano coating comprises a storage mechanism, a feeding mechanism and a workpiece rotating mechanism. The storage mechanism comprises a stirring kettle and a first driving motor. The feeding mechanism comprises a base, a lead screw, a moving block and a second driving motor. A dripping pipe and a coating brush are arranged on the moving block. The workpiece rotating mechanism comprises a driving roller, a driven roller and a third driving motor. The invention further discloses a method for coating the inner wall of the oil casing coupling with the anti-friction nano coating. The method for coating the inner wall of the oil casing coupling with the anti-friction nano coating comprises the following steps that firstly, a workpiece is rotated; secondly, the anti-friction nano coating is evenly stirred; thirdly, the nano coating is brushed while the coating brush moves in a reciprocating mode; and fourthly, drying is conducted. According to the device and method for coating the inner wall of the oil casing coupling with the anti-friction nano coating, the design is novel and reasonable, the device can be obtained conveniently, and the method can be implement conveniently; the application range is wide, and the using effect is good; an oil casing coupling workpiece can be coated with the coating rapidly, and the purpose of improving the viscidity resistance of the oil casing coupling is achieved finally.

Owner:XIAN UNIV OF SCI & TECH

Intrauterine adhesion prevention material

The invention discloses an intrauterine adhesion prevention material, and belongs to the field of medical materials. The intrauterine adhesion prevention material is characterized in that the intrauterine adhesion prevention material is a temperature-sensitive gel; the phase transition temperature of the temperature-sensitive gel is 25-40 degrees; the temperature-sensitive gel consists of a gel main body, a tissue affinity agent, a humectant, a gelling temperature regulation agent and pure water; the gel main body is one or several of poloxamer 407, a polylactide acid / glycolic acid / polyethylene glycol copolymer, poly(N-isopropylacrylamide), chitosan, sodium beta-glycerophosphate, methoxy polyethylene glycol-(sebacic acid-D,L-lactic acid)polyester anhydride-methoxy polyethylene glycol triblock copolymer, cellulose, a cellulose derivative, and polyethylene glycol / polycaprolactone block copolymer; the tissue affinity agent is hyaluronic acid or sodium hyaluronate; the humectant is glycerol or sodium alginate; and the gelling temperature regulation agent is poloxamer 188 or polyethylene glycol. The intrauterine adhesion prevention material provided for people is good in liquidity and can be coated uniformly, and the surface of a wound can be covered quickly and completely.

