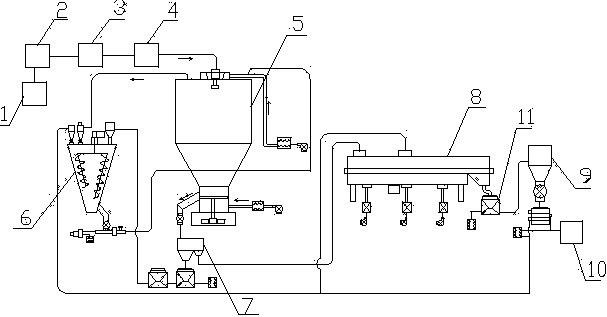

Preparation process and device of vitamin D3 microcapsule powder

A technology of microcapsule powder and preparation process, which is applied in the directions of microcapsules, capsule delivery, medical preparations of inactive ingredients, etc. It can improve the water solubility and palatability, avoid the high temperature of powder spraying, and improve the diffusion of cold water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

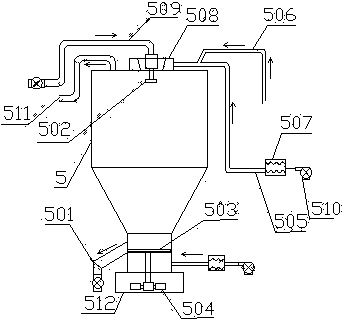

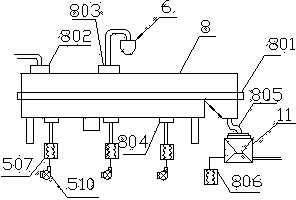

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Preparation of vitamin D3 microcapsule powder:

[0034] (1) Add BHT and VD3 oil to sunflower oil, and drain the oil after completely dissolving at a temperature of 40°C. The oil drain pipe is filtered with a 120-mesh stainless steel screen. The weight ratio of BHT, VD3 oil, and sunflower oil to BHT: VD3 oil: sunflower oil is 0.001:0.5:1.

[0035] (2) Add purified water into the emulsification tank, the ratio of purified water to VD3 oil by weight is 1:4.0, while the jacket is heating up, the ratio of modified starch: maltodextrin: white sugar: VD3 oil is 0.4:4.0:0.5:1 Ratio in parts by weight, feed modified starch, maltodextrin, white sugar, stir to dissolve completely, control the temperature at 50°C, add the VD3 oil mixture to the emulsification kettle, the temperature in the emulsification kettle is 65°C, measure the viscosity, and control it at 30-60 For centipoise, the temperature is controlled at 65°C during the measurement, the emulsion is circulat...

Embodiment 2

[0040] Embodiment 2: Preparation of vitamin D3 microcapsule powder:

[0041] (1) Add BHT and VD3 oil to corn oil, and drain the oil after completely dissolving at a temperature of 50°C. The oil drain pipe is filtered with a 120-mesh stainless steel screen. The weight ratio of BHT, VD3 oil, and corn oil is BHT:VD3 oil : Corn oil is 0.01:5:5.

[0042] (2) Add purified water into the emulsification tank, the ratio of purified water to VD3 oil is 1:5.0, and the ratio of modified starch: maltodextrin: white sugar: VD3 oil is 1: 6.0:1.5:1, feed modified starch, maltodextrin, white sugar, stir to dissolve completely, control the temperature at 60°C, put the VD3 oil mixture into the emulsification kettle, the temperature in the emulsification kettle is 75°C, measure the viscosity, and control it at 30-60 For centipoise, the temperature is controlled at 68°C during the measurement, the emulsion is circulated for 130 minutes, and the viscosity is re-measured after the reflux is complet...

Embodiment 3

[0047] Embodiment 3: Preparation of vitamin D3 microcapsule powder:

[0048] (1) Add BHT and VD3 oil to sunflower oil, and drain the oil after completely dissolving at a temperature of 45°C. The oil drain pipe is filtered with a 120-mesh stainless steel screen. The weight ratio of BHT, VD3 oil, and sunflower oil to BHT: VD3 oil: sunflower oil is 0.001:2:3;

[0049] (2) Add purified water into the emulsification tank, the ratio of purified water to VD3 oil is 1:4.5, and the ratio of modified starch:maltodextrin:white sugar:VD3 oil is 0.6 while the jacket is heating up: 5.0:1:1, feed modified starch, maltodextrin, white sugar, stir to dissolve completely, control the temperature at 55°C, put the VD3 oil mixture into the emulsification kettle, the temperature in the emulsification kettle is 70°C, measure the viscosity, and control it at 30-60 For centipoise, the temperature is controlled at 66°C during the measurement, the emulsion is circulated for 120 minutes, and the viscosit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com