Atmospheric pressure evaporation method for anti-fouling film, atmospheric pressure evaporation apparatus and device for manufacturing anti-fouling film

A film and normal pressure technology, applied in the field of film manufacturing, can solve problems such as repeated coating and poor uniformity of anti-fouling films, and achieve the effects of rapid coating, increased production capacity, and improved output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

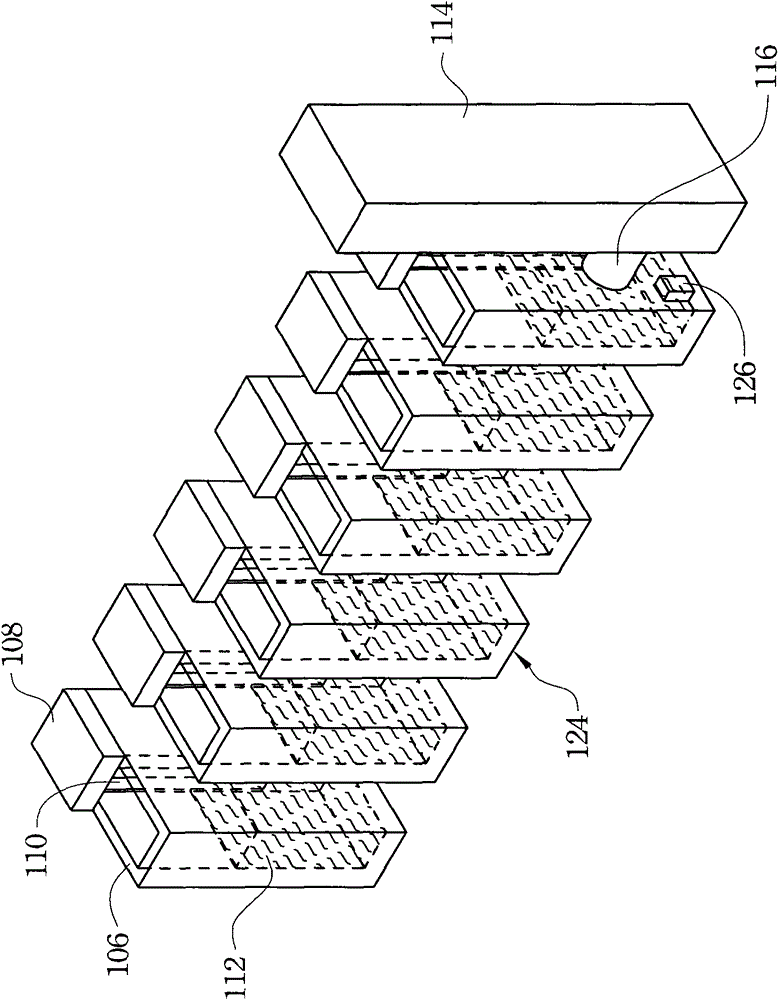

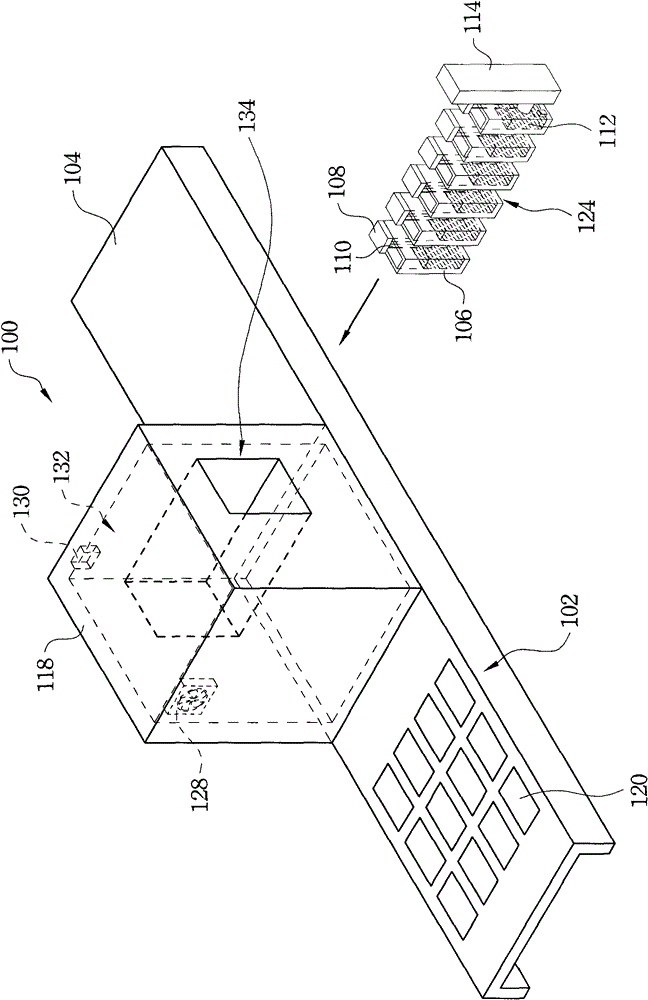

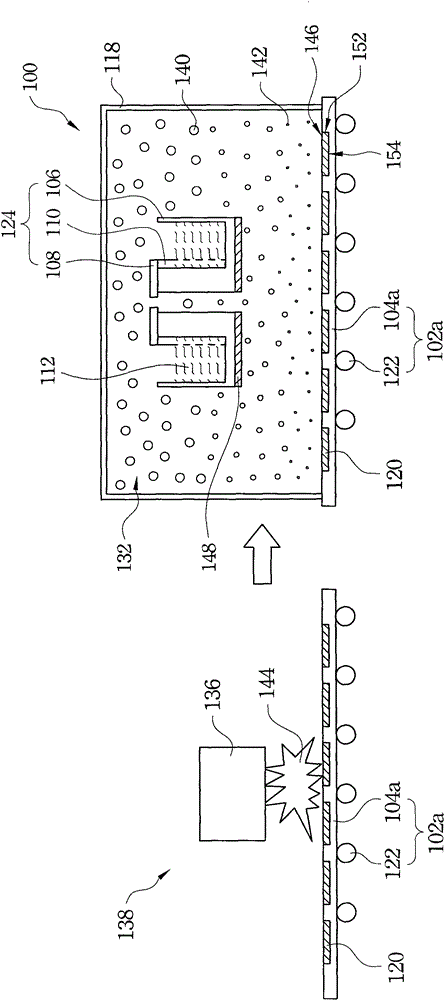

[0063] Please refer to figure 1 and figure 2 ,in figure 1 It is a schematic diagram illustrating an atomization device of an atmospheric pressure evaporation device for an antifouling film according to an embodiment of the present invention, figure 2 is to draw figure 1 Schematic diagram of the atmospheric pressure evaporation device for the antifouling thin film. In this embodiment, if figure 2 As shown, the atmospheric pressure evaporation device 100 for anti-fouling thin films mainly includes a conveying device 102 and an atomizing device 124 . In one embodiment, as figure 1 As shown, the atomizing device 124 includes one or more paint receiving devices 106 , and one or more atomizing components 108 . The transfer device 102 is used to transfer one or more substrates 120 to be processed, such as figure 2 shown. exist figure 2 In the illustrated embodiment, the transfer device 102 may include a carrier member 104 , and the substrate 120 to be processed may be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com