Owner:广州市弘健生物医用制品科技有限公司

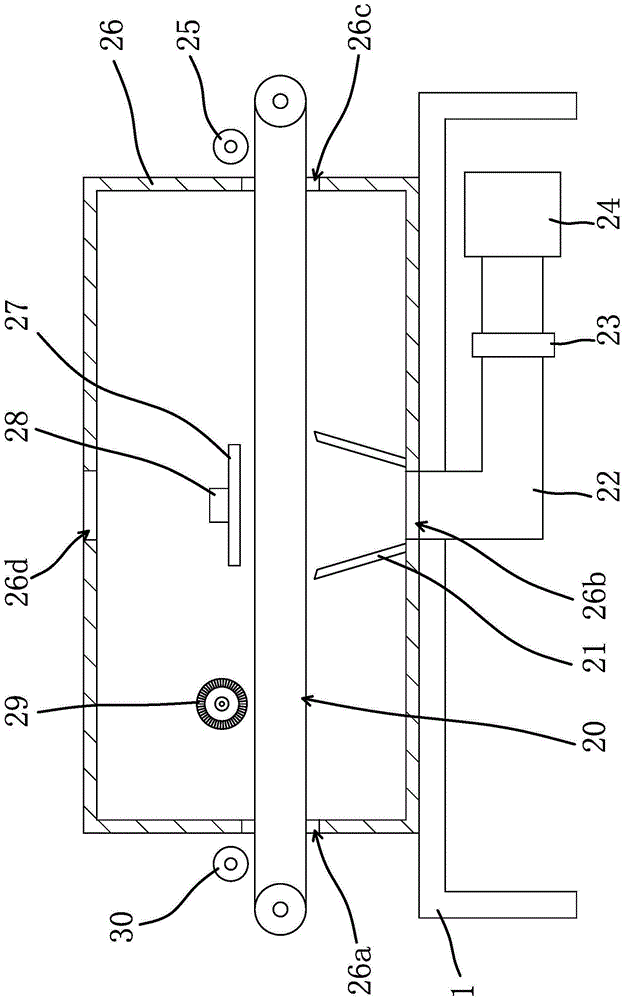

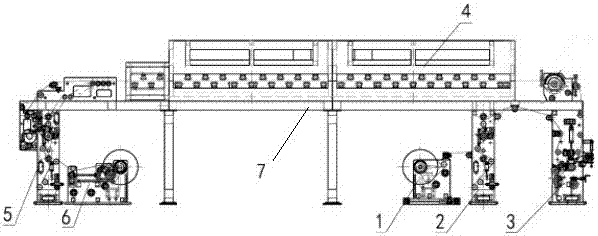

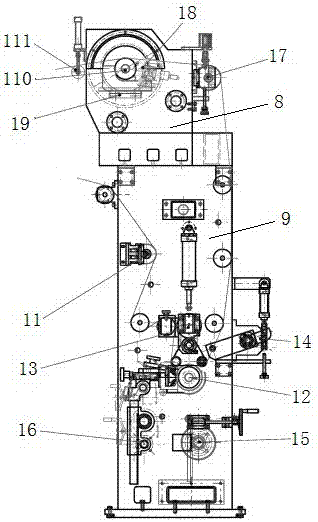

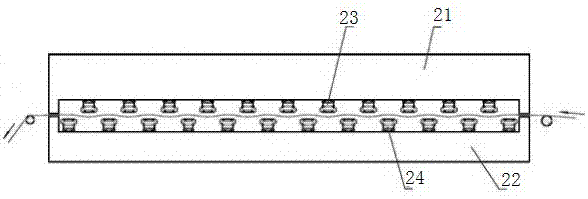

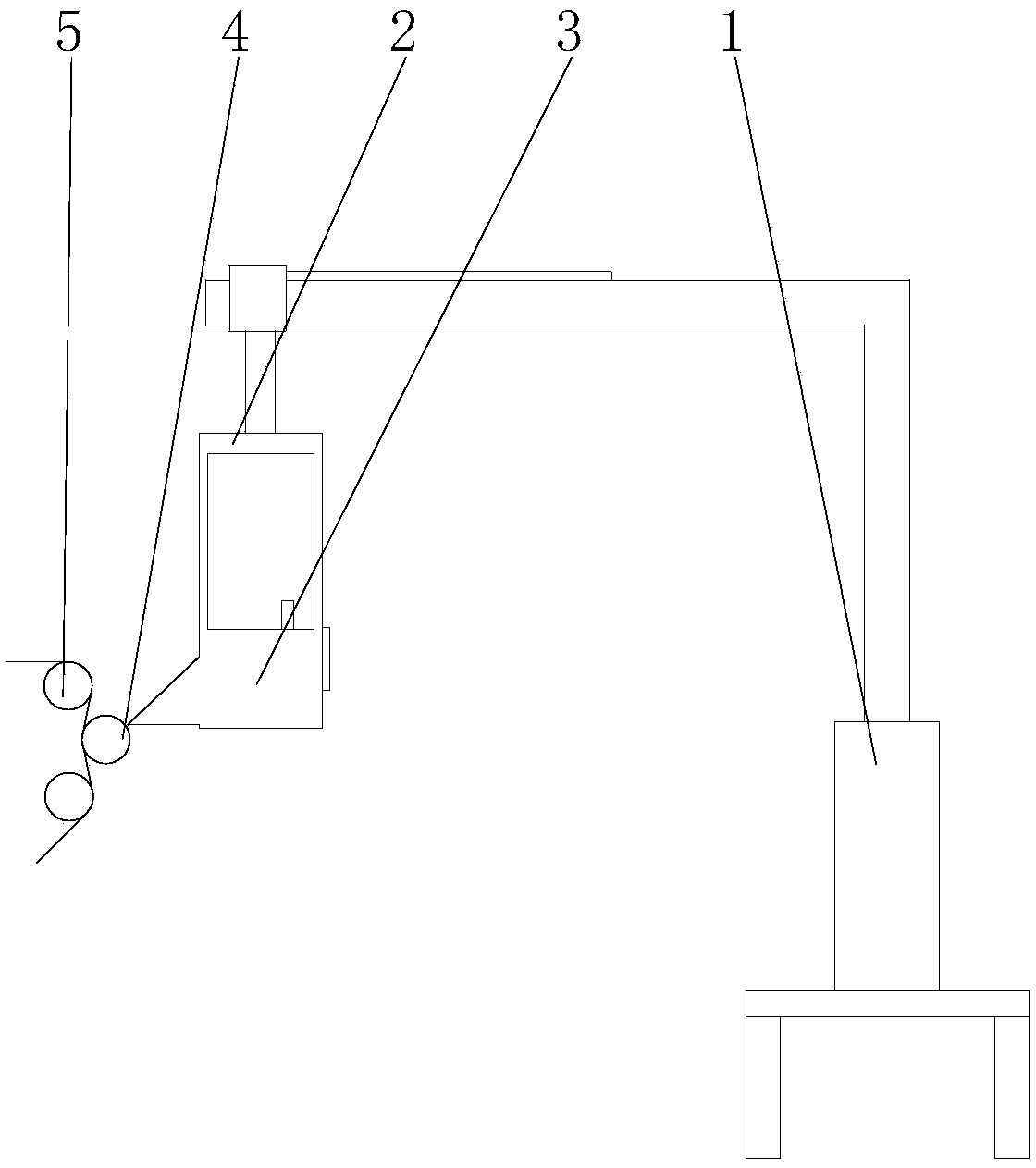

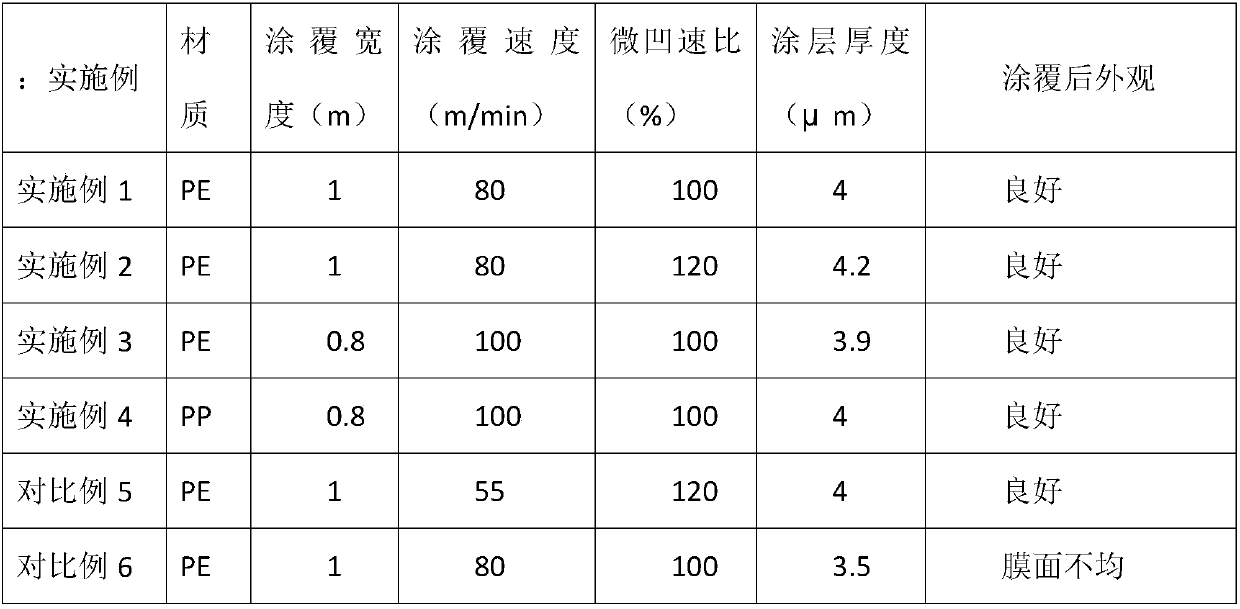

Aluminum foil double-face fast coating device and method

InactiveCN107159524ASave spaceFast coatingPretreated surfacesCoatingsEngineeringStructural engineering

The invention provides an aluminum foil double-face fast coating device. The aluminum foil double-face fast coating device comprises a first frame, an unwinding mechanism, a feeding drawing mechanism, a coating mechanism, a drying oven, a discharging drawing mechanism and a winding mechanism, wherein the unwinding mechanism, the feeding drawing mechanism, the coating mechanism, the drying oven, the discharging drawing mechanism and the winding mechanism are arranged on the first frame. The coating mechanism is a double-face ladder type coating mechanism which comprises a front side coating mechanism body and a back side coating mechanism body. The drying oven is a suspension drying oven. Aluminum foil sequentially passes through the unwinding mechanism, the feeding drawing mechanism, the coating mechanism, the drying oven, the discharging drawing mechanism and the winding mechanism, and then double-face coating is completed. An aluminum foil double-face fast coating method sequentially comprises the steps of unwinding, front side coating, back side coating, double-face drying and winding. According to the aluminum foil double-face fast coating device and method, through the ladder type one-time front side and back side coating and one-time double-face drying technologies, the material conveying path is greatly shortened, fast coating is achieved, the coating speed can reach 150m / min, in addition, the double faces are dried at a time after being coated, the space of the drying oven is saved, the manufacturing cost is reduced, meanwhile, energy is saved by about 160KW / h, and the aluminum foil double-face fast coating device and method are suitable for gravure coating and reverse kiss coating.

Owner:XIAN XINDA MACHINERY

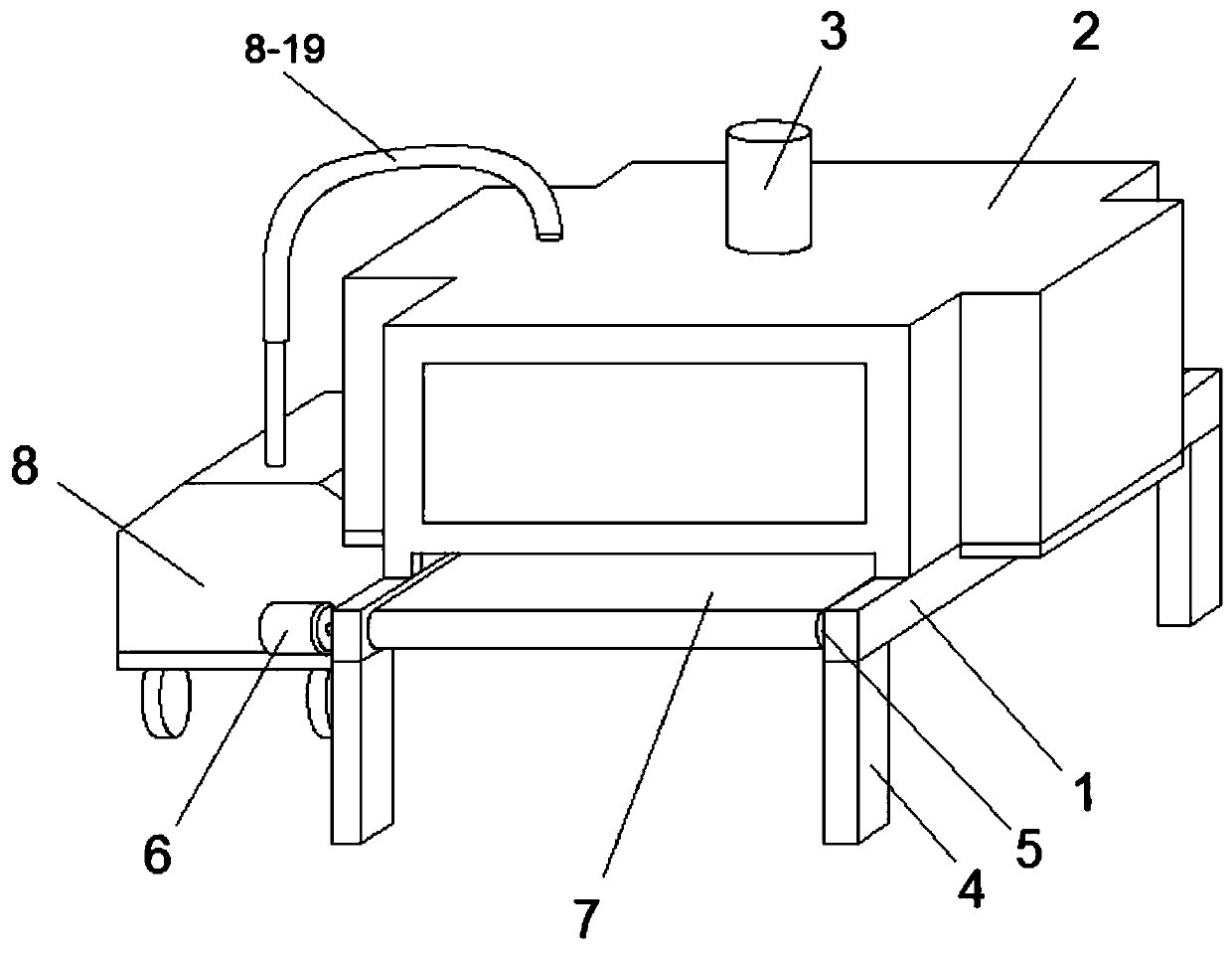

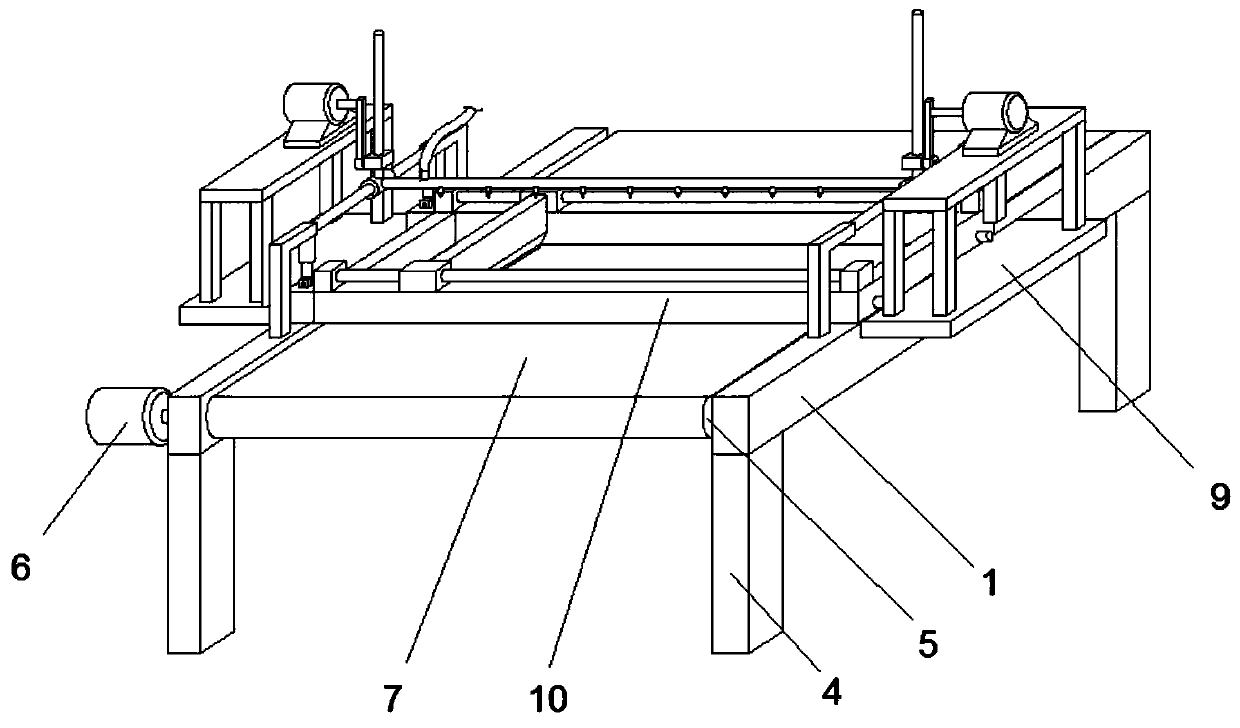

Coating device used for special coating glass fiber cloth preparation

ActiveCN110013930AImprove cleanlinessIncreased flexibility of useSpraying apparatusEngineeringCoating

A coating device used for special coating glass fiber cloth preparation comprises bottom frames, a shell, an exhaust pipe, column feet, a conveying roller, a transmission motor, a conveyor belt, a paint filling device, a spraying tool and a blade coating tool. The bottom frames are symmetrically arranged. The shell is arranged on the top faces of the bottom frames. Each column foot is arranged onthe lower surface of the bottom frame on the corresponding side. The conveying roller is arranged between the bottom frames on the two sides. The conveyor belt is arranged outside the conveying rollerin a wrapping manner. The paint filling device is arranged on one side of the bottom frames. The spraying tool is arranged above the bottom frames. The blade coating tool is arranged above the conveyor belt. The paint filling device is flexible to use and can clean the inner portion of a liquid storage cavity; and the device is stable in system operation, uniform in blade coating and high in coating efficiency.

Owner:镇江安之盾高温纤维制品有限公司

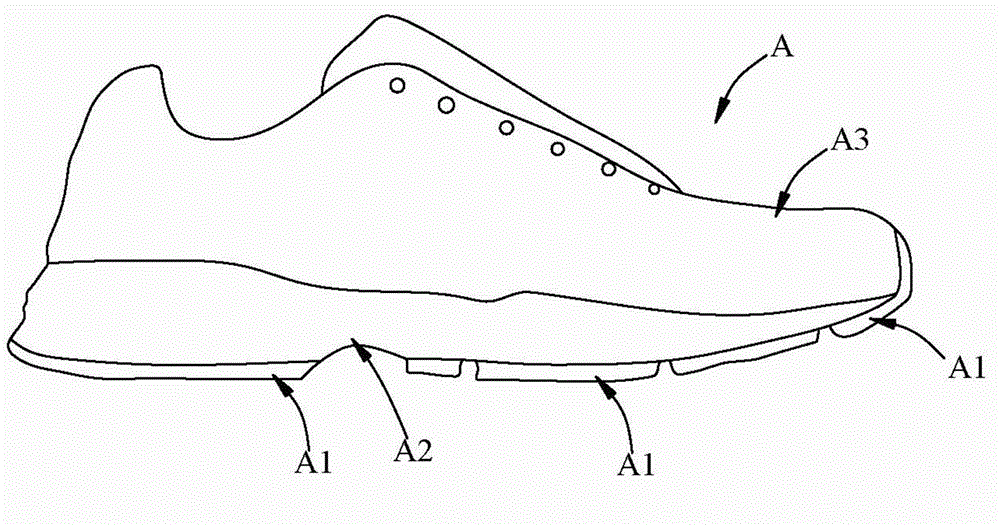

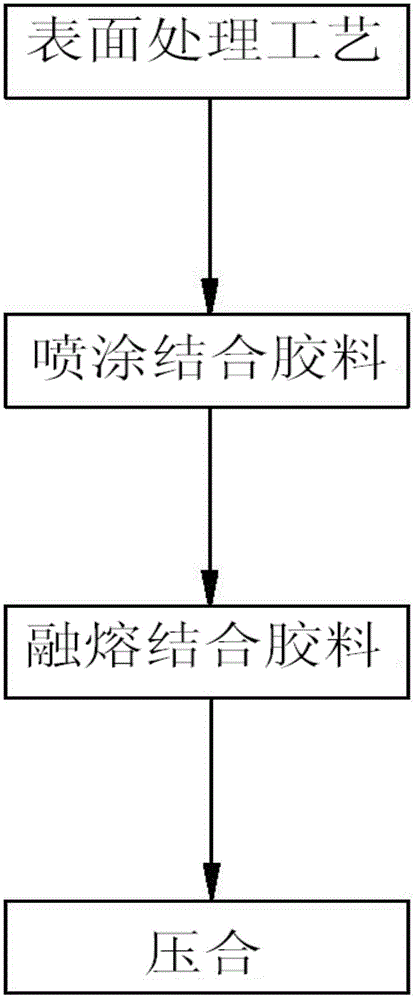

Adhering technique of sole structure

An adhering technique of a sole structure includes the steps of 1, treating surface, to be specific, performing a surface treatment process on joint faces of an outer sole and a mid-sole so that the joint faces form surfaces easy to bond; 2, spraying bonding glue, to be specific, spraying bonding glue in powder to the joint face of the outer sole; 3, meting the bonding glue, to be specific, heating the bonding glue so that the bonding glue attaching to the joint face melts and uniformly locates on the joint face; and 4, preforming press-fitting, to be specific, press-fitting the mid-sole and the outer sole with the joint face of the mid-sole facing the joint face of the outer sole, so that the mid-sole is stably bonded with the outer sole.

Owner:CHERNG TAY TECH CO LTD

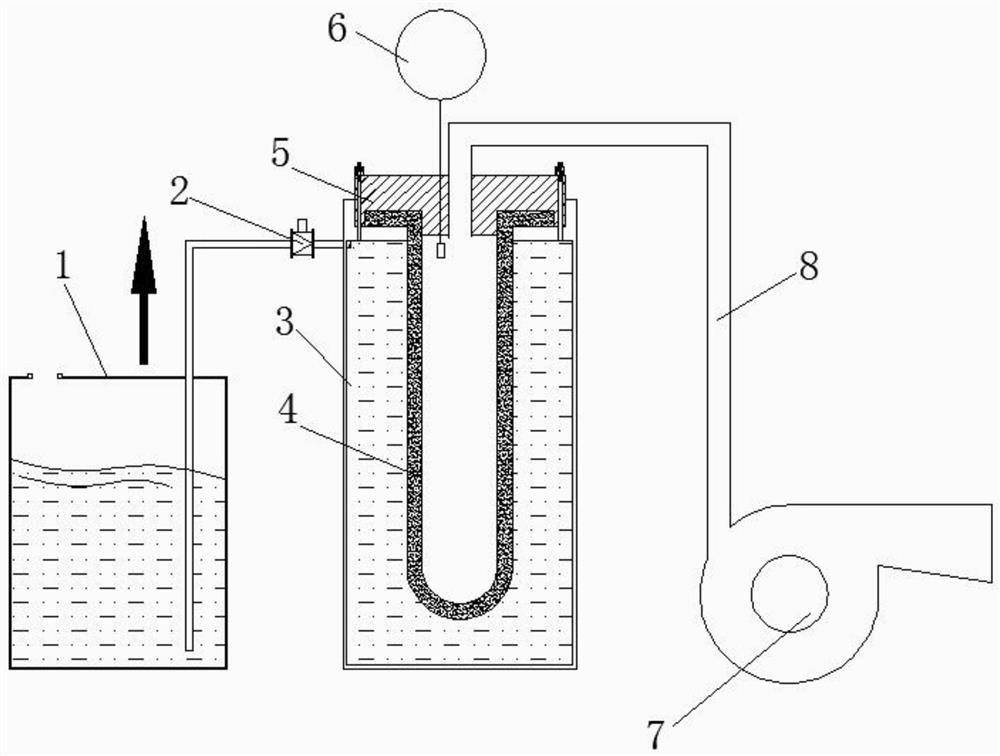

Quick catalyst coating device suitable for ceramic filter pipe

InactiveCN111617927AIncrease profitThoroughly coatedLiquid surface applicatorsCoatingsAutomatic controlControl system

The invention discloses a quick catalyst coating device suitable for a ceramic filter pipe, and belongs to the field of filter pipes. The quick catalyst coating device suitable for the ceramic filterpipe comprises a catalyst stock solution barrel connected with a vacuum chamber through a pipeline, a one-way valve is arranged on the pipeline, the ceramic filter pipe is arranged in the vacuum chamber, a top cover is arranged at the top of the vacuum chamber and fixed at the top of the vacuum chamber through bolts, the ceramic filter pipe is fixed on the top cover, the top cover is connected with a vacuum suction pump through a suction pipeline, and the catalyst stock solution barrel is filled with catalyst stock solution. According to the quick catalyst coating device suitable for the ceramic filter pipe, a vacuum suction technology and an automatic control technology are combined, quick coating of the ceramic filter pipe can be achieved, a liquid level monitoring device installed in the ceramic filter pipe is connected with a control system so that automatic start and stop of the coating of the ceramic filter pipe can be realized, and the whole device is high in catalyst utilization rate, thorough in the coating and short in operation time, and can be used for a mass production process of ceramic catalytic filter pipes.

Owner:安徽紫朔环境工程技术有限公司

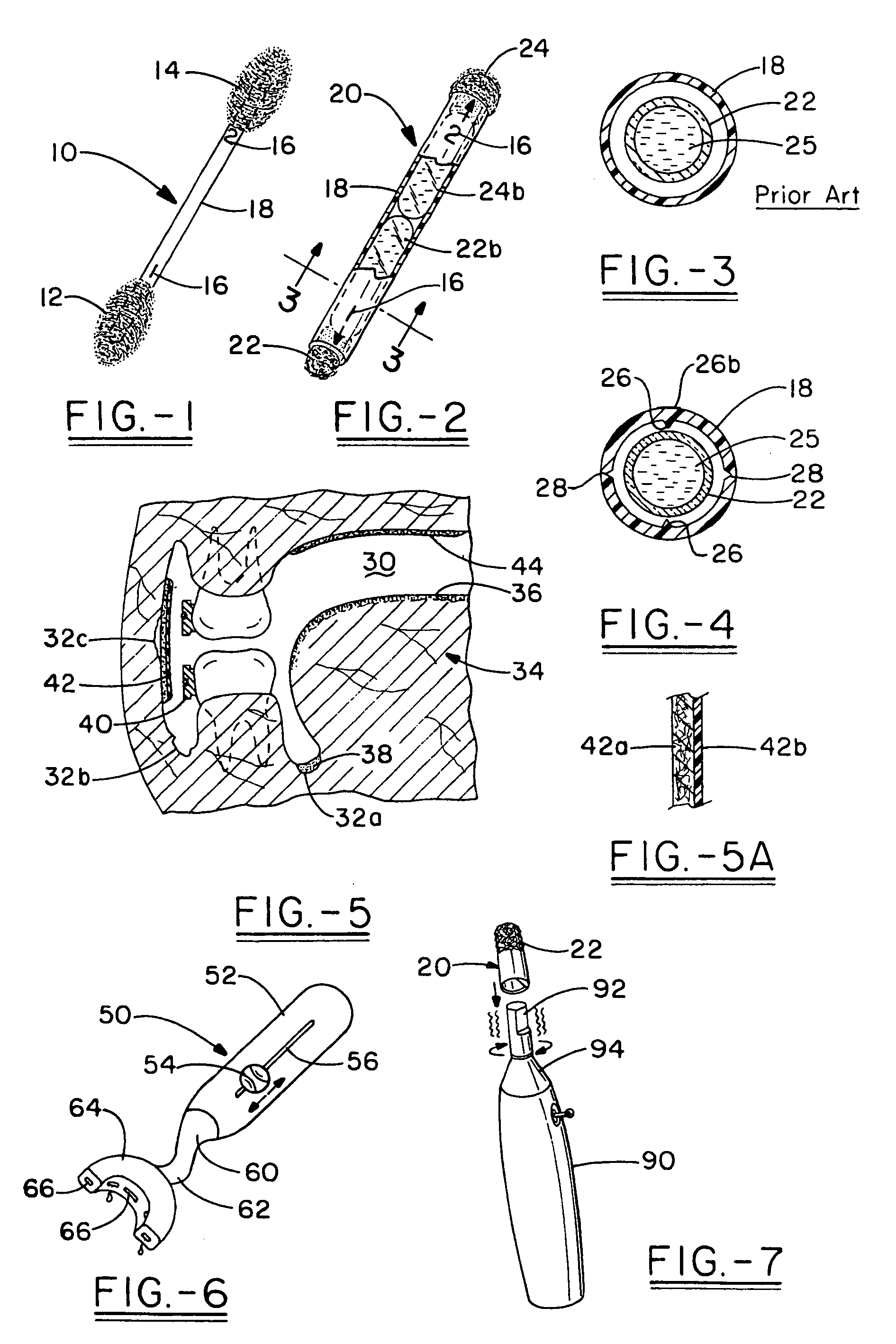

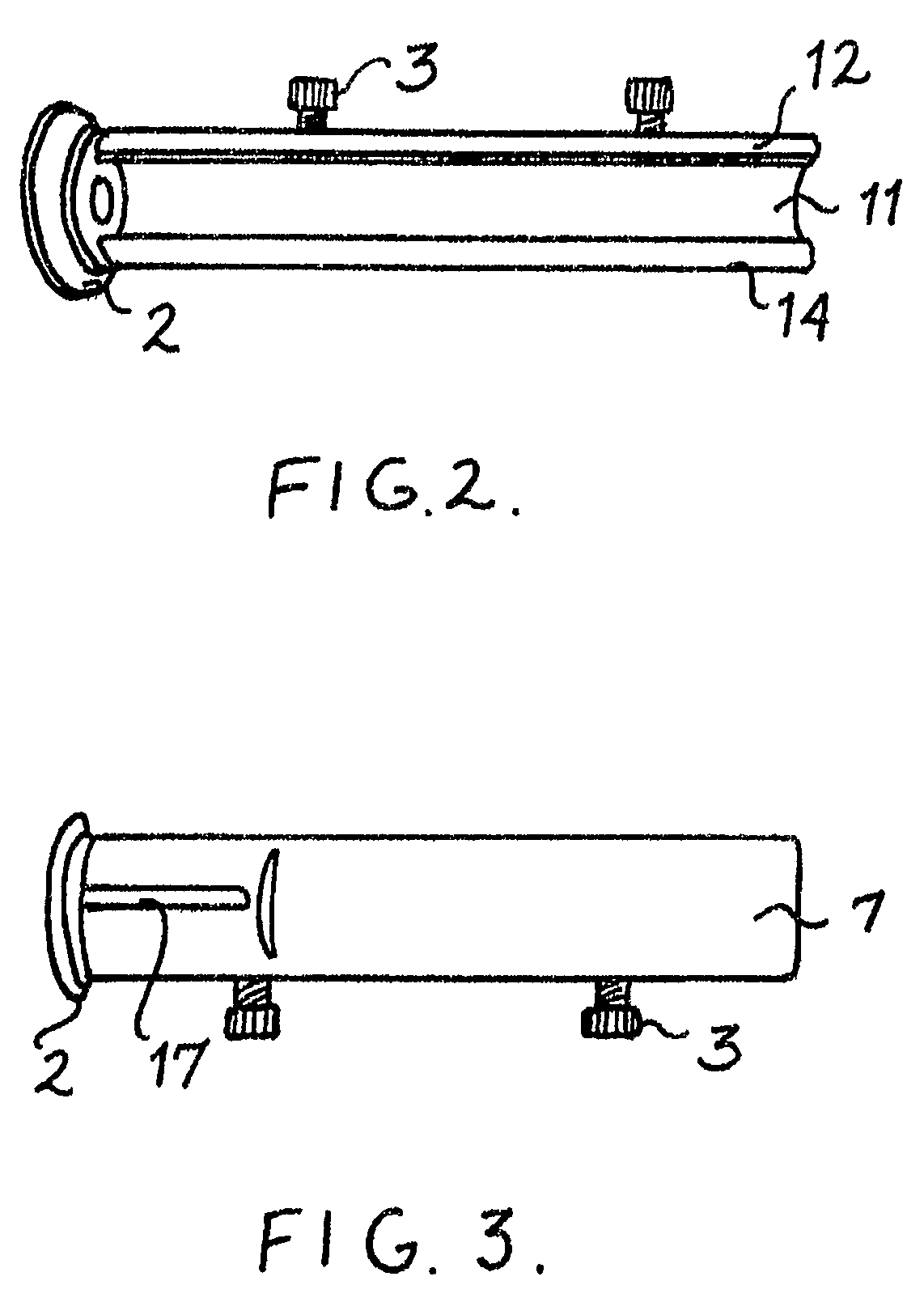

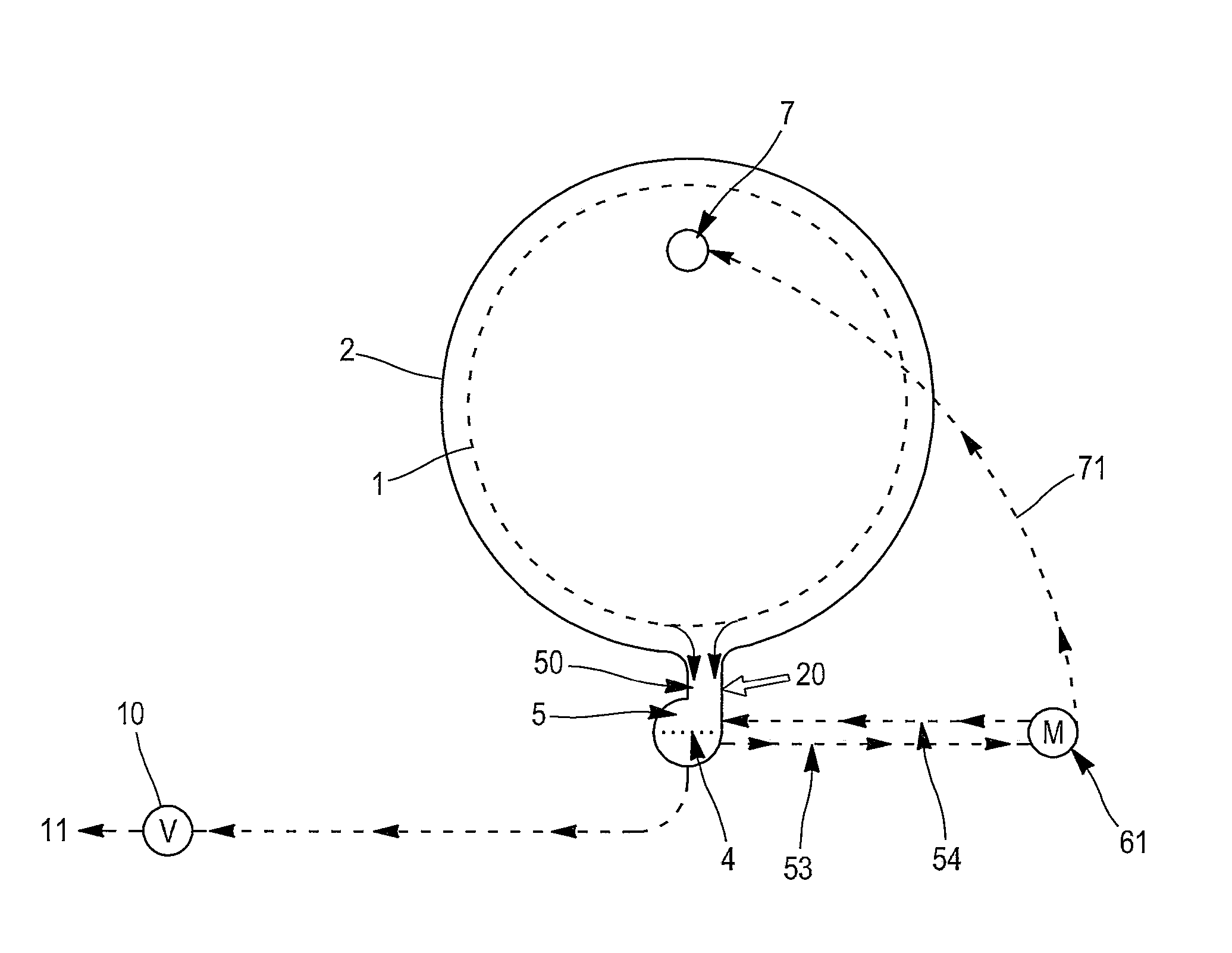

Methods and devices for efficacious treatment of aphthous ulcers

Methods and devices for effectively treating aphthous ulcers are disclosed. The invention employs the removal of the plaque layer of the aphthous ulcer to accelerate healing. Before the plaque layer is removed, the ulcer may be initially anesthetized, by rubbing with an appropriate material and / or compound. Subsequently, an appropriate medicament may be applied to accelerate healing, if desired. The invention teaches the structure and use of applicator / dispenser system employing easily crushable ampoules, containing an aesthetic, and other appropriate medicaments. The invention further teaches the application of slippery surfaces to teeth, teeth appliances, and oral cavity surfaces to inhibit the generation of aphthous ulcers, and to speed their healing. The application, in the form a gel or film, may include a sustained release medicament. Finally, the invention contemplates the use of replaceable and disposable tips for power toothbrushes and the like to aid the treatment of the aphthous ulcers, and the use of dendrimer technology to provide sustained and concentrated local drug action.

Owner:LIN EDWARD D

Method for magnetically and rotatably applying bacteria on culture medium panel

The invention discloses a method for magnetically and rotatably applying bacteria on a culture medium panel. The method comprises the steps of: heating, sterilizing, drying and cooling a magnetic stirring rod to the room temperature for standby application, wherein the length of the magnetic stirring rod is less than the internal diameter of the culture medium panel; arranging the magnetic stirring rod on a central axis of the culture medium panel, dripping a bacterium suspension liquid onto a culture medium through aiming at a central point position of the magnetic stirring rod, and then, covering a petri dish cover; putting the culture medium panel on a magnetic stirring apparatus, driving the magnetic stirring rod to rotate on the surface of the culture medium panel through the magnetic stirring apparatus, and uniformly applying the bacterium suspension liquid on the surface of the culture medium panel; and after the applying is finished, taking the magnetic stirring rod out, and sterilizing and cleaning the magnetic stirring rod for being repeated use. According to the method, the magnetic stirring rod serves as an application tool, and the bacterium suspension liquid is uniformly applied on the surface of the culture medium panel through utilizing the horizontal rotation of the magnetic stirring rod. The non-contact drive of the magnetic stirring rod is ingeniously utilized to apply bacteria in a closed state, so that the bacteria application efficiency is increased, and the operation errors of operators can be reduced.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Axle guide assembly for drywall coating box

An axle guide assembly for a drywall coating box. The axle guide assembly comprises one or more, preferably two, axle guides. Each axle guide is a clip that fits onto an axle of a drywall coating box in order to allow coating mud to be applied to the outside of a corner bead. As the axle guide assembly is slid down the corner bead, mud is applied to the corner bead.

Owner:WATTERS RON

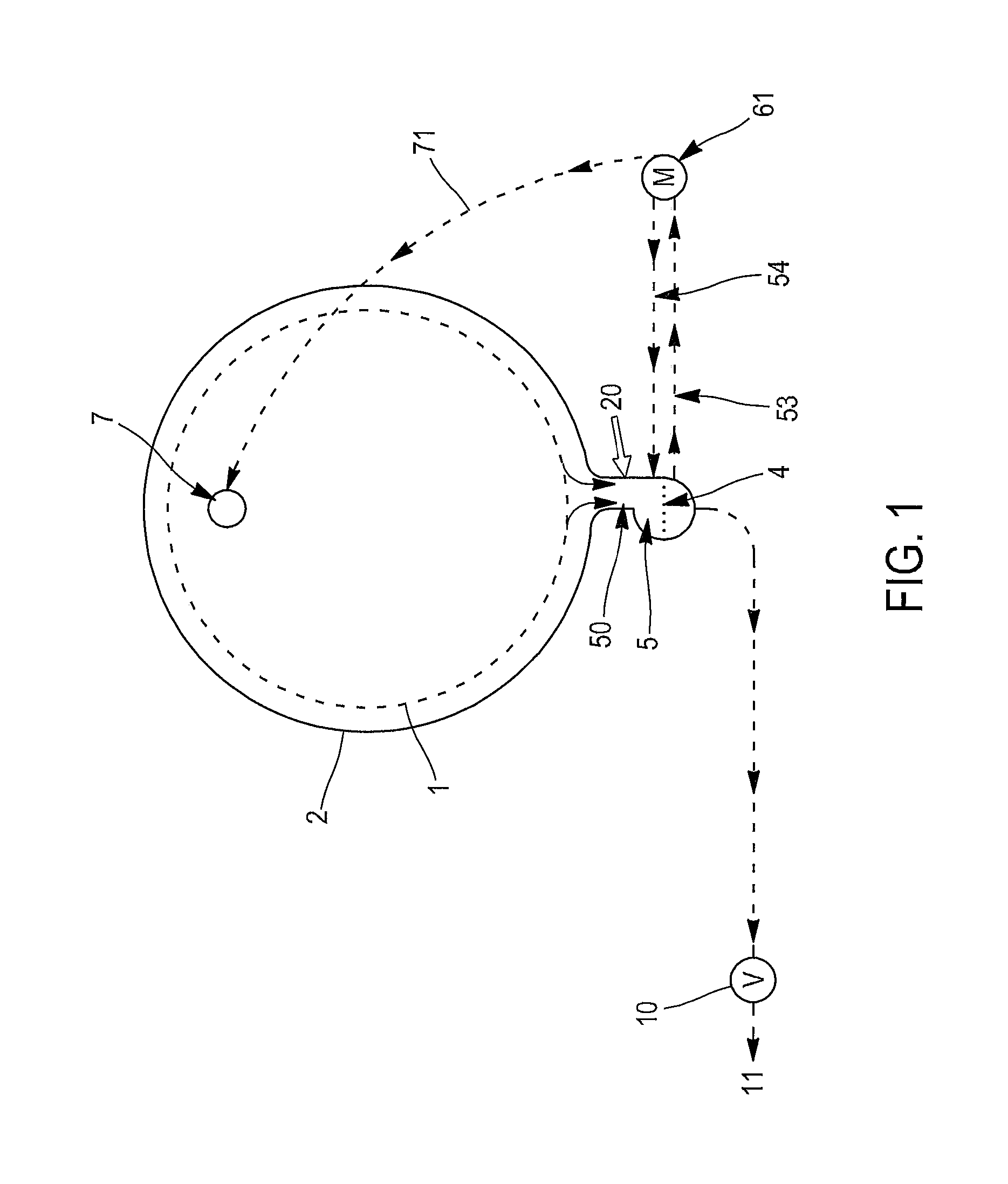

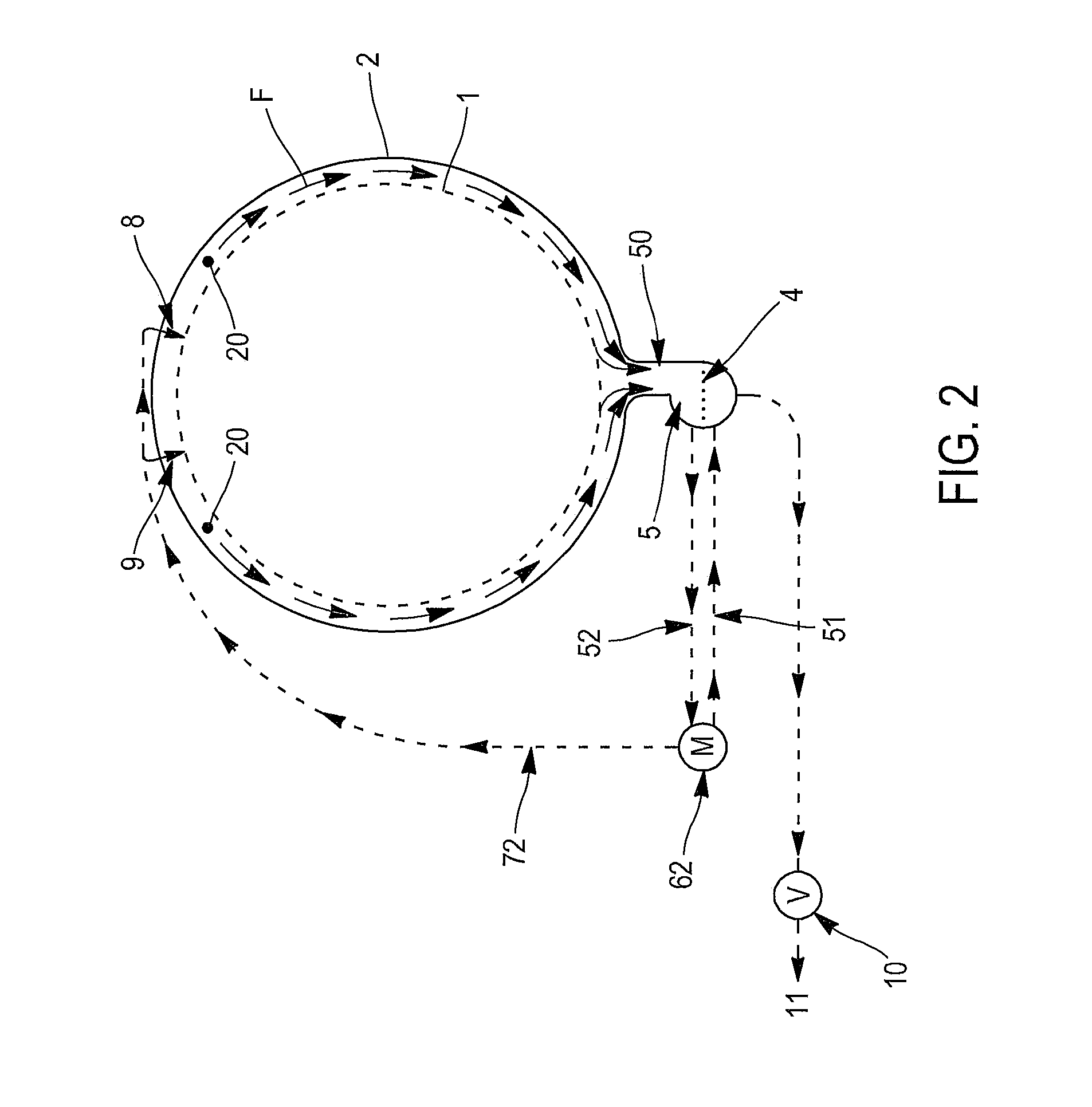

Method and Apparatus for Cleaning Delicate Textiles

InactiveUS20120304394A1Without riskEasy to cleanOther washing machinesDry-cleaning apparatus for textilesChemical compositionEngineering

The invention concerns an apparatus for cleaning delicate textiles, comprising a motorized and rotating drum housed in a fluid tight basket, at least a water inlet and a fluid outlet, at least a first container for a first chemical composition, and a heating means. According to the invention, the first container is appropriate to contain a warm mixture of water and the said first chemical composition, the apparatus comprises at least a conduit cooperating with a circulating means for mixing and circulating the said warm mixture between said first container and said circulating means, a means for injecting or spraying said mixture into said drum and over dry textiles, said circulating means having an inlet for said warm mixture and at least an outlet cooperating with at least a first end of a conduit opening at its second end into the drum. The invention further relates to a method implemented by such an apparatus.

Owner:DAWUDIAN FARIBORZ

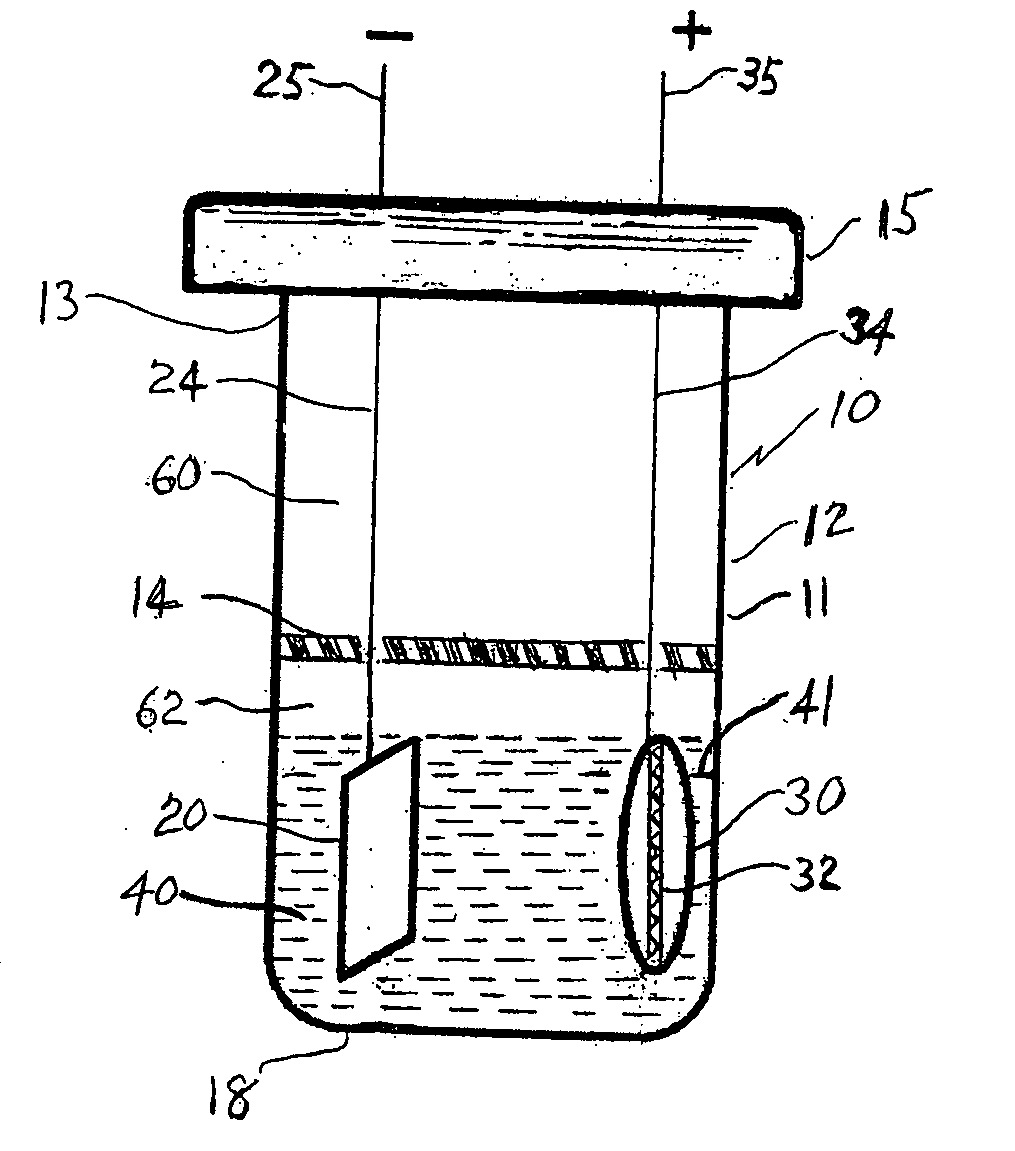

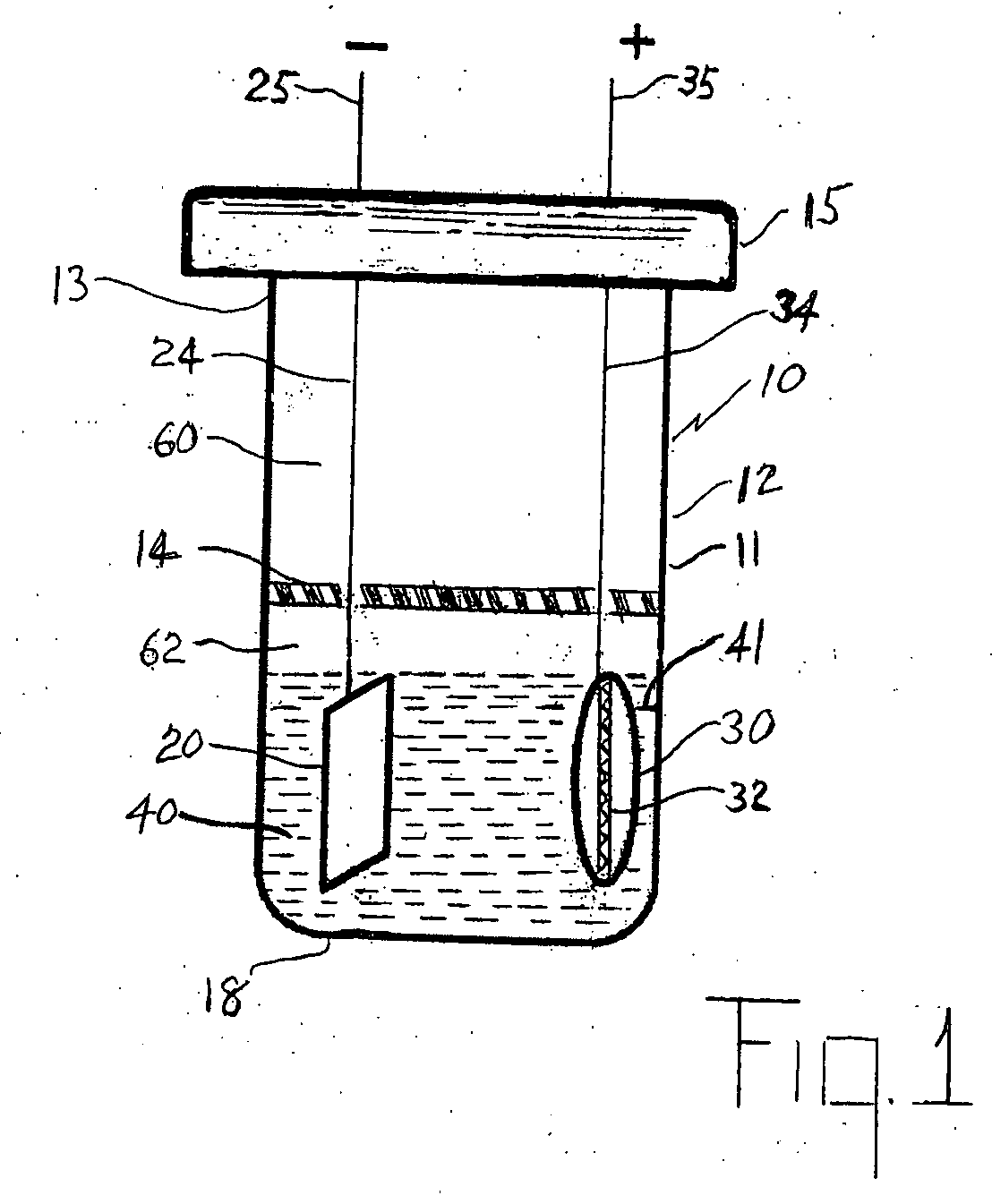

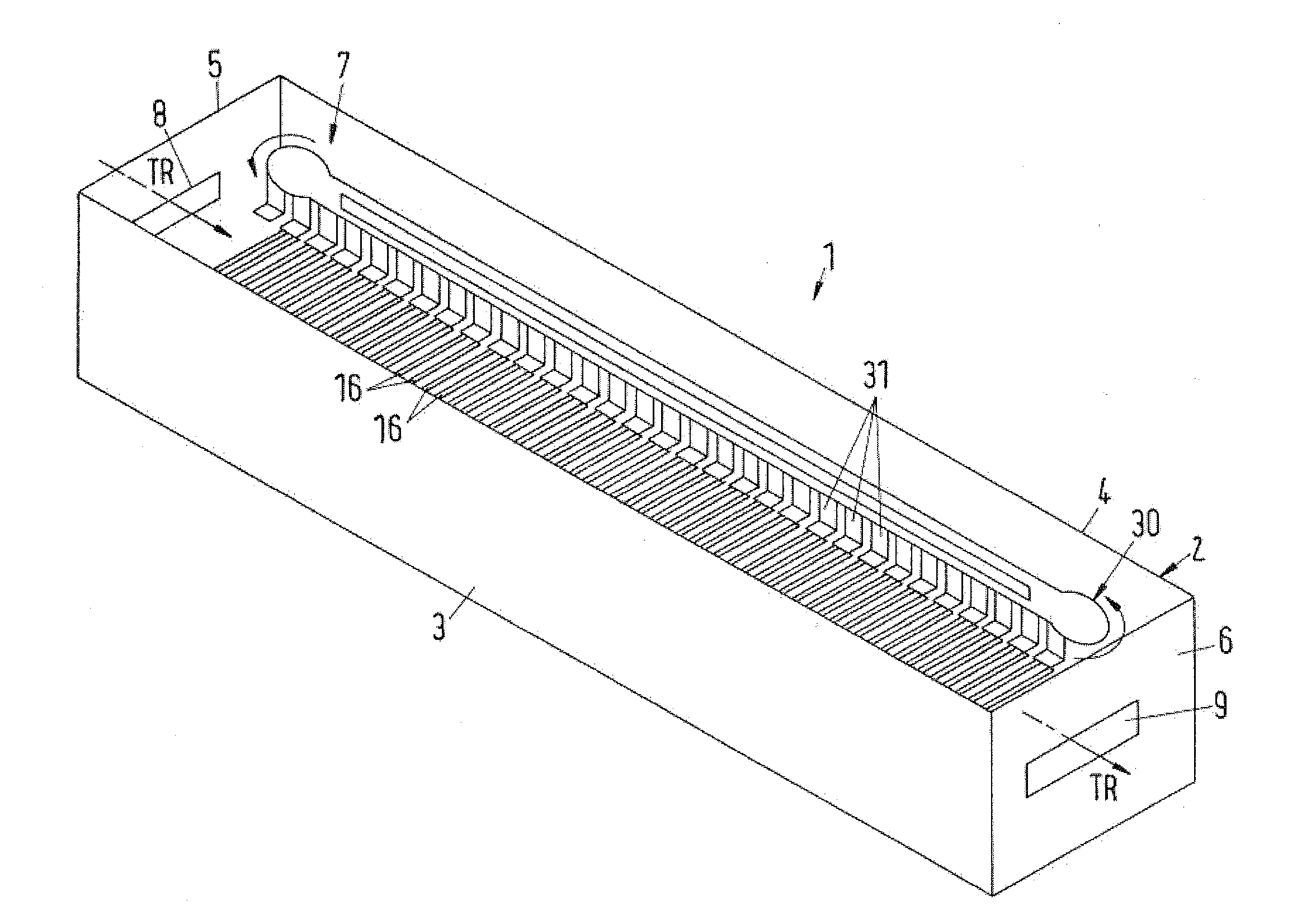

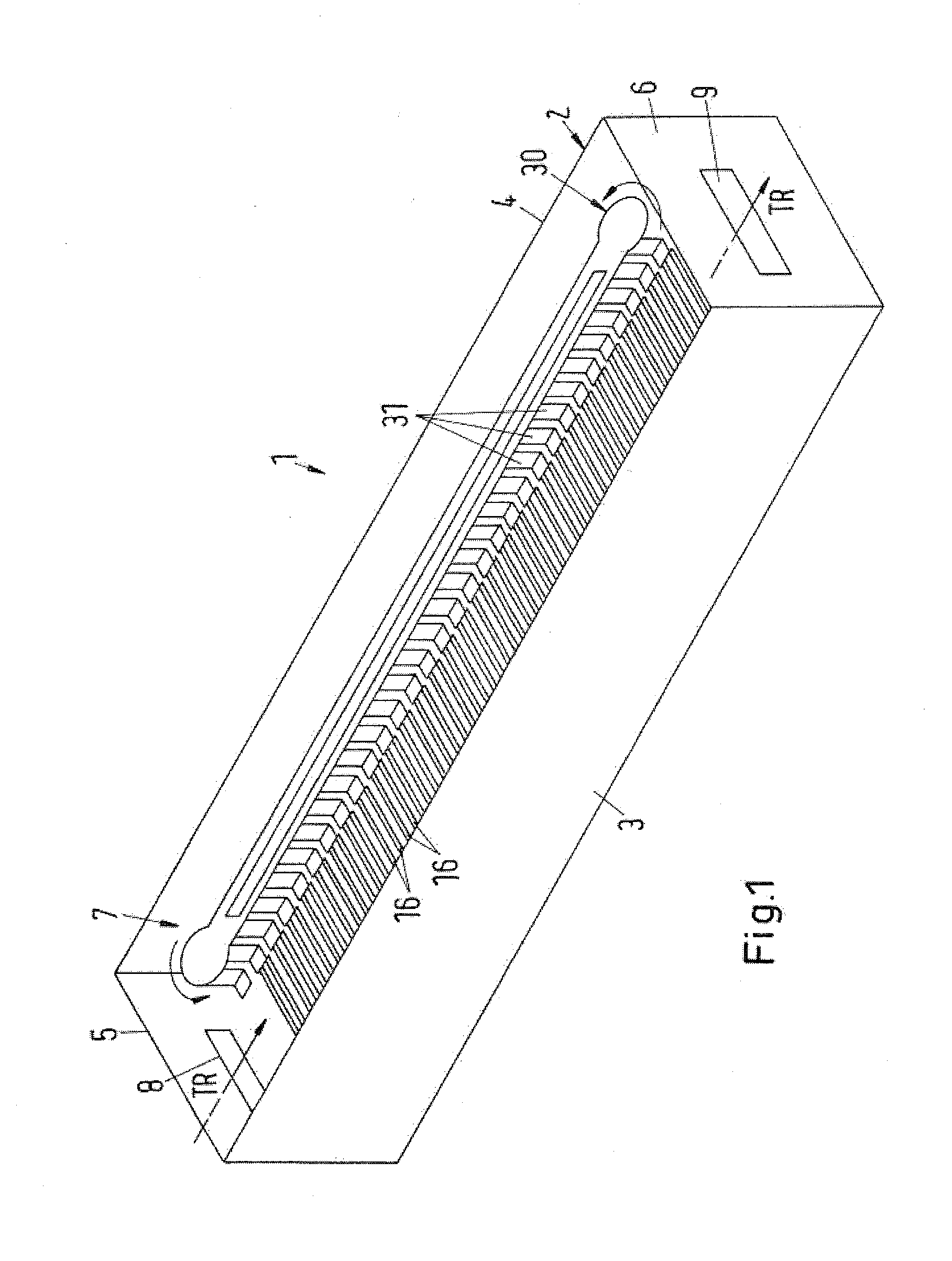

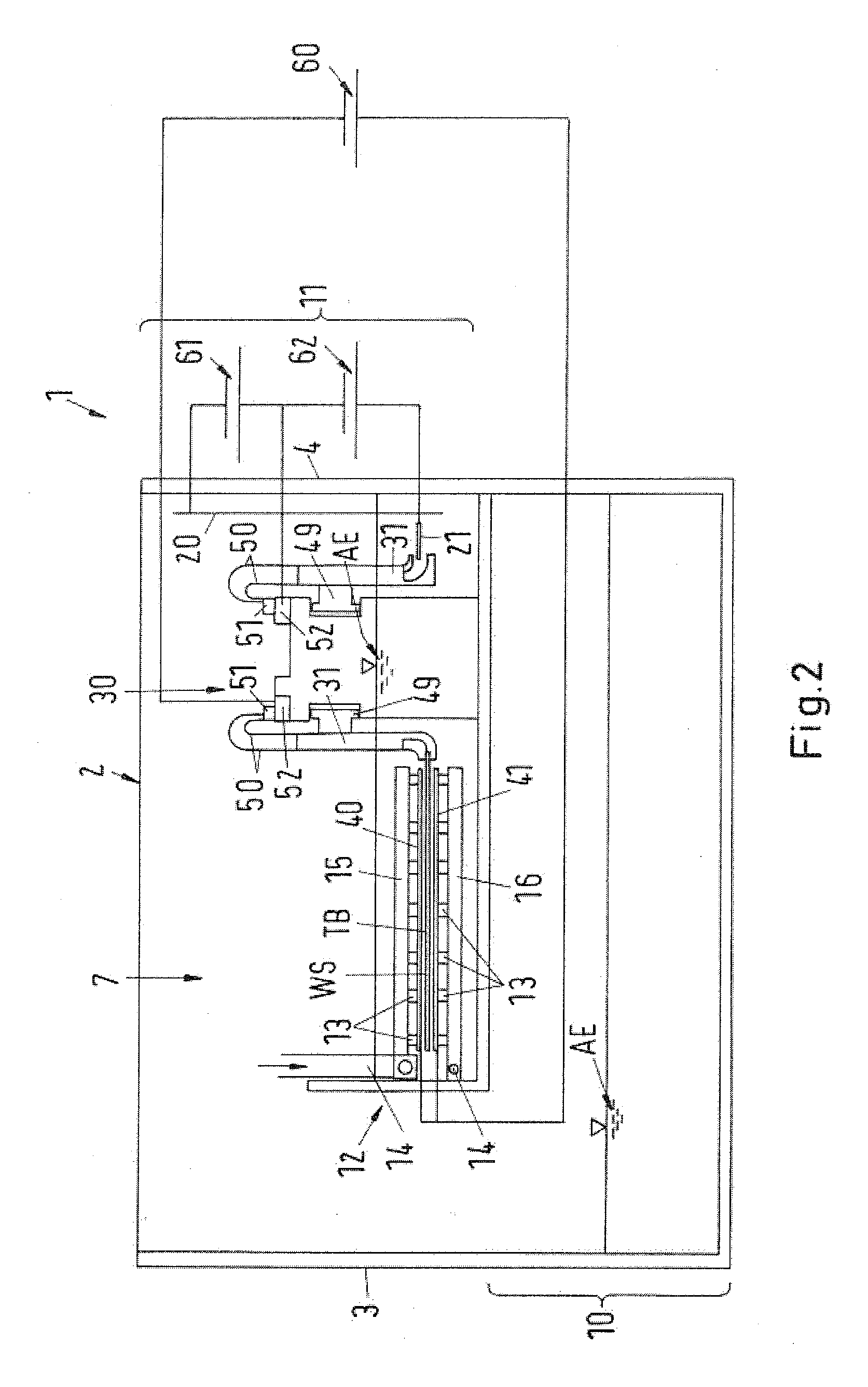

Method and apparatus for electrolytically depositing a deposition metal on a workpiece

For improving the current transfer during the electrolytic metallization of workpieces, a method is proposed: (a) providing a metal depositing apparatus 17, in which the workpiece, at least one anode 40, 41 and a metal deposition electrolyte AE are arranged and which has a device for electric current generation 60 and at least one current feeding device 31 with in each case at least one electrical contact element 34, 35 for making electrical contact with the workpiece; (b) bringing the at least one electrical contact element 34, 35 into contact with the workpiece; and (c) feeding electric current to the workpiece via the at least one electrical contact element 34, 35 in order that the deposition metal deposits on the workpiece. Before method step (b), in a further method step (d), deposition metal is deposited on the at least one electrical contact element 34, 35.

Owner:ATOTECH DEUT GMBH

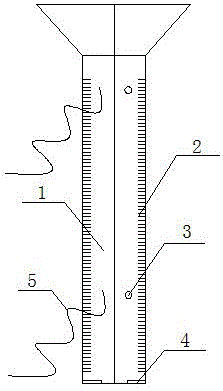

Cherry tree coating device

The invention discloses a cherry tree coating device. The cherry tree coating device comprises a cylindrical pipe body, wherein a funnel-shaped opening part is formed in the top of the pipe body; an opening is formed in the side surface of the pipe body along the axis direction of the pipe body; cilium is distributed on the inner surface of the pipe body; a tether and a stud matched with the tether are arranged on the pipe body; and the tether and the stud are fixed on two sides of the opening in the surface of the pipe body. The device disclosed by the invention is simple in structure and convenient to use, and is capable of rapidly coating trees and ensuring the coating uniformity.

Owner:SICHUAN GUANTENG TECH CO LTD

Electric field coating process of ultrafiltration membrane

ActiveCN106693715AReduce pollutionReduced backwash resistanceSemi-permeable membranesElectrophoretic coatingsModified ultrafiltrationUF - Ultrafiltration

The invention relates to an electric field coating process of an ultrafiltration membrane. The electric field coating process of the ultrafiltration membrane belongs to the technical field of water treatment membrane preparation, and comprises the steps of placing coating liquid containing negative charge TiO2 in a coating pond; immersing an ultrafiltration membrane component and a stainless steel plate electrode in the coating liquid; respectively connecting the ultrafiltration membrane component and the stainless steel plate electrode to positive and negative electrodes of a direct-current power supply; carrying out electric field coating under the electric field intensity being 30V / cm to obtain a coating modified ultrafiltration membrane with a TiO2 granular layer on the ultrafiltration membrane surface based on the ultrafiltration membrane component. The prepared modified ultrafiltration membrane can separate a colloidand a macromolecular organic compound, playing a leading role on membrane pollution, from a membrane surface by depending on the functions of adsorption and interception of a precoated layer on a pollutant, so that the membrane pollution is greatly reduced. During backwashing, the pollutant falls off from the membrane surface along with the precoated layer, the backwashing resistance of the membrane is reduced, and a backwashing effect is improved.

Owner:YANGZHOU UNIV

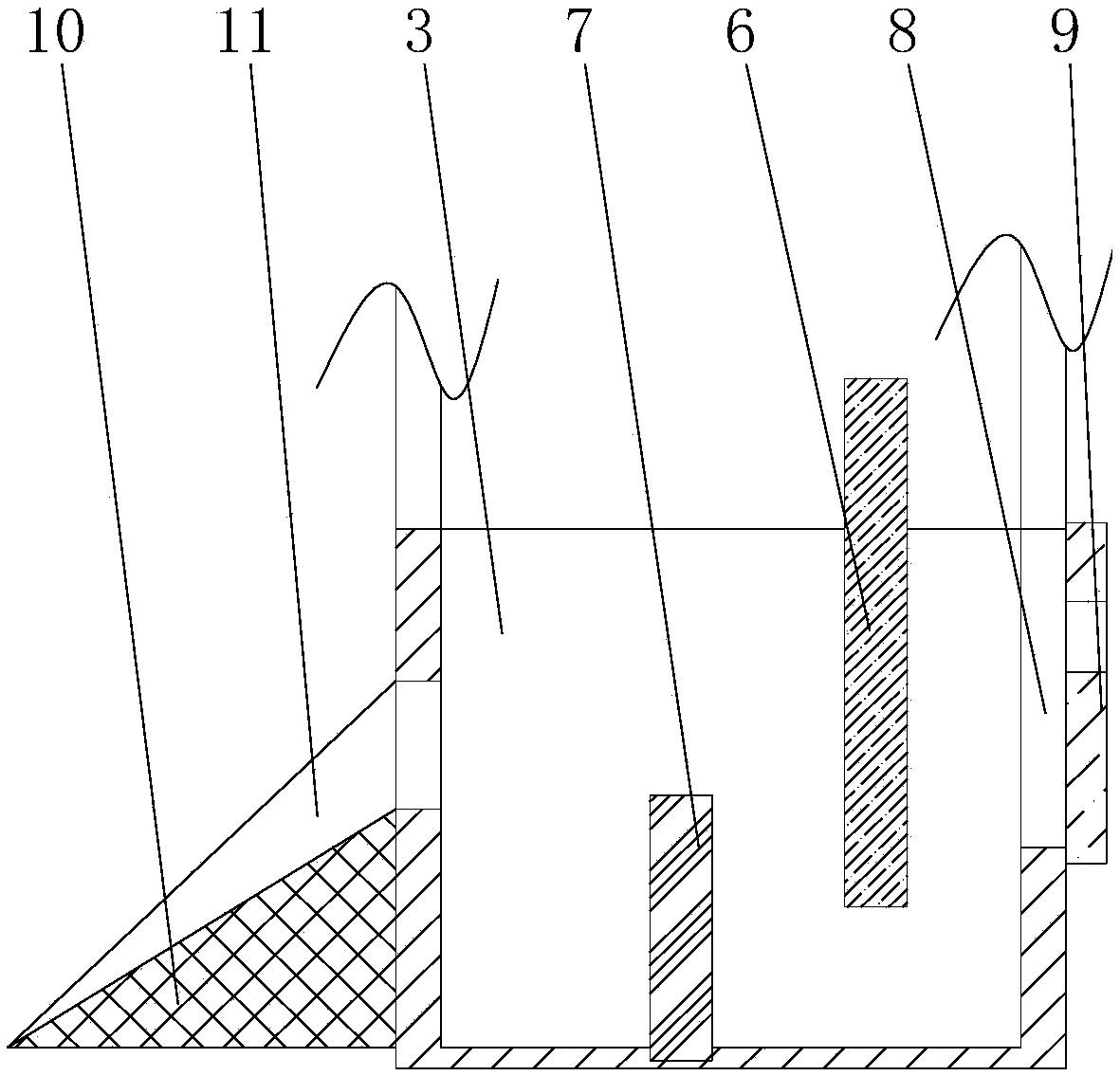

Diaphragm coating device

InactiveCN107930975AReduce wear and tearFast coatingLiquid surface applicatorsCoatingsEngineeringSlide plate

The invention discloses a diaphragm coating device. The diaphragm coating device comprises a liquid storing groove, an anilox roller and a guide roller, wherein the anilox roller and the guide rollerare arranged at the lower side of the liquid storing groove; a slide plate is arranged at one side, close to the anilox roller, of the liquid storing groove; edge guide plates are arranged at two sides of the slide plate; an overflowing groove is formed in the rear side of the liquid storing groove; a liquid baffle plate is in slide connection with the liquid storing groove in the rear side of theoverflowing groove. The diaphragm coating device has the beneficial effects that a coating manner integrating slope current and a micro concave roller is performed, and a scraping knife is not used,so that the abrasion loss of the micro concave roller can be effectively decreased, and the coating can be quickly carried out; the device is simple in structure, low in manufacturing cost, and convenient to maintain and clean in later period; in addition, the slurry is transferred through the micro concave roller, so that the thickener control range of a coating layer is wide, and as a result, the process repeatability is high.

Owner:HEFEI XINGYUAN NEW ENERGY MATERIAL CO LTD

Plum film coating fresh-keeping machine

PendingCN109018492ANot easy to damageContinuous film preservationWrappingFruits/vegetable preservation by coatingPreservativePrunus

The invention relates to the technical field of plum film coating, in particular to a plum film coating fresh-keeping machine. A fruit bin is arranged, a fruit leakage pipe is arranged at the bottom of the fruit bin, film covering treatment is adopted below the fruit leakage pipe, a shear is arranged, after plum fruits fall down, the plum fruits are preserved through a preservative, placed into the fruit bin, leaked downwards through the fruit leakage pipe, under the self gravity effect of the fruits, films fall down and wrap the plum fruits gradually, after the films fall down to the positionbelow the shear, the shear extrudes, seals and shears the films, the plum fruit film coating fresh-keeping process is completed, and the adopted plum film coating fresh-keeping machine is simple in structure, convenient to operate and capable of continuously wrapping multiple plum fruits.

Owner:沿河丽恒生态农牧科技发展有限公司

Anode bar brushing equipment

ActiveCN105032687AFast coatingImprove quality and efficiencyLiquid surface applicatorsCoatingsWear resistantSpray nozzle

The invention discloses anode bar brushing equipment. An in-place detection device is arranged at the joint of a bracket and a frame; a sensor for detecting the position of a movable cross beam is arranged above the bracket; ring-shaped spray heads are arranged on the inner sleeve walls of sleeves; the ring-shaped spray heads are wrapped with wear-resistant sponge sleeves; each ring-shaped spray head comprises a ring-shaped pipe and first and second spray nozzles which are arranged on the ring-shaped pipe at intervals in a staggered way; paint sprayed from the first spray nozzles slantwise flows up to the sides far away from the inner sleeve walls of the sleeves; paint sprayed from the second spray nozzles slantwise flows down to the sides far away from the inner sleeve wall of the sleeves; the ring-shaped pipes are located in the middles of the sleeves; and the liquid outlet of a spray device is connected with the liquid inlets of the ring-shaped pipes respectively through hoses. The anode bar brushing equipment adopting the technical scheme can quickly coat the surface of a bar with paint and improves the coating surface quality and the coating efficiency.

Owner:大庆市中研技术开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com